Lead-free insulation compositions containing metallocene polymers

a technology of metallocene polymer and composition, applied in the field of lead-free insulation composition, can solve the problems of buried power cables being especially vulnerable to water treeing, the actual breakdown of the modular structure of dielectric materials, and the failure of polymeric power cable insulation to undergo treeing, etc., to achieve the effect of improving the performance of polymers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

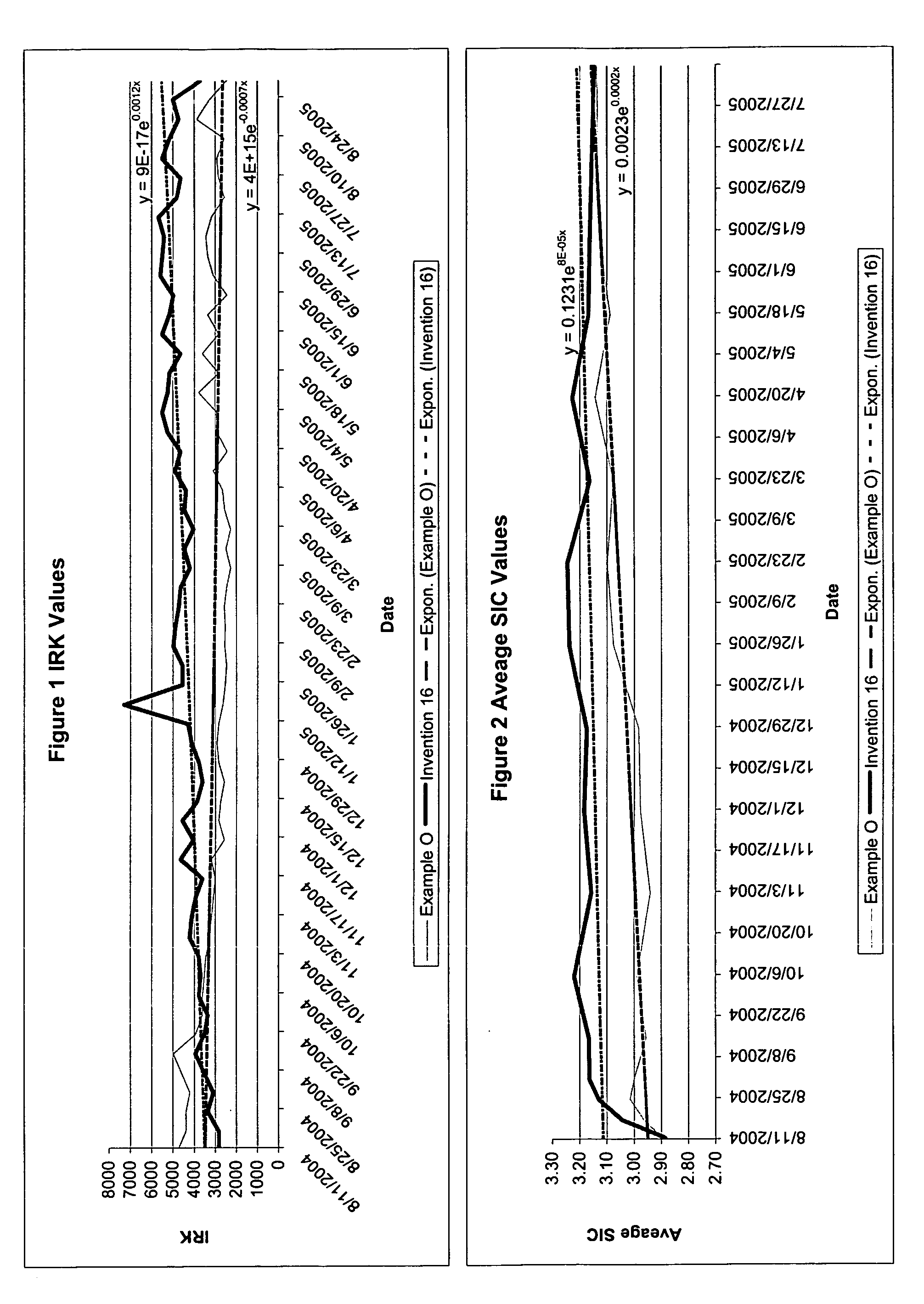

Image

Examples

Embodiment Construction

[0030] The invention particularly relates to polymeric compositions utilizing polyolefins, which compositions have a unique combination of good mechanical properties, good dielectric properties, and good water treeing resistance, as well as a lower melt temperature for improved processability when the compositions include peroxide-containing compounds. The products are extremely useful as lead-free insulation compositions for electric power cables.

[0031] In this description the expression “lead-free” can be considered synonymous with “substantially lead-free” and means that lead-containing substances are not added to the compositions and / or insulations of the invention or the cables that use them. The reality must be recognized, however, that trace or negligible amounts of lead or its derivatives or compounds may be present in the constituent materials that make up the insulation composition and the terms “lead-free” and “substantially lead-free” do not exclude this possible presen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com