Patents

Literature

188results about How to "Achieve friendly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

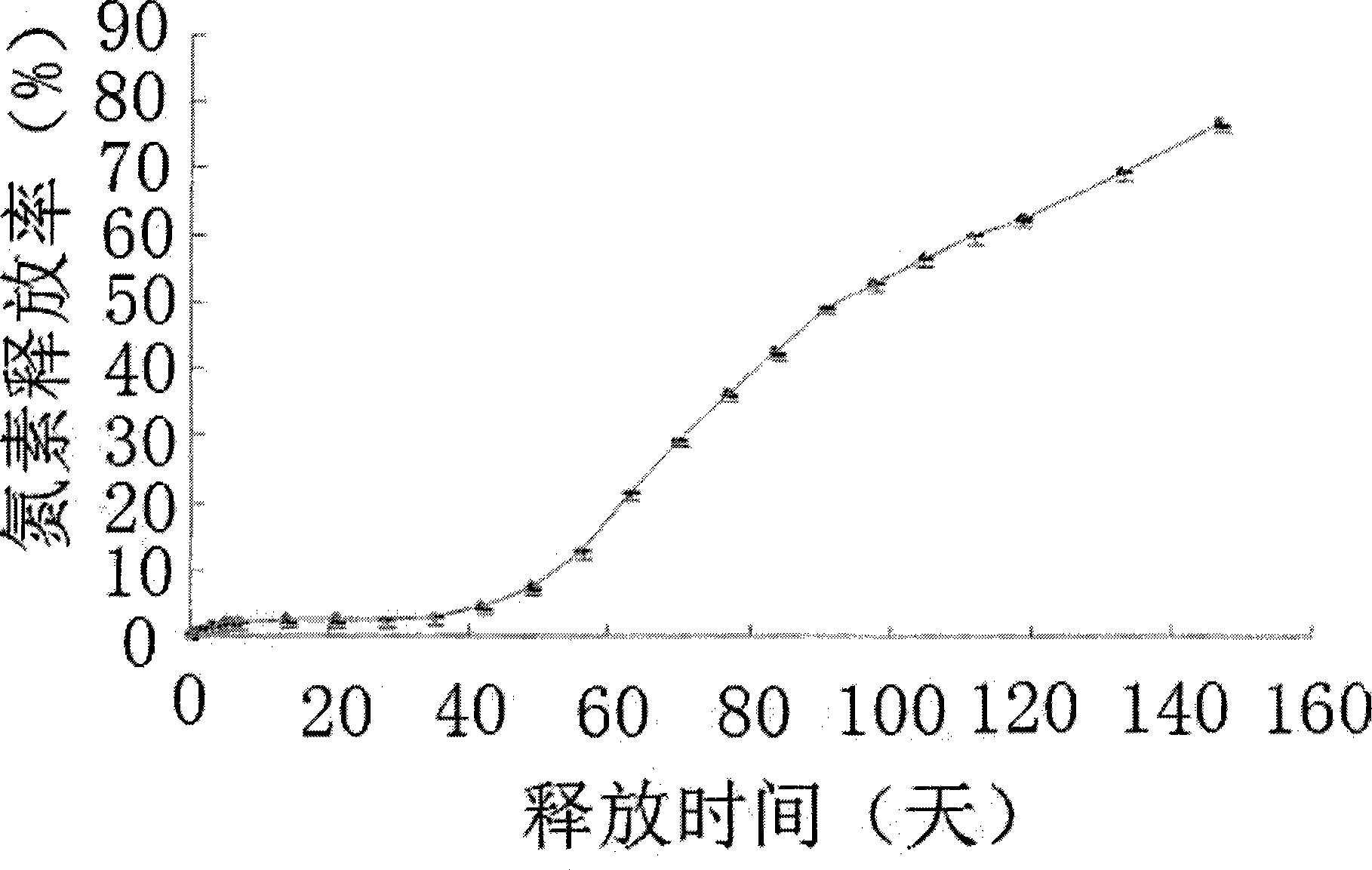

Degradable polymer filmcoated controlled release fertilizer, preparation thereof and special filmcoated material

ActiveCN101323545AHas the ability to degradeAchieve friendlyFertilizer mixturesControl releasePolyol

The invention discloses a polymer coated released fertilizer and a preparation method thereof and a special coating material thereof. The coating material comprises isocyanate, polyol, degradable functional monomer, an aid agent of coating and a chain extender, wherein, the mol ratio between the isocyano group in the isocyanate and the hydroxyl group in the polyol is 1:2 to 2:1 and the mass of the degradable functional monomer is 1 percent to 20 percent of the mass of the coating material. The coated released fertilizer provided by the invention consists of a core and a karyotheca, wherein, the core is granule fertilizer and the karyotheca is prepared from the coating material, and the mass of the karyotheca is 2 percent to 10 percent of the mass of the core. The coating material has good film forming and water resisting performance and can be degraded in nature. The hardness and the elasticity of the material can be adjusted by changing the mixure ratio of the coating material so as to prepare released fertilizers with different releasing periods.

Owner:CNSG ANHUI HONG SIFANG FERTILIZER IND CO LTD

Preparation method of high-strength and antioxidant rare-earth-based smoke denitration catalyst

ActiveCN104209117AReduce escape rateReduce productionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCeriumGlass factory

The invention discloses a preparation method of a high-strength and antioxidant rare-earth-based smoke denitration catalyst. The preparation method of the high-strength and antioxidant rare-earth-based smoke denitration catalyst comprises the following steps: by taking titanium dioxide and montmorillonite as carriers and ammonium metatungstate, cerous nitrate and lanthanum nitrate as active components, mixing, ageing, kneading, forming, drying and roasting with the accompanying of auxiliary materials. The auxiliary materials comprise ammonia water, lactic acid, citric acid, stearic acid, glass fiber, wood pulp, hydroxypropyl methyl cellulose, polyoxyethylene, monoethanolamine and water. The product prepared by the method is separated under a high SO2 smoke condition, nitric oxide in the smoke can be decomposed; meanwhile, the purpose of removing mercury and dioxin can be achieved. According to the preparation method of the high-strength and antioxidant rare-earth-based smoke denitration catalyst, the rare earth elements, namely cerium and lanthanum are used as the active components, so that the addition amount of vanadium is reduced, the toxicity of the product is reduced or the product is non-toxic product, the pressure of the post treatment of the product is reduced; the environmental protection pressure is reduced; the product is environmentally friendly; the product can be widely used in the field of thermal power plants, glass factories and chemical plants.

Owner:山东信义汽车配件制造有限公司

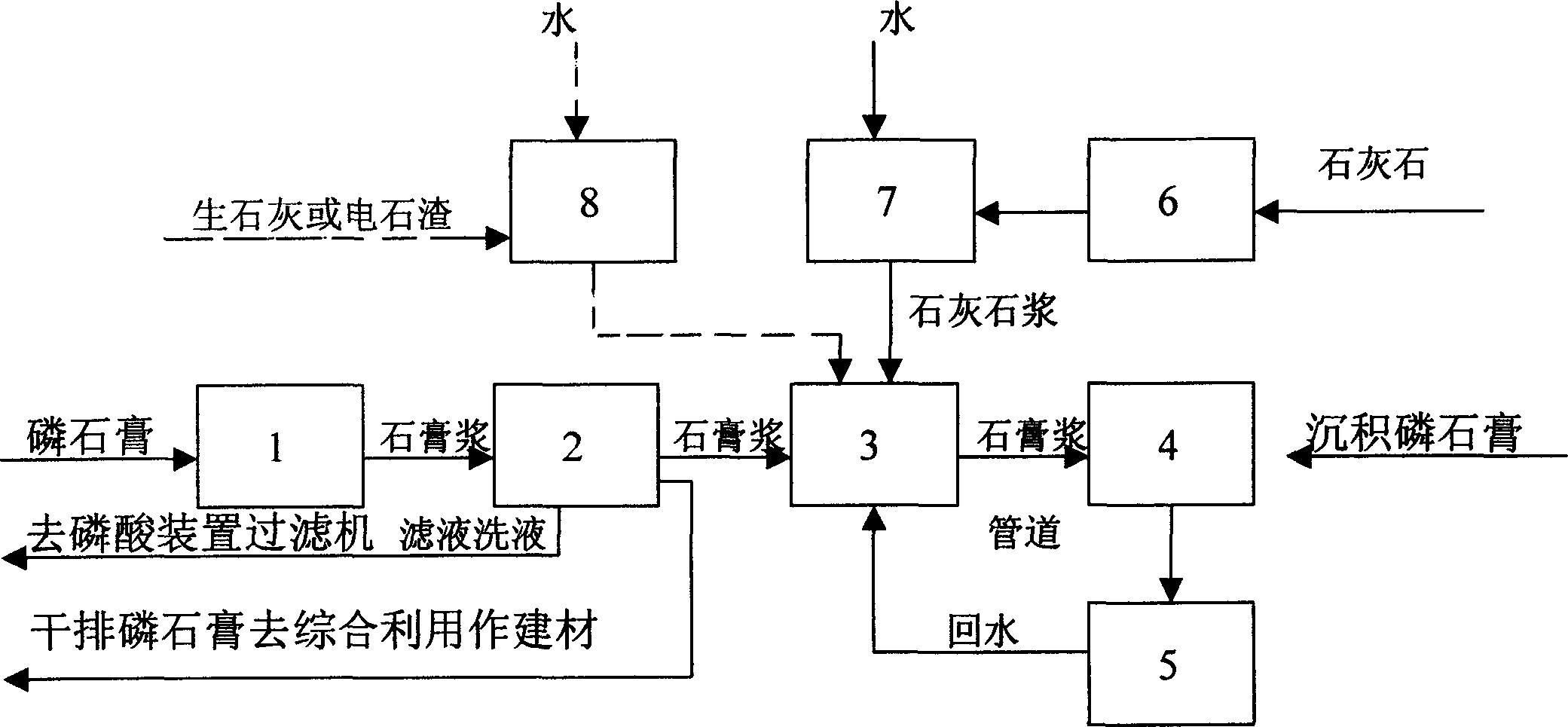

Ardealite innocent treatment method

ActiveCN1876204AMeet environmental protection requirementsReduce Toxic HazardsChemical protectionPhosphoric acidWater soluble

The related innocent treatment method for ardealite as by-product in wet method comprises: adding water and repulping, alternative vacuum filtering and cleaning by water to remove the water-soluble P2O5 and F, returning the filtered liquid to recover the P2O5 and F; sending the cleaned gyps for building, or wet slagging off to send to neutralize with limestone till pH value>=4.5, clearing to obtain the sediment. With low cost, this invention reduces ardealite danger, and improves source utility.

Owner:SHANGHAI NANHUA WATER TREATMENT TECH ENG

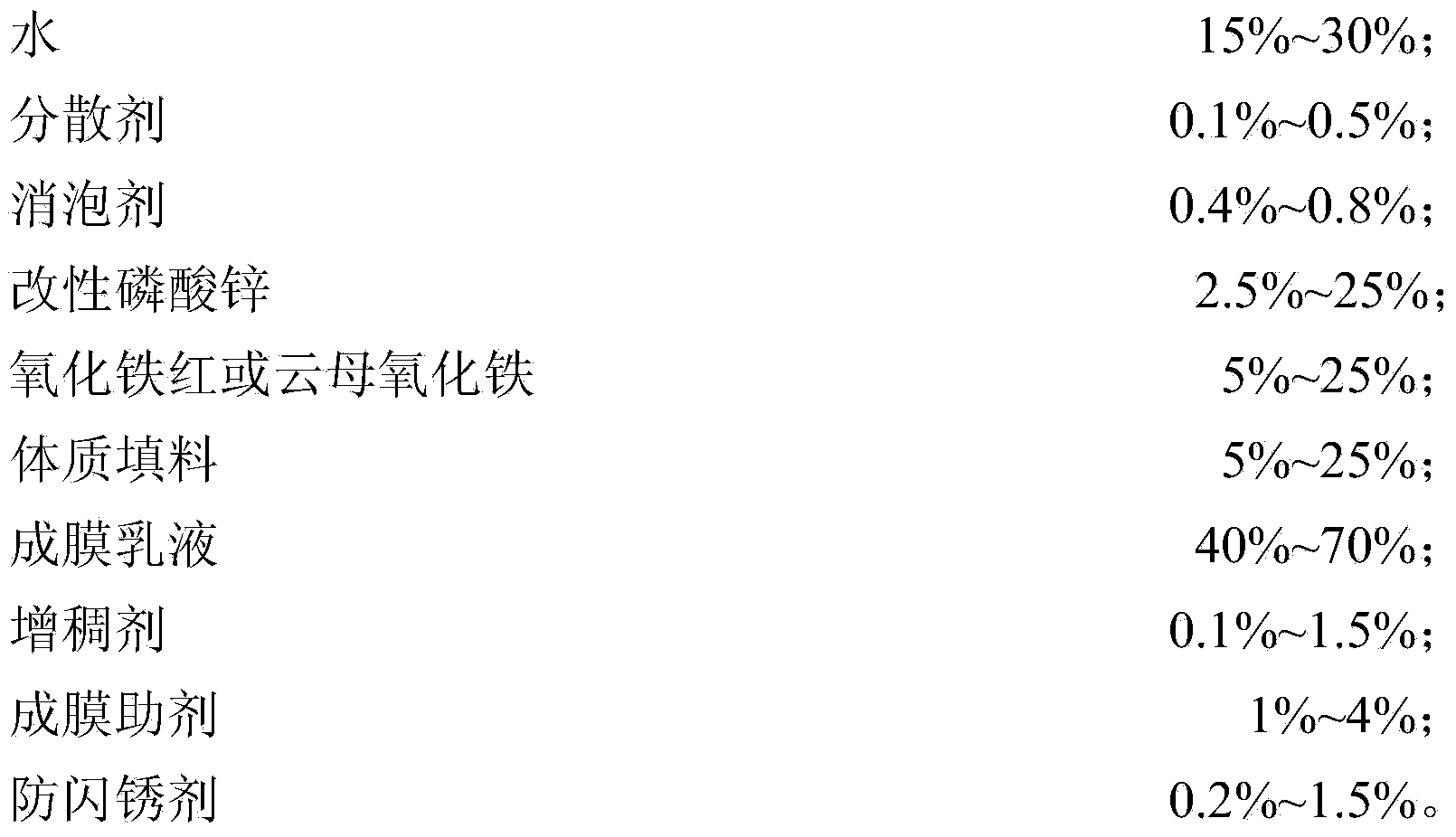

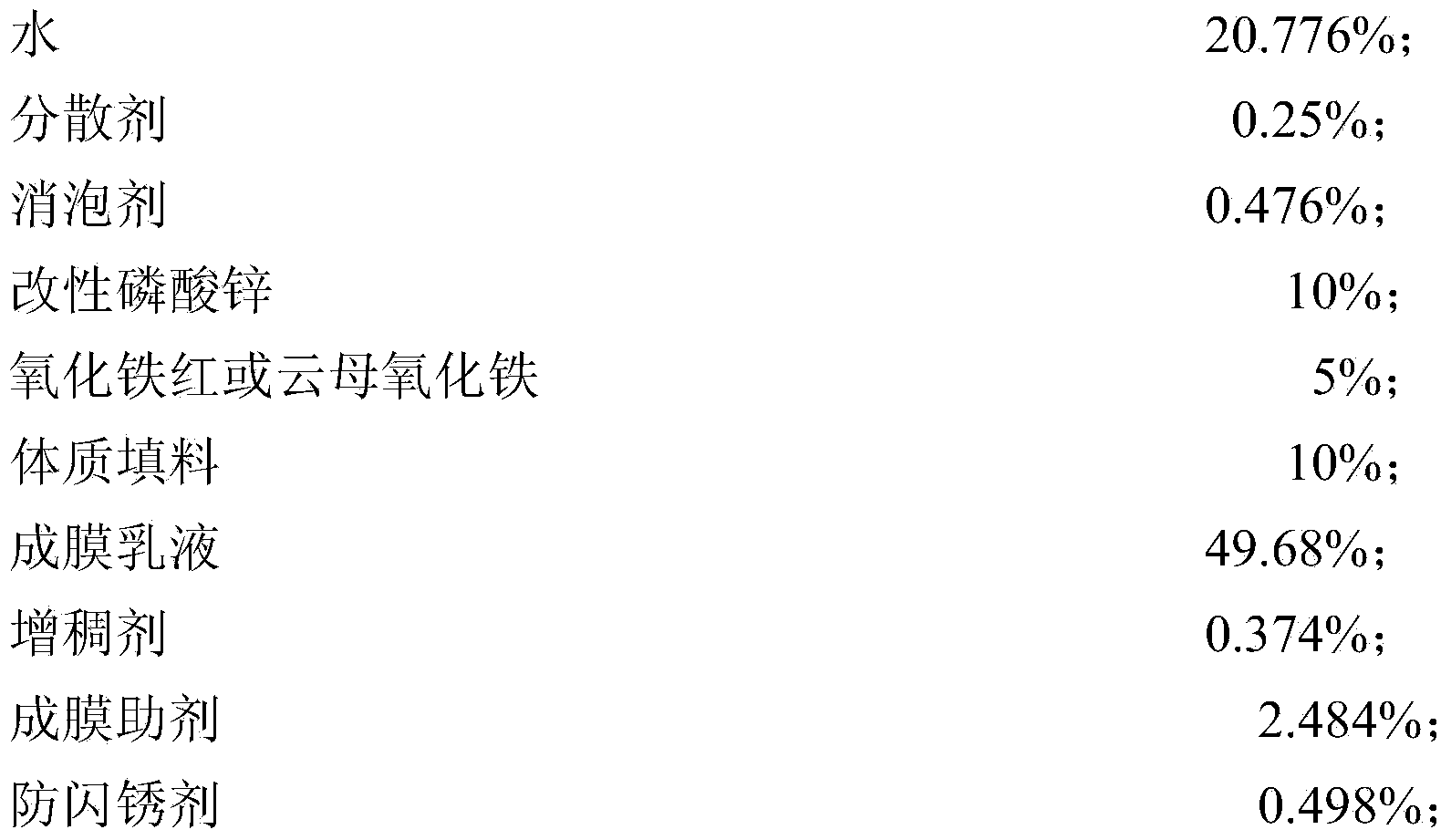

Bottom unified aqueous anticorrosive paint and preparation method

The invention discloses a bottom unified aqueous anticorrosive paint and its preparation method. the paint is composed of the following ingredients, by weight, 15-30% of water, 0.1-0.5% of a dispersant, 0.4-0.8% of an antifoaming agent, 2.5-25% of modified zinc phosphate, 5-25% of iron oxide red or mica iron oxide, 5-25% of a body filler, 40-70% of a film-forming emulsion, 0.1-1.5% of a thickening agent, 1-4% of a film-forming auxiliary agent and 0.2-1.5% of a flash-rust inhibitor. According to the bottom unified aqueous anticorrosive paint, each ingredient with specific weight percentage interacts with each other. Thus, comprehensive performance of the paint is raised, and in particular, anticorrosive performance of the paint is excellent. The paint is environmentally friendly. Problems of heavy odor, high pollution and the like existing in a traditional oil paint are solved. Meanwhile, each anticorrosion index is guaranteed. The product has simple preparation and construction technologies, is easy to carry out, is easy for large-scale industrial production, and has a wide application prospect.

Owner:ZHEJIANG UNIV

Aqueous anticorrosive heat-insulation paint and preparation method

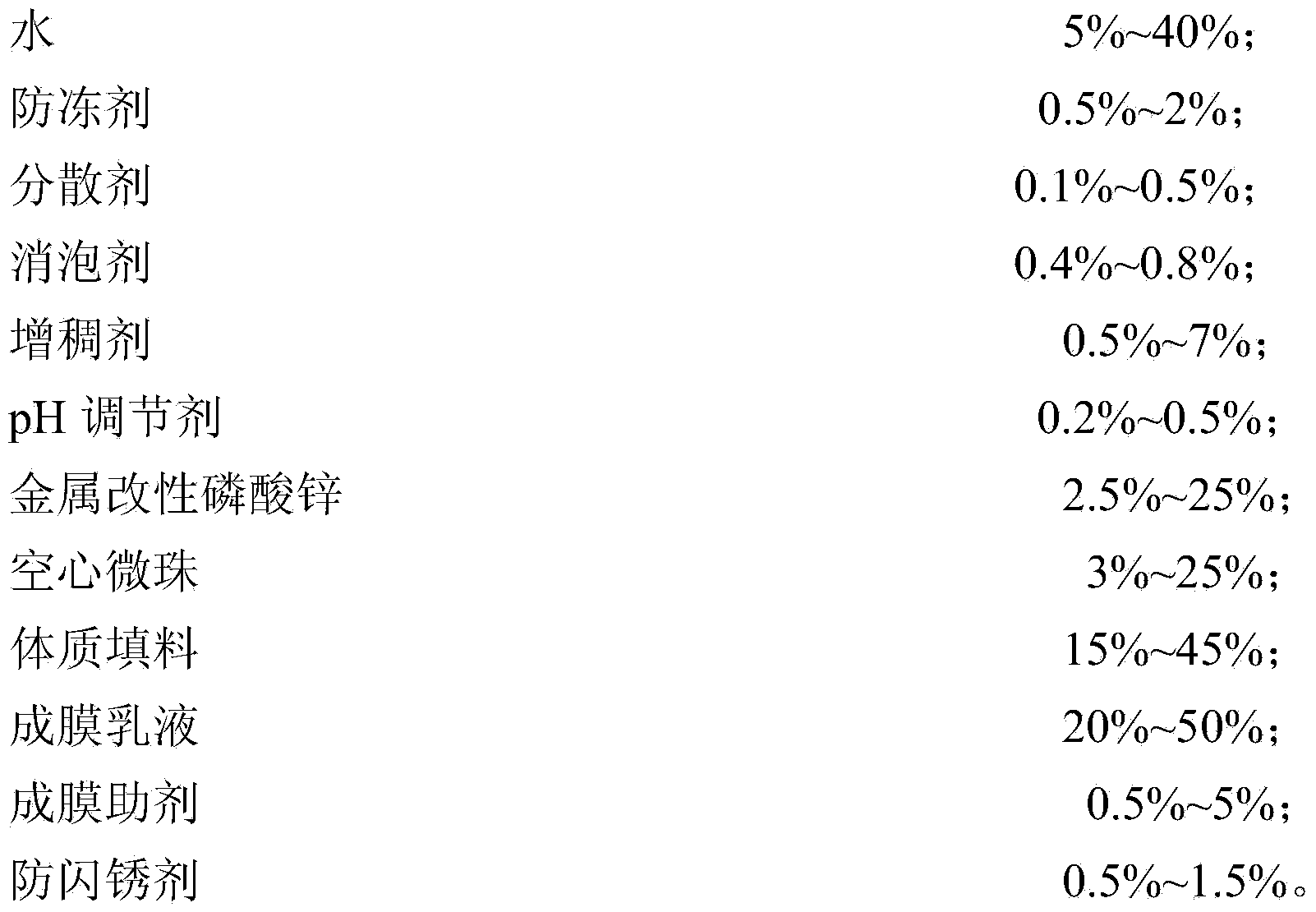

InactiveCN103819989AGood value for moneyWide range of applicationsAnti-corrosive paintsReflecting/signal paintsChemistryEmulsion

The invention discloses an aqueous anticorrosive heat-insulation paint which is prepared from the following raw materials of, by weight, 5-40% of water, 0.5-2% of an antifreezing agent, 0.1-0.5% of a dispersant, 0.4-0.8% of an antifoaming agent, 0.5-7% of a thickening agent, 0.2-0.5% of a pH conditioning agent, 2.5-25% of metal modified zinc phosphate, 3-25% of cenosphere, 15-45% of a body filler, 20-50% of a film forming emulsion, 0.5-5% of a coalescing agent and 0.5-1.5% of a flash-rust inhibitor. The invention also discloses a preparation method of the aqueous anticorrosive heat-insulation paint. The aqueous anticorrosive heat-insulation paint provided by the invention is a single-coating multifunctional paint, has excellent anticorrosive performance and heat-insulation performance to guarantee various anticorrosion and heat-insulation indexes, is beneficial to popularization and utilization, and has a wide application prospect. The method provided by the invention has a simple product preparation and construction process, is easy to carry out, and is easy for industrial large-scale production.

Owner:ZHEJIANG UNIV

Array type continuously-flowing microfluidic chip device and manufacture method and application thereof

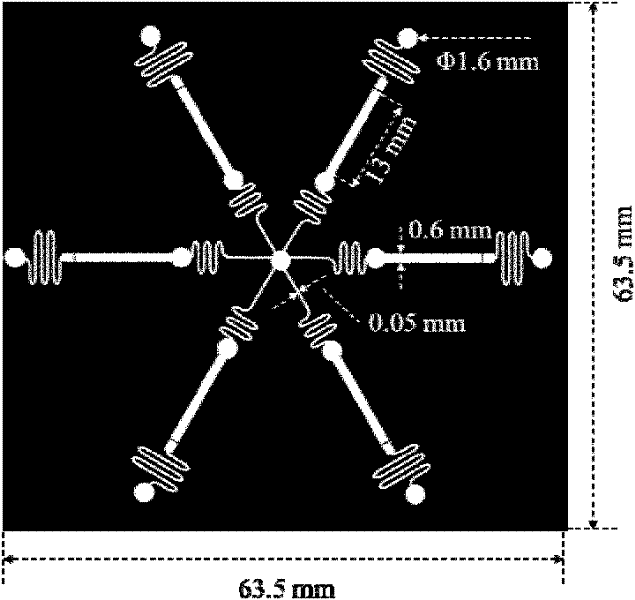

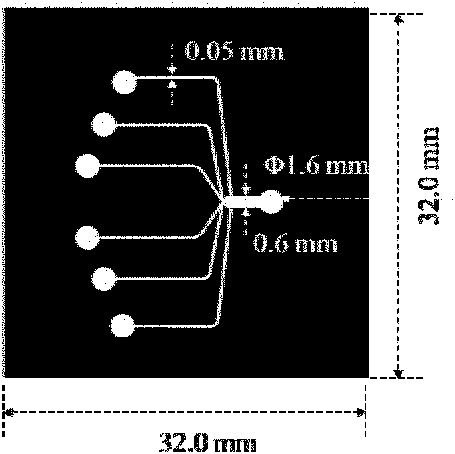

ActiveCN102527306AReduce mixed flowReduce the introductionChemical/physical/physico-chemical processesSolid-phase synthesisReagent

The invention provides an array type continuously-flowing microfluidic chip device and a manufacture method and application thereof. The device comprises a synthetic reaction microchip, a flow splitting microchip and a reagent charge cell, wherein reaction cavity bodies of various reaction units in the synthetic reaction microchip are internally provided with multiple layers of fences and barrages with cofferdam type structures, so that a solid-phase synthesis carrier can be effectively bounded, and the continuous fluid is also guaranteed to be smooth; and a charge module is composed of the flow splitting microchip and the reagent charge cell, so that independent and simultaneously sample introduction of different reagents can be conducted into various reaction units of the synthesis microchip. The microfluidic chip device provided by the invention can be used for the multi-step solid-phase synthesis reaction, the efficiency is high, the amount of reagents used is few, and the manufacture cost is low.

Owner:INST OF CHEM CHINESE ACAD OF SCI

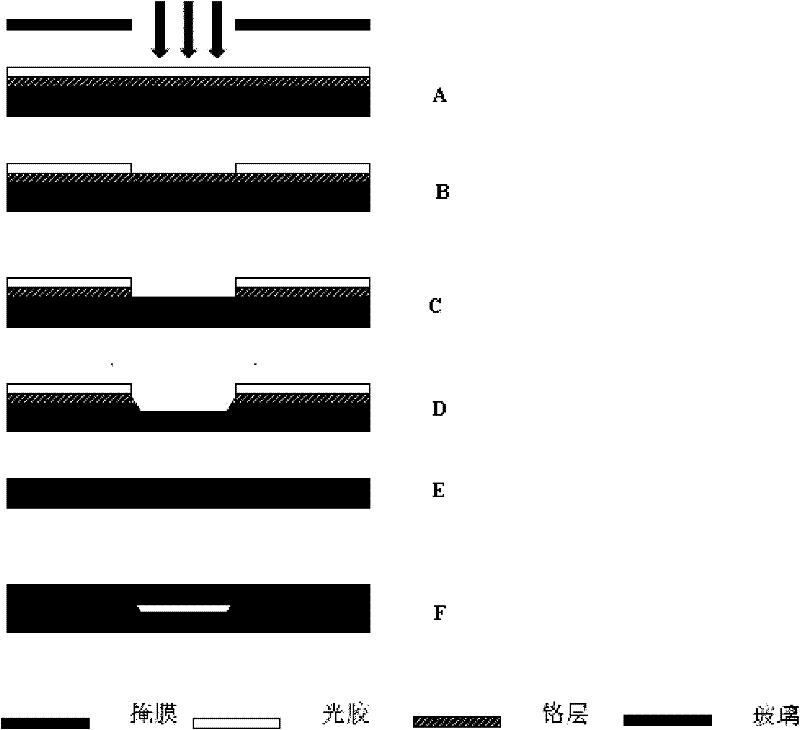

Anti-dazzle method for optical glass by wet process

The invention discloses an anti-dazzle method for optical glass by a wet process. The method specifically comprises the following steps: cleaning, wind-shearing and drying a to-be-processed fresh glass substrate in a dust-free environment; further cleaning the glass substrate by adopting a plasma gas, and roughening the surface of the glass; pre-heating the substrate and maintaining constant temperature; adjusting parameters of a spraying process; coating an anti-dazzle liquid by way of ultrasonic atomization; placing, leveling and carrying out surface dry after coating; roasting and curing to form a film; and slowly cooling the substrate to room temperature and preparing the anti-dazzle glass after examination. Compared with existing anti-dazzle technology, the hardness is increased from 2H to over 5H compared with that of a straight sticker. Compared with conventional anti-dazzling in an etching method, environment-friendliness is realized and Moore phenomenon is reduced. The cleanness is further enhanced and the film binding force is improved by adopting the plasma gas to roughen the glass substrate. The effect of ultrasonic atomization is better than that of common aerodynamic discretion. The atomizing particles are smaller and more uniformly dispersed.

Owner:成都三利亚科技有限公司

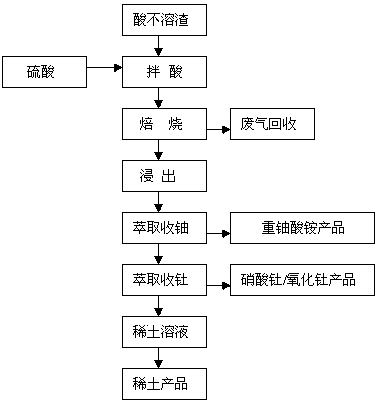

Method for recovering thorium, uranium and rare earth from monazite smelting acid-insoluble slag

The invention provides a separation method for recovering thorium, uranium and rare earth from monazite smelting acid-insoluble slag. The method comprises the following steps of mixing acid-insoluble slag and concentrated sulfuric acid to obtain a uniform mixture, carrying out constant-temperature roasting, adding water into the roasted slag, carrying out leaching at a room temperature, extracting uranium by a tertiary amine extraction agent, extracting thorium from the solution without uranium by a primary amine extraction agent, and carrying out alkali deposition on the solution without uranium and thorium to obtain a rare earth mixture product. The method has simple processes and large scale production feasibility, utilizes common chemical materials having low consumption, can effectively extract rare earth from residual acid-insoluble slag in a monazite smelting process, can acquire single thorium and uranium products, has a total yield more than 90% and slag consumption amount more than 50%, is environmentally friendly and has obvious social and economic benefits.

Owner:HUNAN RARE EARTH METAL MATERIAL RES INST

Formaldehyde-free decorative board and preparation method thereof

InactiveCN101554741BNo pollutionAchieve friendlyPlywood pressesFilm/foil adhesivesSolid woodWood veneer

The invention discloses a formaldehyde-free decorative board and a preparation method thereof. The decorative board is formed by overlaying multiple layers of wood veneers with adhesive, wherein the adhesive is plastic film. The preparation method is as follows: the plastic film is evenly laid between every two adjacent wood veneers, and the use level of the plastic membranes is over 100g / m <2>; a veneer press is used for pressing, with the pressure over 100 tons, the veneer press performs heat pressing firstly and cold pressing later, the temperature of heat pressing is over 100 DEG C and the temperature of the cold pressing is 20 DEG C to 100 DEG C The decorative board contains no formaldehyde, causes no poison or pollution on human body and surrounding environment and truly realizes the environment protection. In addition, the invention adopts the cheap plastic film as the adhesive, the production cost is low, the technology is simple, and qualitative indexes of the product completely satisfy the national standards.

Owner:深圳伟伦嘉禾环保装饰材料有限公司

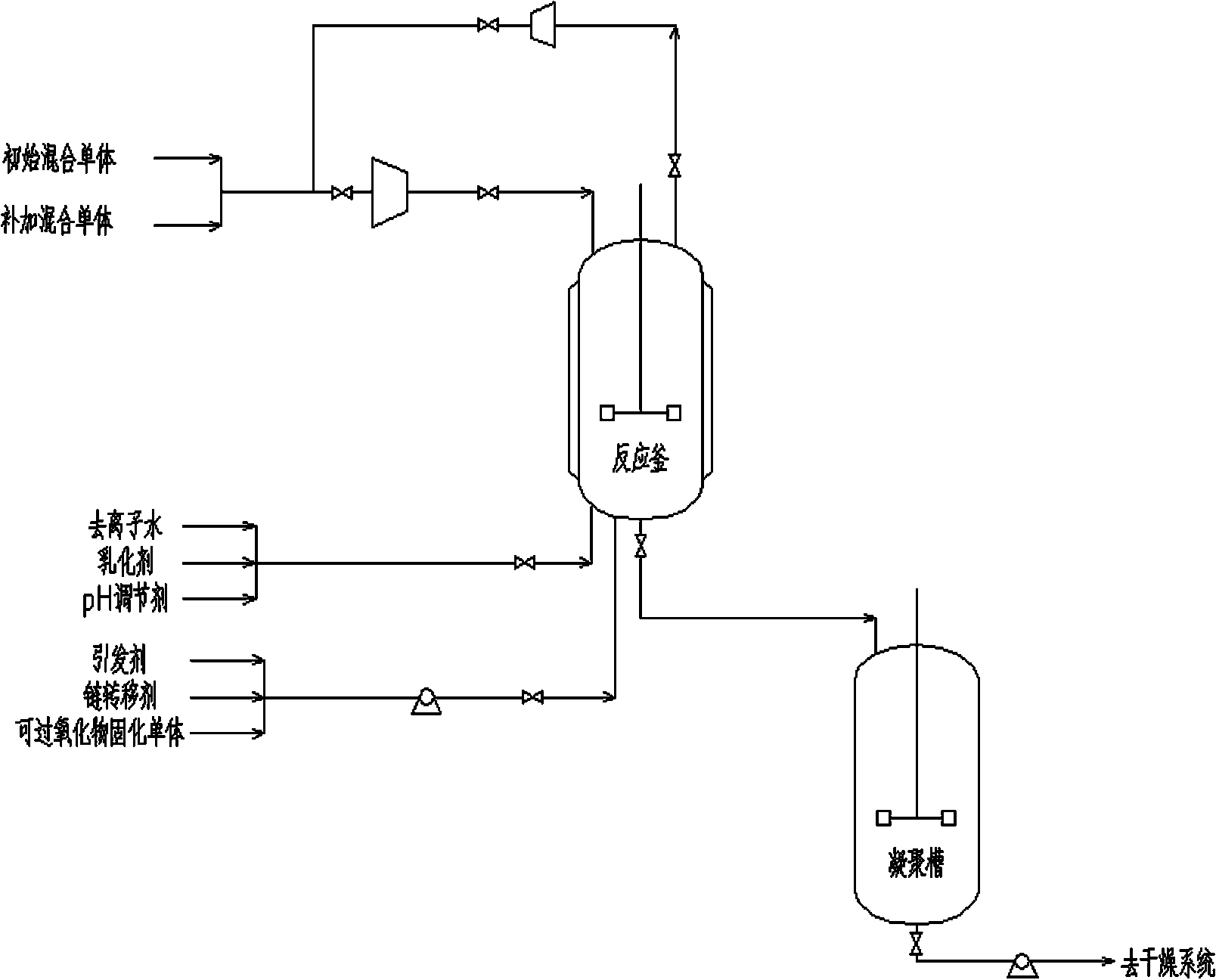

Industrial preparation method of water-soluble resin coating material and application thereof

ActiveCN101544707AIncreased mechanical resistanceImprove water resistanceFertiliser formsFertilizer mixturesControlled releaseResin coating

The invention discloses a preparation method of a water-soluble resin coating material and an application thereof. The preparation method comprises the steps as follows: water and emulsifier are prepared into an emulsifier solution; part of the emulsifier solution and a mixed monomer are prepared into an emulsive monomer; and the rest of the emulsifier solution and the emulsive monomer react under the evocation of an evocating agent to obtain the coating material. The invention realizes a high-temperature coating process of water polymer and adopts industrial-scale equipment and process condition so as to be conveniently used for the manufacture of the controlled-release coating material of an enterprise without pilot test and technique magnification. The Tg temperature of the coating material is 15-100 DEG C, and agglomeration can not occur when the fluidization coating temperature reaches 100 DDG C.

Owner:SOUTH CHINA AGRI UNIV

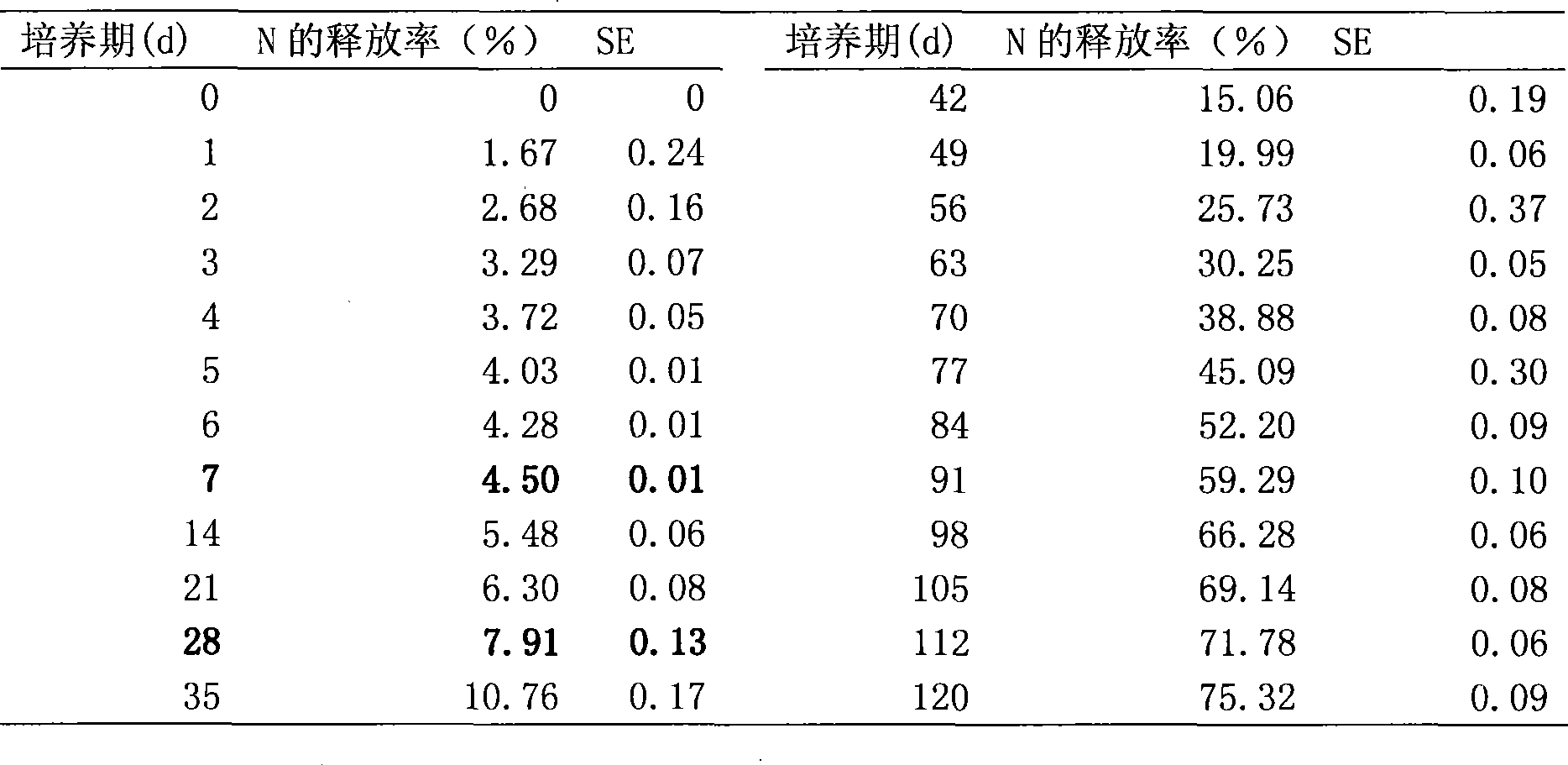

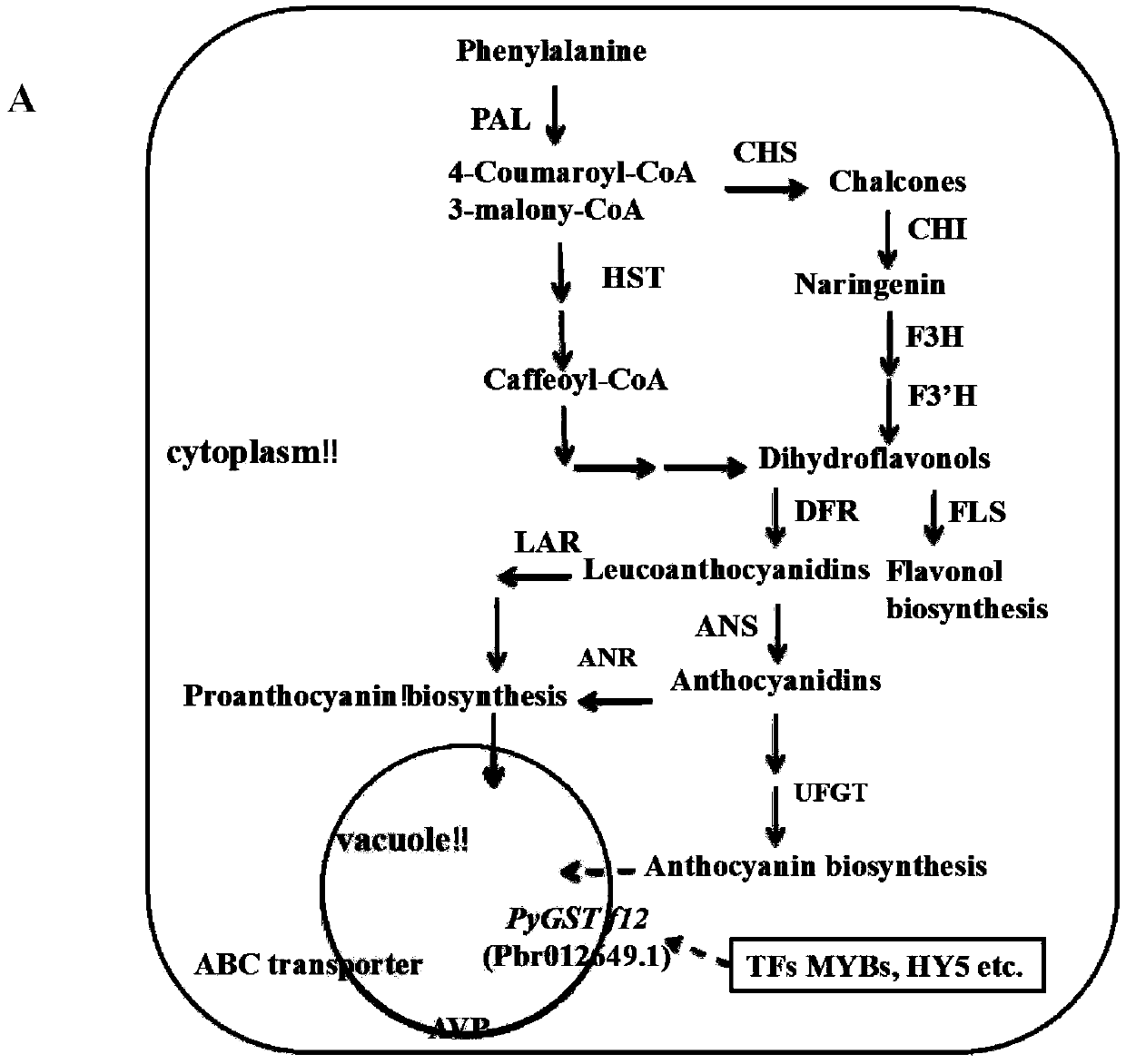

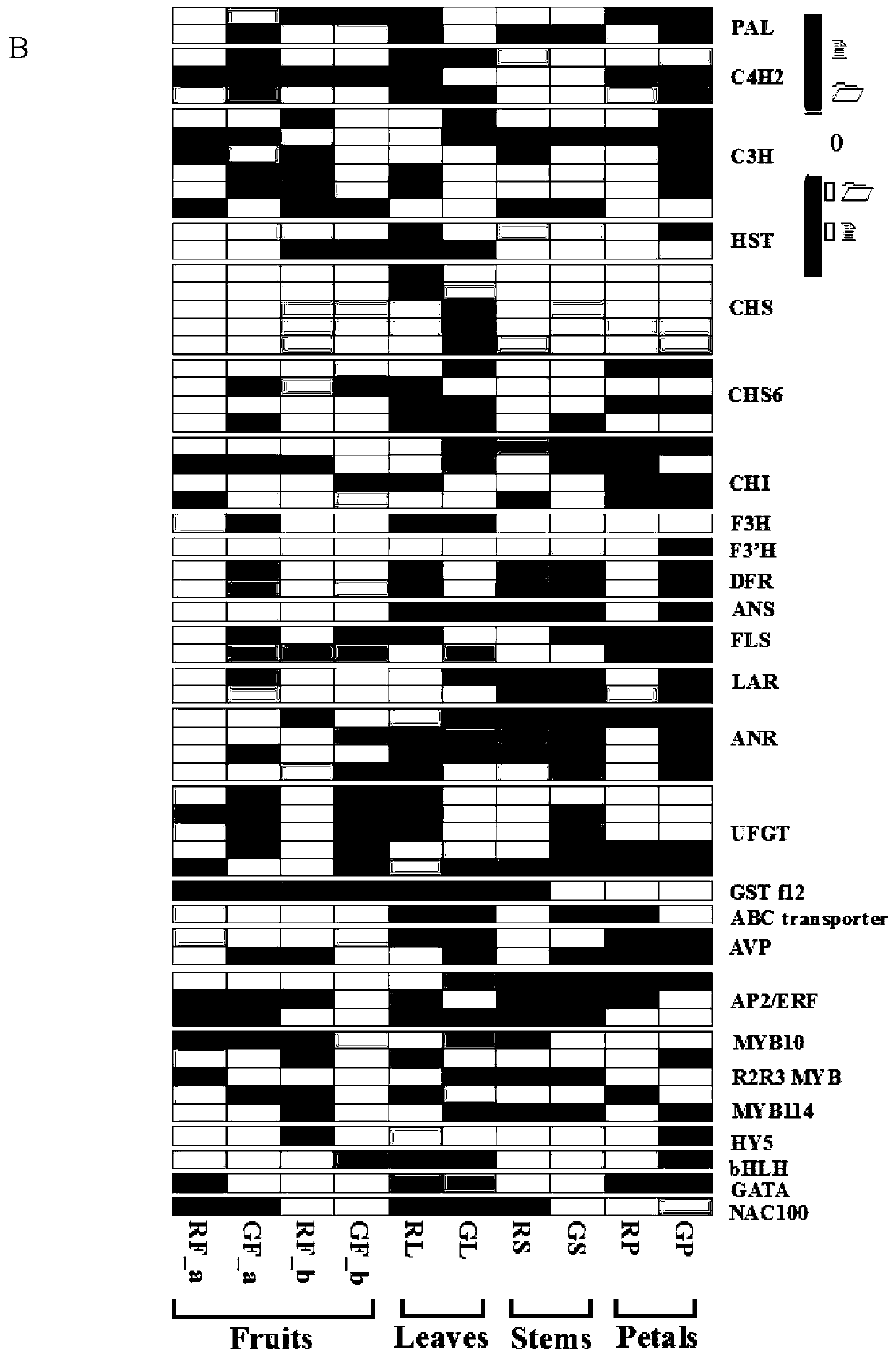

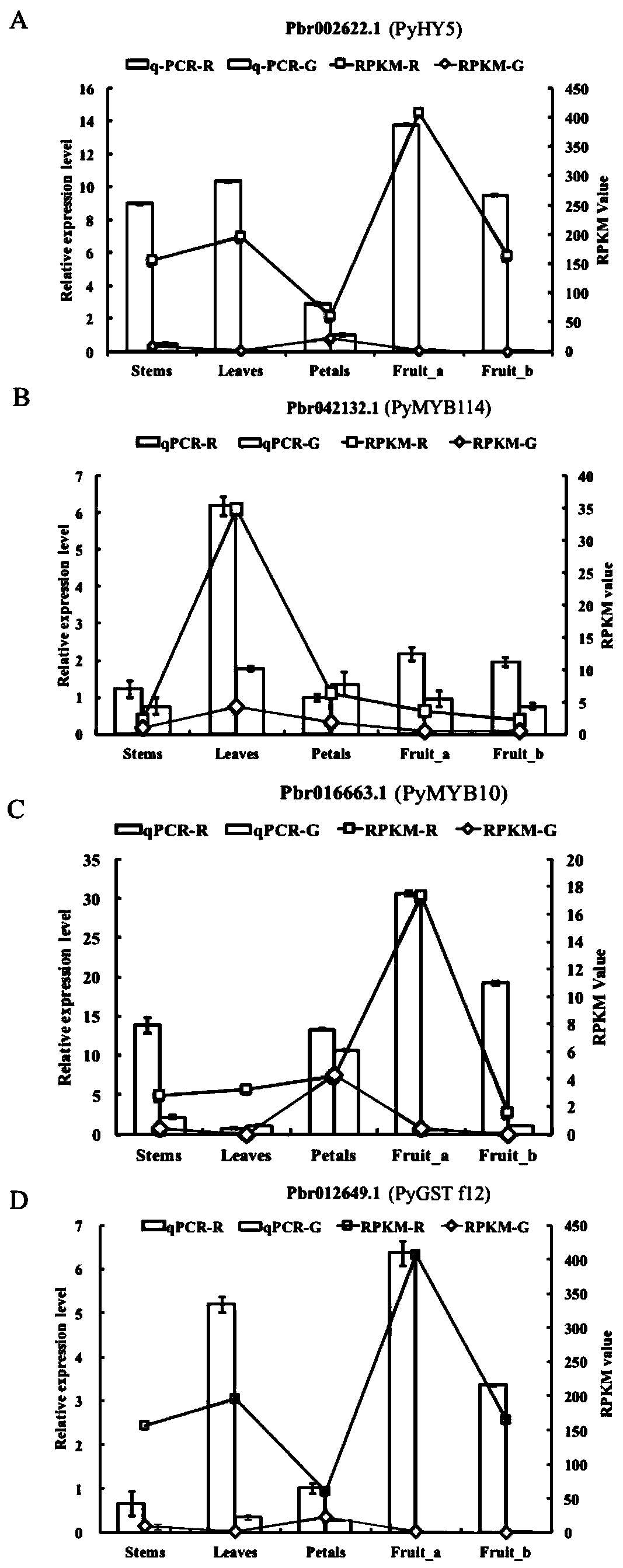

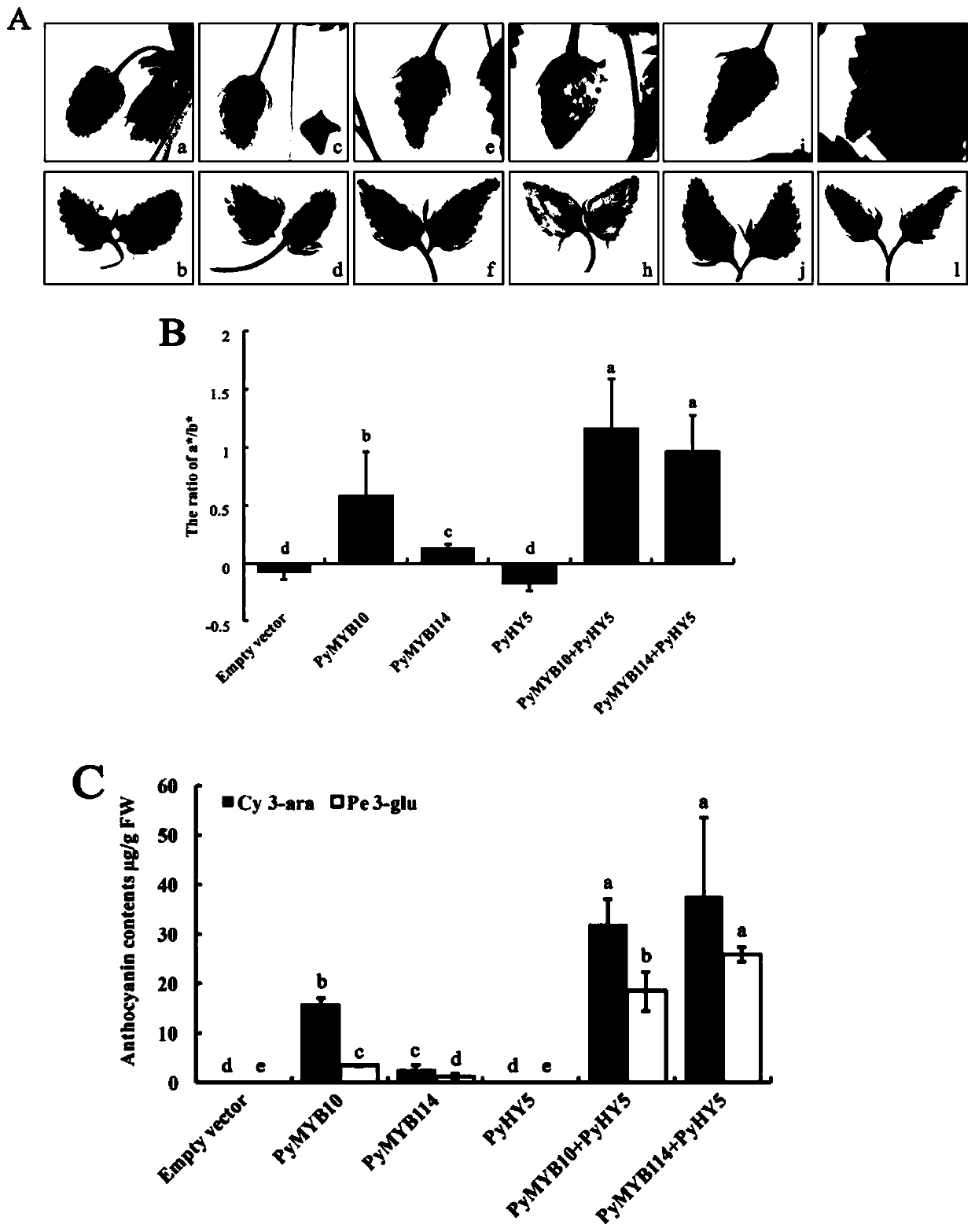

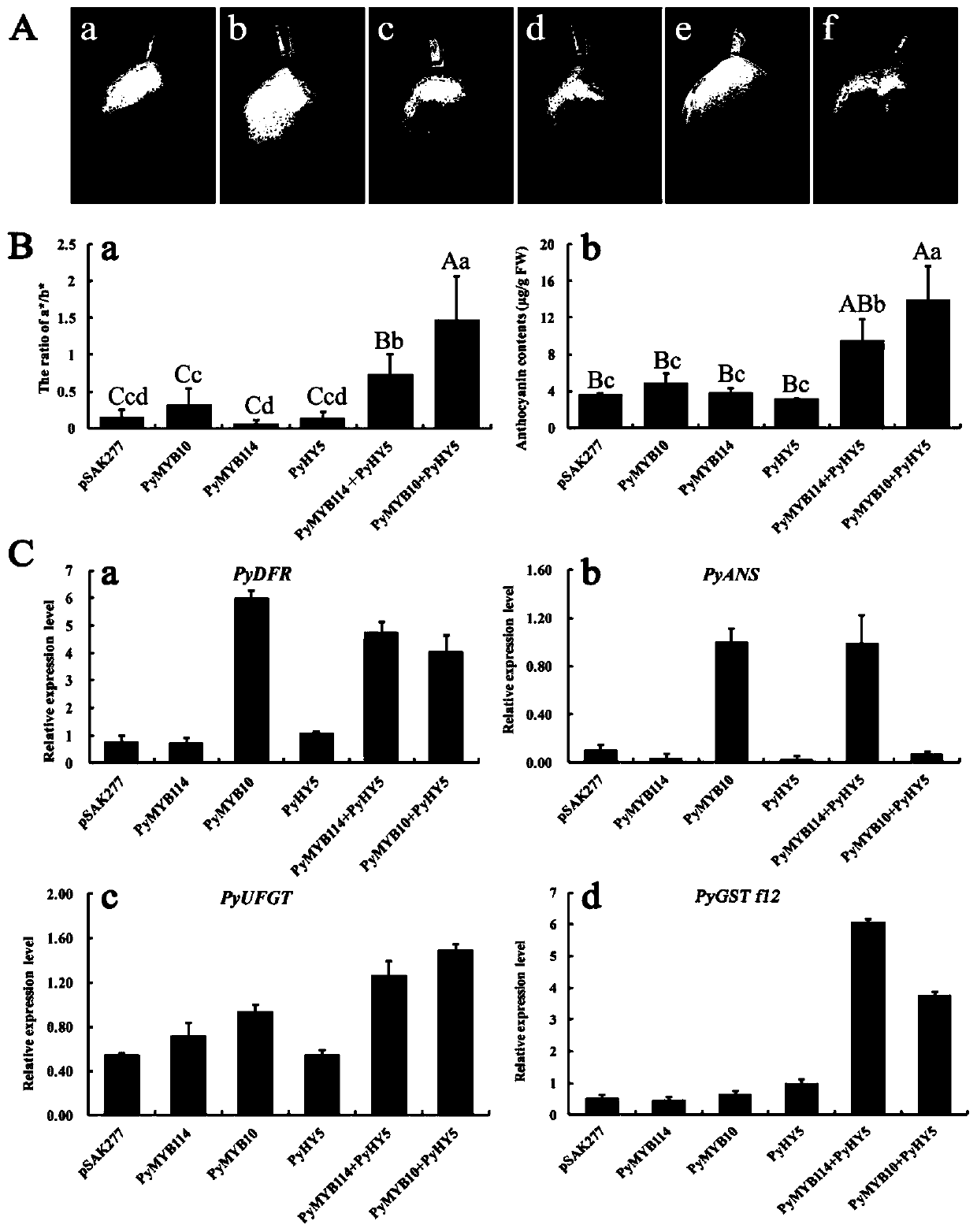

PyGSTf12 gene related to transport of anthocyanin in pear fruits, and recombinant expression vector and application of PyGSTf12 gene

InactiveCN109810990AAchieve friendlyReduce the cost of farmingBacteriaMicrobiological testing/measurementFragariaAgricultural science

The invention discloses a pear transcription factor PyGSTf12, and a recombinant expression vector and application thereof. The sequence difference between the PyGSTf12 and a promoter thereof is used as a molecular marker for identifying red and green peels, wherein the PyGSTf12 and the promoter are respectively separated from 'Red Zaosu' pears and yellow bud mutated fruits thereof, and the nucleotide sequences of the PyGSTf12 and the promoter are respectively as shown in SEQ ID No. 31 and SEQ ID No. 32. By a dual-luciferase report system, an agrobacterium-mediated instant genetic transformation method proves that the PyGSTf12 co-transformed by transcription factors PyHY5 and PyMYB114 promotes accumulation of anthocyanin in strawberry and pear fruits, and the PyGSTf12 promoter promotes thetransport function of the anthocyanin; through discovery of the PyGSTf12 gene, new genetic resources are provided for molecular breeding that promotes synthesis of the anthocyanin in pear peels, and new genetic resources are provided for the implementation of green agriculture; the development and utilization of the genetic resources is beneficial to agricultural cost reduction and environmental friendliness.

Owner:NANJING AGRICULTURAL UNIVERSITY

Pear transcription factor PyHY5, and recombinant expression vector and application thereof

The invention discloses a pear transcription factor PyHY5 and application of a recombinant expression vector of the pear transcription factor PyHY5. The nucleotide sequence of a transcription factor PyHY5 gene which is separated from 'Red Zaosu' pears and has a function of promoting anthocyanin biosynthesis of pear peels is as shown in SEQ ID No. 1, and the encoded amino acid sequence of the transcription factor PyHY5 gene is as shown in SEQ ID No. 2. Transcription factors PyHY5 and PyMYB114 are co-transformed into strawberry and pear fruits by an agrobacterium-mediated transformation method;according to biological function verification, the cloned PyHY5 gene and a cofactor PyMYB114 thereof interact to promote the transport function of anthocyanin in the pear peels; through discovery of new functions of the PyHY5, new genetic resources are provided for molecular breeding that promotes accumulation of the anthocyanin in the pear peels, and new genetic resources are provided for the implementation of green agriculture; the development and utilization of the genetic resources is beneficial to agricultural cost reduction and environmental friendliness.

Owner:NANJING AGRICULTURAL UNIVERSITY

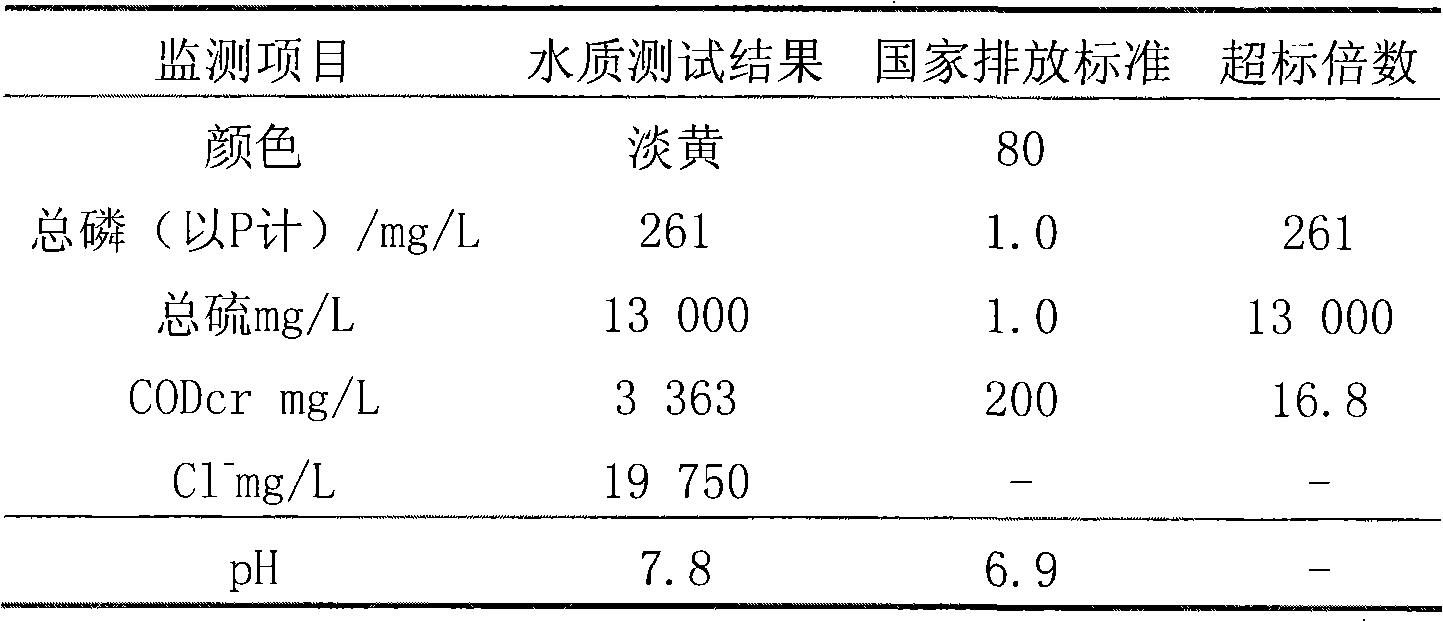

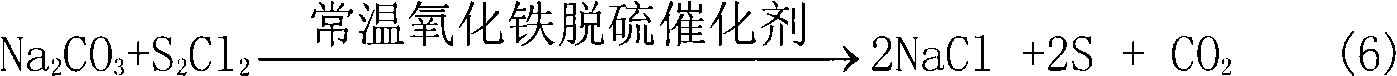

Method for preparing O,O-ethyl thioether substituted phosphorus oxychloride

InactiveCN101293897AMild desulfurization conditionsAchieve friendlyGroup 5/15 element organic compoundsPhosphorus pentasulfideSulfide

The invention relates to a method for preparing O,O-diethyl thiophosphoryl chloride (DETC), comprising the steps of reacting the raw material of phosphorus pentasulfide with anhydrous alcohol to obtain O,O-diethyl phosphorodithioate (referred to as ethyl sulfide); reacting with chlorine gas to obtain crude O,O-diethyl thiophosphoryl chloride; performing desulfuration of the crude O,O-diethyl thiophosphoryl chloride with ferric oxide desulfuration catalyst at room temperature to obtain desulfurized O,O-diethyl thiophosphoryl chloride and crystalline sulfur; and refining the desulfurized O,O-diethyl thiophosphoryl chloride by the steam distillation method to obtain O,O-diethyl thiophosphoryl chloride with high purity (over 99.5%). The method has the advantages of environmentally friendly production process, and high product purity.

Owner:湖北蕲农化工有限公司

Natural laundry emulsion used in ultraviolet washing machine and preparation method thereof

ActiveCN103468429AAchieve friendlyImprove laundry effectInorganic non-surface-active detergent compositionsEmulsionSorbent

The invention relates to a laundry emulsion with P25 nanometer titanium dioxide powder as the main component. The laundry emulsion adopts the P25 nanometer titanium dioxide powder as the main component, the auxiliary materials include an antibacterial agent, adsorbent, water softener, thickener and allowance deionized water, all the components are continuously stirred at a proper temperature according to a certain proportion, and then the uniform and natural laundry emulsion is formed. The laundry emulsion has the advantages of being composed of natural components, being suitable for an ultraviolet washing machine, having the best laundry effect, and being environmentally friendly, free of pollution, not harmful to hands and the skin of the human body, obvious in sterilization effect, high in dirt-removing capacity, capable of degrading pollutants, and favorable for the competitiveness of product development and environment protection.

Owner:ZHEJIANG OCEAN UNIV

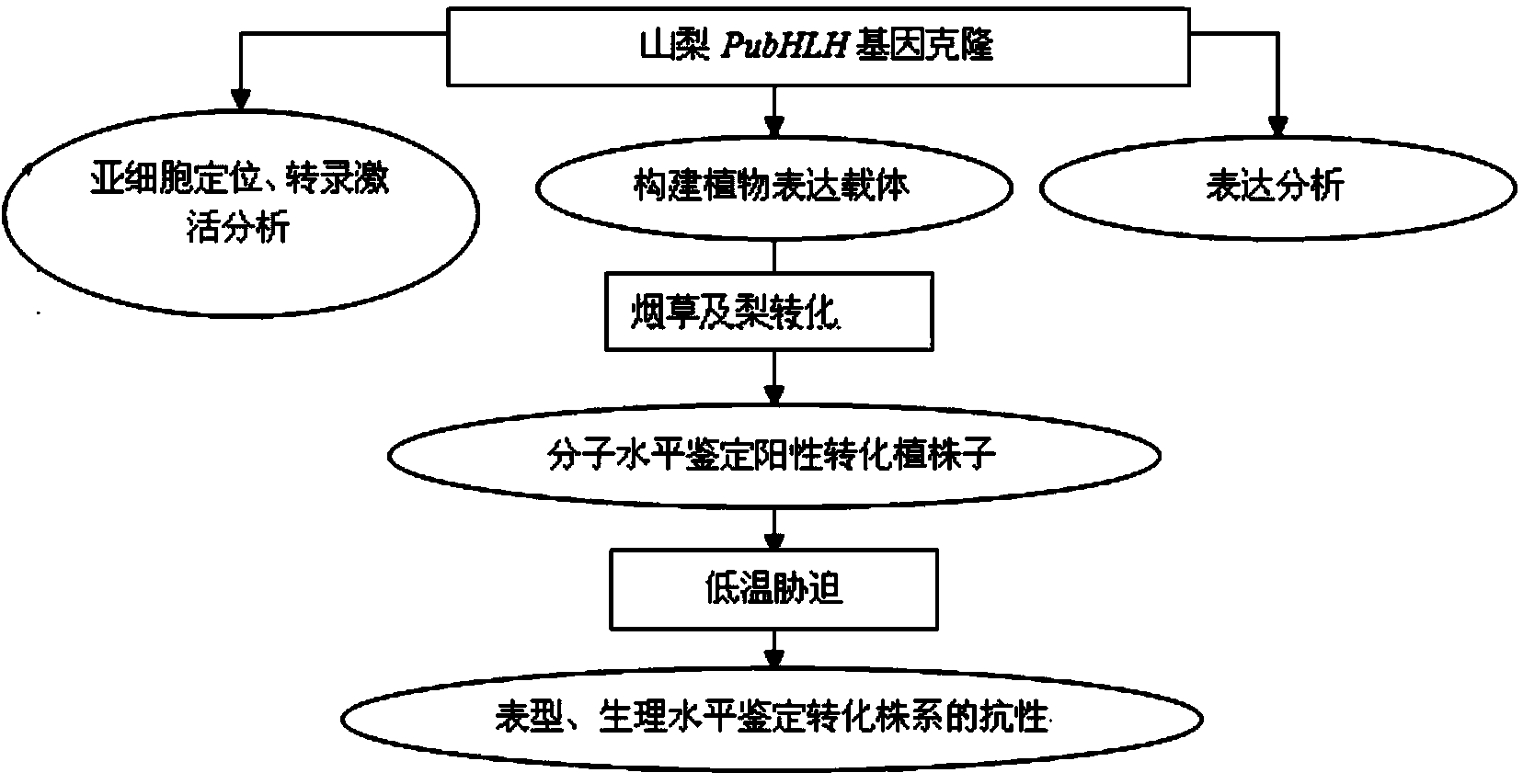

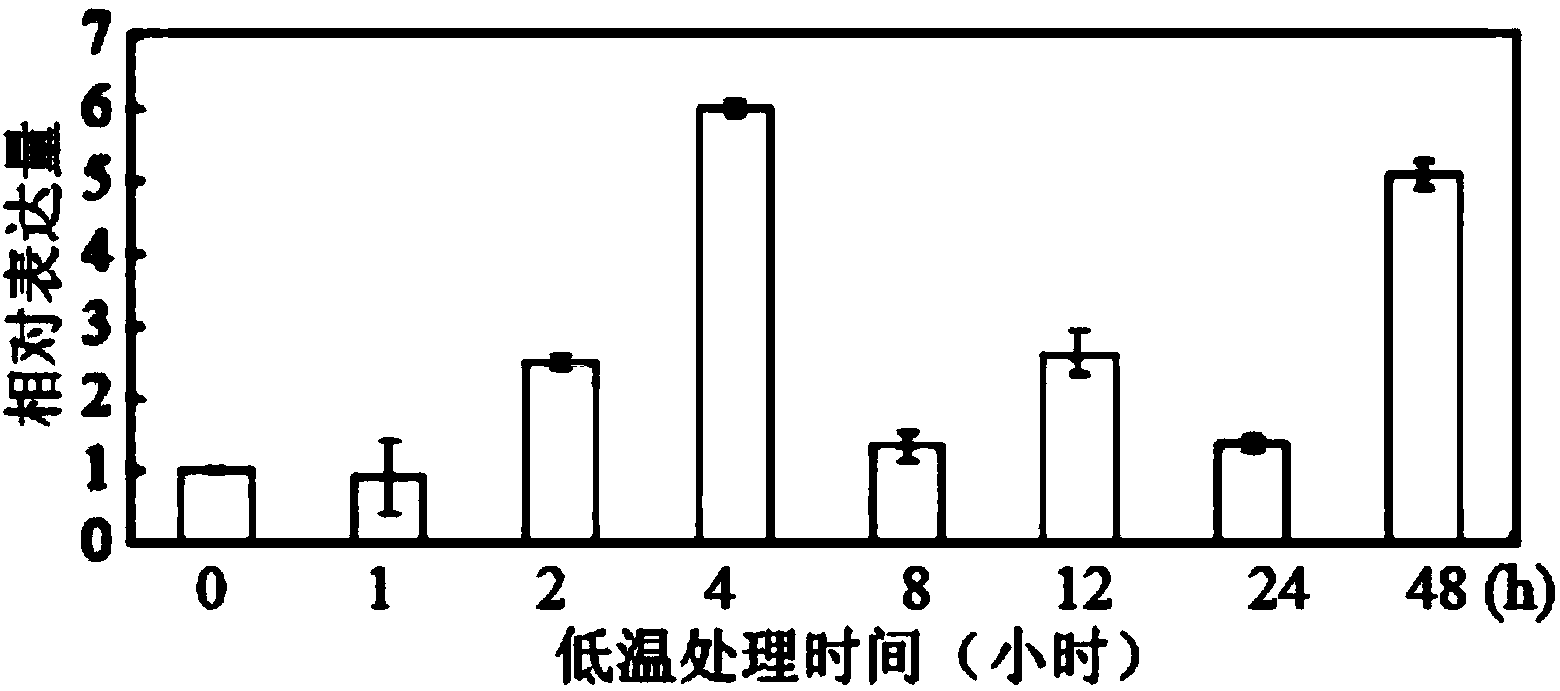

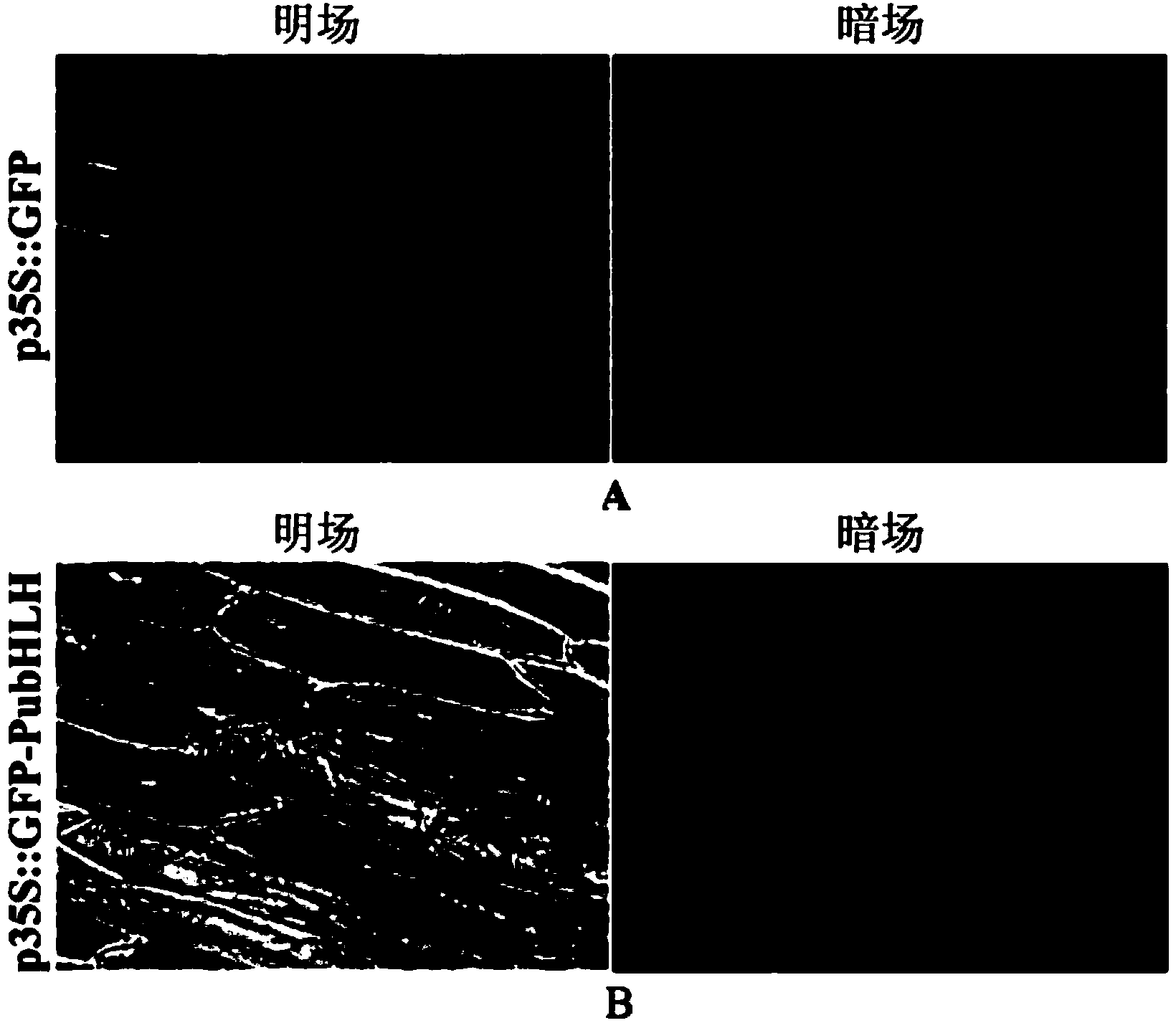

Sorb cold-resistant transcription factor PubHLH and application thereof

ActiveCN104031923AHas the function of regulating cold resistanceImprove cold resistanceBacteriaPlant peptidesBiotechnologyNicotiana tabacum

The invention discloses a sorb cold-resistant transcription factor PubHLH and an application thereof. The nucleotide sequence of sorb bHLH transcription factor gene PubHLH is represented by SEQ ID NO: 1 in a sequence table; 409-2043bp position of the sequence represented by SEQ ID NO: 1 is a coding area of the gene; an amino acid sequence coded by the coding area is represented by SEQ ID NO: 1. A new bHLH gene PubHLH is cloned in the sorb; an agrobacterium-mediated genetic transformation method is used for transforming the gene to tobacco and pear; cold resistance ability of the obtained transgenic plant is obviously improved; biological functional verification shows that the cloned PubHLH gene has cold resistance regulation function. The sorb bHLH transcription factor gene PubHLH provided by the invention can be applied to improvement of plant cold resistance or construction of cold-resistant transgenic plant.

Owner:NANJING AGRICULTURAL UNIVERSITY

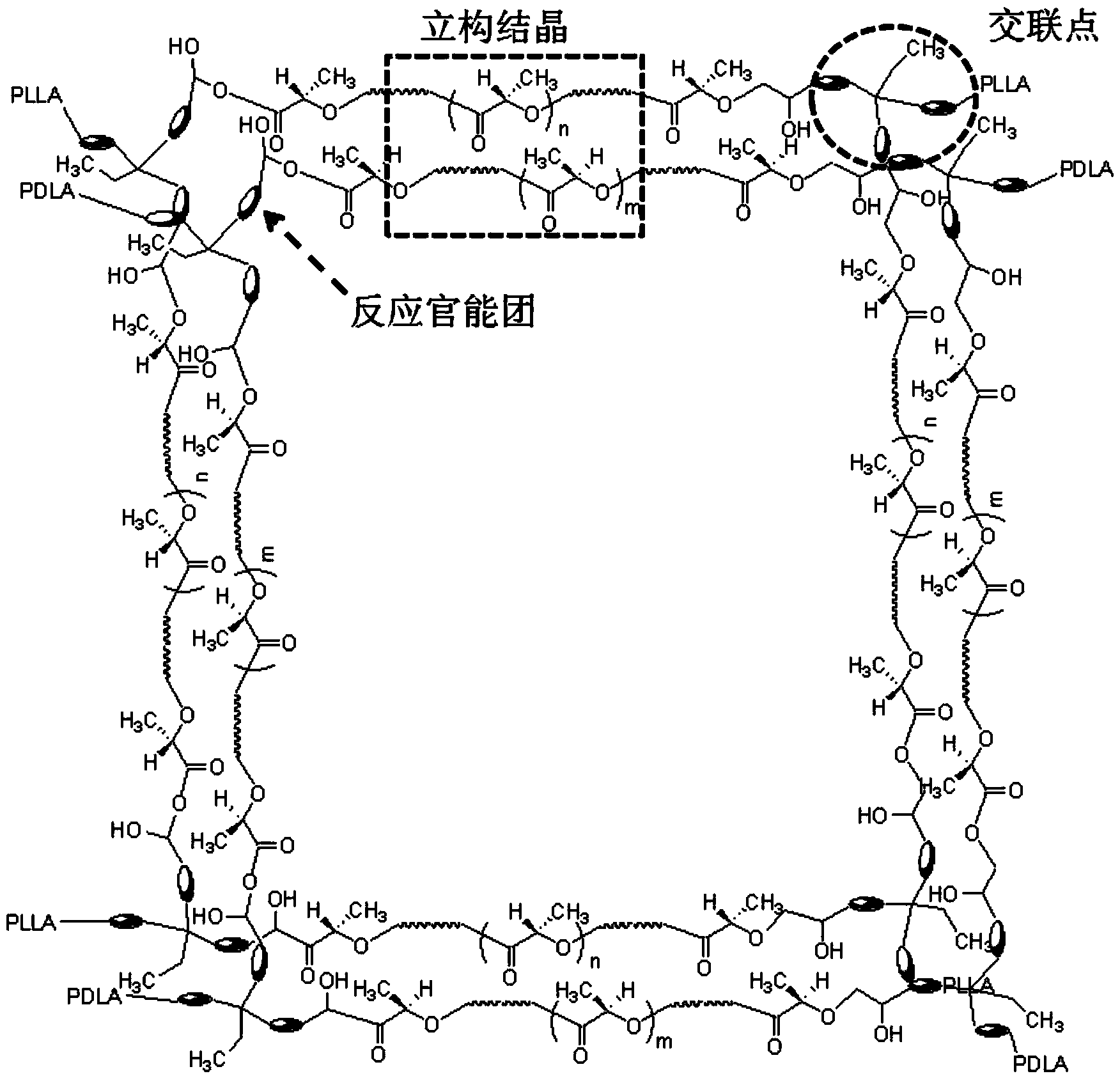

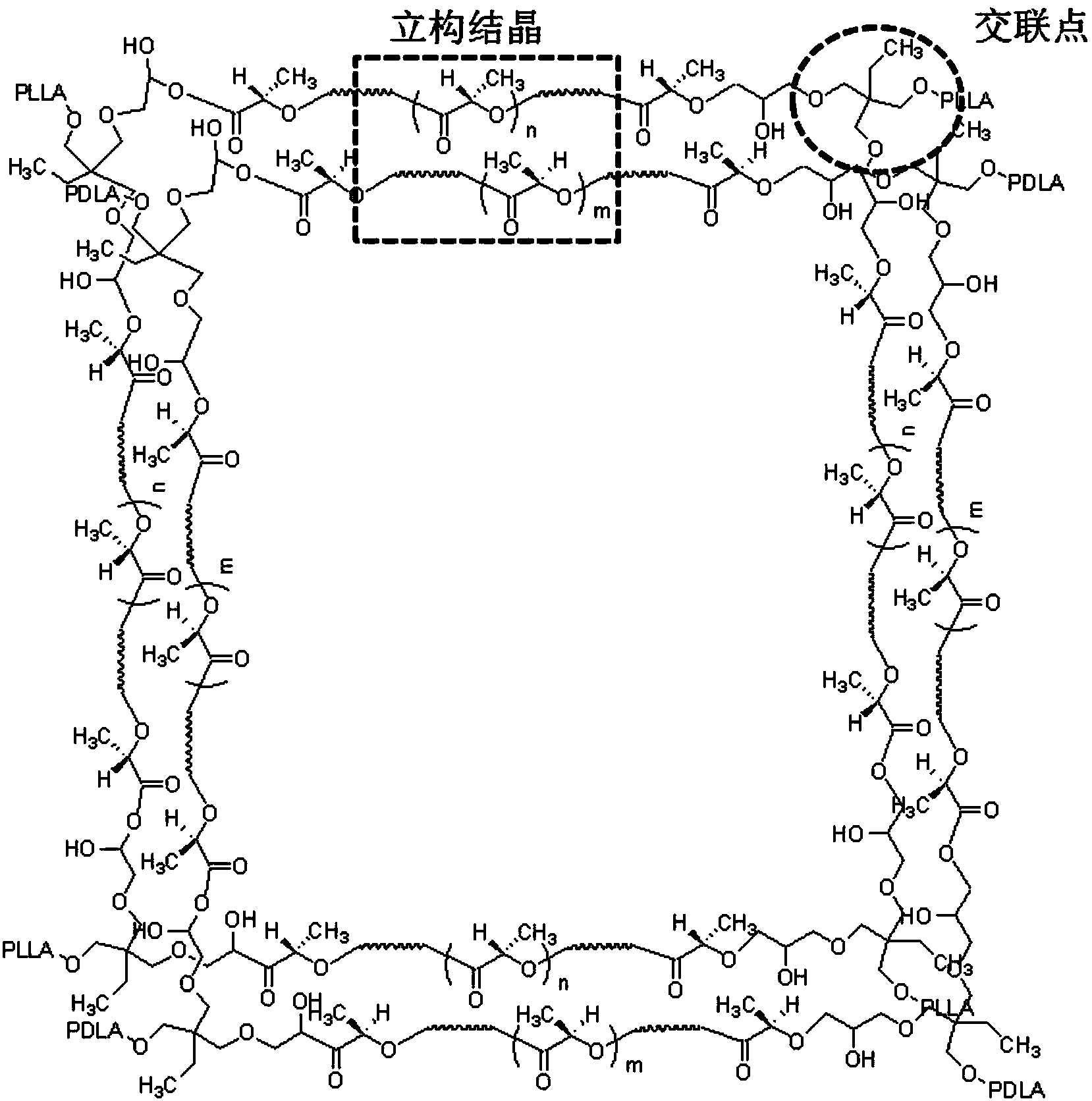

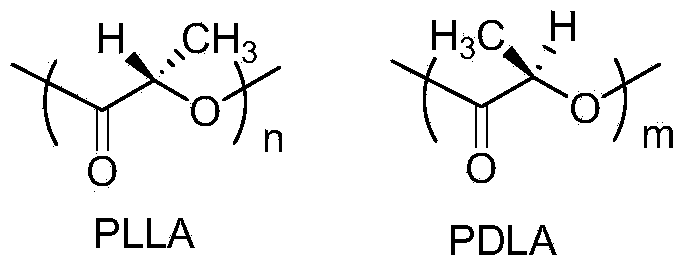

Poly lactic acid stereocomplex with interpenetrating network structure and preparation method thereof

The invention relates to a poly lactic acid stereocomplex with an interpenetrating network structure and a preparation method thereof, belongs to the technical field of high polymer materials, and aims to solve the problems that the conventional poly lactic acid stereocomplex is poor in thermal stability and low in heat-resistance temperature. The preparation method comprises the following steps: mixing L-lactide or D-lactide with an initiator, performing a polymerization reaction to obtain linetype PLLA or PDLA, and adding a cross-linking agent to obtain cross-linking PLLA or PDLA; when the cross-linking PLLA is adopted, adding the cross-linking PLLA into a mixture of D-lactide and the initiator, and heating to polymerize D-lactide to completely react; when the cross-linking PDLA is adopted, adding the cross-linking PDLA into a mixture of L-lactide and the initiator, and heating to polymerize L-lactide to completely react to obtain the poly lactic acid stereocomplex with the interpenetrating network structure. The poly lactic acid stereocomplex has the advantages of high heat-resistance temperature and excellent stability.

Owner:ZHEJIANG HISUN BIOMATERIALS

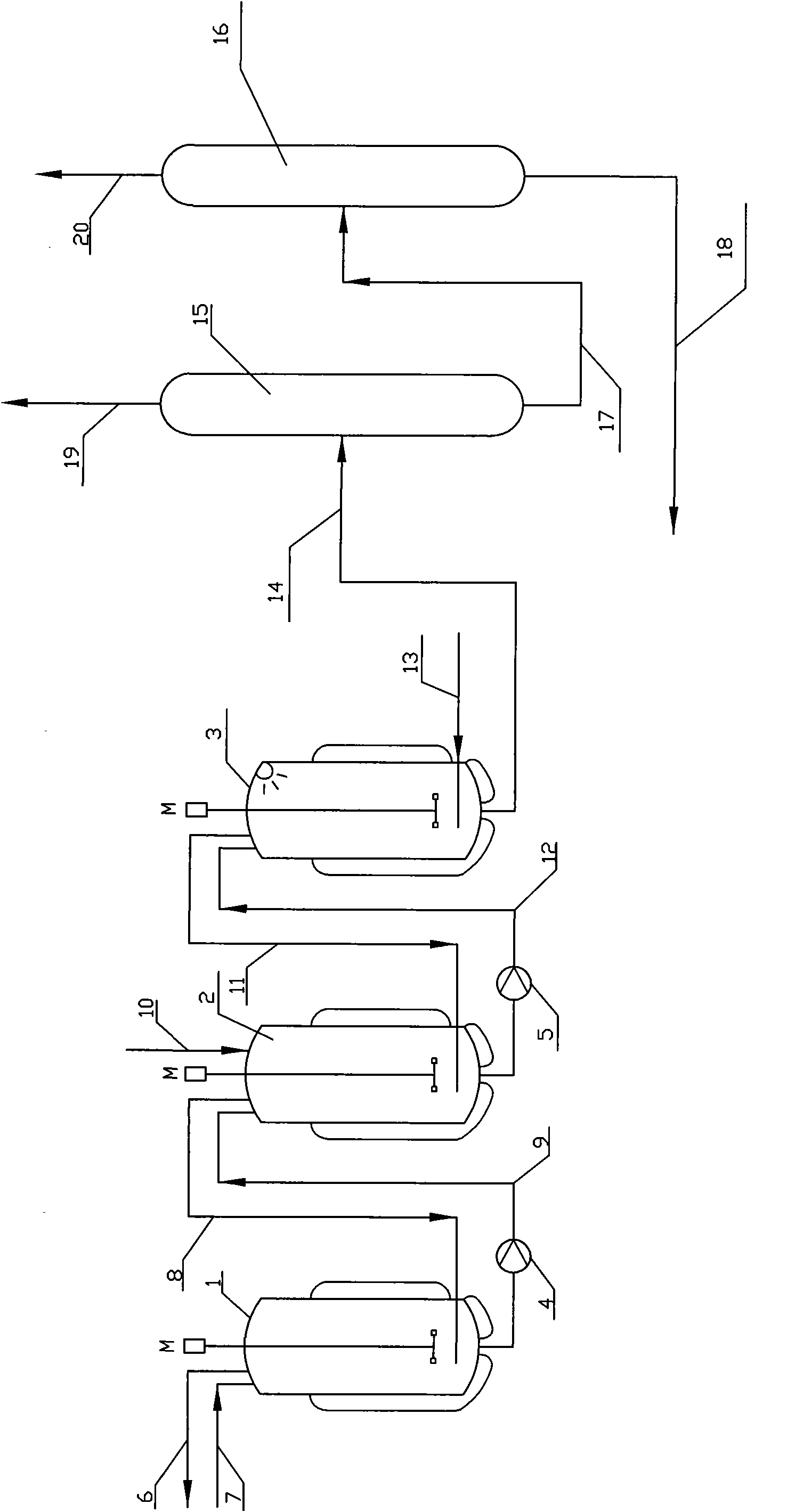

Production method of dichloropropanol

ActiveCN101805243AImprove conversion rateReduce dosagePreparation by halogen introductionBoiling pointDistillation

The invention relates to a production method of dichloropropanol, comprising the following reaction steps: glycerol reacts with gaseous HCl in the presence of organic carboxylic acid catalyst, reaction liquid reactant reacts with gaseous HCl in the presence of Lewis acid catalyst and then reacts with gaseous HCl again under the action of microwave and the stirring action; after passing through a low-boiling-point substance distillation tower and a rectifying tower, the mixture is prepared into the product of the invention. Compared with the prior art, HCl conversion rate is improved by about one time. When the combined catalysis technology of the invention is adopted, the dosage of the organic carboxylic acid catalyst is lowered by half, glycerol conversion rate is improved by 2%, and product yield is improved by 5%; and meanwhile, side reaction is reduced so as to avoid the defect that extra potentially toxic organic carboxylic acid side reaction generates a great quantity of waste, thus protecting environment.

Owner:NINGBO HUANYANG CHEM

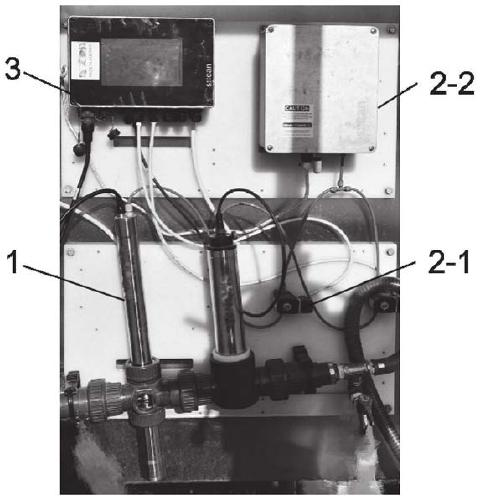

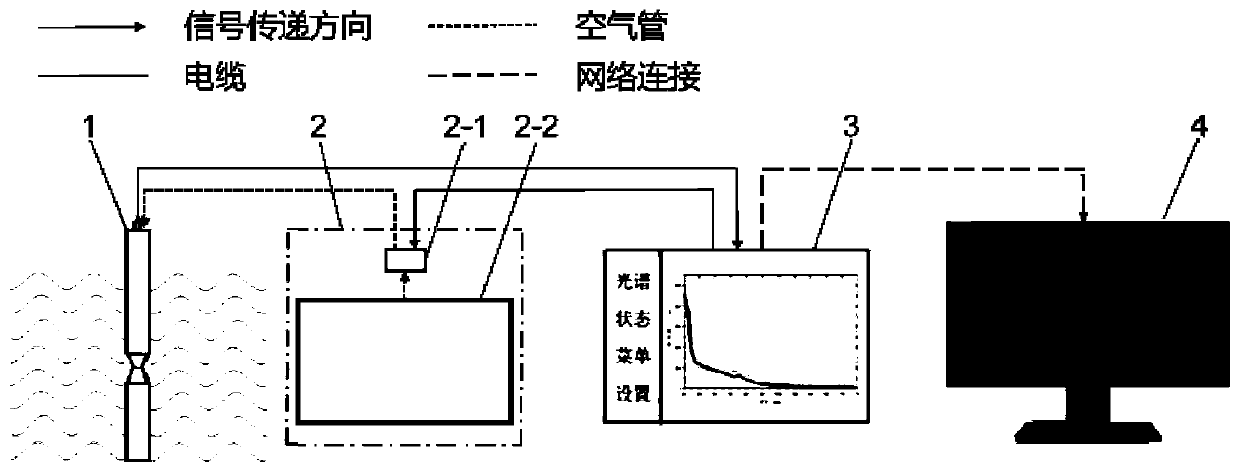

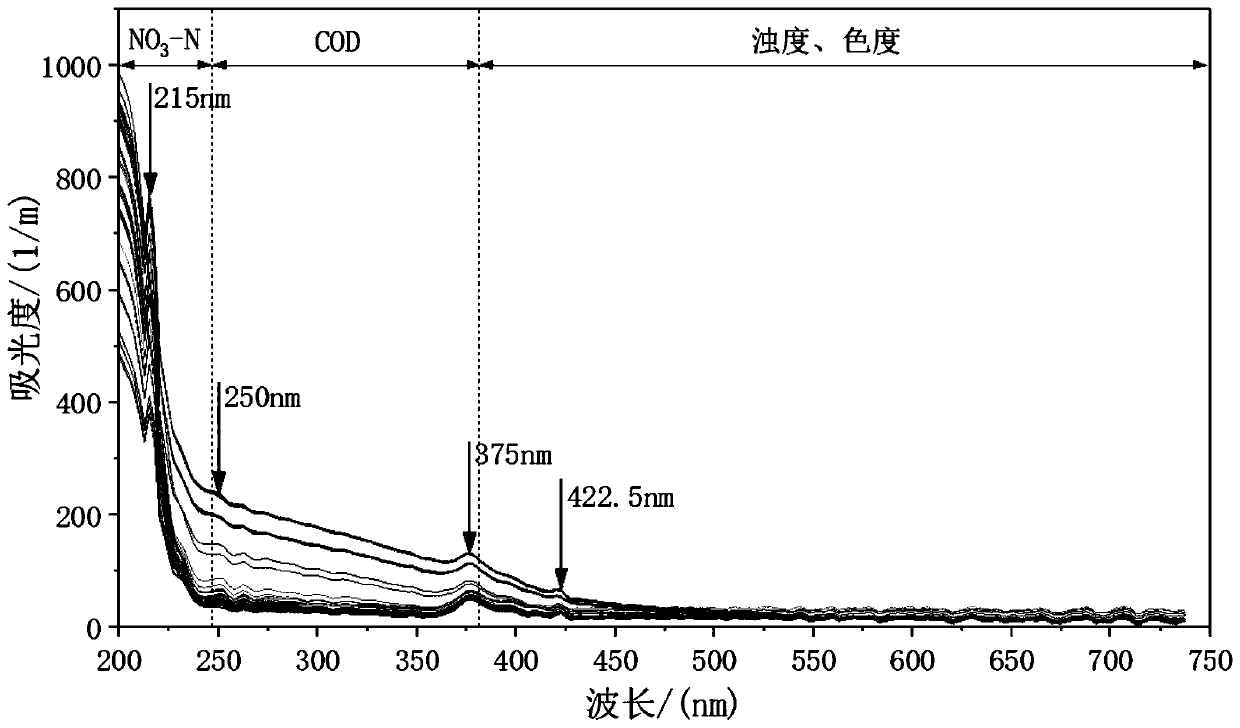

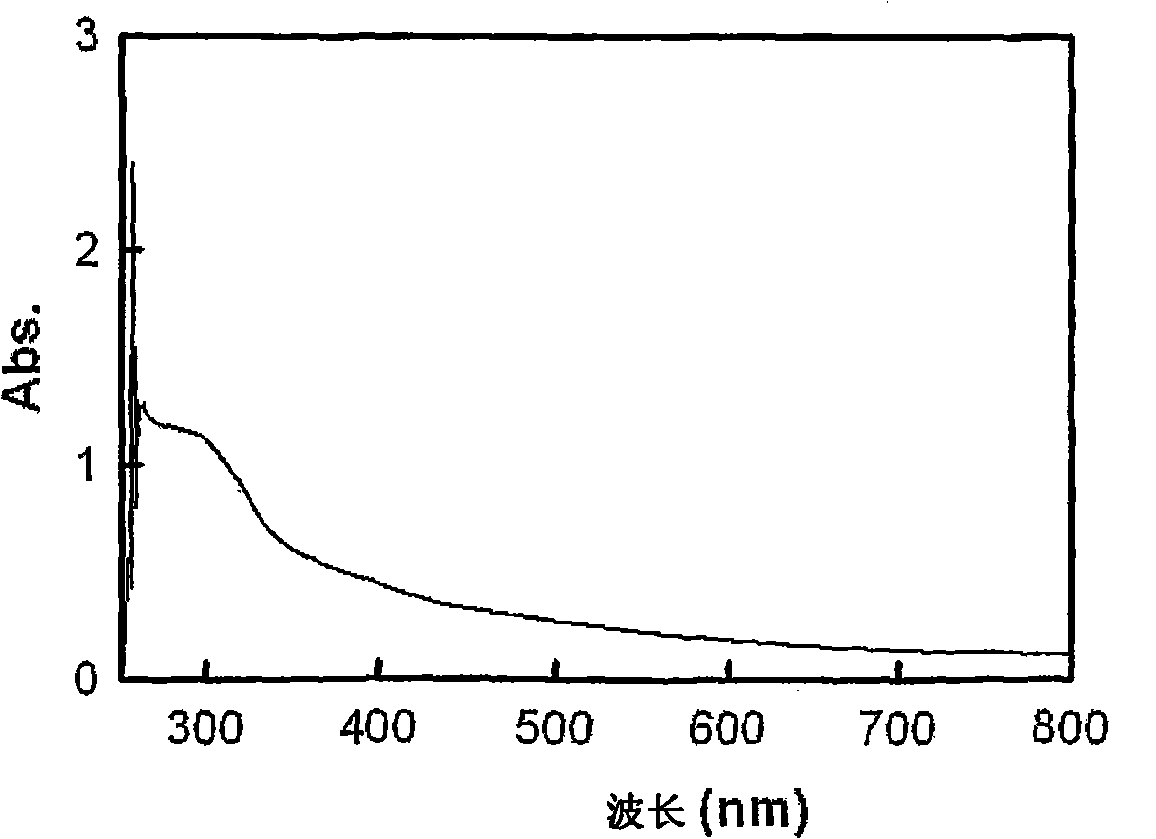

Ultraviolet-visible light full-wavelength scanning sewage quality online rapid detection method and application thereof

PendingCN111351762AAccurate Water Quality TestingShort detection timeGeneral water supply conservationTesting waterWater qualityPhysical chemistry

The invention relates to an ultraviolet-visible light full-wavelength scanning sewage quality online rapid detection method and an application thereof. A full-waveband spectrum detection system is used for carrying out full-waveband scanning on sewage, a water body is directly scanned in an immersion mode, and obtained spectral absorption information of the sewage is transmitted to the full-waveband spectrum detection system; an absorption full-spectrum chart of the sewage is calculated by utilizing the full-waveband spectrum detection system; a multiple regression equation of each to-be-detected substance is obtained by fitting through a multiple regression equation model by utilizing the full-waveband spectrum detection system, wherein the multiple regression equation model is as follows: Yn = A1 * x1 + A2 * x2 +... + A210 * x210 +... + An * xn (n = 215-217), Yn is a target parameter prediction value, and A1 to An are respectively a coefficient of a wavelength corresponding to each model. The full-waveband spectrum detection system is used for detecting water quality parameter values. The simultaneous detection of various substances is realized, the detection time is short and is15 seconds, and the result can be obtained.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

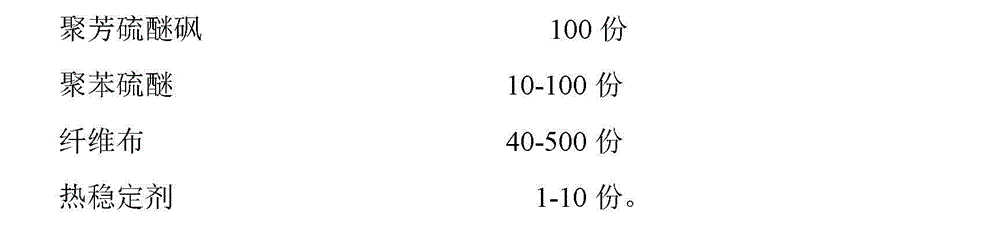

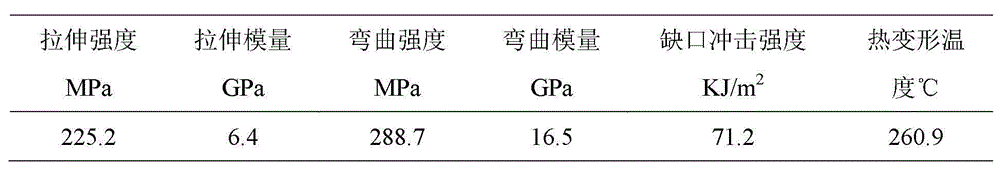

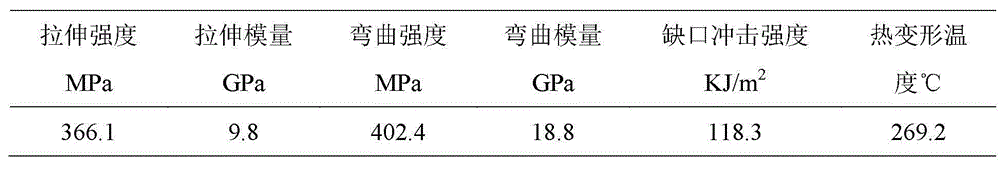

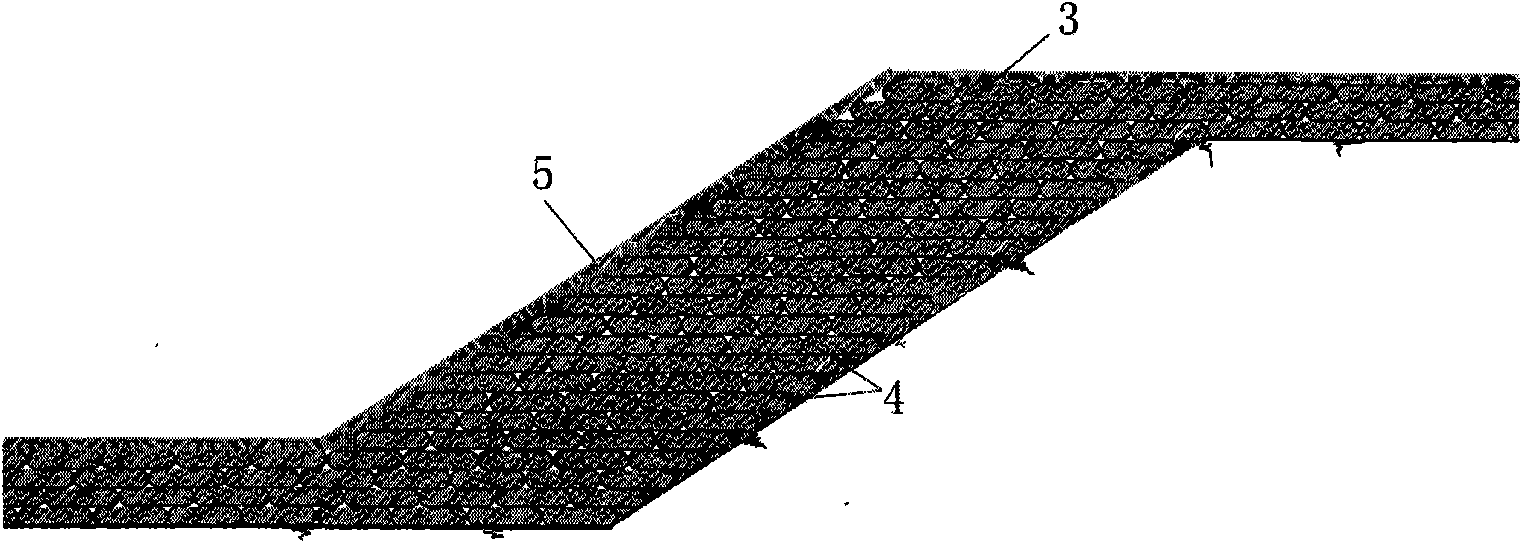

Fibre cloth reinforced modified polyarylene sulfide sulfone composite material and preparation method thereof

ActiveCN102876041AImprove processing fluidityAchieve friendlySynthetic resin layered productsLaminationFiberPolymer science

The invention discloses a fibre cloth reinforced modified polyarylene sulfide sulfone composite material and a preparation method thereof. The fibre cloth reinforced modified polyarylene sulfide sulfone composite material is characterized by comprising the following components in parts by weight: 100 parts of polyarylene sulfide sulfone resin, 10 to 100 parts of polyphenylene sulfide resin and 1 to 10 part(s) of heat stabilizer(s). The preparation method is characterized by comprising the following steps of: drying the components in an oven at a temperature of 100-150 DEG C for 6 to 8 hours, and blending the components in a highly blending machine; fusing and extruding the blended components in a twin-screw extruder at a temperature of 290 to 340 DEG C for pelleting, and drying pellets at a temperature of 100-150 DEG C for 6 to 8 hours; extruding the pellets by a single-screw extruder at a temperature of 290-340 DEG C, and sizing the pellets through a three-roller calender to obtain membranes; alternatively overlapping the membranes with fibre cloth in a sequence of A-layer to B-layer unit structures to form a fibre cloth reinforced polyarylene sulfide sulfone composite layer, wherein A layers are the polyarylene-sulfide-sulfone-based blend membranes, and B layers are the reinforced fibre cloth; and preforming hot pressing on the composite layer at a temperature of 290-360 DEG C and at a pressure of 10-40 MPa for 10 to 40 minutes, and cooling and taking out the composite layer at a temperature of 230 DEG C, thus obtaining the fibre cloth reinforced composite material.

Owner:JIANGSU JICUI ADVANCED POLYMER MATERIAL RES INST CO LTD

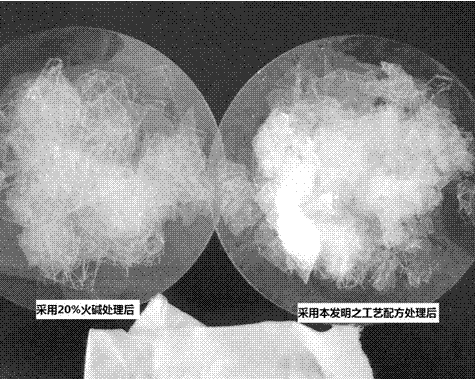

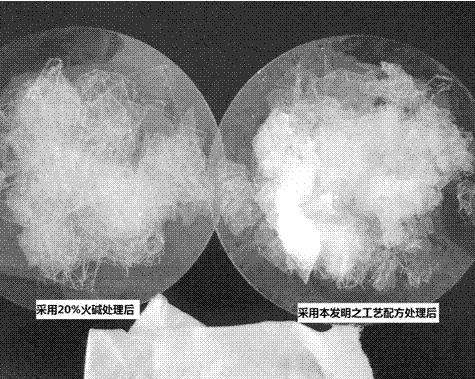

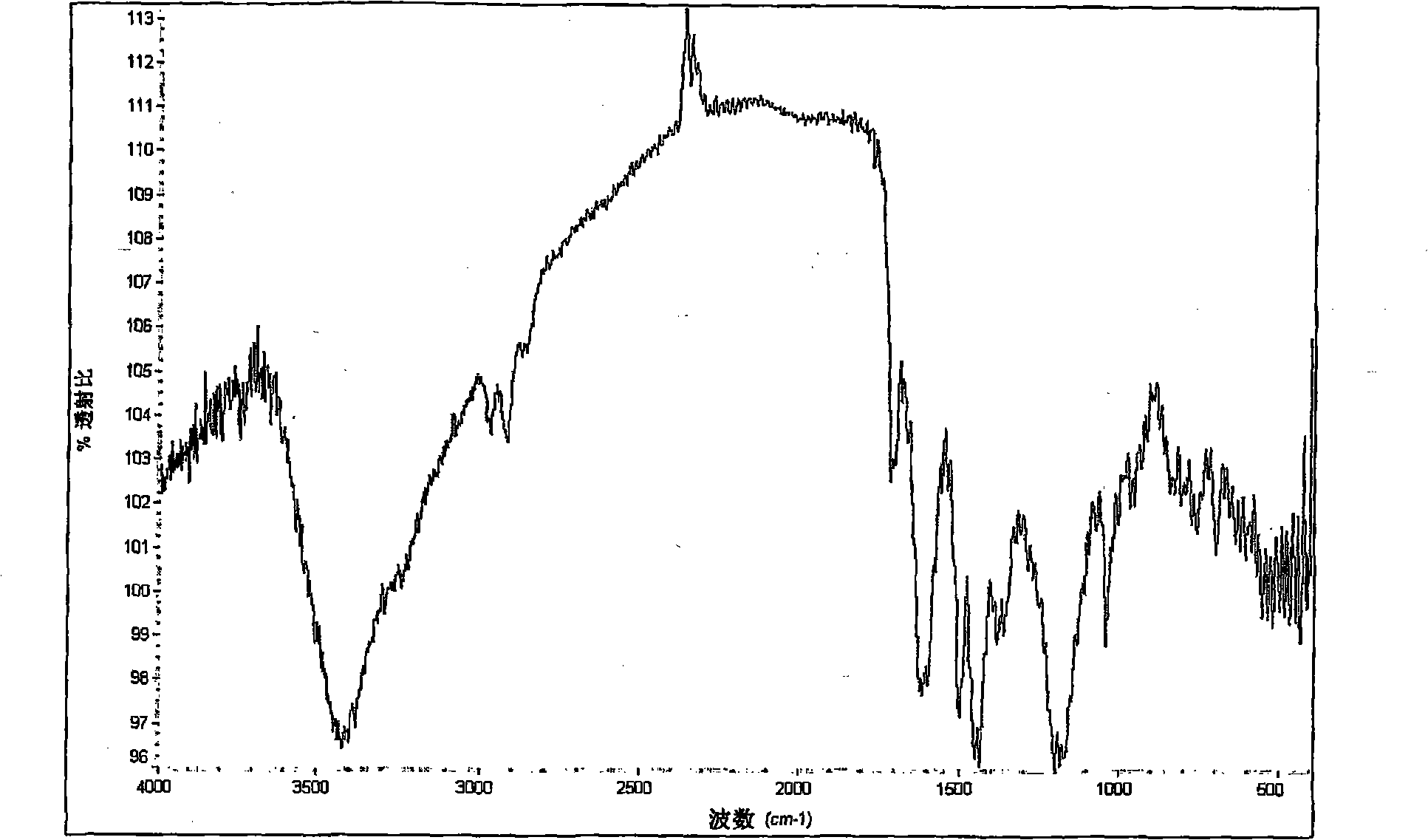

Method for removing surface coating of reflective PET (Polyethylene Terephthalate) aluminium plating film

The invention relates to a PET (Polyethylene Terephthalate) reflective film, in particular to a method for removing the surface coating of a reflective PET aluminium plating film. The method is characterized by comprising the steps of: immersing the reflective PET aluminium plating film into a cleaning solution, and heating at the temperature of 40-100 degrees centigrade, rinsing by using clean water to remove the coating adhered on the PET surface, and airing to obtain the recyclable PET film. The recycled PET film is colourless and transparent on the appearance and has the intrinsic viscosity being about 0.723; the melt strength of the recycled PET film can satisfy requirements of PET extrusion-blown molding (bottle) or even extrusion blown film; and in the same extrusion technological conditions, the intrinsic viscosity of the PET film, which has a yellow appearance and is recycled by using the traditional method of hermetically boiling by using 20% caustic soda at high temperature for more than 24 hours, is reduced to about 0.564 and cannot satisfy the requirements of the extrusion-blown molding (bottle). The test in the invention proves that the method has the advantages of high-efficiency technology, time / water / electricity-saving performance, environment friendliness, zero discharge of waste water and practicability, is benefiical to realization of recycle of the reflective PET aluminium plating film, and is suitable for recycling and practical.

Owner:CHANGZHOU VOCATIONAL INST OF ENG +1

Method for extracting ellagic acid in pomegranate peel residue by using biological enzyme

The invention discloses a method for extracting ellagic acid in pomegranate peel residue by using biological enzyme, belonging to the fields of food, medicine and chemical engineering. The method takes the pomegranate peel residue as raw material and water as solvent, and can be used for preparing the ellagic acid by using the biological enzyme. Biological compound enzyme of degradable ellagitannin can be used for carrying out enzymolysis reaction on the ellagitannin, and alkaline liquor is used for stopping the enzymolysis reaction; simultaneously, an alkaline water system can be formed for extracting the ellagic acid, and crude product of the ellagic acid can be obtained; and the extraction rate of the ellagic acid reaches 12.69-24% based on the content of the ellagitannin obtained in the step (1). The method has simple and continuous technique, environment-friendly manufacturing process, environmental protection and less discharge of the three wastes, and is suitable for large-scale industrialized production.

Owner:CHINA AGRI UNIV

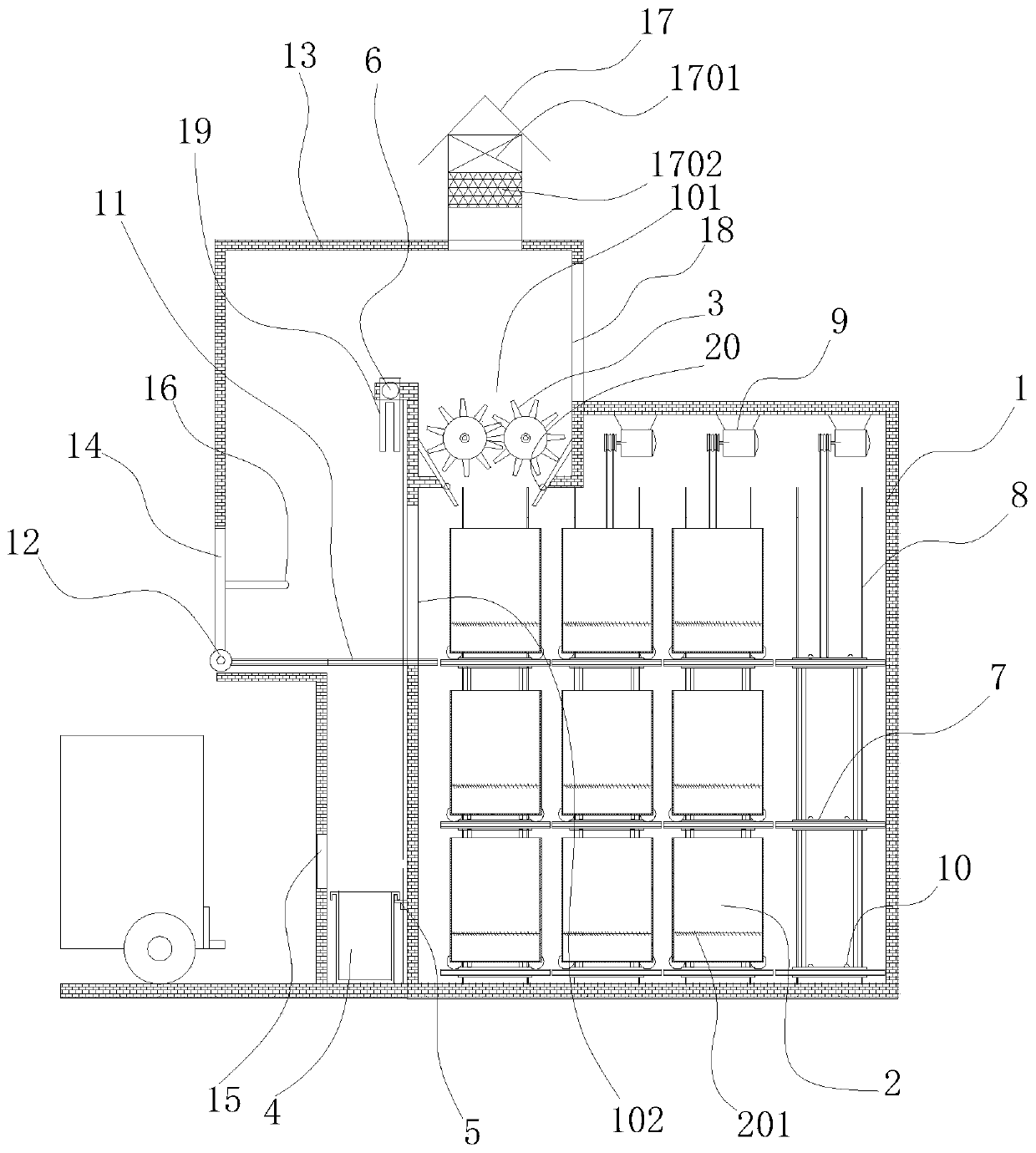

Community household waste pretreatment and temporary storage workstation

ActiveCN110304365AAvoid the problem of easy fermentation and odorPrevent floodingWaste collection and transferRefuse receptaclesDisinfectantPre treatment

The invention discloses a community household waste pretreatment and temporary storage workstation which comprises a first isolation bin (1) and multiple rows and multiple columns of waste storage boxes (2) with horizontal moving and lifting functions. Liquid leakage and storage structures (201) are arranged in the waste storage boxes (2); a feeding structure (101) is arranged on one side of the upper part of the isolation bin (1); a crushing device (3) is arranged in the feeding structure; and a disinfectant and preservative spraying device is arranged under the crushing device. The communityhousehold waste pretreatment and temporary storage workstation is further provided with a waste storage box outward-transporting structure (102), a lifting device (5) for lifting a classified waste classifying and holding device (4), and a turnover device (6). The community household waste pretreatment and temporary storage workstation provided by the invention has a joint function of waste classifying, throwing, large-scale temporary storing, has a crushing function, has multiple anti-ferment corrosion and mildew measures, is beneficial to reducing odor generation and emission and preventingfoul-smelling liquid from flowing disorderly, and is clean and environmental-friendly; meanwhile, pretreatment can be provided for a household waste classifying vehicle, so that classification operation can be conveniently carried out; and the problem of inconvenience in treating large waste at present can be solved.

Owner:ZHEJIANG MEDICAL COLLEGE

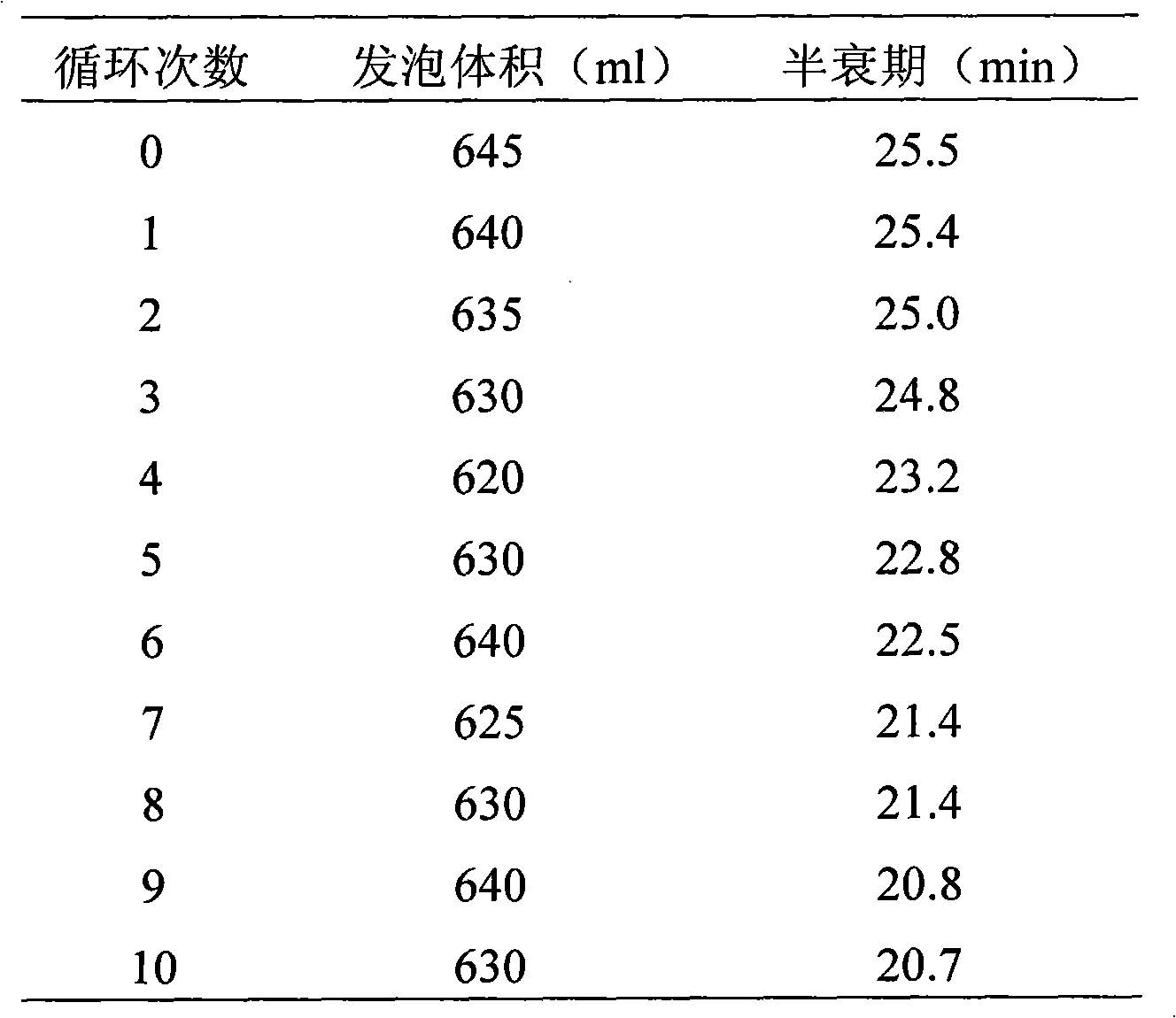

Recyclable foam base fluid for sand-washing well

InactiveCN102031098AAchieve friendlyLow foaming abilityDrilling compositionPropanoic acidSurface-active agents

The invention provides a recyclable foam base fluid for a sand-washing well, comprising an N-alkyl-beta-amino propionic acid type amphoteric surface active agent and water, wherein the molecular formula of the N-alkyl-beta-amino propionic acid type amphoteric surface active agent is RNHCH2CH2COOM, wherein R is straight-chain alkyl group, and M is sodium ion or ammonium ion; and the ratio of partsby weight of the N-alkyl-beta-amino propionic acid type amphoteric surface active agent and water is (0.1-0.6):100. By utilizing the recyclable foam base fluid, the operation cost for foam sand-washing well can be reduced, and the environment-friendly performance can be realized.

Owner:CHINA NAT OFFSHORE OIL CORP +2

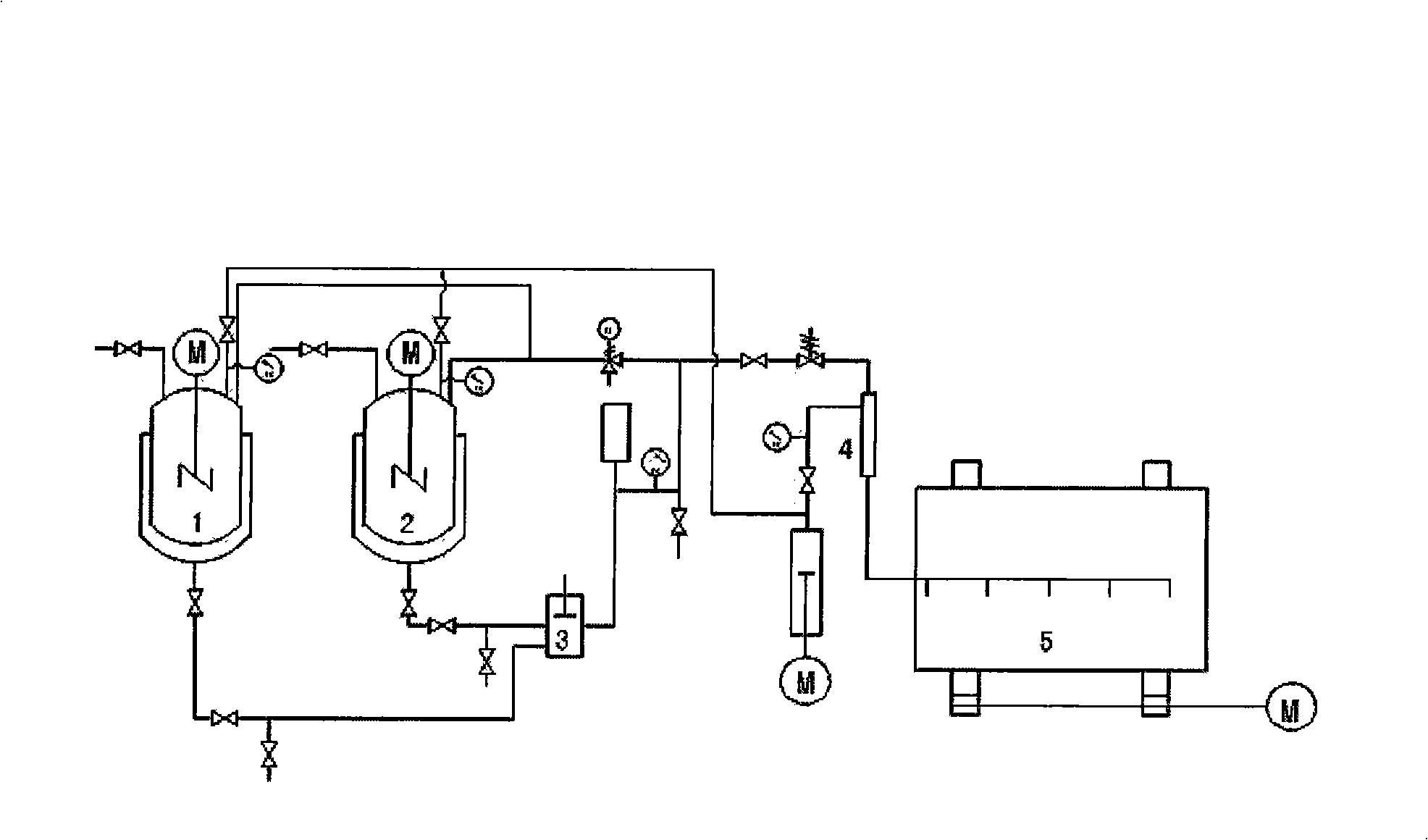

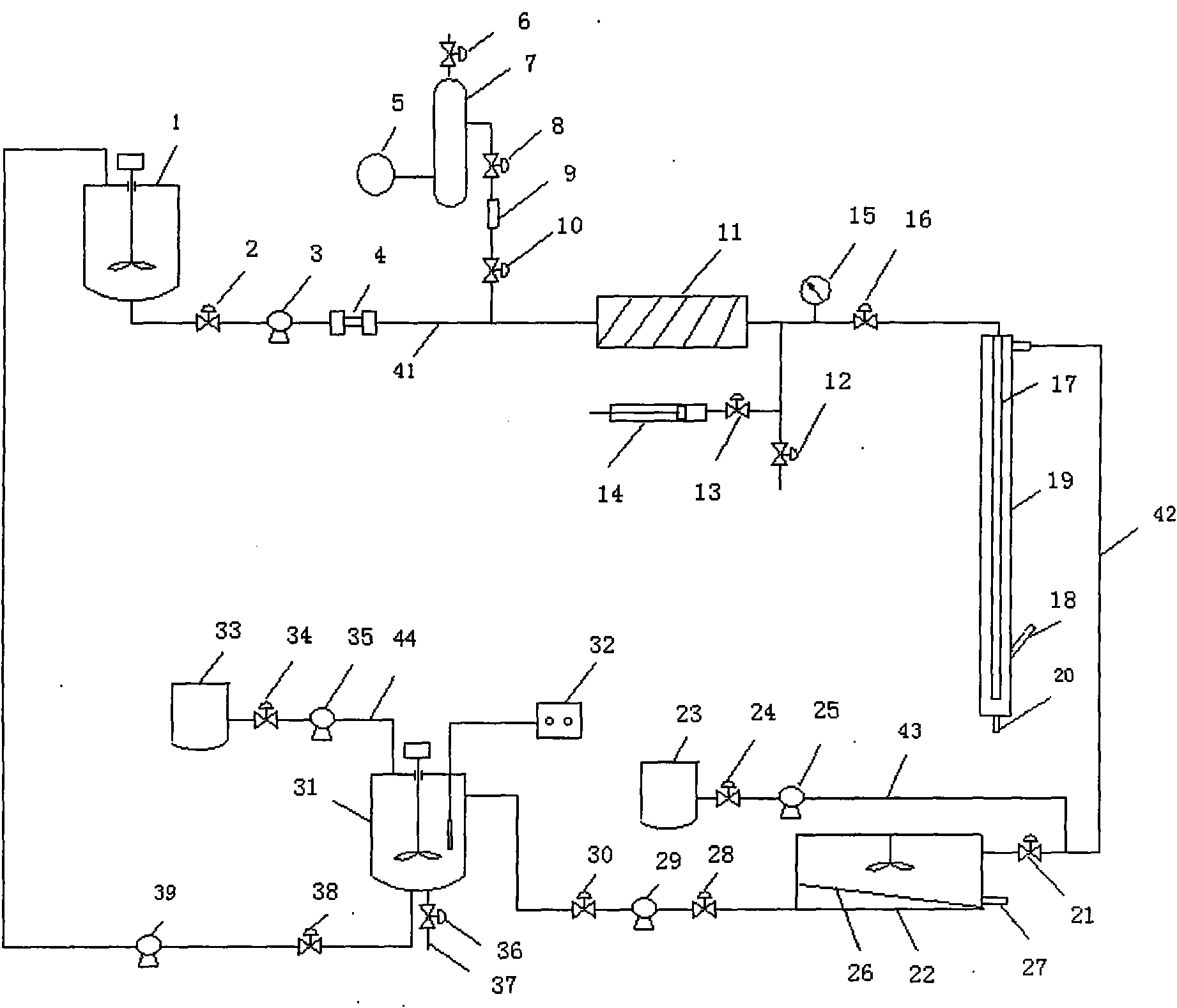

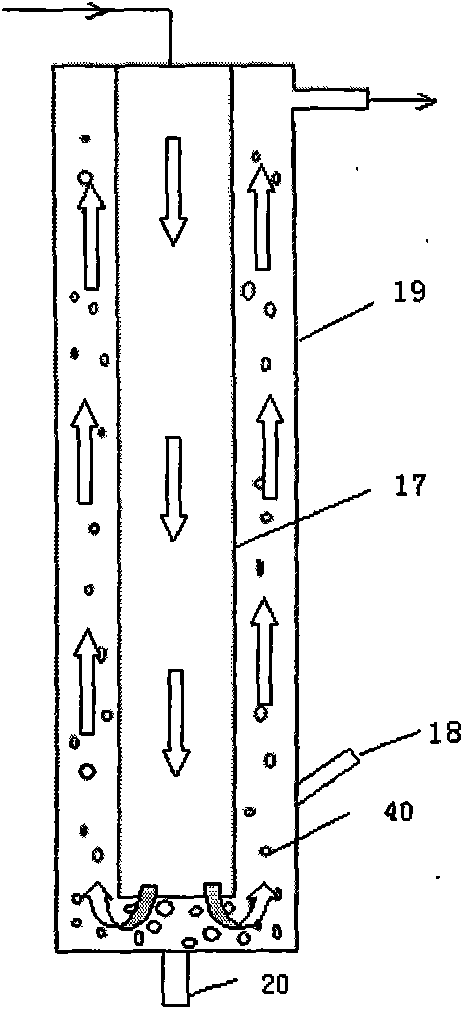

Nano emulsion of peroxide vulcanized fluororubber and polymerization method thereof

The invention discloses a production method of a peroxide vulcanized fluoroelastomer, which comprises the following steps: 1. preparing three fluorine-containing monomer gases, a dispersant, a peroxide vulcanization point monomer, an initiator, a chain-transfer agent, a pH regulator and deionized water; 2. regulating pH value of a dispersion solution mixed from the deionized water, dispersant solution, initiator, chain-transfer agent and pH regulator, evacuating, replacing with nitrogen until the oxygen content is acceptable, and pouring the dispersion solution into a polymerization kettle; 3. collecting the three fluorine-containing monomer gases to a pressostat to keep the pressures of the three gases constant in the pressostat; 4. respectively passing the three fluorine-containing monomer gases through an adjusting valve and a mass flowmeter, evenly mixing in a static mixer, compressing to reaction pressure by a molding press, and sending into the polymerization kettle; 5. adding the peroxide vulcanization point monomer into a measuring pump; and 6. adding the peroxide vulcanization point monomer into the polymerization kettle to perform polymerization reaction with the three fluorine-containing monomer gases in the dispersion solution.

Owner:江苏梅兰化工有限公司

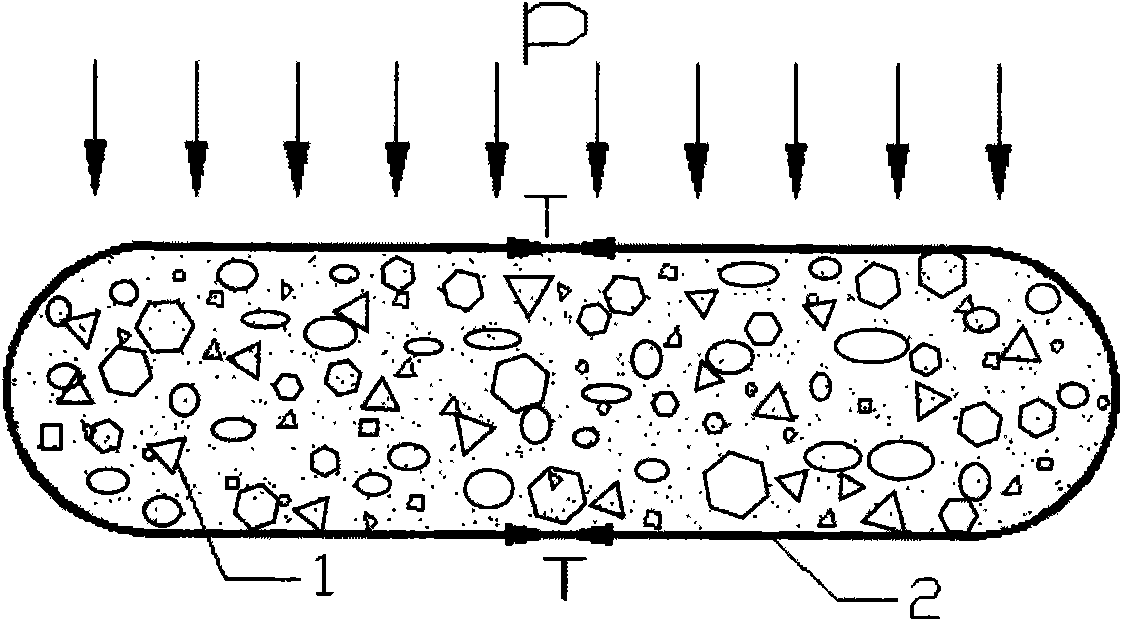

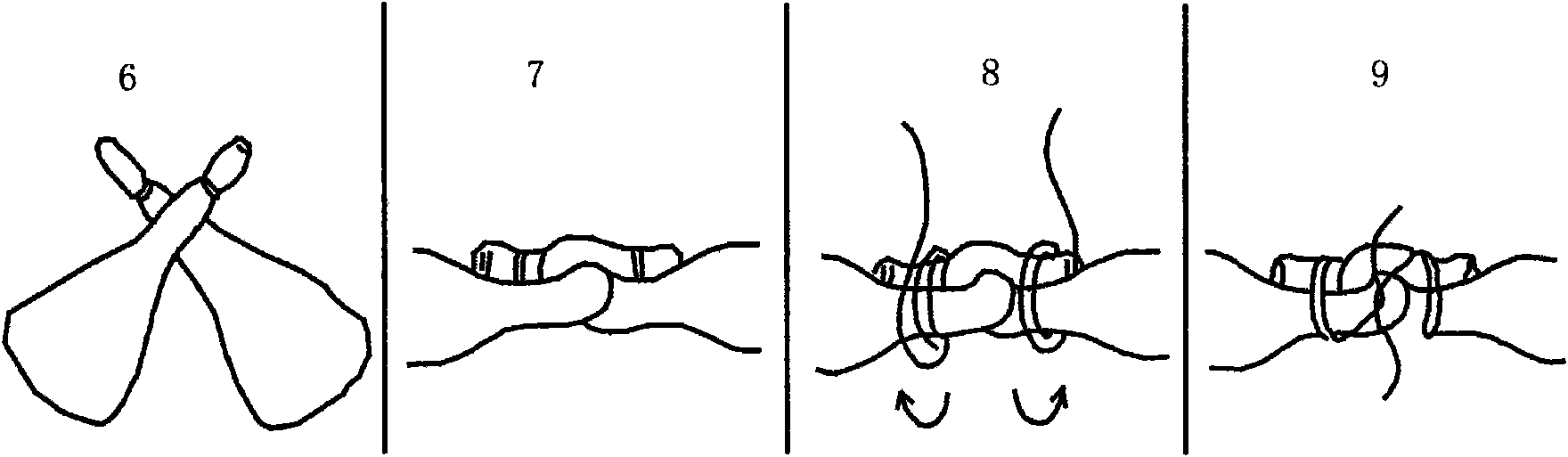

Solid waste earthwork bag and application method thereof

ActiveCN101684652AOmit landfillReduce soil borrowingArtificial islandsRoadwaysFreeze thawingUltimate tensile strength

The invention relates to a solid waste earthwork bag of engineering construction wastes, industrial wastes, stones, dregs and soils of mine tailings, and the like that have no chemical pollutions as well as an application method thereof in a foundation and a side slope. Available crushed solid wastes are directly put into the earthwork bags which are specified strictly, and the solid waste earthwork bags are then piled on the engineering construction foundation and the side slope according to a certain arrangement way and compacted layer by layer by a compacting device to form a building foundation or be used for reinforcing the side slope. As the solid waste soil body restricted and the vibration energy is consumed by the tensile force generated by the compression deformation of the earthwork bag, the whole strength and the shock absorption performance of the solid waste earthwork bag are improved. The solid waste earthwork bag is applied to foundation engineering, saves the resourcesand the land, reduces the vibration, prevents the disaster and the freeze thawing, is green and environment-friendly and has remarkable benefits.

Owner:刘斯宏 +2

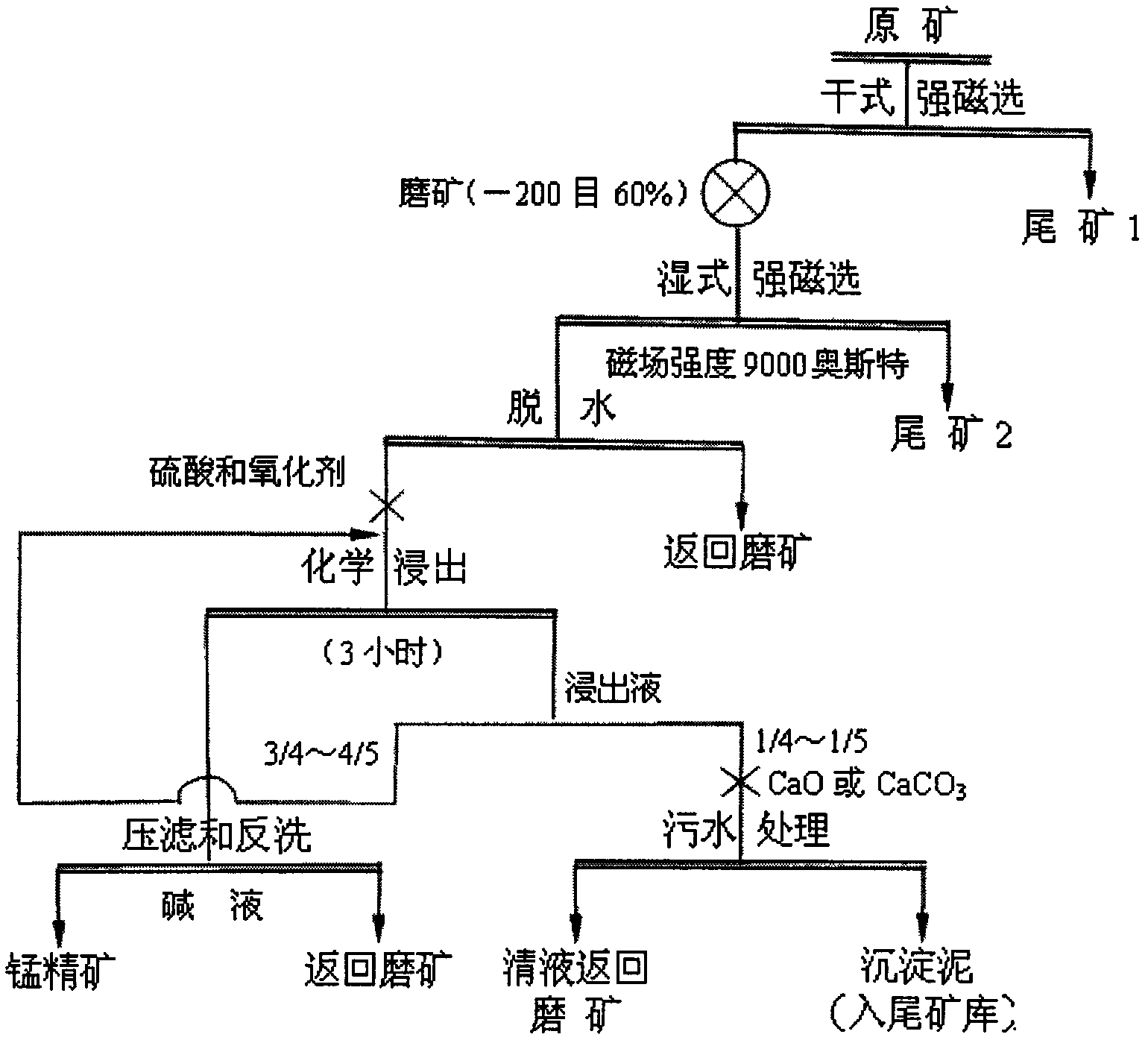

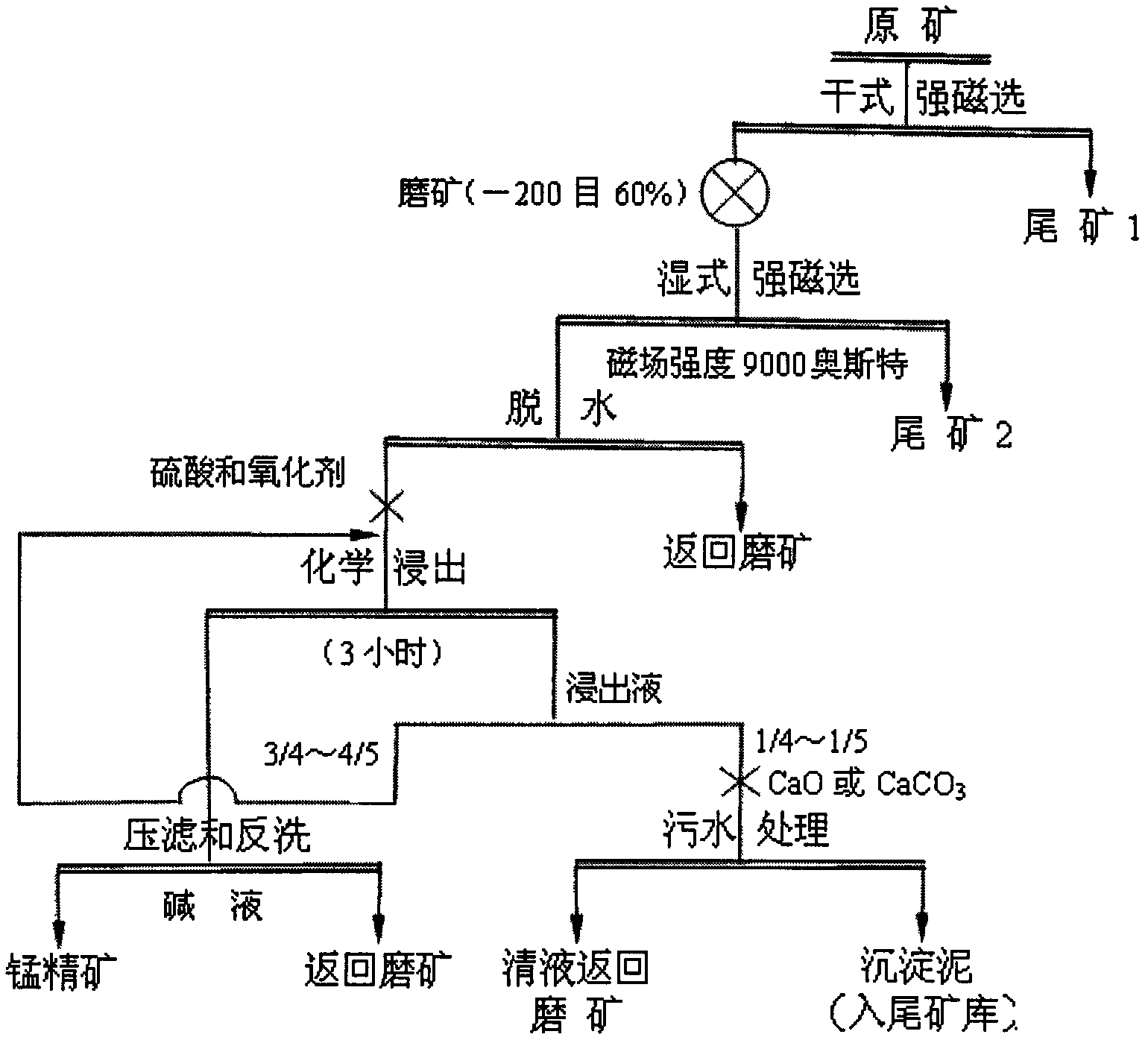

Beneficiation method for high armangite

InactiveCN102174672AReduce the amount of ore entering the grindingAchieve friendlyProcess efficiency improvementWet separationWater useManganese

The invention discloses a beneficiation method for high armangite. The method comprises the following steps of: performing dry-type strong magnetic separation with the magnetic field intensity of 12,000 to 14,000 oersted on the high armangite which comprises 35 to 39 weight percent of manganese and 4 to 6 weight percent of arsenic and serves as a raw material; finely grinding until 60 weight percent of high armangite has the particle size of -0.074 mm by using a ball mill; performing wet-type strong magnetic separation with the magnetic field intensity of 8,000 to 10,000 oersted; performing awet-type chemical extraction reaction by using acid for 2 to 4 hours; and performing neutralization treatment on precipitates by using alkali liquor to obtain a manganese concentrate product which comprises more than or equal to 53.81 weight percent of manganese and less than or equal to 0.35 weight percent of arsenic, wherein the total recovery rate of the manganese is more than or equal to 80 percent. The technology is simple in process flows, and the method is applied to the treatment of minerals similar to tilasite CaMg (F / AsO4); operation wastewater is returned to ore grinding operation for recycling, so that water used during production is saved; leaching residues are treated by calcium salt to meet the emission standard, so that the method is environment-friendly; and the method isrelatively high in economic benefits, social benefits and ecological benefits.

Owner:广西壮族自治区地质矿产测试研究中心

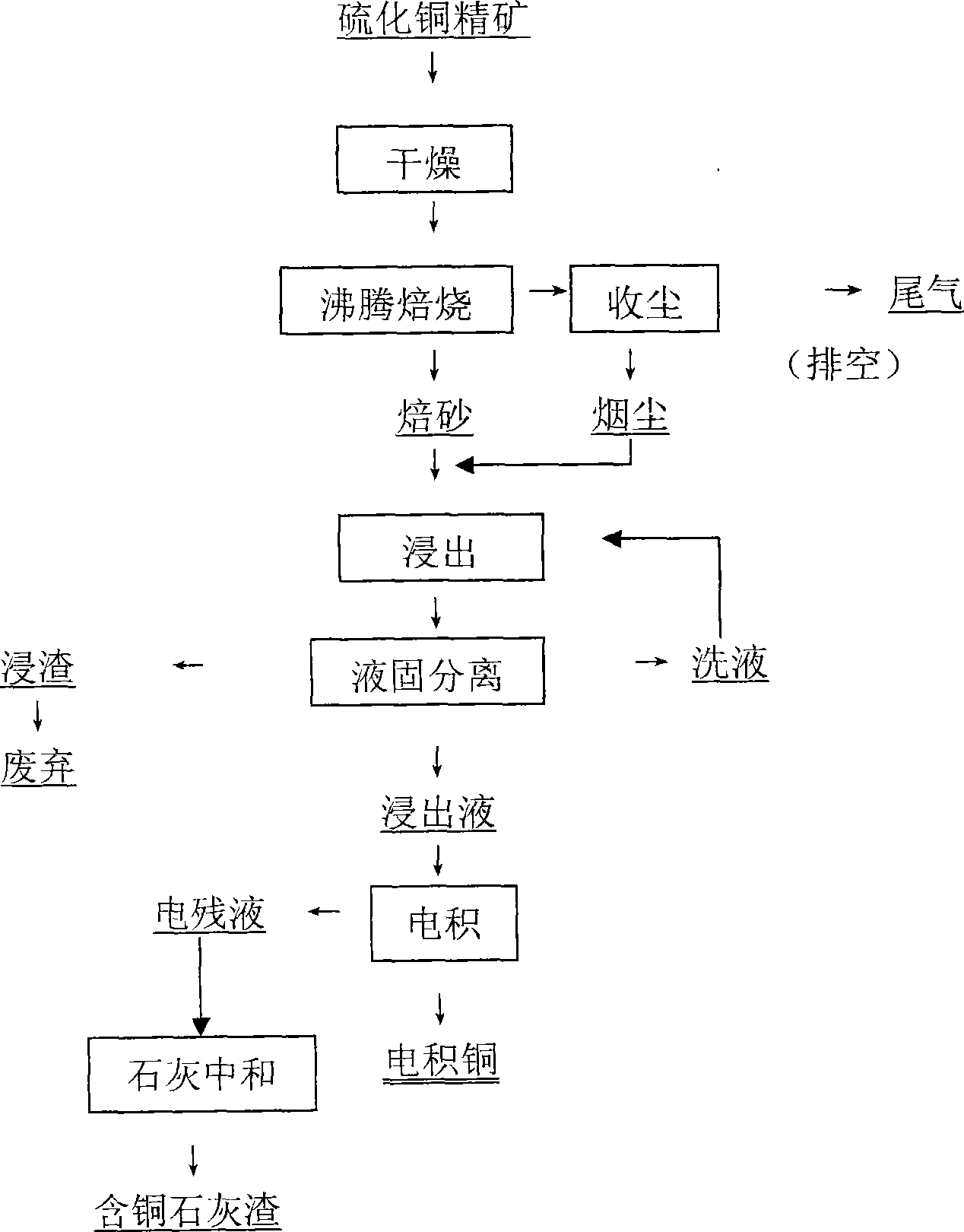

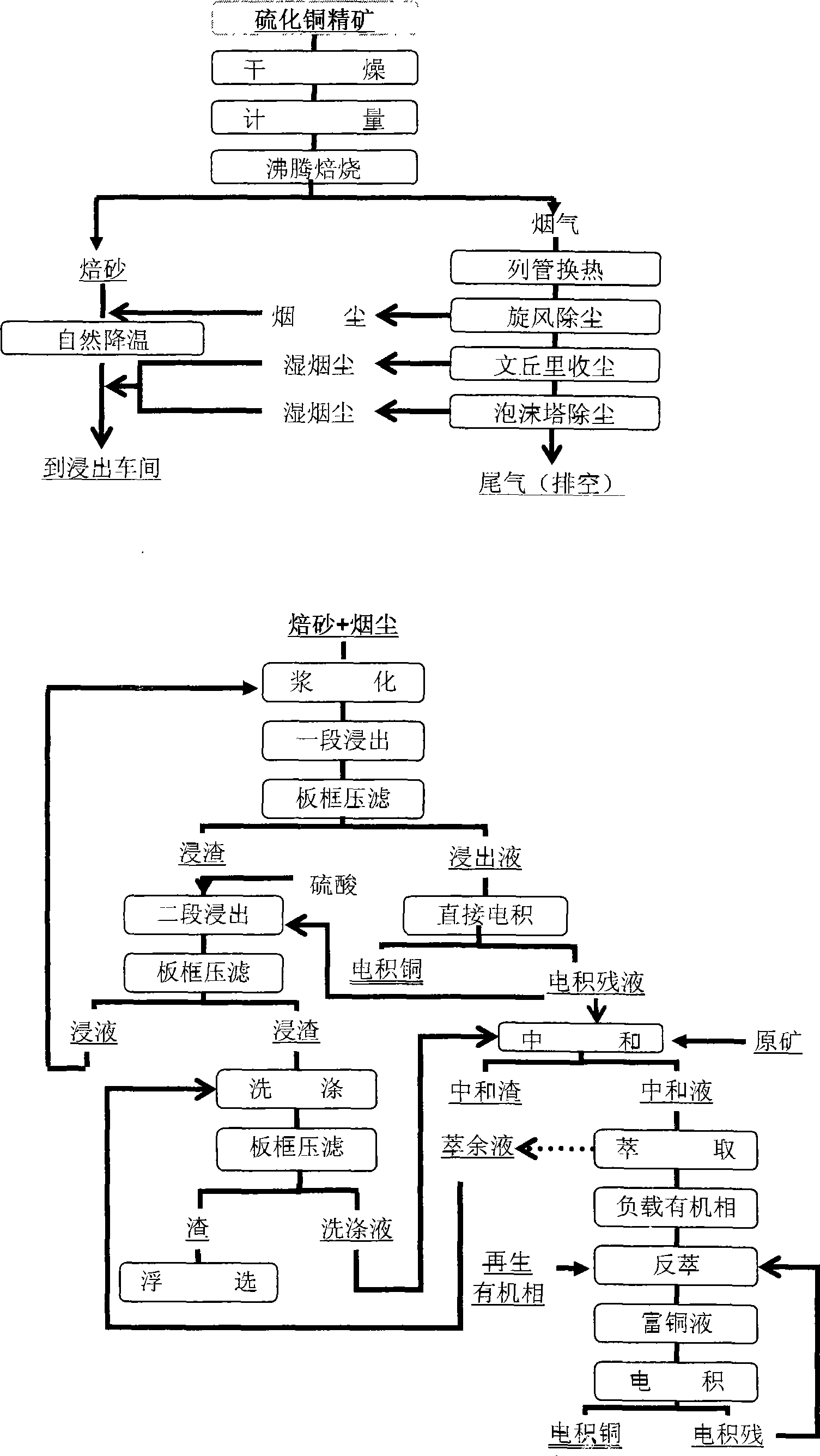

Technique for extracting copper from high-calcium high-magnesium cupric sulfide by wet method

InactiveCN101440434AAvoid dischargeReduce leaching acid consumptionProcess efficiency improvementWater balanceCalciums magnesium

The invention relates to a process for extracting copper from high calcium-magnesium copper sulphite by a wet method. The process uses large amount of calcium oxide and magnesium oxide in mineral to absorb sulfur dioxide gas generated during roasting to reach the effect of self-cleaning roasting, and uses the primary mineral to neutralize redundant immersion liquid and electrolytic residual liquid for extraction to reach water balance and acid balance. At the same time, the process makes full use of copper concentrate containing sulfur, does not need to increase additional fuel, coverts the sulfur to sulfate radical at the same time, reduces acid loss during roasting and leaching, and improves leaching rate. The process overcomes multiple defects in the prior process, and combines main advantages of wet processing. Shown by test results, the leaching rate of cupric acid is more than 99 percent, integrative reclaiming rate of copper is more than 96 percent, rate of dregs is smaller than 40 percent, the weight of electrolytic copper is more than 99. 95 percent, all technical indexes reach domestic advanced level, and tailings are comprehensively utilized, so the process is environment-friendly.

Owner:昆明金湖冶金有限公司

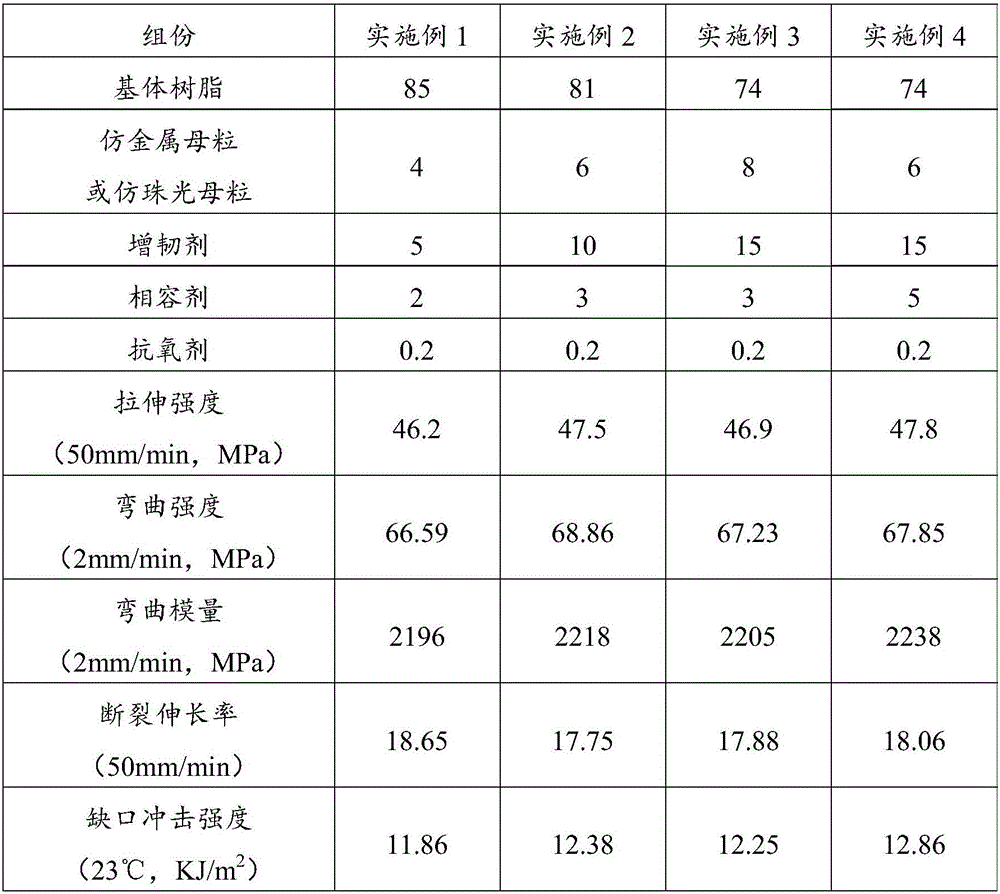

Resin material and preparation method thereof

The invention discloses a resin material and a preparation method thereof. The resin material is prepared from, by weight, 45-85 parts of matrix resin, 2-8 parts of color master-batches, 5-15 parts of flexibilizer, 1-5 parts of compatilizer and 0.05-0.4 part of antioxidant. The color master-batches comprise imitation metal master batches or imitation pearl master batches. According to the technical scheme, the situation that a product with a metal or pearl quality appearance effect can be obtained through direct injection moulding by means of the resin material can be achieved, the production efficiency of imitation metal plastic products and imitation pearl plastic products is improved, energy consumption and the comprehensive cost are reduced, and the resin material is environmentally friendly.

Owner:深圳市前海同益科技研发有限公司

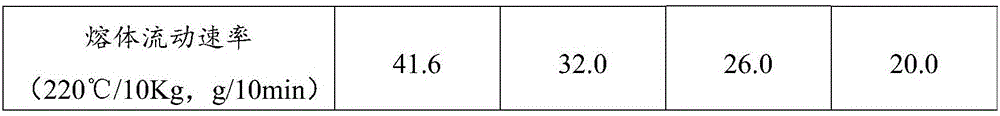

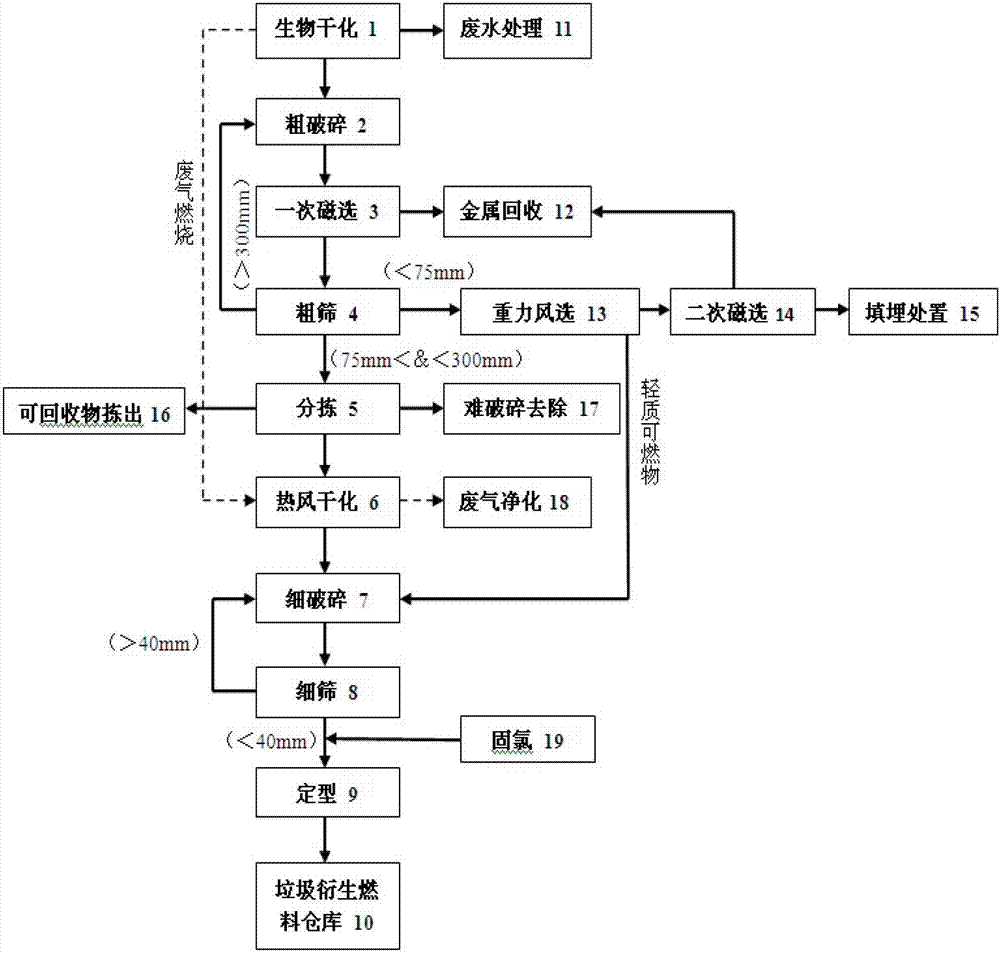

Biological / mechanical technique for preparing high quality refuse derived fuel

ActiveCN103074138AHigh calorific valueImprove stabilitySolid waste disposalBiofuelsRefuse-derived fuelCoupling

The invention discloses a method for preparing high quality refuse derived fuel. The method comprises the following steps: biological drying, coarse crushing, first magnetic separation, riddle, sorting, hot air drying, fine crushing and shaping. A biological and mechanical coupling technique is employed to achieve source tempering of household refuse, substantially reduce harmful components in the refuse, increase calorific value, reduce the preparation cost on RDF, and realize more industrial application value. The method provided by the invention has a variety of effects and advantages, can prepare refuse derived fuel with high calorific value and low pollution at low thermal power and improve stability and applicability of the whole system, conforms to the requirements of sustainable development, conserves resources and protects environment.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com