Discharging device and discharging method for submarine oil-filled cable direct-current withstand voltage test

A technology of withstand voltage test and oil-filled cable, applied in corona discharge devices, measuring devices, circuits, etc., can solve the problems of low reliability of discharge devices, high maintenance costs, long discharge time, etc., to reduce the risk of electric shock, improve Efficiency and time reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

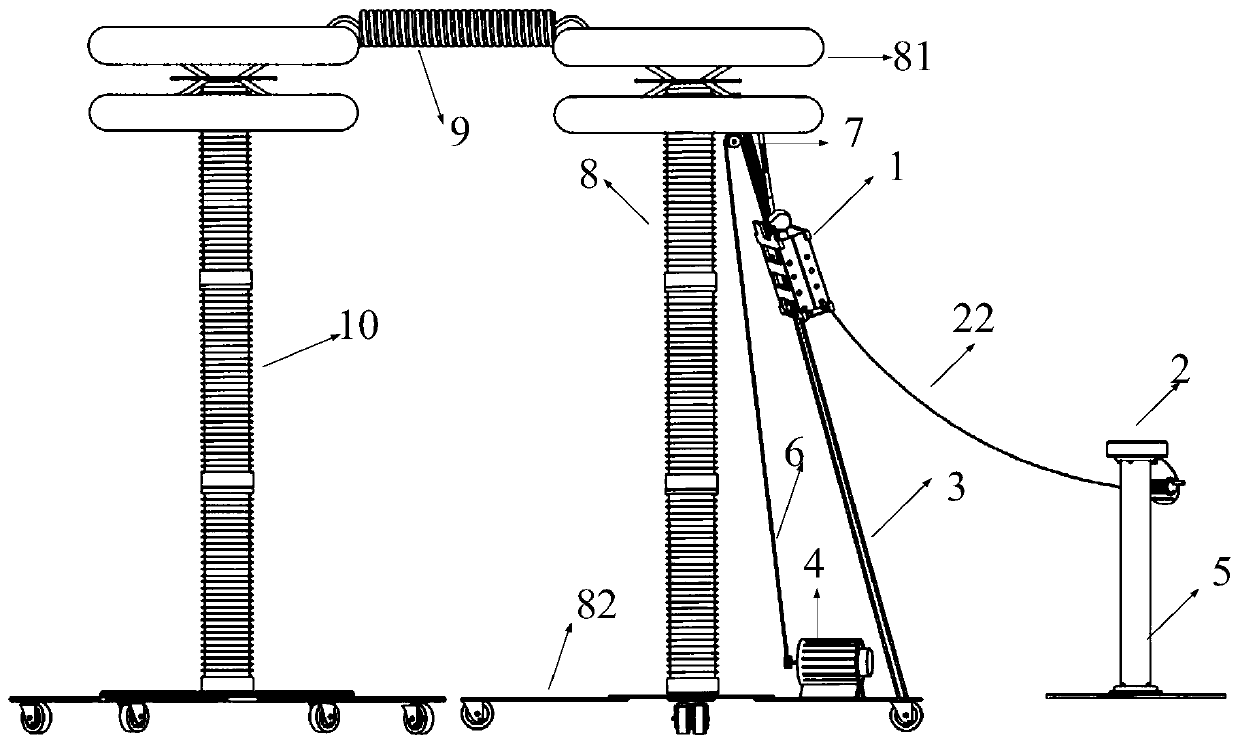

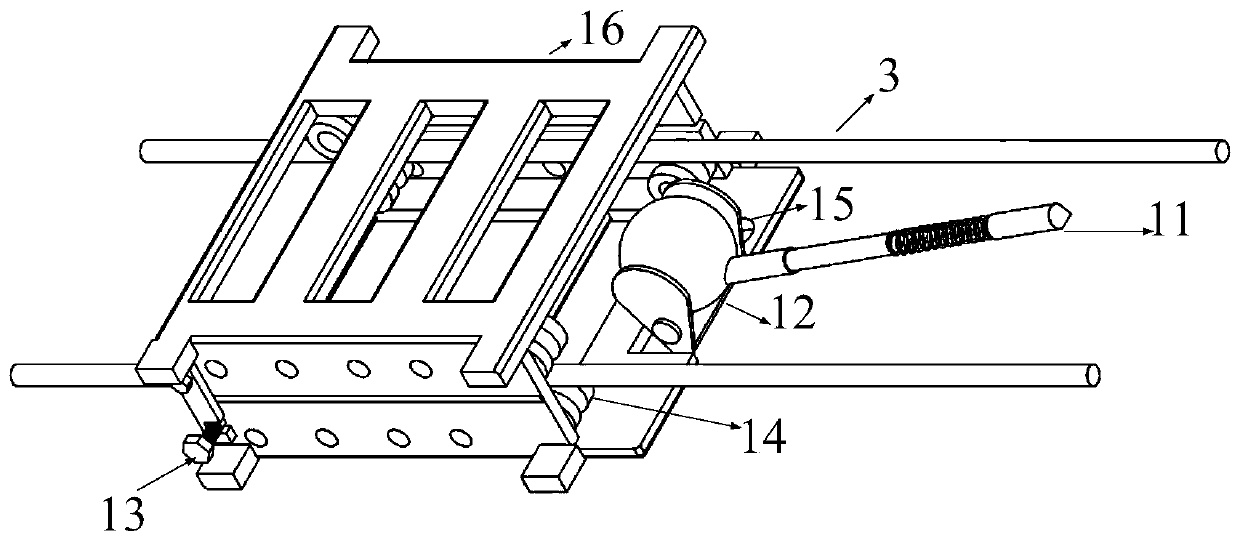

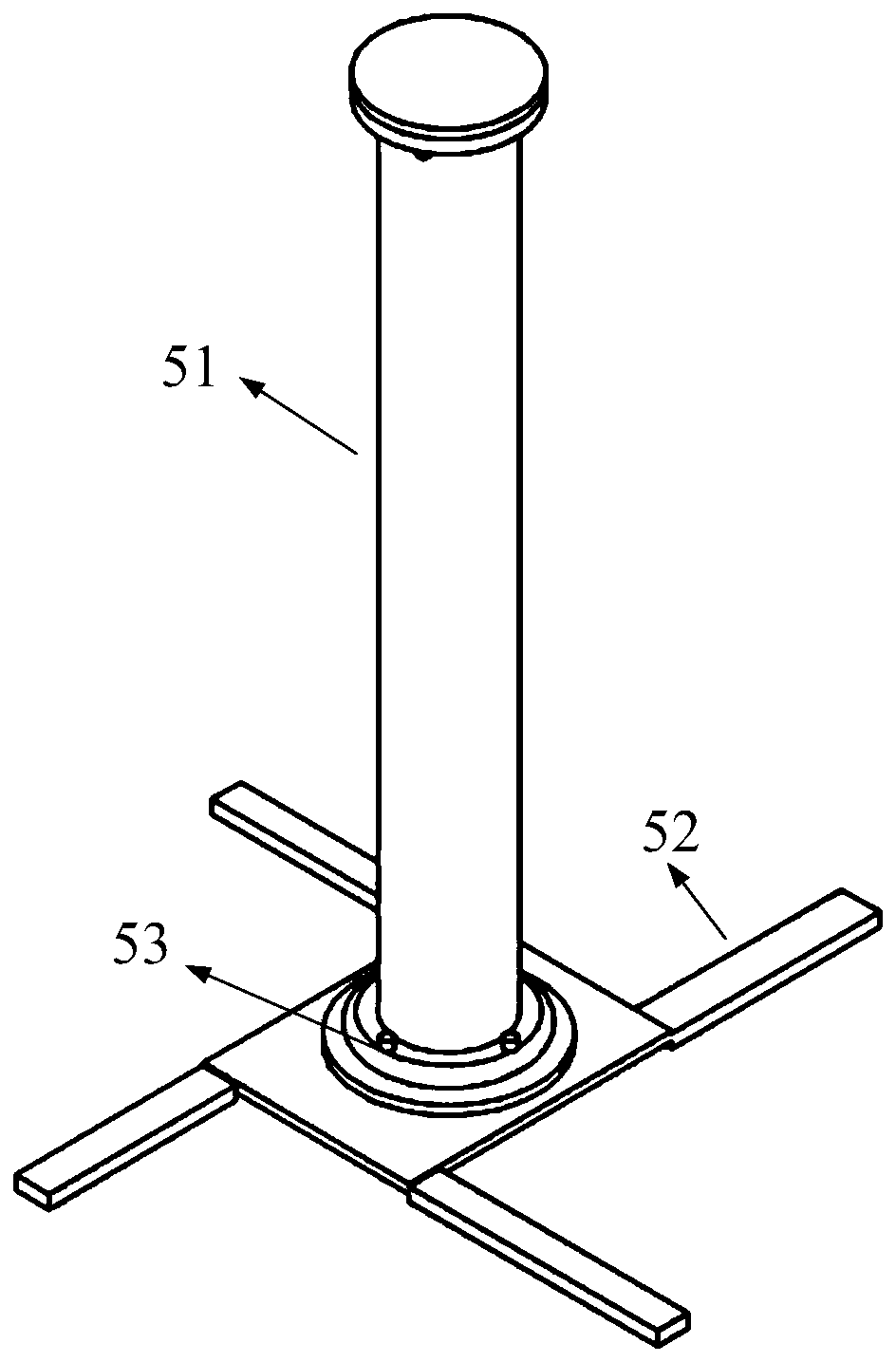

[0037] Such as figure 1 As shown, a discharge device for DC withstand voltage test of submarine oil-filled cables, including discharge car 1, pressure equalizing cover 2, pull rod 3, miniature electric hoist 4, discharge resistor 5, pull rope 6, fixed pulley 7 and high-voltage wire 22 .

[0038] During the DC withstand voltage test, the connection relationship between the submarine cable, the voltage divider and the DC high voltage generator is as follows: Figure 6 As shown, in order to improve the reliability of the test system, two voltage dividers 8 were placed during the test, and the two voltage dividers 8 were respectively placed between the terminals 30 of the three-phase submarine cable. The voltage divider 8 and the DC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com