Patents

Literature

204results about "Concentric cables" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

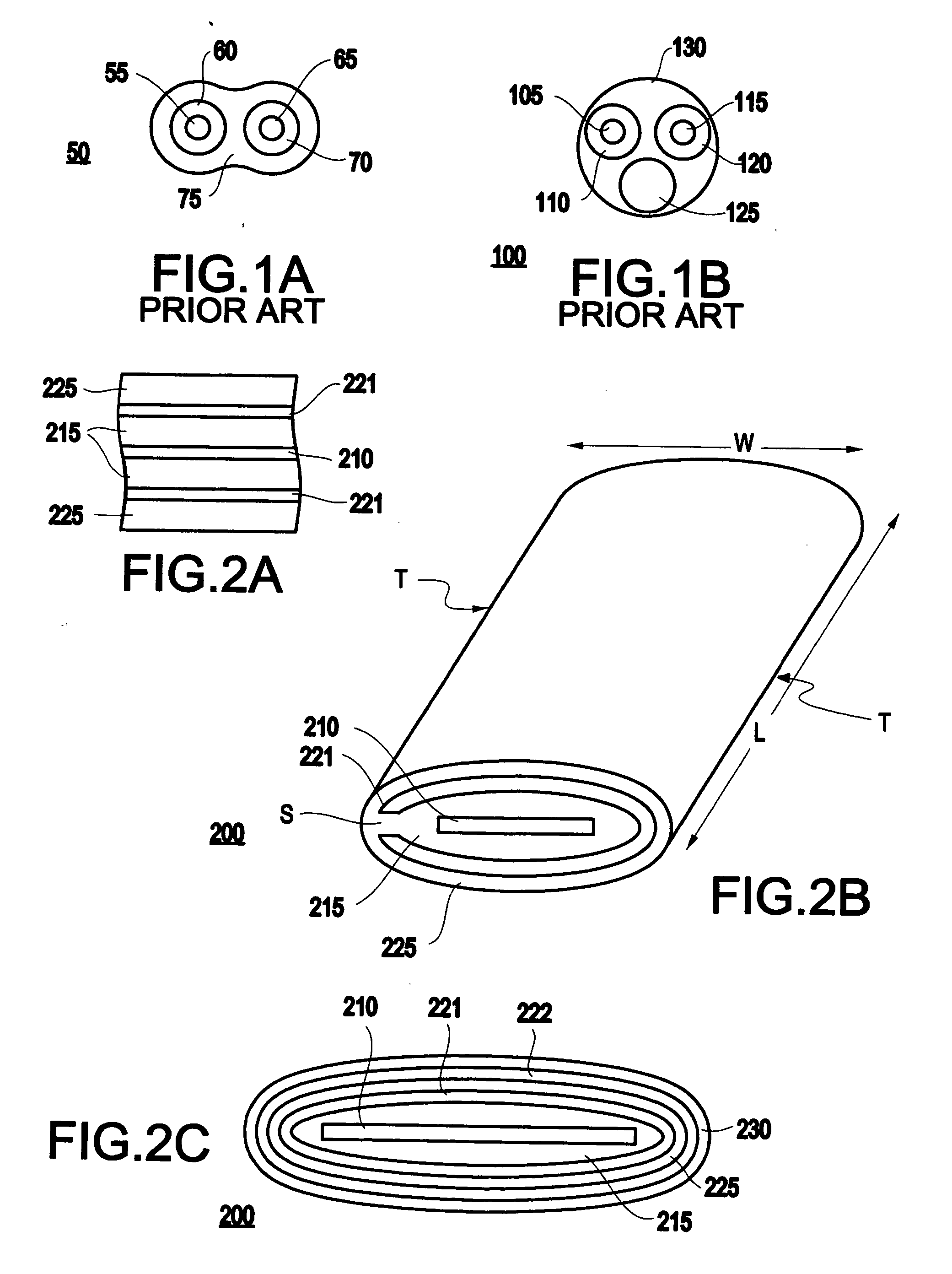

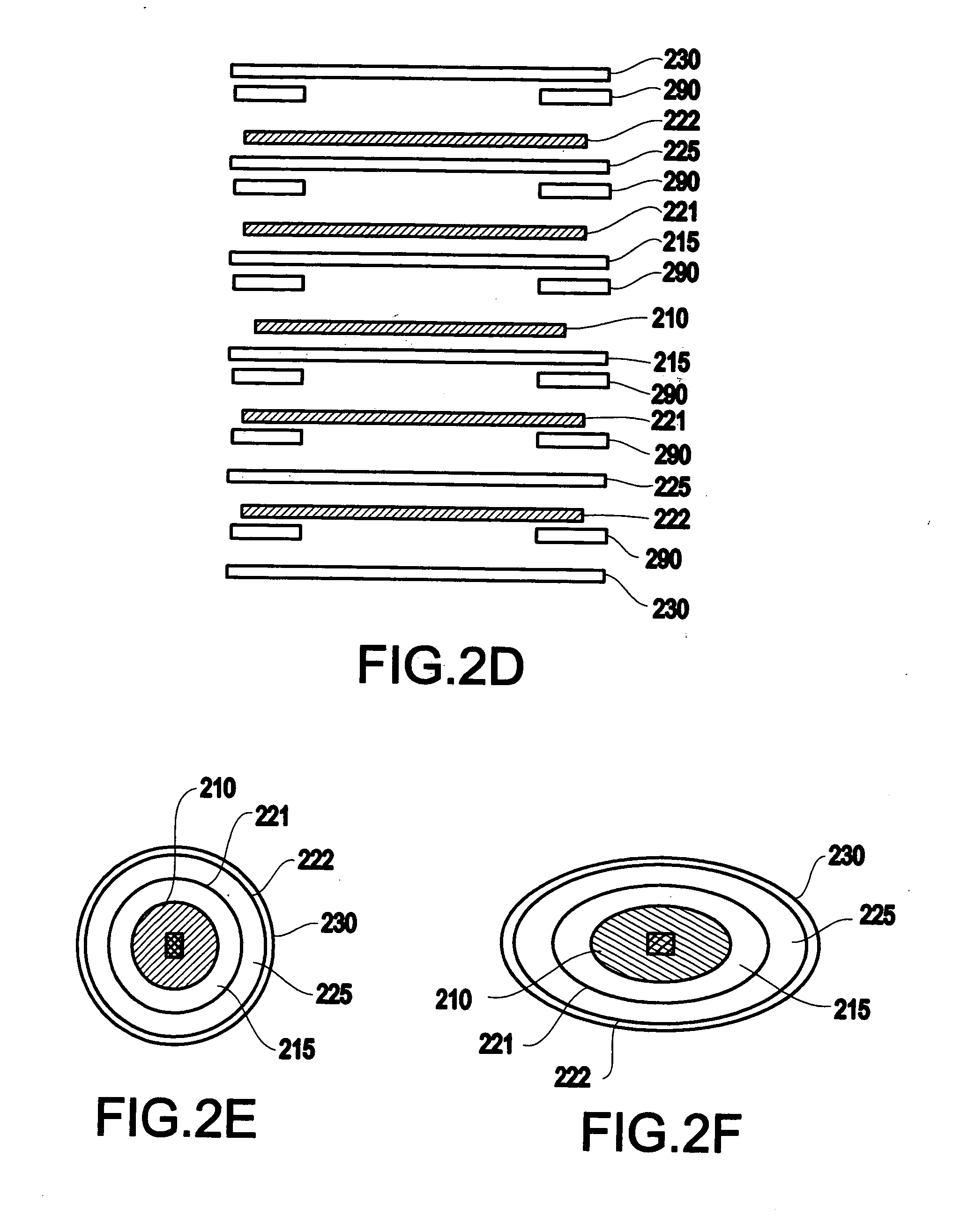

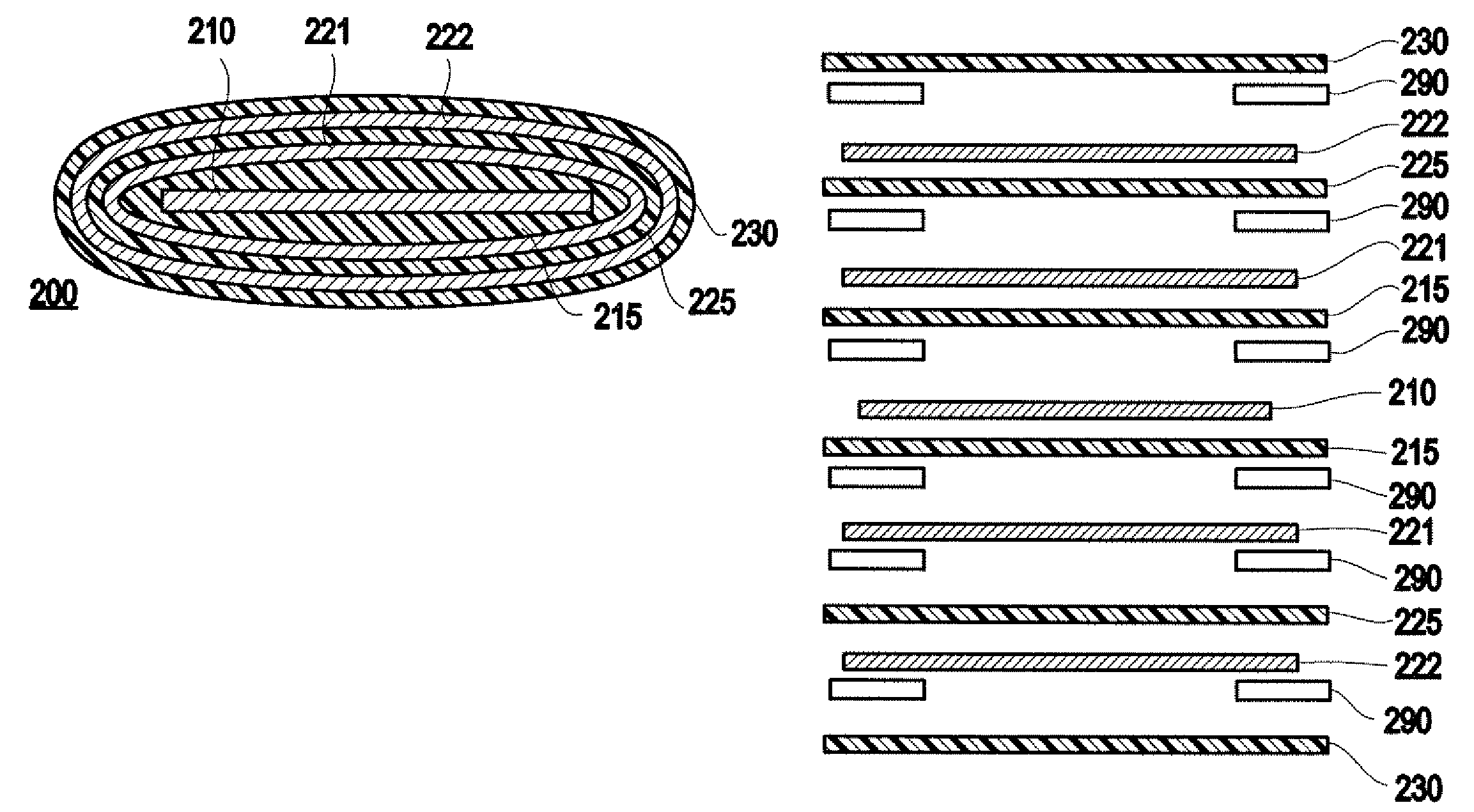

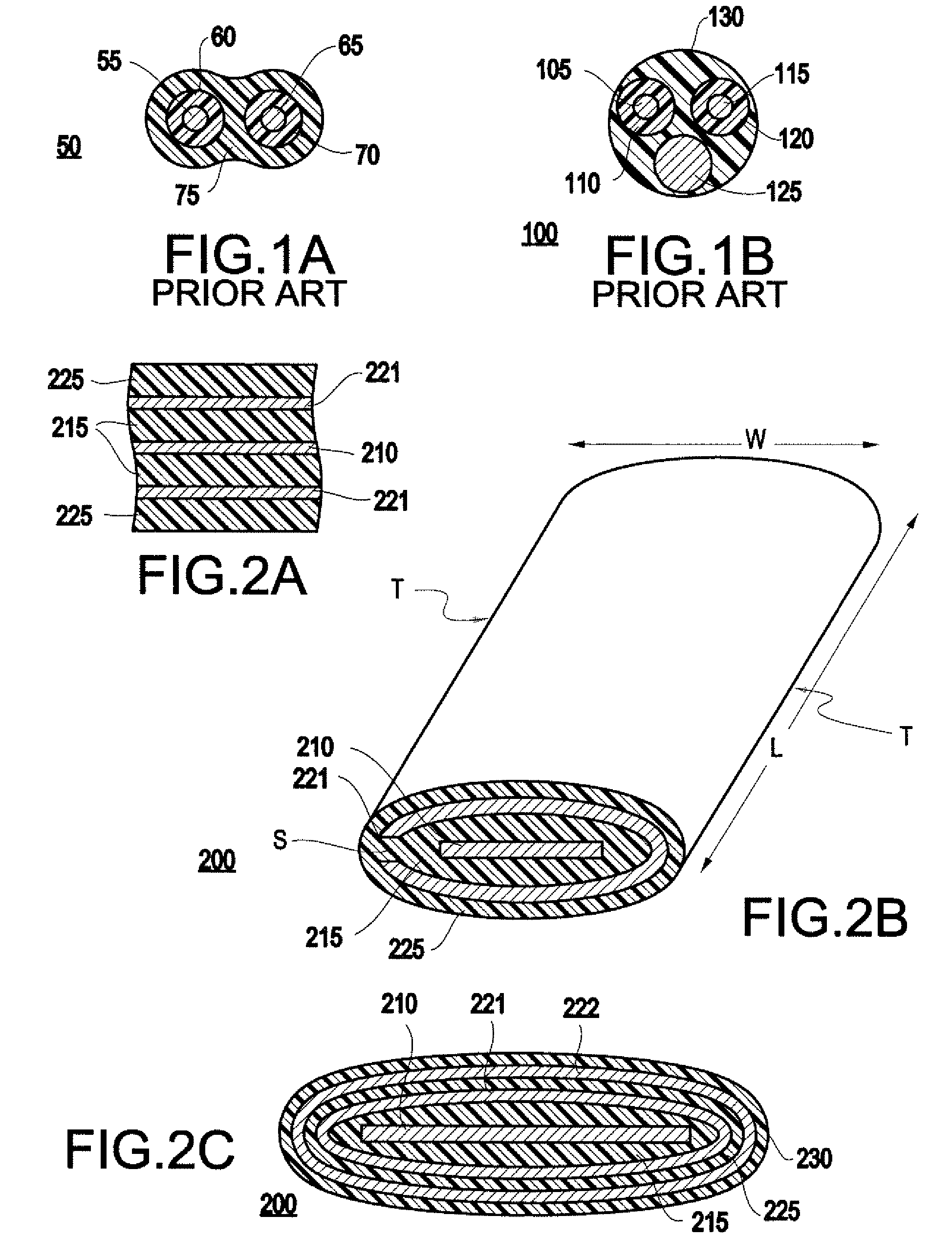

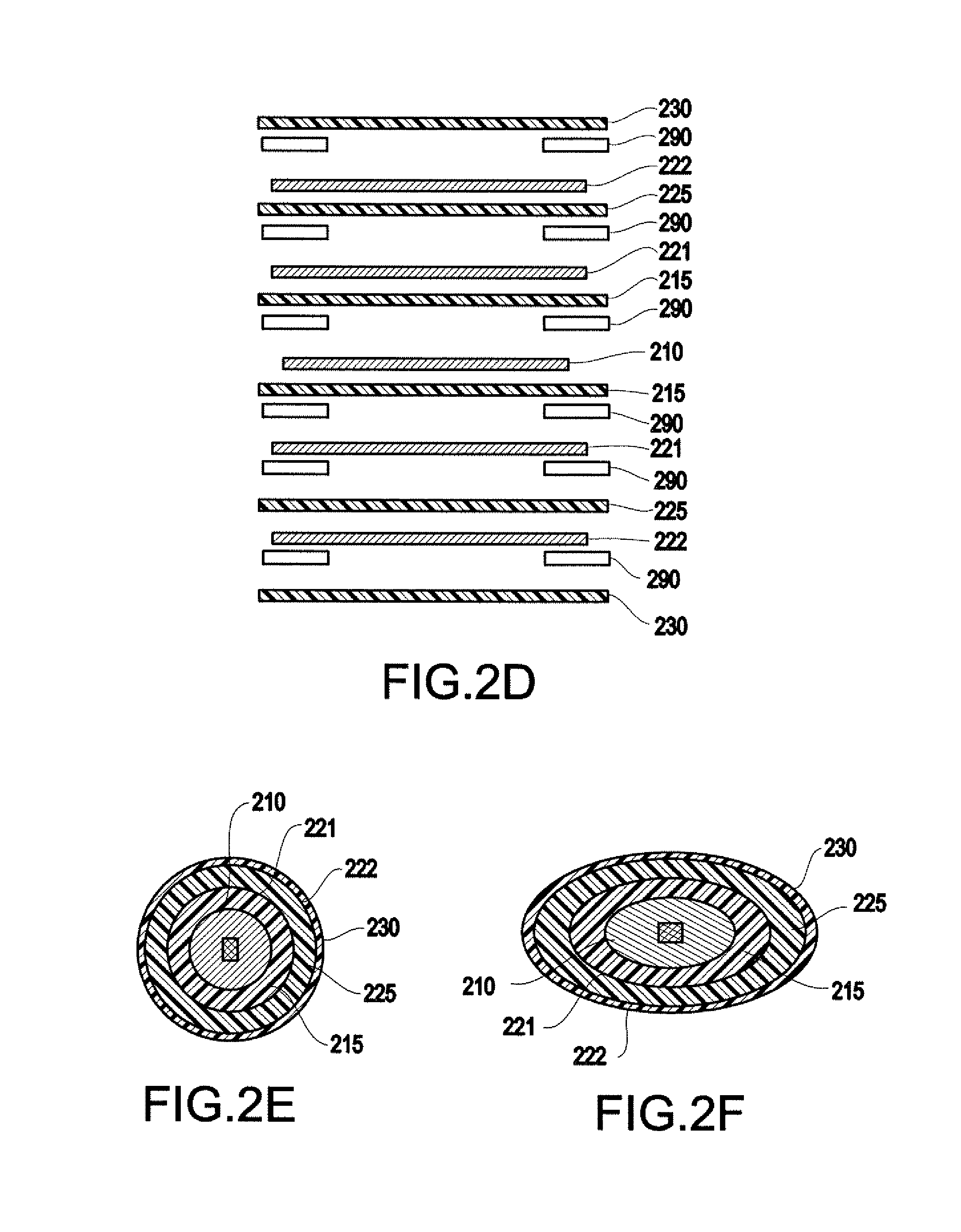

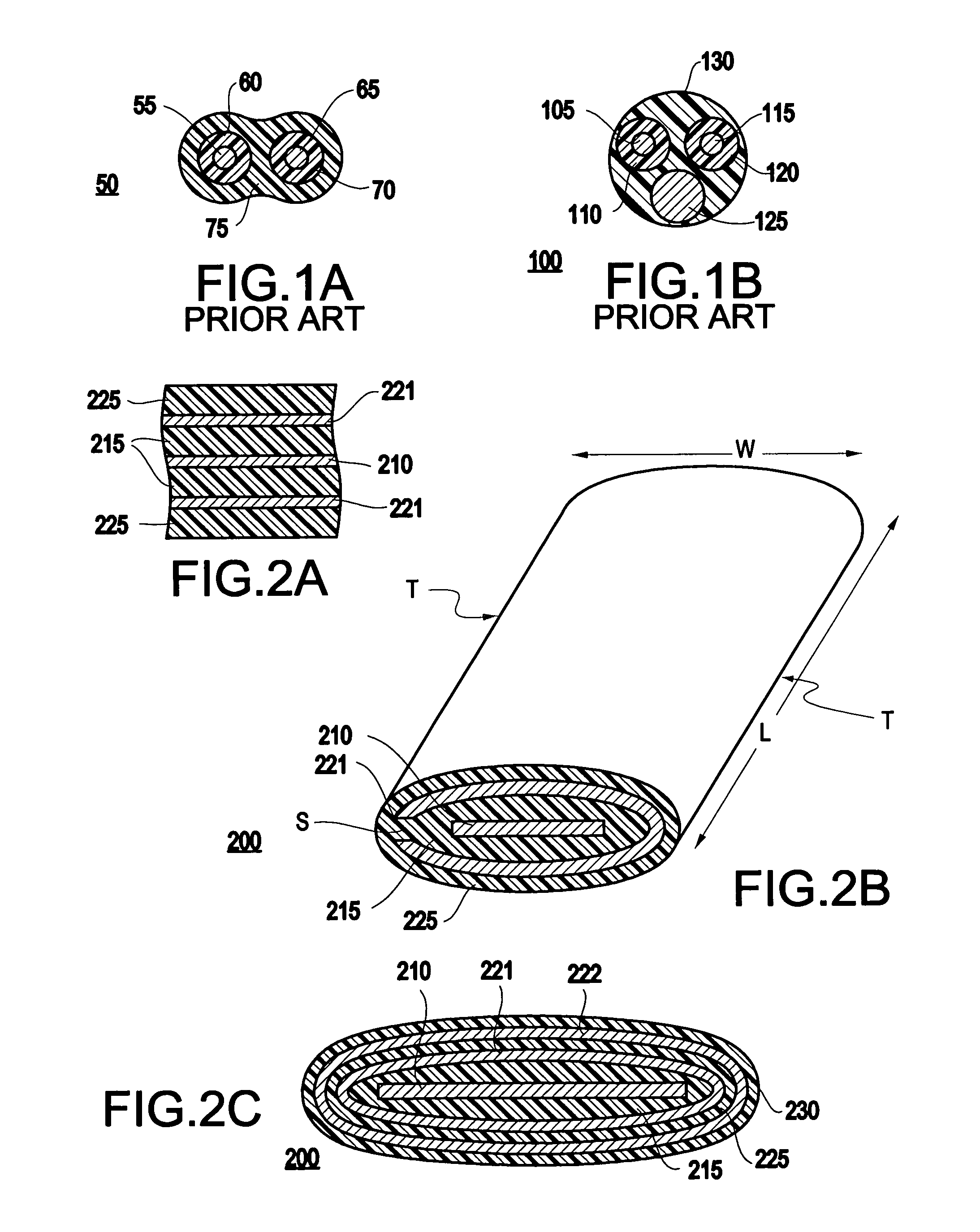

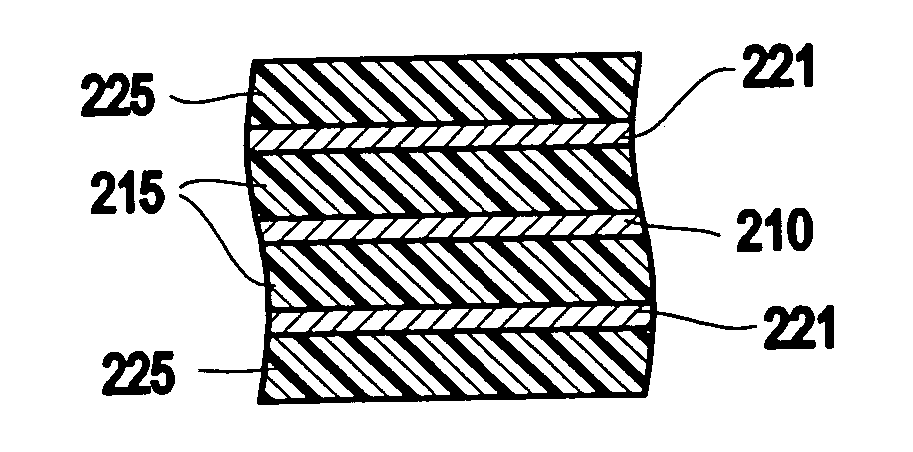

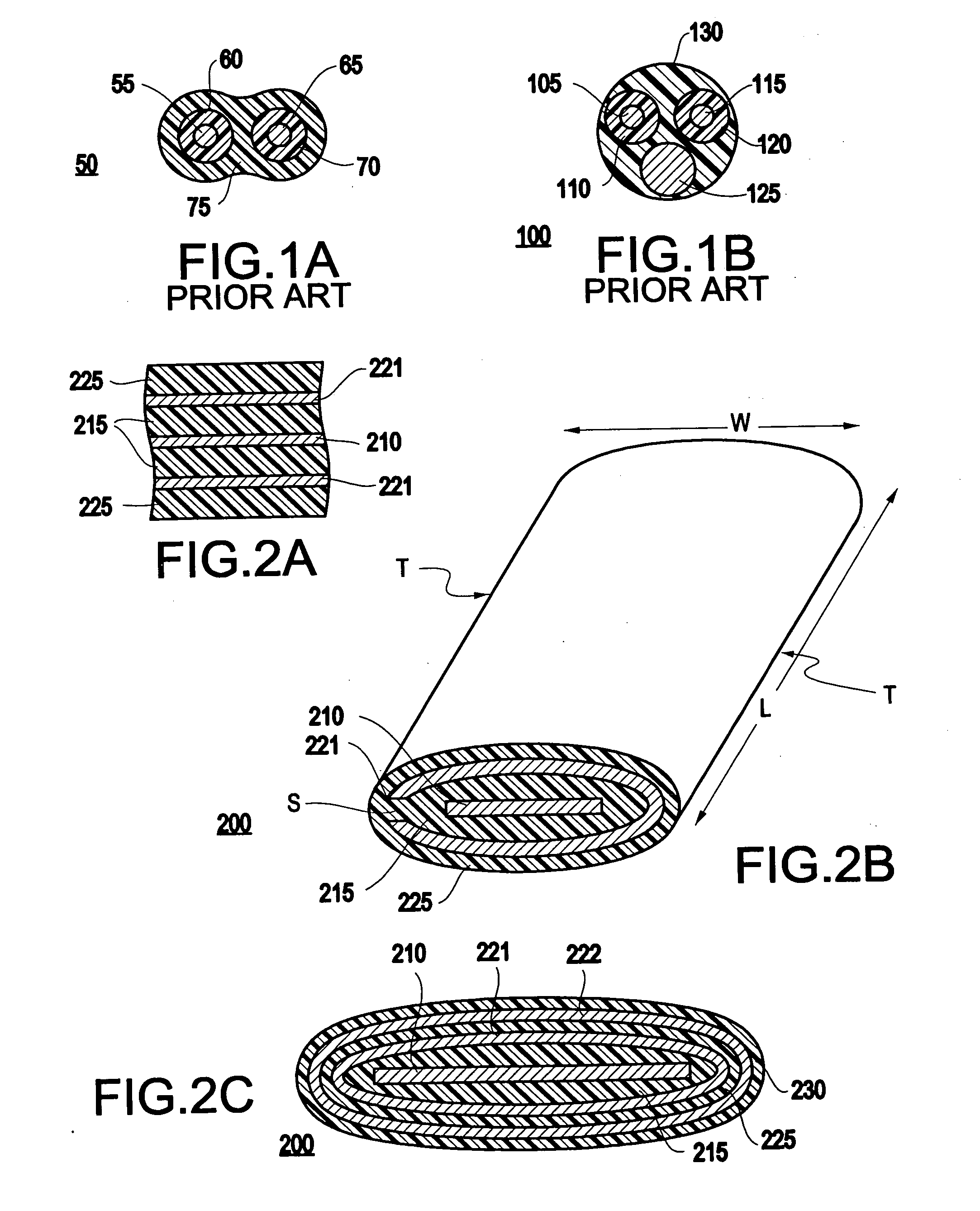

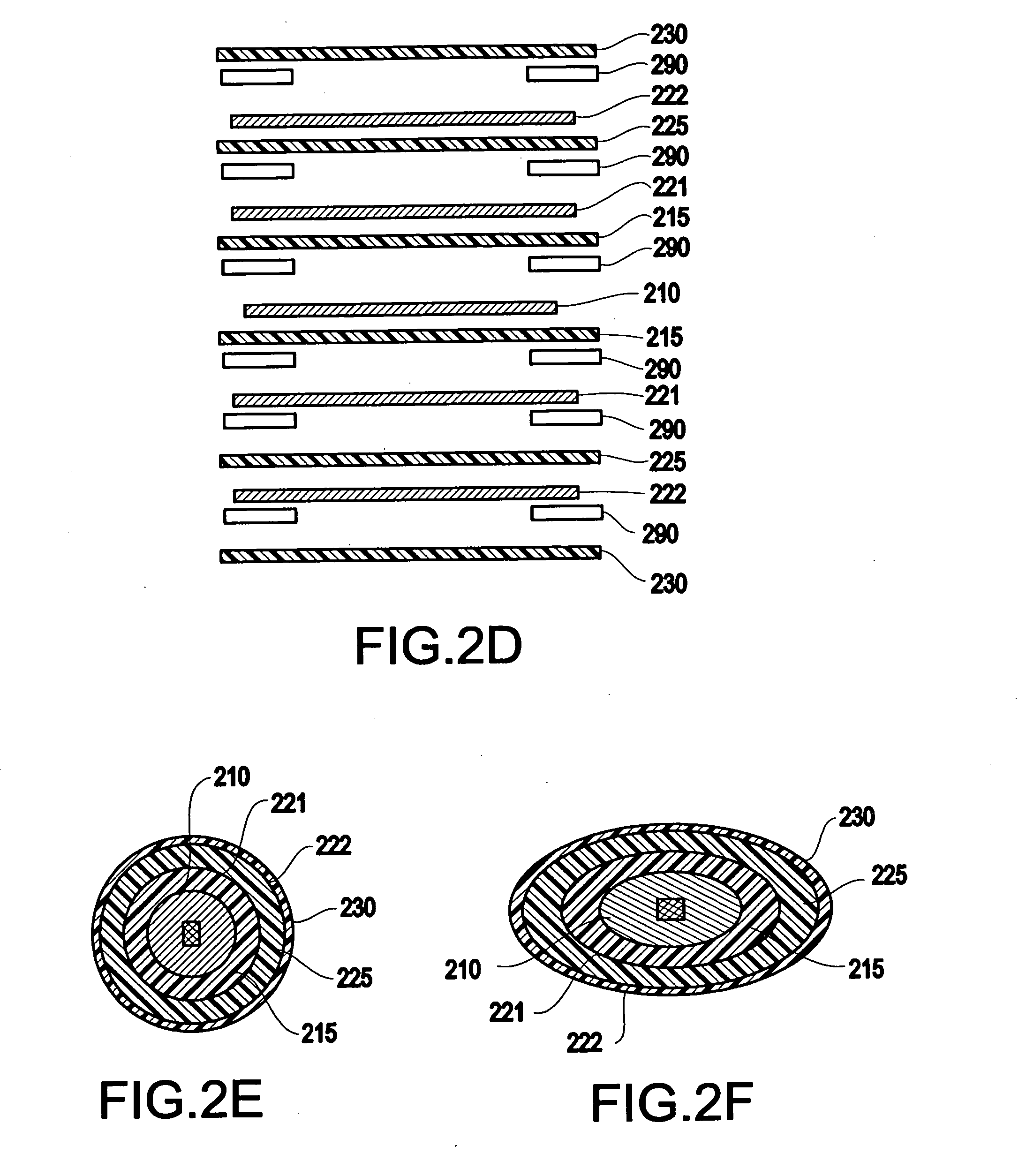

Electrical wire and method of fabricating the electrical wire

InactiveUS20080047727A1Safe and convenientEasy to makeConcentric cablesInsulated cablesElectric forceElectrical conductor

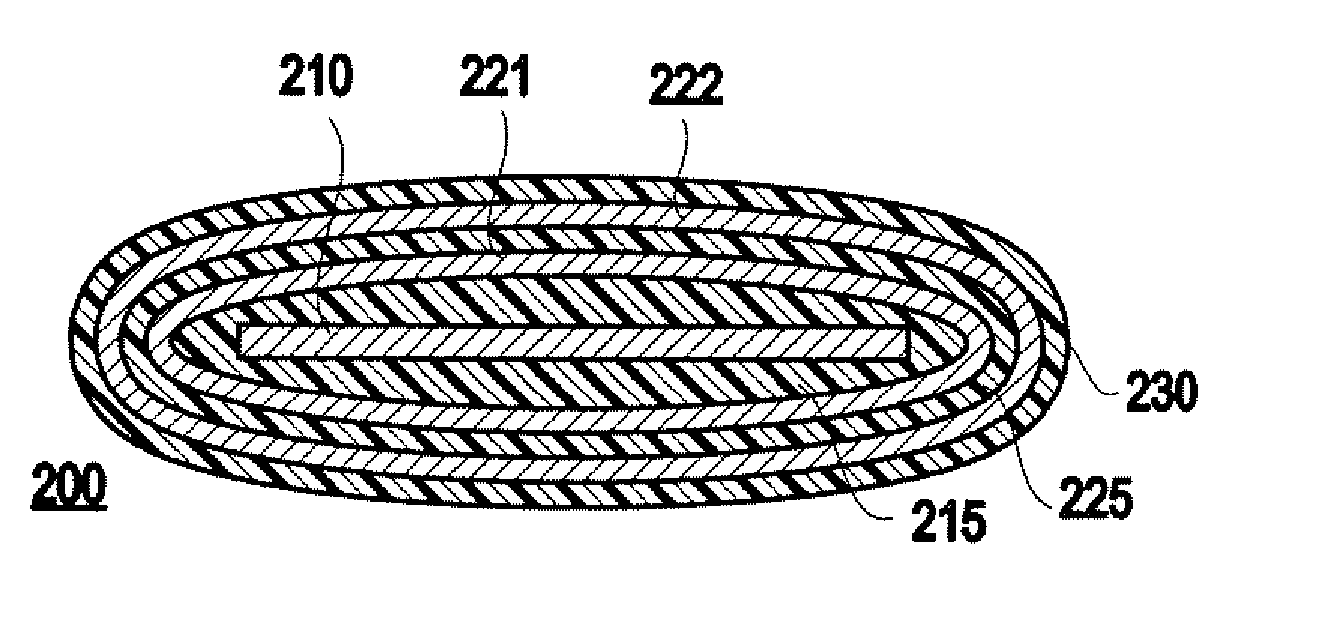

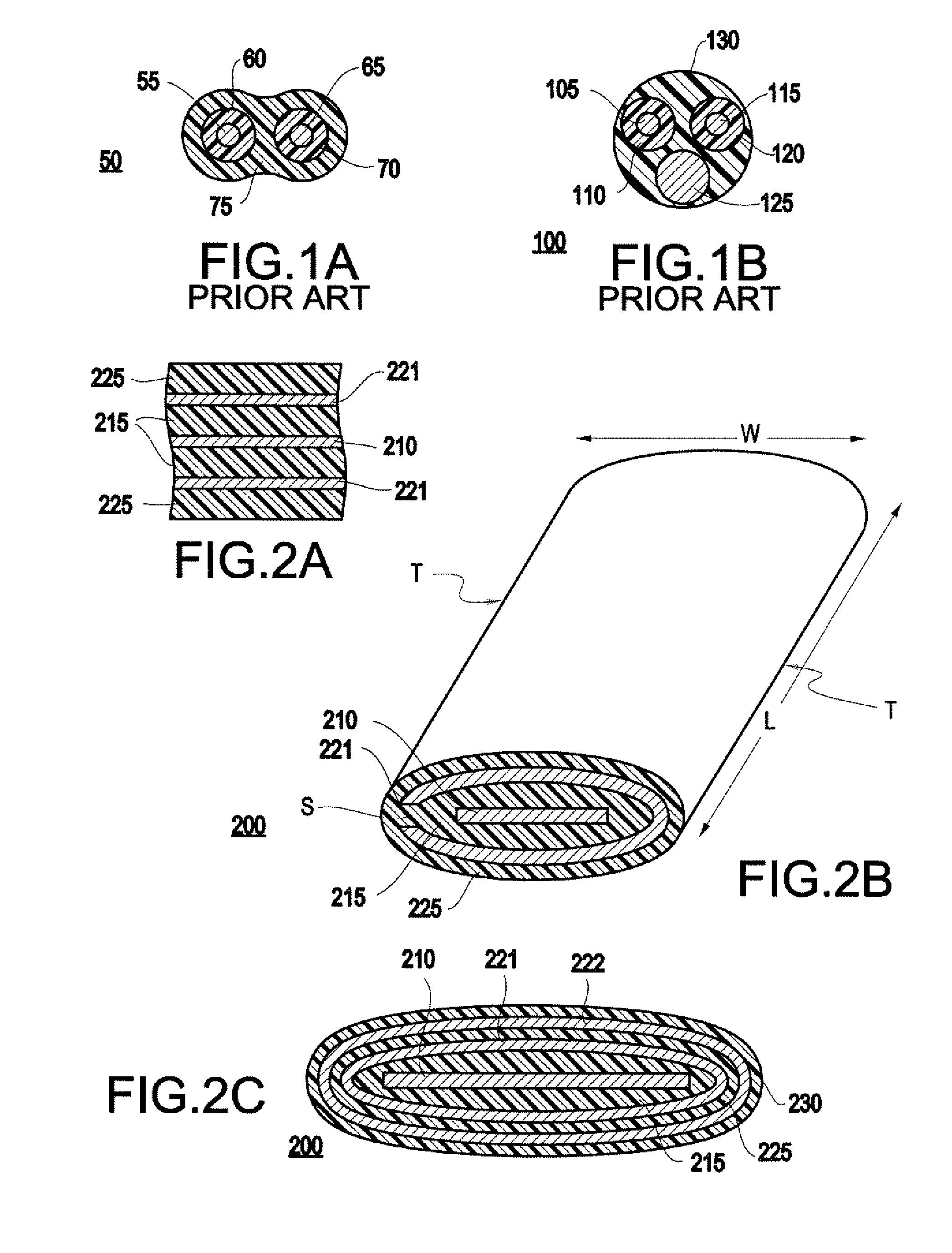

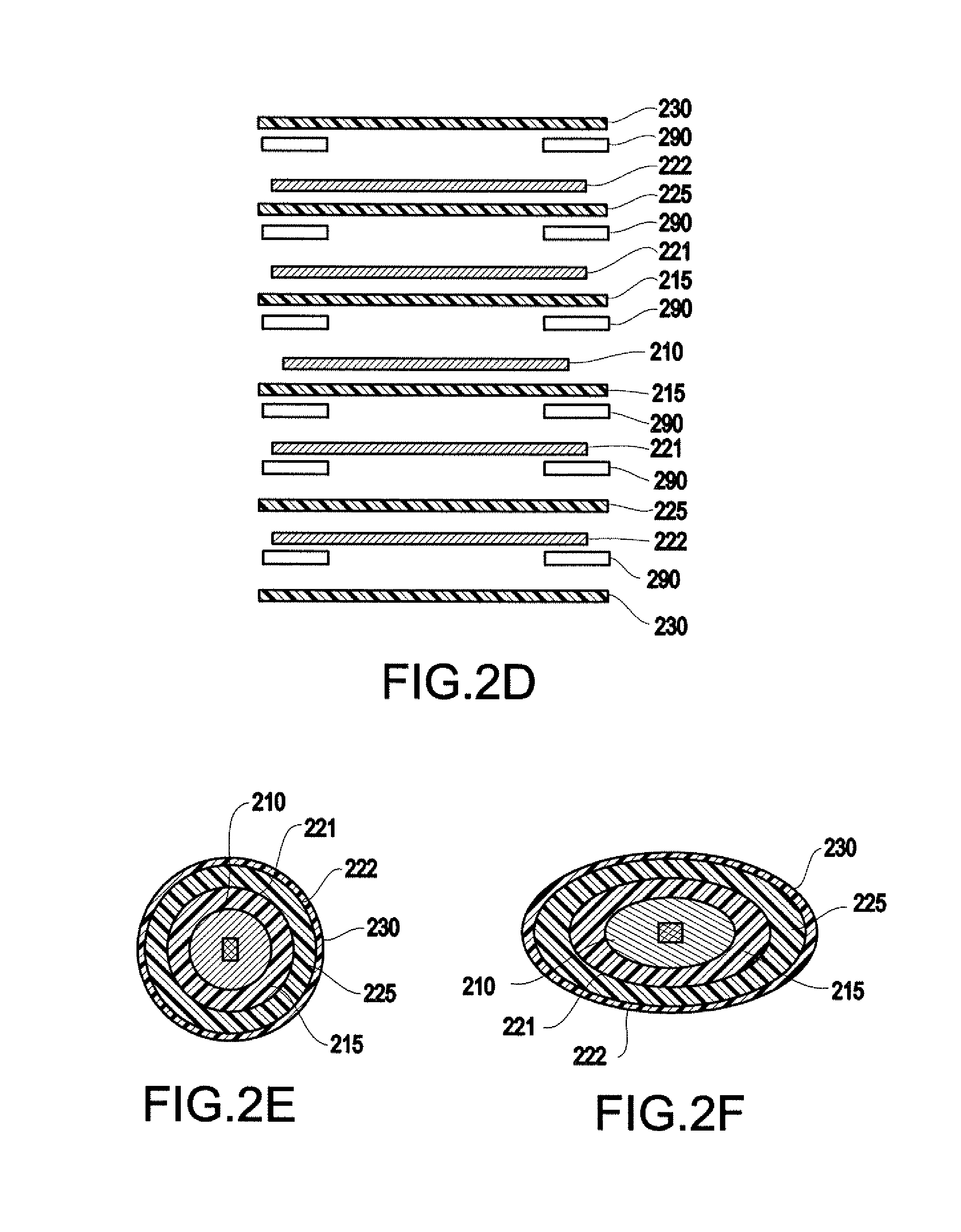

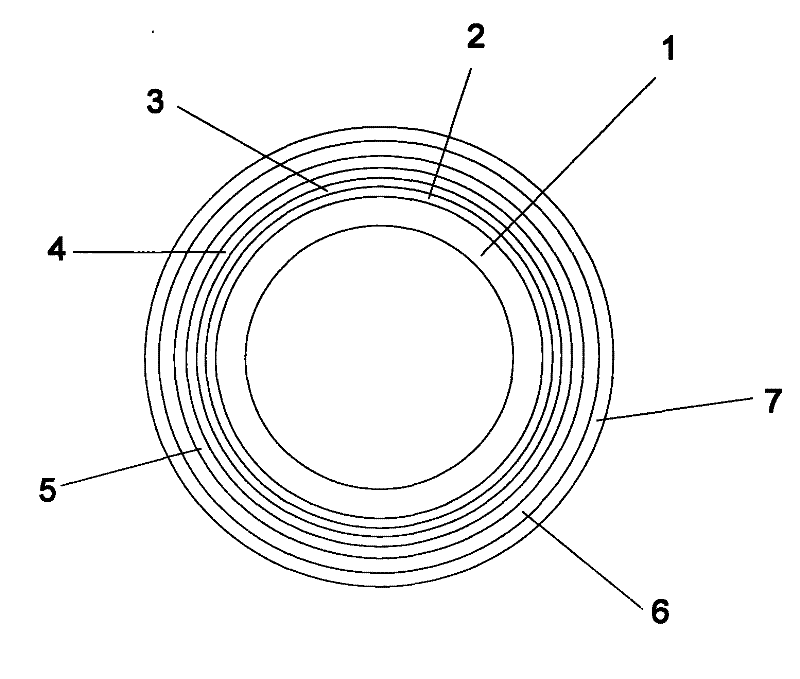

An electrical wire includes at least one electrifiable conductor for delivering electrical power, a first insulating layer formed on one side of the electrifiable conductor, a second insulating layer formed on the opposite side of the electrifiable conductors, a first return conductor formed on the first insulating layer opposite the at least one electrifiable conductor, and a second return conductor formed on the second insulating layer opposite the at least one electrifiable conductor. The at least one electrifiable conductor is at least substantially entrapped by the first and second return conductors such that the distance between said at least one electrifiable conductor and each of said first and second return conductors is no greater than approximately 0.030 inches. At least one of the first insulating layer or the second insulating layer comprises a plurality of insulating layers.

Owner:NEWELL CO INC

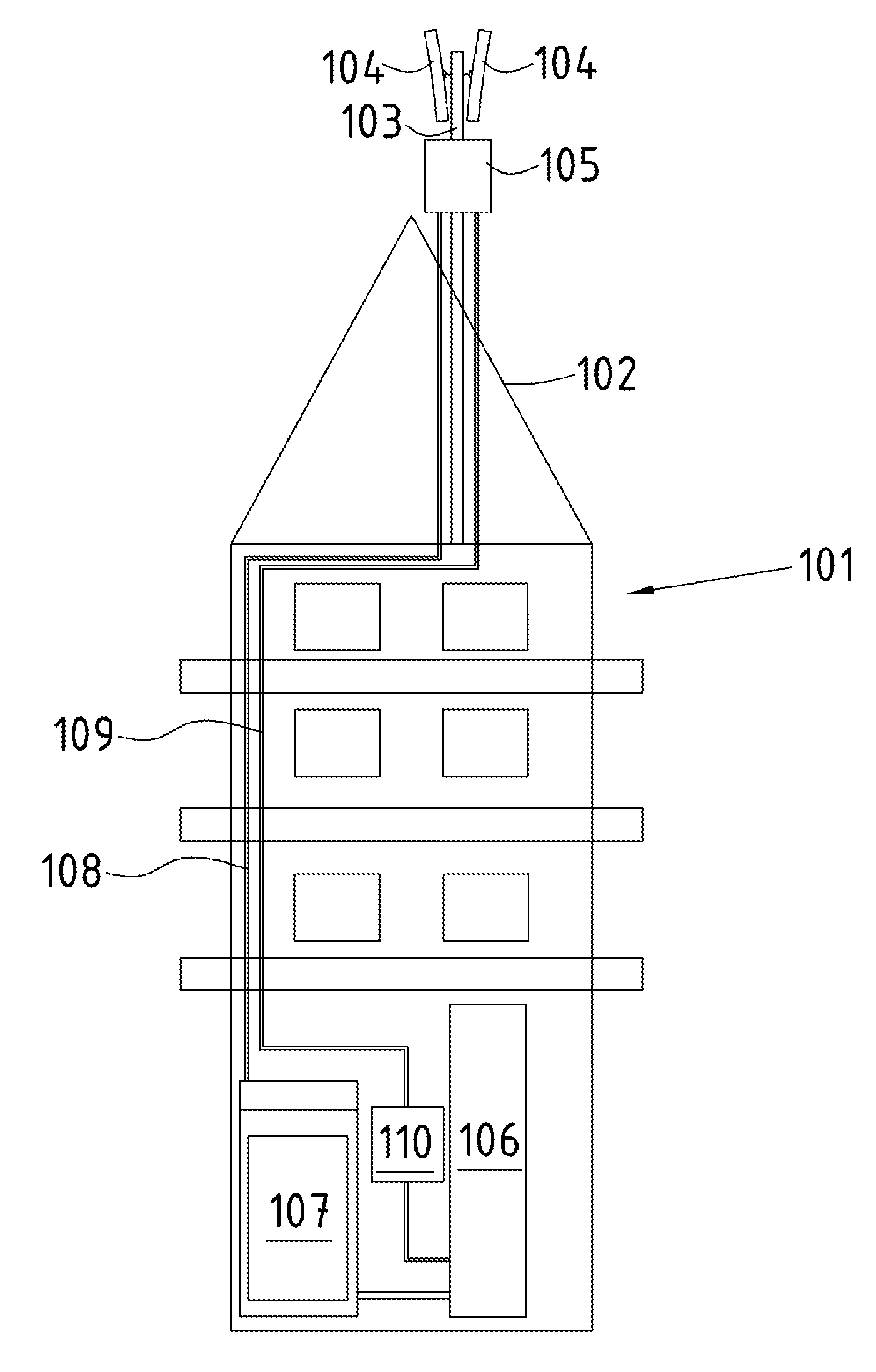

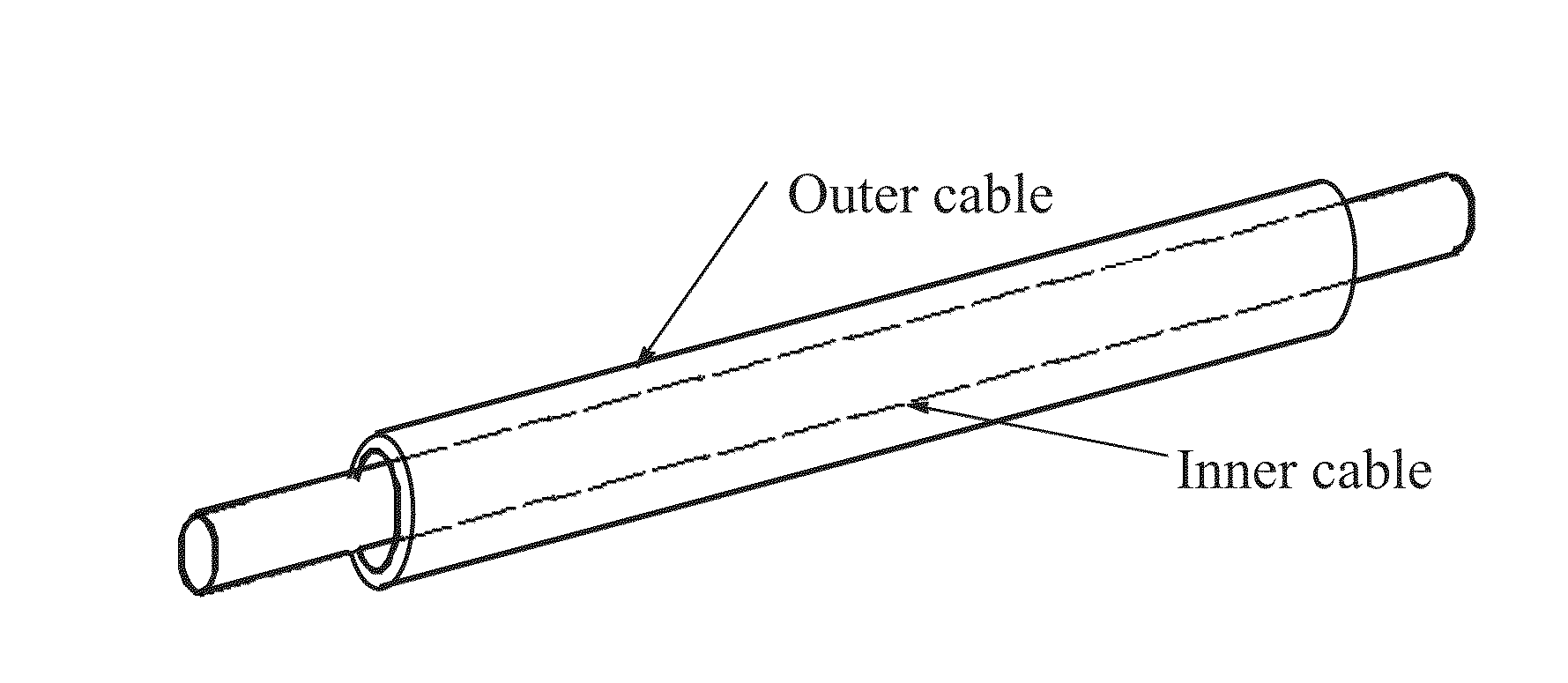

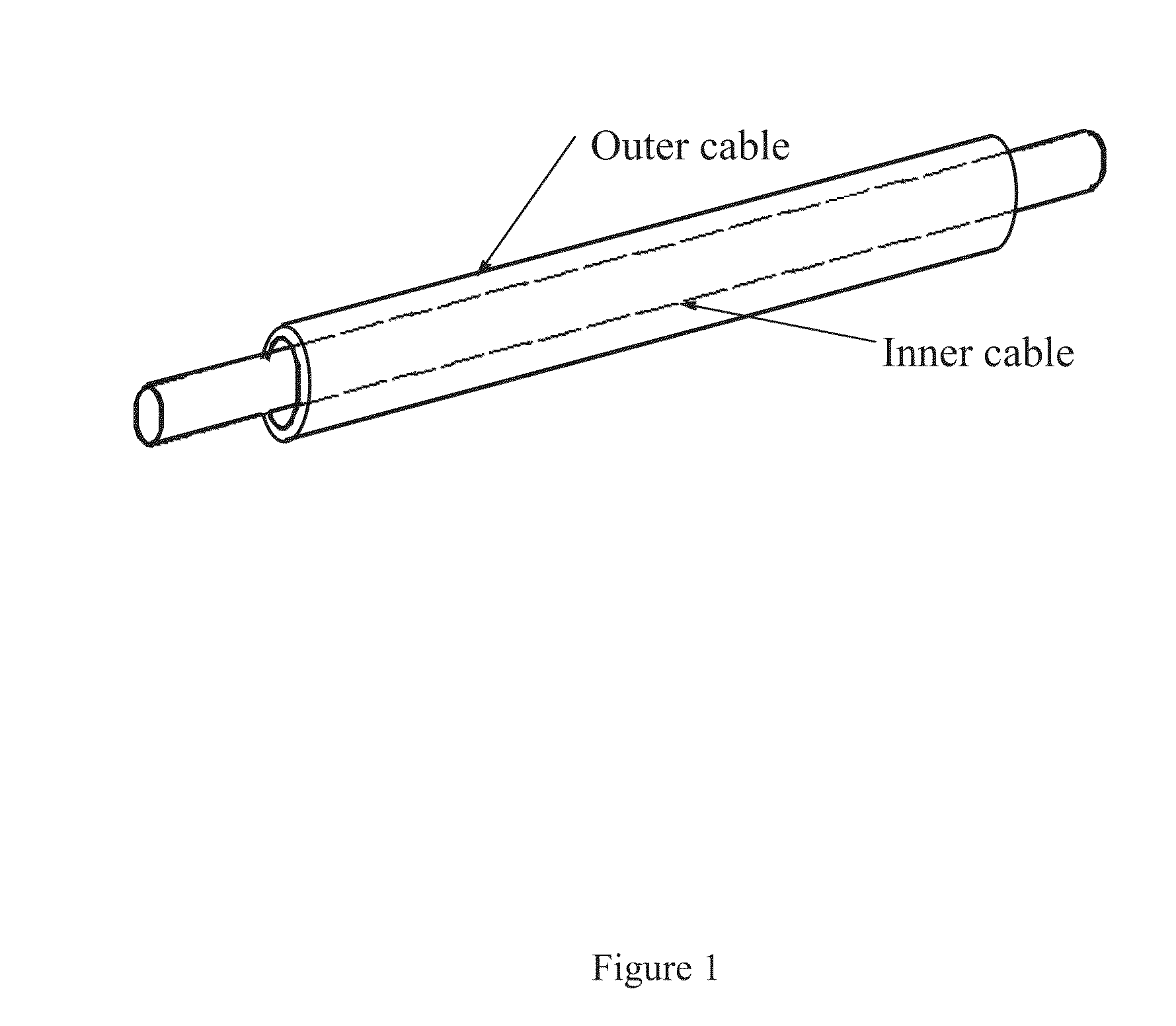

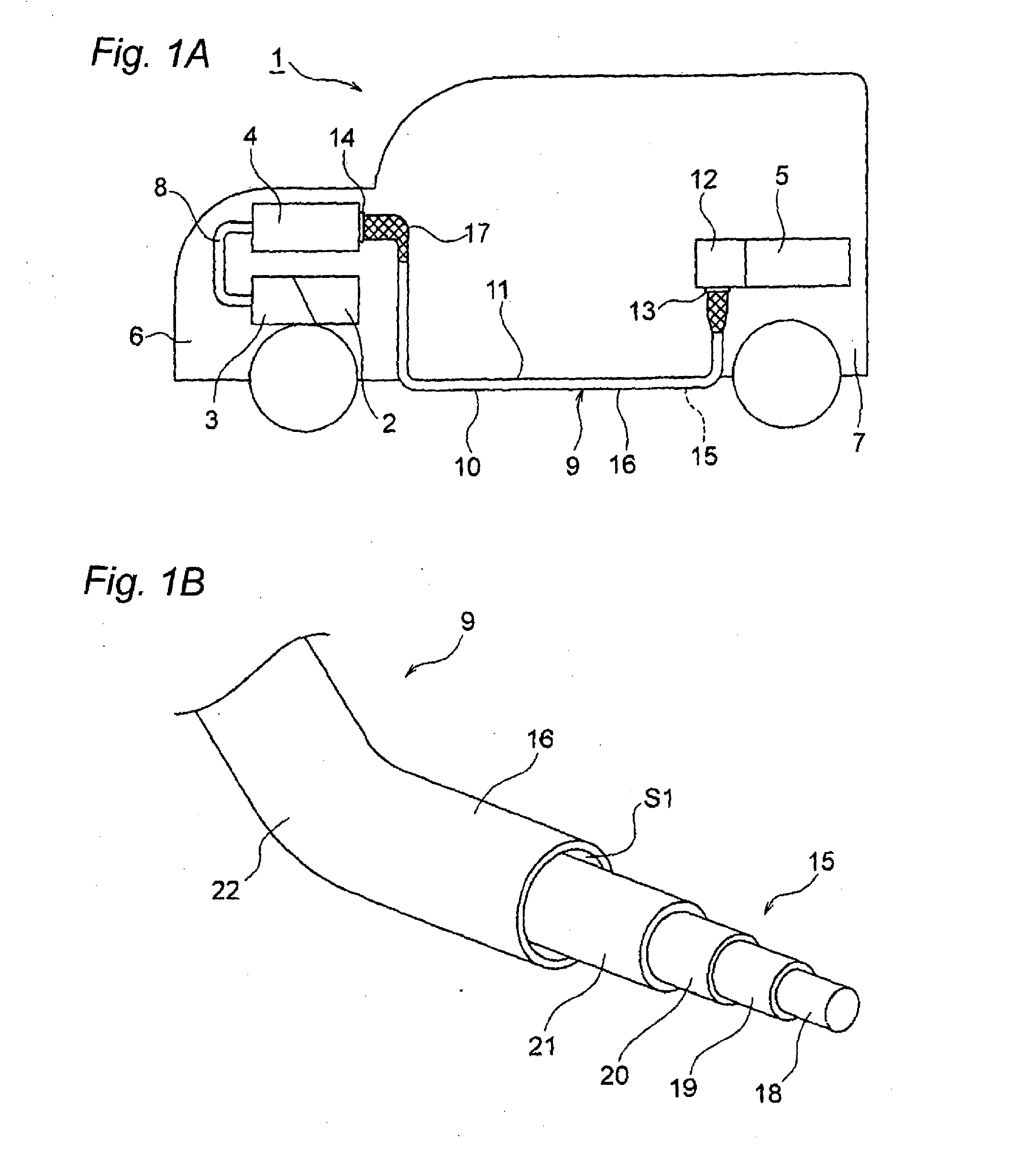

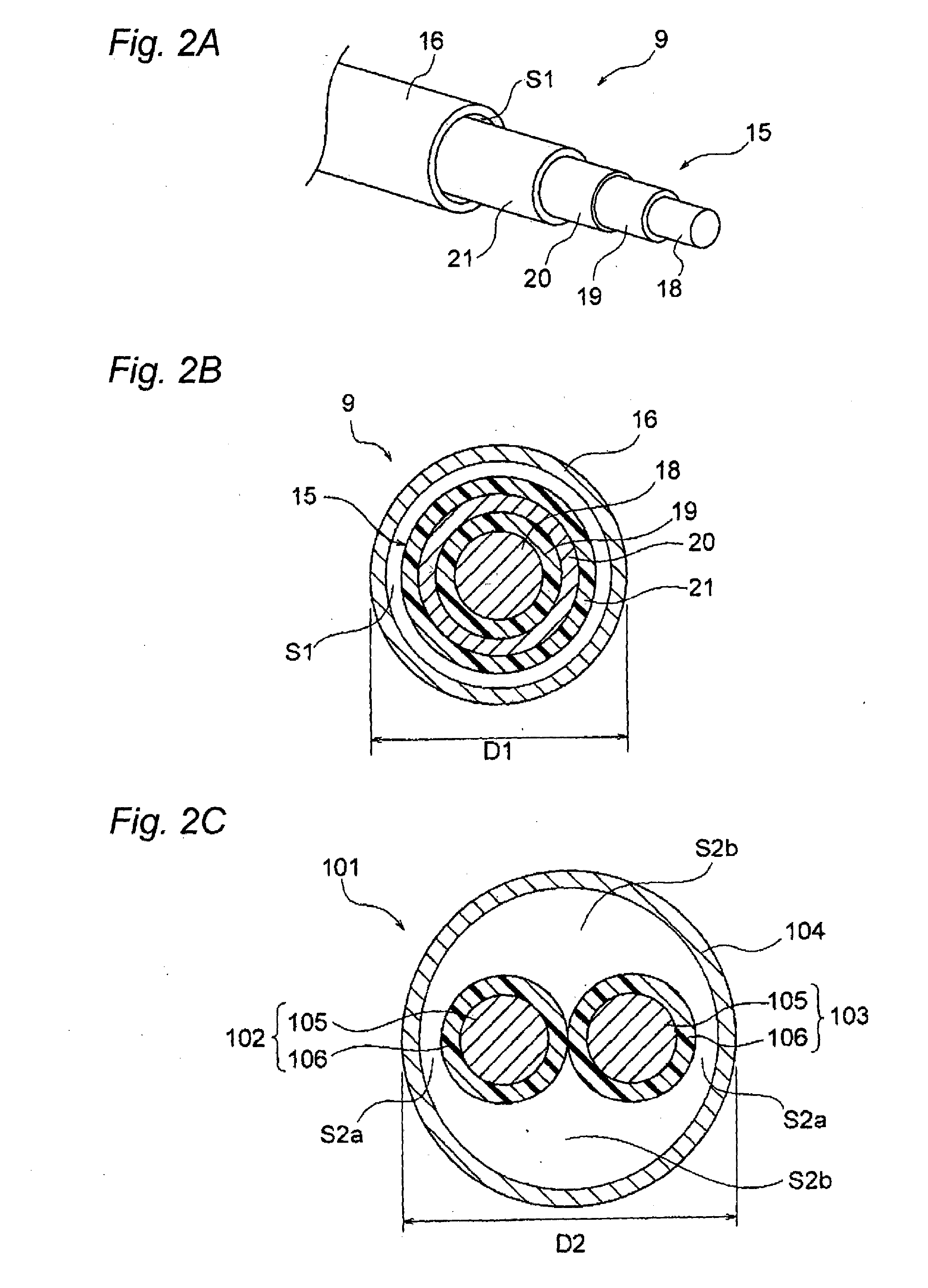

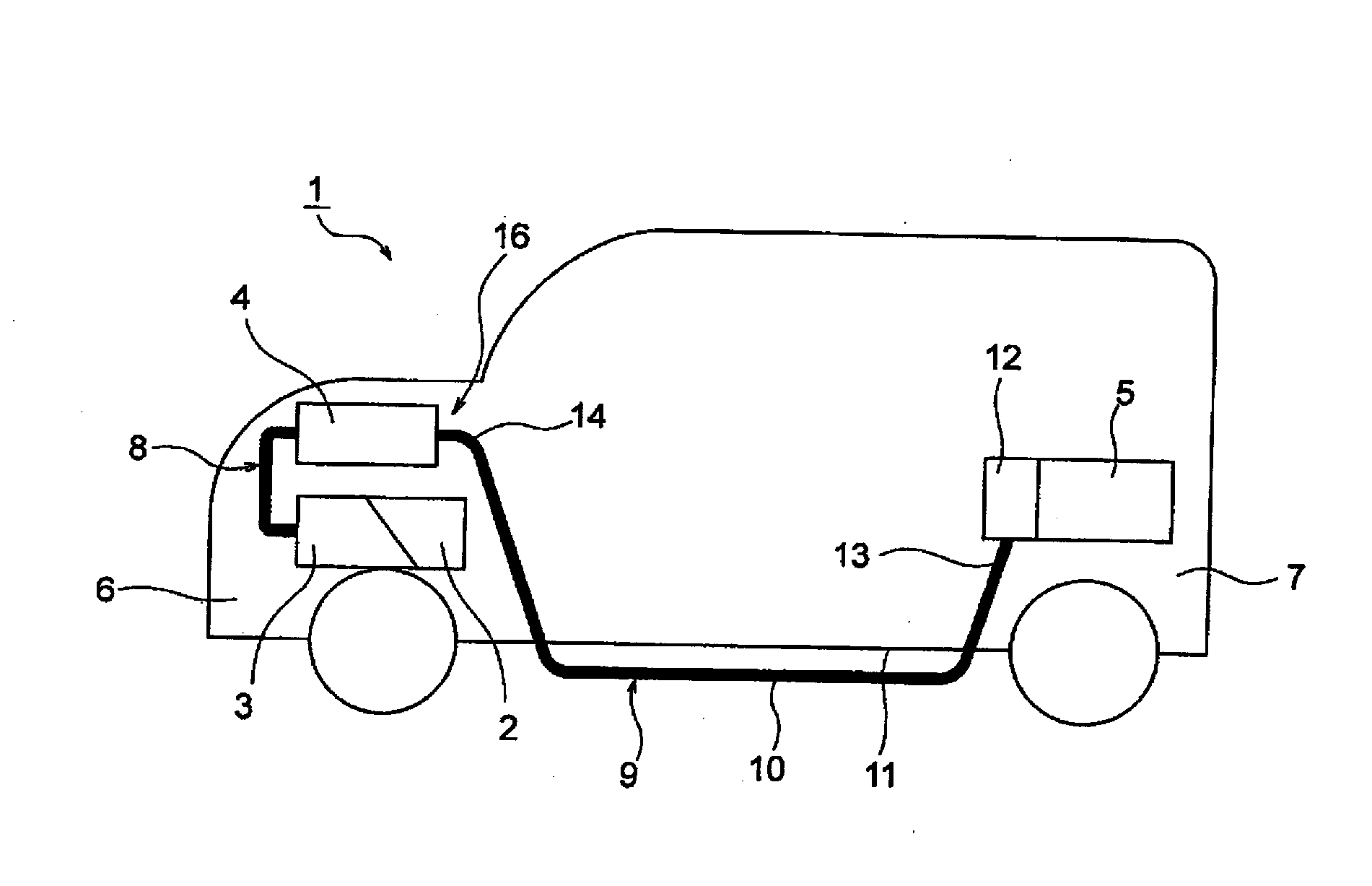

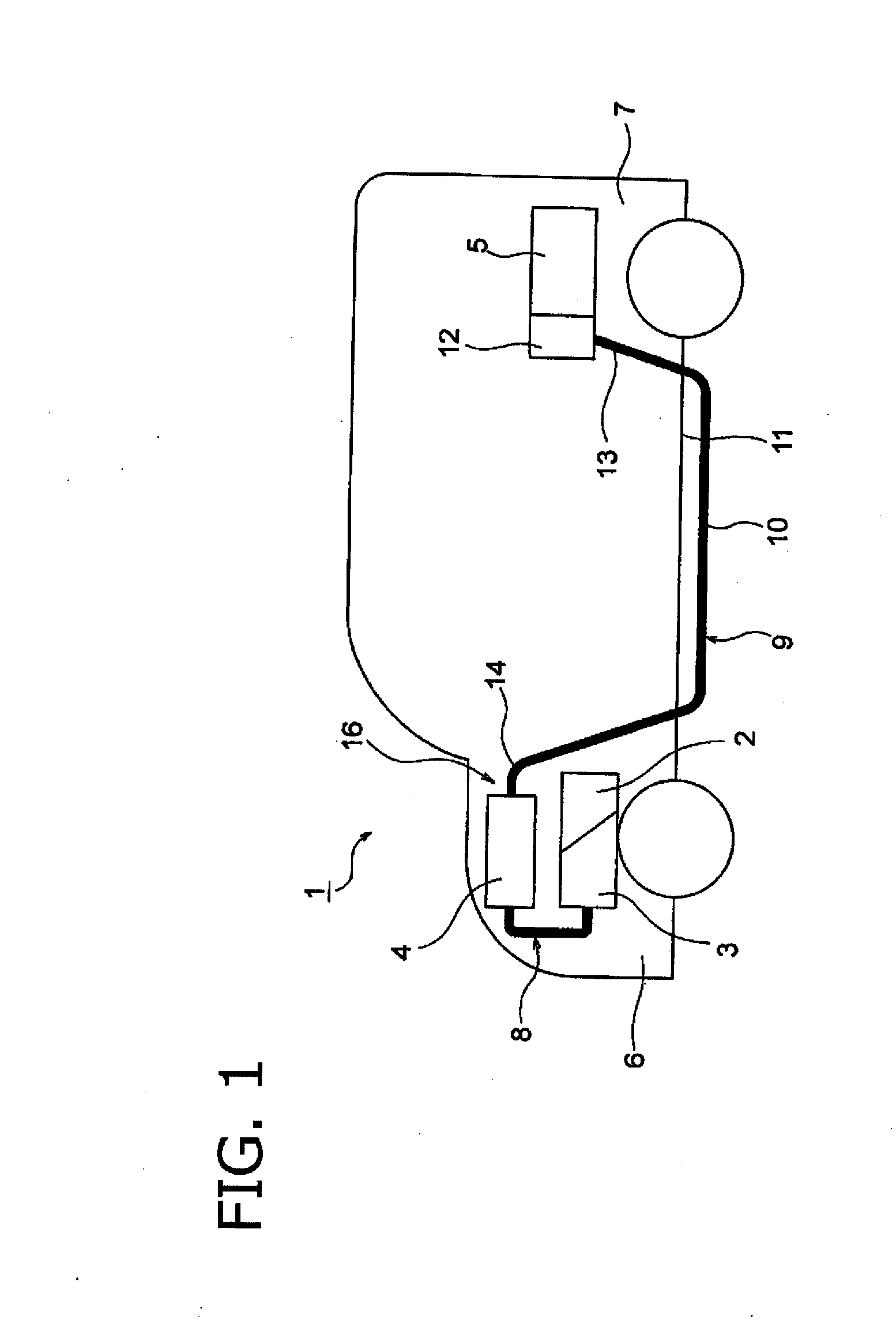

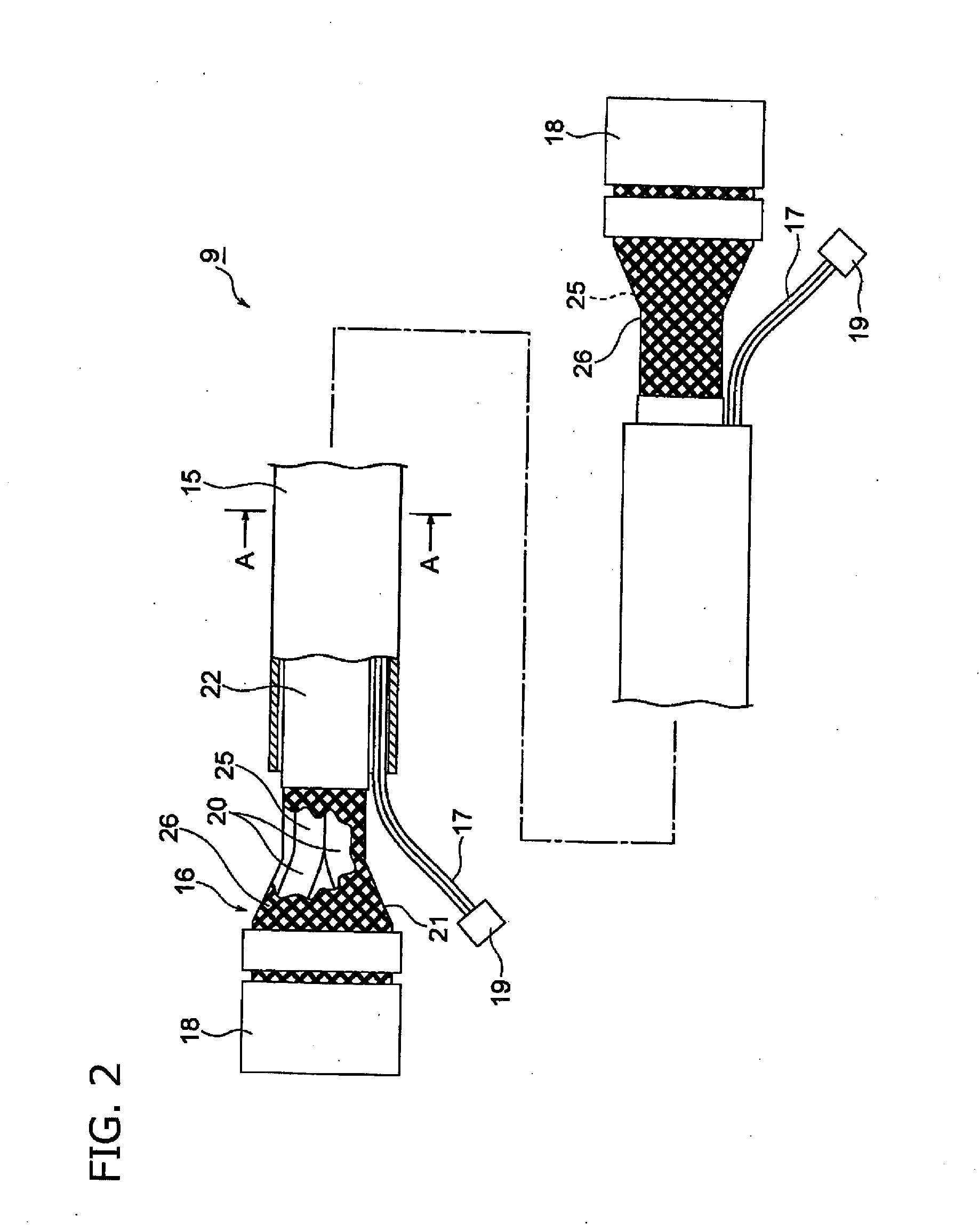

Mobile radio station and hybrid cable for a mobile radio station

ActiveUS20090215492A1Low pour pointConcentric cablesPower cables including communication wiresInterior spaceCoaxial cable

There is provided a hybrid cable that comprises a coaxial cable with an outer conductor and a hollow inner conductor that encloses an inner space. The hybrid cable according to an exemplary embodiment of the present invention may comprise a data line that is arranged in the inner space of the inner conductor.

Owner:VODAFONE HLDG

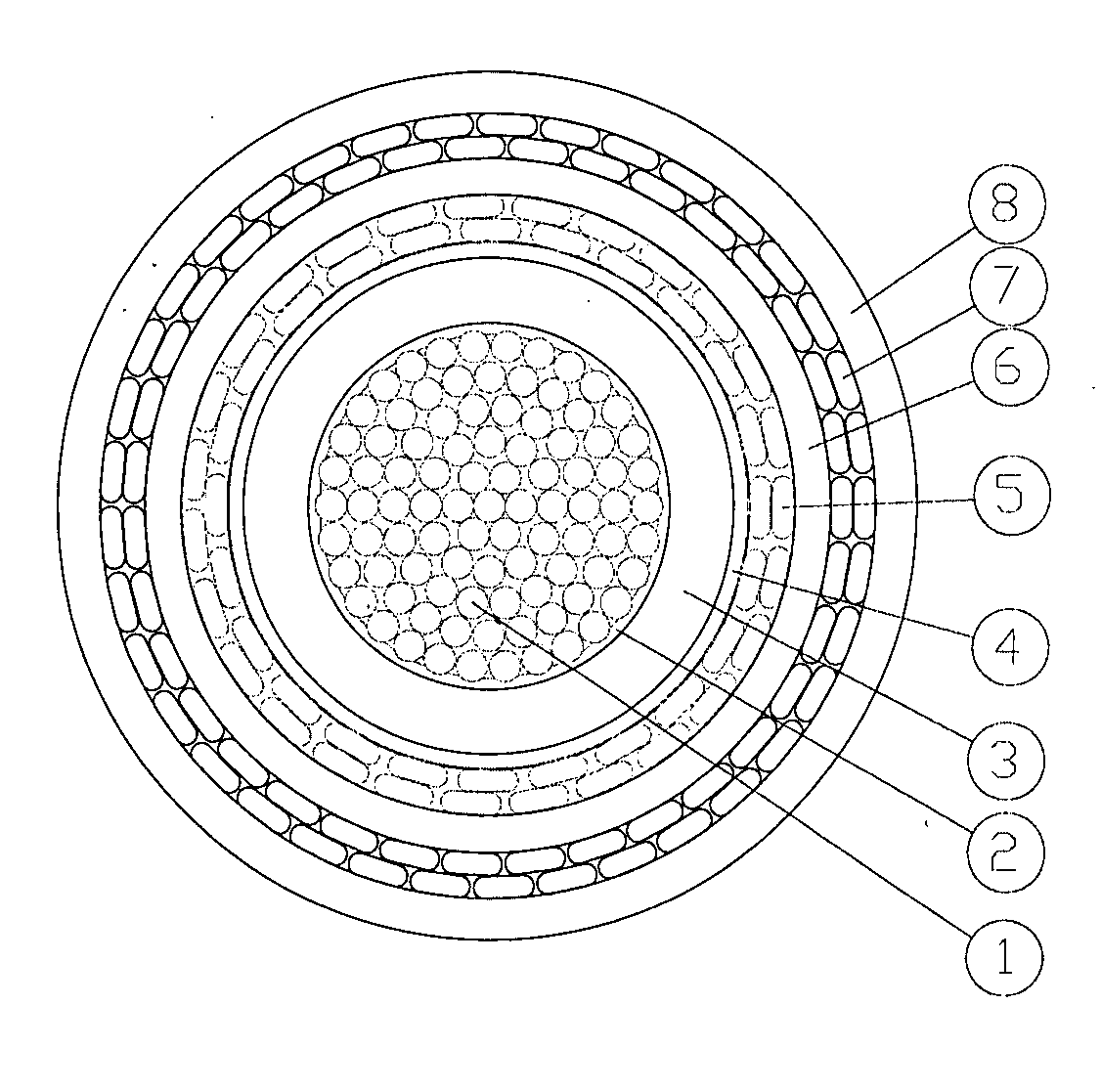

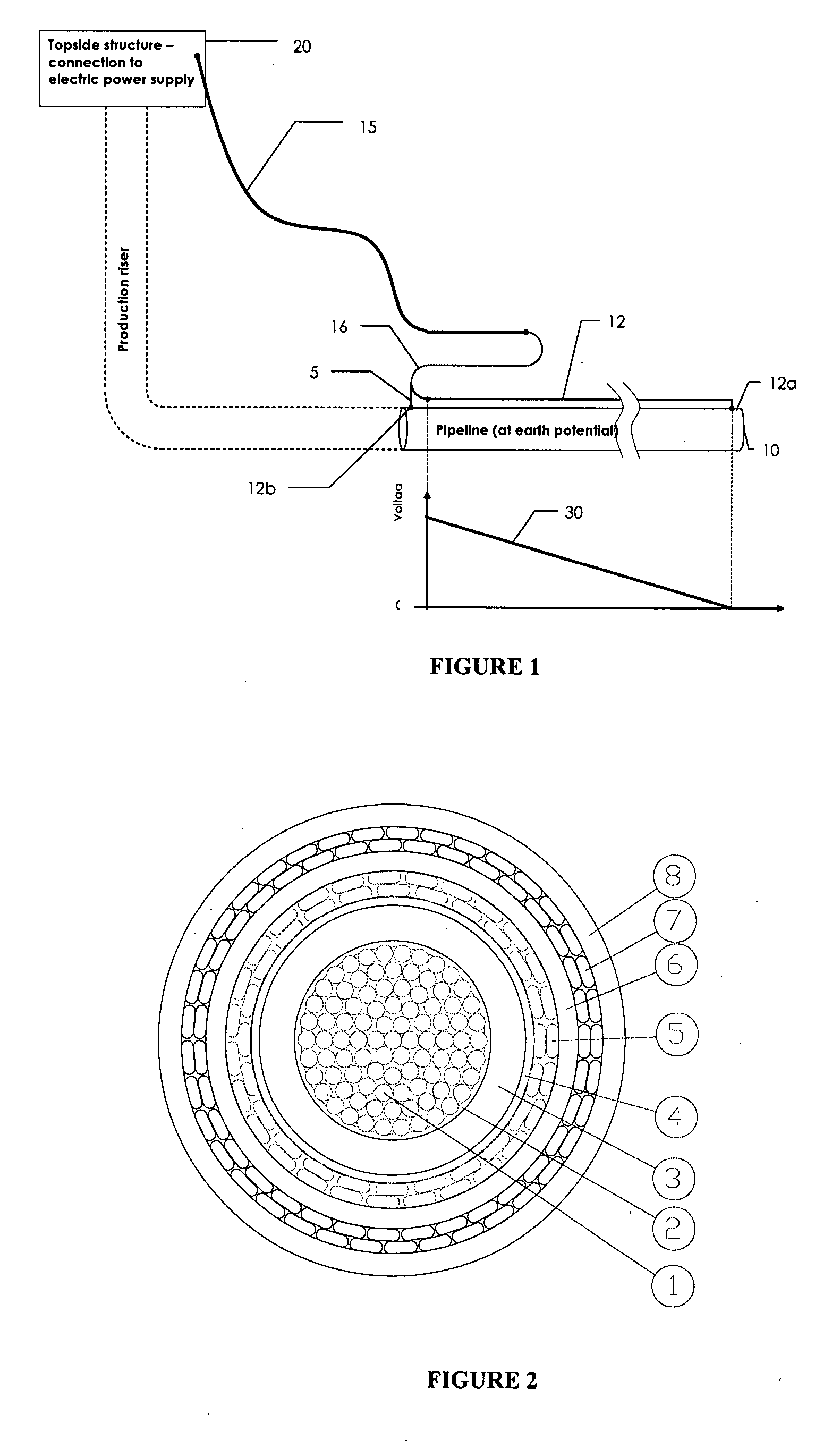

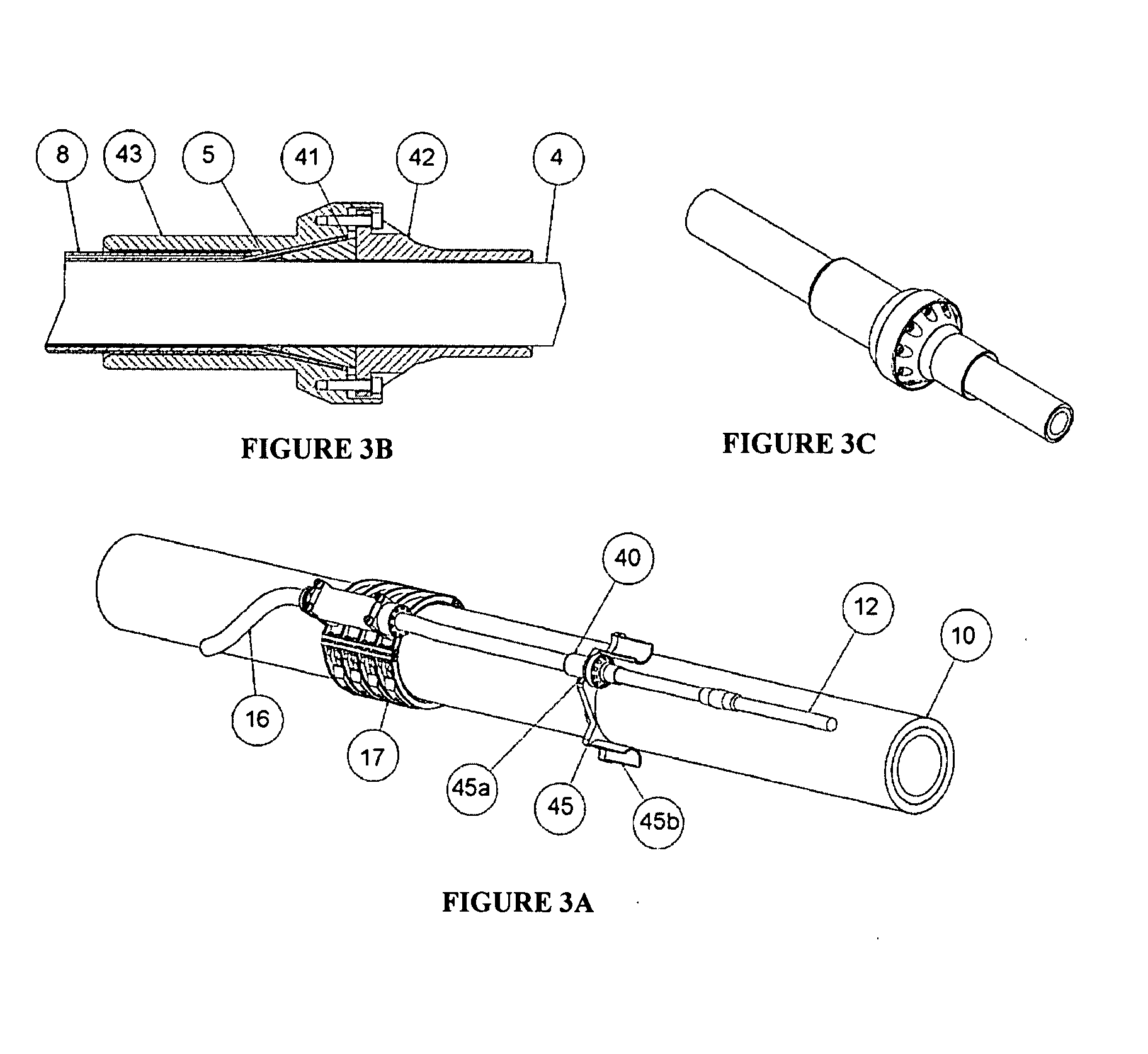

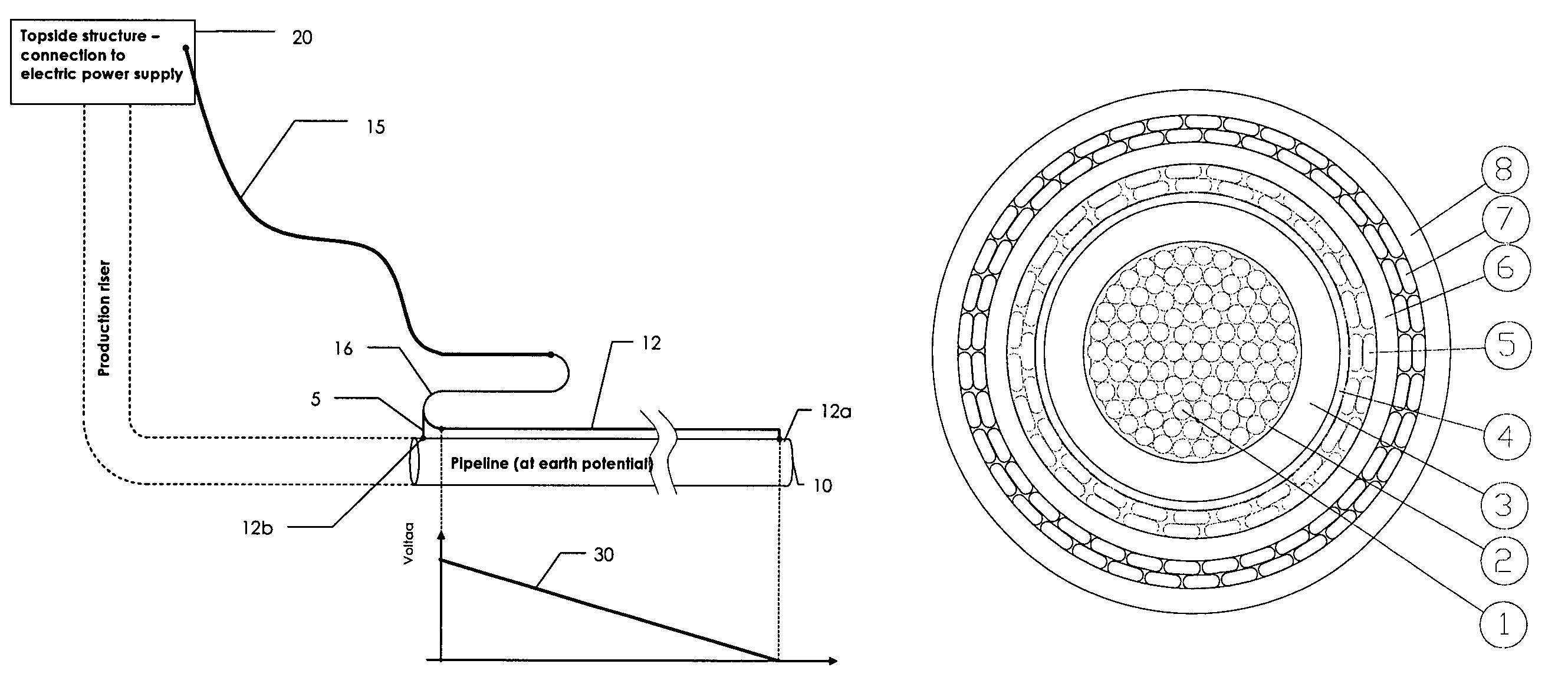

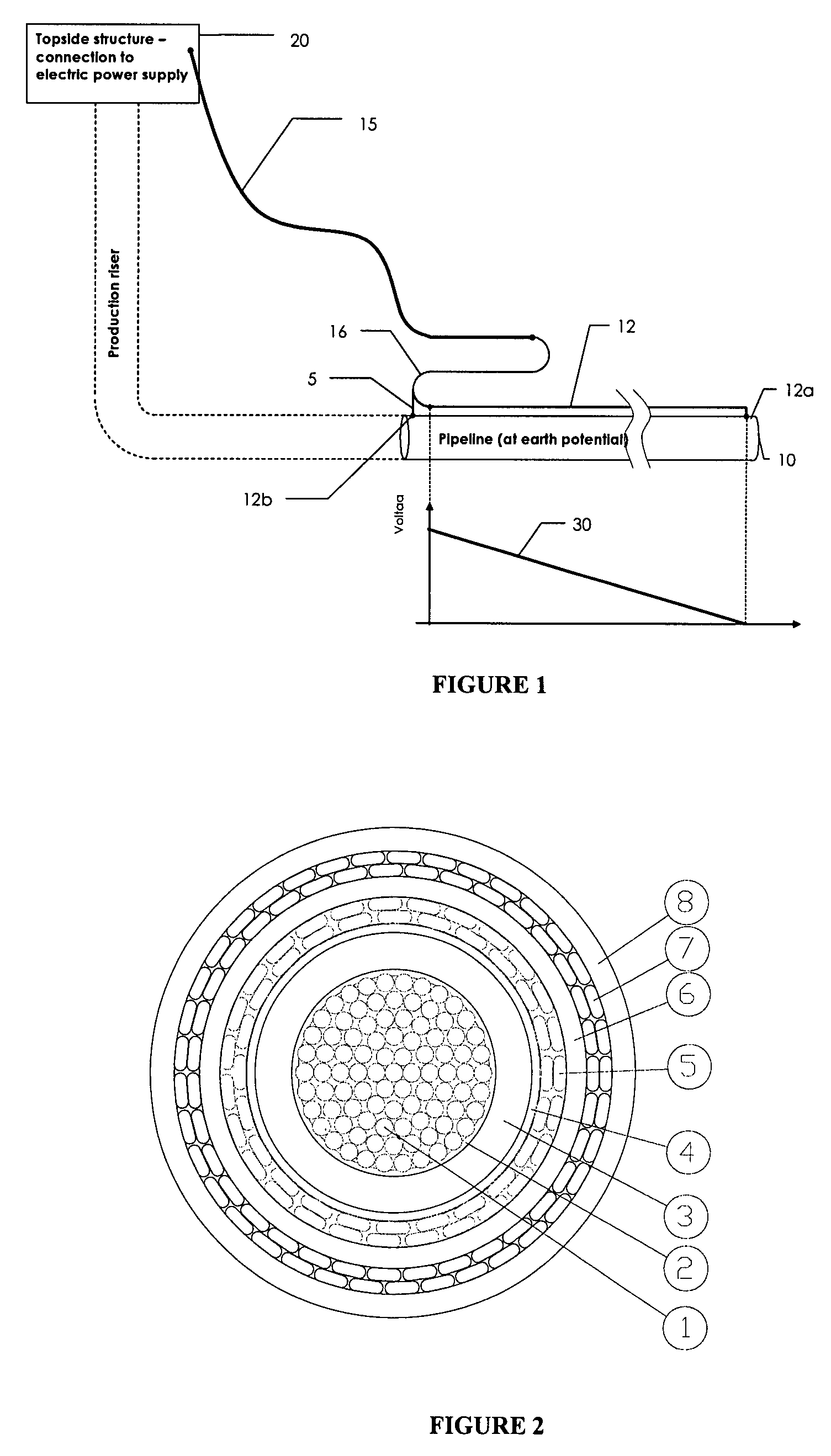

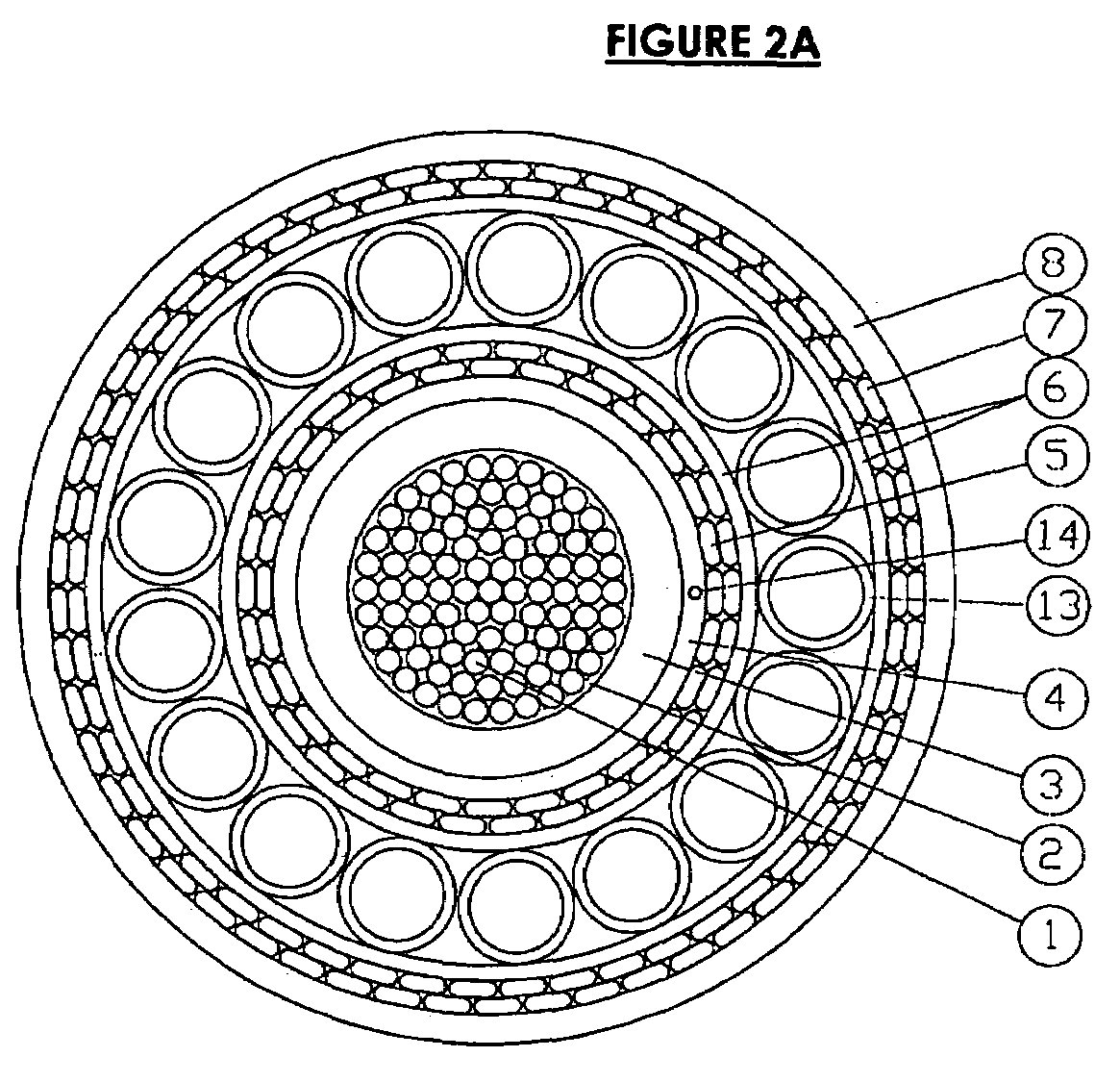

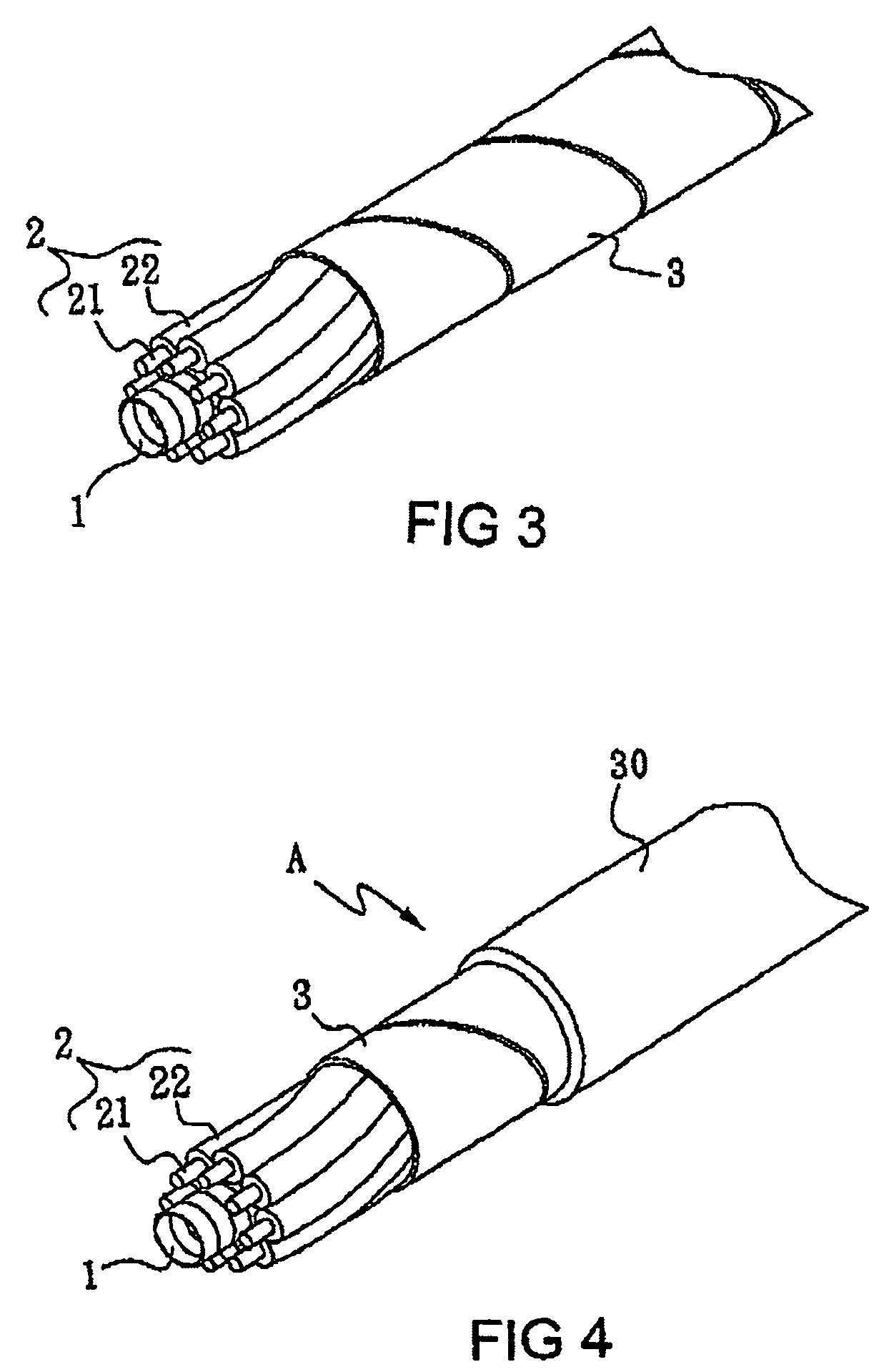

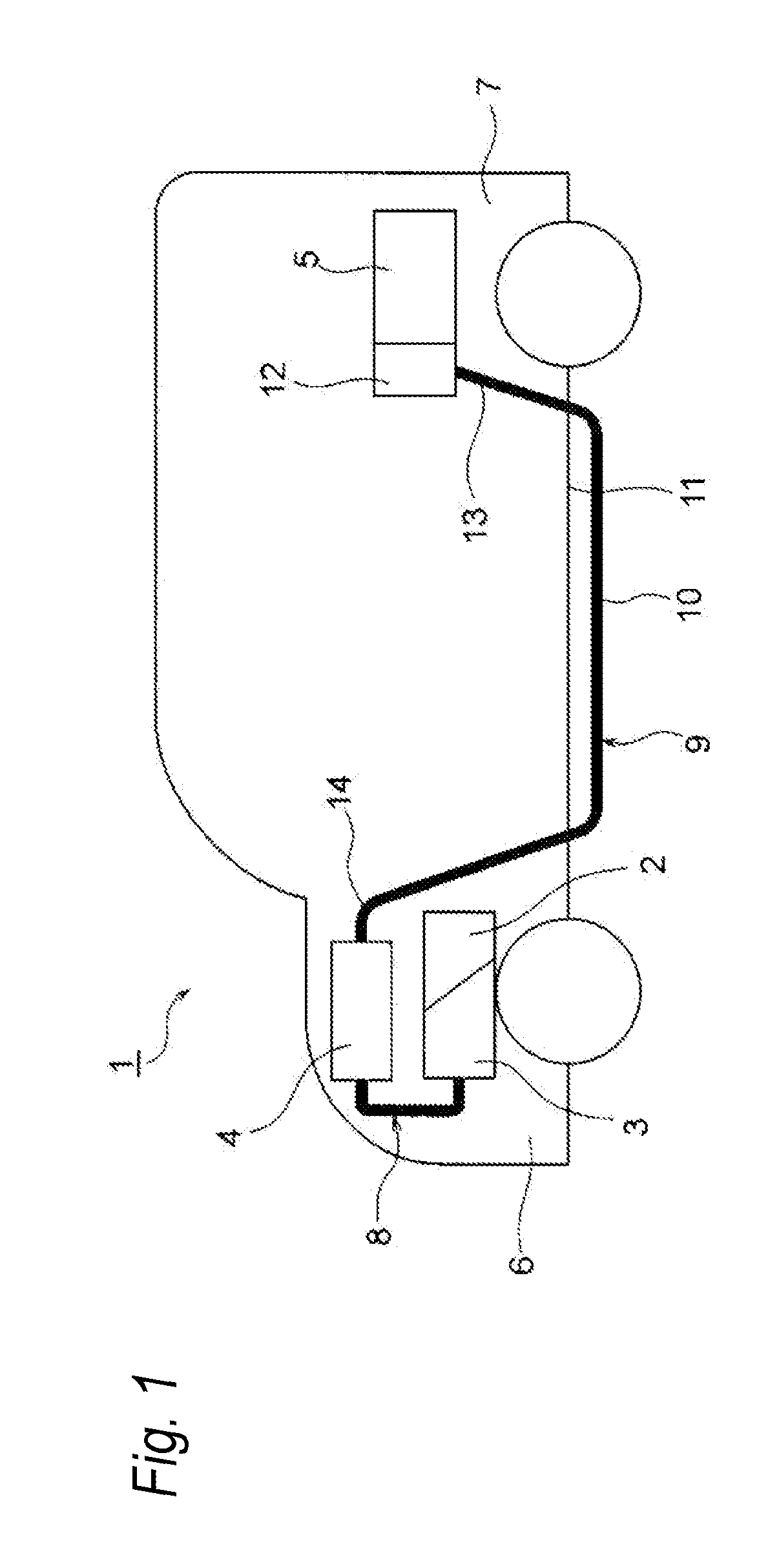

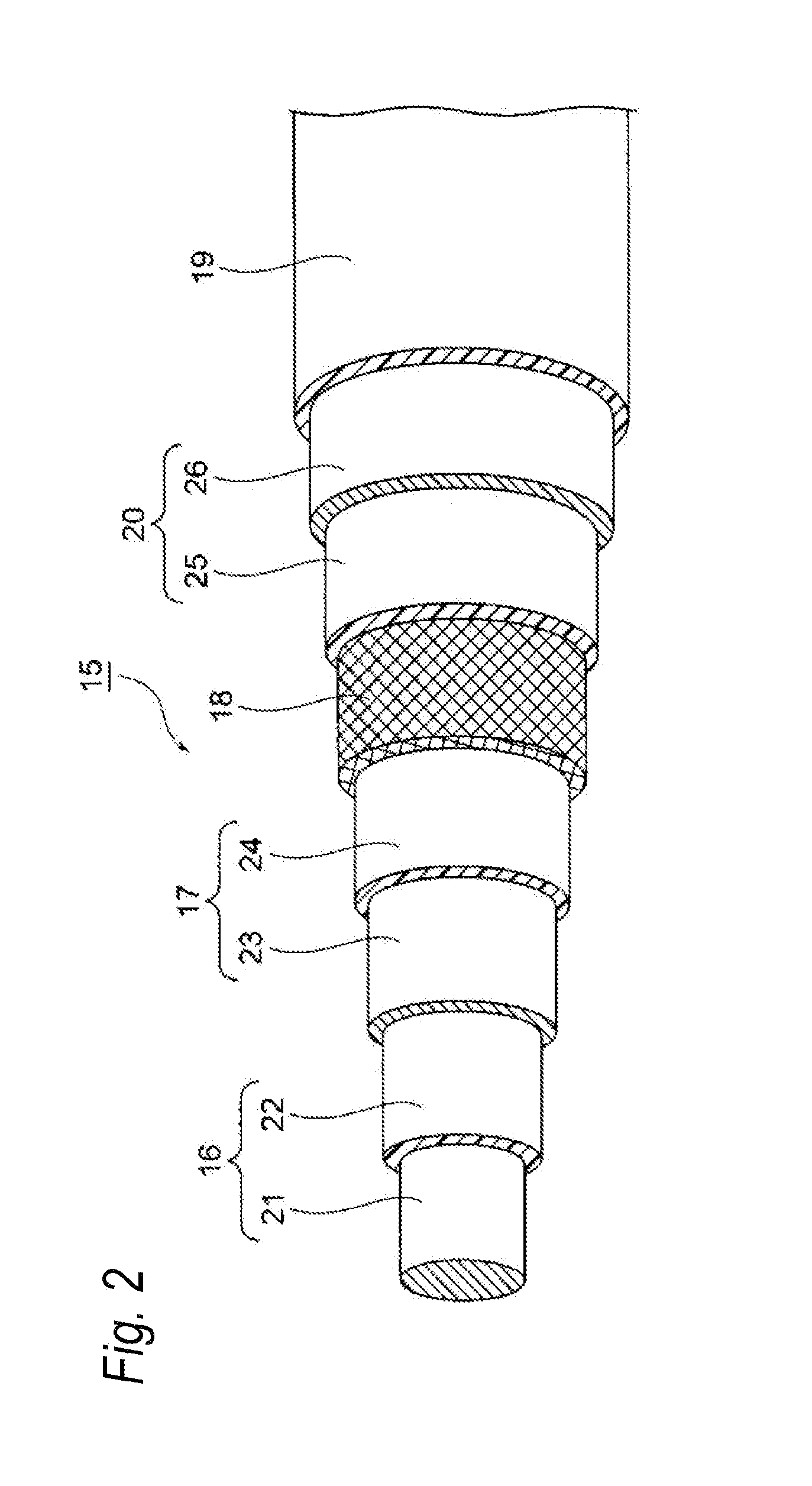

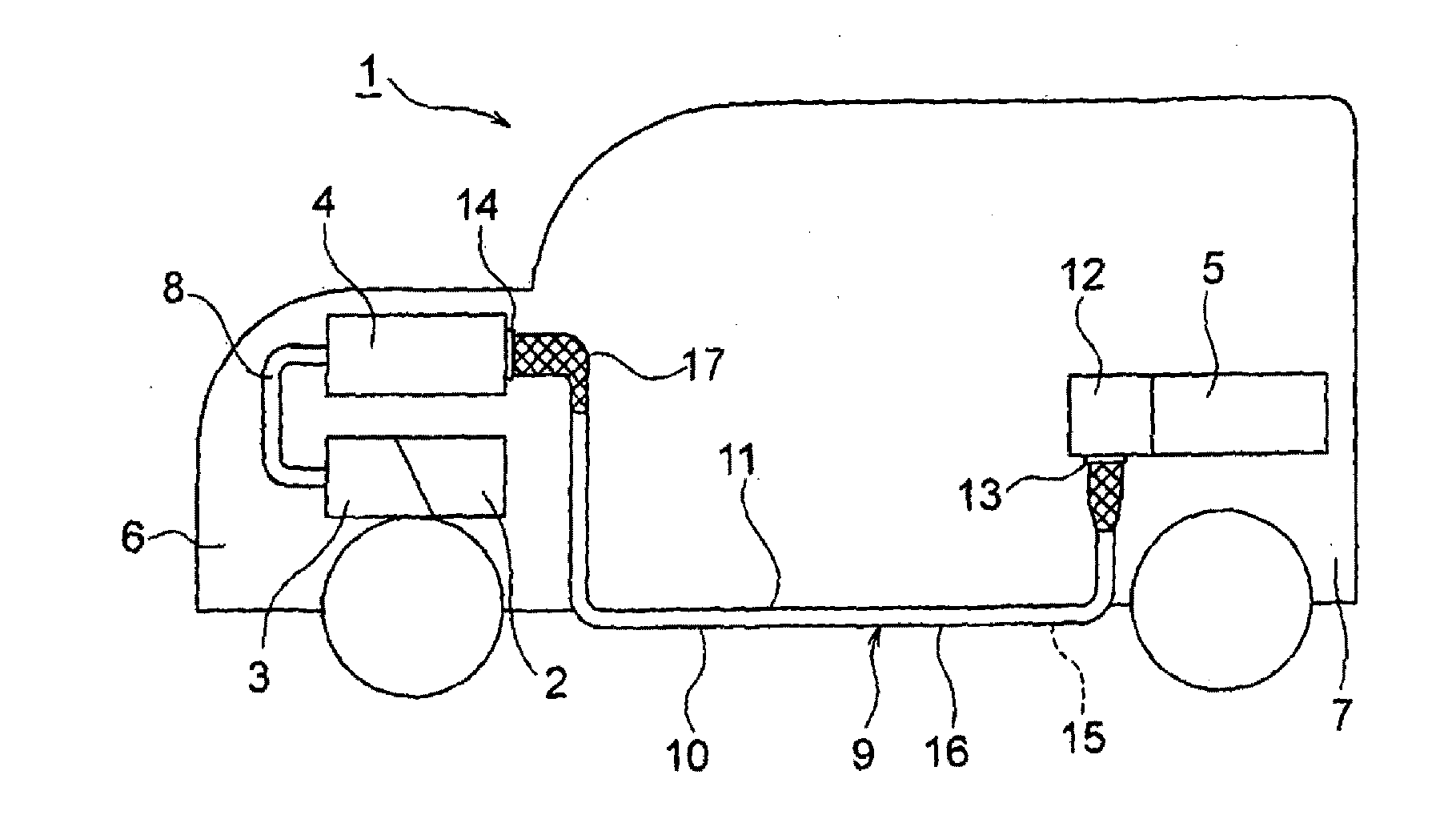

Power cable for direct electric heating system

Electric power cable used as a riser (15) and / or feeder cable (16) in a Direct Electric Heating system for oil or condensate pipelines (10), comprising at least two conductors (1, 5) and insulation layers (3, 6). An outer concentric conductor (5) is connected to a near end of the pipeline, and a central conductor (1) is connected via a piggyback cable (12) to a far end of the pipeline, to provide power for the heating. Another aspect is a terminal assembly adapted to providing an electric connection of the electric power cable with the pipeline (10), where a cone (41) is adapted to squeeze the concentric conductor (5) against a concentric conductor adapter (40).

Owner:NEXANS

Power cable for direct electric heating system

Electric power cable used as a riser (15) and / or feeder cable (16) in a Direct Electric Heating system for oil or condensate pipelines (10), comprising at least two conductors (1, 5) and insulation layers (3, 6). An outer concentric conductor (5) is connected to a near end of the pipeline, and a central conductor (1) is connected via a piggyback cable (12) to a far end of the pipeline, to provide power for the heating. Another aspect is a terminal assembly adapted to providing an electric connection of the electric power cable with the pipeline (10), where a cone (41) is adapted to squeeze the concentric conductor (5) against a concentric conductor adapter (40).

Owner:NEXANS

Wire cable with saving energy

A wire cable of electric conductor forming of multiple metals or alloys includes single (bundle) wire cable or double (bundle) wire cables, in which at least in one bundle of electric conductor, each bundle of electric conductor is composed of slim electric wire made by two or more than two metals or alloys, which is covered by insulator to form a wire cable of electric conductor.

Owner:WU JENG SHYONG +2

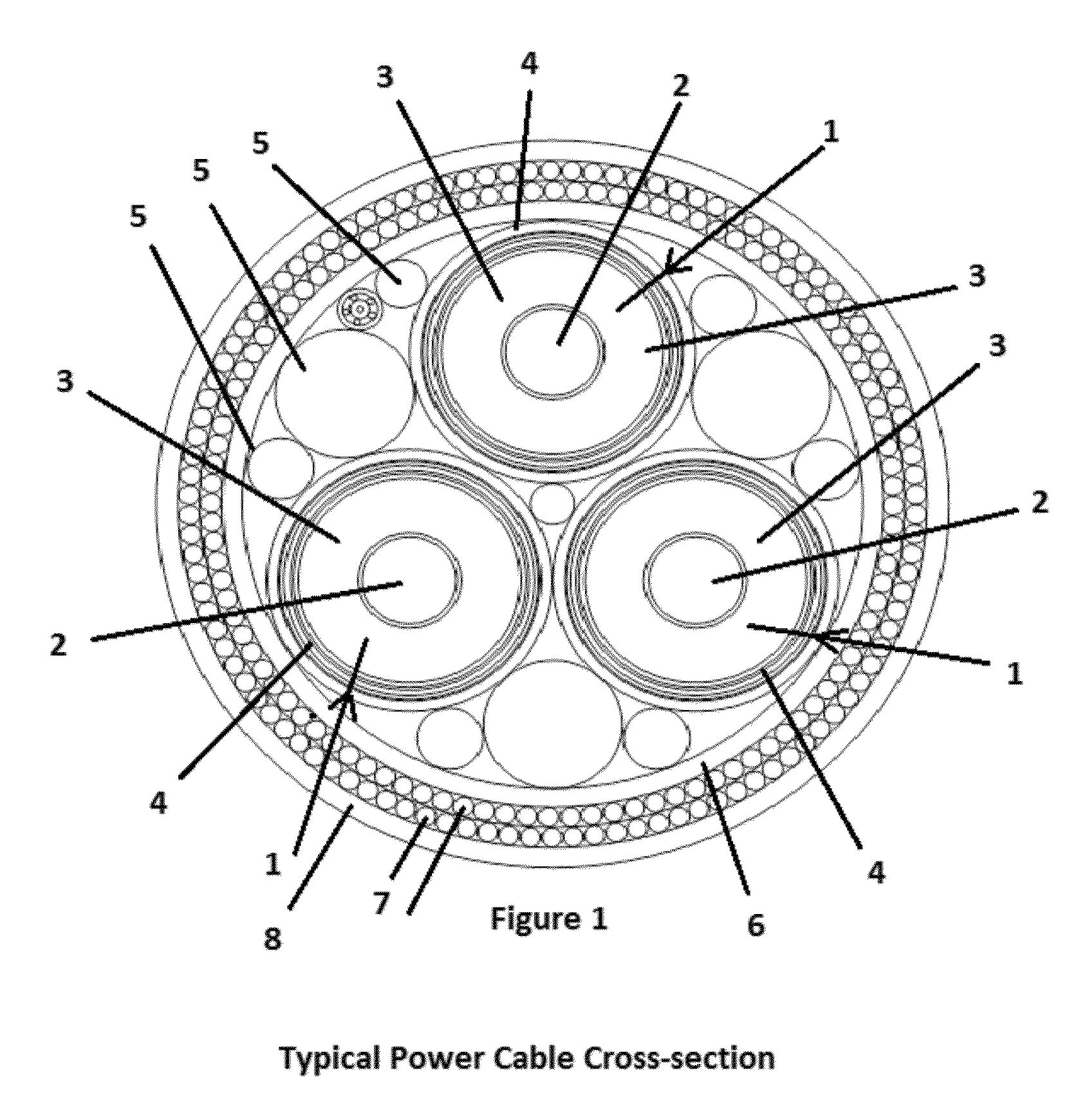

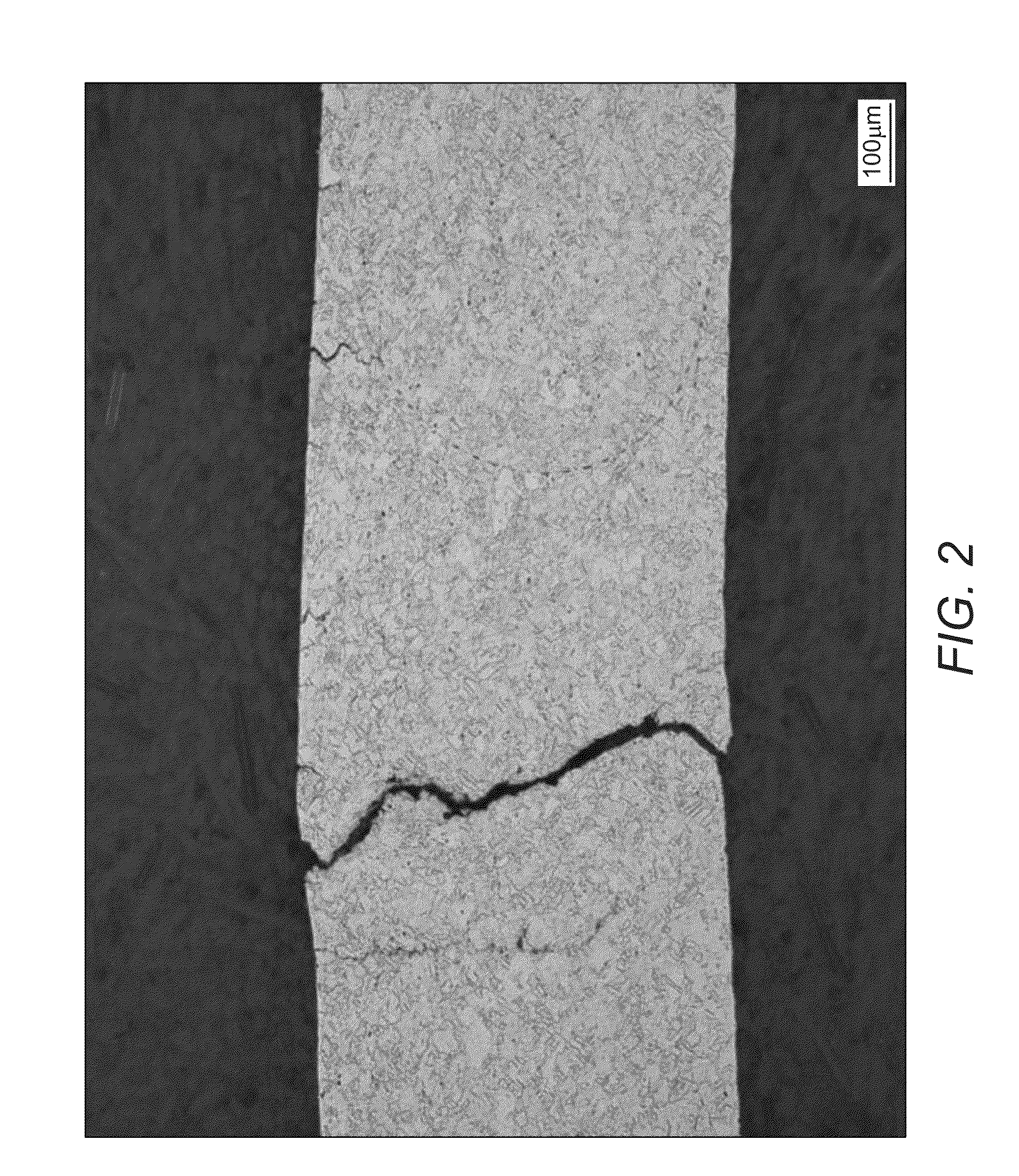

Subsea Cables

InactiveUS20140060884A1High level of resistanceEnhance layeringLine/current collector detailsConcentric cablesCable transmissionElectricity

Herein described is a cable from transmitting electricity, which is particularly useful for subsea applications. A method of manufacturing the cable and a method of transmitting electricity with the cable is also described.

Owner:BPP CABLES

Wire cable with saving energy

InactiveUS7772495B2Save energyIncrease quantity and efficiencyElectrically conductive connectionsConcentric cablesAlloyMetal

A wire cable of electric conductor forming of multiple metals or alloys includes single (bundle) wire cable or double (bundle) wire cables, in which at least in one bundle of electric conductor, each bundle of electric conductor is composed of slim electric wire made by two or more than two metals or alloys, which is covered by insulator to form a wire cable of electric conductor.

Owner:WU JENG SHYONG +2

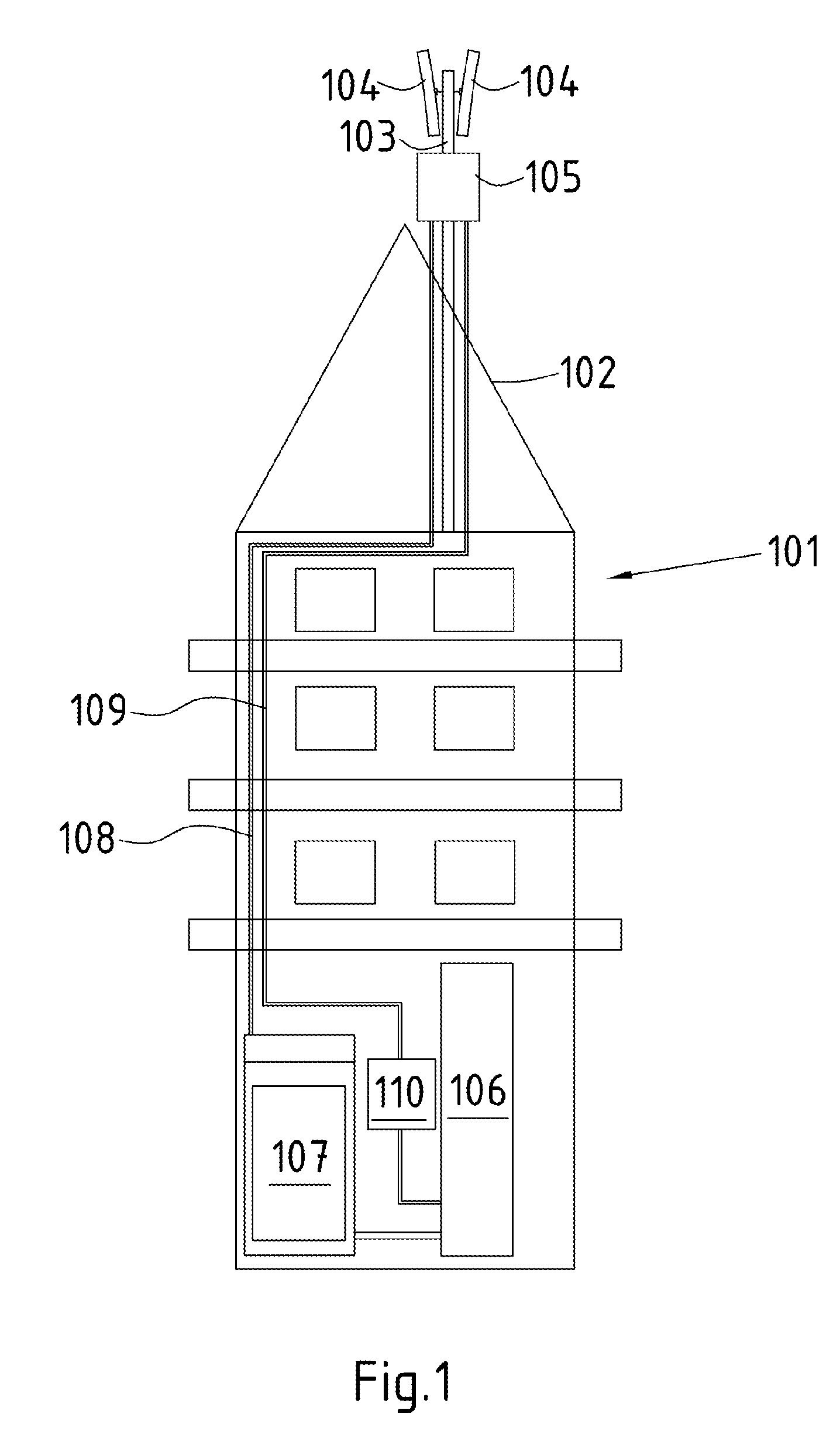

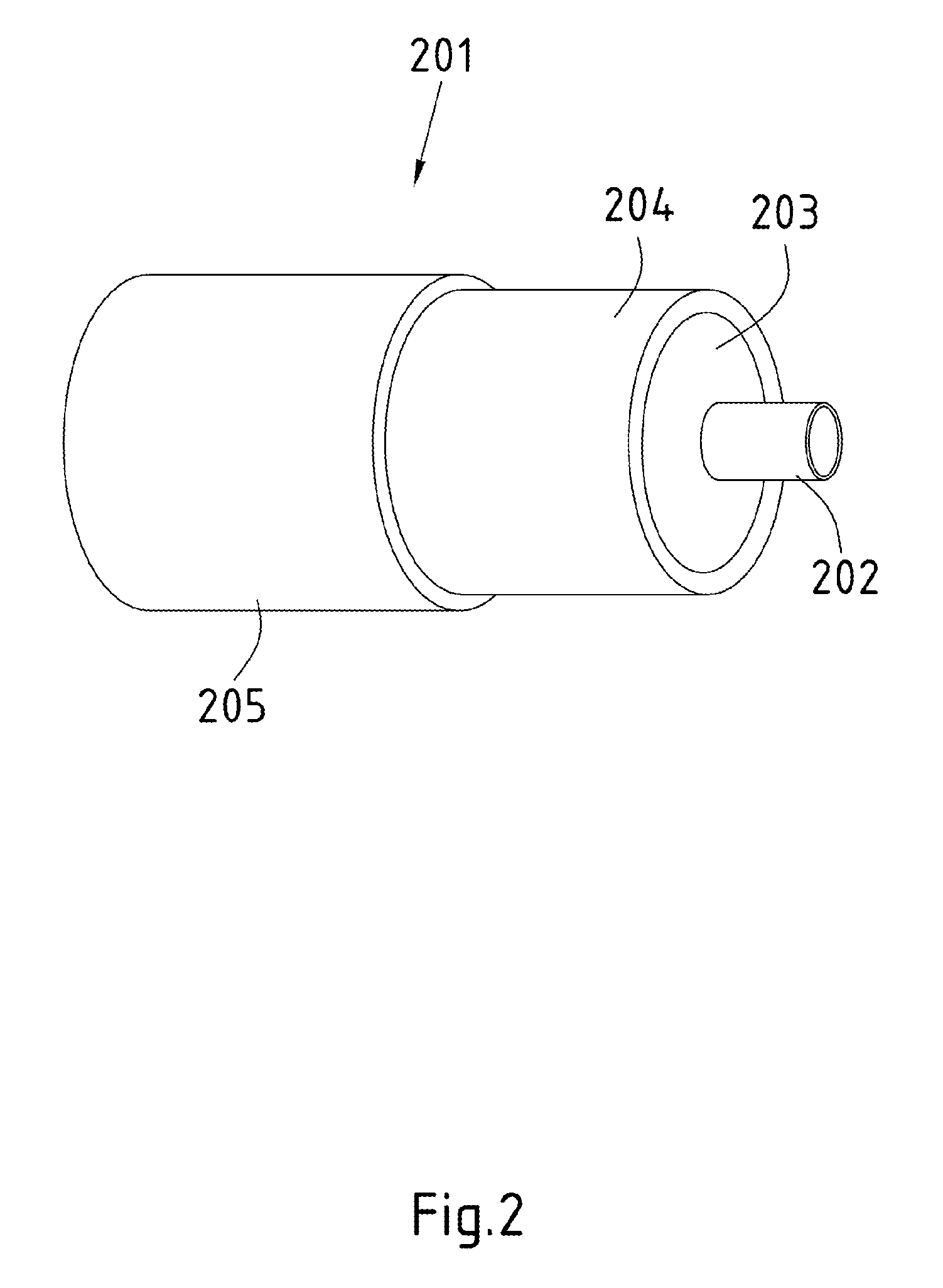

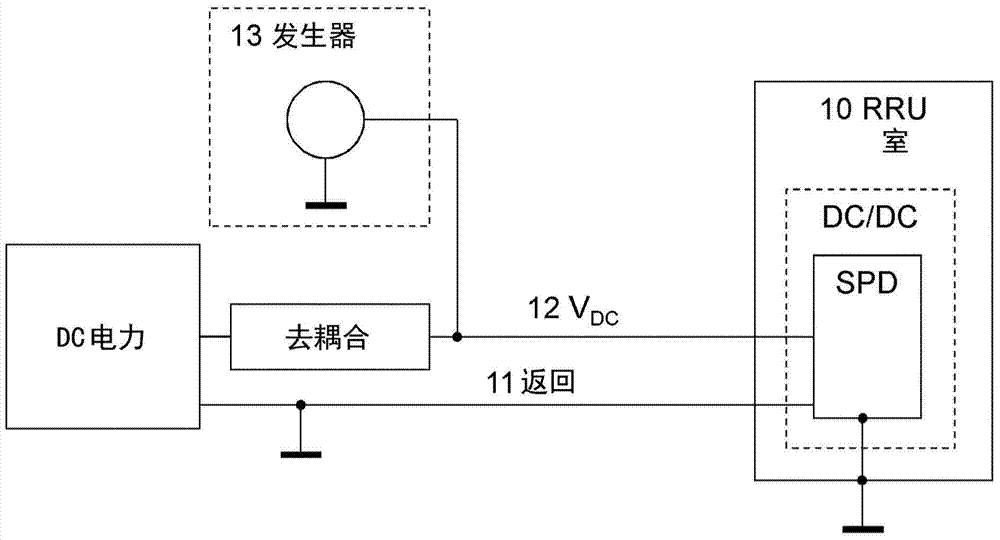

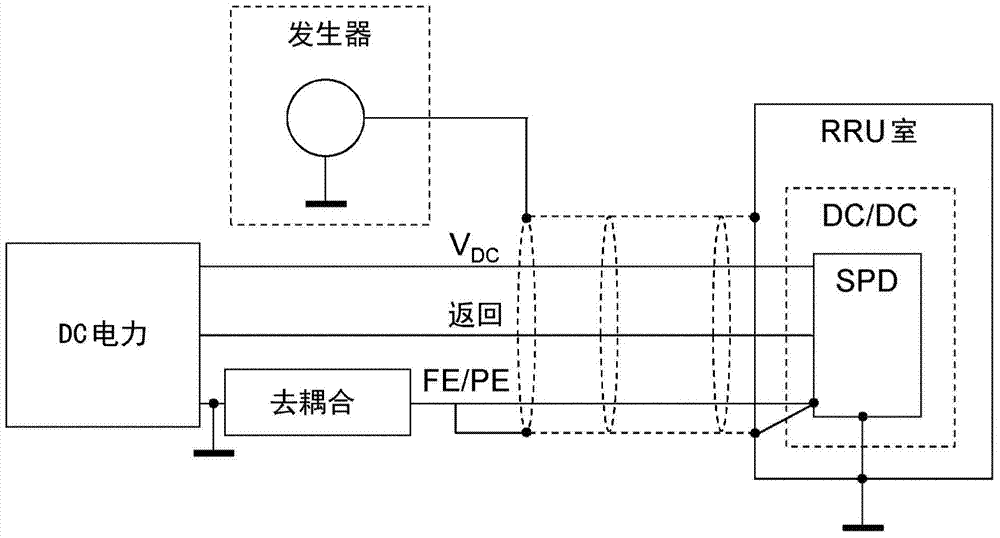

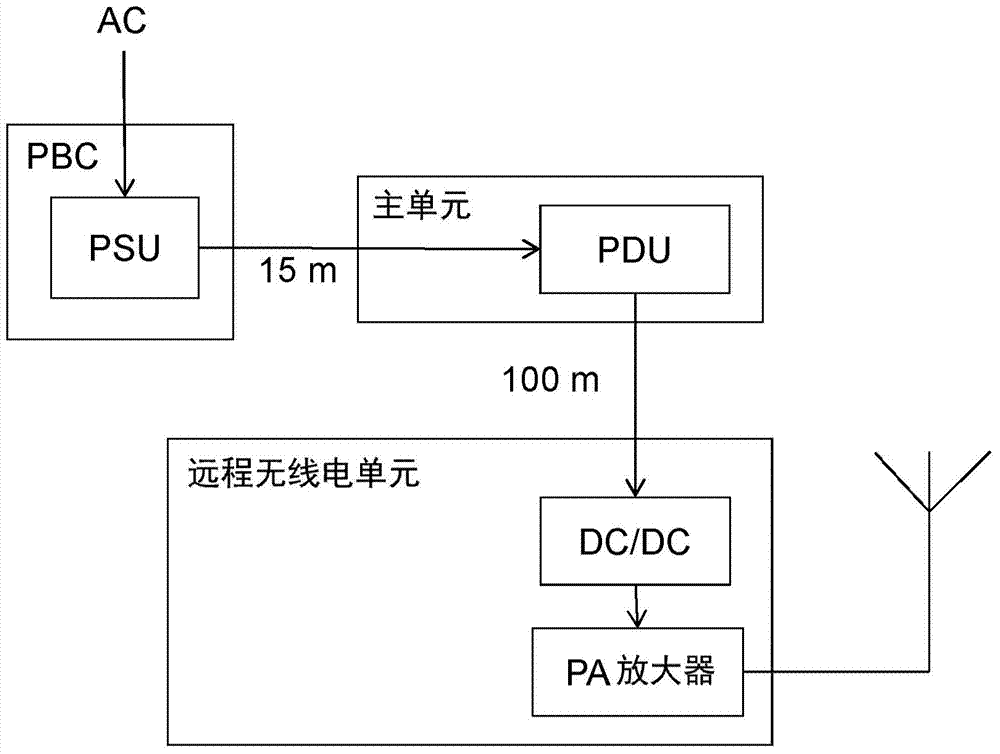

Cable for powering of mast mounted radio equipment

InactiveCN104335294ASmall currentSmall diameterConcentric cablesPower cables including communication wiresRadio equipmentElectrical conductor

A cable (100) for powering of radio equipment (110) mounted on a mast for carrying the radio equipment (110) is disclosed. The cable (100) comprises a first conductor (C) for feeding a current to the radio equipment (110), a return and shielding conductor (R, G) for feeding a return current from the radio equipment (110) and for shielding of the first conductor (C), and an insulating material (l1) disposed between the first conductor (C) and the return and shielding conductor (R, G). The first conductor (C) is at least partially enclosed by the insulating material (I1). A first cross-sectional area of the first conductor (C) is less than a second cross-sectional area of the return and shielding conductor (R, G).

Owner:TELEFON AB LM ERICSSON (PUBL)

Method for manufacturing cu-ag alloy wire and cu-ag alloy wire

InactiveCN101791638AExcellent productivityImprove productivityCoaxial cables/analogue cablesConcentric cablesProduction rateCoaxial cable

Owner:SUMITOMO ELECTRIC IND LTD

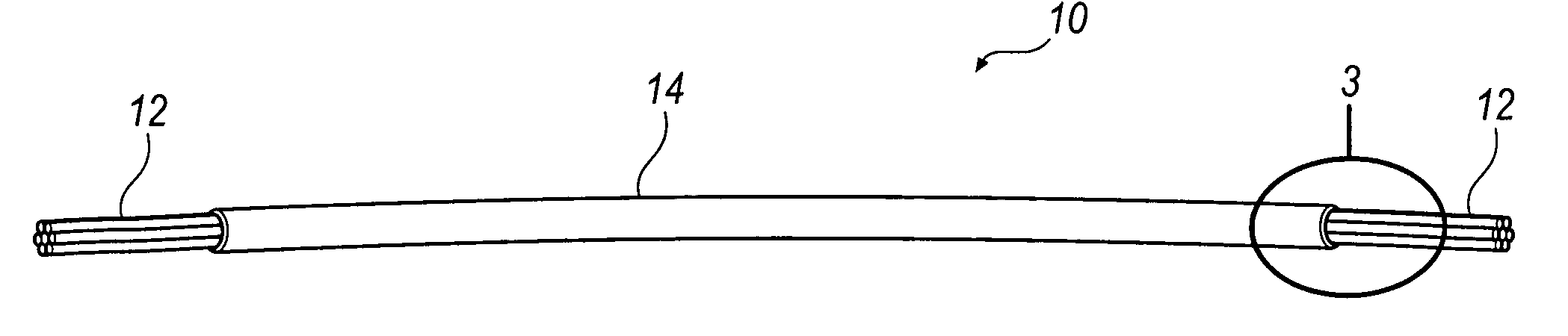

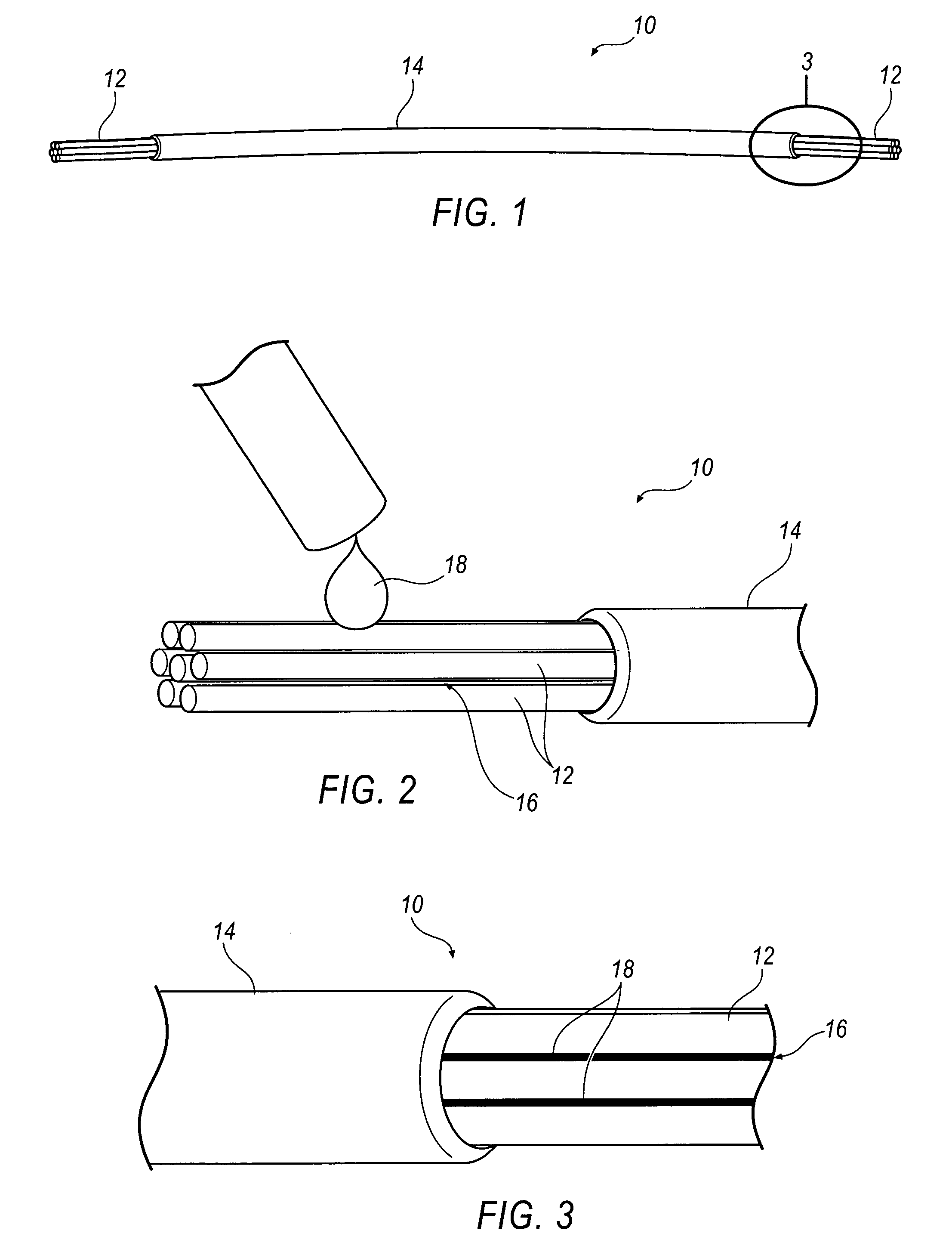

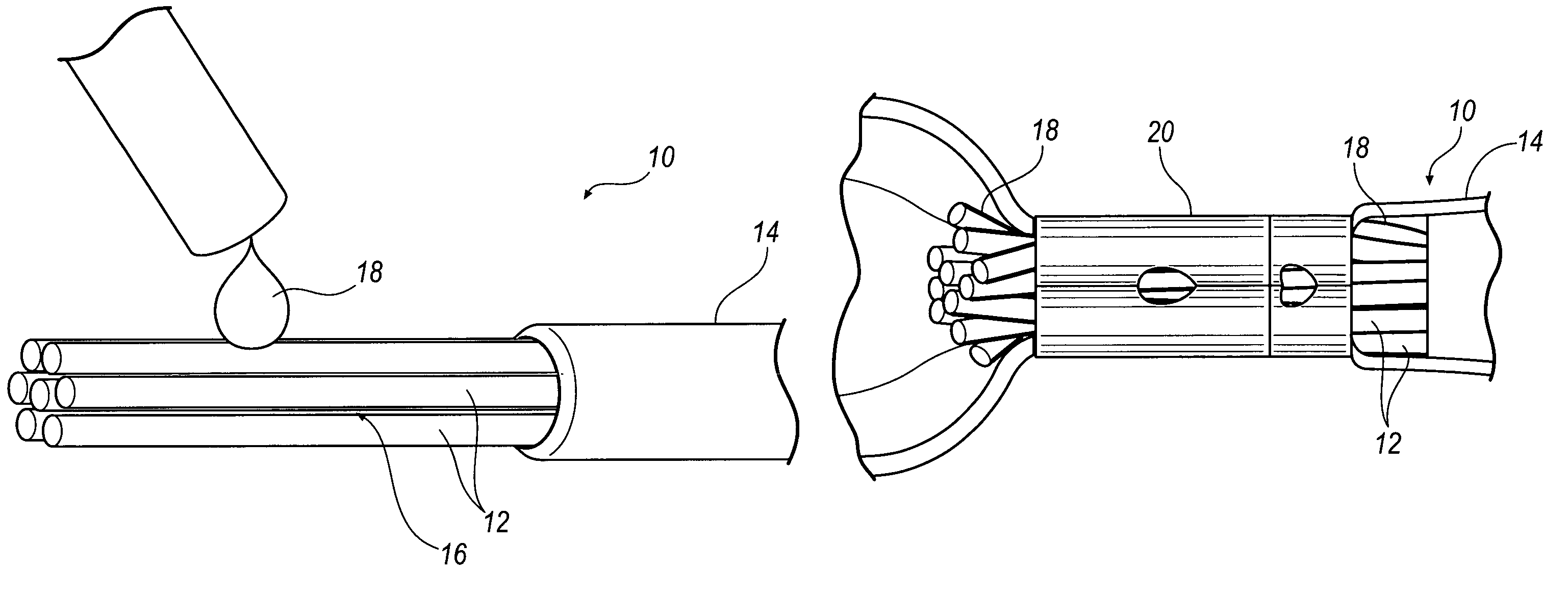

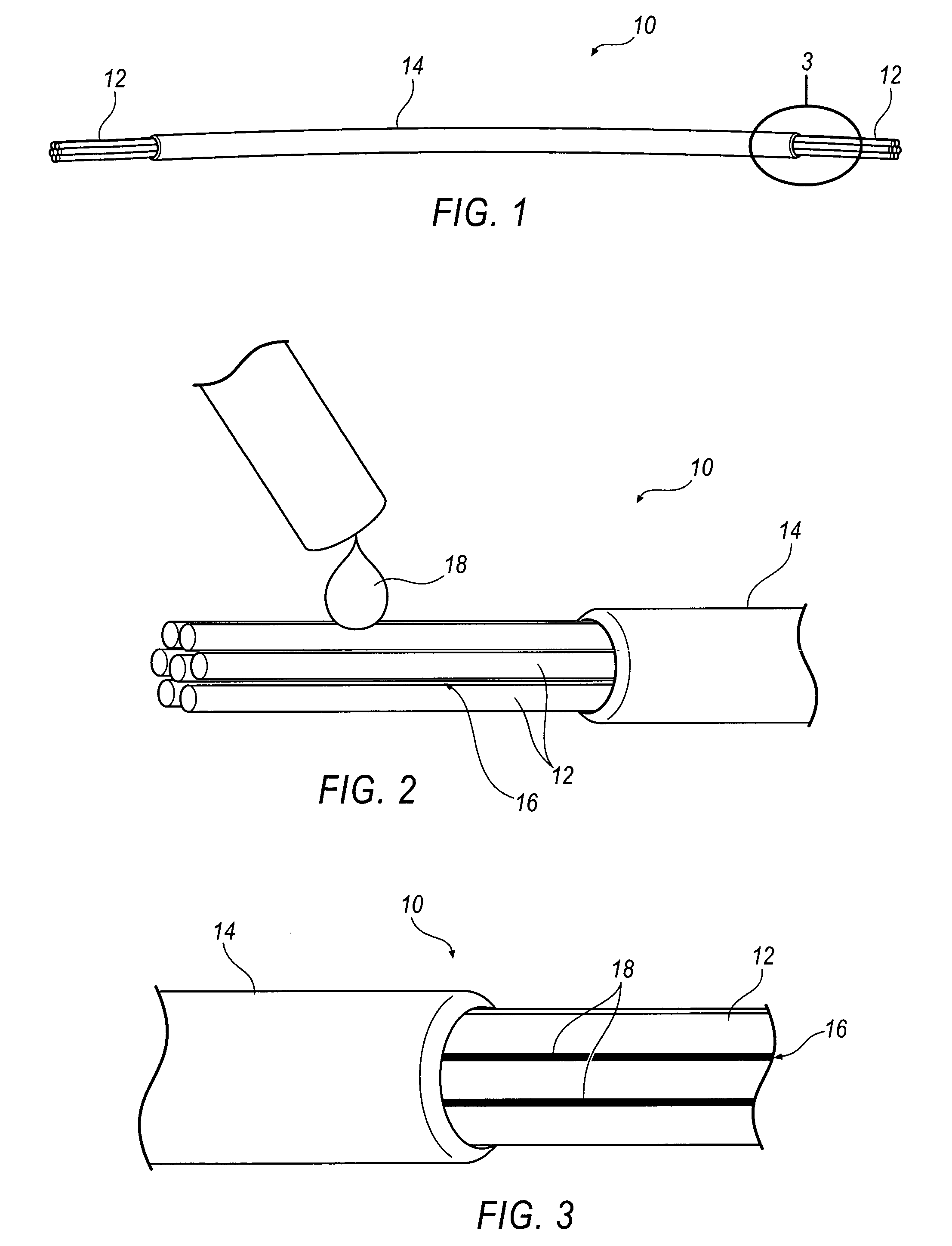

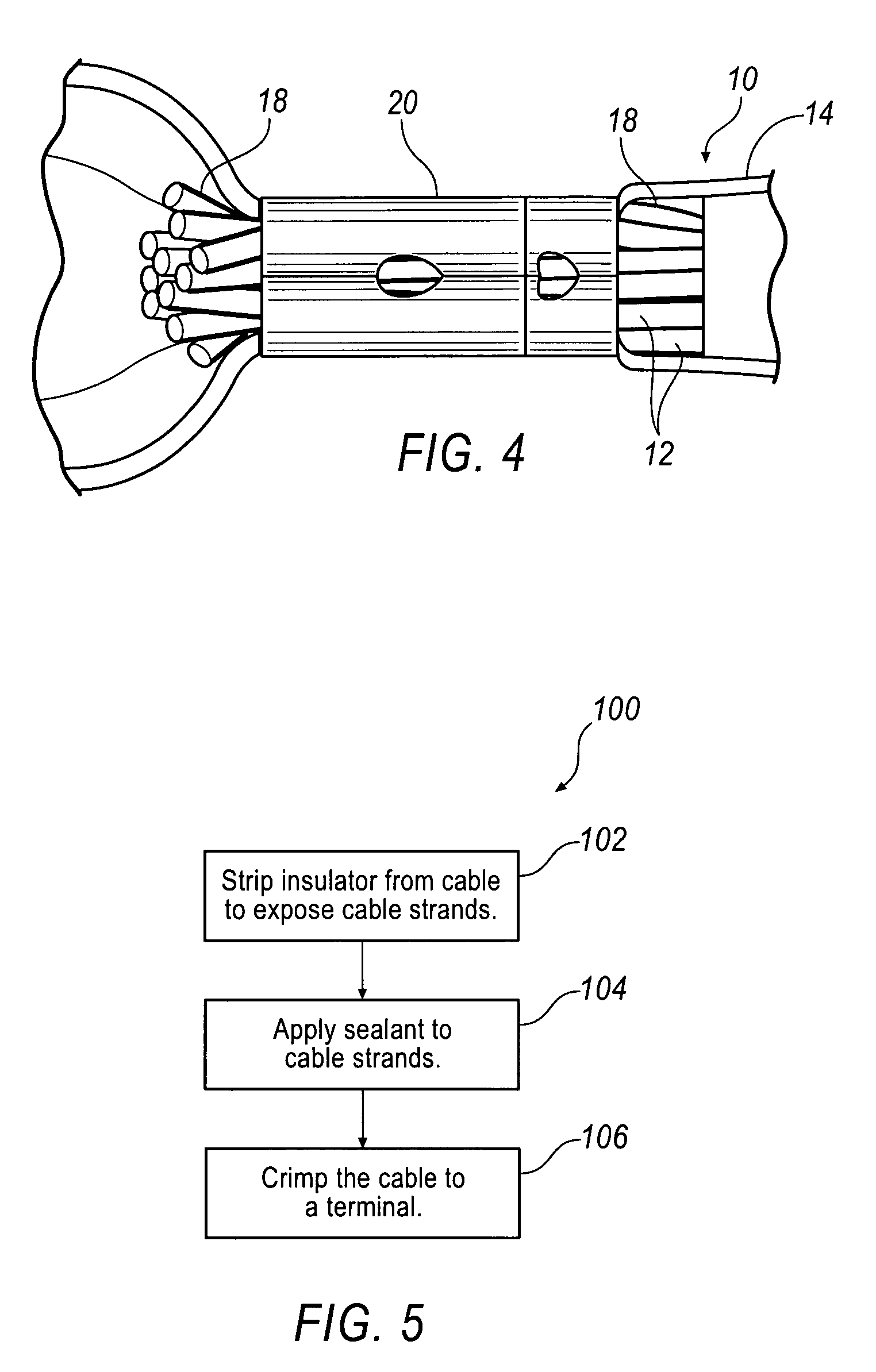

Sealed cable and terminal crimp

A cable includes a plurality of cable strands, an insulator disposed on a portion of the plurality of strands such that the plurality of strands are at least partially exposed, and a sealant disposed between gaps of the plurality of strands and at least partially under the insulator. Moreover, a method includes stripping an insulator from an end of the cable to expose a plurality of cable strands, and applying a sealant to the cable strands such that the sealant is drawn under the insulator and fills in gaps between the cable strands by capillary action.

Owner:APTIV TECH LTD

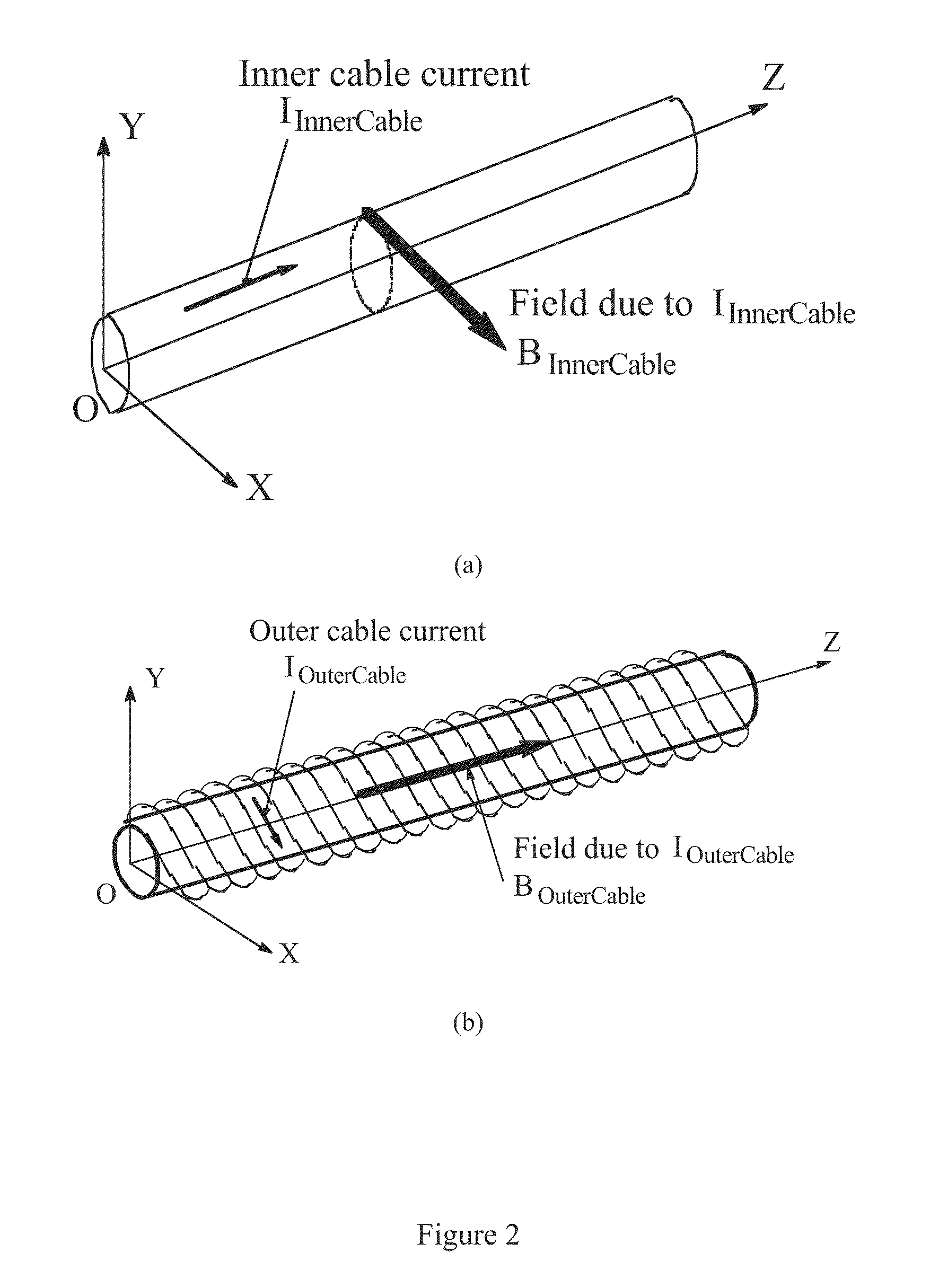

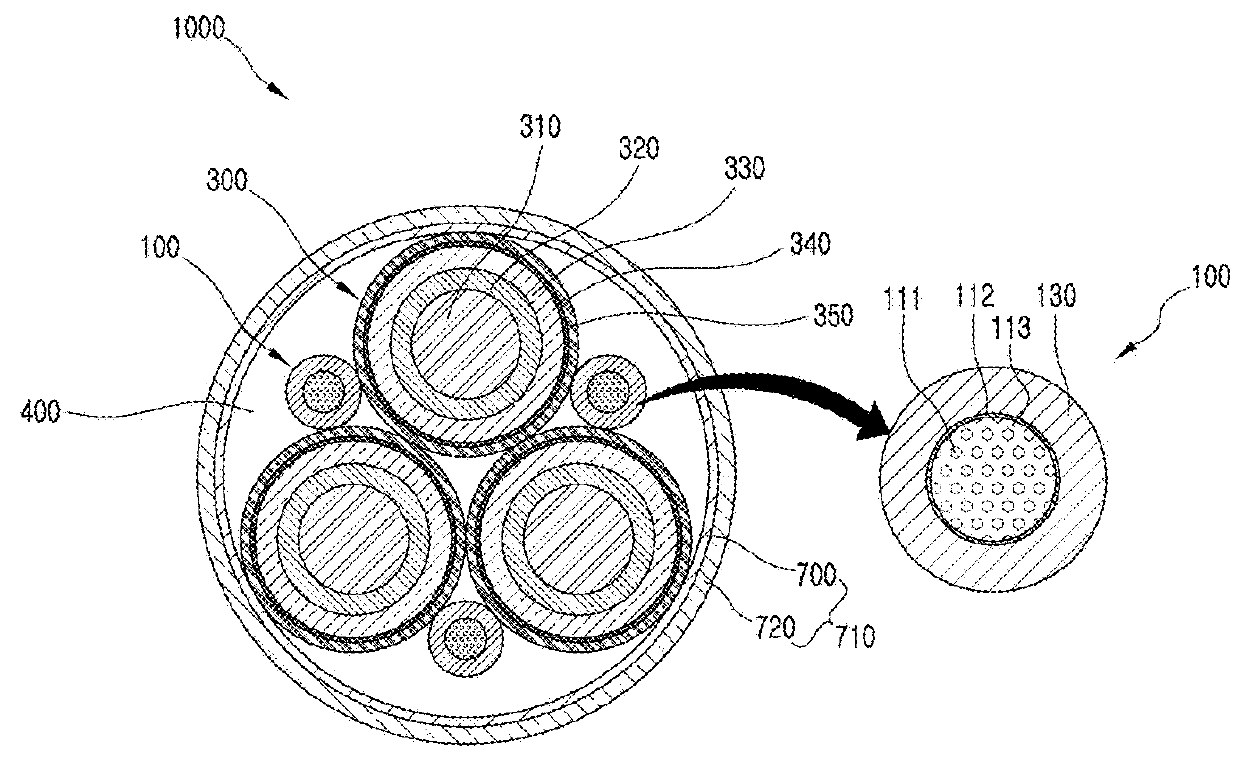

Superconducting Power Cable

InactiveUS20140302997A1Improve performanceSuperconductors/hyperconductorsConcentric cablesPower cableEngineering

A superconducting cable for power lead and transmission applications is disclosed. The high performance power cable comprises two type of different superconducting cable structures arranged co-axially, and the magnetic fields of their transport currents mutually enhance their performances. A further object is a power distribution cable that minimizes the cryogenic losses by a design of the compact cable cross-sections.

Owner:TAKAYASU MAKOTO

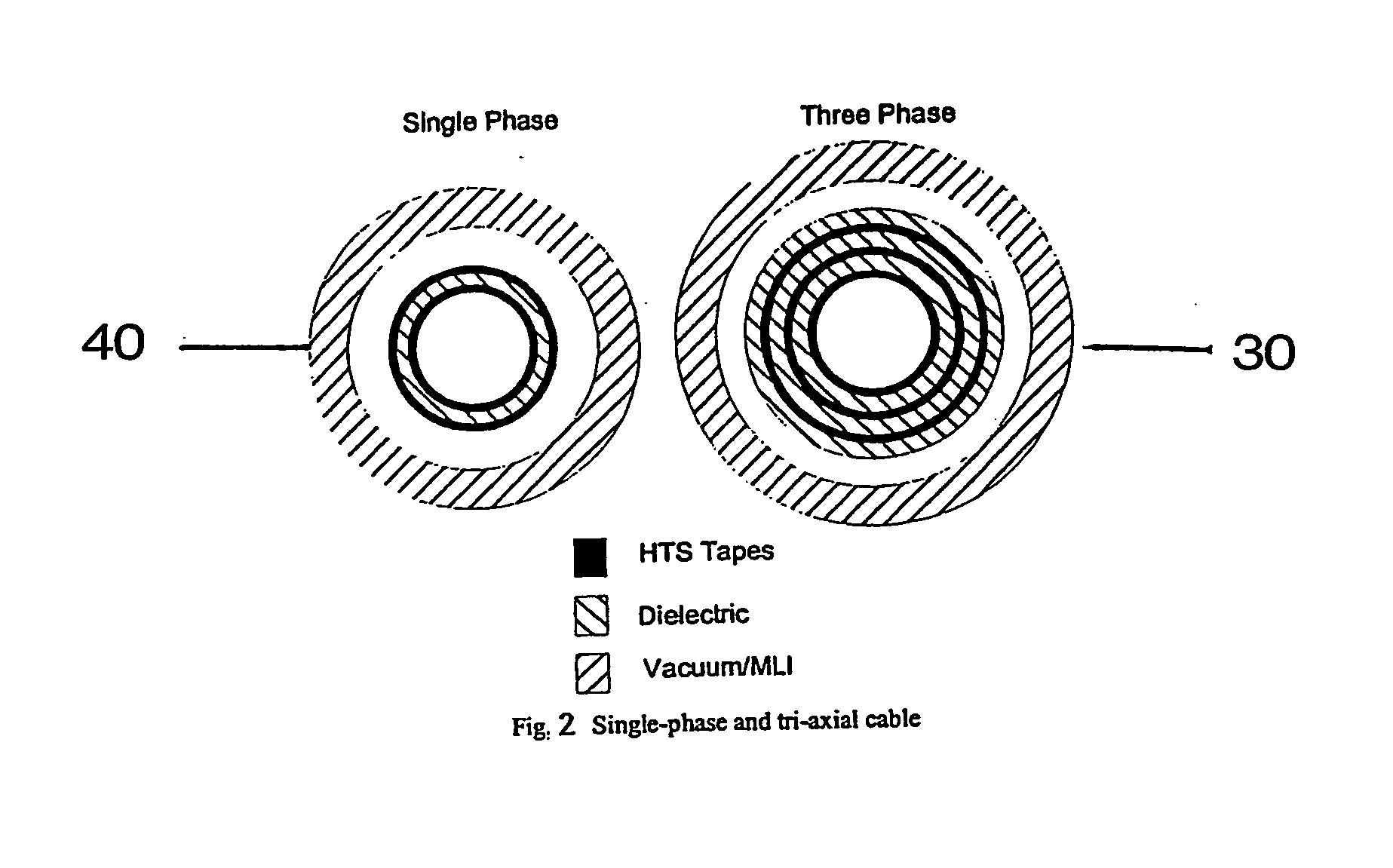

Triaxial hts cable

InactiveUS20040138066A1Superconductors/hyperconductorsConcentric cablesHigh-temperature superconductivityThree-phase

A High-Temperature Superconducting (HTS) transmission cable based on the cold dielectric concept with an HTS shield makes it possible to house all three phases inside a single cryostat without causing large degradation and loss due to magnetic fields generated by the neighboring phases. A further optimization is realized by making the three phases concentric to each other. No shielding layer is required in such a tri-axial configuration. It is more compact and requires only about half of the HTS tapes as that of three separately shielded phases. Each phase advantageously consists of two layers of BSCCO-2223 HTS tapes.

Owner:SOUTHWIRE CO LLC

High frequency power cable

InactiveUS20120234577A1Suppress proximitySuppress skinConcentric cablesPower cables with screens/conductive layersElectric forceElectrical conductor

Disclosed is a high frequency power cable including a central conductor centered in the cable having a plurality of metal strands twisted together in a cylindrical configuration, a conducting layer surrounding the periphery of the central conductor having a plurality of metal strands twisted together in a multilayered configuration, and an insulating layer surrounding the peripheries of the central conductor and the conducting layer.

Owner:LS CABLE & SYST LTD

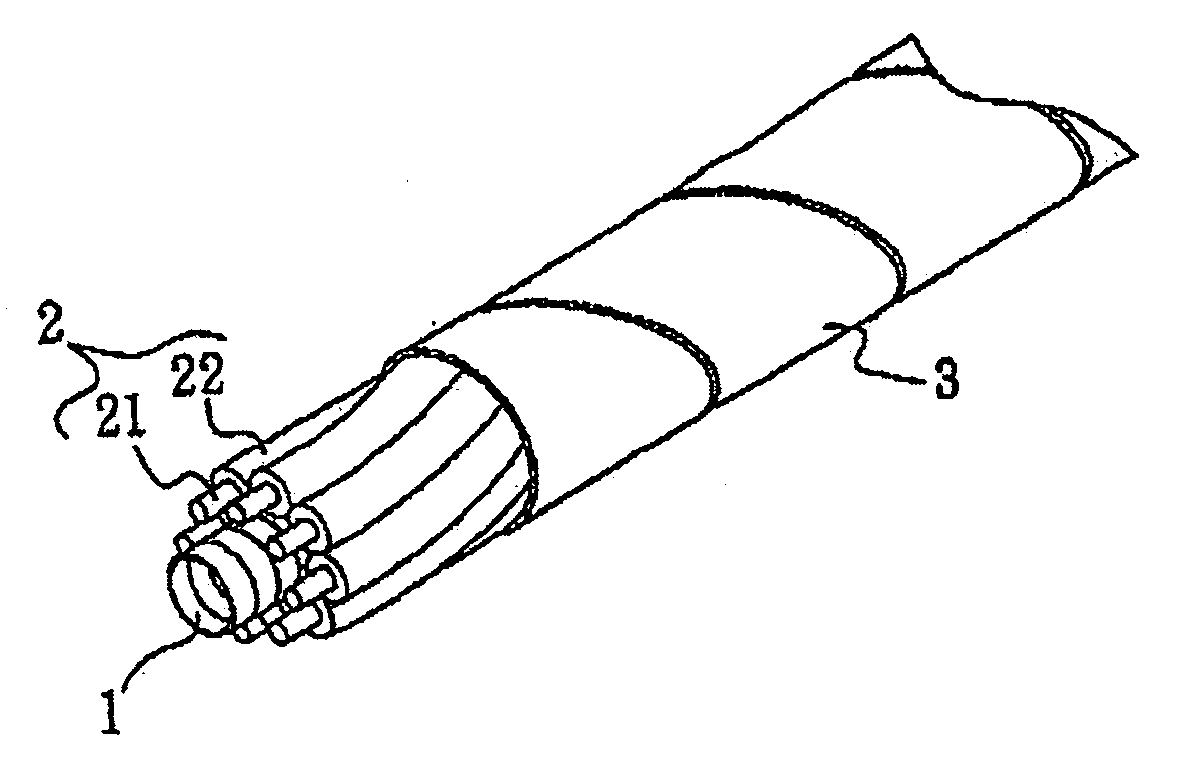

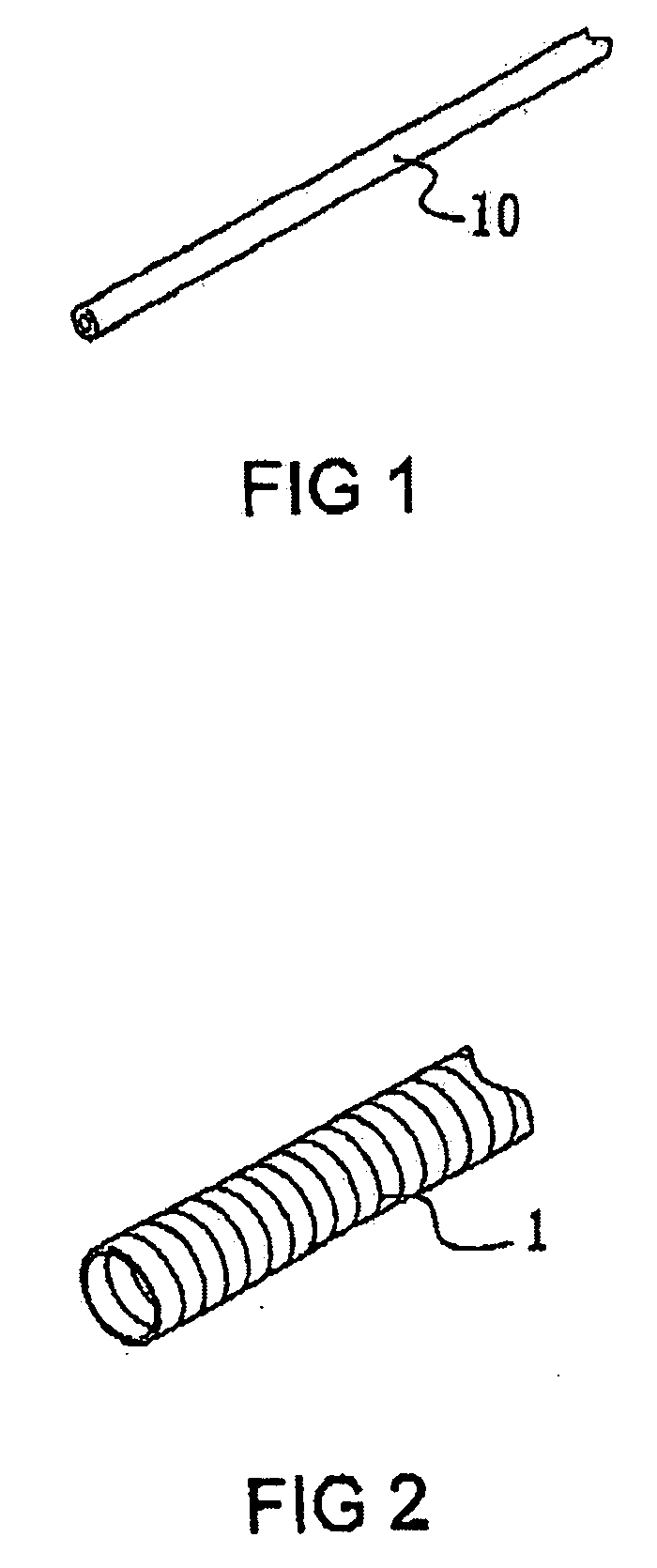

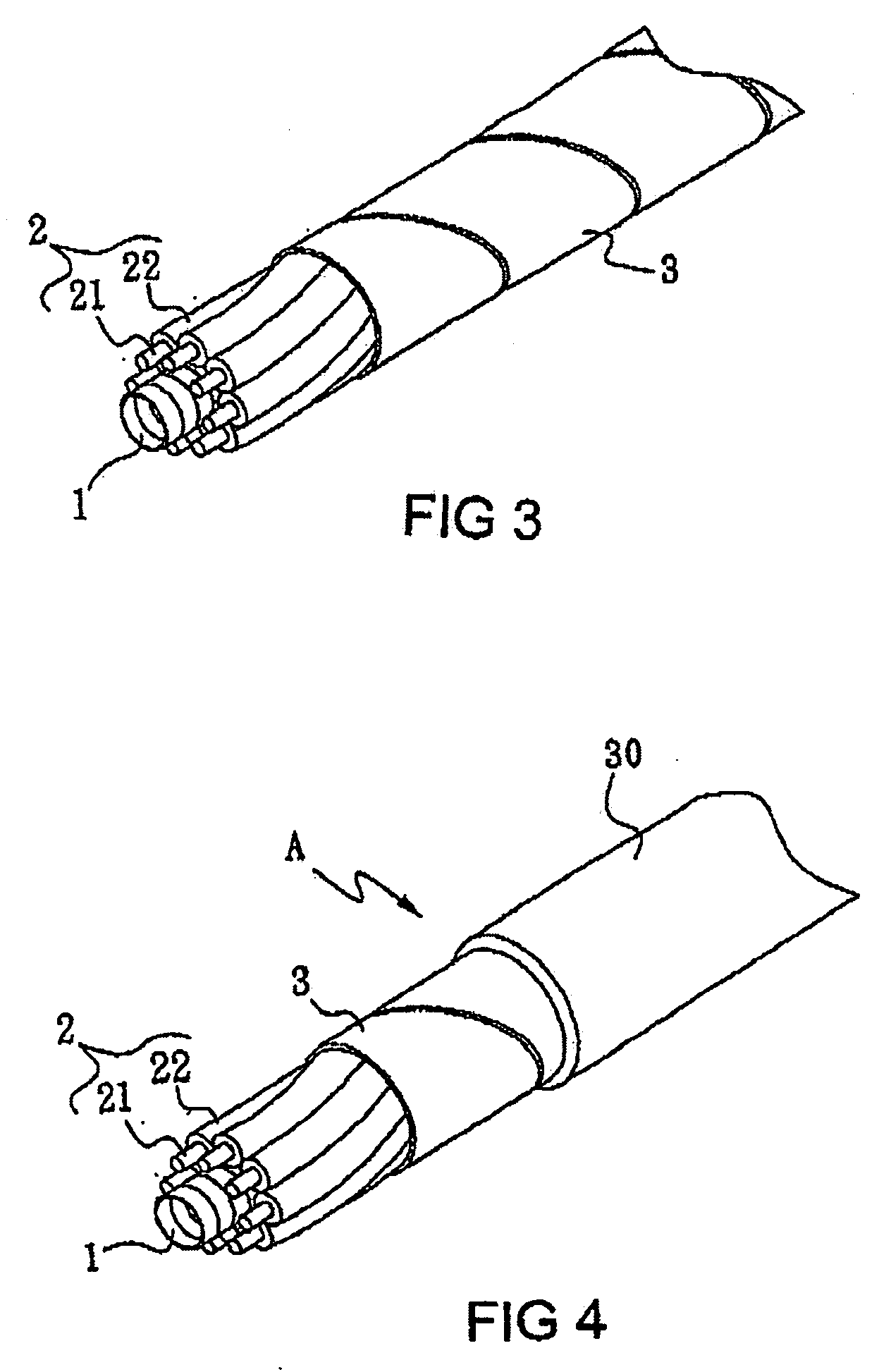

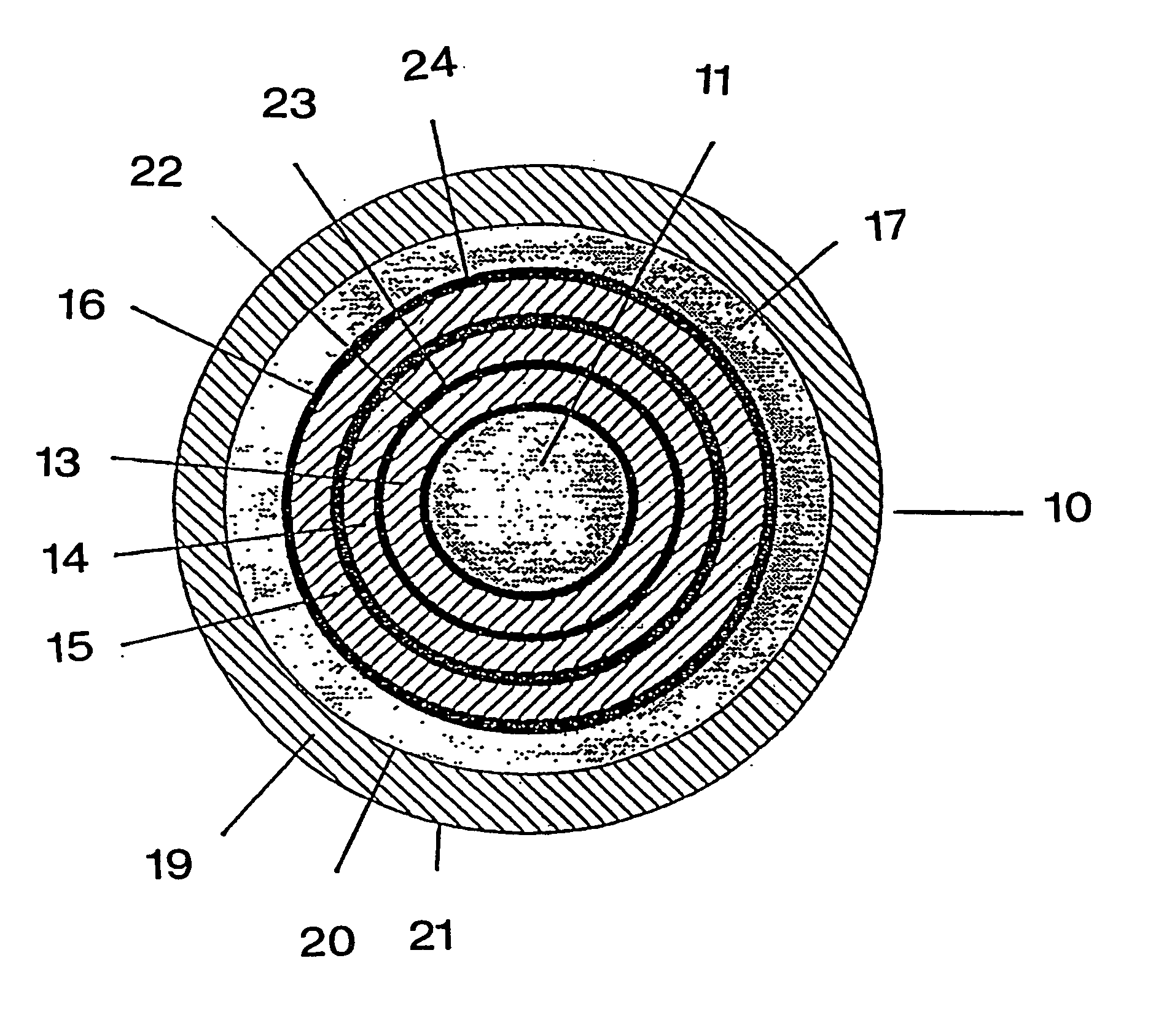

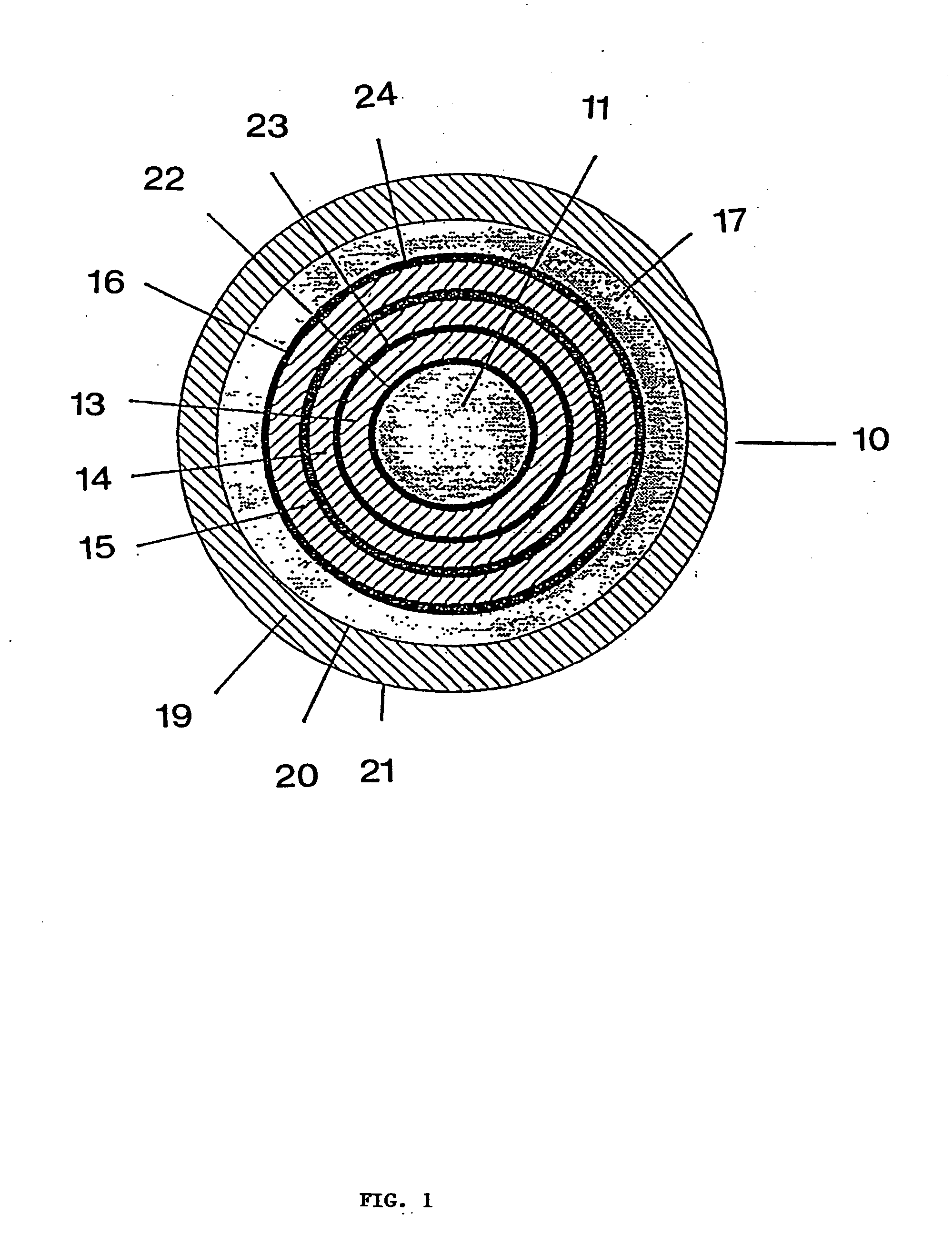

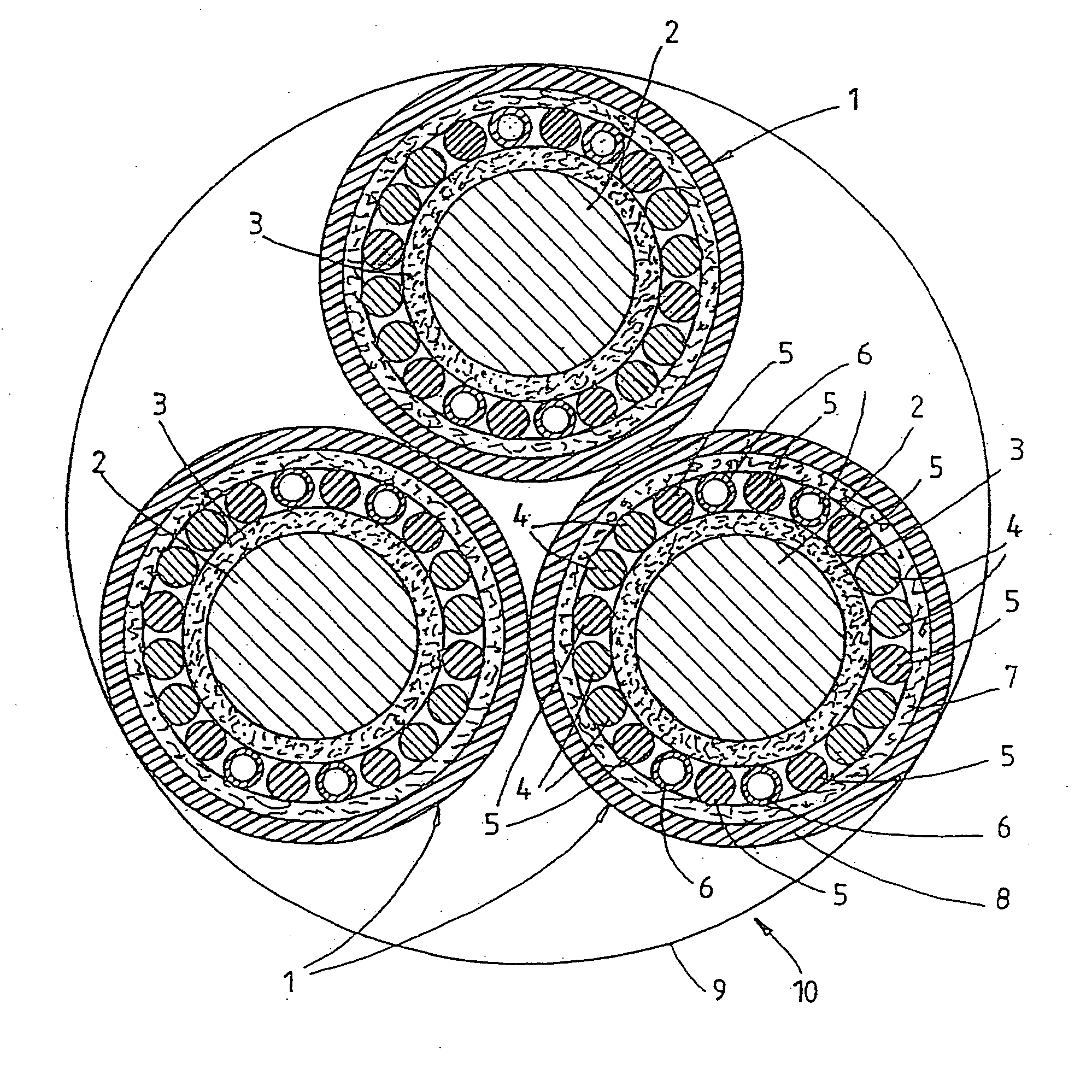

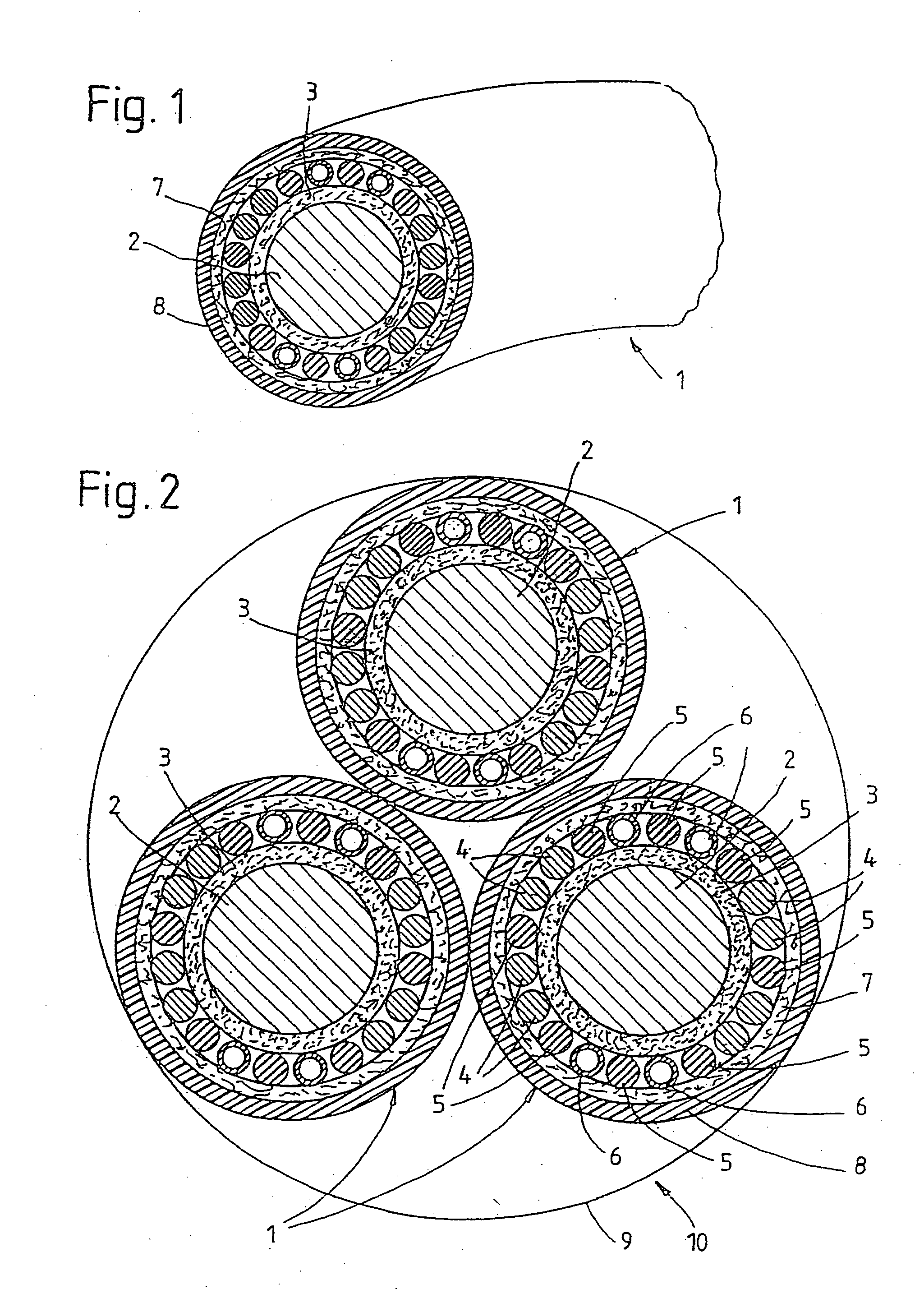

Three-conductor cable

InactiveUS20050167150A1Reduce voltageConcentric cablesPower cables including communication wiresElectrical conductorEngineering

The invention relates to a three-conductor cable (10) consisting of three stranded electric cables (1), each comprising a core that has a current conductor (2) and a neutral and / or return conductor. Each individual cable (1) is essentially characterised in that the neutral and / or return conductor is configured from a number of individual conductors (4), distributed concentrically around the current conductor (2), that an insulating sheath (3) is provided between the current conductor (2) and the distributed individual conductors (4) of the neutral and / or return conductor and that a protective jacket covers the neutral and / or return conductor.

Owner:LEONI STUDER

Electrical wire and method of fabricating the electrical wire

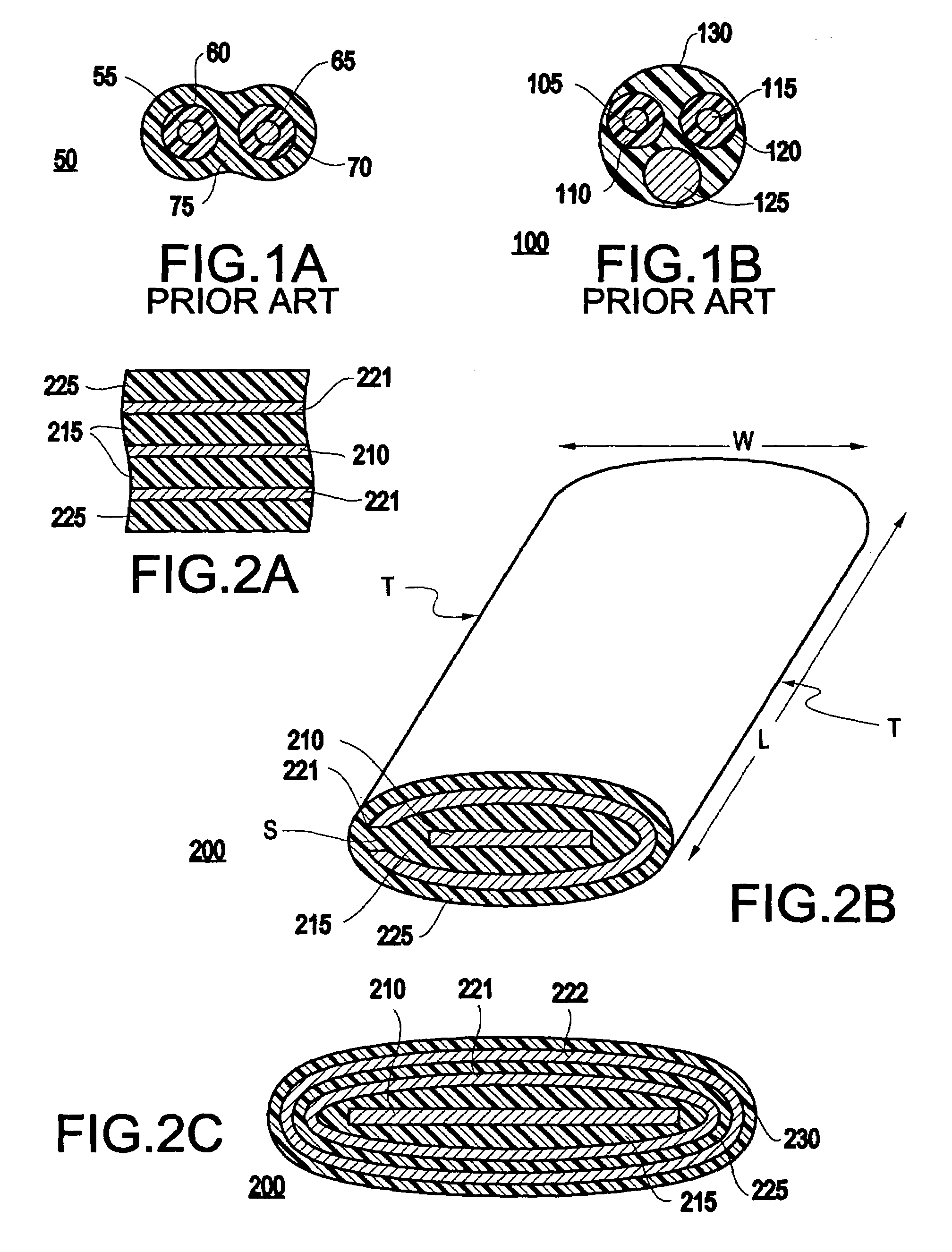

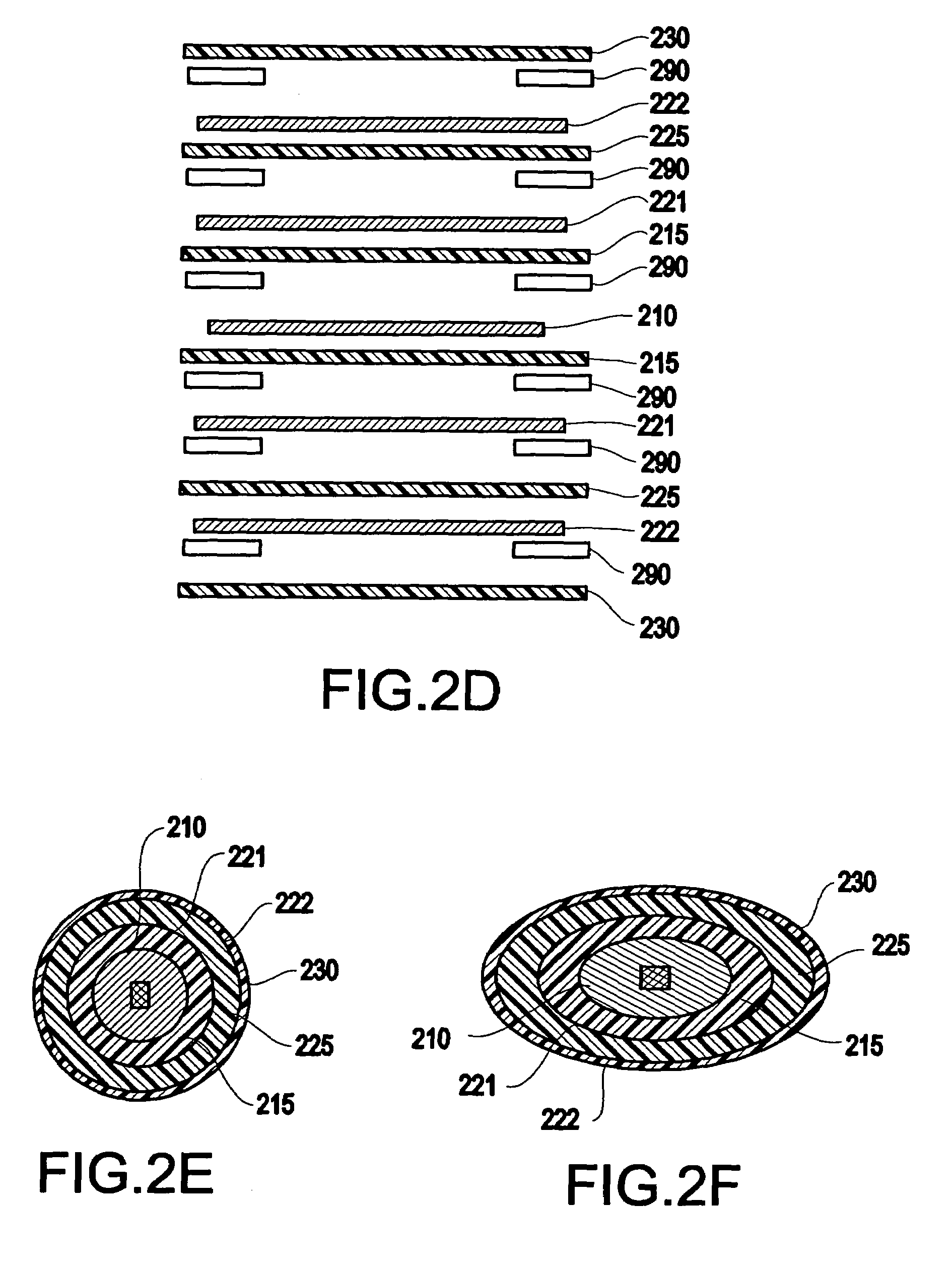

InactiveUS20050042942A1Safe and convenientEasy to makeElectrically conductive connectionsConcentric cablesElectrical conductorEngineering

Owner:SOUTHWIRE CO LLC

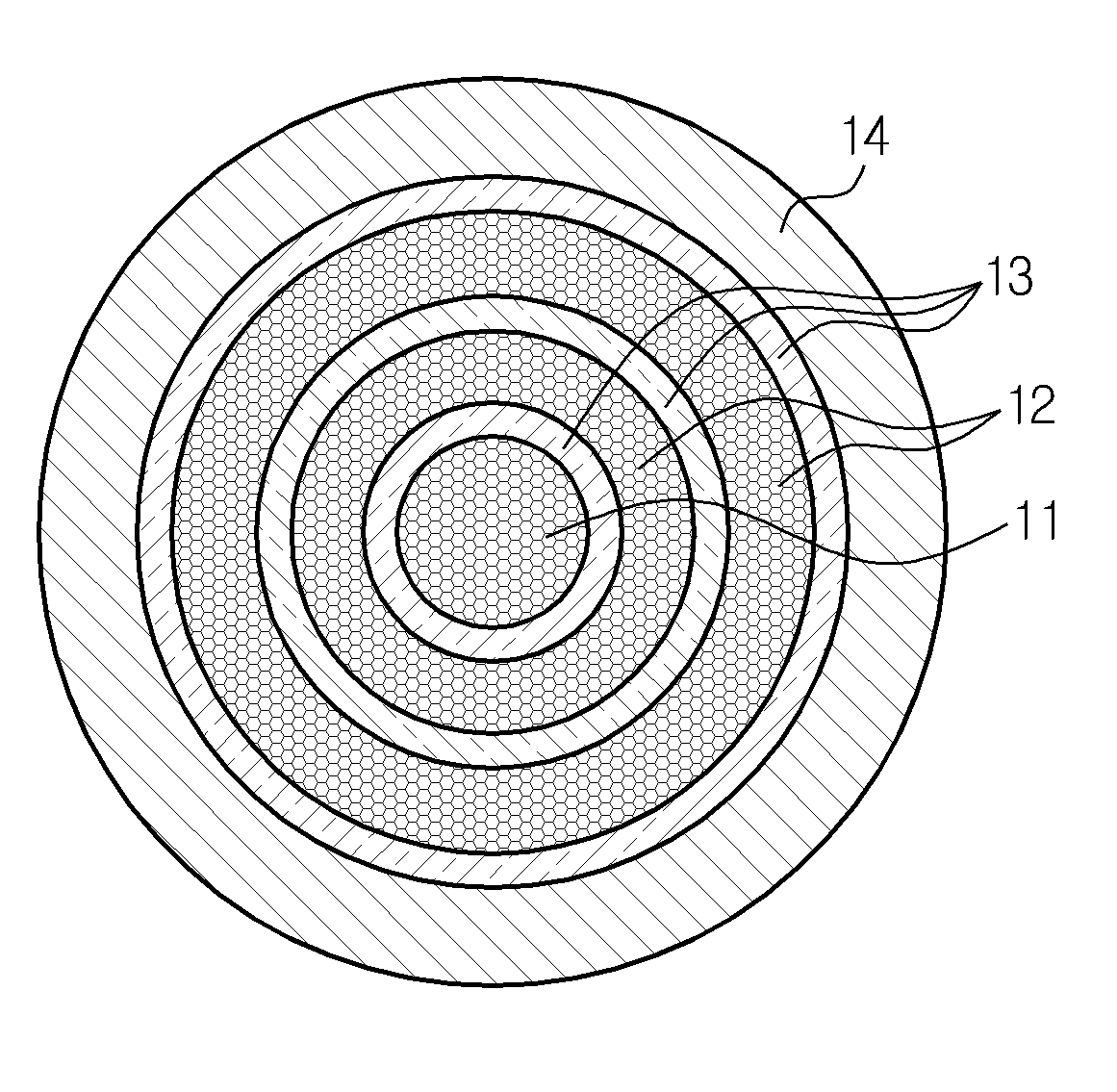

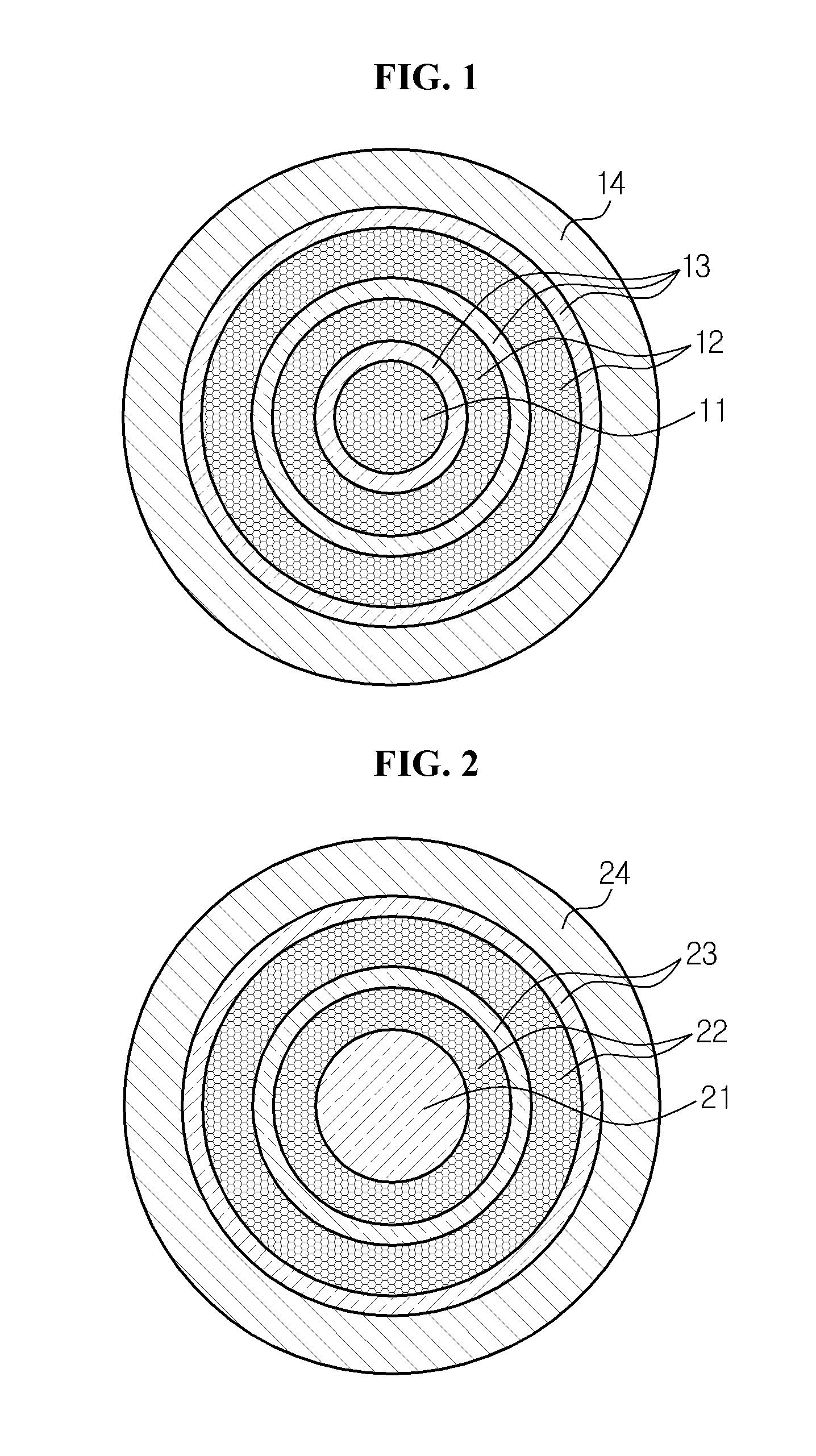

Multi-layer coaxial cable

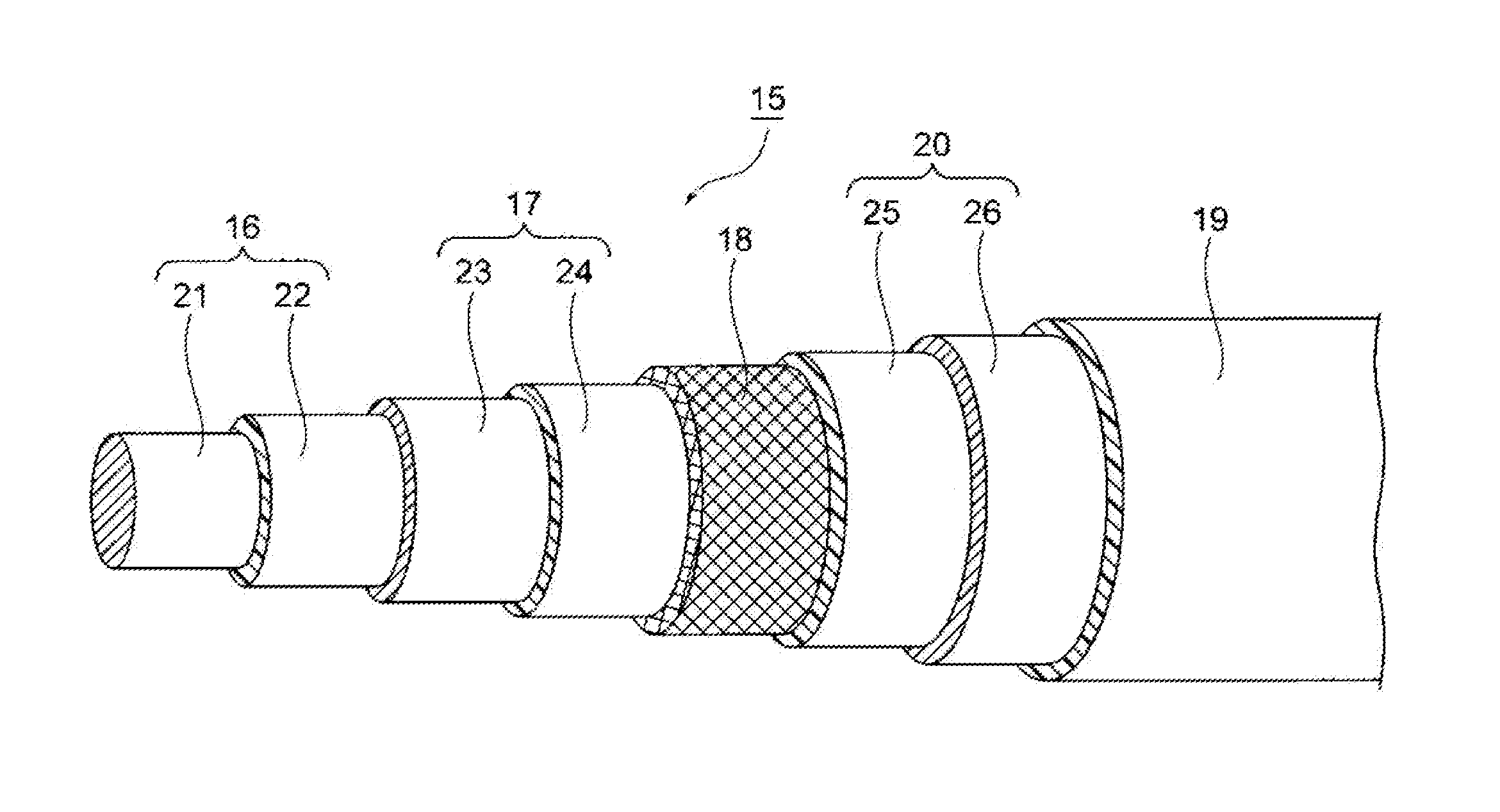

ActiveUS20150083459A1Saving a space for the routing of the cableSmall sizeConcentric cablesConductive materialCoaxial cableElectrical conductor

A multilayer coaxial cable includes high-voltage circuits that are coaxially disposed with each other. The high-voltage circuits include high-voltage conductors and high-voltage insulators that are disposed on the outside of the high-voltage conductors. In addition, the multilayer coaxial cable includes a conductive shield member that is coaxially disposed on the outside of the high-voltage circuits, and an insulating coating member that is coaxially disposed on the outside of the shield member.

Owner:YAZAKI CORP

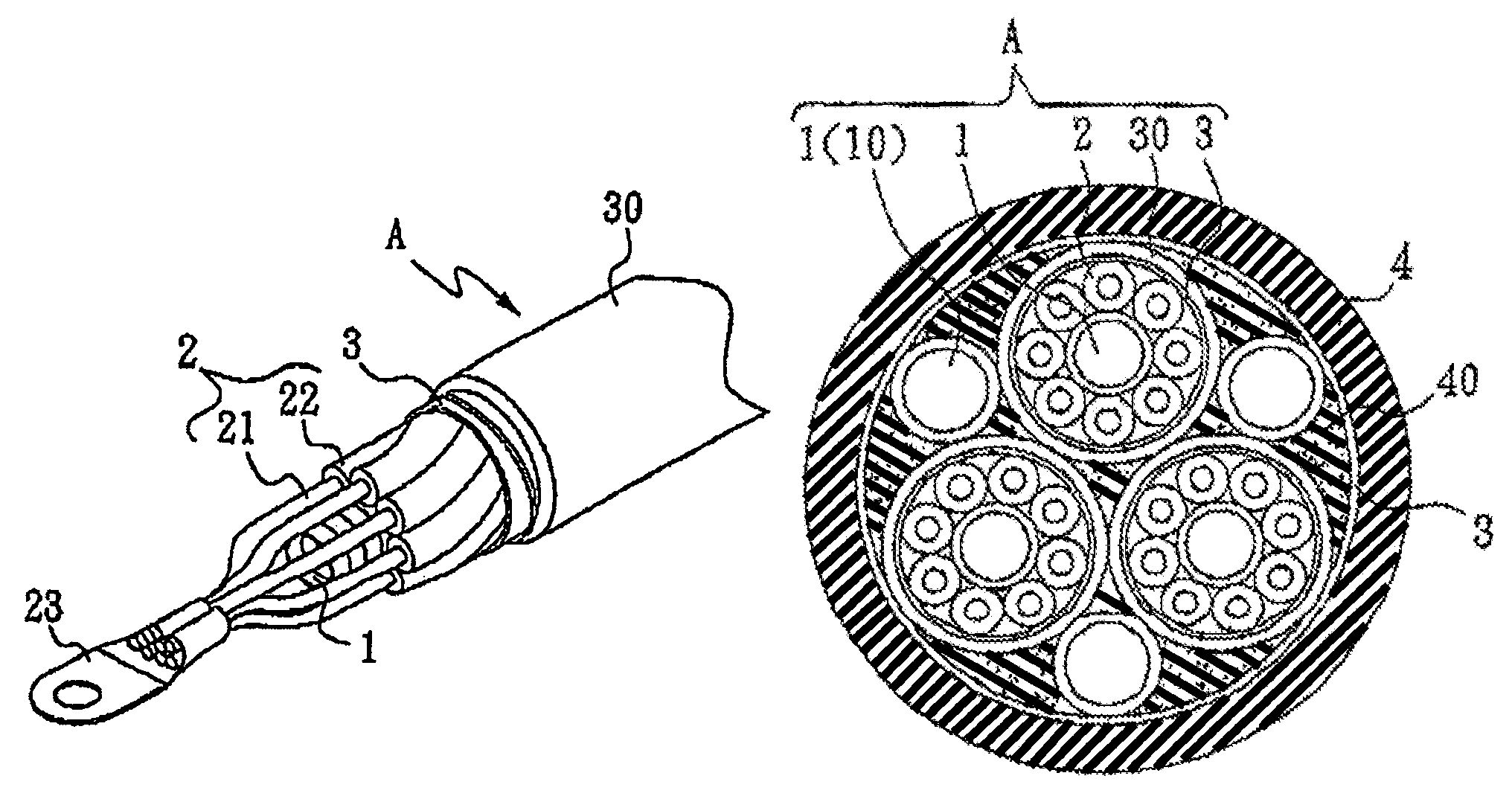

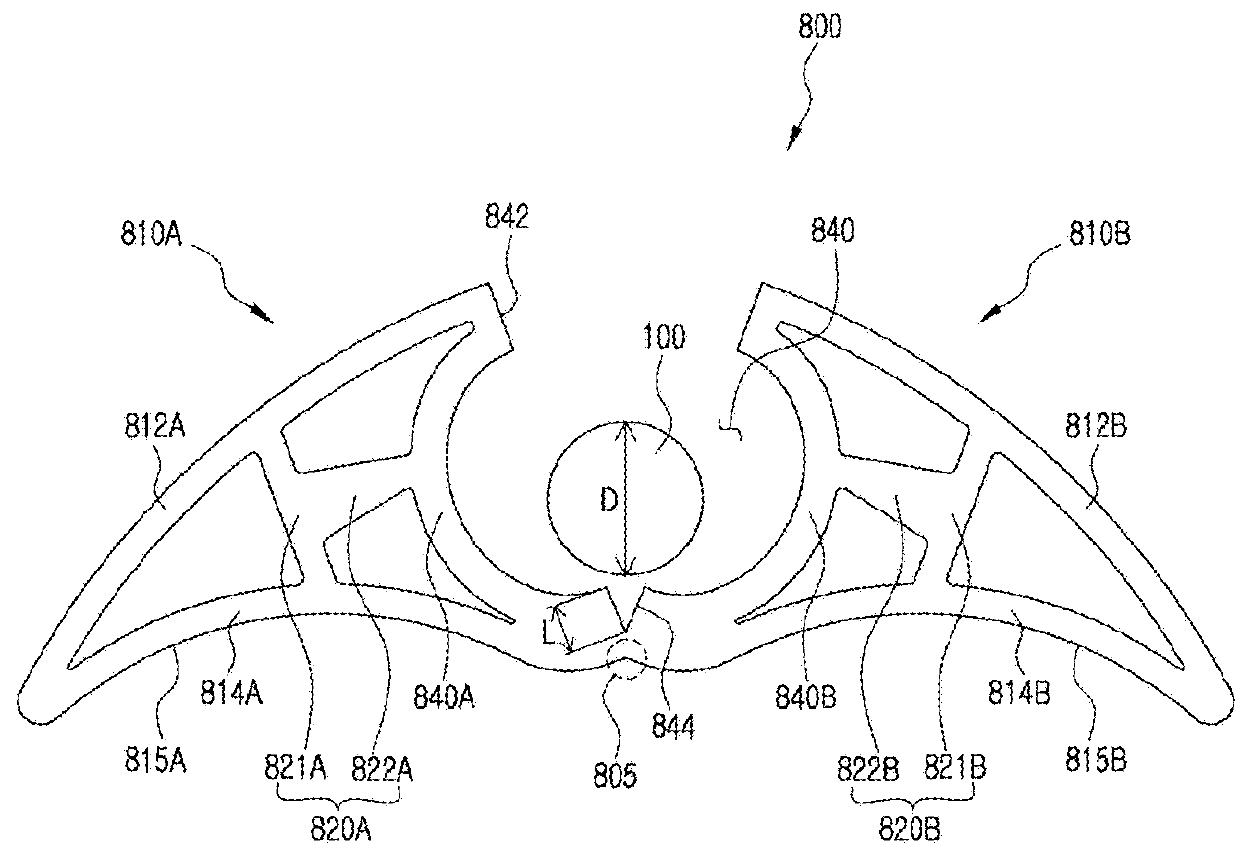

Wire harness

A wire harness includes a coaxial conducting wire including a plurality of high voltage paths which are coaxially aligned, a covering member, accommodating the coaxial conducting wire, and a terminal, connected to one of the high voltage paths disposed outside of another one of the high voltage paths, and including a tubular portion coaxial to the coaxial conducting wire. The terminal includes a connection tubular portion as the tubular portion, a crimping tubular portion connecting the one of the high voltage paths to the connection tubular portion by crimping, and an outside connection terminal integrated with the connection tubular portion.

Owner:YAZAKI CORP

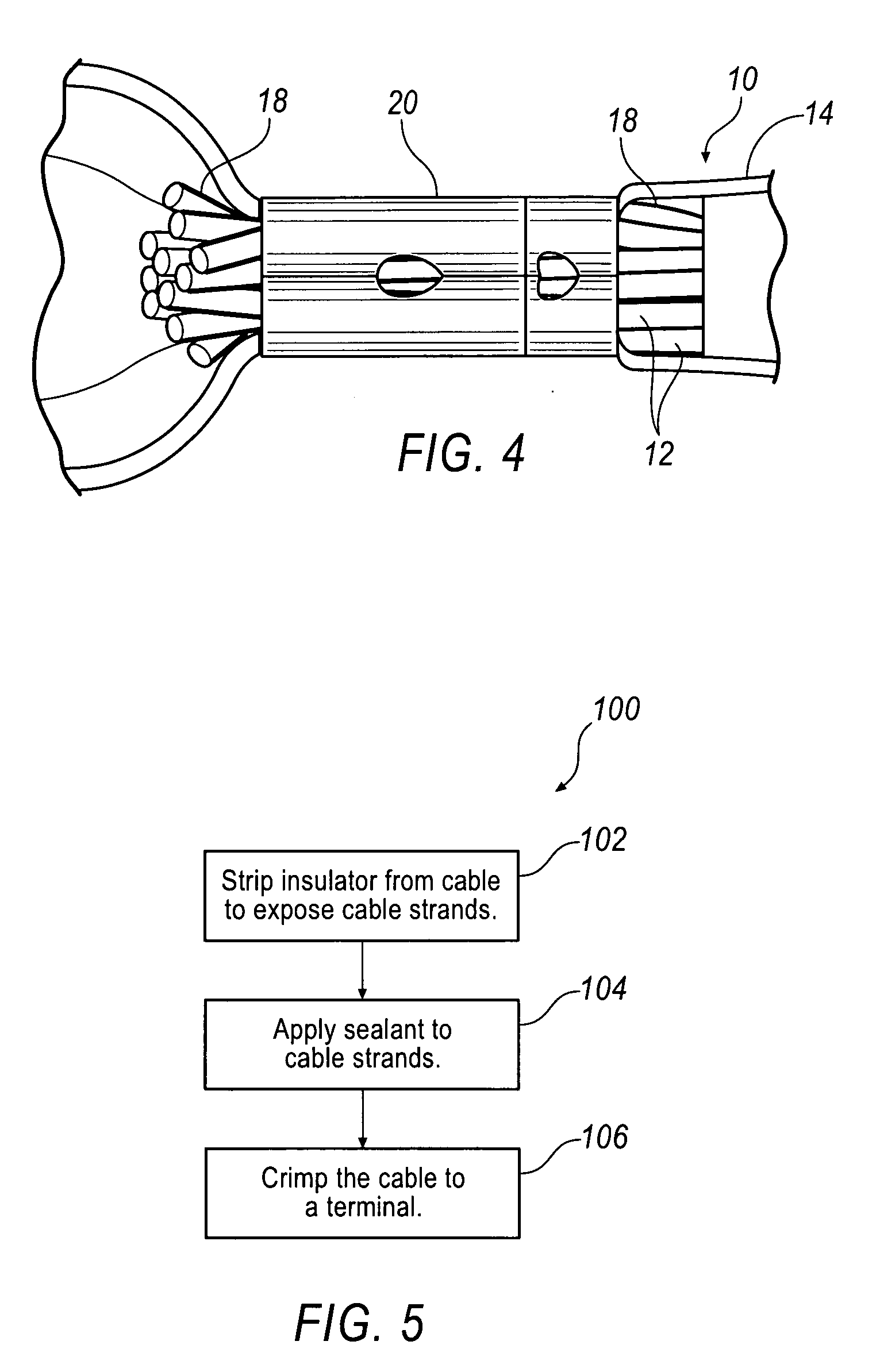

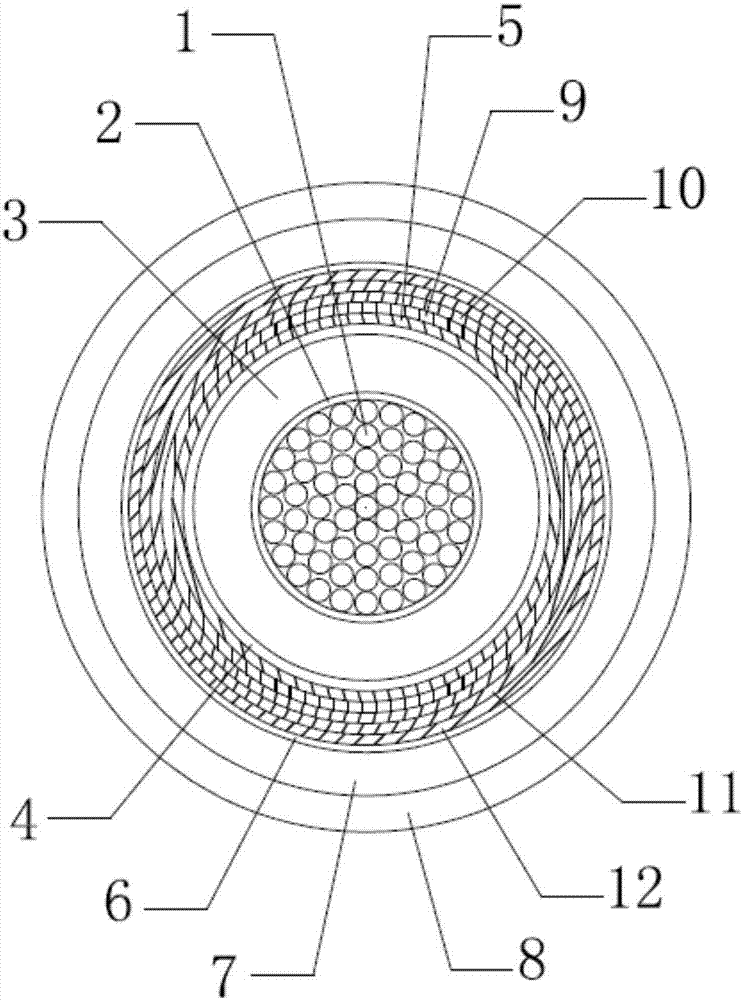

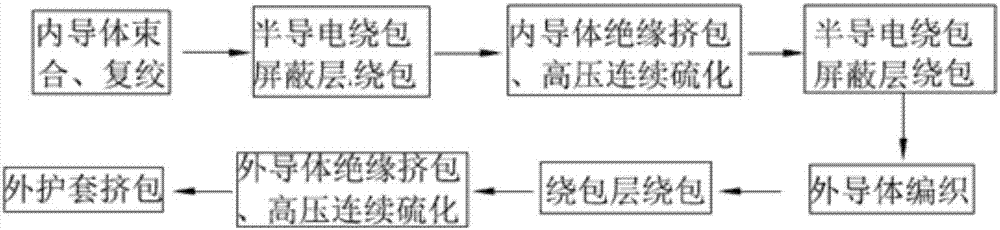

Manufacturing method of cable for high power transmission equipment and cable

InactiveCN107154285ANo damageReduce weightConcentric cablesPower cables with screens/conductive layersReliable transmissionElectrical conductor

A cable for high power transmission equipment, its structure from inside to outside is: inner conductor, first semiconductive wrapping shielding layer, inner conductor insulation, second semiconducting wrapping shielding layer, outer conductor, wrapping layer, Outer conductor insulation and outer sheath. The insulating layer of the inner conductor is made of silicon rubber; the outer conductor is braided with one or more layers of tinned copper wire; the insulating layer of the outer conductor is made of silicon rubber; the outer sheath layer is made of polyurethane. The manufacturing method of the cable comprises: 1) manufacturing the inner conductor; 2) manufacturing the first semiconductive wrapping shielding layer; 3) manufacturing the inner conductor insulating layer; 4) manufacturing the second semiconductive wrapping shielding layer; 5) manufacturing 6) manufacturing the wrapping layer; 7) manufacturing the insulating layer of the outer conductor; 8) manufacturing the outer sheath layer. In each step, a specific process method is adopted, so that the electrical and mechanical properties of the cable prepared by this method can meet or exceed the detection requirements, so that the cable for high-power transmission equipment can transmit high power safely and reliably, and has the advantages of light weight. , miniaturization, low temperature resistance, good flexibility, small bending radius and other excellent performances, suitable for high electric energy technical equipment.

Owner:JIANGSUSNGSHANG CABLE GROUP

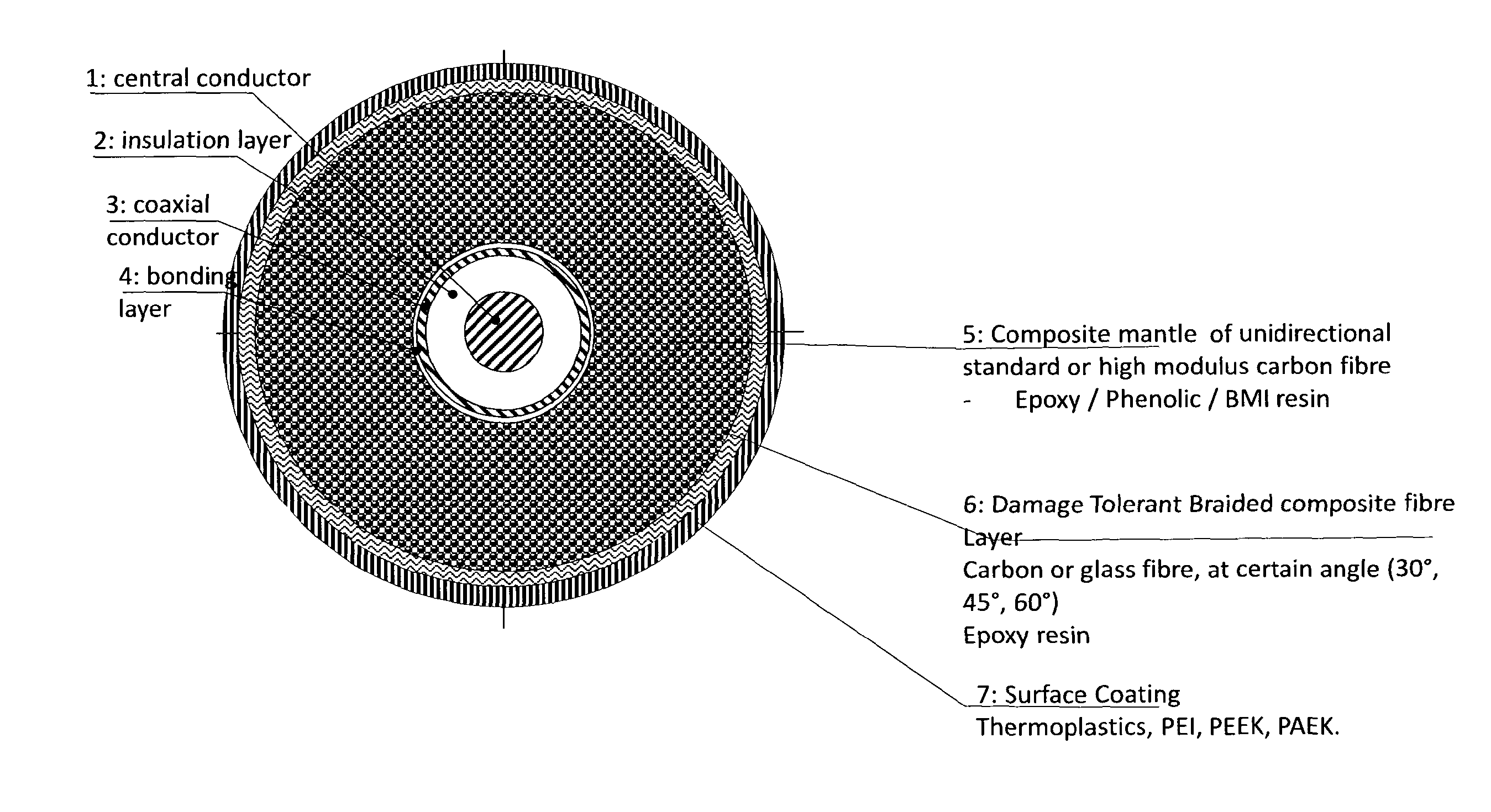

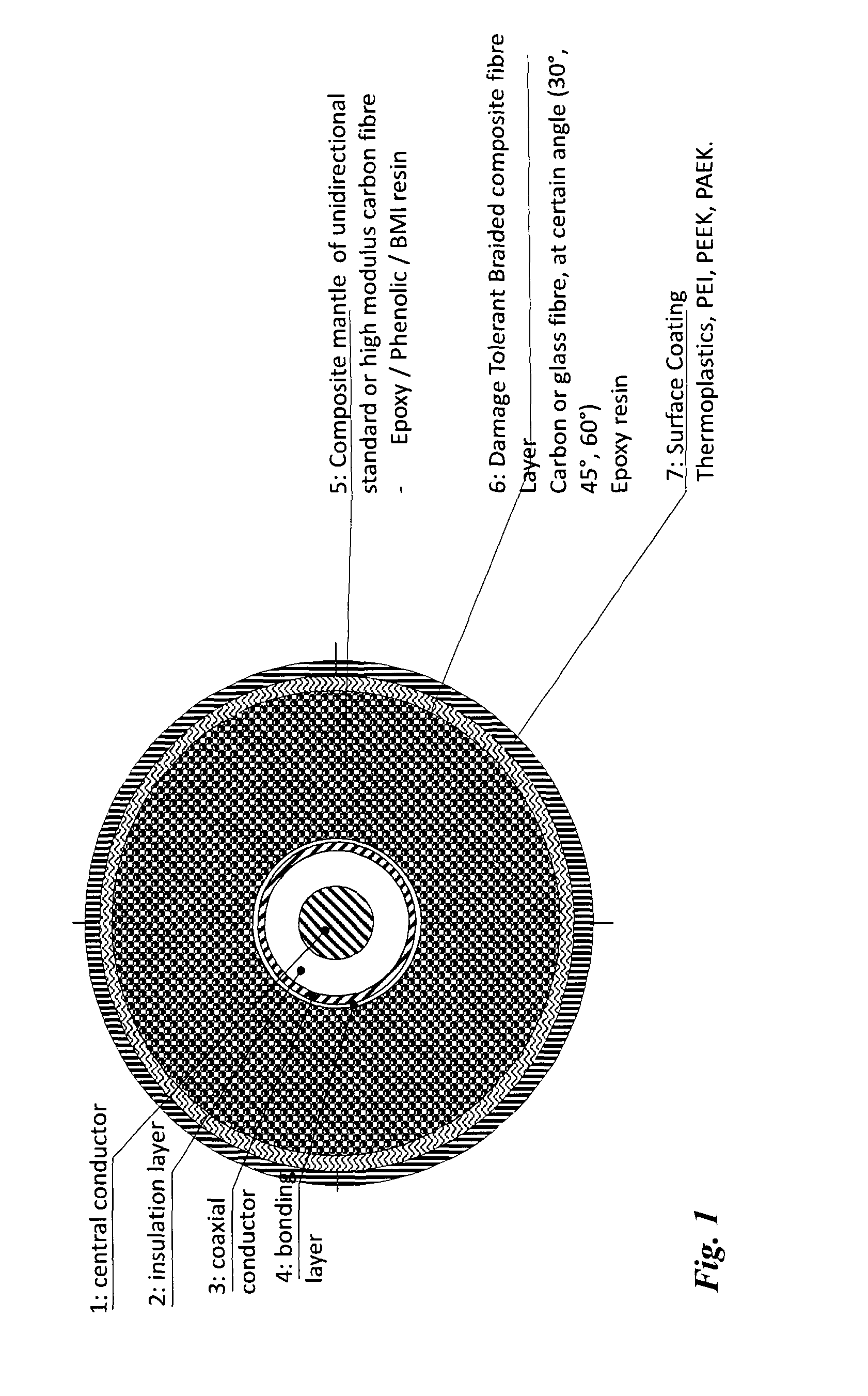

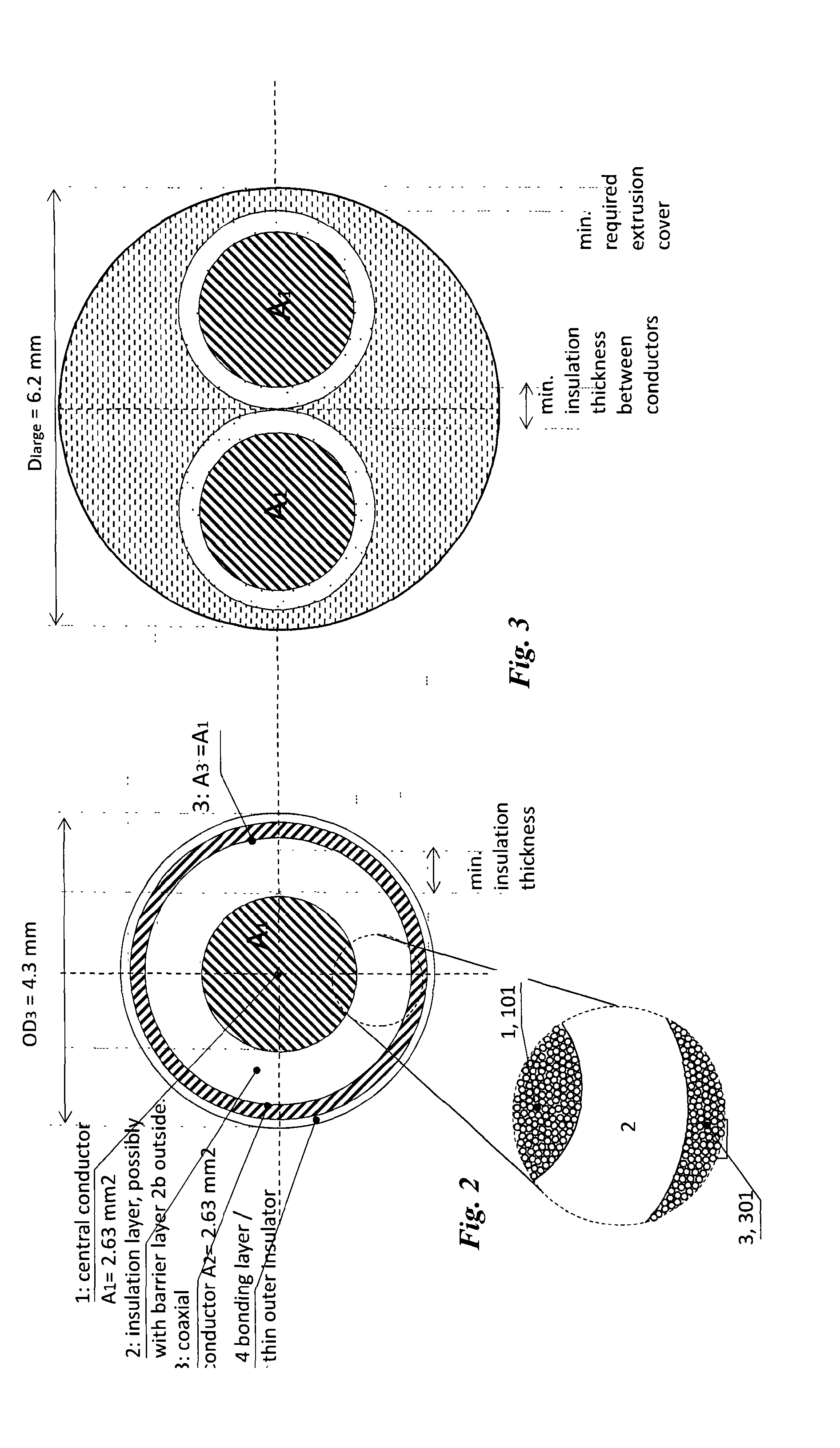

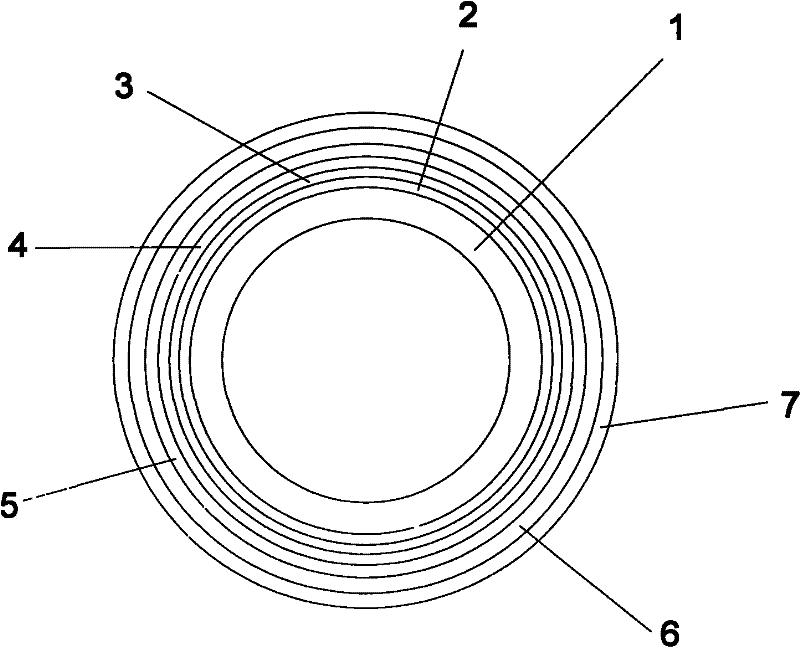

Fibre composite rod petroleum well intervention cable

The fibre composite rod intervention cable is for a petroleum well, and has a length of at least 2 to 10 km or more with the following sequence: a central electrical cable portion, a bonding layer, a generally unidirectional carbon fibre composite mantle layer, a protective, balanced braided fibre composite layer; the central electrical cable portion includes a generally central electrical conductor with a first cross-section conductive area an inner insulation layer on the central electrical conductor, and a coaxial electrical conductor layer having a second cross section conductive area equal to the first cross-section conductive area.

Owner:COMTRAC AS

Dry-type all-insulating tubular bus

ActiveCN102237157AEasy direct moldingSmall skin effect coefficientConcentric cablesInsulated cablesCapacitanceEpoxy

The invention discloses a dry-type all-insulating tubular bus and relates to power generation, transmission, transformation and distribution devices of an electric power system. The dry-type all-insulating tubular bus comprises a hollow conducting tube, a first epoxy resin insulating layer and a first shielding layer, wherein the first epoxy resin insulating layer is coated outside the hollow conducting tube; and the first shielding layer is coated outside the first epoxy resin insulating layer. By using a coaxial capacitance principle and an epoxy resin molding technology, the dry-type all-insulating tubular bus has the advantages of high bus capacity, low volume, energy conservation, maintenance-free performance, safe operation and convenience for large-scale manufacturing.

Owner:SHANGHAI CHANLIAN ELECTRIC TECH

Sealed cable and terminal crimp

A cable includes a plurality of cable strands, an insulator disposed on a portion of the plurality of strands such that the plurality of strands are at least partially exposed, and a sealant disposed between gaps of the plurality of strands and at least partially under the insulator. Moreover, a method includes stripping an insulator from an end of the cable to expose a plurality of cable strands, and applying a sealant to the cable strands such that the sealant is drawn under the insulator and fills in gaps between the cable strands by capillary action.

Owner:APTIV TECH LTD

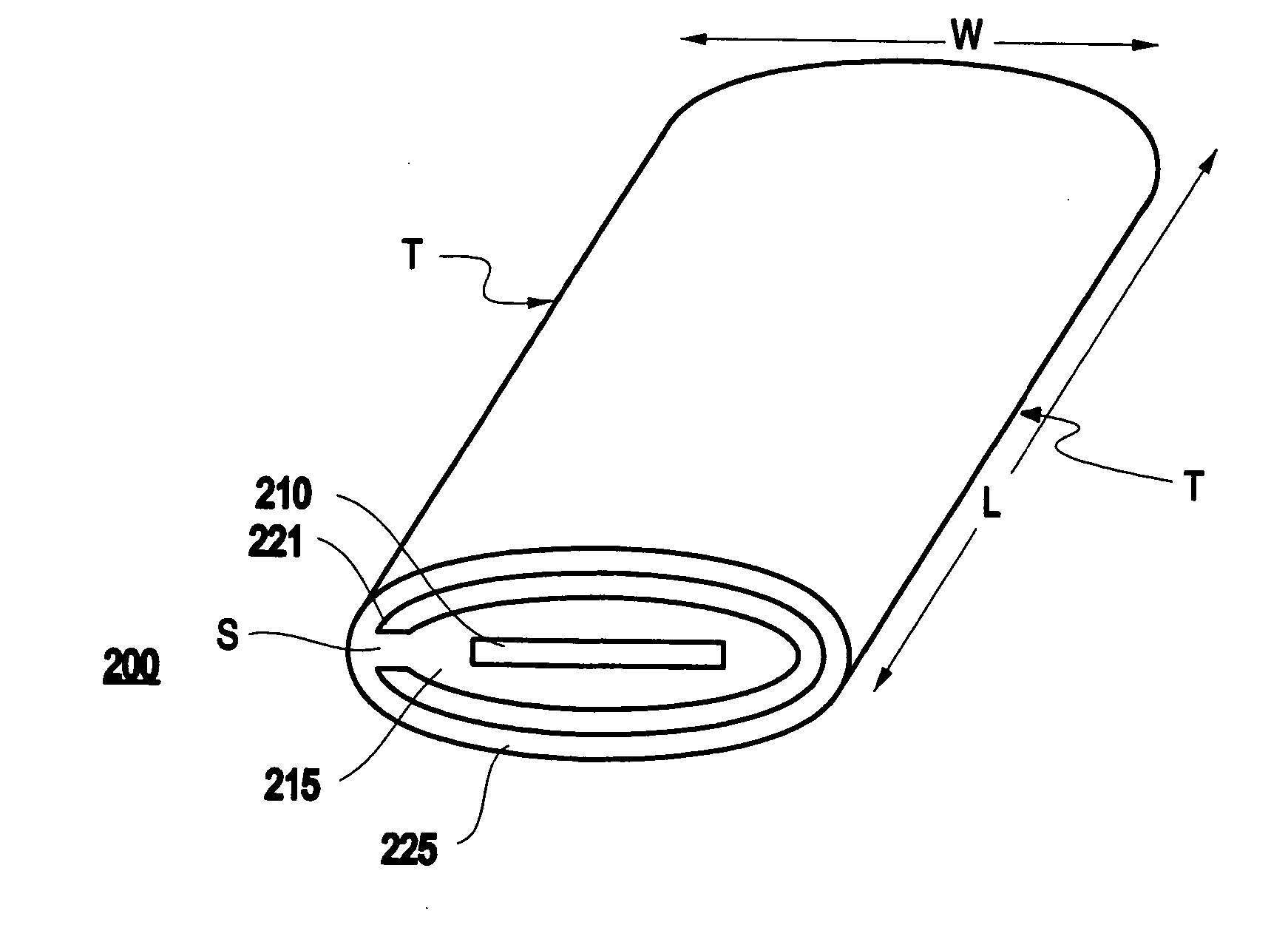

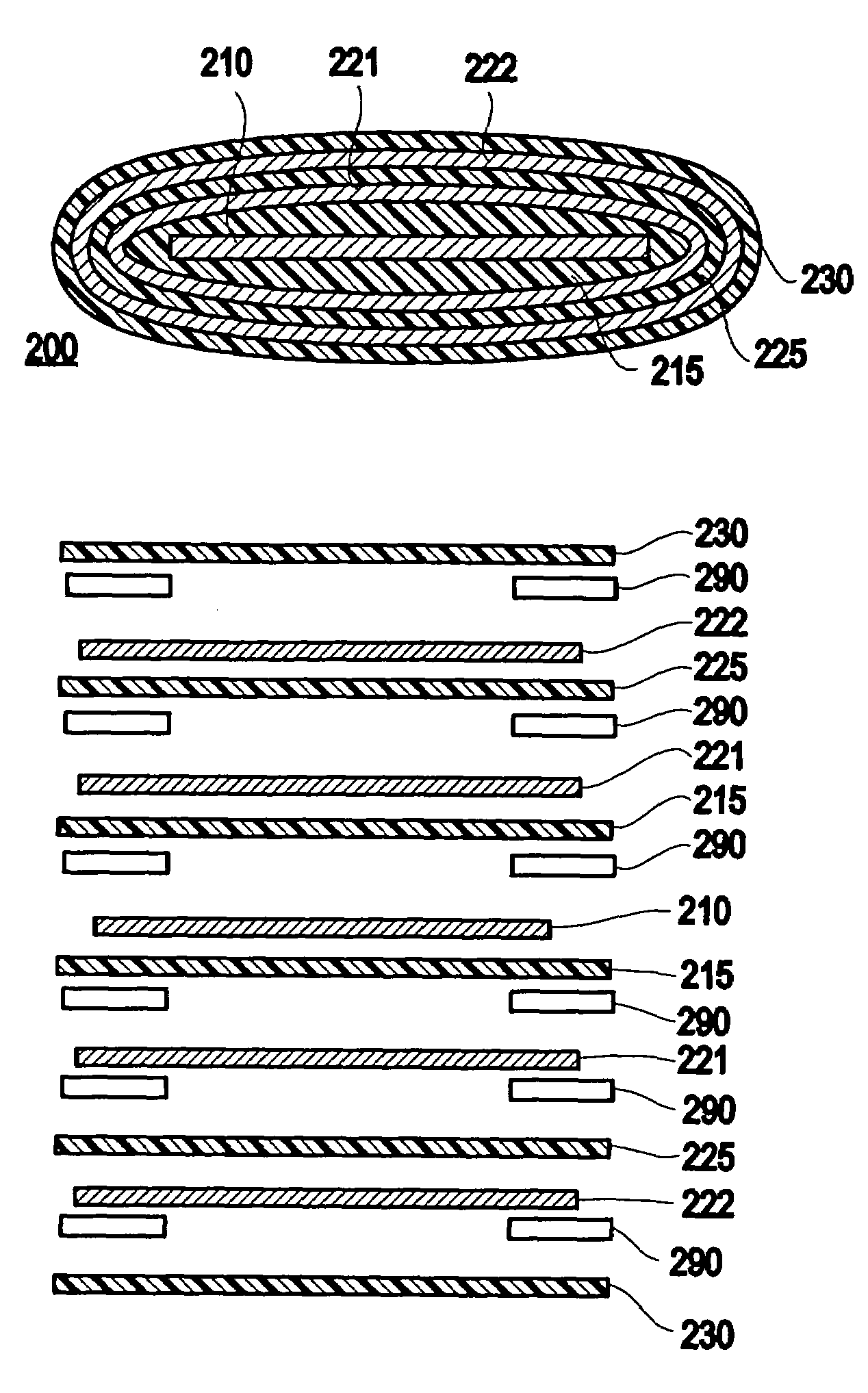

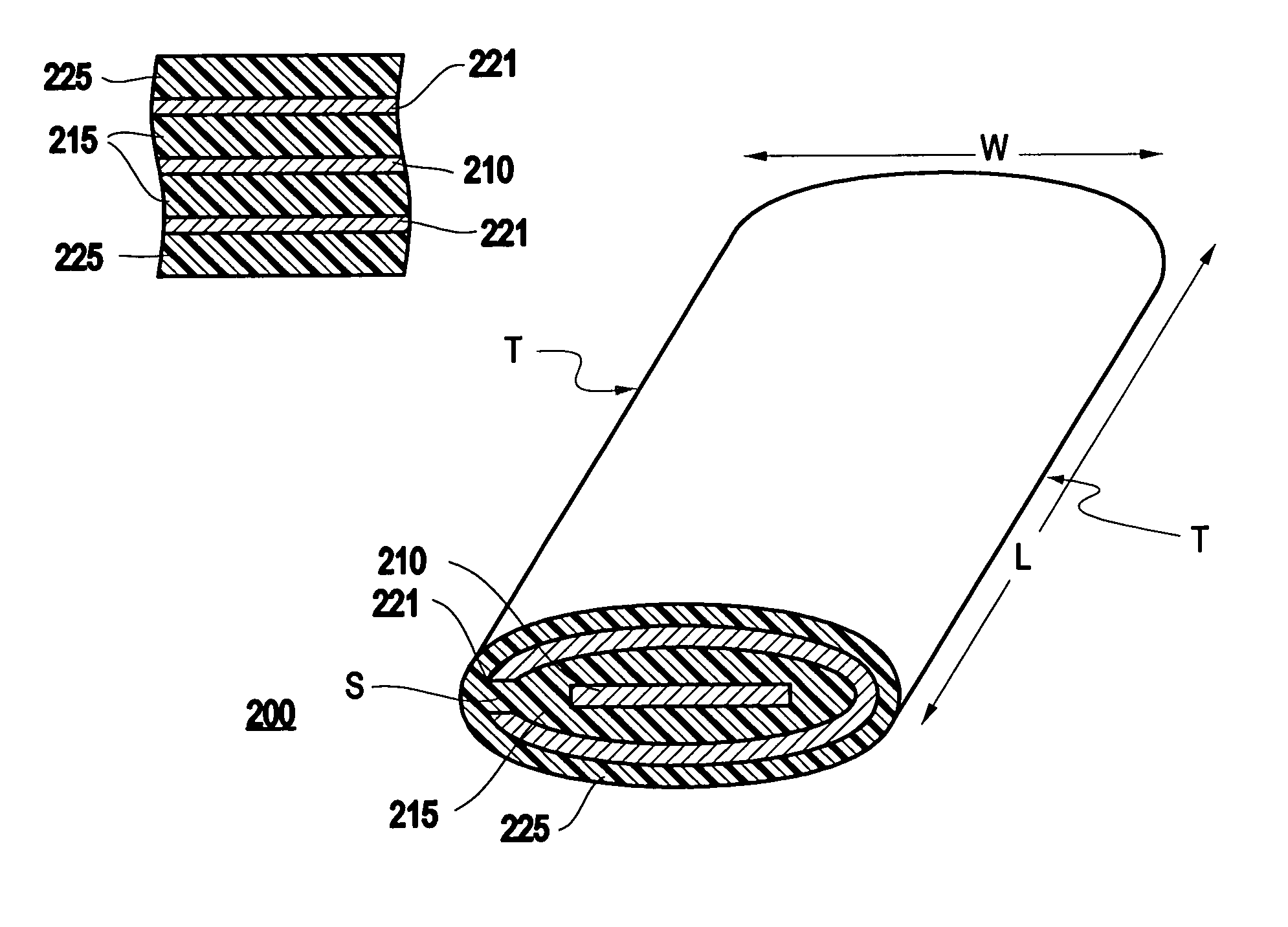

Electrical wire and method of fabricating the electrical wire

InactiveUS7737359B2Easy to makeSafe and convenientPlastic/resin/waxes insulatorsConcentric cablesElectrical conductorEngineering

An electrical wire includes at least one electrifiable conductor for delivering electrical power, a first insulating layer formed on one side of the electrifiable conductor, a second insulating layer formed on the opposite side of the electrifiable conductors, a first return conductor formed on the first insulating layer opposite the at least one electrifiable conductor, and a second return conductor formed on the second insulating layer opposite the at least one electrifiable conductor. The at least one electrifiable conductor is at least substantially entrapped by the first and second return conductors such that the distance between said at least one electrifiable conductor and each of said first and second return conductors is no greater than approximately 0.030 inches. At least one of the first insulating layer or the second insulating layer comprises a plurality of insulating layers.

Owner:NEWELL CO INC

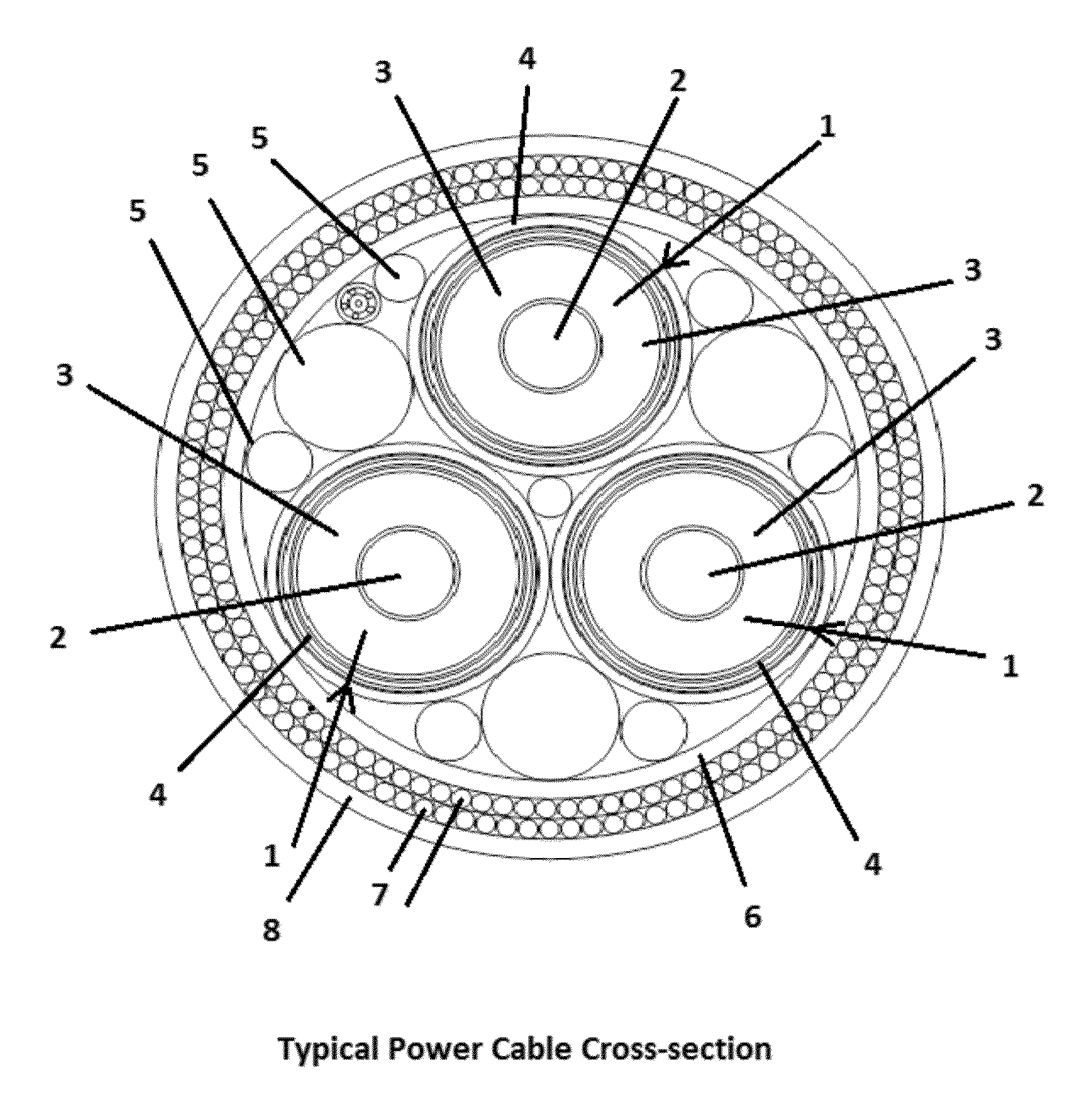

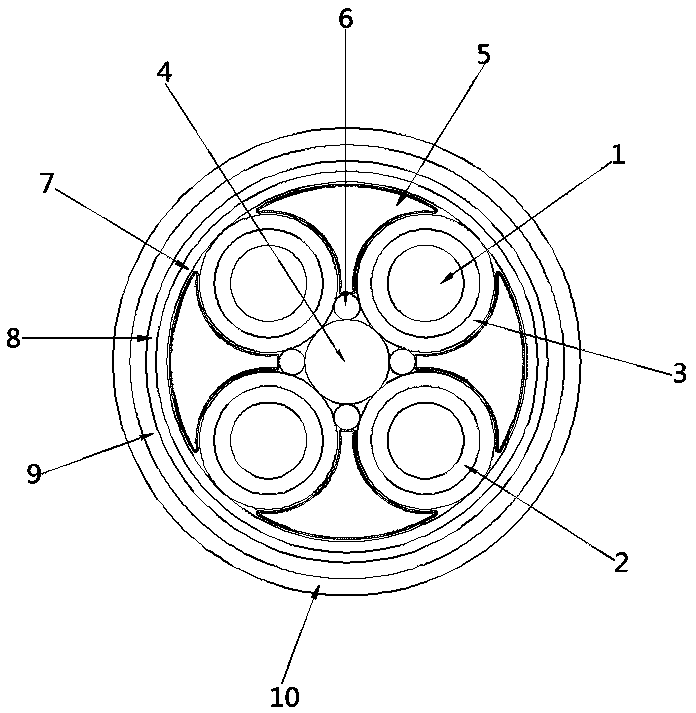

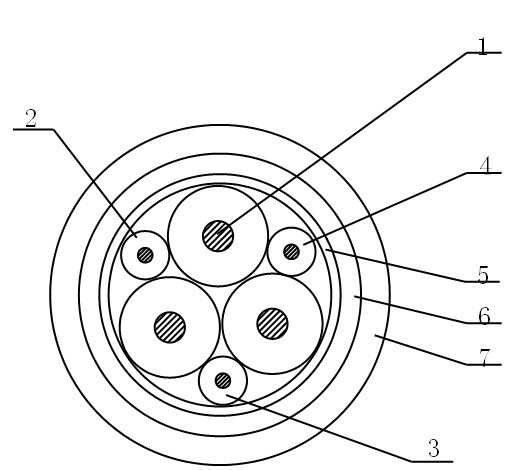

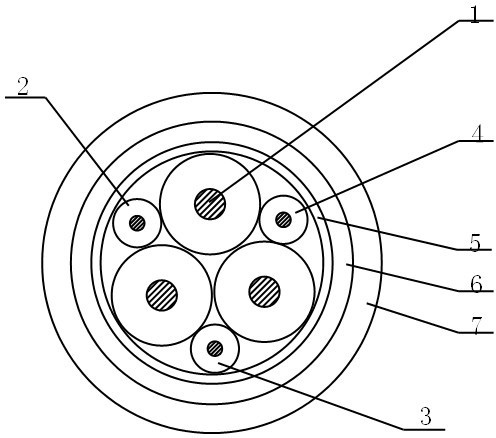

Low-smoke halogen-free flame-retardant coaxial cable with polyethylene insulating polyolefin sheath

InactiveCN111415773AAdequate and effective protectionExtended service lifeCoaxial cables/analogue cablesPlastic/resin/waxes insulatorsLow smoke zero halogenCoaxial cable

The invention discloses a low-smoke halogen-free flame-retardant coaxial cable with a polyethylene insulating polyolefin sheath, and belongs to the field of cables. The low-smoke halogen-free flame-retardant coaxial cable comprises four cable core conductors which are arranged in an annular array; the outer side of the cable core conductors is coated with an insulating layer; the outer side of theinsulating layer is wrapped with an inner shielding layer; the cable core conductor, the insulating layer and the inner shielding layer form a cable core; reinforcing cable cores are arranged among the four cable cores; the four cable cores are tightly attached to the reinforced cable core; a first outer shielding layer is arranged on the outer side of the cable core; a filling layer is arrangedin a gap between the first outer shielding layer and the cable core. According to the low-smoke halogen-free flame-retardant coaxial cable with the polyethylene insulating polyolefin sheath, the insulating layer, the multi-layer shielding layer, the inner sheath and the outer sheath are arranged, so the coaxial cable can be fully and effectively protected, the flame retardance, the oxidation resistance and the shielding performance of the coaxial cable are greatly improved, and the service life of the cable is prolonged.

Owner:JIANGSU PUCAO TECH CO LTD

Wire harness

ActiveUS20150107871A1Complicated workReduced flexibilityConcentric cablesPower cables with screens/conductive layersEngineeringHigh pressure

Owner:YAZAKI CORP

Electrical wire and method of fabricating the electrical wire

InactiveUS7217884B2Easy to makeSafe and convenientPlastic/resin/waxes insulatorsConcentric cablesElectrical conductorElectric wire

Owner:SOUTHWIRE CO LLC

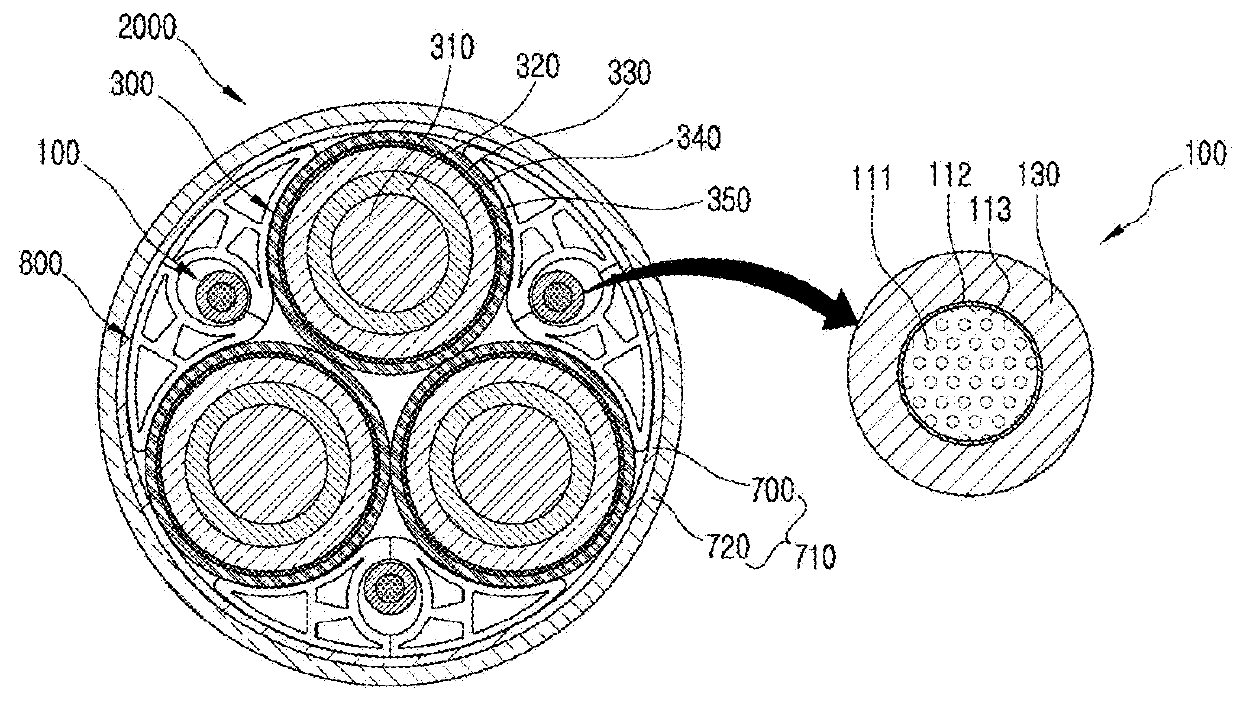

Filler and multicore cable having same

ActiveUS20180268961A1Maintain roundnessConcentric cablesPower cables with screens/conductive layersMulticore cableElectrical conductor

The present invention relates to a filler and a cable having the same and, more particularly, to a filler and a multicore cable comprising a plurality of core portions, which comprises a conductor, and a protective layer that surrounds the core portions, the filler being provided between the core portions and the protective layer of the multicore cable, the filler being characterized by comprising: frame portions comprising a first frame portion and a second frame portion, which are rotated by predetermined angles towards both sides about the center portion thereof and then incised; and a support portion provided between the frame portions so as to connect the frame portions to each other.

Owner:LS CABLE & SYST LTD

Intelligent cable

InactiveCN102610315AReduce investmentQuality assuranceConcentric cablesPower cables with screens/conductive layersPower cableTransmitted power

The invention discloses an intelligent cable. The middle part of the cable is a cable core intertwisted by a power cable, an optical fiber unit, a communication cable and a coaxial radio frequency cable. A belting layer winds outside the cable core, a total shielding layer is arranged outside the belting layer, and the outermost layer squeezes and wraps an outer protective layer. Double metal shielding layers are respectively arranged for the optical fiber unit, the communication cable and the coaxial radio frequency cable. The double metal shielding layers are separated in the middle by using separating covers. The intelligent cable is formed by combining the optical fiber, the communication cable and the coaxial radio frequency cable in a power cable through a simple and accessible method, various signal cables are physically and completely separated during production, so that the cables do not disturb each other in transmission so as to effectively ensure the quality and safety. Meanwhile, the intelligent cable has the functions of transmitting power, communication signals, and wire video signals and the function of optical fiber communication, shares the network infrastructure and greatly reduces the investment on network construction.

Owner:无锡市远登电缆有限公司

Electrical wire and method of fabricating the electrical wire

InactiveUS7145073B2Easy to makeSafe and convenientElectrically conductive connectionsPlastic/resin/waxes insulatorsEngineeringElectric wire

Owner:SOUTHWIRE CO LLC

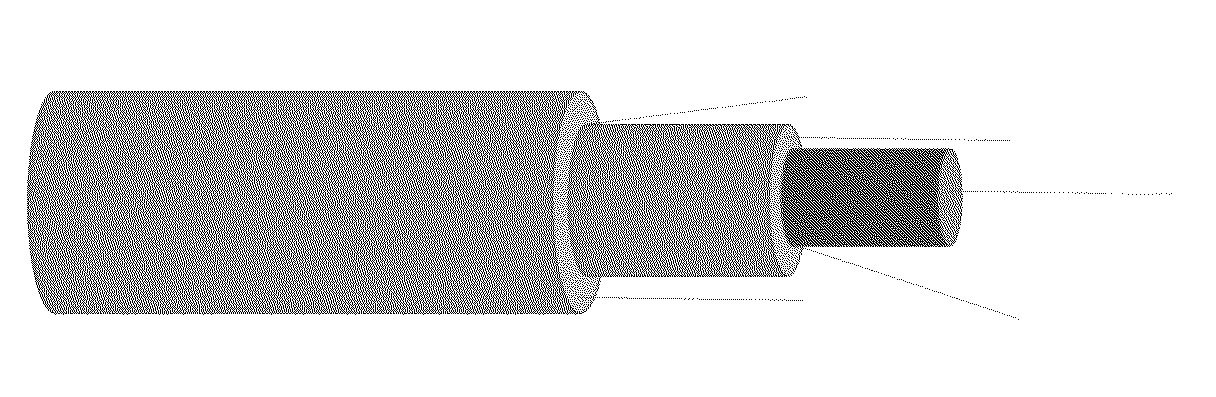

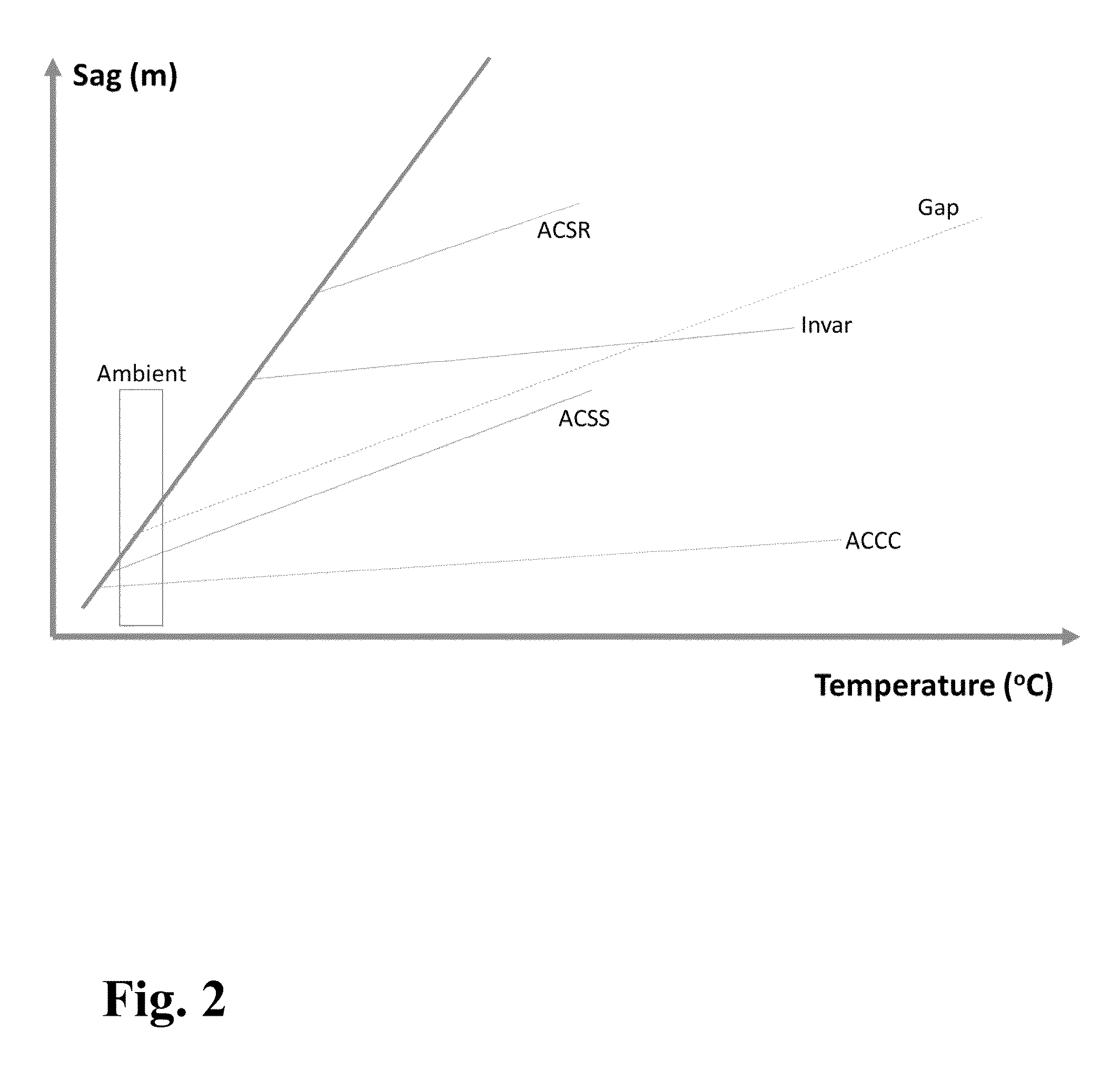

Energy Efficient Conductors With Reduced Thermal Knee Points and The Method of Manufacture Thereof

ActiveUS20160099090A1Reduce pointsIncrease line capacityNon-insulated conductorsConcentric cablesElectric power transmissionPre stress

The present invention relates to electrical conductors for electrical transmission and distribution with pre-stress conditioning of the strength member so that the conductive materials of aluminum, aluminum alloys, copper, copper alloys, or copper micro-alloys are mostly tension free or under compressive stress in the conductor, while the strength member is under tensile stress prior to conductor stringing, resulting in a lower thermal knee point in the conductor.

Owner:TS CONDUCTOR CORP

Electrical wire and method of fabricating the electrical wire

InactiveUS20060207779A1Safe and convenientEasy to makeConcentric cablesInsulated cablesElectrical conductorEngineering

Owner:SOUTHWIRE CO LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com