Biological / mechanical technique for preparing high quality refuse derived fuel

A garbage-derived fuel, high-quality technology, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of high cost and difficulty, and achieve the effect of reducing drying cost, easy to break and disperse, and reduce breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

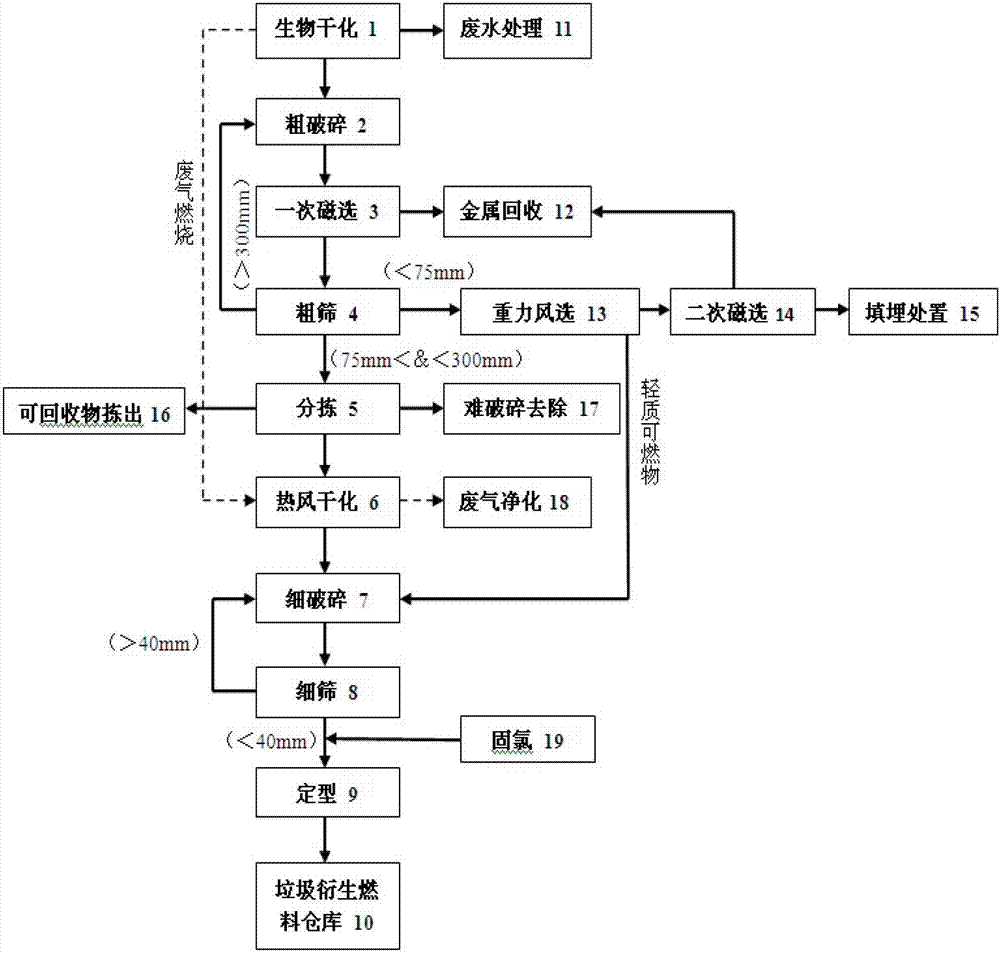

[0025] According to this process flow, it is possible to build a new waste-to-high-quality derivative fuel plant or to use the waste receiving system and flue gas waste heat in an existing waste-to-energy plant to add new ones, which is more cost-effective. figure 1 Equipment layout and installation are required. Garbage is directly poured into the biological drying pool by the municipal transport vehicle for biological drying 1. The biological drying pool has 4 independent units. After each unit receives a certain amount of garbage, it stops receiving the function and transfers to the biological drying process. New To garbage is received by the next unit.

[0026]Biological drying process, using the filtrate containing Thiobacillus ferrooxidans, Leptospira ferrooxidans, Pseudomonas acidovorans and Dehalogenobacter ethylene-producing bacteria to leaching and ventilation accelerated drying of garbage, four types of bacteria According to the concentration ratio between 4:2:1:1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com