Weighing device of carbon extruder

A weighing device and extruder technology, which is applied in the field of extruders, can solve the problems that the weighing device is too simple, and there is no obvious distinction between qualified products and unqualified products, so as to achieve the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

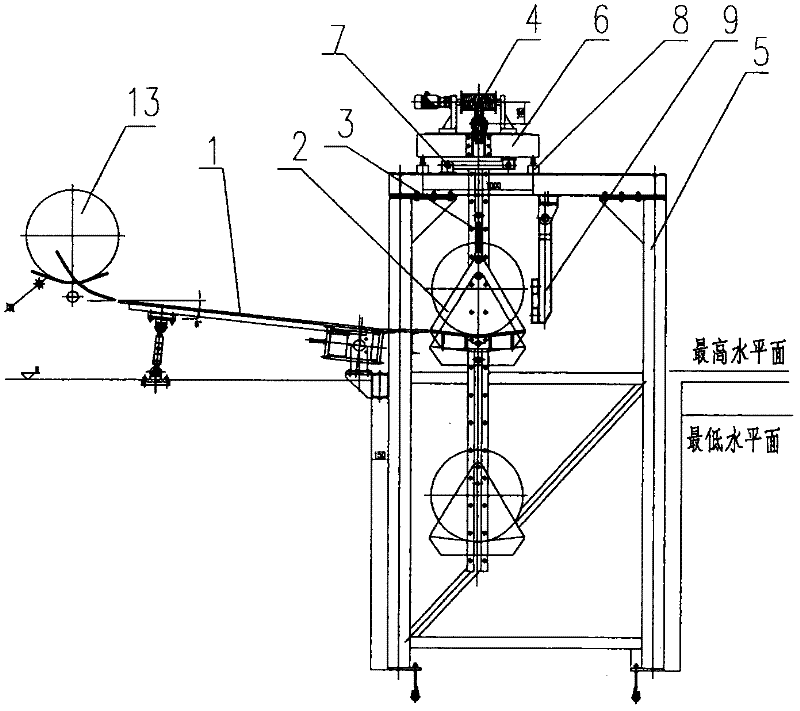

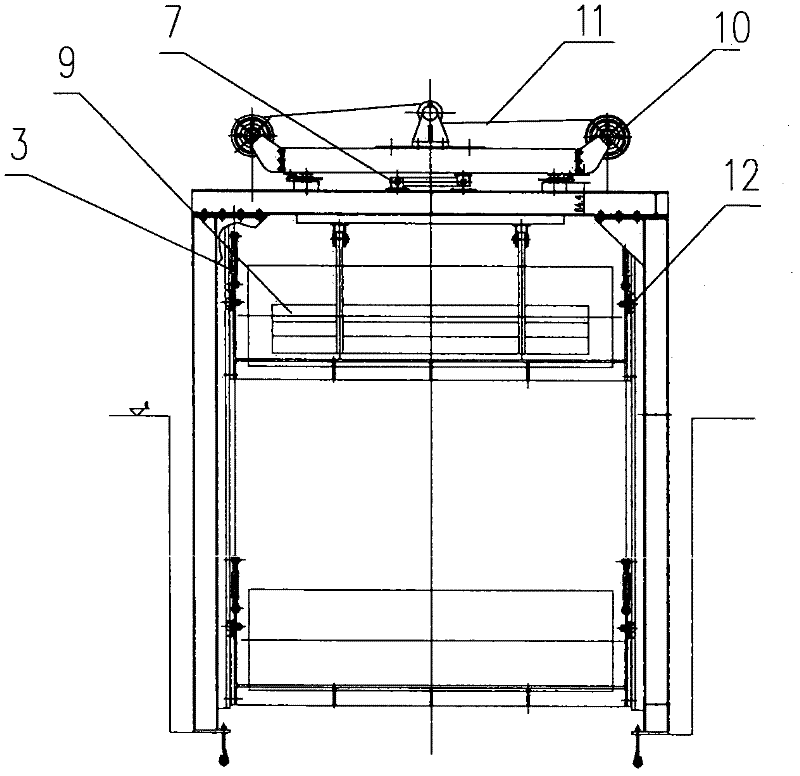

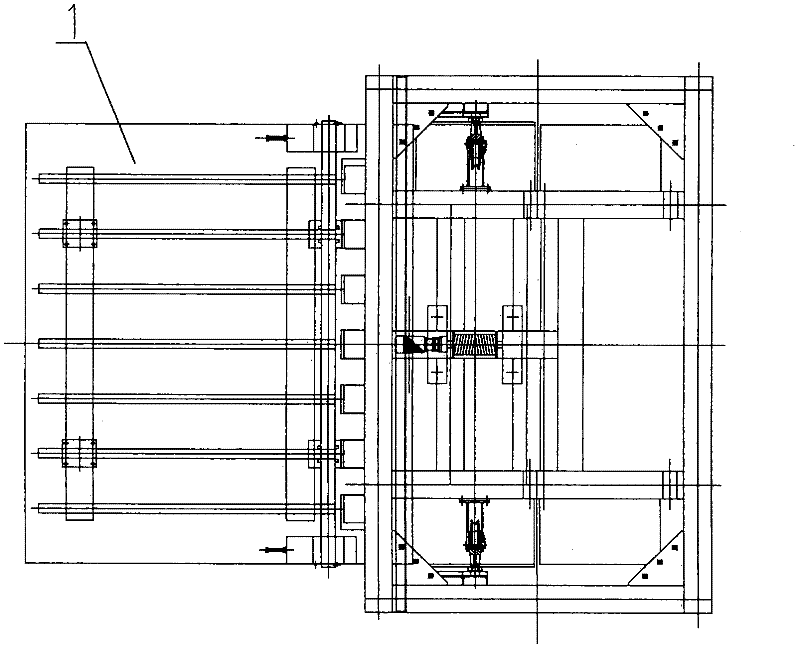

[0014] Such as figure 1 , 2 , 3, a weighing device for a carbon extruder consists of a material receiving plate 1, a hanging basket 2, a rope adjuster 3, a hoist 4, a frame 5, a weighing beam 6, a balancer 7, and a load cell 8. The buffer device 9, the pulley block 10, the winding steel wire rope 11, the guide wheel set 12, the product 13, etc. are composed of four load cells 8, which are symmetrically arranged between the weighing beam 6 and the frame 5, and the weighing beam Fix the hoist 4 on the 6, the winding steel wire rope 11 of the drum of the hoist 4 is connected with the rope adjuster 3, the rope adjuster 3 is connected with the hanging basket 2, and four balancers 7 and the frame are arranged in sequence at the center of the bottom surface of the weighing beam 6 5 connection, there is also a buffer device 9 next to the hanging basket 2 to prevent the product from rolling out of the hanging basket 2. Between the product 13 and the hanging basket 2, a material recei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com