Ammonium-amine coupling activation method based on copper mineral sulfurization floatation system

A mineral and system technology, used in flotation, solid separation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

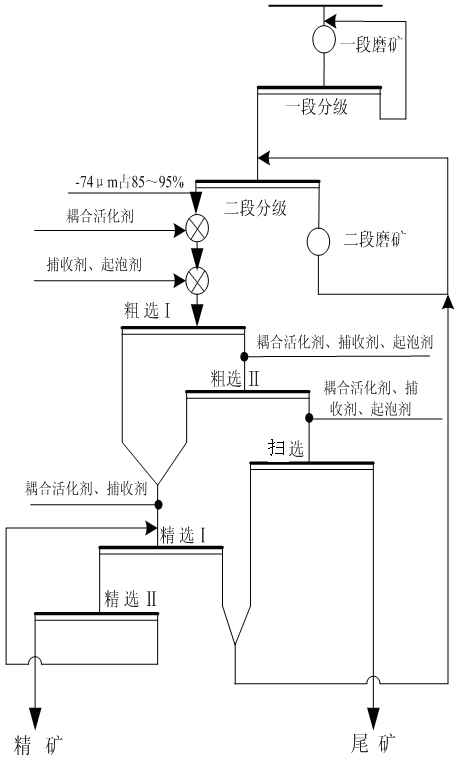

Image

Examples

Embodiment 1

[0021] Copper oxide ore with a copper grade of 1.64% in the raw ore, an oxidation rate of 78.12%, and a binding rate of 17.65%.

[0022] (1) Copper oxide ore undergoes wet grinding to make the ore grind to a fineness of -74μm, accounting for 88%, adjust the mass concentration of the pulp to 30%, enter the first mixing tank, add ammonium bicarbonate 300g / t, phosphoric acid Diammonium hydrogen 300g / t, ammonium humate 150g / t, ethylenediamine phosphate 120g / t, sodium sulfide 1000g / t and stirred at a speed of 200-300r / min for 8min to make the above-mentioned agents in the copper minerals and copper minerals. The activation effect occurs on the surface of the organism.

[0023] (2) Put the pulp obtained in step (1) into the second mixing tank, add 180g / t isoamyl xanthate, 40g / t pine oil, and stir for 2min at a speed of 200-300r / min to make the isoamyl The base xanthate anions adsorb on the surface of copper minerals and copper mineral associations to form a hydrophobic surface.

...

Embodiment 2

[0029] Mixed copper ore with a copper grade of 0.81% in the raw ore, an oxidation rate of 28.12%, and a binding rate of 10.65%.

[0030] (1) After the mixed copper ore is wet-ground, the ore is ground to a fineness of -74μm, accounting for 85%, the mass concentration of the pulp is adjusted to 38%, and it enters the first mixing tank, adding ammonium bicarbonate 100g / t, phosphoric acid Diammonium hydrogen 100g / t, ammonium humate 100g / t, ethylenediamine phosphate 50g / t, sodium sulfide 300g / t and stirred at a speed of 200-300r / min for 8min to make the above agents in copper minerals and copper minerals. Activation reactions occur on the surface of living organisms.

[0031] (2) Put the pulp obtained in step (1) into the second mixing tank, add 100g / t isoamyl xanthate, 30g / t pine oil and stir for 2min at a speed of 200-300r / min to make the isoamyl The xanthate anions adsorb on the surface of copper minerals and copper mineral associations to form a hydrophobic surface, and at th...

Embodiment 3

[0037] Copper oxide ore with a copper grade of 0.94% in the raw ore, an oxidation rate of 78.12%, and a binding rate of 18.12%

[0038] (1) After the copper oxide ore is ground, the ore is ground to a fineness of -74μm, accounting for 95%, the mass concentration of the pulp is adjusted to 25%, and it enters the first mixing tank, adding ammonium bicarbonate 300g / t, hydrogen phosphate 400g / t of diammonium, 200g / t of ammonium humate, 120g / t of ethylenediamine phosphate, 2000g / t of sodium sulfide and stirring at a speed of 200-300r / min for 8min, so that the above-mentioned agents are mixed in copper minerals and copper minerals. Activation reaction occurs on the surface.

[0039] (2) Put the pulp obtained in step (1) into the second mixing tank, add 300g / t isoamyl xanthate, 50g / t pine oil and stir for 4min at a speed of 200-300r / min to make the isoamyl Xanthate anions adsorbed on the surface of copper minerals and copper mineral associations to form a hydrophobic surface.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com