Sulfur/carbon composite material and preparation method thereof

A technology of carbon composite materials and carbon materials, applied in the field of electrochemistry, can solve the problems of low sulfur content in composite materials, difficult to control, and low sulfur loading capacity, and achieve the effects of small particle size, low cost, and low impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

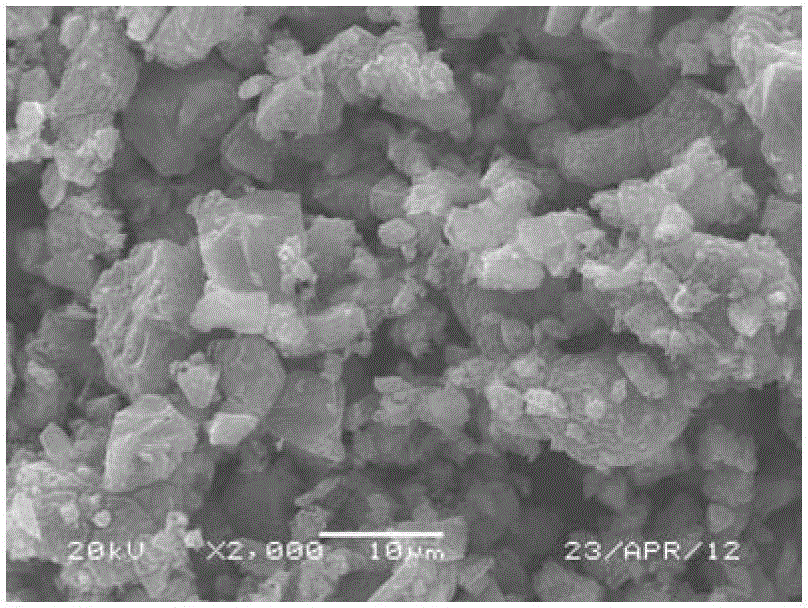

[0051] At room temperature, add 3.2 g of sublimed sulfur to 17 g of ammonium sulfide aqueous solution with a mass concentration of 20% to generate an ammonium polysulfide solution; then add 0.08 g of surfactant polyethylene glycol octyl phenyl to the ammonium polysulfide solution in turn ether and 0.8 g of activated carbon, stirred for 2 hours, and after stirring evenly, the mixture was placed in an ultrasonic cleaner for 1 hour at a power of 150W for ultrasonic oscillation, and then placed in a magnetic stirrer to stir at a certain speed, heated to 95 ° C, so that more The sulfur generated by the thermal decomposition of ammonium sulfide is deposited in-situ into the pores of the activated carbon material, and then separated by filtration to obtain a sulfur / carbon composite material and a filtrate; the obtained sulfur / carbon composite material is washed with distilled water until neutral, and then heated at 80 °C. Vacuum drying to obtain a sulfur / carbon composite material with...

Embodiment 2

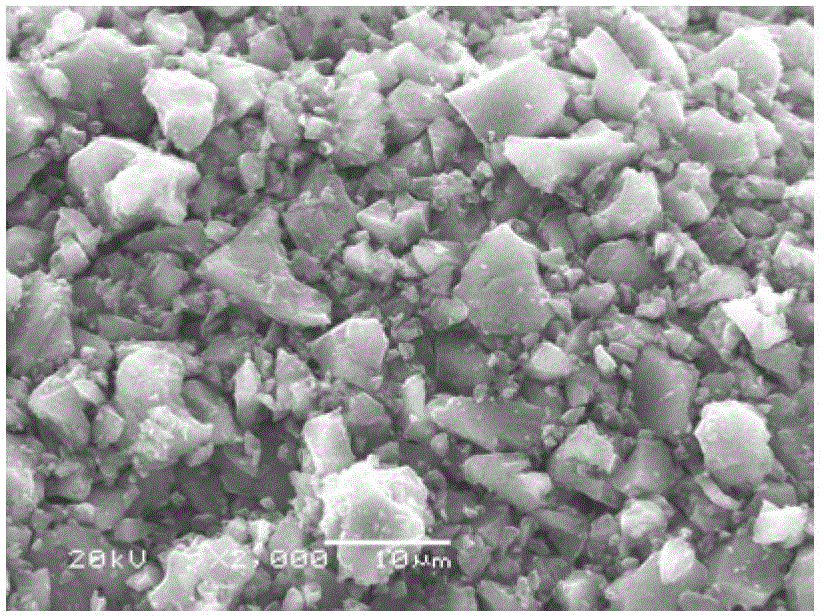

[0055] At room temperature, add 3.2g of sublimed sulfur to 17g of ammonium sulfide solution with a mass concentration of 20% to generate ammonium polysulfide solution; then add 0.32g of surfactant polyethylene glycol and 3.2g of activated carbon to the ammonium polysulfide solution in turn , stir for 1h, and after stirring evenly, the mixture is placed in an ultrasonic cleaner with a power of 100W for ultrasonic oscillation for 1h, and placed in a magnetic stirrer to stir at a certain speed, and heated to 95 ℃, so that ammonium polysulfide is heated and decomposed to form The sulfur in situ was deposited into the pores of the carbon material, and then centrifuged to obtain the sulfur / carbon composite material and filtrate; the obtained sulfur / carbon composite material was washed with ethanol to neutrality, and then vacuum-dried at 70 °C to obtain the sulfur / carbon composite material. / carbon composites.

Embodiment 3

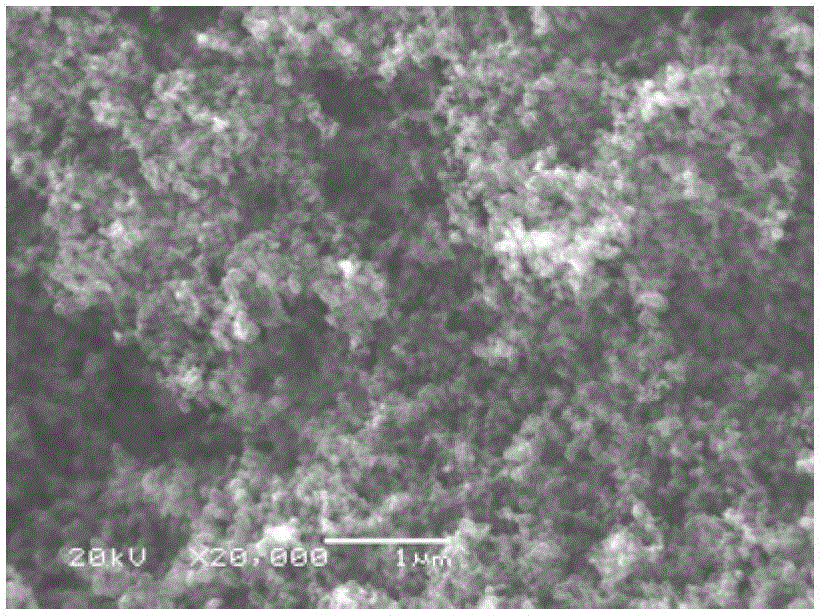

[0057] At room temperature, add 3.2g of sedimentary sulfur to 6.8g of ammonium sulfide solution with a mass concentration of 20% to generate ammonium polysulfide solution; then add 0.21g of surfactant polyethylene glycol and 1.37g of ammonium polysulfide solution to the solution in turn Carbon black, stirred for 1 hour, and after stirring evenly, the mixture was placed in an ultrasonic cleaner with a power of 60W for ultrasonic oscillation for 1 hour, and placed in a magnetic stirrer to stir at a certain speed, and heated to 120 ° C to heat the ammonium polysulfide. The decomposed sulfur is deposited in-situ into the pores of the carbon material, filtered and separated to obtain a sulfur / carbon composite material and a filtrate; the obtained sulfur / carbon composite material is washed with distilled water until neutral, and then vacuum-dried at 80 °C to obtain the sulfur / carbon composite material. / carbon composites.

[0058] Electrochemical performance testing of sulfur / carbon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com