Thermoplastic elastomer composition for sports floor and preparation method thereof

A thermoplastic elastomer and composition technology, applied in the field of thermoplastic elastomer composition for sports flooring and its preparation, can solve the problems of poor crack resistance, shortened service life of sports floor, poor deformation resistance, etc., and achieve toughness enhancement , enhance the bonding force, and increase the probability of meeting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

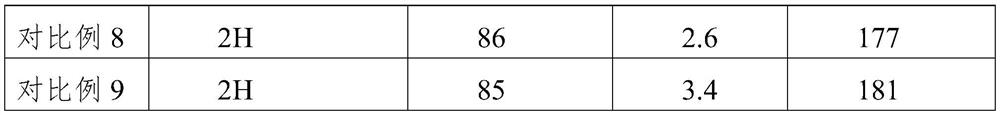

Examples

Embodiment 1

[0030] A thermoplastic elastomer composition for sports flooring, the composition of the elastomer composition includes the following raw materials in parts by weight:

[0031] 90 parts of butadiene rubber powder, 60 parts of natural rubber powder, 40 parts of polyvinyl chloride resin, 40 parts of epoxy resin, 60 parts of polystyrene, 20 parts of talcum powder, 20 parts of white carbon black, 40 parts of benzene glycol, benzene 40 parts, 20 parts of stearic acid, 15 parts of zinc oxide, 15 parts of thiophenolic compound, 10 parts of silane coupling agent, 10 parts of stabilizer, 10 parts of plasticizer, 15 parts of crosslinking agent, and 15 parts of vulcanizing agent.

[0032] A preparation method for a thermoplastic elastomer composition for sports floors, comprising the following steps:

[0033] (1) Weigh benzenediol, benzene and butadiene rubber powder in proportion, mix them evenly, extract until the solution is colorless, dry the solution at 80°C, treat it with microwave...

Embodiment 2

[0038] A thermoplastic elastomer composition for sports flooring, the composition of the elastomer composition includes the following raw materials in parts by weight:

[0039] 110 parts of butadiene rubber powder, 80 parts of natural rubber powder, 60 parts of polyvinyl chloride resin, 50 parts of epoxy resin, 70 parts of polystyrene, 30 parts of talcum powder, 30 parts of white carbon black, 60 parts of benzene glycol, benzene 60 parts, 30 parts of stearic acid, 25 parts of zinc oxide, 25 parts of alkylphenol disulfide, 20 parts of silane coupling agent, 20 parts of stabilizer, 20 parts of plasticizer, 25 parts of crosslinking agent, 25 parts of vulcanizing agent share.

[0040] A preparation method for a thermoplastic elastomer composition for sports floors, comprising the following steps:

[0041] (1) Weigh benzenediol, benzene and butadiene rubber powder in proportion, mix them evenly, extract until the solution is colorless, dry the solution at 80°C, treat it with micro...

Embodiment 3

[0046] A thermoplastic elastomer composition for sports flooring, the composition of the elastomer composition includes the following raw materials in parts by weight:

[0047] 100 parts of butadiene rubber powder, 70 parts of natural rubber powder, 50 parts of polyvinyl chloride resin, 45 parts of epoxy resin, 65 parts of polystyrene, 25 parts of talcum powder, 25 parts of white carbon black, 50 parts of benzene glycol, benzene 50 parts, 25 parts of stearic acid, 20 parts of zinc oxide, 20 parts of alkylphenol disulfide, 15 parts of silane coupling agent, 15 parts of stabilizer, 15 parts of plasticizer, 20 parts of crosslinking agent, 20 parts of vulcanizing agent share.

[0048] A preparation method for a thermoplastic elastomer composition for sports floors, comprising the following steps:

[0049] (1) Weigh benzenediol, benzene and butadiene rubber powder in proportion, mix them evenly, extract until the solution is colorless, dry the solution at 80°C, treat it with micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com