Recyclable foam base fluid for sand-washing well

A foam and base fluid technology, applied in the field of recyclable foam base fluid, can solve the problems of large amount of waste, unfavorable environmental protection, increase the cost of foam sand flushing and well cleaning, etc., and achieve the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

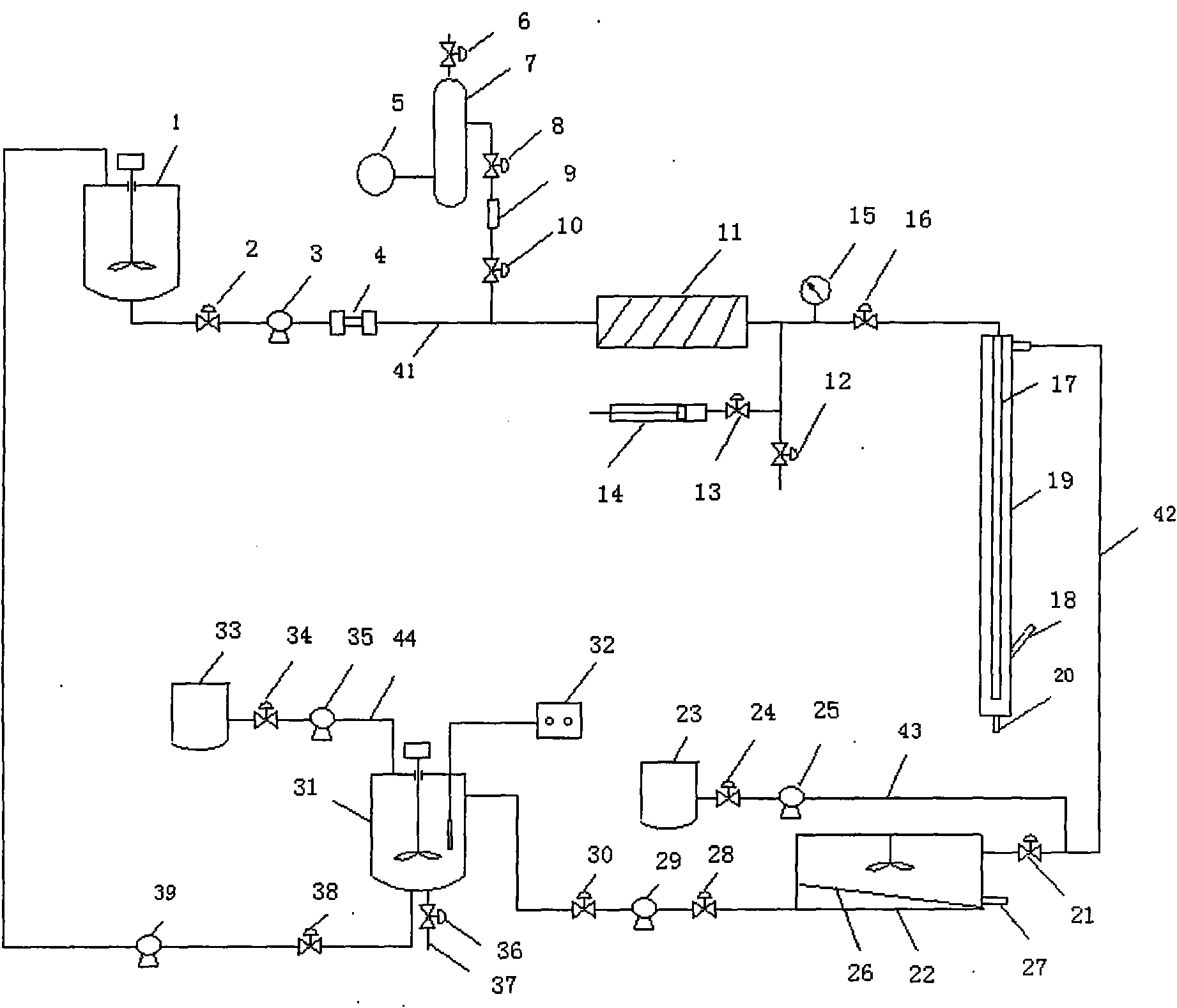

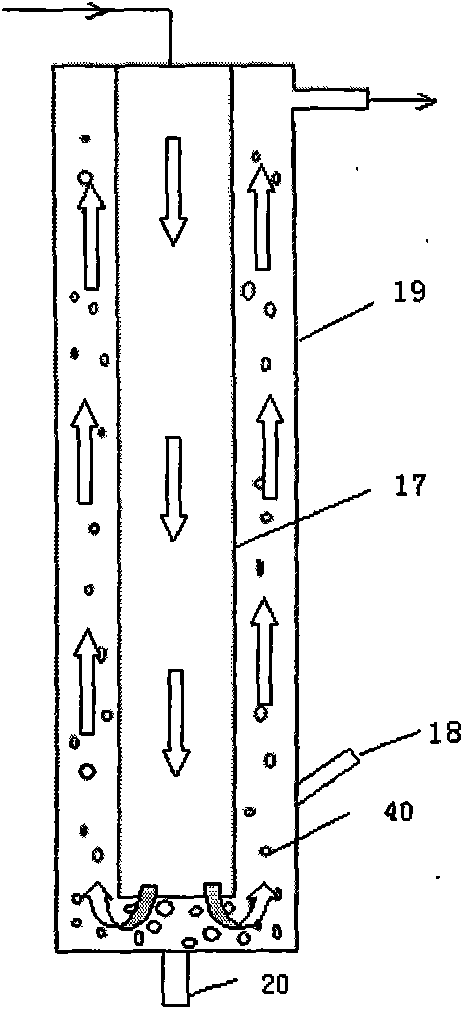

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1, the preparation of recyclable foam base fluid and its cycle performance test

[0027] Prepare 100L recyclable foam base liquid, calculated in parts by mass, the composition of the foam base liquid is: 0.5 part C 12 h 25 NHCH 2 CH 2 COONa, 0.05 part C 14 h 29 O(CH 2 CH 2 O) 2 SO 3 Na, 0.05 part C 12 h 25 N(CH 3 ) 2 O, 0.2 parts of C 10 h 21 COONa, 0.1 part xanthan gum (relative molecular weight is 1×10 6 g / mol, the aqueous solution viscosity of 1% xanthan gum at 25°C is 1200mpa.s-1700mpa.s), 0.1 parts of CMC (relative molecular weight is 6×10 3 g / mol, the viscosity of 1% CMC aqueous solution at 25°C is 1500mpa.s-3000mpa.s), and the rest is tap water.

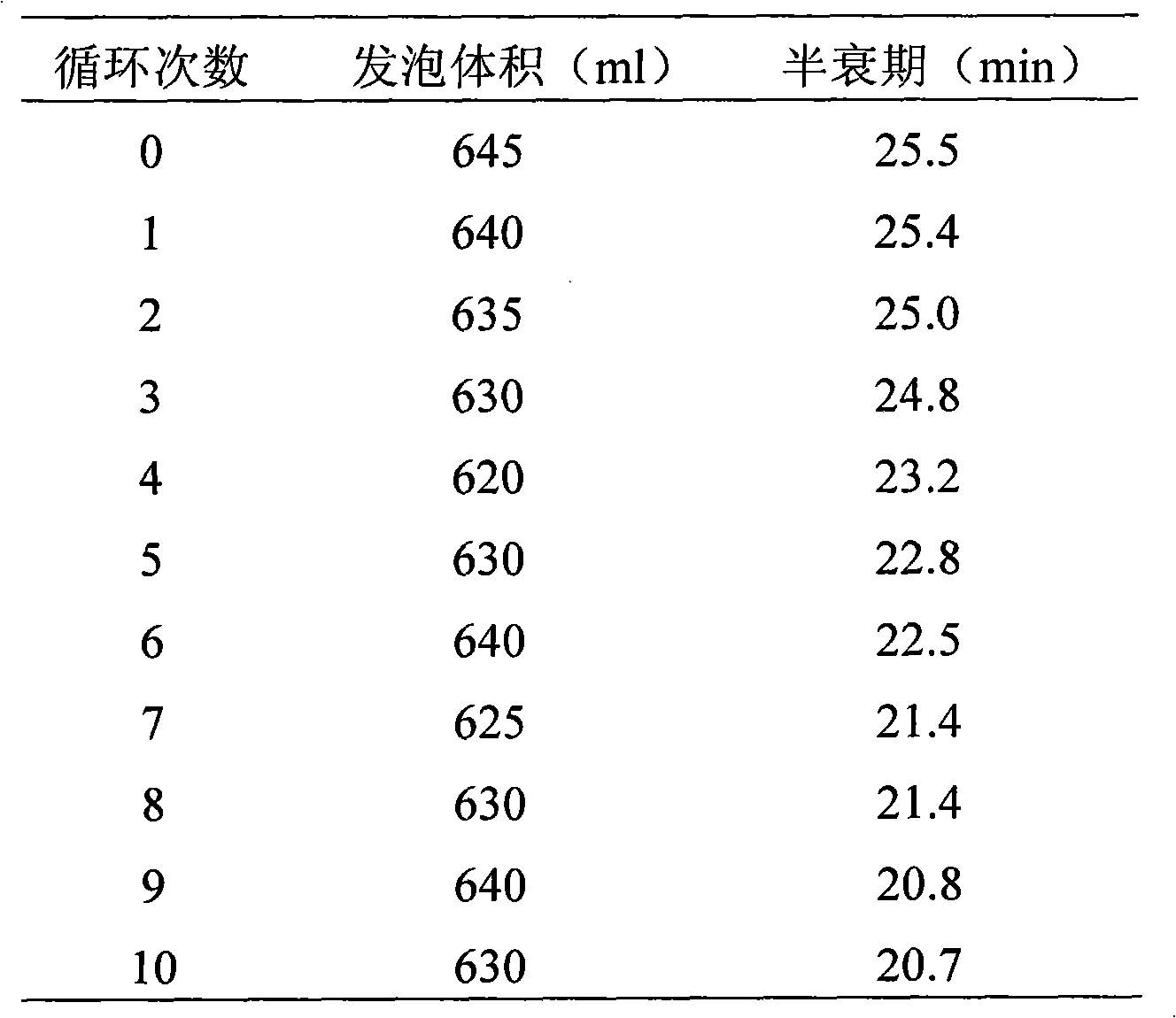

[0028] The circulation performance test of the foam base fluid with the above composition was carried out by using the above circulation device, and the foam quality and half-life were tested by a Waring mixer.

[0029] In order to facilitate the observation and monitoring of the performance ...

Embodiment 2

[0032] Embodiment 2, the preparation of recyclable foam base fluid and its cycle performance test

[0033] Prepare 130L recyclable foam base liquid, calculated in parts by mass, the formula of foam base liquid is: 0.4 part C 14 h 29 NHCH 2 CH 2 COONa, 0.05 part C 12 h 25 O(CH 2 CH 2 O) 2 SO 3 Na, 0.1 part C 14 h 29 N(CH 3 ) 2 O, 0.1 parts of C 17 h 35 COONa, 0.2 parts xanthan gum (relative molecular weight is 2×10 7 g / mol, the aqueous solution viscosity of 1% xanthan gum at 25°C is 1200mpa.s-1700mpa.s), 0.2 parts of CMC (relative molecular weight is 2×10 4 g / mol, the viscosity of 1% CMC aqueous solution at 25°C is 1500mpa.s-3000mpa.s), and the rest is tap water.

[0034] The circulation performance test of the foam base fluid with the above composition was carried out by using the above circulation device, and the foam quality and half-life were tested by a Waring mixer.

[0035] In order to facilitate the observation and monitoring of the performance of the f...

Embodiment 3

[0038] Embodiment 3, the preparation of recyclable foam base fluid and its cycle performance test

[0039] Prepare 120L recyclable foam base liquid, calculated in parts by mass, the formula of foam base liquid is: 0.5 part C 12 h 25 NHCH 2 CH 2 COONa, the rest is tap water.

[0040] The circulation performance test of the foam base fluid with the above composition was carried out by using the above circulation device, and the foam quality and half-life were tested by a Waring mixer.

[0041] In order to facilitate the observation and monitoring of the performance of the foam after each cycle, the foam base liquid after the defoaming was started for the next cycle every 2.5 minutes; at the same time, samples were taken, and the foam quality and half-life were tested with a Waring mixer. The monitoring results are shown in Table 3 Show. It can be seen from Table 3 that after 5 cycles of the foam base liquid, the foaming volume and half-life decrease slightly, but the quartz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com