Graphene oxide film based on dopamine biomimetic modification as well as preparation method and application thereof

A graphene membrane, dopamine technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of reducing hydrophilic and oleophobic capabilities, insufficient mechanical strength and stability of graphene membranes, etc. Not easy to fall off and break, good for preservation and reusability, suitable for large-scale production and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

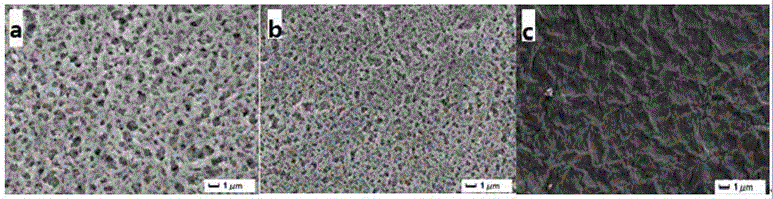

[0036] (1) A commercial mixed cellulose ester membrane with a pore size of 0.22 μm was soaked in deionized water for about 1 h to remove surface impurities. Spread the washed membrane on a petri dish, and add 20 mL of 50 mmol / L Tris-HCl buffer solution (pH=8.5) and 20 mg of dopamine hydrochloride in sequence. Then, the culture dish was placed in a full-temperature shaking incubator, the reaction temperature was set at 25 °C, the rotation speed was set at 40 rpm, and the reaction time was 12 h. Finally soak in deionized water for later use to obtain a dopamine-modified mixed cellulose ester film.

[0037] (2) Fix the membrane prepared in step (1) on a vacuum filtration device, add 60 mL of 1 mg / L graphene oxide solution, and vacuum filter at 0.02 MPa to form a membrane. After natural drying at room temperature, a graphene oxide film modified based on dopamine was obtained.

[0038] (3) After mixing 0.6 g of Tween 20, 120 mL of water and 4 mL of petroleum ether, it was stirred...

Embodiment 2

[0043] (1) A commercial mixed cellulose ester membrane with a pore size of 0.22 μm was soaked in deionized water for about 1 h to remove surface impurities. Spread the washed membrane on a petri dish, and add 50 mL of 50 mmol / L Tris-HCl buffer solution (pH=8.5) and 50 mg of dopamine hydrochloride in sequence. Then, the culture dish was placed in a full-temperature shaking incubator, the reaction temperature was set at 25 °C, the rotation speed was set at 50 rpm, and the reaction time was 15 h. Finally soak in deionized water for later use to obtain a dopamine-modified mixed cellulose ester film.

[0044](2) Fix the membrane prepared in step (1) on a vacuum filtration device, add 50 mL of 1 mg / L graphene oxide solution, and vacuum filter at 0.05 MPa to form a membrane. After natural drying at room temperature, a graphene oxide film modified based on dopamine was obtained.

[0045] (3) After mixing 1.3 g of Tween 80, 120 mL of water and 4 mL of mineral oil, and ultrasonically ...

Embodiment 3

[0049] (1) A commercial mixed cellulose ester membrane with a pore size of 0.45 μm was soaked in deionized water for about 1 h to remove surface impurities. Spread the washed membrane on a petri dish, and add 60 mL of 50 mmol / L Tris-HCl buffer solution (pH=8.5) and 60 mg of dopamine hydrochloride in sequence. Then the culture dish was placed in a full-temperature shaking incubator, the reaction temperature was set at 25°C, the rotation speed was set at 60 rpm, and the reaction time was 20 h. Finally soak in deionized water for later use to obtain a dopamine-modified mixed cellulose ester film.

[0050] (2) Fix the membrane prepared in step (1) on a vacuum filtration device, add 40 mL of 1 mg / L graphene oxide solution, and vacuum filter at 0.07 MPa to form a membrane. After natural drying at room temperature, a graphene oxide film modified based on dopamine was obtained.

[0051] (3) After mixing 0.3 g of cetyltrimethylammonium bromide, 120 mL of water and 4 mL of n-hexane, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com