Clearance compensation type annular oil groove sliding shoe for plunger hydraulic pump

A technology of gap compensation and annular oil groove, which is applied in variable displacement pump components, pump components, liquid fuel engines, etc., can solve problems such as deformation of the sliding shoe, increased local wear, and easy inclination of the sliding shoe to reduce the radial Pressure gradient, avoid surface deformation, realize the effect of automatic compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

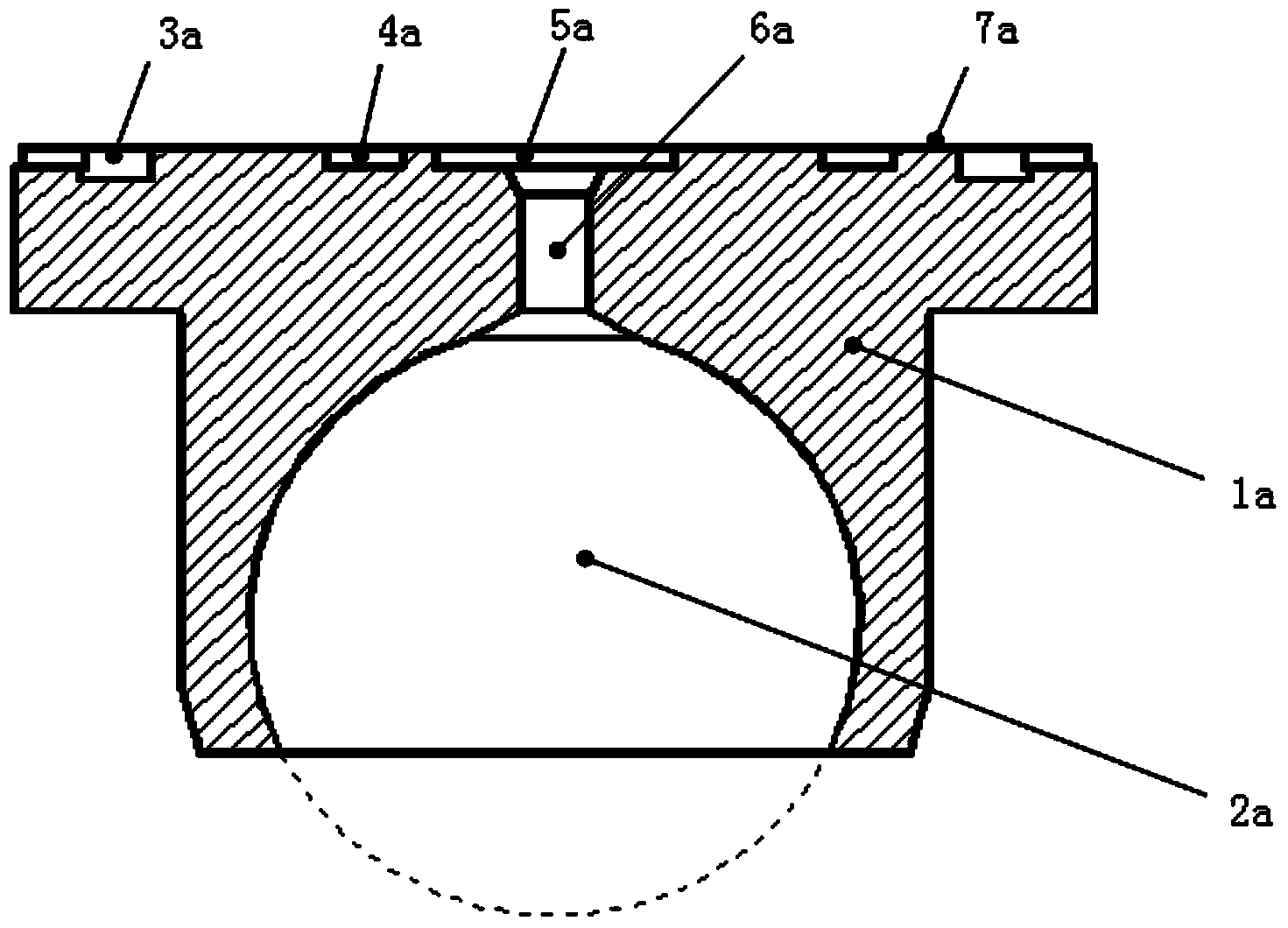

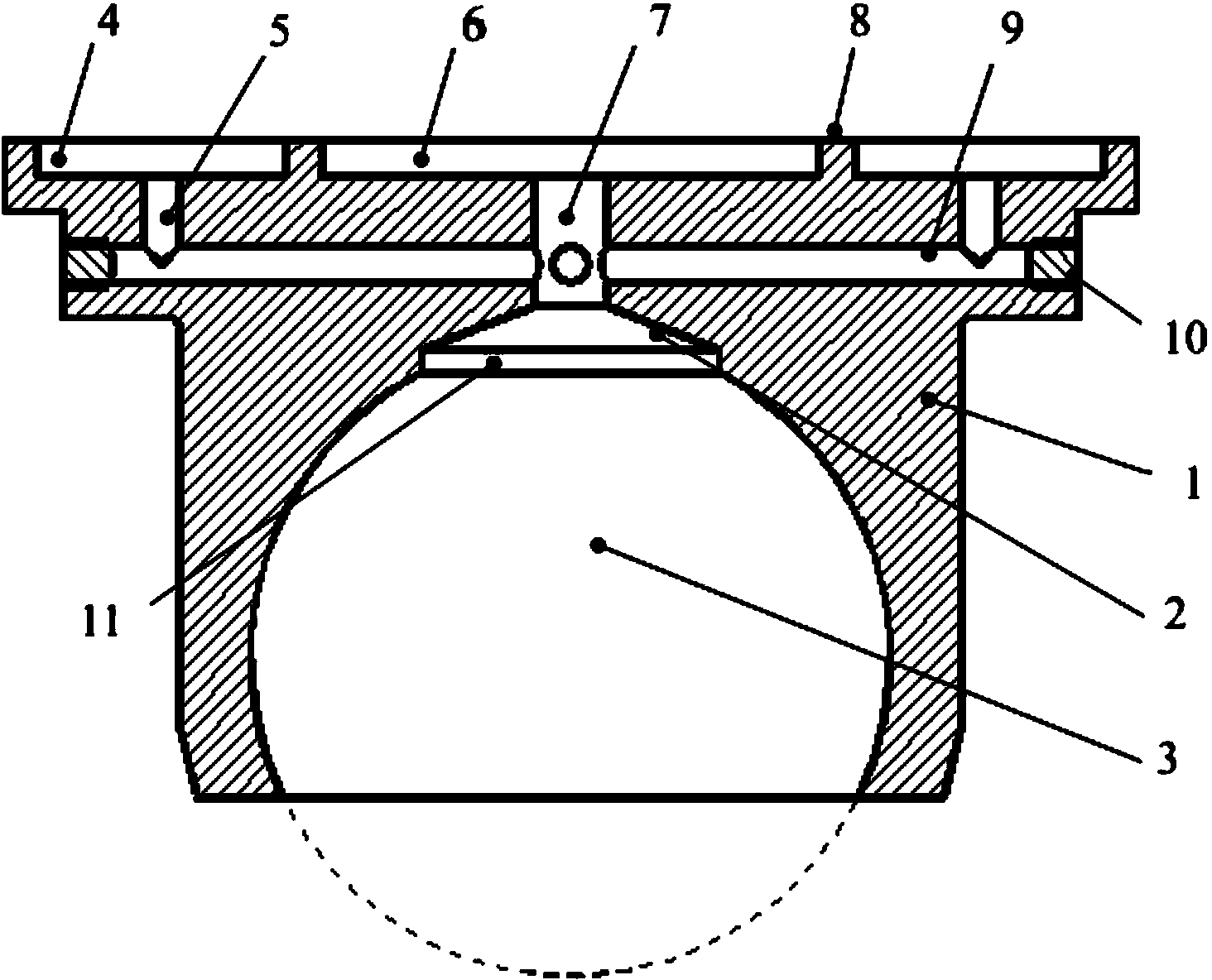

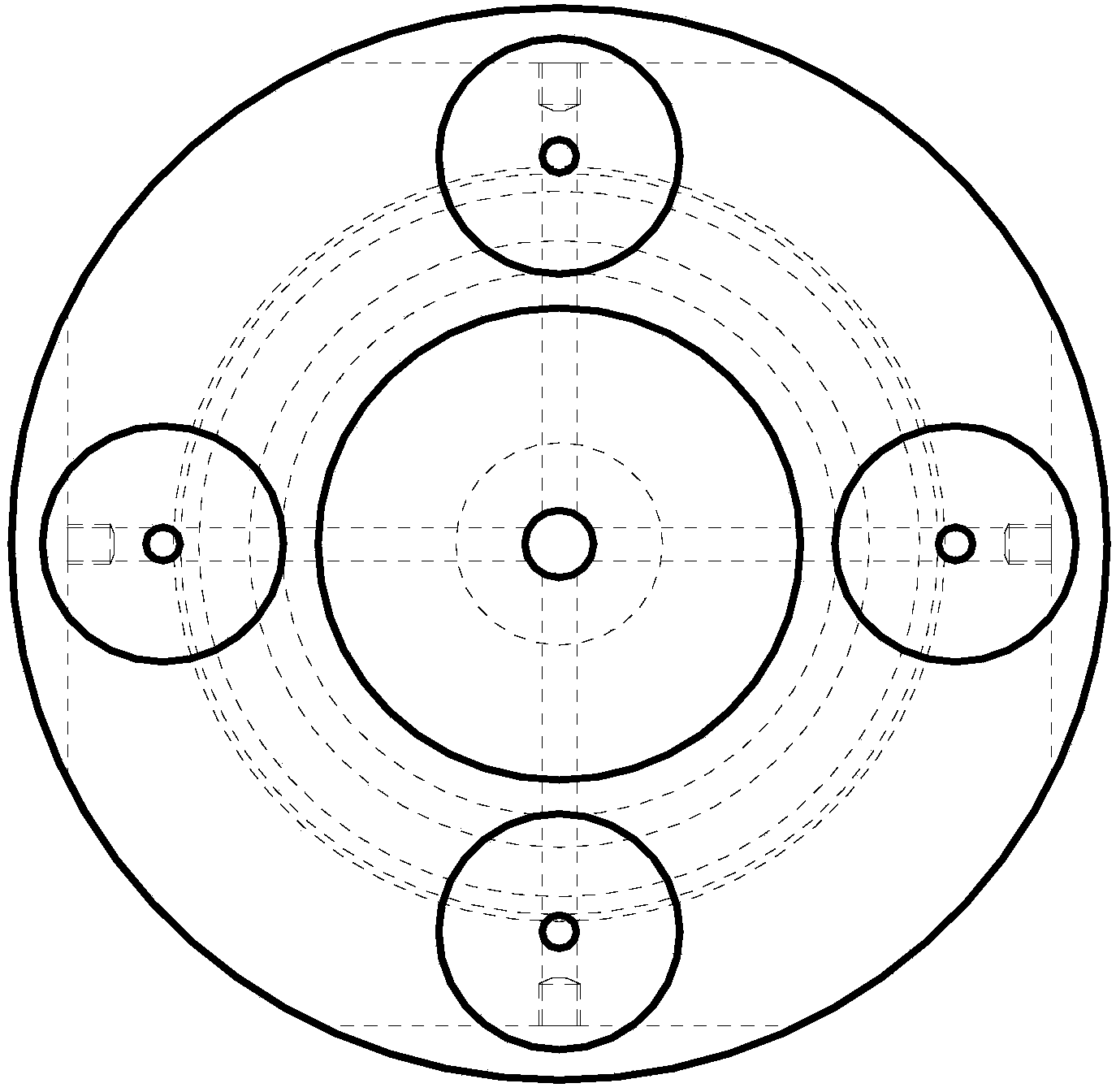

[0032] Such as figure 2Shown is a structural schematic diagram of the present invention, a clearance-compensating annular oil groove slide shoe for a plunger hydraulic pump, the slide shoe includes a slide shoe body 1, and one end of the slide shoe body 1 is matched with the size of the plunger ball head The trapezoidal groove 2 of the ball socket and the ball socket 3 of the shoe, the other end is the end face 8 in contact with the swash plate, the middle part of the end face 8 is provided with a concave ring groove 6, and the middle part of the concave ring groove 6 is provided with a damping hole b7, the damping The hole b7 communicates with the shoe ball socket 3 through the ball socket trapezoidal groove 2. A round platform 11 is provided between the grooves 2, and two communicating oil passages 9 perpendicular to each other and crossing each other are arranged inside the shoe body 1, and the communicating oil passages 9 are vertically communicated with the damping hole ...

Embodiment 2

[0038] In this embodiment, the diameter of the communicating oil passage 9 is 3 mm, and the rest are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com