Color rubber and plastic heat-insulating material and preparation method thereof

A thermal insulation material, rubber and plastic technology, applied in the field of equipment thermal insulation materials and construction, can solve the problem that the internal structure of the color rubber and plastic thermal insulation material cannot be stabilized, the color rubber and plastic thermal insulation material cannot be uniformly foamed, and the air temperature and the temperature of the cooling water tank are unstable, etc. problems, to shorten the plasticizing time, enhance the anti-aging ability, and achieve the effect of consistent color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

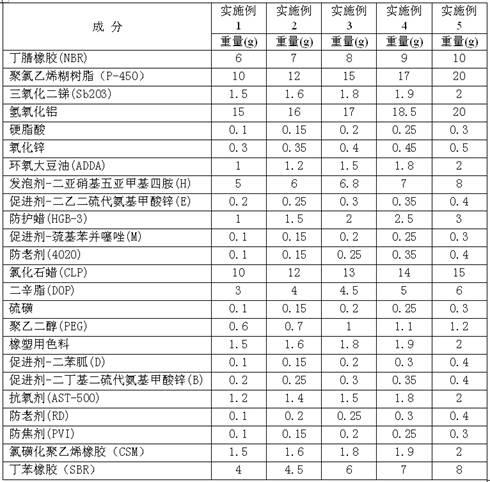

Examples

Embodiment 3

[0033] The preparation side of embodiment three comprises the following steps:

[0034] (1) take the raw material by the weight of the components in the above-mentioned each embodiment and each component;

[0035] (2) High-temperature rubber mixing: nitrile rubber, chlorosulfonated polyethylene rubber (CSM), and styrene-butadiene rubber weighed in parts by weight

[0036] (SBR), polyvinyl chloride paste resin (P-450), aluminum hydroxide, polyethylene glycol, antimony trioxide, protective wax, oxidized paraffin wax, antioxidant (4020), antioxidant (RD), antioxidant (AST-500), dioctyl ester (DOP), and epoxidized soybean oil (ADDA) are placed in the mixing chamber and mixed until 150°C for discharge;

[0037] (3) Open refining: the discharge of step (2) is poured into the open mill section, the cut film thickness is 6.5mm, the film width is 550mm, and the film length is 2250mm;

[0038] (4) Finished rubber mixing: anti-scorch agent, foaming agent-dinitrosopentamethylenetetramin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com