Flat-panel vapor chamber

A vapor chamber and flat plate technology, applied in indirect heat exchangers, heat exchange equipment, lighting and heating equipment, etc., can solve problems such as surface deformation, reduce surface deformation, improve work performance, prevent surface collapse and surface deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

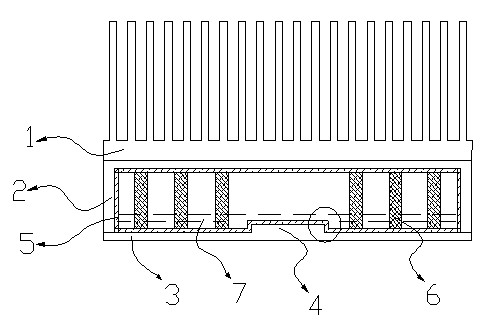

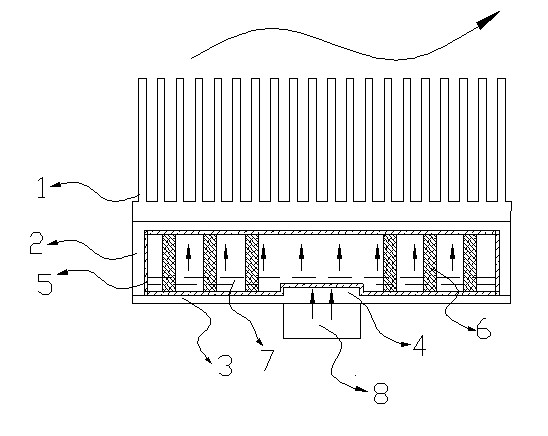

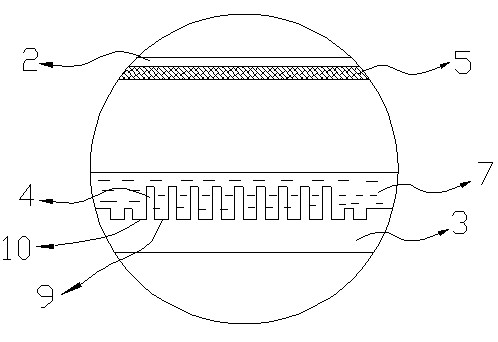

[0022] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0023] like figure 1 As shown, an embodiment of the present invention includes heat dissipation fins 1 and a metal cavity, the metal cavity is composed of a box body 2 and a cover plate 3, the inside of the metal cavity is evacuated, filled with a liquid working medium 7, the box The body 2 is in close contact with the cooling fins 1, the inner wall of the box body 2 has a capillary core 5, and there is a support body 6 between the box body and the cover plate;

[0024] The central part of the inner wall surface of the cover plate 3 has a boss 4, and the thickness of the boss is 0.2mm; the cross-sectional area of the boss is equal to the contact area of the heat source; the inner wall surface of the cover plate 3 comprising the boss has a capillary core 5, and the capillary core 5 is Sintered metal powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com