Patents

Literature

96 results about "Filled cable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

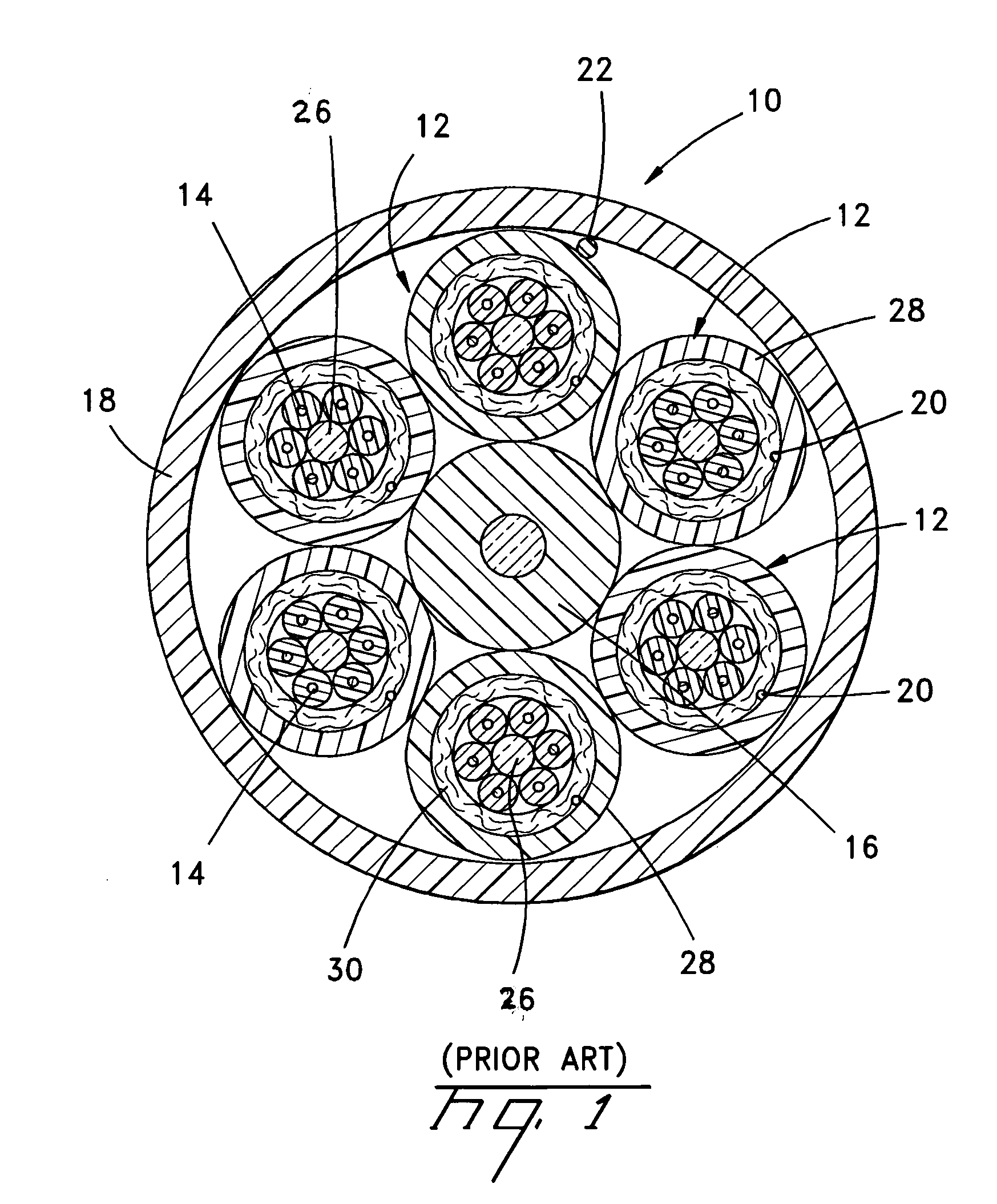

In telecommunication, a filled cable is a cable that has a non-hygroscopic material, usually a gel called icky-pick, inside the jacket or sheath. The nonhygroscopic material fills the spaces between the interior parts of the cable, preventing moisture from entering minor leaks in the sheath and migrating inside the cable.

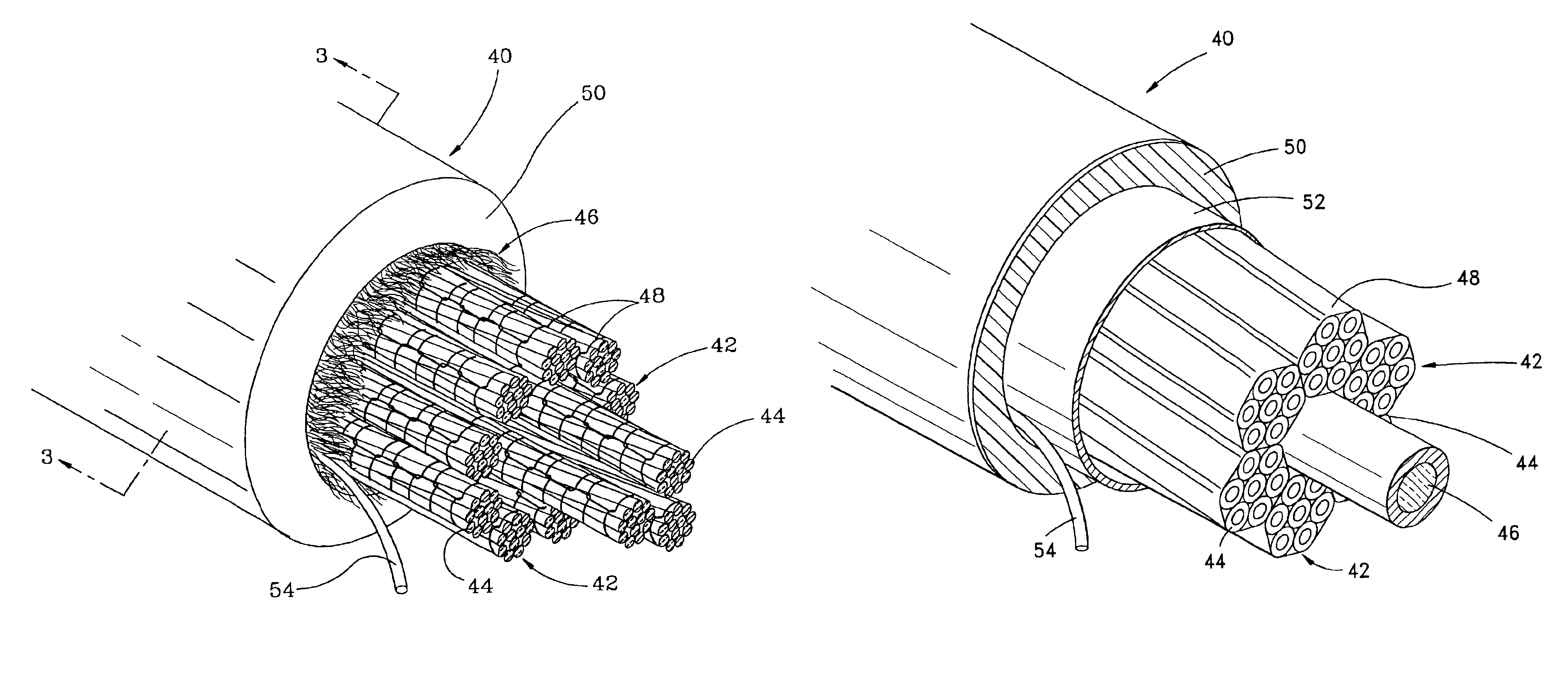

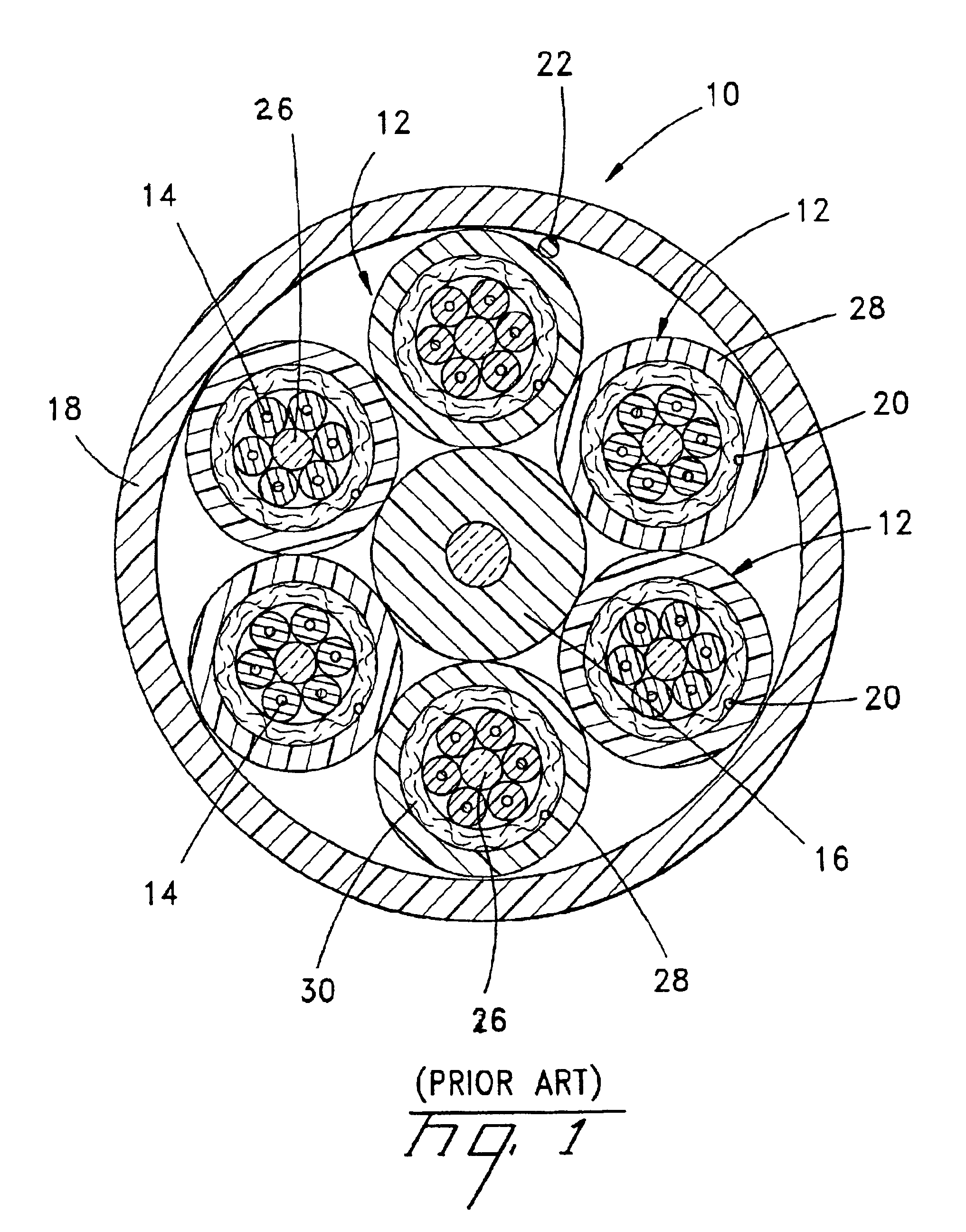

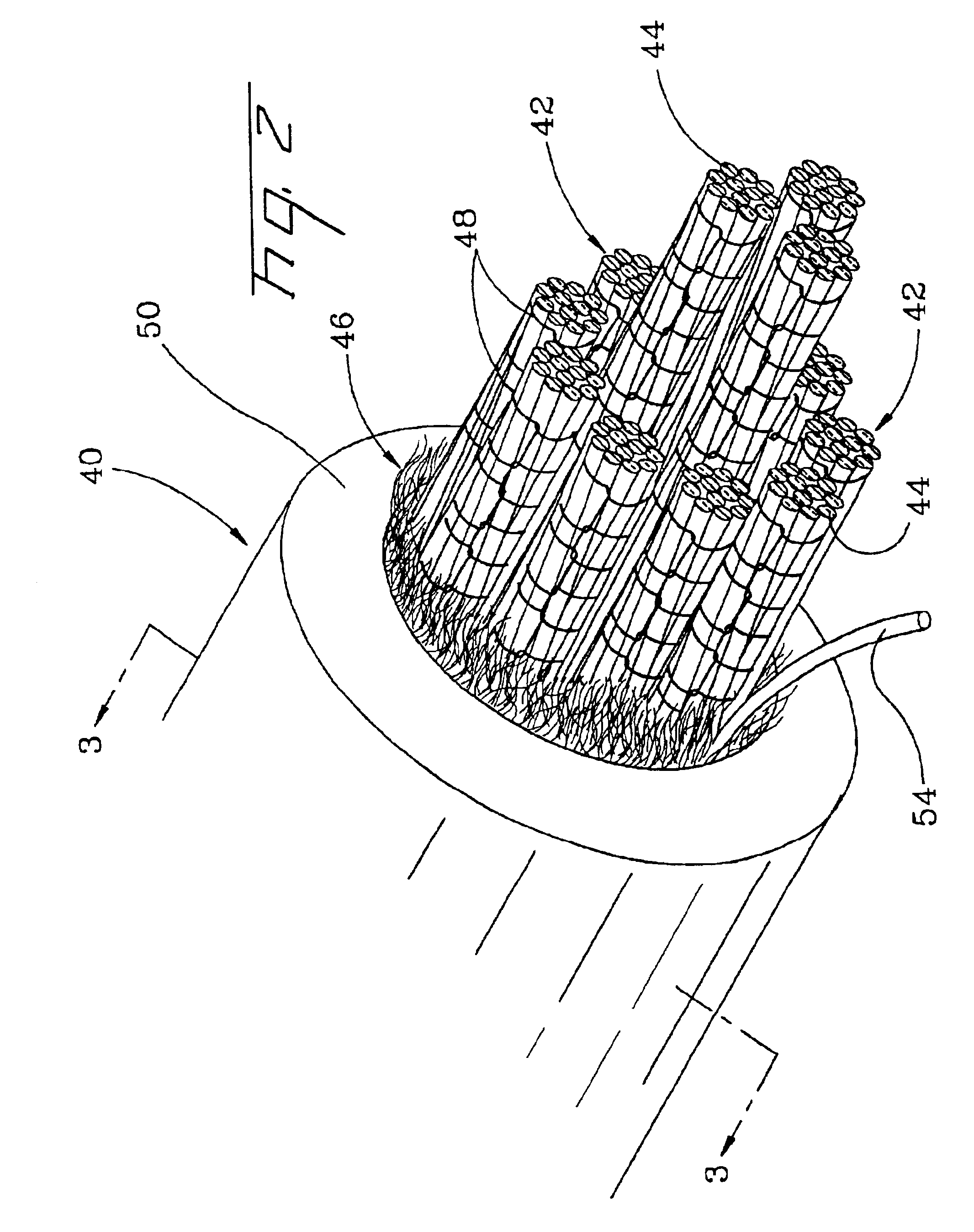

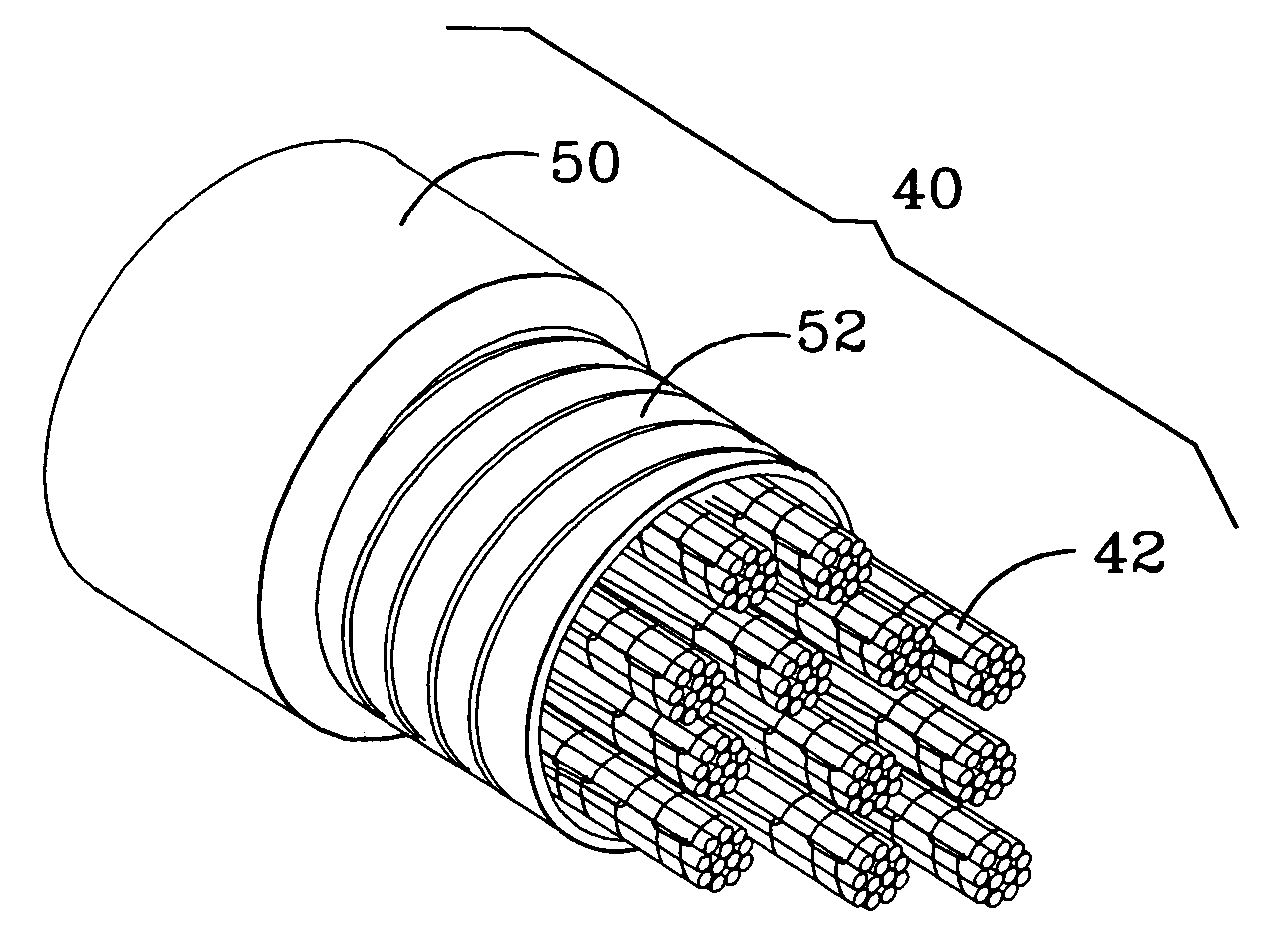

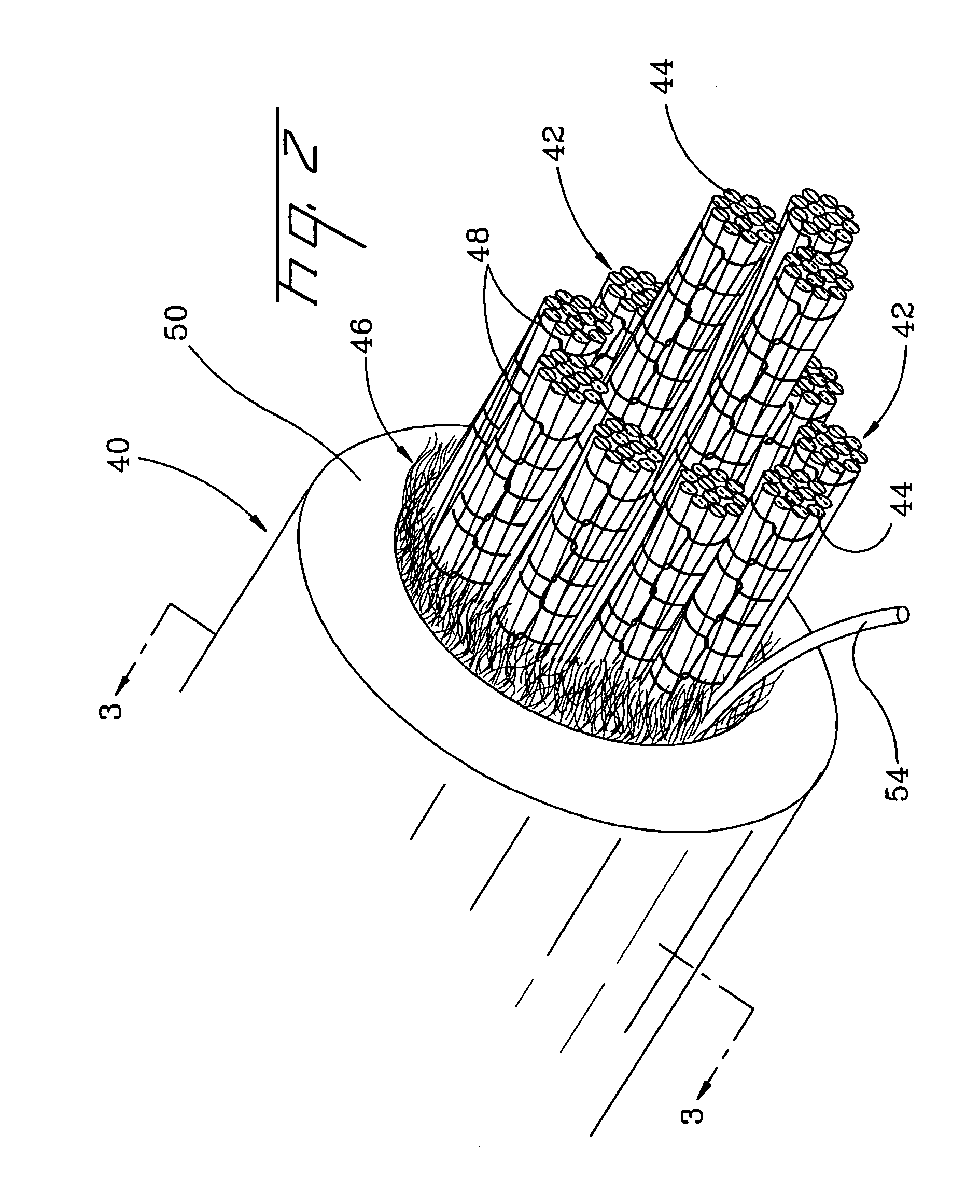

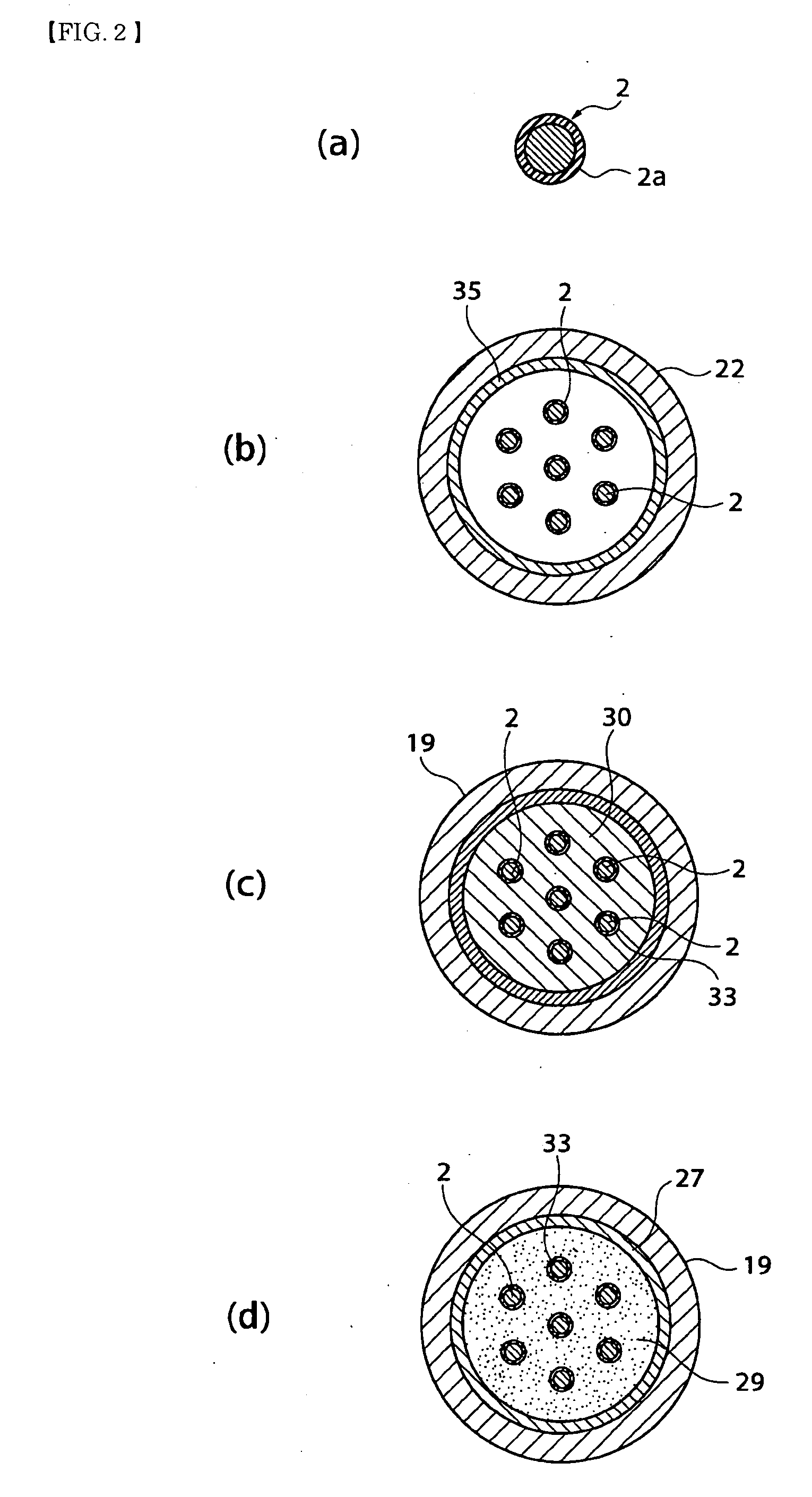

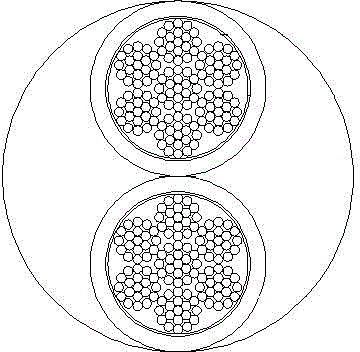

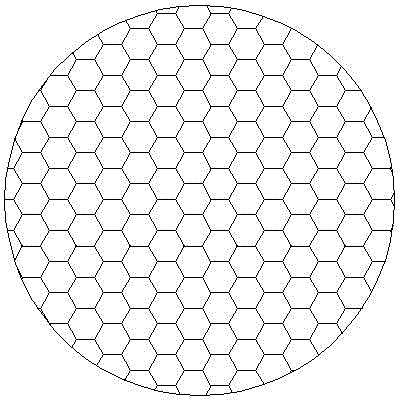

High density fiber optic cable

A fiber optic cable includes at least one at least one bundle having a plurality of non-tight buffered optical fibers and a binder element for maintaining the integrity of the bundle. The binder element may be, for example, a binder thread. The fiber optic cable may exclude a grease or a grease-like composition being in contact with the at least one bundle for filling interstices of the cable thereby blocking water from flowing through the cable. The fiber optic cable also includes a separation layer for inhibiting adhesion between the bundles of optical fibers and the cable jacket. In another embodiment, a fiber optic cable includes a plurality of optical fibers and a binder element forming at least one bundle. The at least one bundle is surrounded by an armor layer and the fiber optic cable excludes a cable jacket within the armor layer.

Owner:CORNING OPTICAL COMM LLC

High density fiber optic cable

A fiber optic cable includes at least one at least one bundle having a plurality of non-tight buffered optical fibers and a binder element for maintaining the integrity of the bundle. The binder element may be, for example, a binder thread. The fiber optic cable may exclude a grease or a grease-like composition being in contact with the at least one bundle for filling interstices of the cable thereby blocking water from flowing through the cable. The fiber optic cable also includes a separation layer for inhibiting adhesion between the bundles of optical fibers and the cable jacket. In another embodiment, a fiber optic cable includes a plurality of optical fibers and a binder element forming at least one bundle. The at least one bundle is surrounded by an armor layer and the fiber optic cable excludes a cable jacket within the armor layer.

Owner:CORNING OPTICAL COMM LLC

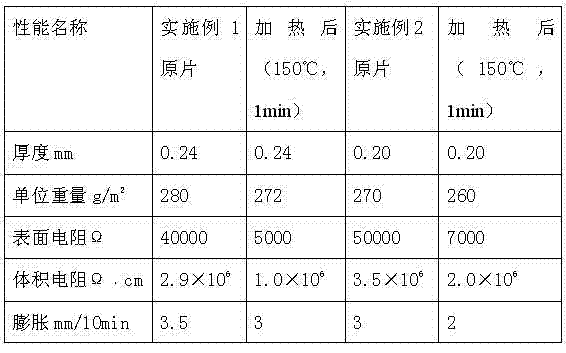

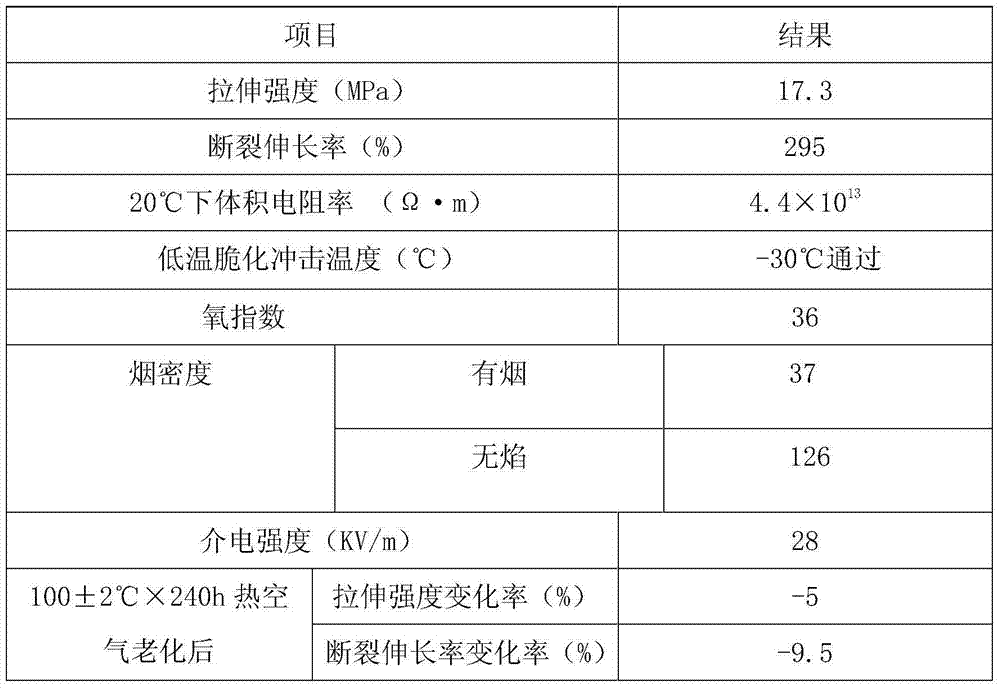

Preparation method of deep sea cable filling strip

ActiveCN102286162AExtended service lifeSimple production processSubmarine cablesInsulated conductorsElectrical conductorFilled cable

A preparation method of a deep sea cable filling strip relates to a preparation method of a conductor filling strip. The preparation method comprises the following process steps: mixing rubber, a vulcanizing agent, a vulcanization accelerator, an antiager, a plasticizer, a reinforcing filler and a tackifier in parts by weight; and then calendering, slitting and packaging to obtain the finished product. The method has a simple production technology, stable technical properties and high practicability; the product is used in the cable and the cable core of the optical cable, the product has high strength, uniform thickness and a good saturated water absorption effect and has the functions of shielding and buffering the electric field; and the product also has viscoelasticity, thus the filling cable core is stronger and the service life of the optical cable can be prolonged.

Owner:沈阳天荣电缆材料有限公司

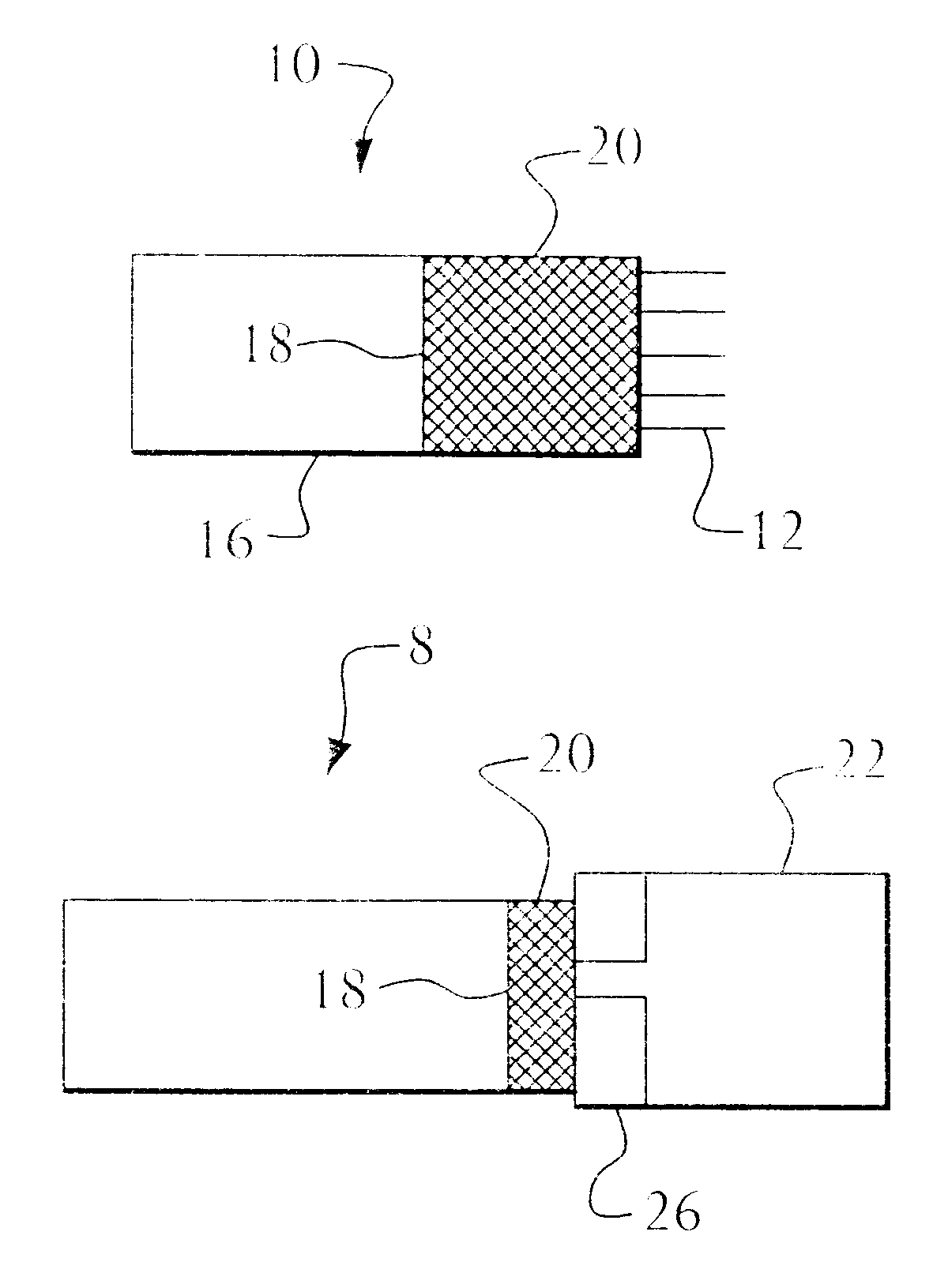

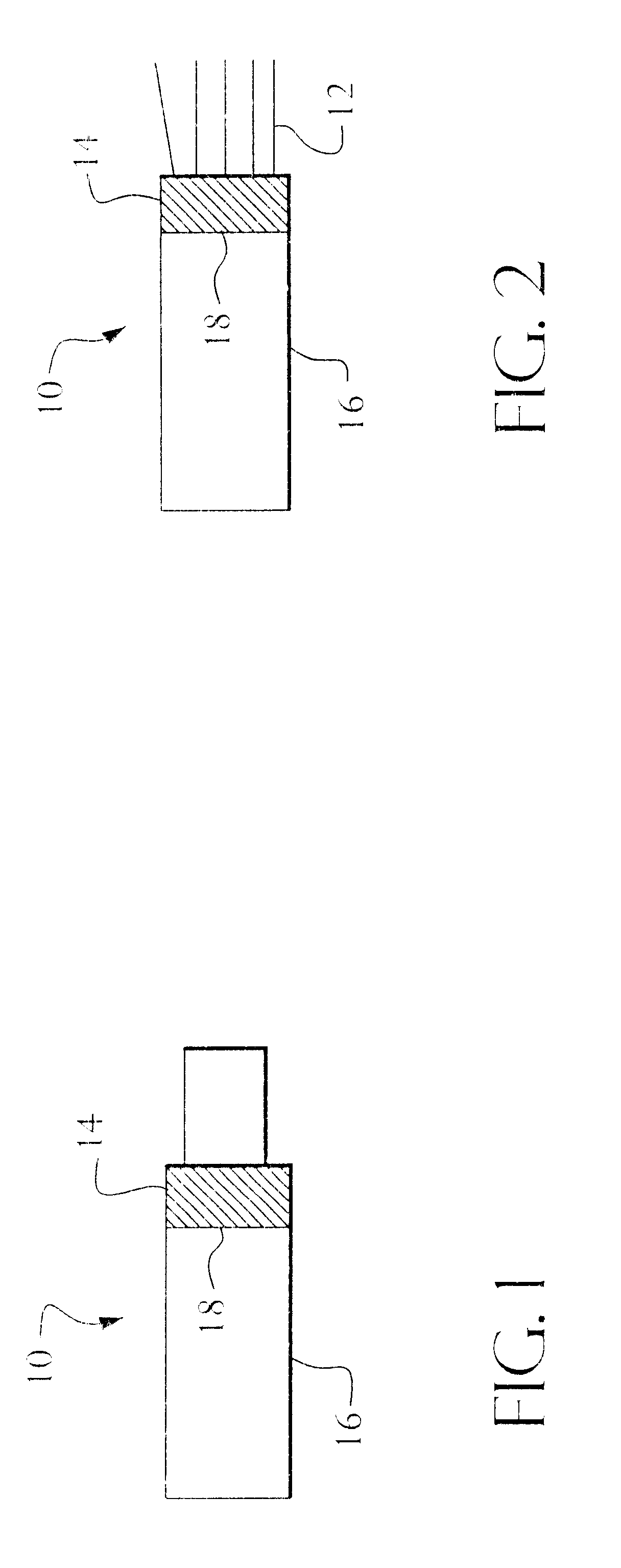

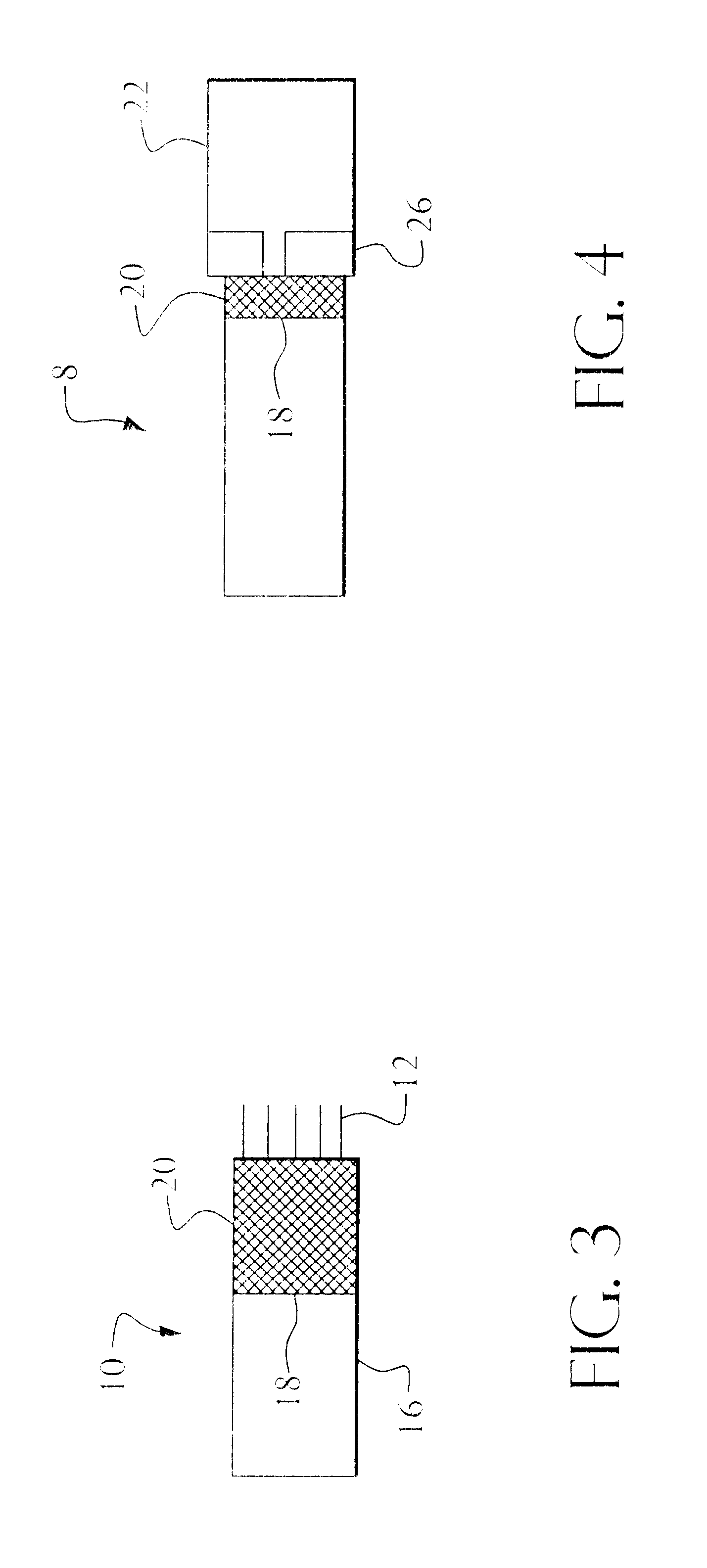

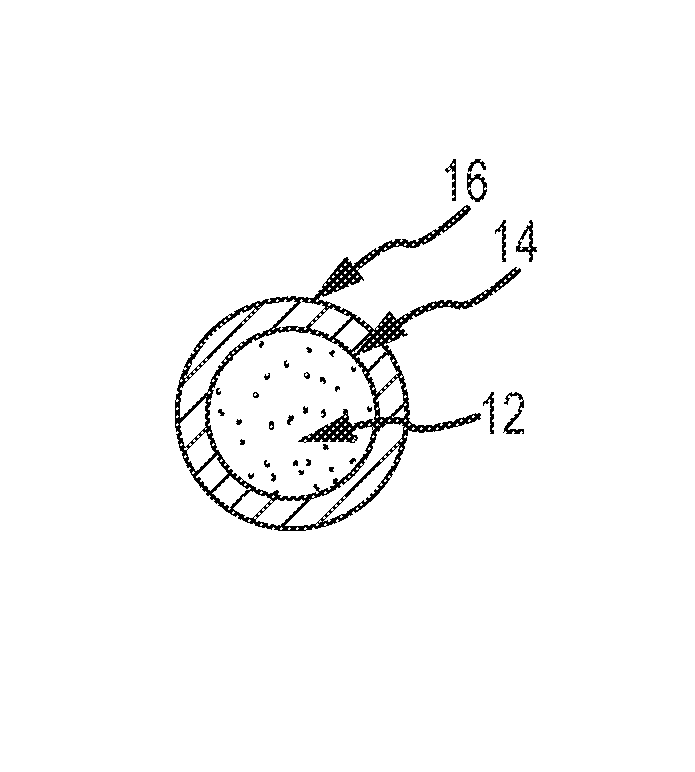

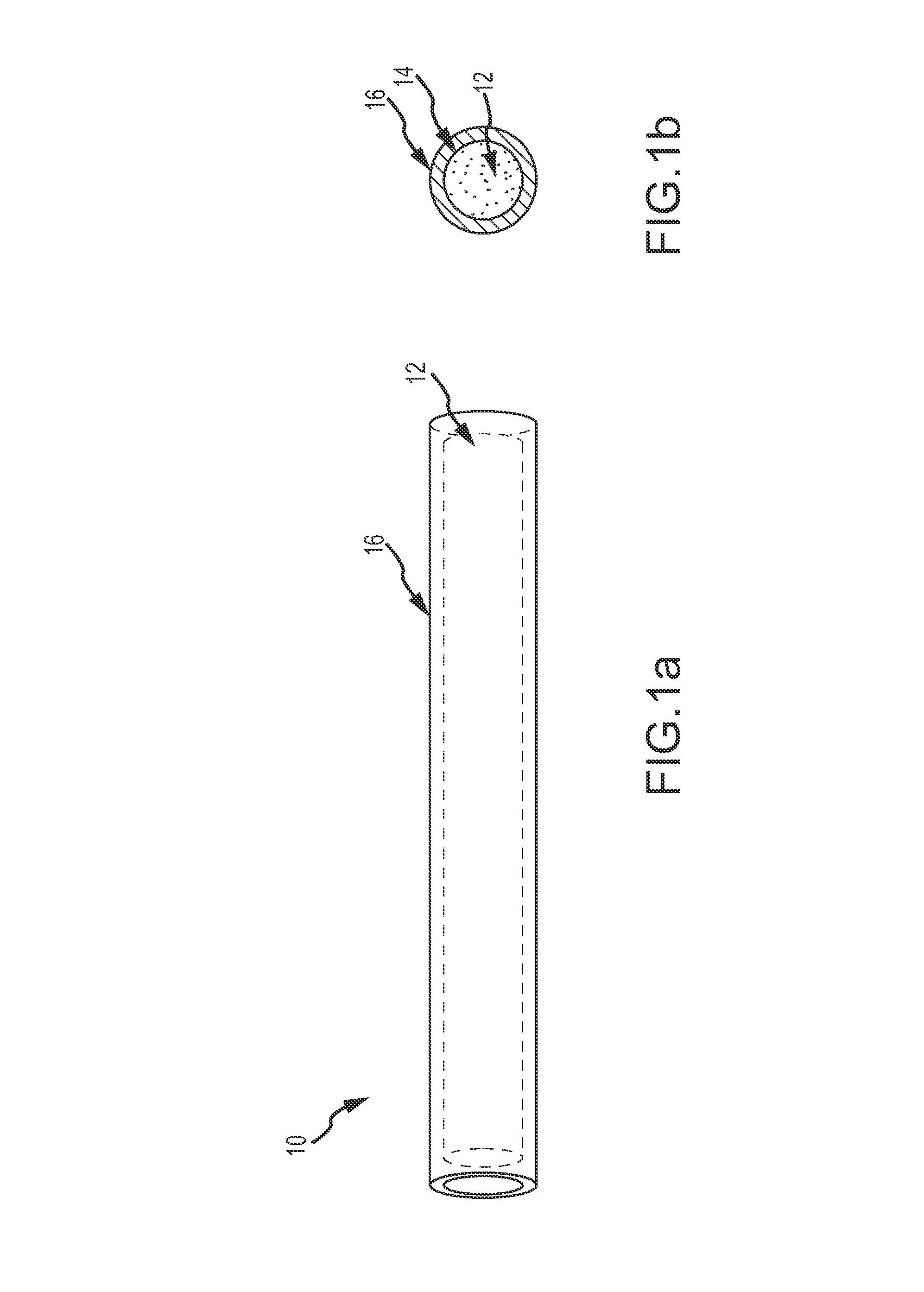

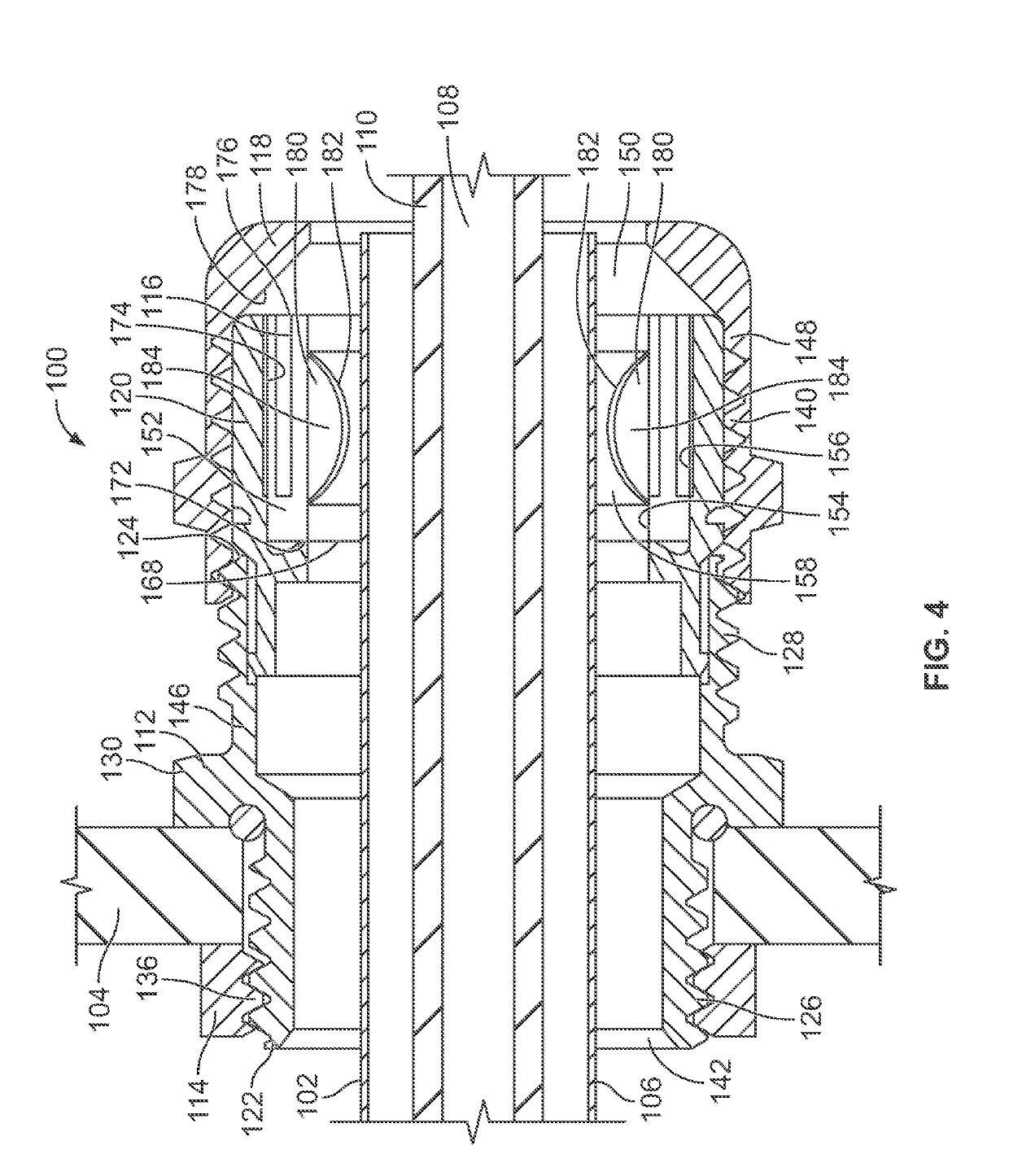

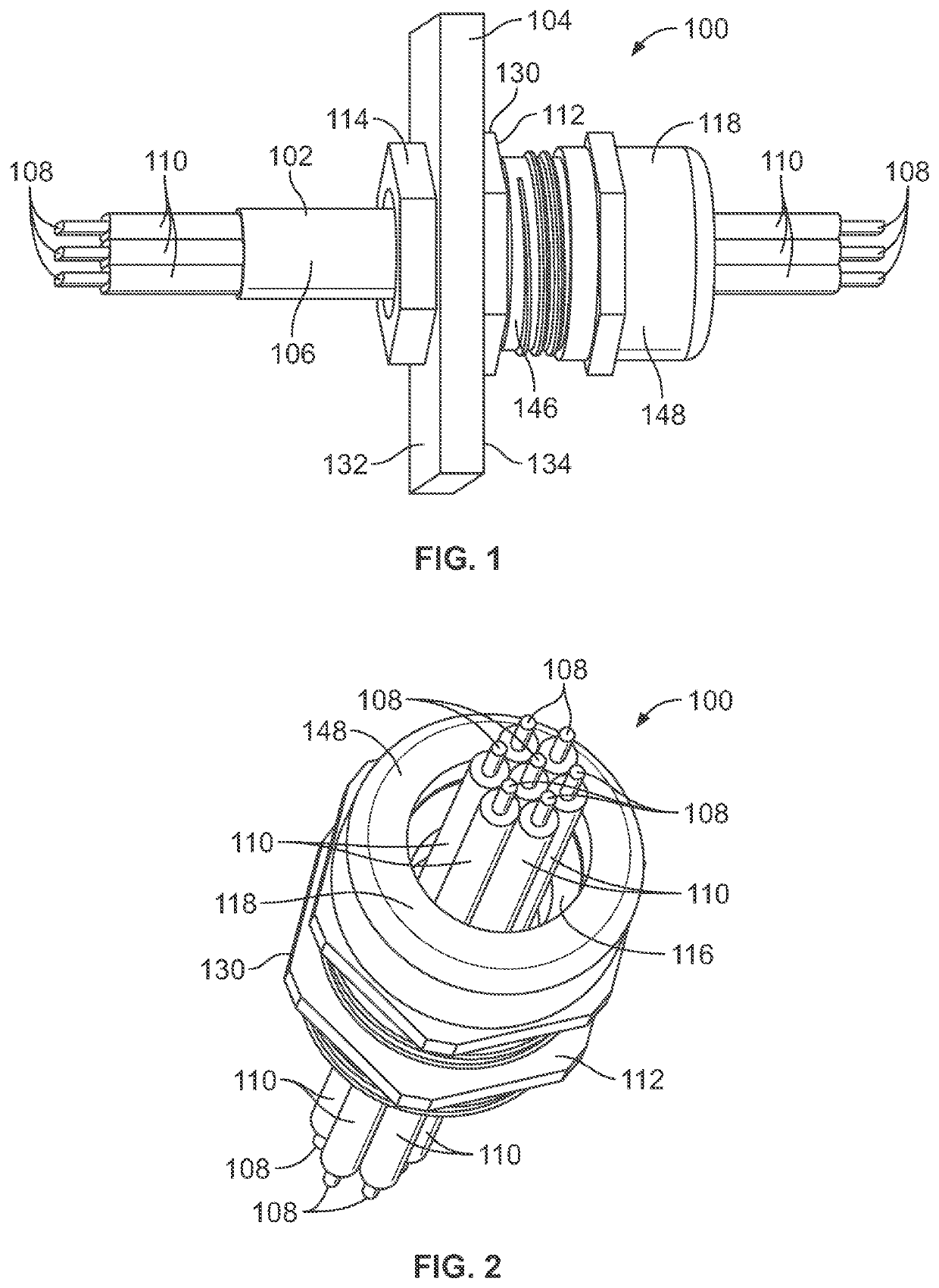

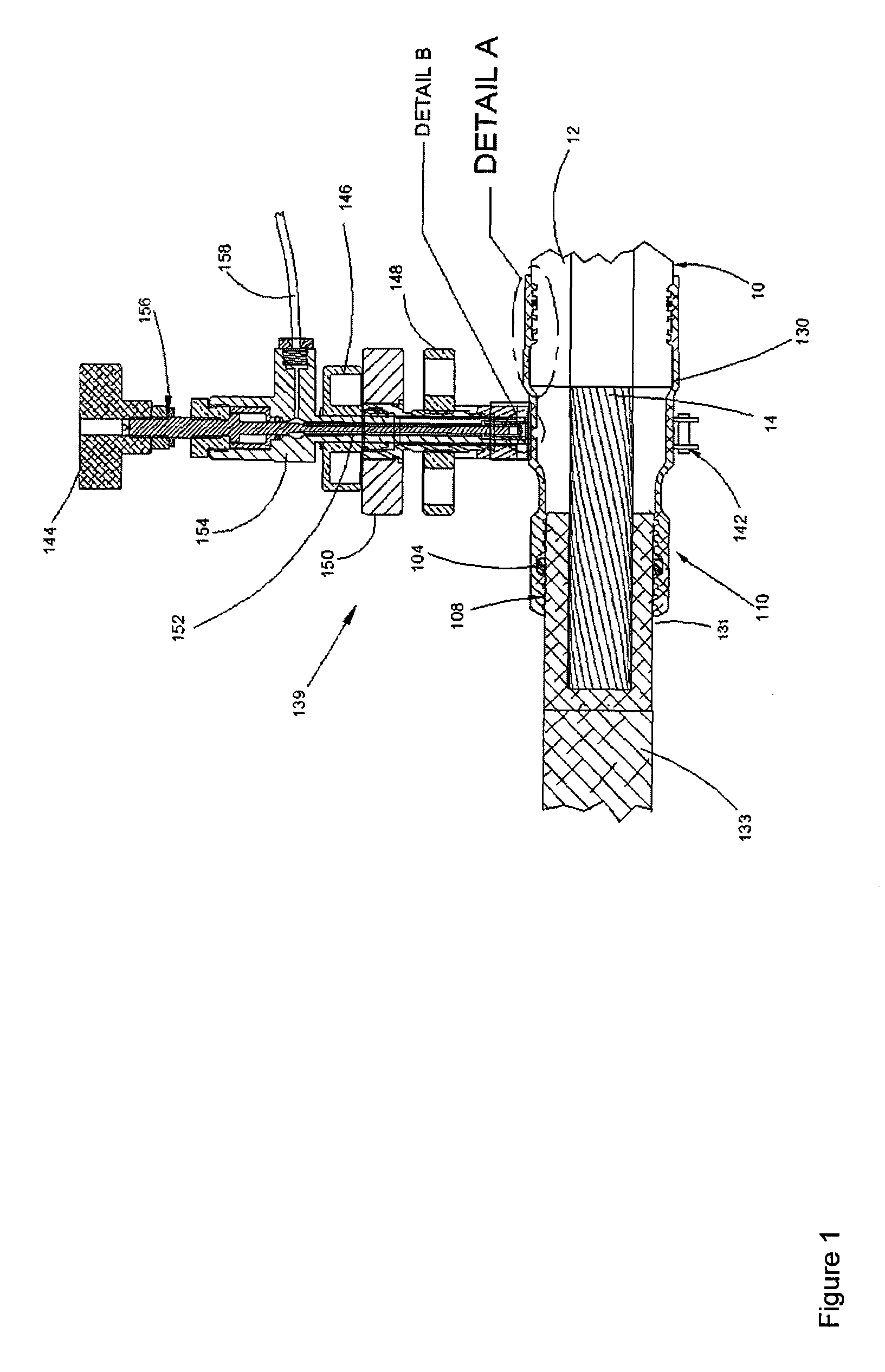

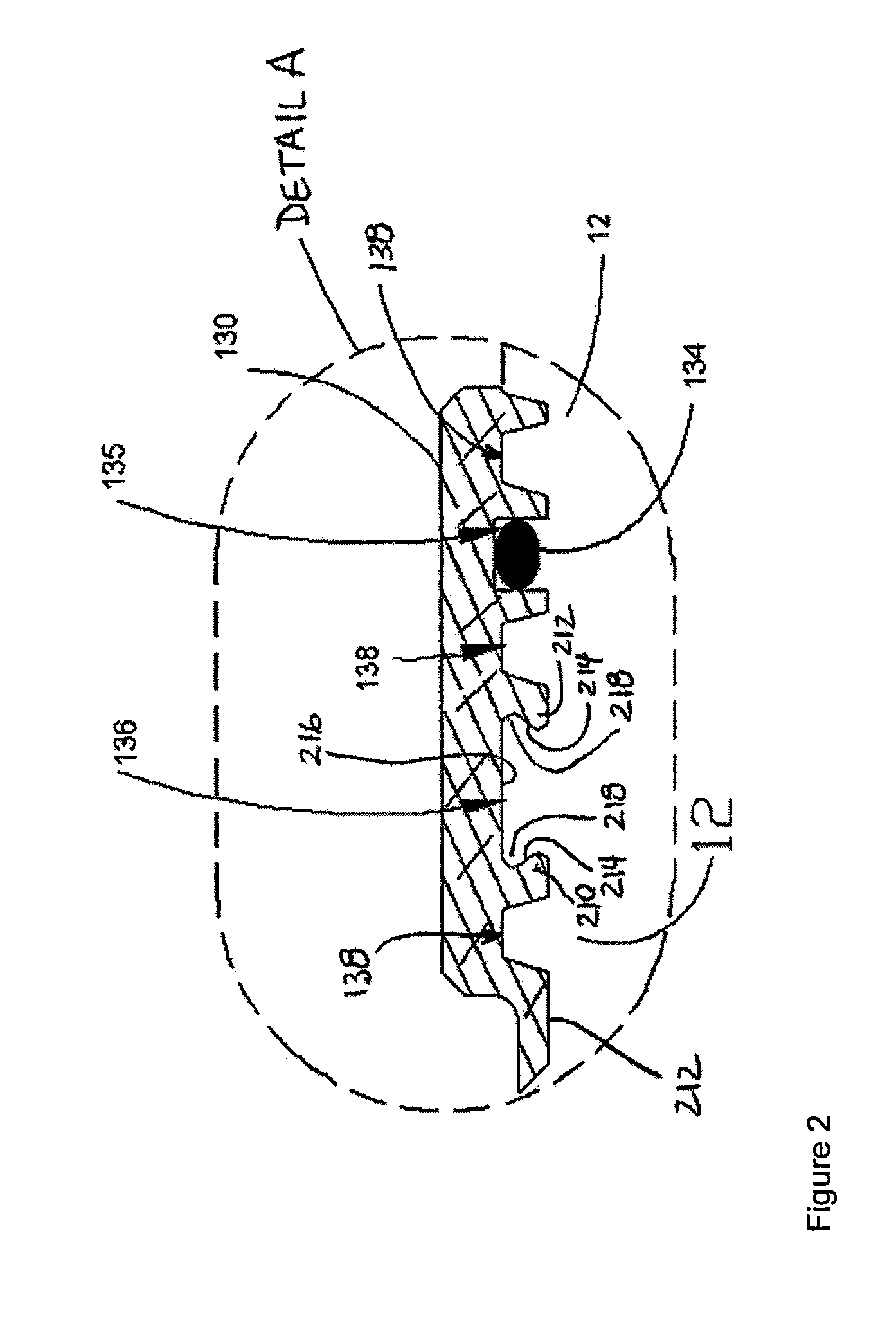

Shielded cable and connector assembly

InactiveUS6302740B1Line/current collector detailsRelieving strain on wire connectionShielded cableFilled cable

The present invention relates to a method of fabricating a shielded cable-connector assemblage (8) and to a shielded cable-connector assemblage (8) fabricated in accordance with the method. The assemblage (8) comprises at least one cable (10) which includes, among other things, conductors (12), a braided metal shield (14), and an outer mantle (16), and further comprises a connector (22). The method comprises the steps of folding a part of the braided metal shield (14) back over the outer mantle surface (16) of the cable; mounting a shielding element (20) so as to cover the whole of the junction between the backwardly folded braided metal shield (14) and the conductors (12) and to be in electrical contact with the braided metal shield (14); fitting a connector (22) to each cable (10) to form a cable-connector assembly; fixedly mounting each cable-connector assembly (10, 22) in a molding device; and molding a strain relieving element (28) such as to fill the space between the cable (10) and the connector (22) and to fixate said cable and connector in relation to one another.

Owner:INTERCONNECT

Insulation compositions containing metallocene polymers

ActiveUS20050133248A1Improve performanceBiocideFatty substance preservation using additivesFilled cableAntioxidant

Novel additive systems for metallocene based filled cable insulation are disclosed. These systems provide excellent protection against thermal degradation, better cure state and reduced dissipation factor after prolonged heat exposure. The additives may contain one or more hindered amine light stabilizers and amine antioxidants.

Owner:GENERAL CABLE TECH CORP

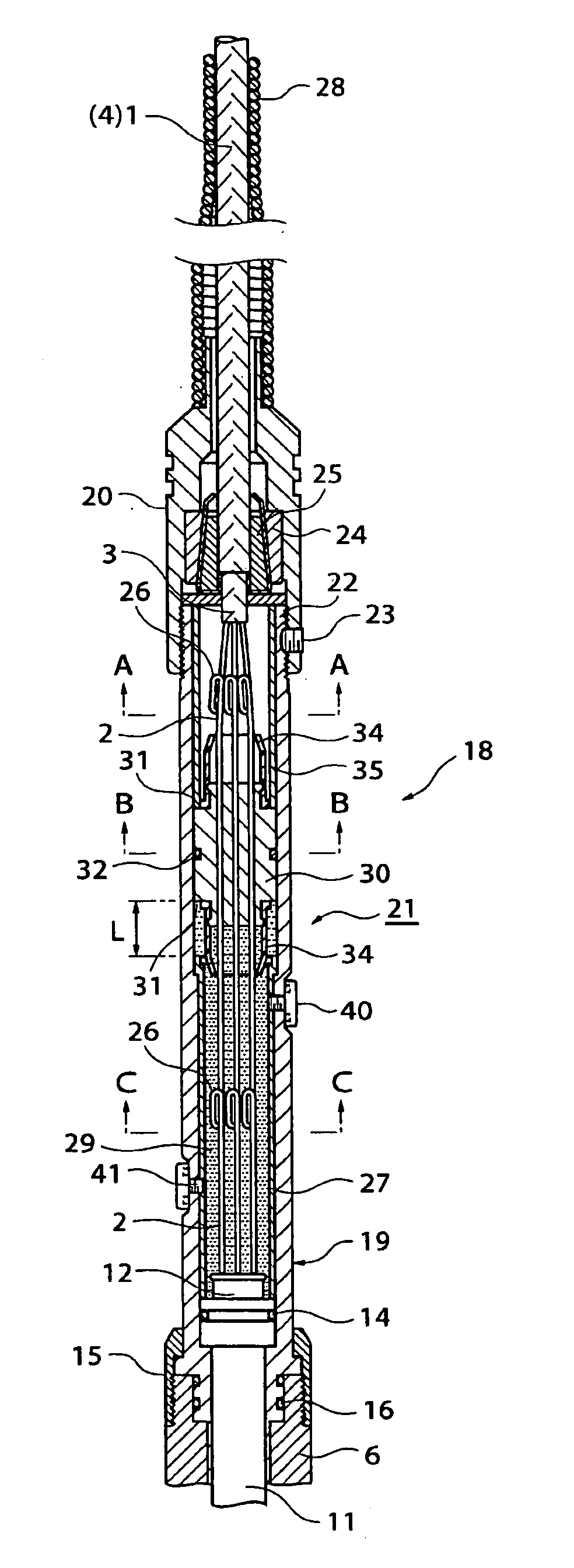

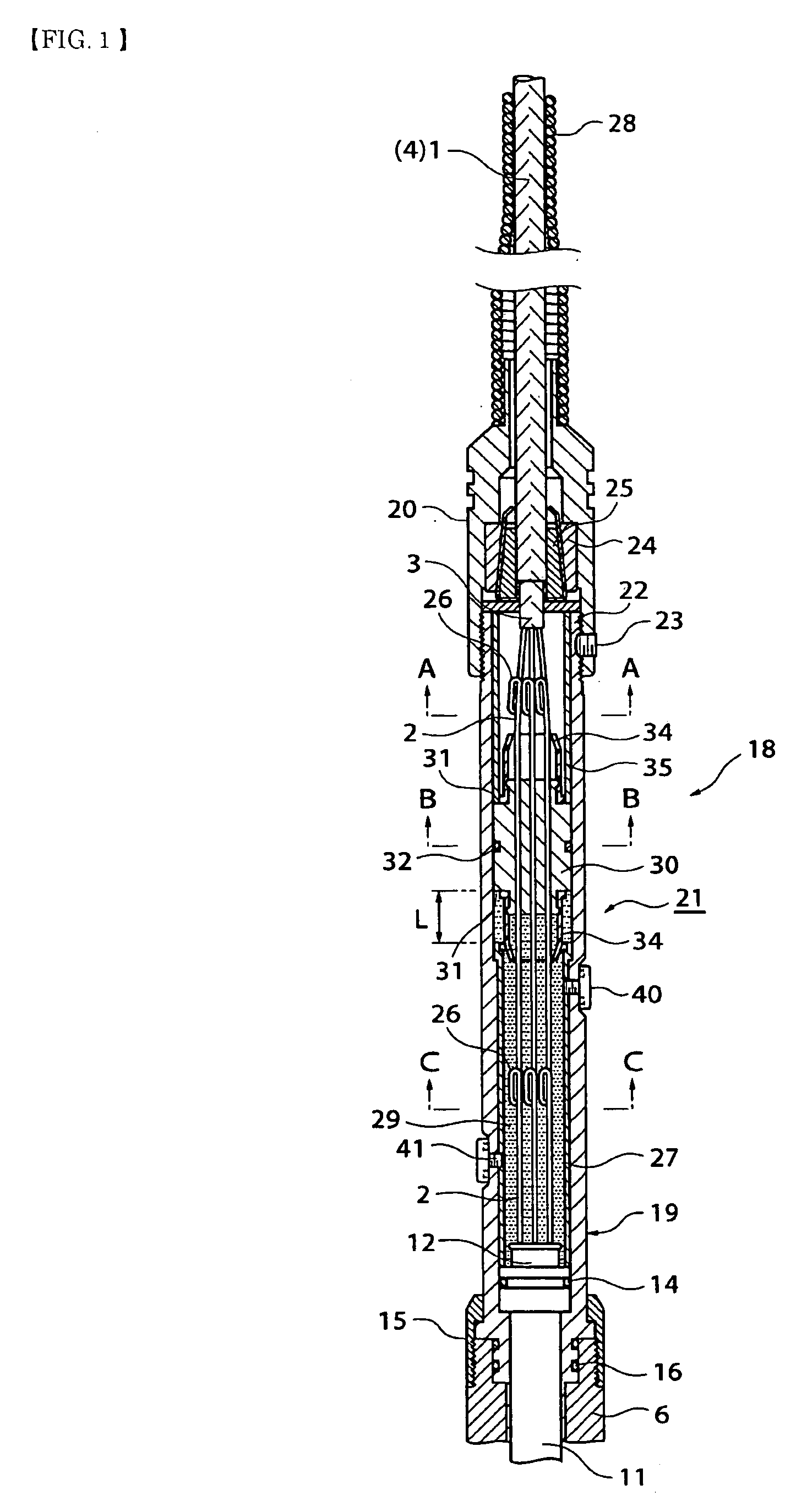

Structure for a cable connection head

InactiveUS20050274514A1Low viscosityRule out the possibilitySurveyDrilling rodsFilled cableContinuous use

[PROBLEM] To fill a cable connection head with an insulating oil and provide a movable lid member of the oil to ensure a long-term insulating property in the cable connection head and enable long-term continuous use of a measuring device. [MEANS FOR SOLUTION] A cable connection head 18 having a head body 21 comprised of a bottom head body 19 and a top head body 20 connected to a measuring device body 6, having a well logging cable 1 passed through the top head body 30, and having core conductors of sheathed cables 2 connected to a connector 11 fit into the bottom head body 19, wherein the bottom head body 19 is filled with a low viscosity insulating oil 29 with a specific gravity heavier than the borehole fluid, outflow of the low viscosity insulating oil 29 is prevented, and a movable sealing member 30 preventing entry of borehole fluid is provided movably inside the bottom head body 19.

Owner:JAPAN PETROLEUM EXPLORATION CO LTD

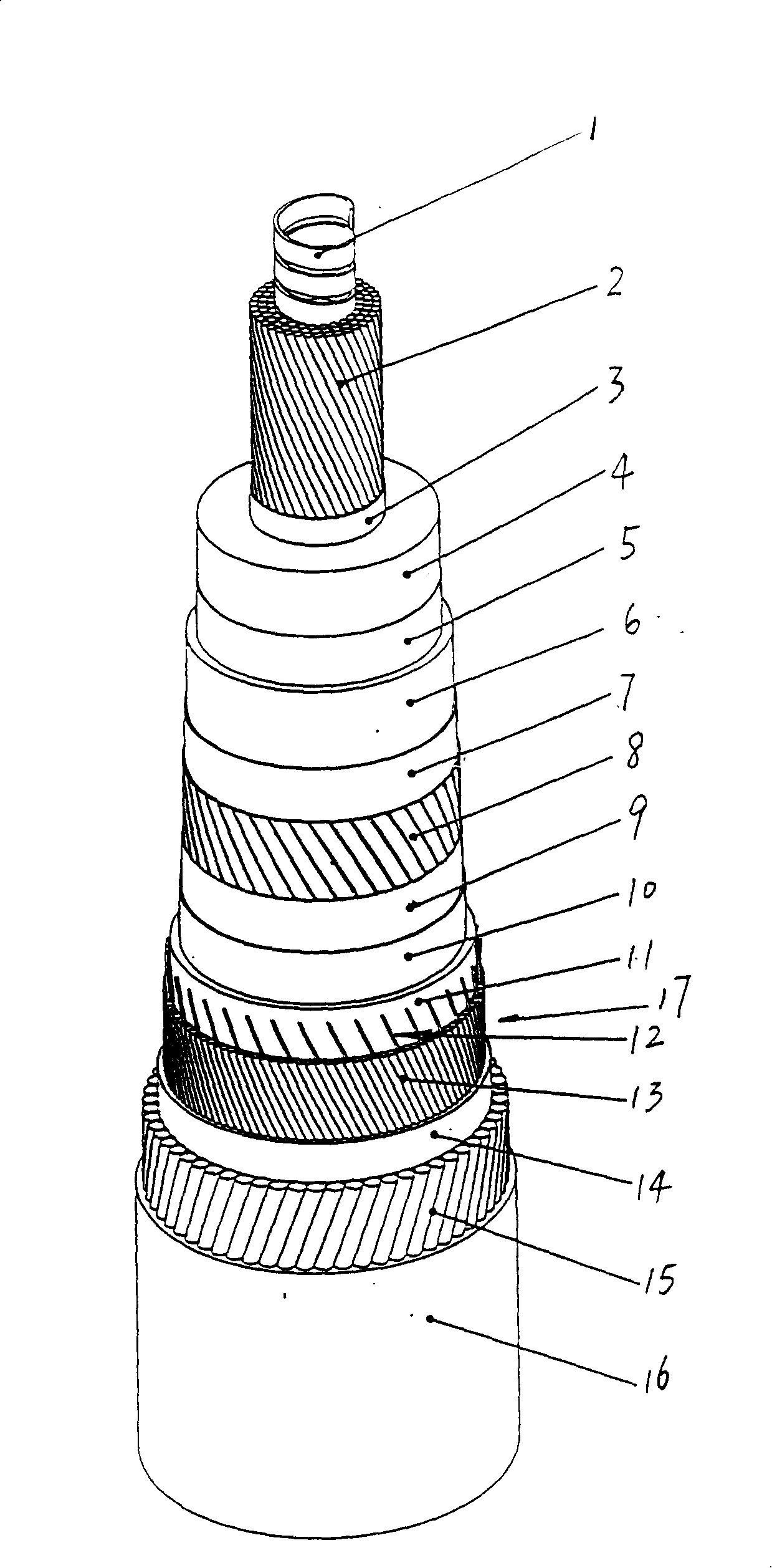

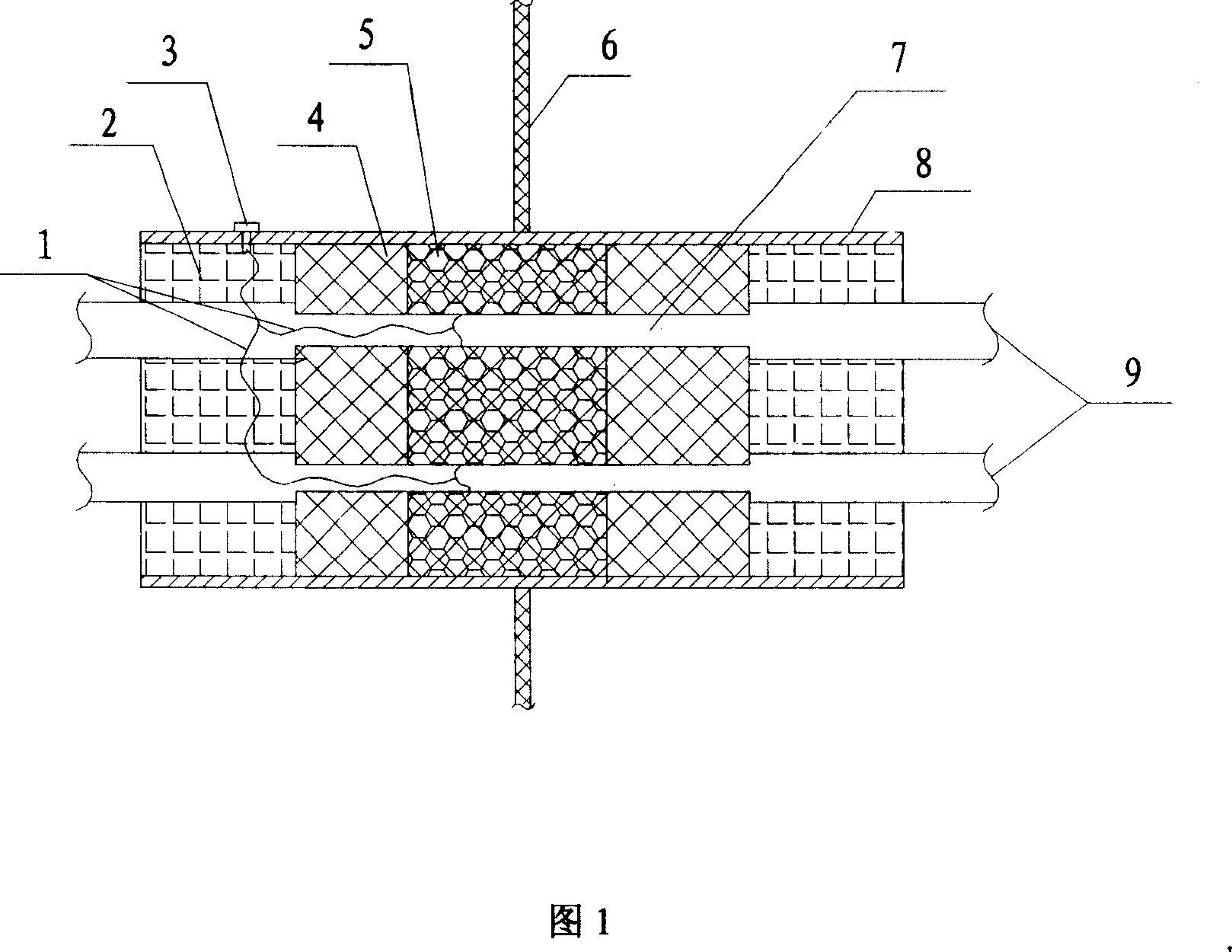

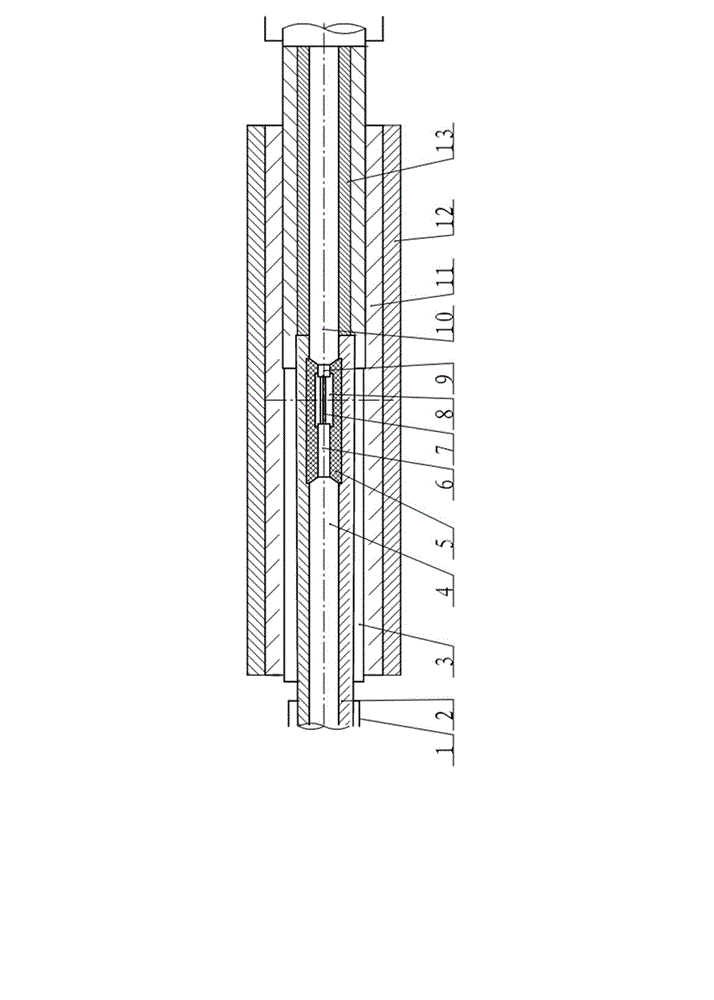

Optical fibre composite electric power seabed oil-filled cable

InactiveCN101211680ASafe and reliable protection performanceIncrease ampacityCommunication cablesSubmarine cablesOcean bottomFilled cable

The invention discloses an optical fiber composite power seabed oil-filled cable, which is characterized in that a light unit layer is arranged in a defending layer. The light unit layer is twisted by an optical fiber and polyethylene filled bar at interval. A metal protecting layer comprises a lead protecting layer, wherein a return feeder layer is arranged outside the lead protecting layer. The return feeder layer is assembled by a flat copper line. A lining layer is arranged between the lead protecting layer and the return feeder layer. The return feeder layer is arranged in the metal protecting layer so as to improve the short circuit current of the metal protecting layer and help to improve the current carrying amount of the cable at the same time. The invention has the advantages of higher electrical performance and sufficient mechanical intensity by combining the seabed optical fiber cable and seabed power cable.

Owner:上海电缆厂集团有限公司

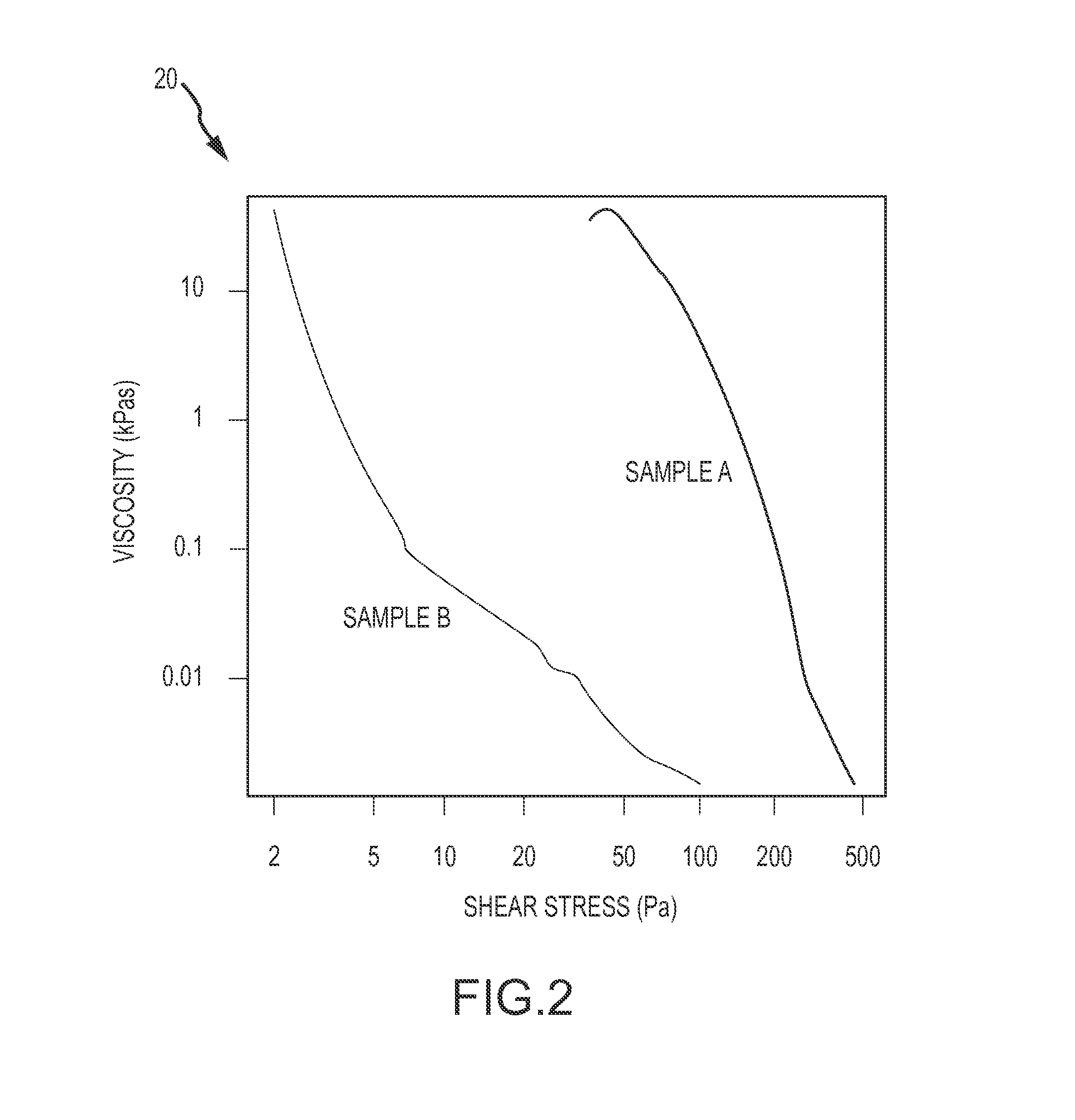

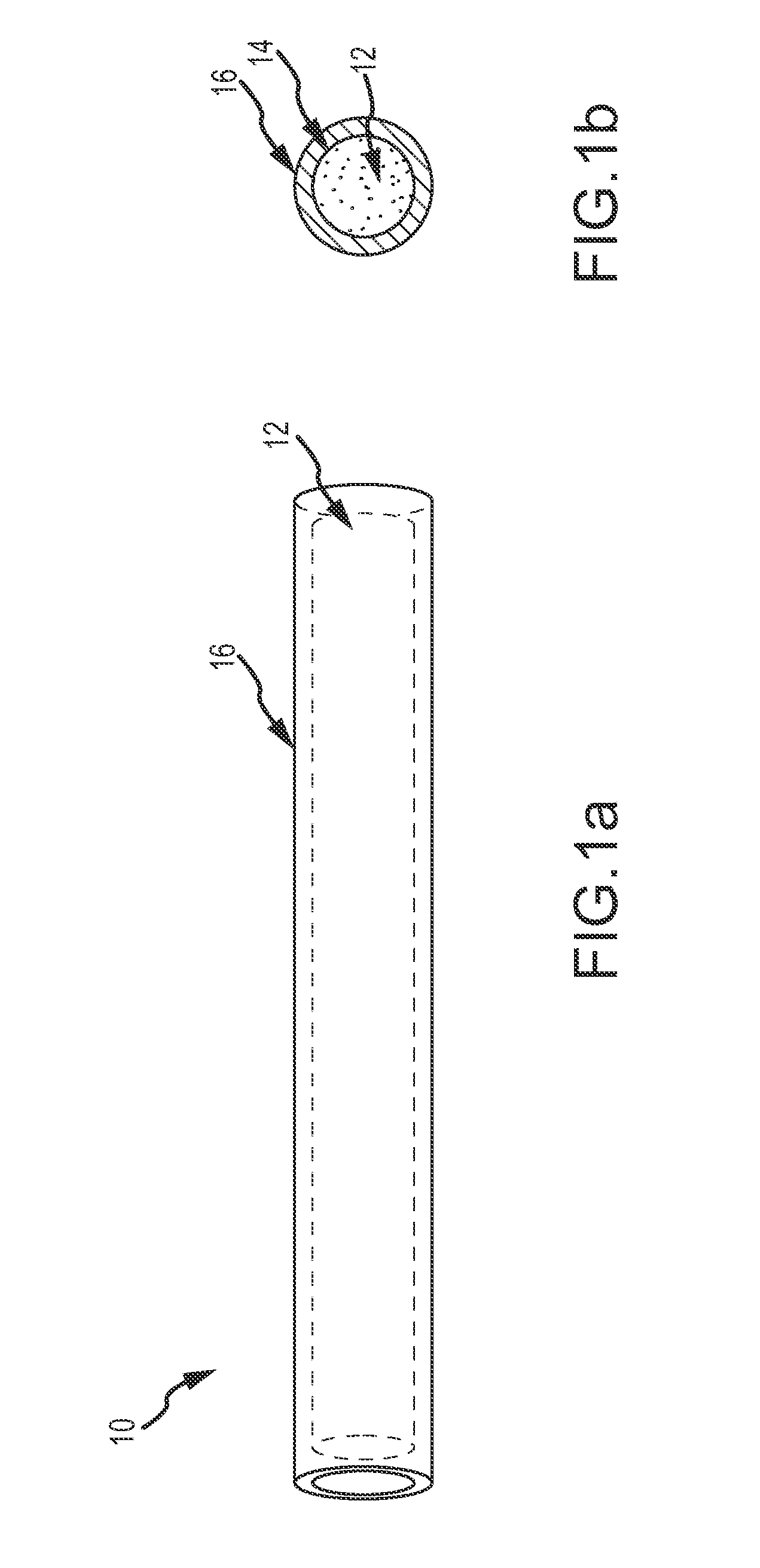

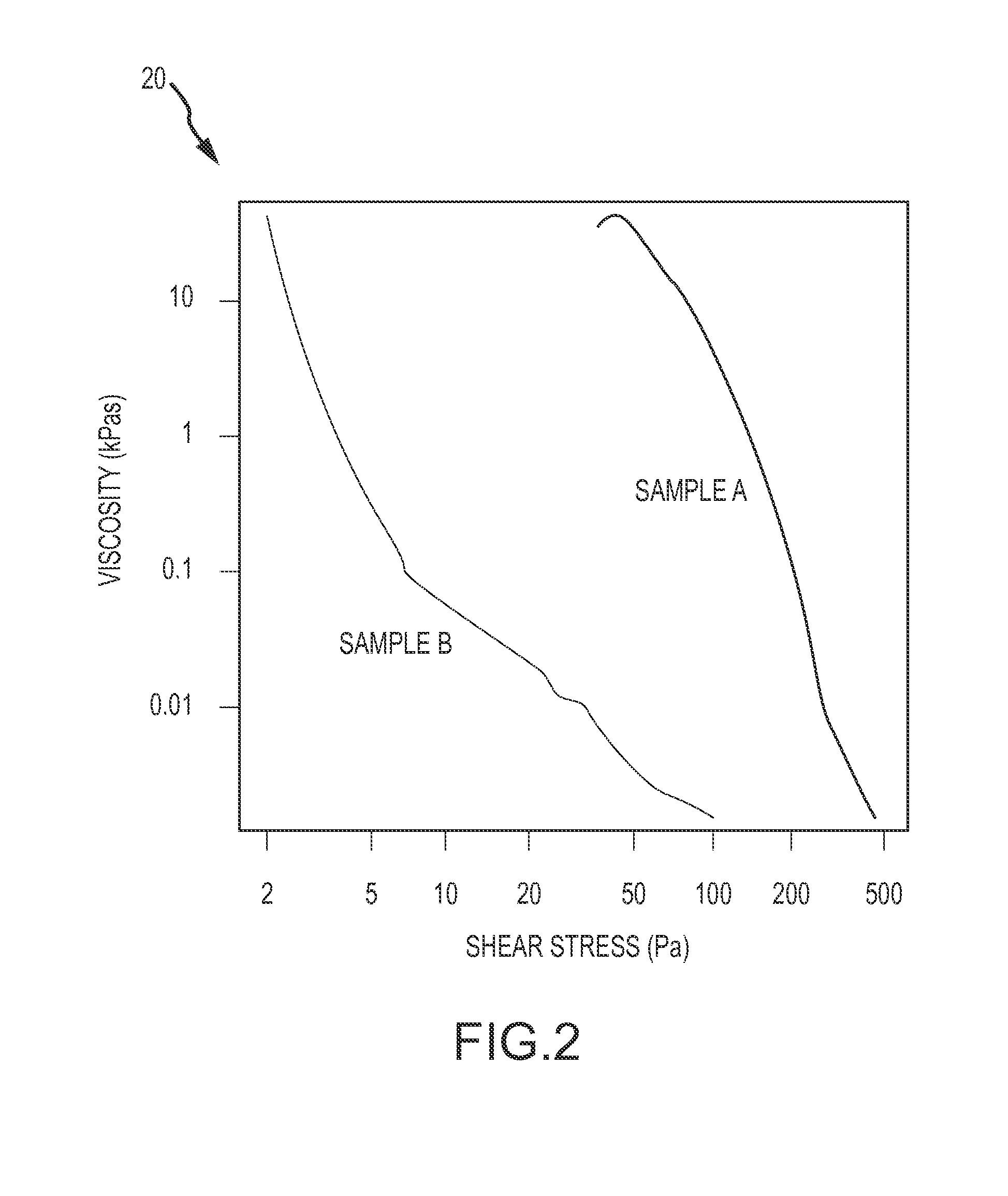

Non-newtonian fluid (NNF) filled cable and method

A composite cable and method provides for control of the cable, and particularly its vibration modes, in response to a wide range of resonant and non-resonant energy input. The cable comprises a non-Newtonian fluid (NNF) in a cavity of a flexible tube. The NNF is characterized by viscosity that varies with shear stress. A load applies shear stress to the NNF changing its viscosity to dampen motion of the cable. The cable may comprise inner and outer tubes that are separated by a NNF. The inner tube may be filled with the same or different NNF, a Newtonian fluid or void. A magnetic field magnetic field may be applied to further control the viscosity of the NNF. The magnetic field may be controlled in response to a sensed condition of the cable indicative of shear stress in the NNF to provide either positive or negative feedback.

Owner:RAYTHEON CO

Lead-free insulation compositions containing metallocene polymers

ActiveUS20070100032A1Improve performanceNon-fibrous pulp additionPaper/cardboardFilled cableAntioxidant

Novel additive systems for lead-free filled cable insulation are disclosed. These systems provide improved electrical and mechanical properties. The base polymer may be metallocene based, non metallocene based or combinations thereof. The additives may contain one or more hindered amine light stabilizers, mercapto compounds, and optionally, amine antioxidants.

Owner:GENERAL CABLE TECH CORP

Cable penetrating technology for electromagnetic shielding cabin

InactiveCN101031196ASimple construction methodPractical construction methodMagnetic/electric field screeningCircuit arrangements on insulating boardsFilled cableEngineering

The invention features the following: using metallic filament ball to fill the gap between cables or between cable and bulkhead, and filling the conducting daub and sealant at both side of the metallic filament ball; and further, the cable, conducting daub, sealant and metallic filament are loaded together into a cable pipe, and the cable pipe passes through the bulkhead and makes a sealed connection with the bulkhead.

Owner:JIANGNAN SHIPYARD GRP CO LTD

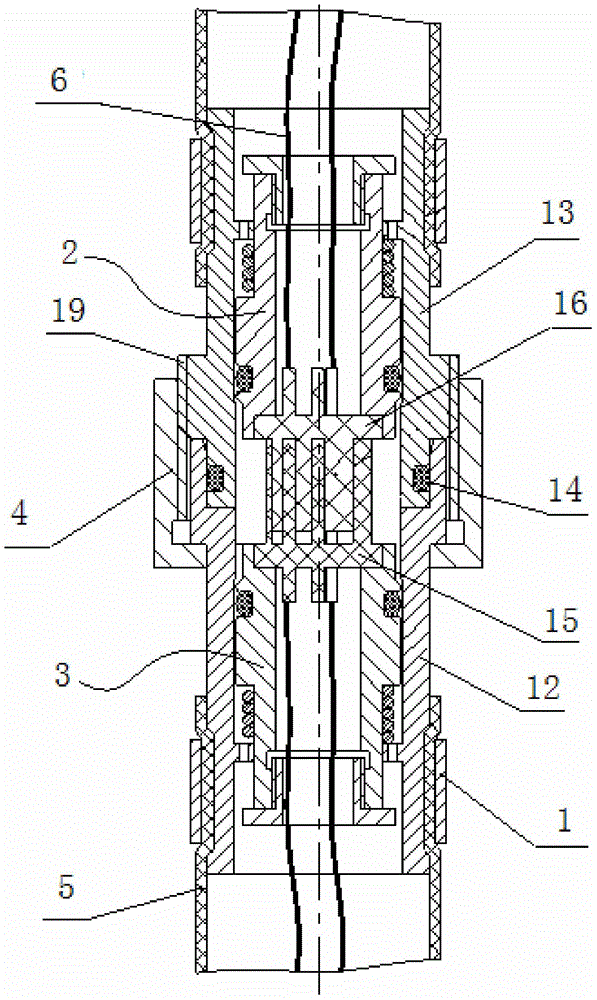

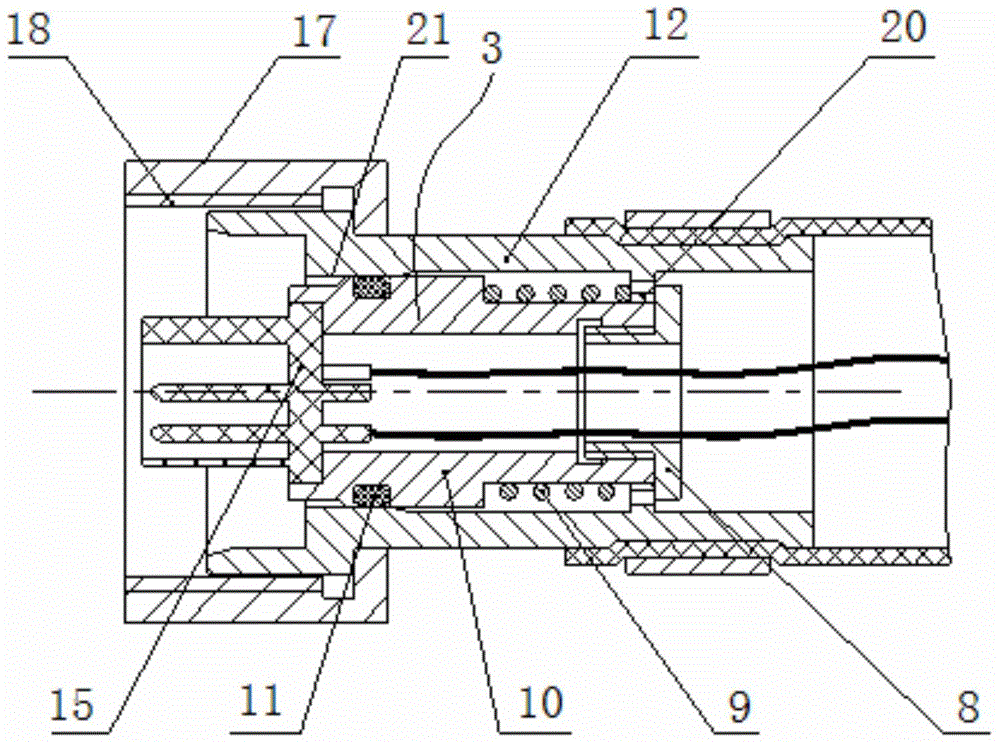

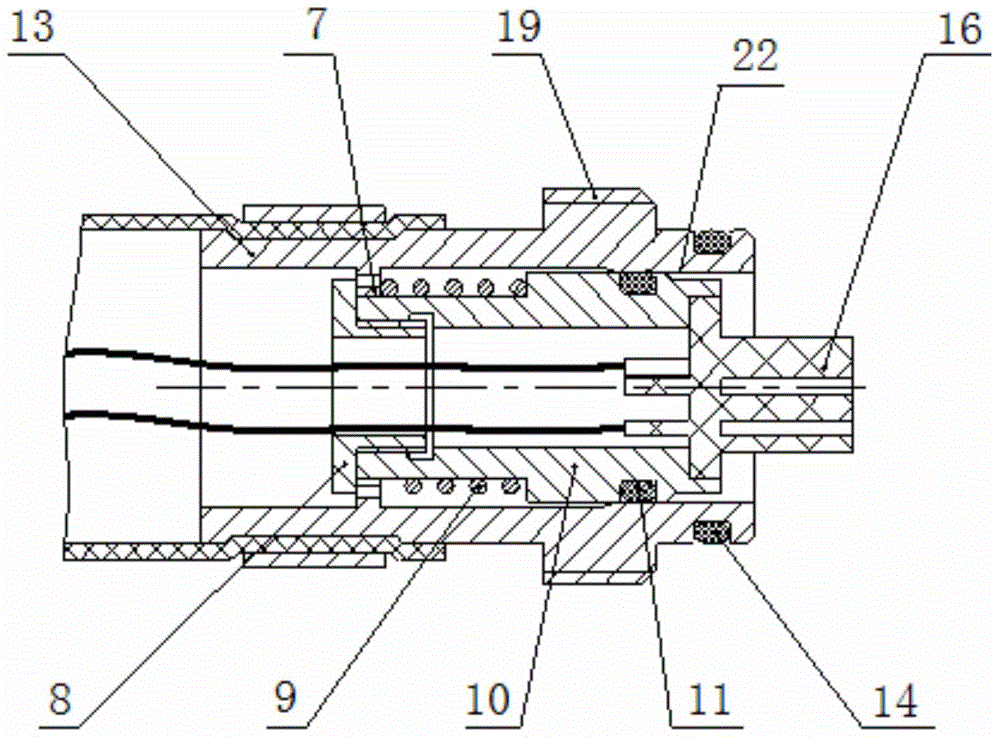

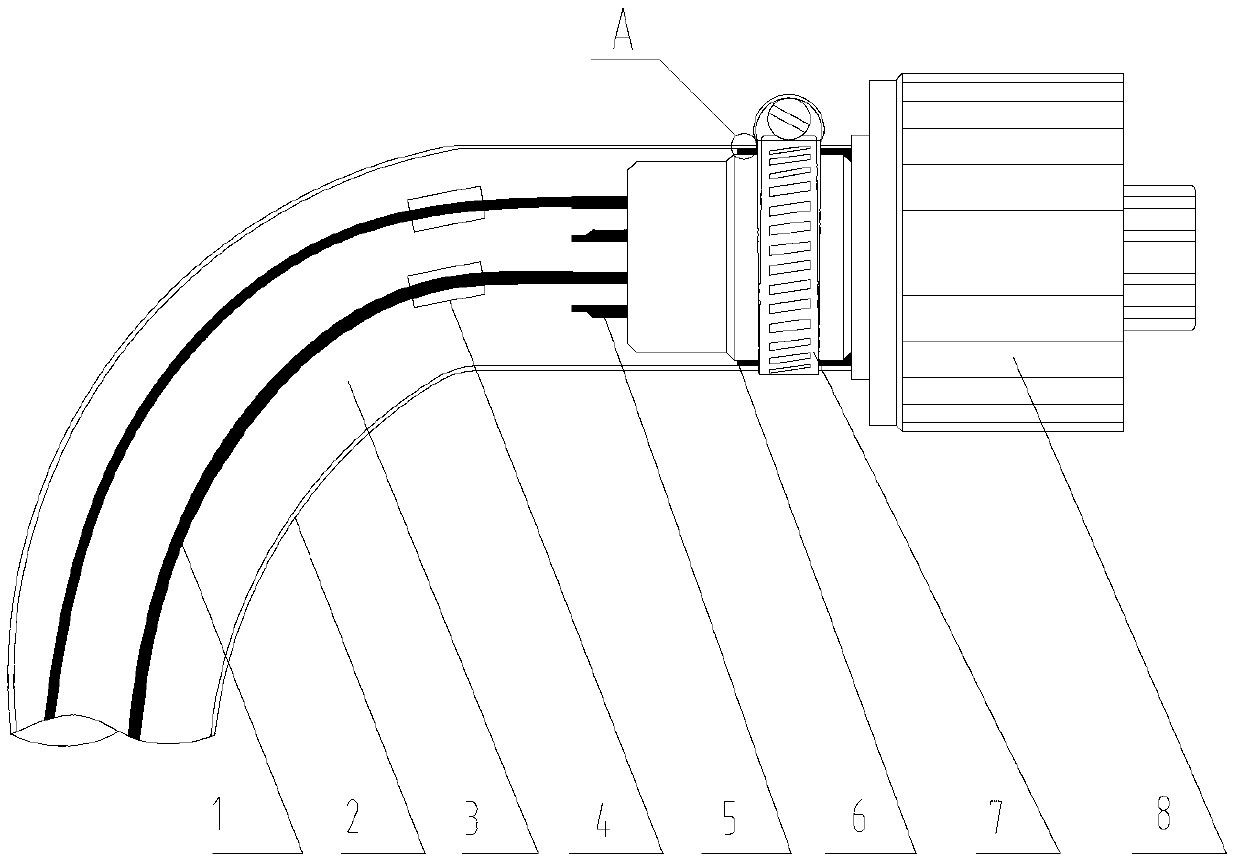

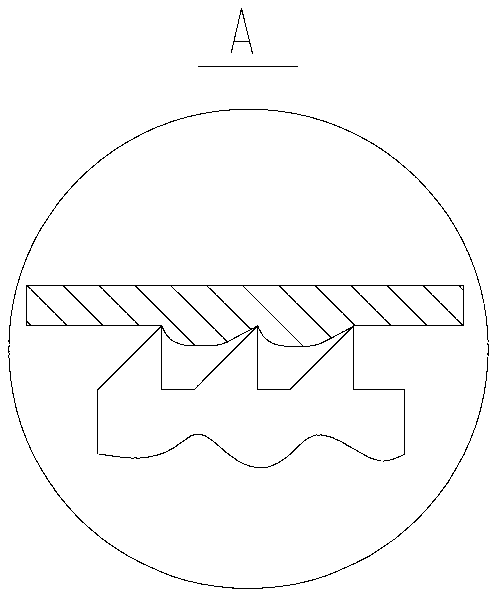

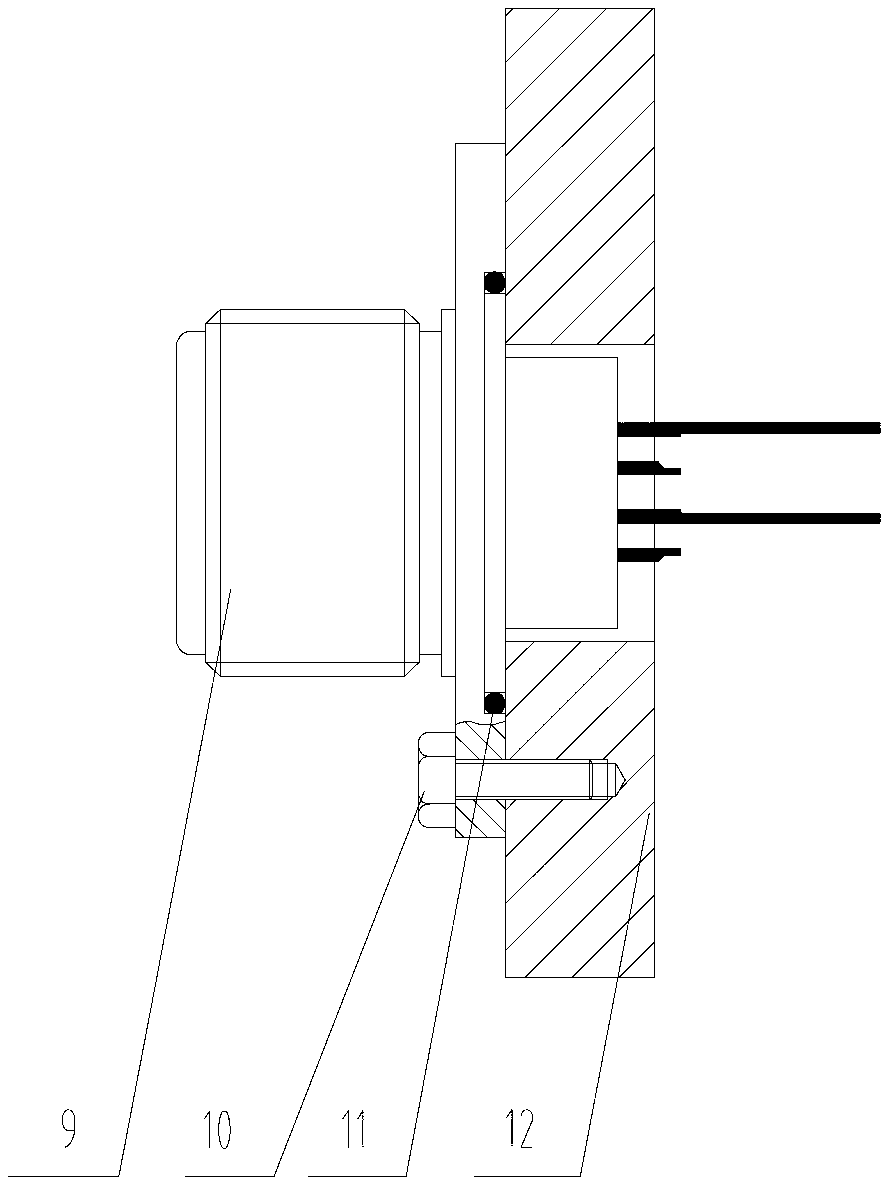

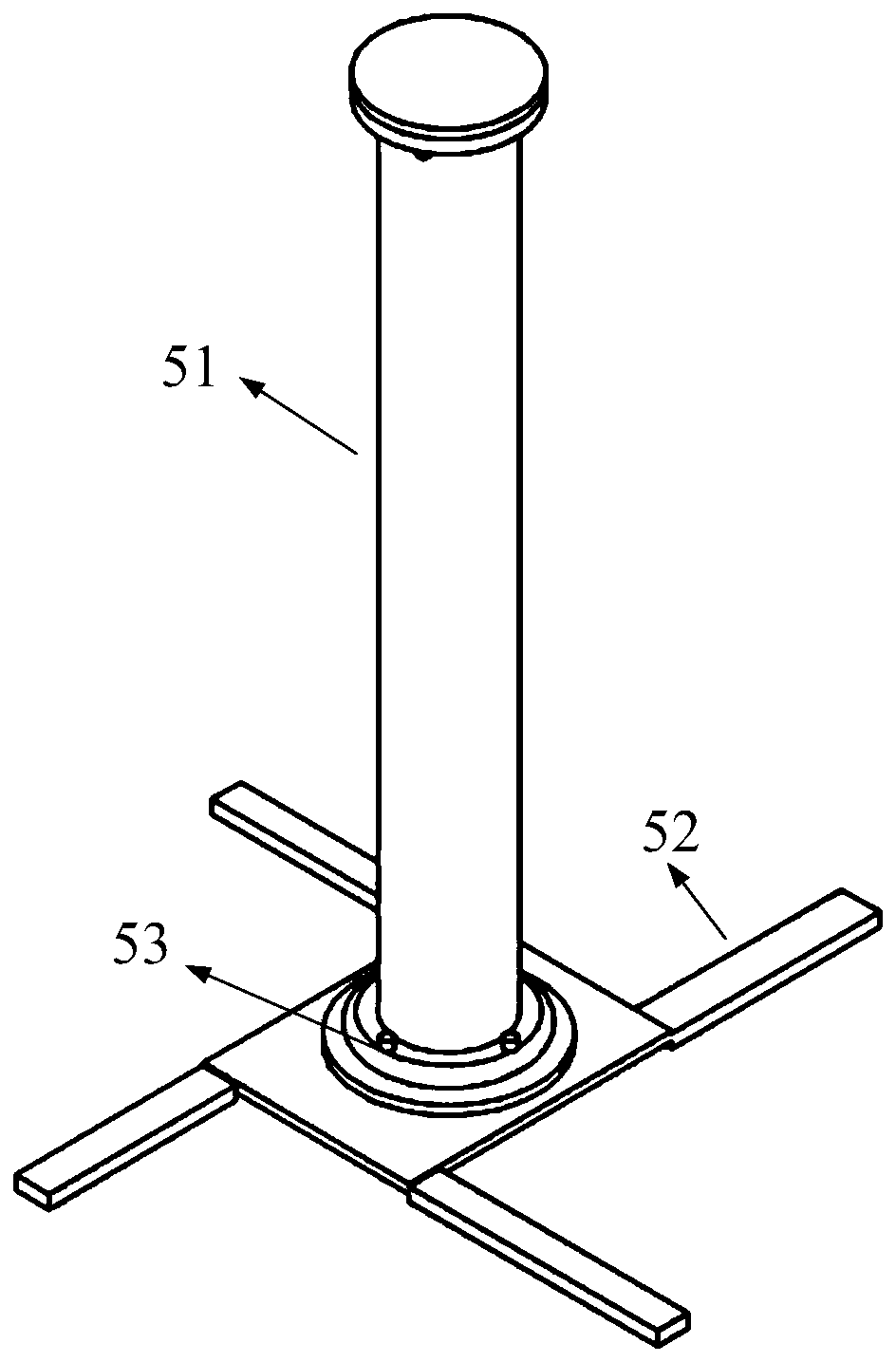

Deep-sea oil-filled cable quick butt-joint device

ActiveCN105655800AQuick dockingReliable electrical connectionCoupling device detailsTwo-part coupling devicesFilled cableButt joint

The invention relates to the field of deep-sea cables, and specifically relates to a deep-sea oil-filled cable quick butt-joint device. The device comprises a quick insertion sleeve, a quick insertion core, a locking cap and a hoop. The quick insertion sleeve includes a socket assembly and a sleeve. The quick insertion core includes a plug assembly and a core tube. The front end of a base of the socket assembly is equipped with a socket. The front end of a base of the plug assembly is equipped with a plug. Connection of the circuit in an oil-filled cable is realized through butt joint of the socket and the plug. The front ends of the bases of the socket assembly and the plug assembly are each sleeved with a sealing ring. The sleeve is internally provided with a raised inner hole surface. The core tube is internally provided with a raised inner cavity surface. The socket assembly opens or closes an oil path as the sealing ring moves in or out of the inner hole surface of the sleeve along with the base, and the plug assembly opens or closes an oil path as the sealing ring moves in or out of the inner cavity surface of the core tube along with the base. The front ends of the sleeve and the core tube are fixedly connected by the locking cap, and the rear ends of the sleeve and the core tube are each connected with an oil path. Quick butt joint of an oil-filled cable is realized, and electrical connection is facilitated.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Flame-retardant waterproof ointment incompatible with flame-retardant sheath material and used for filling cable

InactiveCN102708974AExtended shelf lifeFast water absorptionInsulated cablesFibre mechanical structuresChemical industryFilled cable

The invention relates to the technical field of chemical industry and particularly relates to a flame-retardant waterproof ointment incompatible with a flame-retardant sheath material and used for filling a cable. The waterproof ointment is characterized by comprising the following raw material components in percentage by weight: 65-75% of base oil, 4-8% of oil stabilizer, 1-2% of antioxidant, 3-8% of thickener, 3-8% of fire retardant, 3-15% of waterproofing agent and 5-10% of absorptive particles. Compared with the prior art, the flame-retardant waterproof ointment has the following advantages: the quality guarantee period of products is greatly prolonged, the initial water absorption speed is greatly quickened, the initial expansion speed is quicker; the dropping point of the products is higher, the cone penetration is greater, and the thixotropic property is better; and a photoelectric cable made from the flame-retardant waterproof ointment is longer in service life.

Owner:STATE GRID CORP OF CHINA +1

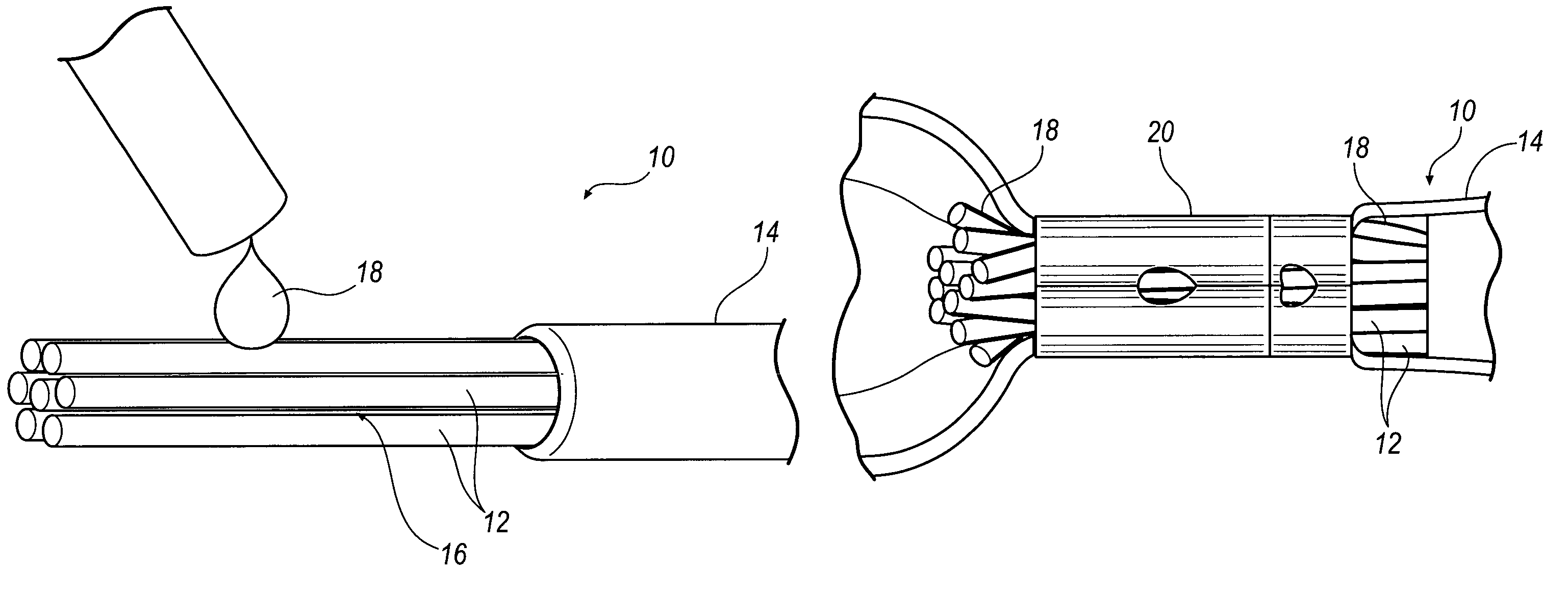

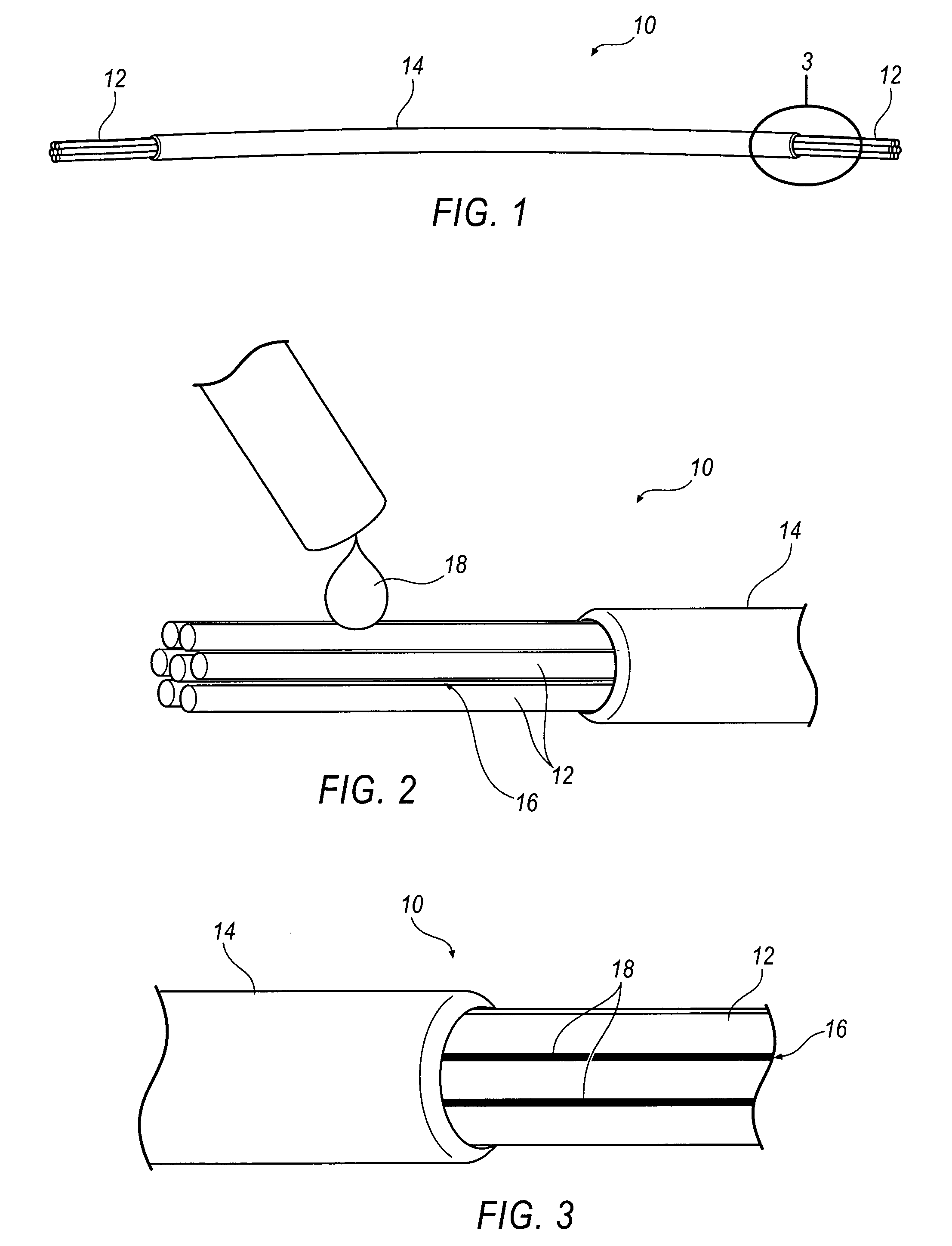

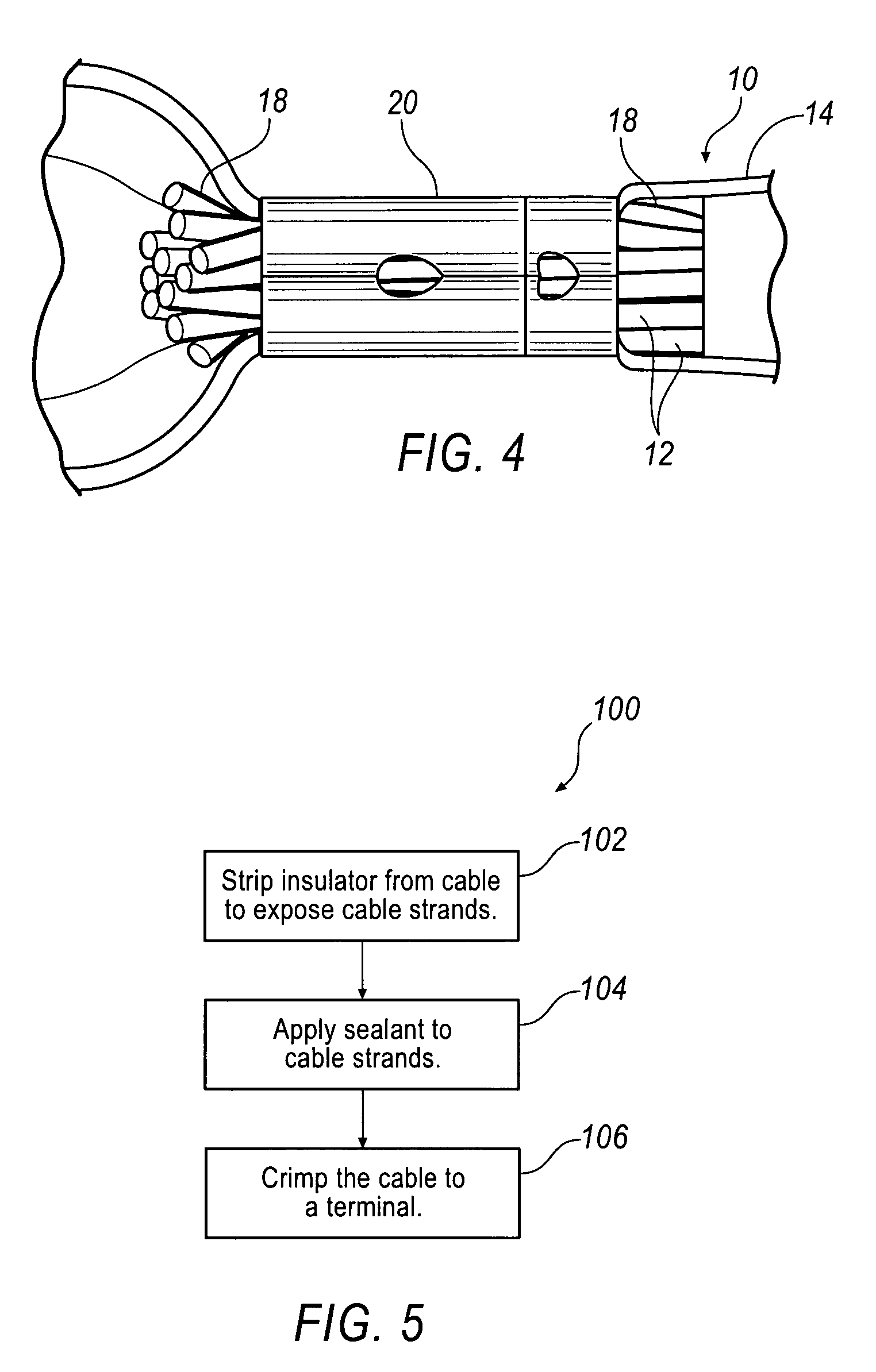

Sealed cable and terminal crimp

A cable includes a plurality of cable strands, an insulator disposed on a portion of the plurality of strands such that the plurality of strands are at least partially exposed, and a sealant disposed between gaps of the plurality of strands and at least partially under the insulator. Moreover, a method includes stripping an insulator from an end of the cable to expose a plurality of cable strands, and applying a sealant to the cable strands such that the sealant is drawn under the insulator and fills in gaps between the cable strands by capillary action.

Owner:APTIV TECH LTD

Cable fillers

ActiveCN101807451AReduce pollutionAvoid affecting performancePlastic/resin/waxes insulatorsInsulated cablesLow-density polyethyleneFoaming agent

The invention relates to cable fillers, belonging to fillers in a cable. The cable fillers comprise the components of low density polyethylene plastics, high density polyethylene plastics, polypropylene plastics, graphite, foaming agent and fire retardant. The cable filler strip prepared by the cable filter in the invention has stable molding, fills cable gaps fully, ensures round appearance of the cable when the cable is formed, and has the advantages of high mechanical strength, good surface tightness, watertightness, moisture resistance, difficult fracture, small density, good flame retardant property, economy and practicability and the like.

Owner:四川新蓉电缆有限责任公司

Underwater oil-filled cable and manufacturing method thereof

ActiveCN103280661AEasy to useLow priceLine/current collector detailsCoupling device detailsFilled cableAdhesive

The invention provides an underwater oil-filled cable and a manufacturing method thereof. The underwater oil-filled cable mainly comprises watertight plugs, a lead, a plastic hose, compensation oil and clamping devices; the lead is wrapped inside the underwater oil-filled cable by the plastic hose to realize the isolation of the inside from water; and the pressure difference of the inside and the outside caused by the water pressure is balanced by the compensation oil in the plastic hose. When the underwater oil-filled cable is manufactured, the lead is cut off according to the required length of the cable and the cut cable is enabled to penetrate into the plastic hose; the corresponding watertight plugs are respectively welded at two ends of the lead; after the welding is finished, one end of the lead is clamped by using the clamping devices such as AB adhesive and a hoop; then the compensation oil is filled into the plastic hose from the other end of the lead; and after the plastic hose is fully filled with the compensation oil, the plastic hose is clamped by the clamping devices, and finally the whole oil-filled cable is manufactured. The underwater oil-filled cable has the advantages of low price, great underwater work depth, simpleness and convenience in manufacture, safety and reliability in use and low possibility of being scratched.

Owner:中国船舶重工集团公司第七〇二研究所

Insulation compositions containing metallocene polymers

Novel additive systems for metallocene based filled cable insulation are disclosed. These systems provide excellent protection against thermal degradation, better cure state and reduced dissipation factor after prolonged heat exposure. The additives may contain one or more hindered amine light stabilizers and amine antioxidants.

Owner:GENERAL CABLE TECH CORP

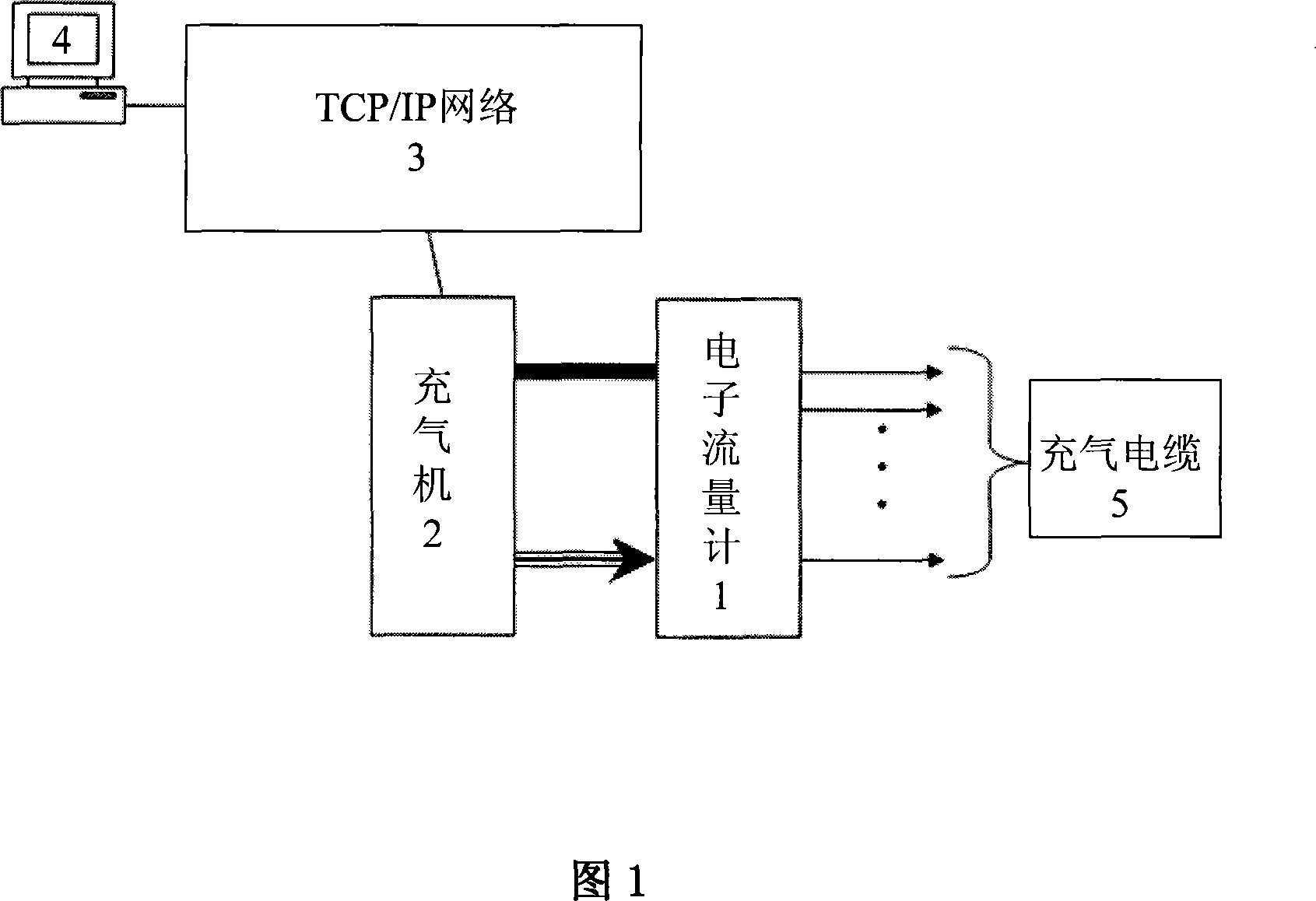

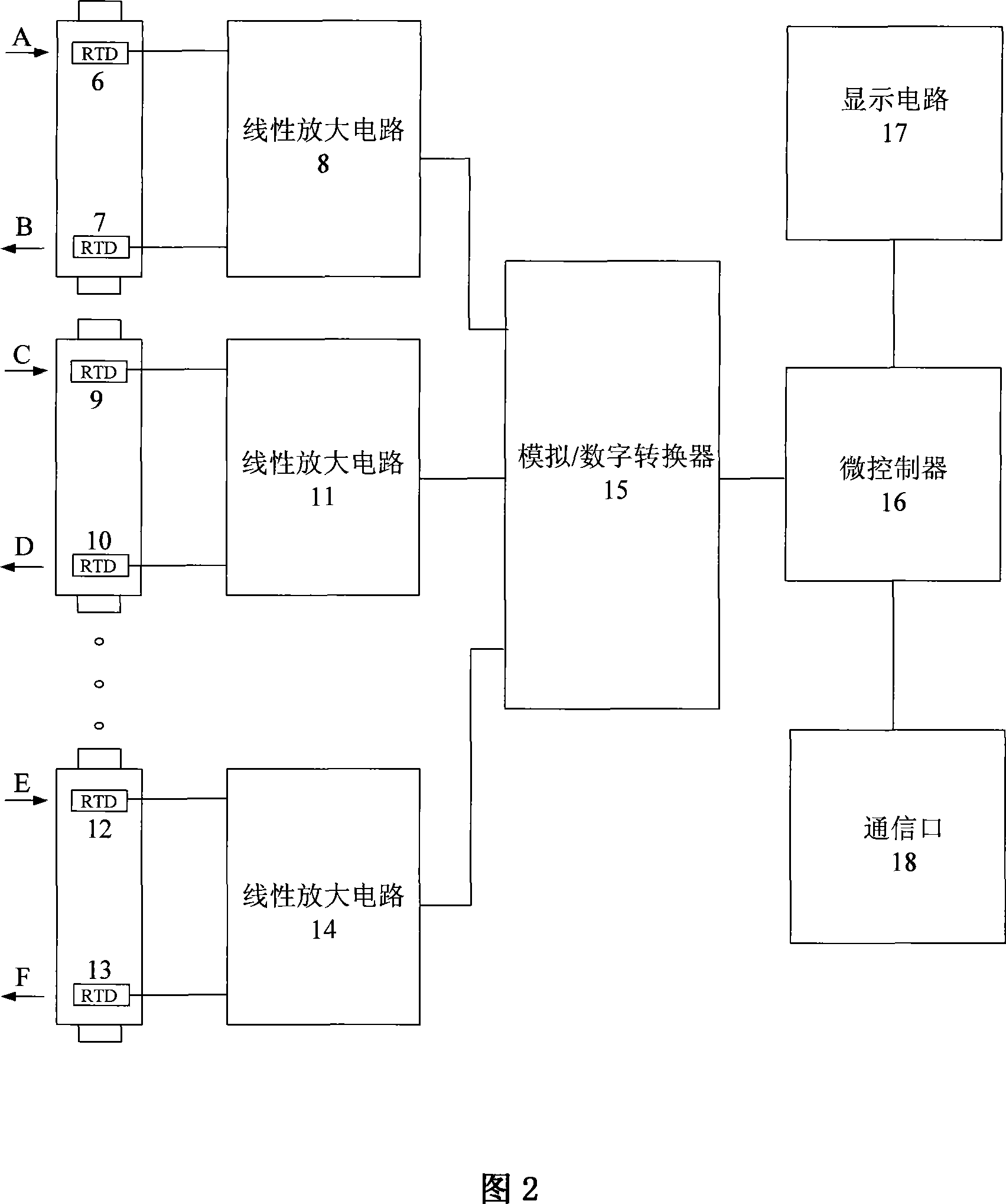

Real-time multichannel gas flow monitoring method for gas-filled cable

InactiveCN101046425ARealize real-time monitoringQuick responseMeasurement of fluid loss/gain rateFilled cableEngineering

The real-time multichannel gas flow monitoring method for gas-filled cable includes connecting the gas output of inflator, the gas passage of electronic flow meter and the gas inlets of the gas-filled cables; connecting the electronic flow meter electrically to the inflator and setting two platinum thermal resistors into each of the inflating gas passage; measuring the temperature difference of each platinum thermal resistor, amplifying the temperature difference signal, A / D converting, treating and calculating in the micro controller to obtain flow rate data; displaying and transmitting the flow rate data to the upper computer for real-time monitoring. The present invention can realize the remote monitoring and maintenance on cables.

Owner:SUZHOU NEW DACHENG TECH DEV

Hard grade epr insulation compositions

Novel additive systems for lead-free filled cable insulation are disclosed. These systems provide improved electrical and mechanical properties. The composition contains a base polymer of a polyethylene and an elastomer, a filler, and additives of hindered amine light stabilizers and phenolic antioxidants.

Owner:GENERAL CABLE TECH CORP

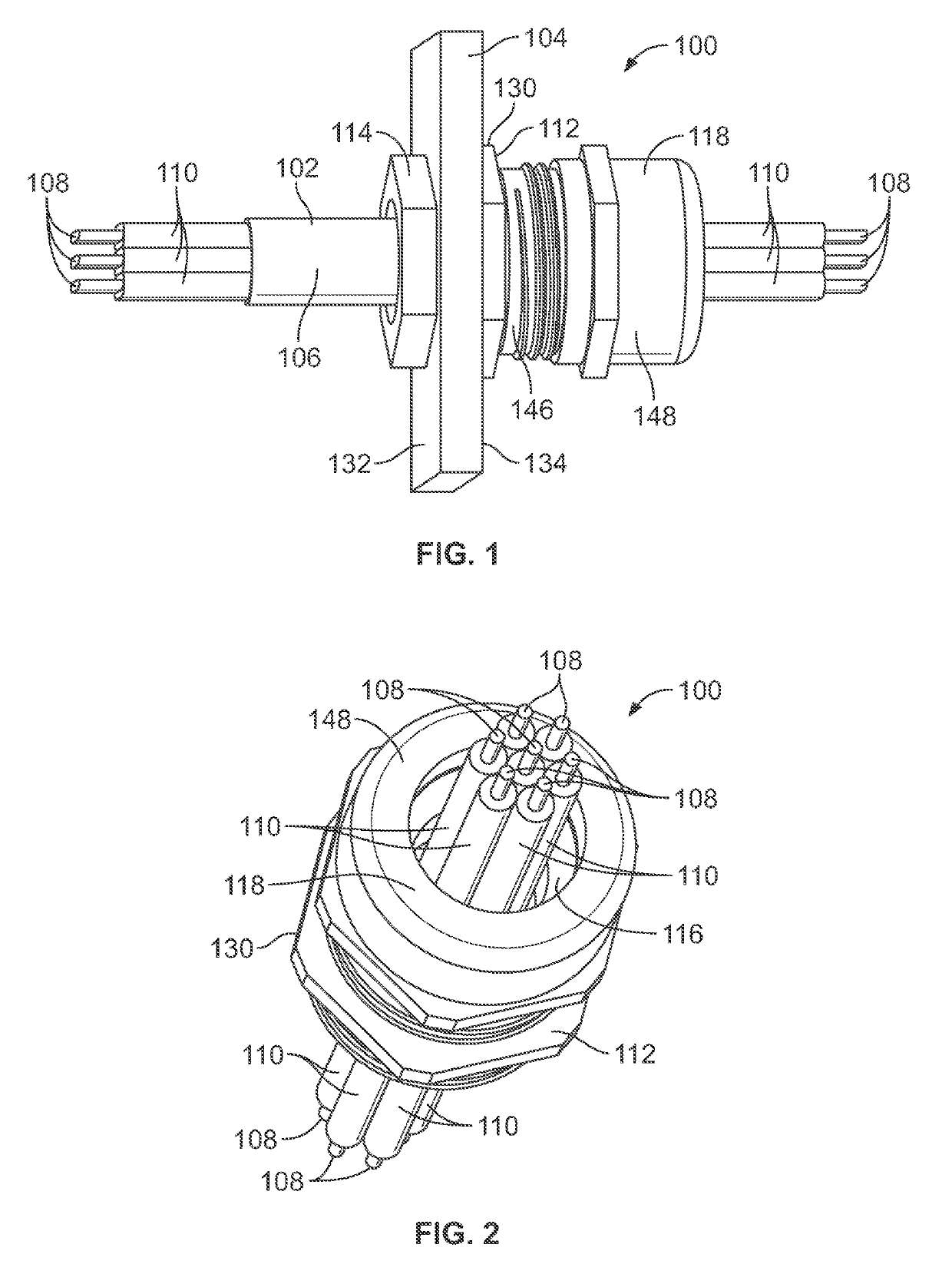

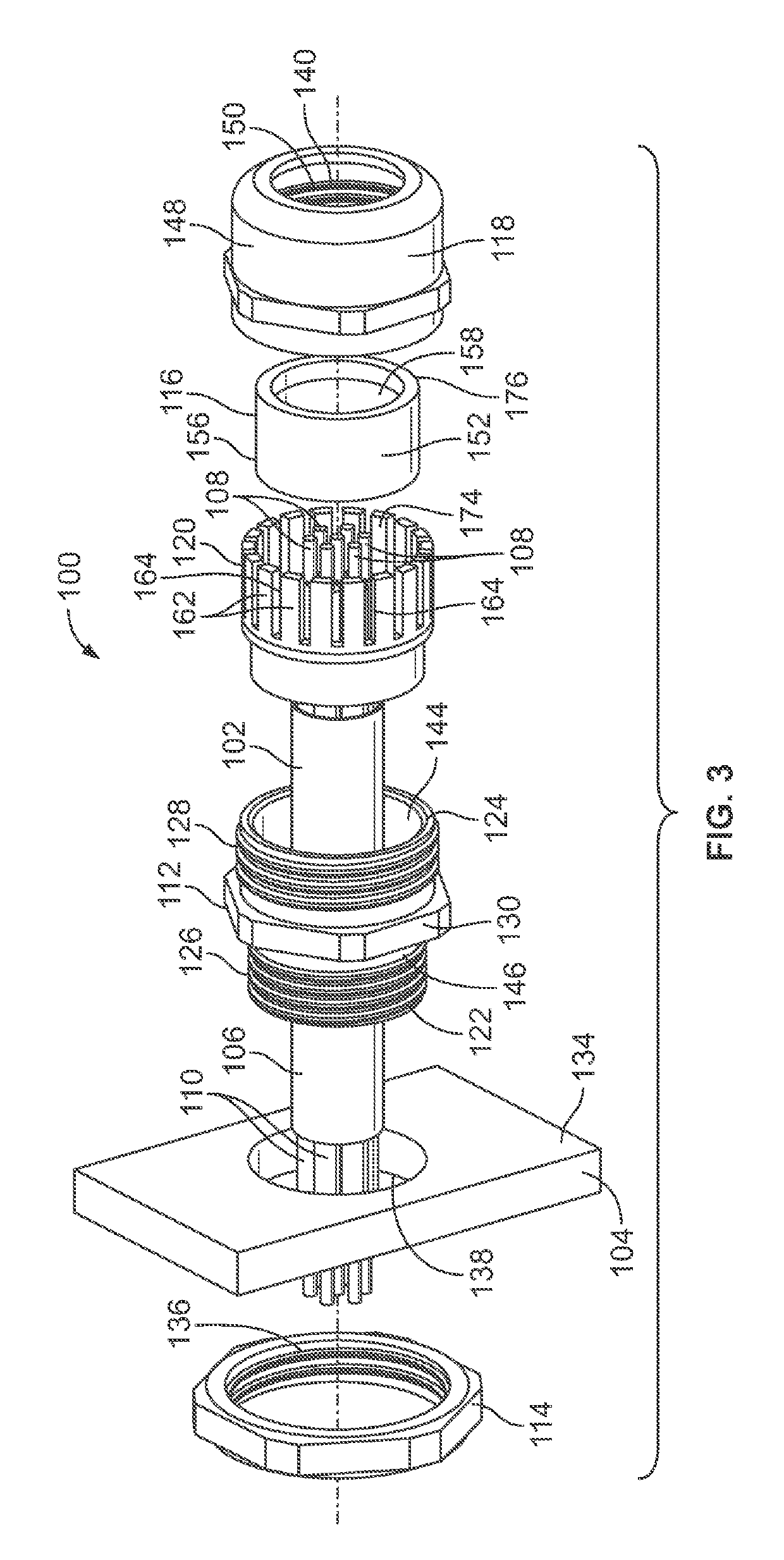

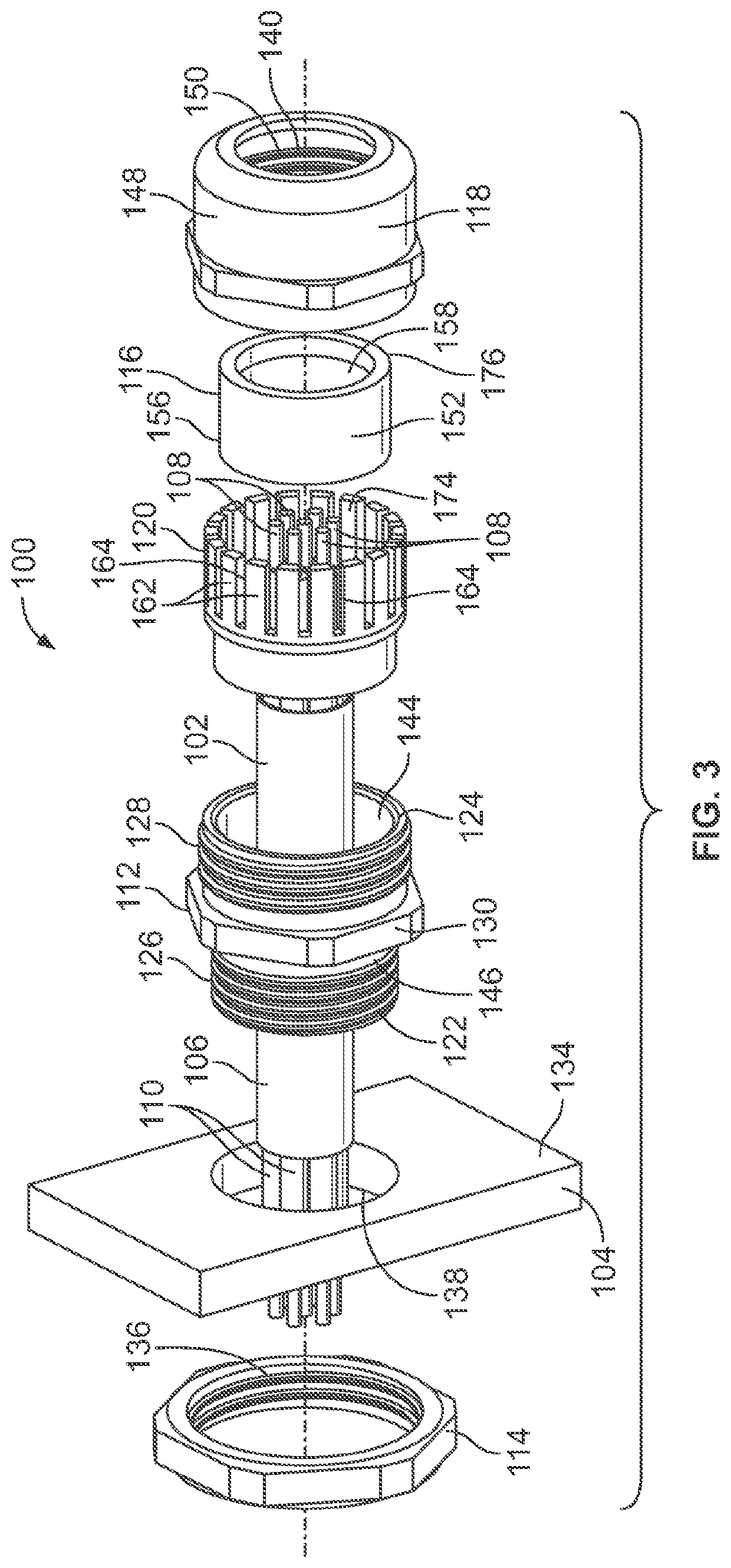

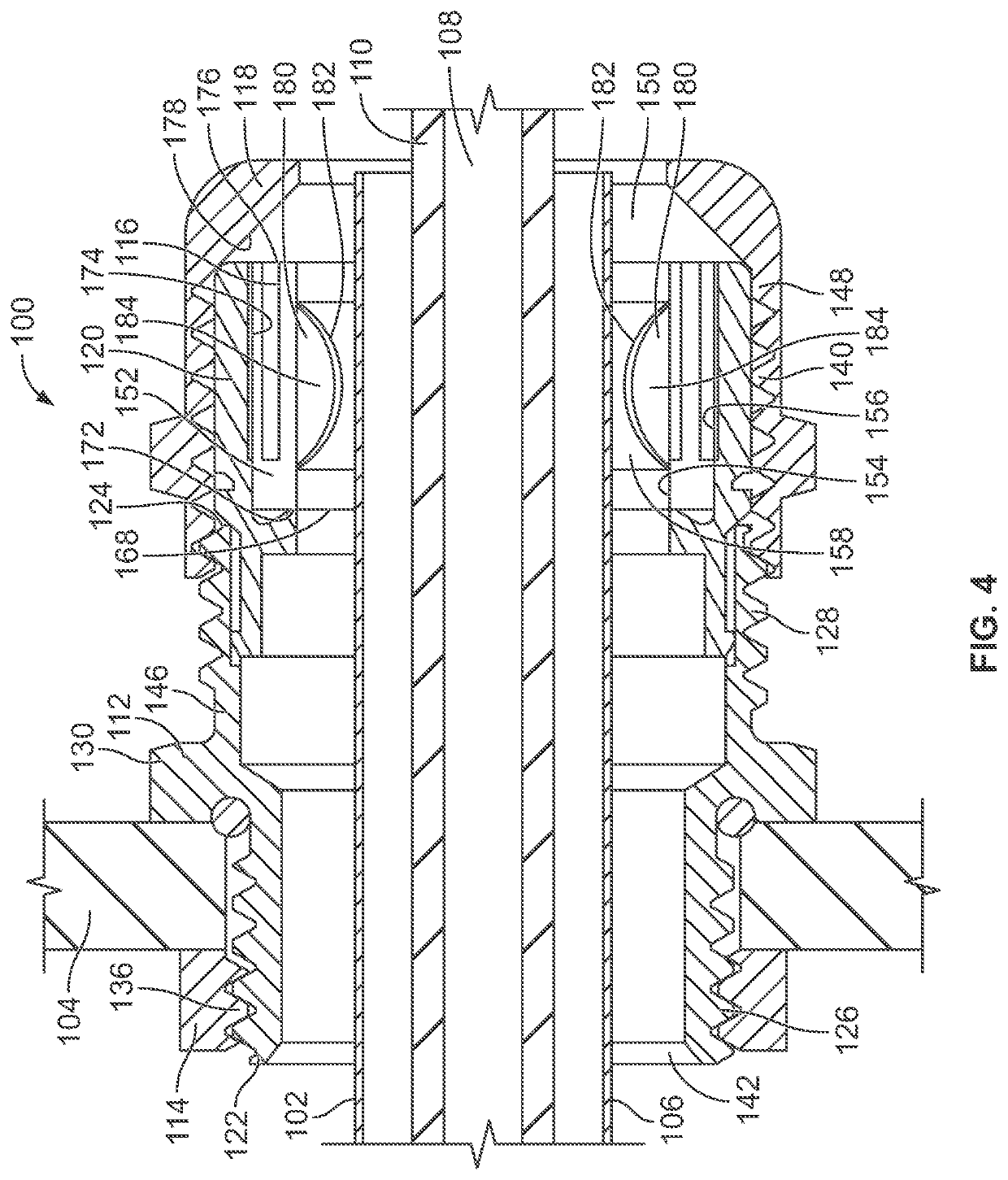

Sealant filled cable gland

A cable gland for providing strain relief and sealing for a cable that can be coupled to a device. The cable gland includes a sealing gland having a sealant. Upon assembly of the cable gland, the sealing gland is compressed in a manner that can releases, or otherwise can facilitate the displacement of, the sealant about an interface between a portion of the cable and the sealing gland, and / or into spaces between exposed insulative jackets and / or conductors of the cable. The sealant can include a curable viscous sealant that is housed within a package of the sealing gland, the package being configured to rupture upon compression of the sealing gland. Alternatively, the sealant can be a malleable sealant material that can be pressed or otherwise displaced to form a seal between the sealing gland and cable and / or into the spaces between exposed insulative jackets and / or conductors of the cable.

Owner:THOMAS & BETTS INT INC

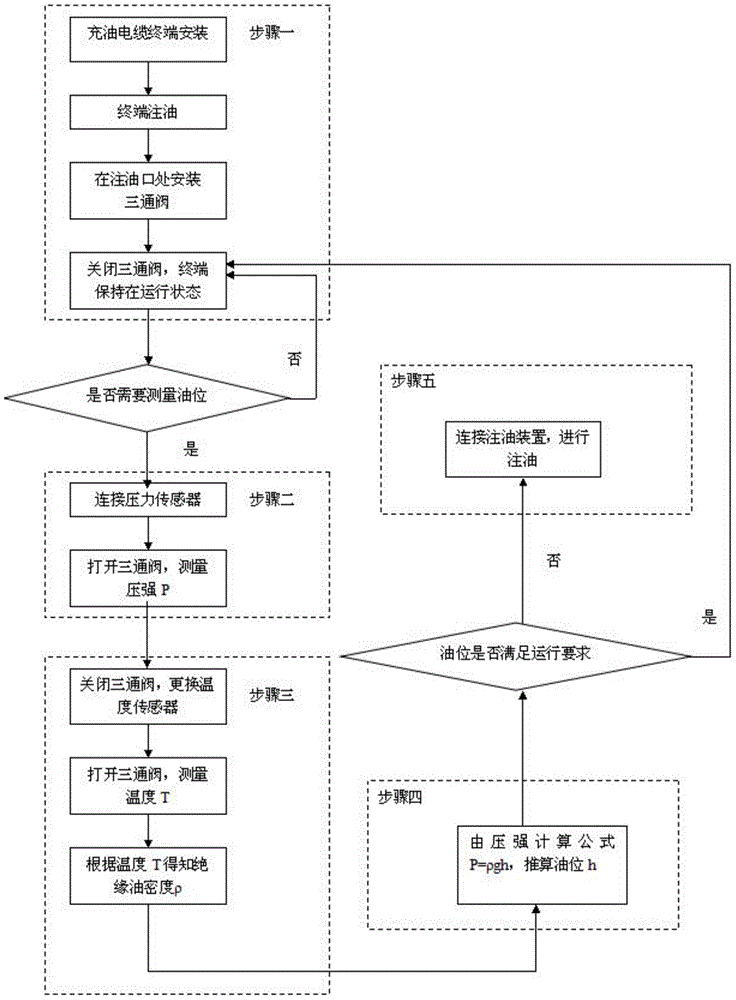

Oil-filled cable terminal oil level measuring and oil supplementing method

InactiveCN104677459AKnow exactly what's going onReduce defectsCable fittings in presence of gas/oilLevel indicators by pressure measurementFilled cableVolumetric Mass Density

The invention relates to an oil-filled cable terminal oil level measuring and oil supplementing method. The method is mainly characterized by comprising the following steps of (1) mounting a three-way valve on an oil filling port of an oil-filled cable terminal, wherein the three-way valve is closed when the oil-filled cable terminal runs normally; (2) measuring the intensity of pressure (P) generated by insulating oil in the oil-filled cable terminal; (3) measuring the temperature (T) of the insulating oil in the oil-filled cable terminal and calculating out the density (rho) of the insulating oil; (4) calculating the liquid level h of the insulating oil in the oil-filled cable terminal; and (5) filling the oil-filled cable terminal with oil if the liquid level h of the insulating oil in the oil-filled cable terminal does not meet the operating requirement. The method is reasonable in design; the measurement of the liquid level of the insulating oil in the oil-filled cable terminal is realized, and meanwhile, the oil is supplemented when the insufficient oil quantity is found, so operators can know the operating situation accurately and eliminate defects in time.

Owner:STATE GRID CORP OF CHINA +1

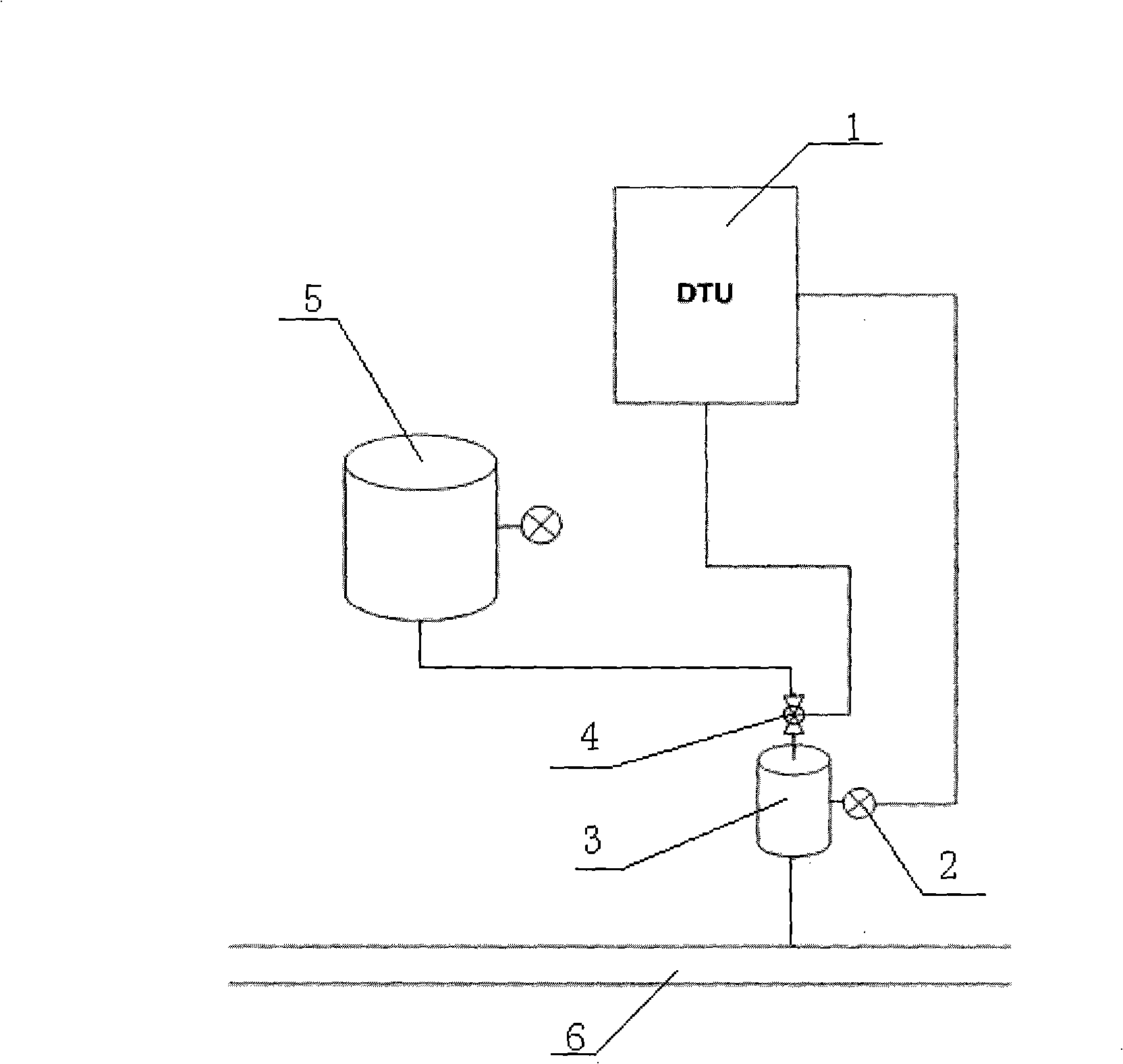

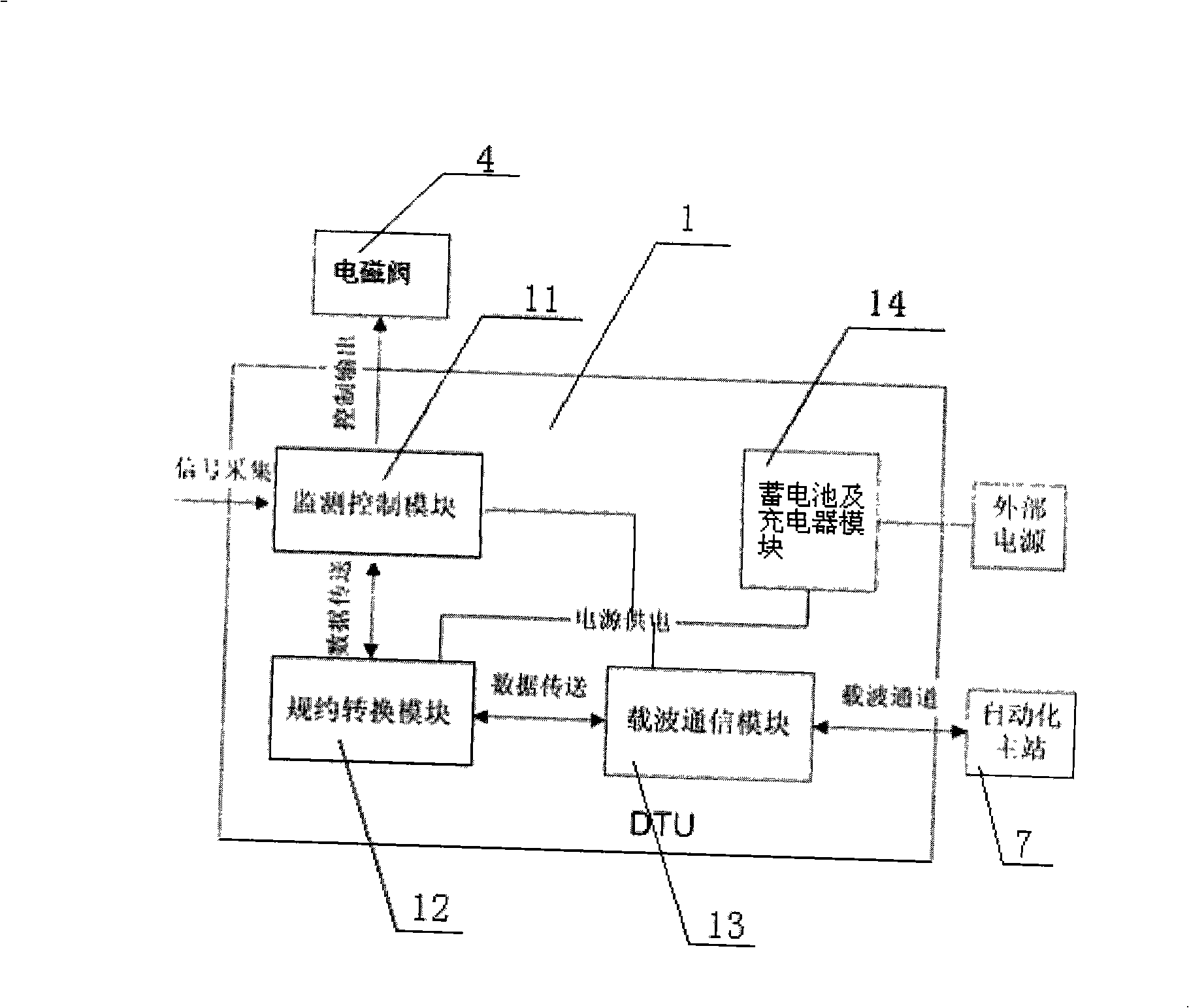

Automatic emergency oil supply system of oil-filling cable

ActiveCN101295865AImprove rescue efficiencyReduce the risk factor of failureEnergy efficient ICTElectric signal transmission systemsFilled cableElectric power system

The invention relates to a cable fault treatment system in a power system, in particular to an automatic emergency oil supply system of an oil-filled cable. The oil supply system comprises an oil-filled cable and a plurality of groups of common pressure tanks connected with the oil-filled cable. One port of the common pressure tanks is connected with an electromagnetic valve and the other port is connected with an oil pressure transmitter; a cable fault diagnosis automation device is connected between the electromagnetic valve and the oil pressure transmitter; the other port of the electromagnetic valve is connected with a standby pressure tank. By adopting the technical solving proposal, the problem of protection oil leakage caused by fault during the immediate compensation of the oil-filled cables is totally solved, thereby reducing fault danger coefficient, improving rescue efficiency in the oil leakage accident of the oil-filled cables, winning valuable time for power recovery and providing safety measures for rescue personnel.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +2

Monolayer-armored and double-layer-armored submarine optical cable transition soft connector and connection method thereof

ActiveCN102722011ASave assembly timeMeet construction requirementsFibre mechanical structuresCommunications systemFilled cable

The invention relates to a monolayer-armored and double-layer-armored submarine optical cable transition soft connector and a connection method thereof. The monolayer-armored and double-layer-armored submarine optical cable transition soft connector and the connection method are suitable for connection of submarine optical cable plants in a submarine optical fiber communication system. The monolayer-armored and double-layer-armored submarine optical cable transition soft connector comprises an optical fiber, a monolayer-armored submarine optical cable stainless steel pipe, outer-sleeved stainless steel pipes, a double-layer-armored submarine optical cable stainless steel pipe, a monolayer-armored submarine optical cable core, a wrapping filling cable core, a double-layer-armored submarine optical cable core, an inner-layer pre-twisting steel wire, a middle-layer pre-twisting steel wire and an outer-layer pre-twisting steel wire, wherein the stainless steel pipe is sleeved outside the optical fiber, the outer-sleeved stainless steel pipes are sleeved on connection-end stainless steel pipes of the monolayer-armored submarine optical cable stainless steel pipe and the double-layer-armored submarine optical cable stainless steel pipe, the wrapping filling cable core is wrapped on the connection-end stainless steel pipes and the outer-sleeved stainless steel pipes, a monolayer-armored submarine optical cable armored stainless steel wire, the inner-layer pre-twisting steel wire, the middle-layer pre-twisting steel wire and the outer-layer pre-twisting steel wire are sequentially twisted outside the wrapping filling cable core, and a polypropylene rope is twisted on the outer-layer pre-twisting steel wire and bonded with the outer-layer pre-twisting steel wire through pitch.

Owner:ZHONGTIAN TECH SUBMARINE CABLE CO LTD

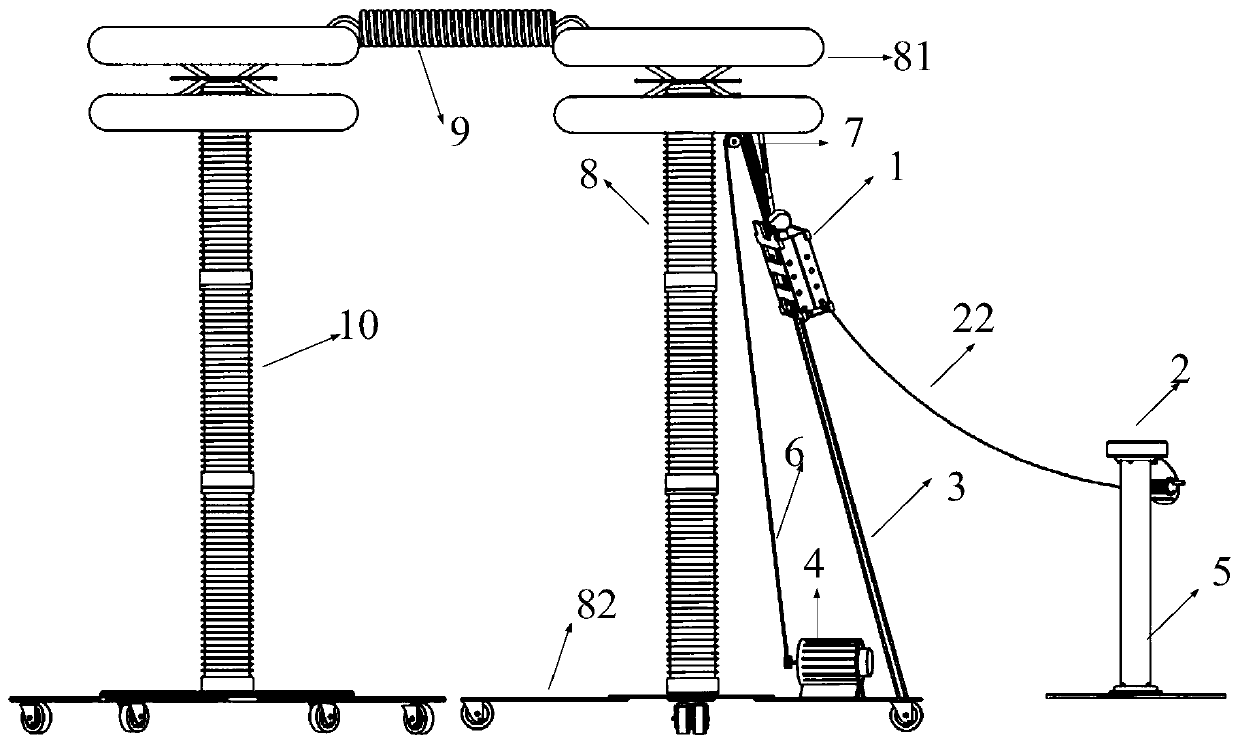

Discharging device and discharging method for submarine oil-filled cable direct-current withstand voltage test

InactiveCN110687405AQuick releaseShorten discharge timeTesting dielectric strengthCorona dischargeElectrical resistance and conductanceFilled cable

The invention discloses a discharging device for submarine oil-filled cable direct-current withstand voltage test. The discharging device comprises a discharging vehicle, a pull rod, a discharging resistor, a transmission device and a high-voltage wire. The discharging vehicle comprises a discharging tip, a universal ball, a pulley and a vehicle body, wherein the pulley is installed on the side face of the vehicle body and is in rolling connection with the pull rod; the universal ball is rotationally installed at the upper end of the vehicle body; the discharging tip is fixed to the universalball; and the transmission device is used for driving the discharging vehicle to slide along the pull rod to make the discharging tip contacted with or separated from equipment to be discharged. The invention also discloses a discharging method for the submarine oil-filled cable direct-current withstand voltage test. The discharging device and the discharging method can quickly release the residual charges accumulated on the tested equipment body, so that the efficiency of the withstand voltage test is effectively improved, and the safety of the withstand voltage test is ensured.

Owner:EXAMING & EXPERIMENTAL CENT OF ULTRAHIGH VOLTAGE POWER TRANSMISSION COMPANY CHINA SOUTHEN POWER GRID

Crush-resistance light cable filler and manufacturing method thereof

The invention discloses crush-resistance light cable filler and a manufacturing method thereof. The crush-resistance light cable filler comprises, by weight, 20-22 parts of EPDM rubber, 5-7 parts of modified hard clay, 7-9 parts of natural mica, 4-6 parts of kaolin, 2.5-3.5 parts of silane coupling agent, 1.5-2.5 parts of flame retardant, 0.4-0.8 part of antioxygen, 1.2-1.8 parts of white carbon black, 3-5 parts of silicium-calcium slag, 0.5-1.4 parts of silicone oil, 2.2-3.2 parts of glass beads and 0.3-0.9 part of volcanic ash. Cable gaps can be fully filled, the roundness of the appearance in the cable forming process is guaranteed, and the crush-resistance light cable filler further has the advantages of being high in mechanical strength, good in surface sealing property, capable of achieving the crush-resistance function and low in weight.

Owner:ANHUI TIANYUAN CABLE

Non-newtonian fluid (NNF) filled cable and method

ActiveUS20120267205A1Prevent movementEnvelopes/bags making machinerySpringsResonant energyNegative feedback

A composite cable and method provides for control of the cable, and particularly its vibration modes, in response to a wide range of resonant and non-resonant energy input. The cable comprises a non-Newtonian fluid (NNF) in a cavity of a flexible tube. The NNF is characterized by viscosity that varies with shear stress. A load applies shear stress to the NNF changing its viscosity to dampen motion of the cable. The cable may comprise inner and outer tubes that are separated by a NNF. The inner tube may be filled with the same or different NNF, a Newtonian fluid or void. A magnetic field magnetic field may be applied to further control the viscosity of the NNF. The magnetic field may be controlled in response to a sensed condition of the cable indicative of shear stress in the NNF to provide either positive or negative feedback.

Owner:RAYTHEON CO

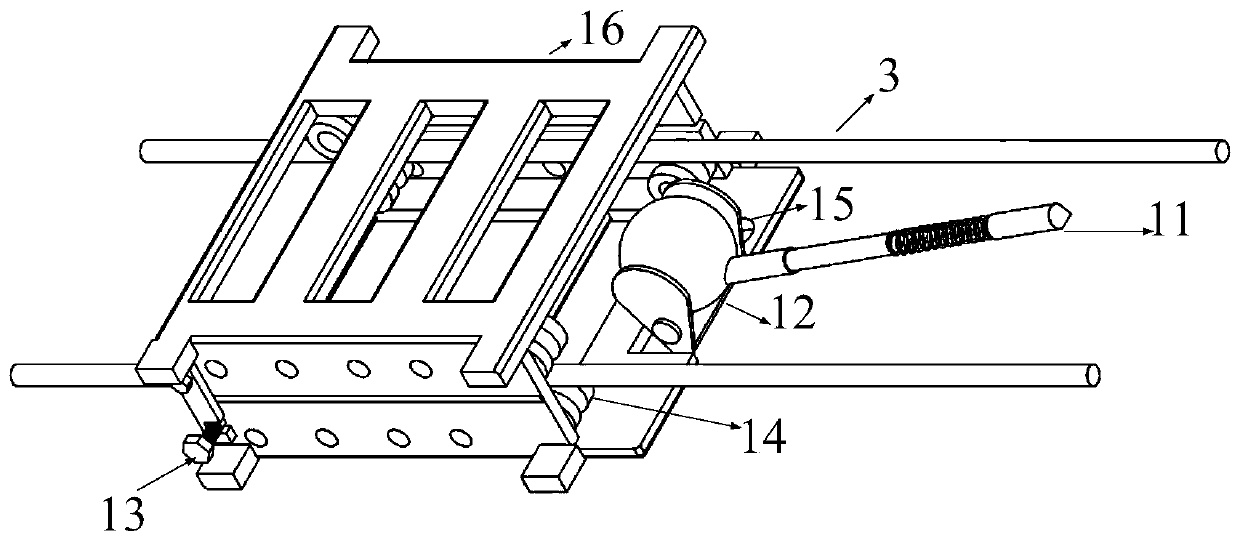

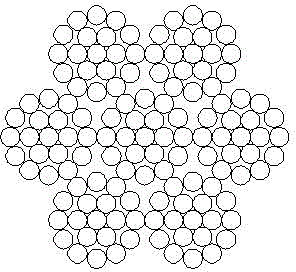

Preparation method and compacting stranding device of compacting soft structure conductor

ActiveCN104700965AReduce voidsSmall outer diameterCable/conductor manufactureYarnElectrical conductor

The invention discloses a preparation method and a compacting stranding device of a compacting soft structure conductor. The preparation method and the compacting stranding device of the compacting soft structure conductor are used to prepare the compacting soft structure conductor formed by stranding at least one cable conductor and plied yarns in unidirectional mode. Nonwovens and a wrapping belt such as a metal belt, a semi-conductive belt, a fireproof belt and a waterproof belt wrap the exterior of the compacting soft structure conductor. The preparation method and the compacting stranding device of the compacting soft structure conductor solve the problems that an existing incongruous stranded conductor is not compact in structure and large in external diameter, leaves out a cabling filling step through special sector and tile structures, decreases the external diameter of a cable, and reduces the weight of the cable. Simultaneously, Due to the unidirectional stranding structure of the compacting soft structure conductor, bending performance, especially torsion resistance of the compacting soft structure conductor is greatly improved, and when the compacting soft structure conductor is twisted for 10000 times by + / - 1440 degrees at room temperature, filaments of the compacting soft structure conductor can not be broken, and change value of resistance of the compacting soft structure conductor is less than or equal to 4%.

Owner:JIANGSU ZHONGTIAN TECH CO LTD +1

Environment-friendly filled cable material

ActiveCN103571087AImprove flame retardant performanceHigh temperature resistantInsulated cablesInsulated conductorsFilled cablePolyvinyl chloride

The invention provides an environment-friendly filled cable material which is prepared from the following raw materials in parts by weight: 80-90 parts of polyvinyl chloride resin, 5-8 parts of environment-friendly stabilizer, 1-2 parts of modifier CPE, 1-2 parts of barium stearate, 40-50 parts of light calcium carbonate, 10-15 parts of hollow glass microsphere, 5-8 parts of talcum powder, 4-5 parts of molybdenum oxide, 3-4 parts of copper oxide, 50-60 parts of tributyl citrate, 0.1-1 part of calcium stearate, 5-6 parts of nano bowlder powder, 15-25 parts of sodium tripolyphosphate, 0.5-1.0 part of PE (polyethylene) wax, 1-2 parts of urotropine and 12-15 parts of modifying filler. The environment-friendly filler has the advantages of environment friendliness, favorable flame retardancy, high temperature resistance, low smoke, easy stripping, favorable compatibility and favorable molding property. The preparation method is simple and easy to implement and convenient for industrial production; and the produced environment-friendly filled cable material has the characteristics of stable quality and low cost.

Owner:WUHU HANGTIAN SPECIAL CABLE FACTORY

Sealant filled cable gland

A cable gland for providing strain relief and sealing for a cable that can be coupled to a device. The cable gland includes a sealing gland having a sealant. Upon assembly of the cable gland, the sealing gland is compressed in a manner that can releases, or otherwise can facilitate the displacement of, the sealant about an interface between a portion of the cable and the sealing gland, and / or into spaces between exposed insulative jackets and / or conductors of the cable. The sealant can include a curable viscous sealant that is housed within a package of the sealing gland, the package being configured to rupture upon compression of the sealing gland. Alternatively, the sealant can be a malleable sealant material that can be pressed or otherwise displaced to form a seal between the sealing gland and cable and / or into the spaces between exposed insulative jackets and / or conductors of the cable.

Owner:THOMAS & BETTS INT INC

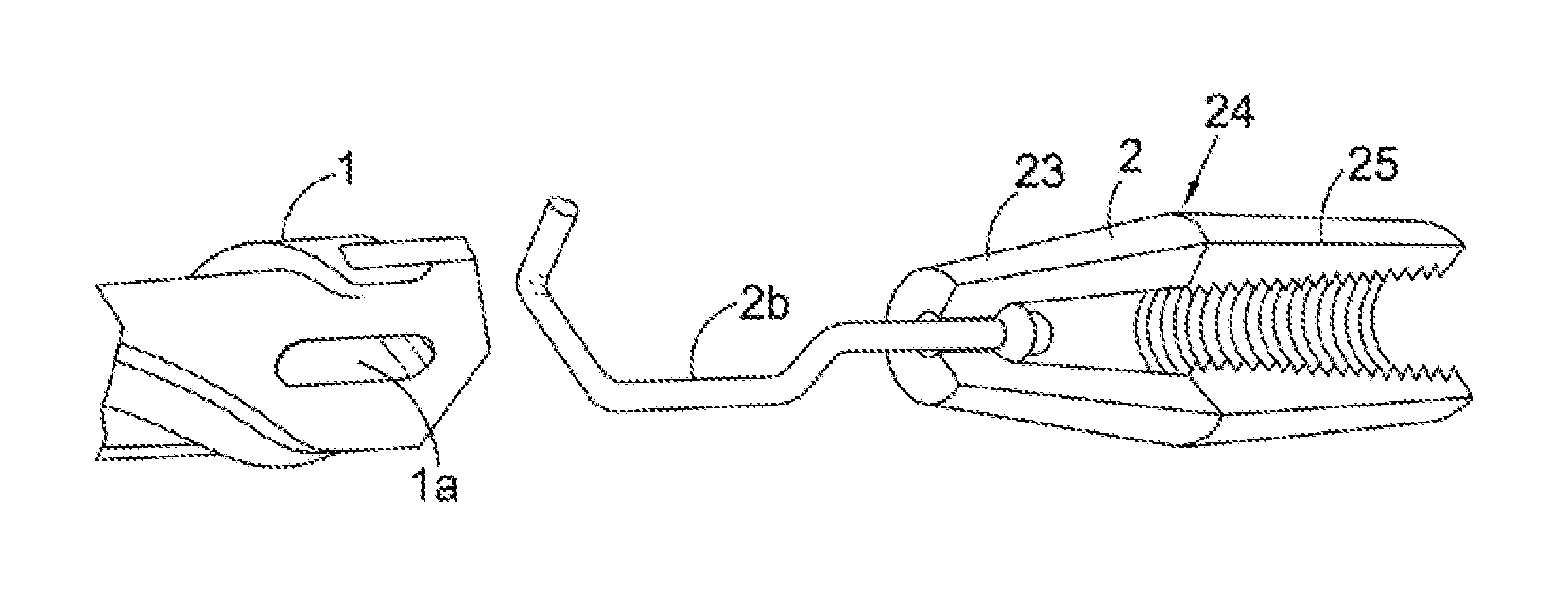

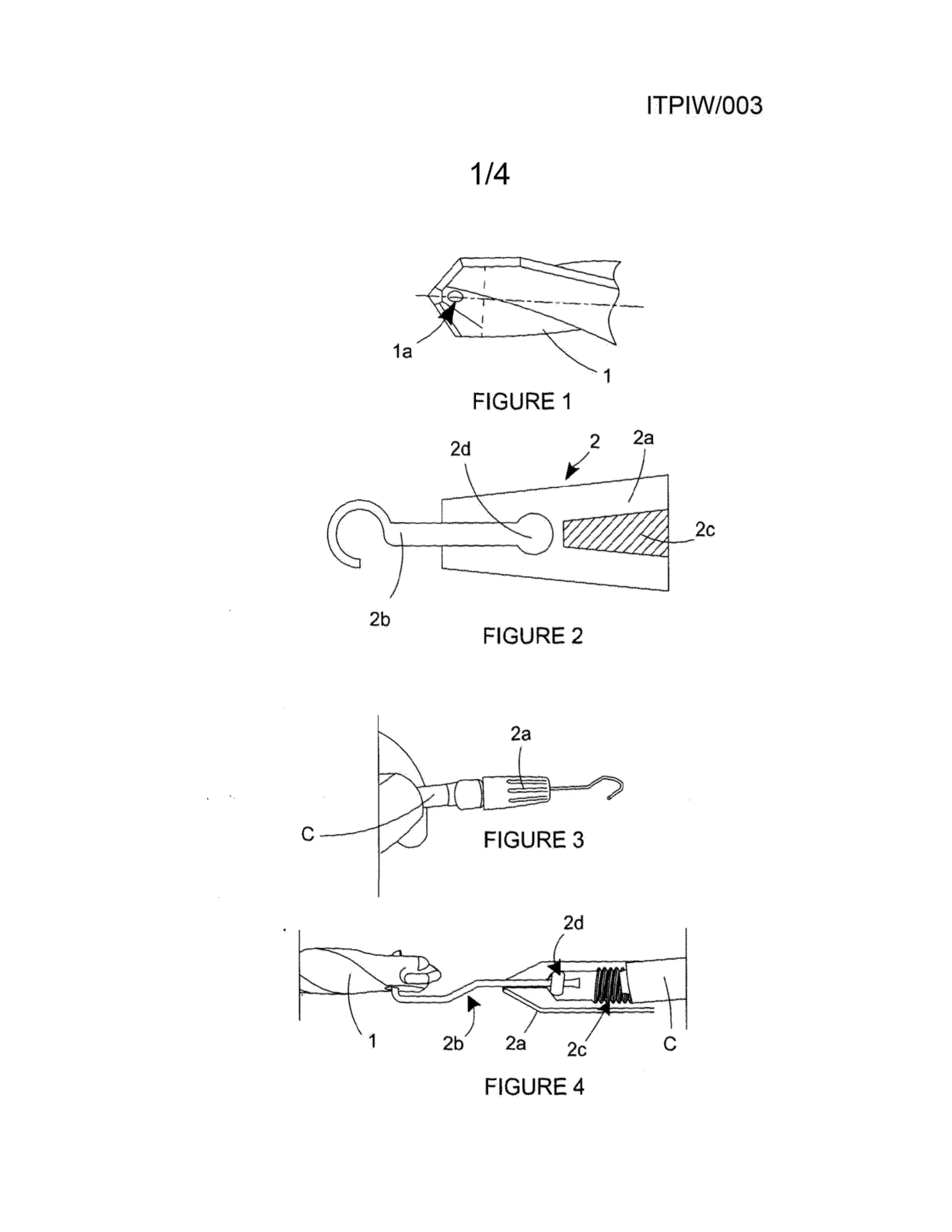

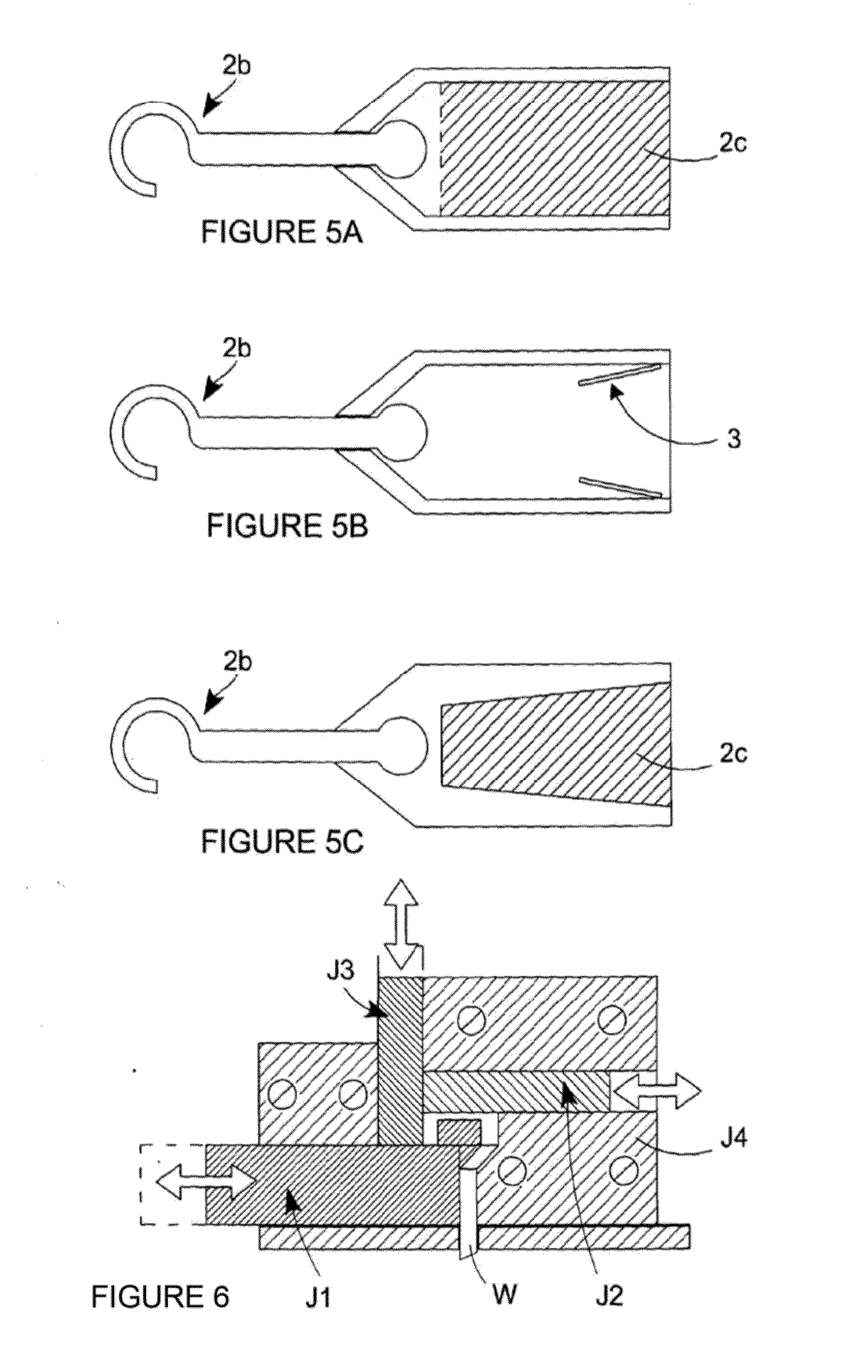

Fishing adapter

ActiveUS20140124717A1Easily and reliably securedEasy to manufactureWaterborne vesselsFilament handlingFilled cableCoupling

The present invention concerns fishing adapters for pilling a cable or the like through a hole drilled in a wall or other structure and in one aspect comprises a drill bit connector to enable the adapter to be demountably attached to a drill bit and an item connector to enable a cable or other elongate / linear item to be attached to the adapter, wherein the adapter further has a rotary coupling between the drill bit connector and the item connector to permit the drill bit to rotate as the adapter with cable or other elongate / linear item attached is pulled through a drilled hole without significantly twisting said cable or other elongate / linear item.

Owner:MALTBY MALORY

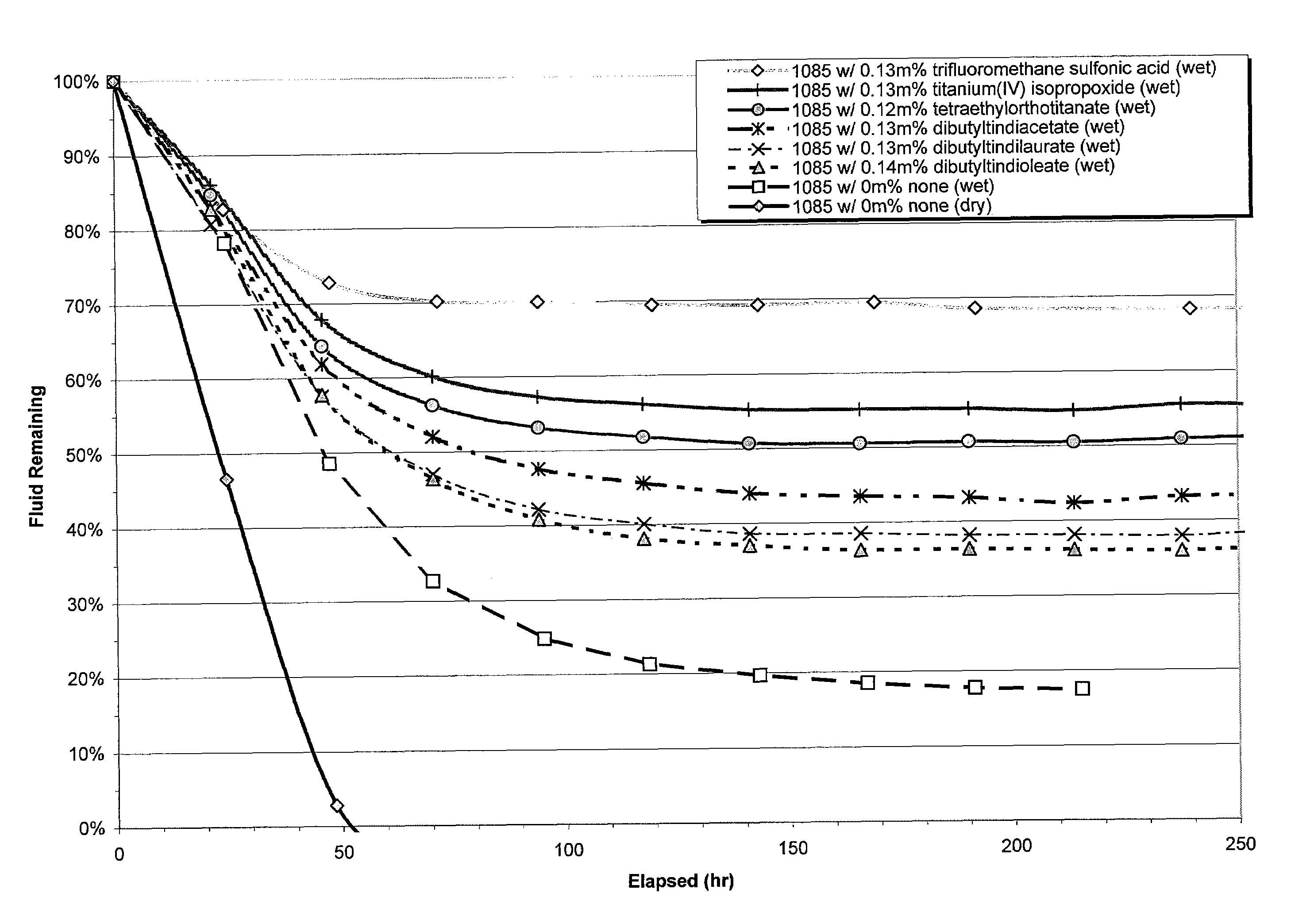

Acid-catalyzed dielectric enhancement fluid and cable restoration method employing same

ActiveUS7700871B2Liquid spraying plantsPlastic/resin/waxes insulatorsDielectricOrganometallic catalysis

A dielectric enhancement fluid composition having at least one organoalkoxysilane and an acid catalyst having a pKA less than about 2.1 and a method for using the composition to enhance the dielectric properties of an electrical cable having a central stranded conductor encased in a polymeric insulation and having an interstitial void volume in the region of the conductor, the method comprising at least partially filling the interstitial void volume of the cable with the composition. The fluid composition may further include an organometallic catalyst and a corrosion inhibitor.

Owner:NOVINIUM LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com