Stable multilayer-film structural foaming agent and preparation method thereof

A multi-layer film and foaming agent technology, applied in the direction of fire-resistant coatings, etc., can solve the problems of unsatisfactory results, inconvenient operation, uneven distribution and other problems, and achieve the effects of excellent foaming performance, improved stability and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

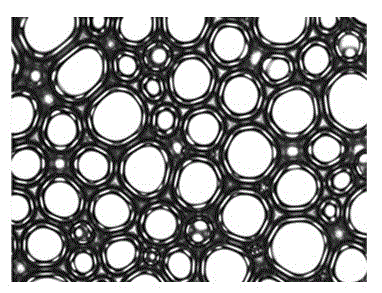

Image

Examples

Embodiment 1

[0021] A stable multilayer film structure foaming agent and a preparation method thereof. Under the condition of 15~25°C, first use 20~30wt% of the main agent, 30~40wt% of the auxiliary agent and 40~50wt% of the foam stabilizer as raw materials, and then add 10~15 times the mass of the raw materials to remove Ionized water, stirring for 5~10min, the stirring speed is 800~1000r / min. A stable multilayer film structure foam is obtained.

[0022] In this embodiment: the main agent is sodium lauryl sulfate; the auxiliary agent is lauryl alcohol; the foam stabilizer is sodium carboxymethyl cellulose.

[0023] The stable multi-layer film structure foam agent prepared in this example has been tested: the expansion ratio is 5.5-6.5; the bleeding volume in 1h is 0-1mL, and the collapse volume in 1h is 0-2mL; the bleeding volume in 2h is 2-4mL, and the collapse volume in 2h 5~6mL.

Embodiment 2

[0025] A stable multilayer film structure foaming agent and a preparation method thereof. Except following raw material, all the other are with embodiment 1.

[0026] In this embodiment: the main agent is sodium dodecylbenzenesulfonate; the auxiliary agent is polyethylene glycol; the foam stabilizer is gelatin.

[0027] The stable multi-layer film structure foam agent prepared in this example has been tested: the expansion ratio is 5.5-6.5; the bleeding volume in 1h is 0-2mL, and the collapse volume in 1h is 0-3mL; the bleeding volume in 2h is 3-5mL, and the collapse volume in 2h 6~8mL.

Embodiment 3

[0029] A stable multilayer film structure foaming agent and a preparation method thereof. Except following raw material, all the other are with embodiment 1.

[0030] In this embodiment: the main agent is sodium dodecyl sulfonate; the auxiliary agent is cetyl alcohol; the foam stabilizer is sodium carboxymethyl starch.

[0031] The stable multi-layer film structure foam agent prepared in this example has been tested: the expansion ratio is 5.5-7.0; the bleeding volume in 1h is 0-0.5mL, and the collapse volume in 1h is 0-1mL; the bleeding volume in 2h is 1-2mL, and it collapses in 2h Volume 2~4mL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com