Environment-friendly filled cable material

A cable material and environmental protection technology, applied in the field of environmental protection filled cable material and its preparation, can solve the problems of poor weather resistance, affecting the physical and mechanical properties and processing technology performance of the cable material, and the low temperature resistance is not very good, and achieves easy peeling and preparation. The method is simple, easy to implement, and the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

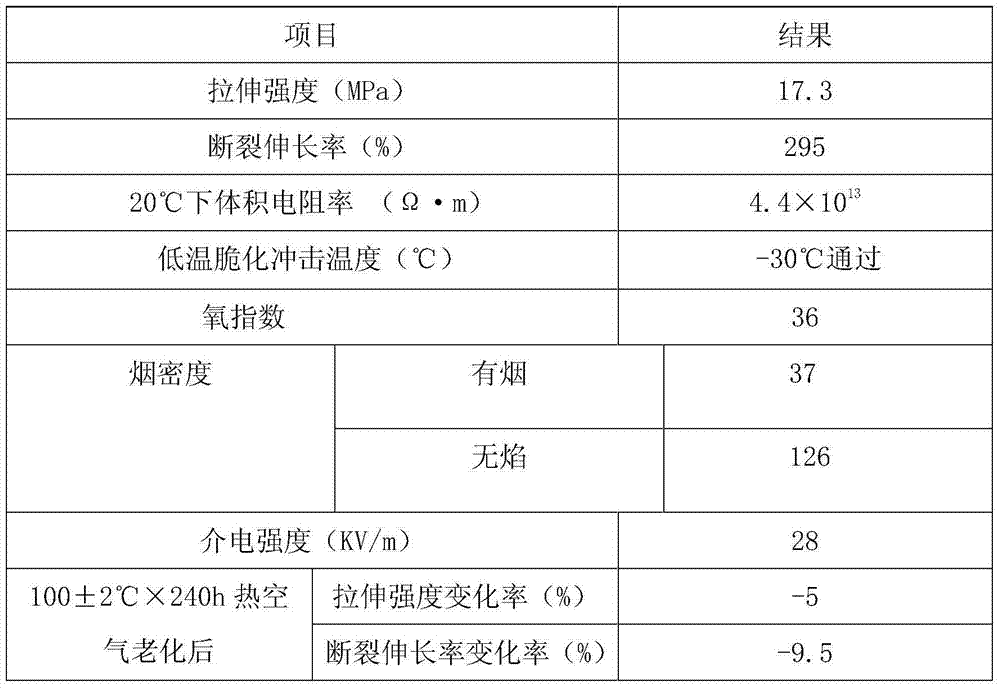

Image

Examples

Embodiment Construction

[0012] Environmentally friendly filling cable material, made of the following weight (kg) raw materials:

[0013] Polyvinyl chloride resin 88, environmental protection stabilizer 6, modifier CPE1, barium stearate 2, light calcium carbonate 43, hollow glass beads 12, talc 7, molybdenum oxide 5, copper oxide 3, tributyl citrate Ester 55, calcium stearate 0.5, nano jade powder 6, sodium tripolyphosphate 18, PE wax 0.6, urotropine 1, modified filler 14.

[0014] The preparation method of the cable material of the present invention:

[0015] Weigh each component raw material according to the formula ratio, stir the weighed component raw material in a high-speed mixer, and then mix it at a temperature range of 150-180℃, twin-screw extrusion, grinding surface eagerly Granulation, cyclone separator feeding, vibrating screen sieving and packaging, the finished product of environmentally friendly filling cable material is obtained.

[0016] Among them, the modified filler is prepared by the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com