Micro-polluted surface water treatment method based on bio-membrane reactor

The technology of a biofilm reactor and a treatment method is applied in the field of micro-polluted surface water treatment based on the biofilm reactor, which can solve the problems of increasing the difficulty of physical and chemical restoration of micro-polluted surface water, and achieves a simple structure, The effect of increasing the contact time and strong load impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

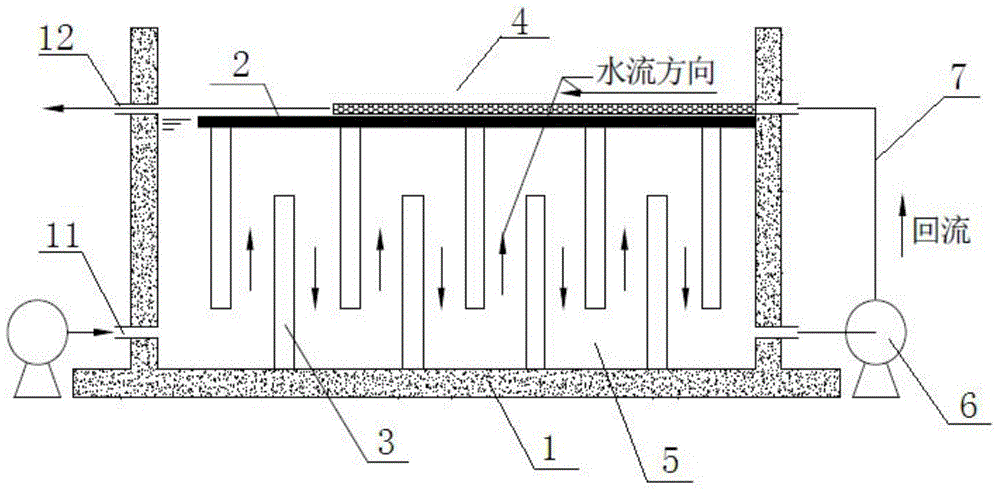

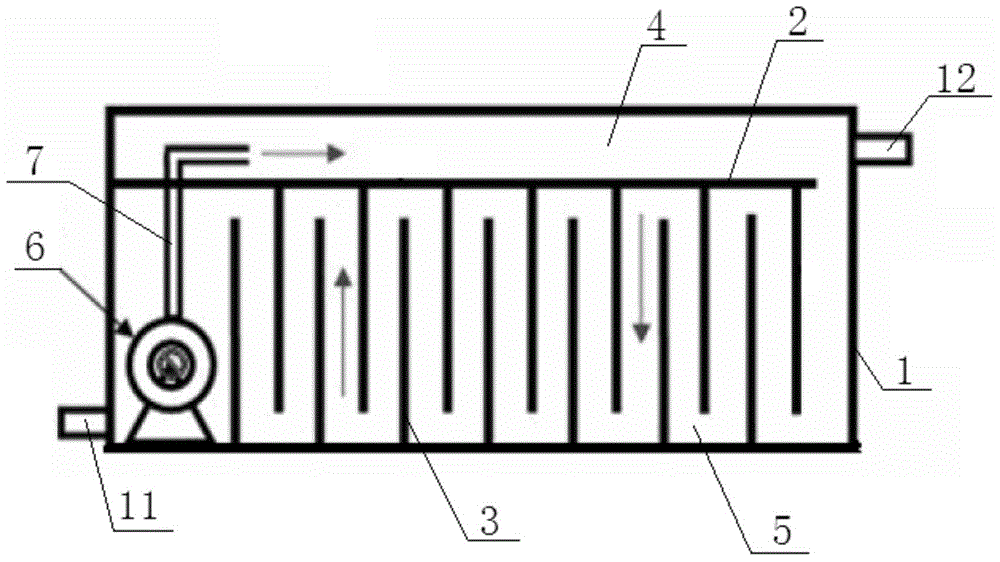

[0039] A ceramic carrier water pump drives a baffled internal circulation biofilm reactor, such as figure 1 As shown, it includes a reactor shell 1, one end of the reactor shell 1 is provided with a water inlet 11 and a water outlet 12, and the inside of the reactor shell 1 is provided with an isolation plate 2, and the isolation plate 2 divides the interior of the reactor into an upper dissolved oxygen zone 4 and the biodegradation zone 5 below, and one end of the dissolved oxygen zone 4 is directly connected with the biodegradation zone 5, and the other end is connected with the circulation pipe 7 through the circulation pump 6, so that the waste water to be treated continuously flows through the dissolved oxygen zone 4 and the biodegradation zone 5, 9 deflectors 3 are arranged vertically at intervals in the biodegradation zone 5, and the deflectors 3 are arranged alternately in order to form a channel that can make the solution deflect up and down in the reactor, and the def...

Embodiment 2

[0055] Use the biofilm reactor of this embodiment 1 to carry out denitrification treatment to slightly polluted surface water:

[0056] When the reactor operates as a continuous flow, the water source of the Guilin Park section of the Caohejing River, a branch of the Huangpu River, Longhua Port, Shanghai, is taken as the raw water.

[0057] When the reactor operates in batch mode, refer to Example 1 for water source preparation.

[0058] The batch reactor dephosphorization test was carried out from July to August 2010. When the reactor was operated intermittently, the water inlet pump was turned off, the reactor was filled with water to be treated, the circulation pump was turned on at a speed of 50.0rmp, and the raw water was Laboratory water distribution (C:N:P=100:5:1), in which the nitrogen source is prepared with ammonium chloride, which is ammonia nitrogen, and the experiments without aeration and aeration were used to study the effect of dissolved oxygen on the concentr...

Embodiment 3

[0061] Use the biofilm reactor of this embodiment 1 to carry out denitrification treatment to slightly polluted surface water:

[0062] When the reactor operates as a continuous flow, the water source of the Guilin Park section of the Caohejing River Road, a branch of the Huangpu River, Longhua Port, Shanghai, is taken as the raw water.

[0063] When the reactor operates in batch mode, refer to Example 1 for water source preparation.

[0064] Treat natural river water by continuous flow operation. When the hydraulic retention time (HRT) is greater than 6.0 hours, the reactor has a significant degradation effect on organic matter, and the reactor effluent COD Cr The concentration is significantly lower than the reactor influent COD Cr Concentration, effluent COD Cr The concentration reaches the Ⅱ~Ⅲ waters stipulated in the "Surface Water Environmental Quality Standard"; this experiment uses a biofilm reactor to treat COD Cr The removal effect of COD has a very obvious correl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com