Patents

Literature

124 results about "Cellulose ester membrane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

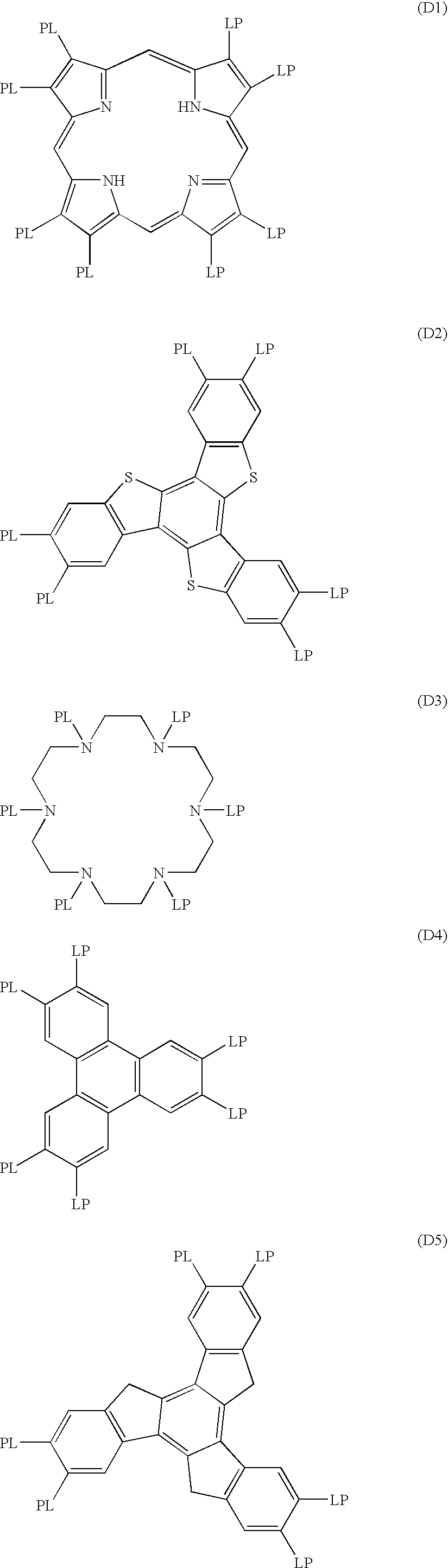

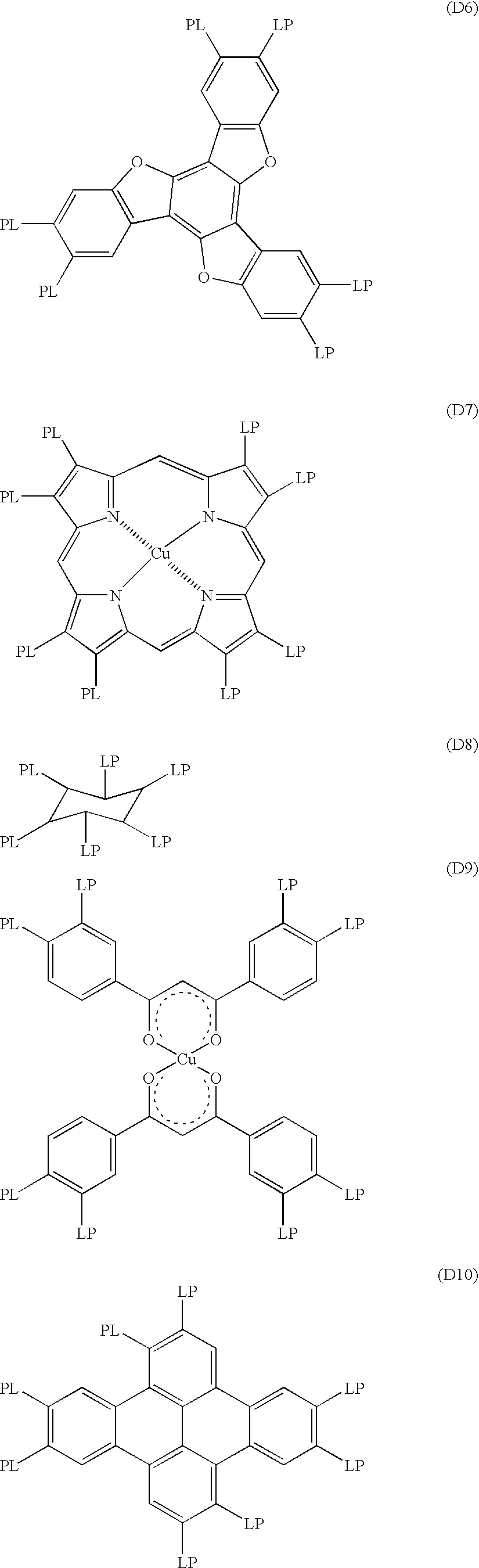

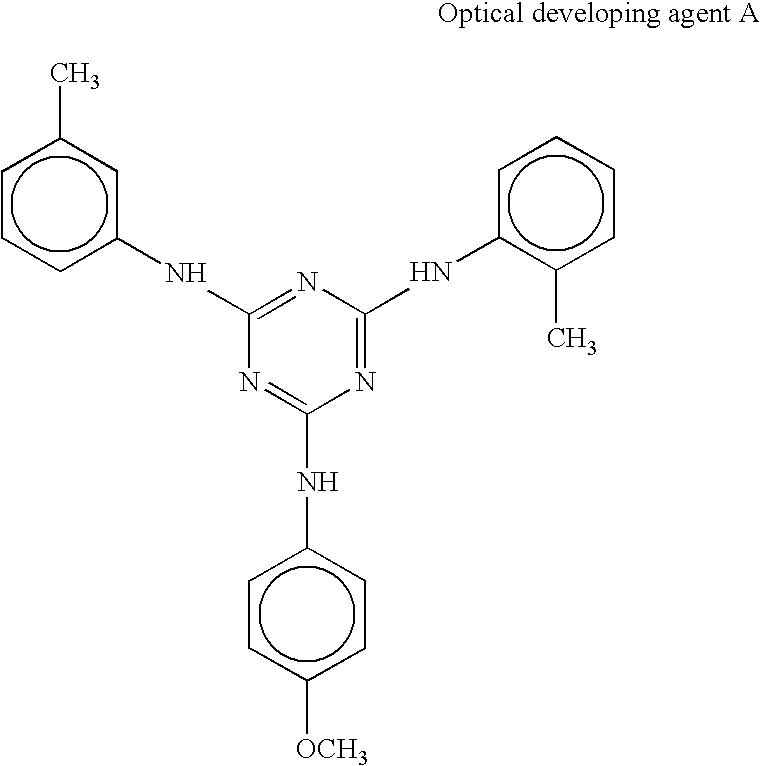

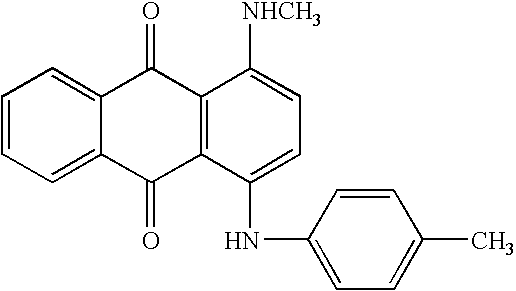

Optically anisotropic cellulose ester film containing discotic compound

InactiveUS6630973B1Increases retardation valueRetardation valueLiquid crystal compositionsStatic indicating devicesCellulose ester membraneLiquid-crystal display

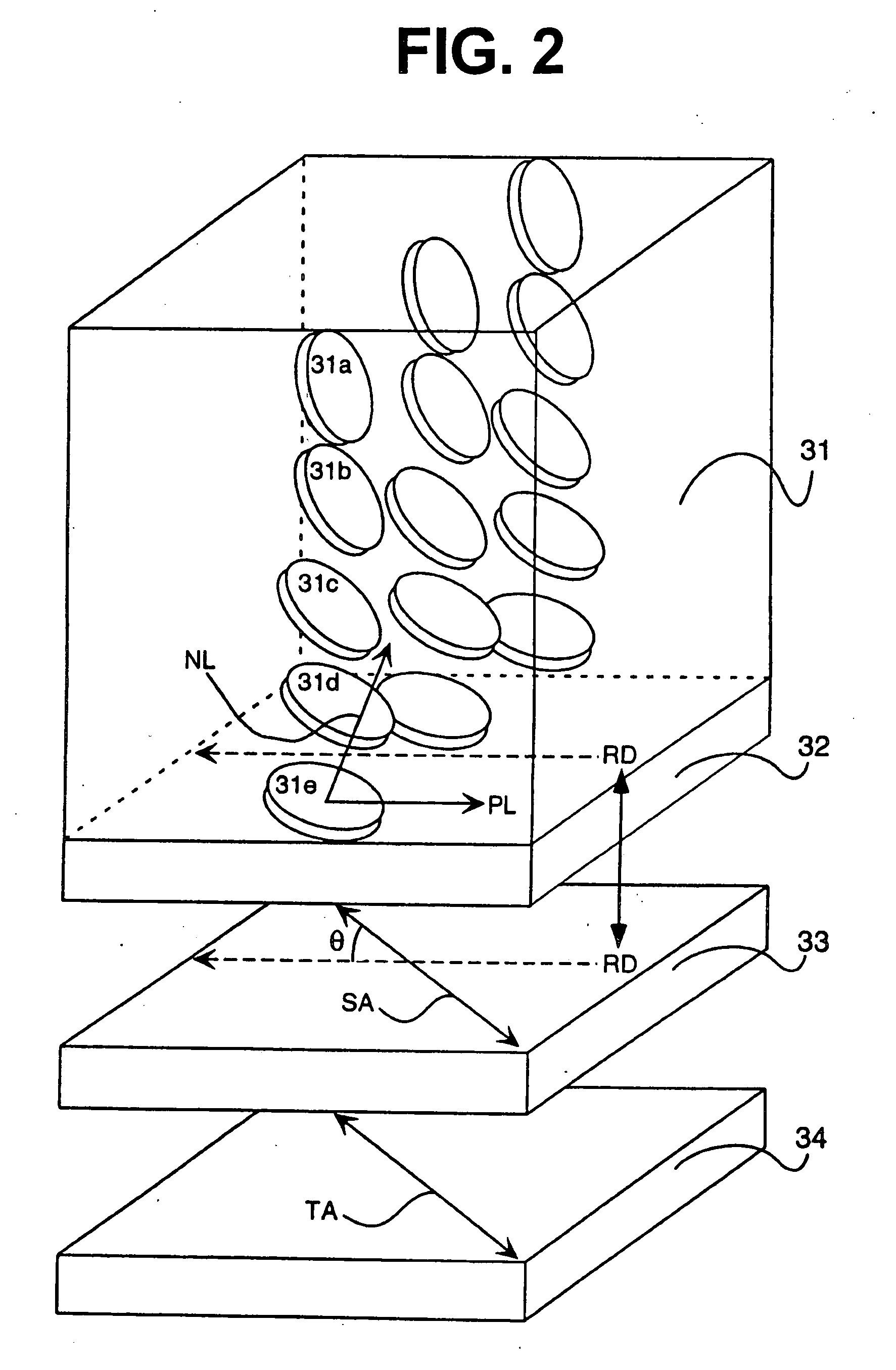

An optically anisotropic cellulose ester film is disclosed. The film contains a discotic compound in an amount of 0.01 to 20 weight parts based on 100 weight parts of cellulose ester. The film has a Rth<550 >retardation value in the range of 60 to 1,000 nm. The cellulose ester film can be used in an optical compensatory sheet, an ellipsoidal polarizing plate and a liquid crystal display.

Owner:FUJIFILM CORP

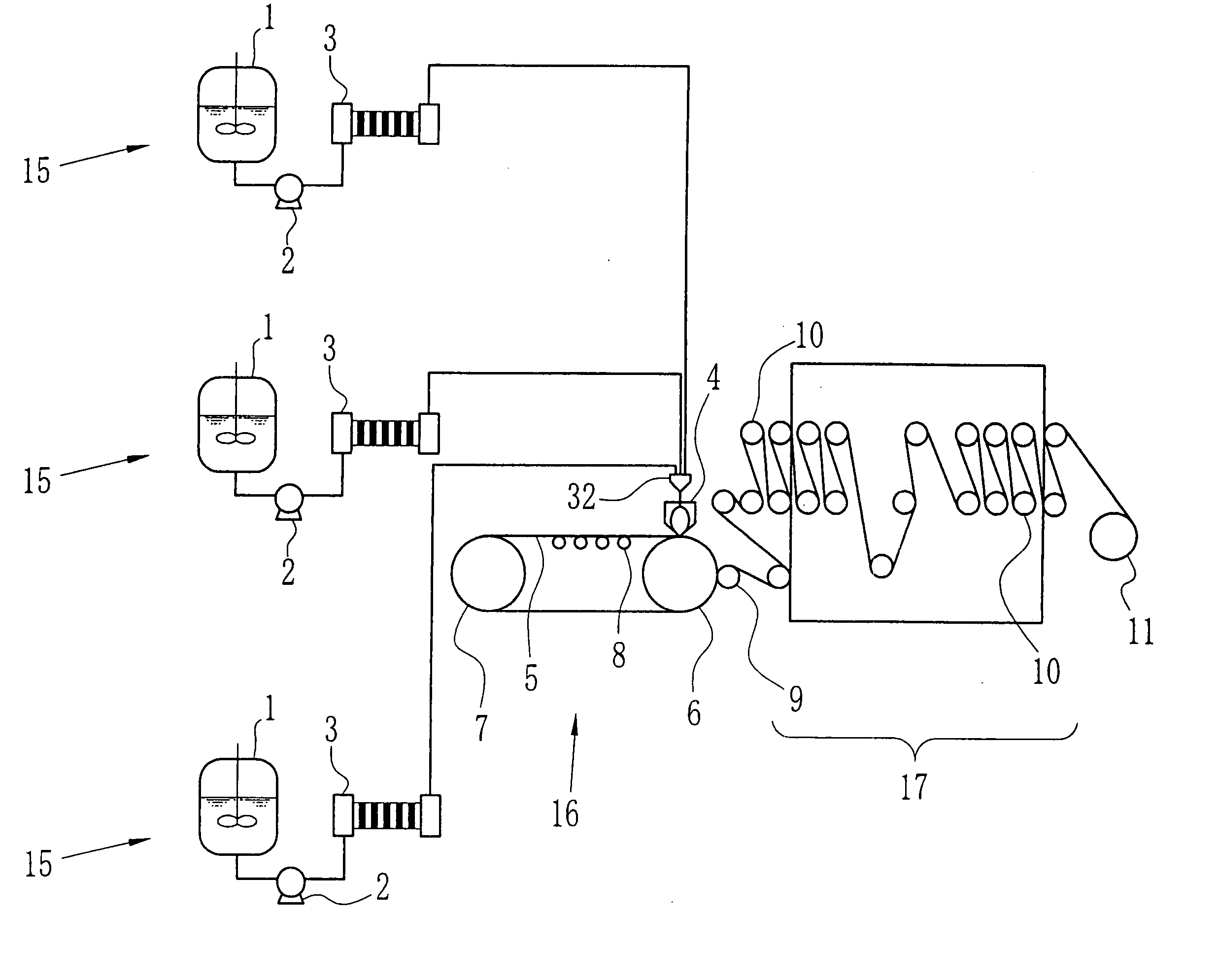

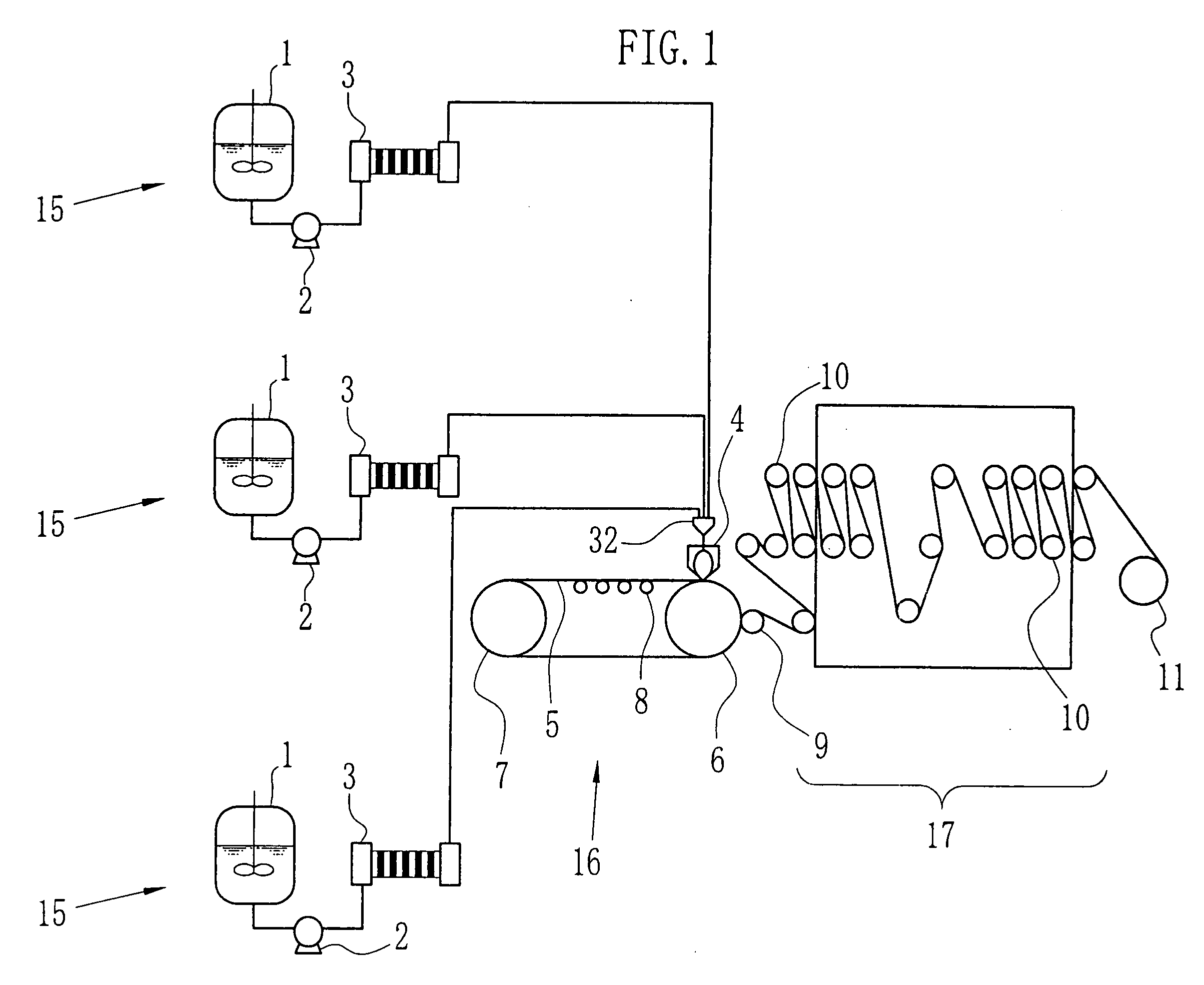

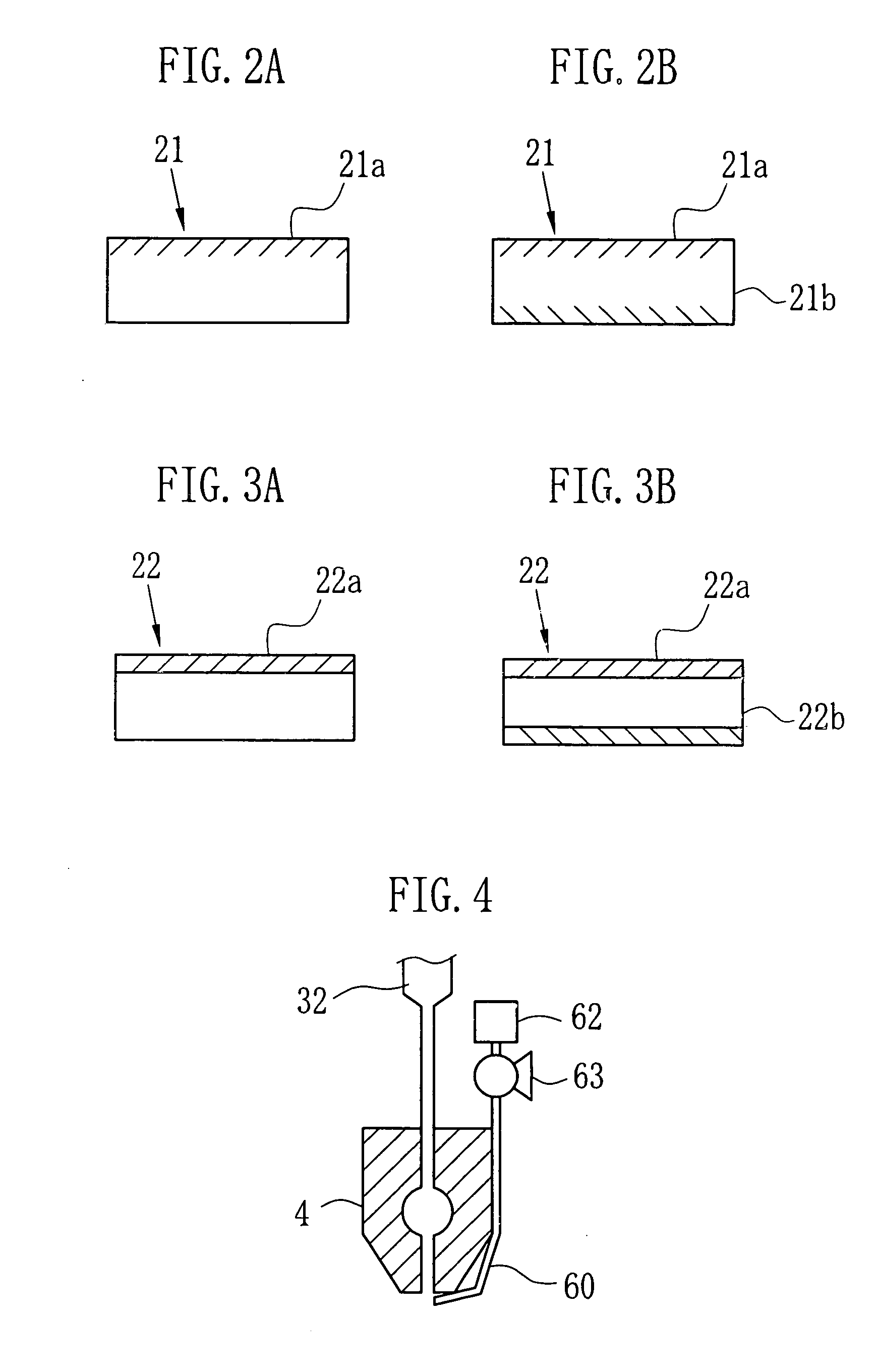

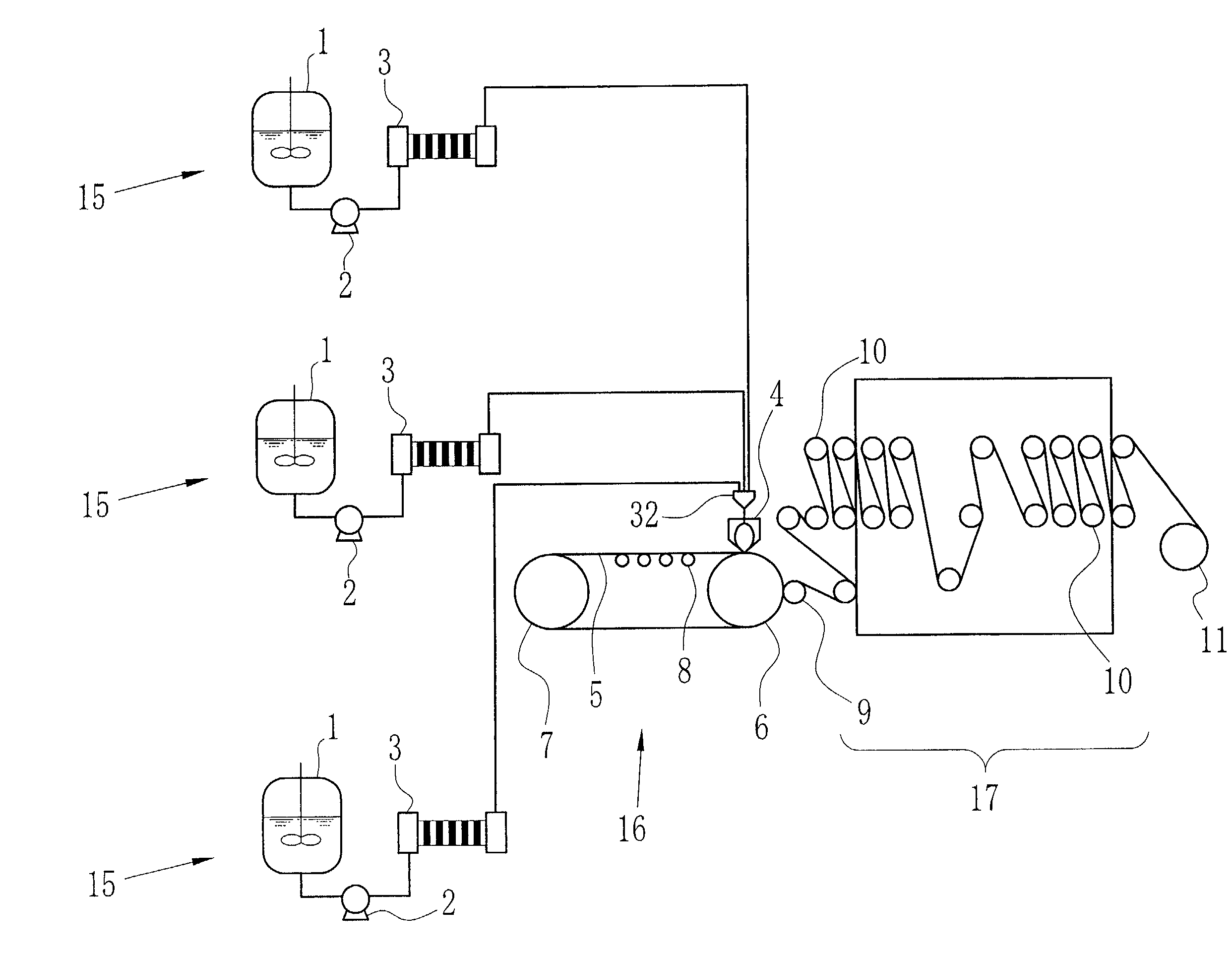

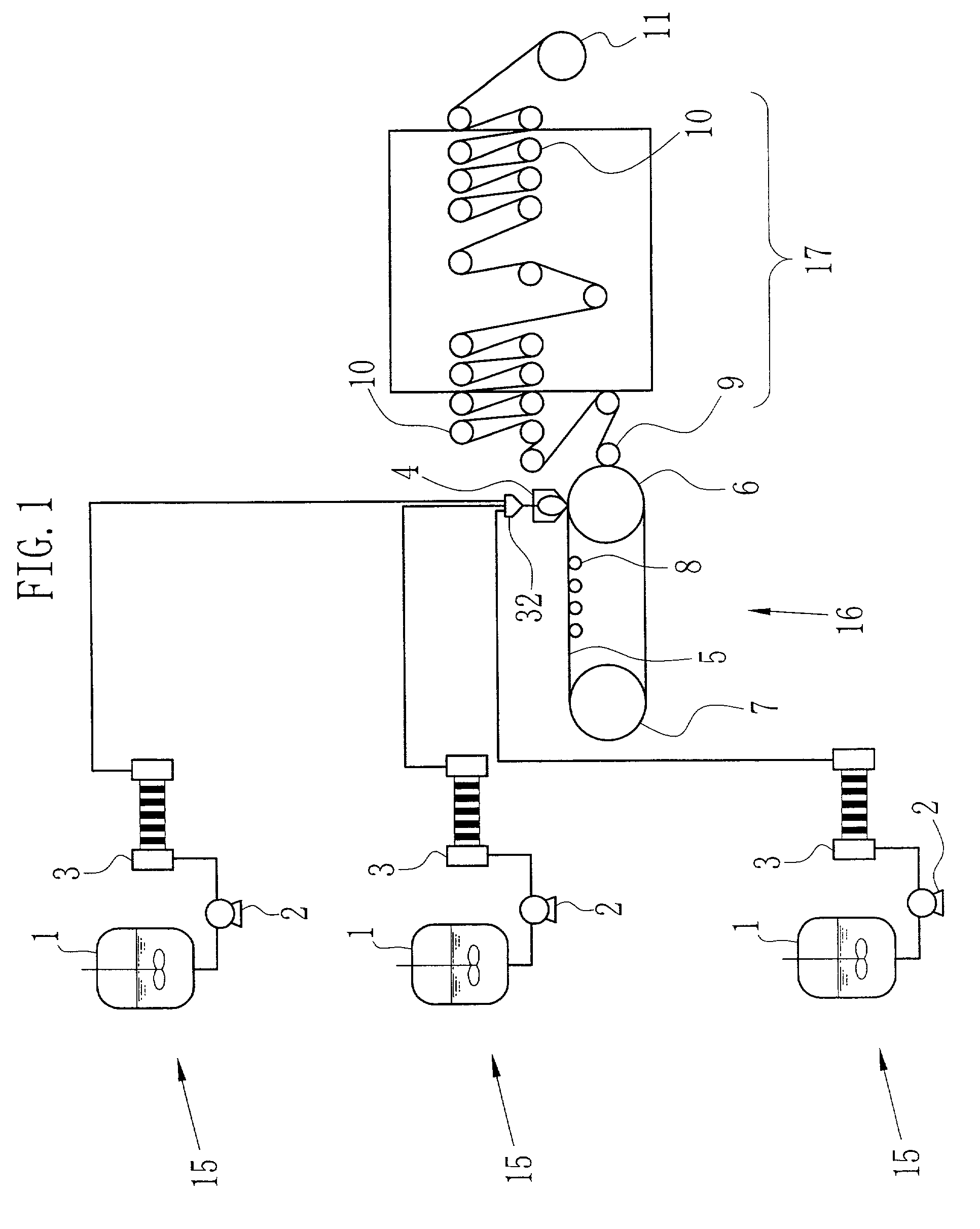

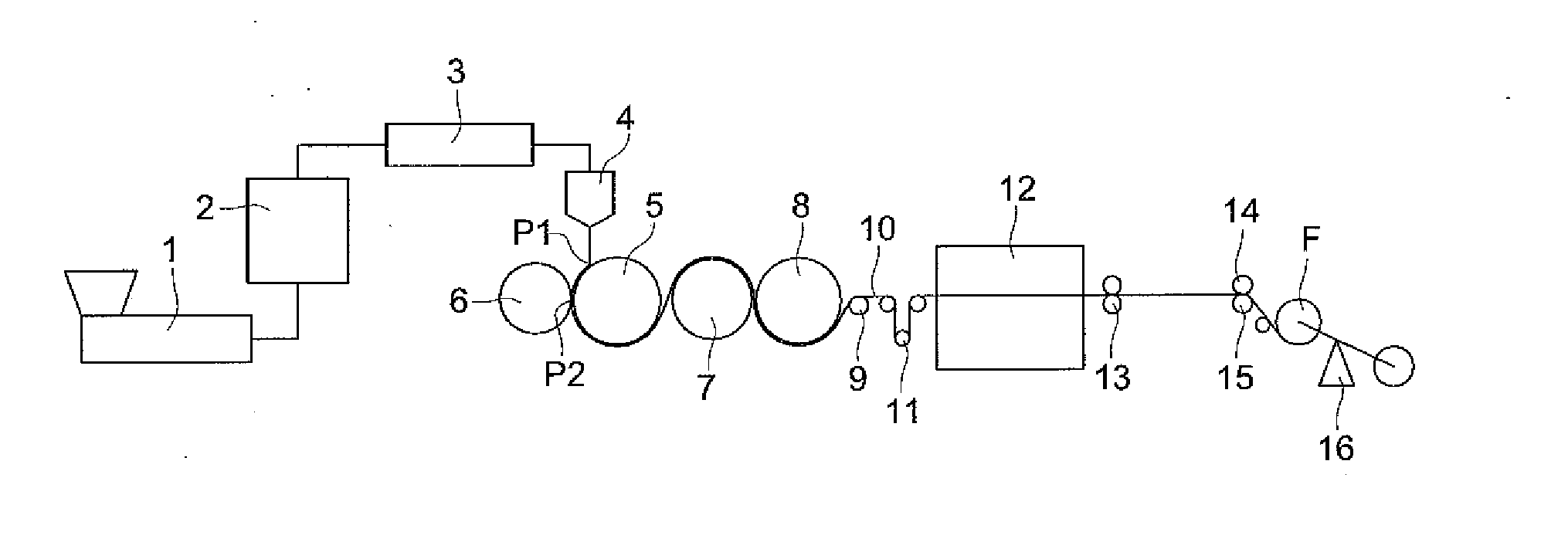

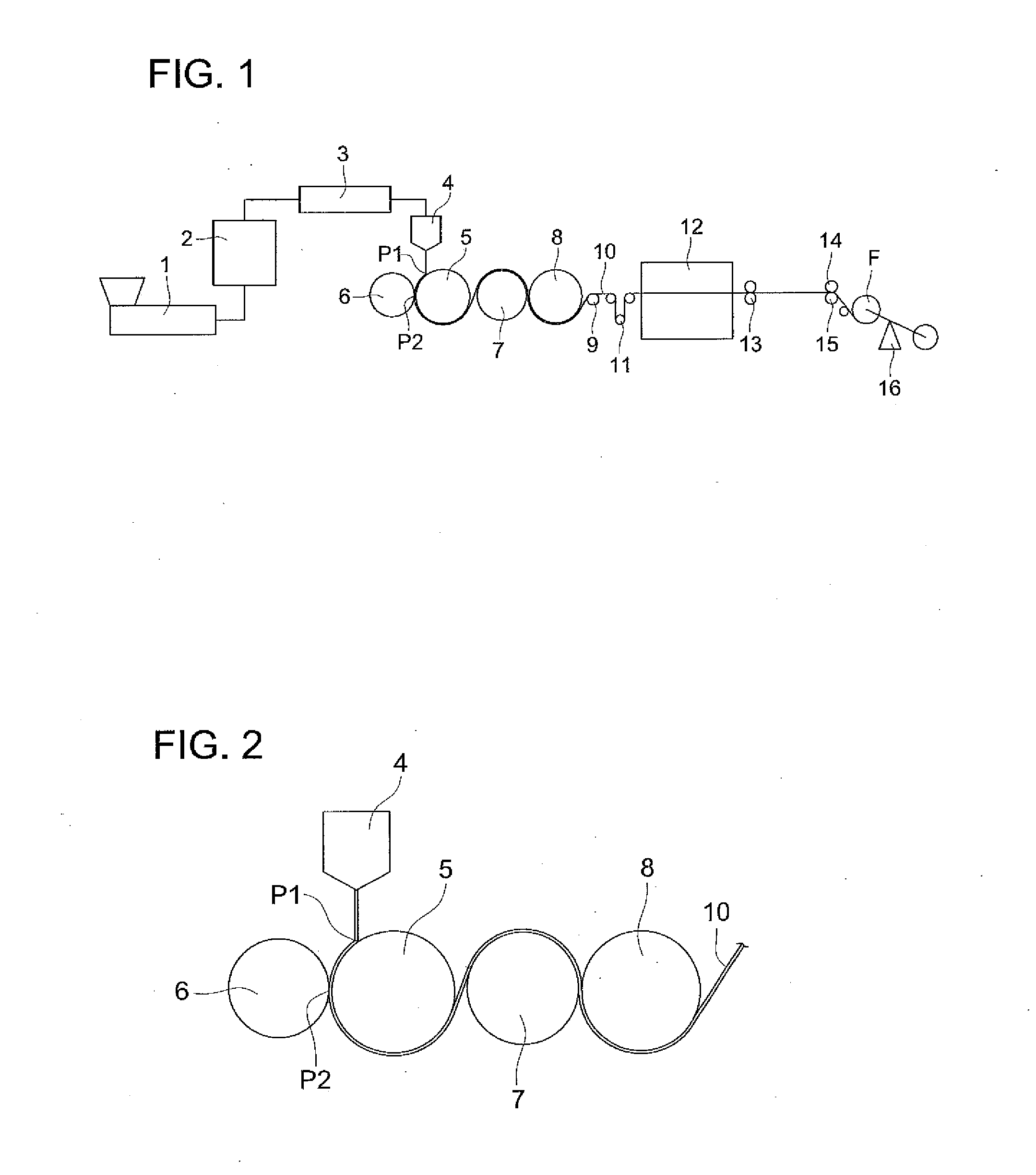

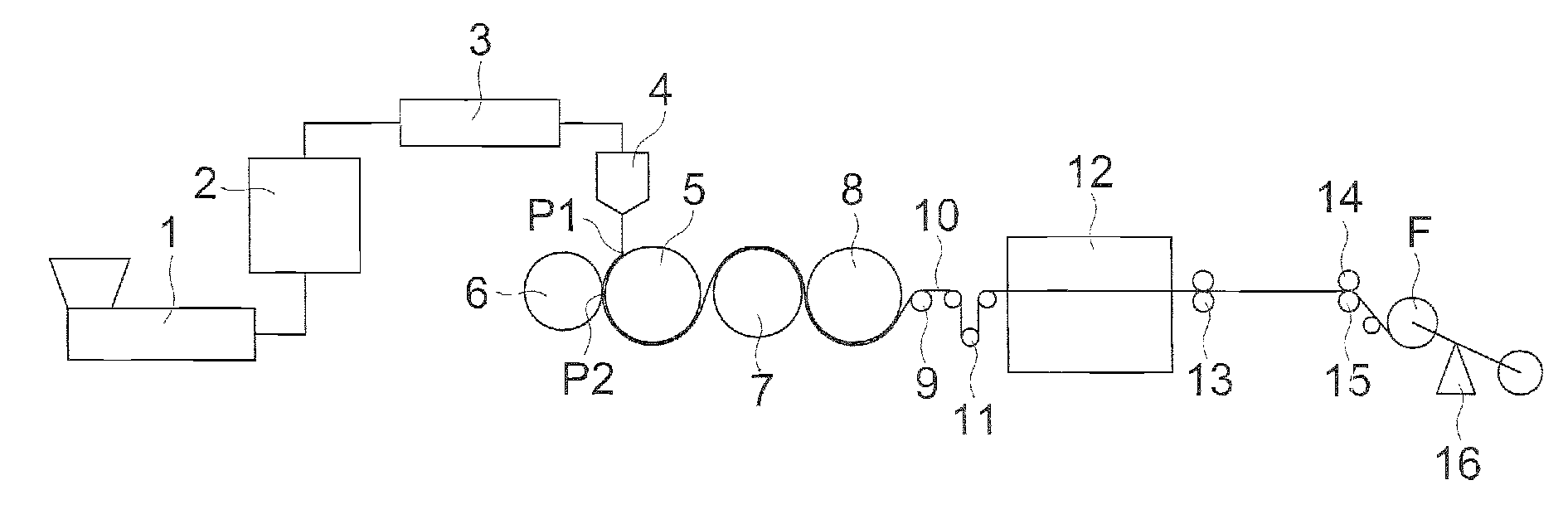

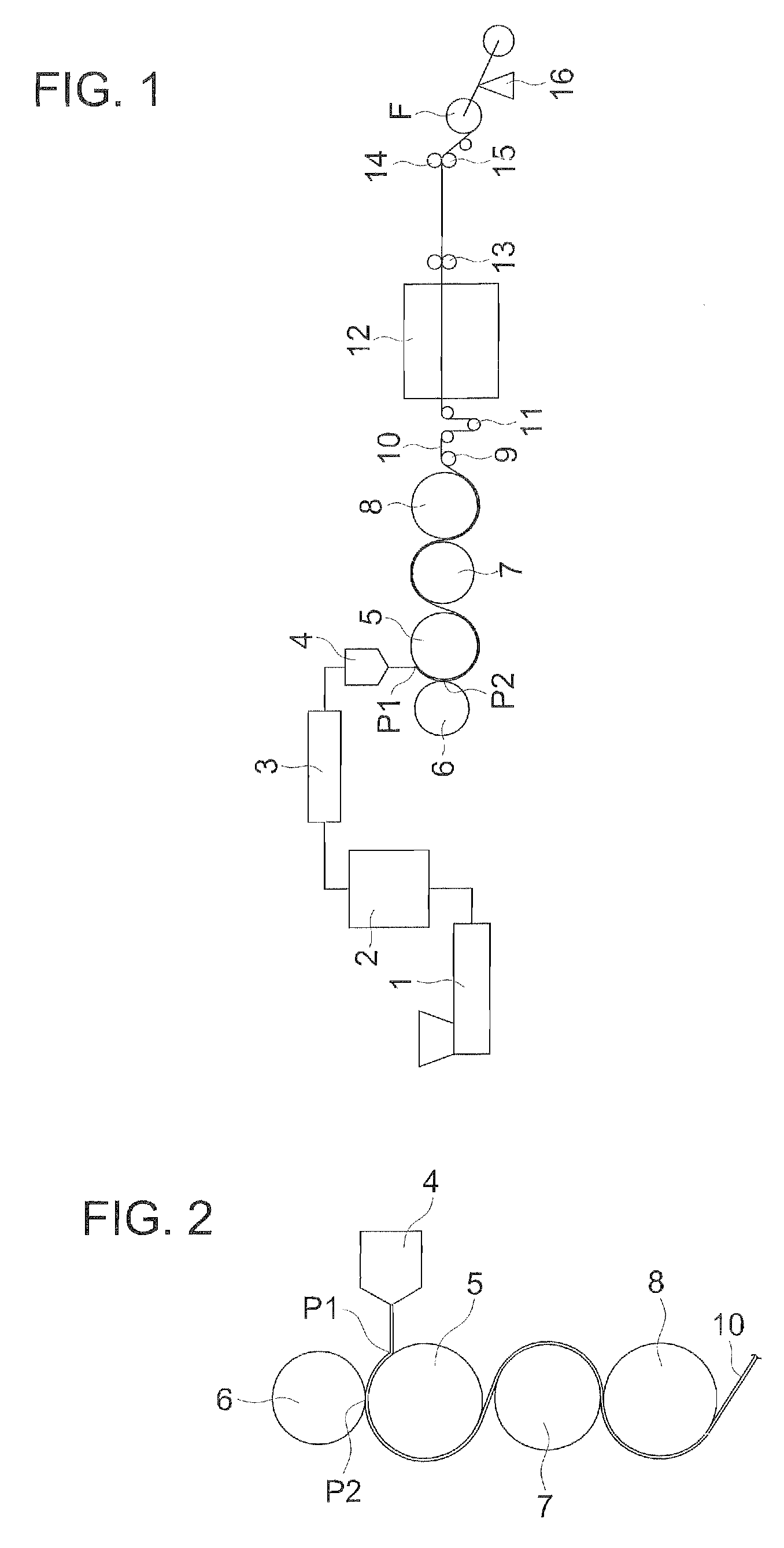

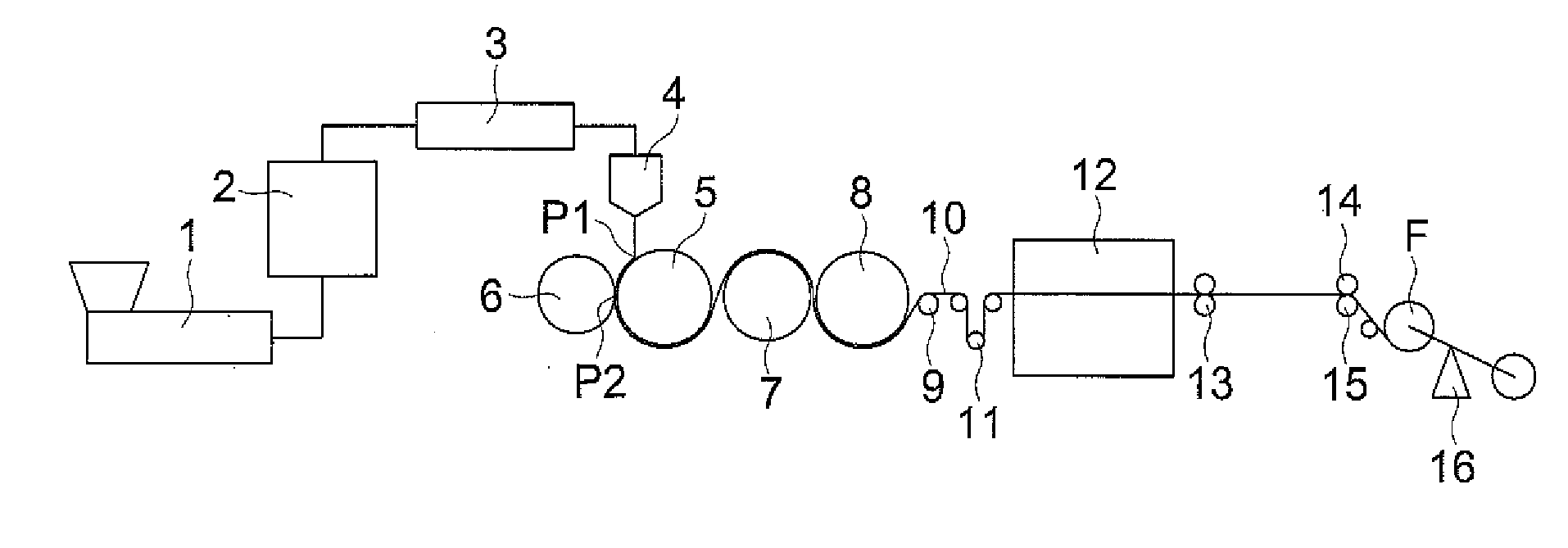

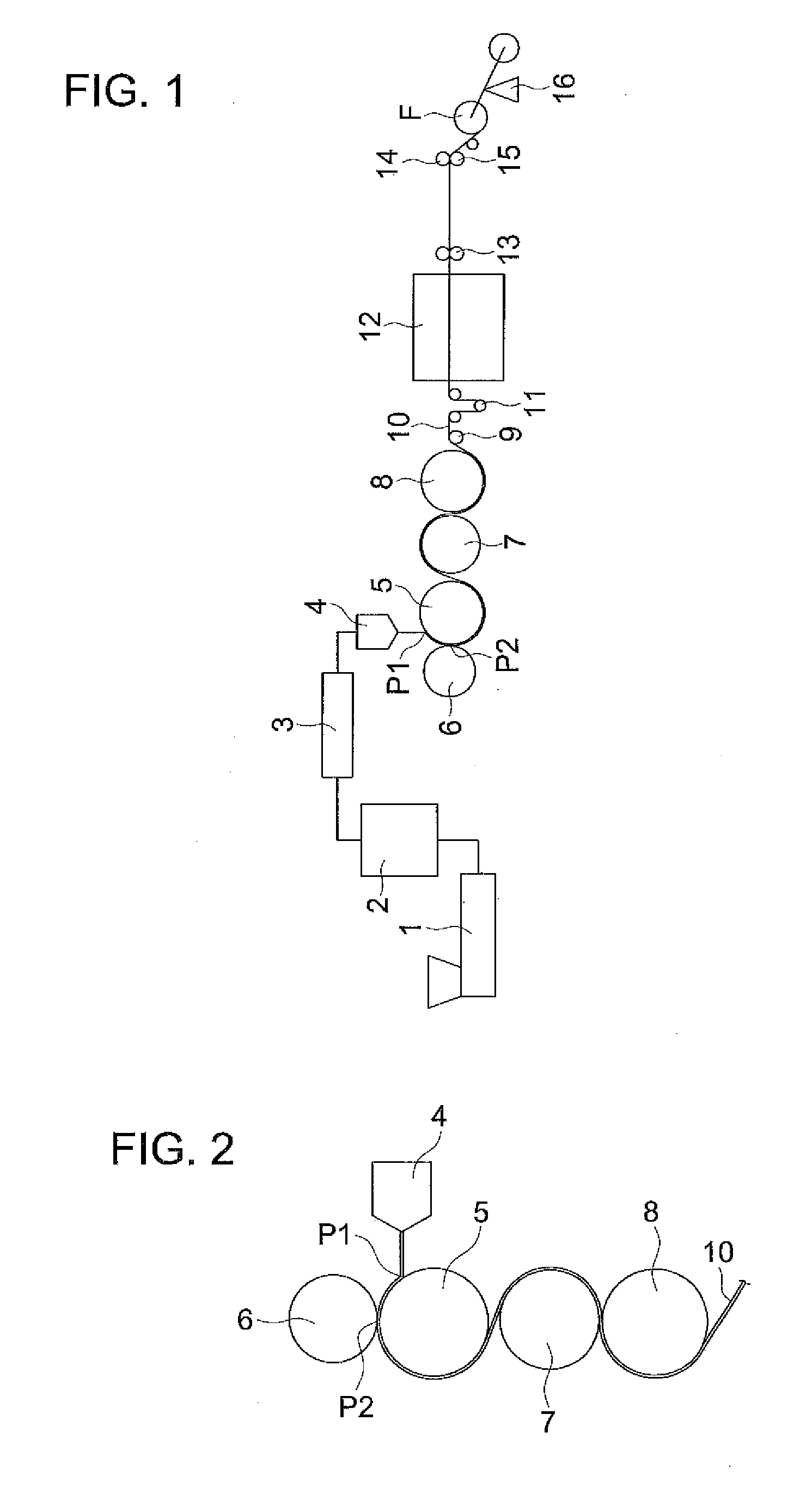

Method for producing of cellulose ester film

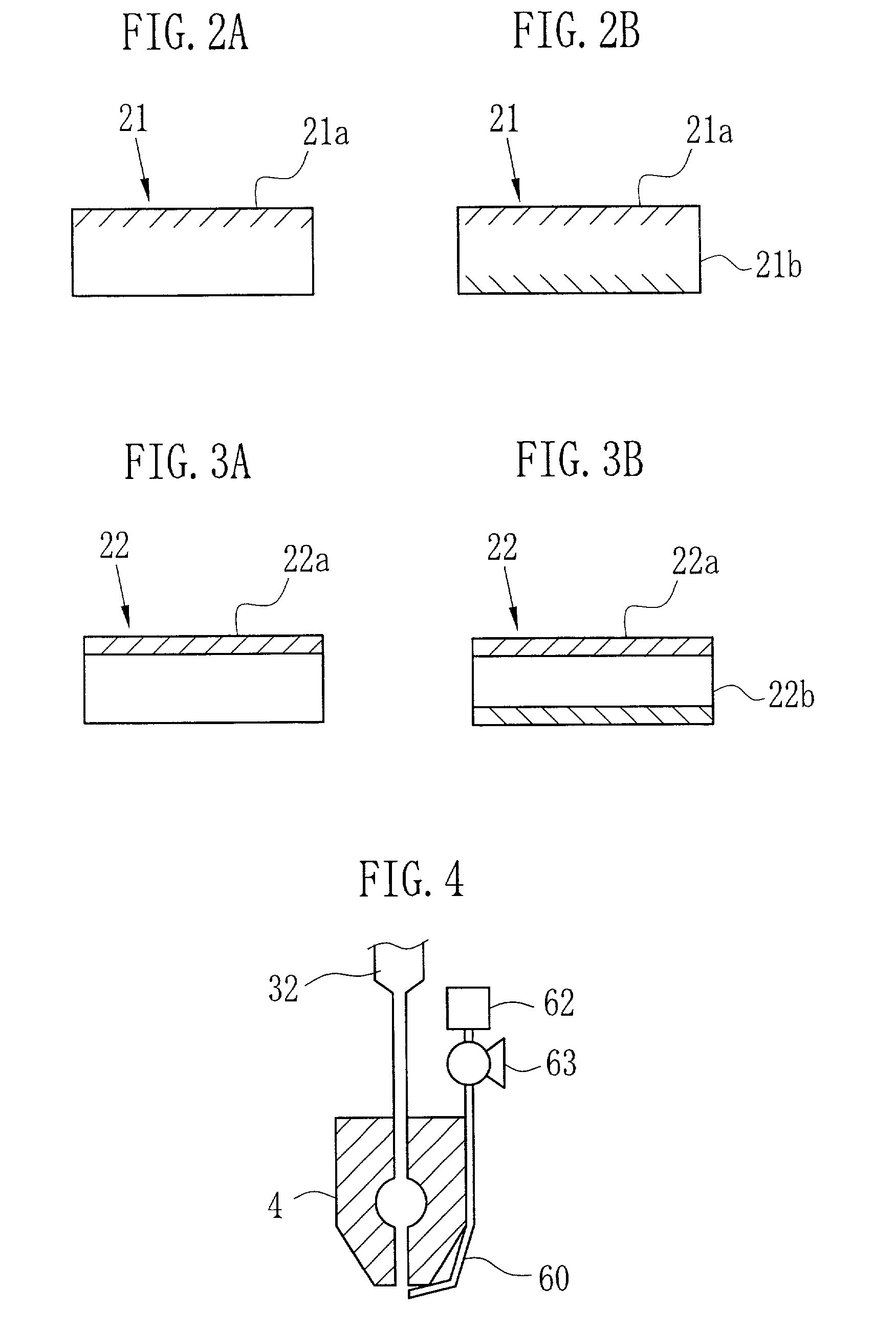

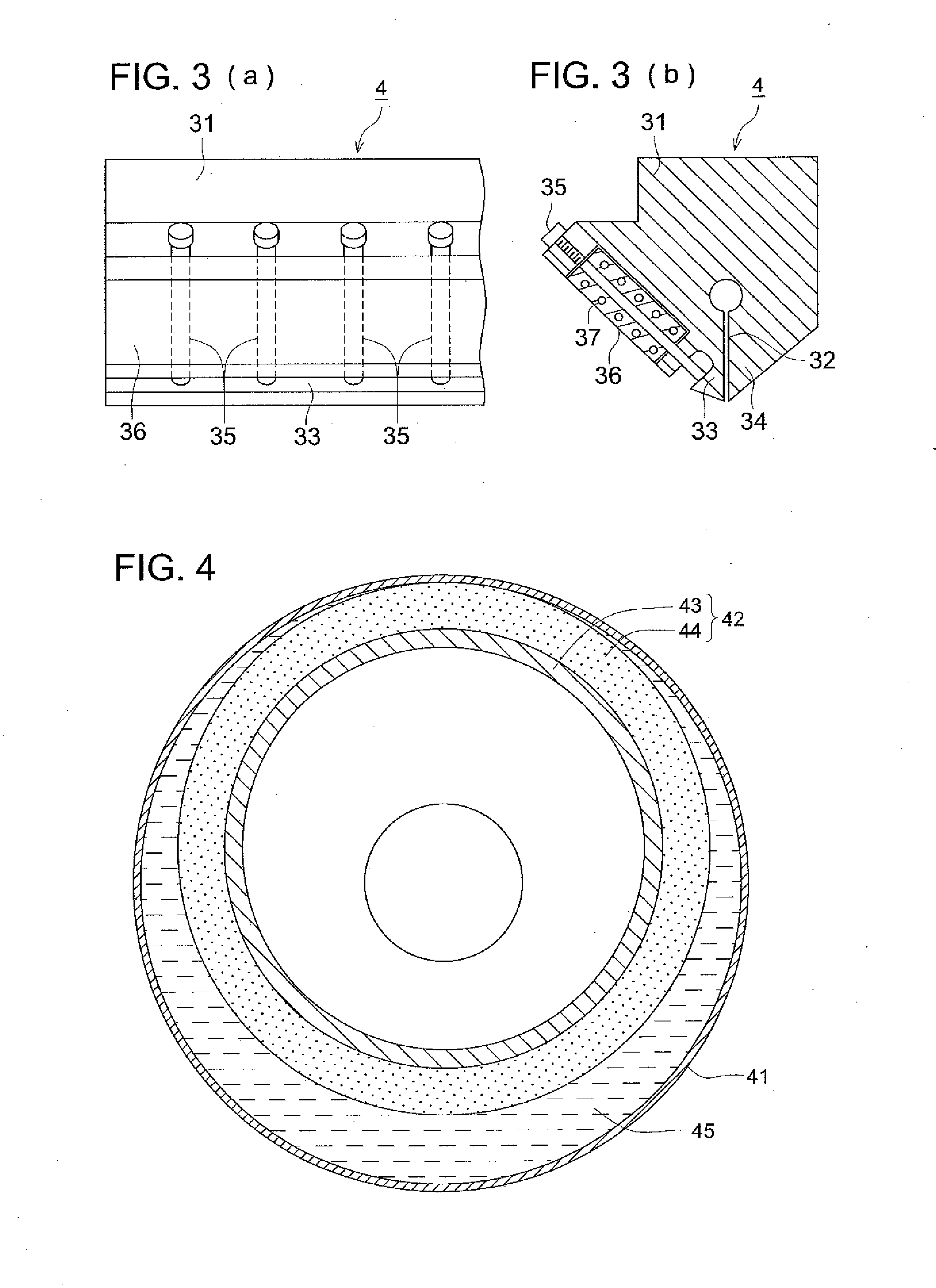

InactiveUS20050133953A1Prevent skinAvoid it happening againFlat articlesCoatingsCarbon numberCellulose ester membrane

In order to produce a cellulose ester film constructed of a front layer, an intermittent layer and a rear layer, a dope solution is doped on a supporter. In at least one of the front layer and the rear layer, a mass ratio of a cotton linter to a wood pulp (cotton linter / wood pulp) is between 5 / 95 and 0 / 100, and a solvent of the dope contains more than 15 wt. % alcohols and hydrocarbons whose carbon number each is 1-10. Further, a ratio of a solid content density of a solution for forming the front layer and the rear layer to a solid density of a solution for forming the intermittent layer is less than 0.9 wt. %, and a total thickness of the solutions for front and rear layers is more than 5% of the dope ribbon.

Owner:FUJIFILM CORP

Method of producing of cellulose ester film

InactiveUS20030015820A1Quality improvementAvoid it happening againLayered productsFlat articlesCarbon numberCellulose ester membrane

In order to produce a cellulose ester film constructed of a front layer, an intermittent layer and a rear layer, a dope solution is doped on a supporter. In at least one of the front layer and the rear layer, a mass ratio of a cotton linter to a wood pulp (cotton linter / wood pulp) is between 5 / 95 and 0 / 100, and a solvent of the dope contains more than 15 wt. % alcohols and hydrocarbons whose carbon number each is 1-10. Further, a ratio of a solid content density of a solution for forming the front layer and the rear layer to a solid density of a solution for forming the intermittent layer is less than 0.9 wt. %, and a total thickness of the solutions for front and rear layers is more than 5% of the dope ribbon.

Owner:FUJIFILM CORP

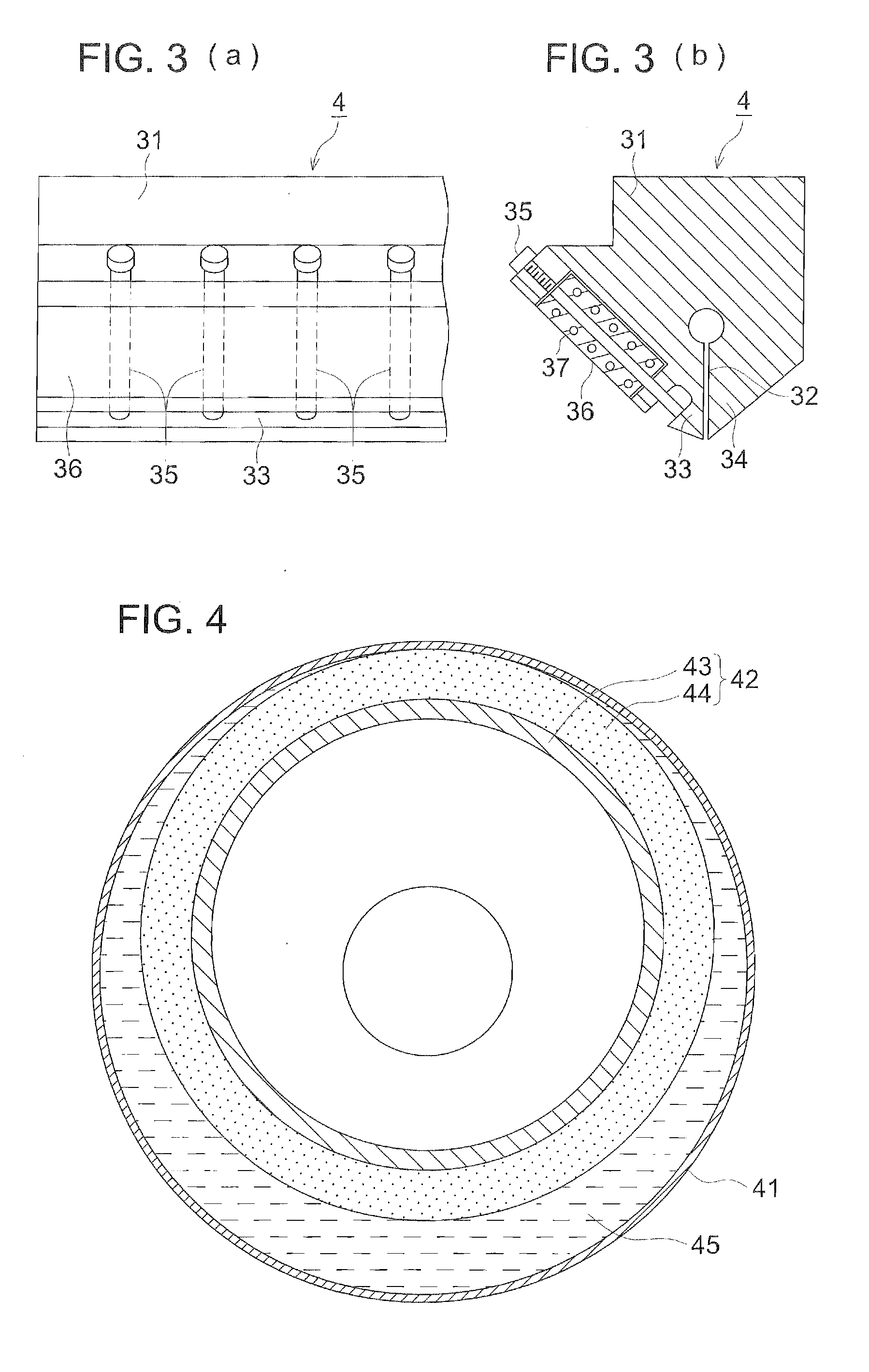

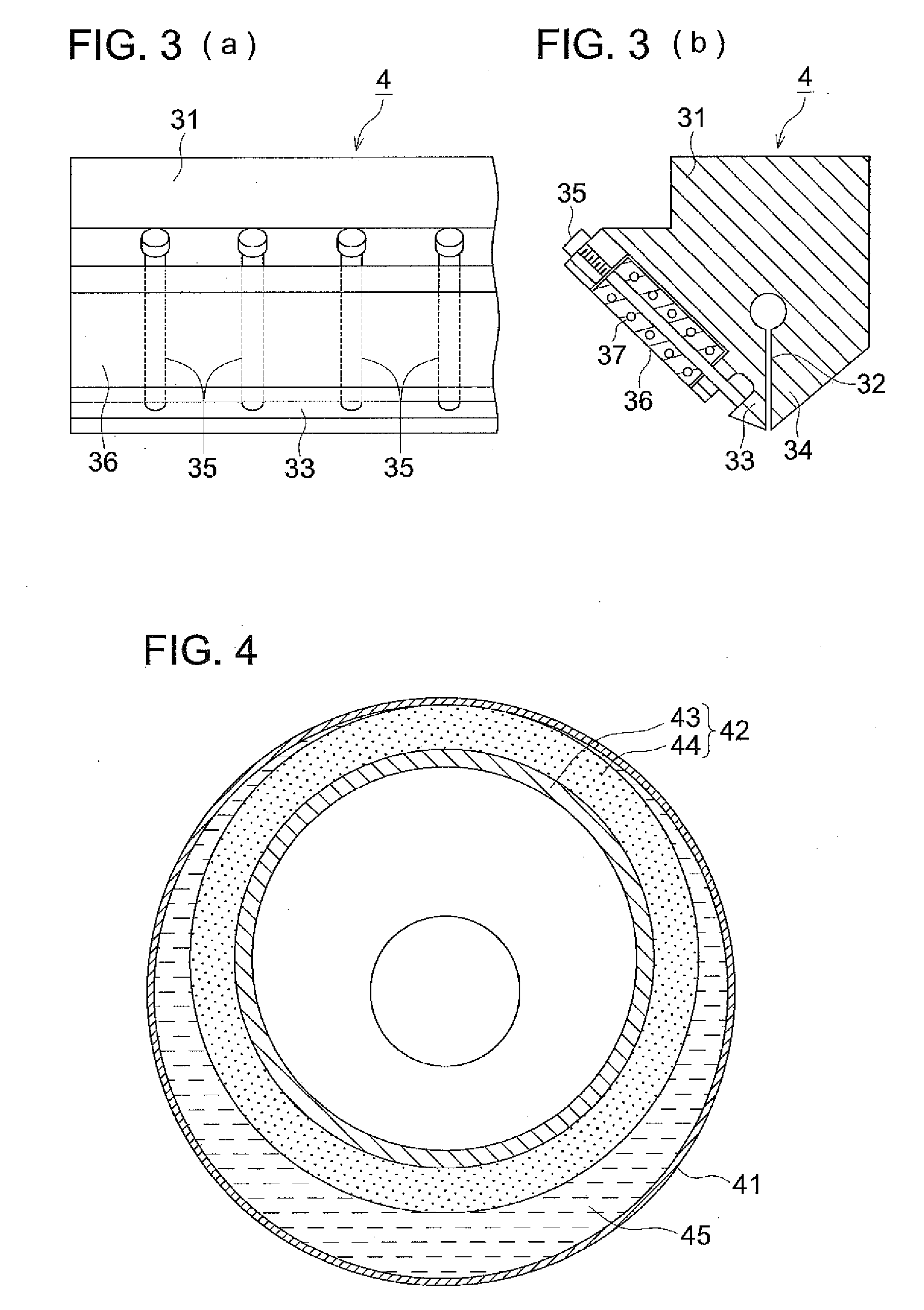

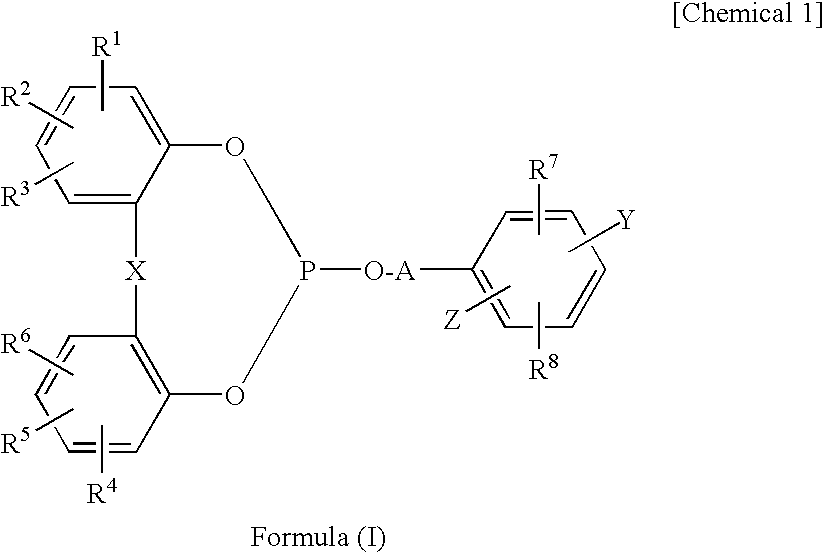

Optical Film, Method of Producing the Same and Image Displaying Apparatus Employing the Optical Film

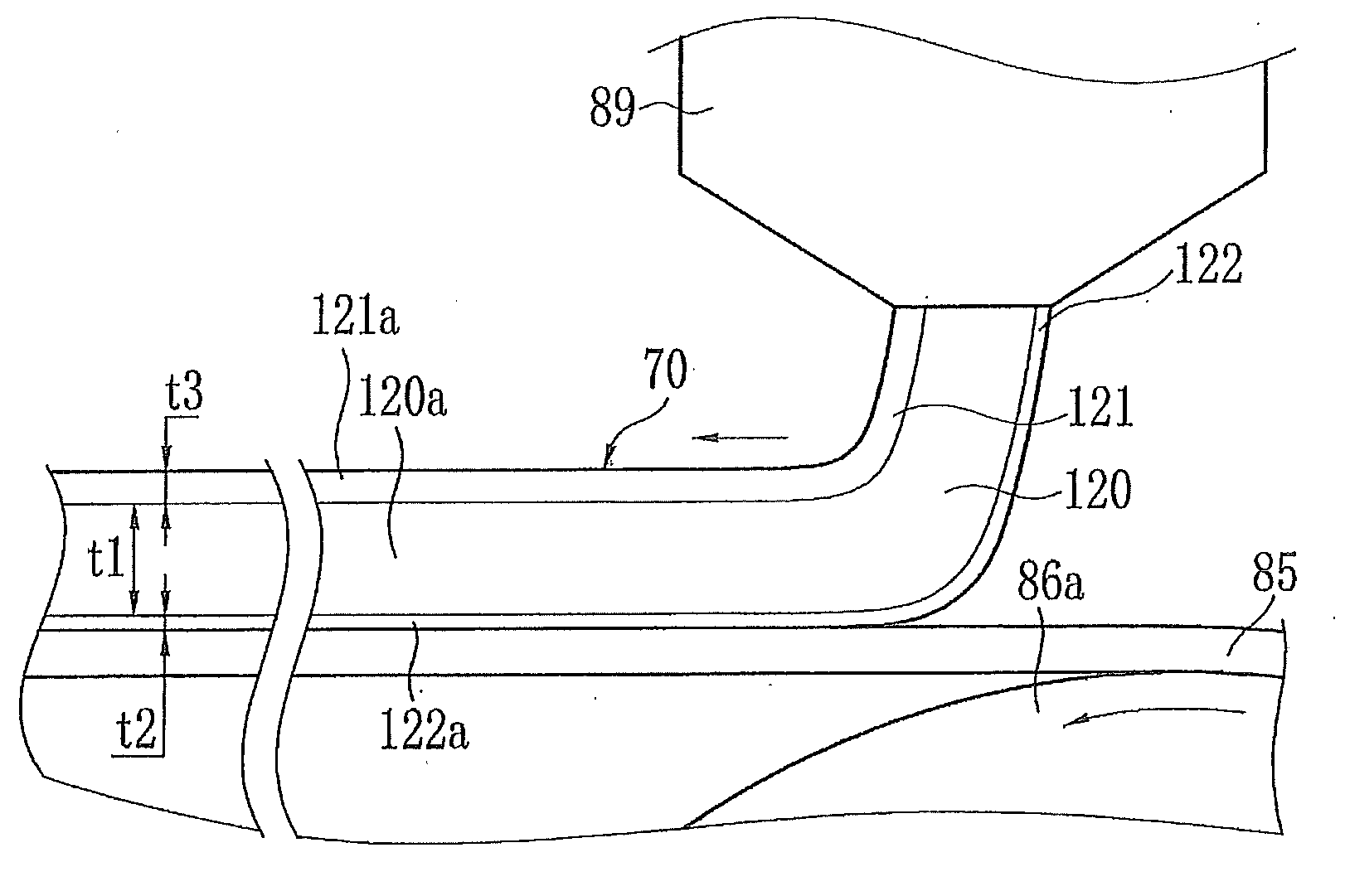

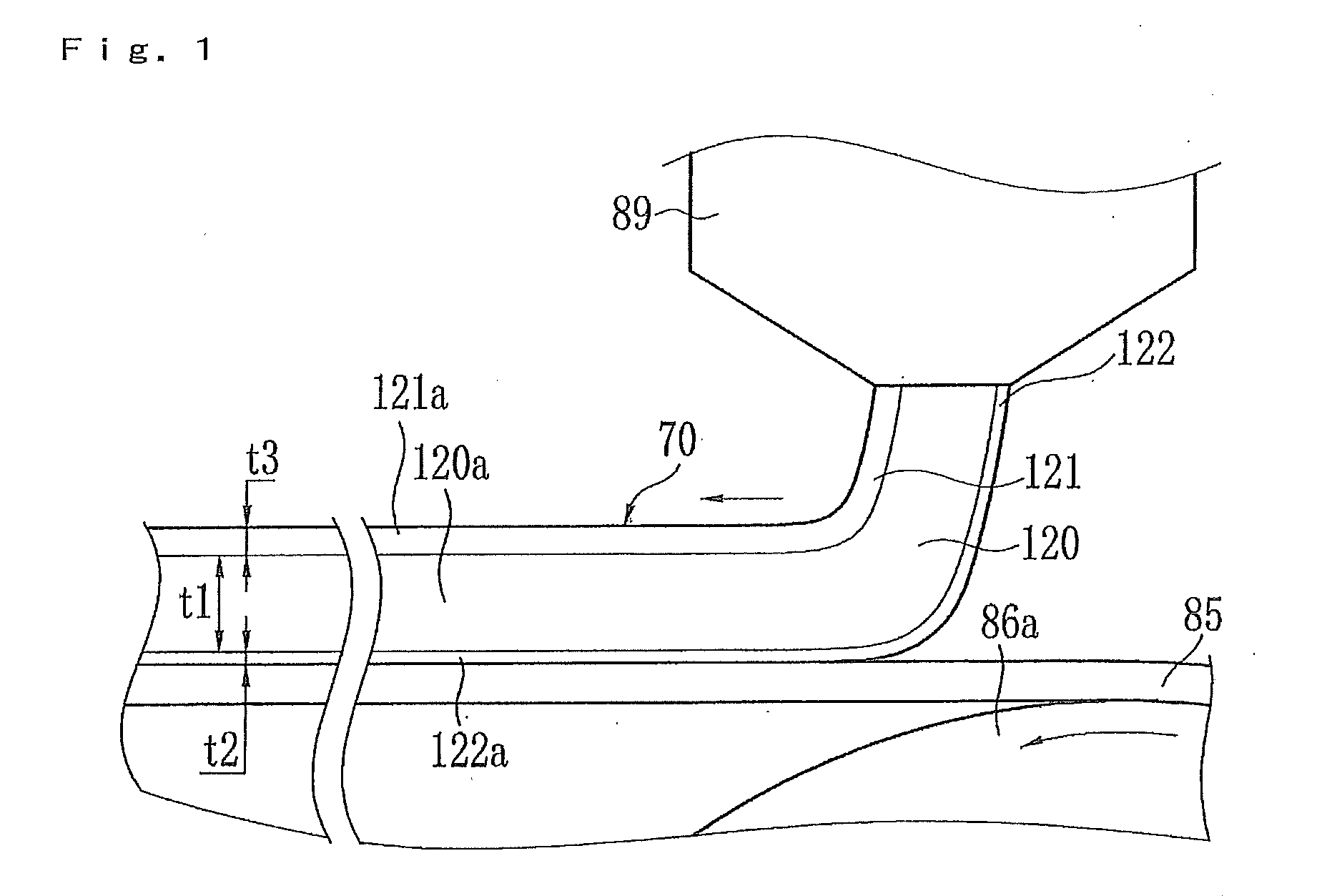

InactiveUS20090286098A1Reduce in quantitySynthetic resin layered productsCellulosic plastic layered productsCellulose ester membraneOptical thin film

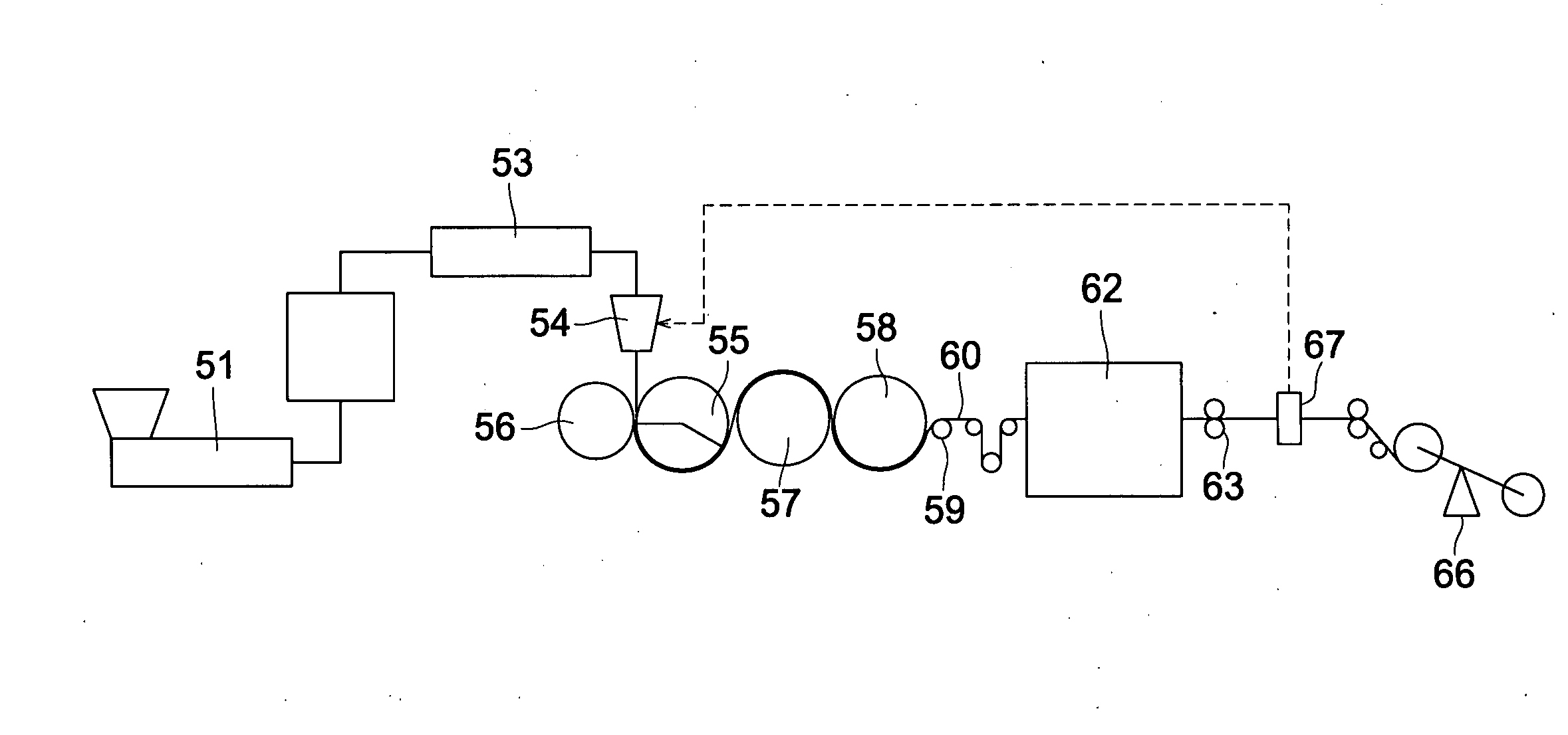

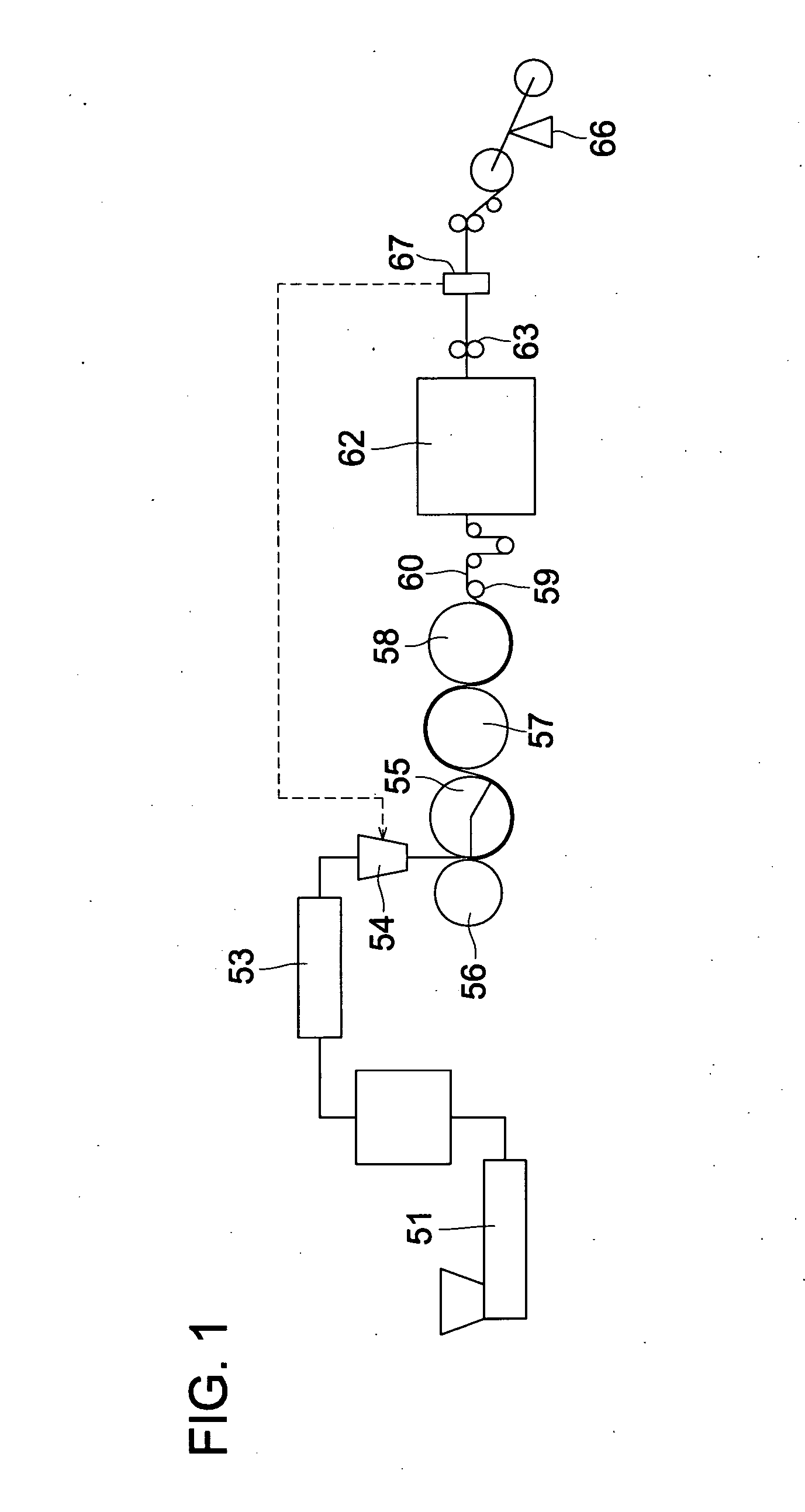

A method for producing an optical film, characterized by extruding a melt containing a cellulose ester resin from a casting die to thereby form a long length cellulose ester film at a draw ratio of 5 to 30, slitting both sides of the long length cellulose ester film and winding the same in roll form, and while unrolling the long length cellulose ester film from the roll, carrying out continuous coating of the surface hereof with an optical function layer.

Owner:KONICA MINOLTA OPTO

Cellulose ester film, cellulose ester dope, protective film of polarizing plate and polarizing plate

InactiveUS6974608B2Reduce penetrationImprove retentionLiquid crystal compositionsOptical filtersTectorial membraneCellulose ester membrane

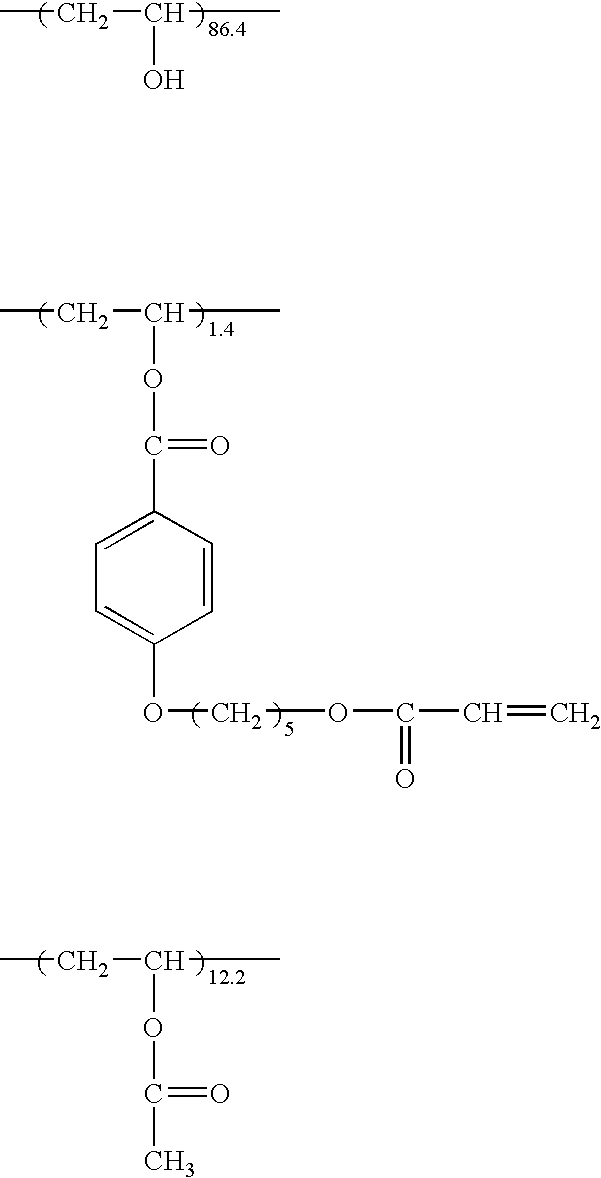

Disclosed is a cellulose ester film comprising a polymer prepared by polymerizing at least one ethylenically unsaturated monomer selected from vinyl esters, vinyl esters having a functional group, acrylic esters, and acrylic esters having a functional group, wherein the polymer has a weight average molecular weight of not more than 5,000.

Owner:KONICA CORP

Optical compensation film, viewing angle compensation integral type polarizing plate and liquid crystal display apparatus

ActiveUS6881457B2Excellent viewing angle compensation functionIncreased durabilityLiquid crystal compositionsDomestic cooling apparatusCellulose ester membraneLiquid-crystal display

An optical compensation film comprising a cellulose ester film is disclosed. In the film, (a) each of photoelastic coefficient C(md) in a mechanical direction and photoelastic coefficient C(td) in the transverse direction of the cellulose ester film is 1×10−9 to 1×10−13 Pa−1 and C(md)<C(td), (b) retardation R0 within the plane of the cellulose film defined by Formula (I) is 20 to 70 nm, (c) retardation Rt of the cellulose ester film in a thickness direction, defined by Formula (II) is 70 to 400 nm, and (d) both of a dimensional variation ratio S(md) in the mechanical direction and a dimensional variation ratio S(td) in the transverse direction of the cellulose ester film prior to and after being allowed to stand at ambient conditions of 80° C. and 90 percent relative humidity for 50 hours are −1 to 1 percent, and |S(md)|>|S(td)|.

Owner:KONICA MINOLTA INC

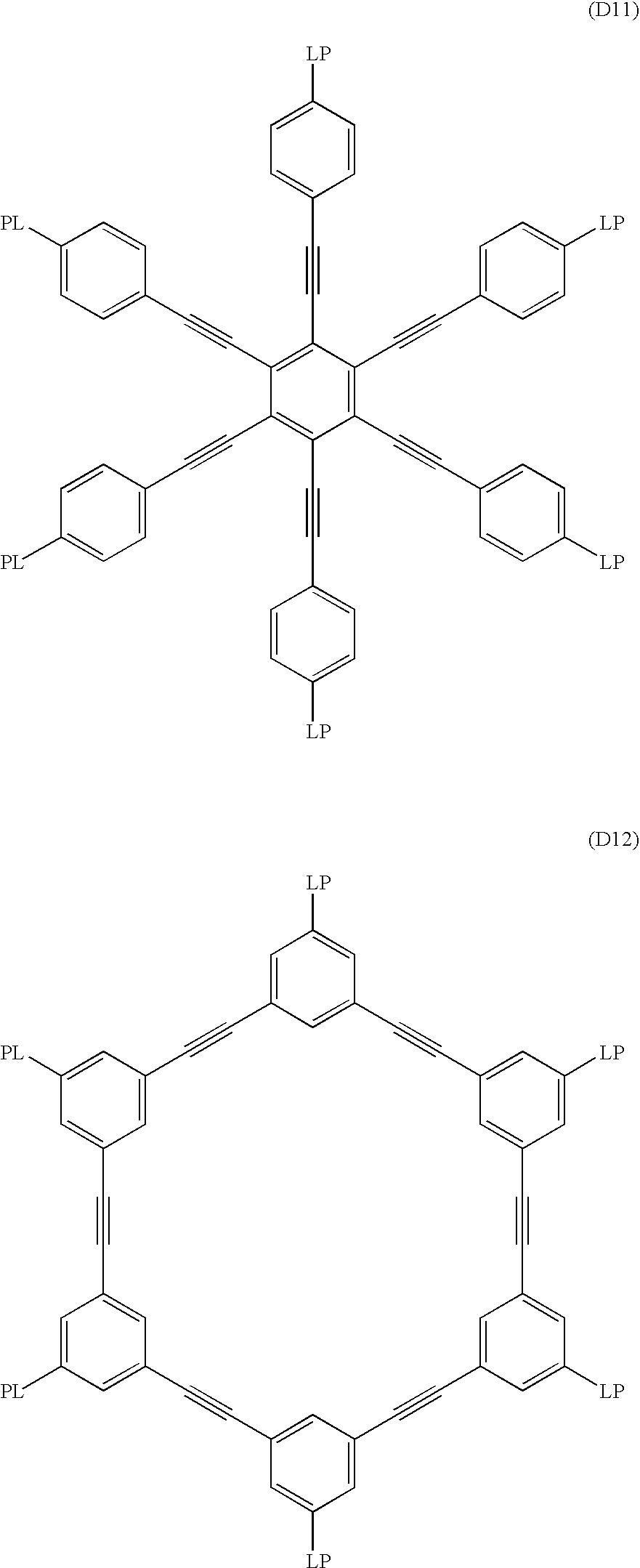

Method for manufacturing cellulose ester film, and cellulose ester film, optical film, polarizing plate and liquid crystal display device using the same

InactiveUS20060069192A1Excellent optical propertiesGood dimensional stabilityAbsorbent padsThin material handlingCellulose ester membranePolymer science

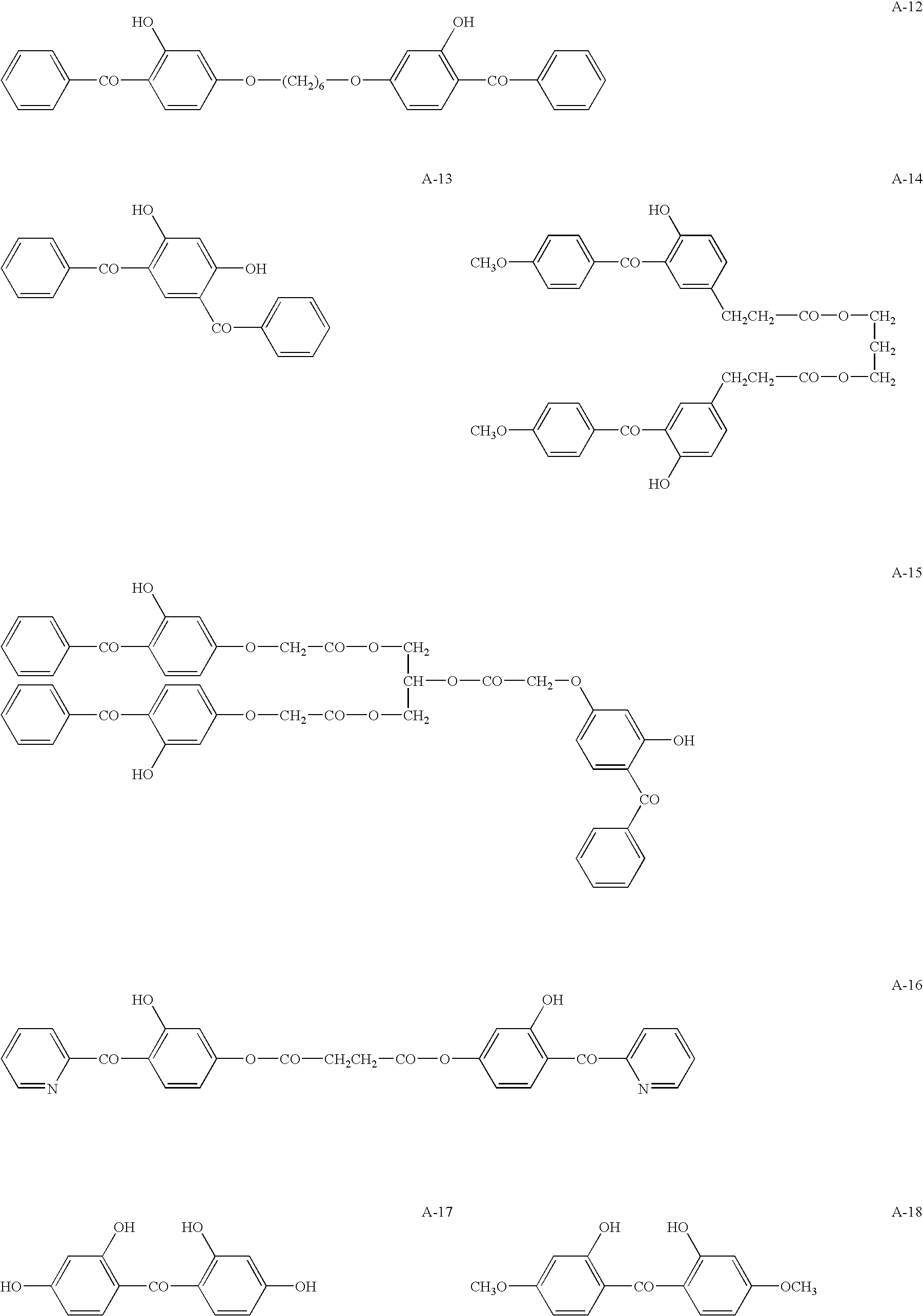

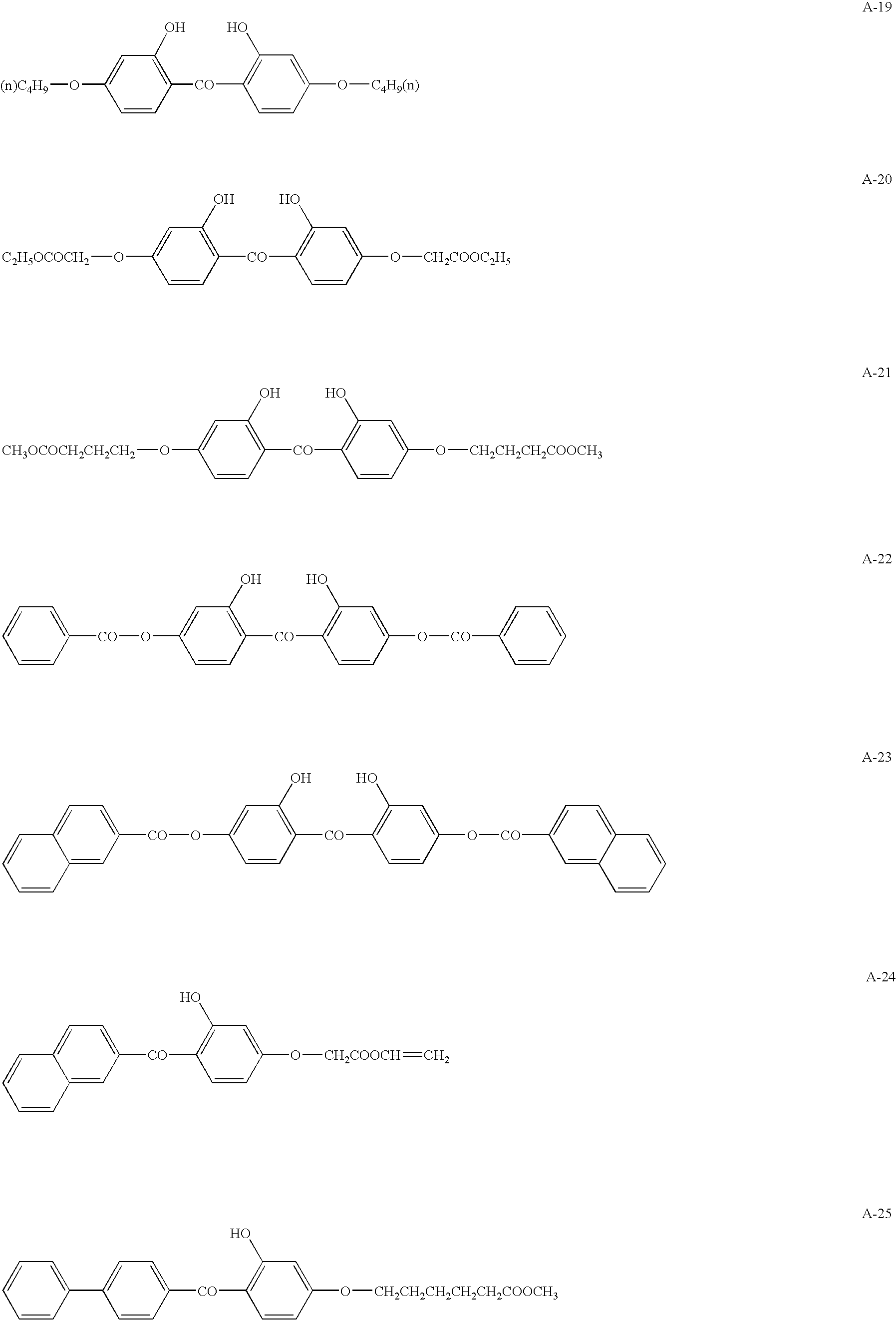

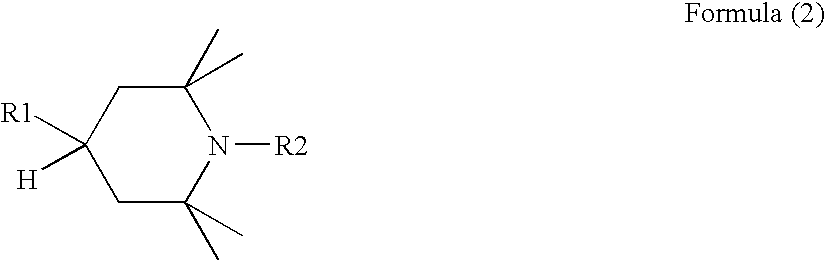

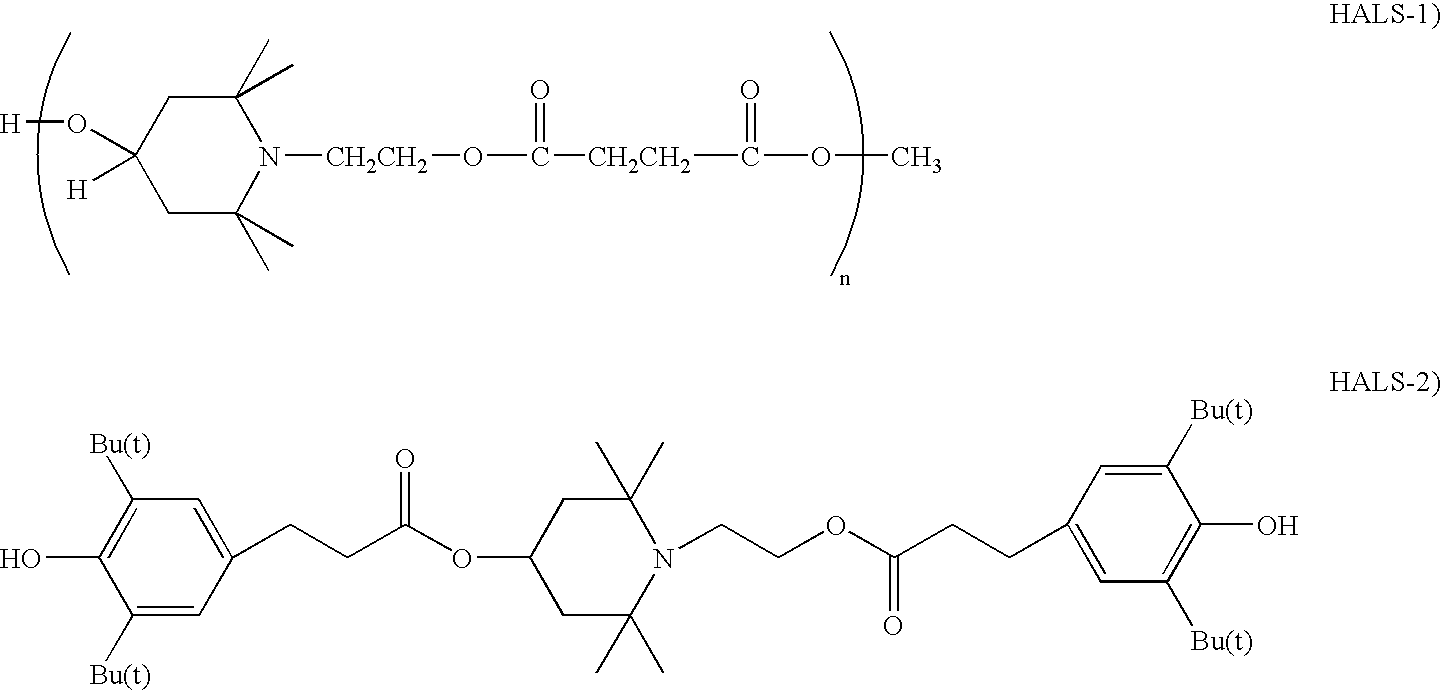

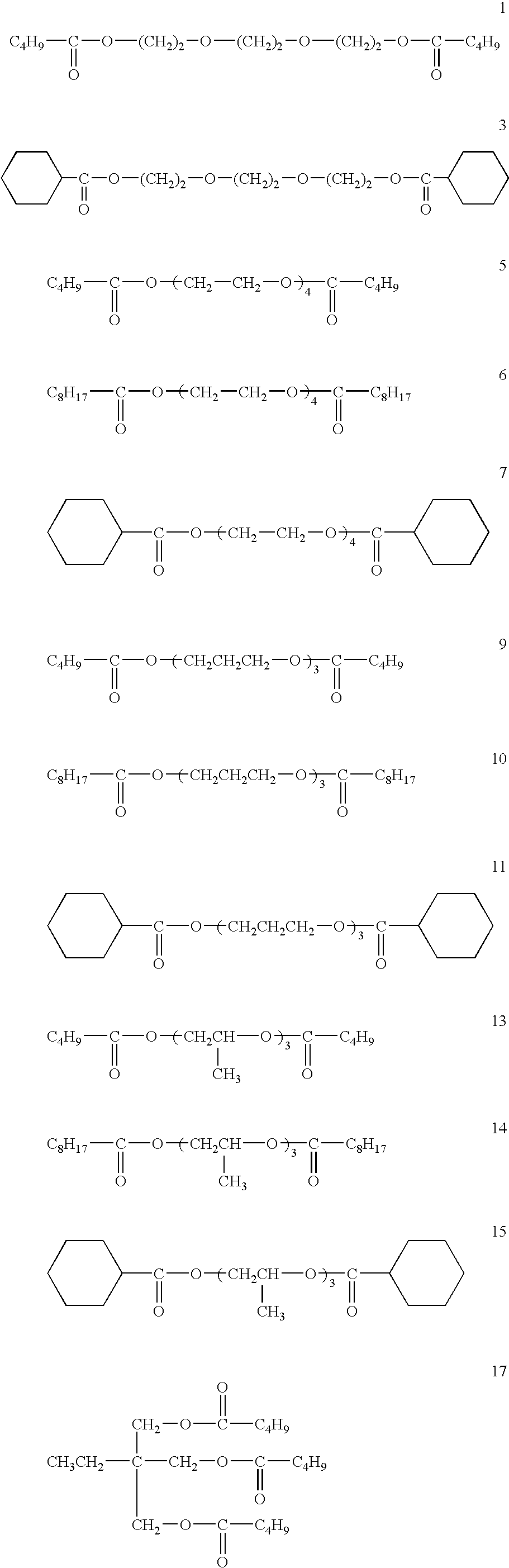

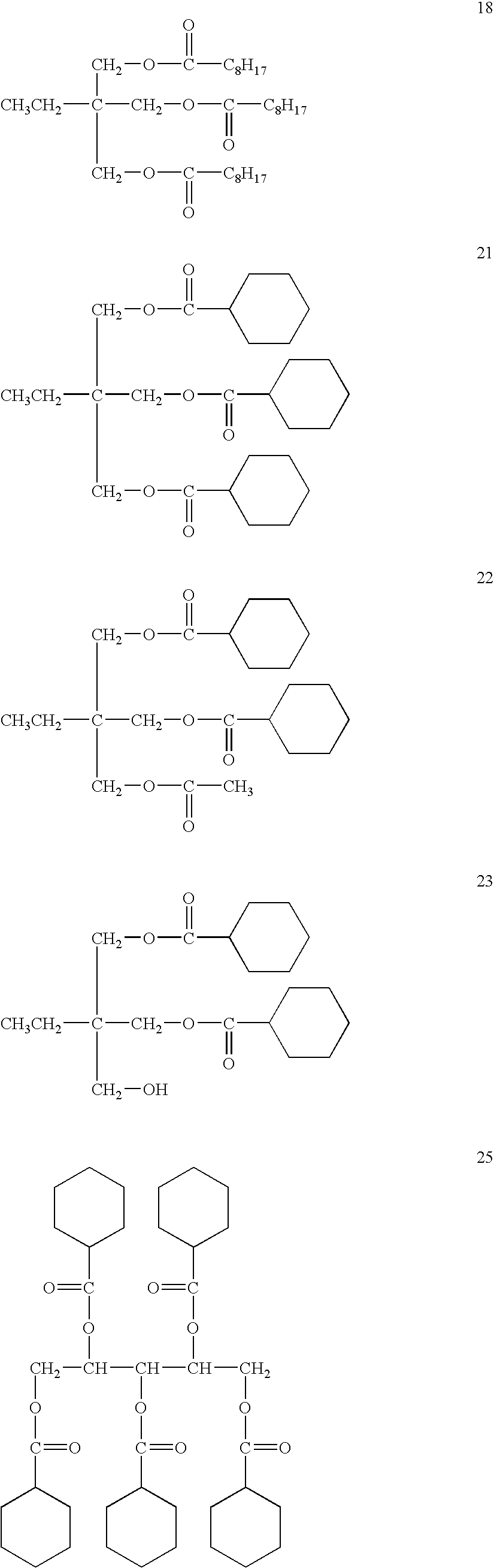

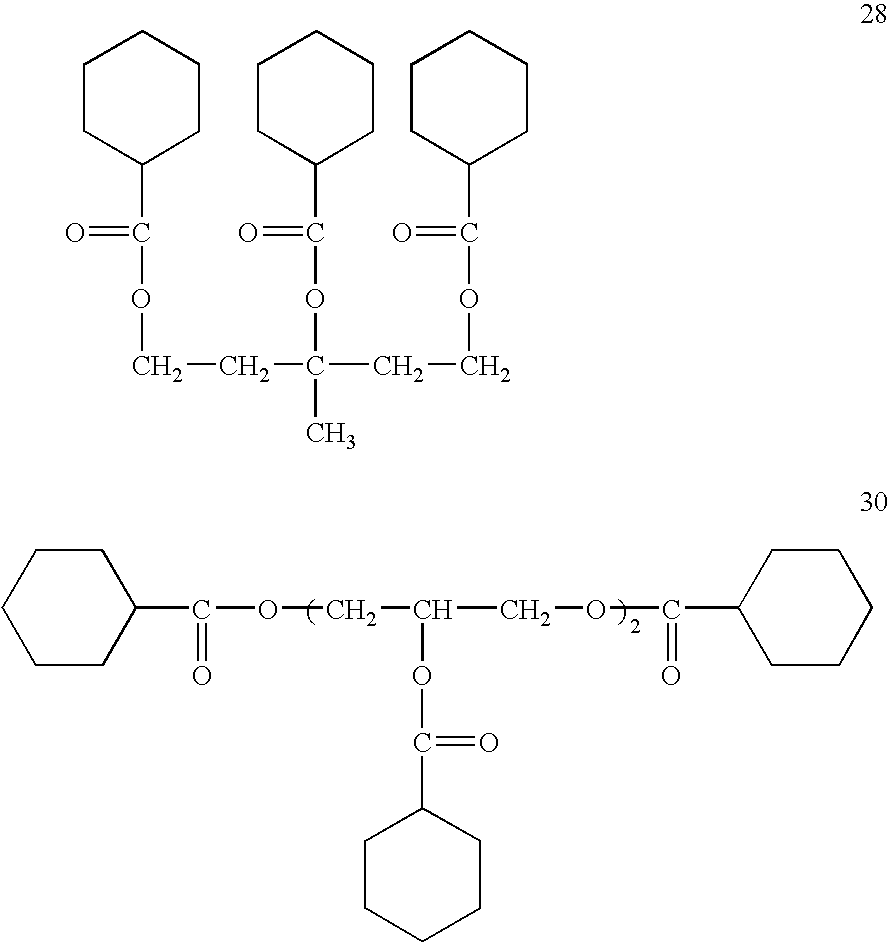

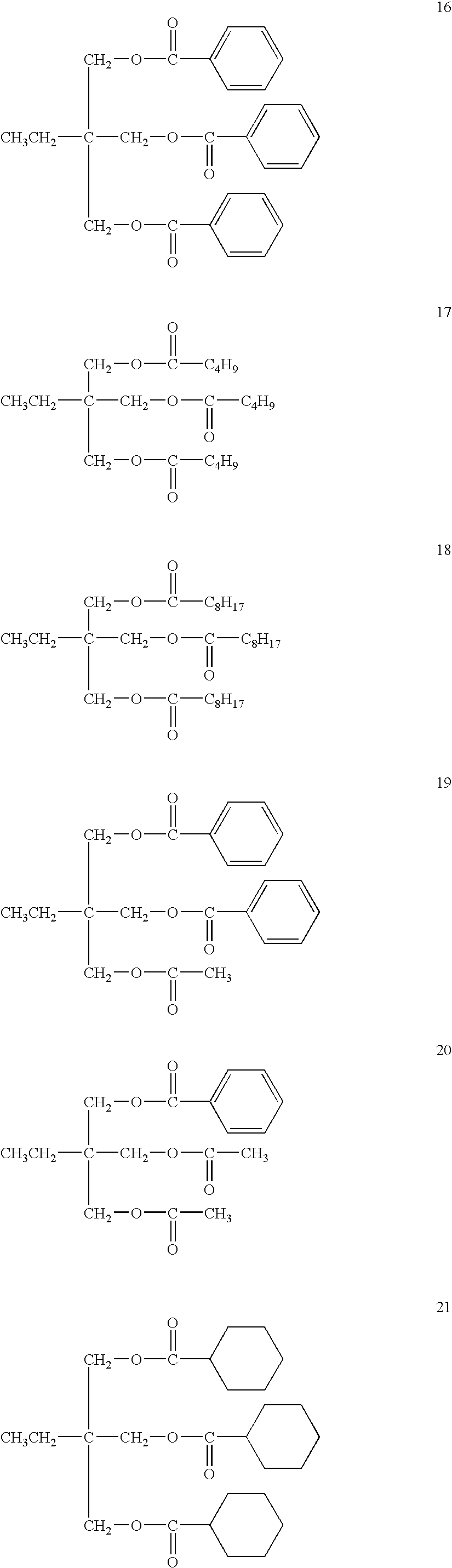

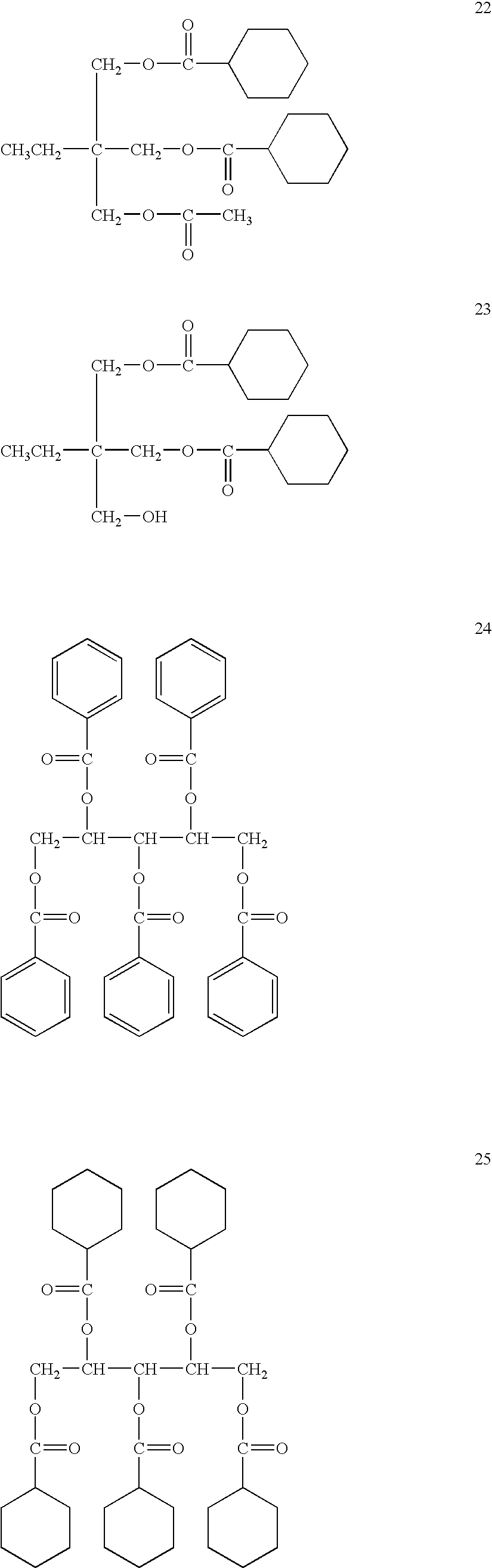

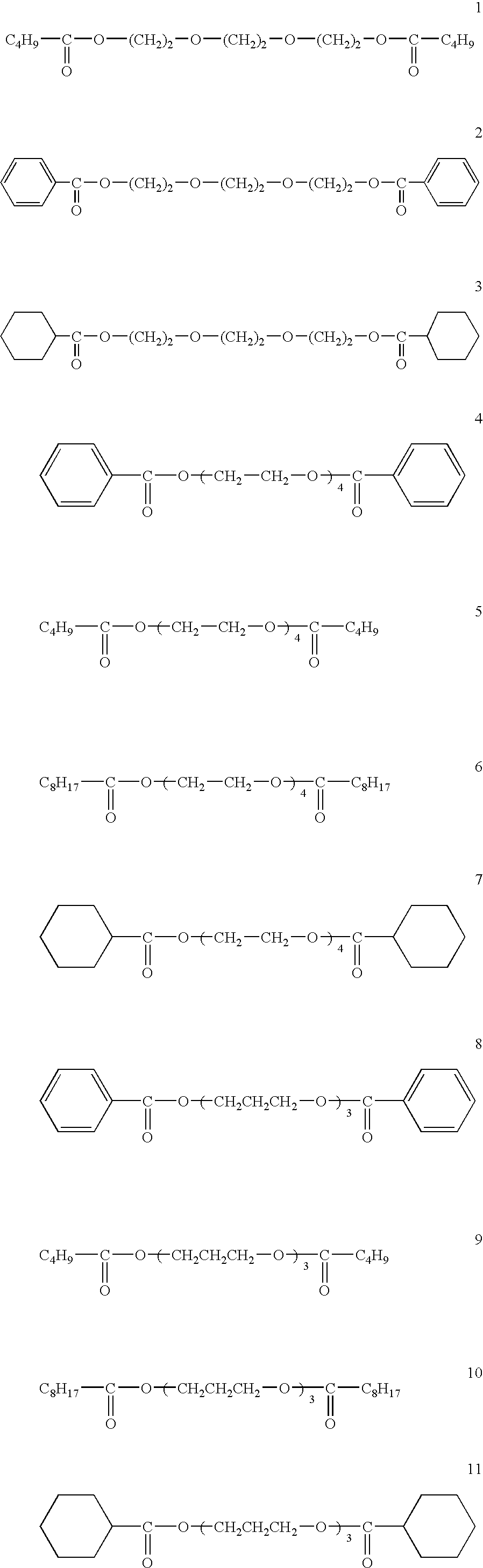

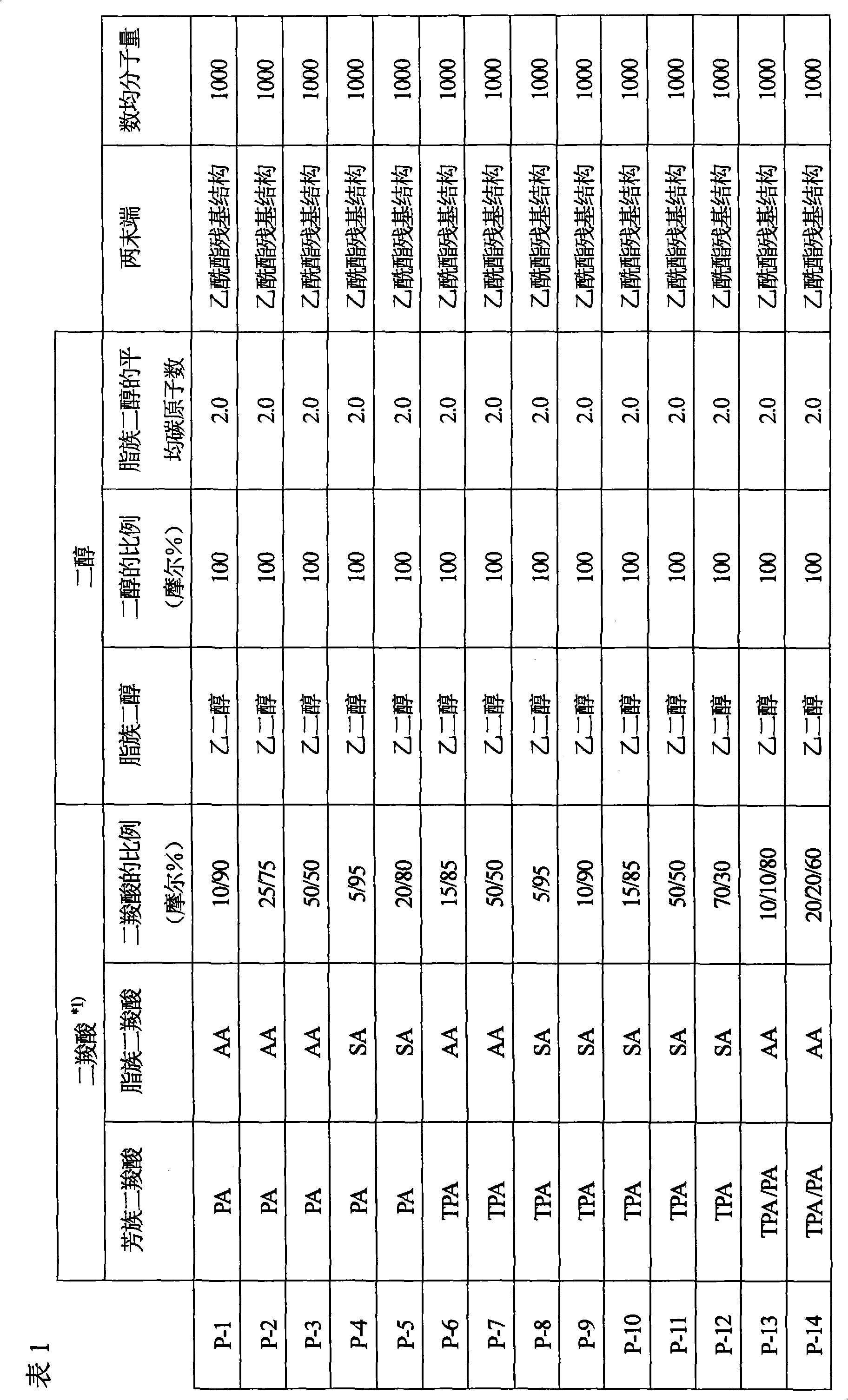

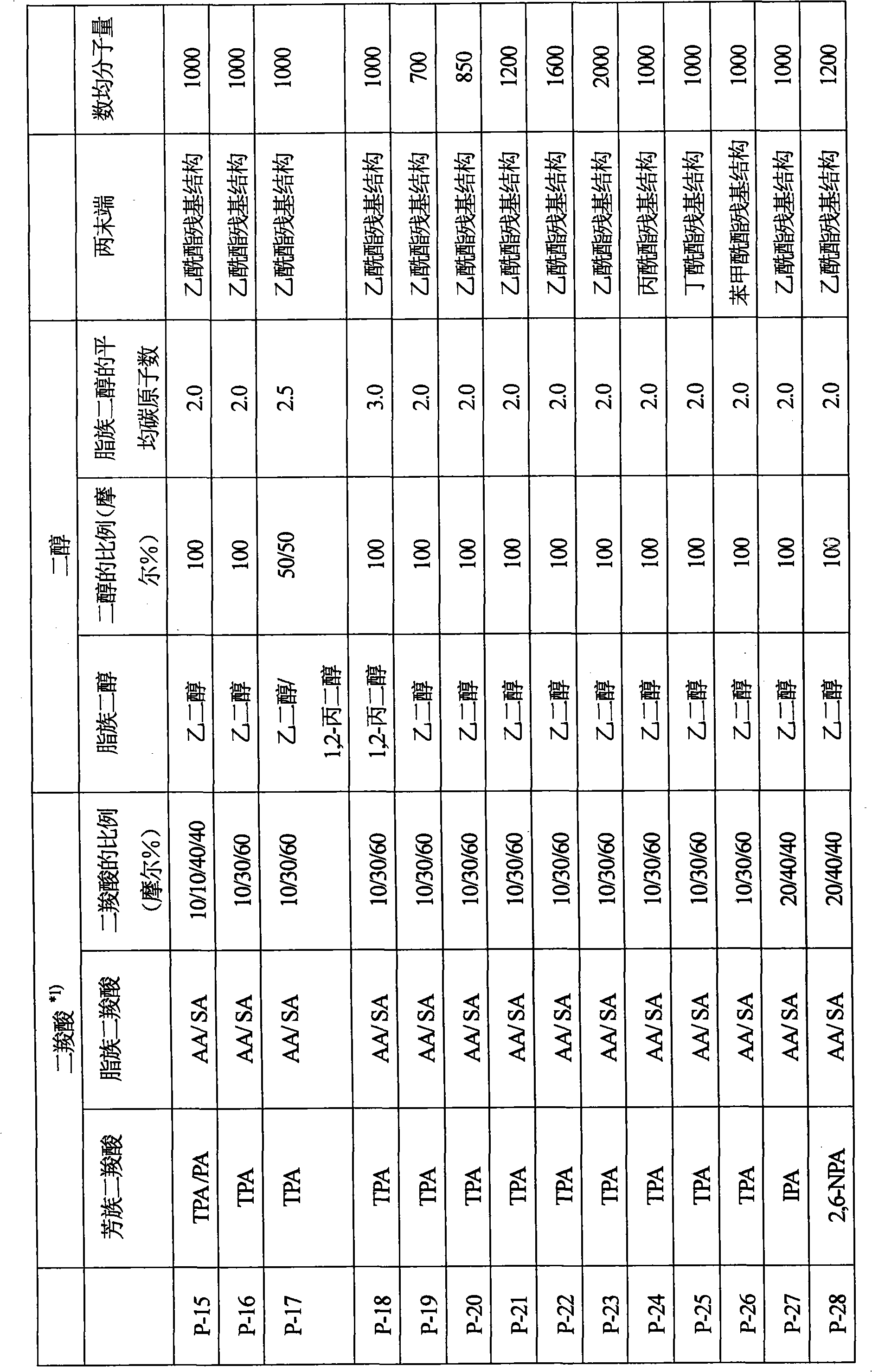

A method for manufacturing a cellulose ester film comprising the steps of 1) mixing a cellulose ester exhibiting a water content of not greater than 3.0 weight %, at least one plasticizer selected from the groups A and B in an amount of one to thirty weight % of the cellulose ester, and at least one additive selected from the groups of C and D in an amount of 0.01 to 5 weight % of the cellulose ester to obtain a mixture, group A: ester plasticizers formed from a polyhydric alcohol and a monohydric carboxylic acid; group B: ester plasicizers formed from a polyhydlic carboxylic acid and a monohydric alcohol; group C: hindered phenol anti-oxidants; group D: hindered amine light stabilizers, 2) heating to melt the mixture at a temperature (Tm) of between 150 and 300° C., and 3) forming a cellulose ester film with a melt casting method employing the melted mixture.

Owner:KONICA MINOLTA OPTO

Process for Cross-Linking Cellulose Ester Membranes

ActiveUS20080179248A1Improve rigidityImprove stabilityIon-exchange process apparatusMembranesCellulose ester membraneCross-link

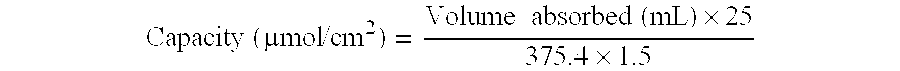

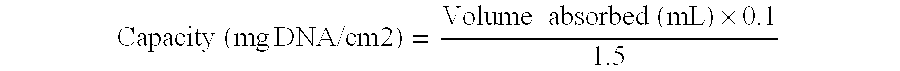

The invention relates to a process for making porous cross-linked cellulose membranes and processes for coupling a chromatography ligand to cross-linked cellulose membranes. The invention provides methods for separating a first component from a second component in a solution based upon a difference in the size of the first and second components, and methods for separating target molecules from other components in a solution comprising use of membranes obtainable by the process of the invention. The method has particular utility in separating proteins from cell lysates and cultures.

Owner:CYTIVA BIOPROCESS R&D AB

Cellulose and cellulose ester film

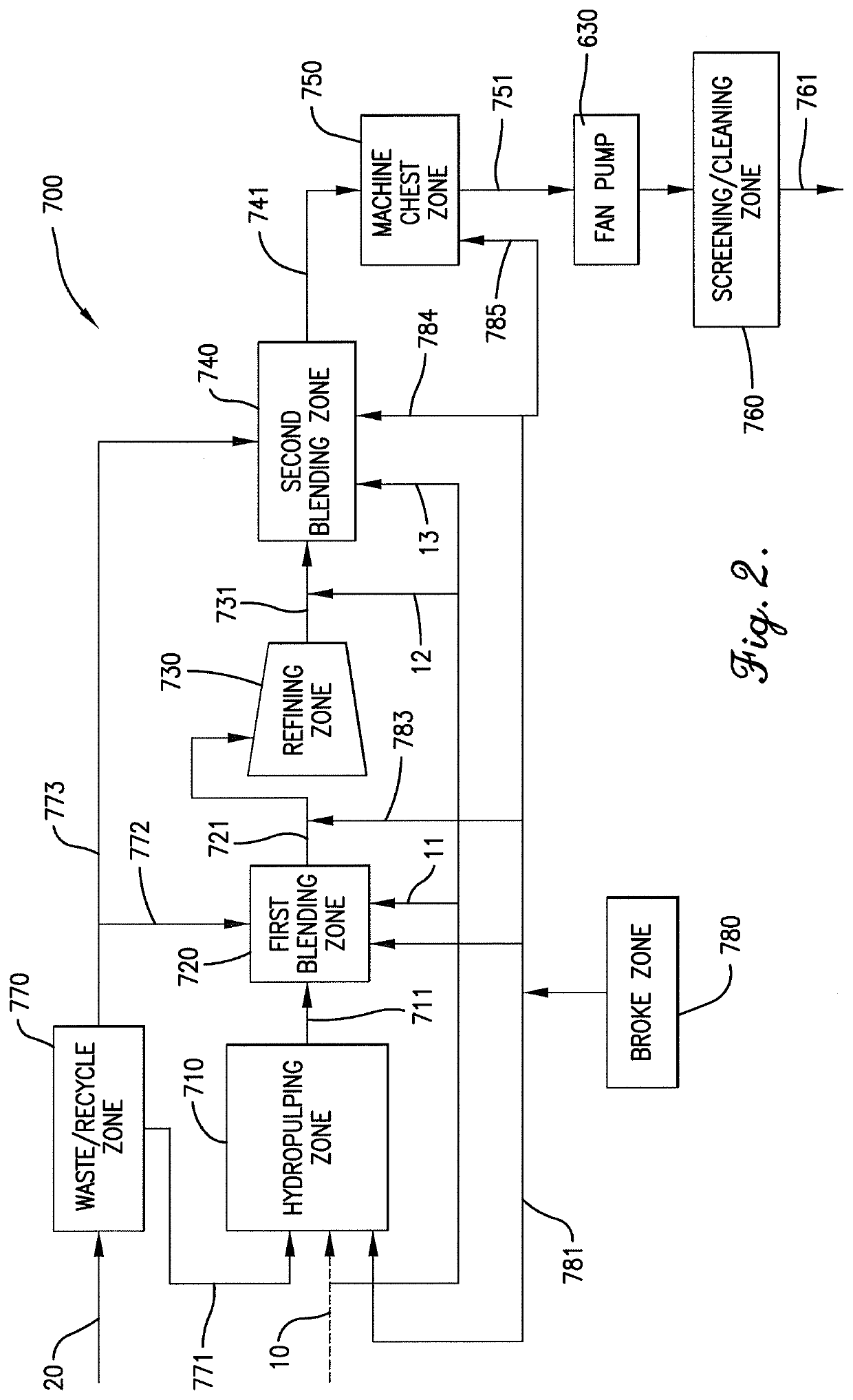

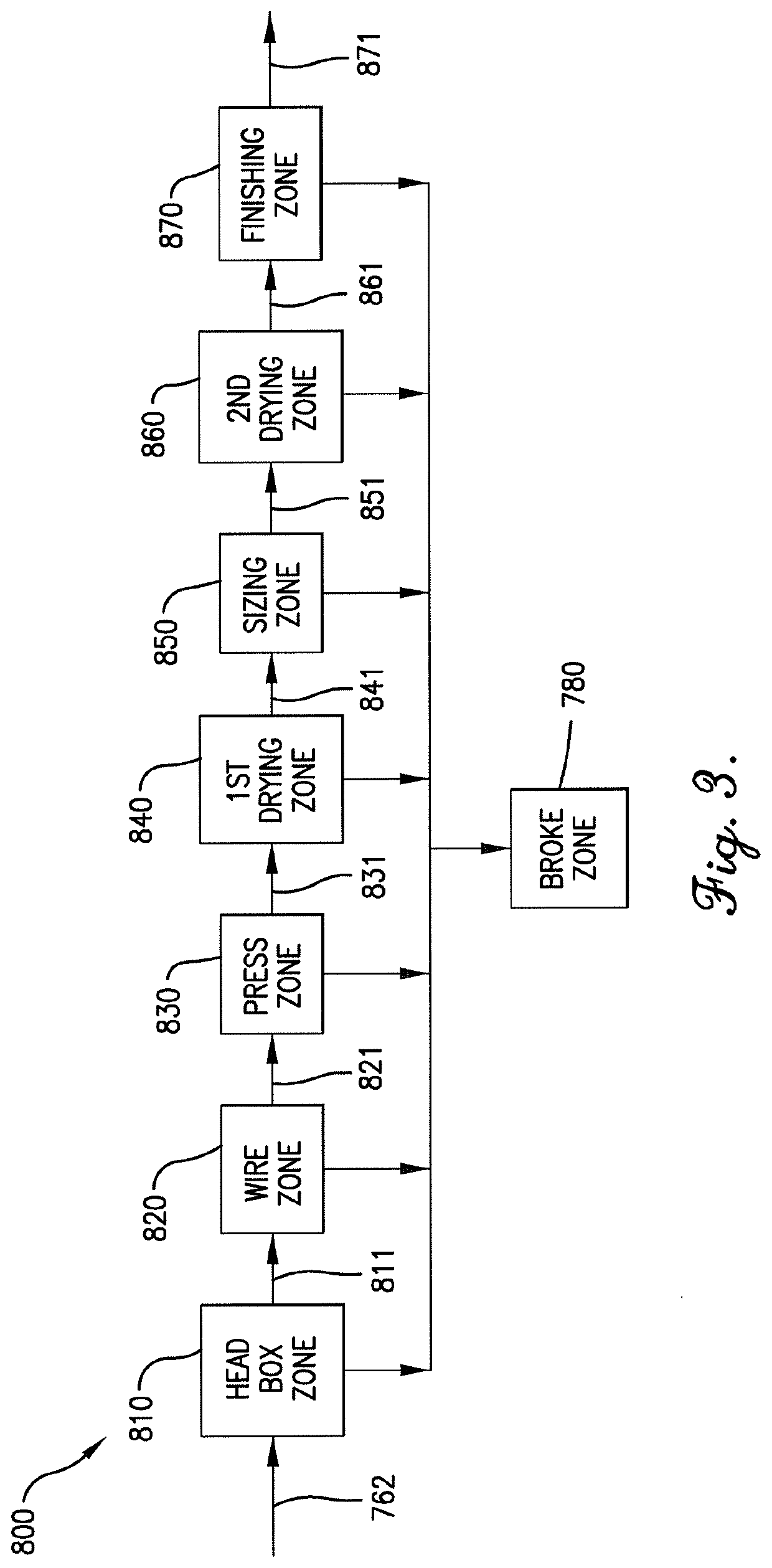

ActiveUS20200063353A1Reduce consistencyLow variabilityNon-fibrous pulp additionSpecial paperCellulose ester membranePolymer science

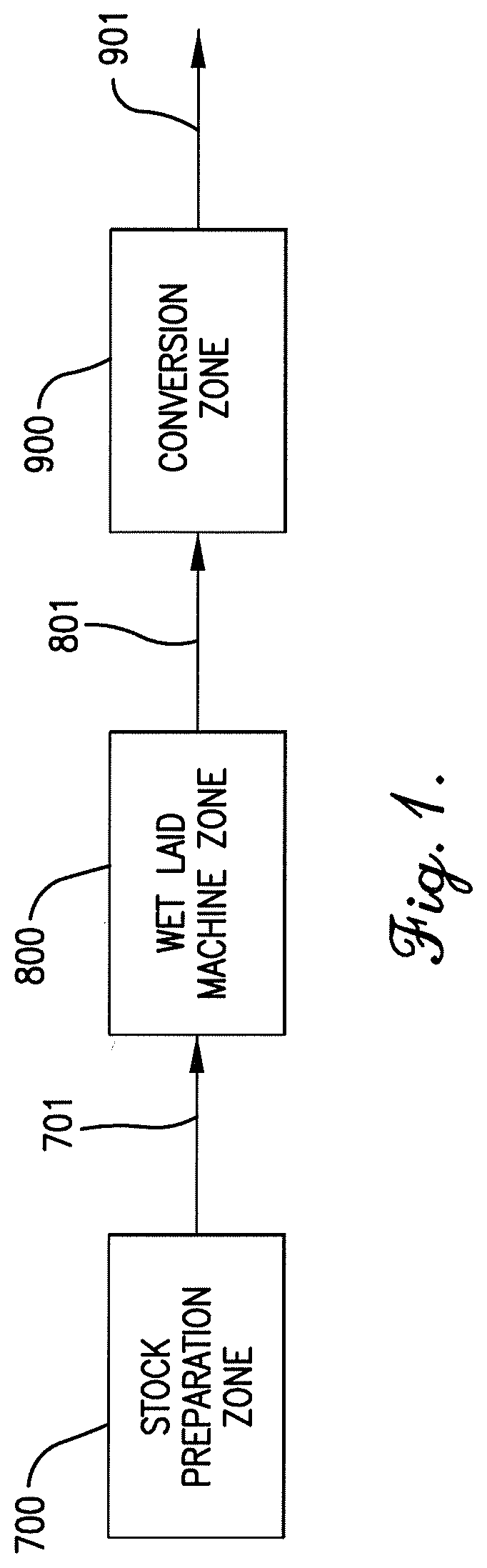

A film is made from a wet laid product containing cellulose fibers and cellulose ester fibers and a plasticizer. The film can be made by heat pressing the wet laid sheet to form a film having a continuous phase of cellulose ester resin and a discontinuous phase of cellulose fibers.

Owner:EASTMAN CHEM CO

Cellulose ester film, polarizing plate for in-plane-switching mode display and in-plane-switching mode display using the cellulose ester film

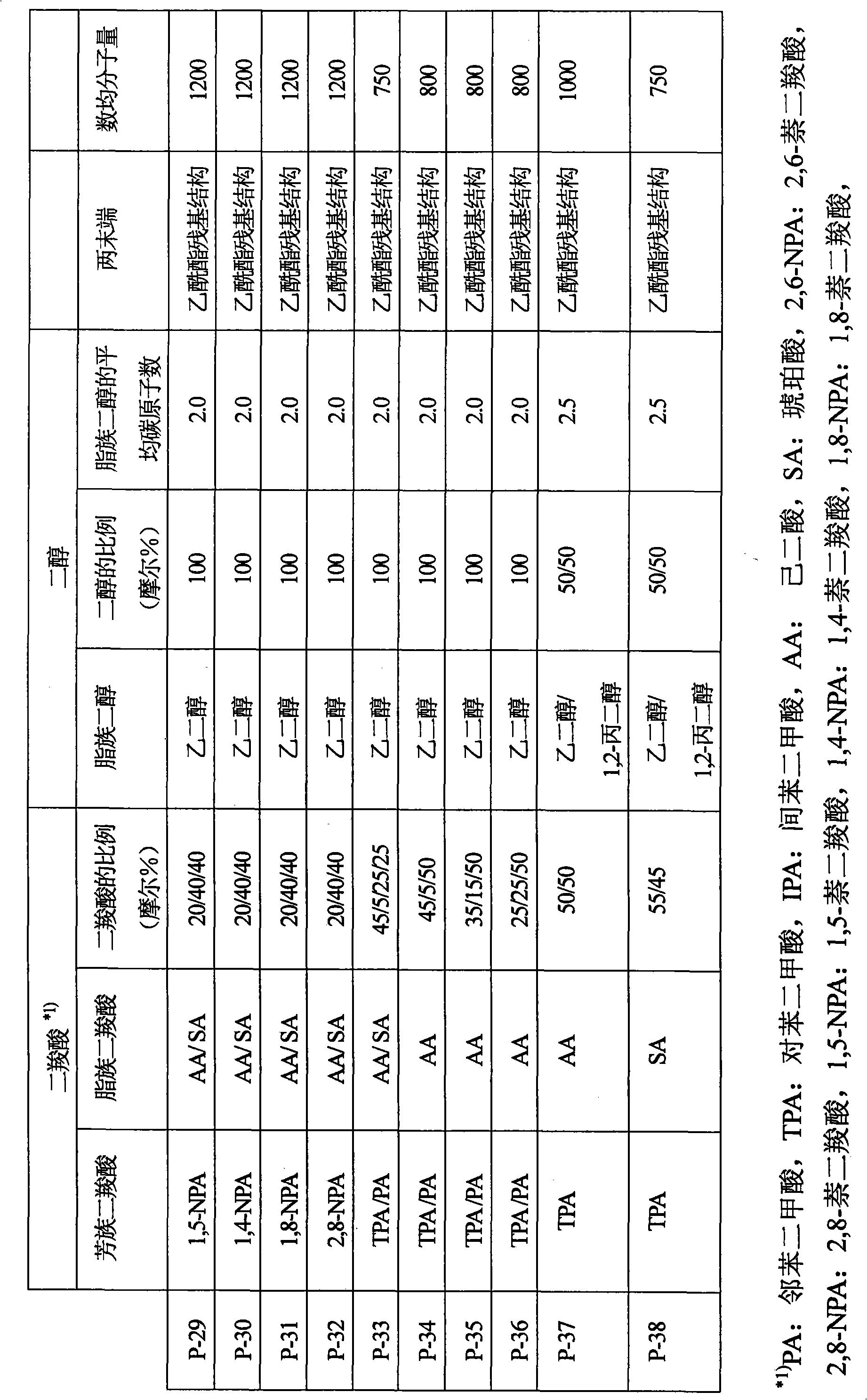

InactiveUS20070048462A1Good angle stabilityImprove flatnessLiquid crystal compositionsProtein adhesivesIn planePolyester

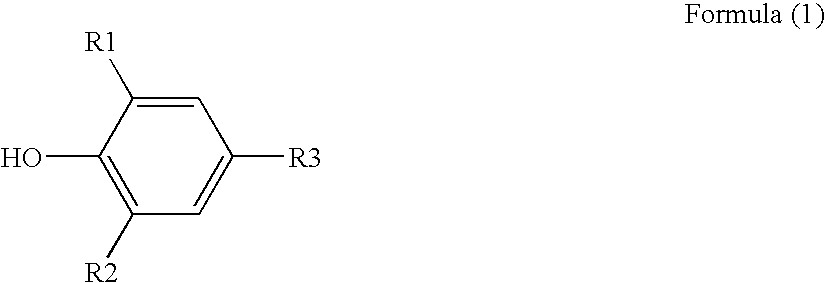

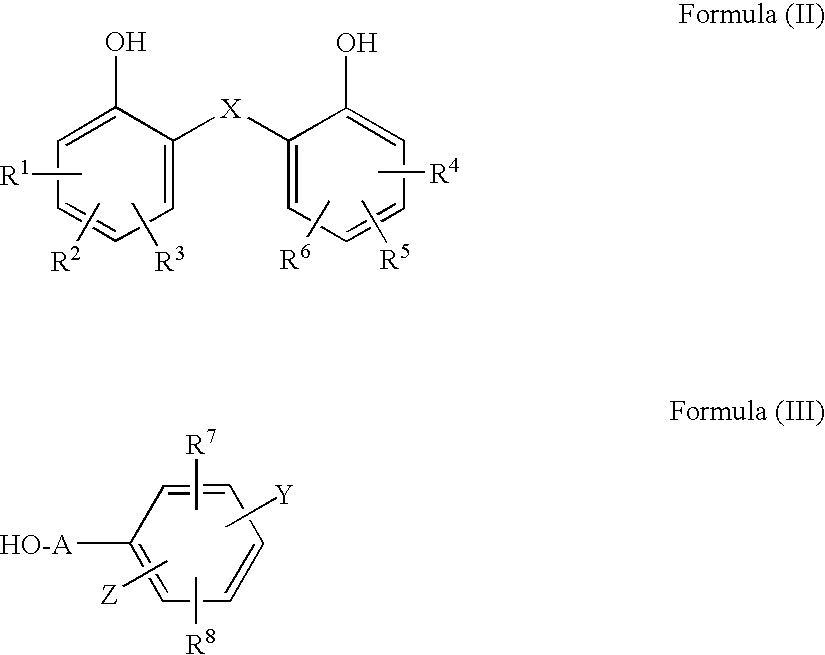

A cellulose ester film containing a polyester represented by Formula (1) or (2), wherein an in-plane retardation value (Ro) is 0 to 5 nm and a retardation value in a thickness direction (Rt) is −20 to 10 nm, Ro and Rt being measured at 23° C. and 55% RH: B1-(G-A-)mG-B1 Formula (1) wherein B1: monocarboxylic acid, G: dihydric alcohol, A: dibasic acid, B1, G and A contain no aromatic ring, m: repeat number, plural B1 may be the same or different, and plural G may be the same or different; and B2-(A-G-)nA-B2 Formula (2) wherein B2: monoalcohol, G: dihydric alcohol, A: dibasic acid, provided that none of B2, G and A contains an aromatic ring, n: repeat number, plural B2 may be the same or different, and plural G may be the same or different.

Owner:KONICA MINOLTA OPTO

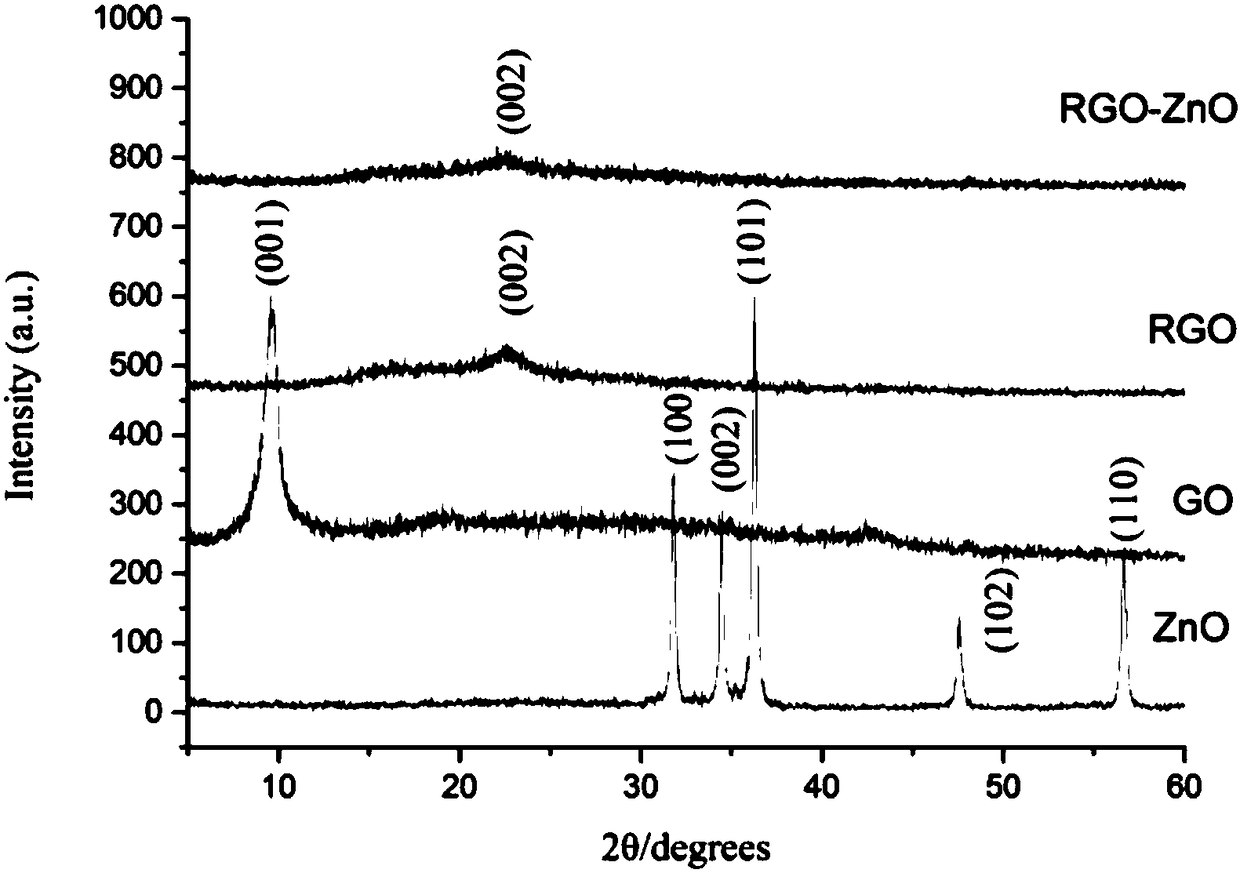

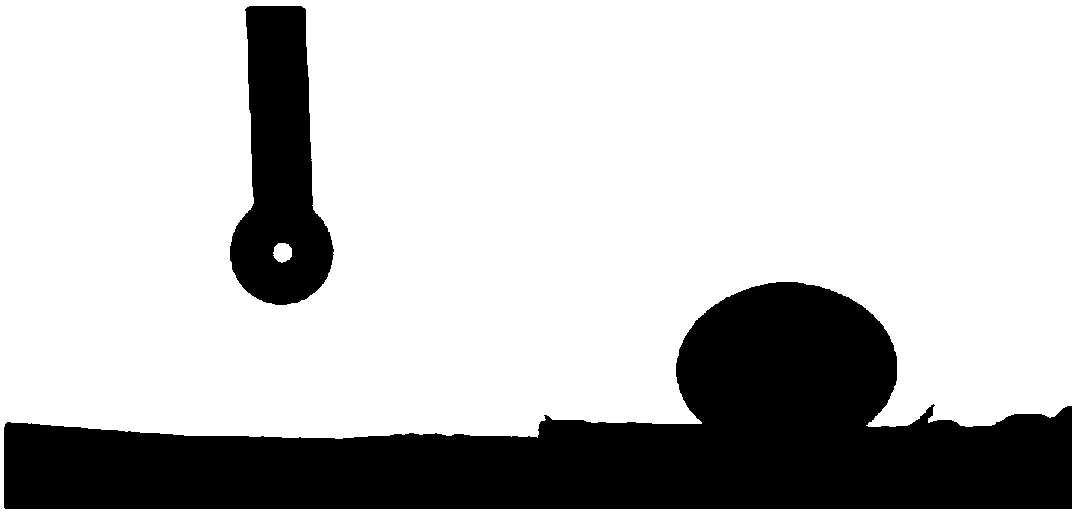

Ultra-hydrophilic-superoleophobic reduced graphene oxide filtering membrane and use

InactiveCN108159889AUndisturbedSimple processMembranesSemi-permeable membranesCellulose ester membraneFiltration

The invention relates to an ultra-hydrophilic-superoleophobic reduced graphene oxide filtering membrane and use, and belongs to the technical field of separation membrane preparation. First, grapheneoxide and nano-zinc oxide are added to distilled water and ultrasonically dispersed; a dopamine solution containing dopamine hydrochloride is added and mechanically stirred; the mixed solution is thensuction-filtered and deposited onto the surface of a mixed cellulose ester membrane by vacuum suction filtration, and the ultra-hydrophilic-underwater superoleophobic unsupported reduced graphene oxide filtering membrane is obtained by drying and self falling. The reduced graphene oxide membrane has the advantages of high water permeation selectivity, flux and stability, and membrane pollution resistance, can effectively separate oily wastewater, provides an efficient, environmentally friendly and economic technical means, and has important practical significance.

Owner:JIANGSU UNIV

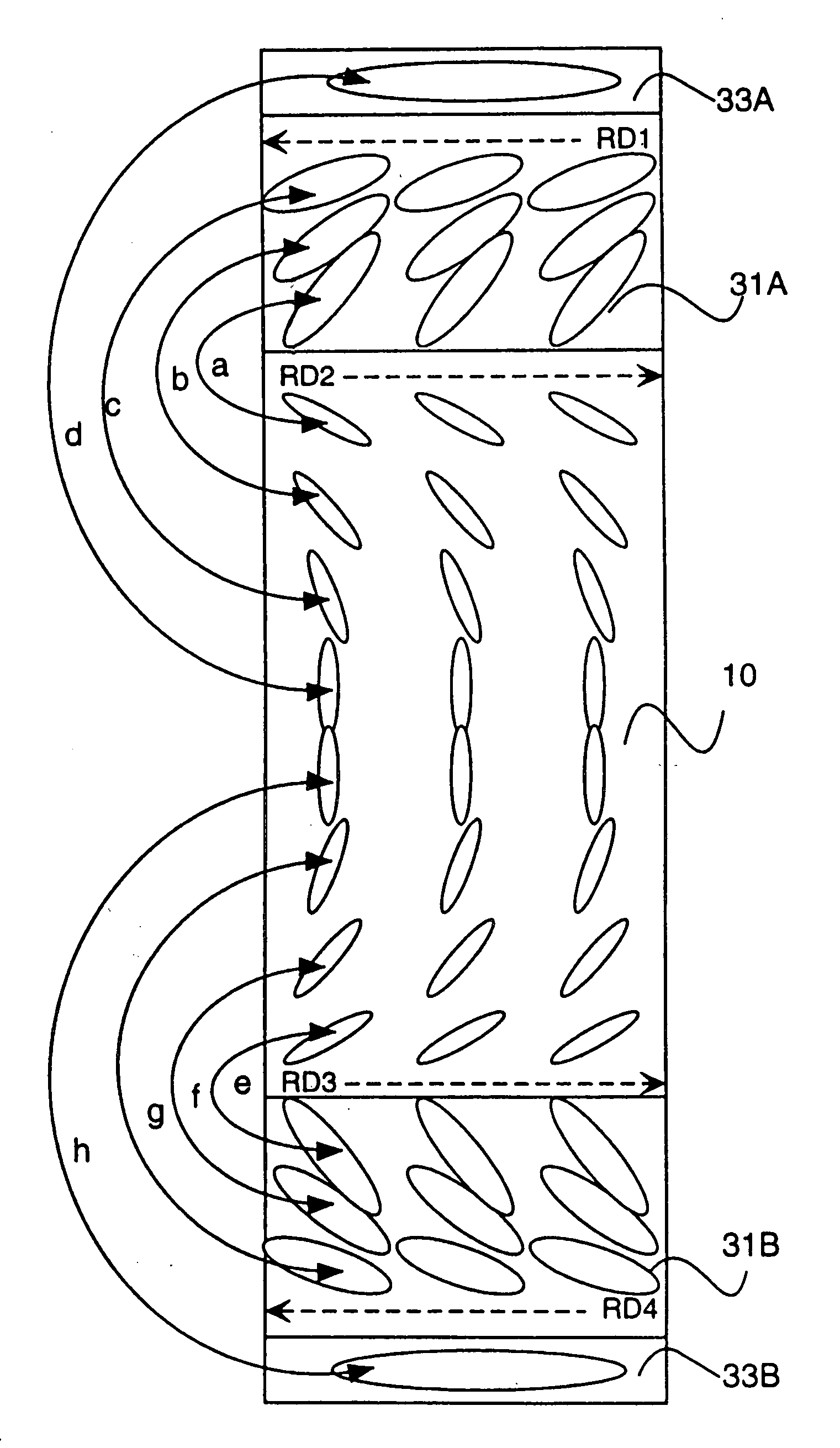

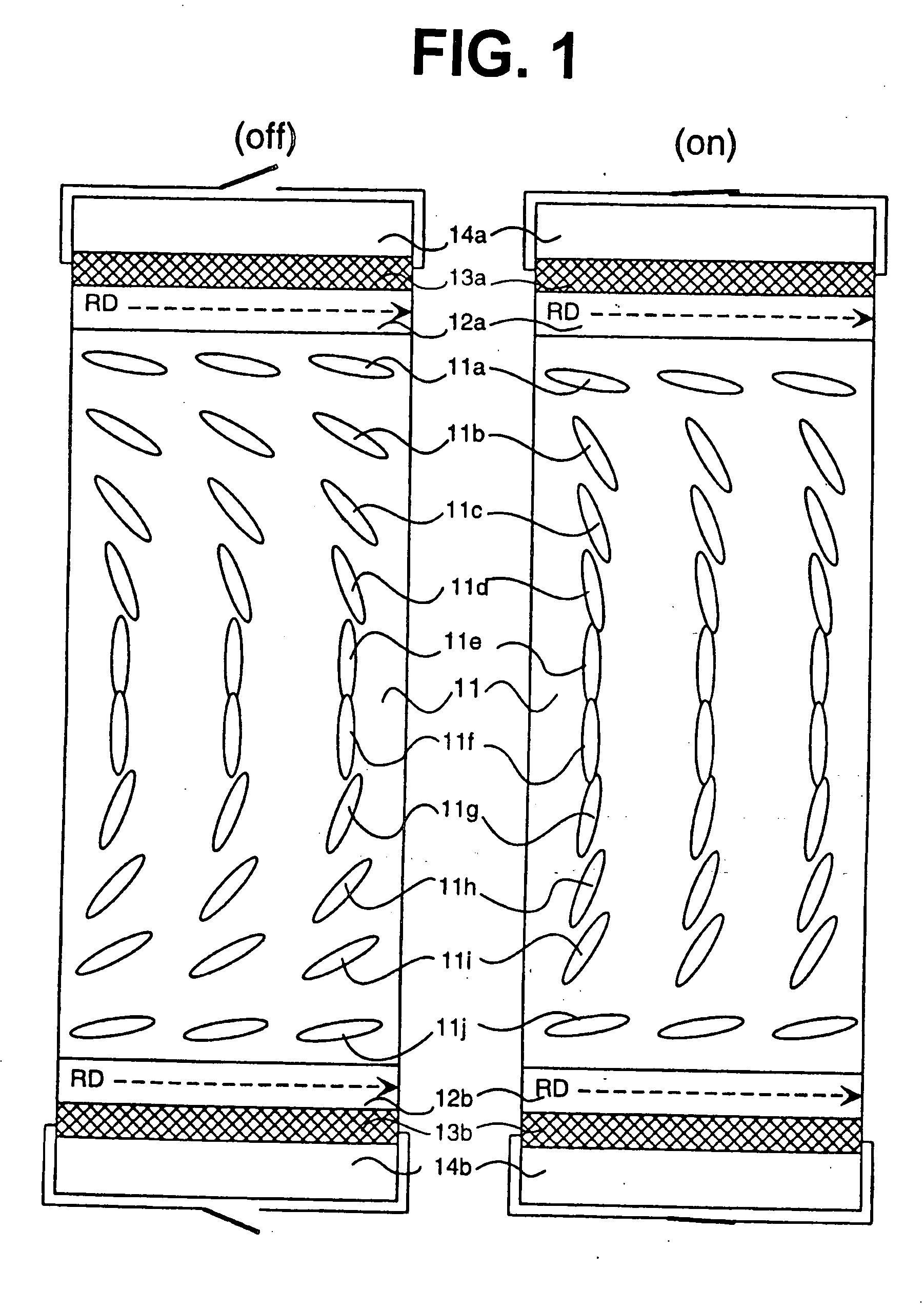

Optical compensating sheet having cellulose ester film, alignment film, and optically anisotropic layer comprising liquid-crystalline molecules with fixed alignment

InactiveUS20040052977A1Fine surfaceImprove adhesionLiquid crystal compositionsPolarising elementsCrystallographyCellulose ester membrane

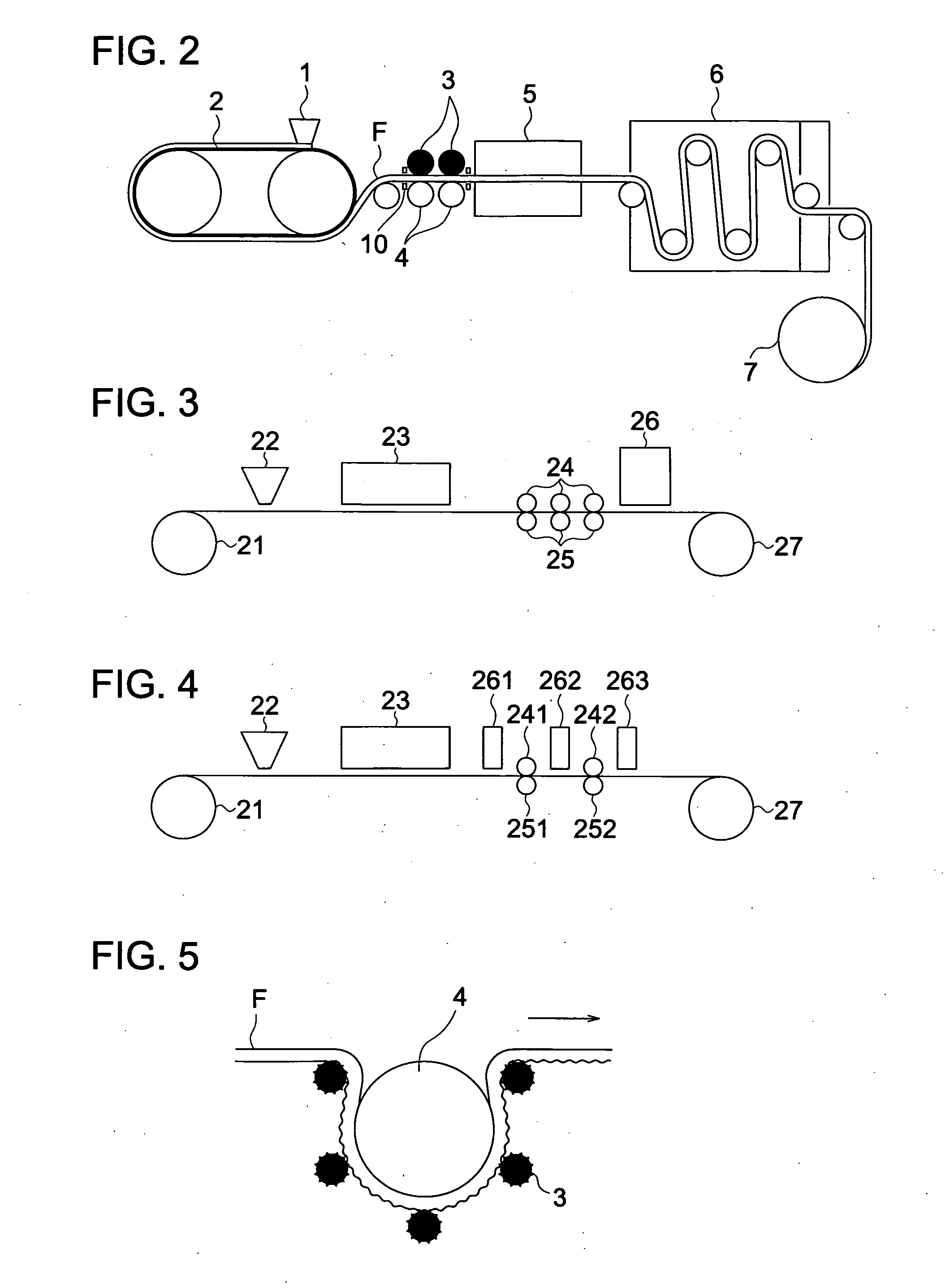

An optical compensatory sheet comprises a cellulose ester film, an orientation layer and an optically anisotropic layer formed of liquid crystal molecules in this order. Alignment of the liquid crystal molecules is fixed. An alkaline solution is coated on a surface of the cellulose ester film to saponify the surface. The saponified surface is coated with a coating solution of the orientation layer.

Owner:FUJIFILM CORP

Polarizing plate and liquid crystal display apparatus using the same

InactiveUS7704570B2Good dimensional stabilityHighly stabilized viewing angleLiquid crystal compositionsPolarising elementsCellulose ester membranePhosphoric Acid Esters

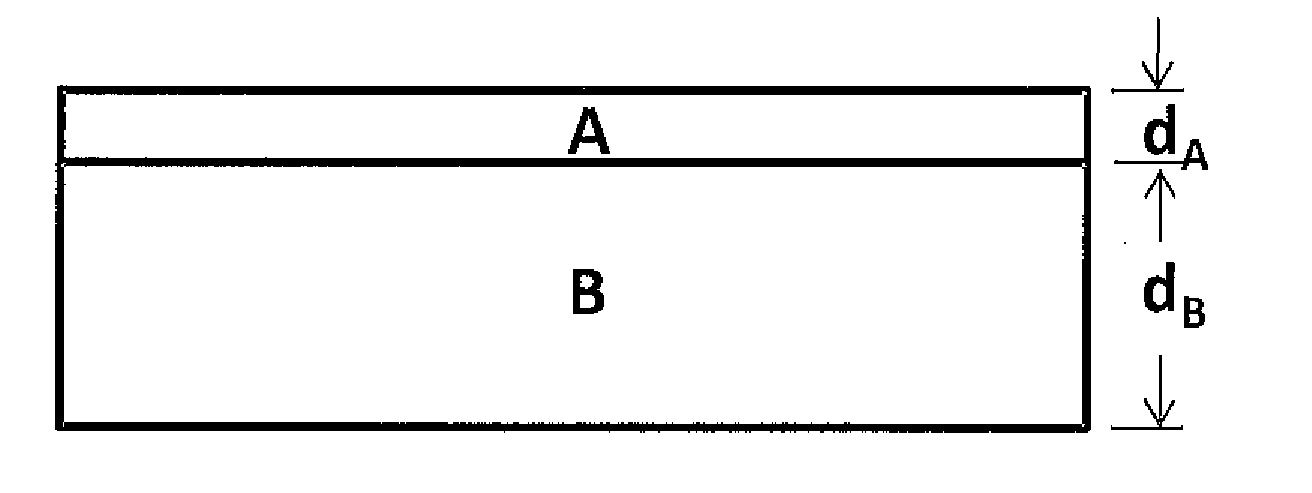

A polarizing plate includes two transparent supports A and B; and a polarizer sandwiched between the two transparent supports A and B; wherein (i) the transparent support A is a stretched cellulose ester film (a) which contains a non-phosphoric acid ester plasticizer and substantially does not contain a phosphoric acid ester plasticizer, and wherein (ii) the transparent support B is a stretched cellulose ester film (b) which has a retardation value R0 of from 0 nm to 10 nm and a retardation value Rt of from −30 nm to 20 nm, and the retardation value R0 and the retardation value Rt are defined by the following formulas (I) and (II):Ro=(nx−ny)×d Formula (I):Rt={(nx+ny) / 2−nz}×d. Formula (II):

Owner:KONICA MINOLTA OPTO

Method of producing cellulose ester film, cellulose ester film, polarizing plate and liquid crystal display

InactiveUS20100151156A1Improve flatnessLow moisture permeabilityLiquid crystal compositionsCeramic shaping apparatusPolyesterOrganic acid

Disclosed is a method for producing a cellulose ester film wherein a film-forming material containing the following components A-C is heated and melted, and a cellulose ester film is formed therefrom by melt-casting. A: a cellulose resin, B: an ester compound obtained by condensing an organic acid represented by Formula (1) and a polyalcohol, and C: an aliphatic polyester or an aliphatic-aromatic copolymer.

Owner:KONICA MINOLTA OPTO

Cellulose ester film, polarizer and liquid crystal display device

InactiveUS20110001904A1Improve production efficiencyImprove surface conditionSynthetic resin layered productsPolarising elementsCellulose ester membraneCarbon number

A cellulose ester film comprising at least one polycondensate ester that comprises a dicarboxylic acid residue mixture having an average carbon number of from 5.5 to 10.0 and comprising an aromatic dicarboxylic acid residue and an aliphatic dicarboxylic acid residue, and an aliphatic diol residue having an average carbon number of from 2.5 to 7.0.

Owner:FUJIFILM CORP

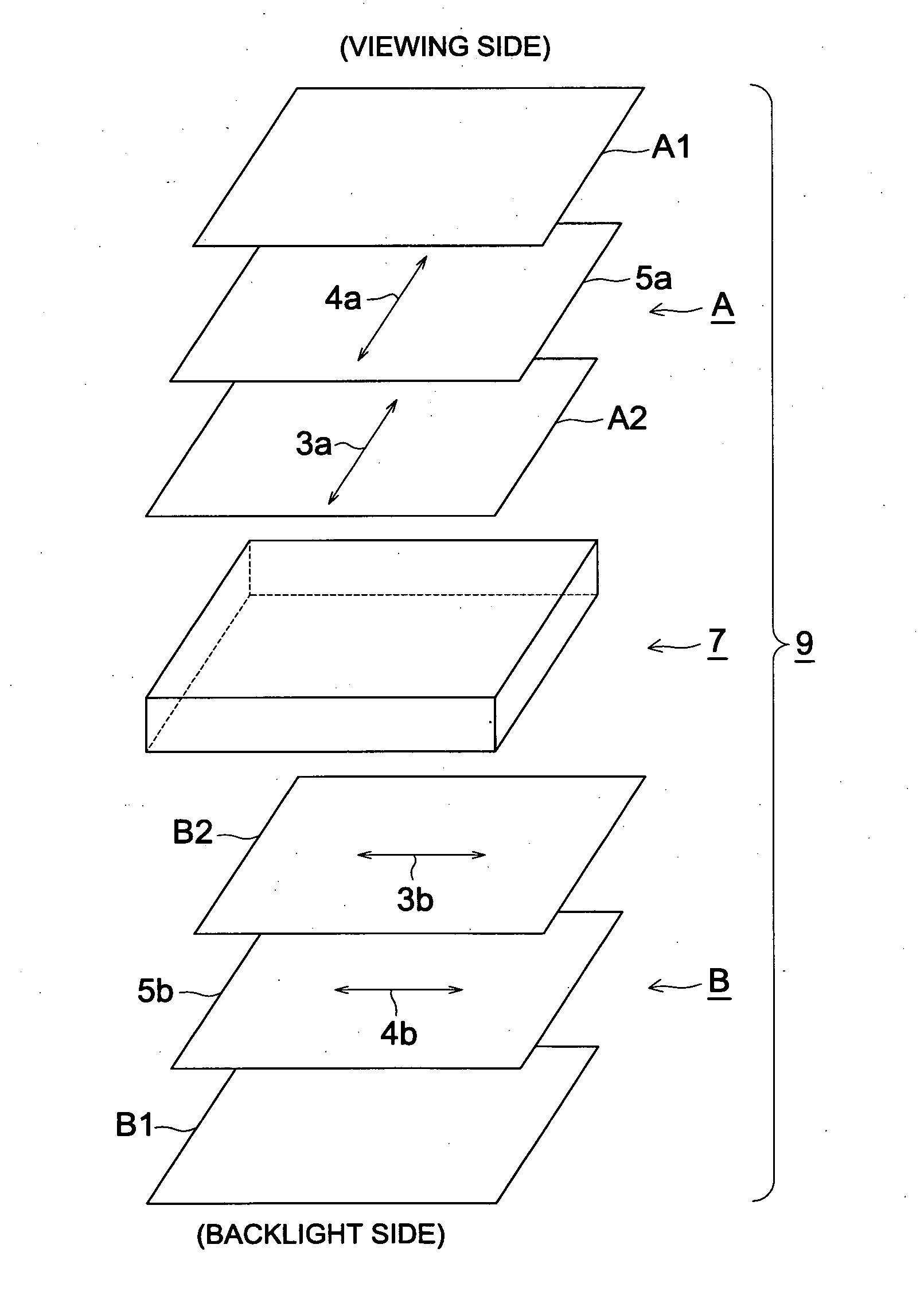

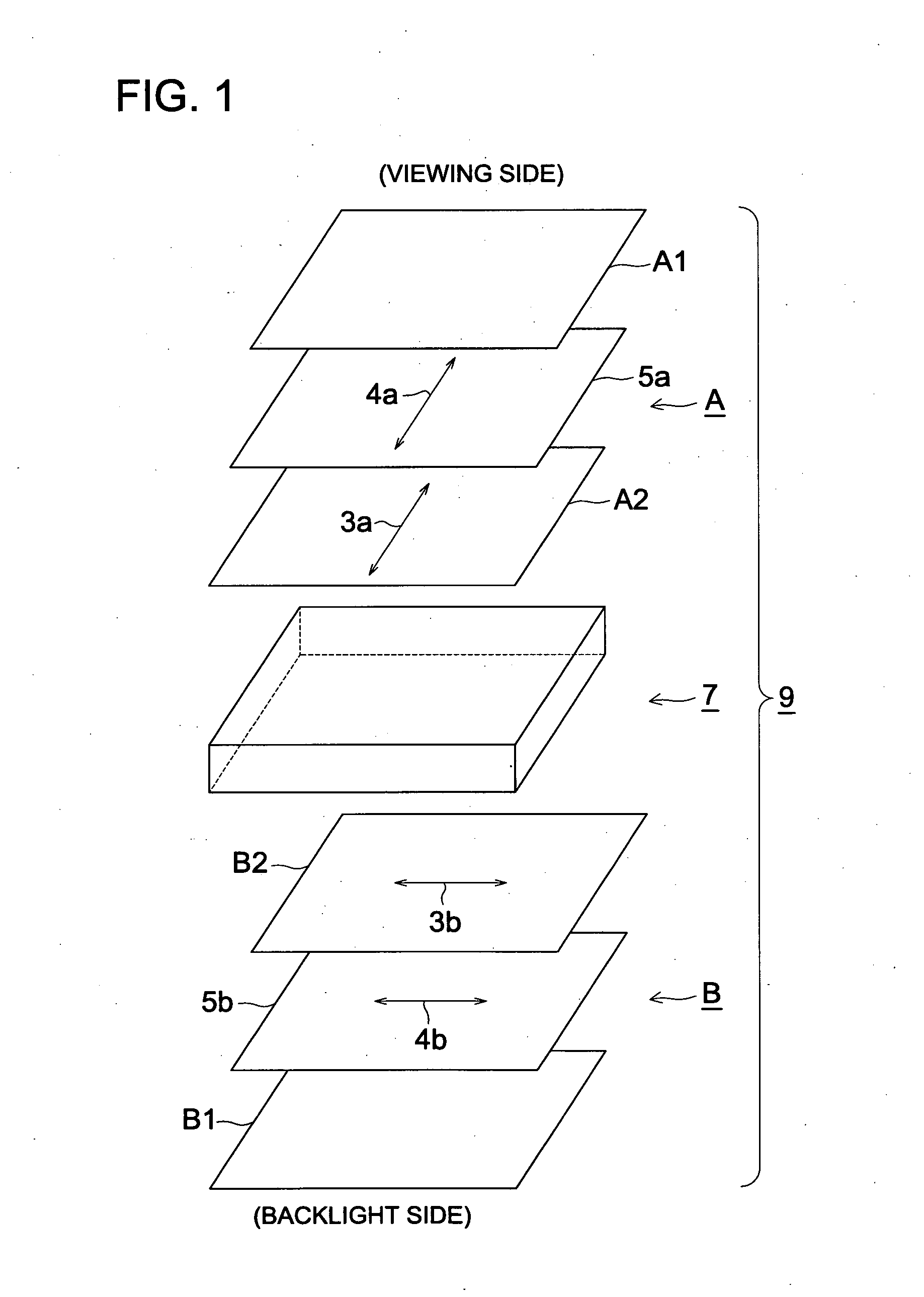

Liquid crystal display device

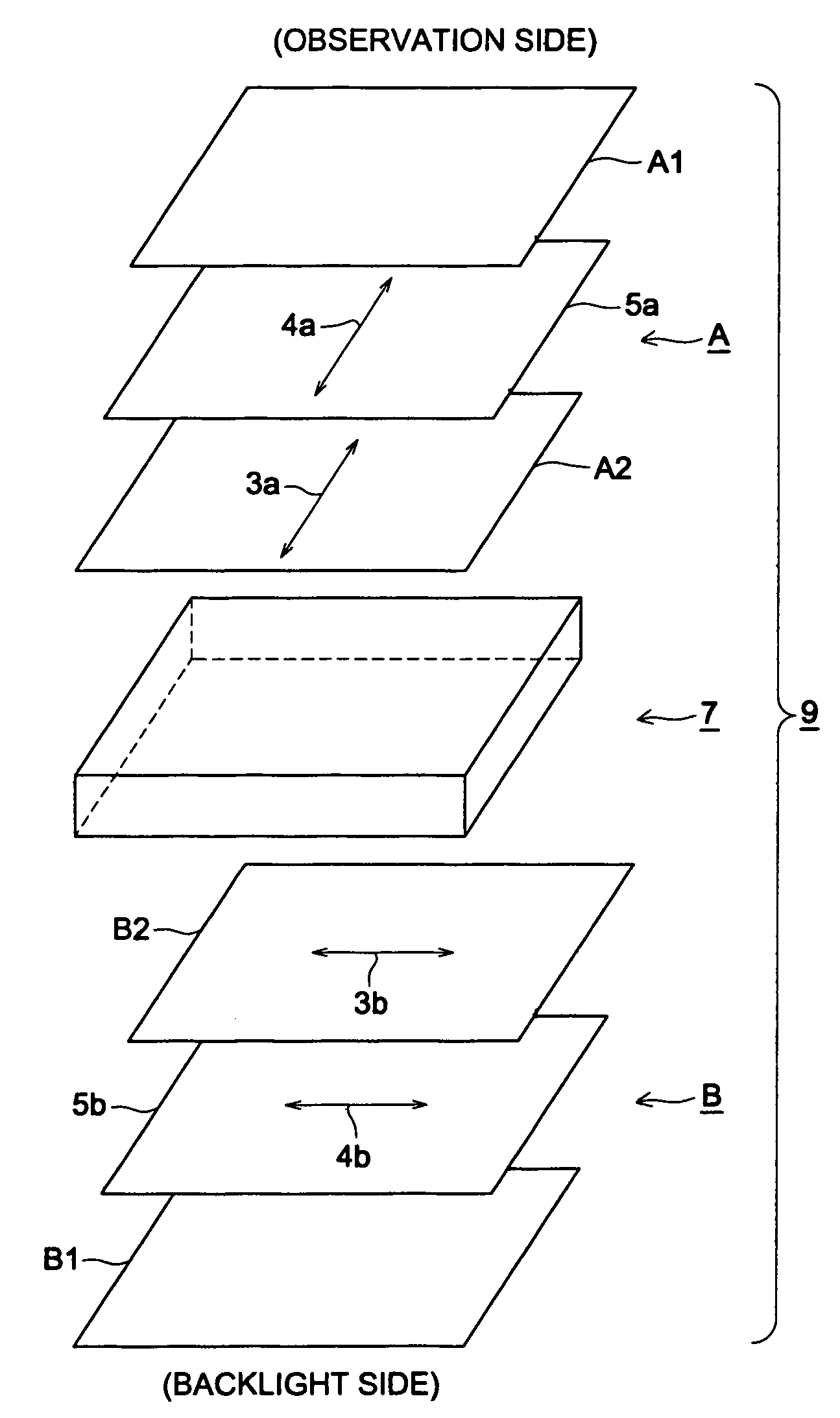

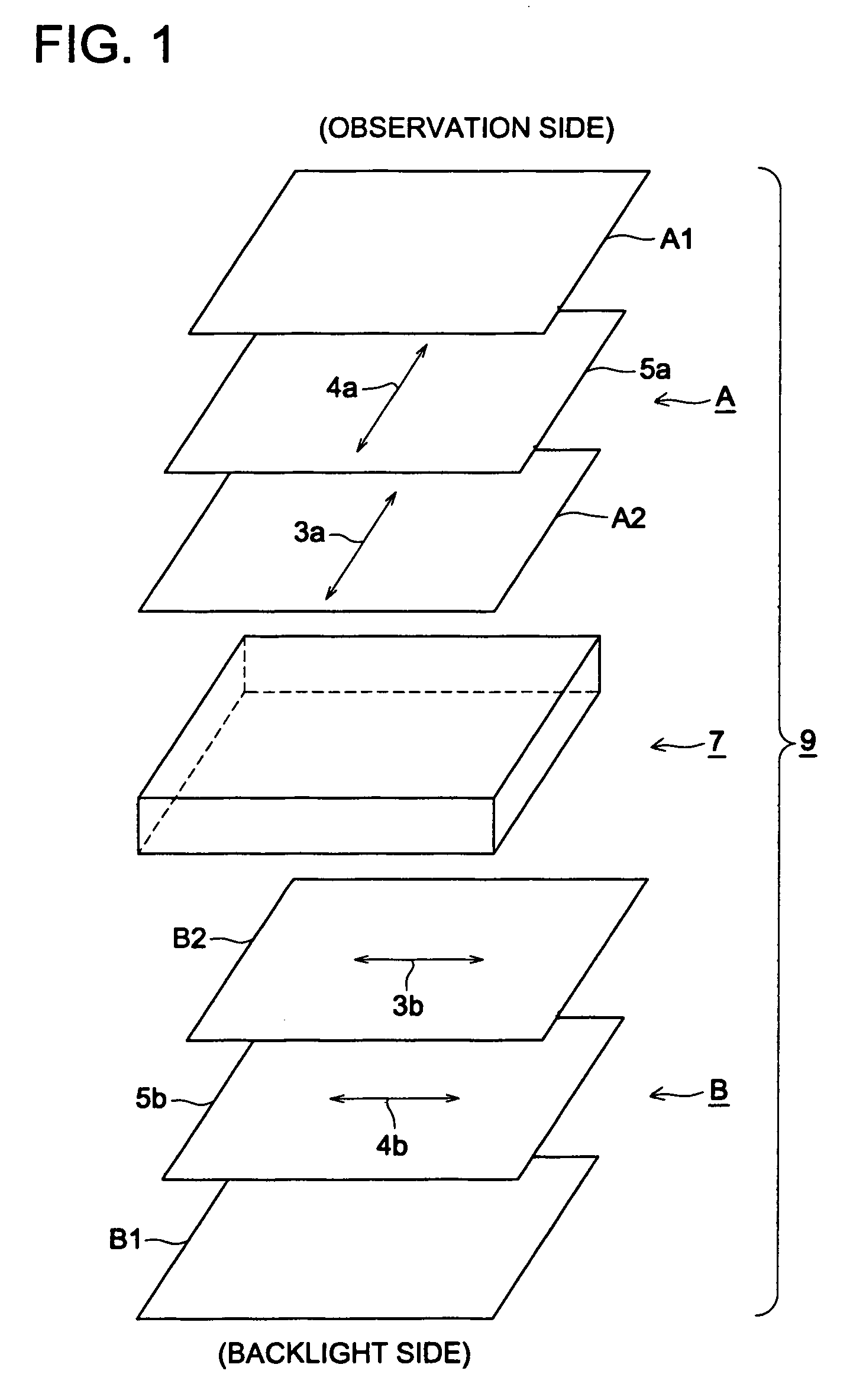

ActiveUS7471360B2Little color changeIncrease contrastLiquid crystal compositionsPolarising elementsCellulose ester membraneCrystallography

A liquid crystal display device comprising a liquid crystal display in which polarizing plates A and B are provided so as to be held between a vertical orientation mode crystal cell and the corresponding liquid crystal cell, wherein the polarizing layer A comprises the polarizing plate protective films A1 and A2 and the polarizing layer B comprises the polarizing plate protective films B1 and B2, and at least one of the polarizing plate protective films A2 and B2 that are disposed at the liquid crystal cell side is a cellulose ester film Y that simultaneously satisfies the condition that retardation value Ro is 0 to 10 nm and Rt is −20 to 20 nm shown by the equation below, and at least one of the polarizing plate protective films A2 and B2 is the optical compensation film W which has an optically anisotropic layer.

Owner:KONICA MINOLTA OPTO

Cellulose ester film, its manufacturing method, optical retardation film, optical compensation sheet, elliptic polarizing plate, and image display

InactiveUS20070178252A1Preventing the plasticizer from bleeding outMinimizing bleeding outLiquid crystal compositionsPolarising elementsCellulose ester membraneFiber

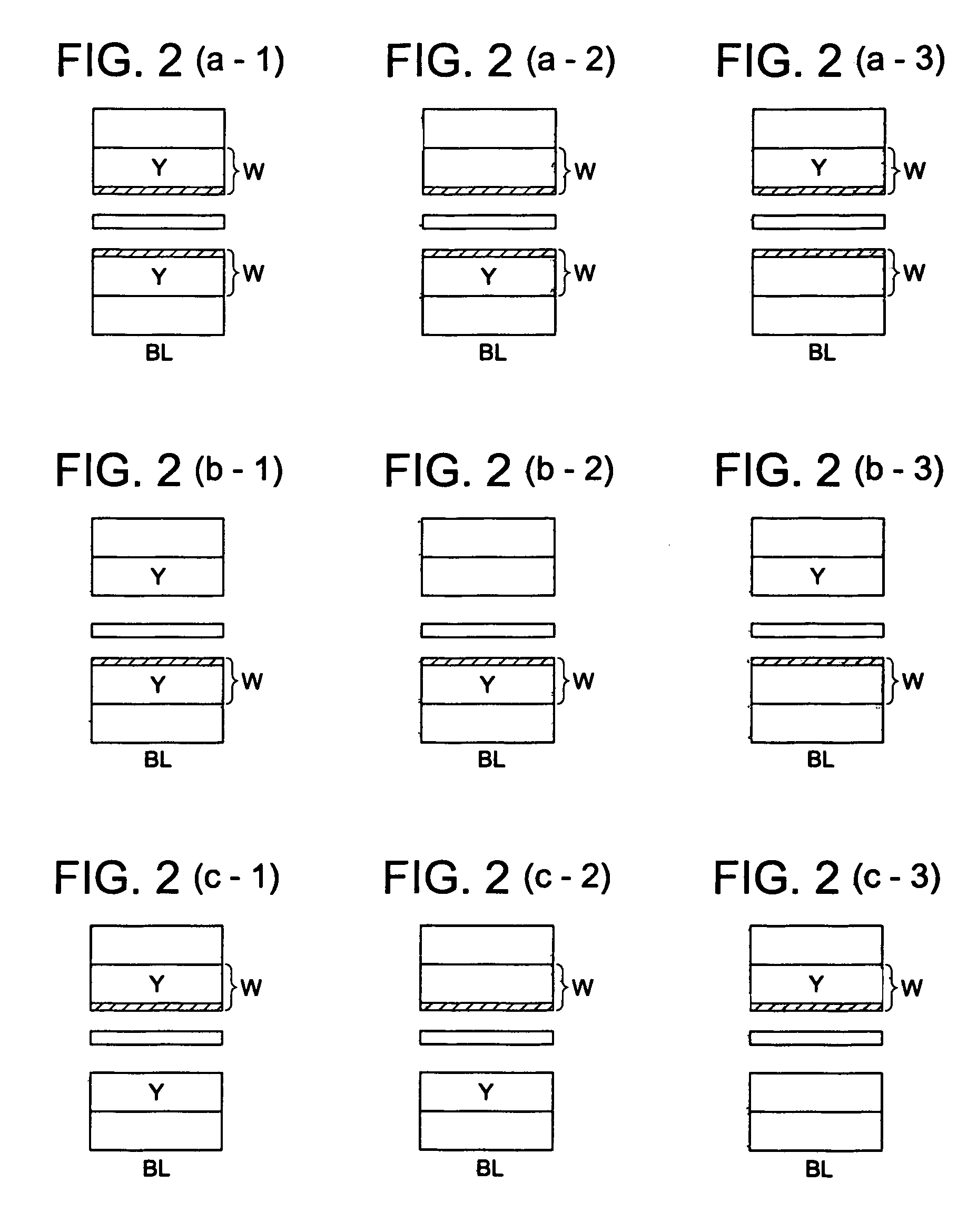

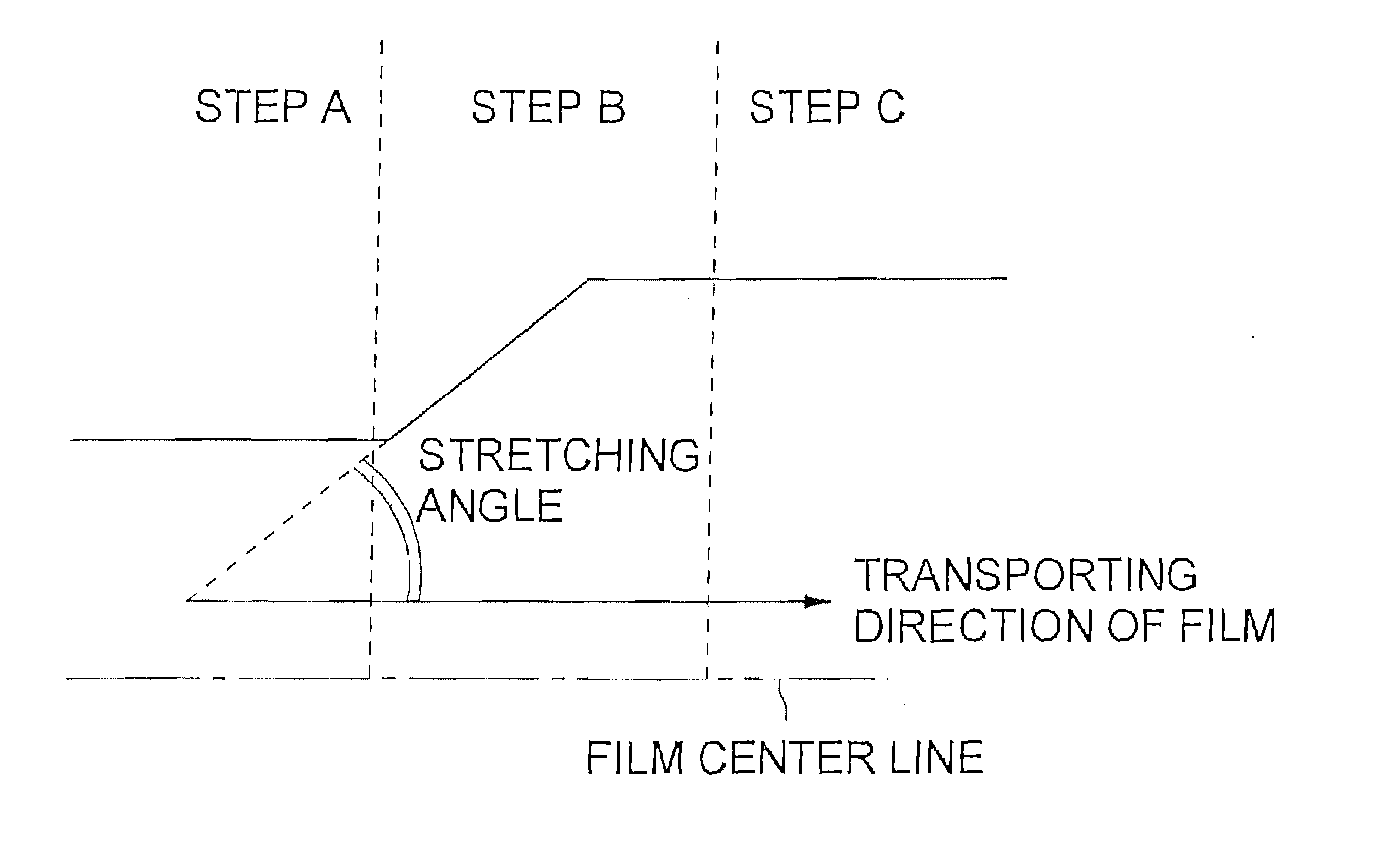

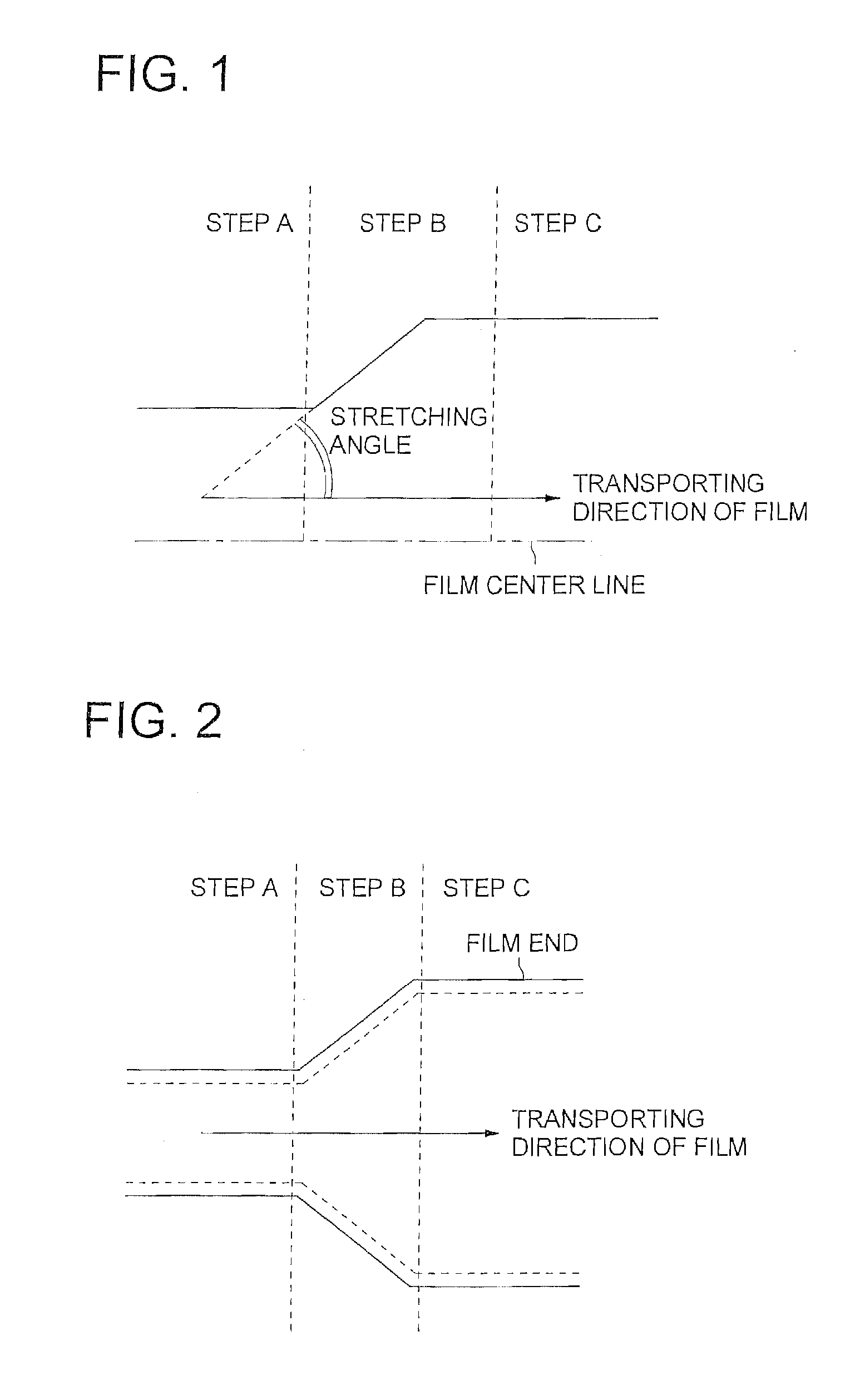

A manufacturing method of a cellulose ester film satisfying the relationships, Nx>Ny>Nz, and 0.8≦Rt / R0<3.5, the method comprising casting a cellulose ester dope containing a solvent of a good solvent and a poor solvent on a support to form a web; peeling the web from the support; transporting the peeled web (step D0); holding the edges in the transverse direction of the web (step A); stretching the resulting web in the transverse direction while applying a tension; reducing the tension in the transverse direction of the web; and drying the stretched web, wherein the residual solvent content of the web is 5 to 90% by weight at the beginning in the step A, and the residual poor solvent content in the residual solvent content of the web is from 15 to 95% by weight at the terminal point in the Step D0.

Owner:KONICA CORP

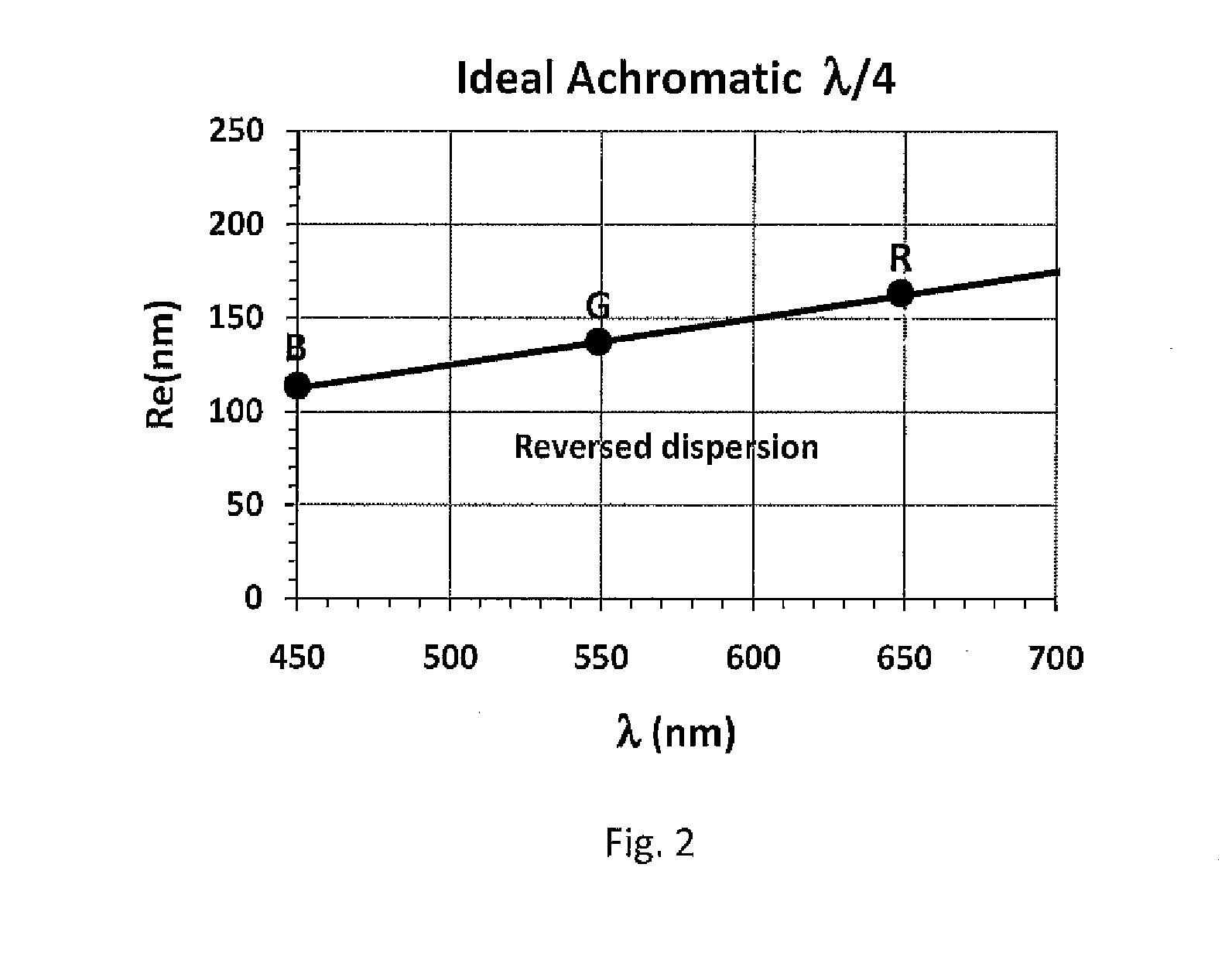

Multilayer and single layer cellulose ester films having reversed optical dispersion

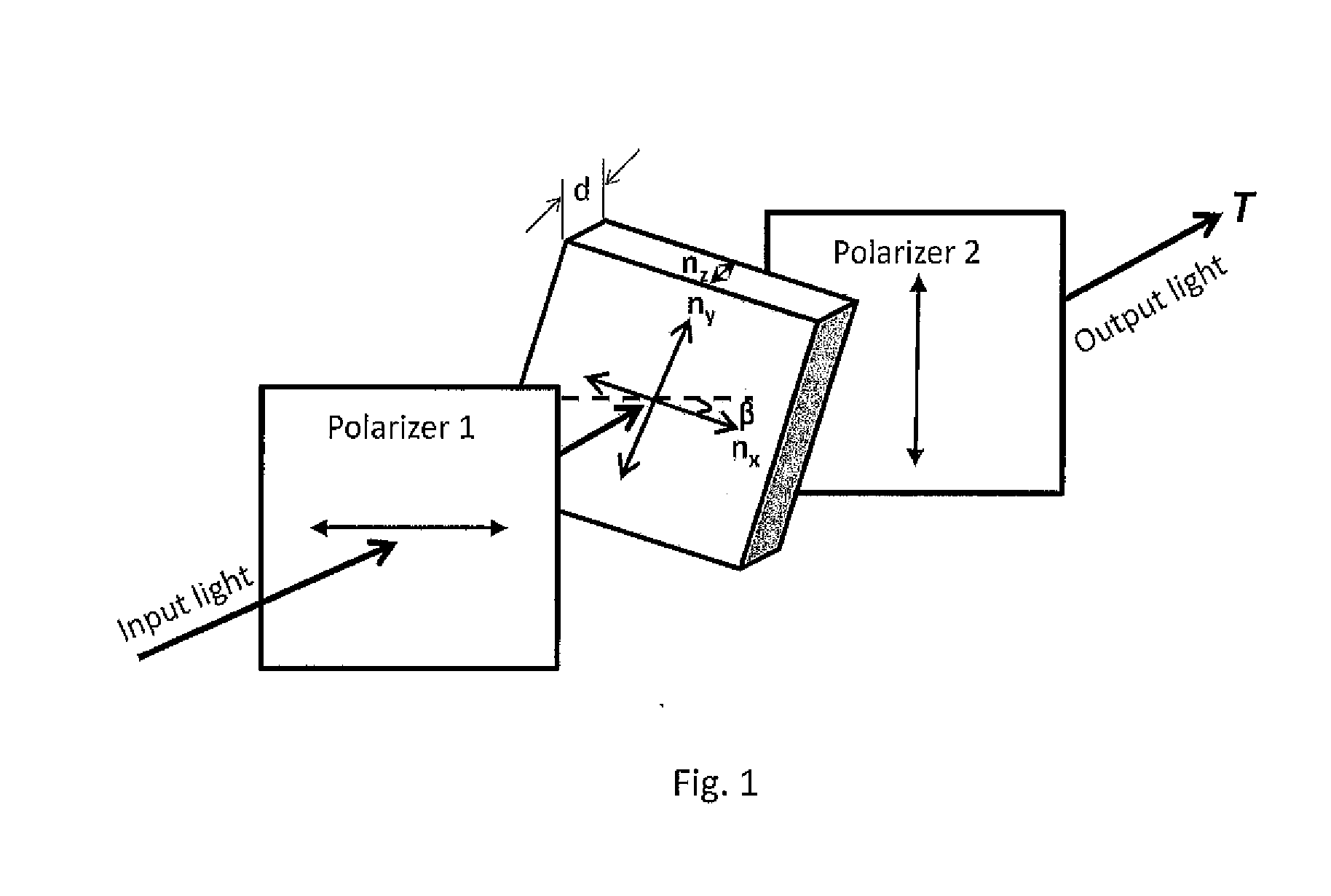

InactiveUS20140168770A1High optical retardationReversed dispersionSynthetic resin layered productsCellulosic plastic layered productsCellulose ester membraneColor shift

The present invention relates to a single layer mixed cellulose ester film having a reversed optical dispersion. The mixed cellulose ester material has a DSOH from 0.35 to 1.35. By manipulating the thickness of the film, and the film stretching conditions, desirable optical retardation and optical dispersion properties can be obtained. The film can be used as an optical waveplate in liquid crystal displays to improve viewing angle, contrast ratio, and color shift.

Owner:EASTMAN CHEM CO

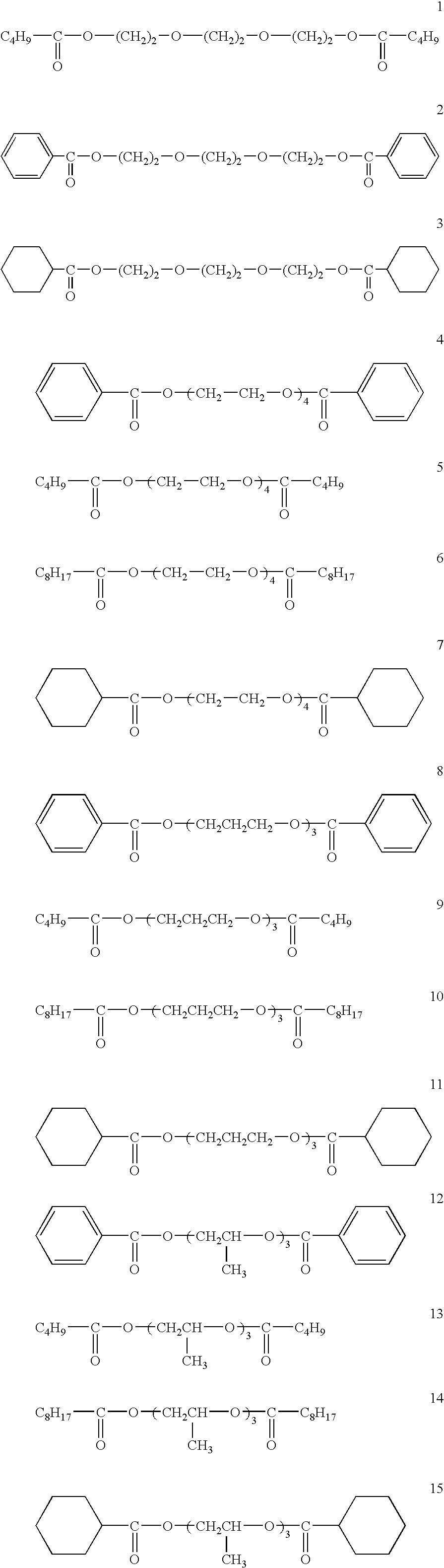

Process for producing cellulose ester film, cellulose ester film, polarization plate and display unit

InactiveUS20090306361A1Decreasing foreign materialImprove flatnessSugar derivativesPolarising elementsForeign matterCellulose ester membrane

A process for producing a cellulose ester film that is produced by a melt casting method using no solvent at film formation, and that attains reduction of bright spot foreign matter, excelling in planarity, and that attains reduction of staining, excelling in dimensional stability. It is also intended to provide such a cellulose ester film, a polarizing plate and a liquid crystal display unit. There is provided a process for producing a cellulose ester film, characterized by forming into a film a material containing a cellulose ester and an ester compound of 1 to 7.5 distribution coefficient obtained by condensation of a polyhydric alcohol and an organic acid of the general formula: (1) according to a melt casting method.

Owner:KONICA MINOLTA OPTO

Cellulose ester film, polarizer and liquid crystal display device

InactiveUS20090317567A1Improve stabilityHigh RthLiquid crystal compositionsThin material handlingCellulose ester membranePolymer science

A cellulose ester film with Rth>0 nm comprising a cellulose ester having a total degree of substitution of at least 2.3 and a polymer X with a weight-average molecular weight of 500-100000 satisfying 30%≦A≦100%, wherein A indicates the polymerization ratio of a monomer whose homopolymer has a negative birefringence, is excellent in humidity stability and wet heat durability.

Owner:FUJIFILM CORP

Cellulose ester film, optically compensatory film, polarizing plate, and liquid crystal display device

ActiveUS20100308264A1Avoid big failuresHardly generates bleed-outLiquid crystal compositionsDiffusing elementsCarbon numberCellulose ester membrane

A cellulose ester film is provided and includes a polycondensate obtained from a diol and a dicarboxylic acid, and the polycondensate contains the following (1) and (2).(1) A dicarboxylic acid residue containing an aromatic dicarboxylic acid residue and an aliphatic dicarboxylic acid residue having an average carbon number of 4.0 to 5.0, in which a ratio of the aromatic dicarboxylic acid residue represented by the following equation is from 40% by mole to 95% by mole:The ratio of the aromatic dicarboxylic acid residue=[(the number of moles of the aromatic dicarboxylic acid residue) / ((the number of moles of the aromatic dicarboxylic acid residue)+(the number of moles of the aliphatic dicarboxylic acid residues))]×100.(2) An aliphatic diol residue having an average carbon number of 2.0 to 3.0.

Owner:FUJIFILM CORP

Liquid crystal display having liquid crystal cell of bend alignment mode or hybrid alignment mode

InactiveUS20060114385A1Prevent inversionImprove viewing angle character characterPolarising elementsNon-linear opticsCellulose ester membraneIn plane

A liquid crystal cell of bend alignment mode or hybrid alignment mode should be optically compensated suitably enough to display an image of high contrast. In the displayed image, change of hue is little, and no inversion of gradation is observed. In a liquid crystal display having a liquid crystal cell of bend alignment mode and a pair of polarizing plates, one of the polarizing plates comprises a polarizing membrane and two optically anisotropic layers. A first optically anisotropic layer is made from discotic compounds oriented in hybrid alignment, and is placed so that a direction giving the maximum refractive index in plane may be essentially at 45° to a transmission axis in plane of the polarizing membrane. The second optically anisotropic layer consists of a cellulose ester film, and is placed so that a direction giving the maximum refractive index in plane may be essentially parallel or perpendicular to a transmission axis in plane of the polarizing membrane. The liquid crystal cell of bend alignment mode and the first and second optically anisotropic layers have appropriate optical characters measured at any wavelength of 450 nm, 550 nm and 630 nm. Similar optical characters are also effective in a liquid crystal cell of hybrid alignment mode.

Owner:FUJIFILM CORP

Cellulose Ester Film, Light Diffusing Film, Polarizing Plate, and Liquid Crystal Display

ActiveUS20100233389A1Excellent more in optical isotropyExcellent characteristicsLiquid crystal compositionsLayered productsCellulose ester membraneLiquid-crystal display

Disclosed is a cellulose ester film which, when used in a polarizing plate, can impart excellent dimensional stability, curling properties and surface properties to the polarizing plate. Also disclosed is a light-scattering-film, a polarizing plate or a liquid crystal display element which is produced by using the cellulose ester film, and therefore has more excellent optical anisotropy, higher surface properties and a smoother surface, causes less curling, and has good surface quality. The cellulose ester film comprises 1 to 50% by mass (inclusive) of microparticles having an average particle diameter of 1 to 400 nm (inclusive) and a compound showing negative birefringence in the direction of drawing, and has a retardation value (R0) defined by the equation (I) of 0 to 5 nm (inclusive) and a retardation value (Rt) defined by the equation (II) of −10 to 20 nm (inclusive), both measured at 23° C. and 55% RH: Equation (I): R0=(nx−ny)×d; and Equation (II): Rt=[(nx+ny) / 2×nz]×d.

Owner:KONICA MINOLTA OPTO

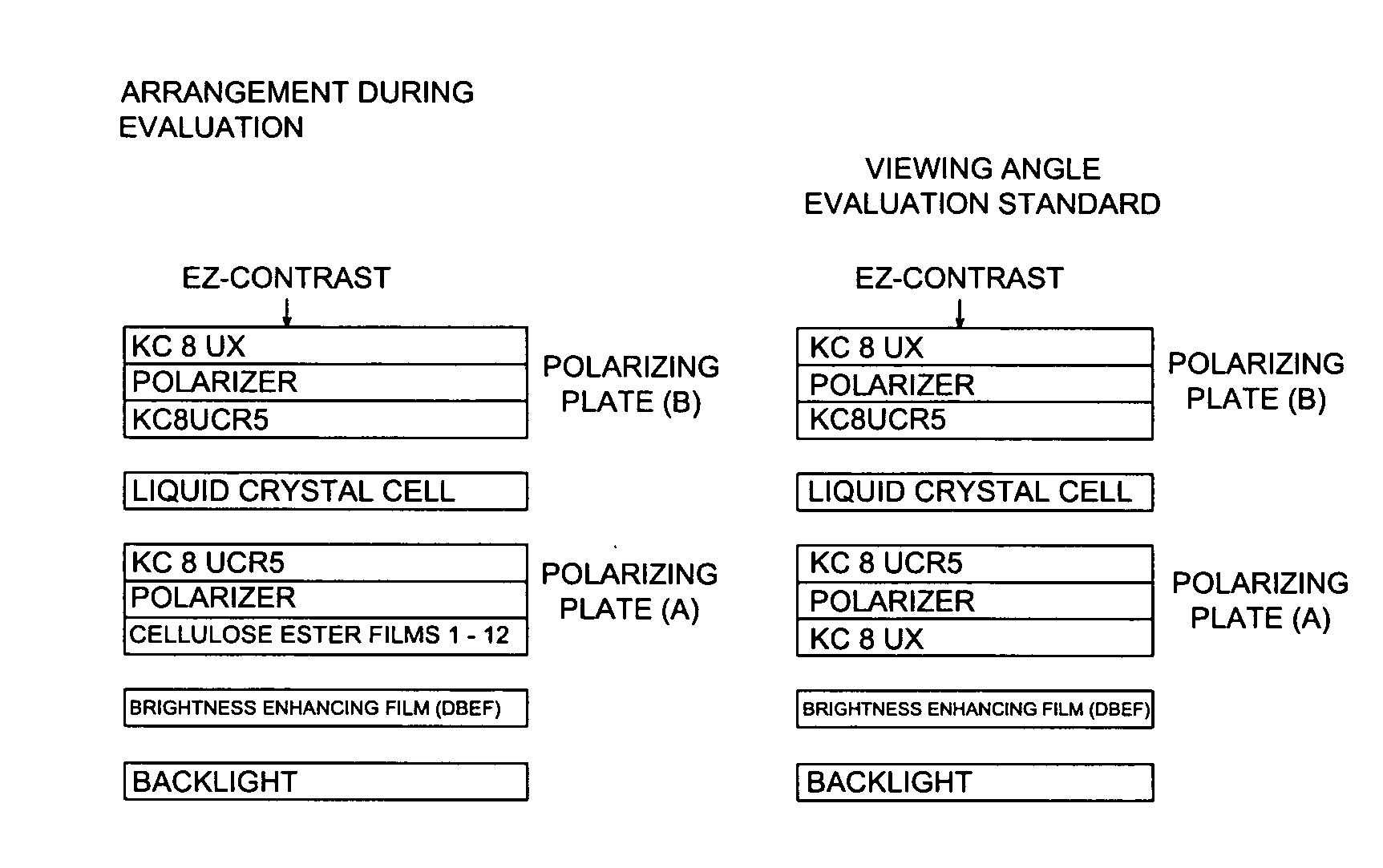

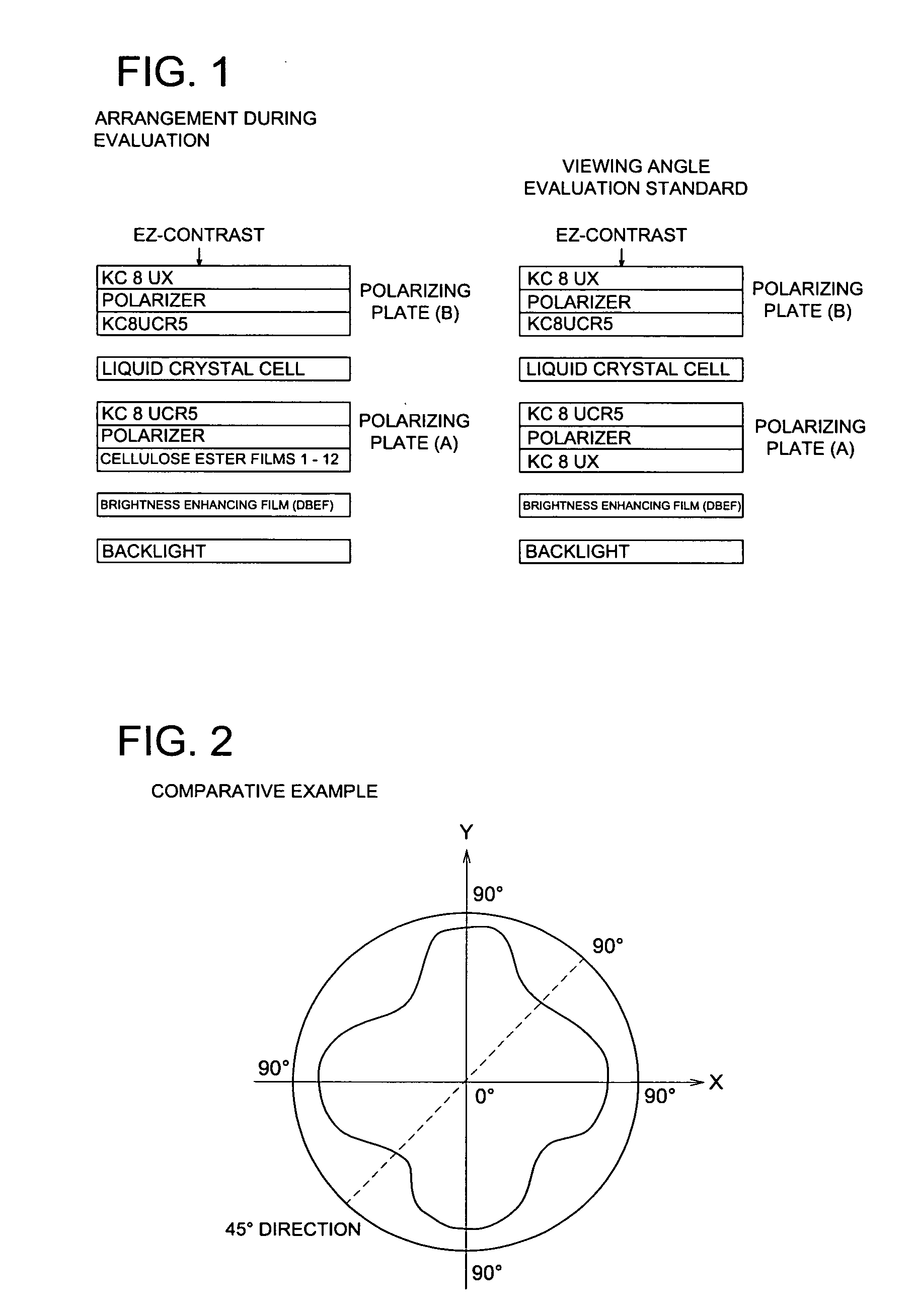

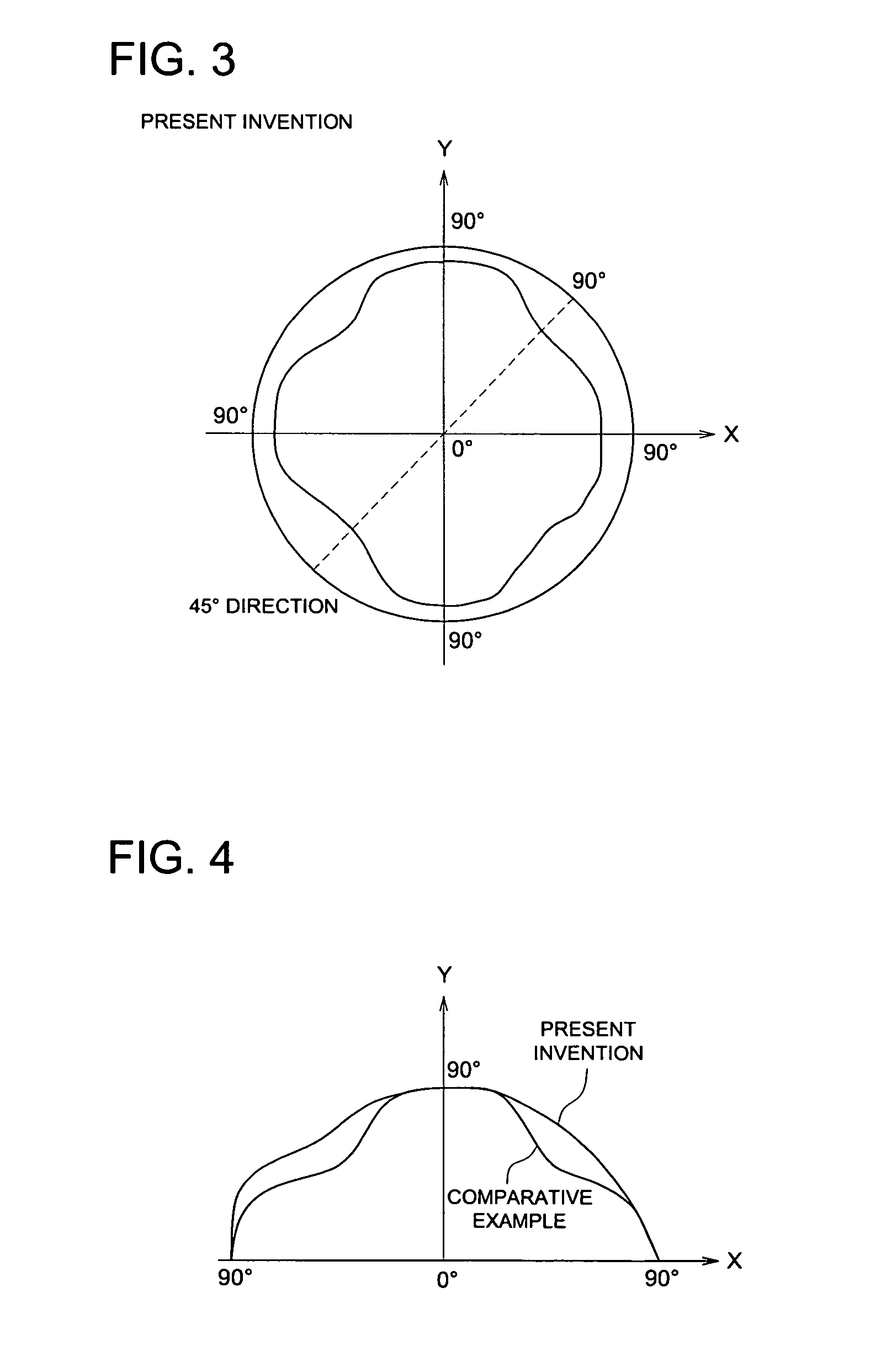

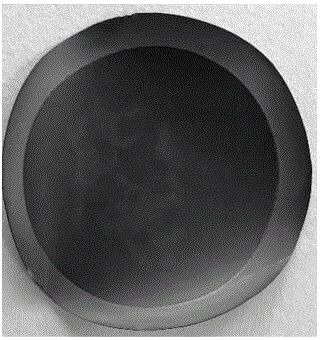

Liquid crystal display

InactiveUS20070046872A1Minimizing displayIncrease brightnessPolarising elementsNon-linear opticsTectorial membraneCellulose ester membrane

A liquid crystal display comprising: a brightness enhancing film, polarizing plate (A), a liquid crystal cell, polarizing plate (B) laminated in that order, Wherein (i) polarizing plate (A) has a polarizing plate protective film facing the brightness enhancing film; (ii) the polarizing plate protective film is a cellulose ester film; (iii) an in-plane retardation value Ro(550) of the of the cellulose ester film represented by Formula (I) is 0 to 5 nm; and (iv) a retardation value in a thickness direction Rt(550) of the of the cellulose ester film represented by Formula (II) is −15 to 15 nm, Ro(550)=(Nx−Ny)×d Formula (I) Rt(550)={(Nx+Ny) / 2−Nz}×d. Formula (II)

Owner:KONICA MINOLTA OPTO

Graphene oxide film based on dopamine biomimetic modification as well as preparation method and application thereof

InactiveCN106823825AReduce porositySmall apertureSemi-permeable membranesCellulose ester membraneReusability

The invention relates to a graphene oxide film based on dopamine biomimetic modification as well as a preparation method and application thereof, and belongs to the field of film material preparation. The preparation method comprises the following steps of: firstly preparing a mixed cellulose ester film modified by dopamine by using a mussel biomimetic method; and then carrying out vacuum drawing and filtering of a graphene oxide solution on the surface of the film, and drying to obtain the film. The film is capable of filtering stable oil-water emulsion of a surface active agent and has the advantages of high separation efficiency, good stability and reusability. The preparation method has the beneficial effects that the film is prepared by vacuum drawing and filtering, the preparation method is simple, needed raw materials are mild without toxicity and are easily available, and the film is suitable for large-scale production and application.

Owner:JIANGSU UNIV

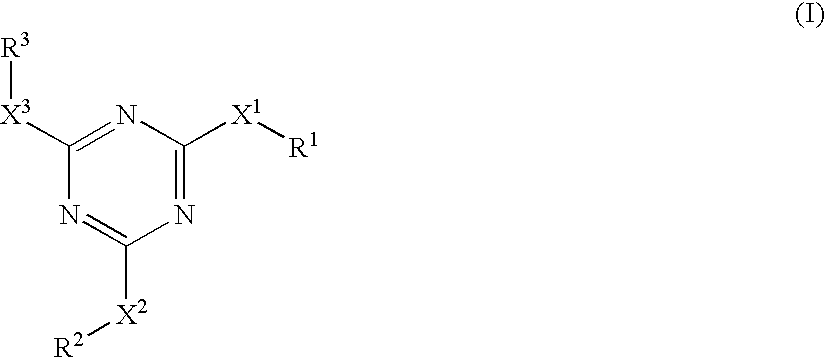

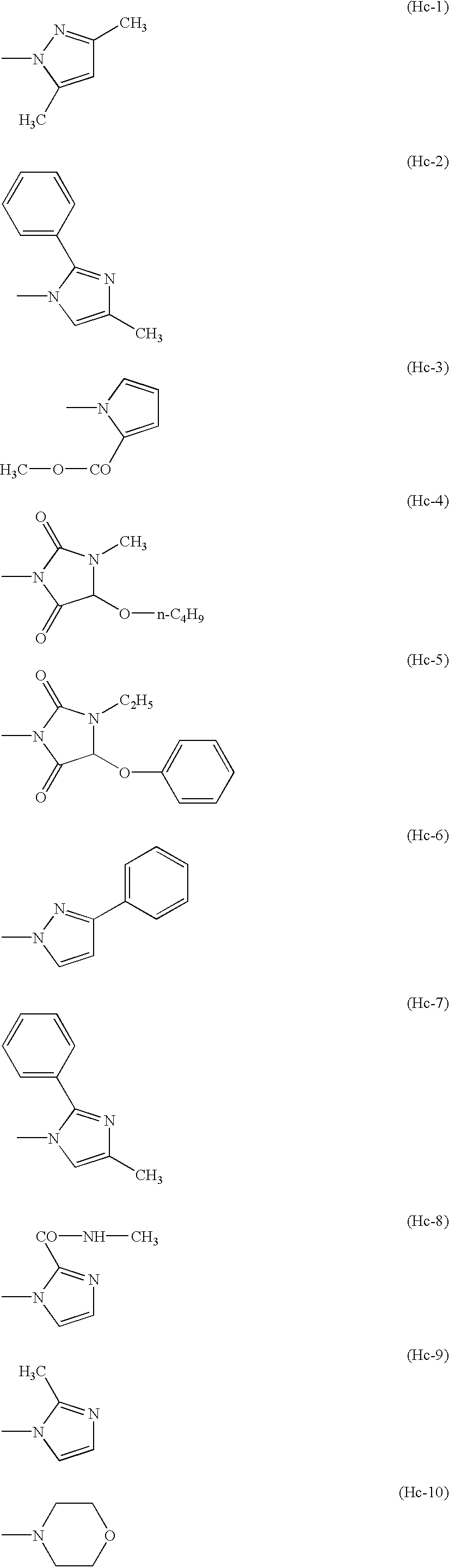

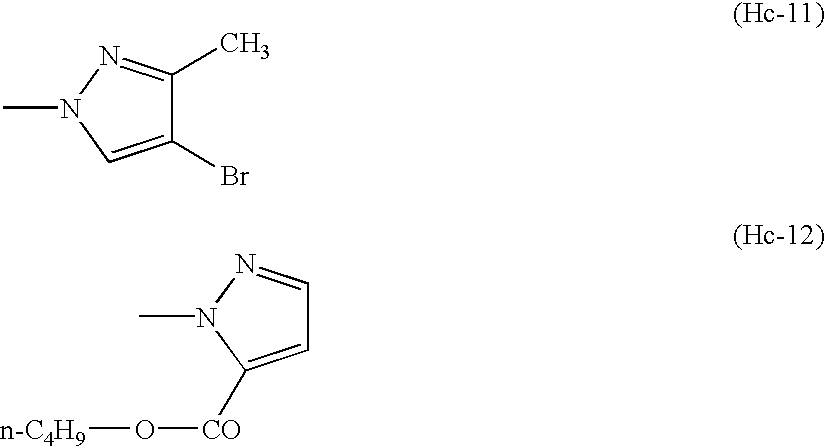

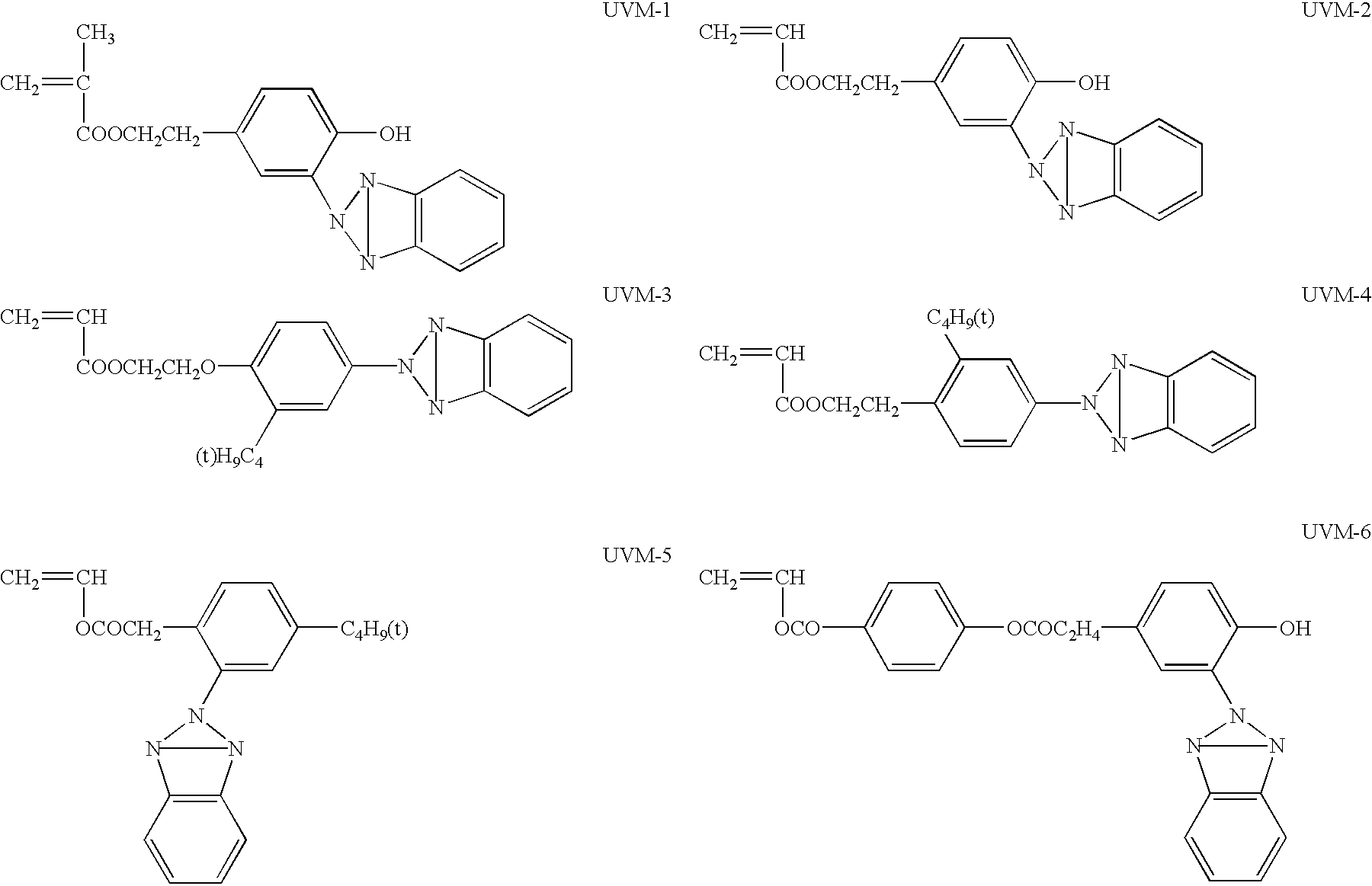

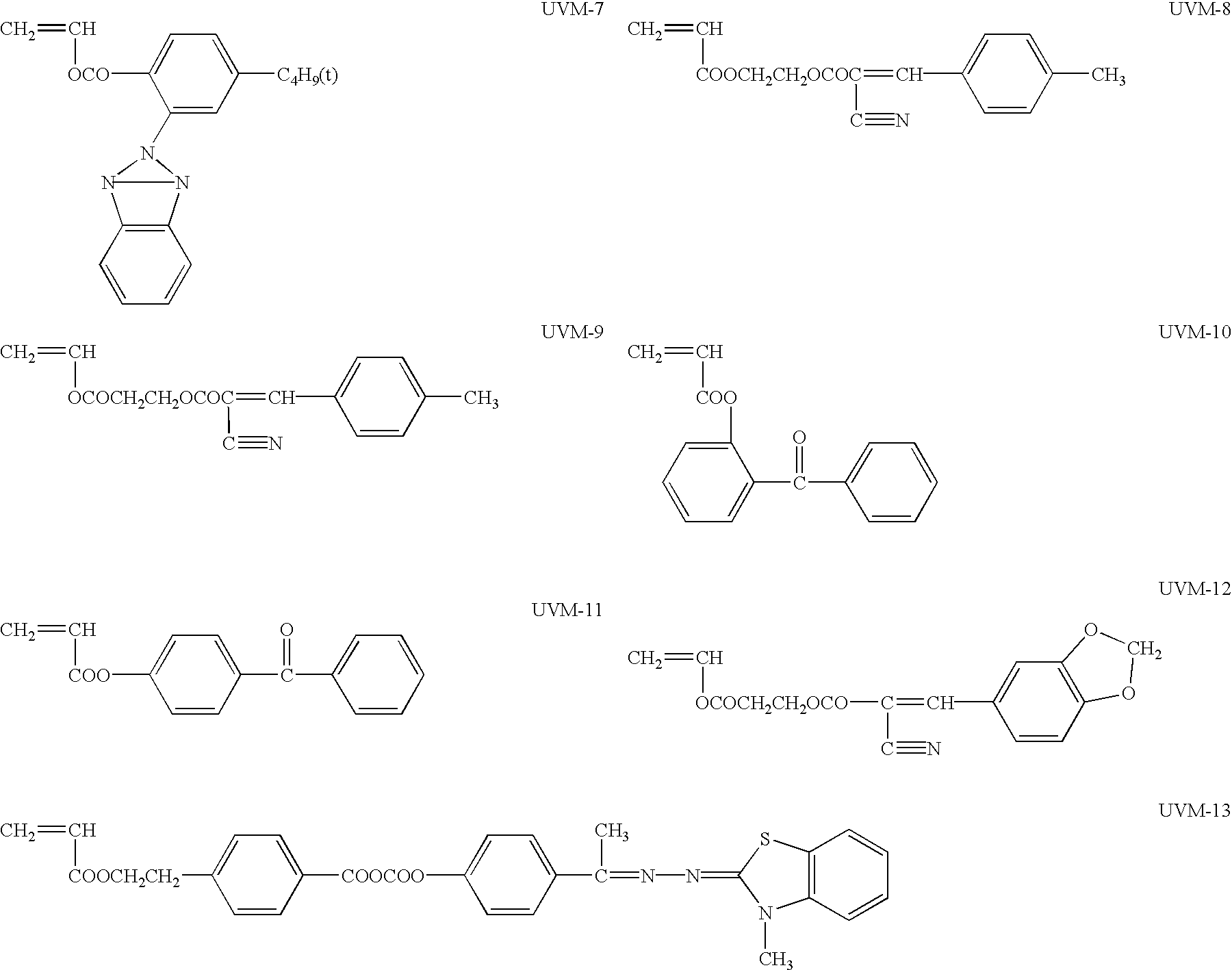

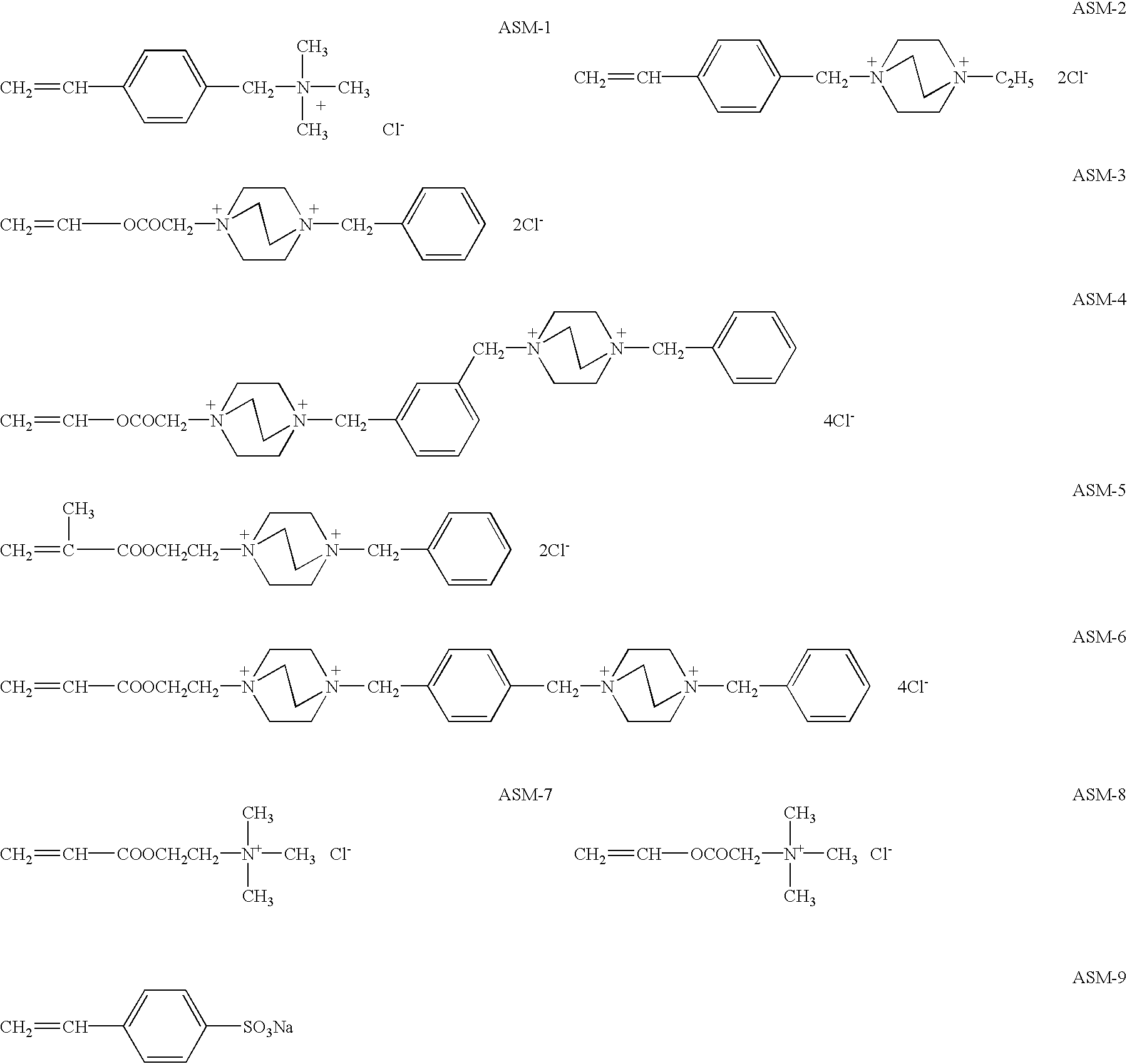

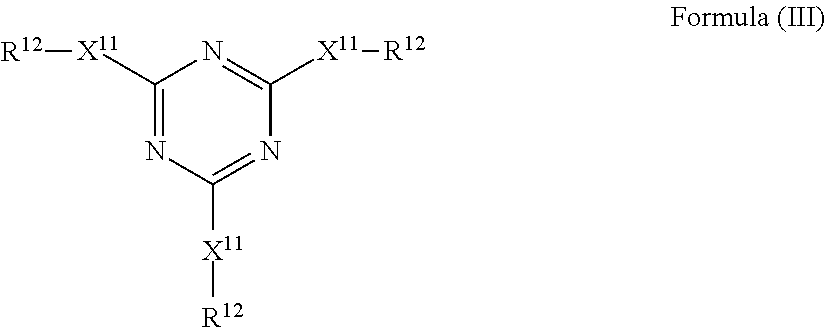

Polarizing plate protective film and method for manufacturing the same, polarizing plate and method for manufacturing the same, and liquid crystal display device

InactiveUS20090185112A1Liquid crystal compositionsOptical articlesTectorial membraneCellulose ester membrane

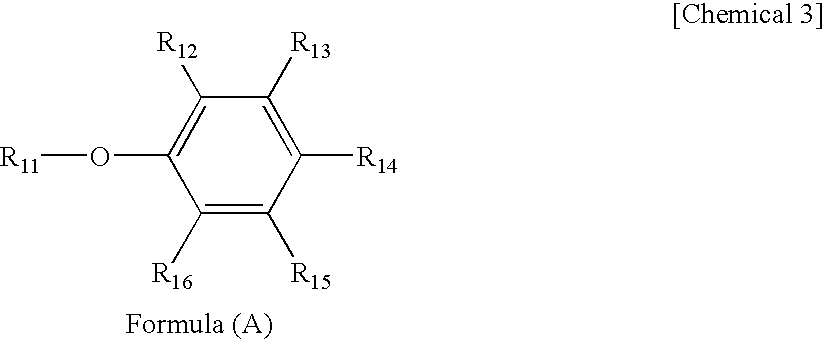

A protective film for polarizers which comprises a cellulose ester film and which, even when stored for long, suffers no film deformation failures such as ridging and protrusion failures; a process for producing the protective film; a polarizer; a process for producing the polarizer; and a liquid-crystal display employing the polarizer. The process for producing a protective film for polarizers is characterized by forming a melt comprising a cellulose ester and at least one member selected among compounds respectively represented by the following general formulae (1) to (3) into a continuous cellulose ester film by melt casting and winding the film into a roll.[Chemical formula 1] General formula (1) (In the formula, R1 to R5 each represents a substituent.) [Chemical formula 2] General formula (2) (In the formula, R1 to R6 each represents a substituent.) [Chemical formula 3] General formula (3) (In the formula, Rf represents perfluoroalkyl, Rc represents alkylene, Z represents a nonionic polar group, n is 0 or 1, and m is an integer of 1-3.)

Owner:KONICA MINOLTA OPTO

Cellulose Ester Film, Manufacturing Method Thereof, Optical Film, Polarizing Plate and Liquid Crystal Display

InactiveUS20090074989A1Reduce manufacturing burdenReduce burden facility burdenLiquid crystal compositionsSynthetic resin layered productsCellulose ester membraneLiquid-crystal display

An objective is to provide a cellulose ester film which can reduce a manufacturing burden and a facility burden caused by drying and recovering of a solvent used in the production process, a manufacturing method of the cellulose ester film and an optical film, and to specifically provide a polarizing plate employing the optical film as an excellent polarizing plate protective film exhibiting reduced fluctuation of retardation property in the width direction and a liquid crystal display employing the polarizing plate. Also disclosed is a cellulose ester film containing at least one compound having a phenol structure and a phosphite ester structure in a molecule.

Owner:KONICA MINOLTA OPTO

Cellulose ester film, retardation film, polarizing plate and liquid crystal display device

InactiveCN101580597AProcess pollution is smallIncrease productivityPolarising elementsNon-linear opticsCellulose ester membraneLiquid-crystal display

Provided is a cellulose ester film including a polycondensed ester which is obtained from a mixture containing an aromatic dicarboxylic acid, an aliphatic dicarboxylic acid, an aliphatic diol having an average carbon atom number of from 2.0 to 3.0 and a monocarboxylic acid, and both terminals of which are a monocarboxylic acid ester derivative.

Owner:FUJIFILM CORP

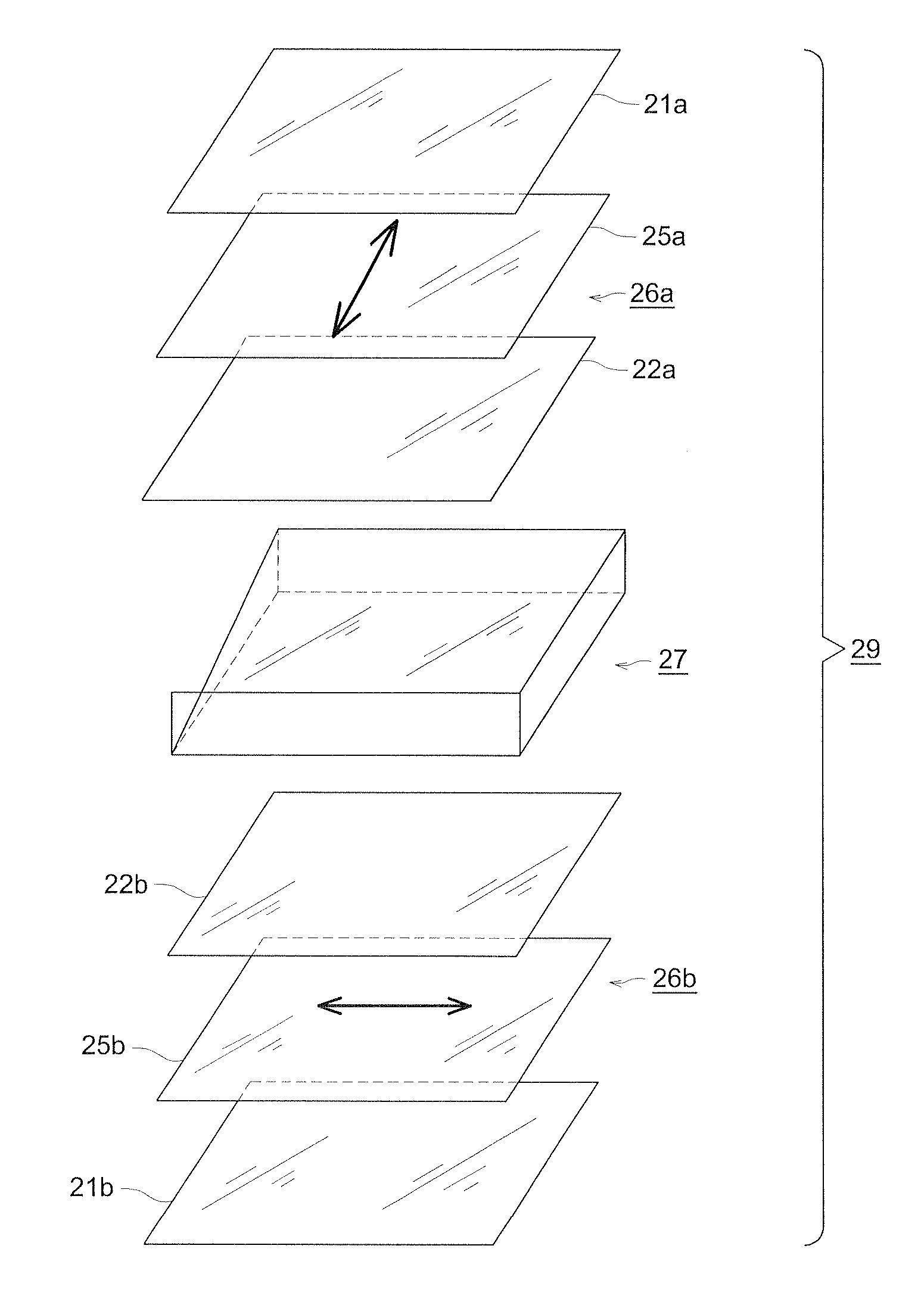

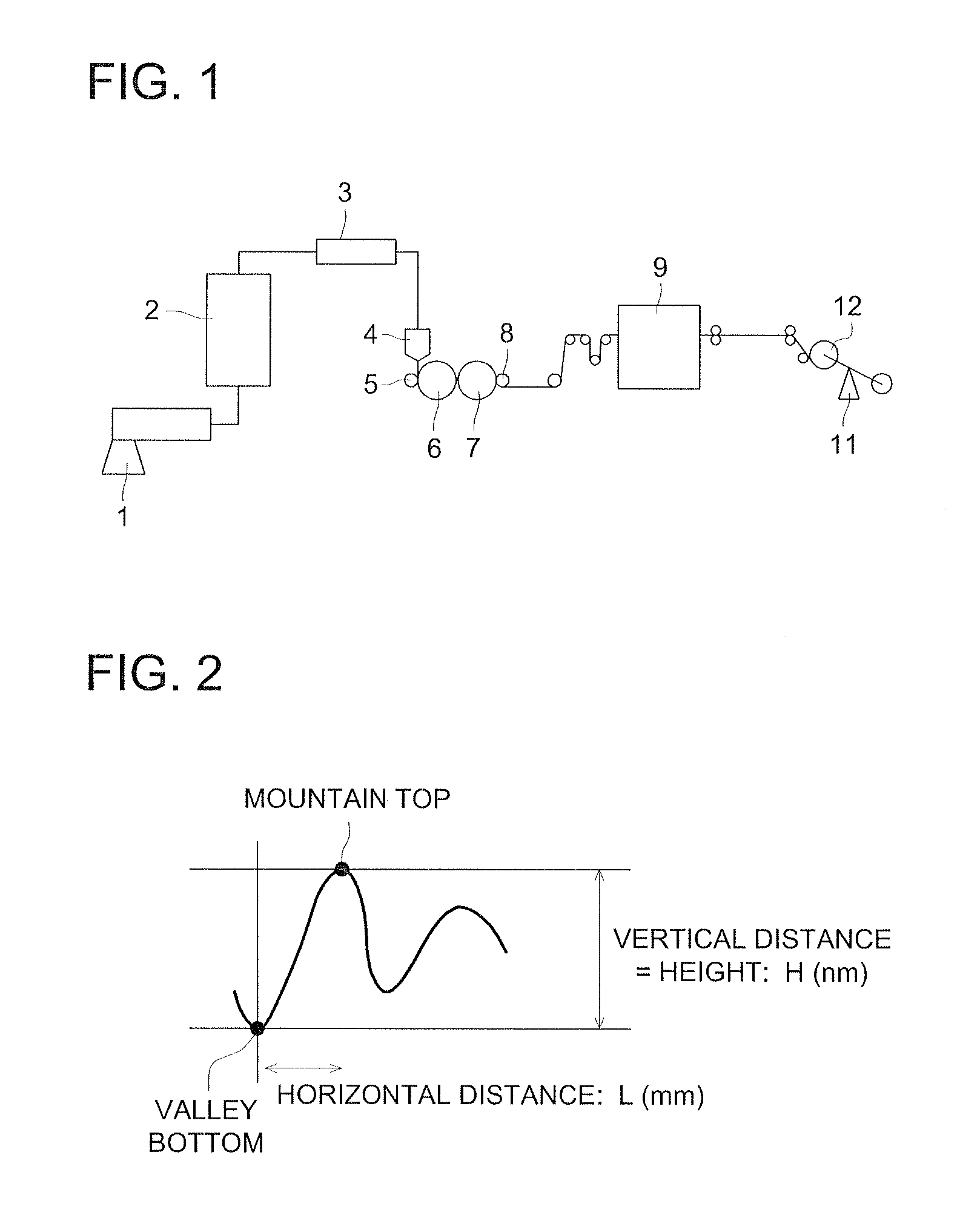

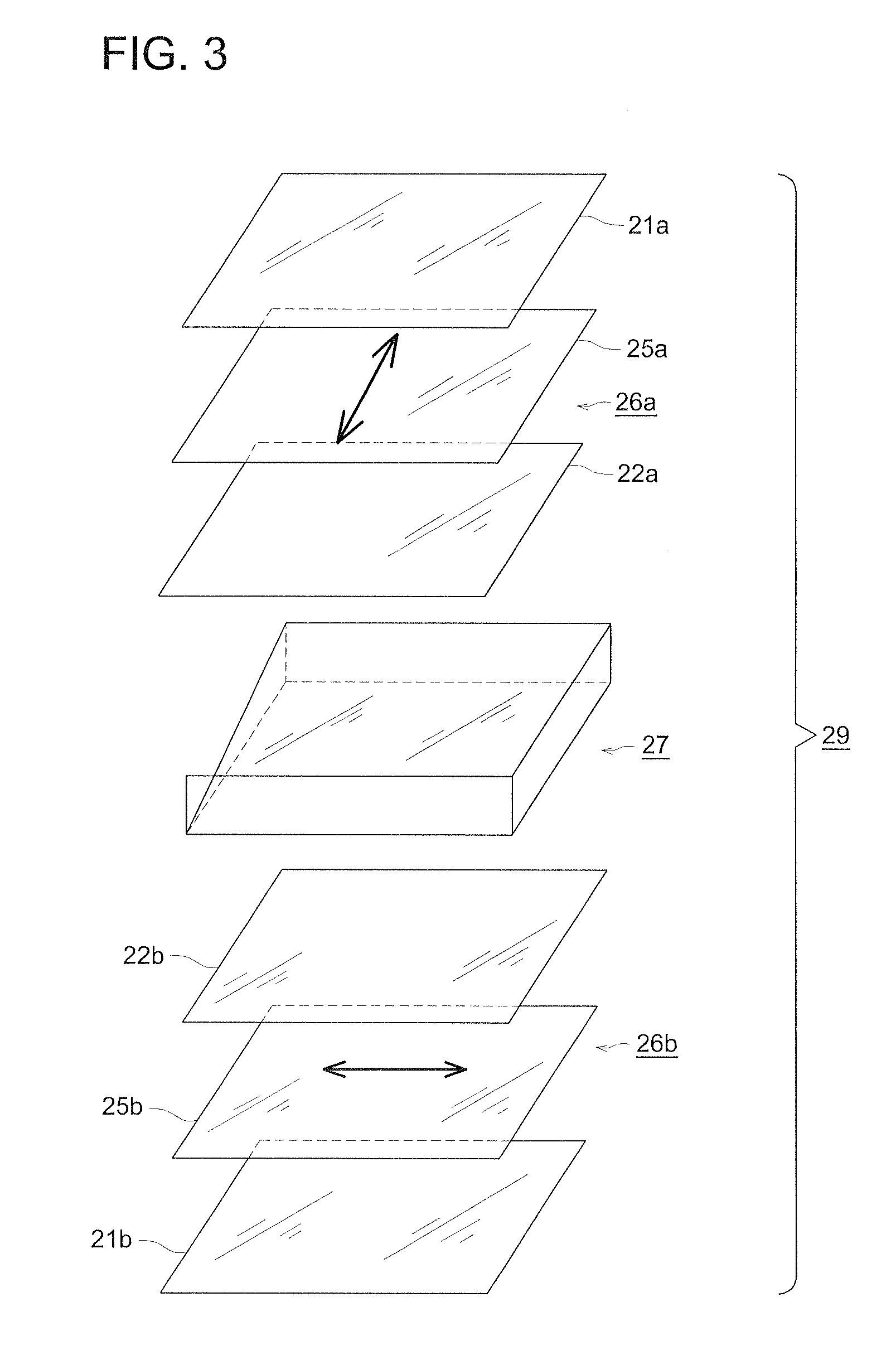

Rolled optical film

InactiveUS20070128381A1Leakage is generatedLiquid crystal compositionsLayered productsCellulose ester membraneMaterials science

A rolled optical film includes a cellulose ester film which has a width of from 1 m to 3 m and a length of 500 m or more and is shaped in a rolled film. The cellulose ester film includes streaks from 1 line to 20 lines per 10 mm in a lateral direction thereof in which the streaks have a height of from 50 nm to 300 nm, an inclination of from 50 nm / mm to 300 nm / mm and a continuous length of 50 cm or more in a longitudinal direction thereof and the cellulose ester film does no includes a streak which has a height of 300 nm or more, an inclination of 300 nm / mm or more and a continuous length of 50 cm or more in a longitudinal direction thereof.

Owner:KONICA MINOLTA OPTO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com