Cellulose ester film, retardation film, polarizing plate and liquid crystal display device

A technology of cellulose ester film and polycondensate, applied in polarizing elements, instruments, optics, etc., can solve problems such as dissatisfaction, film area defects, and operation errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

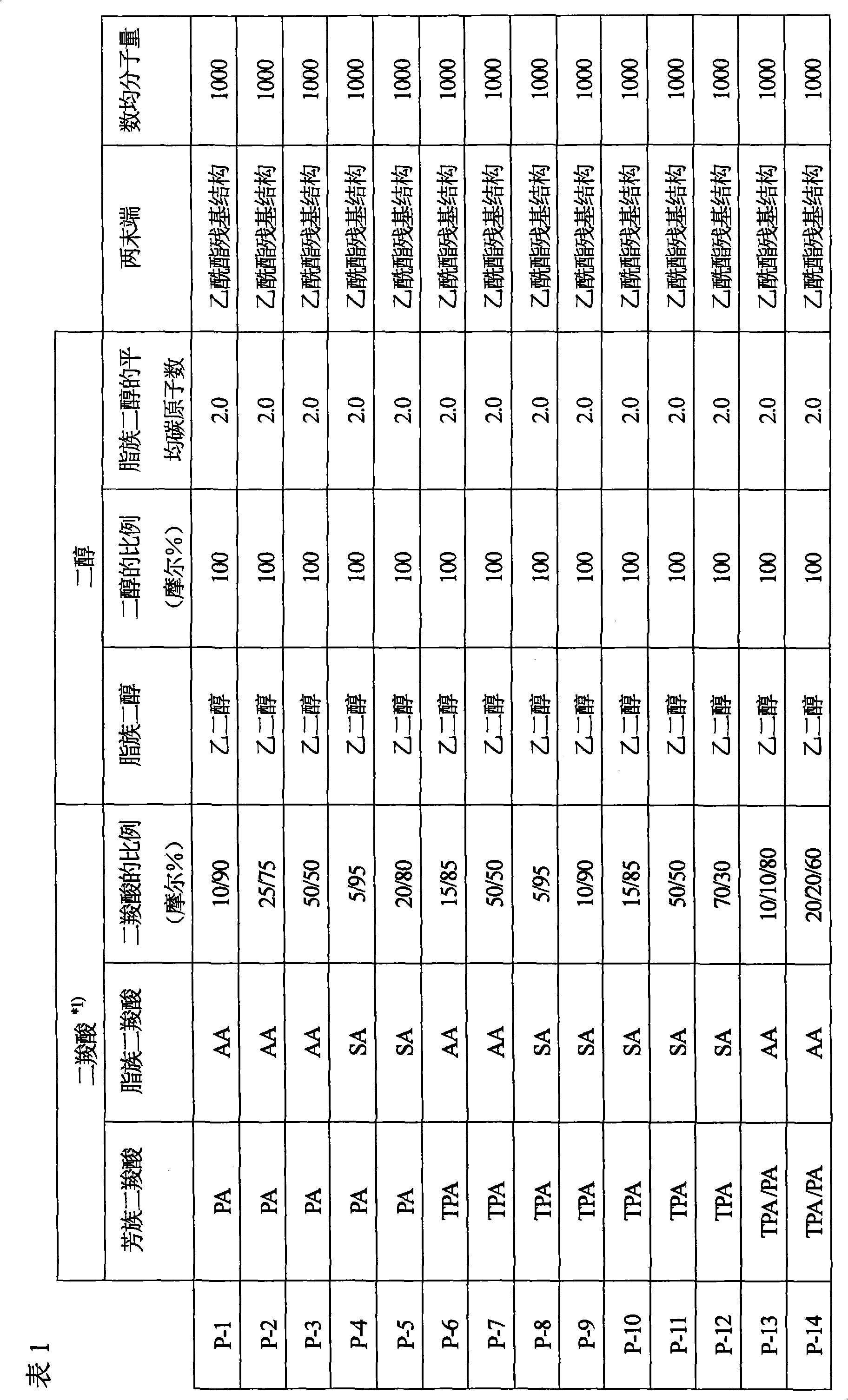

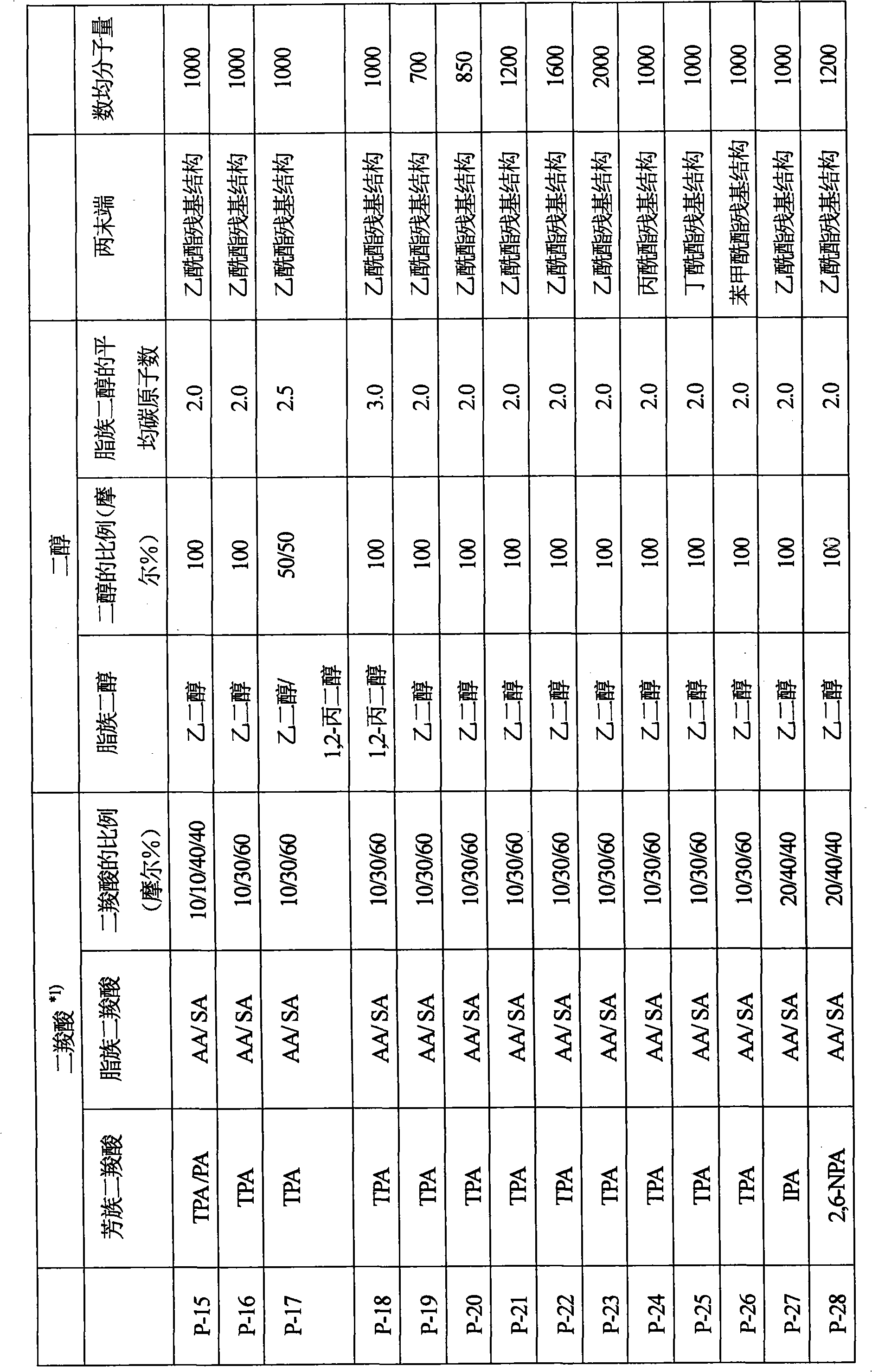

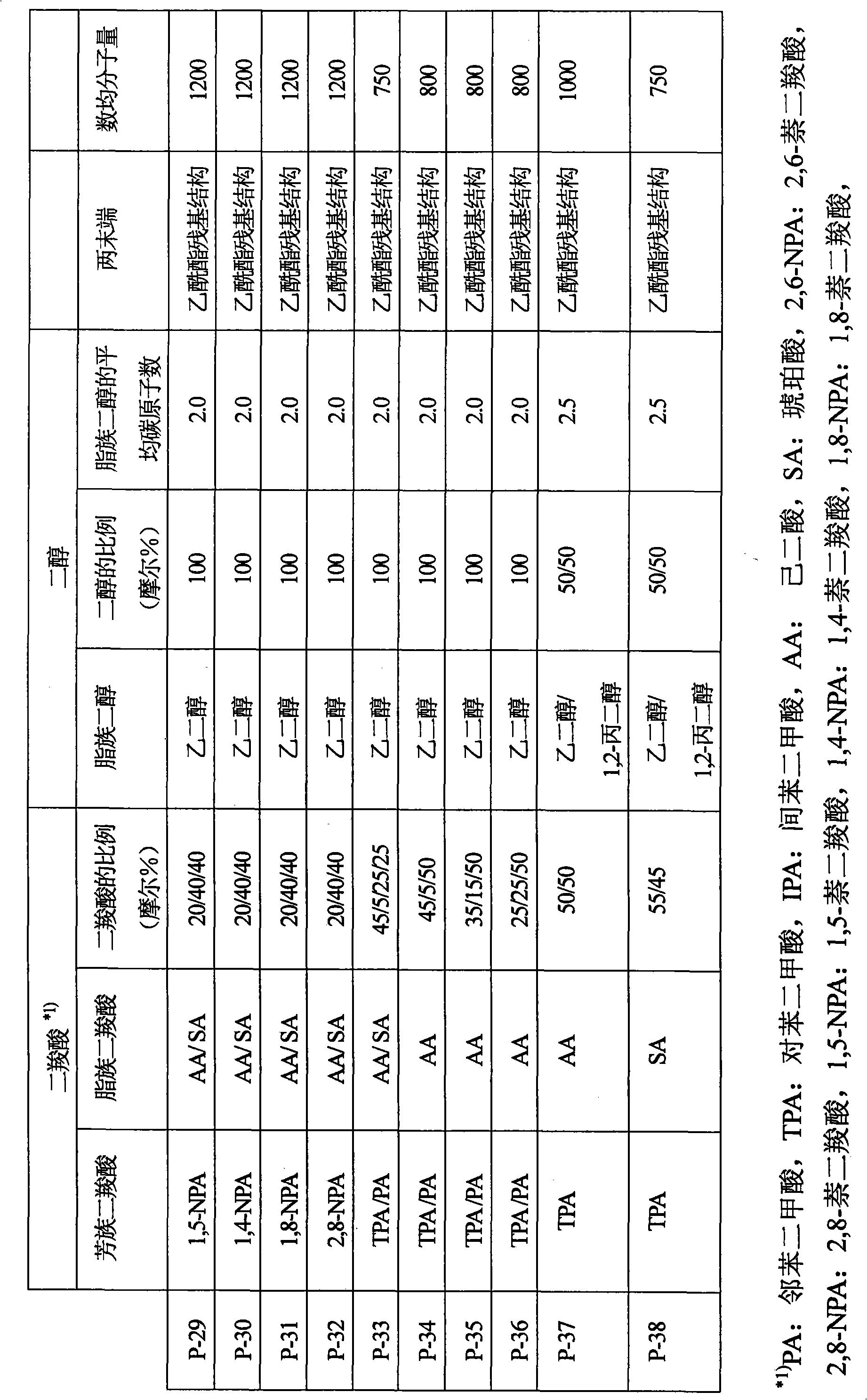

preparation example Construction

[0072] [Preparation of Cellulose Acylate Film]

[0073] The cellulose acylate film of the present invention can be produced by a solvent casting method. In the solvent casting method, a film is produced by using a solution (dope) of cellulose acylate dissolved in an organic solvent.

[0074] Preferred organic solvents include solvents selected from ethers having 3-12 carbon atoms, ketones having 3-12 carbon atoms, esters having 3-12 carbon atoms, and halogenated hydrocarbons having 1-6 carbon atoms .

[0075] Ethers, ketones and esters may each have a cyclic structure. Compounds having any two or more of ether, ketone and ester functional groups (ie -O-, -CO- and -COO-) can also be used as the organic solvent. The organic solvent may have other functional groups such as alcoholic hydroxyl groups. In the case of an organic solvent having two or more functional groups, it is preferable that the number of carbon atoms thereof falls within the range of the aforementioned prefe...

Embodiment 1

[0192] [Example 1: Preparation of Cellulose Acylate Film 101]

[0193] (Preparation of Cellulose Acylate Solution A-1)

[0194] Cellulose acylate solution A-1 was prepared by charging the following composition into a mixing tank and stirring while heating to dissolve the various ingredients. The degree of acetyl substitution was determined according to ASTM D-817-91. Viscosity-average polymerization was measured by the intrinsic viscosity method of Uda et al. Spend.

[0195] Composition of Cellulose Acylate Solution A-1

[0196] Cellulose acylate (acetyl substitution degree: 2.86, viscosity average degree of polymerization: 310): 100 parts by mass

[0197] The above polycondensation ester P-8: 12 parts by mass

[0198] Dichloromethane: 384 parts by mass

[0199] Methanol: 69 parts by mass

[0200] Butanol: 9 parts by mass

[0201] (Preparation of Matting Agent Dispersion B-1)

[0202] The following composition was charged into a dispersing machine and stirred to disso...

Embodiment 2

[0255] [Example 2: Preparation of Cellulose Acylate Film 201]

[0256] (Preparation of Cellulose Acylate Solution A-2)

[0257] Fill the following composition into a mixing tank and stir to dissolve the ingredients. The solution was further heated at 90° C. for about 10 minutes and filtered through a filter paper having an average pore size of 34 μm and a sintered metal filter having an average pore size of 10 μm, whereby cellulose acylate solution A-2 was prepared.

[0258] Components of Cellulose Acylate Solution A-2

[0259] Cellulose acylate (acetyl substitution degree: 2.86, viscosity-average degree of polymerization: 310): 100.0 parts by mass

[0260] The above polycondensation ester P-15: 12.0 parts by mass

[0261] Dichloromethane: 403.0 parts by mass

[0262] Methanol: 60.2 parts by mass

[0263] (Preparation of Matting Agent Dispersion B-2)

[0264] After that, the following composition containing the cellulose acylate solution prepared above was charged into a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com