Electromagnetic induction pipe 3pe anti-corrosion quick stripping device

A peeling device and induction technology, applied in induction heating, induction heating control, cleaning hollow objects, etc., can solve the problems of safety, speed, and applicability, and achieve the effect of saving manpower, shortening working time, and precise control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

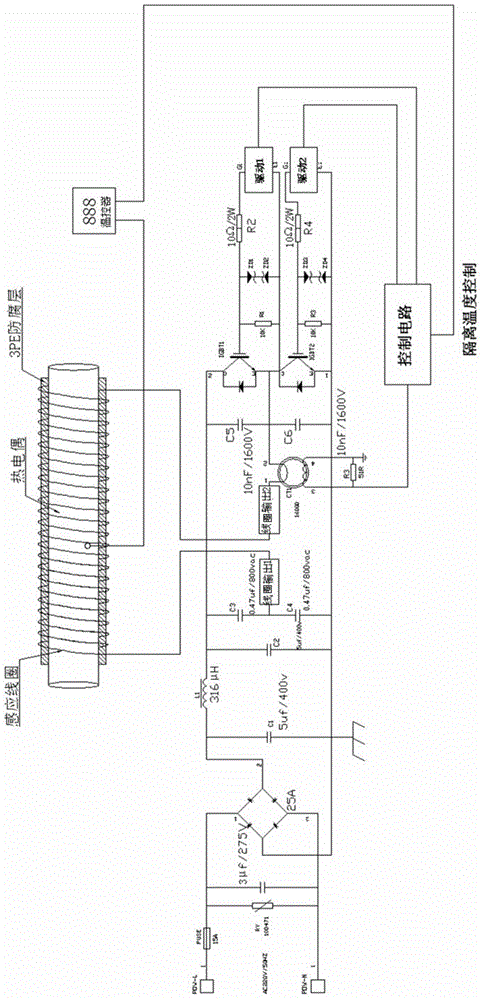

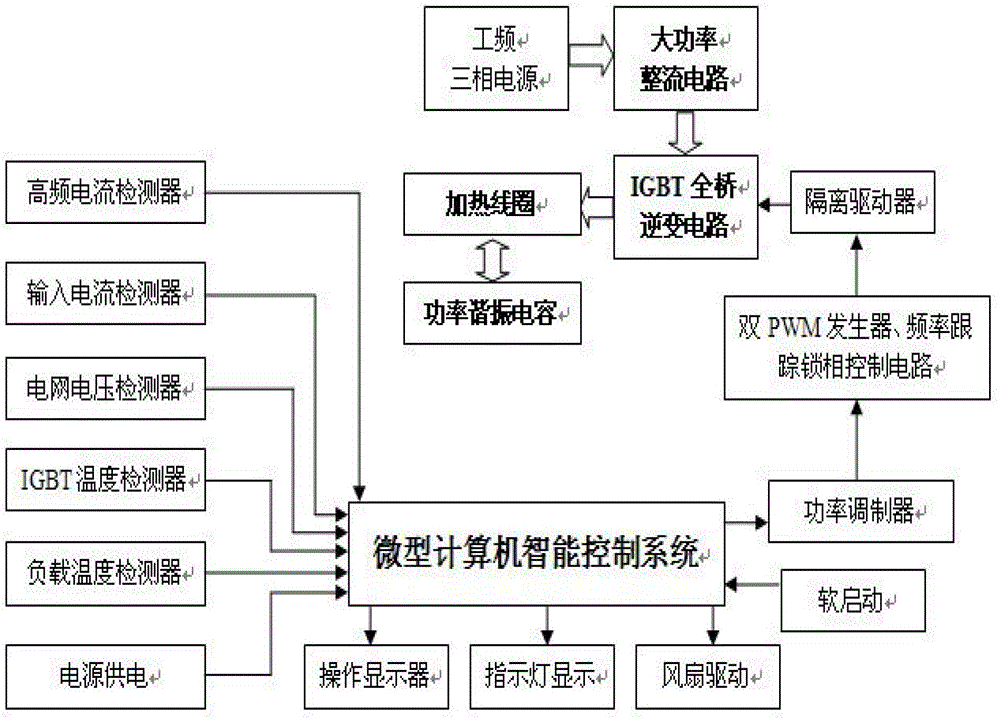

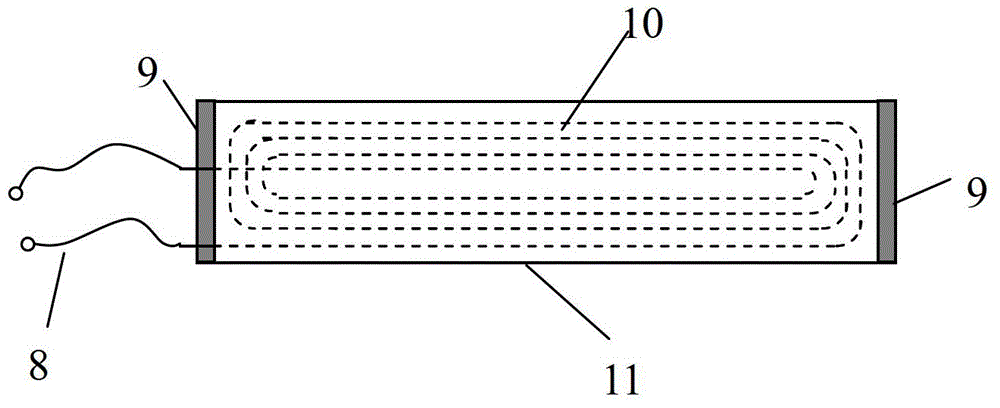

[0047] Embodiment. This example is an experimental prototype, and its constitution is as Figure 1-Figure 4 shown. This electromagnetic induction type pipeline 3PE anti-corrosion layer quick peeling device is composed of two parts: electromagnetic heating control system and fast-installed flame-retardant heating belt heating coil. The output of the electromagnetic heating control system is connected to the quick-loading flame-retardant heating belt. The electromagnetic heating control system such as figure 1 As shown, including single-chip microcomputer control system, input current detection, temperature detection, heating load adaptation detection, grid voltage detection, display, power modulator, dual PWM generator, frequency tracking phase-locked control circuit, isolation driver, main power supply , High frequency overcurrent protection. The output of input current detection, temperature detection, heating load adaptation detection and grid voltage detection is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com