Patents

Literature

111results about How to "Fully vulcanized" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of hydrogenation catlayst

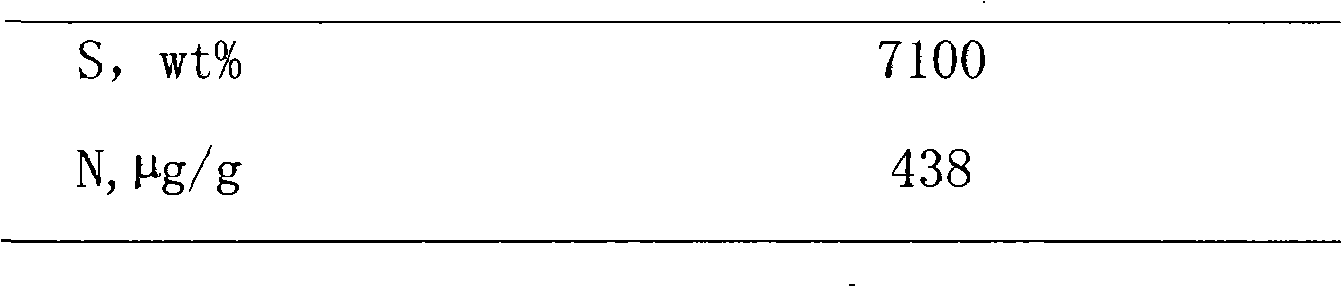

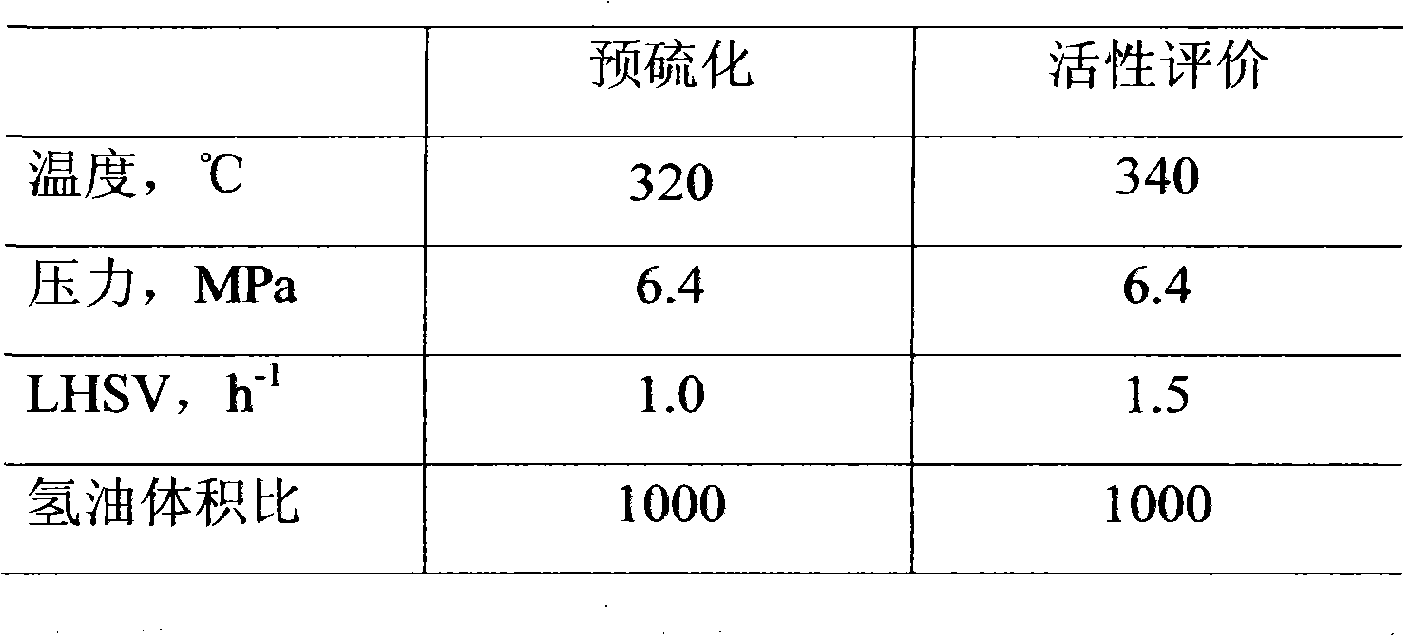

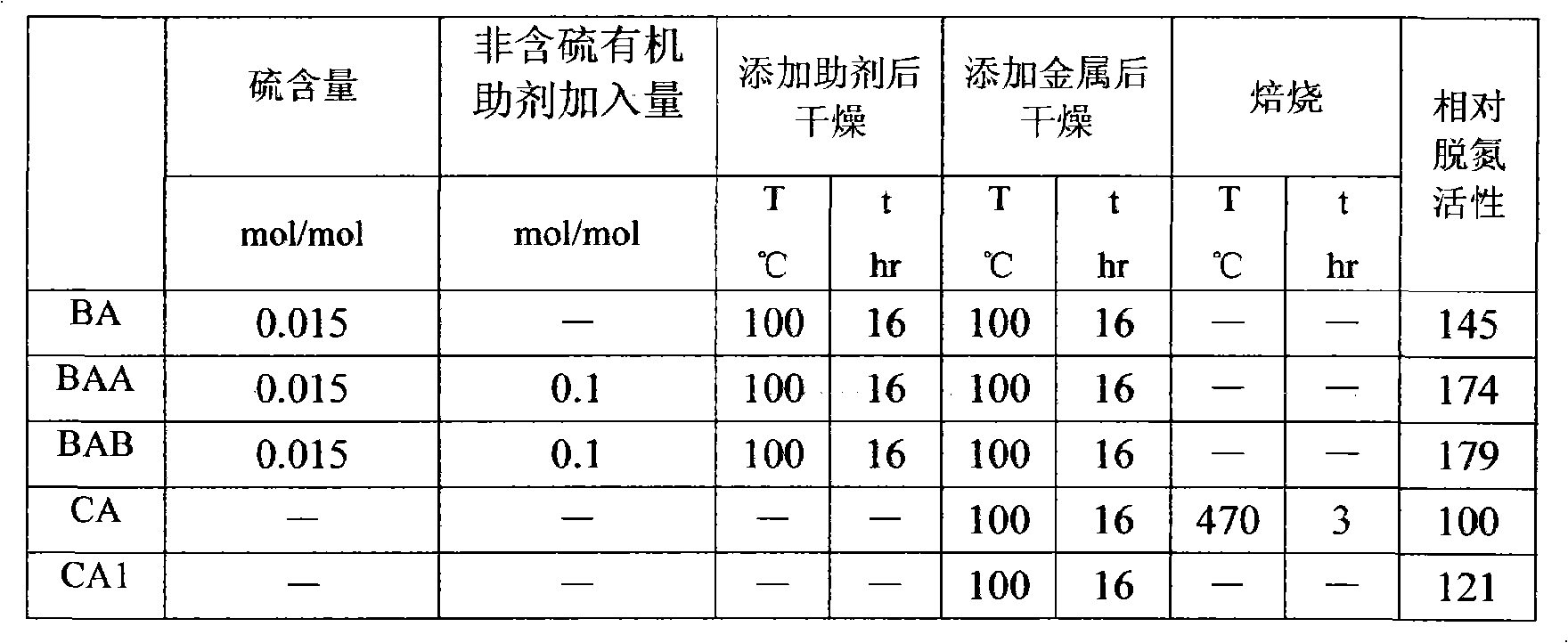

ActiveCN101279291AEasy to useInhibit aggregationOrganic-compounds/hydrides/coordination-complexes catalystsRefining to eliminate hetero atomsPorous catalystSulfur

The present invention relates to a preparation method for a hydrotreating catalyst, which induces organic additives before, in the middle of or after inducing the active metal components on a porous catalyst carrier; wherein, at least one organic additive is an organic additive containing sulfur; then carries out one or a plurality of drying steps after inducing the active metals or the organic additives with a drying temperature lower than 300 DEG C but without baking processes in the preparation process of the catalyst. The use property of the hydrotreating catalyst prepared by the method of the present invention can be further improved and the method can be applied to various hydrotreating catalyst processes.

Owner:CHINA PETROLEUM & CHEM CORP +1

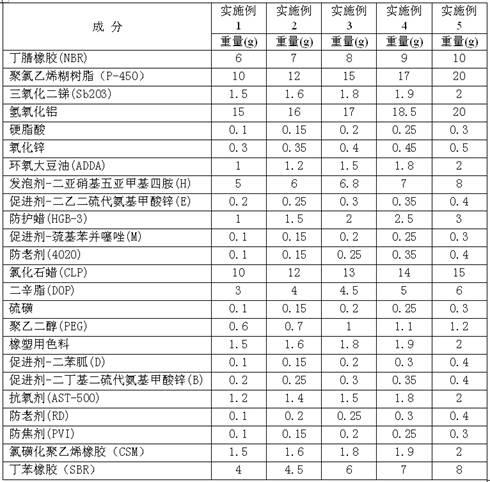

Color rubber and plastic heat-insulating material and preparation method thereof

The invention relates to a color rubber and plastic heat-insulating material and a preparation method thereof. The rubber and plastic heat-insulating material is prepared from polrvinyl chloride paste resin, dinitrosopentamethylene tetraamine, an antiager, styrene rubber, protective wax, an antioxidant, chlorosulfonated polyethylene rubber, diphenyl guanidine, mercaptobenzothiazole, zinc dibutyl dithiocarbamate, zinc diethydithiocarbamate and the like. The performance and the color difference of the product are stabilized by adding a coloring material to perform banburying on the finished rubber again and combining a new vulcanizing foaming technology and a super-long water-cooling system; the prepared color rubber and plastic heat-insulating material does not have fibers and dust, prevents dew formation, has a smooth surface and high cleanliness, has the same bright color as equipment, is environmentally-friendly and non-toxic, reduces secondary construction, saves cost, greatly improves the using performance of the product, prolongs the service life and takes full advantage of the product performance.

Owner:WINCELL INSULATION CO LTD

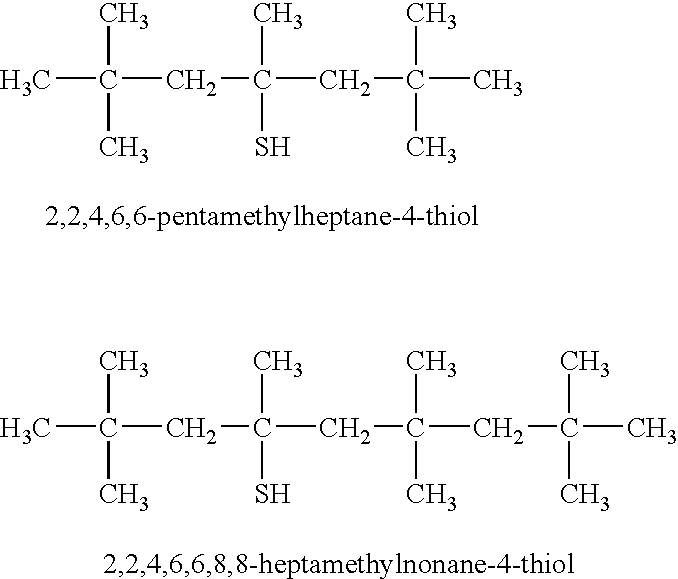

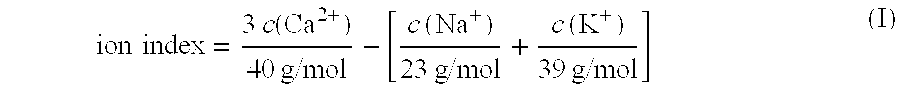

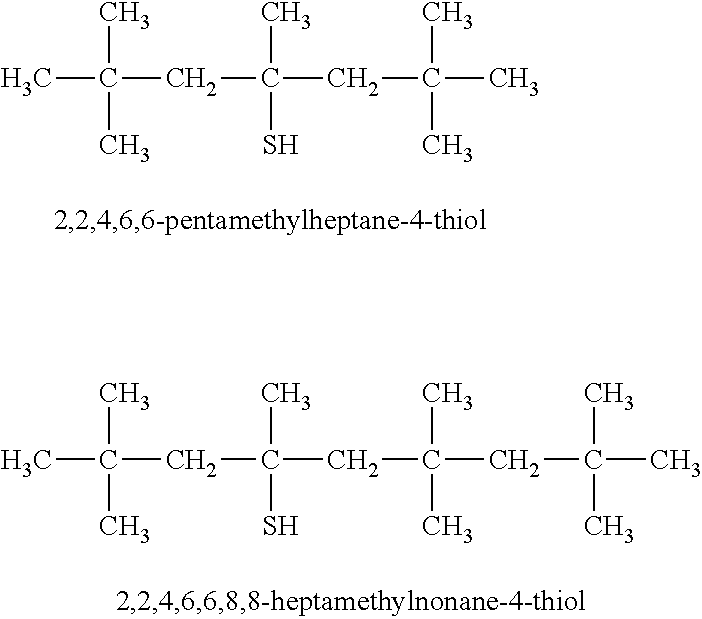

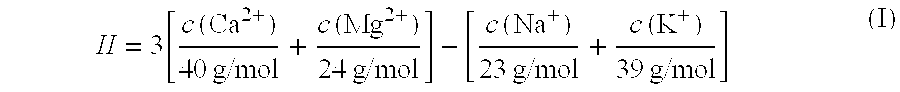

Nitrile rubbers

An improved polymerization and work-up process makes it possible to produce specific nitrile rubbers which have a particular ion index which is responsible for an excellent vulcanization rate and leads to vulcanizates having an advantageous property profile.

Owner:ARLANXEO DEUT GMBH

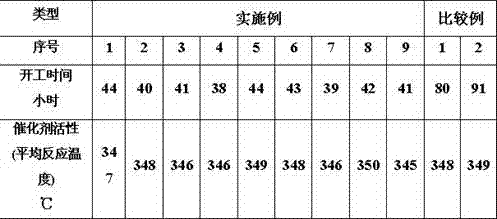

Hydrocracking startup method

ActiveCN107446616AIntensified vulcanization process inside the extenderHigh activityCatalyst protectionMolecular sieve catalystsHydrogenLow nitrogen

The invention discloses a hydrocracking startup method. The hydrocracking startup method comprises the following steps: introducing low-nitrogen startup oil, hydrogen and a sulfurizing reagent into a hydrocracking unit; then carrying out sulfuration on a hydrocracking catalyst at a constant temperature of 220 to 260 DEG C; after the content of hydrogen sulfide in to-be-cycled hydrogen reaches 3000 to 5000 ppm, reducing the adding rate of the sulfurizing reagent and increasing the bed temperature of the hydrocracking catalyst; when the bed temperature of the hydrocracking catalyst reaches 310 to 330 DEG C, increasing the adding rate of the sulfurizing reagent; and continuing constant-temperature sulfuration, then allowing the temperature to rise to 340 to 350 DEG C and introducing raw oil for a reaction, wherein the amount of the hydrocracking catalyst is 0.5 to 8% by weight. The method provided by the invention is short in time for startup, raw material switching and entry into a stable production state, avoids the consumption of a passivating agent and potential hazards during ammonia injection in the startup process, reduces energy consumption, and decreases pollution of the passivating agent to environment and harm of the passivating agent to human beings.

Owner:CHINA PETROLEUM & CHEM CORP +1

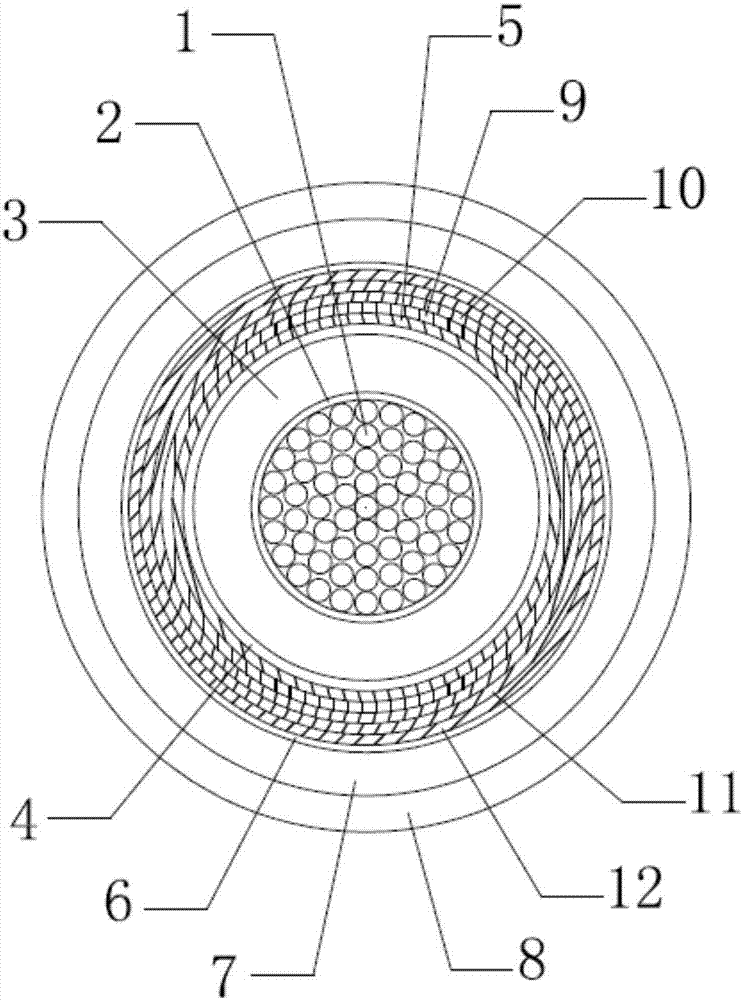

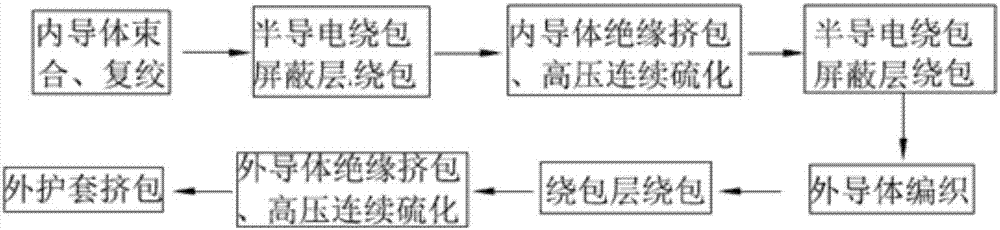

Manufacturing method of cable for high power transmission equipment and cable

InactiveCN107154285ANo damageReduce weightConcentric cablesPower cables with screens/conductive layersReliable transmissionElectrical conductor

A cable for high power transmission equipment, its structure from inside to outside is: inner conductor, first semiconductive wrapping shielding layer, inner conductor insulation, second semiconducting wrapping shielding layer, outer conductor, wrapping layer, Outer conductor insulation and outer sheath. The insulating layer of the inner conductor is made of silicon rubber; the outer conductor is braided with one or more layers of tinned copper wire; the insulating layer of the outer conductor is made of silicon rubber; the outer sheath layer is made of polyurethane. The manufacturing method of the cable comprises: 1) manufacturing the inner conductor; 2) manufacturing the first semiconductive wrapping shielding layer; 3) manufacturing the inner conductor insulating layer; 4) manufacturing the second semiconductive wrapping shielding layer; 5) manufacturing 6) manufacturing the wrapping layer; 7) manufacturing the insulating layer of the outer conductor; 8) manufacturing the outer sheath layer. In each step, a specific process method is adopted, so that the electrical and mechanical properties of the cable prepared by this method can meet or exceed the detection requirements, so that the cable for high-power transmission equipment can transmit high power safely and reliably, and has the advantages of light weight. , miniaturization, low temperature resistance, good flexibility, small bending radius and other excellent performances, suitable for high electric energy technical equipment.

Owner:JIANGSUSNGSHANG CABLE GROUP

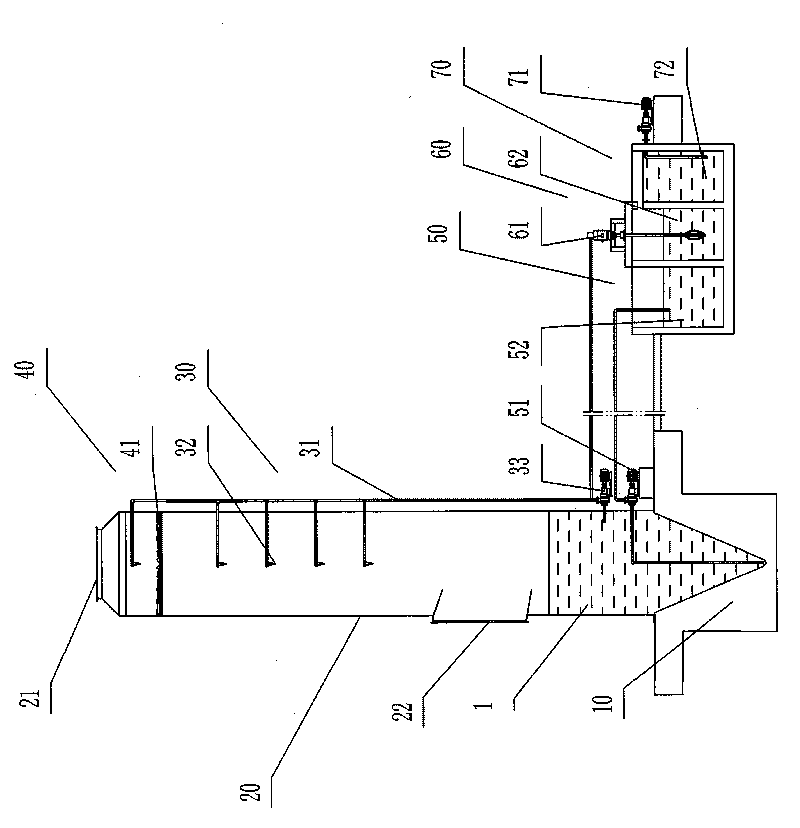

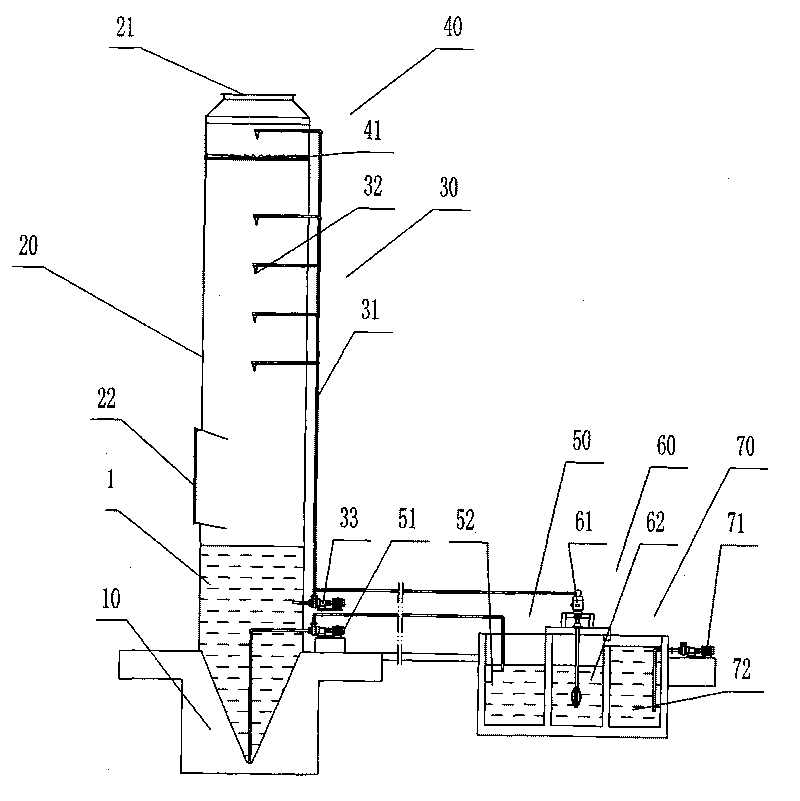

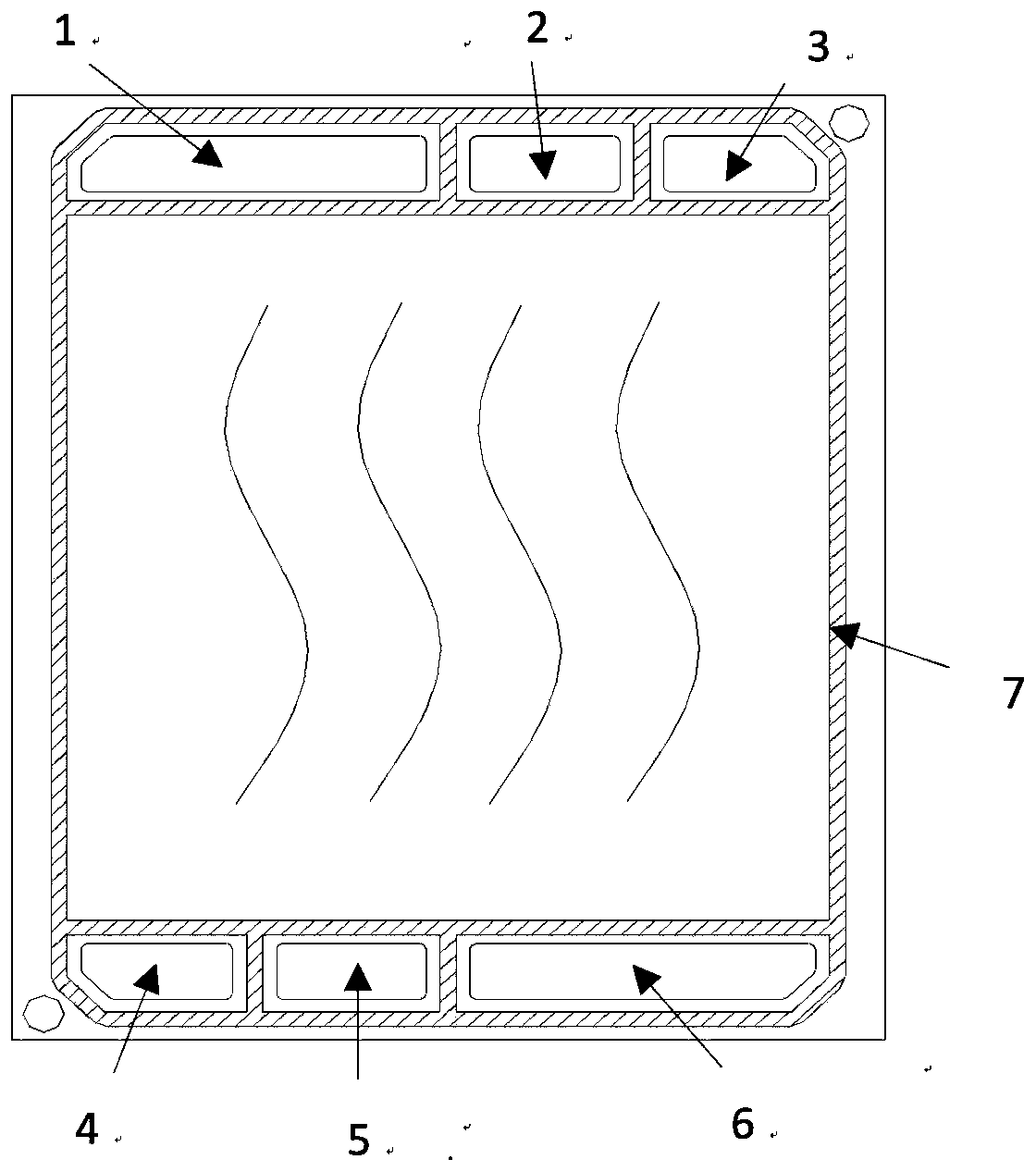

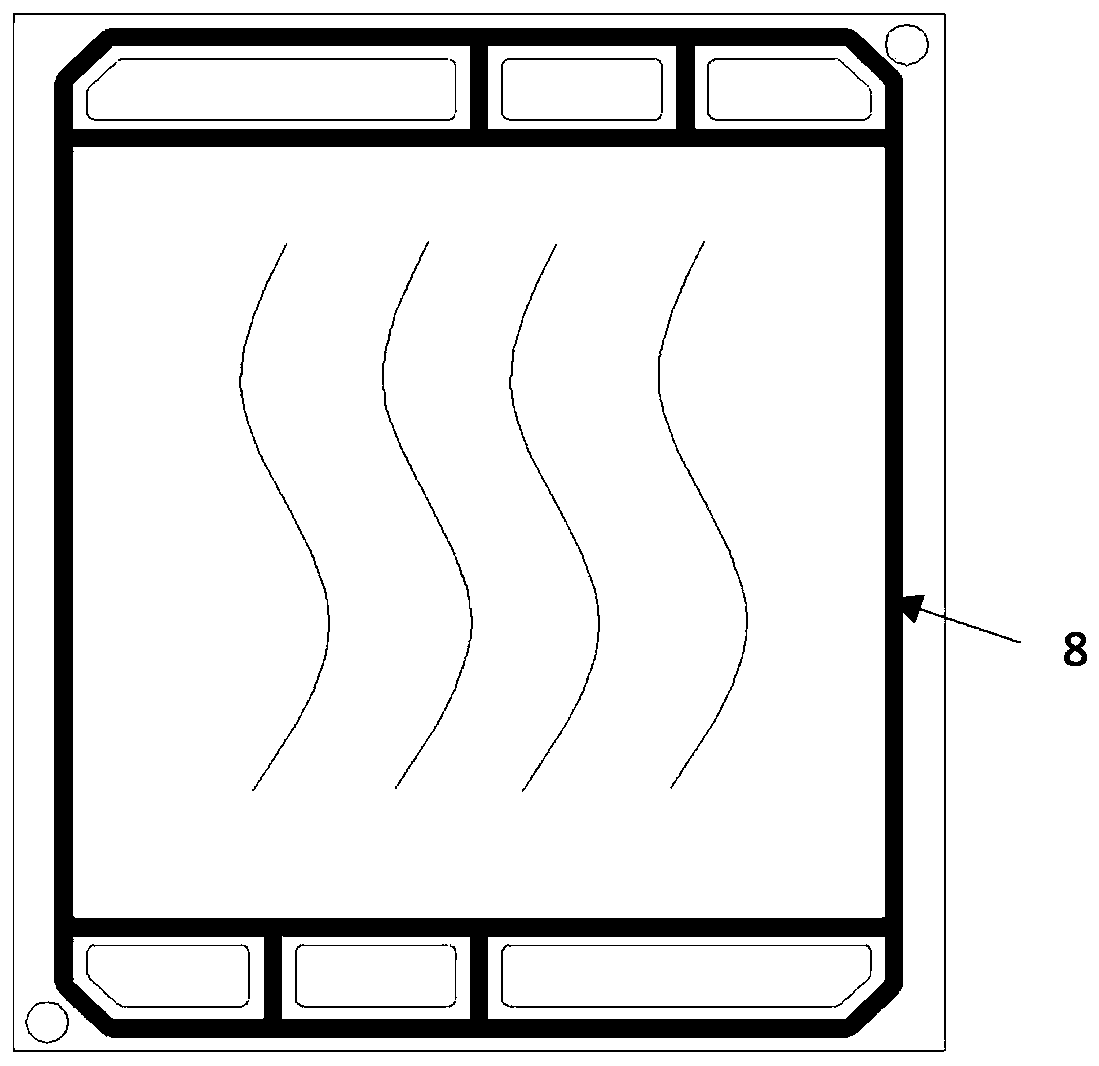

Internally circulating wet flue gas desulfurization tower

InactiveCN101716455AFully vulcanizedIncrease profitLighting and heating apparatusDispersed particle separationFlue gasWater resources

The invention relates to an internally circulating wet flue gas desulfurization tower which is used for industrial flue gas desulfurization. The internally circulating wet flue gas desulfurization tower comprises a tower foundation and a tower body. The tower body is internally provided with a wet flue gas desulfurization system; the upper end of the tower body is provided with a flue gas outlet at which a demisting system is arranged, the lower end of the tower body is provided with a flue gas inlet and the bottom of the tower body is provided with a slurry tank; the upper part of the slurry tank is connected with a slurry supplementing system, and the lower part of the slurry tank is connected with a deashing system; the tower body is externally provided with a slurrying system; and the slurrying system is connected with the wet flue gas desulfurization system through a spraying circulating pump. The internally circulating wet flue gas desulfurization tower can remove the harmful components in the flue gas, reduce the pollution and the emission and effectively save water resource.

Owner:汪晋武

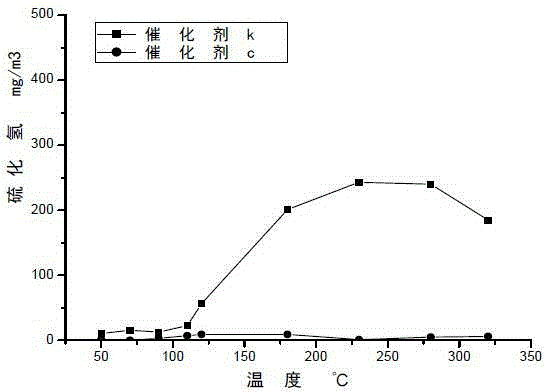

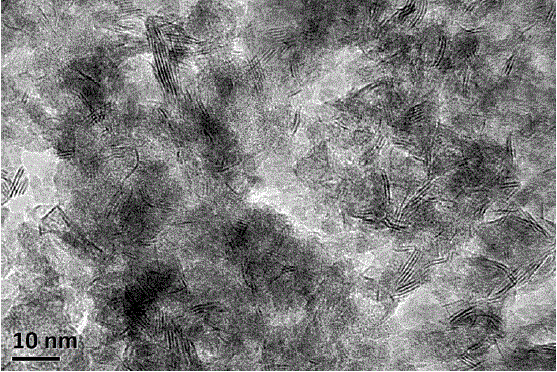

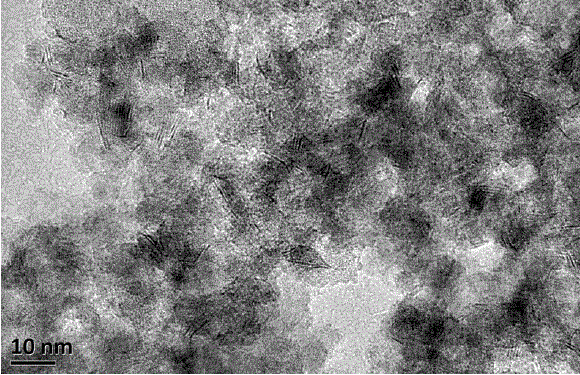

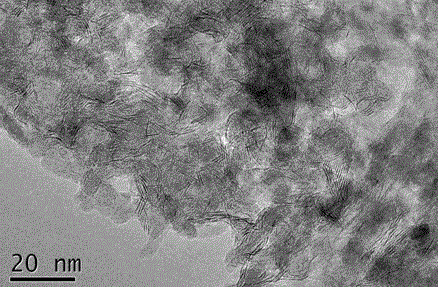

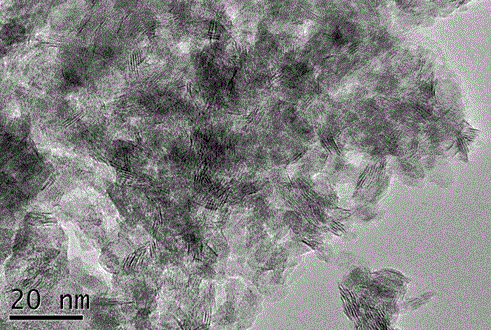

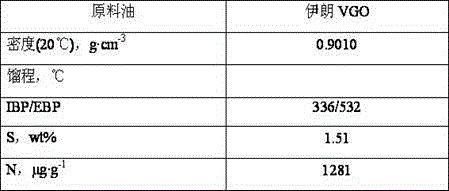

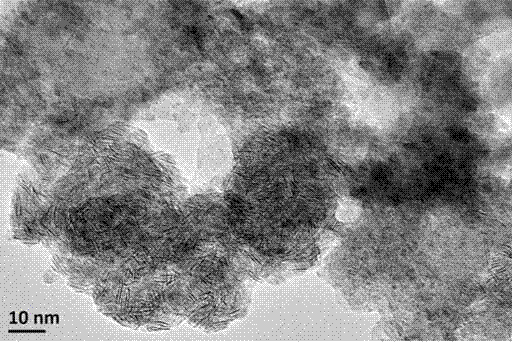

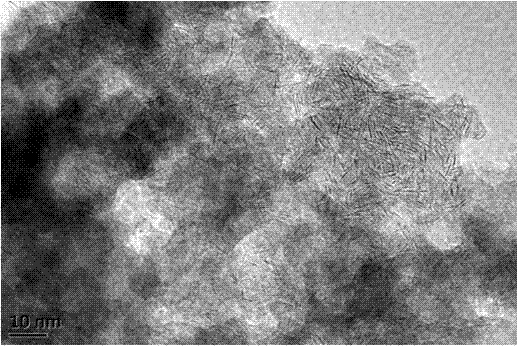

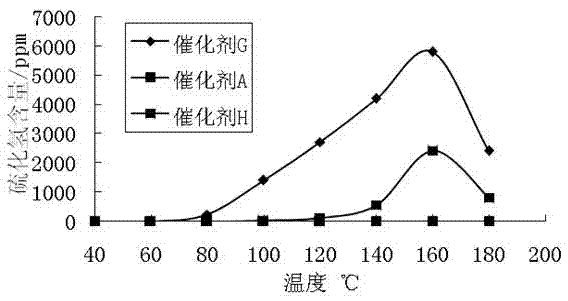

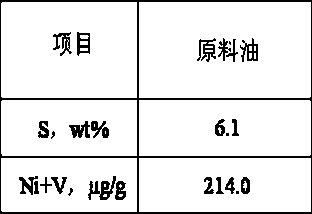

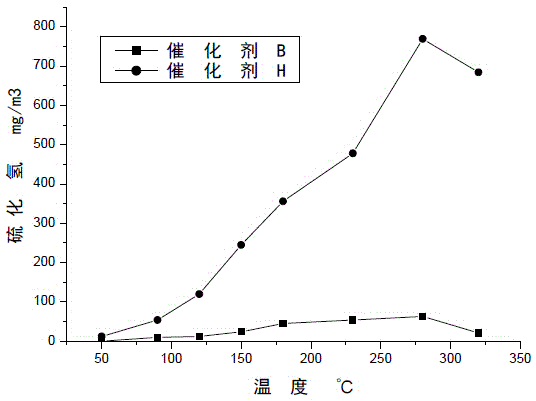

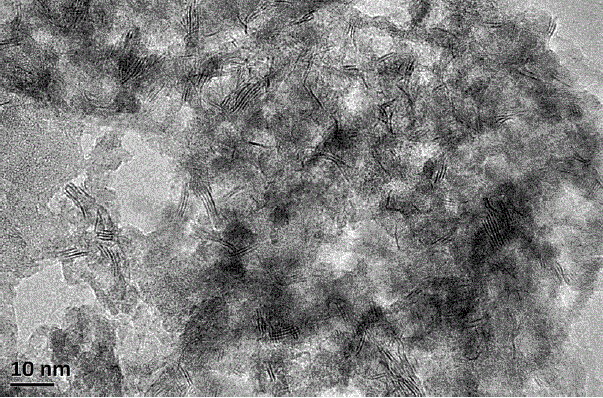

Vulcanization method of selective hydrodesulfurization catalyst of FCC (Fluid Catalytic Cracking) gasoline

ActiveCN103773435AIncrease system pressureFully vulcanizedOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationVulcanizationSulfur

The invention discloses a vulcanization method of a selective hydrodesulfurization catalyst of FCC (Fluid Catalytic Cracking) gasoline. The method is as follows: in a vulcanization process of the selective hydrodesulfurization catalyst, first vulcanizing under a low pressure and at a low temperature, then vulcanizing under a high system pressure and at a high temperature so as to facilitate production of more CoMoS phases and make the CoMoS phases more dispersive to produce more sulfur vacancies and form more desulfurization centers and promote the formation of the active center of direct desulfurization. The vulcanization method can improve the catalyst desulfurization activity, at the same time, and the olefin saturation properties basically remains unchanged, so that the hydrodesulfurization selectivity of the FCC gasoline is effectively improved. The method can be applied to a variety of hydrodesulfurization catalysts of the FCC gasoline, and is especially suitable for hydrodesulfurization catalysts containing additives with selective desulfurization effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Regeneration method of hydrogenation catalyst

ActiveCN106694058AHigh activityGood dispersionCatalyst regeneration/reactivationCatalyst activation/preparationOxygenOrganic compound

The invention discloses a regeneration method of a hydrogenation catalyst. The method comprises the following steps: 1, the hydrogenation catalyst to be regenerated is in contact with an oxygen-containing gas to carry out carbon burning regeneration; and 2, an organic compound is introduced to a carbon-burnt catalyst obtained in step 1, and at least one low-temperature heat treatment is carried out, wherein no calcination is carried out. The regenerated catalyst realizes direct in-situ sulfuration of metals on the surface of the catalyst without a generation reaction of hydrogen sulfide or a sulfuration reaction of hydrogen sulfide and the active metal in the sulfuration starting process, so the initial sulfuration temperature at working starting of the catalyst is greatly improved, the problem of too fast temperature rising in the catalyst sulfuration process is solved, and the starting time is greatly shortened.

Owner:CHINA PETROLEUM & CHEM CORP +1

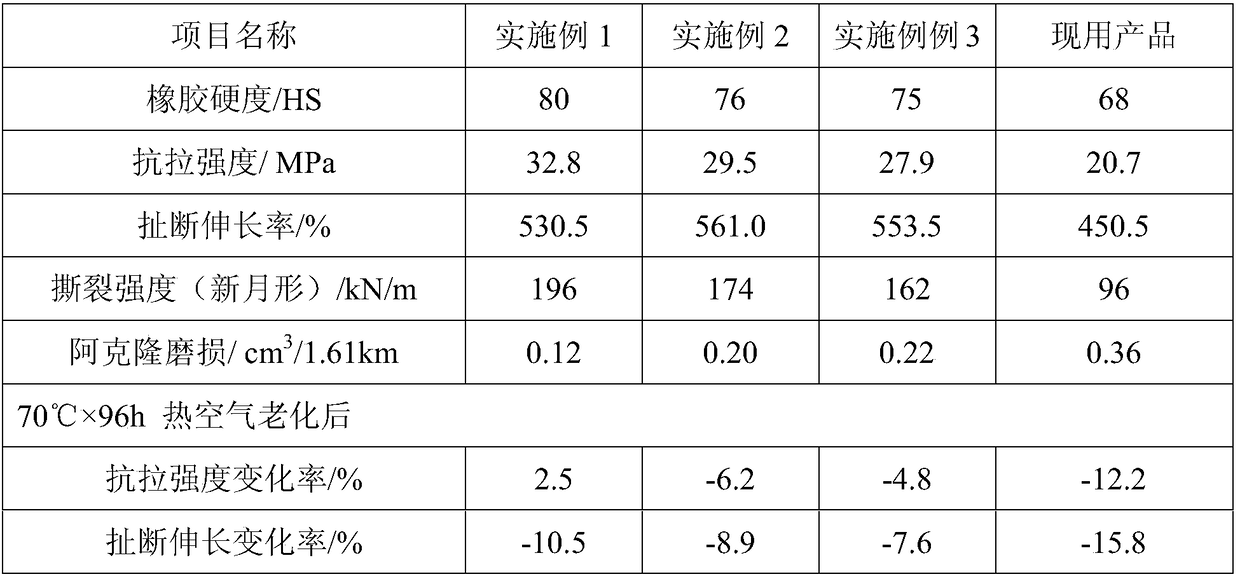

Rubber track

The invention discloses a rubber track. The rubber track is prepared from raw materials including raw rubber, sulfur, an accelerant, magnesia, zinc oxide, an anti-aging agent, a titanate coupling agent, an anti-coking agent, carbon black, a flame retardant, micro-crystal wax and a light stabilizer through plastication, mixing and final refining. The strength and wear resistance of rubber are enhanced by adding different raw rubber components, carbon black, the titanate coupling agent and the like. The aging resistance of rubber is improved and the service life of rubber is prolonged by addingthe anti-aging agent, the anti-coking agent and the light stabilizer. Thus, the rubber track has the characteristics of high strength and high reliability.

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD

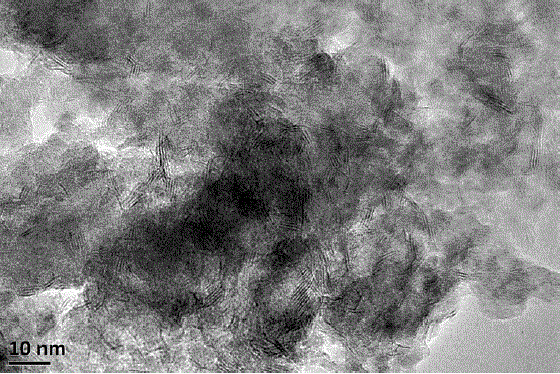

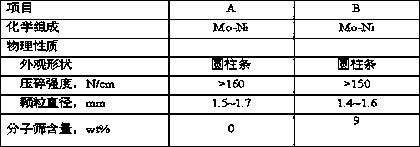

Preparation method of vulcanized hydrogenation catalyst

ActiveCN108067271AHigh catalytic activityReduce manufacturing costPhysical/chemical process catalystsHydrocarbon oils treatmentPore diameterSlurry

The invention discloses a preparation method of a vulcanized hydrogenation catalyst. The method comprises the steps as follows: (1) a vulcanizing agent, a vulcanizing aid, an emulsifier and additive particles are uniformly mixed, the mixture is subjected to a constant-temperature reaction, then, an aqueous solution containing hydrogenation active metal is added, the mixture reacts for 5-60 min, the additive particles are removed by separation, and a liquid mixture I is obtained; (2) a peptizing agent, water and urea are uniformly mixed and a liquid mixture II is obtained; (3) an aluminum source is added to an acidic aqueous solution for slurry making, the liquid mixtures I and II are added, and the slurry is mixed uniformly; (4) the slurry in the step (3) is subjected to quick evaporativeconcentration to form concentrated slurry, slow drying treatment is performed, and a semi-dried material is obtained; (5) the semi-dried material obtained in the step (3) is ground, subjected to extrusion molding and roasting, and the vulcanized hydrogenation catalyst is obtained. The catalyst preparation and vulcanizing processes are completed simultaneously, and the catalyst has uniform pore diameter distribution, is simple to prepare and has wider market application prospects.

Owner:CHINA PETROLEUM & CHEM CORP +1

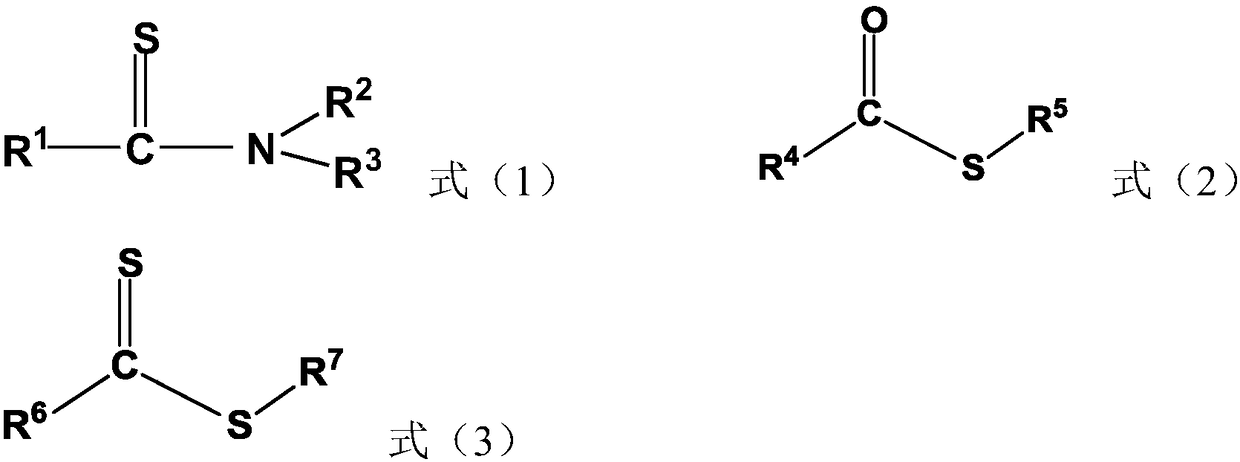

Preparation method of sulfuration-type hydrogenation catalyst

ActiveCN103801336ASimple production processReduce manufacturing costPhysical/chemical process catalystsRefining to eliminate hetero atomsOrganic sulfide compoundMetal

The invention discloses a preparation method of a sulfuration-type hydrogenation catalyst. The preparation method is as follows: using a carrier precursor and an organic sulfide and an auxiliary agent for kneading, molding and drying, loading a hydrogenation active metal component, and then performing heat treatment to obtain the sulfuration-type hydrogenation catalyst. The method is simple in preparation process and low in cost. The prepared sulfuration-type hydrogenation catalyst is good in sulfuration effect and high in hydrogenation activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of hydrotreating catalyst

ActiveCN104549519AIncrease profitActive site fullOrganic-compounds/hydrides/coordination-complexes catalystsRefining to eliminate hetero atomsDispersityActive component

The invention discloses a preparation method of a hydrotreating catalyst. The preparation method comprises the following steps: (1) pulping dry alumina glue, adding organic salt, uniformly mixing the pulped dry alumina glue and the organic salt, performing solid-liquid separation and drying on the mixture so as to obtain modified dry alumina glue powder; (2) pulping the modified dry alumina glue powder, adding the pulped modified dry alumina glue powder in a heteropoly phospho-molybdic acid (H2PMo12O40) solution, performing a reaction on the organic salt in the solution and heteropoly phospho-molybdic acid, and after reaction, performing solid-liquid separation, drying, extrusion molding and calcination on the mixture so as to obtain a catalyst precursor; (3) dipping the catalyst precursor in activated metal promoter, and drying and calcining the catalyst precursor so as to obtain a catalyst product. For the catalyst prepared by adopting the method disclosed by the invention, the active components are uniformly distributed in the catalyst, so that the catalyst is easy to vulcanize; the activated metal has high dispersity on the surface of the catalyst, so that the activity of the catalyst is improved, the use ratio of the activated metal is increased, and the service life of the catalyst is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrotreating catalyst intermediate, hydrotreating catalyst, and preparation methods of hydrotreating catalyst intermediate and hydrotreating catalyst

ActiveCN106946807ASolve the problem of rapid temperature riseWay stablePhysical/chemical process catalystsOrganic chemistryVulcanizationHydrogenation reaction

The present invention discloses a hydrotreating catalyst intermediate, a hydrotreating catalyst, and preparation methods of the hydrotreating catalyst intermediate and the hydrotreating catalyst. According to the present invention, the hydrotreating catalyst intermediate comprises a hydrogenation activity metal component, a carrier component and a specific organic compound, and can complete the vulcanization process without a hydrogen sulfide generation reaction and a vulcanization reaction between hydrogen sulfide and an active metal, such that the problem that the temperature increase is too rapid during the catalyst vulcanization process can be avoided; the hydrotreating catalyst is the vulcanization type hydrotreating catalyst having complete significance, and after the hydrotreating catalyst is loaded into the hydrogenation reaction device, the hydrogenation reaction temperature can be directly achieved so as to substantially shorten the startup time; and the catalyst has advantages of complete vulcanization, good metal dispersibility, and good hydrogenation property.

Owner:CHINA PETROLEUM & CHEM CORP +1

Heavy oil hydrotreating catalyst and preparation method thereof

ActiveCN111375399AMore hydrogenation activityImprove hydrogenation activityCatalyst carriersHeterogenous catalyst chemical elementsActivated carbonPtru catalyst

The invention discloses a heavy oil hydrotreatment catalyst and a preparation method thereof, the heavy oil hydrotreatment catalyst comprises a hydrogenation active metal component and a carrier, thehydrogenation active metal component is one or more of VIB group metals and / or VIII group metals, and the carrier is petroleum coke-based activated carbon. The preparation method comprises the following steps: uniformly mixing petroleum coke, a pore-enlarging agent and an activating agent and then carrying out activating treatment; mixing the obtained sample with an acid solution, uniformly mixing, washing and drying to obtain a carrier; introducing the hydrogenation active metal into the carrier, and then drying and roasting to obtain the heavy oil hydrotreating catalyst. According to the invention, petroleum coke-based activated carbon is used as a carrier of the catalyst, so that the carbon deposition resistance of the catalyst is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

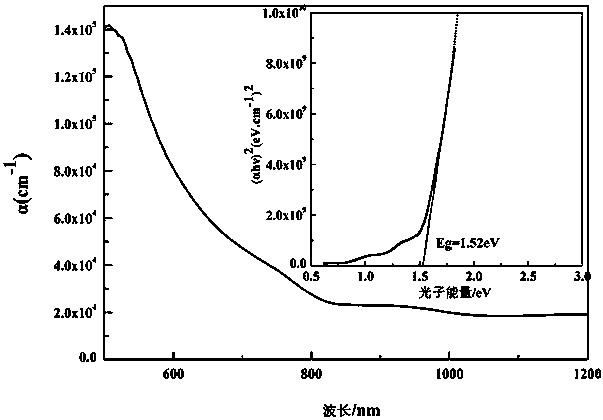

Preparation method of copper antimony sulfur film material

ActiveCN107829071AHigh purityFlat and dense surfaceVacuum evaporation coatingSputtering coatingSulfurCopper

The invention discloses a preparation method of a copper antimony sulfur film material. The preparation method of the copper antimony sulfur film material comprises the following steps: the surface ofa substrate is cleaned; the co-sputtering deposition of a Cu-Sb-S prefabricated layer is performed on the cleaned surface of the substrate through a radio-frequency or direct-current reaction; the substrate deposited with the Cu-Sb-S prefabricated layer on the surface is put in a reactive atmosphere for high-temperature annealing treatment; and the surface of the Cu-Sb-S prefabricated layer afterhigh-temperature annealing treatment is etched to obtain the copper antimony sulfur film material. The preparation method of the copper antimony sulfur film material has the advantages of low cost, easy control and adjustment of film components, good reproducibility, large-area growth of films and the like; and the prepared films achieve excellent component controllability and uniformity and excellent crystallization quality and properties.

Owner:CENT SOUTH UNIV

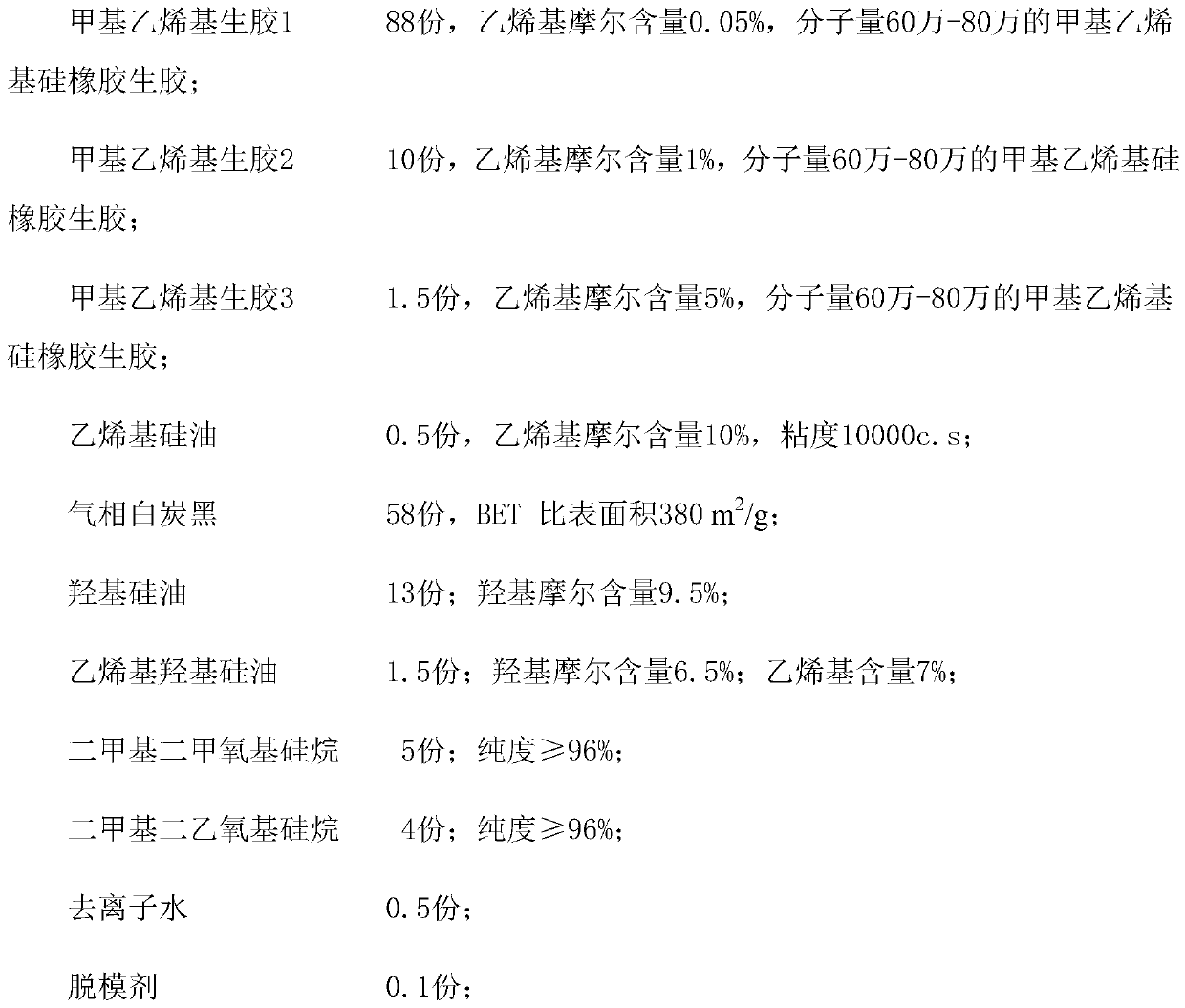

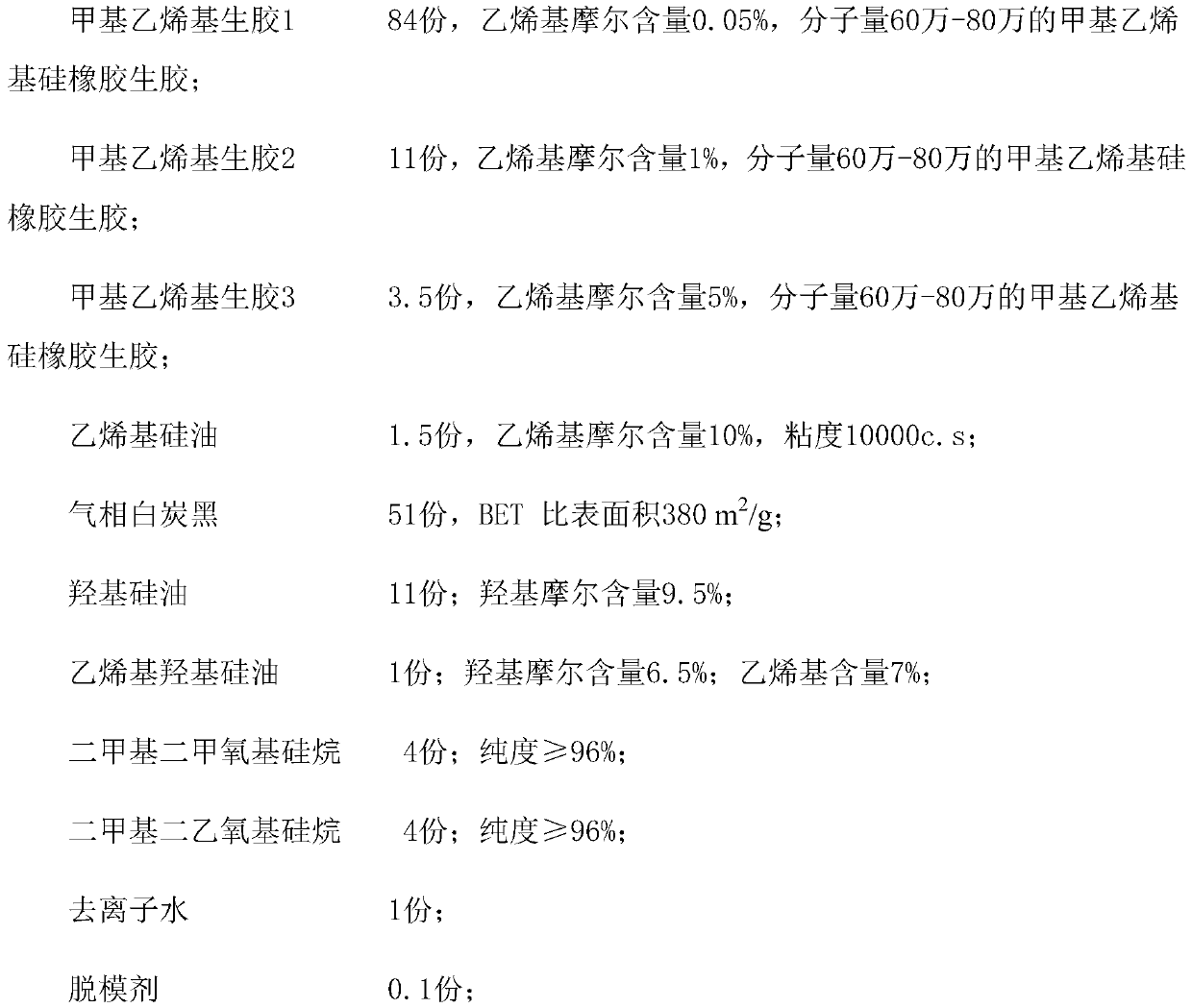

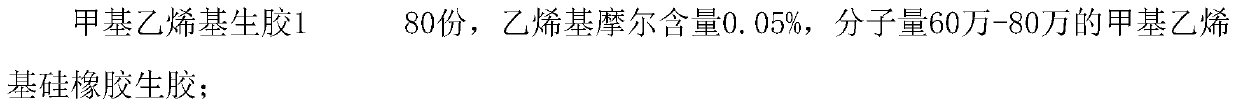

Silicone rubber masterbatch, silicone rubber and preparation method of silicone rubber

The invention belongs to the field of silicone rubber, and discloses silicone rubber masterbatch. The silicone rubber masterbatch comprises the following components in parts by weight of: 80-90 partsof polysiloxanes di-Me Me vinyl vinyl group-terminated crude rubber of which the vinyl mol content is 0.03%-0.23% and the molecular weight is 600-800 thousands, 7-16 parts of the polysiloxanes di-Me Me vinyl vinyl group-terminated crude rubber of which the vinyl mol content is 1%-5% and the molecular weight is 600-800 thousands, 1.5-5 parts of the polysiloxanes di-Me Me vinyl vinyl group-terminated crude rubber of which the vinyl mol content is 3%-10% and the molecular weight is 600-800 thousands, 0.5-1.5 parts of of silicone oil of which the vinyl mol content is 5%-30% and the stickiness is 10-100 thousands, 51-63 parts of fumed silica, 10-13 parts of hydroxyl silicone oil, 1-2 parts of vinyl hydroxyl silicone oil, 4-7 parts of dimethyl dimethoxy silicane, 4-5 parts of dirthoxydimethylsilane, 0.5-1 part of pure water; and 0.1-0.2 part of a demoulding agent. The silicone rubber obtained from the silicone rubber masterbatch can meet the requirements of medical throat hood pipes for goodshaping bending degree, good appearance transparency, freedom from bubbles, freedom from gelatin of products, and good ageing performance after being used for a long term. Besides, the invention further provides a preparation method of the silicone rubber.

Owner:XINAN TIANYU SILICONE CO LTD

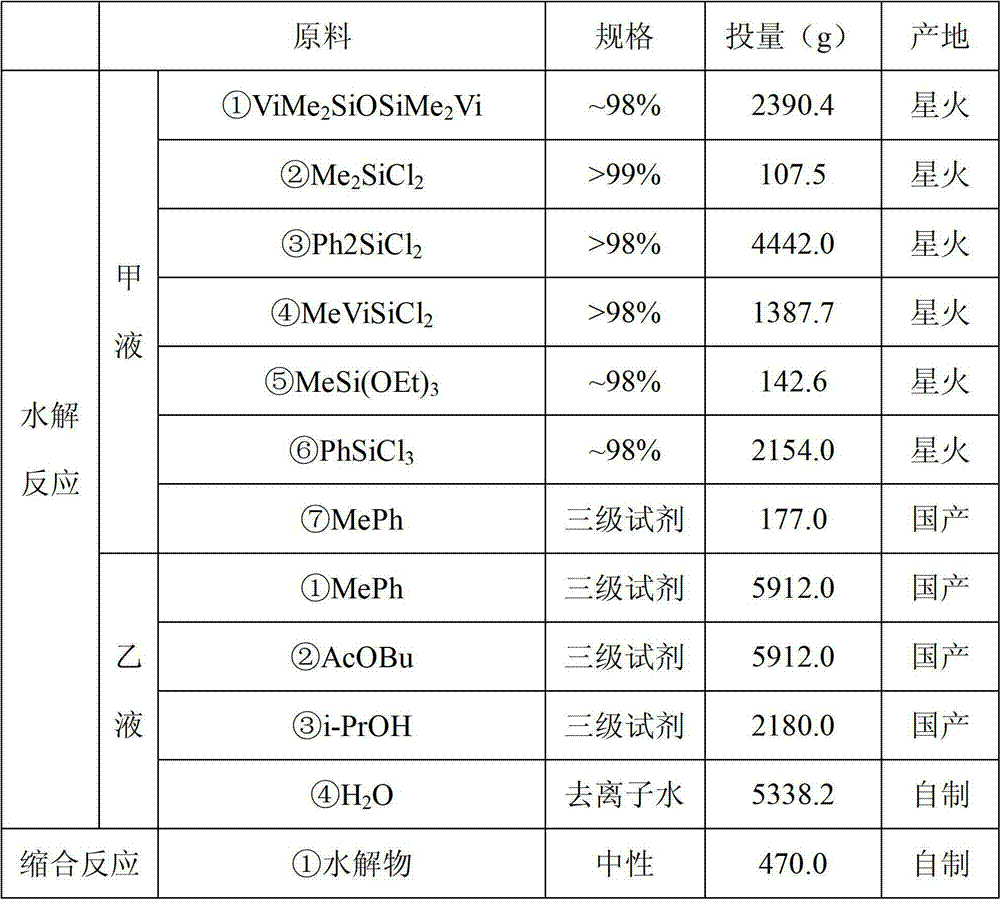

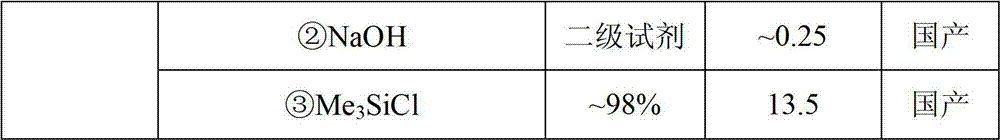

LED (light-emitting diode) packaging adhesive and production method thereof

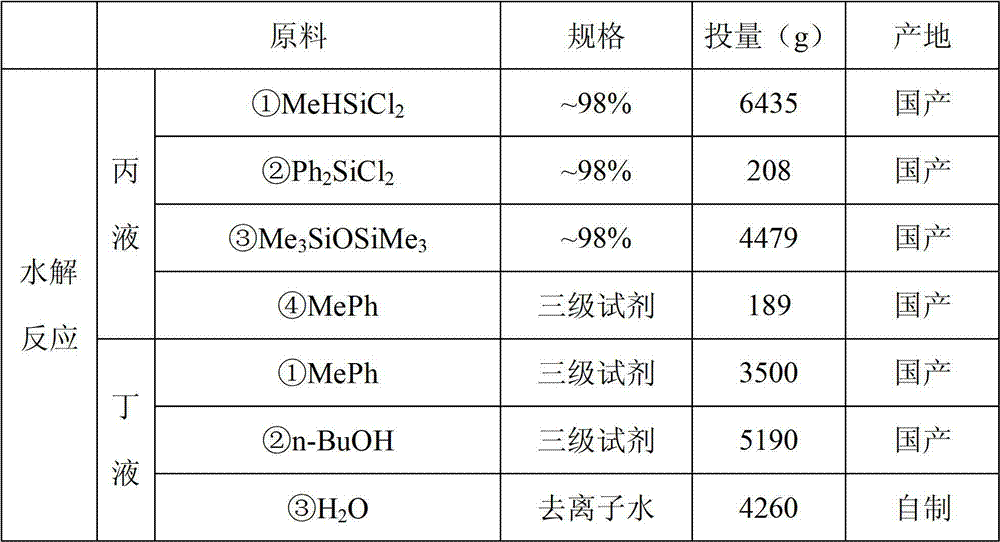

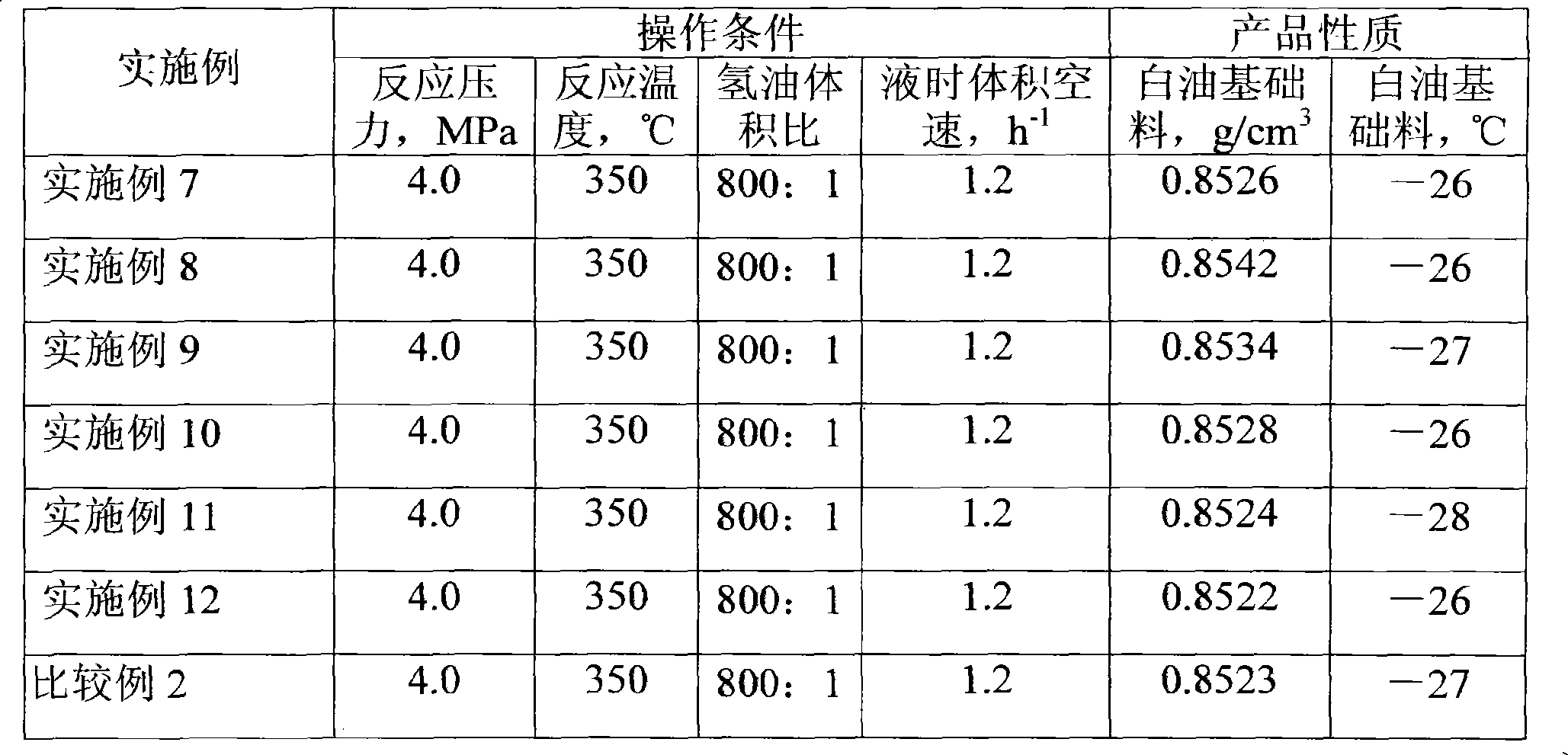

The invention relates to an LED (light-emitting diode) packaging adhesive with high refraction index. A production method for the LED packaging adhesive comprises the following steps of: performing hydrolysis reaction on liquid A and liquid B to obtain hydrolysate and performing condensation under the catalysis of an alkaline catalyst to obtain a component A-based adhesive; performing hydrolysis reaction on liquid C and liquid D to obtain hydrolysate and performing condensation under the catalysis of an alkaline catalyst to obtain a component B-based adhesive; and mixing the component A-based adhesive and the component B-based adhesive to obtain the LED packaging adhesive. The LED packaging adhesive improves the plasticity of high-hardness vulcanization pieces, completely avoids lamp failure and yellowing phenomenon caused by the colloid, has high compactness and low air permeability of the molecular structure and has extremely high luminous flux.

Owner:兆舜科技(广东)有限公司

Porous propping agent combination and preparation method thereof

ActiveCN101417247AShorten start timeIncrease productivityCatalyst carriersCatalyst activation/preparationVulcanizationAgent Combination

The invention discloses a porous propping agent combination and a preparation method thereof; the propping combination comprises a porous propping agent, sulfur which occupies 20-300 percent of the weight of the porous propping agent, organic solvent which occupies 0-50 percent of the weight of the porous propping agent and auxiliary agent which occupies 0-25.0 percent of the weight of the porous propping agent. The propping agent combination is suitable for hydrogenation disposal process. The porous propping agent combination provides vulcanizing agent for the oxidated hydrogenation catalyst, shortens the commencement time of the device, improves the production efficiency, overcomes the defects of pre-vulcanization in the device, and can solve the problem of concentrative heat discharge of pre-vulcanized catalyst outside the device. Furthermore, the sulfur introduced in the porous propping agent is mainly arranged in holes of the propping agent, increases no volume of the propping agent, thus affecting no disposal quantity of the device further.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-temperature-stable type modified asphalt and preparation method thereof

The invention provides high-temperature-stable type modified asphalt. The high-temperature-stable type modified asphalt is prepared from the following components: matrix asphalt, rubber powder, natural rubber, aromatic lightweight oil, polyester fibers, polyethylene and sulfur; a preparation method comprises the following steps: (1) heating the matrix asphalt to 200 to 210 DEG C; then adding the matrix asphalt into a stirring tank; adding the rubber powder and the natural rubber into the stirring tank, and continually stirring for 30 to 40min to obtain a mixture I; (2) adding the aromatic lightweight oil, the polyester fibers and the polyethylene into the stirring tank respectively and carrying out primary stirring; when the temperature in the stirring tank is 150 to 160 DEG C, adding thesulfur and carrying out secondary stirring to obtain a mixture II; (3) pumping the mixture II into a development tank, wherein the fermentation time is 45 to 55min; cooling to obtain the high-temperature stable type modified asphalt. The high-temperature stable type modified asphalt provided by the invention has the advantages of high stability and good elastic recovery; the preparation method issimple, has an easy-to-control process and is applicable to popularization and application.

Owner:SHANDONG XINGHUO SCI TECH INSTITYTE

Peroxide vapor sulfurizing process for EPDM rubber pipe

InactiveCN101020349AImprove appearance qualityAvoid interferenceTubular articlesFirst FillWater vapor

The present invention discloses peroxide vapor sulfurizing process for EPDM rubber pipe, and features that after the rubber pipe is set inside the sulfurizing tank, water vapor is first filled into the tank to exhaust air before performing normal sulfurizing process. The EPDM rubber pipe through the said process has sufficient sulfurizing, no stickness surface and high performance, and is suitable for use in automobile.

Owner:ANHUI ZHONGDING SEALING PARTS +1

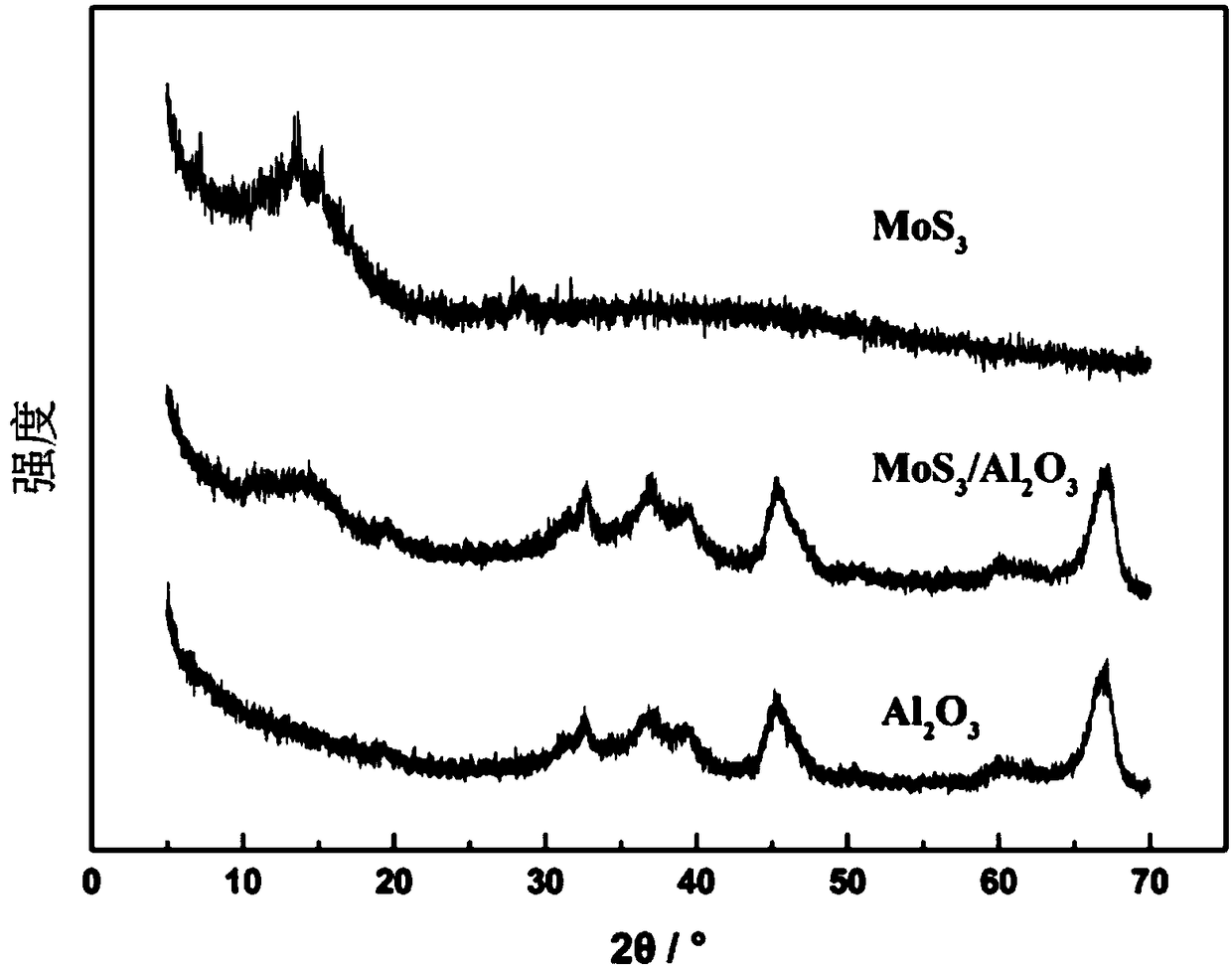

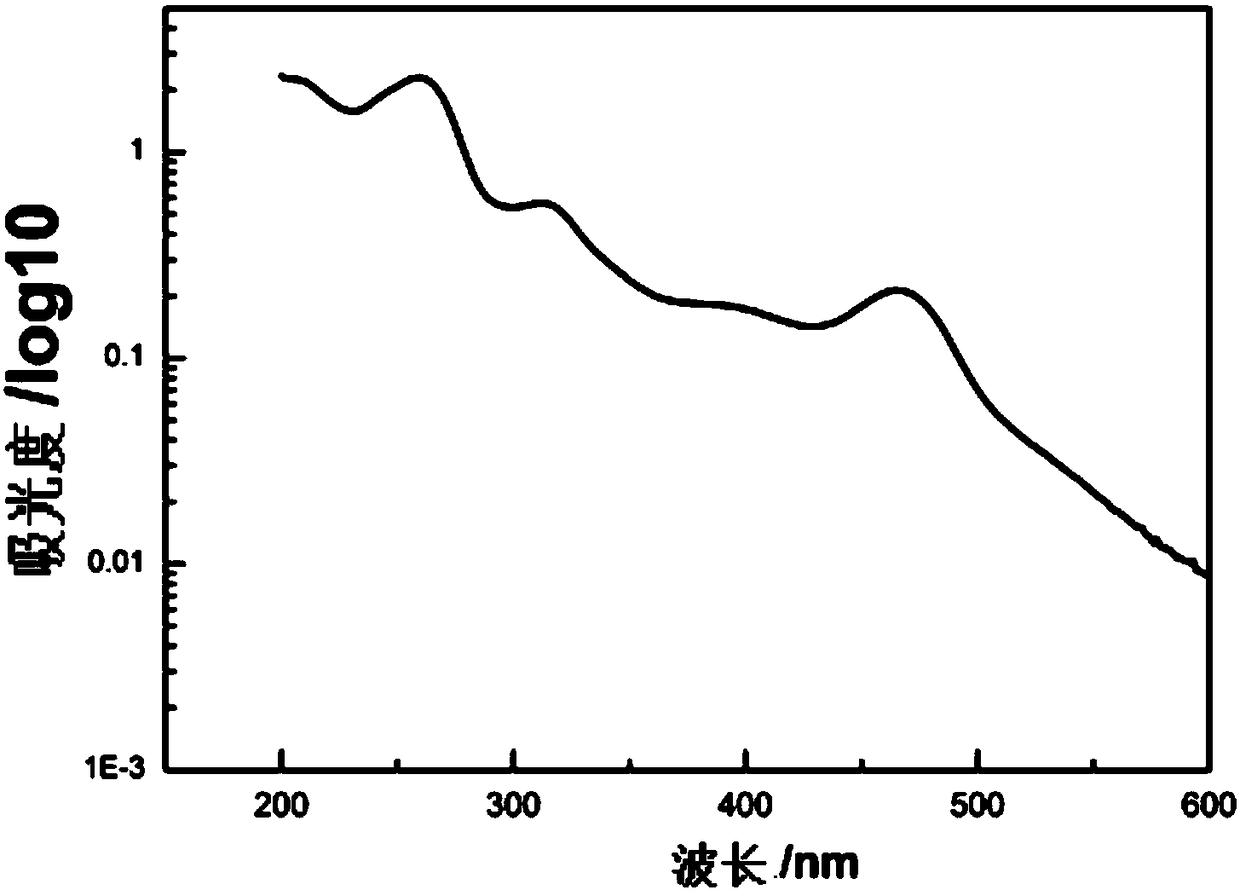

Hydrogenation catalyst and preparation method and application thereof

ActiveCN108722441AImprove hydrogenation performanceFully vulcanizedCatalyst activation/preparationHydrocarbon oils treatmentMolybdateVulcanization

The invention relates to the field of hydrogenation and refining, and discloses a hydrogenation catalyst and a preparation method and application thereof. The catalyst comprises a carrier, and activemetal components which are loaded on the carrier, wherein the active metal components include Mo and at least one VIII cluster metal element; Mo is in a form of trisulfide; the VIII cluster metal element is in a form of salt. The hydrogenation catalyst preparation method comprises the following steps: dipping the carrier in a molybdate tetrathiolate solution; thermally processing in an insert atmosphere or reduction atmosphere to obtain a composite material A, wherein Mo in the composite material A is in the form of trisulfide during thermal processing; dipping the composite material A in a solution containing the VIII cluster metal salt; drying the dipped solid material. With the adoption of the preparation method, the vulcanization process is eliminated; the active components of the prepared catalyst are fully vulcanized; the hydrogenation performance of the catalyst is obviously improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

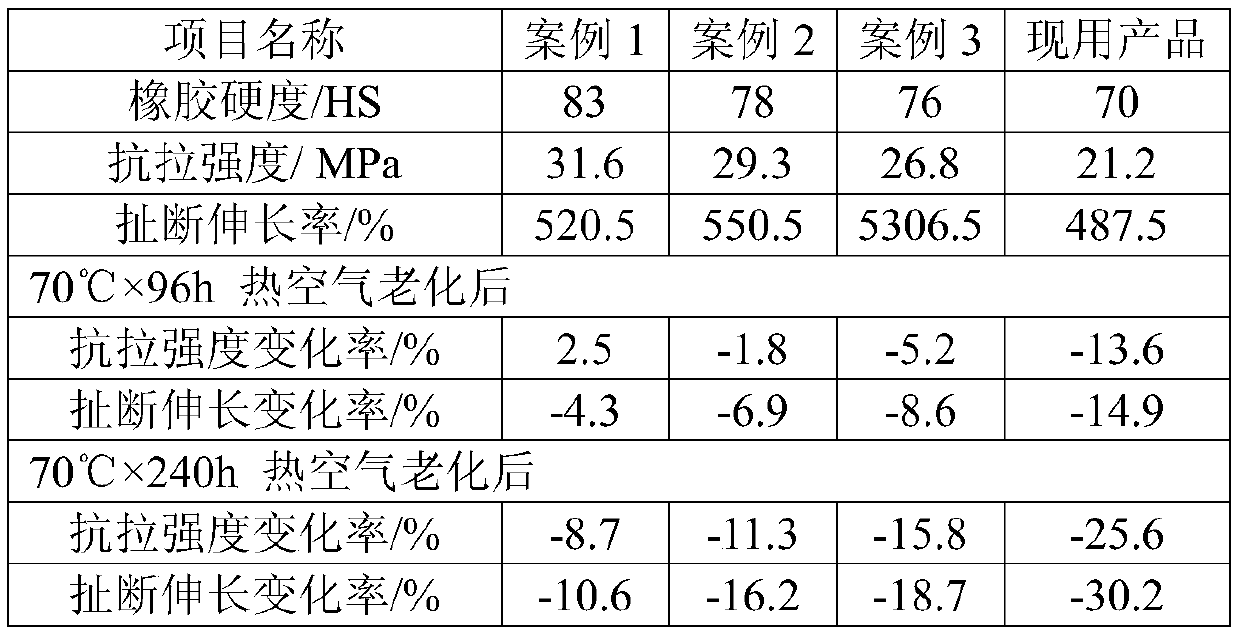

Aging-resistant rubber belt track

The invention discloses an aging-resistant rubber belt track. Raw materials comprise rubber, accelerant, magnesium oxide, zinc oxide, an anti-aging agent, carbon black, a silane coupling agent kh550,scorch retarder PVI, stearic acid, low-density naphthenic oil, superfine active clay, calcium carbonate, a light stabilizer and a fire retardant, and the aging-resistant rubber belt track is producedthrough initial mixing, mixing, packing and batch-out. Through different rubber components, by adding the anti-aging agent, the scorch retarder, the fire retardant, the carbon black, the superfine active clay, the light stabilizer and the like, the aging-resistant performance and the intensity of the rubber are improved, and the service life of the rubber is prolonged; and the accelerant, the magnesium oxide, the zinc oxide, the silane coupling agent kh550 and the like are adopted for promoting a vulcanization process of the rubber, so that vulcanization of the rubber is fuller.

Owner:XCMG CONSTR MACHINERY

Preparation method for vulcanized sealant for fuel cells

InactiveCN110474068AShort vulcanization timeSuitable for industrial productionFinal product manufactureSealing/support meansFuel cellsMicrowave

The invention discloses a preparation method for a vulcanized sealant for fuel cells. The preparation method includes the following steps: S1, selecting unvulcanized raw rubber, a vulcanizing agent and a catalyst to put into microwave generator equipment; S2, setting power, starting a microwave generator, performing vulcanization, and stopping a microwave heating process after M sec; S3, after cooling for L sec, restarting the microwave to perform vulcanization, and stopping the microwave heating process after N sec; and S4, cycling the step S2-S3 for multiple times, and performing an intermittent pulse vulcanization process until an appropriate vulcanized sealant is obtained. The preparation method is simple, high in production efficiency and low in energy loss, vulcanization uniformity can be effectively promoted, and product quality can be enhanced.

Owner:SHANGHAI ELECTRICGROUP CORP

Start working method of hydrogenation catalyst

ActiveCN106694041ARaise the initial vulcanization temperatureReduce start timeHydrotreatment operations starting-upOrganic-compounds/hydrides/coordination-complexes catalystsChemistrySimple Organic Compounds

The invention discloses a start working method of a hydrogenation catalyst. The start working method comprises following steps: 1, a sulfuration-type hydrogenation catalyst is delivered into a reactor; 2, an insert gas is introduced into the reactor to replace air in the reactor, and the sulfuration-type hydrogenation catalyst is subjected to sulfuration in the insert gas atmosphere; 3, after sulfuration, the inert gas is replaced by hydrogen gas, the pressure and the temperature in the reactor are adjusted to a reaction pressure and a reaction temperature when gas flow is stable, and a raw material oil is introduced for hydrogenation, wherein the sulfuration-type hydrogenation catalyst comprises a hydrogenation active metal component, a carrier, and an organic compound. In start working sulfuration, the metal on the surface of the hydrogenation catalyst is subjected to in-suit sulfuration directly, generation reaction of hydrogen sulfide and sulfuration reaction of hydrogen sulfide with active metal are not needed, the initial sulfuration temperature in catalyst start working is increased greatly, rapid temperature increasing in catalyst sulfuration is avoided, and start working time is shortened greatly.

Owner:CHINA PETROLEUM & CHEM CORP +1

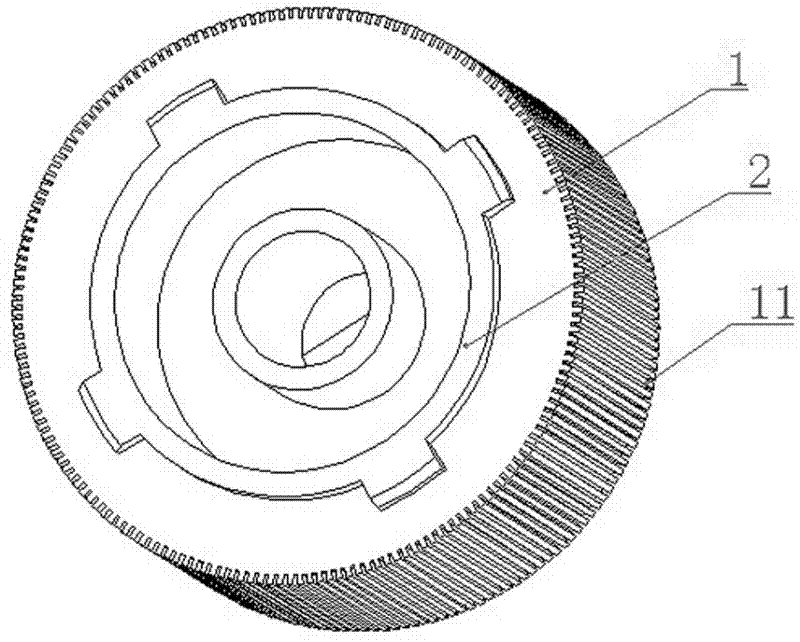

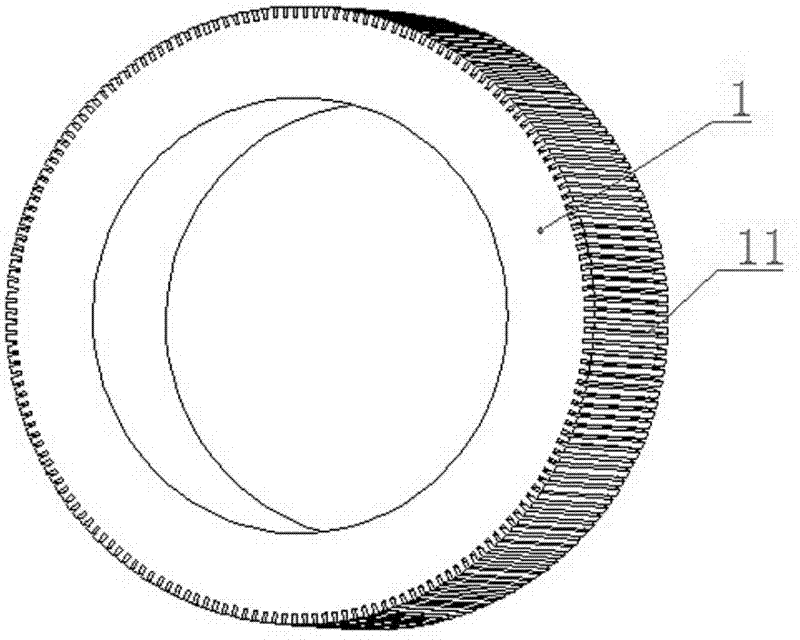

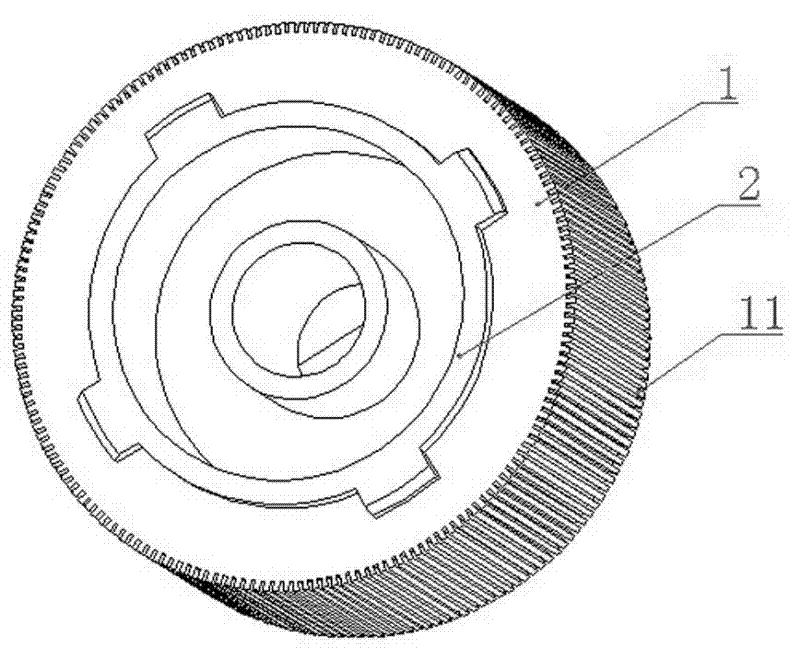

Paper feeding wheel and manufacturing method thereof

ActiveCN102358527AEasy to demouldImprove work efficiencyArticle feedersMetal layered productsAntioxidantHardness

The invention discloses a paper feeding wheel and a manufacturing method thereof. The paper feeding wheel consists of a plastic framework and a rubber wheel sleeved on the plastic framework, wherein the rubber wheel is made of a rubber composition; and the rubber composition comprises rubber with high wear resistance and strength, an effective rubber vulcanizing system, more than one antioxidants, and a proper amount of reinforcing filler and softening agent, wherein the effective rubber vulcanizing system is suitable for a composition of butadiene rubber and natural rubber; one of the more than one antioxidant has a function of assisting in demoulding after rubber is vulcanized; and the proper amount of reinforcing filler and softening agent can improve the strength of the rubber wheel and cannot obviously improve hardness. The invention has the advantages that: the manufacturing process is simple, and the rubber wheel is formed by a mold through one-time compression moulding, and is not required to be processed; the surface of the paper feeding wheel is hardly subjected to frost spray; and the frictional property of the surface of the paper feeding wheel can be kept for a long time.

Owner:BEIJING LASER HI TECH CO LTD

Nitrile rubbers

ActiveUS8389623B2Fast initial and full vulcanizationImproved profileGroup 4/14 element organic compoundsRotary stirring mixersNitrile rubberVulcanization

An improved polymerization and work-up process makes it possible to produce specific nitrile rubbers which have a particular ion index and a particular magnesium content which is responsible for an excellent vulcanization rate and leads to vulcanizates having an advantageous property profile.

Owner:ARLANXEO DEUT GMBH

Rapid start-up method of hydrocracking catalyst

ActiveCN109777475AAvoid investingCatalyst activity is stableHydrocarbon oil crackingMolecular sieveChemistry

The invention discloses a rapid start-up method of a hydrocracking catalyst. The start-up method comprises the following steps: introducing raw material oil in the vulcanization process, after vulcanization is completed, adjusting a reaction temperature, and when the mass yield of light oil less than 360 DEG C is stabilized at 35-40%, adjusting to a hydrocracking reaction condition to carry out ahydrocracking reaction, wherein the hydrocracking catalyst comprises 0-10% of a molecular sieve by weight, and the molecular sieve comprises, but not limited, a Y type or a USY (Ultra-Stable Y Zeolite) type molecular sieve. The method is simple in start-up and raw material switching process, stable in operation and capable of avoiding consumption of a passivant in the start-up process and potential danger in the ammonia injection process.

Owner:CHINA PETROLEUM & CHEM CORP +1

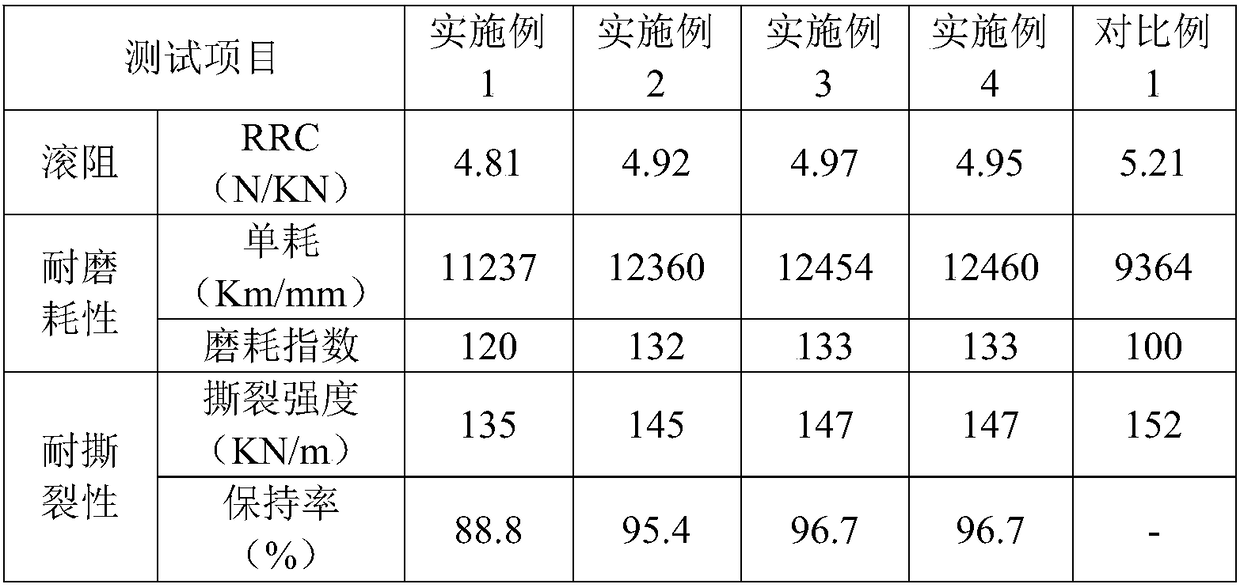

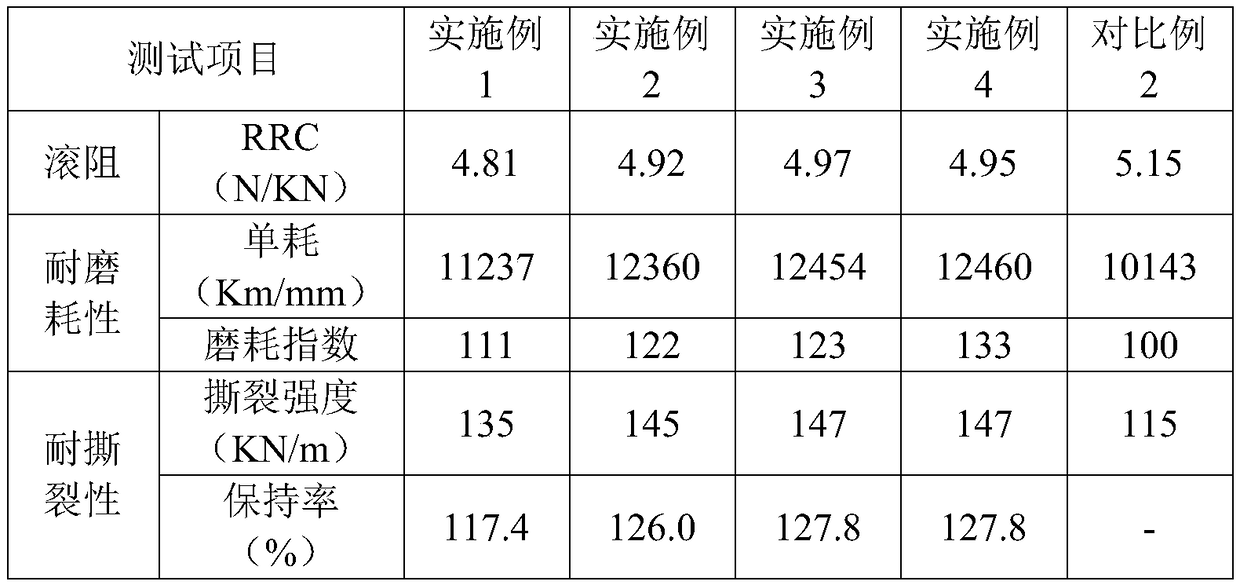

Rubber composition for all-steel tread, and preparation method thereof

InactiveCN109021325AExcellent abrasion resistanceCompromise with tear resistanceSpecial tyresRolling resistance optimizationRubber materialRolling resistance

The invention provides a rubber composition for an all-steel tread, and a preparation method thereof. The rubber composition for the all-steel tread comprises, by weight, natural rubber, neodymium branched cis-polybutadiene rubber, carbon black, a dispersant, an anti-aging agent, sulfur, an accelerator, an activator and a scorch retarder. The rubber composition is prepared by five-stage mixing. The all-steel tread rubber composition of the invention adopts an N134 pure carbon black filling system, and the use amount of carbon black is controlled within an appropriate range, so the rubber material has a low rolling resistance and a high wear resistance; the system branched cis-polybutadiene rubber is used, so the tear resistance of the tread is considered while reducing the rolling resistance and improving the wear resistance; and the five-stage mixing preparation method is beneficial to promote the contact and reaction of the N134 carbon black with the natural rubber and the neodymiumbranched cis-polybutadiene rubber in order to produce more carbon black binder, so the rolling resistance, the wear resistance and the tear resistance are comprehensively improved.

Owner:GITI RADIAL TIRE (ANHUI) CO LTD

High temperature resistant organic plastic alloy material and preparation method thereof

InactiveCN102952412AImprove the degree of vulcanization and foamingHigh heat resistanceAl powderBenzoyl peroxide

The invention provides a high temperature resistant organic plastic alloy material which is prepared from the following ingredients in parts by weight: 30-50 parts of difluoro propyl ethylene based rubber or methylvinylsiloxane methyl vinyl silicone rubber, 10-20 parts of ABS (Acrylonitrile Butadiene Styrene) resin, 10-20 parts of PET ( Poly Ethylene Terephthalate), 1-5 parts of diphenyl silandiol, 2-8 parts of toluenesulfonyl semicarbazide, 1-5 parts of ammonium carbonate, 1-5 parts of benzoyl peroxide tertiary butyl, 0.5-2 parts of curing agent, 0.5-2 parts of lauryl alcohol, 0.5-2 parts of graphene and 0.2-0.6 part of aluminium powder. The high temperature resistant organic plastic alloy material provided by the invention has the advantages of good high temperature resistance, high mechanical property and high foaming ratio.

Owner:广东瑞森联信科技有限公司

Adhesive for hot water-cured lining hard rubber and preparation method thereof

ActiveCN102127378ALower vulcanization temperatureFully vulcanizedNatural rubber adhesivesNon-macromolecular adhesive additivesPolymer scienceVulcanization

The invention relates to an adhesive for lining hard rubber, in particular to an adhesive for hot water-cured lining hard rubber, which is a mixture of components A and B in a weight part ratio of 4:1. The component A comprises 100 parts of natural rubber, 1 to 3 parts of pigment, 20 to 40 parts of sulfur, 50 to 150 parts of zinc oxide, 15 to 40 parts of tackifying resin, 1 to 3 parts of accelerator DM1, 2 to 5 parts of mixed oil 933 and 400 to 700 parts of mixed solvent, wherein the mixed solvent is 2 or 3 of toluene, dimethylbenzene and gasoline. The component B comprises solution of polyisocyanate. Before use, the component B is added into the component A, the components are mixed uniformly (for at least 1 minute), and the adhesive for brushing can be obtained. The adhesive is applicable to hot water-cured lining hard rubber and has big adhesion force.

Owner:SHANGHAI SHUANGPU ANTICORROSION RUBBER LINING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com