Manufacturing method of foam with air holes

A manufacturing method and foam technology, applied in the field of foam gaskets, can solve the problems such as loss of elasticity of shoe gasket 5, no longer recycling, incomplete hole shape, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

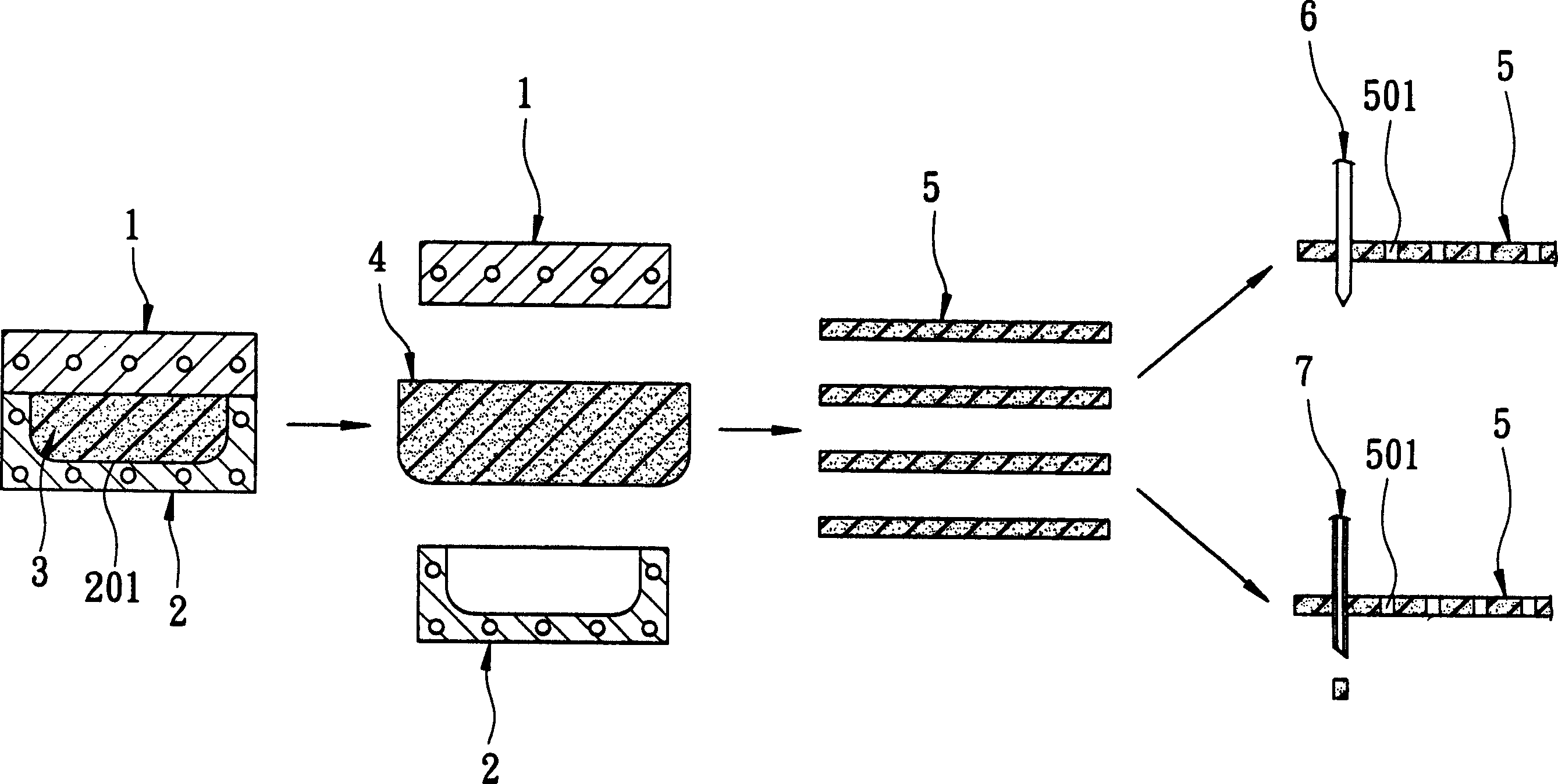

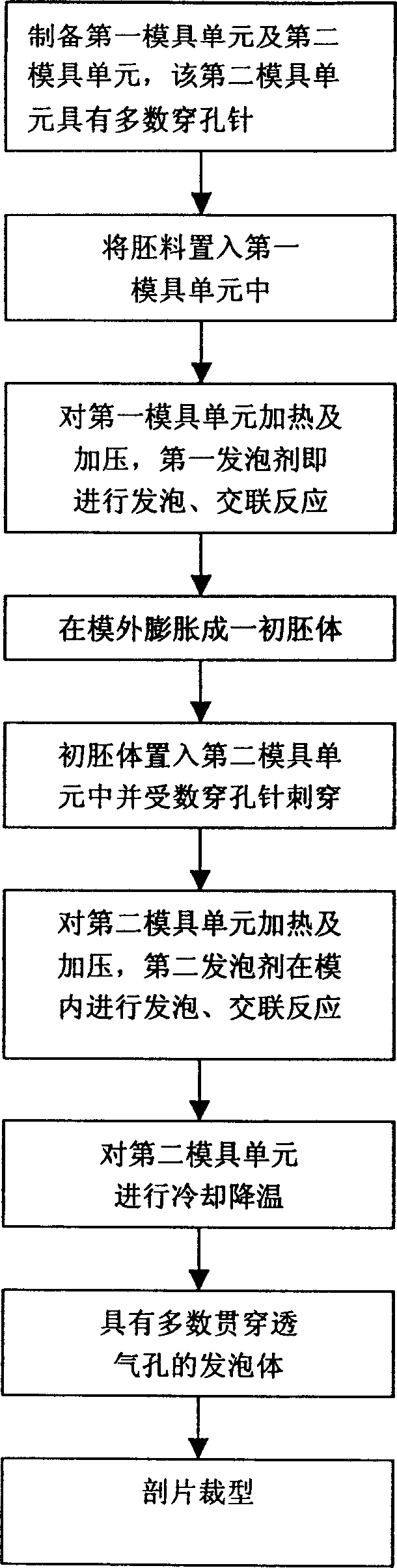

[0023] refer to figure 2 , image 3 And Fig. 4, the first preferred embodiment of the manufacturing method of the foamed body with vent hole of the present invention comprises the following steps:

[0024] Step 1: Prepare a first and a second mold unit 10 , 20 . The first and second mold units 10 and 20 each have a first and second mold base 11 and 21, a first and second mold cover 12 and 22 that can be closed or separated from the first and second mold bases 11 and 21 , a first and a second mold cavity 13, 24 can be formed when they are closed to each other. The second mold unit 20 has a plurality of perforating pins 23 fixed on the second mold cover 22-mold top surface 221, and these perforating needles 23 can be extended from the mold top surface 221 to the second mold base 21-mold The bottom surface 211 runs through the second mold cavity 24 , and the bottom surface 211 of the mold is provided with a plurality of concave holes 212 for inserting and positioning the perf...

Embodiment 2

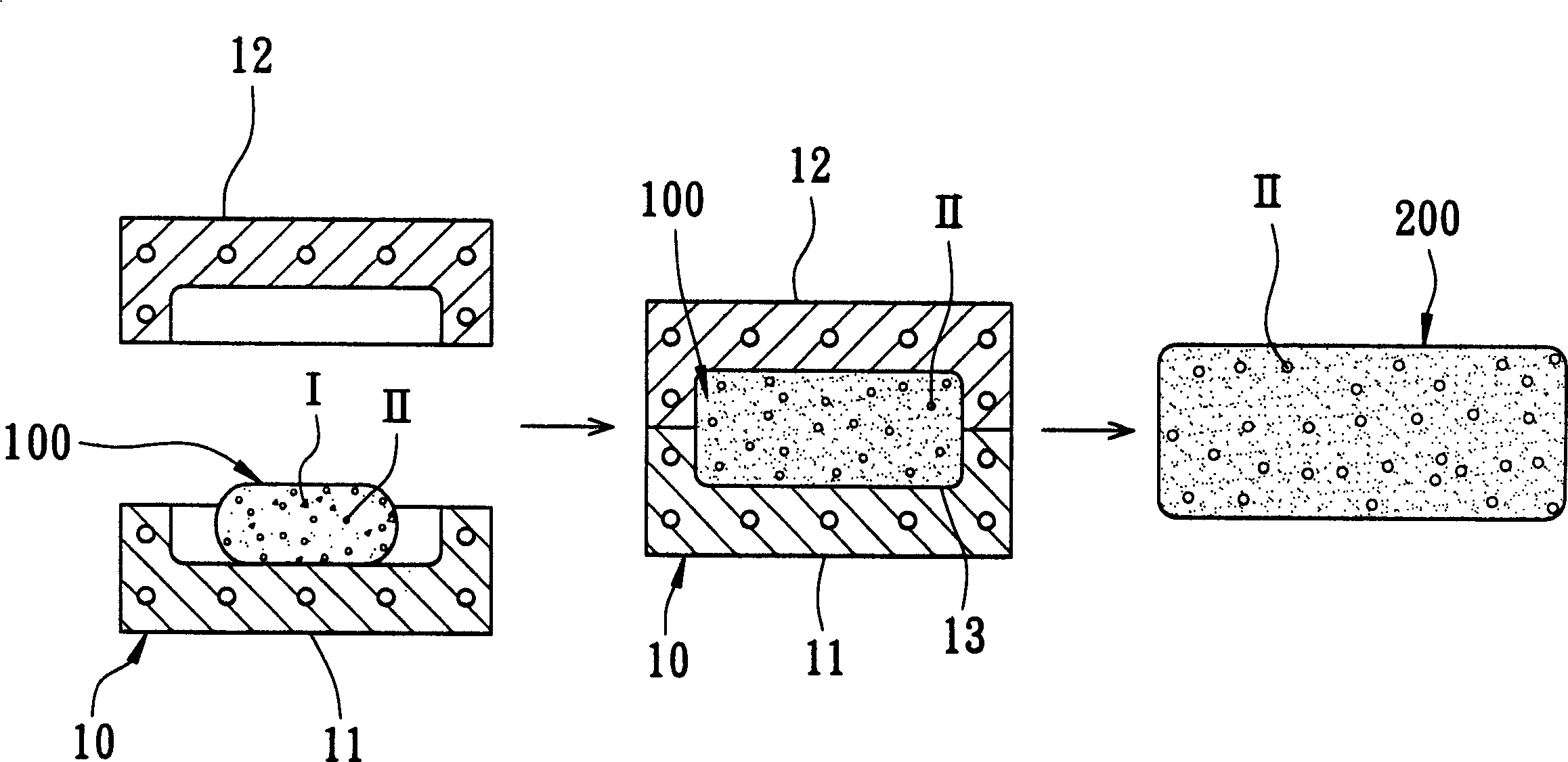

[0039] Another example Figure 6 As shown, the manufacturing method of the second embodiment of the present invention includes the following steps: (A) preparing a first and second mold unit identical to that of the first embodiment. (B) Putting a blank into the first mold unit, the blank only contains a foaming agent. (C) heating and pressurizing the first mold unit, when the billet has reached the reaction temperature and controlling the reaction time, the foaming and crosslinking reactions of the billet are not completely completed. (D) Opening the first mold unit to expand and form an incompletely foamed embryo outside the mold, the volume of the embryo being larger than the first cavity but smaller than the second cavity. (E) Putting the uncooled and solidified primordial body into the second mold unit and piercing it with the perforating needles. (F) heating and pressurizing the second mold unit, and making the embryonic body continue to complete foaming and crosslinki...

Embodiment 3

[0041] another example Figure 7 As shown, the manufacturing method of the third embodiment of the present invention includes the following steps: (A) preparing a mold unit, the mold unit has a plurality of piercing needles inside. (B) Putting an unfoamed billet (which can be solid raw meal or melted liquid raw meal) into the mold unit and pierced by the perforating needles. (C) heating and pressurizing the mold unit, and making the billet complete foaming and crosslinking reactions in the mold. (D) After the foaming and cross-linking reactions of the billet are completed in the mold, the mold unit can be cooled and lowered in temperature. (E) Opening the mold unit to obtain a foam body with a plurality of penetrating air holes. (F) Slicing and cutting the foam. Therefore, it is also possible to make a foam with air holes by using a single mold unit with a plurality of perforating needles.

[0042] It is worth mentioning that the blank material of the present invention is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com