Patents

Literature

124results about How to "Fully foamed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

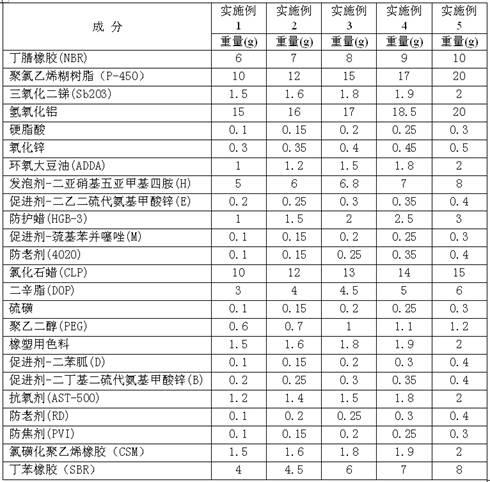

Color rubber and plastic heat-insulating material and preparation method thereof

The invention relates to a color rubber and plastic heat-insulating material and a preparation method thereof. The rubber and plastic heat-insulating material is prepared from polrvinyl chloride paste resin, dinitrosopentamethylene tetraamine, an antiager, styrene rubber, protective wax, an antioxidant, chlorosulfonated polyethylene rubber, diphenyl guanidine, mercaptobenzothiazole, zinc dibutyl dithiocarbamate, zinc diethydithiocarbamate and the like. The performance and the color difference of the product are stabilized by adding a coloring material to perform banburying on the finished rubber again and combining a new vulcanizing foaming technology and a super-long water-cooling system; the prepared color rubber and plastic heat-insulating material does not have fibers and dust, prevents dew formation, has a smooth surface and high cleanliness, has the same bright color as equipment, is environmentally-friendly and non-toxic, reduces secondary construction, saves cost, greatly improves the using performance of the product, prolongs the service life and takes full advantage of the product performance.

Owner:WINCELL INSULATION CO LTD

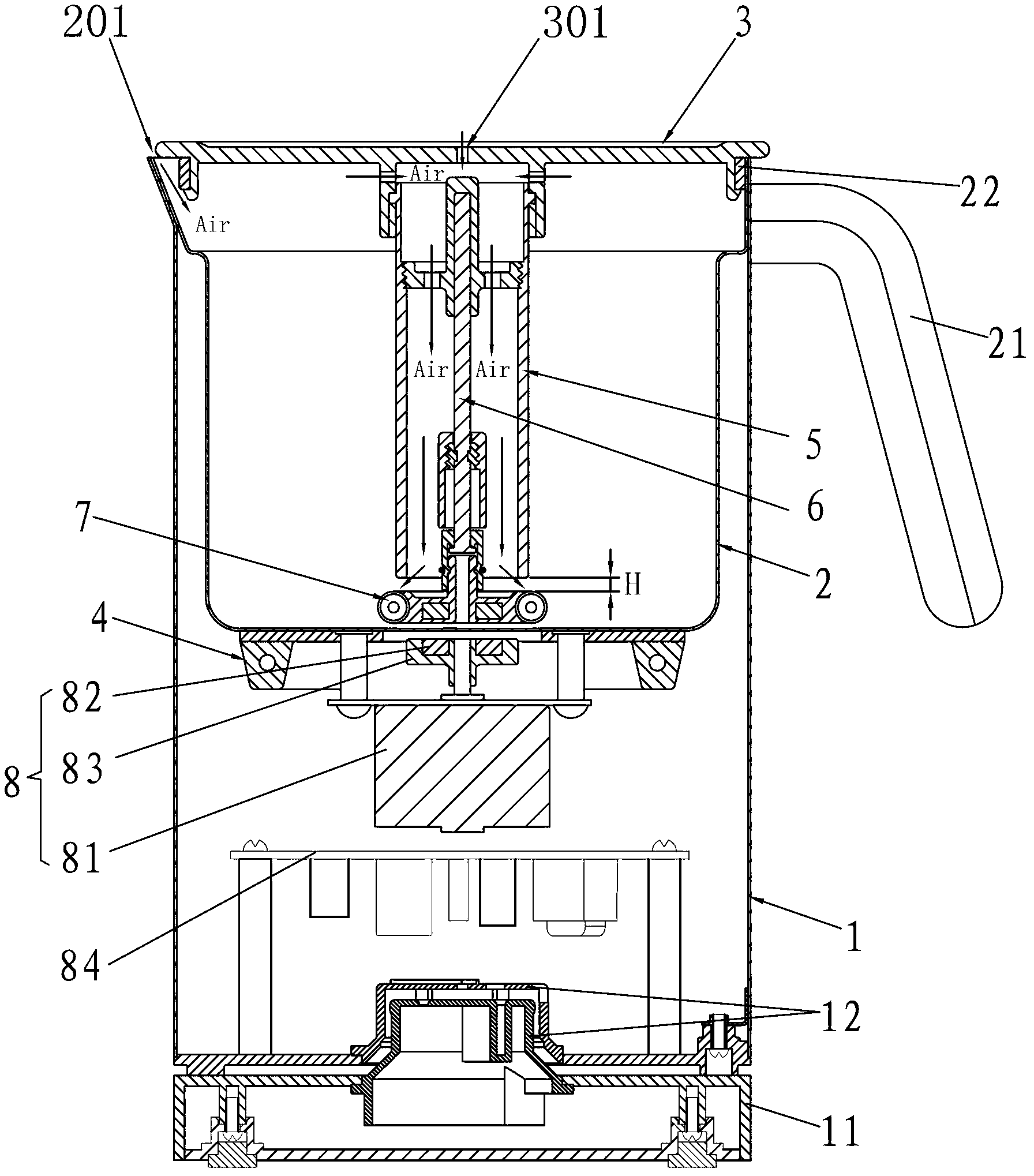

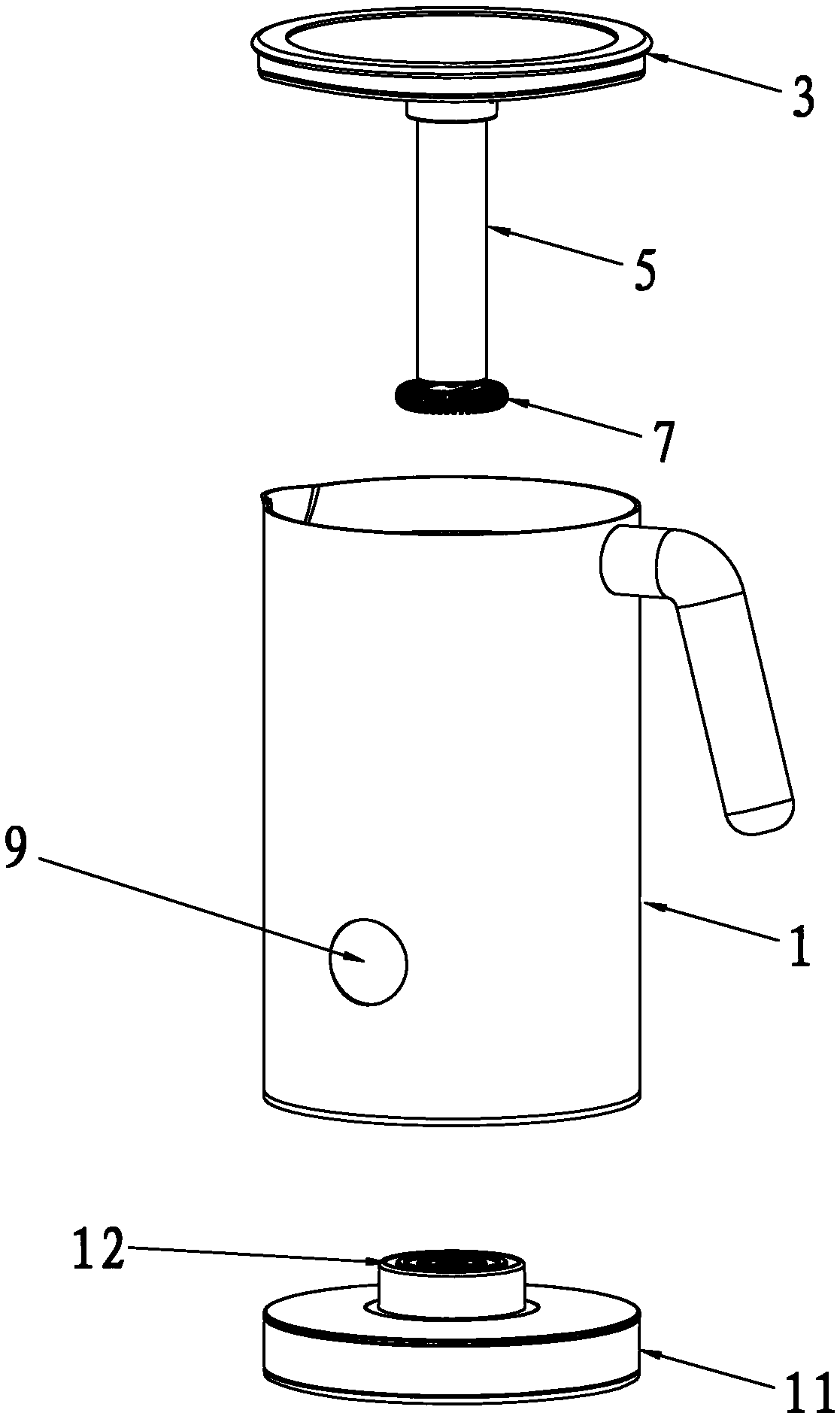

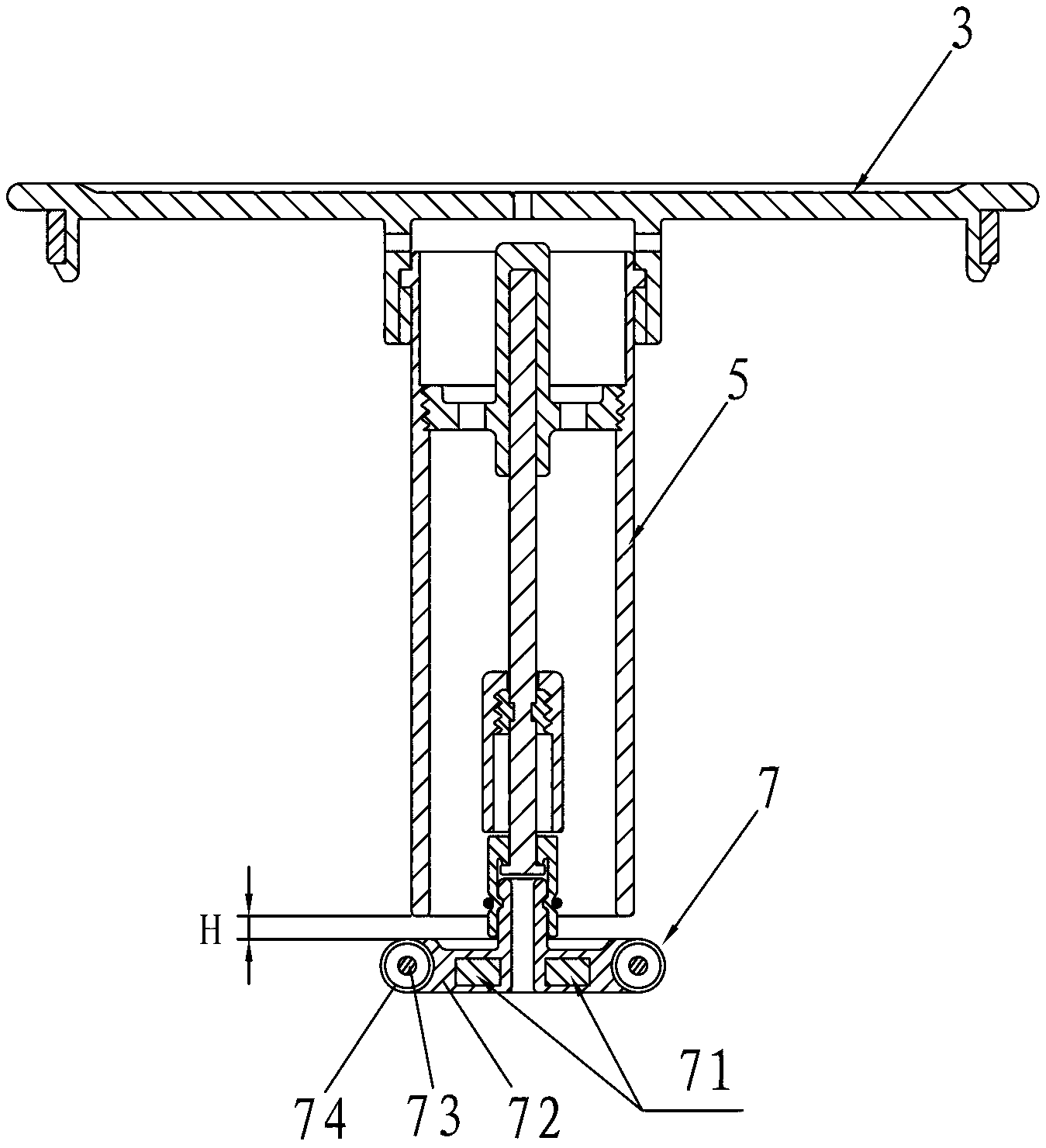

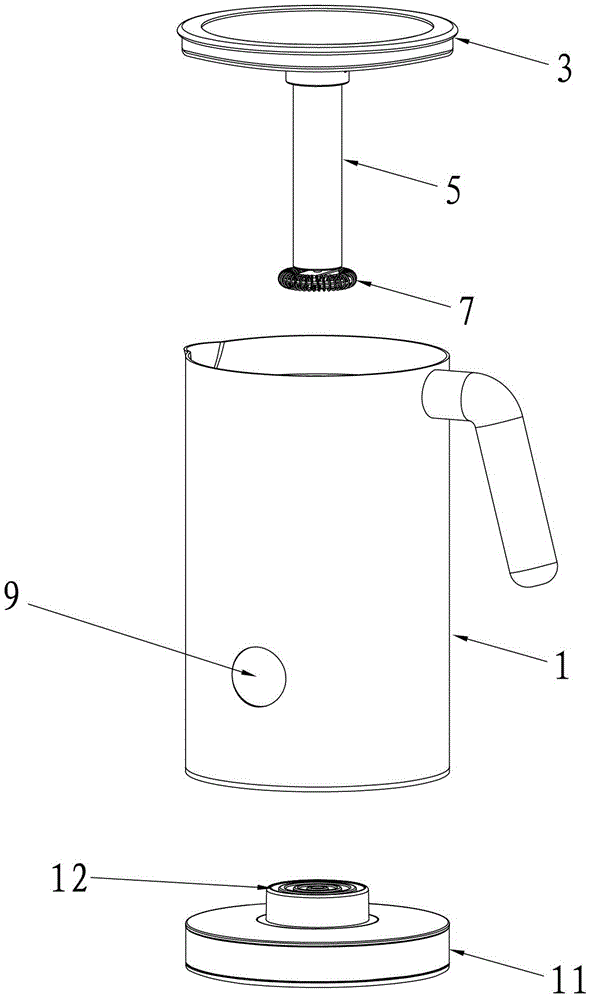

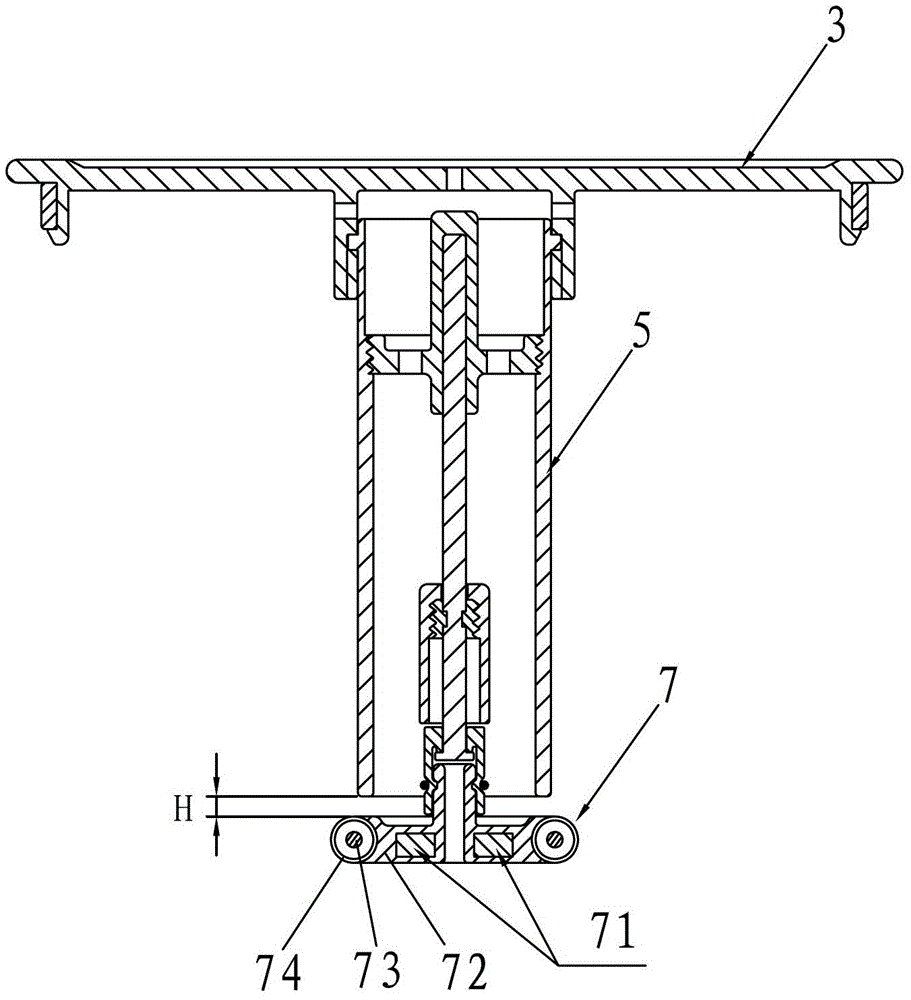

Milk foaming machine

The invention belongs to the field of devices for forming foam through milk, and provides a milk foaming machine. The milk foaming machine comprises an outer shell, a container cover and a magnetic driving device. A container and a heating device are arranged in the outer shell. The magnetic driving device is arranged under the container. The container cover is arranged at the upper end of the container. An air pipe is arranged in the container and communicated with the outside of the container. The lower end of the air pipe is connected to a stirring shaft. A stirrer is connected to a portion, at an outlet of the lower end of the air pipe, of the stirring shaft. The lower end of the air pipe is provided with an opening. According to the milk foaming machine, in the overall rotating operation process of the stirrer, air is continuously led into a foaming area nearby the stirrer via the air pipe located above the stirrer through negative pressure generated by the stirrer during rotation, so that the air needed for continuous stirring and foaming is supplied, and the milk foaming is more sufficient and fine. Moreover, the milk foaming machine is simple in structure, fast to produce and assemble, low in cost, convenient to use by consumers, easy to clean and economical to use.

Owner:熊兴剑

PVC (polyvinyl chloride) foamed artificial leather and preparation method thereof

The invention discloses PVC (polyvinyl chloride) foamed artificial leather and a preparation method thereof. The PVC foamed artificial leather comprises a fabric base material, a foaming layer and a surface layer which are attached from inside to outside sequentially, wherein the foaming layer comprises components in parts by weight as follows: 95-105 parts of PVC resin, 75-85 parts of filling powder, 75-85 parts of a plasticizer, 3.5-4.0 parts of a stabilizer, 4.5-5.5 parts of a foaming agent and 9.5-10.5 parts of masterbatch; the surface layer comprises components in parts by weight as follows: 65-75 parts of PVC resin, 6-8 parts of filling powder, 46-52 parts of a plasticizer, 1.5-3 parts of a stabilizer and 4.5-5.5 parts of masterbatch. The preparation method comprises steps as follows: (1), blending; (2), mixing, open milling and filtering; (3), calendering attachment; (4), cooling; (5), foaming; (6), embossing, cooling and rolling-up to obtain a finished PVC foamed artificial leather product. The artificial leather prepared with the method feels good, and is good in texture, high in breathability and good in wear resistance.

Owner:DONGTAI FUAN SYNTHETIC MATERIAL CO LTD

Screw rod cleaning material and preparation method of screw rod cleaning material

The invention discloses a screw rod cleaning material and a preparation method of the screw rod cleaning material. A recipe of the cleaning material comprises 100 weight parts of ethylene vinyl acetate copolymers (EVA) or low-density polyethylene (LDPE) or elastic bodies, 1 to 20 weight parts of foaming agents, 1 to 10 weight parts of whitening agents and 1 to 5 weight parts of filling agents. The EVA is ethylene vinyl acetate copolymers, and the LDPE is high-pressure low-density polyethylene. Compared with the prior art, the screw rod cleaning material has the advantages that the cleaning material produced by the recipe is an expansion material, and in the cleaning process, the cleaning material can be expanded, i.e. the volume is increased during the cleaning through the expansion of the cleaning material, so cleaning dead corners are eliminated, the used cleaning materials are few, the use cost is reduced, and in addition, the cleaning effect is better. The preparation method of the cleaning material has the advantages that the process is simple, the production is convenient, the quality is stable, the whole production can be completed only through a mixing machine and an extruding machine, the operation is safe and sanitary, and the screw rod cleaning material belongs to a product with good economy and market prospects.

Owner:宁波市金穗橡塑机电有限公司

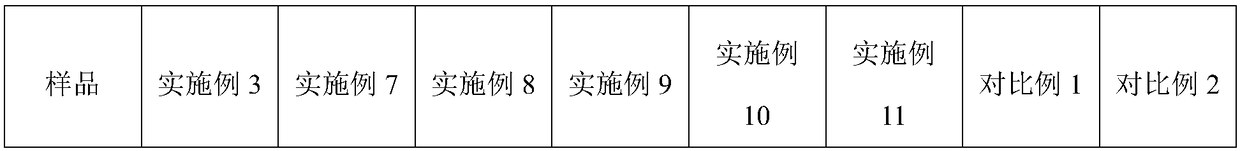

Rubber-plastic blending foam material and preparation method thereof

The invention belongs to the technical field of high polymer materials, and particularly relates to a rubber-plastic blending foam material and a preparation method thereof. The rubber-plastic blending foam material is prepared from components in parts by weight as follows: 25-35 parts of a rubber-plastic blending material, 5-8 parts of a foaming agent, 0.05-0.3 parts of a vulcanizing agent, 1.5-1.8 parts of an accelerant, 25-35 parts of filler, 5-8 parts of carbon black, 0.5-1 part of paraffin, 15-20 parts of chlorinated paraffin, 0.1-0.2 parts of stearic acid, 1-2 parts of epoxy soybean oil,0.3-0.5 parts of zinc oxide, 0.5-1 part of polyethylene glycol and 0.1-0.5 parts of an anti-aging agent. By means of proportion optimization selection of the components, content of chlorine ions in the obtained rubber-plastic blending foam material is lower than 400 ppm, and after a copper pipe is wrapped with the material and used for 240 h at the temperature of 60 DEG C and humidity of 95% plusor minus 3%, the color of the copper pipe can be close to that of a copper tube which is not wrapped with the rubber-plastic blending foam material.

Owner:HEBEI SHENZHOU THERMAL INSULATION BUILDING MATERIAL GRP CO LTD

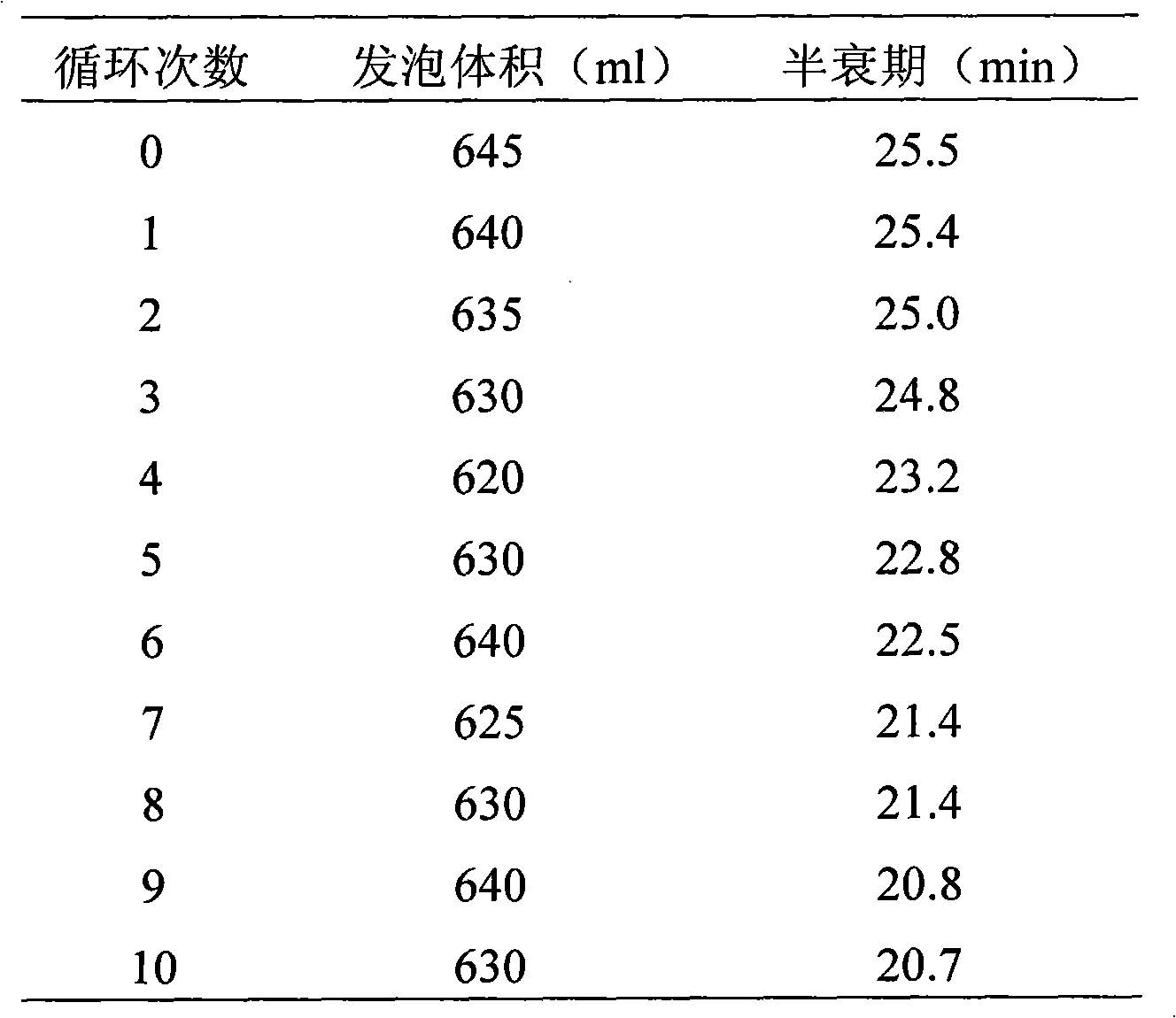

Recyclable foam base fluid for sand-washing well

InactiveCN102031098AAchieve friendlyLow foaming abilityDrilling compositionPropanoic acidSurface-active agents

The invention provides a recyclable foam base fluid for a sand-washing well, comprising an N-alkyl-beta-amino propionic acid type amphoteric surface active agent and water, wherein the molecular formula of the N-alkyl-beta-amino propionic acid type amphoteric surface active agent is RNHCH2CH2COOM, wherein R is straight-chain alkyl group, and M is sodium ion or ammonium ion; and the ratio of partsby weight of the N-alkyl-beta-amino propionic acid type amphoteric surface active agent and water is (0.1-0.6):100. By utilizing the recyclable foam base fluid, the operation cost for foam sand-washing well can be reduced, and the environment-friendly performance can be realized.

Owner:CHINA NAT OFFSHORE OIL CORP +2

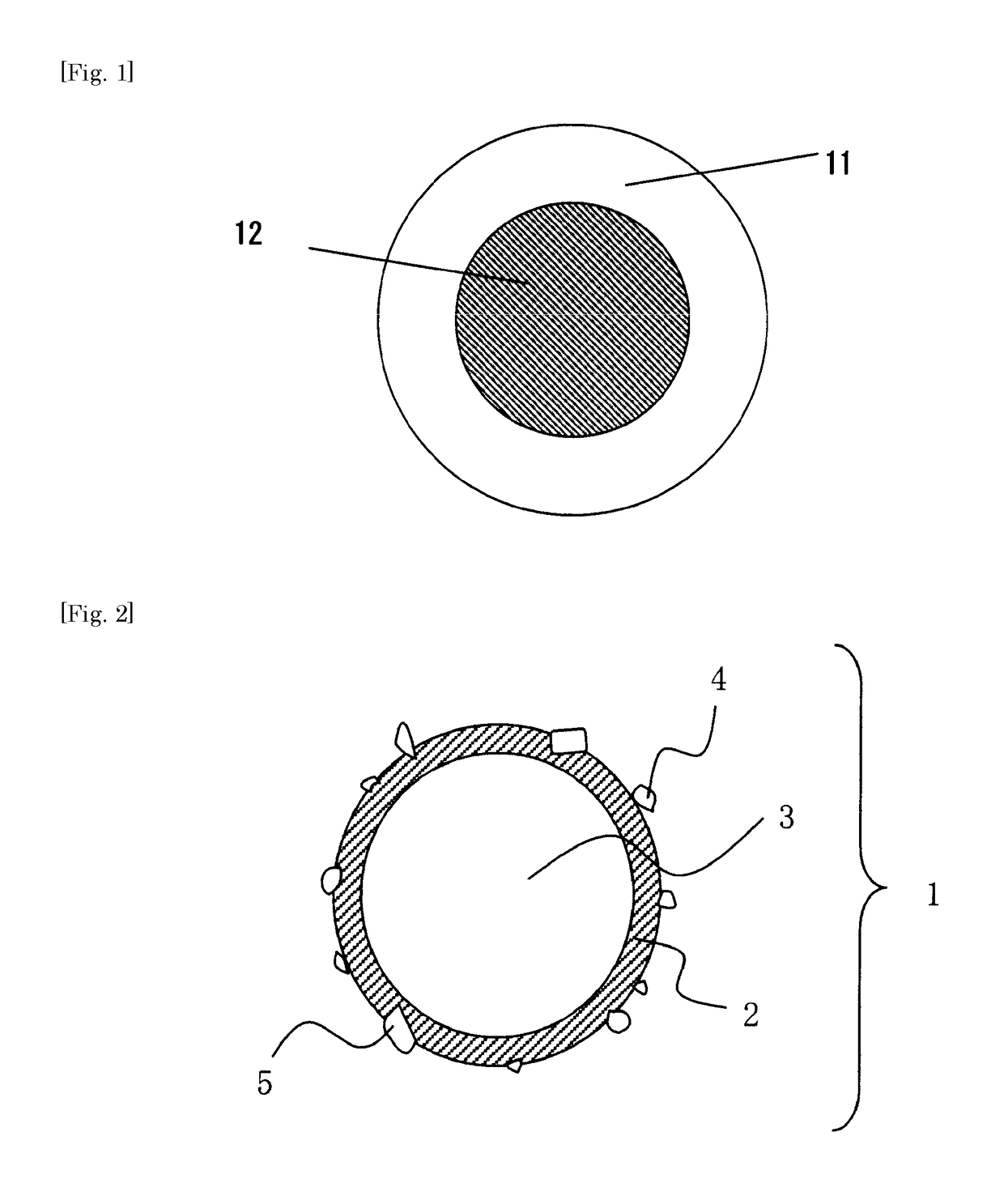

Heat-expandable microspheres, process for producing the same and application thereof

ActiveUS10023712B2Improve acceleration performanceImprove machinabilityOther chemical processesMicroballoon preparationMethacrylateMicrosphere

Heat-expandable microspheres having an almost spherical shape and high expansion performance and exhibiting good workability when mixed with a resin, a process for producing the heat-expandable microspheres, and applications thereof. The heat-expandable microspheres include a thermoplastic resin shell and a blowing agent encapsulated therein and vaporizable by heating. The thermoplastic resin is produced by polymerizing a polymerizable component containing a methacrylate monomer and a carboxyl-containing monomer, and optionally containing a nitrile monomer in an amount ranging from 0 to 30 parts by weight to 100 parts by weight of the total amount of the methacrylate monomer and the carboxyl-containing monomer. The blowing agent contains a hydrocarbon having at least 8 carbon atoms per molecule.

Owner:MATSUMOTO YUSHI SEIYAKU

Method for producing hollow glass spheres by using waste glass

InactiveCN104891813AIncrease productivityIncrease temperatureGlass shaping apparatusGlass productionCelluloseSoluble glass

The invention provides a method for producing hollow glass spheres by using waste glass, which comprises the following step: washing waste glass and crushing, adding 3-10% of feldspar, 0-6% of talcum, 1-3% of soda ash, 1-5% of limestone, 1-3% of soluble glass, 1-2% of white copperas zinc sulfate and 1-3% of calcium sulfate according to waste glass weight, performing ball milling on mixed material, adding paste containing starch and cellulose, performing spray drying at 1100-1200 DEG C, heating and spheroidizing to obtain the hollow glass spheres. By using the method of the invention, waste can be changed into valuables, production efficiency of the hollow glass spheres can be increased, and cost is reduced.

Owner:周佐石

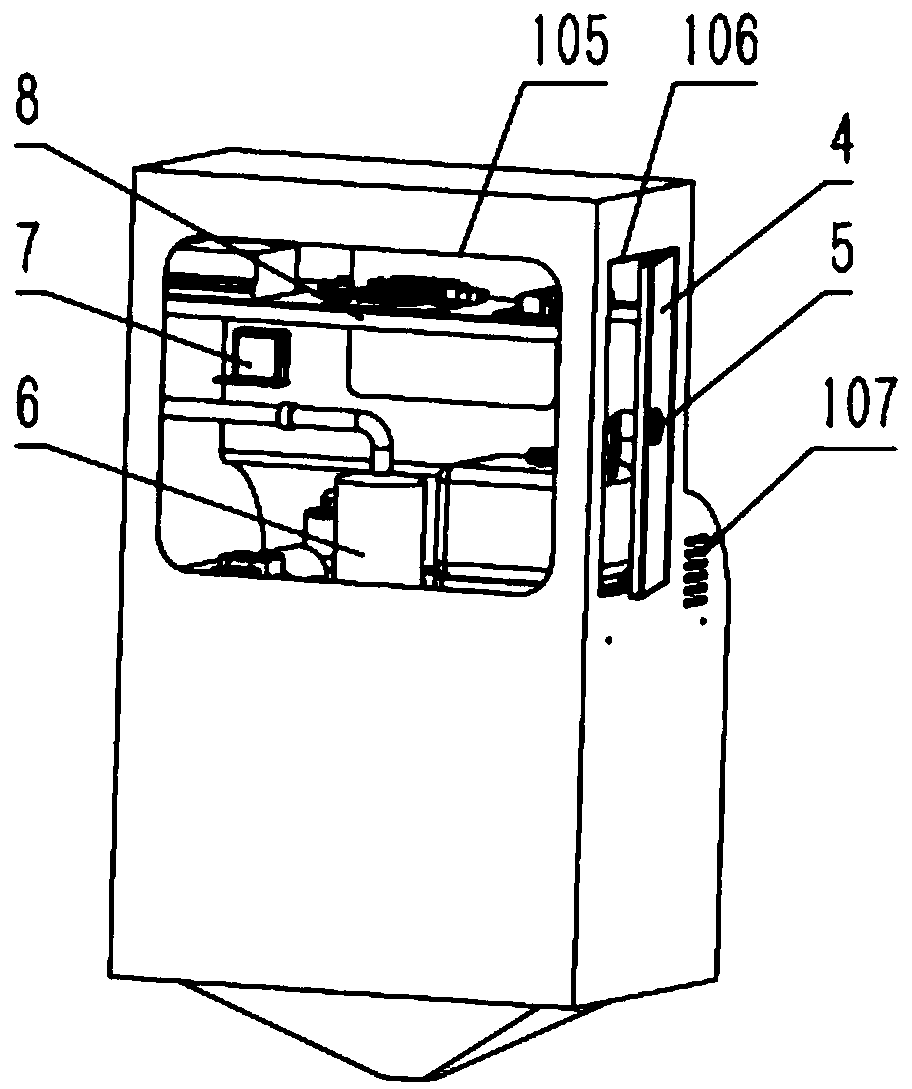

Hand washer capable of detecting bacteria and method of using the same

PendingCN109222717AImprove ease of useImprove efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringIdentification device

The invention provides a hand washer capable of detecting bacteria, and belongs to the field of cleaning devices. The hand washer includes a main housing, a hand-washing function assembly and a control panel. The hand washing functional assembly is installed inside the main housing, comprises a mounting plate and a water supply part, a hand washing liquid part, a drying part, a bacterial detectionand identification device and a sensor mounted on the mounting plate, and a control board for system control is also mounted in the main case, wherein the control board is respectively connected withthe water supply part, the hand washing liquid part, the drying part, the bacterial detection and identification device and the sensor. A hand washing method capable of detecting bacteria also includes a method of using the hand washing method to improve the quality of the hand washing.

Owner:济南图马机电设备有限公司

Stable multilayer-film structural foaming agent and preparation method thereof

The invention particularly relates to a stable multilayer-film structural foaming agent and a preparation method of the stable multilayer-film structural foaming agent. The technical scheme is that the preparation method comprises steps as follows: getting 20 to 50wt% of main agent, 20 to 50wt% of assistant and 20 to 50wt% of foam stabilizer as the raw materials at 15 to 25 DEG C; then adding foam stabilizer of which the mass is 10 to 20 times that of the raw materials mentioned above; and agitating for 5 to 15 minutes, so as to obtain the stable multilayer-film structural foaming agent, wherein the main agent is one of sodium lauryl sulfate, sodium dodecyl benzene sulfonate, sodium dodecyl sulfate, alkylphenol ethoxylates and fatty alcohol-polyoxyethylene ether; the assistant is one of dodecanol, polyethylene glycol, setanol, octadecanol and lauromacrogol; and the foam stabilizer is one of sodium carboxymethylcellulose, gelatin, sodium carboxymethyl starch, arabia gum adhesive and hydroxyethyl cellulose. The preparation method has the characteristics of being simple, convenient to operate, and short in preparation time and the like; and the prepared stable multilayer-film structural foaming agent is relatively small in dimension, uniform in distribution, full in foaming and high in stability.

Owner:WUHAN UNIV OF SCI & TECH

Preparation method of cellulose modified phenolic foams

The invention discloses a preparation method of cellulose phenolic foams. The preparation method comprises the following steps: preparing a mixed aqueous solution containing 7wt% of sodium hydroxide and 12wt% of urea, precooling the mixed aqueous solution to -12 DEG C, adding crushed cellulose, and stirring for 2-5 minutes to obtain a transparent cellulose solution; adding the cellulose solution into phenol to obtain biomass phenol; mixing the biomass phenol with formaldehyde according to a mole ratio of 1:1.5-1:2.0, adding a catalyst to perform condensation polymerization, performing reduced pressure dehydration, cooling and discharging to obtain fluid cellulose phenolic resin; and uniformly mixing 100 parts of fluid cellulose phenolic resin, 4-8 parts of surfactant, 3-10 parts of foaming agent and 10-20 parts of curing agent in parts by weight, foaming for 10-20 minutes at 60-80 DEG C to obtain the cellulose modified phenolic foams. By adopting the preparation method disclosed by the invention, cellulose replaces part of phenol, so that the production cost of the phenolic foams is reduced, and meanwhile, efficient utilization of biomass resources is promoted.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

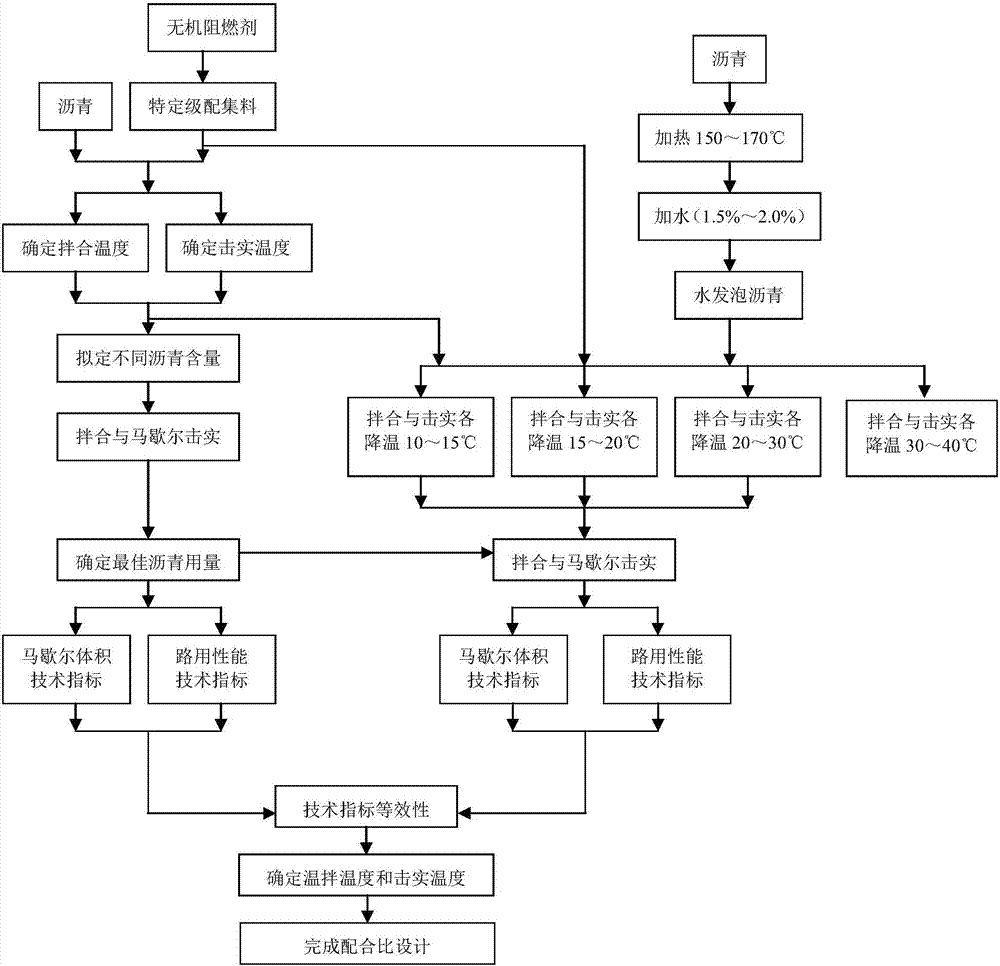

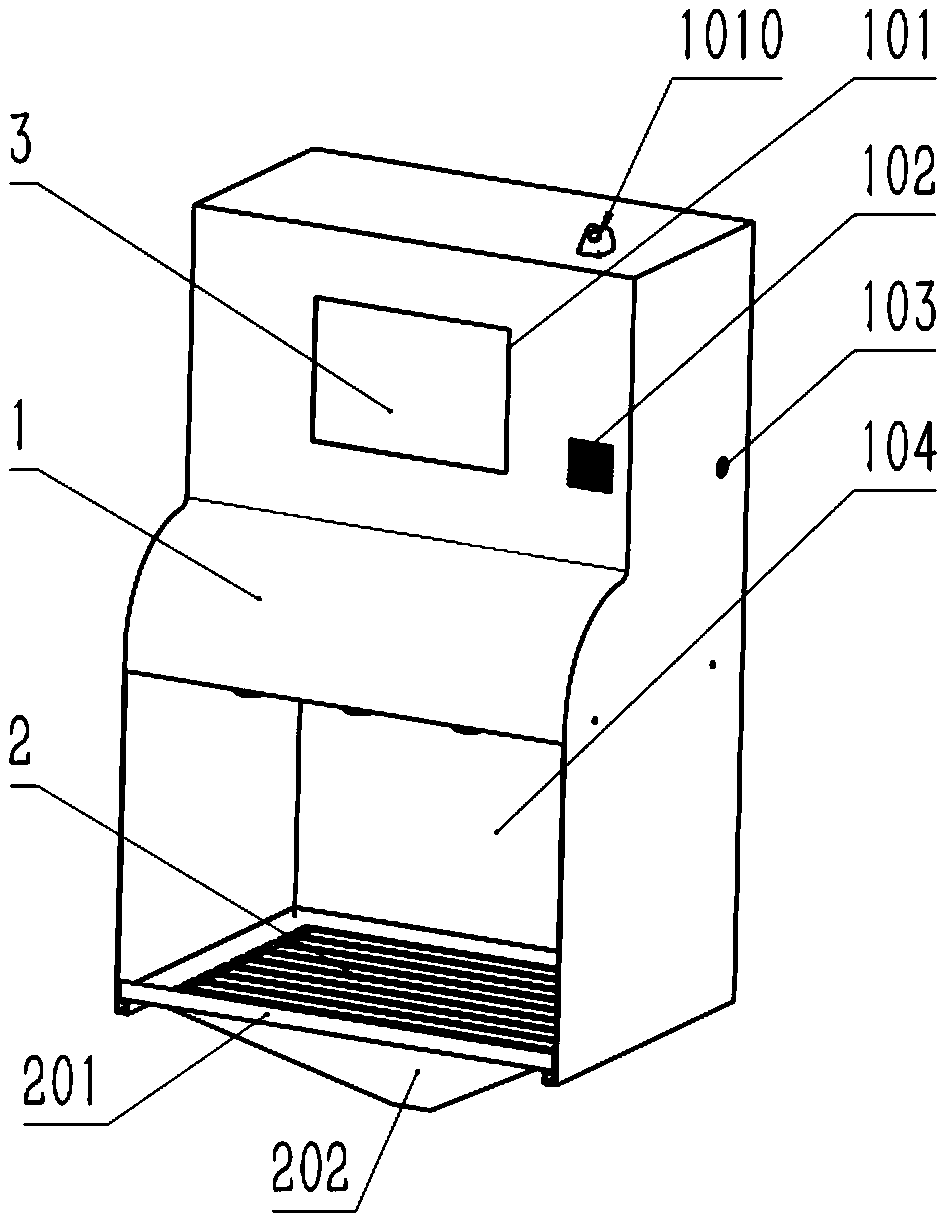

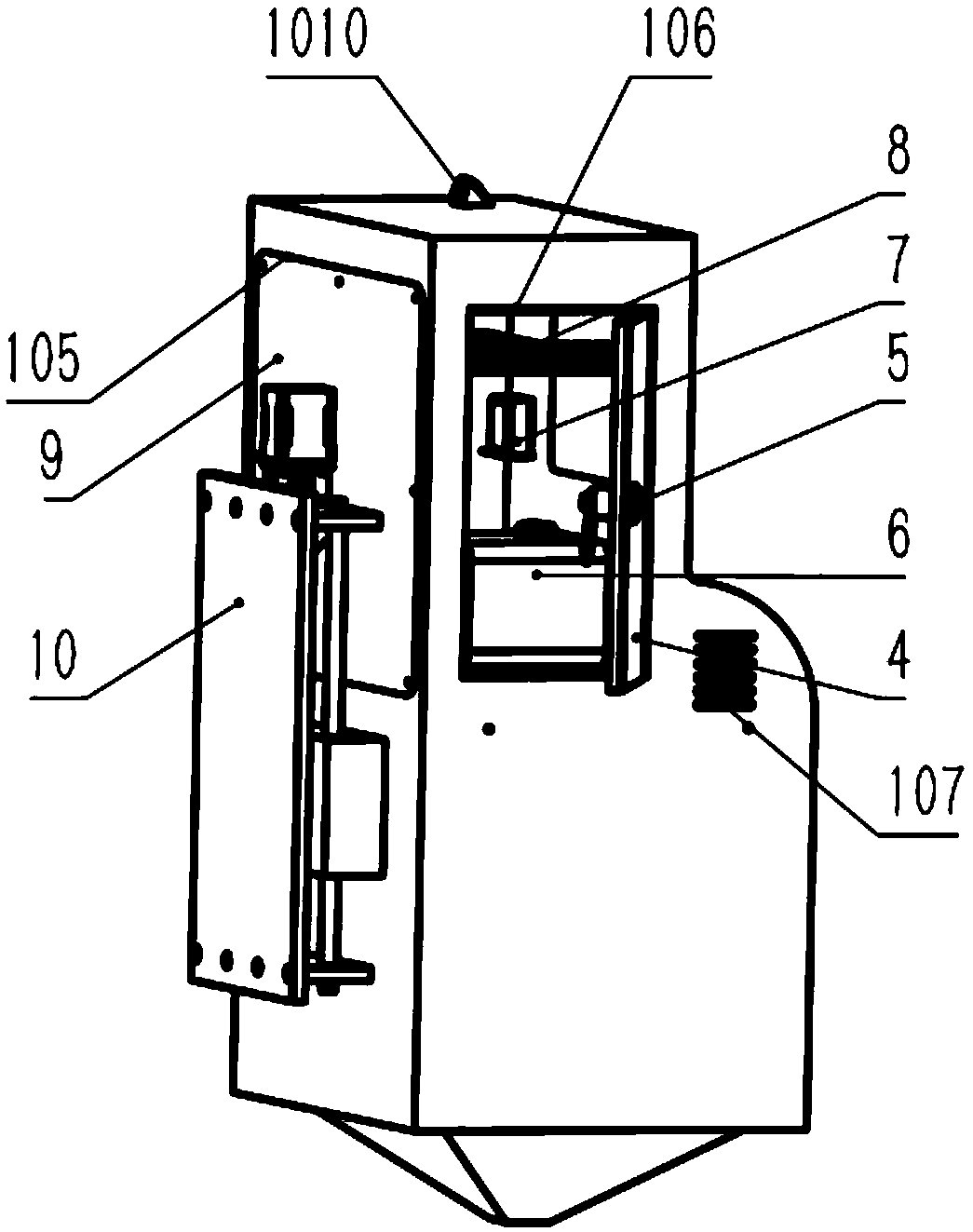

Water-blown warm-mix flame-retardant asphalt mixture, and preparation and design method thereof

The invention discloses a water-blown warm-mix flame-retardant asphalt mixture and a preparation method thereof. According to the invention, through comprehensive utilization of a water-blown asphalt warm-mixing technology and an asphalt flame-retardation technology, construction temperature of an asphalt pavement is effectively reduced, the safety factor of a tunnel asphalt pavement is increased, and the advantages of energy conservation, emission reduction, greenness, environmental protection, reduction in construction cost, improvement of warm-mixing construction technology for tunnel flame-retardant asphalt pavements and the like are obtained. The invention also provides a design method for the water-blown warm-mix flame-retardant asphalt mixture. The method utilizes the concept of equivalent design of basic mix ratios and technique indexes to improve the traditional design method for the warm-mix flame-retardant asphalt mixture, provides bases for the design of the water-blown warm-mix flame-retardant asphalt mixture and fills a gap in the design method for the water-blown warm-mixed flame-retardant asphalt mixture.

Owner:SUZHOU UNIV OF SCI & TECH

Preparation process of high-resilience daily melamine foam

The invention discloses a preparation process of high-resilience daily melamine foam. The preparation process comprises the specific steps of: (1) adding melamine into a formaldehyde solution, heatingthe obtained mixture for a reaction so as to generate melamino-formaldehyde resin, adding polyvinyl butyral, polyester polyol and a polyether-modified polysiloxane copolymer while stirring is conducted, introducing nitrogen into the above materials, and keeping the reaction going on to obtain modified melamine resin after dehydration; (2) mixing and stirring the modified melamine resin, a surfactant and a foaming agent uniformly so as to obtain a first material for later use; (3) mixing and stirring iso-octyl 3-mercaptopropionate and a liquid curing agent evenly so as to obtain a second material for later use; (4) stirring the first material continuously, conducting preheating, then adding the second material into the first material, and keeping stirring to obtain a mixture; (5) transferring the mixture to a microwave oven for microwave foaming so as to produce the melamine foam. According to the preparation process of the high-resilience daily melamine foam, the melamine foam has theadvantages of excellent resilience performance.

Owner:JIAXING HANGXING FINE CHEM

Preparation method of instant self-heating sea cucumber

InactiveCN101138353AUnique craftIndividual freshMeat/fish preservation by heatingFood preparationFlavorCold winter

The present invention provides a manufacturing method of instant self-heating sea cucumber; dried sea cucumber is taken as the raw material and added with a self-heating bag and outfit with a plastic bag after the treating processes of manufacture, preservation, sterilization and air seasoning. The instant self-heating sea cucumber made with the present invention can be preserved under normal temperature and is convenient for people to eat; the individual of the instant self-heating sea cucumber is fresh and living and the body is full; the manufactured sea cucumber has the connatural flavor of marine products and the taste and the meat are smooth, soft and flexible; the sea cucumber is delicious and can be automatically heated quickly. People can enjoy hot sea cucumber no matter on field study and tour or in cold winter; therefore, the instant self-heating cucumber is an optimum instant nutritious food, which is convenient for eating.

Owner:孟贤玉

Preparation method for light and high thermal conductivity carbon-based material

The invention relates to a preparation method for a light and high thermal conductivity carbon-based material. The light and high thermal conductivity carbon-based material in a porous structure is prepared through a series of process flows by taking carbon fiber in vapor phase growth or high thermal conductivity mesophase pitch chopped fiber as a reinforcement body and mesophase pitch as an adhesive. The light and high thermal conductivity carbon-based material is different from a conventional compact high thermal conductivity carbon / carbon composite material. The inner part of the light and high thermal conductivity carbon-based material is in the porous structure and the density is just 1 / 3-1 / 4 of that of the compact high thermal conductivity carbon / carbon composite material. The light and high thermal conductivity carbon-based material is also different from a conventional foam carbon material. On the premise of equivalent density, the compression strength of the material is much greater than that of the foam carbon material. The light and high thermal conductivity carbon-based material is expected to be widely popularized and applied in the field of thermal management, chemical energy storage, catalysis and the like.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

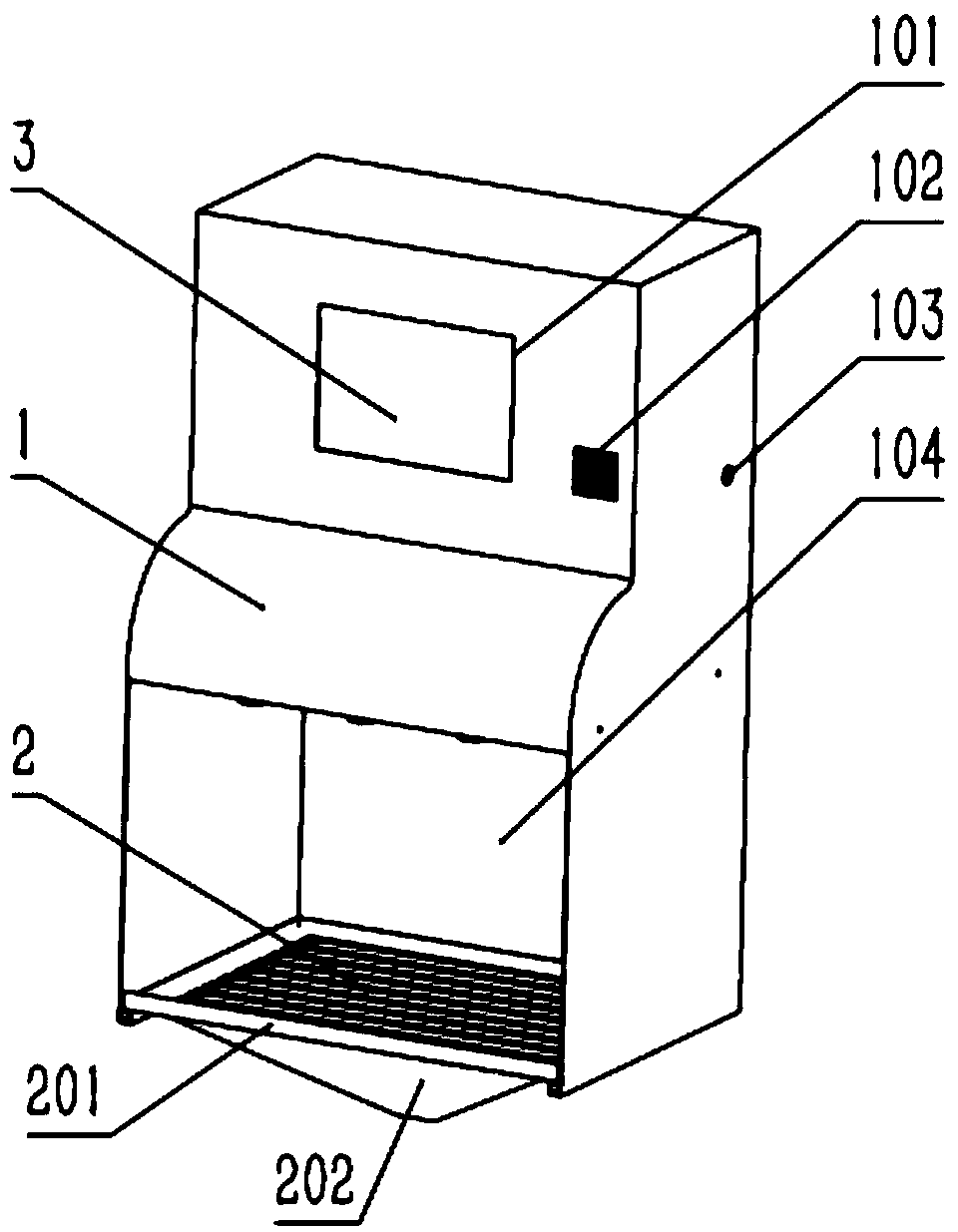

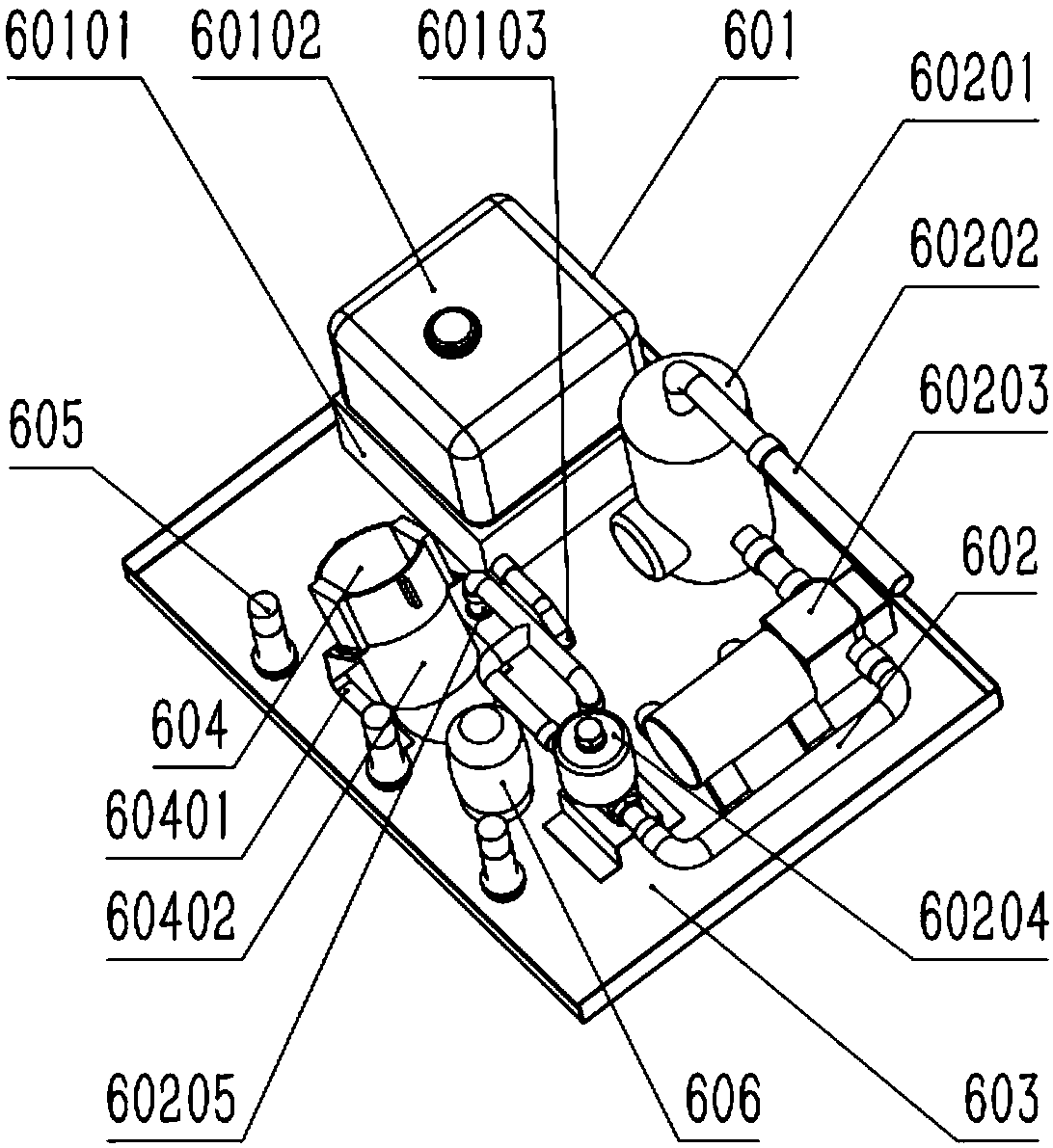

Intelligent hand washing machine with adjustable height

PendingCN109222716AImprove ease of useImprove efficiencyHolders and dispensersAgricultural engineeringFully automatic

The invention provides an intelligent hand washing machine with adjustable height, and belongs to the field of cleaning equipment, and comprises a main shell, a hand washing functional assembly, a control board and a lifting frame. The hand washing functional assembly and the control board are installed in the main shell, and the control board is connected with the hand washing functional assemblyto control the hand washing process of the hand washing functional assembly. A lifting frame supporting that main shell and adjustable in height is also arrange under the main shell, the lifting frame is connected with a control panel, and the height of the lifting frame is controlled and adjusted by the control panel. The fully automatic hand washer with adjustable height can automatically adjust the height of the hand washer according to the height of the human body, so as to meet the needs of people with different heights, and at the same time, can automatically complete the hand washing process by induction.

Owner:济南图马机电设备有限公司

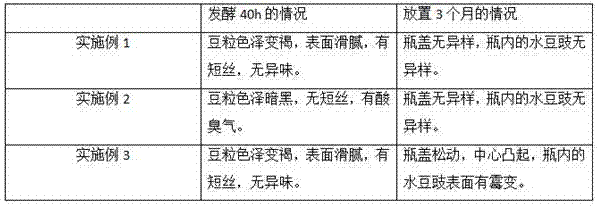

Method for preparing fermented soybeans in water

InactiveCN107028096AEasy to shapeIncrease productivityFood preservationFood ingredient for microbe protectionYeastWarm water

The invention discloses a method for preparing fermented soybeans in water. The method comprises the specific steps of step one, raw material treatment: after soybeans are soaked by warm water, steaming is performed for 9-15 min under pressurization of 0.15 Mpa; step two, fermented soya bean yeast cultivation; step three, fermentation: during the fermentation period, stirring is performed slightly every 12 h; step four, pH adjustment: 8-10 lemon slices are placed on the surfaces of the fermented soybeans in water, warm water with the temperature of 30 EDG C to 35 DEG C is sprayed to the lemon slices uniformly by a watering pot, the spraying amount of the warm water is 0.5 kg, the lemon slices are covered and placed for 1 h after spraying, and the lemon slices are taken out; step five, seasoning: 40 g of pepper is added, and the mixture is stirred uniformly; step six, sterilization and filling: the mixture is heated to 90 DEG C to 93 DEG C, the temperature is kept for 20 min, and filling is performed while the mixture is hot. According to the method for preparing the fermented soybeans in water, complete appearances of the soybeans can be kept, the processing time is shortened, the phenomena of rancidity and stinking are avoided, and the expiration date of the fermented soybeans in water is prolonged.

Owner:YUQING COUNTY TOAST FLAVOR FOOD

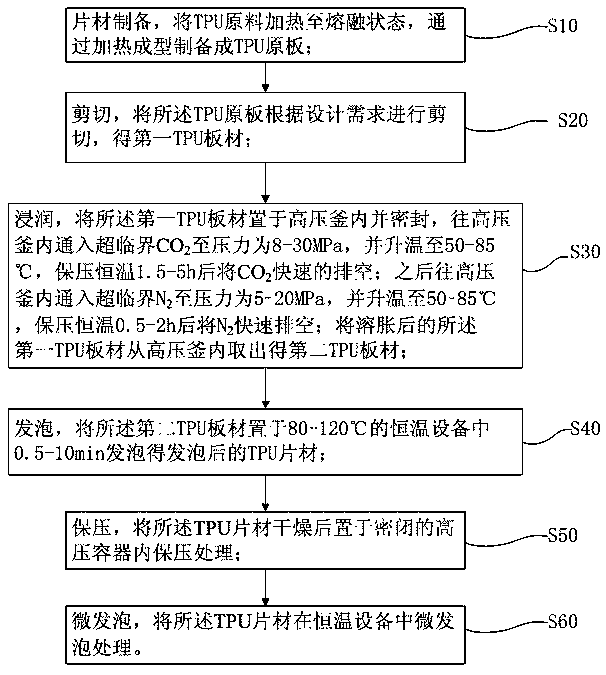

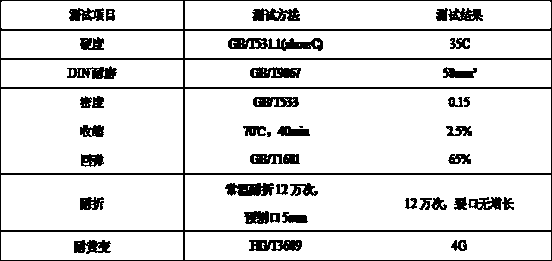

TPU sheet foaming process

The invention provides a TPU sheet foaming process which comprises the following steps: preparing a sheet to obtain a TPU raw plate; shearing to obtain a first TPU plate; soaking, namely putting the first TPU plate into a high-pressure kettle, sealing, introducing supercritical CO2 into the high-pressure kettle until the pressure is 8-30MPa, heating to 50-85 DEG C, maintaining the pressure and theconstant temperature for 1.5-5 hours, and quickly emptying CO2; introducing supercritical N2 into the high-pressure kettle until the pressure is 5-20 MPa, heating to 50-85 DEG C, maintaining the pressure and the constant temperature for 0.5-2 hours, and quickly emptying N2; taking out the swollen first TPU plate from the high-pressure kettle to obtain a second TPU plate; and foaming to obtain theTPU sheet. The invention discloses a TPU sheet foaming process. The TPU sheet is directly prepared through foaming by adopting an infiltration process combining supercritical CO2 and supercritical N2, the product prepared by adopting the process is good in flatness and plumpness, the phenomena of edge curling and the like are avoided, the production convenience is provided for downstream manufacturers, and the equipment investment of the downstream manufacturers is greatly reduced.

Owner:锋特(福建)新材料科技有限公司

Heatproof environment-friendly material for preventing noise pollution and manufacturing method thereof

InactiveCN106800794AControl combinationHigh temperature resistantLiquid crystal compositionsFoaming agentAdditive ingredient

The invention relates to a heatproof environment-friendly material for preventing noise pollution and a manufacturing method thereof. The environment-friendly material is prepared from a liquid crystal high-molecular polymer and an additive; the additive comprises a dispersing agent, a physical foaming agent and a flexibilizer; the dispersing agent is hydroxypropyl methyl cellulose; the physical foaming agent is fluorocarbon; and the flexibilizer is liquid ethylene propylene rubber. The various ingredients of the heatproof environment-friendly material for preventing the noise pollution respectively account for the percentage by weight as follows: the liquid crystal high-molecular polymer accounts for 88.5 to 90.5 percent; the hydroxypropyl methyl cellulose accounts for 1.8 to 2.8 percent; the fluorocarbon accounts for 4.5 to 6.2 percent; and the liquid ethylene propylene rubber accounts for 2.5 to 4.4 percent. The heatproof environment-friendly material provided by the invention is good in moldability, tenacity and noise reduction performance, resistant to high temperature, and friendly to the environment.

Owner:福州市天伟达电子科技有限公司

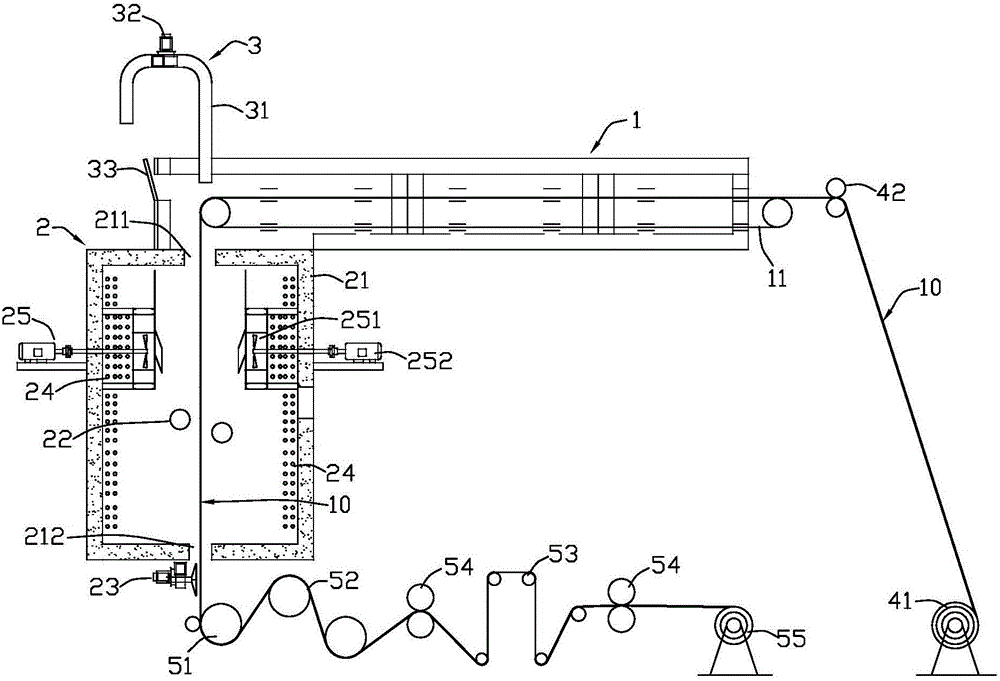

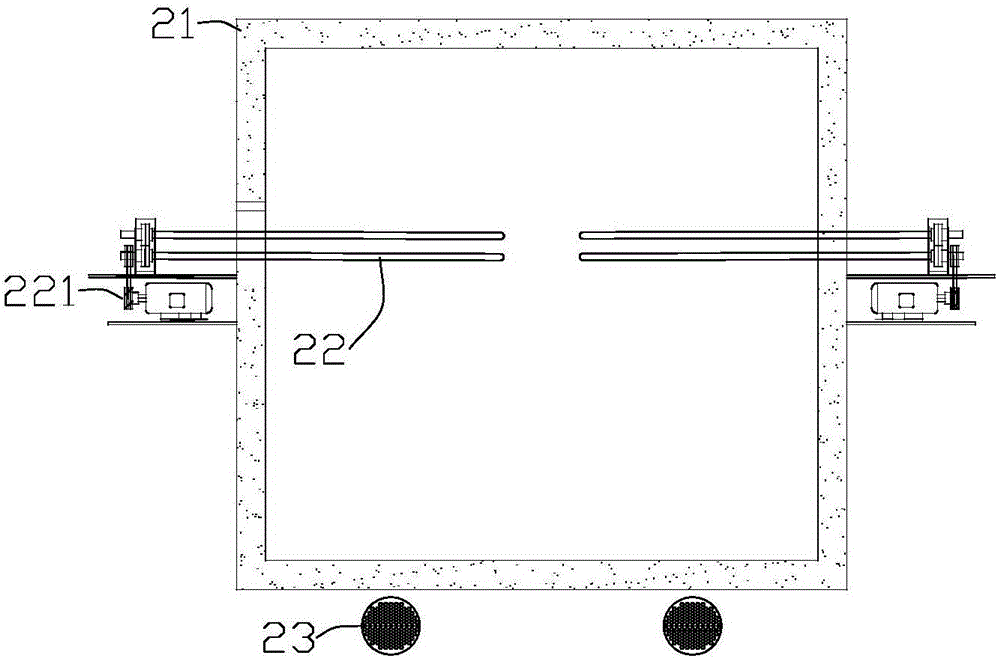

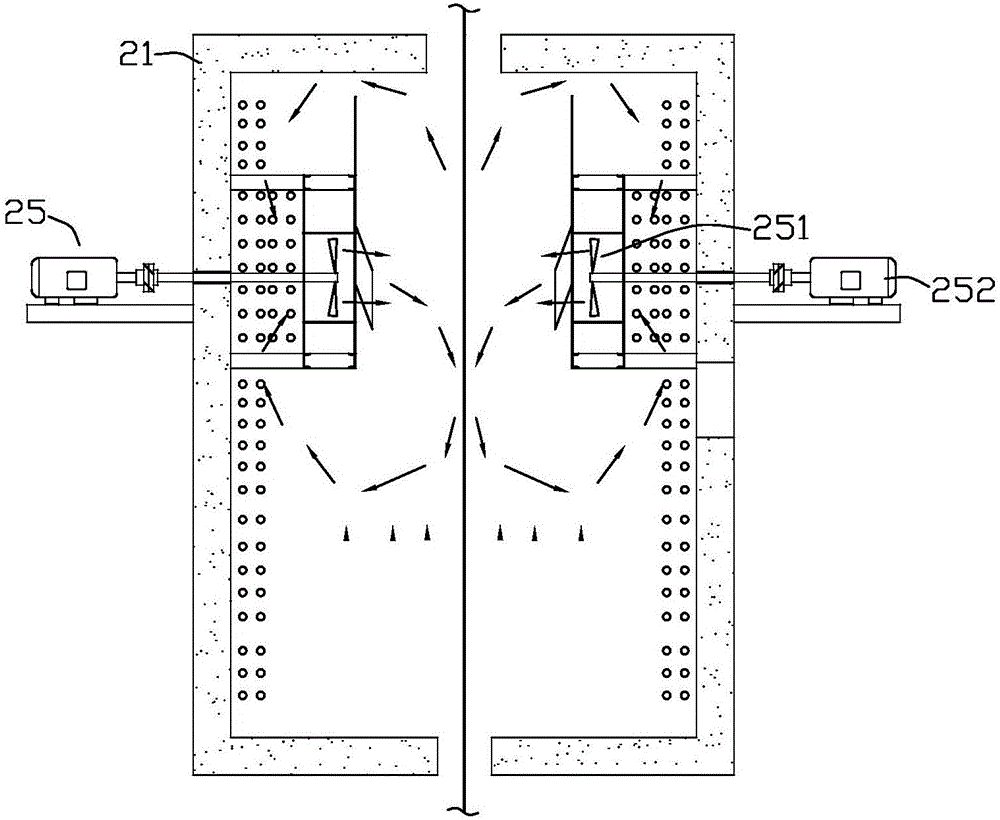

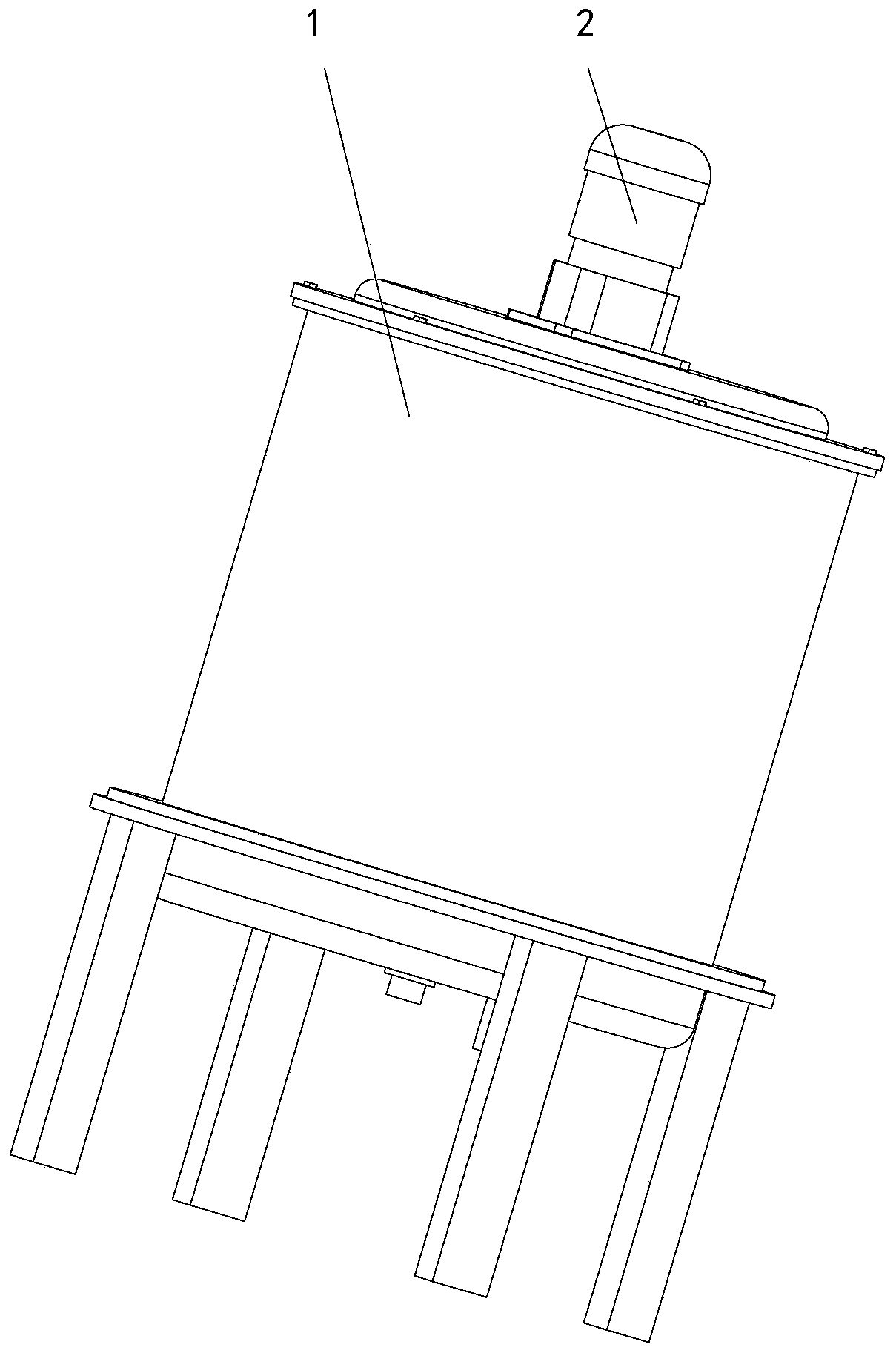

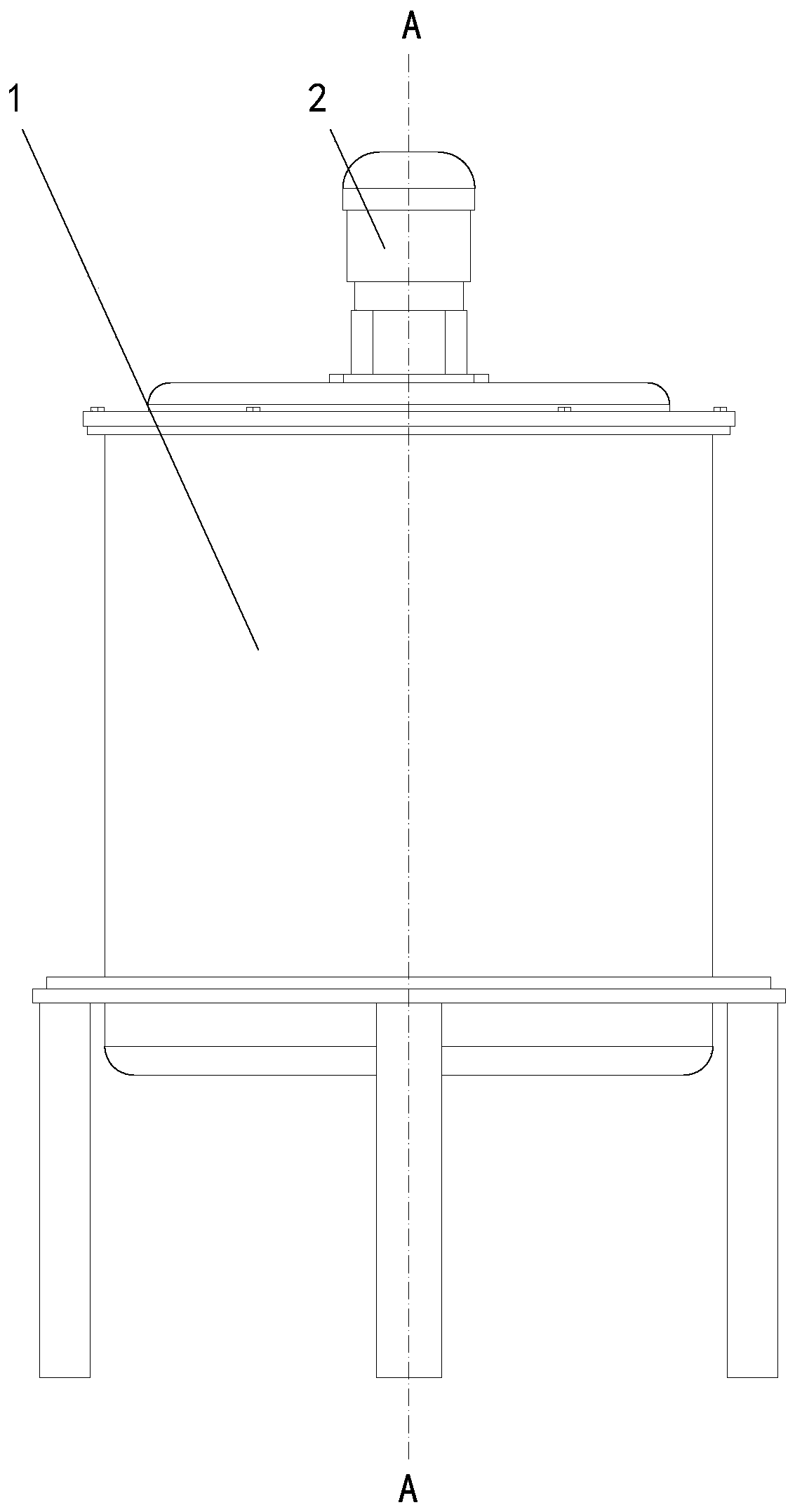

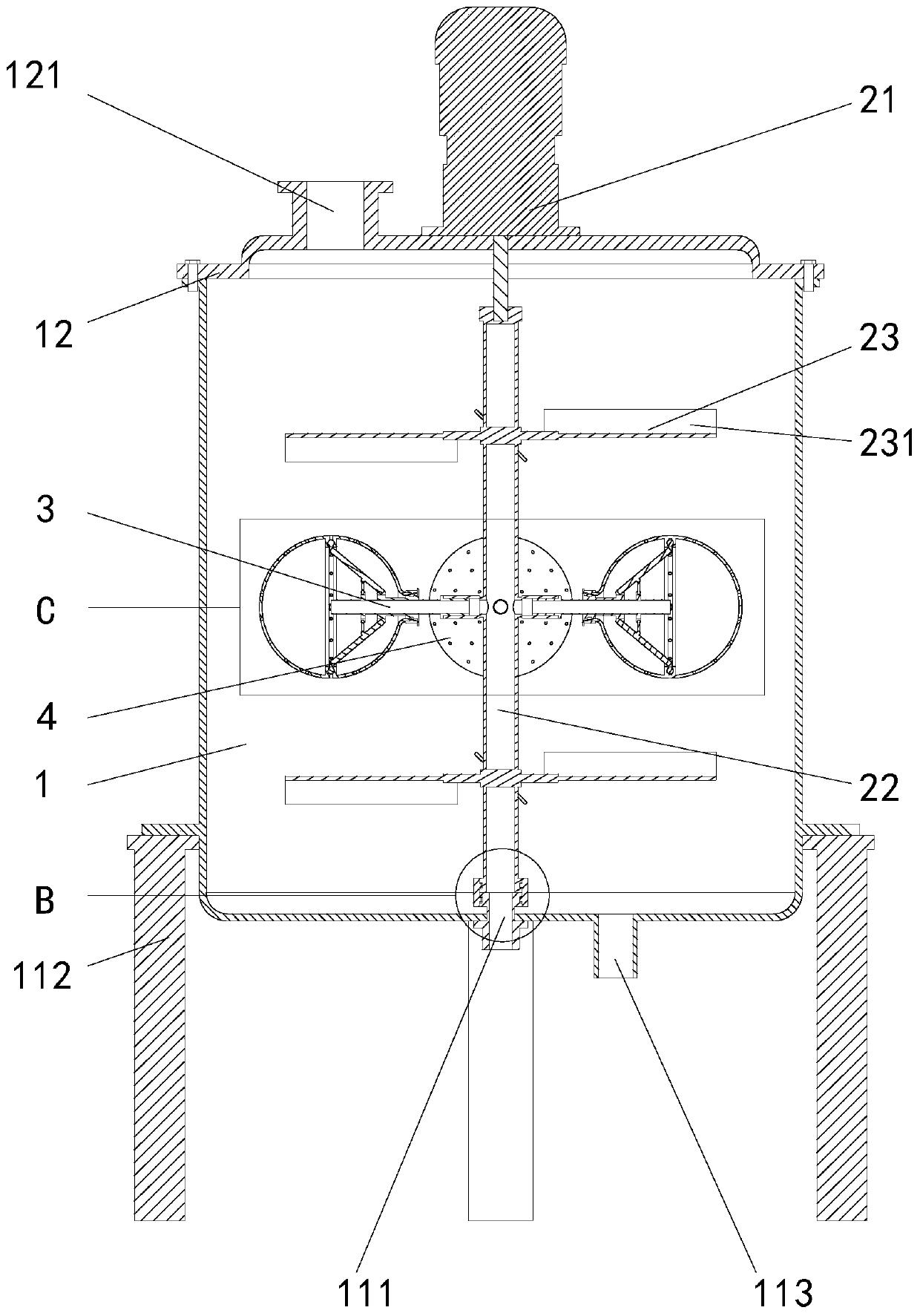

Foaming furnace

The invention discloses a foaming furnace which comprises a horizontal furnace and a vertical furnace, wherein a foamed sheet is fed through the horizontal furnace and the vertical furnace in sequence so as to be heated and foamed; the vertical furnace is arranged below the horizontal furnace; the vertical furnace comprises a furnace body of which the inlet is communicated with the outlet of the horizontal furnace, a heating device and an unfolding device; the heating device is arranged inside the furnace body so as to form a heating field through which the foamed sheet passes; the unfolding device comprises at least one pair of unfolding rollers which are arranged inside the furnace body so as to clamp and unfold the foamed sheet, and a sucking mechanism which is arranged at the outlet of the furnace body so as to suck and unfold the foamed sheet. According to the foaming furnace disclosed by the invention, via cooperation between the unfolding rollers and the sucking mechanism inside the vertical furnace, the foamed sheet can be relatively well unfolded and can be relatively completely and uniformly foamed, the product quality can be improved, the production capacity can be increased, and the purpose of energy conservation can be achieved.

Owner:HUBEI XIANGYUAN NEW MATERIAL TECH INC

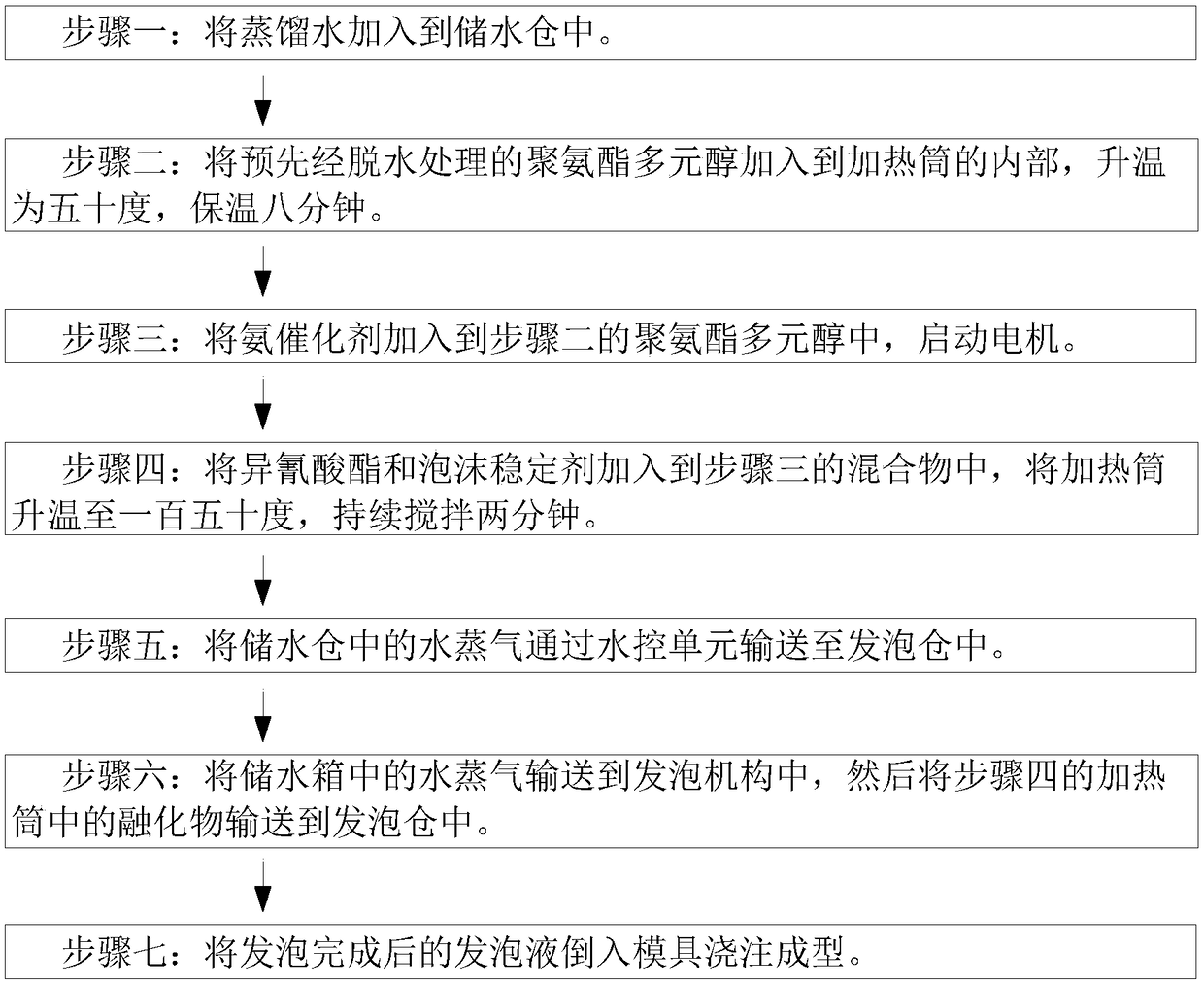

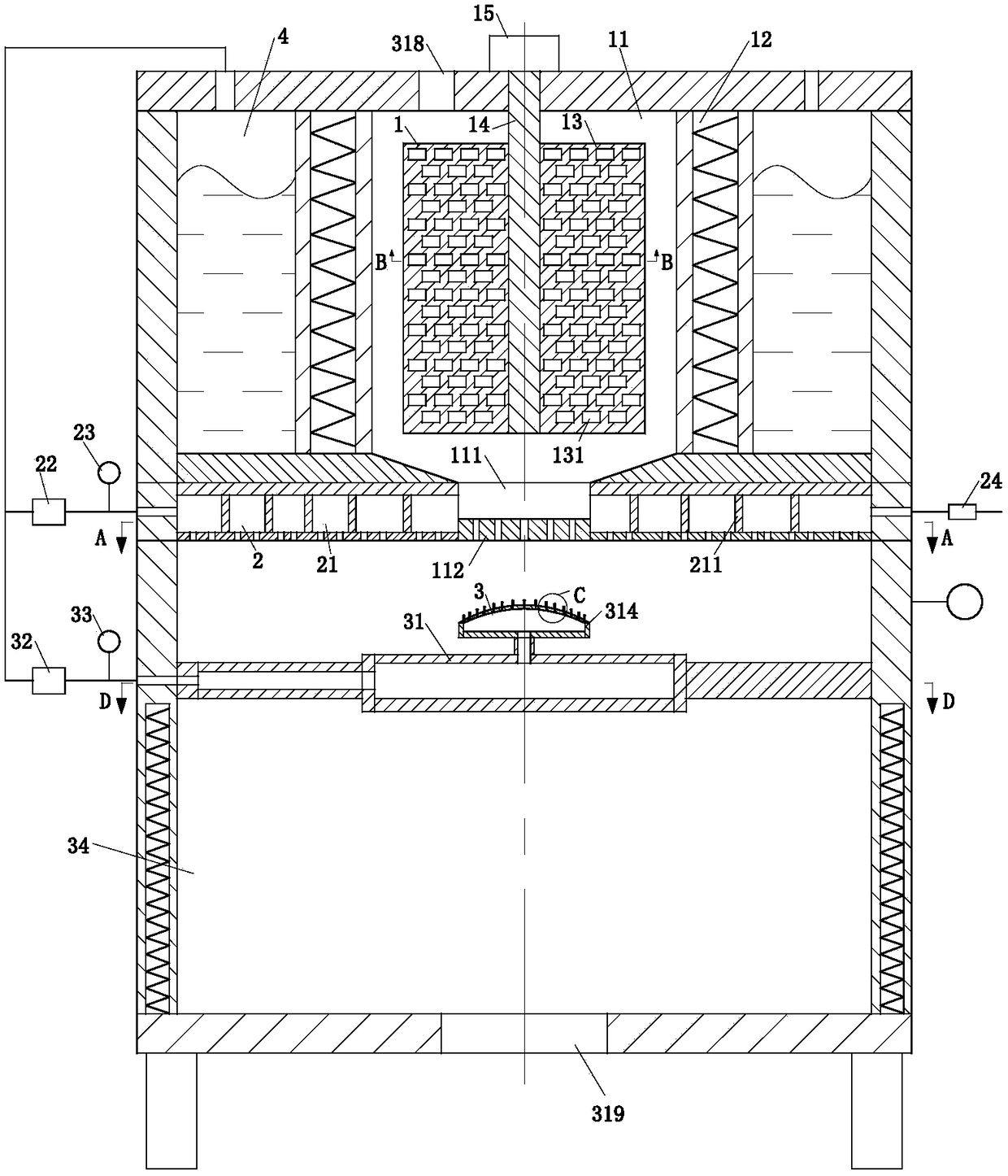

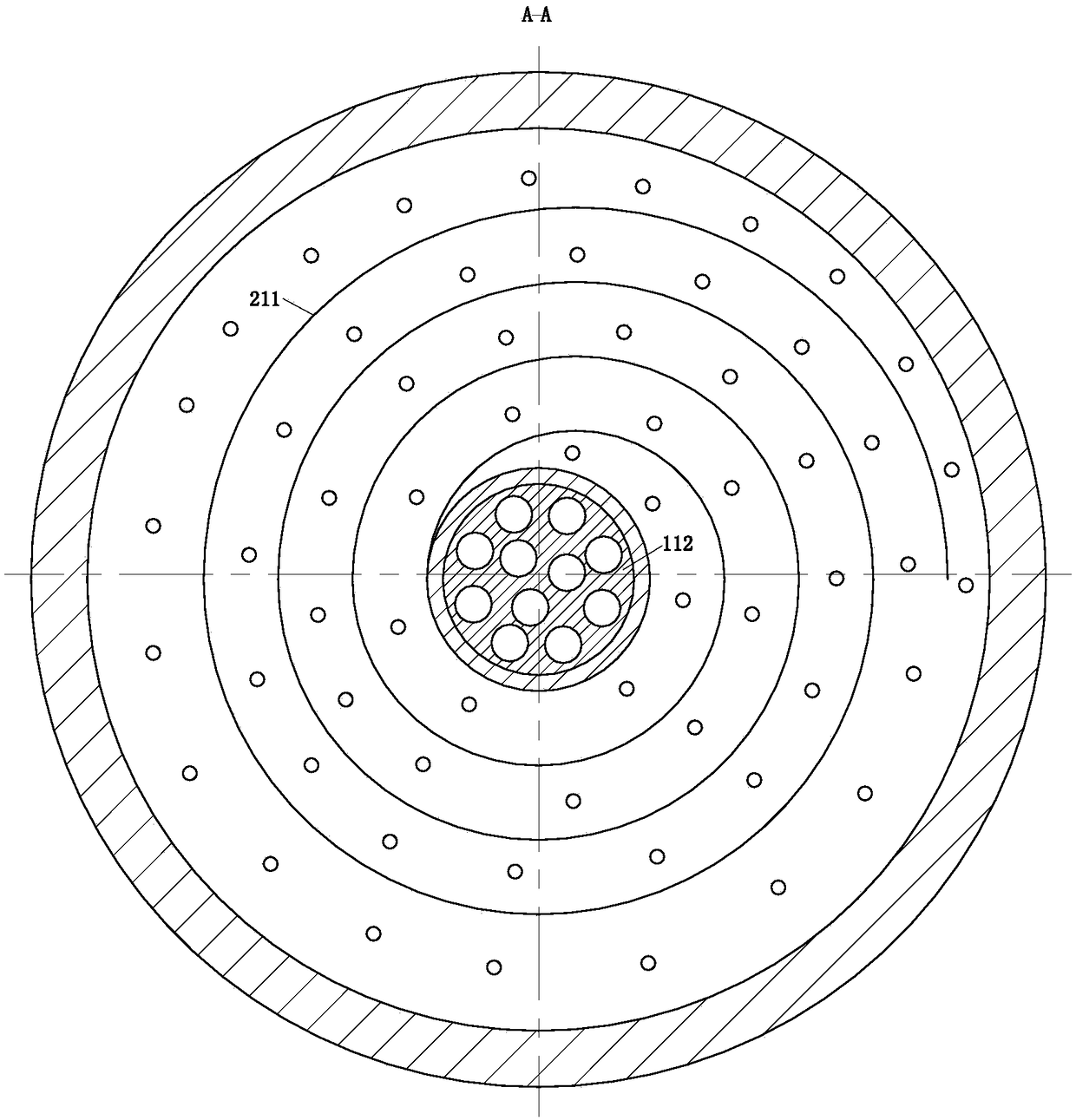

Processing technique for polyurethane heat insulating plate

The invention belongs to the technical field of synthesis and foaming of polyurethane and particularly provides a processing technique for a polyurethane heat insulating plate. The processing technique comprises step I to step VII; the step I to step IV are used for pretreating raw materials; the step V to step VII are used for carrying out foaming reaction of the raw materials; the technique adopts a foaming device; the foaming device comprises a mixing unit, a water control unit and a foaming unit; the mixing unit comprises a mixing bin, a heating cylinder, four mixing plates, a rotating rodand a motor; the mixing bin is cylindrical; the left side of the upper surface of the mixing bin is provided with a No.1 opening; the hating cylinder is fixedly installed inside the mixing bin; the four mixing plates are arranged inside the cylindrical heating cylinder; the mixing unit is used for mixing the raw materials; and the water control unit is matched with the foaming unit so as to foamthe raw materials. The processing technique provided by the invention is mainly used for implementing large-batch production of heat insulating materials, can improve the uniformity of the raw materials, can make the raw materials be foamed fully and improves the foaming efficiency of the raw materials.

Owner:长春华力汽车部件有限公司

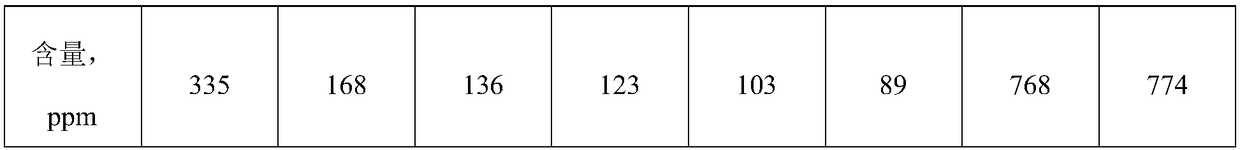

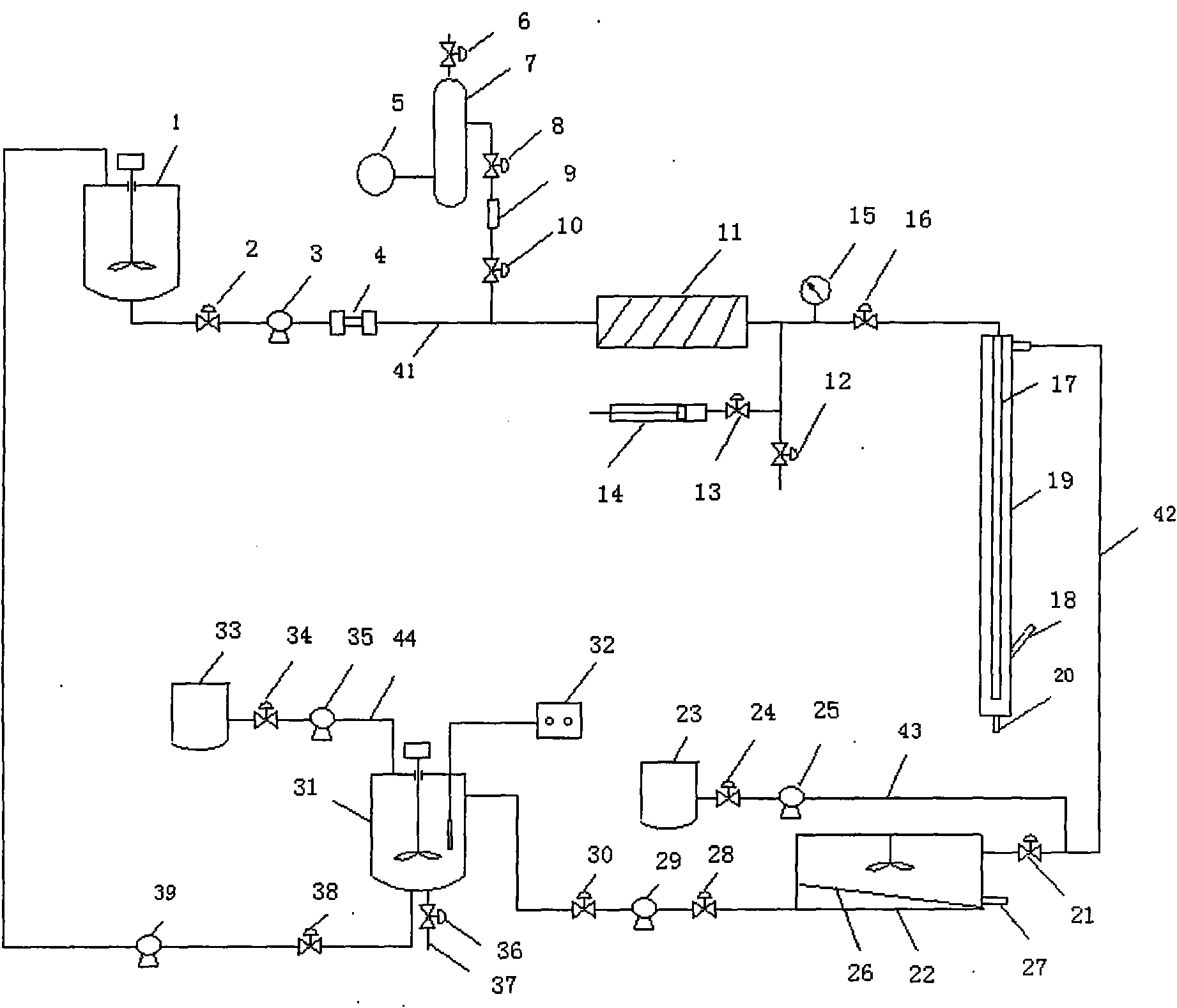

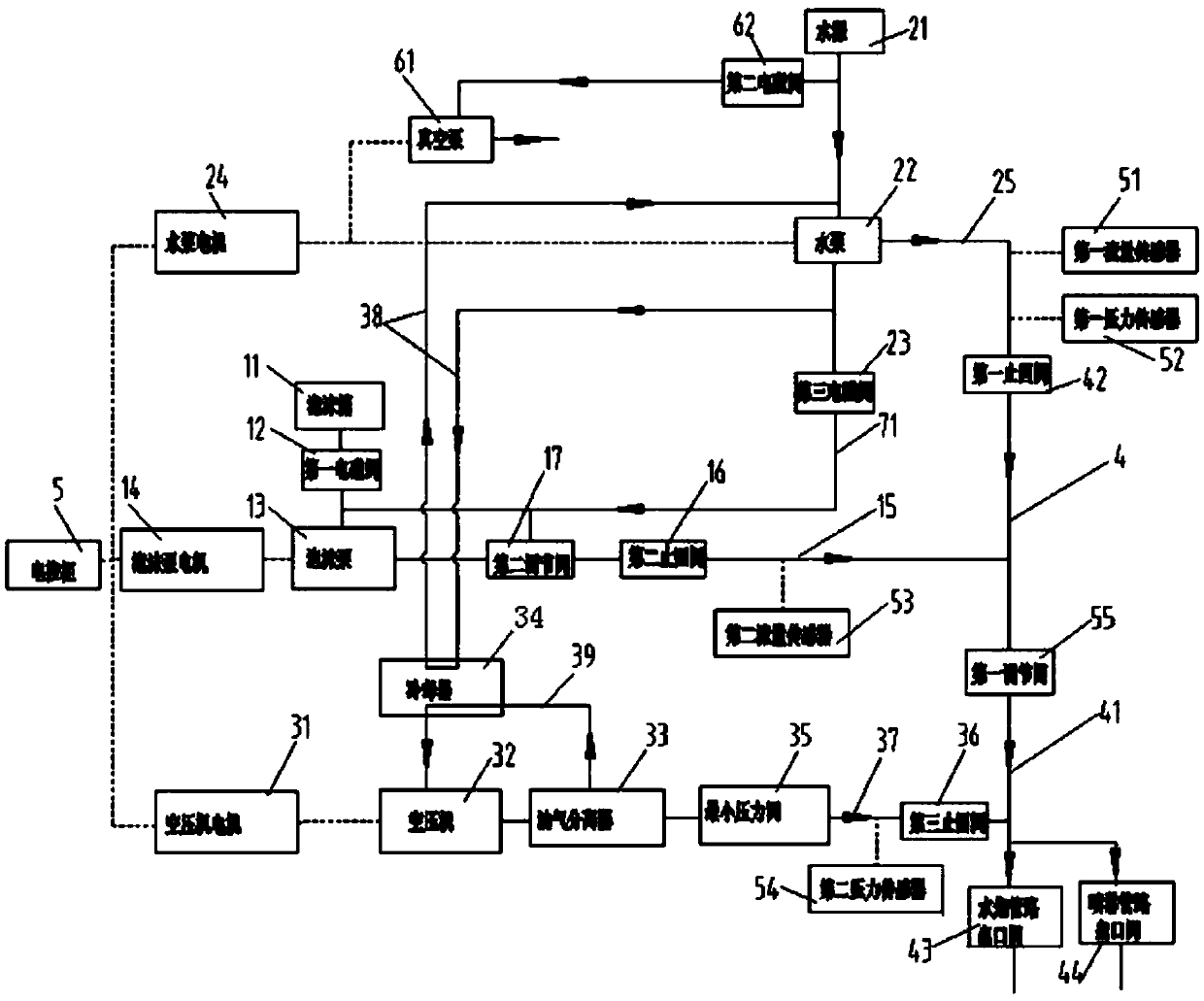

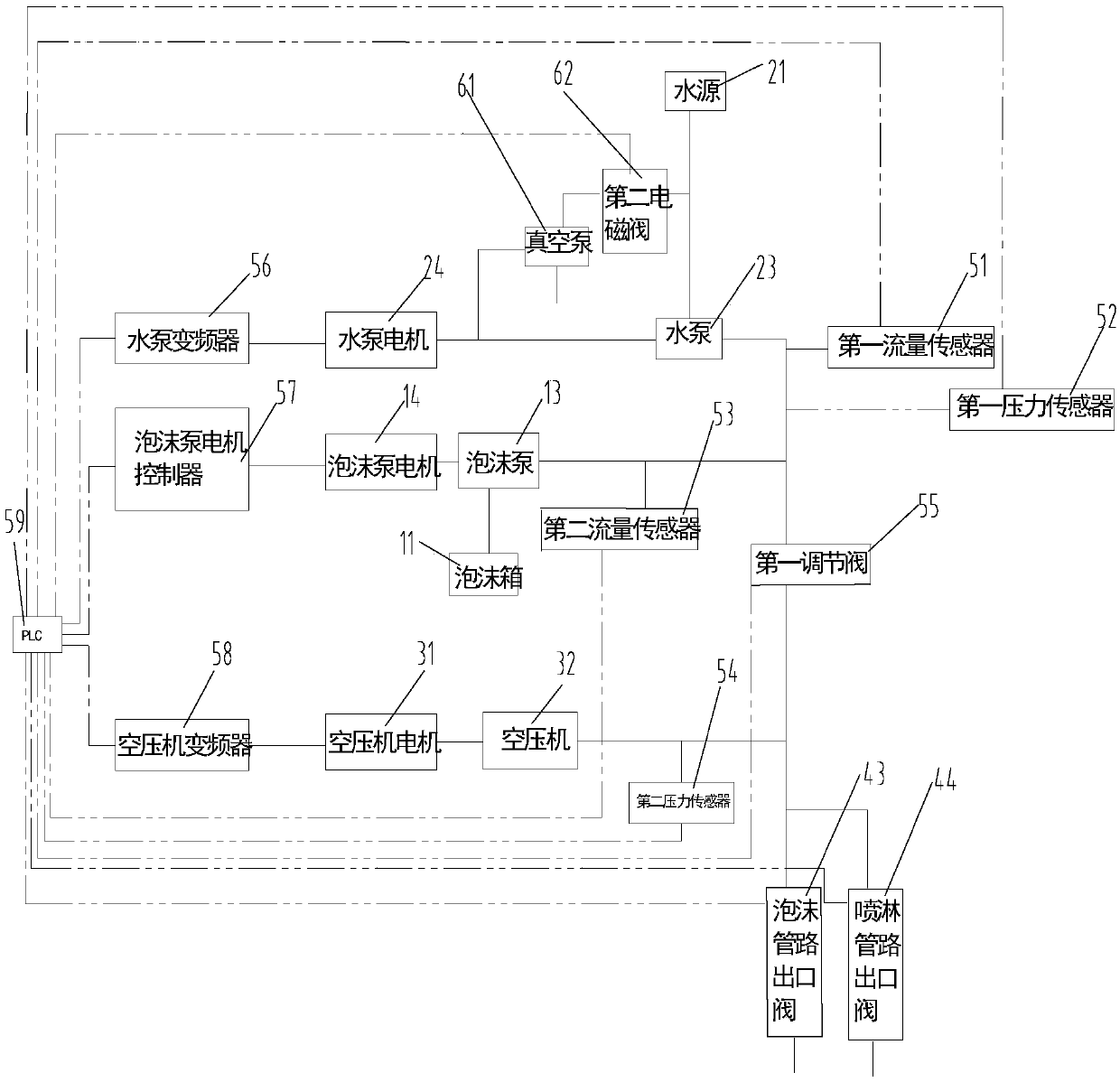

Fixed type class B foam extinguishing device and control method thereof

The invention relates to a fixed type class B foam extinguishing device and a control method thereof. Through the combination of a foam pump system, a water pump system and an air compressor system, class B foam, water and compressed air are mixed, foam formed at a spraying outlet is full in foaming, wild fire is not liable to be formed, and the foam can be used for extinguishment of oil fire andother liquid fire disasters. The water pump system, the air compressor system and the foam pump system are driven by individual power. Closed-loop control is conducted on a water pump, an air compressor and a foam pump through a PLC, the foam proportion can be adjusted in a large range, meanwhile the water flow can be adjusted in a large range, and thus the adjusting range of the extinguishing device becomes larger and can be adjusted freely between 20%-100% of the maximum flow. Through the fixed type class B foam extinguishing device and the control method thereof, the firefighting problem oflarge liquid fire disasters is solved.

Owner:西安航天泵业有限公司

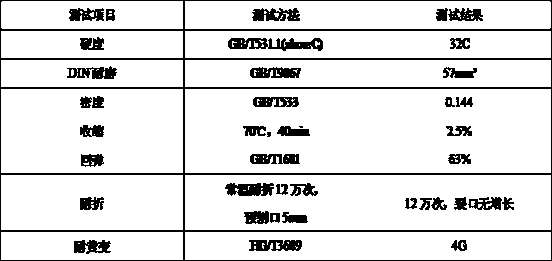

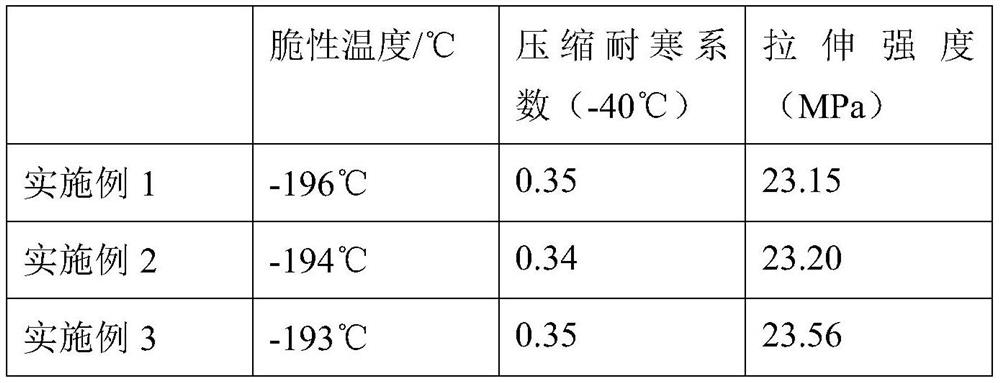

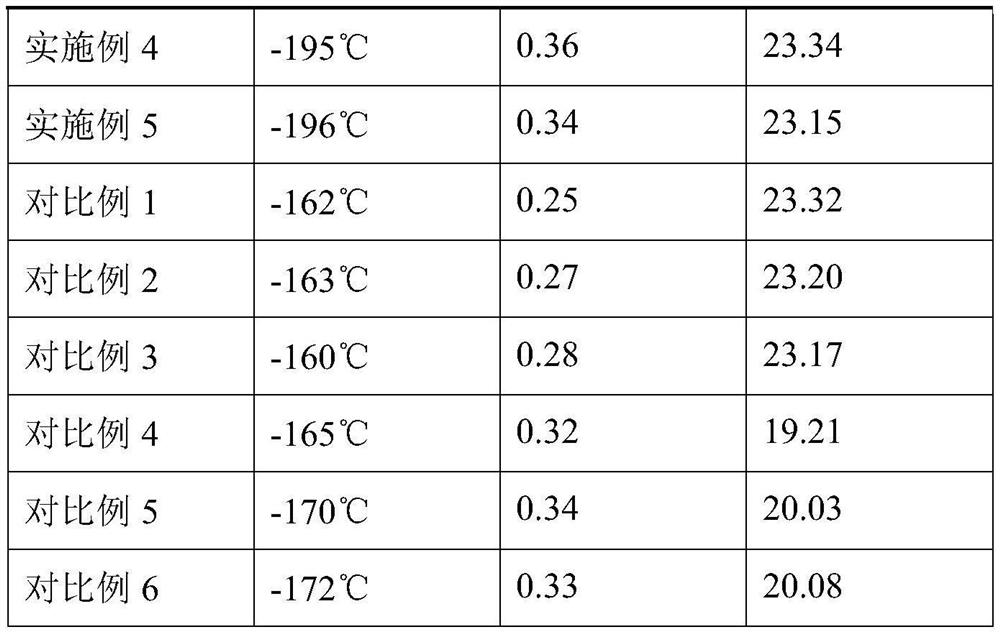

Ultralow-temperature-resistant rubber and plastic product and preparation method thereof

ActiveCN111662512AImprove ultra-low temperature resistanceHigh gum contentPolymer scienceVulcanization

The invention belongs to the technical field of rubber and plastic products, and provides an ultralow-temperature-resistant rubber and plastic product. The product comprises, by mass, 20-25 parts of ethylene propylene diene monomer rubber. 3-5 parts of butyl rubber, 1-1.5 parts of butadiene rubber, 5-7 parts of a foaming agent, 20-30 parts of a flame retardant, 6-8 parts of operating oil, 4-7 parts of a low-temperature plasticizer, 0.3-0.5 part of an activator, 0.1-0.3 part of stearic acid, 3-5 parts of protective wax, 3-5 parts of an accelerant, 0.5-0.8 part of a vulcanizing agent and 0.1-0.2part of pigment. The ethylene propylene diene monomer, the butyl rubber, the butadiene rubber, the foaming agent, the flame retardant, the pigment, the operating oil, the low-temperature plasticizer,the protective wax, the activator and the stearic acid are subjected to banburying, discharging, open milling, compound milling and storage for 22-26 h, the vulcanizing agent and the accelerant are added, and mixing, extrusion molding and vulcanization foaming are conducted to obtain the ultralow-temperature-resistant rubber and plastic product. Through the technical scheme, the problem of poor low-temperature resistance of rubber in the prior art is solved.

Owner:HEBEI SHENZHOU THERMAL INSULATION BUILDING MATERIAL GRP CO LTD

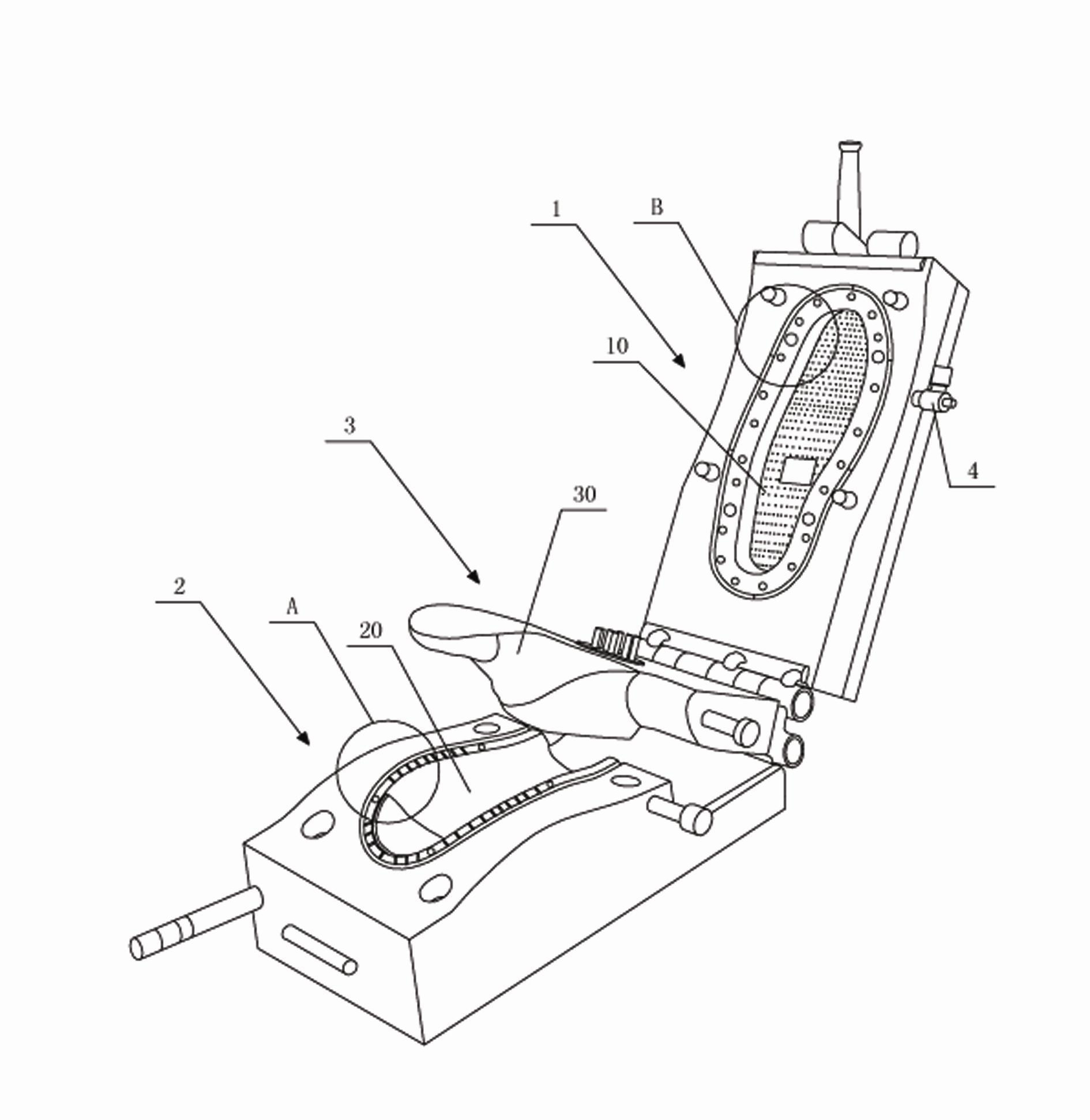

Blow shoe mould

Owner:JINJIANG ZHONGTIAN MOLD

Wood plastic board and preparation method thereof

The invention provides a wood plastic board, and belongs to the technical field of composite board preparation. According to the wood plastic board, ecological wood powder replaces part of wood powder, resources can be saved, PVC (polyvinyl chloride), calcium powder, wood powder and ecological wood powder can be uniformly mixed in the presence of stabilizers, a homogeneous system is formed, besides, the homogeneous system is sufficiently foamed under combined action of raw materials such as foam regulators, foaming agents and stearic acid, and the mechanical property and the product qualification ratio of the wood plastic board are improved. An embodiment shows that the tensile strength of the wood plastic board reaches 23.0-23.9MPa, the shore hardness of the wood plastic board is 58-64HD,and the wood plastic board has an excellent mechanical property.

Owner:六盘水康博木塑科技有限公司

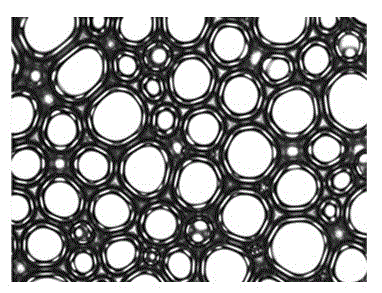

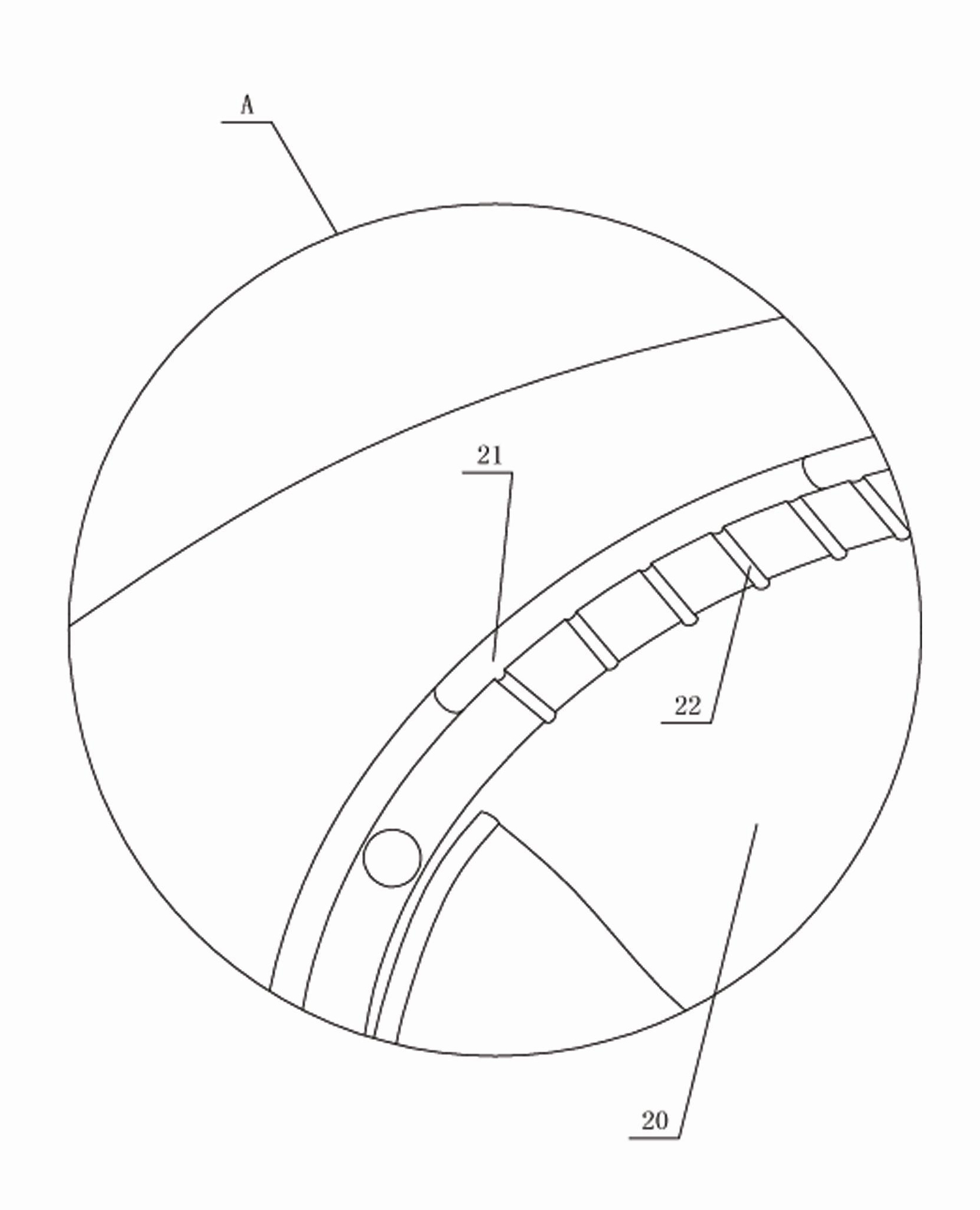

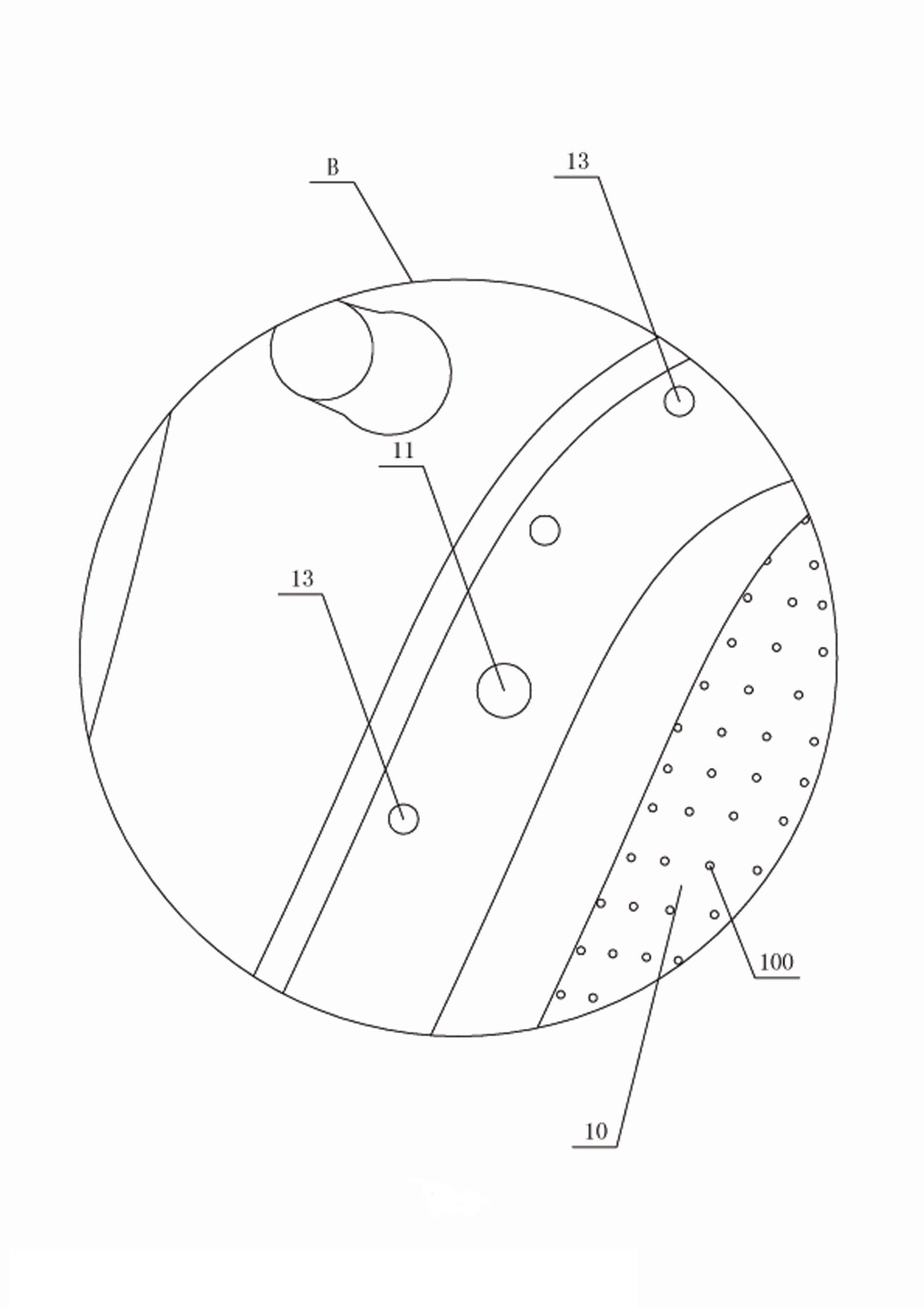

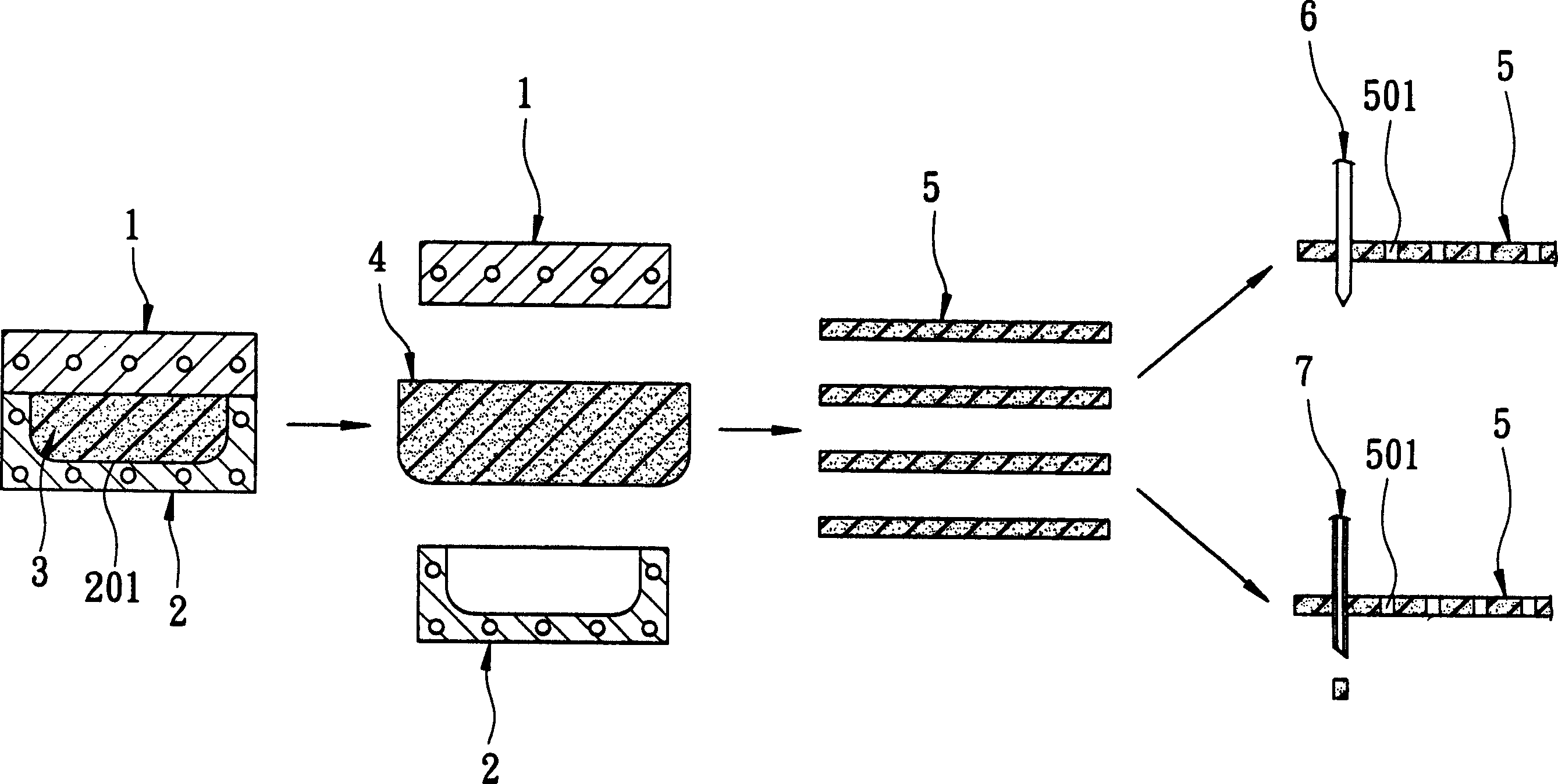

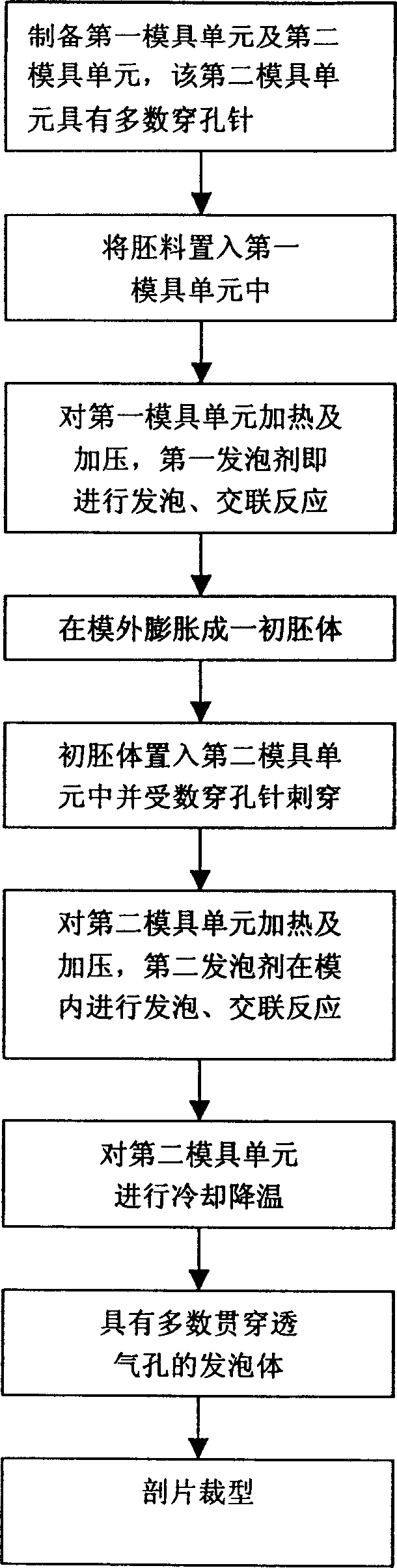

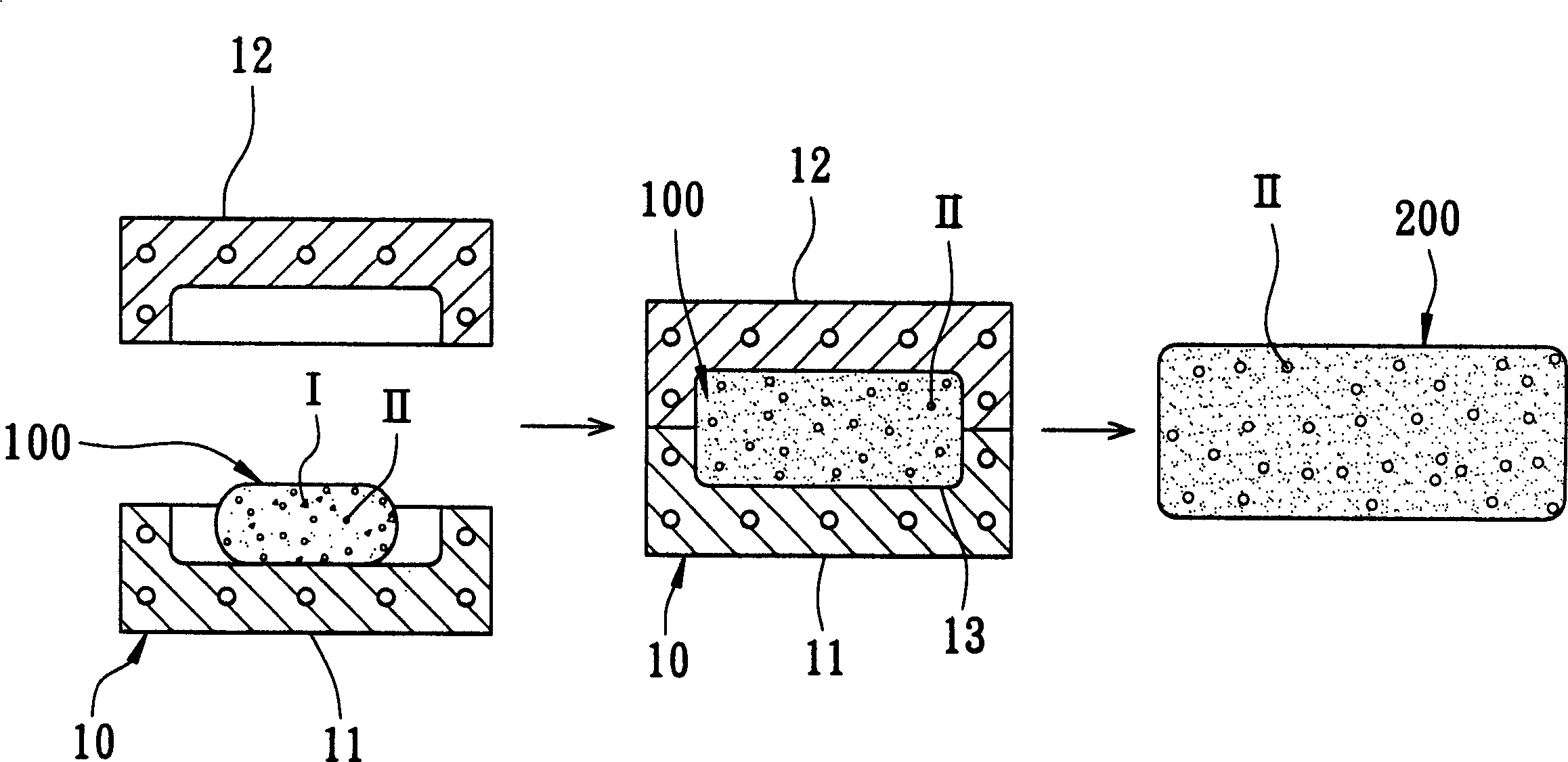

Manufacturing method of foam with air holes

The making process of foamed body with air permeable holes includes the steps of setting the material to be foamed inside a mold with needles, heating and pressurizing the mold for foaming and cross-linking, cooling the mold and demolding. The foamed body may be further cut to required sizes. Or, the material may be first heated and pressurized inside one first mold to form the initial blank, and then foamed and cross-linked in the second mold with needles to obtain the foamed body with air permeable holes.

Owner:刘坤钟

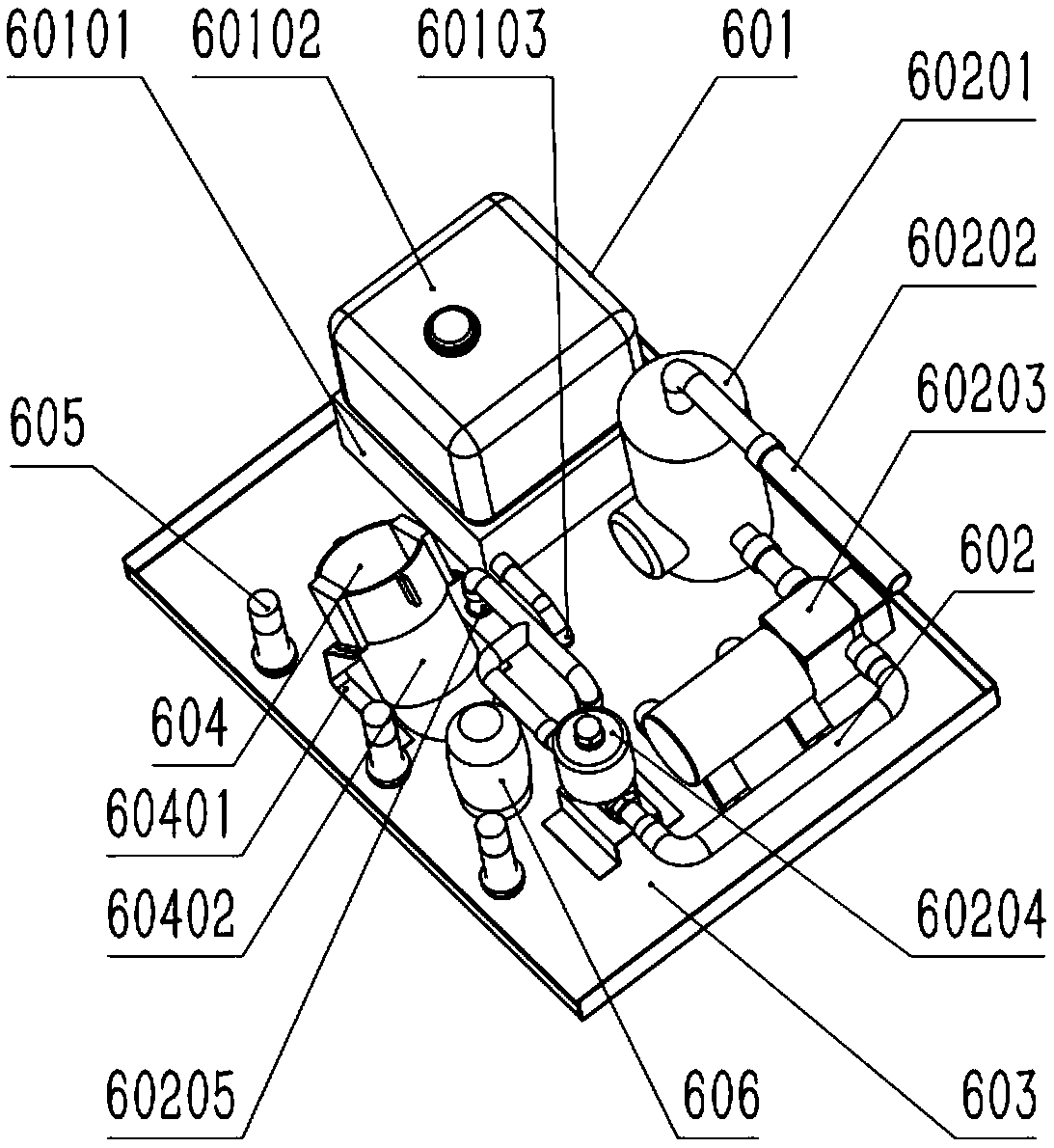

Aqueous film-forming foam fire extinguishing device

InactiveCN108159606AReduce hydraulic frictionIncrease foaming rateFire rescueEngineeringLiquid storage tank

The invention discloses an aqueous film-forming foam fire extinguishing device. The aqueous film-forming foam fire extinguishing device comprises a liquid storage tank, a second mixing box, a second high-pressure pump, a water box and a first mixing box. A base is tightly welded to the lower portion of the liquid storage tank, a liquid drain pipe is arranged at the upper end of the liquid storagetank, a liquid drain valve is arranged on the outer surface of the liquid drain pipe, and a support is arranged at the lower end of the liquid drain valve. According to the aqueous film-forming foam fire extinguishing device, a swirling device is installed in a fire-fighting lance, the swirling device is composed of a central conical hole and a plurality of inclined holes evenly distributed in theperiphery, an included angle is formed between each inclined hole and the axis of the swirling device, the inflow end face and the outflow end face of the swirling device are provided with forty five-degree chamfers, and the effect of reducing hydraulic friction can be achieved. Aqueous film-forming foam mixed liquid enters the swirling device to form a swirling current and a straight current, the swirling current is sufficiently swirled and atomized through a gradually contracted long cone type current mixing cavity, kinetic energy is increased step by step, the swirling current is jetted out from a nozzle through liquid jetting holes, and thus water atomization and mixed foaming are achieved, and the effect of conducting long-distance jetting according to a preset angle can be effectively achieved.

Owner:上海智密技术工程研究所有限公司

Chemical material polyurethane foaming machine

The inventing discloses a chemical material polyurethane foaming machine which comprises a foaming machine shell and a stirring mechanism fixedly mounted on the foaming machine shell for mixing a foaming agent. The foaming machine shell comprises a foaming barrel, a joint pipe penetrating into the foaming barrel vertically is arranged at the bottom of the foaming barrel, the stirring mechanism comprises a hollow stirring shaft penetrating into the foaming machine shell and a connecting sleeve rotatably connected to the lower end of the stirring shaft, the connecting sleeve is also connected to the upper end of the joint pipe, the joint pipe are connected to the stirring shaft, a plurality of connected ventilating branch pipes are distributed on the stirring shaft, and the foaming machine also comprises an inner supporting mechanism fixedly mounted on each ventilating branch pipe and a flexible glue air bag mounted on each inner supporting mechanism. The foaming machine integrates an air inlet mechanism and a stirring mechanism through a gas circuit design, so that the foaming efficiency and the effect and quality of forming a foaming material are improved greatly.

Owner:山东誉中新材料股份有限公司

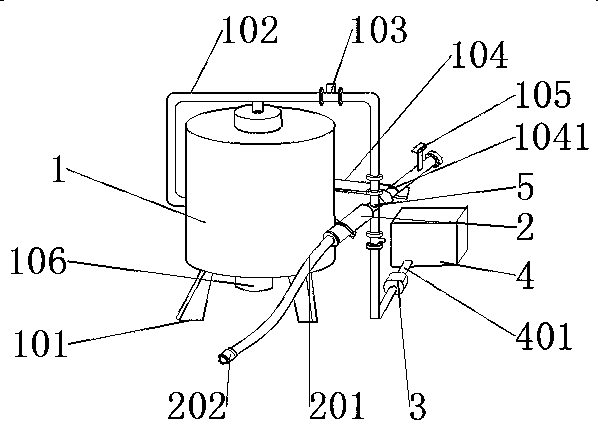

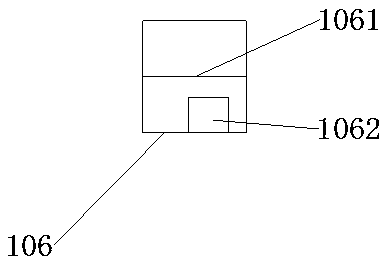

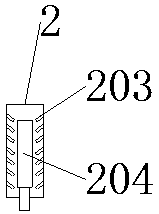

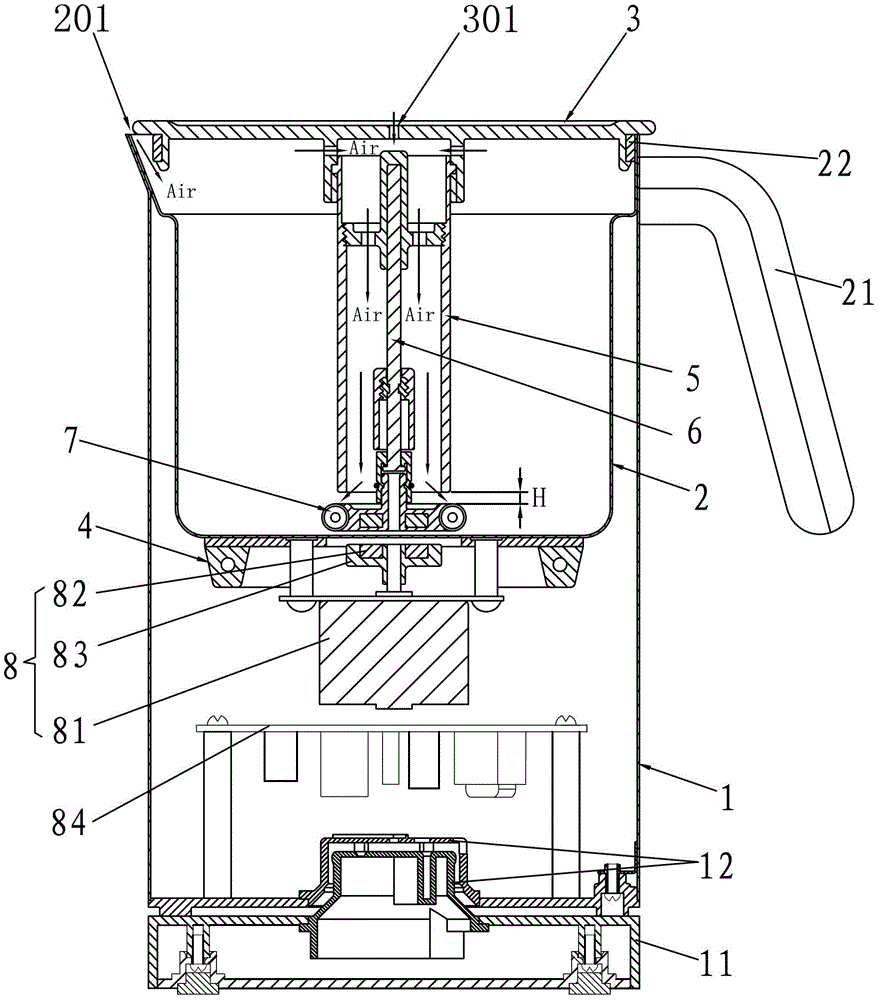

milk foaming machine

The invention belongs to the field of devices for forming foam through milk, and provides a milk foaming machine. The milk foaming machine comprises an outer shell, a container cover and a magnetic driving device. A container and a heating device are arranged in the outer shell. The magnetic driving device is arranged under the container. The container cover is arranged at the upper end of the container. An air pipe is arranged in the container and communicated with the outside of the container. The lower end of the air pipe is connected to a stirring shaft. A stirrer is connected to a portion, at an outlet of the lower end of the air pipe, of the stirring shaft. The lower end of the air pipe is provided with an opening. According to the milk foaming machine, in the overall rotating operation process of the stirrer, air is continuously led into a foaming area nearby the stirrer via the air pipe located above the stirrer through negative pressure generated by the stirrer during rotation, so that the air needed for continuous stirring and foaming is supplied, and the milk foaming is more sufficient and fine. Moreover, the milk foaming machine is simple in structure, fast to produce and assemble, low in cost, convenient to use by consumers, easy to clean and economical to use.

Owner:熊兴剑

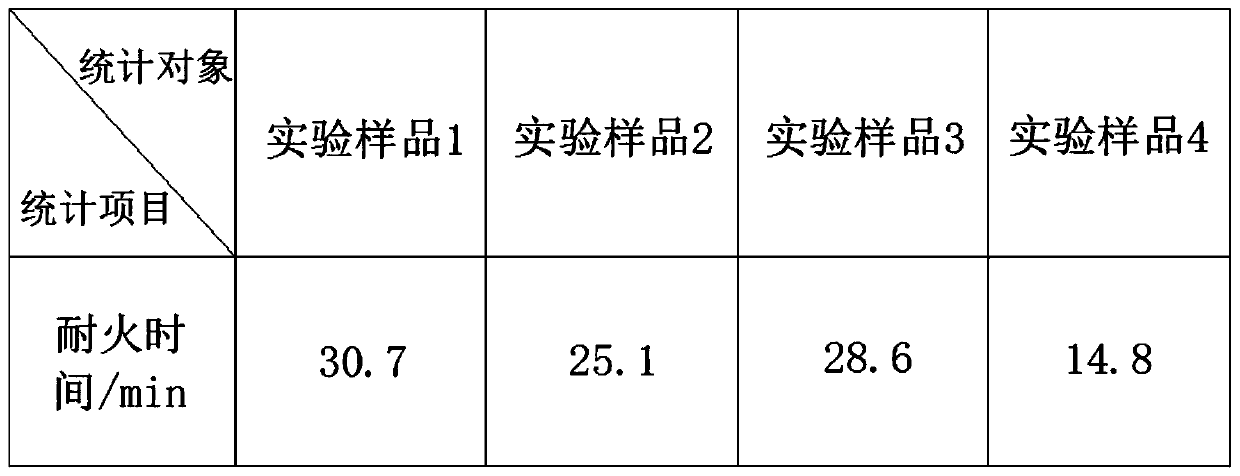

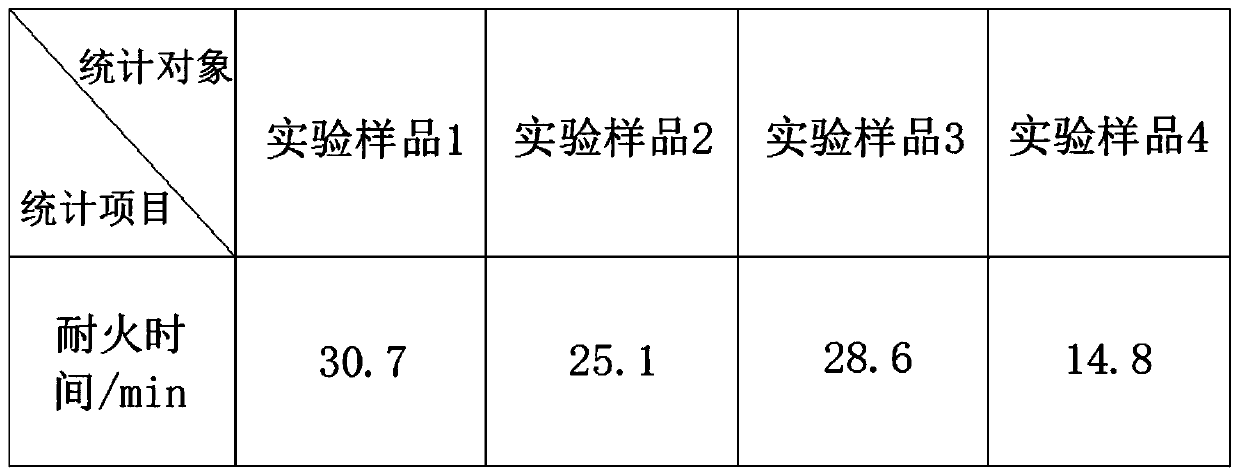

Fireproof flame-retardant inorganic coating

The invention discloses a fireproof flame-retardant inorganic coating. Raw materials of the inorganic coating comprise, in parts by weight, 30-40 parts of silica sol, 30-40 parts of heat insulation aggregate, 5-10 parts of titanium dioxide, 10-20 parts of chlorinated paraffin, 2-3 parts of a foaming catalyst, 1-3 parts of a flame retardant, 1-3 parts of a thickening agent and the balance of clearwater, wherein the heat insulation aggregate is one or a combination of more of expanded perlite, expanded vermiculite, diatomite, fly ash hollow microspheres or sepiolite powder. The invention relates to the technical field of coatings. The fireproof flame-retardant inorganic coating Can well resist external conventional fire disasters, and achieves the purpose of improving the fire resistance ofthe coating through improvement of internal components of the inorganic coating, thus the heat conductivity coefficient is substantially reduced, the fire resistance grade is improved, and further the fire resistance and the fire retardation of the inorganic coating material are enhanced. An inorganic glazed body is formed through an endothermic reaction when meeting fire so as to isolate the air, and the purposes of non-combustible gas emission through decomposition, smoke abatement and combustion blocking are well achieved.

Owner:江门市涂霸建材实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com