Oil-filled cable terminal oil level measuring and oil supplementing method

An oil-filled cable and terminal technology, which is applied in the field of oil level measurement and oil replenishment at the oil-filled cable terminal, can solve the problems of inconvenience, inability to accurately judge the oil quantity of the terminal, and inability to provide basis for maintenance plan formulation, so as to eliminate defects and facilitate operation the effect of the situation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific implementation methods;

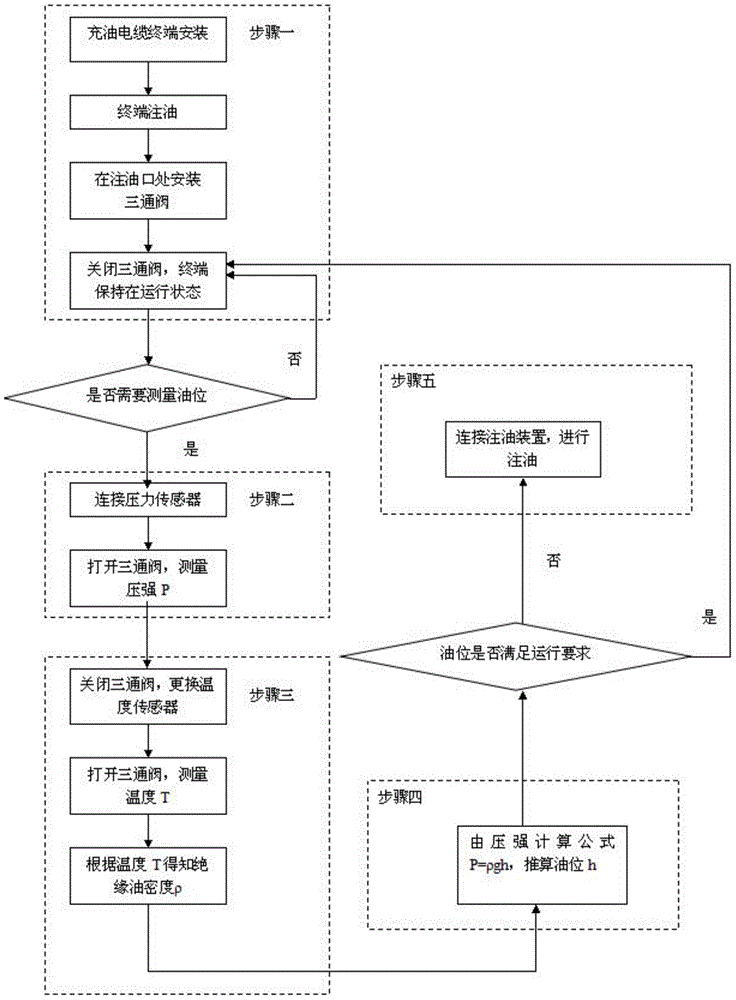

[0019] A method for oil level measurement and oil replenishment at an oil-filled cable terminal, such as figure 1 shown, including the following steps:

[0020] Step 1: Install a three-way valve at the oil filling port at the end of the oil-filled cable.

[0021] In this step, after the oil-filled cable terminal is installed and filled with oil normally, install a three-way valve at the oil injection hole of the oil-filled cable terminal. When the oil-filled cable terminal is in normal operation, the three-way valve is in the closed state.

[0022] Step 2: Measure the pressure P generated by the insulating oil inside the oil-filled cable terminal.

[0023] When it is necessary to measure the oil level inside the oil-filled cable terminal, first connect the three-way valve to the external pressure sensor, and then open the three-way valve to measure the pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com