Patents

Literature

30results about How to "Process pollution is small" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

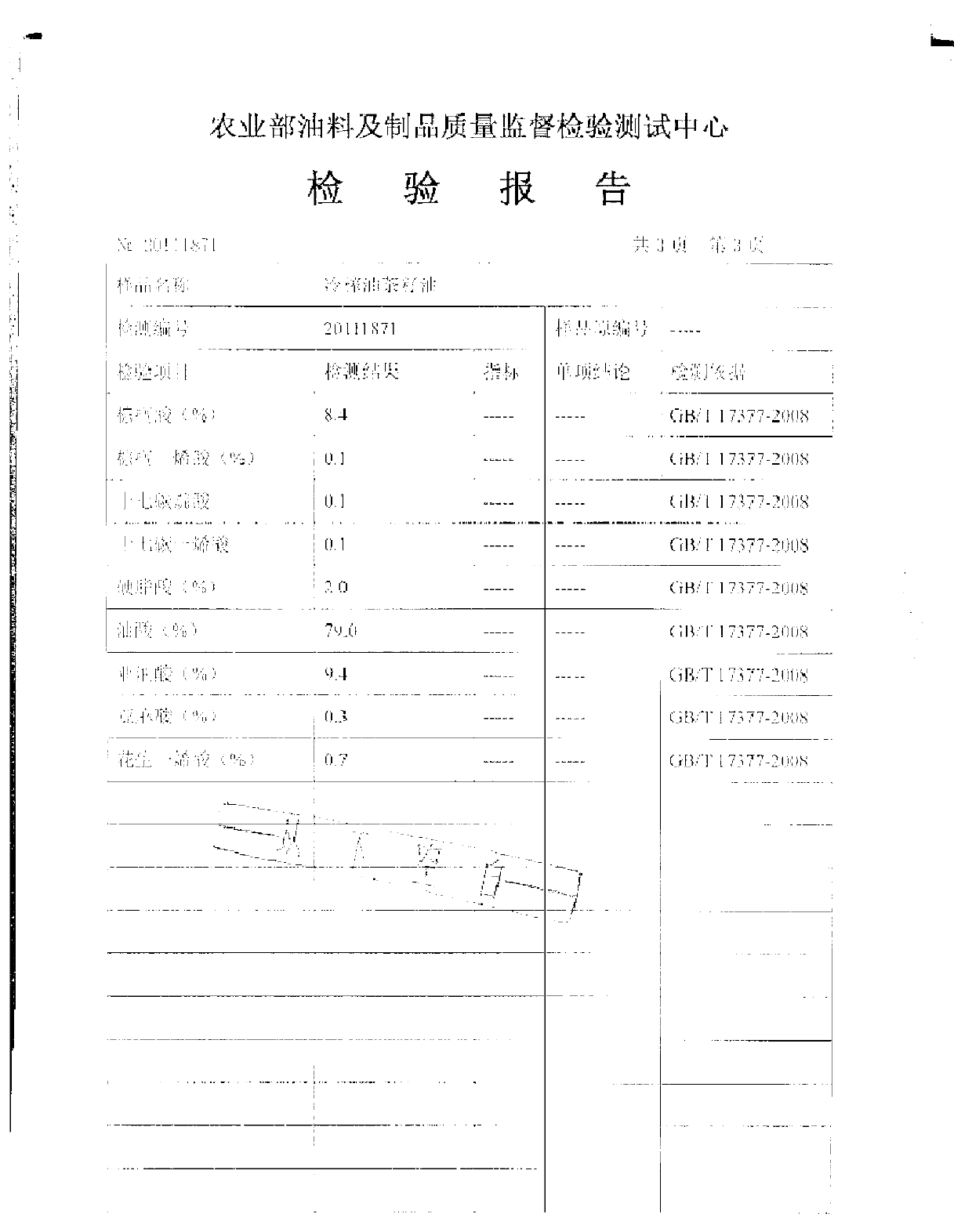

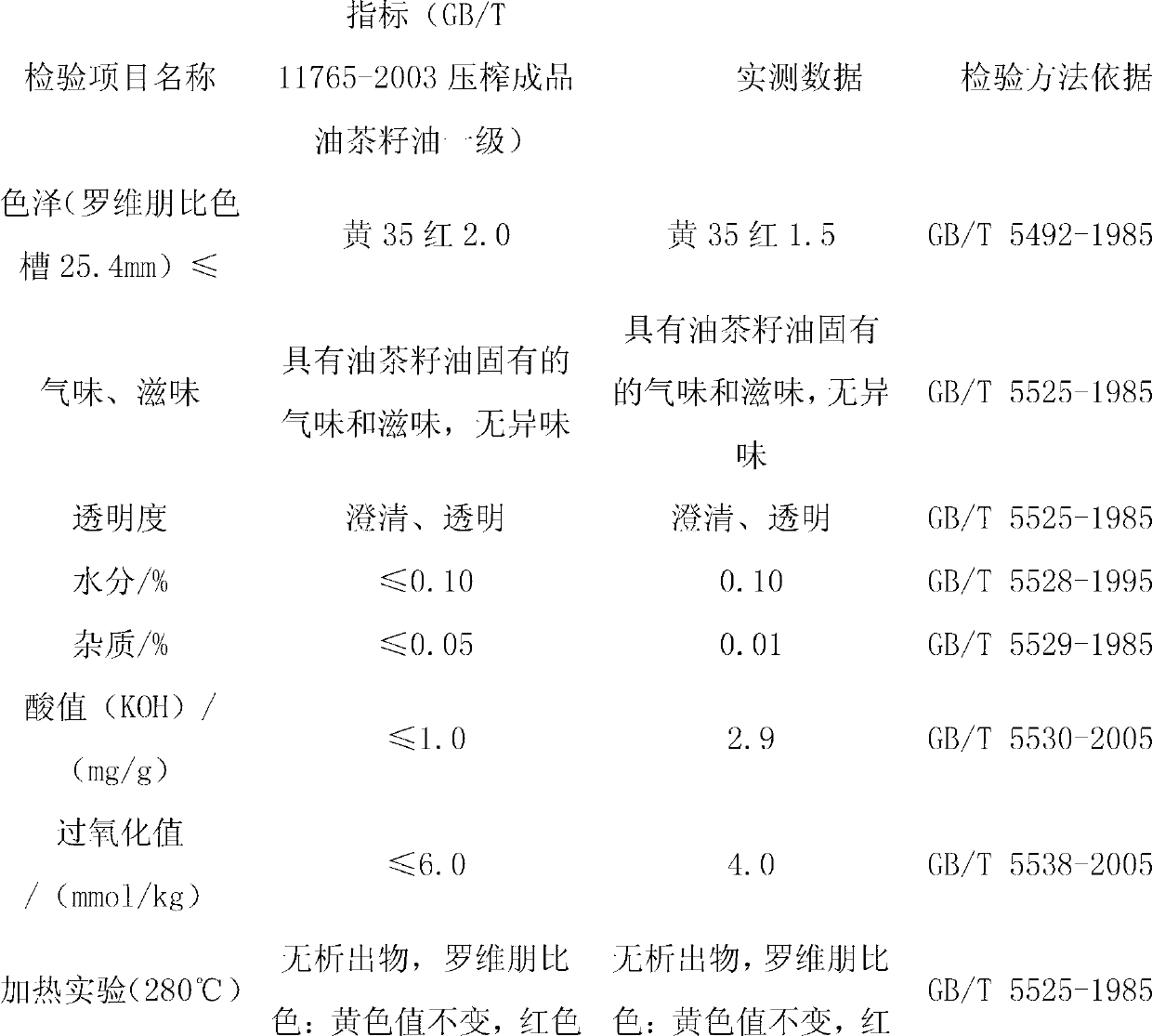

Method for preparing tea seed oil in low-temperature cold pressing manner

InactiveCN102965187AHigh mechanical wearReduce oil yieldFatty-oils/fats refiningFatty-oils/fats productionFlavorEngineering

The invention provides a method for preparing tea seed oil in a low-temperature cold pressing manner. The method comprises the following steps of cleaning tea seeds, removing shells and separating, milling oil at normal temperature, washing in water at low temperature, dehydrating under negative pressure, refining at low temperature, filtering for many times, winterizing and dewaxing. The method for preparing the tea seed oil in the low-temperature cold pressing manner, provided by the invention, has the advantages of simple process, low energy consumption and high oil yield; and the prepared tea seed oil has shallow color, high quality and comprehensive nutrition, and also keeps the original flavor of tea oil.

Owner:安徽新世界绿洲茶油有限公司

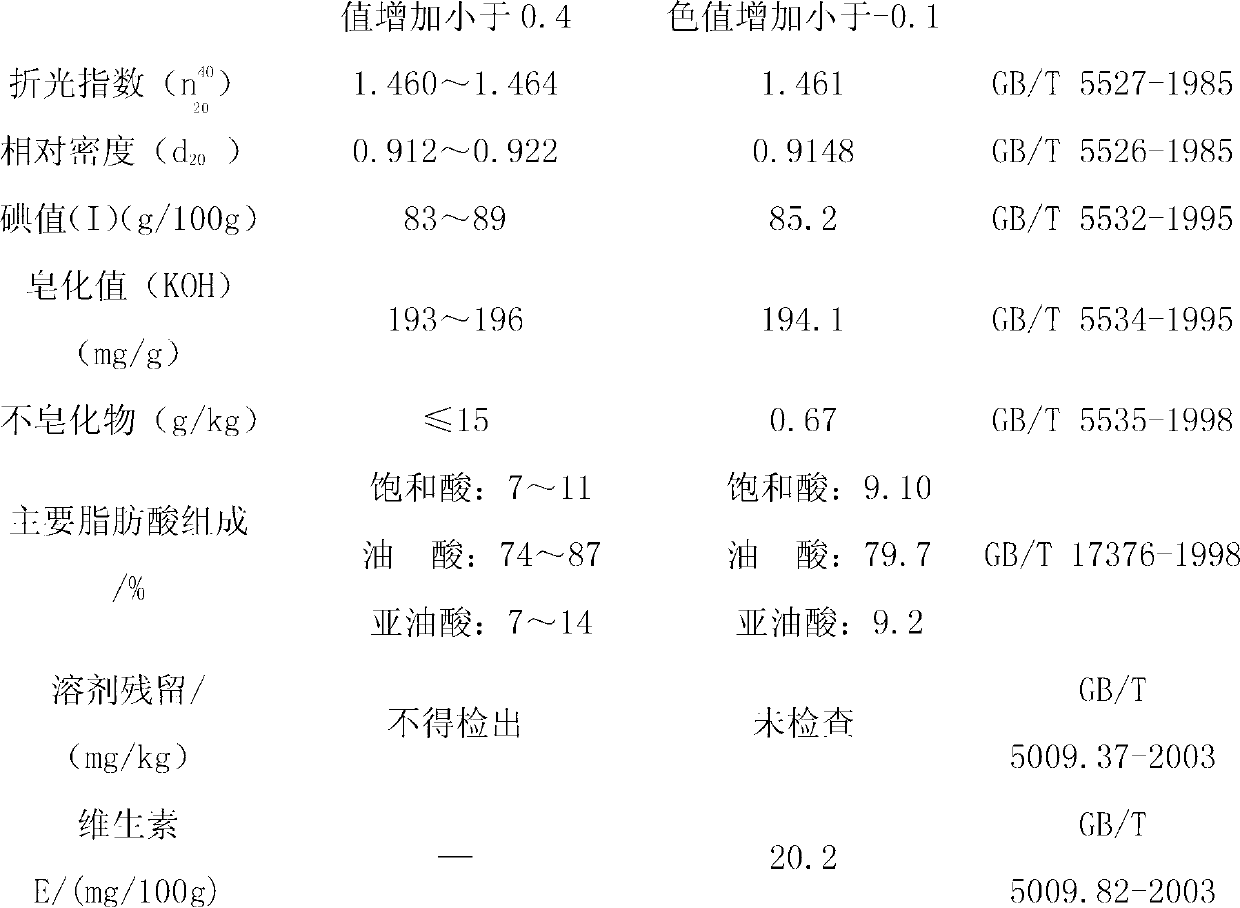

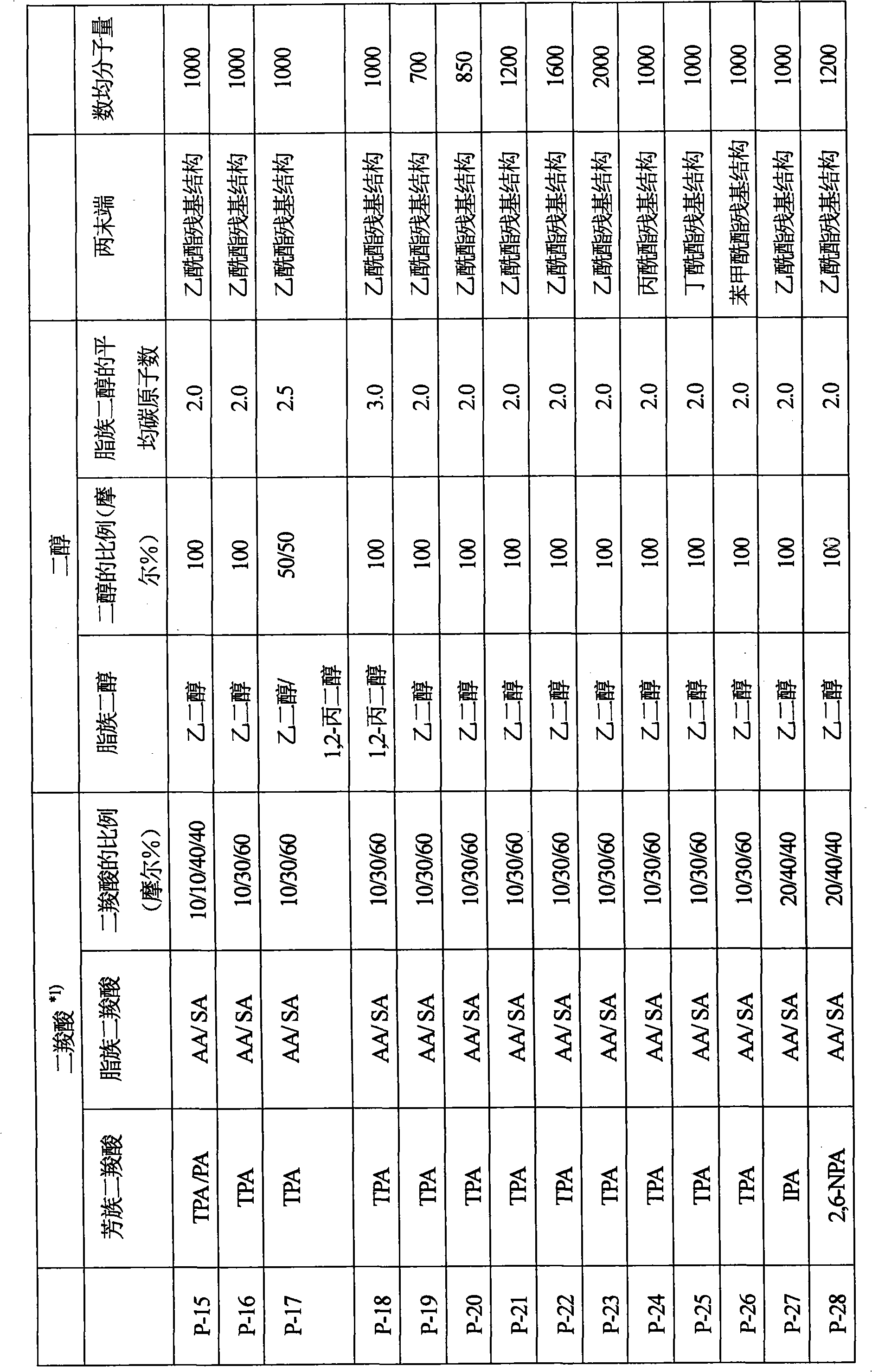

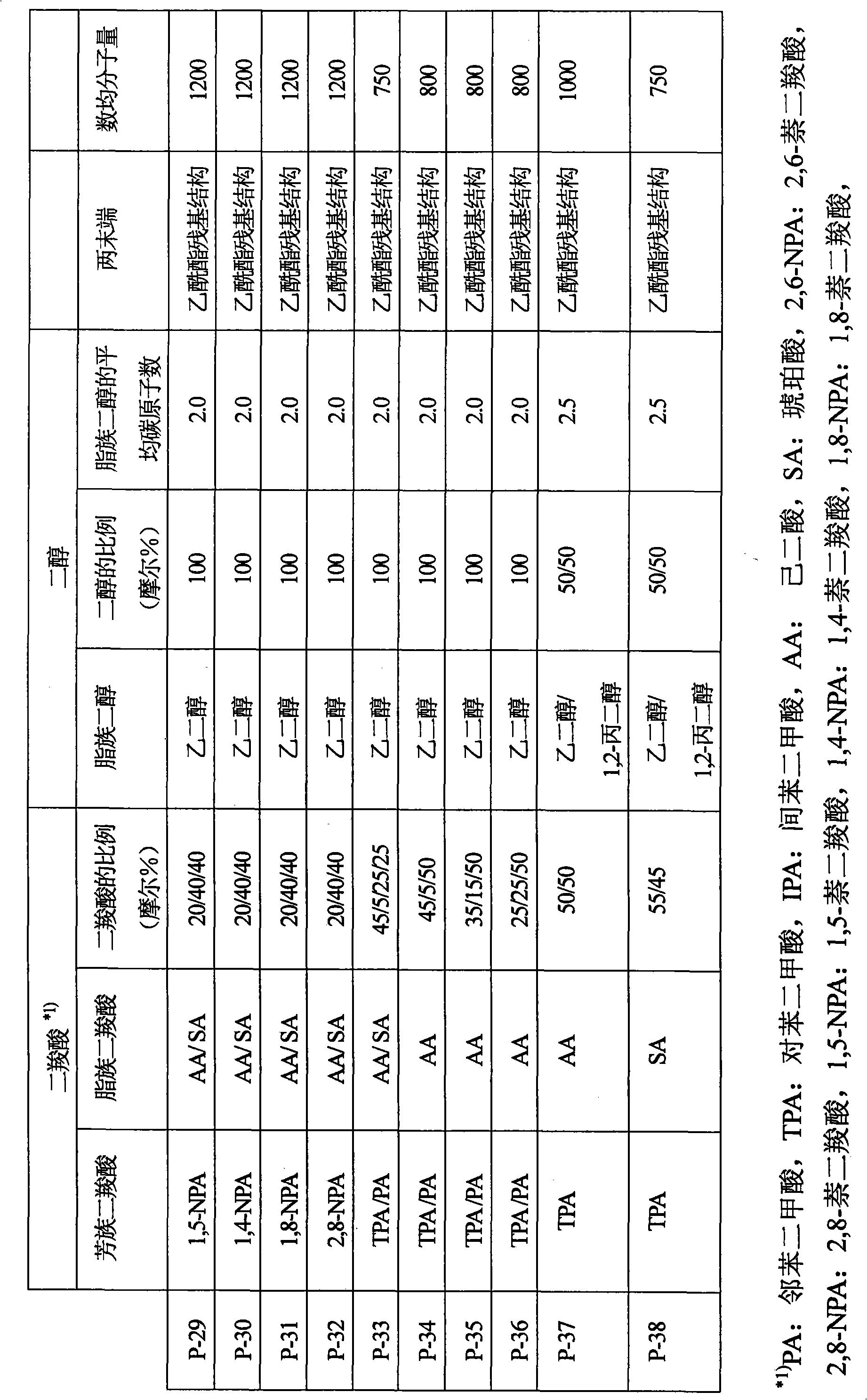

Cellulose ester film, retardation film, polarizing plate and liquid crystal display device

InactiveCN101580597AProcess pollution is smallIncrease productivityPolarising elementsNon-linear opticsCellulose ester membraneLiquid-crystal display

Provided is a cellulose ester film including a polycondensed ester which is obtained from a mixture containing an aromatic dicarboxylic acid, an aliphatic dicarboxylic acid, an aliphatic diol having an average carbon atom number of from 2.0 to 3.0 and a monocarboxylic acid, and both terminals of which are a monocarboxylic acid ester derivative.

Owner:FUJIFILM CORP

Method for extracting high-purity scutellarin from breviscpini

ActiveCN101497637AAchieve separationHigh puritySugar derivativesSugar derivatives preparationFlocculationOrganic solvent

The invention relates to a method for extracting high-purity scutellarin from breviscapin. The method comprises the following steps: the breviscapin raw material is extracted by using organic solvent, the filtrate is added with clarifying agent for coagulation and clarifying, the coagulated and clarified filtrate is absorbed by macroporous absorbent resin and is eluted with water, the water eluent is concentrated through a reverse osmosis membrane or nanofiltration membrane, the concentrated solution is added with the organic solvent for standing and precipitation, the sediment is filtered and collected, the aqueous solution of the organic solvent is added and stirred to be suspendible, and after standing a night, the sediment is filtered, collected and washed to be near-neutral with water to obtain the high-purity scutellarin after drying. The alkali is not used in the entire process, the clarifier is used for removing the water insoluble matter, the impurity removal is carried out by using the macroporous absorbent resin, the concentration is carried out by using the reverse osmosis membrane or the nanofiltration membrane, the scutellarin plant salt is prevented from being heated and degraded in water, the content of the prepared scutellarin can reach above 97 percent, the quality is stable, the process is simple and the pollution is little.

Owner:YUNNAN PHYTOPHARML +1

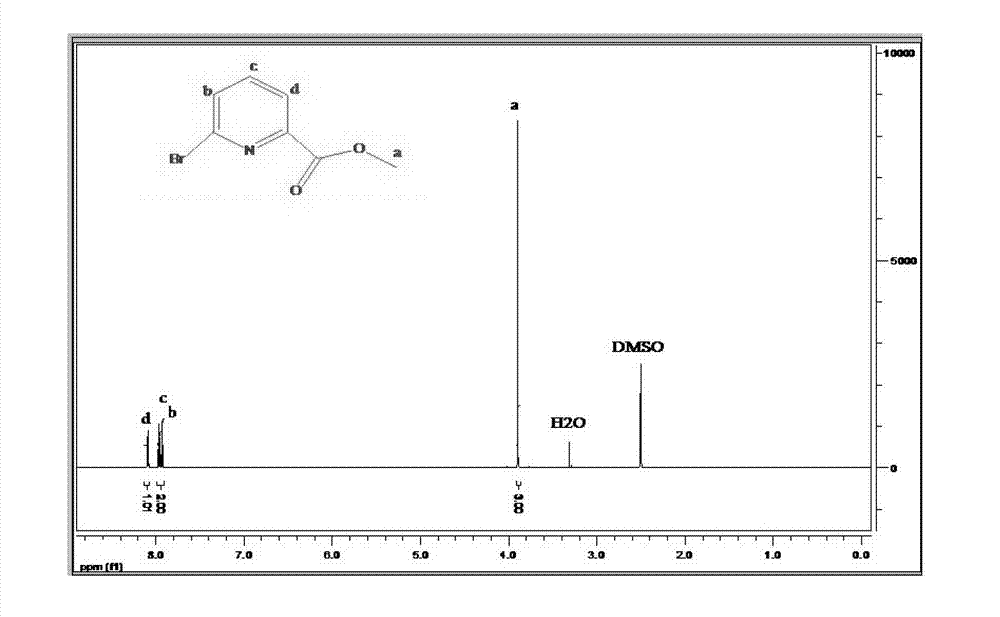

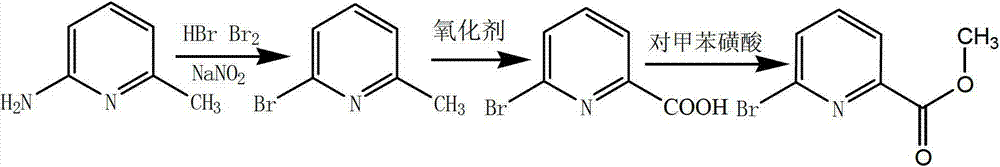

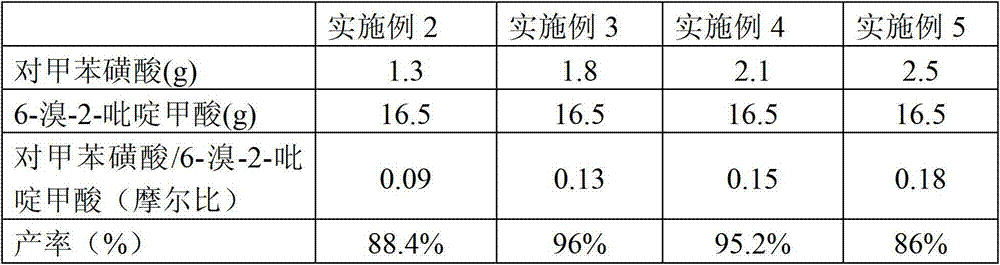

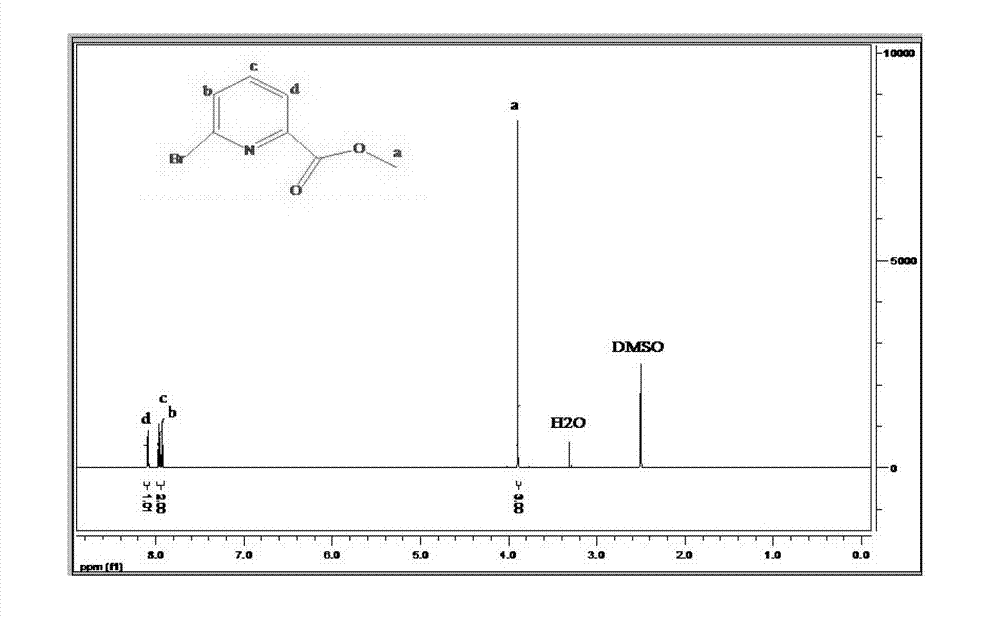

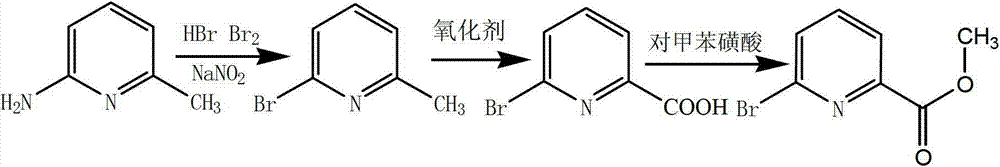

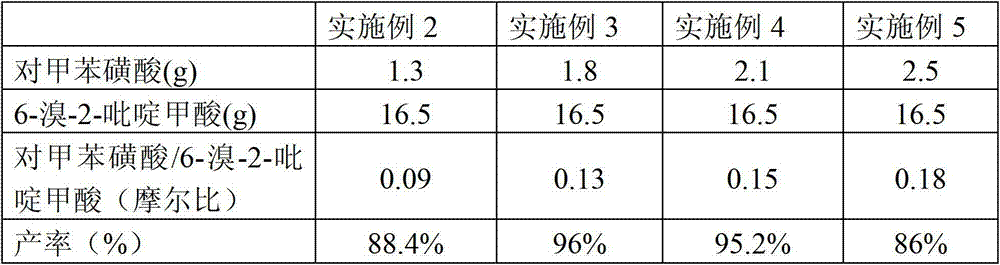

Preparation method of 6-bromine-2-pyridine methyl formate

ActiveCN103086964AOvercome the deficiency of many side effectsLess side effectsOrganic chemistryCarboxylic acidSolvent

The invention relates to a preparation method of 6-bromine-2-pyridine methyl formate. The preparation method comprises the step of catalyzing esterification reaction of 6-bromine-2-pyridine carboxylic acid by taking p-toluenesulfonic acid as a catalyst, to be specific, heating and fluxing absolute methanol, the 6-bromine-2-pyridine carboxylic acid and the p-toluenesulfonic acid for 2-8 hours under stirring, cooling to a room temperature after reaction is ended, rotary drying a reaction system, dissolving solids in an organic solvent, washing, drying, filtering, concentrating, recrystallizing a concentrated product by a mixed solvent to obtain the 6-bromine-2-pyridine methyl formate, wherein a preferable molar ratio of the 6-bromine-2-pyridine carboxylic acid and the p-toluenesulfonic acid is 1: (0.1-0.16). According to one embodiment of the invention, the 6-bromine-2-pyridine carboxylic acid is obtained through diazotization, bromination and oxidation of 6-amino-2-methylpyridine. The preparation method is few in side reaction and simple in aftertreatment and is suitable for industrial production; and the product is easy to separate and has high yield, high purity and good quality.

Owner:BEIJING GREENCHEM TECH

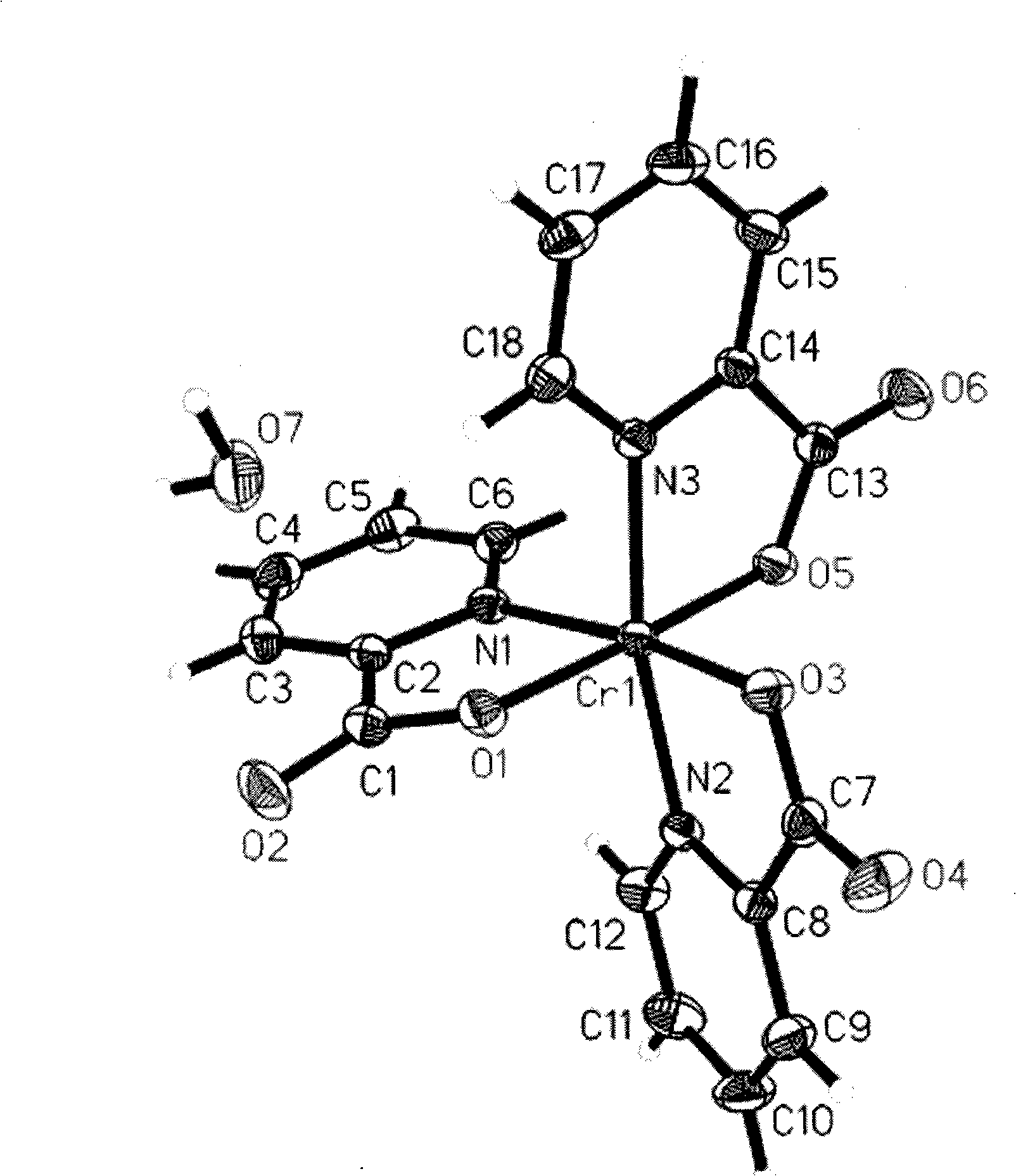

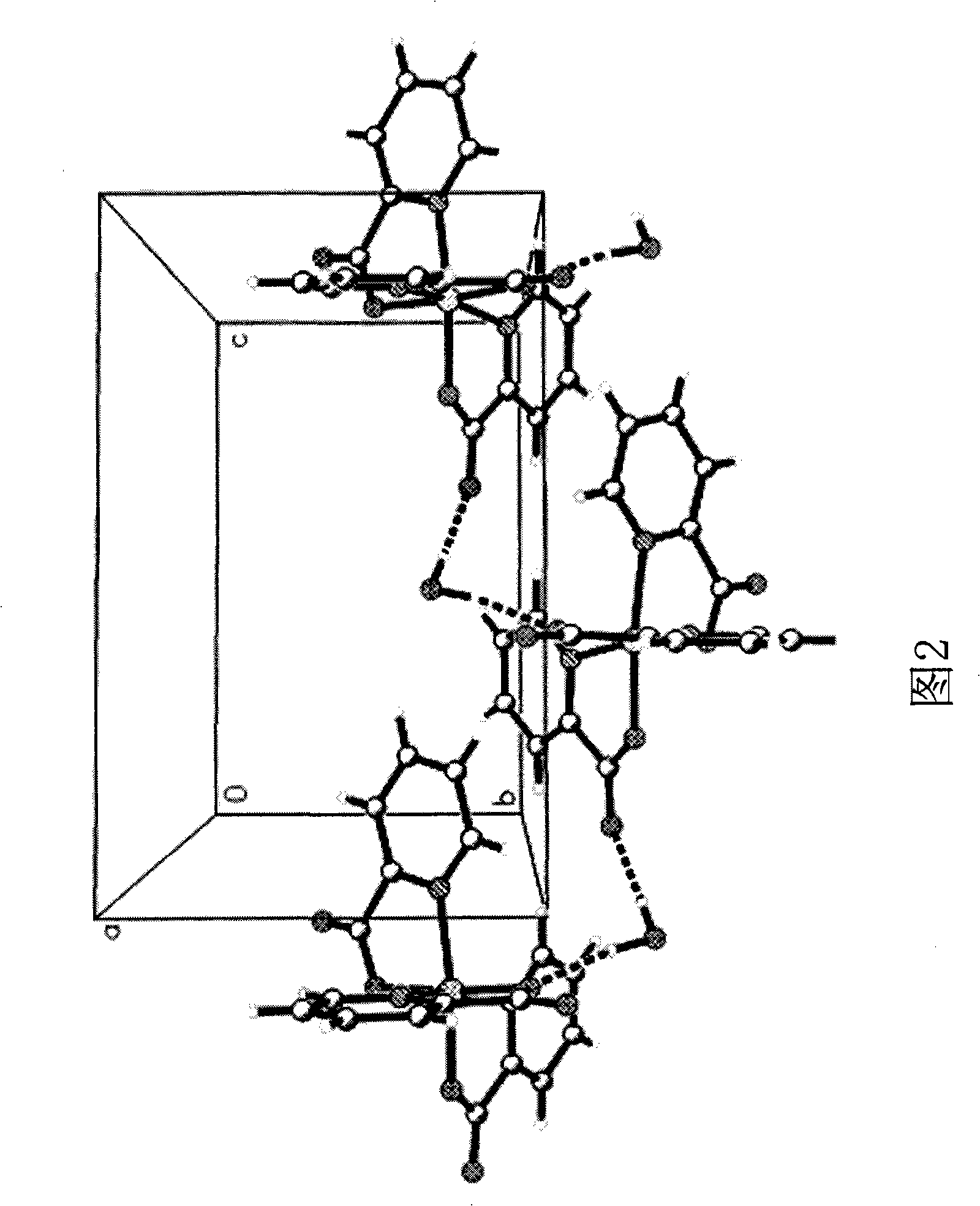

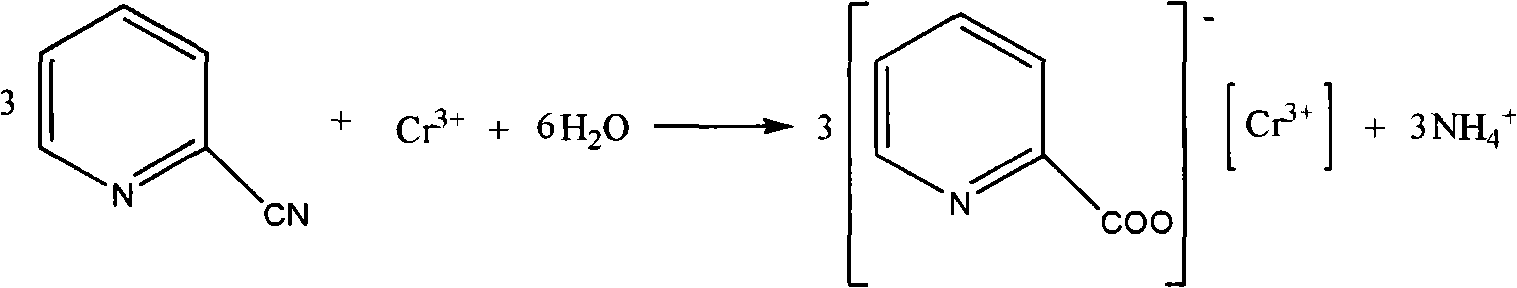

Synthesis process for chromium picolinate

InactiveCN101318929AProcess pollution is smallAtom utilization is highOrganic chemistryChromiumGreen production

The invention discloses a process for synthesizing chromium picolinate. The process uses 2-pyridinecarbonitrile and chromic salt as reactants to generate the chromium picolinate by one-step hydro-thermal synthesis reaction at a temperature of between 80 and 200 DEG C under 2 to 3 standard atmospheric pressure. The process has simple operation, easily realizes mass production, and greatly reduces the manufacturing cost; moreover, the whole process is a green production with low environmental pollution.

Owner:WENZHOU UNIVERSITY

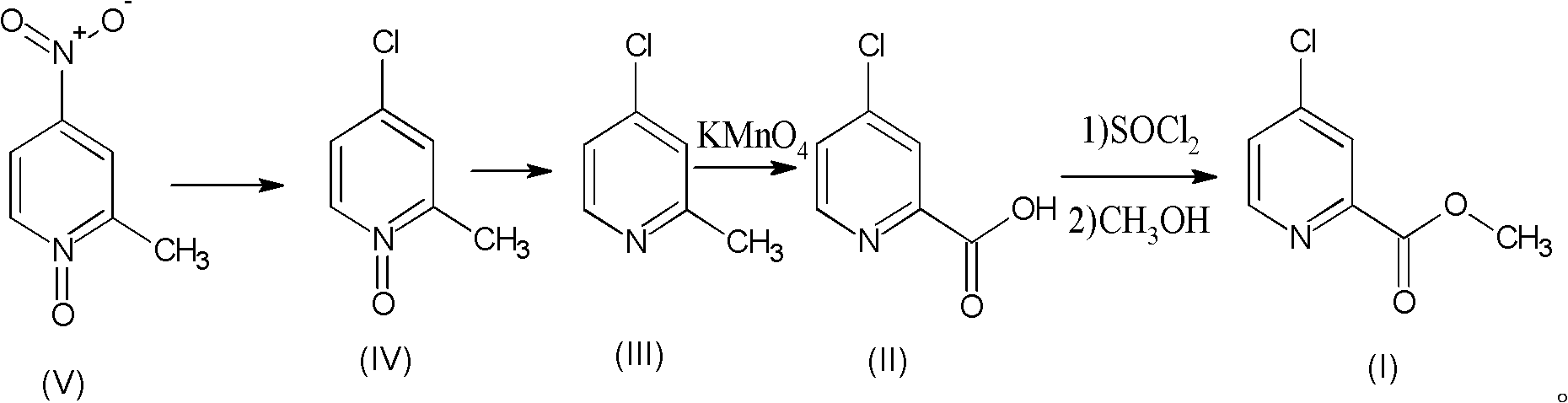

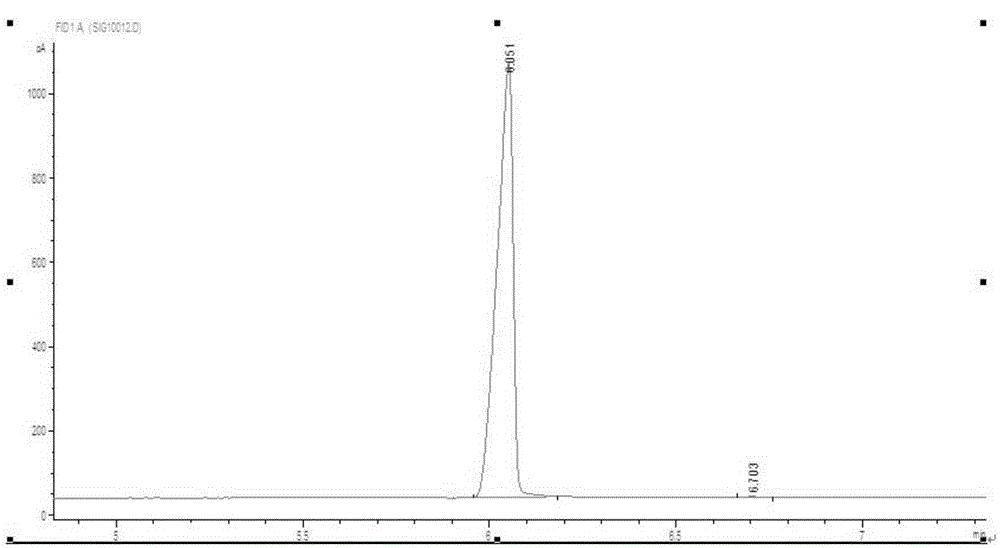

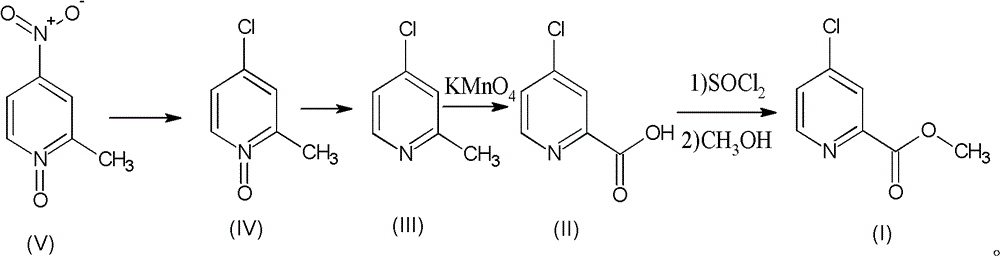

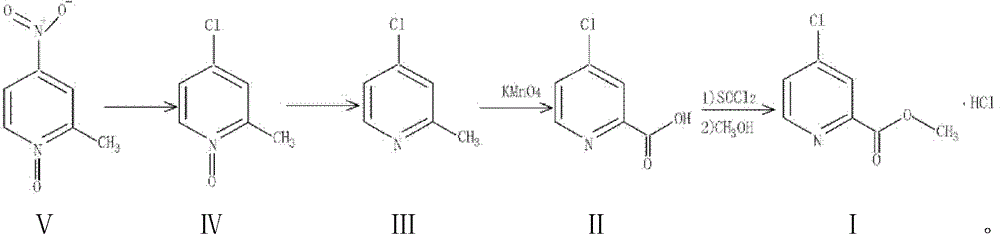

Preparation process of high-purity 4-chloro-2-pyridinecarboxylate hydrochloride

The invention relates to a preparation process of high-purity 4-chloro-2-pyridinecarboxylate hydrochloride, which comprises the following steps of reacting 2-methyl-4-nitropyridine-N-oxide taken as a starting raw material with hydrochloric acid to obtain 4-chloro-2-methyl-pyridine-N-oxide; then dripping phosphorus trichloride into an organic solvent, carrying out reaction for generating 4-chloro-2-methylpyridine, further adding potassium permanganate into water for carrying out oxidation reaction, thus obtaining 4-chloro-2-picolinate; and mixing the 4-chloro-2-picolinate with the catalytic amount of DMF (dimethyfumarate), dripping thionyl chloride, and finally carrying out esterification reaction with methanol so as to obtain the 4-chloro-2-pyridinecarboxylate hydrochloride. The total yield can be up to 36.8%, and the purity can be 99.8% according to the HPLC (high performance liquid chromatography) detection. The process has the advantages of being rich in raw material resources, small in whole process pollution, conductive to controlling three wastes and easy for realizing industrial production.

Owner:SHANDONG JINCHENG PHARMACEUTICAL GROUP CO LTD

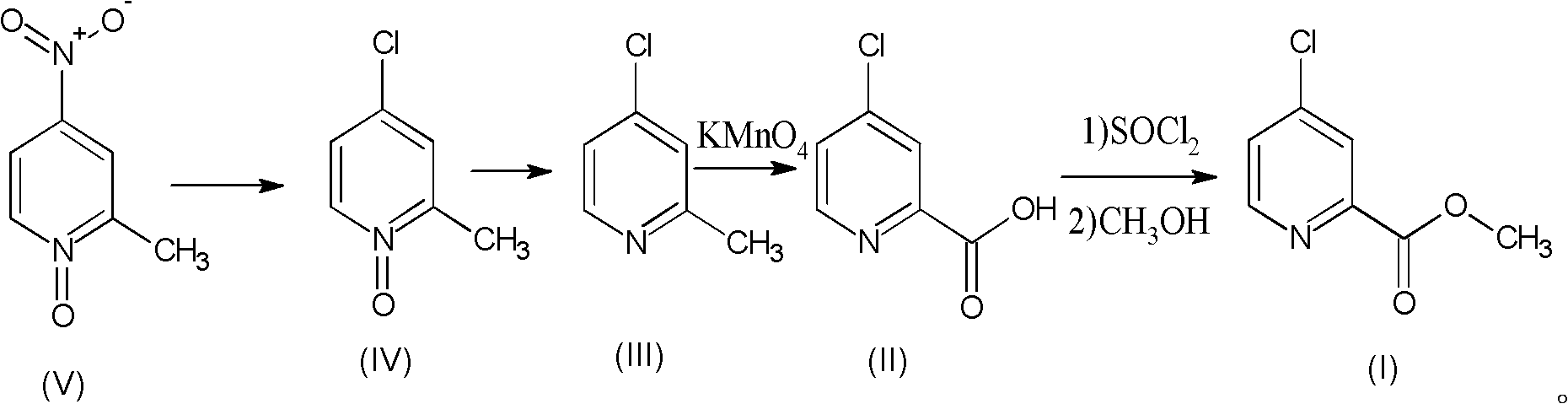

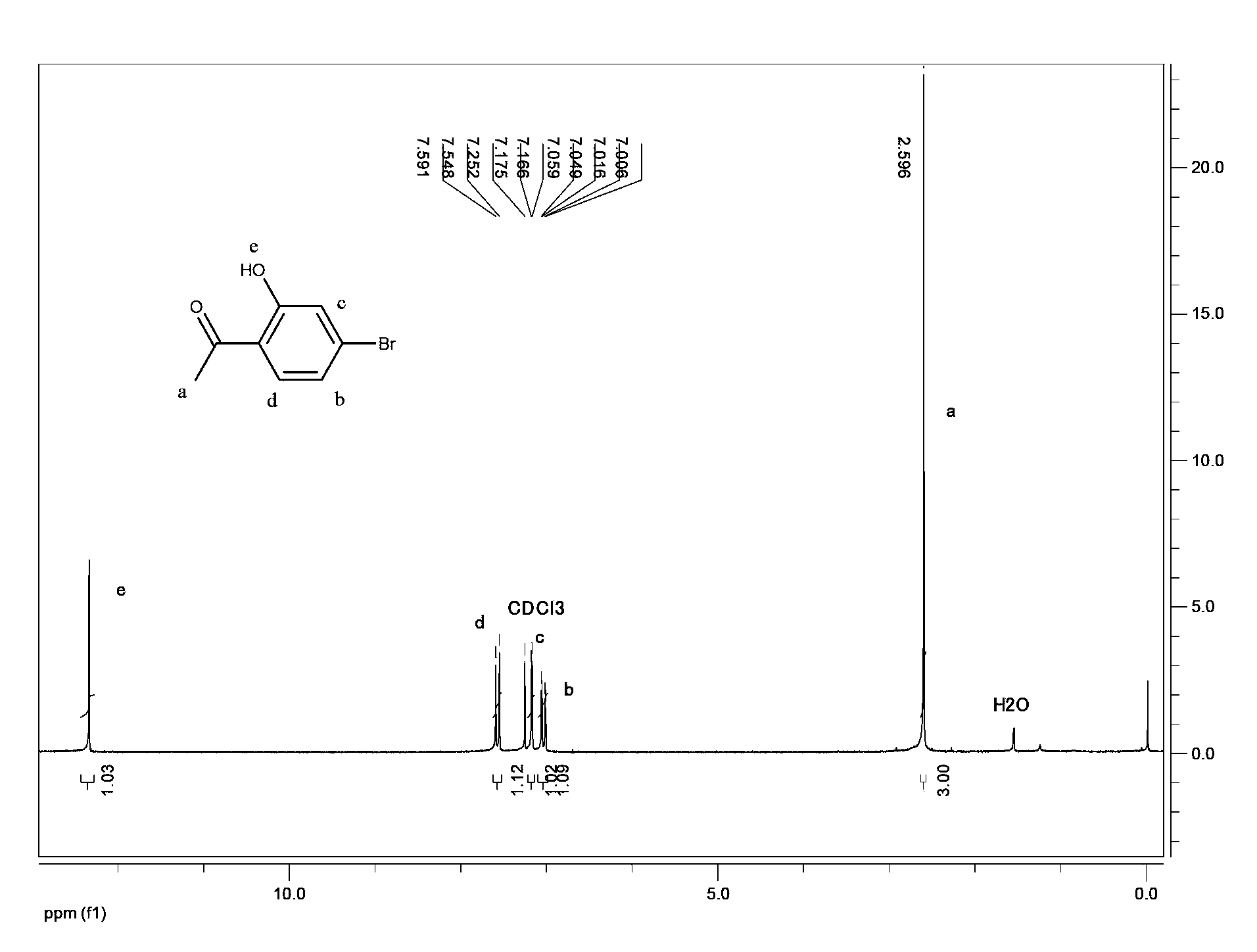

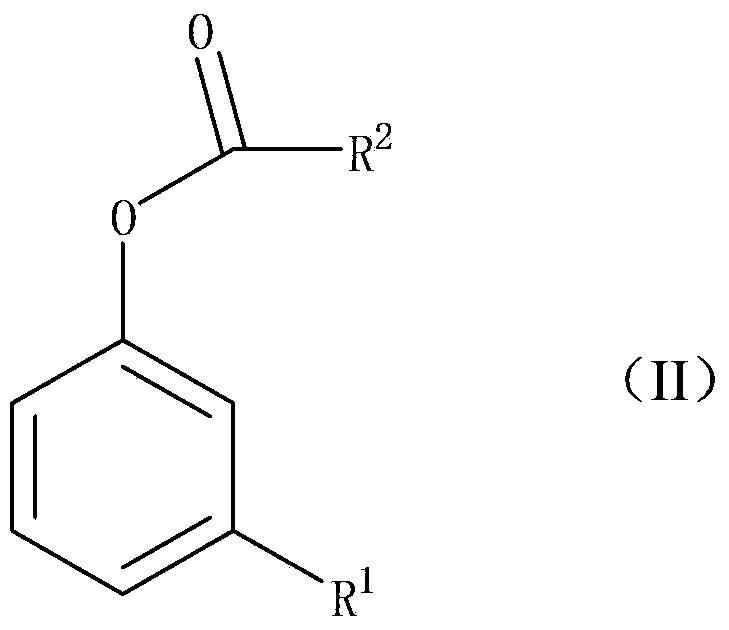

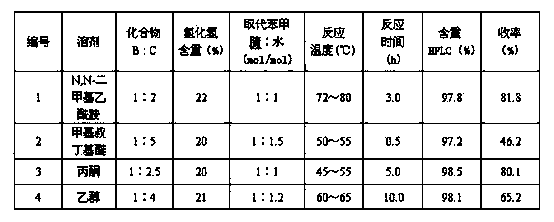

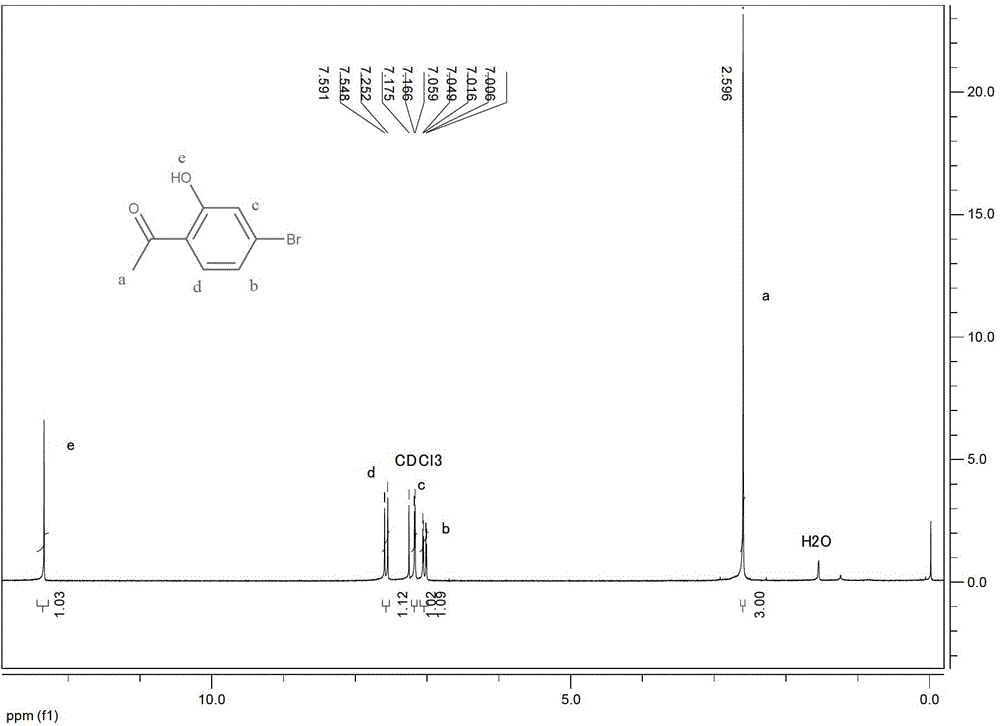

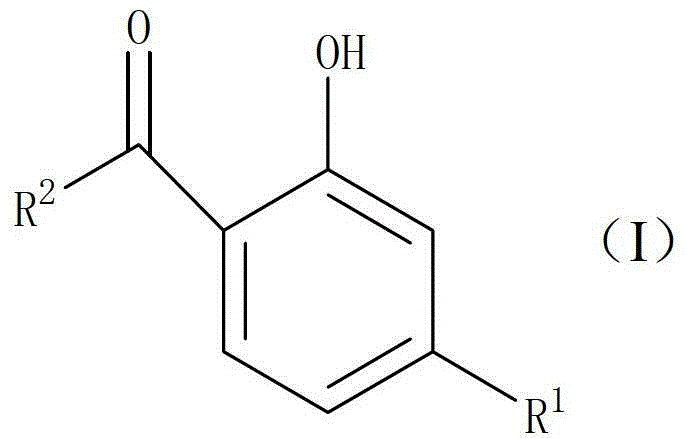

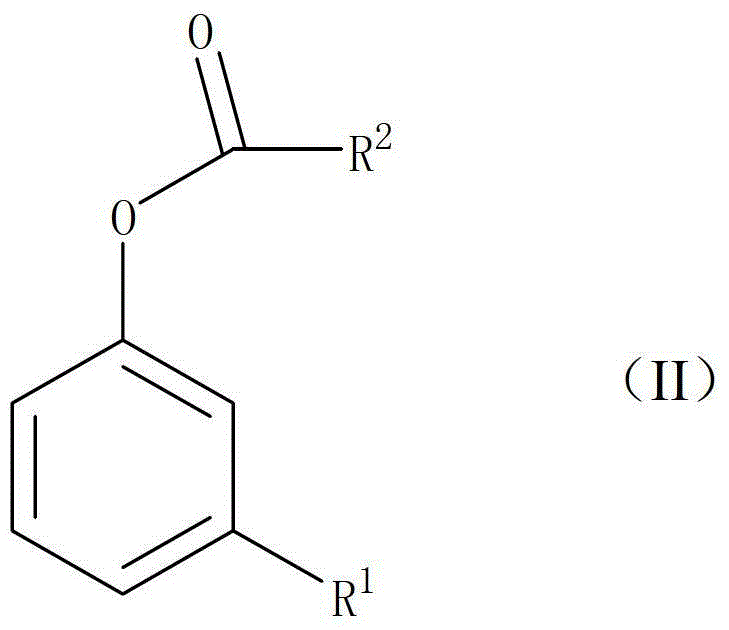

Preparation method of 2-hydroxyl-4-substituted arone compound

ActiveCN103408414AHigh catalytic activityHigh activityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsQuaternary ammonium cationSulfate radicals

The invention discloses a preparation method of a 2-hydroxyl-4-substituted arone compound. A Bronsted-Lewis dual acidic ionic liquid is taken as a catalyst to catalyze 3-substituted phenolic ester to undergo a Fries rearrangement reaction. The Bronsted-Lewis dual acidic ionic liquid catalyst is a quaternary ammonium salt ionic liquid containing dual acidity, contains a Lewis acid site of copper ions or zinc ions and a Bronsted acid site of a sulfonic group. The Bronsted acid site of the sulfonic group takes the quaternary ammonium salt as a cation and adopts a sulfate radical as an anion. The dual acidic ionic liquid catalyst has strong catalytic activity, high reaction selectivity, and an ortho product with high yield and high purity can be obtained. The reaction aftertreatment is simple and safe, has less pollution, and the catalyst can be used repeatedly. Specifically, the raw material 3-substituted phenolic ester of the Fries rearrangement reaction can be obtained by reaction of 3-substituted phenol with an acylation reagent acyl chloride.

Owner:BEIJING GREENCHEM TECH

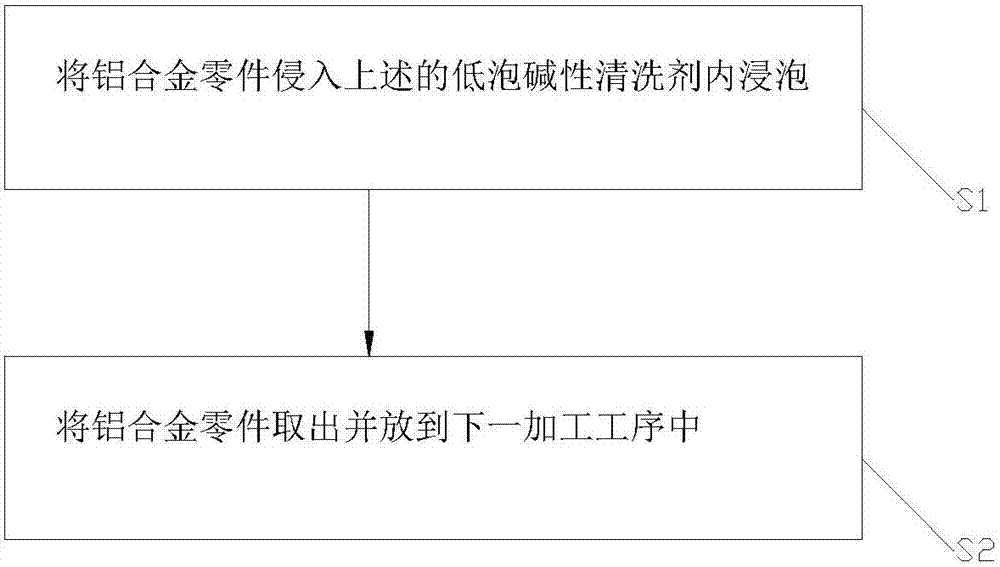

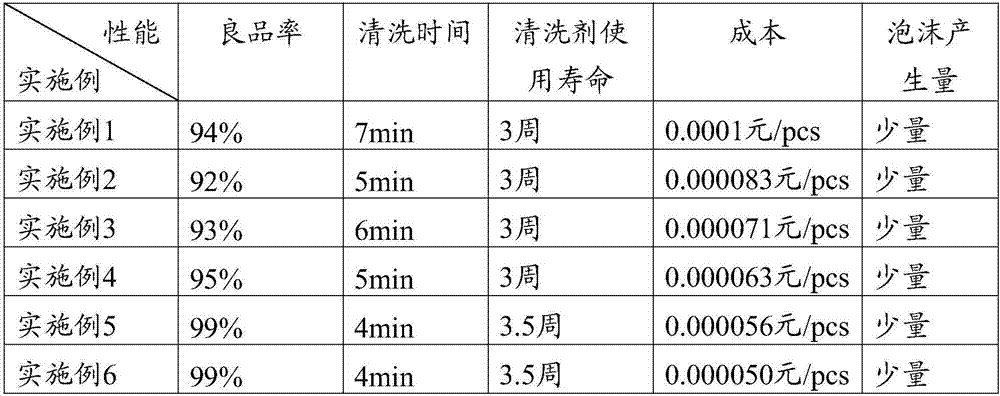

Low-foam alkaline cleaner and aluminum alloy part cleaning method

The invention discloses a low-foam alkaline cleaner and an aluminum alloy part cleaning method. The low-foam alkaline cleaner comprises the following materials in parts by mass: 9.5-15.5 parts of sodium dodecyl benzene sulfonate, 19.5-25.5 parts of sodium hydroxide, 11.5-18.5 parts of sodium carbonate, 10.5-14.5 parts of sodium metasilicate, 4.5-8.8 parts of octaphenyl polyoxyethyiene and the balance of water. The low-foam alkaline cleaner is excellent in cleaning capability, long in service life and low in cost, generates less foam in the cleaning process, and causes less pollution to procedures after cleaning; and by use of the low-foam alkaline cleaner, the aluminum alloy part cleaning method is better in cleaning effect and lower in cost.

Owner:SHENZHEN MENGZHIFANG COMM PROD

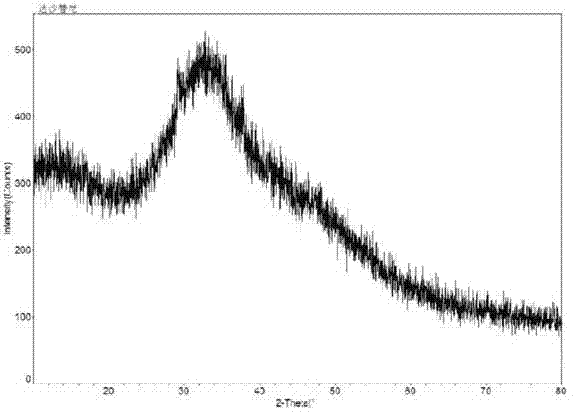

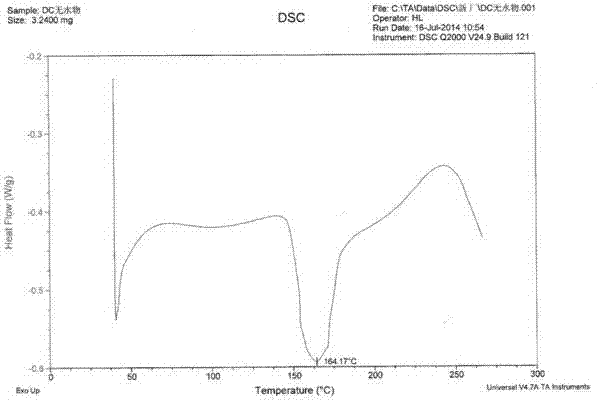

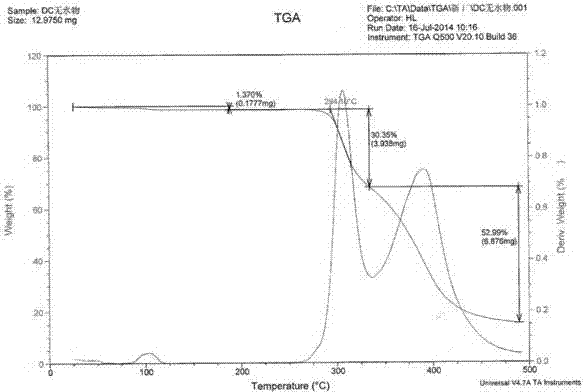

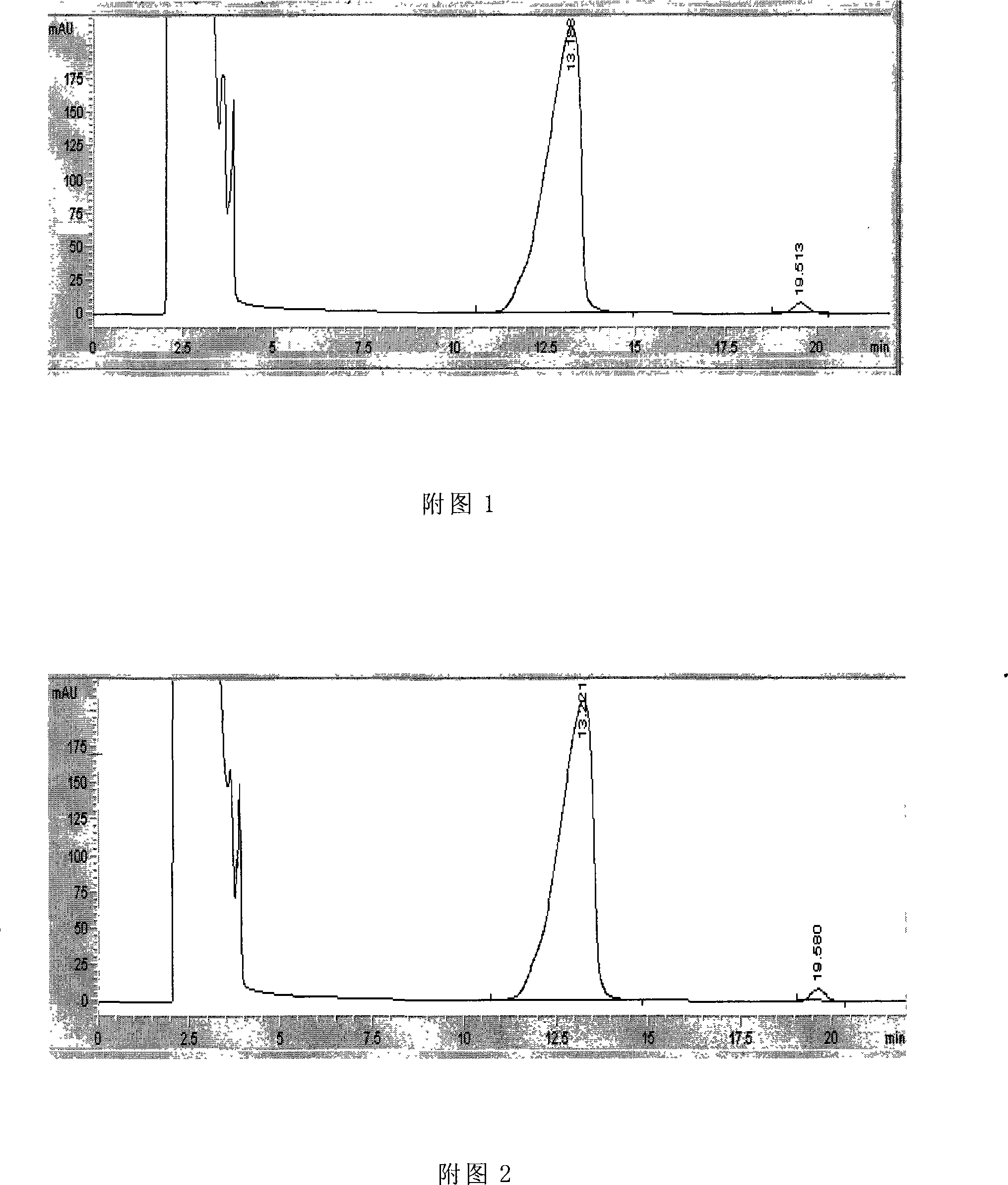

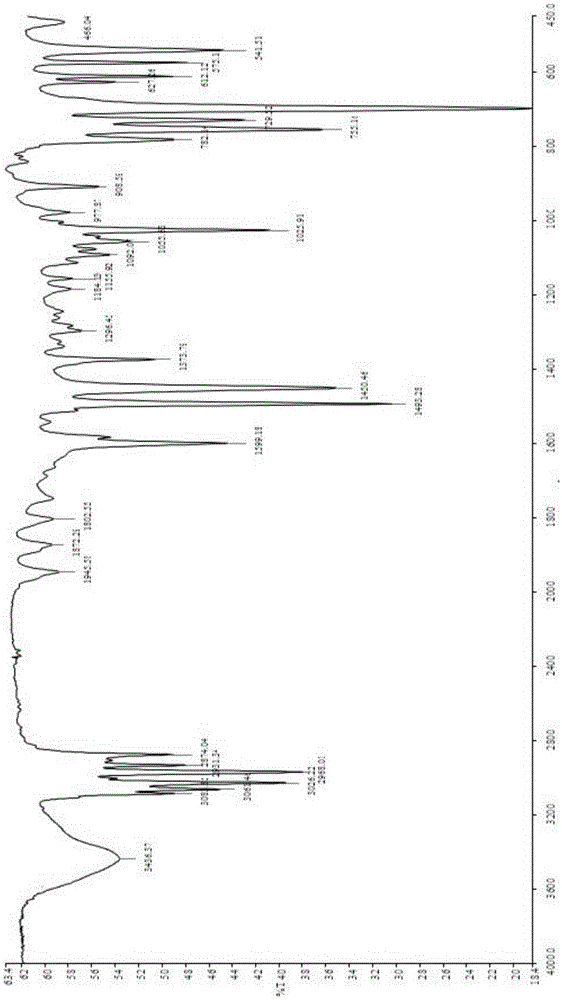

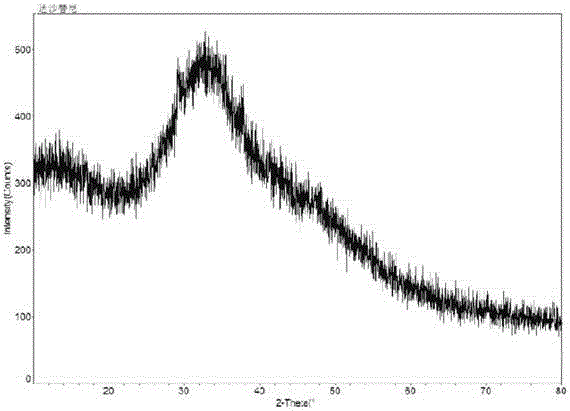

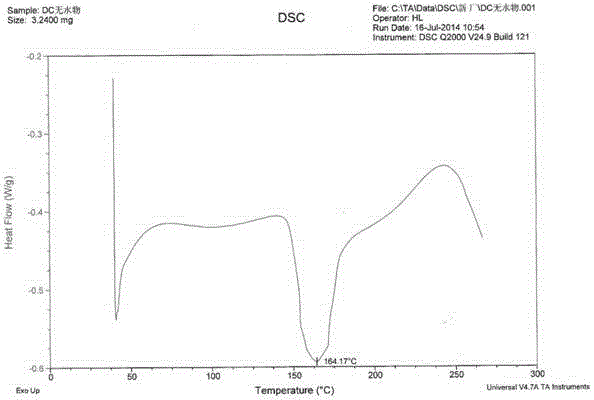

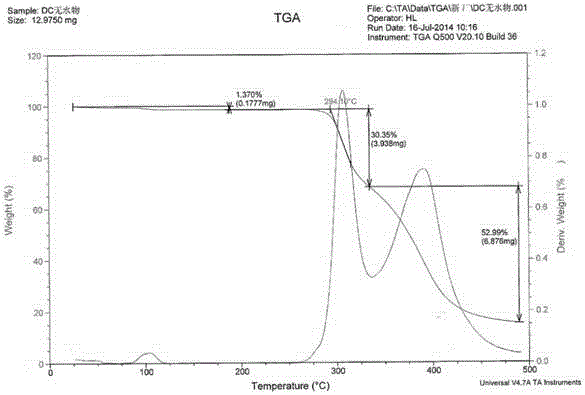

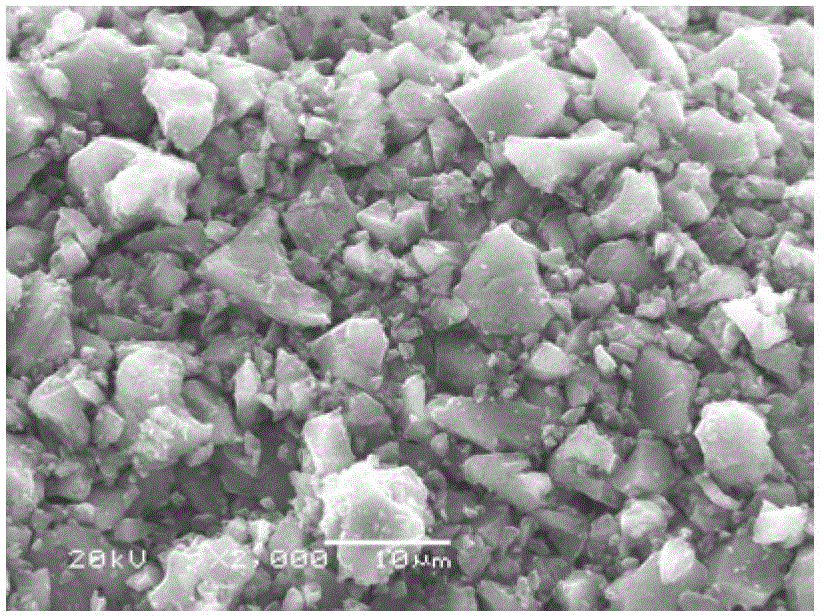

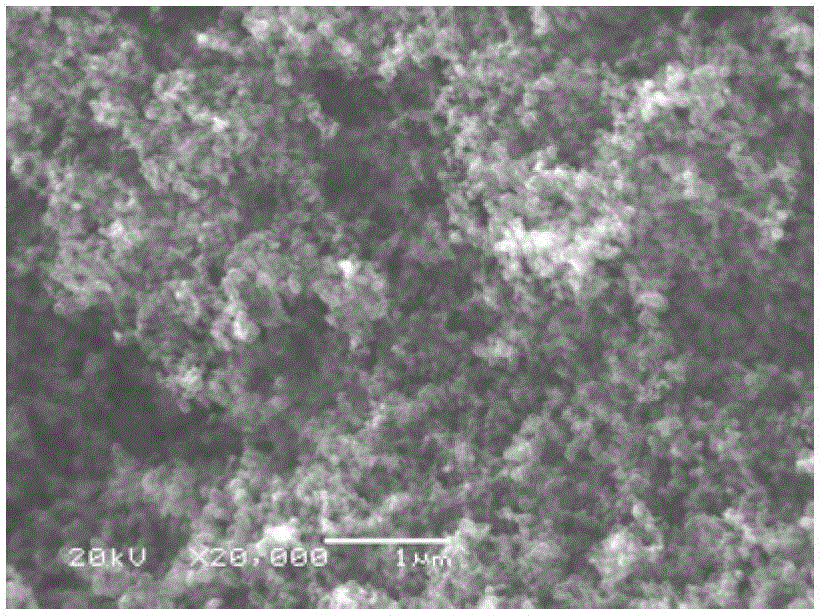

Preparation method of amorphous dasatinib

The invention relates to a preparation method of amorphous dasatinib, wherein the preparation method includes the steps: dissolving raw materials of various crystal types of dasatinib in an anhydrous organic solvent at the temperature of 60-100 DEG C, adding a cosolvent for helping dissolution, and thus obtaining a fully-dissolved dasatinib solution; carrying out spray drying on the dasatinib solution, carrying out cyclone isolation, and rapidly precipitating to obtain a dasatinib solid powder; drying the dasatinib solid powder under reduced pressure, removing the solvent, and thus obtaining the dasatinib amorphous product. Through testing, the prepared amorphous dasatinib has the moisture content generally less than 2%, and is nearly anhydrous dasatinib. The method is suitable for converting various crystal types of dasatinib into the dasatinib amorphous product having the residual solvent consistent with Chinese pharmacopoeia, and the preparation yield reaches up to more than 99%. Moreover, the method has the advantages of simple operation, less operation steps, less using solvent, small process pollution, low cost and the like, and is suitable for large-scale industrialized production.

Owner:深圳市新浩瑞医药科技有限公司

Preparation of kilogram-grade scale high-purity monosialotetrahexosylganglioside

ActiveCN101177439BHigh content of main ingredientsLittle side effectsSugar derivativesUnknown materialsDEAE SephadexPig brain

The invention discloses a manufacturing technique for extracting, separating and purifying kilogram-grade scale high purity GM1 using fresh pig brain tissue as raw material, which is characterized in that large sized extraction pot and adsorption resin with large holes, DEAE Sephadex A-25 and silica gel layer are utilized to build a set of manufacturing technique. The invention has the advantagesof elimination of toxic solvent chloroform in mobile phase in traditional method, less pollution for whole process, simple process, low cost and applicability to industrialized production.

Owner:LUNAN PHARMA GROUP CORPORATION

Ammonia recovery system for wastewater with high content of ammonia and nitrogen

InactiveCN108341418AImprove recycling efficiencyHigh puritySolidificationLiquefactionHigh concentrationAmmonia storage

The invention provides an ammonia recovery system for wastewater with high content of ammonia and nitrogen. The system comprises the following process steps the wastewater with high content of ammoniaand nitrogen is introduced into a stripping tower for stripping to generate high-concentration ammonia gas, the ammonia gas with moisture is introduced into a water washing tower, after water washingand impurity removal are conducted through the water washing tower, the moisture in the ammonia gas is removed through a mist eliminator, a pressure regulating tube and a filter in sequence, then theammonia gas is conveyed to an ammonia compressor for compression and pressurization, and finally the ammonia gas is condensed by a condenser to obtain liquid ammonia; liquid ammonia flows into an ammonia reflux tank serving as a transfer station and partially flows back into the water washing tower for secondary recycling, and other liquid ammonia is conveyed to an ammonia storage tank to obtainpure liquid ammonia. Through reasonable process improvement and parameter setting, the efficiency of recovering the high ammonia nitrogen wastewater is effectively improved, the purity of recovered liquid ammonia is high, the problems of secondary pollution and high energy consumption during ammonia recycling are solved, the ammonia recovery cost is reduced, and the environmental pollution is reduced.

Owner:ANHUI COSTAR BIOCHEM CO LTD

Preparation method of 1,1-diphenyl ethane

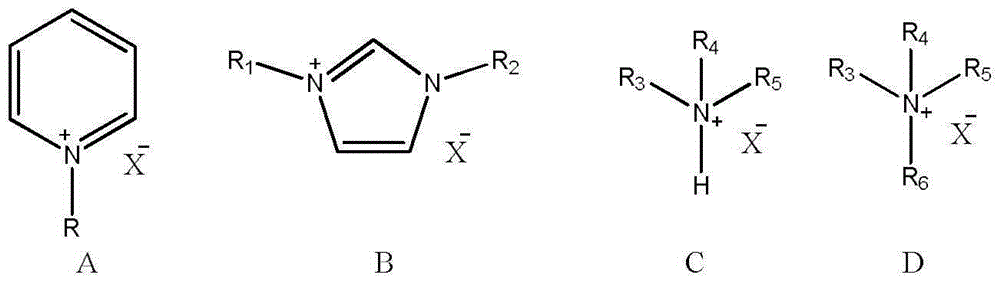

InactiveCN105418348AHigh catalytic activityAchieve friendlyHydrocarbonsHydrocarbon by hydrocarbon and non-hydrocarbon condensationBenzenePyridinium

The present invention discloses a preparation method of 1,1-diphenyl ethane. The preparation method comprises the following steps: using ionic liquid as a catalyst, and reacting benzene with 1,1-dichloroethane for 3-6 hours at 0-80 DEG C; and synthesizing 1,1-diphenyl ethane, wherein the precursor compound of the ionic catalyst is selected from pyridinium halide, imidazolium halide, trialkylamine halide and quaternary ammonium salt. The preparation method has the beneficial effects that the synthesis process is simple, the yield is high, and the process pollution is low. The catalytic activity of the ionic liquid used in the preparation method disclosed by the present invention is high without adding any other auxiliary agent or organic agent; and the used ionic liquid is free of pollution to the environment, and after the reaction, the ionic liquid can be separated and recovered conveniently and can be reused, so that the environmentally-friendly catalytic process is realized.

Owner:LIAONING PETROCCHEM VOCATIONAL & TECH COLLEGE +1

In-situ and inclusion polymerization process of preparing composite particle/epoxy resin nano material

The present invention discloses an in-situ and inclusion polymerization process of preparing composite nano particle / epoxy resin material. The epoxy resin is biphenol A type epoxy resin; and the nano particle is nano SiO2, nano montmorillonite, nano TiO2, nano CaCO3 or nano ZnO. Via the in-situ polymerization and inclusion polymerization on the surface of nano inorganic particles, the inorganic nano particles with strong autoagglutination are dispersed homogeneously in epoxy resin matrix. The preparation process using water as solvent is simple, low in cost and less pollutant, needs no solvent recover equipment and is favorable to application in industry.

Owner:ZHEJIANG UNIV

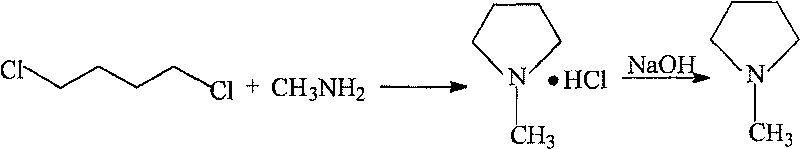

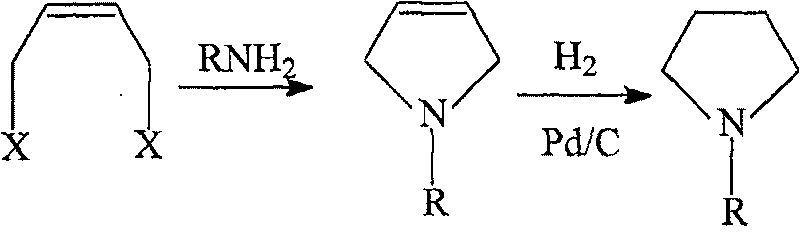

Method for preparing N-alkyl pyrrolidine

ActiveCN101182304BRich sourcesHigh yieldOrganic chemistryChemical recyclingSystem pressurePyrrolidine

The present invention discloses a preparation method of N-alkyl pyrrolidine which is an intermediate used for the pharmaceutical and chemical materials. The method is that ammonia or organic amine aqueous solution is controlled at 30 DEG C, at the same time cis-1, 4-dihalogen-butylene and organic alkali or inorganic alkali solution is dripped within one to five hours, the pH value is controlled between 11 to 12, after dripping, the solution continuously reacts for one to ten hours under 30 DEG C to 100 DEG C to generate N-alkyl-3-dihydropyrrole; then organic inert solvent, the N-alkyl-3-dihydropyrrole and 5 percent of Pd / C catalyst are added into a high-pressure vessel to be heated to 30 DEG C to 100 DEG C to be led to H2O, the system pressure is controlled as 0.2 to 1.0MPa, and the N-alkyl pyrrolidine is generated after the reaction for two to twelve hours. The source of the materials of the present invention is abundant; the product has the high yield and good purity and is easy forpurifying; the requirement of required equipments is comparatively low; the present invention causes little pollution, is in favor of treating the three wastes and is easy for realizing the industrialized production.

Owner:SHANDONG JINCHENG PHARMACEUTICAL GROUP CO LTD

Preparation method of 6-bromine-2-pyridine methyl formate

ActiveCN103086964BOvercome the deficiency of many side effectsLess side effectsOrganic chemistryCarboxylic acidSolvent

The invention relates to a preparation method of 6-bromine-2-pyridine methyl formate. The preparation method comprises the step of catalyzing esterification reaction of 6-bromine-2-pyridine carboxylic acid by taking p-toluenesulfonic acid as a catalyst, to be specific, heating and fluxing absolute methanol, the 6-bromine-2-pyridine carboxylic acid and the p-toluenesulfonic acid for 2-8 hours under stirring, cooling to a room temperature after reaction is ended, rotary drying a reaction system, dissolving solids in an organic solvent, washing, drying, filtering, concentrating, recrystallizing a concentrated product by a mixed solvent to obtain the 6-bromine-2-pyridine methyl formate, wherein a preferable molar ratio of the 6-bromine-2-pyridine carboxylic acid and the p-toluenesulfonic acid is 1: (0.1-0.16). According to one embodiment of the invention, the 6-bromine-2-pyridine carboxylic acid is obtained through diazotization, bromination and oxidation of 6-amino-2-methylpyridine. The preparation method is few in side reaction and simple in aftertreatment and is suitable for industrial production; and the product is easy to separate and has high yield, high purity and good quality.

Owner:BEIJING GREENCHEM TECH

Preparation process of high-purity 4-chloro-2-pyridinecarboxylate hydrochloride

Owner:SHANDONG JINCHENG PHARMACEUTICAL GROUP CO LTD

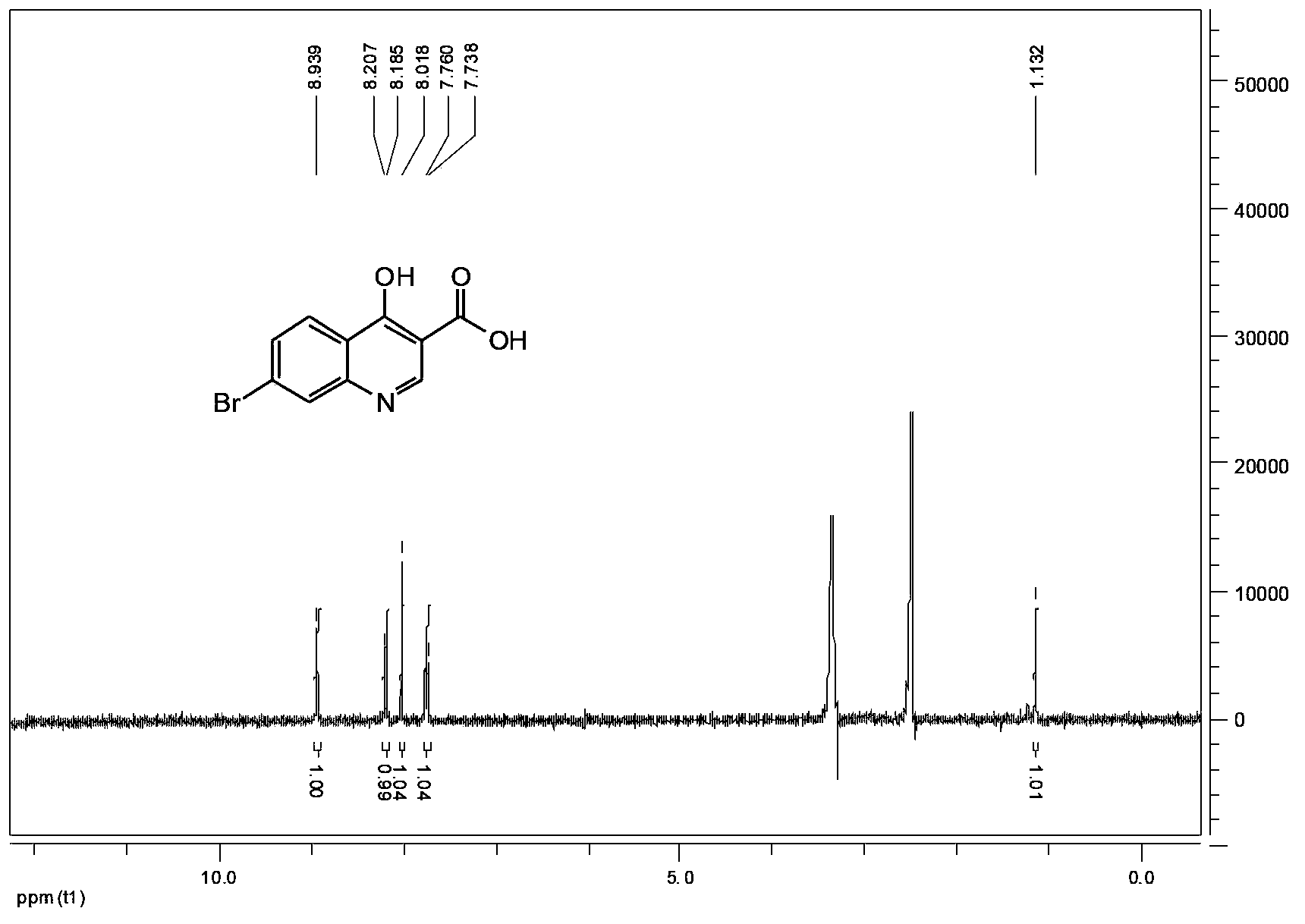

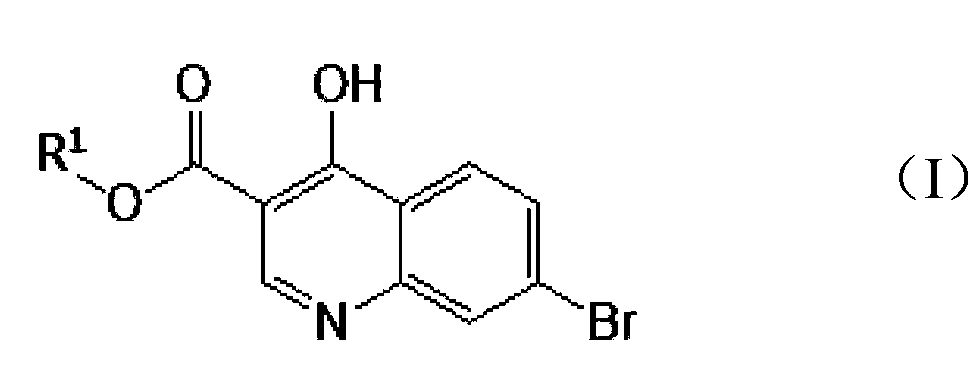

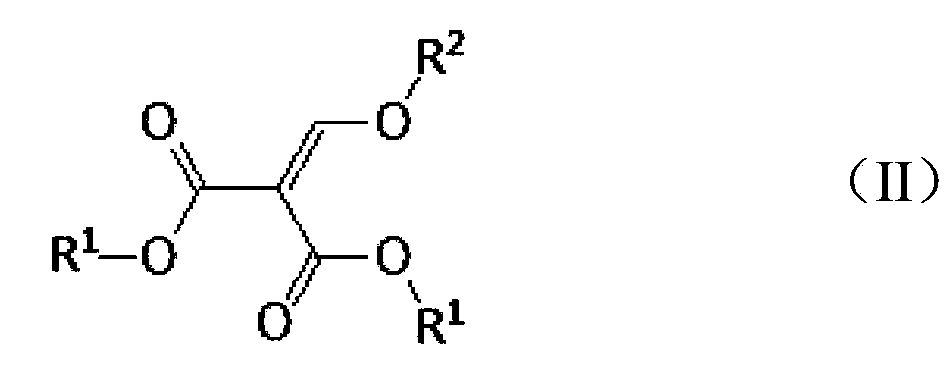

Preparation method of 7-bromo-4-hydroxy-3-quinoline carboxylic acid

ActiveCN103113298BEasy to separateSimple post-processingOrganic chemistryMalonic acidOrganic solvent

The invention relates to a preparation method of 7-bromo-4-hydroxy-3-quinoline carboxylic acid. The preparation method comprises that hydrochloric acid serves as a catalyst to catalyze 7-bromo-4-hydroxy-3-quinoline carboxylic acid (C1-3) alkyl ester for carrying out hydrolysis reaction, specifically, the preparation method comprises the following steps of: heating and refluxing 7-bromo-4-hydroxy-3-quinoline carboxylic acid (C1-3) alkyl ester, an organic solvent and 1-2 mol / L hydrochloric acid aqueous solution for 0.5-2 hours under stirring, and then filtering and washing filter cake to obtain 7-bromo-4-hydroxy-3-quinoline carboxylic acid. In an embodiment of the invention, 7-bromo-4-hydroxy-3-quinoline carboxylic acid (C1-3) alkyl ester is obtained by condensation and cyclization of m-bromoaniline and (C1-2) alkoxy methylene malonic acid bi(C1-3) alkyl ester. The preparation method is few in side reactions, simple in after-treatment, liable to separate the product, high in yield and high in product purity, so that the preparation method is suitable for industrial production.

Owner:BEIJING GREENCHEM TECH

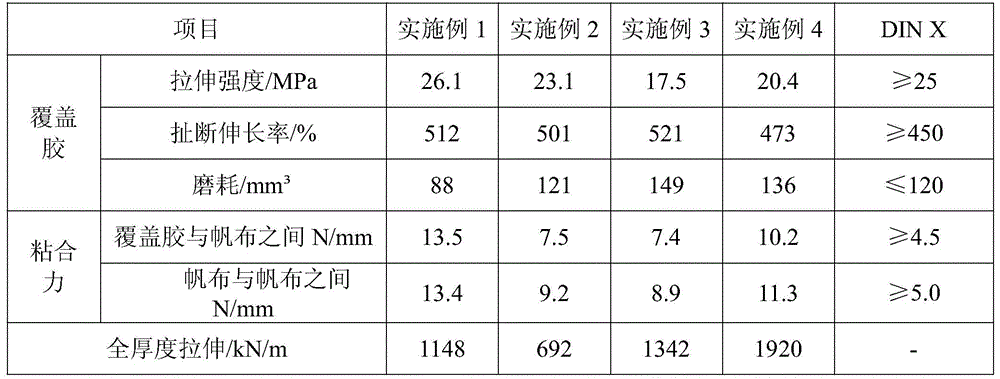

Preparation method of basalt fiber conveyor belt

ActiveCN104692027BReduce weightReduce energy consumptionConveyorsNatural rubber adhesivesPolymer scienceAdhesive

Owner:WUXI BOTON CONVEYOR SOLUTION CO LTD

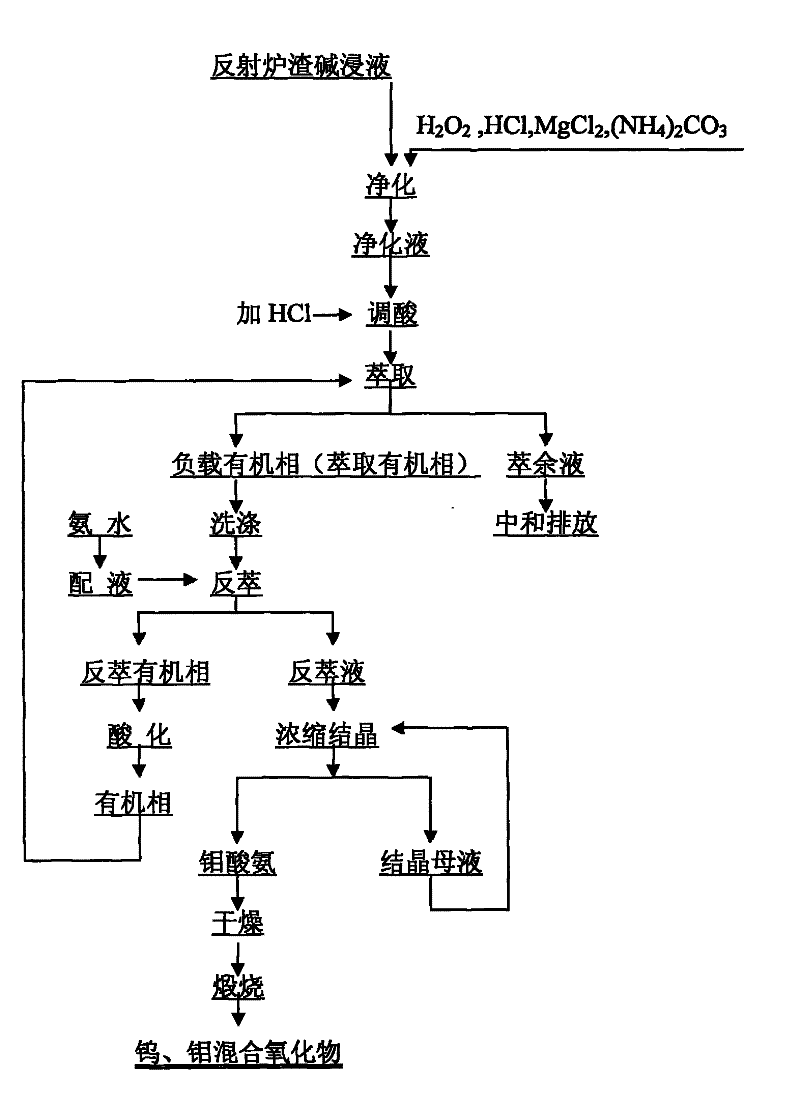

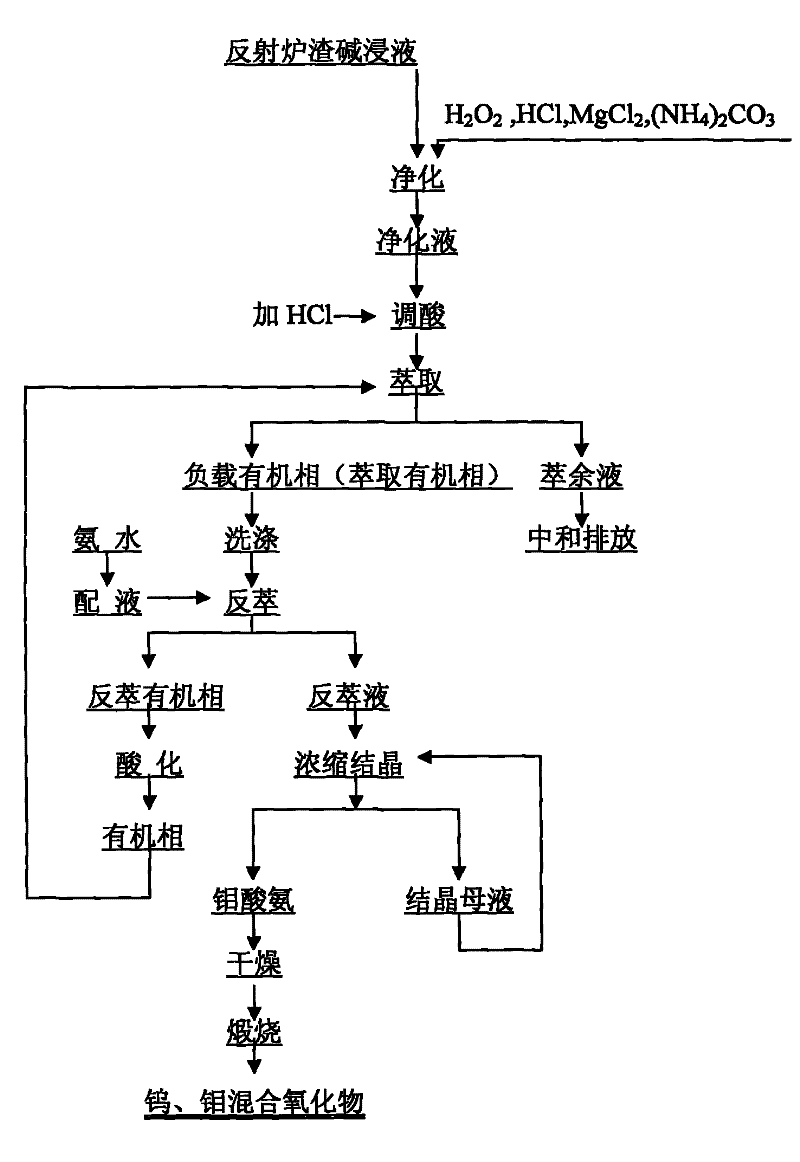

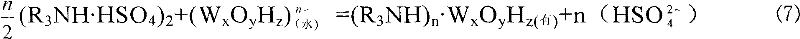

Comprehensive recovery method of tungsten and molybdenum from slag of bismith smelting furnace

InactiveCN101613805BHigh extraction recoveryAdaptableProcess efficiency improvementRecovery methodSal ammoniac

The invention provides a comprehensive recovery method of tungsten and molybdenum from the slag of bismith smelting furnaces and bismith reverberatory furnaces, comprising the following steps: soaking the slag of bismith smelting furnaces and bismith reverberatory furnaces with alkali to obtain alkali leaching solution, oxidizing the alkali leaching solution with H2O2, adjusting the PH value withacid, then adding MgCl2 and (NH4)2CO3 to removing S<2->, SiO2, As and P for decontamination, extracting tungsten and molybdenum with N235 from the purified solution, washing the extract with water, back-extracting with ammonia water, concentrating and crystallizing the back-extracting solution and finally obtaining tungsten and molybdenum mixed oxides by roasting. The method has less pollution, strong adaptability, high tungsten and molybdenum recovery rate, and the tungsten recovery rate is more than 90% and the molybdenum recovery rate is more than 95%, thus reducing the production cost andproviding a new method for recycling tungsten and molybdenum simultaneously.

Owner:HUNAN RES INST FOR NONFERROUS METALS +1

The preparation method of amorphous dasatinib

The invention relates to a preparation method of amorphous dasatinib, wherein the preparation method includes the steps: dissolving raw materials of various crystal types of dasatinib in an anhydrous organic solvent at the temperature of 60-100 DEG C, adding a cosolvent for helping dissolution, and thus obtaining a fully-dissolved dasatinib solution; carrying out spray drying on the dasatinib solution, carrying out cyclone isolation, and rapidly precipitating to obtain a dasatinib solid powder; drying the dasatinib solid powder under reduced pressure, removing the solvent, and thus obtaining the dasatinib amorphous product. Through testing, the prepared amorphous dasatinib has the moisture content generally less than 2%, and is nearly anhydrous dasatinib. The method is suitable for converting various crystal types of dasatinib into the dasatinib amorphous product having the residual solvent consistent with Chinese pharmacopoeia, and the preparation yield reaches up to more than 99%. Moreover, the method has the advantages of simple operation, less operation steps, less using solvent, small process pollution, low cost and the like, and is suitable for large-scale industrialized production.

Owner:深圳市新浩瑞医药科技有限公司

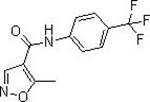

A kind of preparation method of leflunomide

ActiveCN111233779BRaw materials are cheap and easy to getReduce manufacturing costOrganic chemistryHydroxylamineHydroxylamine Hydrochloride

The invention relates to a new preparation process of leflunomide, a medical raw material drug, which uses ethyl acetoacetate as a raw material to cyclize with hydroxylamine hydrochloride to obtain leflunomide. This process can not only better control the content of 3-methyl isomer and 4-trifluoromethylaniline in the leflunomide product, but also has a higher yield and is more concise. The process produces less industrial waste water and waste gas, is more environmentally friendly, and can effectively reduce production costs and corrosion of equipment.

Owner:煌途医药(无锡)有限公司

Method for extracting coconut oil from coconut bran

InactiveCN100579377CDestroy the emulsification systemPromote precipitationEdible oils/fatsWarm waterOil emulsion

The invention discloses a method used for extracting coconut oil from a coconut cake, and the steps are: one or more than two of cellulose, hemicellulase or papain are combined to make into enzyme water solution with which the coconut cake is mixed and stirred, kept warm, stirred with warm water and further grinded by a colloid mill; serous fluid obtained obtains thin coconut cream after going through tailings separation; the thin coconut cream goes through layers separation after placed stilly; a free oil layer, an emulsion layer, a serum layer and a precipitation bed are taken out respectively; the obtained free oil layer and the emulsion layer are mixed together to obtain oil emulsion mixture in which water and salt are added, and then the papain is added for continuing zymolysis and the salt is added for supplementing; the mixture is placed stilly to lead the free oil to float upward to get the coconut oil; the coconut oil is extract out, washed by water and filtered, and high-quality coconut oil with the water content less than or equal to 0.1 percent is obtained after going through vacuum drying. The invention has simple technique process, low production cost, high oil production rate, little pollution, high product quality and high comprehensive utilization value of byproducts.

Owner:COCONUT RES INST OF CHINESE ACAD OF TROPICAL AGRI SCI

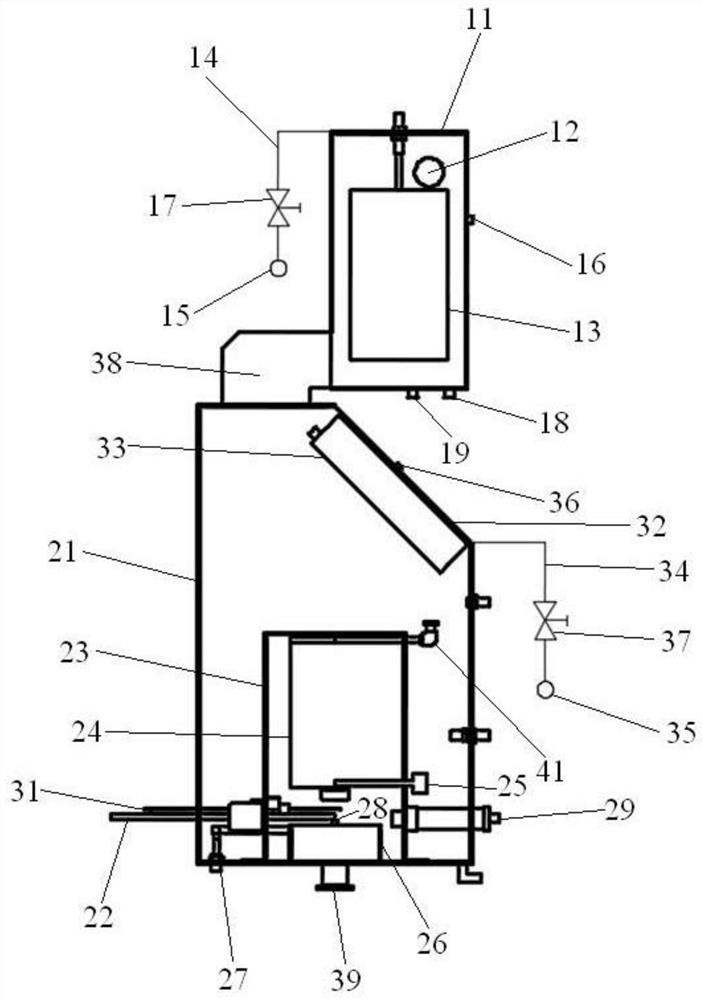

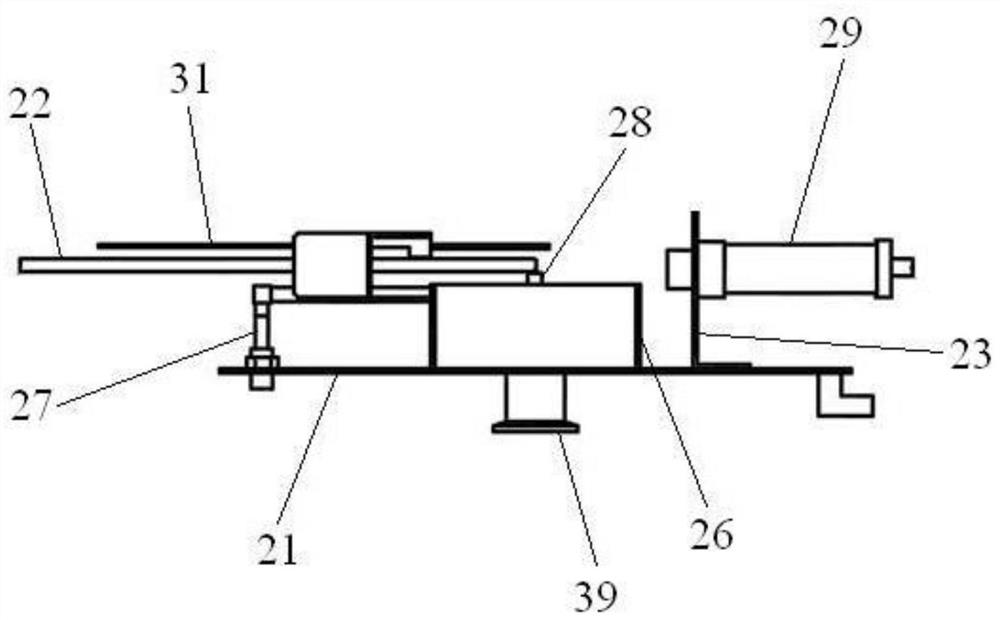

Combustible gas treatment device

ActiveCN113091074AReduce concentrationProcess pollution is smallDispersed particle separationIncinerator apparatusThermodynamicsCombustion chamber

The invention provides a combustible gas treatment device, which is used for treating combustible gas in process waste gas discharged by a process chamber. The combustible gas treatment device comprises a combustion chamber and an absorption and storage chamber, wherein the combustion chamber is used for communicating the process chamber with the absorption and storage chamber; a high-temperature combustion assembly is arranged in the combustion chamber, the high-temperature combustion assembly is used for combusting combustible gas in the process waste gas discharged into the combustion chamber, and the combusted process waste gas enters the absorption and storage chamber; and a manufacturing material of the absorption and storage cavity can absorb and store the combustible gas in the process waste gas after combustion, and a first exhaust structure is arranged on the absorption and storage cavity and used for discharging the process waste gas which is not absorbed and stored. According to the combustible gas treatment device provided by the invention, the amount of the combustible gas discharged to the outside can be reduced, the process pollution is reduced, and the process safety is improved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

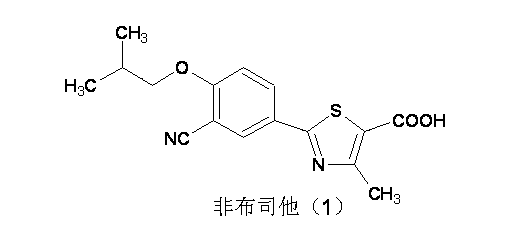

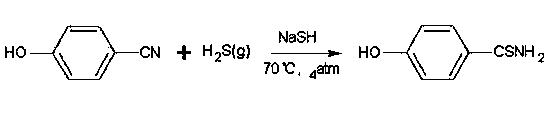

Preparation method of 3,4-substitituted thiobenzamide and application of 3,4-substitituted thiobenzamide in febuxostat synthesis

InactiveCN104163782ALow equipment requirementsProcess pollution is smallOrganic chemistryNew medicationsThio-

The invention relates to a preparation method of 3,4-substituted thiobenzamide. The 3,4-substituted thiobenzamide prepared by the method can be used to synthesis of febuxostat, a novel drug for treating gout.

Owner:CHONGQING SHENGHUAXI PHARMA CO LTD +1

Method for extracting high-purity scutellarin from breviscpini

ActiveCN101497637BPrevent heat degradationQuality improvementSugar derivativesSugar derivatives preparationFlocculationOrganic solvent

Owner:YUNNAN PHYTOPHARML +1

Preparation method of 2-hydroxyl-4-substituted arone compound

ActiveCN103408414BHigh catalytic activityHigh activityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsQuaternary ammonium cationSulfate radicals

The invention discloses a preparation method of a 2-hydroxyl-4-substituted arone compound. A Bronsted-Lewis dual acidic ionic liquid is taken as a catalyst to catalyze 3-substituted phenolic ester to undergo a Fries rearrangement reaction. The Bronsted-Lewis dual acidic ionic liquid catalyst is a quaternary ammonium salt ionic liquid containing dual acidity, contains a Lewis acid site of copper ions or zinc ions and a Bronsted acid site of a sulfonic group. The Bronsted acid site of the sulfonic group takes the quaternary ammonium salt as a cation and adopts a sulfate radical as an anion. The dual acidic ionic liquid catalyst has strong catalytic activity, high reaction selectivity, and an ortho product with high yield and high purity can be obtained. The reaction aftertreatment is simple and safe, has less pollution, and the catalyst can be used repeatedly. Specifically, the raw material 3-substituted phenolic ester of the Fries rearrangement reaction can be obtained by reaction of 3-substituted phenol with an acylation reagent acyl chloride.

Owner:BEIJING GREENCHEM TECH

Method for preparing coconut oil by treating coconut milk with papaya pulp

InactiveCN101185510BDestroy the organizational systemGuaranteed not to deteriorateEdible oils/fatsFood preparationPectinaseBeta-Carotene

The invention discloses a preparation method of coconut oil by treating coconut milk with pawpaw juice, which is characterized in that: 60-90 percent maturated fresh pawpaw are prepared and made into pawpaw juice while the fresh coconut meat is mashed and pressed into coconut milk; then water, pawpaw juice and pectinase are added into coconut milk, mixed together and then treated with zymohydrolysis in heat insulation; after standing, the solution is divided into oil layer, emulsion layer, serum layer and precipitation layer which are taken out respectively; a oil emulsion mixture obtained by mixing the oil layer and the emulsion layer is added with water and then treated with zymohydrolysis in heat insulation, added with white sugar and treated with standing for stratification; the upper coconut oil layer which is separated from the lower water layer is washed with water and filtered and then treated with vacuum drying to produce high-quality coconut oil which contains Beta-carotene. The invention has simple technical process, low cost, high oil-production efficiency, high comprehensive utilization rate of side products, low pollution, meanwhile the coconut oil produced which contains natural Beta-carotene has beautiful colors and long guarantee period.

Owner:COCONUT RES INST OF CHINESE ACAD OF TROPICAL AGRI SCI

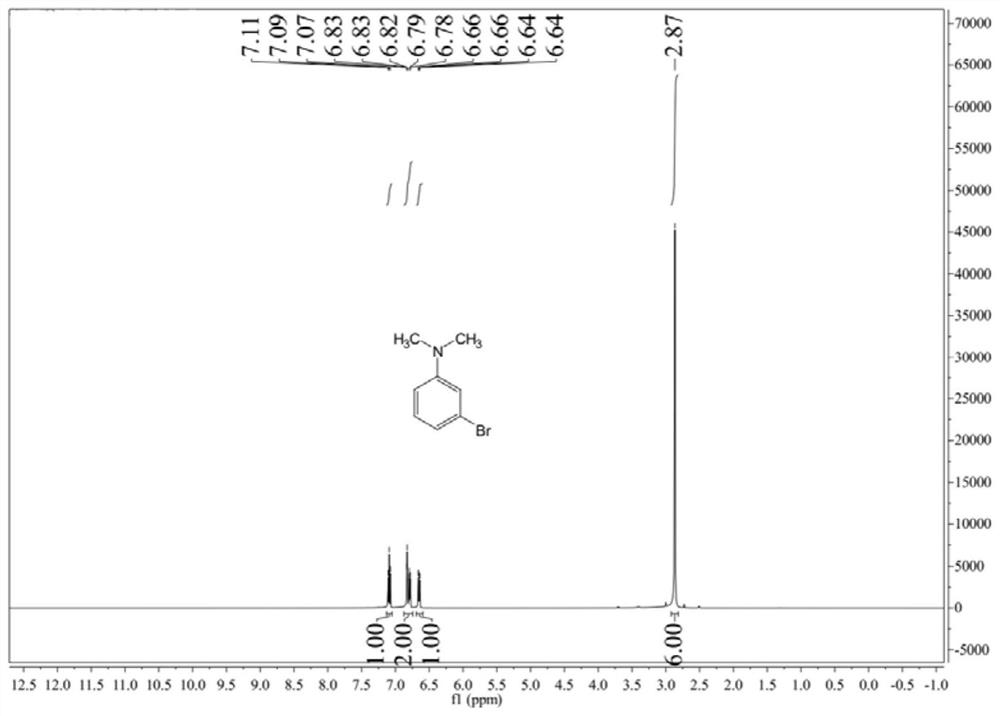

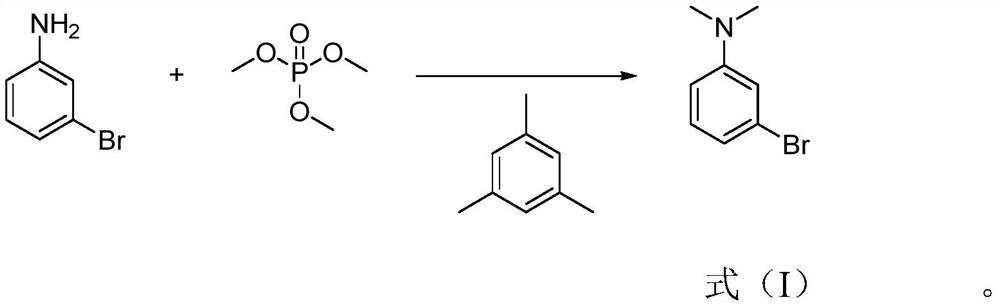

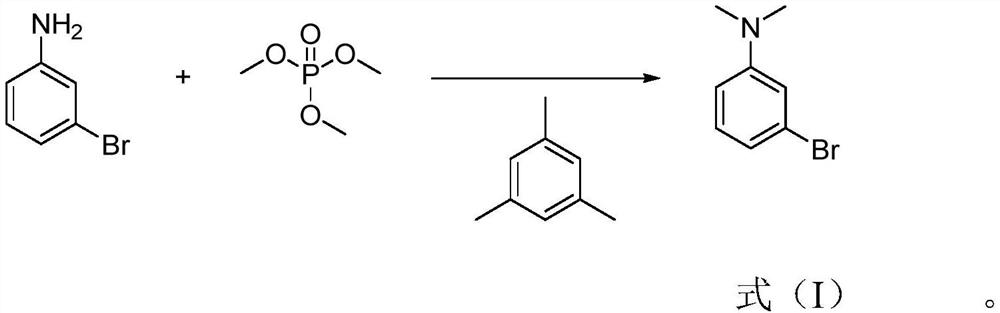

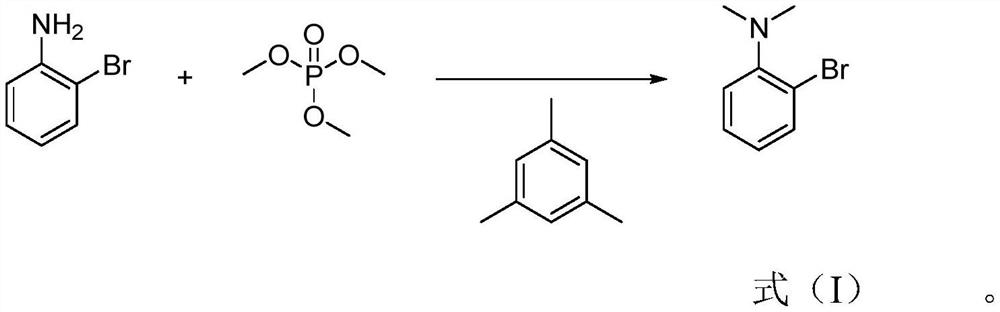

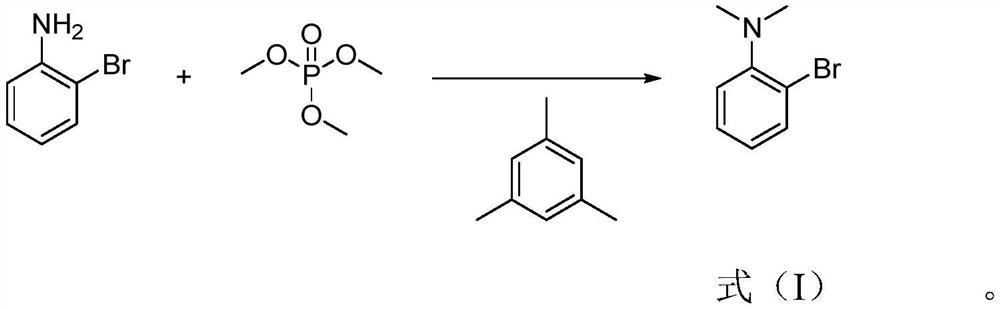

Preparation method of 3-bromo-N, N-dimethylaniline

PendingCN114573460AHigh yieldImprove controllabilityChemical recyclingAmino preparation by functional substitutionDimethylaniline N-oxideBiochemical engineering

The invention relates to a preparation method of 3-bromo-N, N-dimethylaniline, which is characterized in that mesitylene is used as a reaction solvent to participate in methylation reaction of trimethyl phosphate and m-bromoaniline to prepare the 3-bromo-N, N-dimethylaniline. According to the preparation method disclosed by the invention, a high-yield and high-quality product is obtained, harsh reaction conditions of an existing process are avoided, the reaction conditions are mild, the safety is high, the controllability is high, the whole process is small in pollution, few in three wastes, few in side reaction, simple in post-treatment, easy in product separation, simple in process operation and low in cost, and the preparation method is particularly suitable for large-scale industrial production.

Owner:BEIJING GREENCHEM TECH

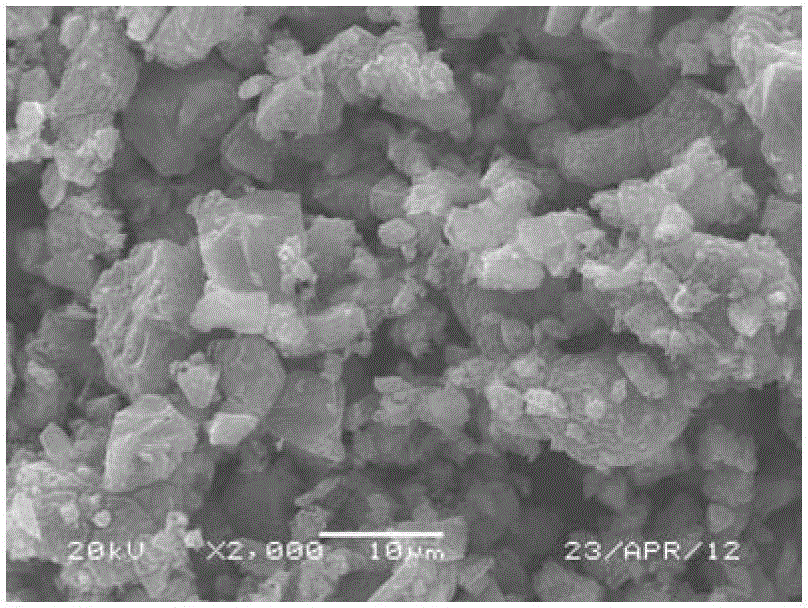

Sulfur/carbon composite material and preparation method thereof

ActiveCN103178247BTightly boundReduce dissolution lossMaterial nanotechnologyNon-aqueous electrolyte accumulator electrodesCarbon compositesDecomposition

The invention discloses a sulfur / carbon composite material and a preparation method thereof. Nanometer sulfur is uniformly filled in a pore path of a carbon material in the sulfur / carbon composite material to form the nanometer sulfur particle / carbon composite material. The preparation method comprises the following steps of: (1) reacting an aluminum sulfide solution with a sulfur source to generate an aluminum polysulfide solution; (2) adding a surface active agent and the carbon material into the aluminum polysulfide solution, uniformly stirring the resulting product, placing the uniformly stirred solution in an ultrasonic cleaner to carry out ultrasonic oscillation, and heating the resulting product to cause the sulfur generated by decomposition to in situ deposit to the pore path of the carbon material to obtain the sulfur / carbon composite material. According to the sulfur / carbon composite material, a sulfur particle and a carbon particle are tightly bound, the application of the sulfur / carbon composite material as the positive material of a lithium sulfur battery facilitates the reduction of solution loss of an active substance and the inhibition of shuttle effect, aluminum sulfide is generated from the ammonia gas and the hydrogen sulfide, which are generated by the decomposition of the aluminum polysulfide, through a condenser to be recycled, the technical process causes little pollution, the preparation method is simple in technology, low in cost and short in time, sulfur content is high, controllable, and strong in repeatability, and the sulfur / carbon composite material is easy for mass production.

Owner:CENT SOUTH UNIV

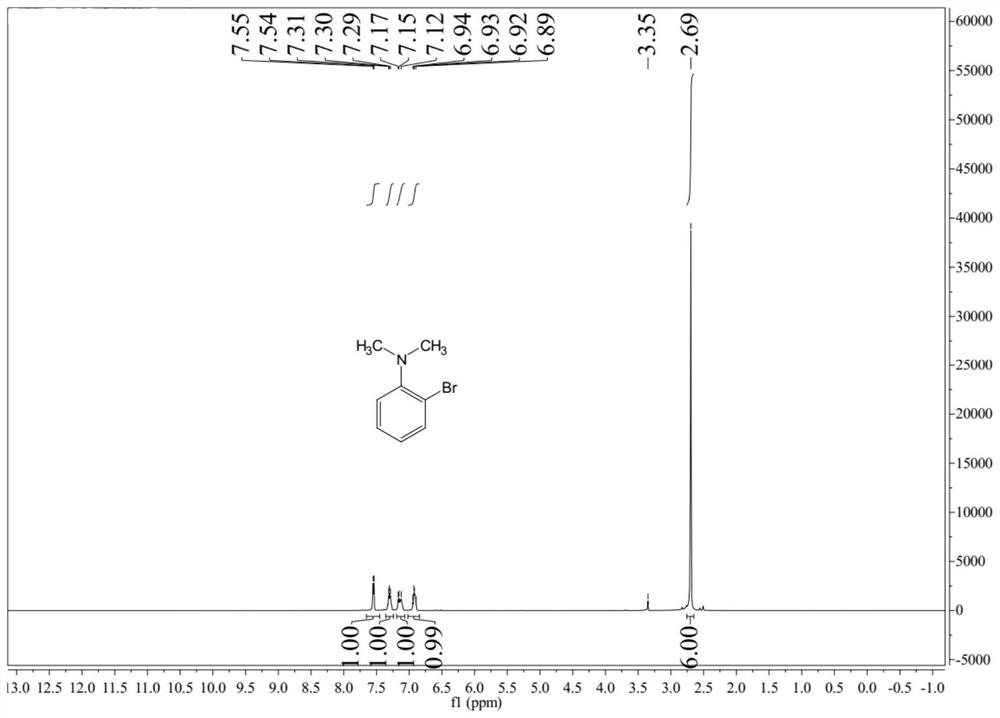

Preparation method of 2-bromo-N, N-dimethylaniline

PendingCN114605267AAtom utilization is highHigh yieldOrganic compound preparationAmino compound preparationDimethylaniline N-oxideBiochemical engineering

The invention relates to a preparation method of 2-bromo-N, N-dimethylaniline, which is characterized in that mesitylene is used as a reaction solvent to participate in methylation reaction of trimethyl phosphate and o-bromaniline to prepare the 2-bromo-N, N-dimethylaniline. The use of bromine is avoided, and the whole process is small in pollution; the side reaction is few, the post-treatment is simple, the product is easy to separate, and the process operation is simple; meanwhile, compared with a bromination method under the condition of single bromine in the prior art, the yield is increased by 3 times, the yield is high, the product purity is high, the cost is lower, the reaction condition is mild, the controllability is high, the safety is high, and the method is particularly suitable for large-scale industrial production.

Owner:BEIJING GREENCHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com