Patents

Literature

105 results about "Service engineer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

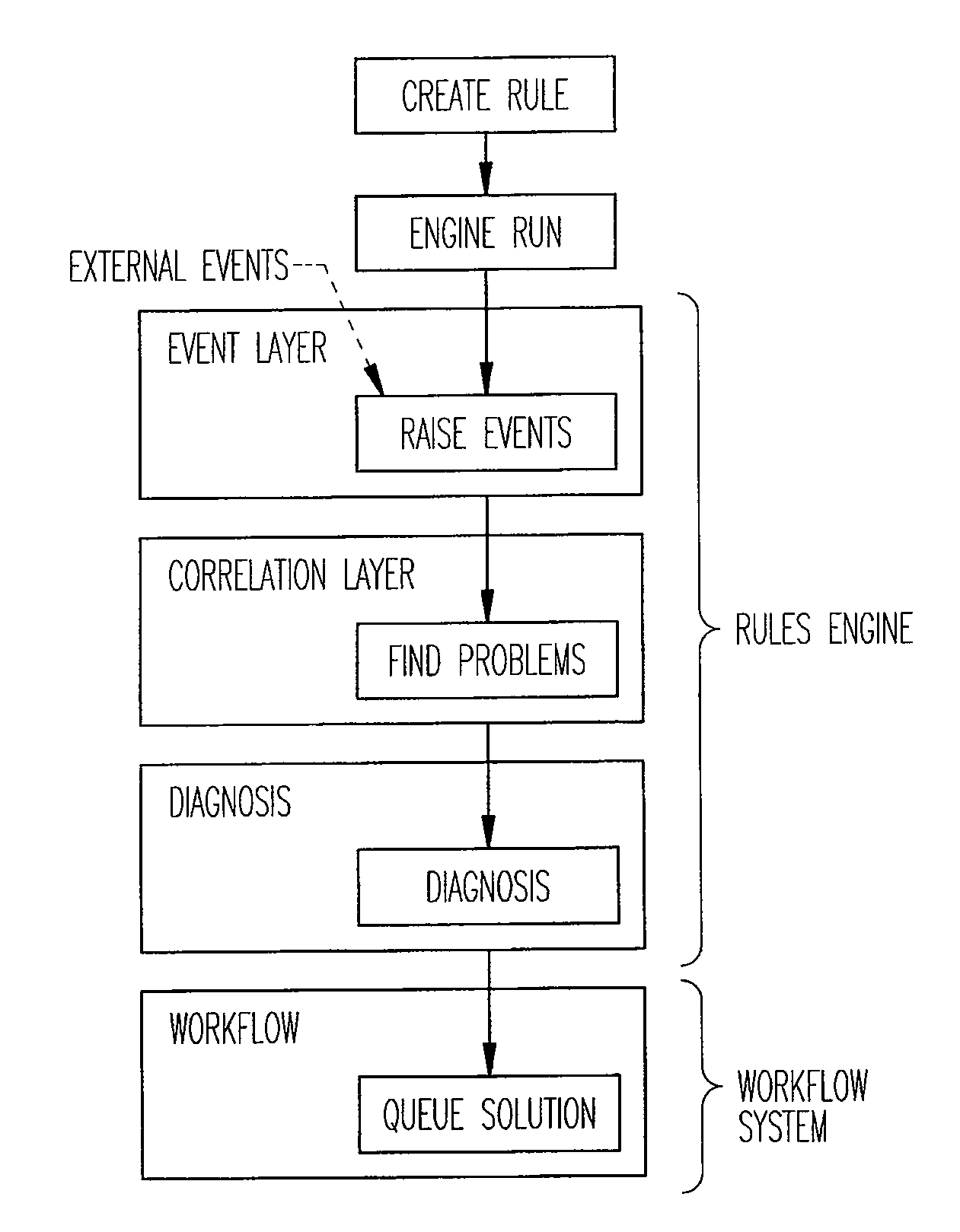

Mobile phone network management systems

ActiveUS20090075655A1Improve performanceSolve the real problemTransmitters monitoringReceivers monitoringNetwork managementService engineer

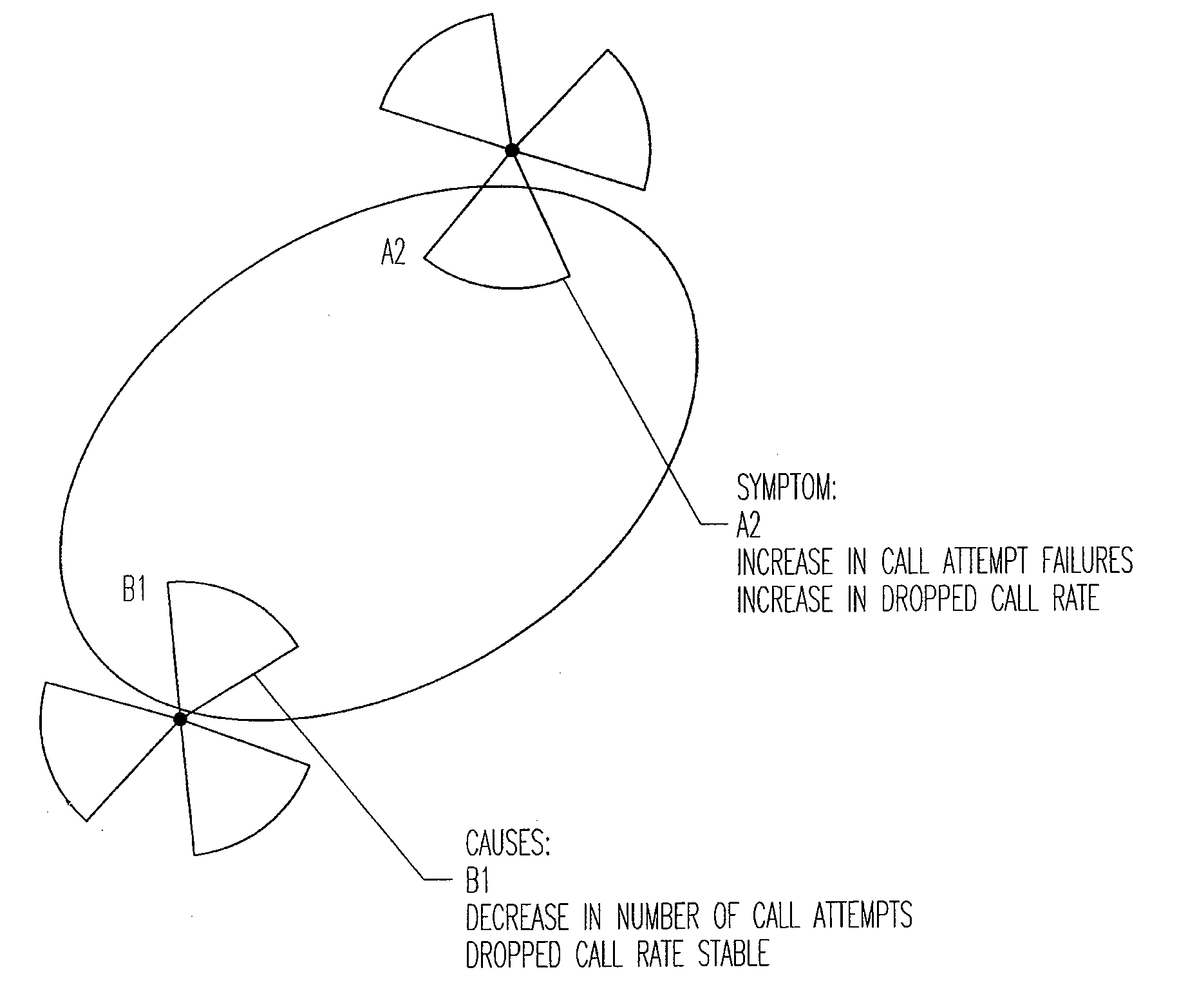

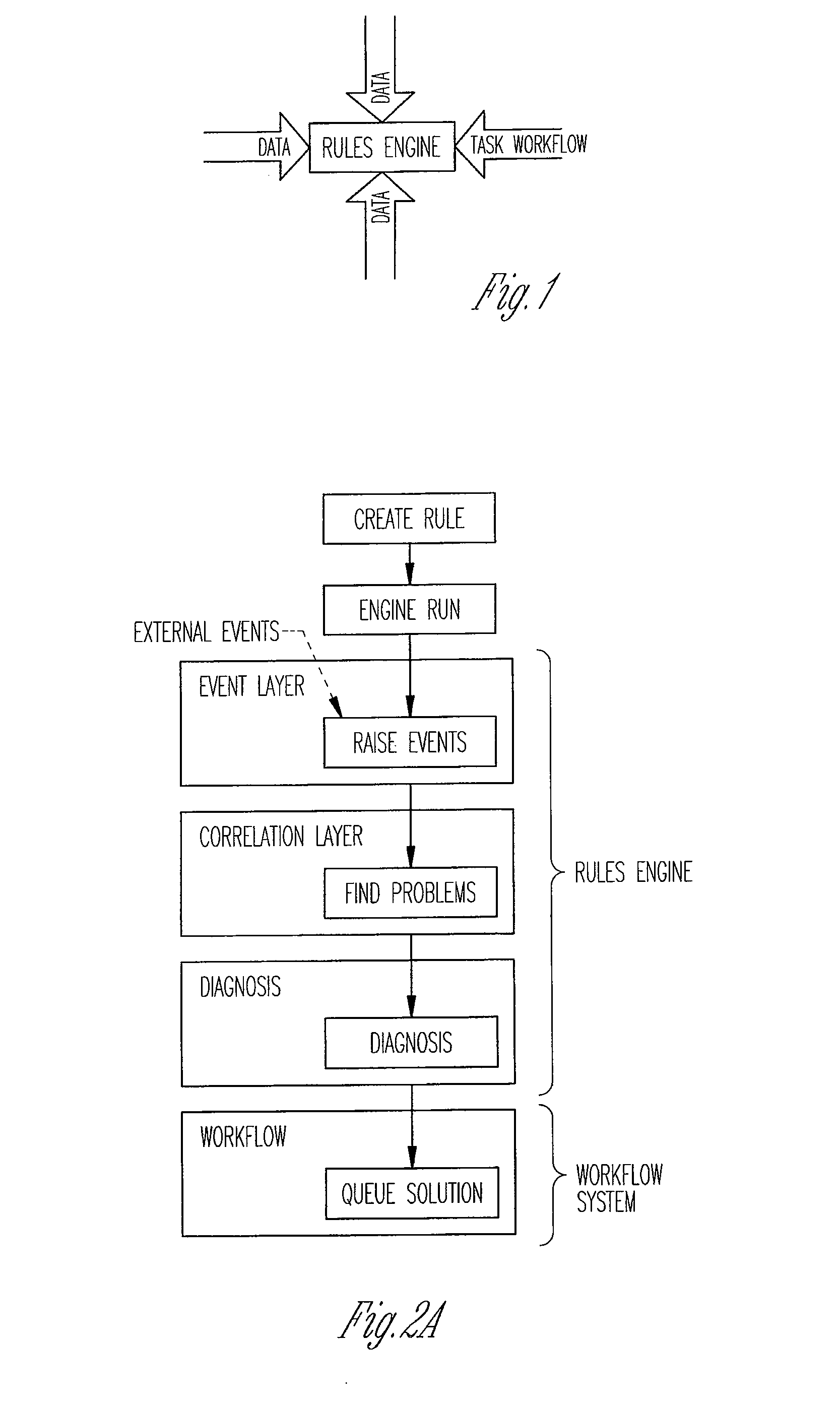

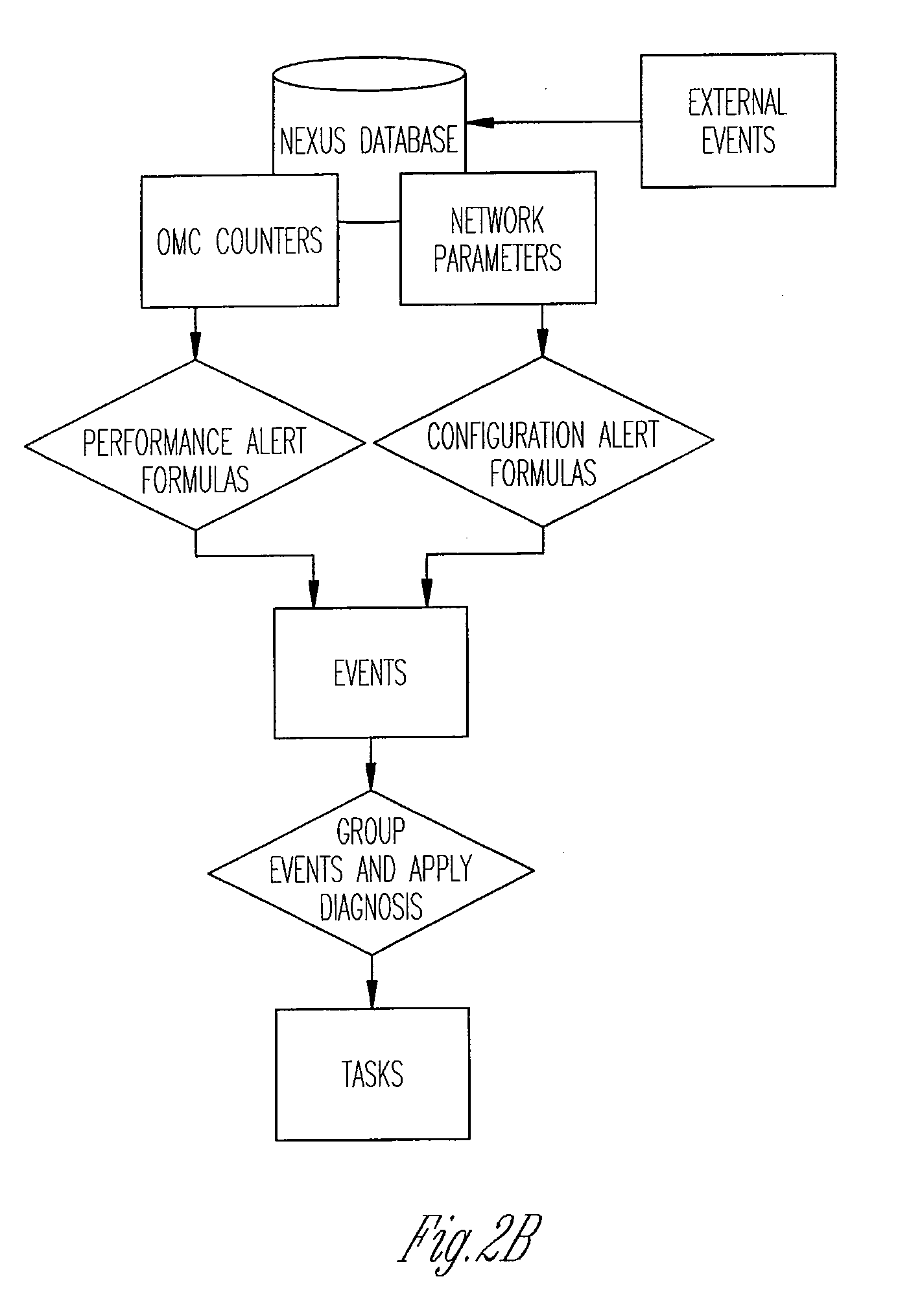

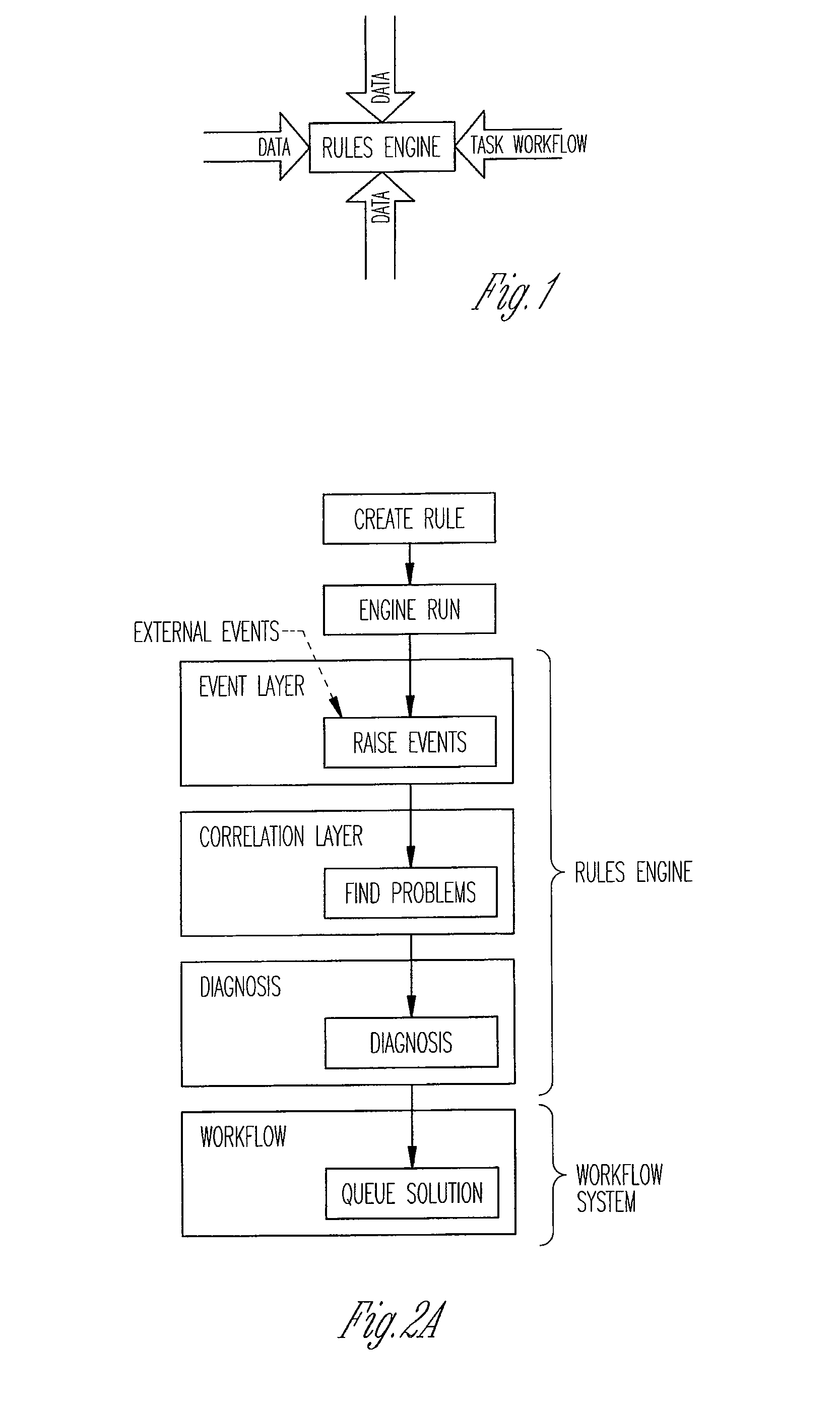

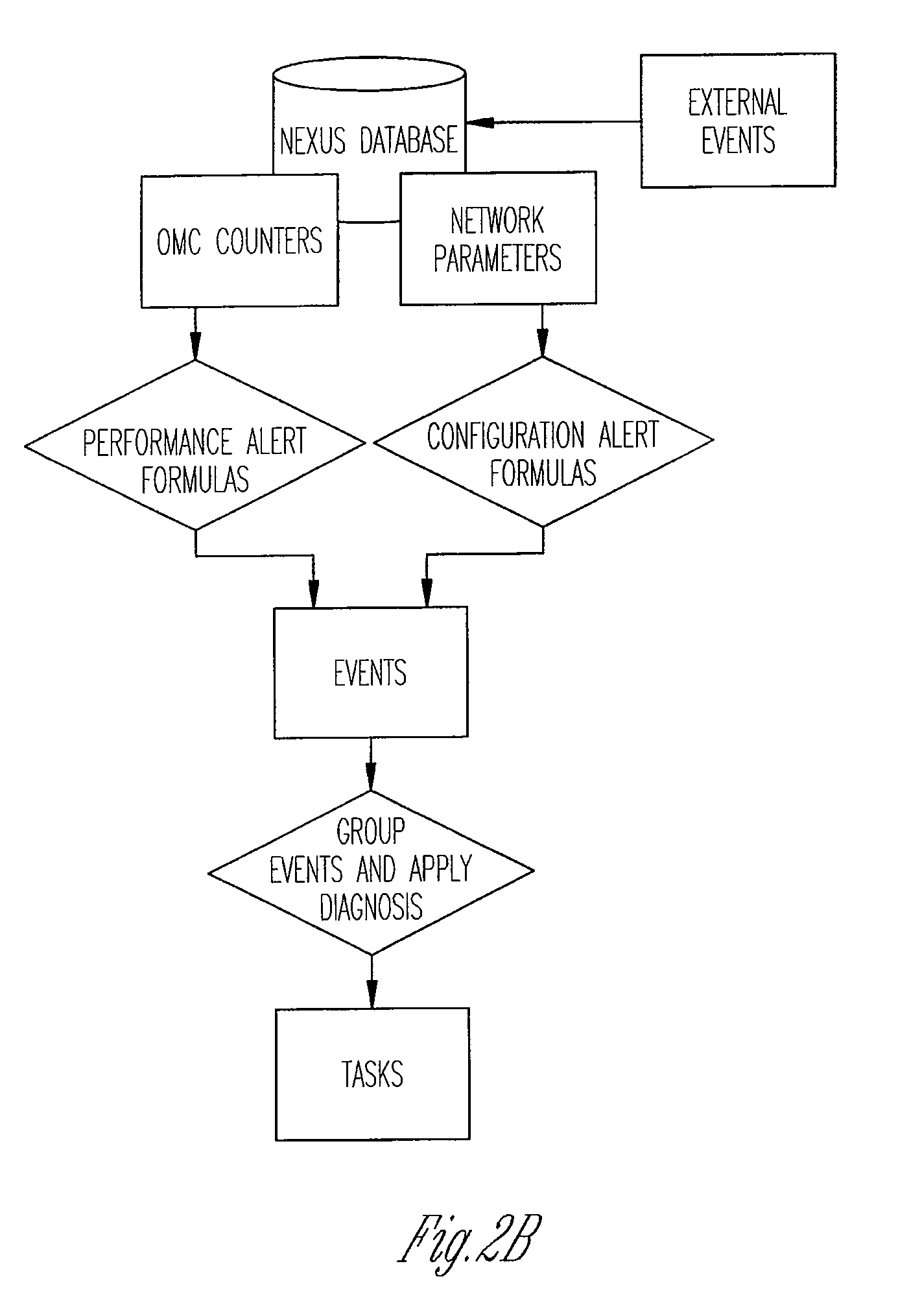

This invention relates to systems and methods for managing and optimizing mobile phone networks. A system for maintaining or optimizing a mobile phone network, the system includes a plurality of data feed inputs including at least one performance data feed input to receive performance data relating to performance of said mobile phone network over a first time period and at least one configuration data feed input to receive configuration data relating to configuration of said mobile phone network over a second time period; and a radio performance optimization system coupled to said plurality of data feed inputs, said radio performance optimization system including a rules engine to operate on said performance data and on said configuration data in accordance with a set of hierarchical rules and to output one or more tasks for network optimization, a said task including a definition of a potential fault, exception or optimization of said network to be investigated by a service engineer.

Owner:ACTIX

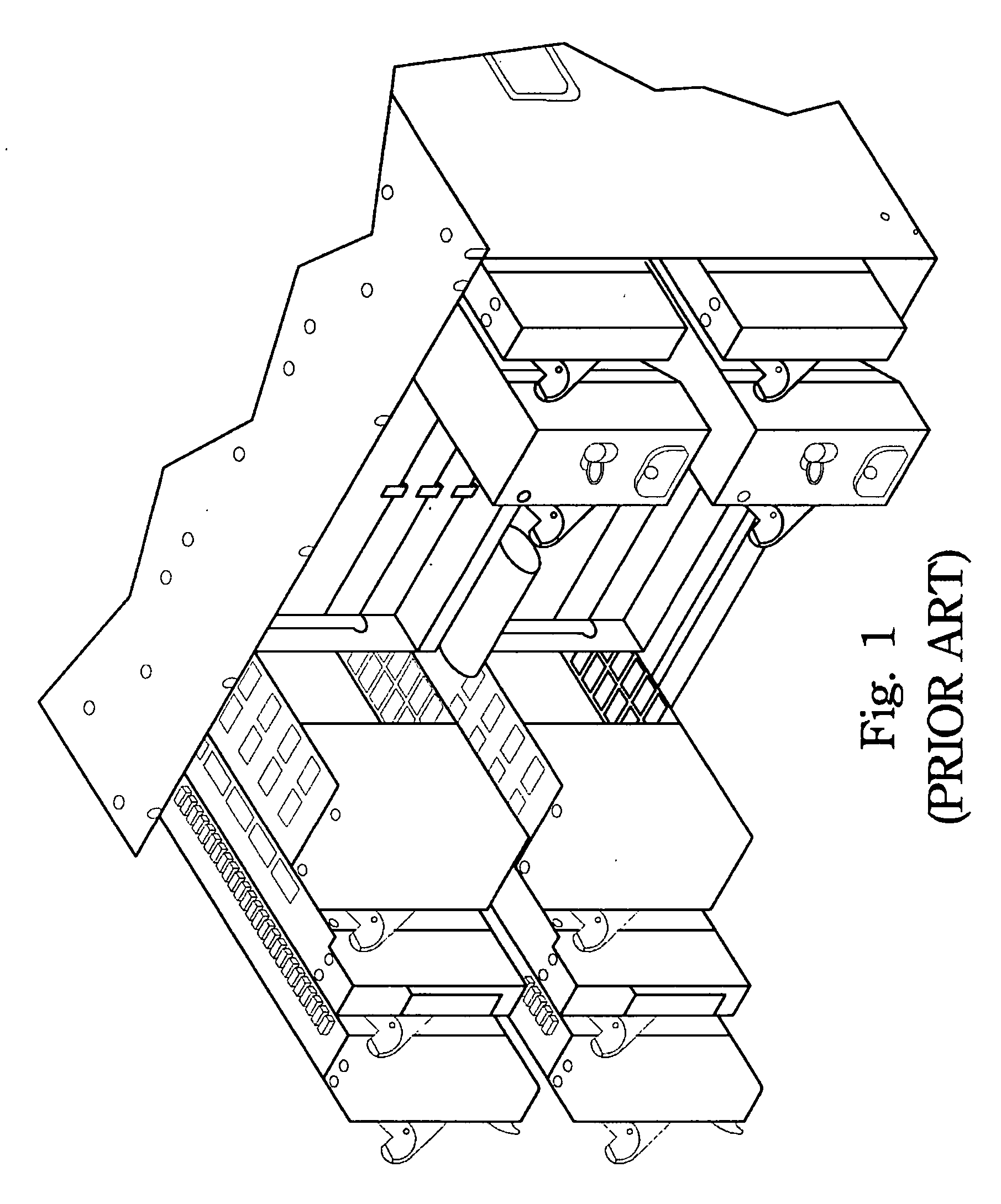

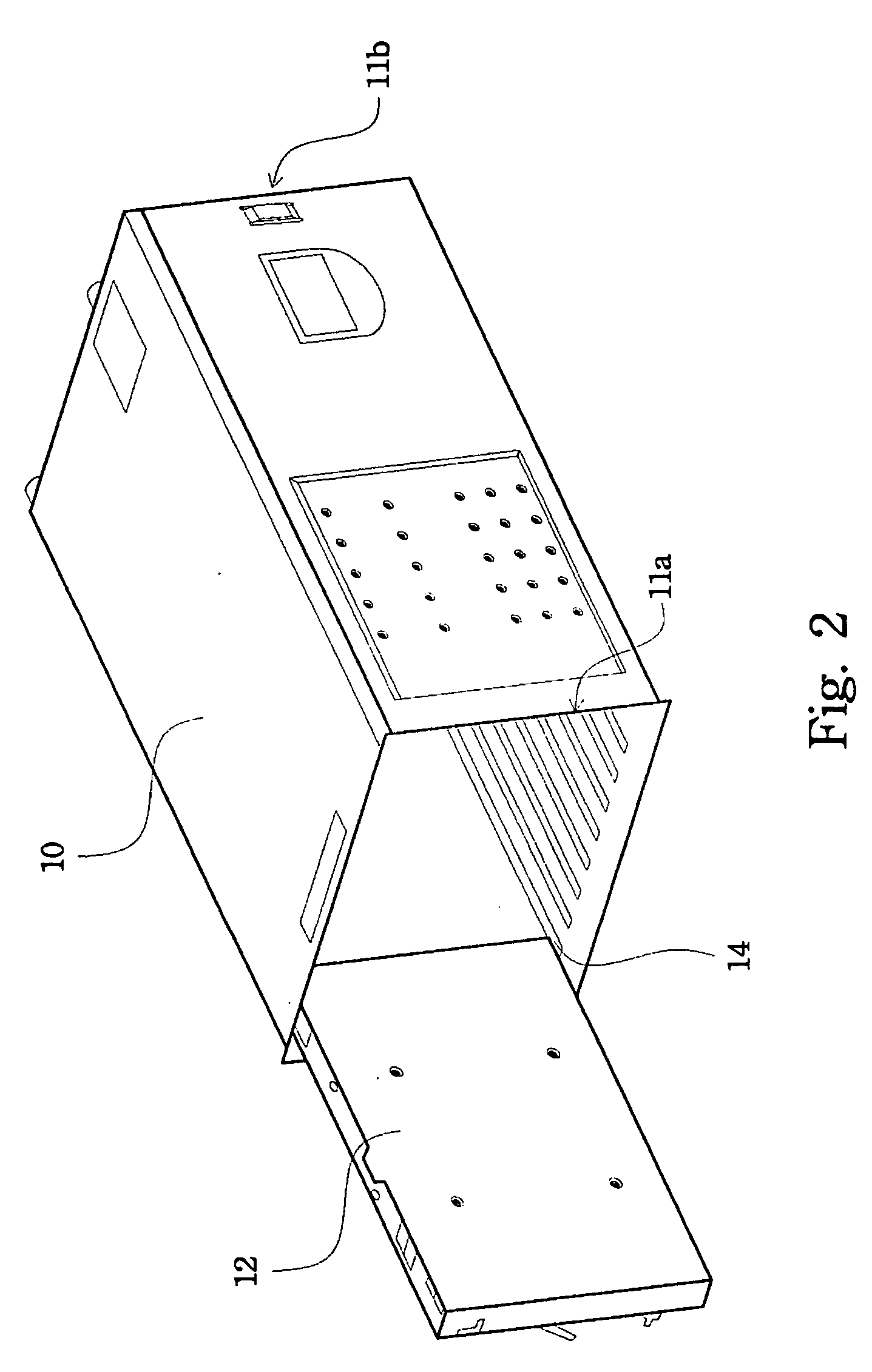

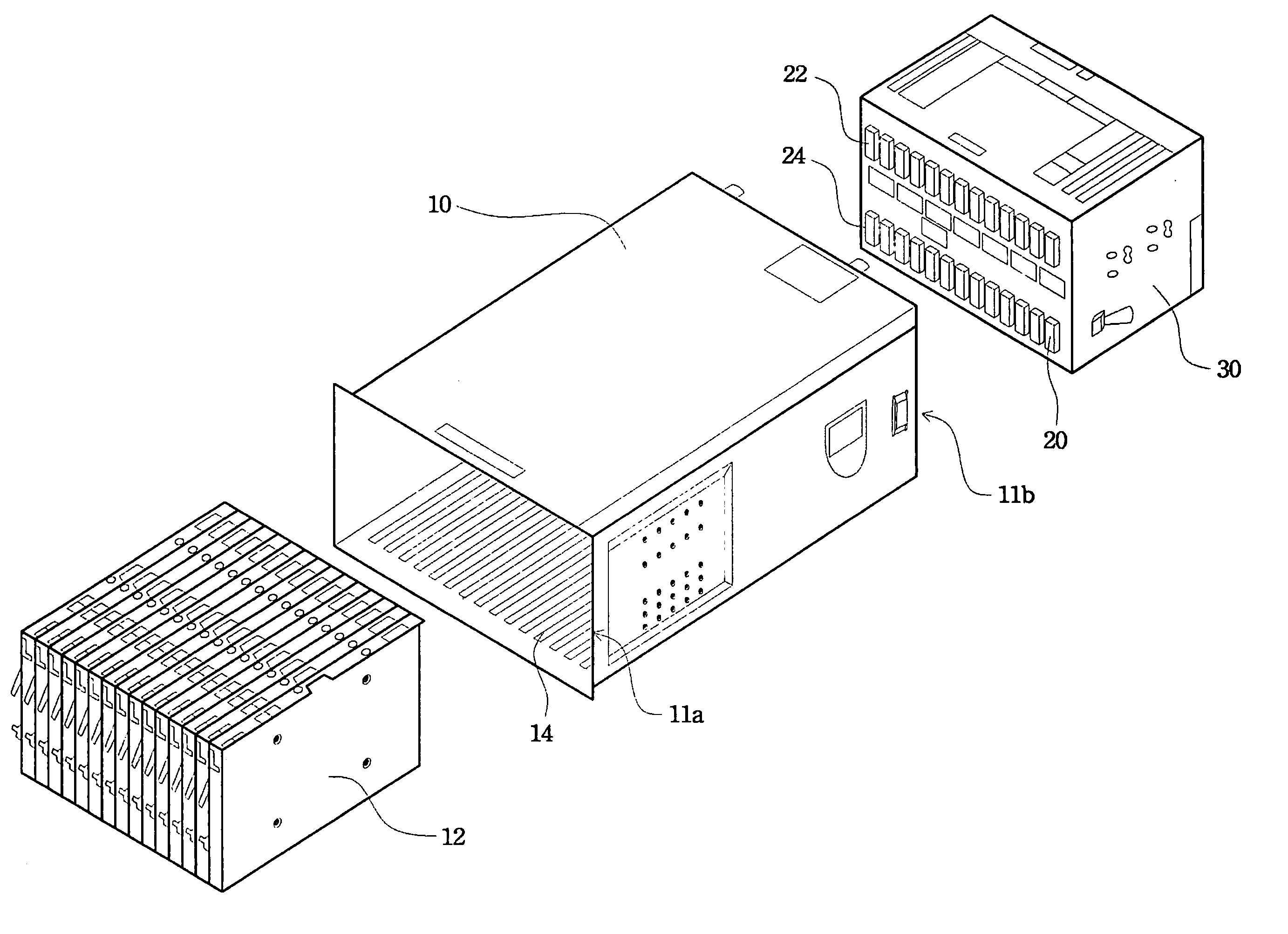

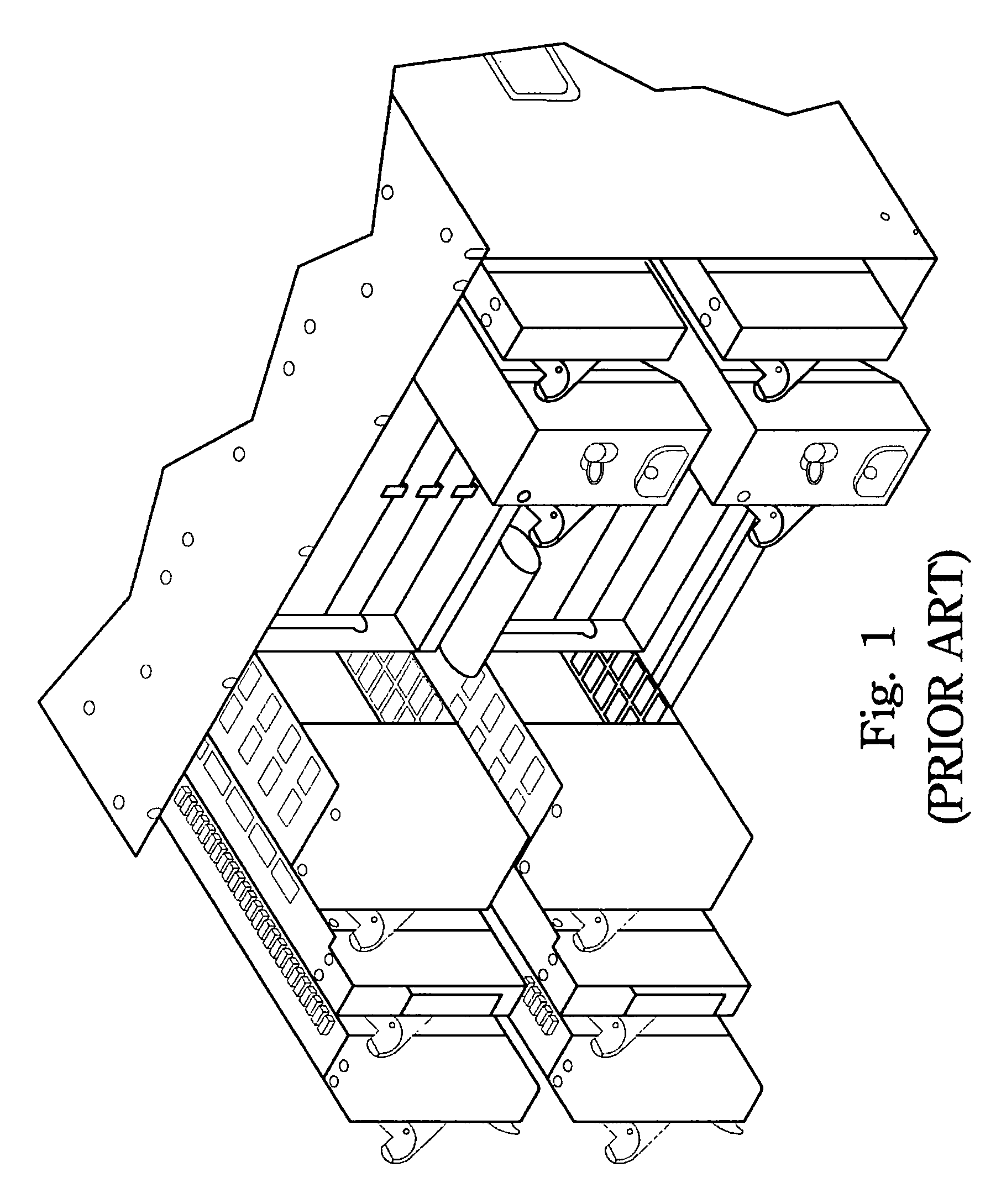

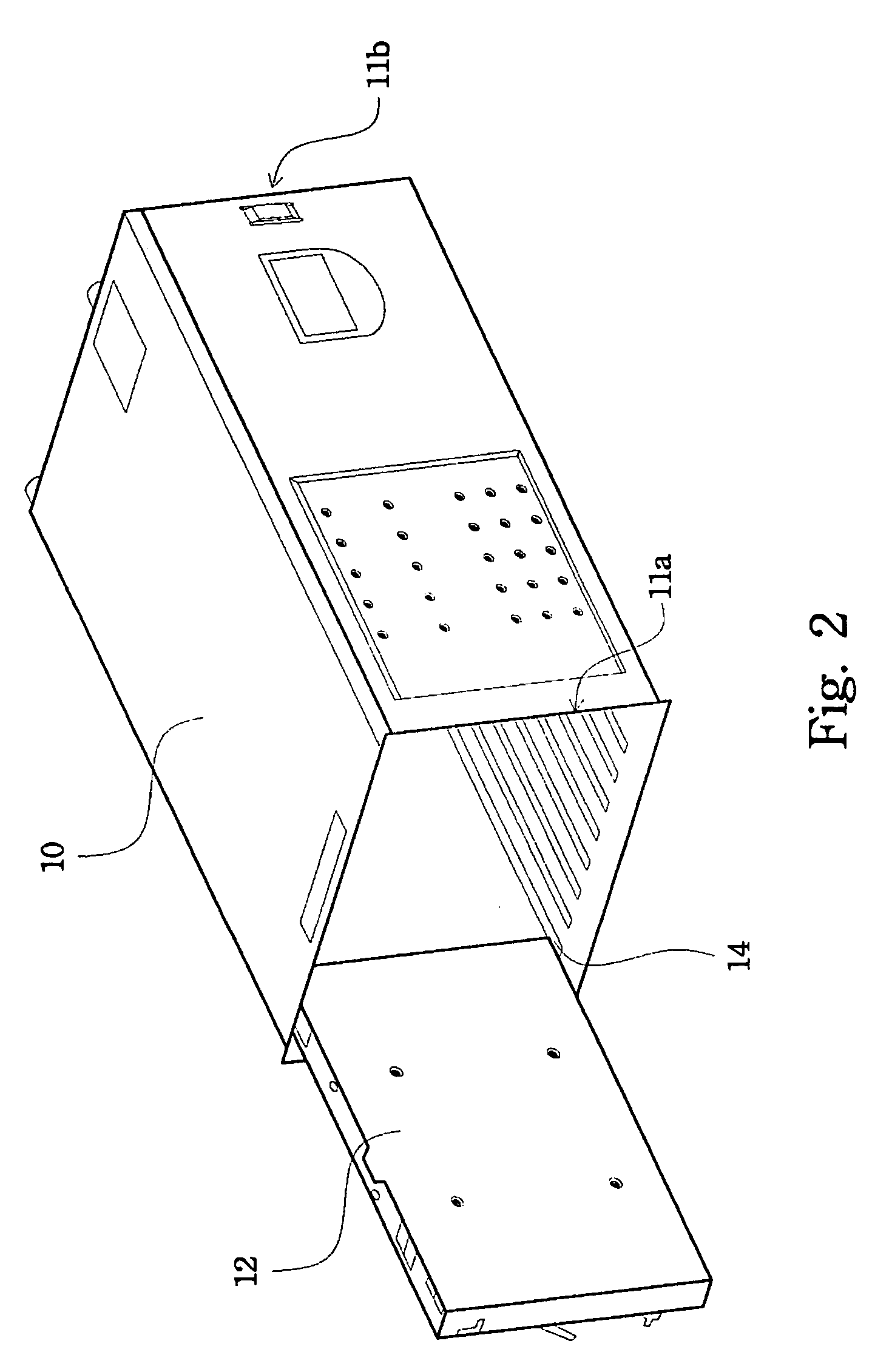

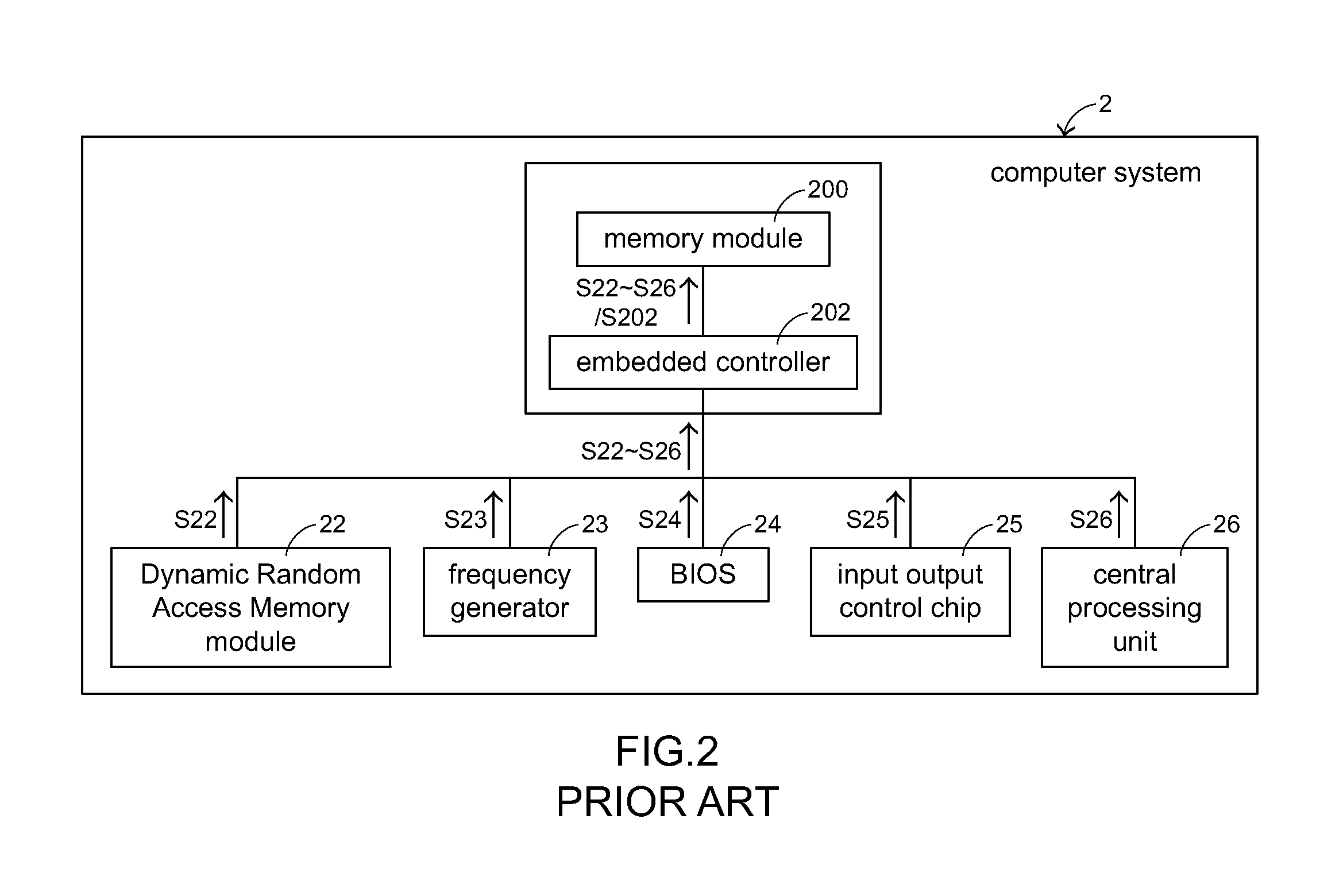

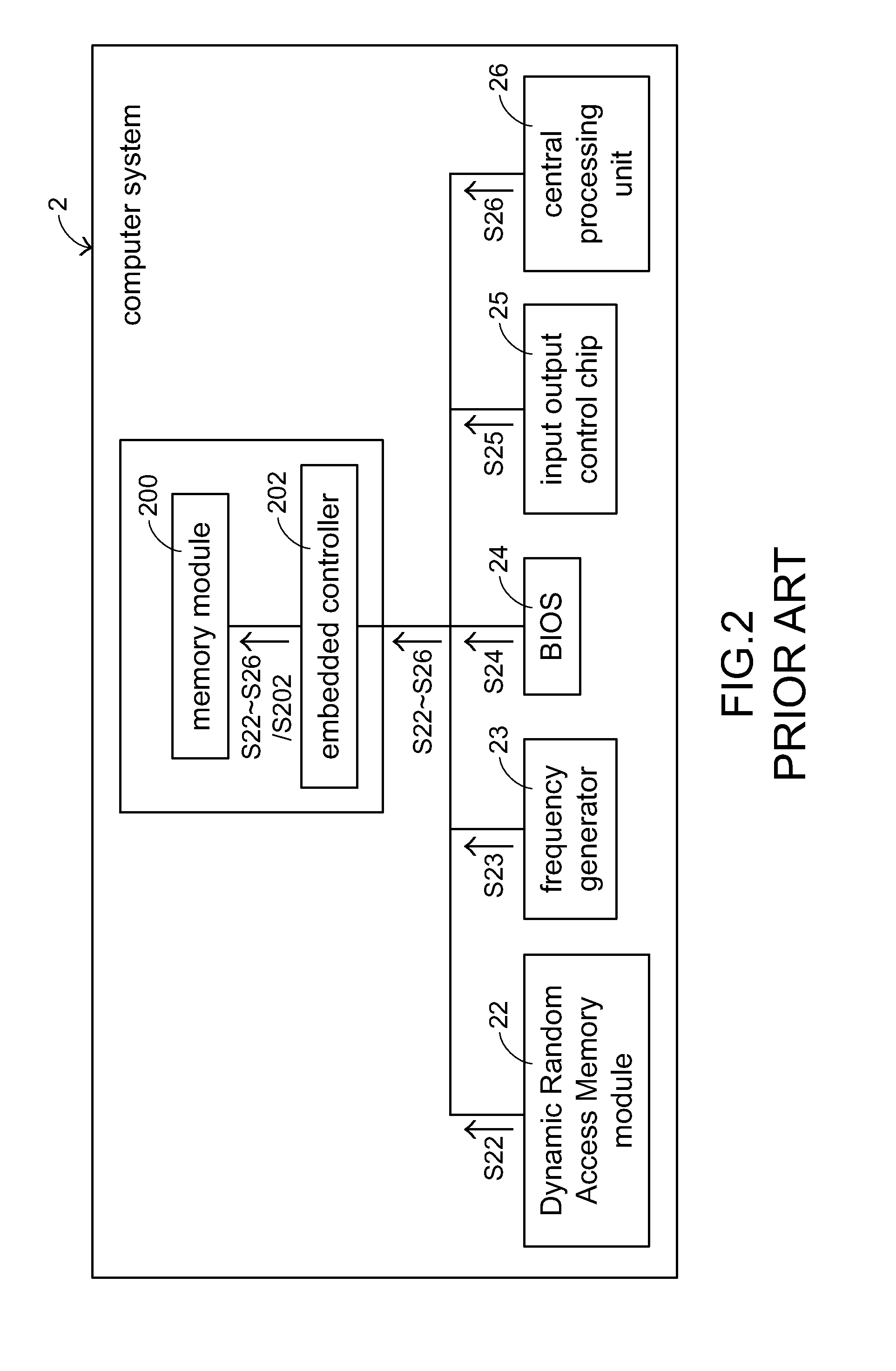

Blade server system

ActiveUS20060221579A1Easy to disassembleEasy maintenanceServersDigital data processing detailsService engineerEmbedded system

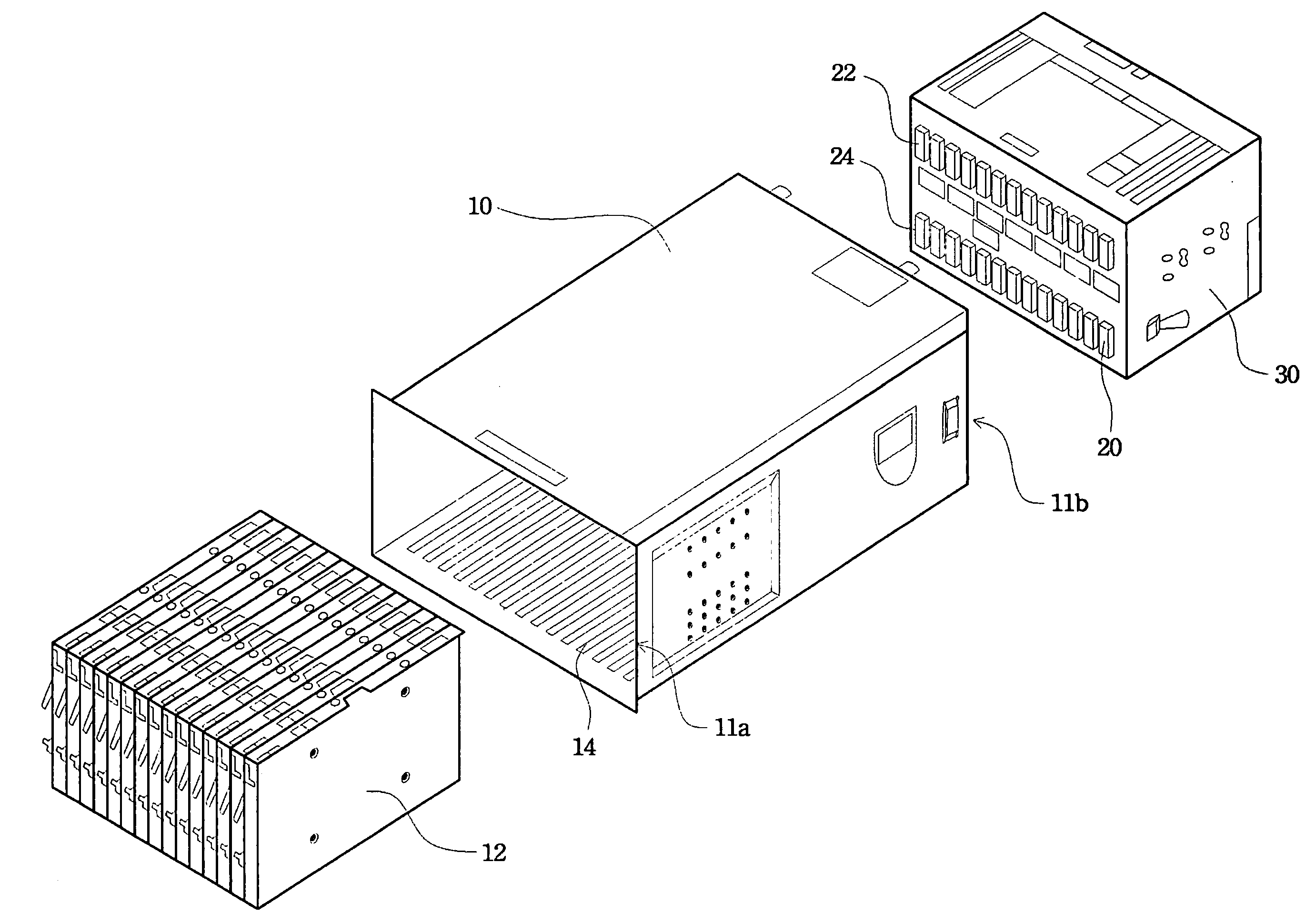

A blade server system is described. The blade server system includes a main chassis, a rear module chassis and a mid-plane. The main chassis is formed with slots into which a plurality of sever blades are slidablely inserted from the front end of the main chassis. The rear module chassis is removablely mounted to the rear end of the main chassis, and divided into plural partitions for housing different component modules. The mid-plane is mounted to an end of the rear module chassis, and includes a first face and an opposite second face. The first face has plural connectors electrically connected to the server blades and the second face has plural connectors electrically connected to the component modules. Therefore, when maintenance is needed for the mid-plane, the service engineer only needs to withdraw the entire rear module chassis as a whole, without the need to remove the individual component modules.

Owner:QUANTA COMPUTER INC

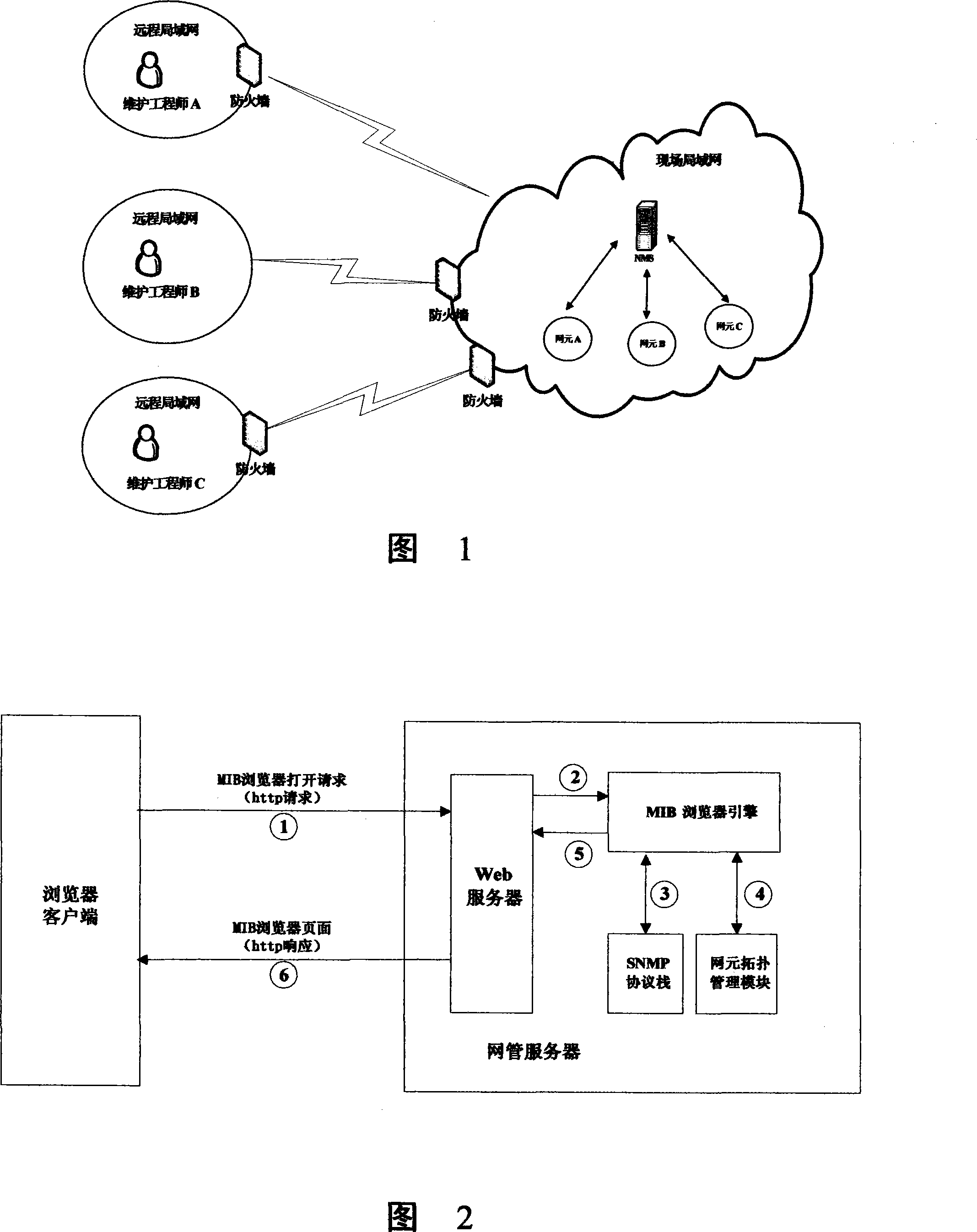

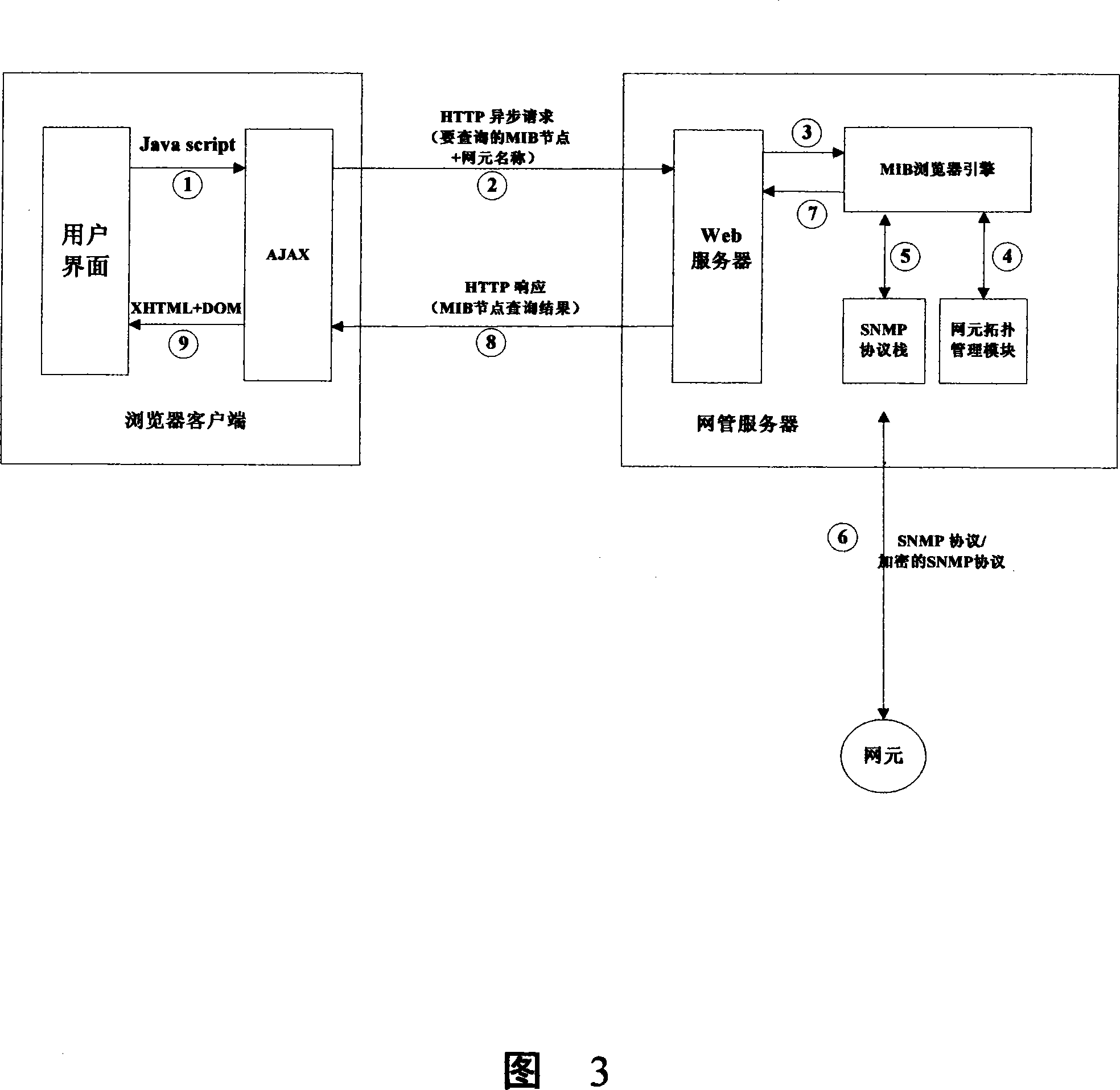

Network management system of implementing remote browse network element MIB node

InactiveCN101159607ALow network requirementsData switching networksSpecial data processing applicationsWeb serviceComputer module

The invention provides a network management system for implementing the remote browsing of a network element MIB mode. In a browser / server-supported SNMP network management system, based on the AJAXWeb technique, the engines of a Web server and a MIB browser are embedded inside a network management server, so that a service engineer can remotely log in the Web server and directly select the network element from the MIB browser to initiate a query or set up a command; and an asynchronous http request is constructed by an AJAX technical module and sent to the Web server inside the network management server. Therefore, the invention realizes the remote access, even the setup of current value of the related MIB node in the remote field network element, and implements the real-time on-line state diagnosis and analysis.

Owner:UTSTARCOM TELECOM CO LTD

Blade server system

ActiveUS7193847B2Easy to disassembleEasy maintenanceServersVolume/mass flow measurementService engineerEmbedded system

A blade server system is described. The blade server system includes a main chassis, a rear module chassis and a mid-plane. The main chassis is formed with slots into which a plurality of sever blades are slidablely inserted from the front end of the main chassis. The rear module chassis is removablely mounted to the rear end of the main chassis, and divided into plural partitions for housing different component modules. The mid-plane is mounted to an end of the rear module chassis, and includes a first face and an opposite second face. The first face has plural connectors electrically connected to the server blades and the second face has plural connectors electrically connected to the component modules. Therefore, when maintenance is needed for the mid-plane, the service engineer only needs to withdraw the entire rear module chassis as a whole, without the need to remove the individual component modules.

Owner:QUANTA COMPUTER INC

Mobile phone network management systems

ActiveUS8032131B2Improve performanceSolve the real problemTransmitters monitoringReceivers monitoringTelephone networkNetwork management

A system for maintaining or optimizing a mobile phone network, the system includes a plurality of data feed inputs including at least one performance data feed input to receive performance data relating to performance of said mobile phone network over a first time period and at least one configuration data feed input to receive configuration data relating to configuration of said mobile phone network over a second time period; and a radio performance optimization system coupled to said plurality of data feed inputs, said radio performance optimization system including a rules engine to operate on said performance data and on said configuration data in accordance with a set of hierarchical rules and to output one or more tasks for network optimization, a said task including a definition of a potential fault, exception or optimization of said network to be investigated by a service engineer.

Owner:ACTIX

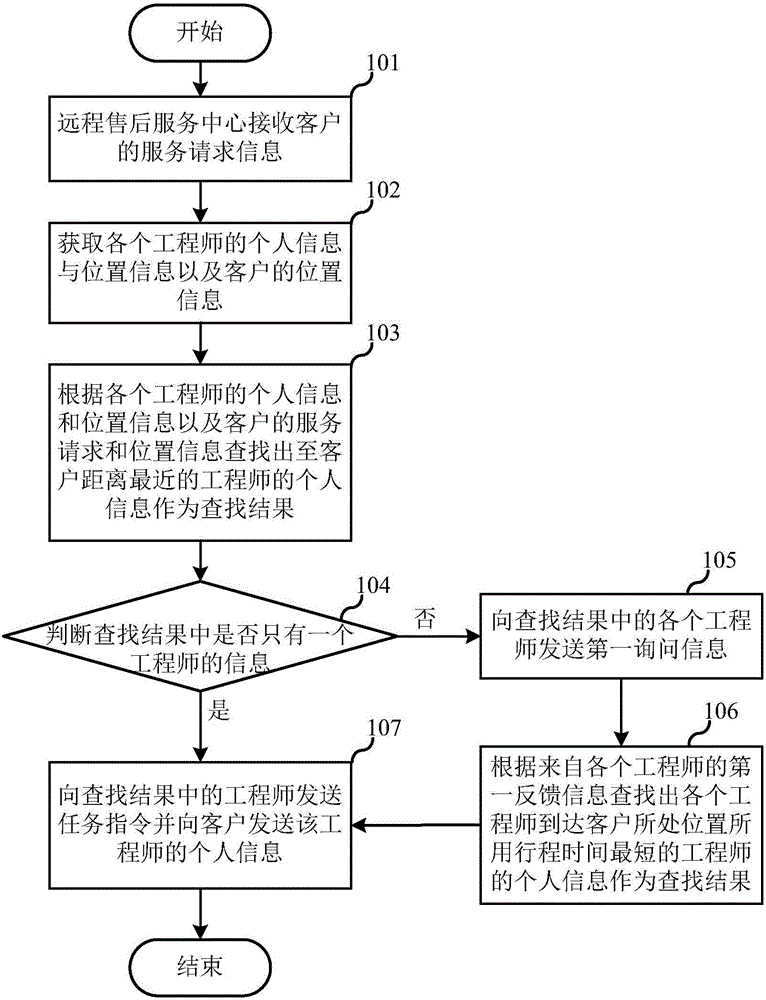

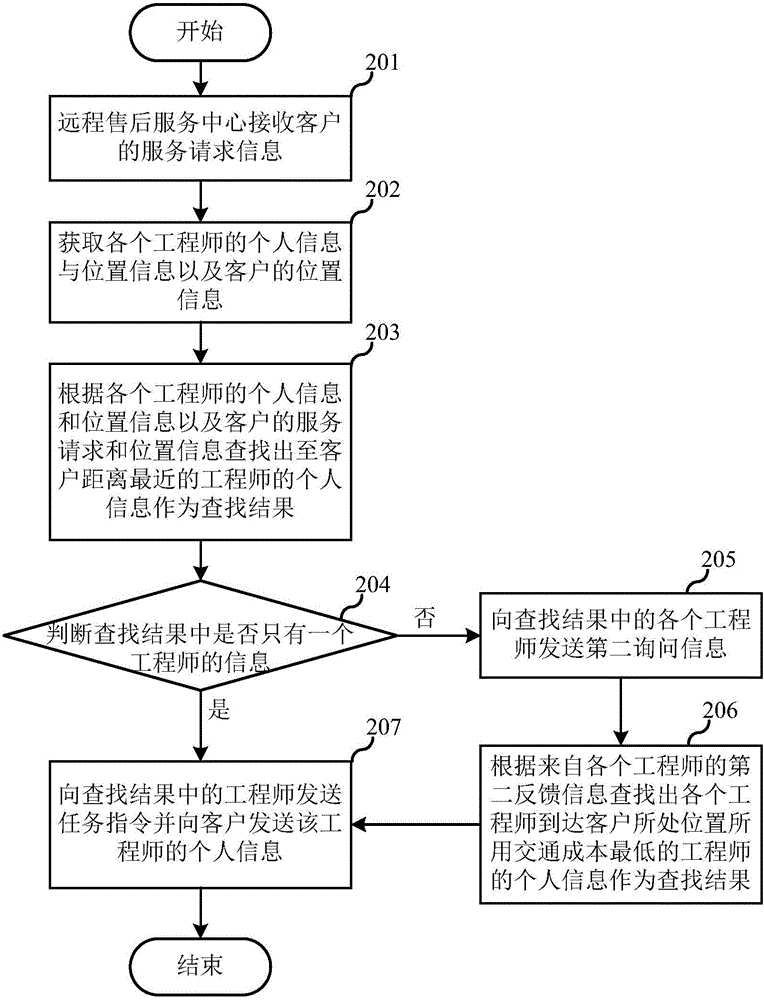

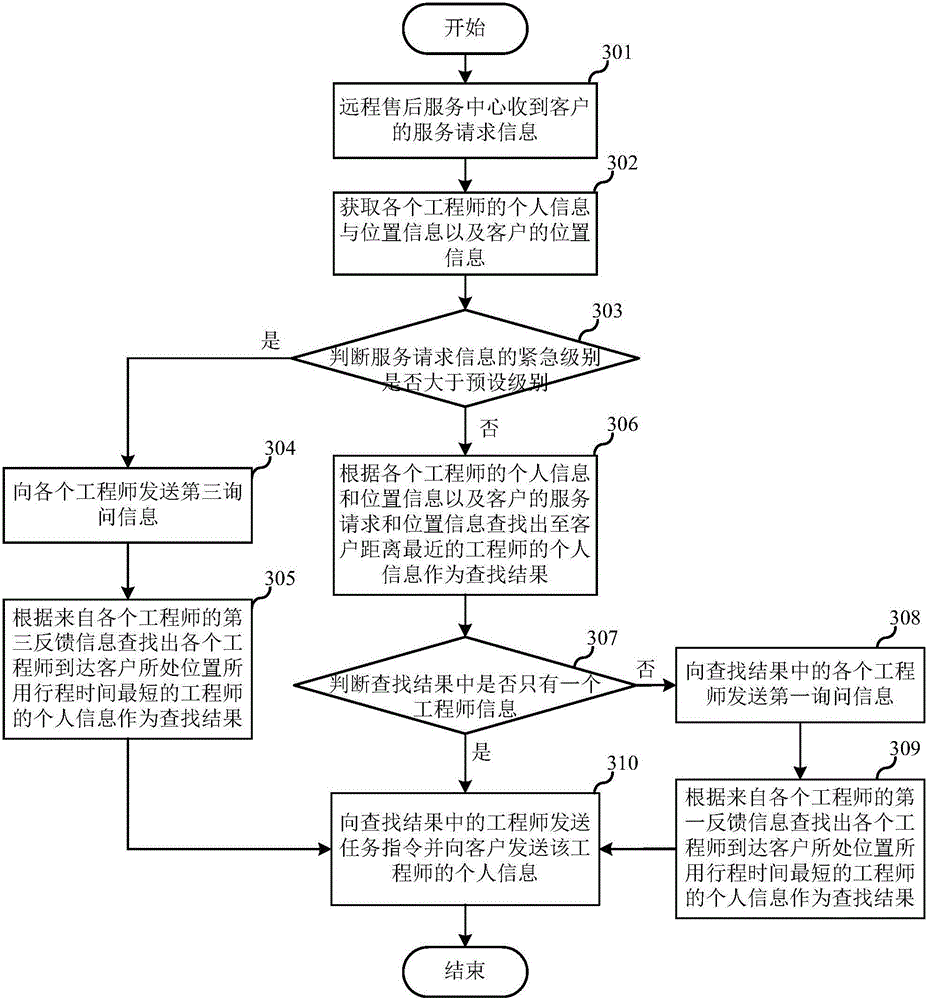

Intelligent scheduling method

InactiveCN105787659AReduce cumbersome processOptimize allocationResourcesCommerceService engineerComputer science

The invention relates to the field of intelligent scheduling and discloses an intelligent scheduling method. The intelligent scheduling method comprises the following steps: after service request information of clients is received, obtaining personal information and position information of each engineer and position information of the clients, according to the service request information, the personal information and the position information of each engineer and the position information of the clients, searching for the personal information of engineers which accord with client service requests and accords with a preset distribution strategy as a search result; and then according to the search result, distributing the engineers to the clients. Compared to the prior art, after-sale service tasks can be distributed to the engineers according to the position information and service requests of the clients needing after-sale service and the preset distribution strategy, the automation degree is high, the after-sale service engineers are more simply and conveniently scheduled, and the work efficiency of the after-sale service is improved.

Owner:SHAGNHAI YIN SCI&TECH CO LTD

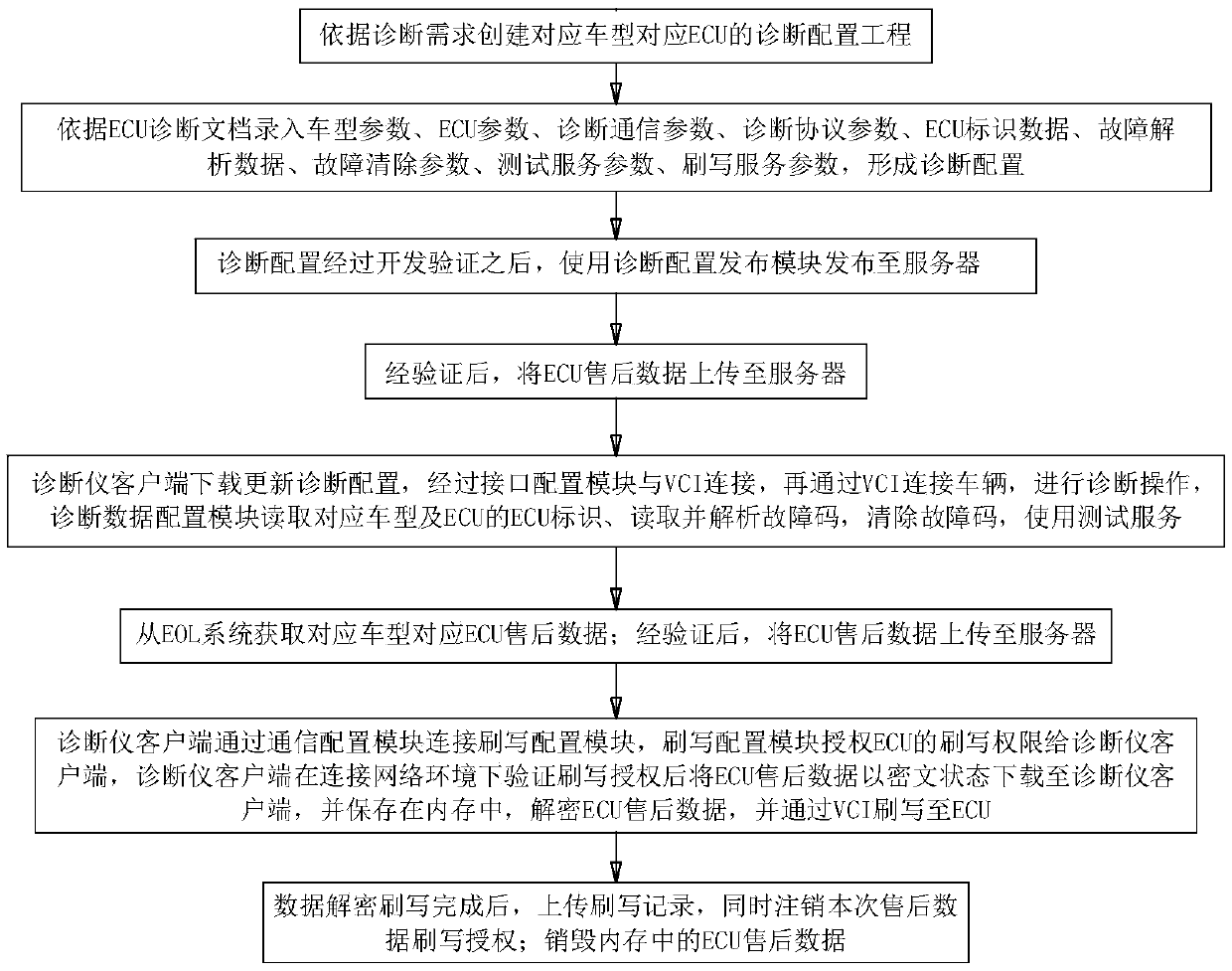

Multi-client extendable vehicle diagnosis software development system and method

InactiveCN109102591AReach the goal of controlled flashingImprove securityRegistering/indicating working of vehiclesSoftware designEngineeringSoftware development

The invention belongs to the technical field of vehicle diagnosis, and particularly relates to a multi-client extendable vehicle diagnosis software development system and method. An automotive engineer uses each module to develop, test and verify an ECU (Electronic Control Unit) diagnosis configuration, and uses each module to release or update the ECU diagnosis configuration and after-sale data of an ECU to an after-sale server; an after-sale service engineer audits to release a new ECU diagnosis configuration and new after-sale data of the ECU, and authorizes the ECU diagnosis configurationand the after-sale data of the ECU to a diagnostic unit user; and the diagnostic unit user uses various clients, the clients include other mobile intelligent equipment, such as a computer operating aWindows system, a smart phone operating an Android system, a smart phone operating an iOS system and the like, the clients are connected with a network salve server to automatically update the ECU diagnosis configuration, authorization information is verified on line, and the authorization information comprises adaptive objects, writing times, limiting time and the like of the after-sale data of the ECU.

Owner:WUHAN EUREKA CONTROL SYST CO LTD

Remote collaborative diagnosis system of numerical-control machine tool on basis of internet of things

InactiveCN102880115AAccurately getGet efficientlyProgramme controlComputer controlNumerical controlGeneral Packet Radio Service

The invention discloses a remote collaborative diagnosis system of a numerical-control machine tool on the basis of the internet of things. The remote collaborative diagnosis system comprises a source data acquisition device and is provided with GSM (global system for mobile communications), GPRS (general packet radio service) and 3G (the 3rd generation telecommunication) data relay nodes, a system data center, a remote collaborative fault diagnosis expert system and result feedback. The remote collaborative diagnosis system has the advantages that accidents and faults in a different field can be remotely diagnosed, maintenance schemes for fault equipment can be timely formulated according to real-time state signals of the running equipment, fault information and selectable field sound-image signals, and maintenance staff in a different place can directly and remotely adjust and modify data for the fault equipment by the aid of relevant equipment until the faults are removed. When necessary, maintenance engineers in the field can be guided for maintenance or the maintenance engineers in the field and the maintenance staff in the different place can jointly complete a maintenance task by the aid of field multimedia sound-image communication, and accordingly the remote collaborative diagnosis system plays an extremely important role in removing non-electrical faults or faults with signals which cannot be measured by electric sensors.

Owner:张华君

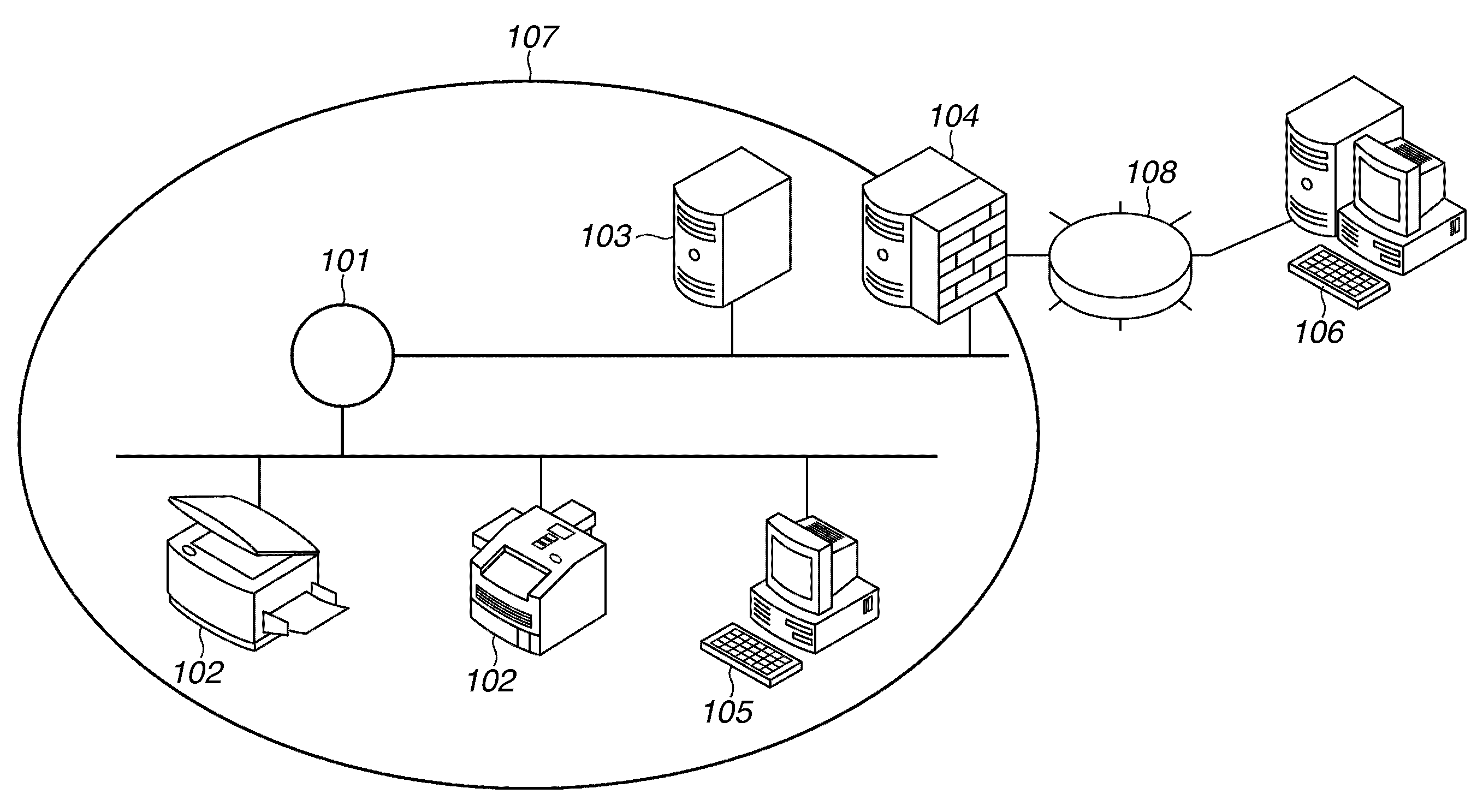

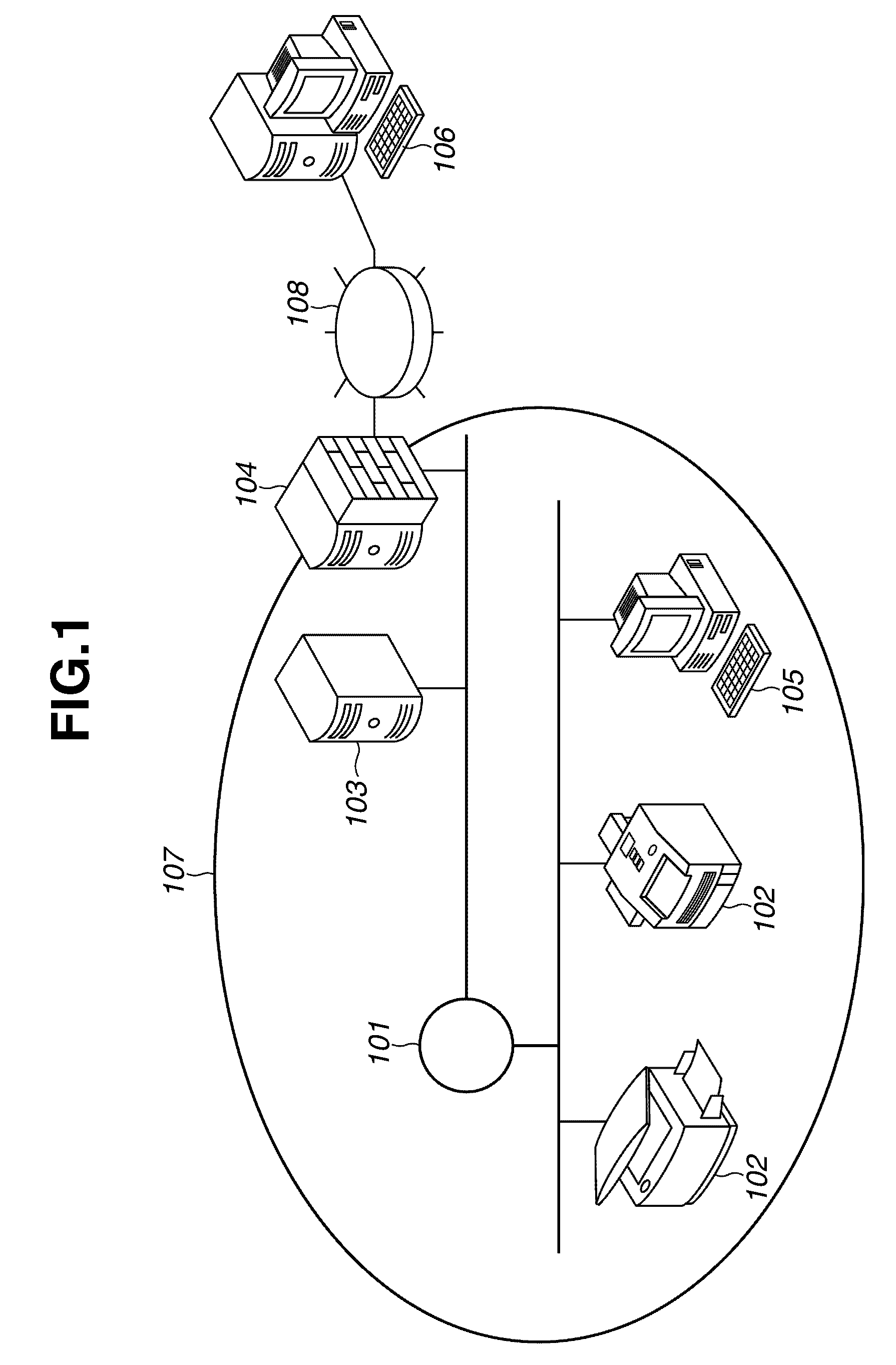

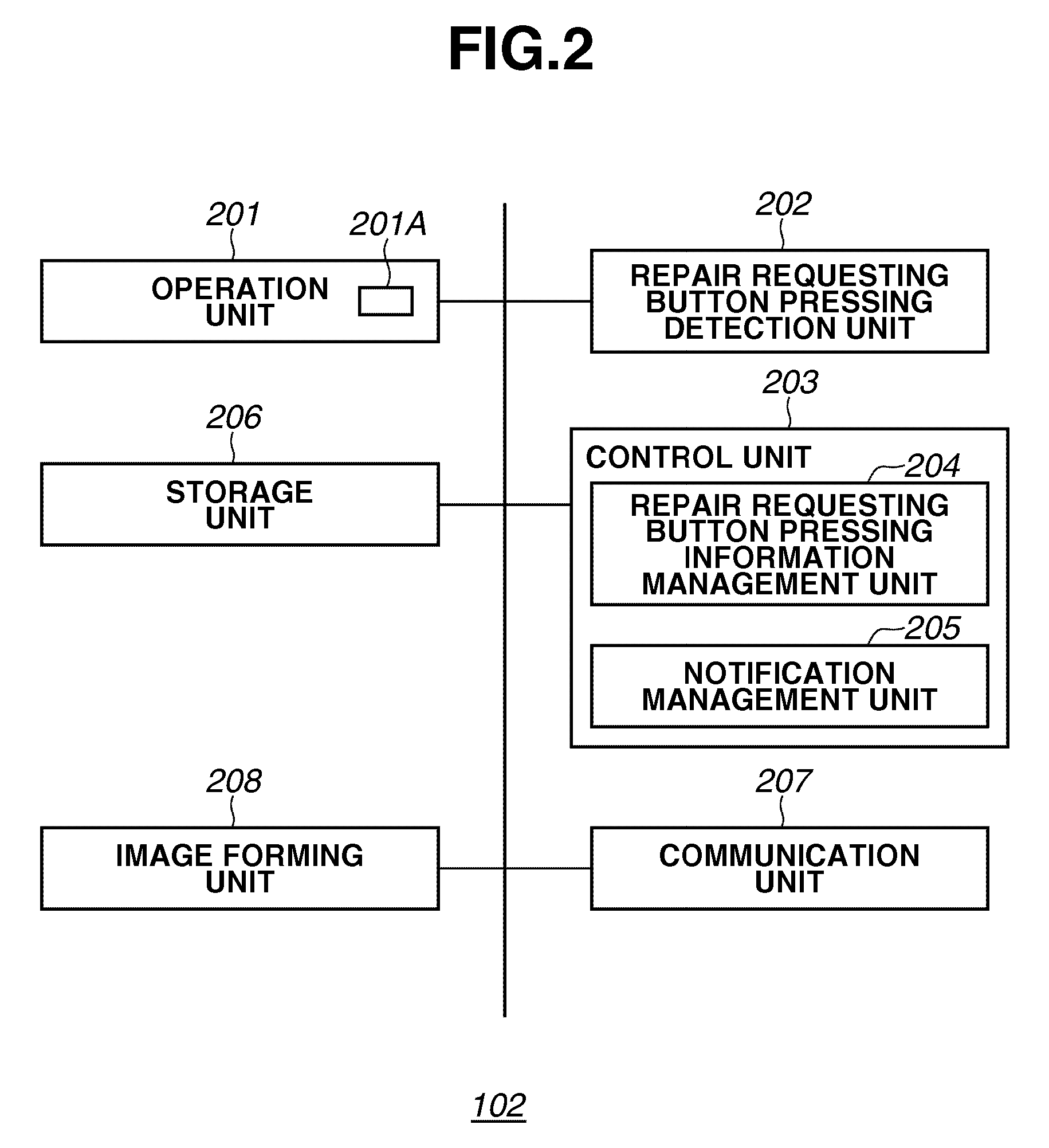

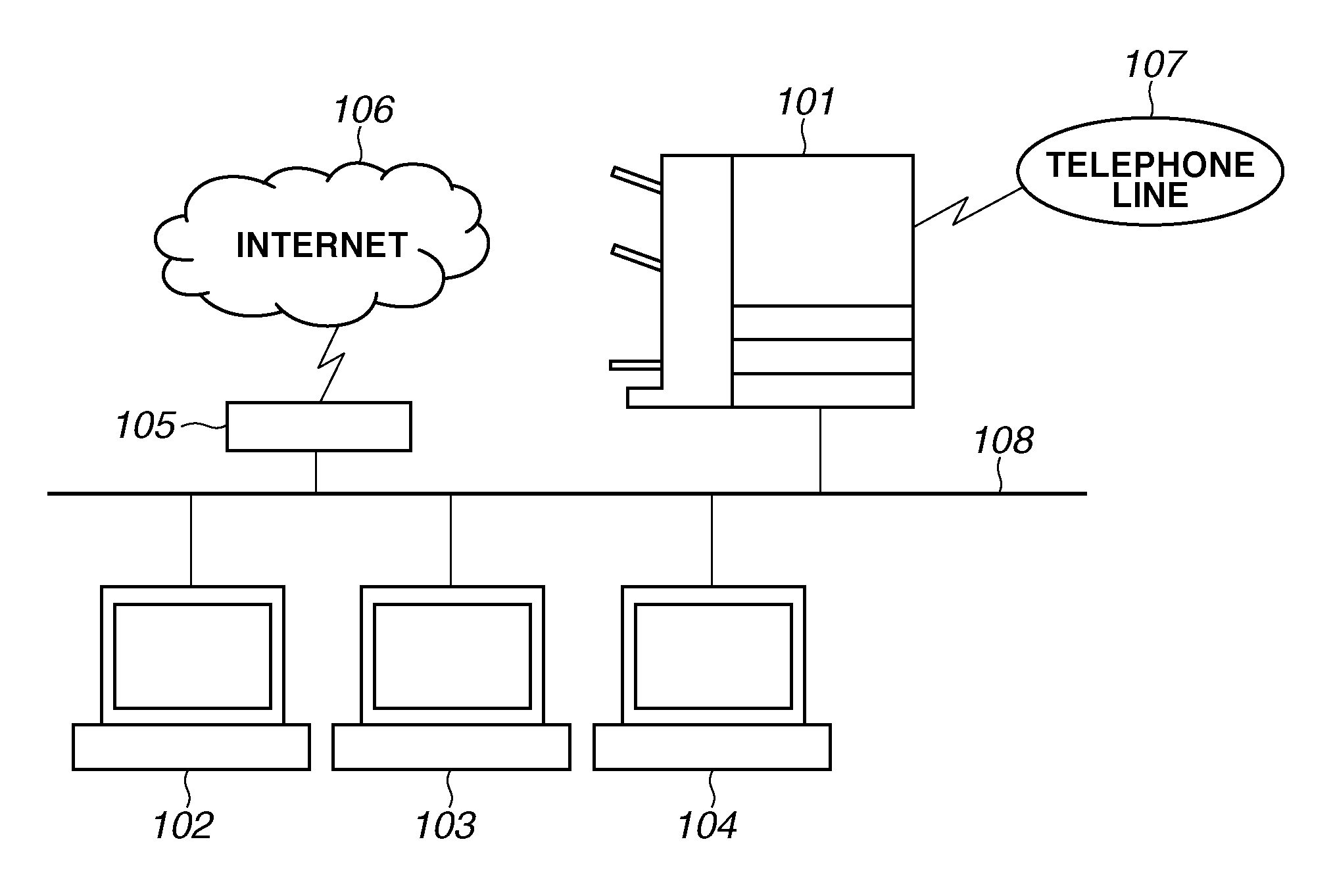

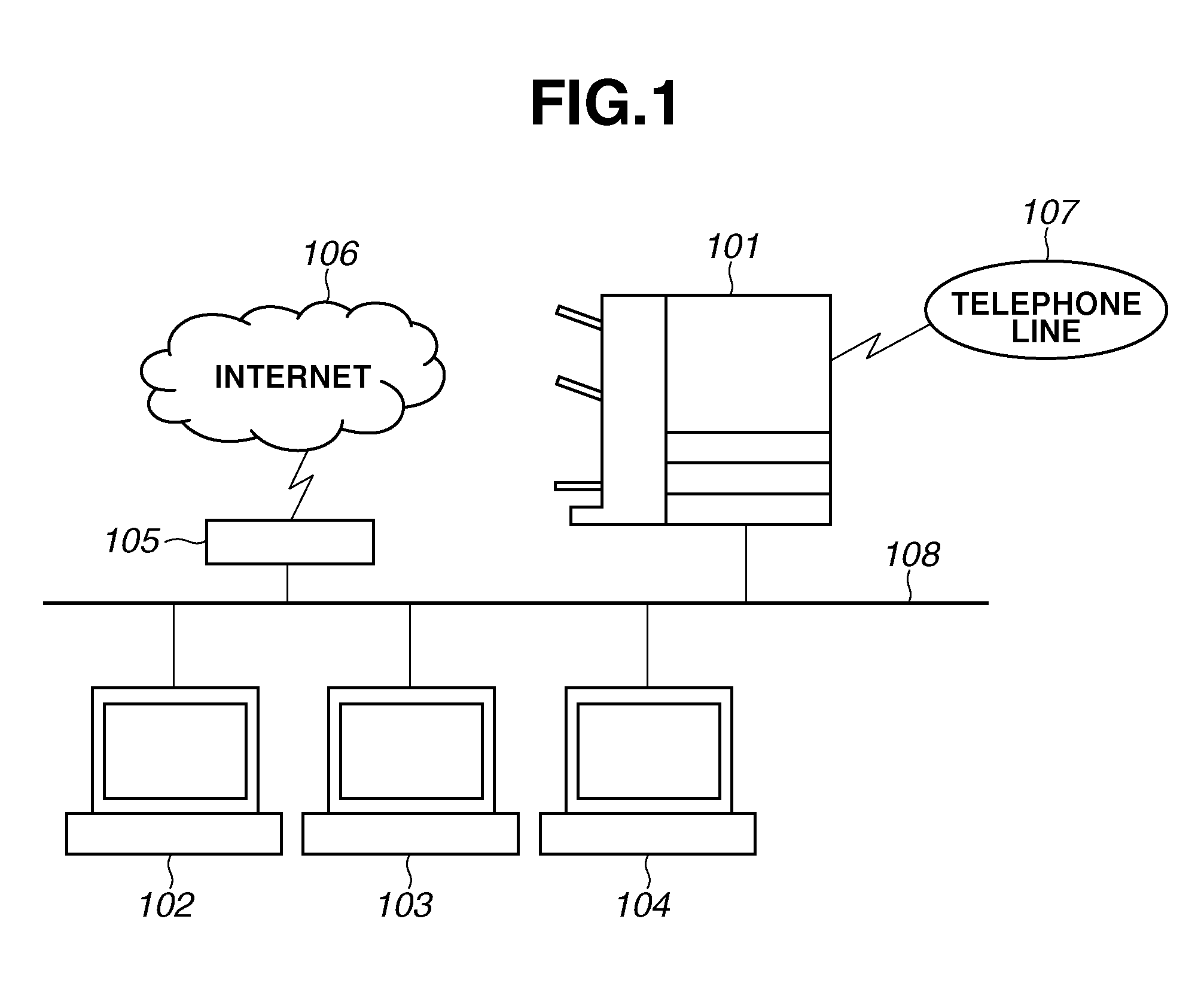

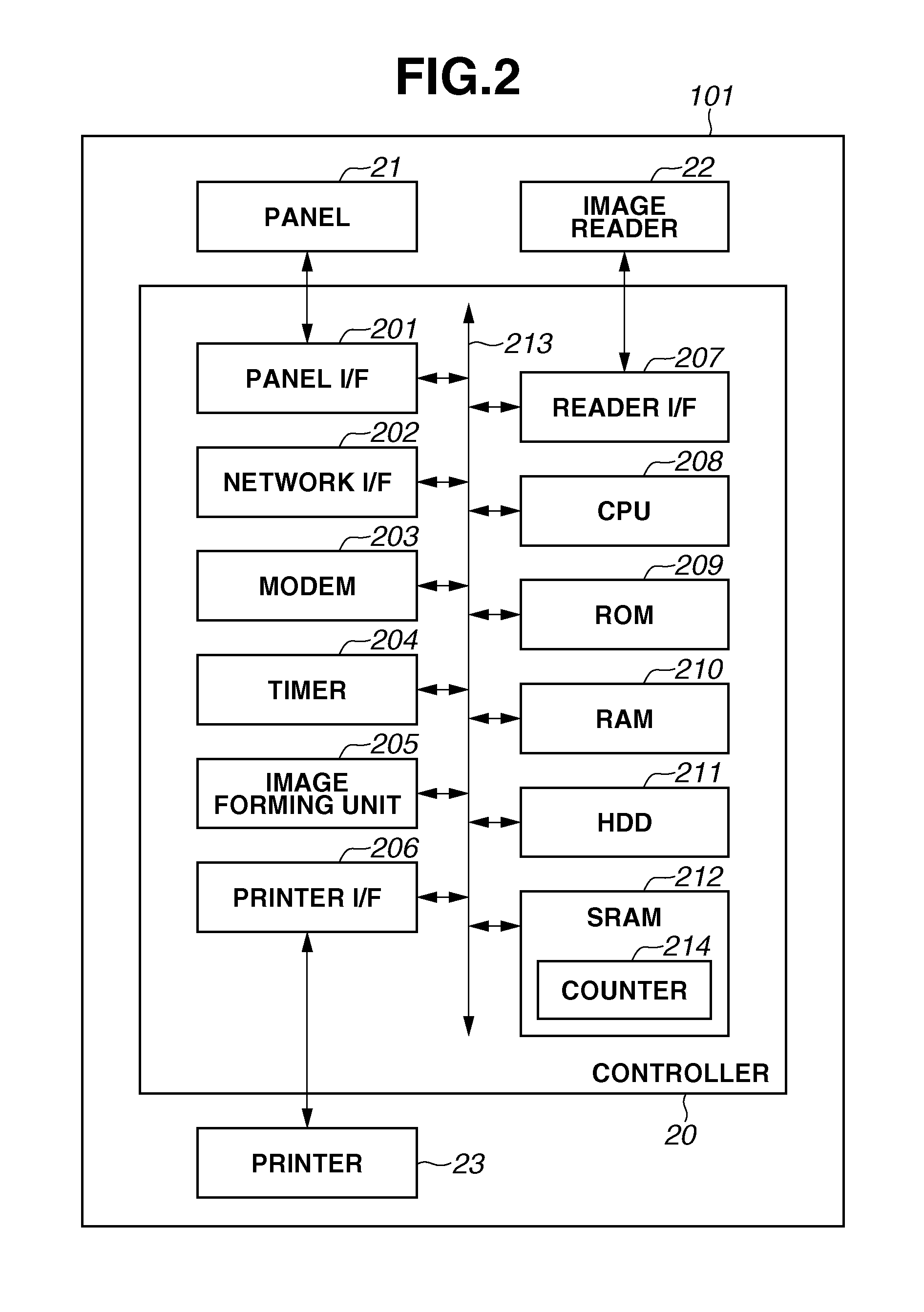

Management server, image forming apparatus, and management method therefor

InactiveUS20090213418A1Efficient schedulingVisual presentationPictoral communicationComputational scienceImage formation

A management server manages a plurality of image forming apparatuses capable of executing a data communication and executes processing for dispatching a service engineer with respect to an image forming apparatus. The management server executes first detection processing for detecting an image forming apparatus that requires the dispatch of a service engineer based on first analysis processing executed by using either one or both of operation information and failure information about the plurality of image forming apparatuses stored on RAM. The management server executes second detection processing for detecting an image forming apparatus that requires the dispatch of a service engineer based on second analysis processing executed by either one or both of the stored operation information and failure information about the plurality of image forming apparatuses in response to the first detection processing having detected the image forming apparatus that requires the dispatch of a service engineer.

Owner:CANON KK

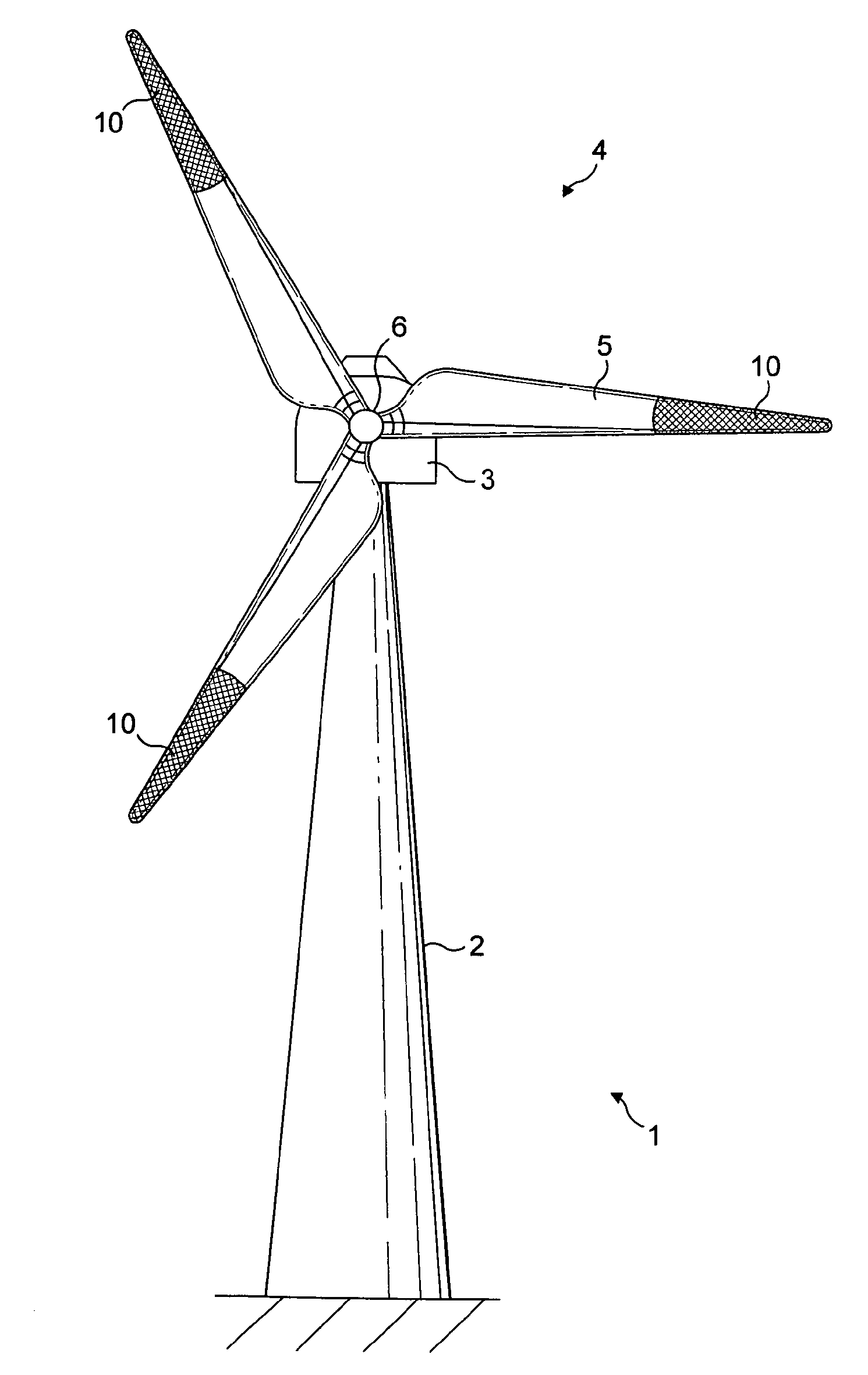

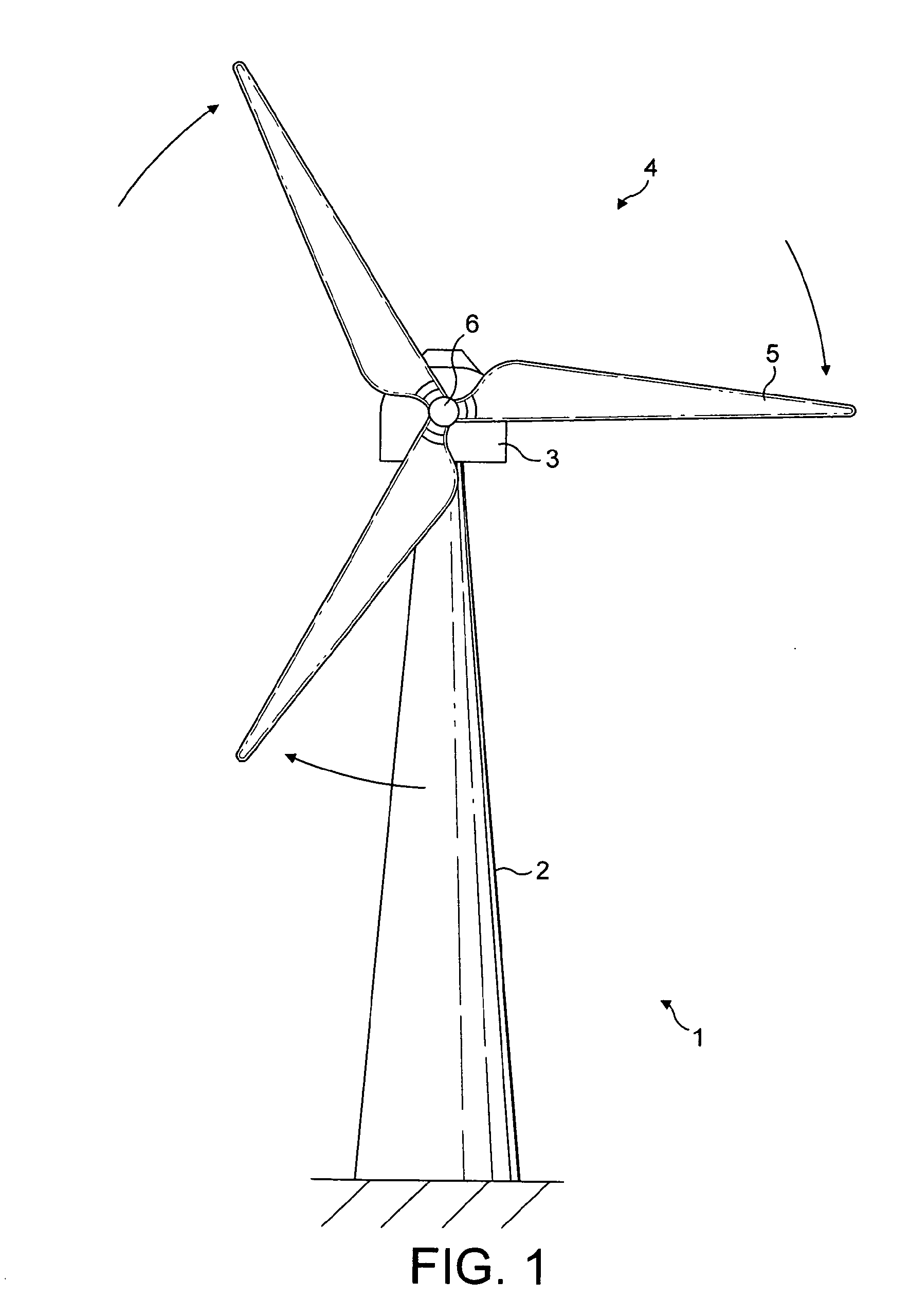

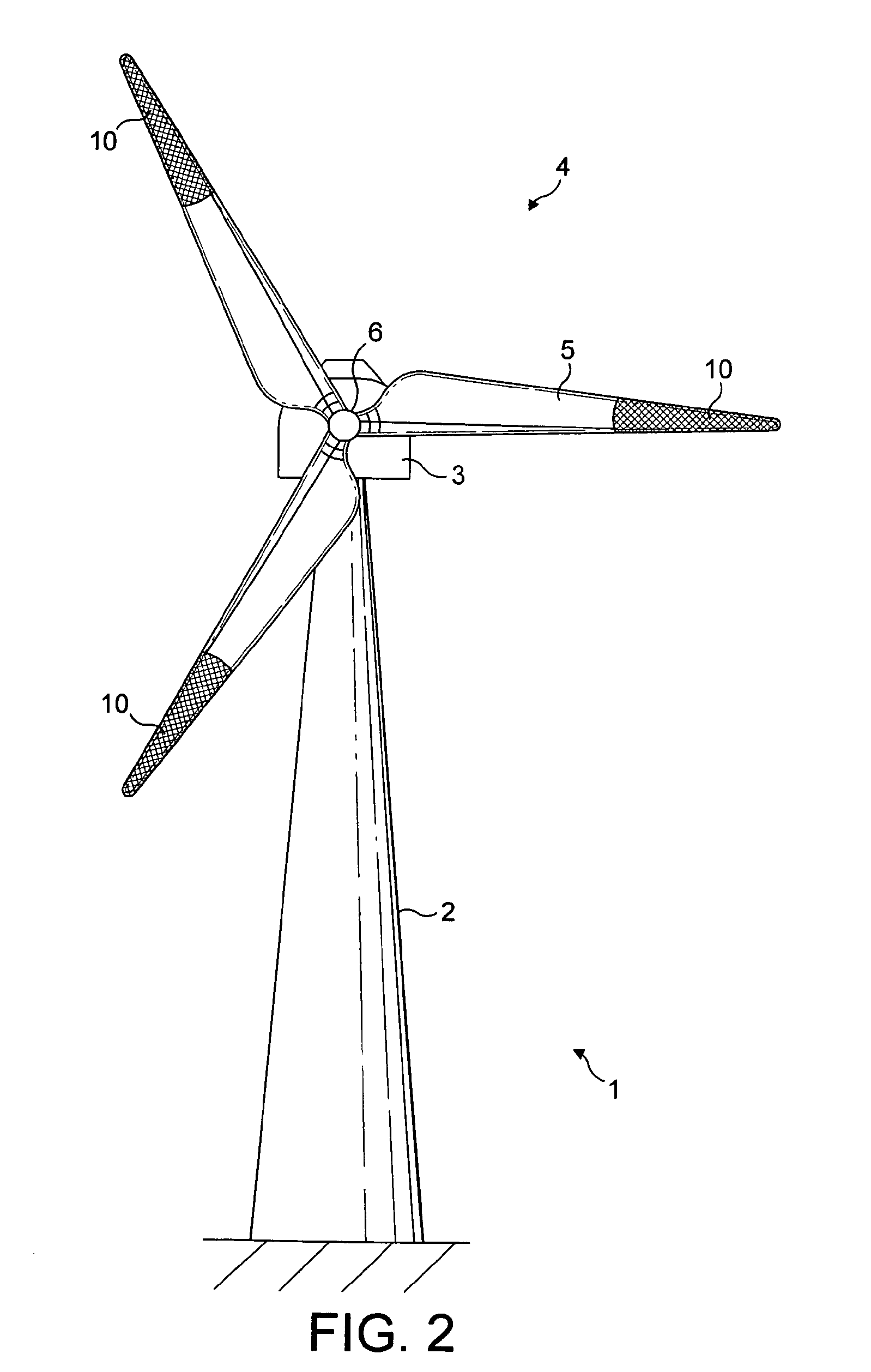

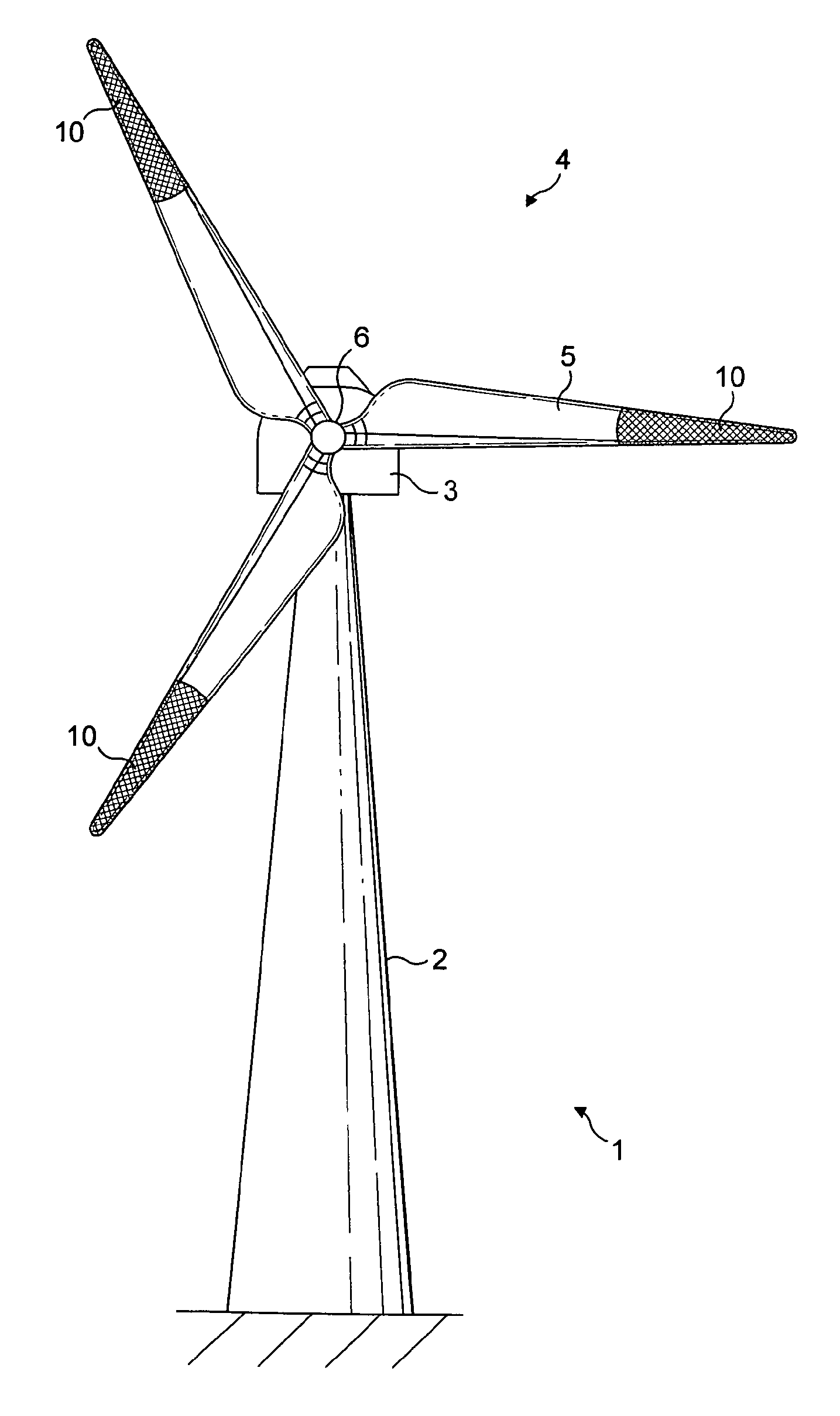

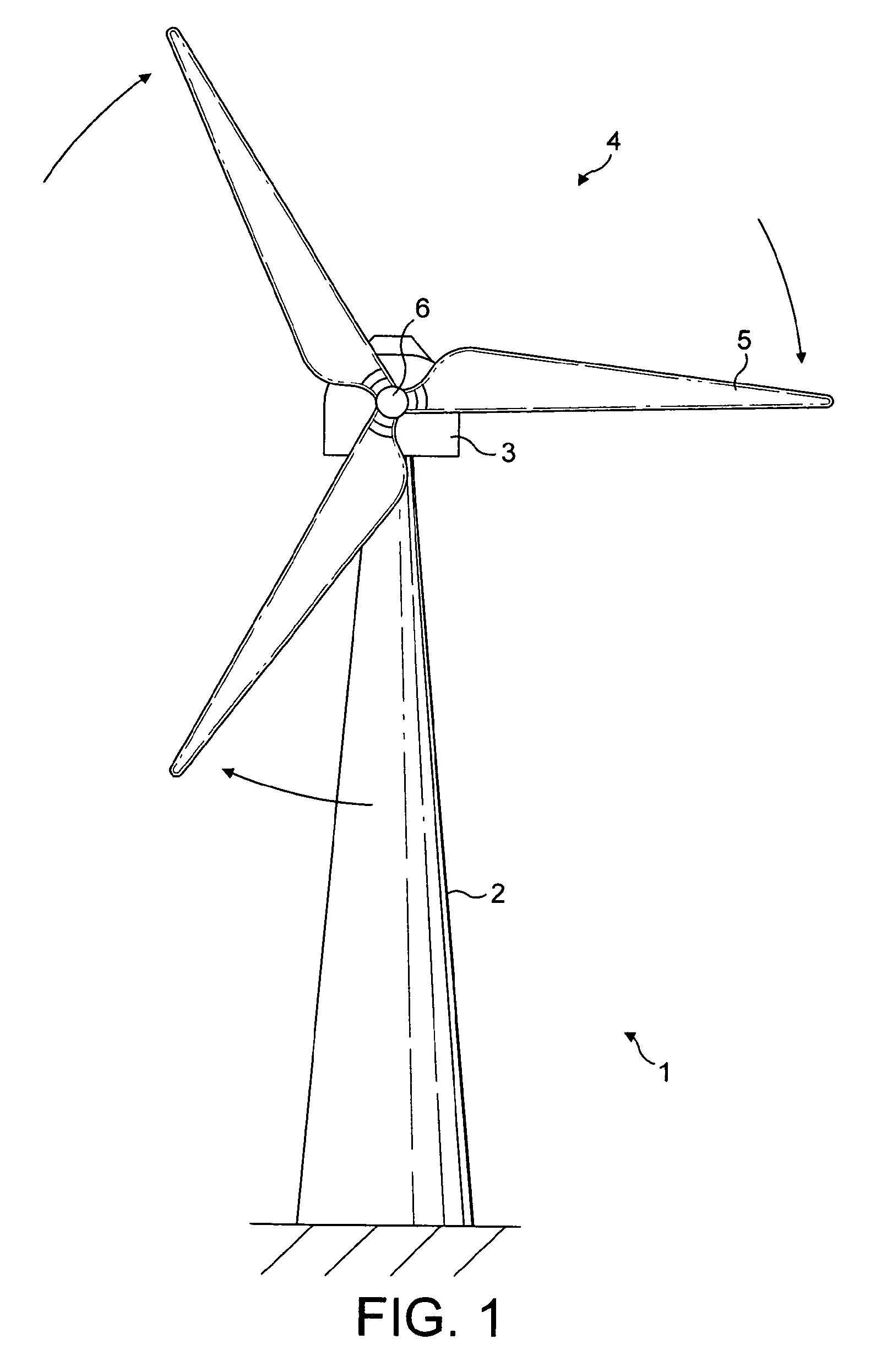

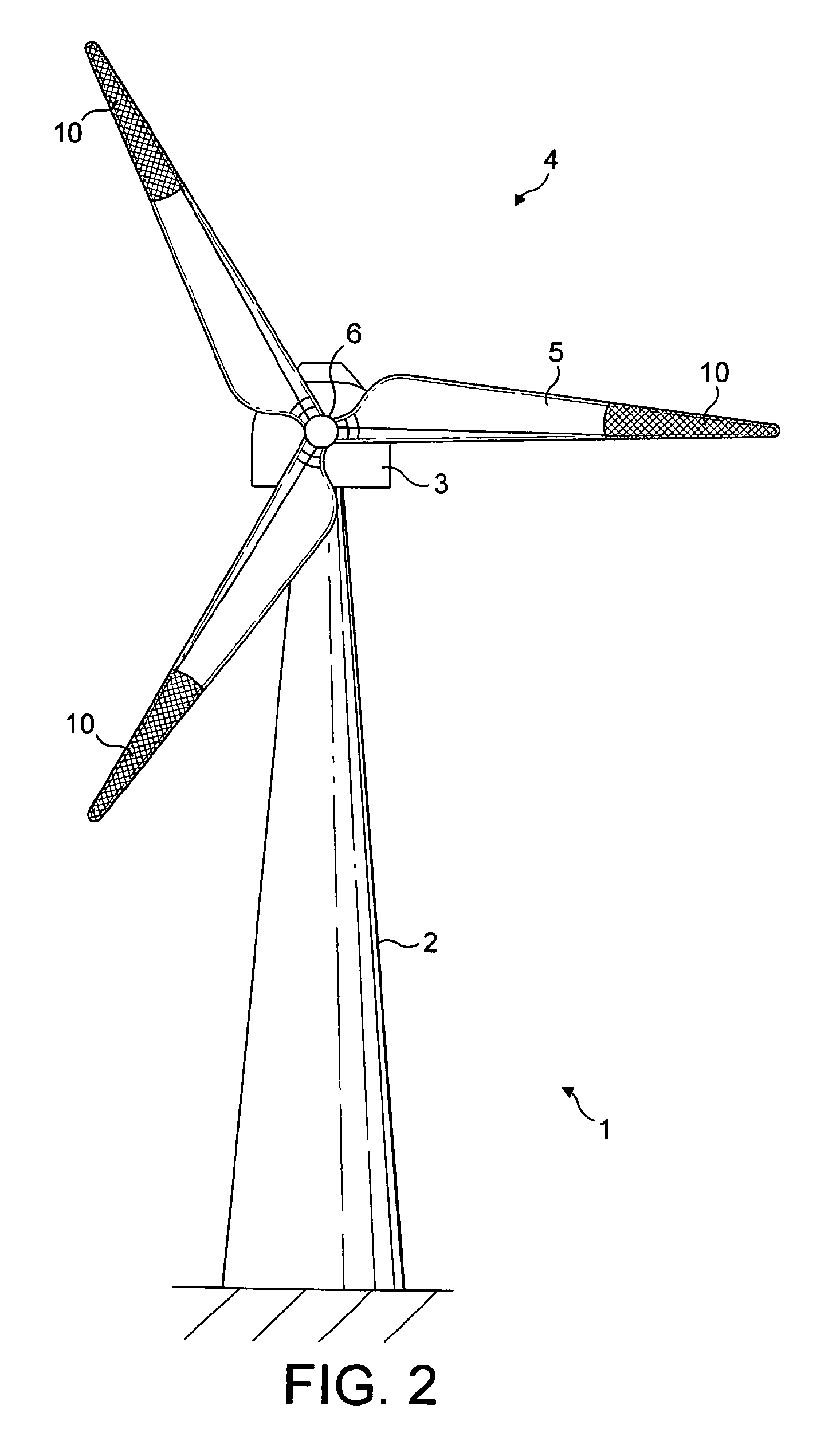

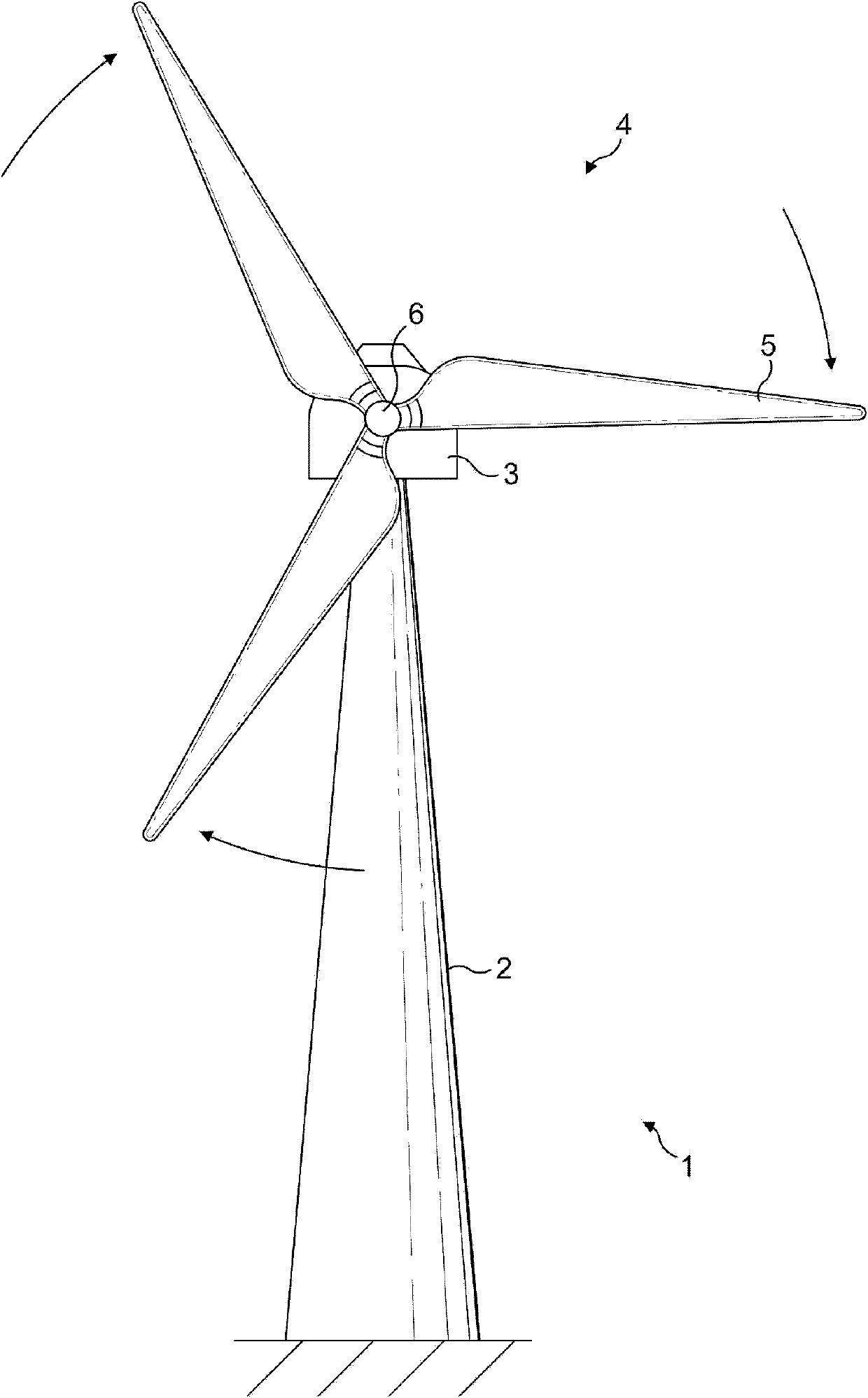

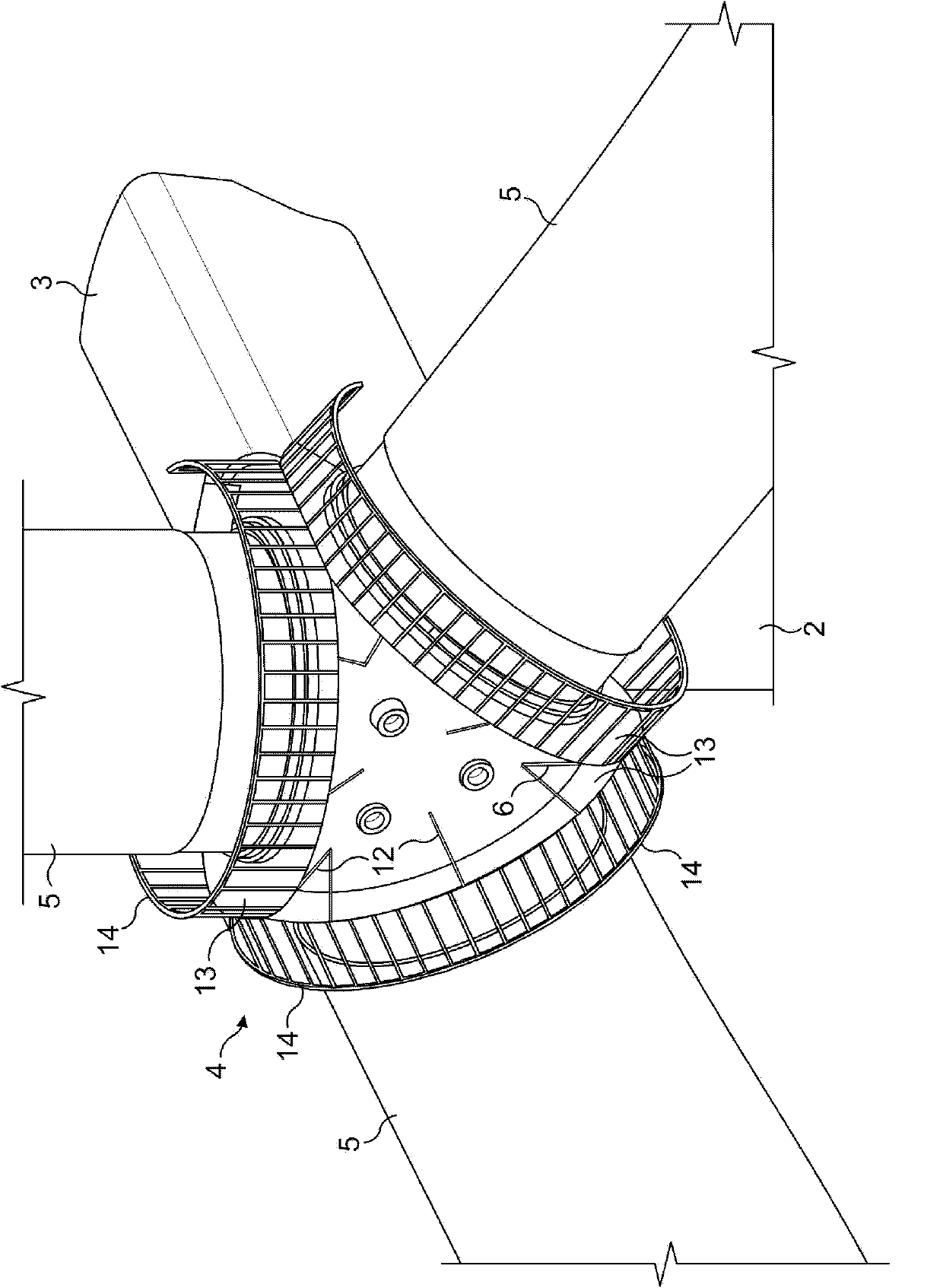

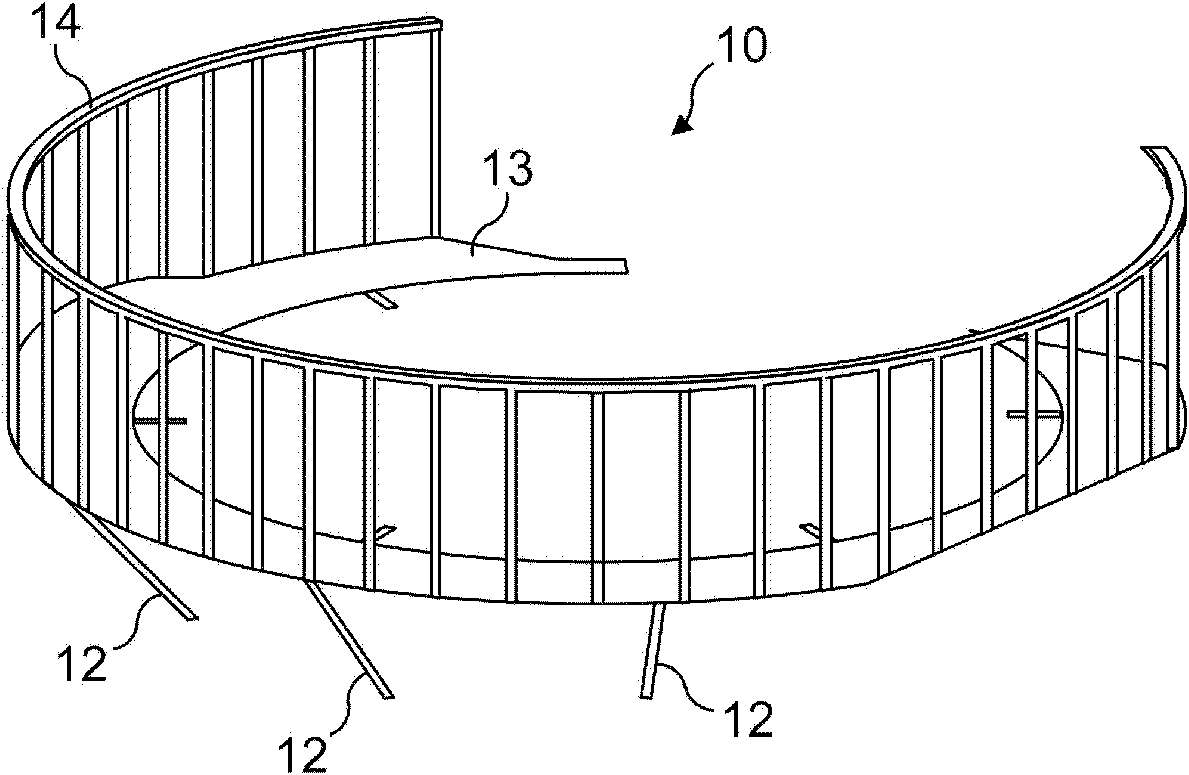

Anti-oscillation apparatus and technique for securing wind turbine blades against oscillations

ActiveUS20120301293A1Easily be attached to bladeEasy to makePropellersWind motor controlLow speedTurbine blade

The invention relates to a method of operating a wind turbine (1) to guard against oscillations of the wind turbine blades (5) when they are at a standstill or idling at low speeds, and to a wind turbine blade anti-oscillation apparatus (10). The apparatus comprises a releasably attachable blade cover (10) that provides a non-aerodynamic surface for a region of the blade. This has been found to prevent air flow adhering to the blade and periodically detaching in a phenomenon known as vortex shedding, and therefore prevents oscillations of the blade becoming problematic. The blade cover can comprise a sleeve (10) of a net-like material, that can be positioned on the blade either before installation or in the field by service engineers using guide lines 16 and 17.

Owner:VESTAS WIND SYST AS

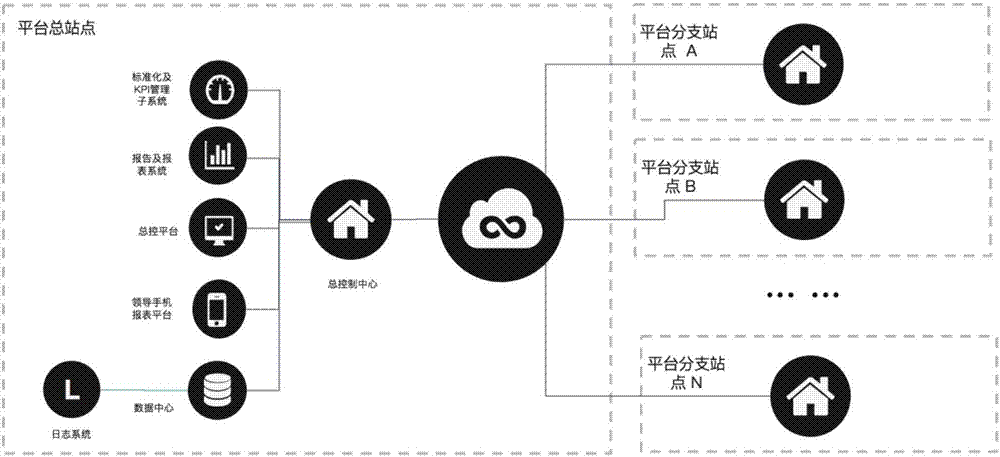

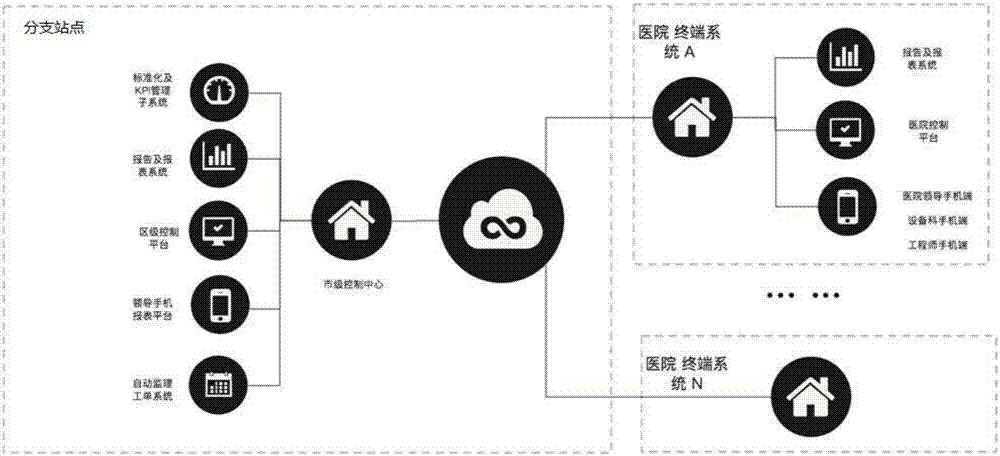

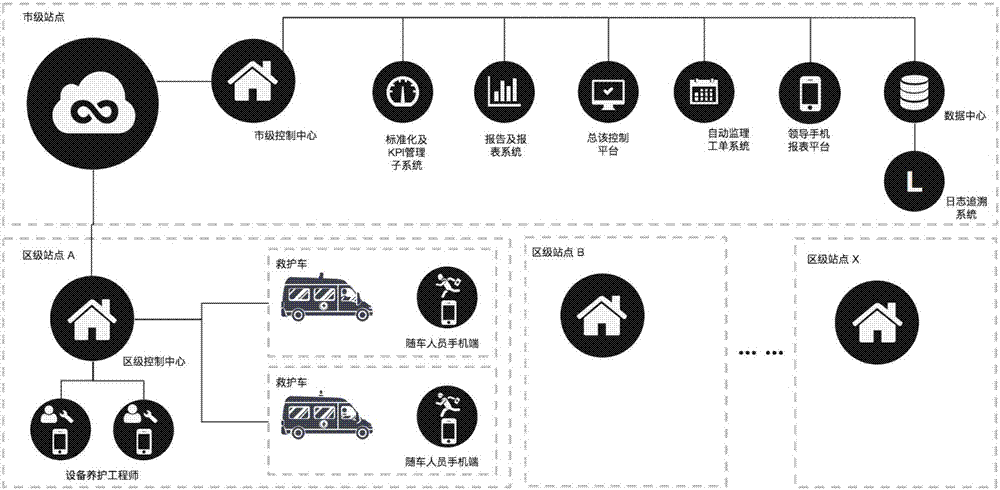

Whole life cycle management system for equipment of hospital equipment divisions

The invention provides a whole life cycle management system for equipment of hospital equipment divisions. The system comprises an application terminal, a base station and a cloud server, wherein the application terminal is used for transmitting data information through a wireless network, and diffuses by taking the cloud server as center and taking the base station as a branch node so as to form a reticular structure; the application terminal comprises an equipment repair input terminal and an information reception terminal; the equipment repair input terminal is used for transmitting a data signal to the base station through the wireless network; the base station is used for transmitting the data signal to the cloud server; the cloud server is used for calculating and storing the data; the information reception terminal is used for querying repair information from the cloud server through the base station and carrying out equipment maintenance work in time; after the maintenance work is completed, maintenance engineers carry out maintenance progress information filling through the information reception terminal; and the equipment repair input terminal is capable of querying the maintenance condition progress from the cloud server through the base station. The system provided by the invention has the advantages of being low in using cost and more convenient in equipment repair and maintenance.

Owner:天津市联大医用设备有限公司

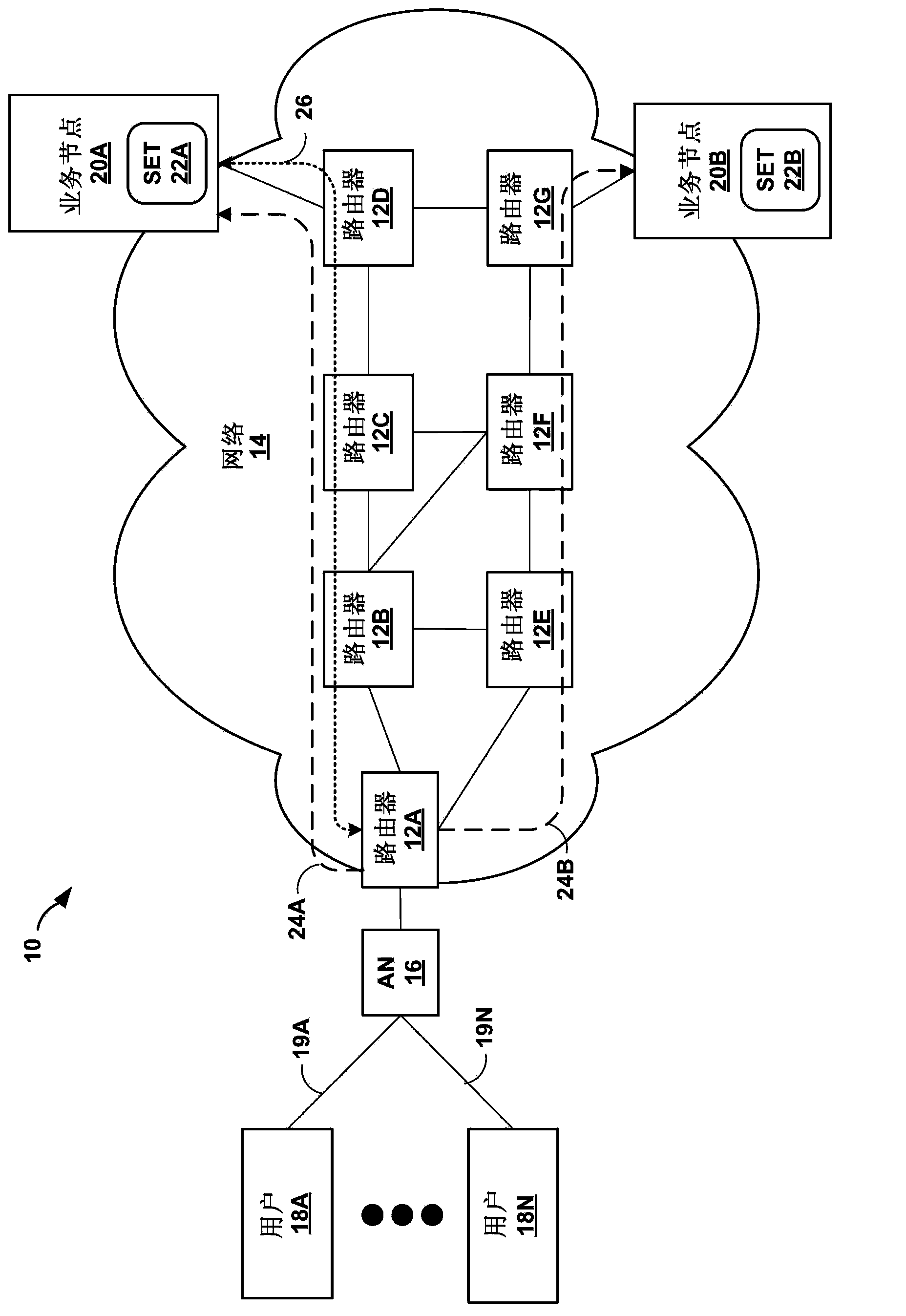

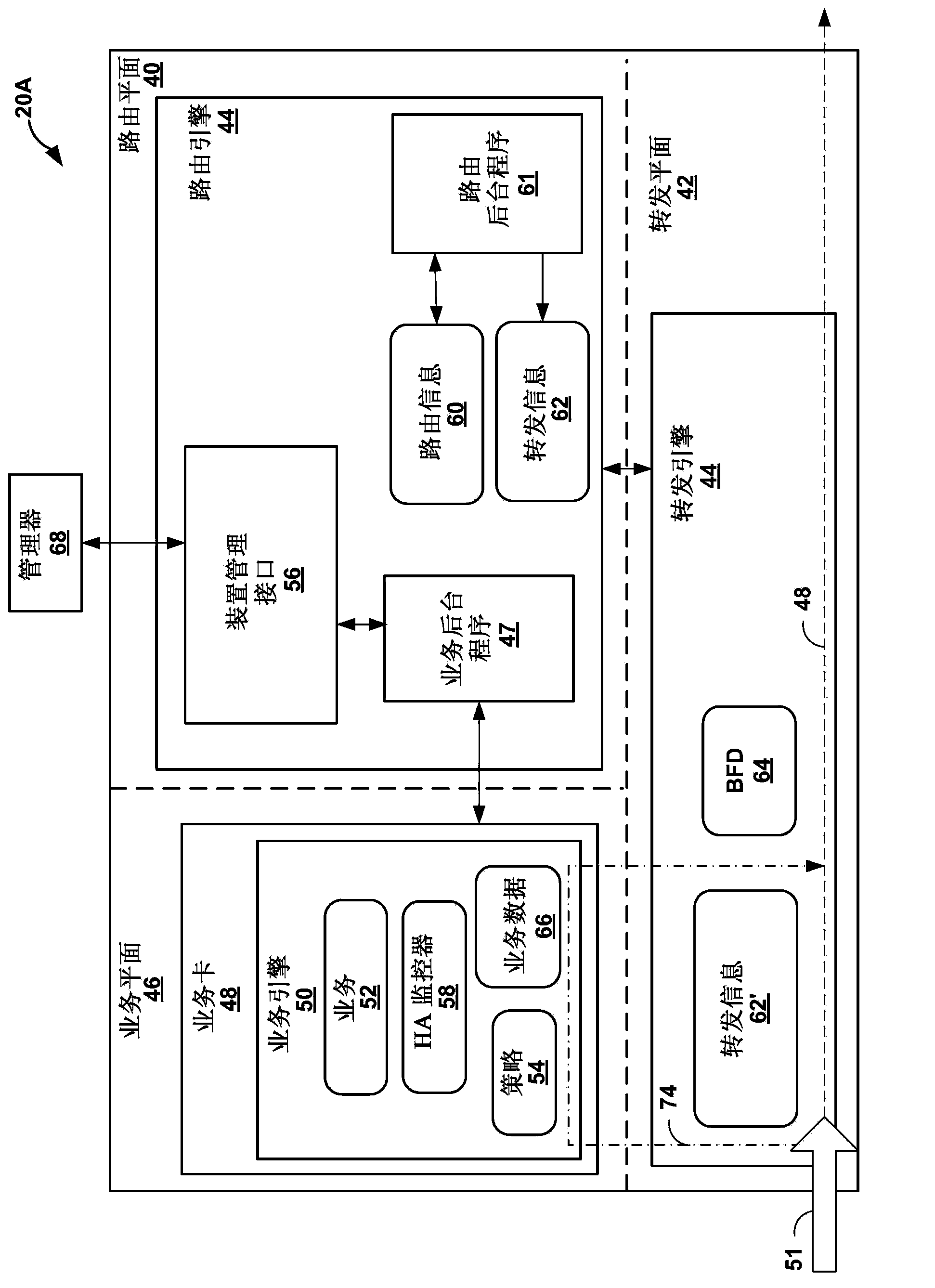

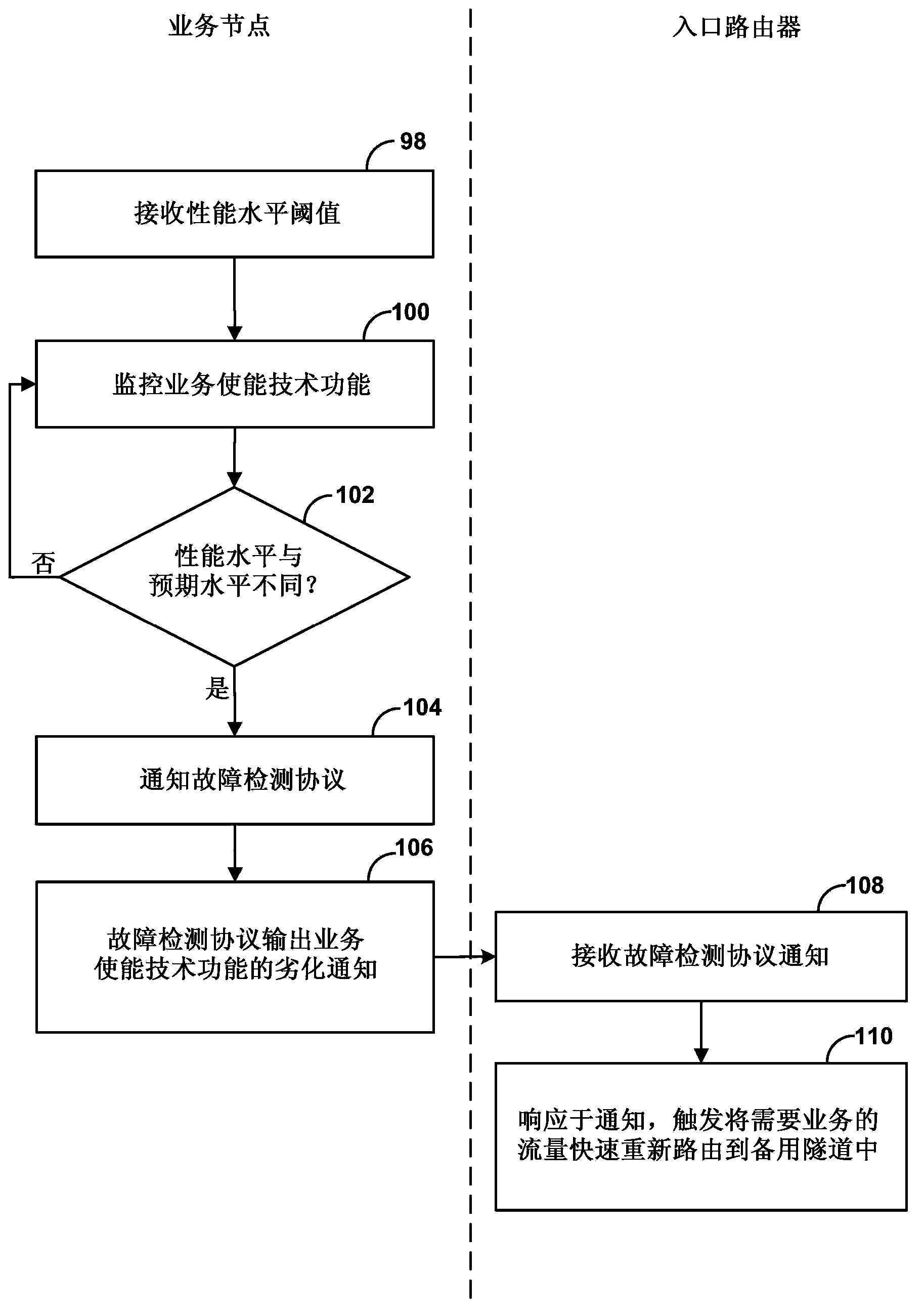

Service plane triggered fast reroute protection

Techniques are described for detecting failure or degradation of a service enabling technology function independent from an operational state of a service node hosting the service enabling technology function. For example, a service node may provide one or more service enabling technology functions, and service engineered paths may be traffic-engineered through a network to service node network devices that host a service enabling technology function. A monitor component at the service layer of the service node can detect failure or degradation of one or more service enabling technology functions provided by the service node. The monitor component reports detection of failure or degradation to a fault detection network protocol in a forwarding plane of the service node. The fault detection network protocol communicates with an ingress router of a service engineered path to trigger fast reroute by the ingress of traffic flows to bypass the affected service enabling technology function.

Owner:JUMIPER NETWORKS INC

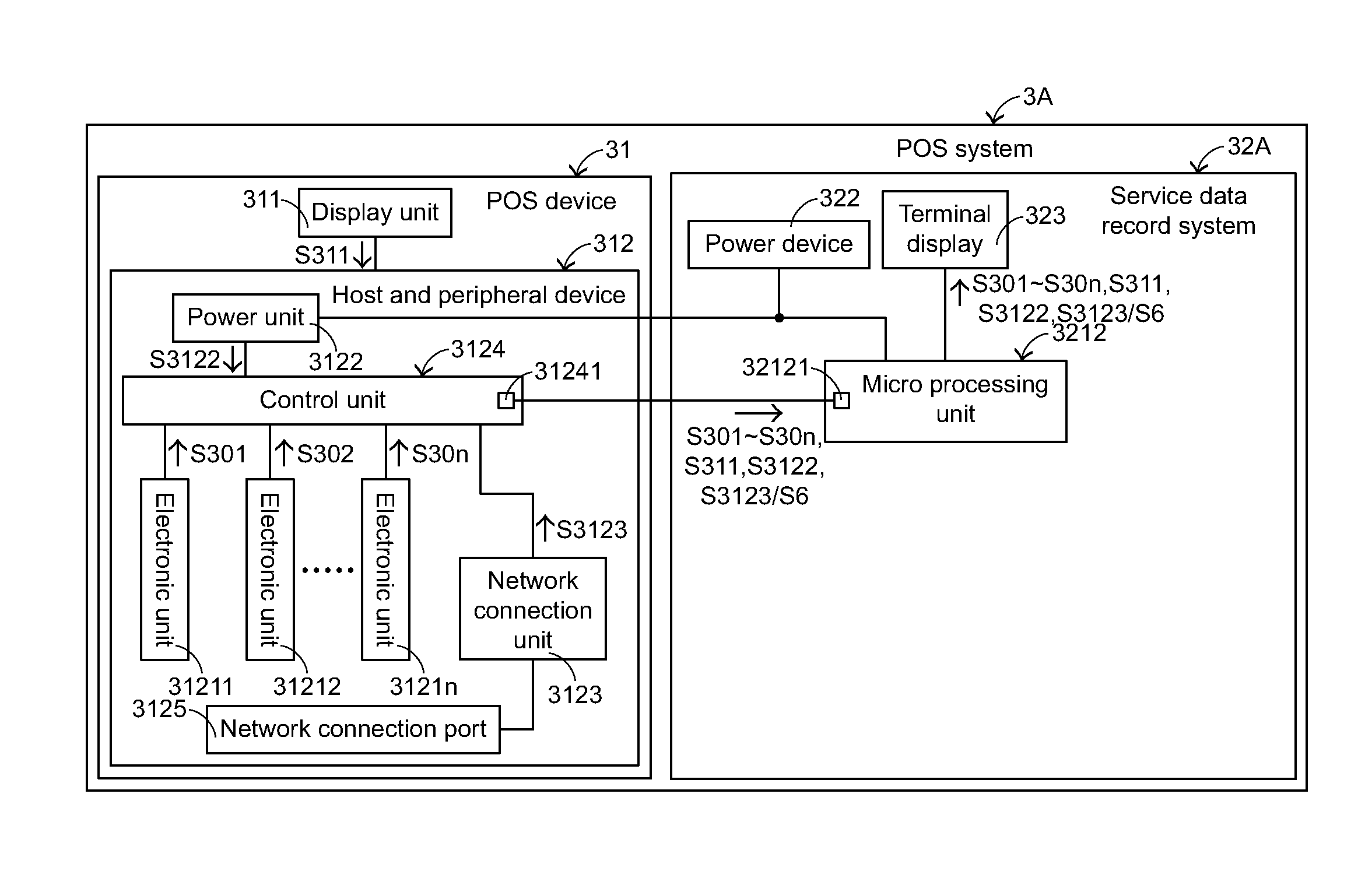

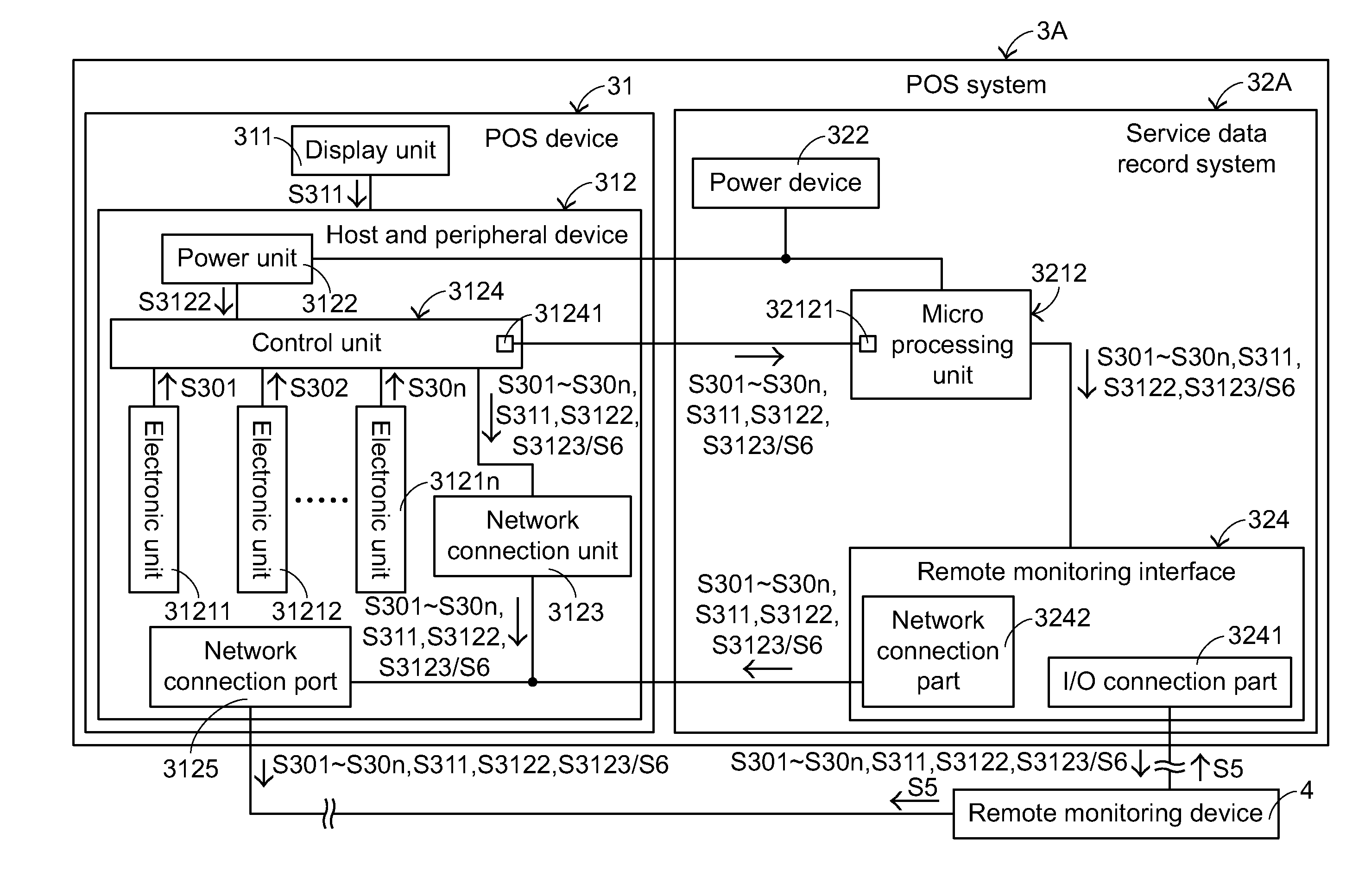

Service data record system and POS system with the same

A service data record system and a POS system with the service data record system are provided. The service data record system is used to display a data of an electronic device. The electronic device includes at least one electronic unit and a power unit. The service data record system includes a power device, a terminal display, a remote monitoring interface and a micro processing unit. By the micro processing unit, the electronic data set of the electronic unit may be displayed on the terminal display or transmitted to a remote monitoring device. Moreover, the pre-designate event of the electronic device may be displayed on the terminal display. According to the pre-designate event, it is convenient for a service engineer to conduct breakdown maintenance of the electronic device.

Owner:FLYTECH TECH

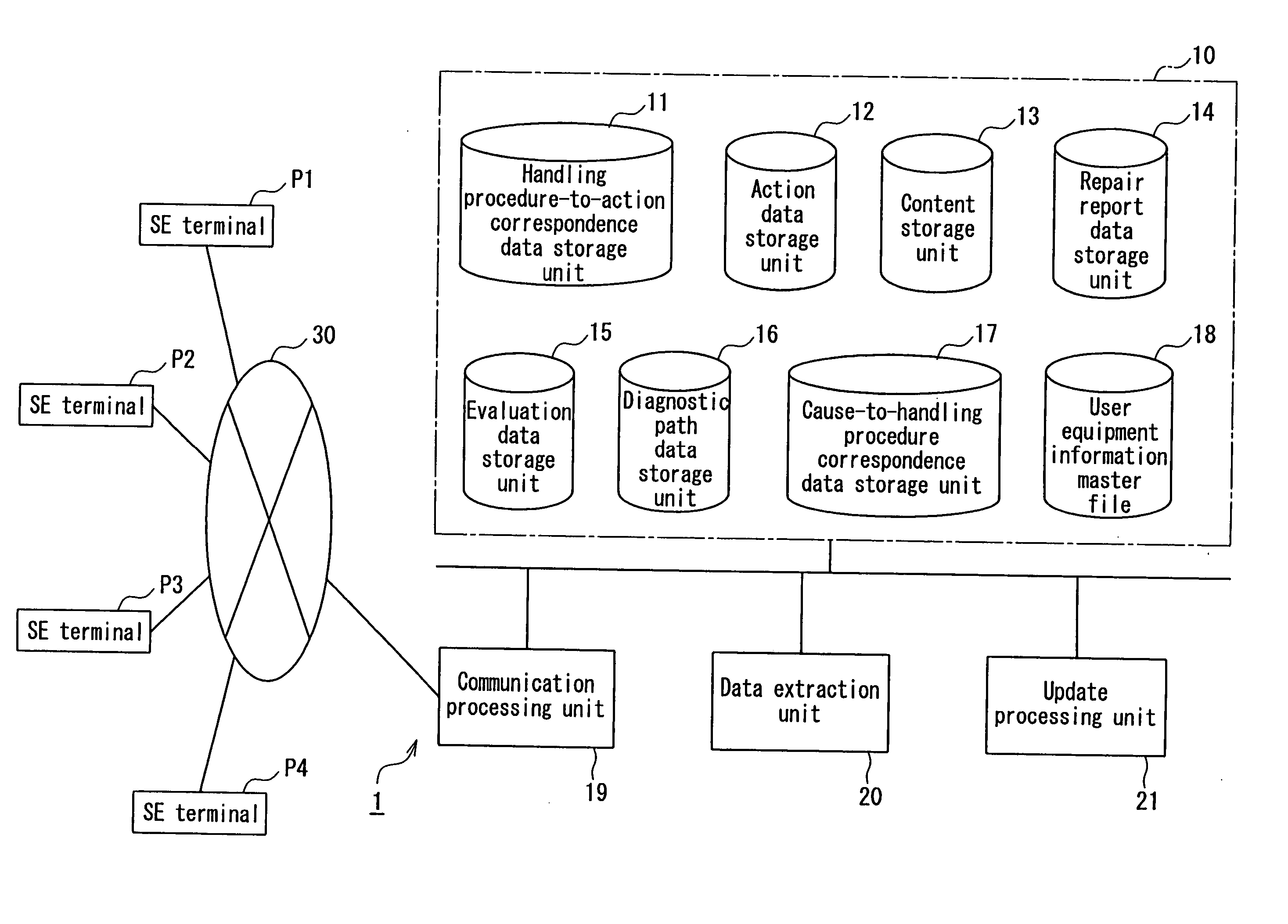

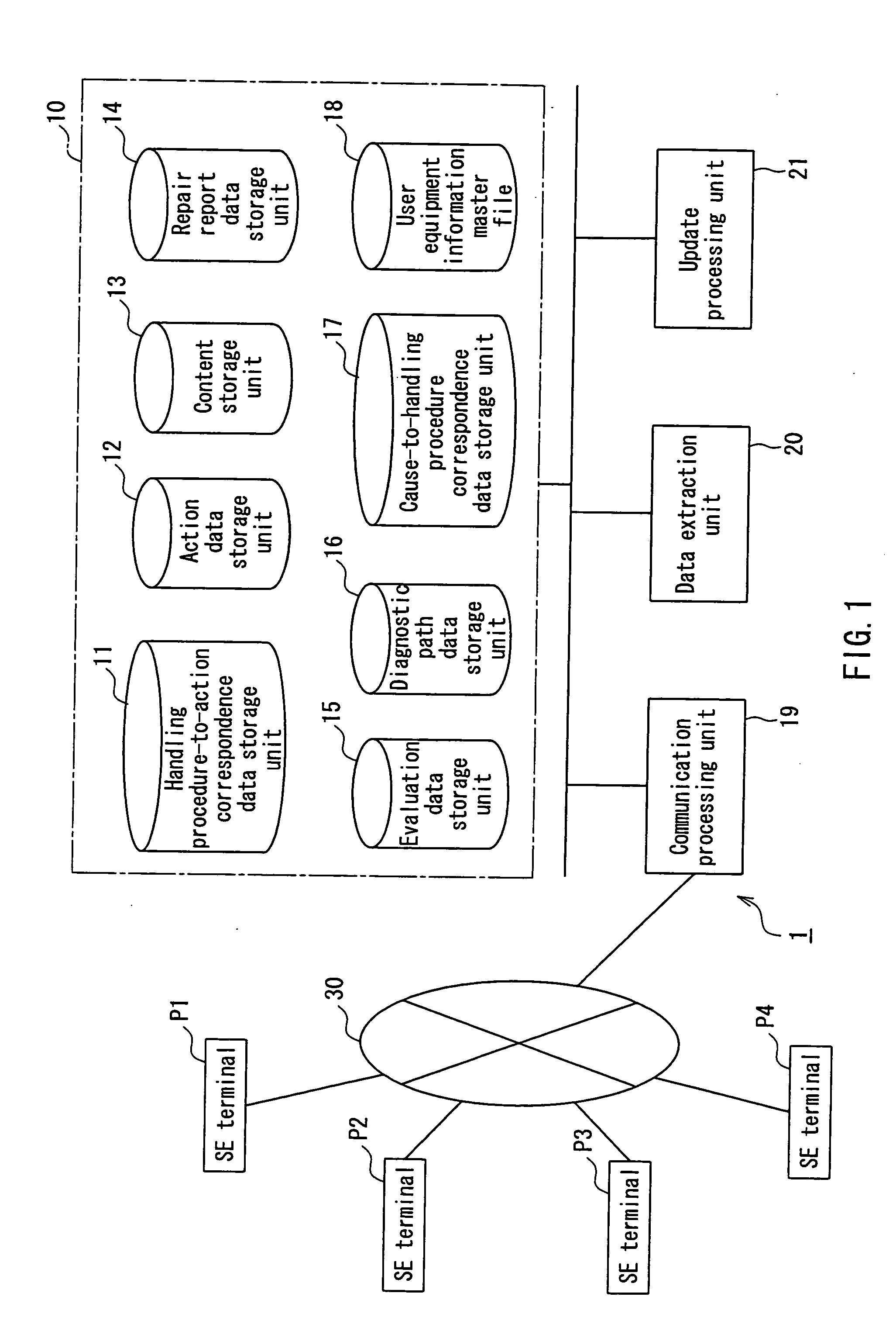

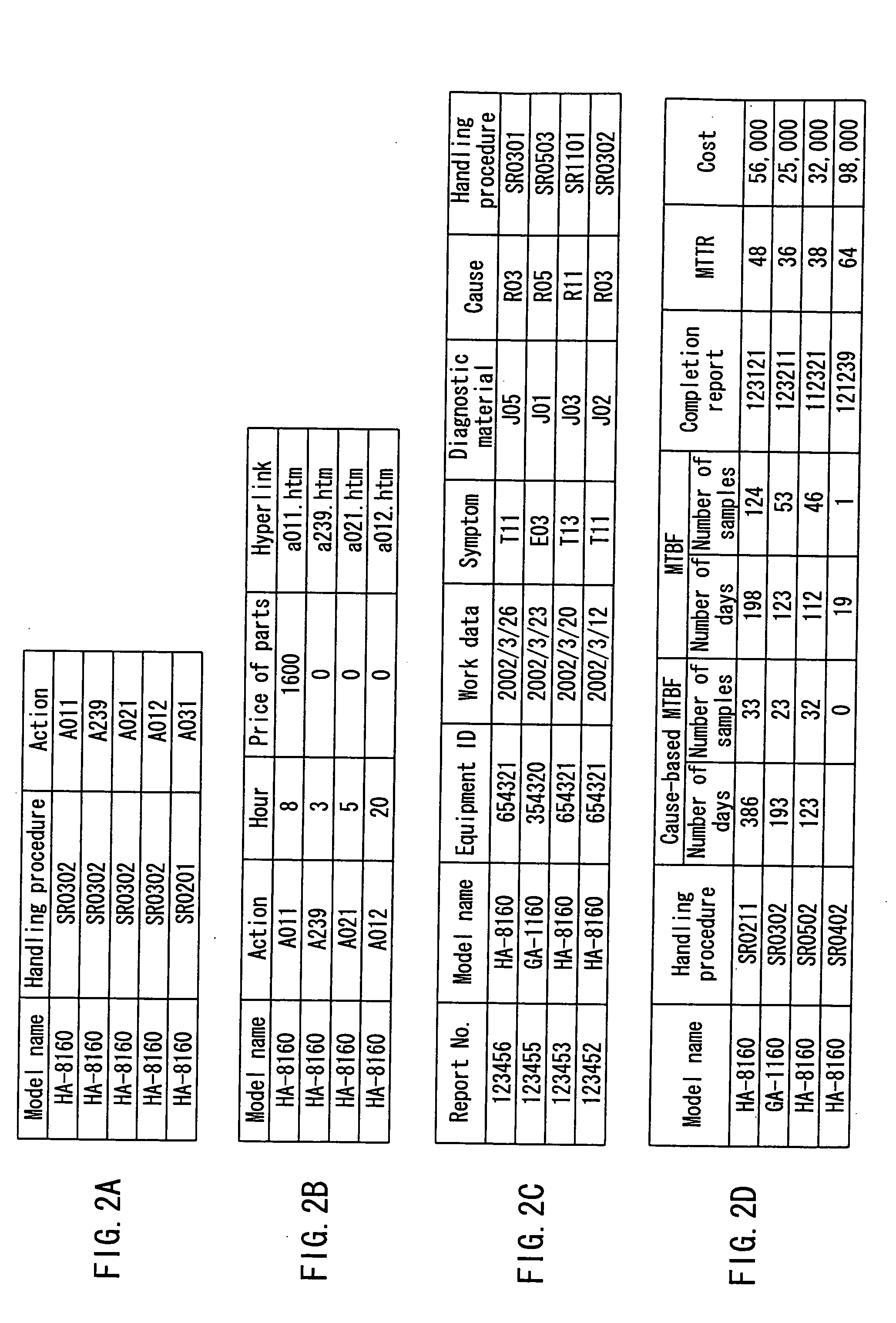

Trouble countermeasure support system and terminal device connected to the same

InactiveUS20050177341A1Effective judgmentDetermine the causes of the trouble more efficientlyDetecting faulty hardware by remote testTesting/monitoring control systemsData ingestionSupporting system

An online manual capable of efficiently identifying a trouble cause and not requiring trouble for updating. A service engineer (SE) connects an SE terminal to a service support system (1) and transmits a trouble event caused in a device to be repaired. In a judgment route data storage section (16), judgment materials for identifying a symptom cause are stored in the descending order of the goodness of fit. A data extraction section (20) extracts the judgment material in that order and represents it to the SE terminal. When the SE selects a judgment material matched with the state of the device to be repaired, the data extraction section (20) extracts a countermeasure action content corresponding to the judgment material from the countermeasure-action data storage section (11), an action data storage section (12), and a content storage section (13) and displays it on the SE terminal.

Owner:ARKRAY INC

Anti-oscillation apparatus and technique for securing wind turbine blades against oscillations

ActiveUS9316202B2Easy to makeEasily be attached to bladePropellersBlade accessoriesTurbine bladeService engineer

The invention relates to a method of operating a wind turbine (1) to guard against oscillations of the wind turbine blades (5) when they are at a standstill or idling at low speeds, and to a wind turbine blade anti-oscillation apparatus (10). The apparatus comprises a releasably attachable blade cover (10) that provides a non-aerodynamic surface for a region of the blade. This has been found to prevent air flow adhering to the blade and periodically detaching in a phenomenon known as vortex shedding, and therefore prevents oscillations of the blade becoming problematic. The blade cover can comprise a sleeve (10) of a net-like material, that can be positioned on the blade either before installation or in the field by service engineers using guide lines 16 and 17.

Owner:VESTAS WIND SYST AS

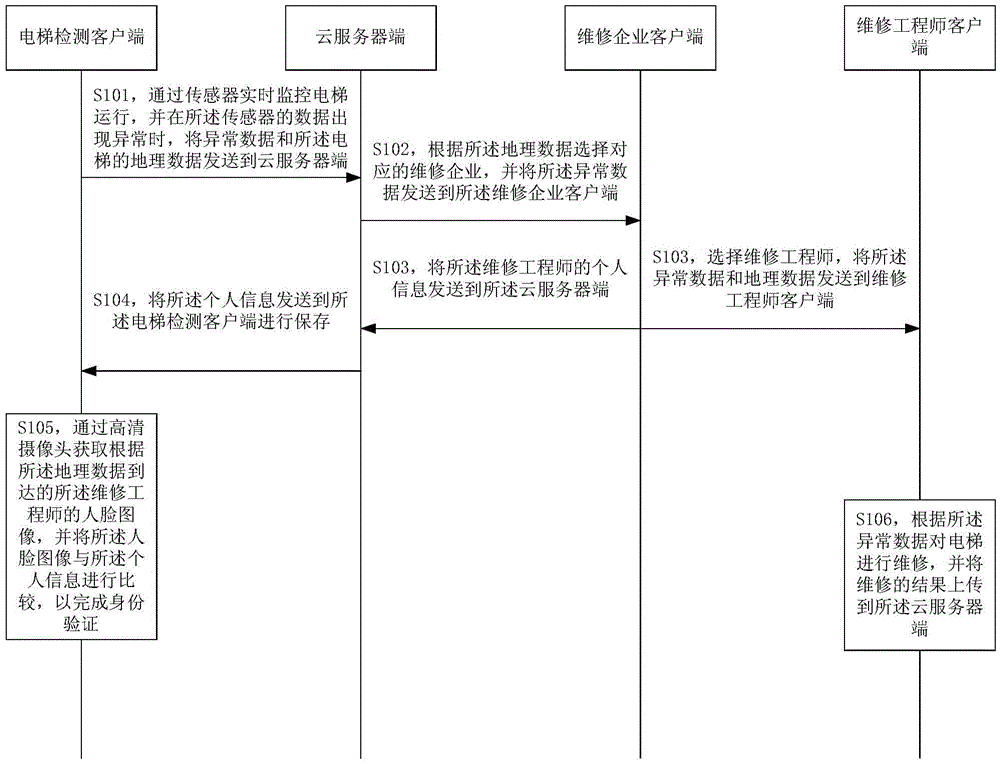

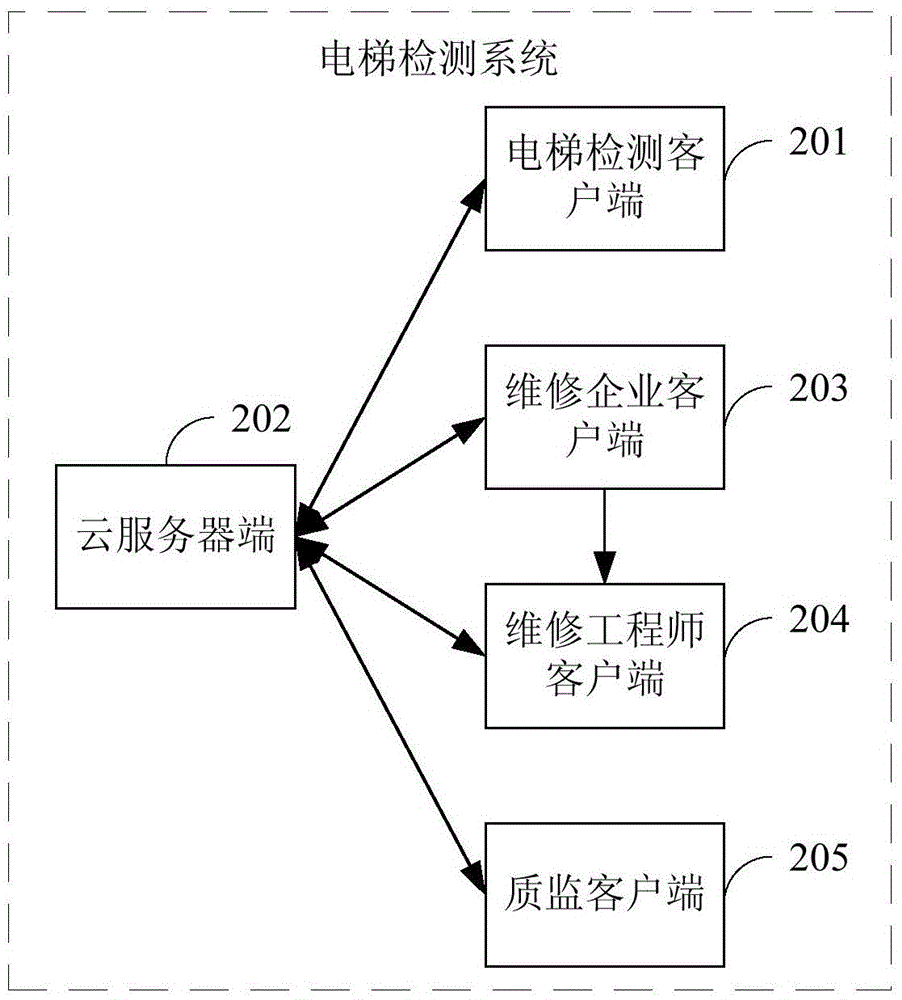

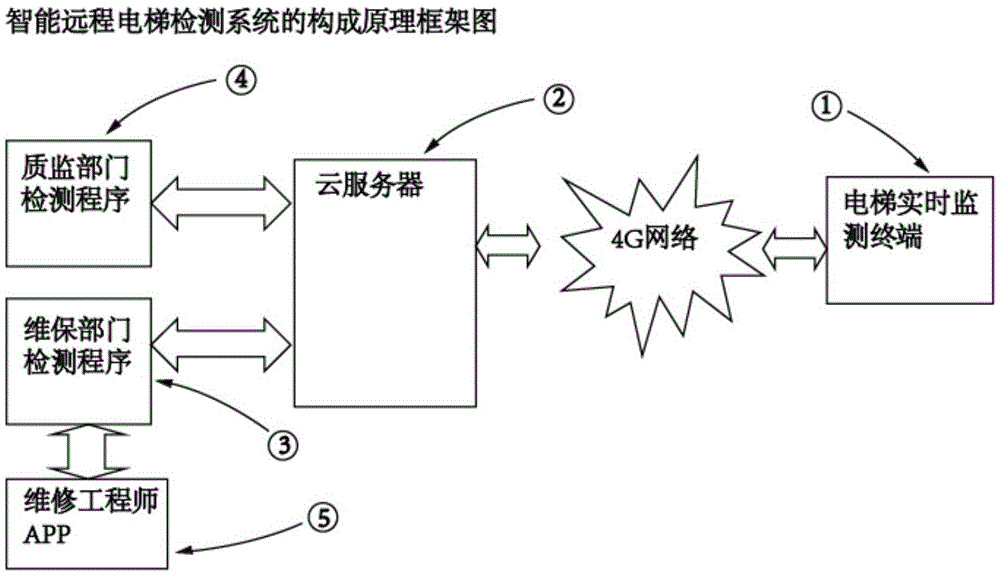

Elevator detecting method and system

The invention is applicable to the field of elevator detection and provides an elevator detecting method and an elevator detecting system. The elevator detecting method comprises the following steps that an elevator detecting client monitors elevator operation in real time via a sensor and sends abnormal data and the geographic data of the elevator to a cloud server side when data of the sensor is abnormal; the cloud server side selects a corresponding repair enterprise according to the geographic data and sends the abnormal data to the client side of the repair enterprise; and the client side of the repair enterprise selects a repair engineer, sends the abnormal data and the geographic data to the client side of the repair engineer, and sends the personal information of the repair engineer to the cloud server side. According to the implementation of the embodiment of the invention, all parties related to repair of the elevator can timely and accurately know the operation condition of the elevator, thus guaranteeing the personal safety of elevator users.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Service data record system and POS system with the same

A service data record system and a POS system with the service data record system are provided. The service data record system transmits a data of an electronic device to a remote monitoring device. The electronic device includes plural electronic units and a power unit. The service data record system includes a power device, a remote monitoring interface and a micro processing unit. The micro processing unit is connected with the electronic device, the remote monitoring interface and the power device. By the micro processing unit, the electronic data set of the electronic unit may be externally transmitted to the remote monitoring device. Moreover, the pre-designate event of the electronic device may be externally transmitted to the remote monitoring device. According to the pre-designate event, it is convenient for a service engineer to make the preparation before repair or maintenance.

Owner:FLYTECH TECH

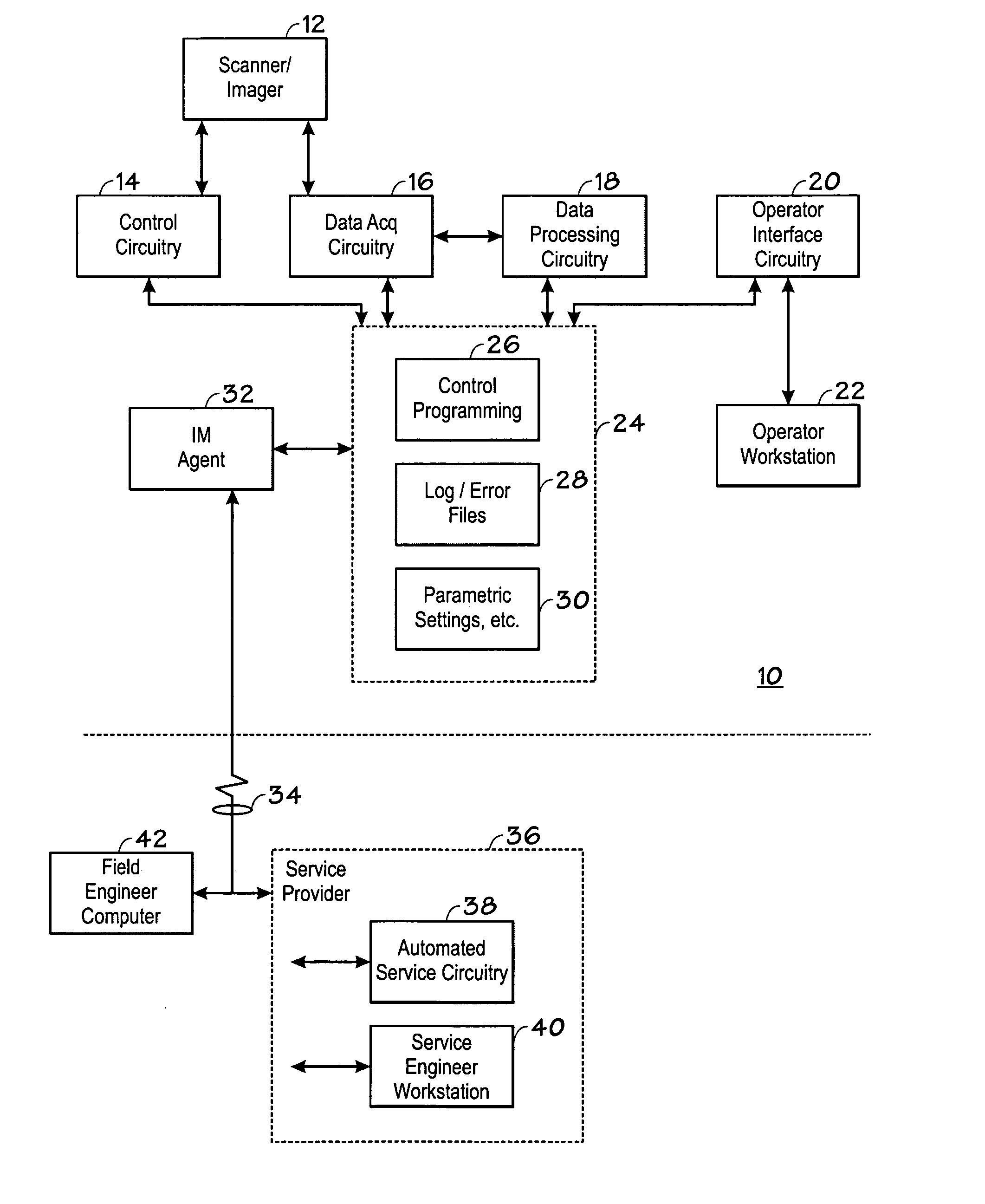

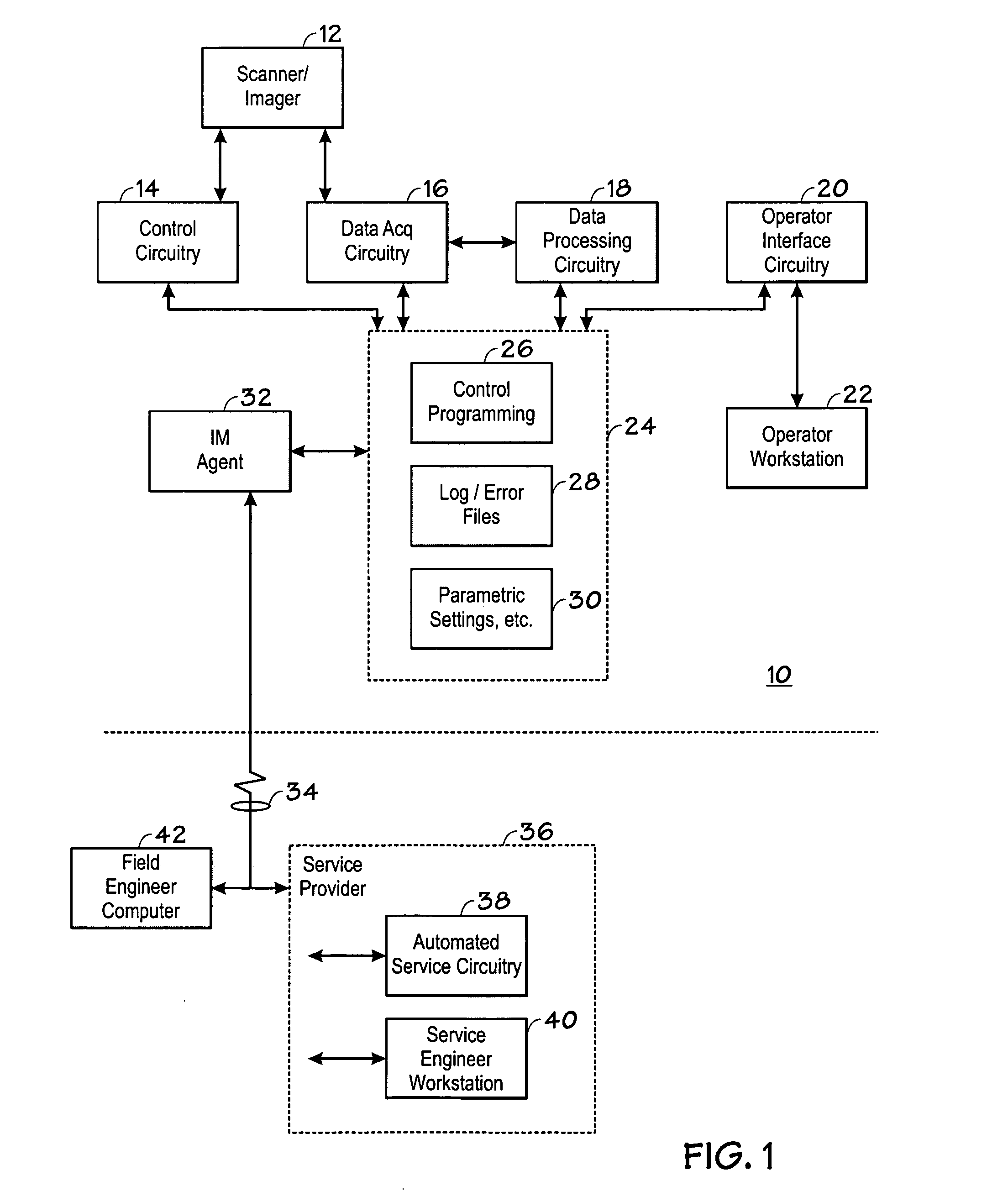

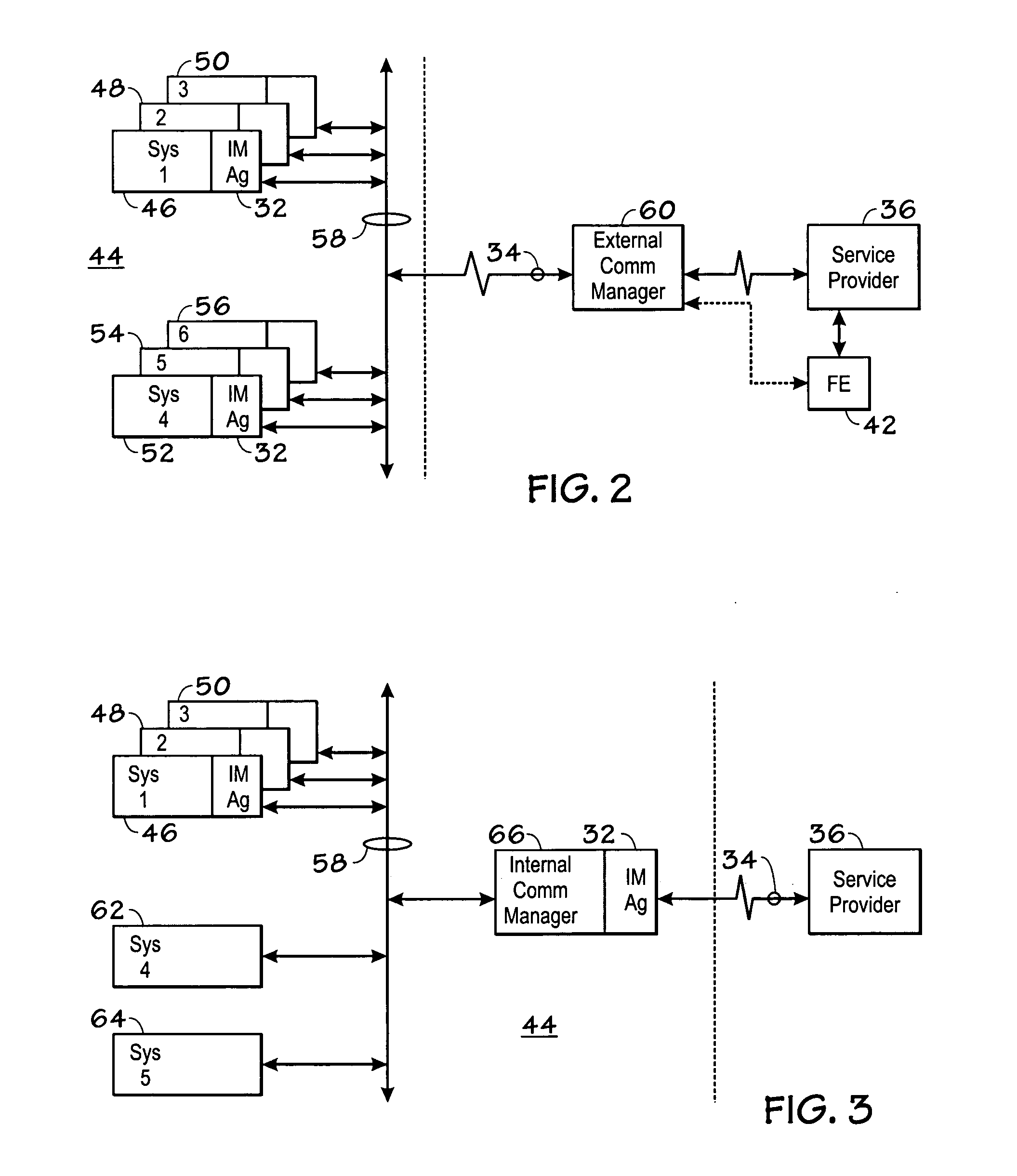

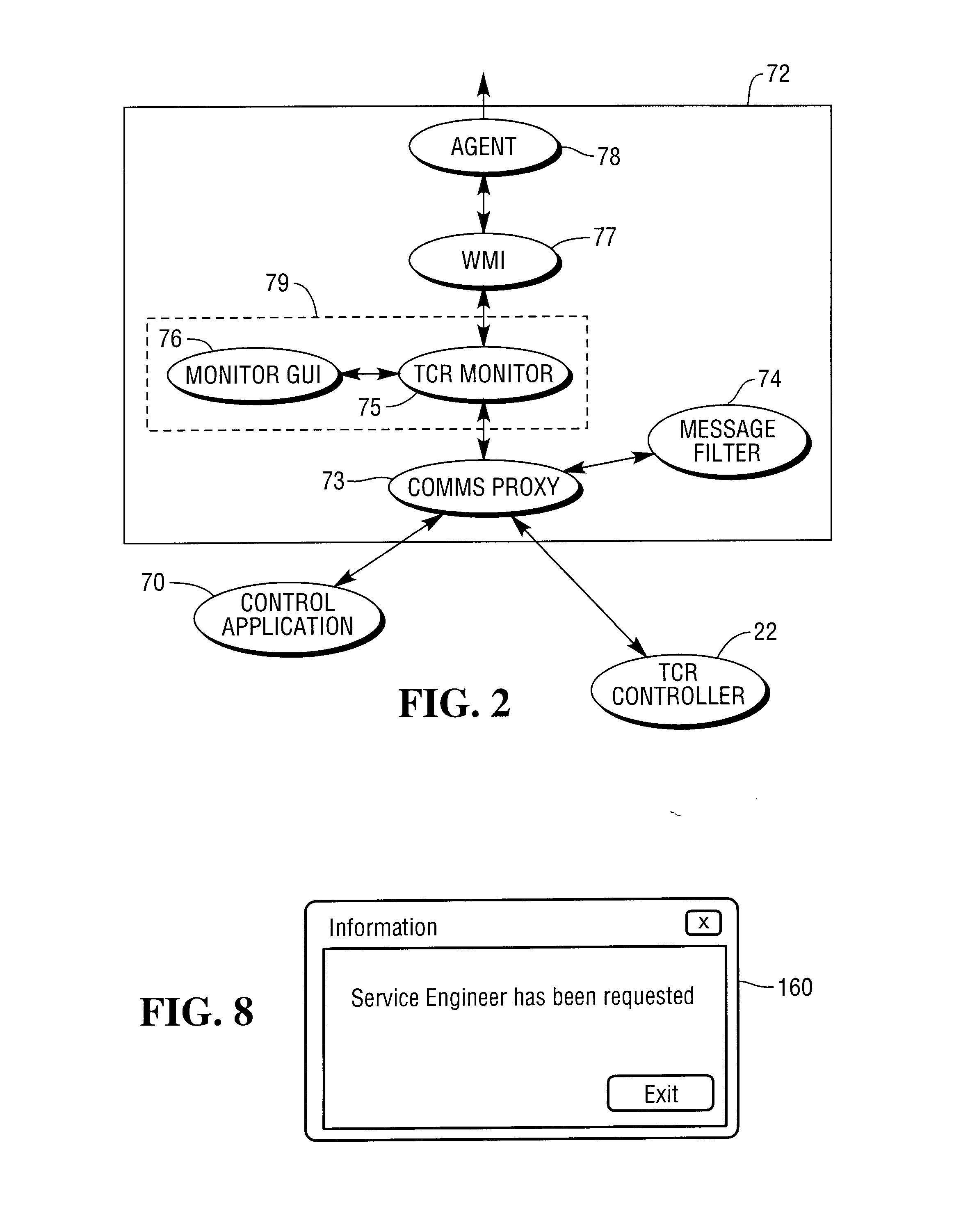

Medical diagnostic system data exchange method and system

A technique is disclosed for exchanging data between a medical diagnostic imaging system and a remote service provider. The system includes the use of an instant messaging (IM) agent stored an operative on the imaging system and at the remote service provider. A human operator at the imaging system may initiate an IM session with the service provider, or such sessions may be initiated either by the service provider or automatically by the imaging system or by computers at the service provider. The IM session may include the exchange of service data, log files, error files, as well as general information on the operation and servicing of the imaging system. The IM session may supplement or replace telephonic exchanges, electronic messages, or even certain personal visits by service engineers.

Owner:GENERAL ELECTRIC CO

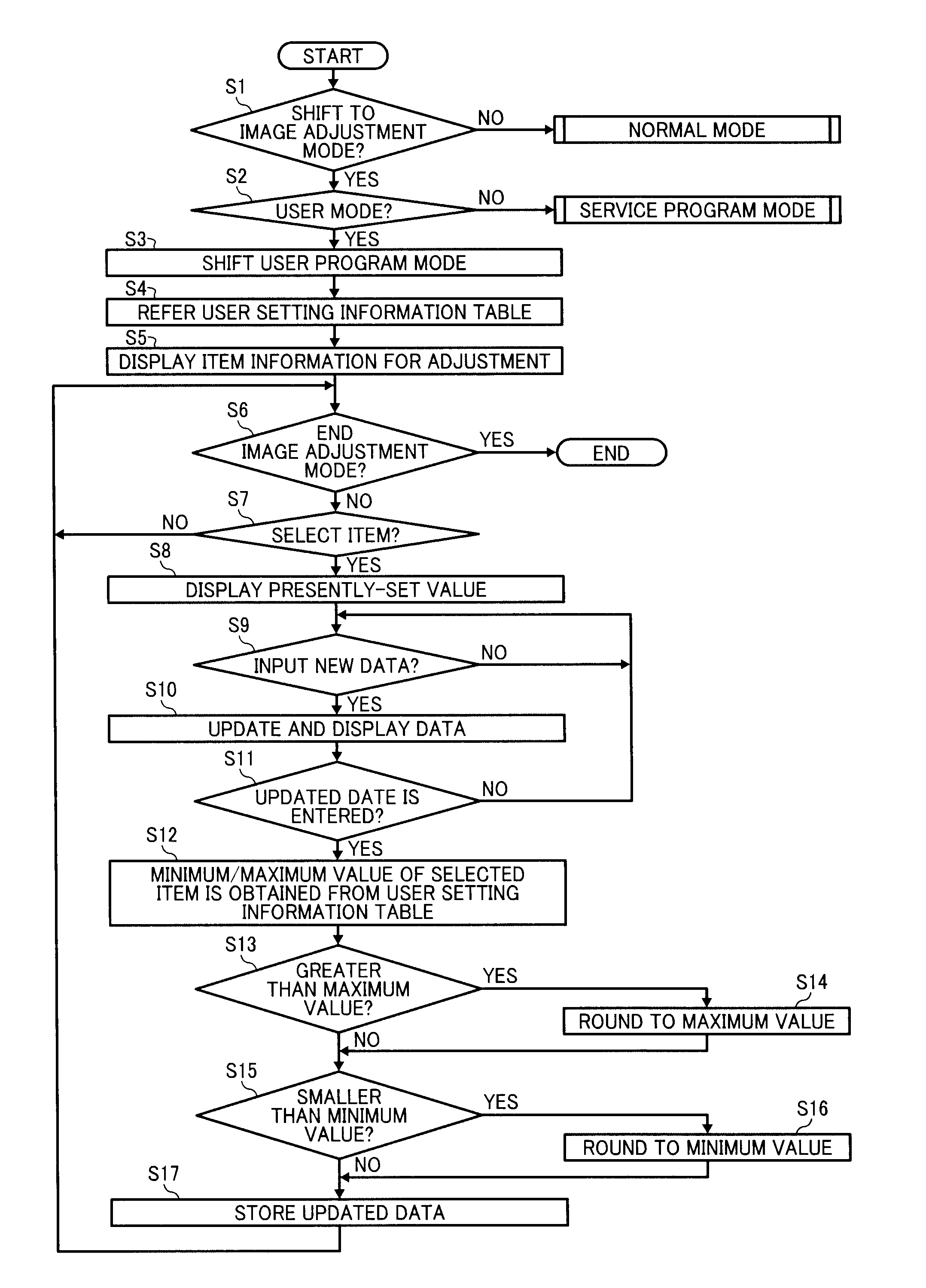

Image forming apparatus, control method for image forming apparatus, and storage medium

ActiveUS20140368854A1Visual presentation using printersDigital output to print unitsImage formationOperation mode

An image forming apparatus makes printing performed for maintenance by a service engineer charge-free, and prevents a print method for the service engineer from being used by a user. The image forming apparatus includes an input unit configured to input an image, a print unit configured to print the image input by the input unit, and a control unit configured to control the image input by the input unit to be output to the print unit and update a charging counter when the image forming apparatus operates in a first operation mode, and configured to control a specific pattern image to be superimposed on the image input by the input unit and the image with the superimposed specific pattern image to be output to the print unit without updating the charging counter when the image forming apparatus operates in a second operation mode.

Owner:CANON KK

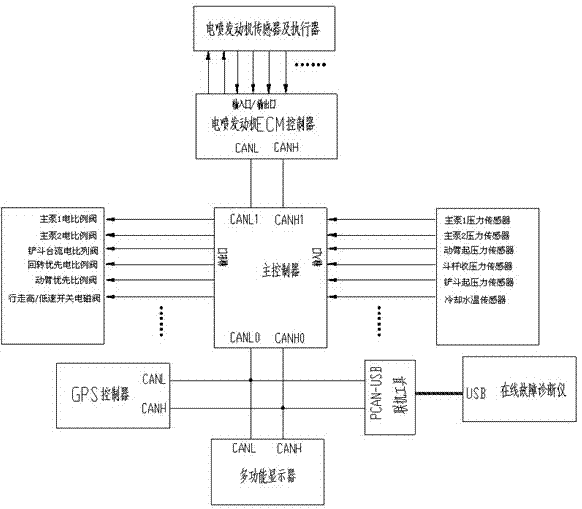

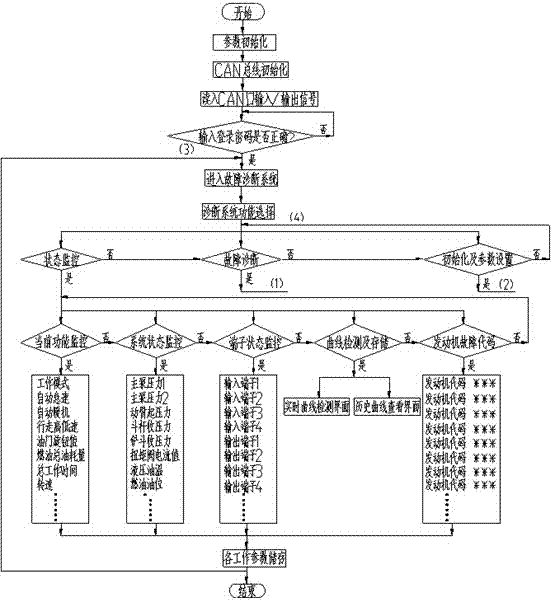

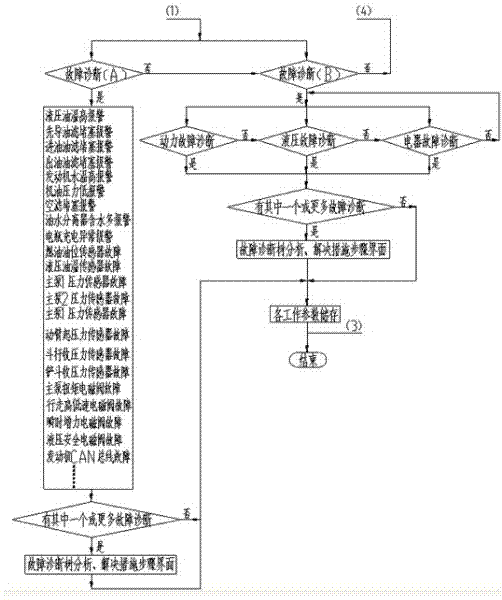

Online fault diagnosis system and method for excavator

ActiveCN102433911AHigh hardware configurationMature technologySoil-shifting machines/dredgersMulti-function displayDiagnosis methods

The invention discloses an online fault diagnosis system and method for an excavator, which belong to the technical field of fault diagnosis in the excavator. The system comprises an online fault diagnosis instrument, a main controller, an electronic injection engine ECM (Engine Control Module) controller, a multifunctional display, and a GPS (Global Position System) controller; and the fault diagnosis method is realized by using the system. The online fault diagnosis system and method disclosed by the invention have the beneficial effects that: a general MID (Mobile Internet Device) on the market is selected and used as an fault diagnosis instrument, and the general MID has high hardware configuration, mature technique and good software development base platform and is convenient to carry and easy to develop a novel application software; the system mainly performs the communication among various data and information through a local area network formed by CAN (Control Area Network) buses; and the fault diagnosis instrument can monitor more working states, analyze the working states and modify parameters of the whole excavator on line and the like, so that much working state data of the whole excavator can be provided for repair engineers and technical staffs.

Owner:XCMG EXCAVATOR MACHINERY

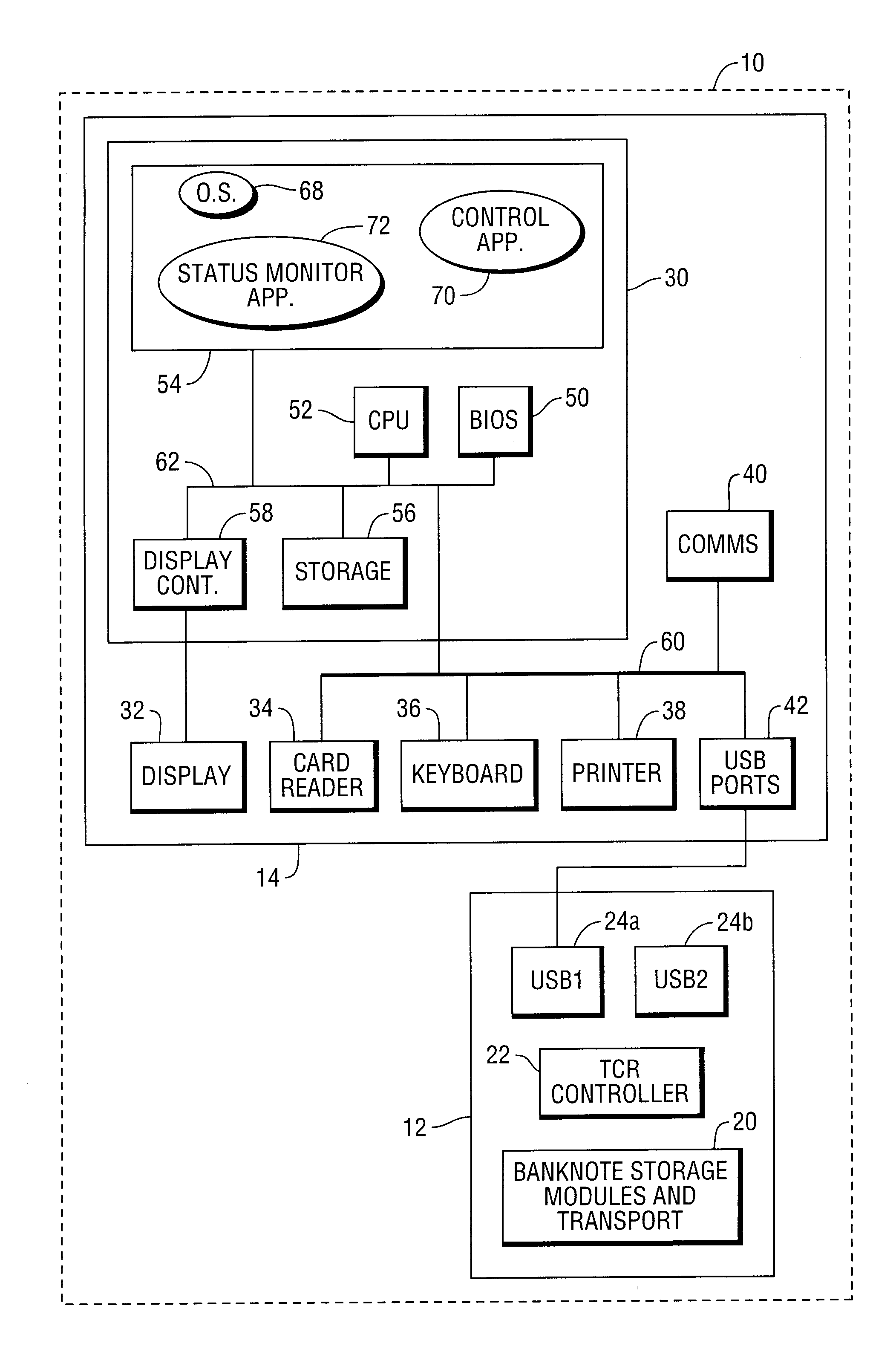

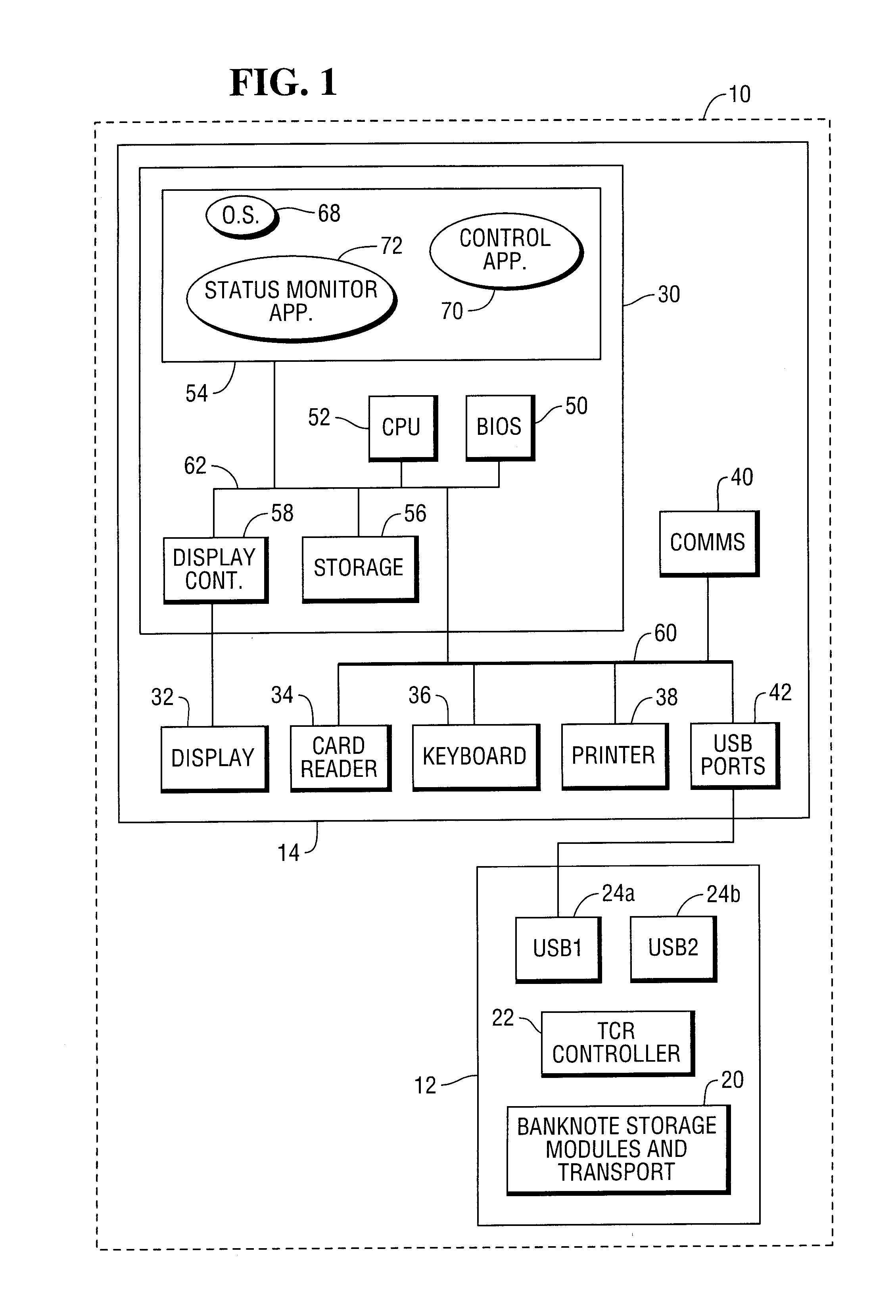

Assisted service terminal

ActiveUS20120023028A1Save precious resourcesSimplify the management processComplete banking machinesATM softwaresComputer terminalApplication software

An assisted service terminal is described. The terminal comprises a currency dispenser; and an operator computer coupled to the currency dispenser. The operator computer includes: (i) an agent arranged to communicate status information to a remote management system, and (ii) a dashboard application. The dashboard application is arranged to (a) receive status messages from the currency dispenser indicative of a fault in the currency dispenser, (b) present the received status messages to an operator, and (c) notify the agent to issue a request to create an incident on the remote management system in response to the operator indicating that the fault cannot be resolved without a visit from a service engineer.

Owner:NCR CORP

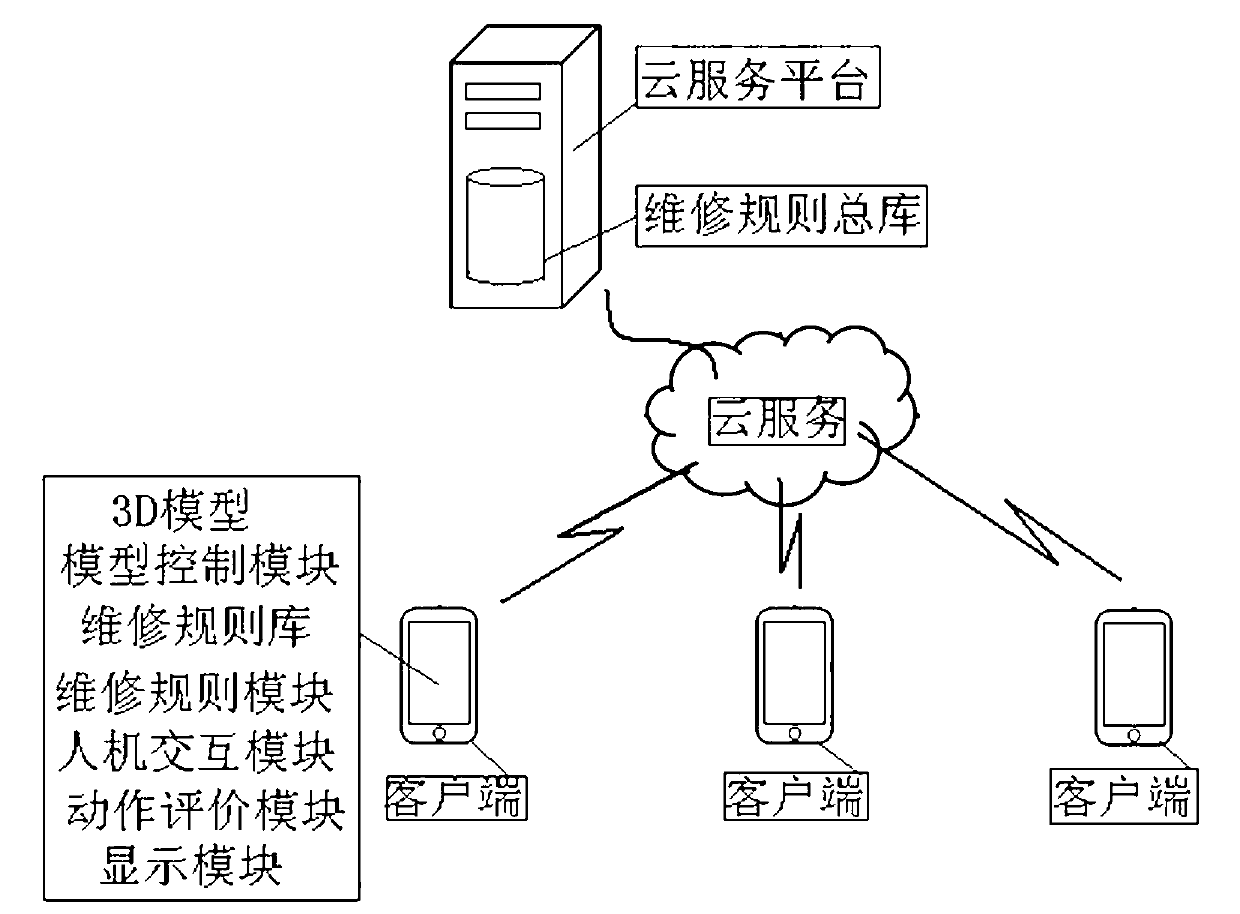

Mechanical device maintenance training system and method by using 3D (three-dimensional) technology

ActiveCN103280147ASwift and skillful methodQuick and skilled stepsEducational modelsAnimationComputer module

The invention provides a 3D (three-dimensional) model-based maintenance training system for equipment such as engineering machinery, construction machinery, mining machinery and agricultural machinery, wherein the maintenance training system can be used for displaying internal structures and processes of complete machines and parts, installing and maintaining the machines. The maintenance training system comprises a 3D model of the equipment, a display module for displaying the 3D model state, a man-machine interactive module used for receiving user operation instructions, a model control module used for controlling the connection relations and states of all parts of the 3D model according to the user operation instructions, a maintenance rule module used for generating and maintaining maintenance rules of the engineering equipment, and an action evaluation module used for recording and evaluating the user operation instructions. According to the maintenance training system provided by the invention, the maintenance process of the engineering equipment is demonstrated by using the 3D model and Flash technology animation, so a maintenance engineer or a user can be trained, maintenance processes of the maintenance engineer or the user can be guided, and simulation can be provided to the maintenance engineer or the user, so the maintenance engineer or the user can quickly and skillfully master maintenance methods and steps. The system can be further operated on a cloud platform.

Owner:JIANGSU TONGRUI DEV INFORMATION TECH

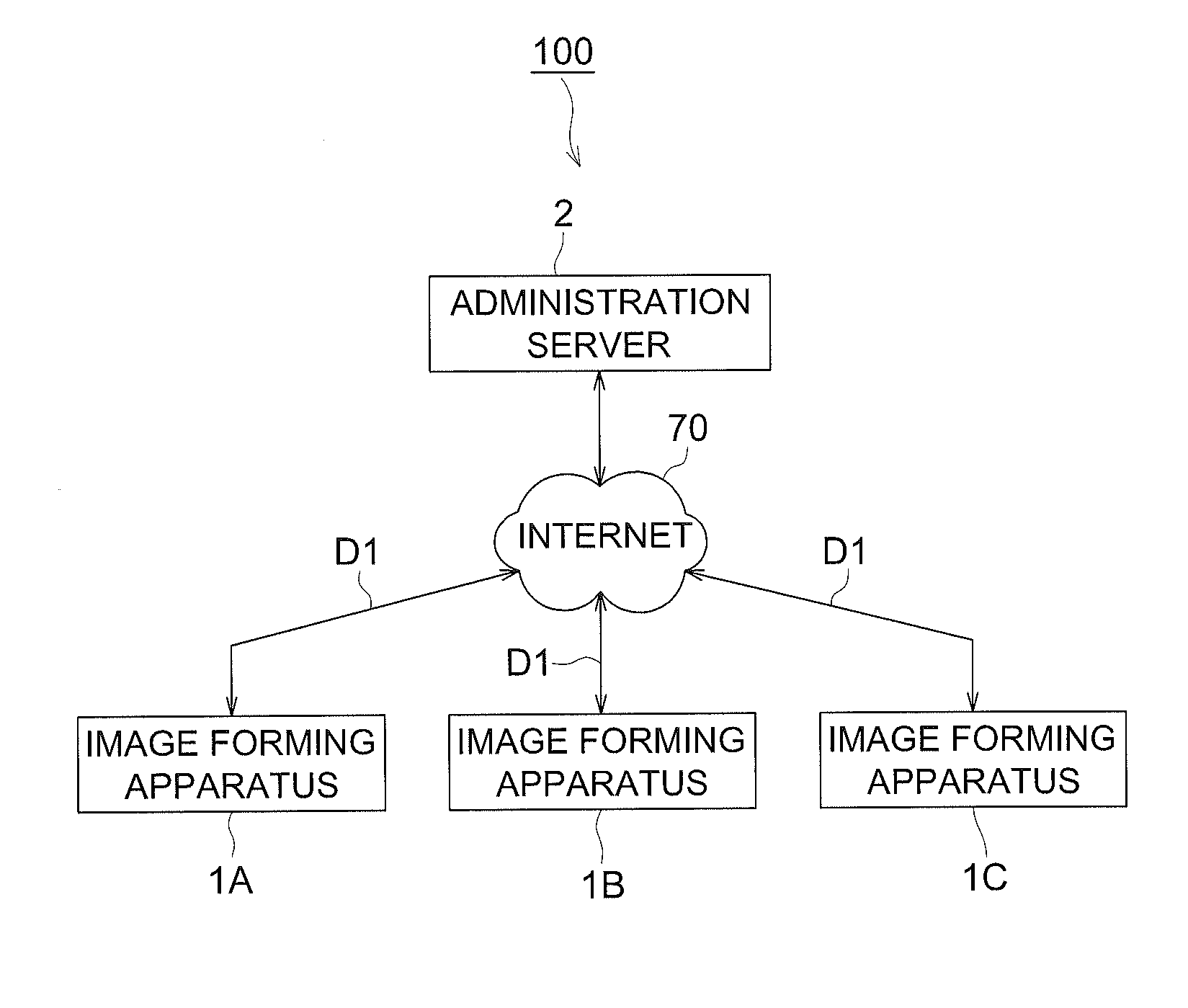

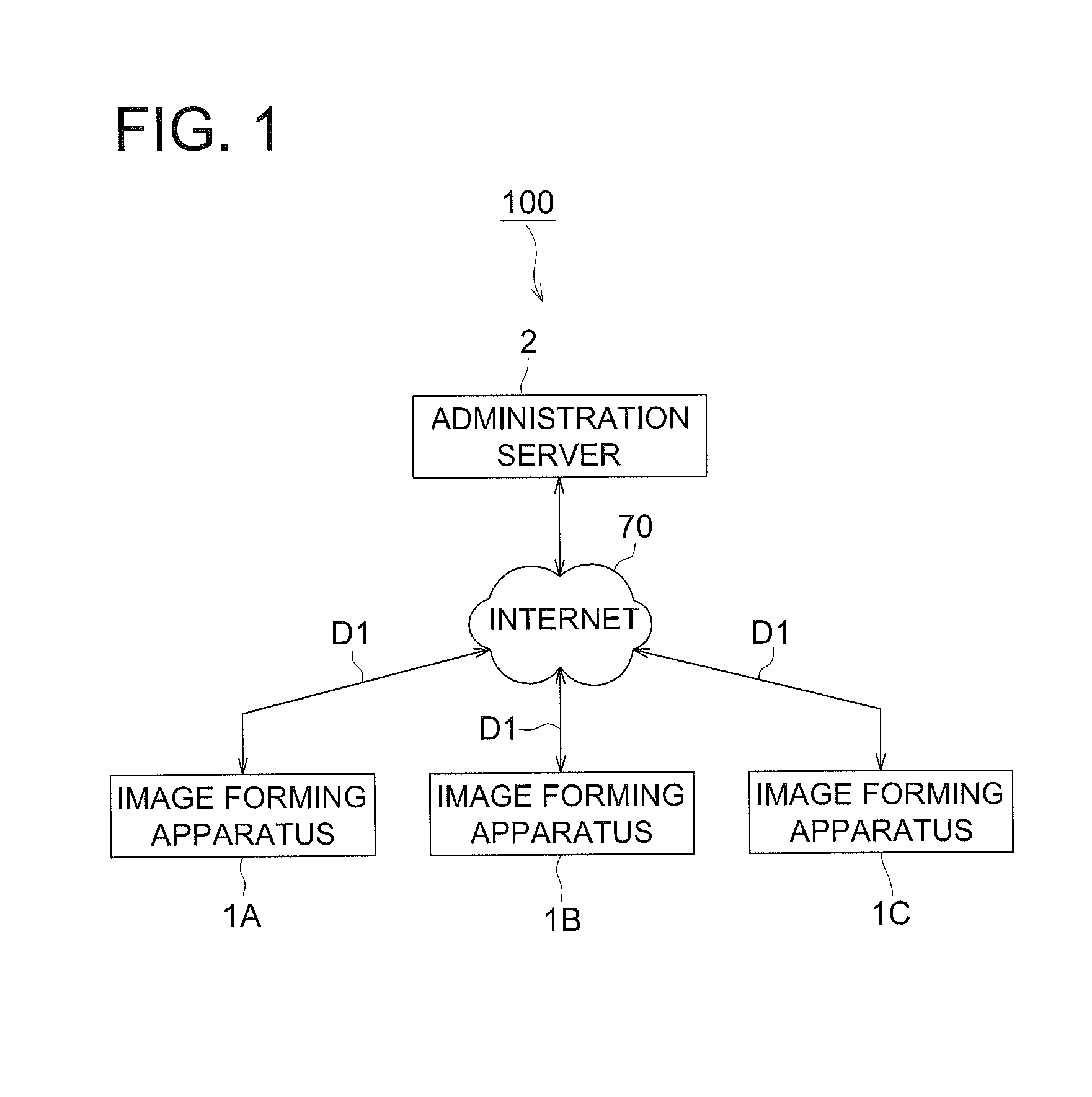

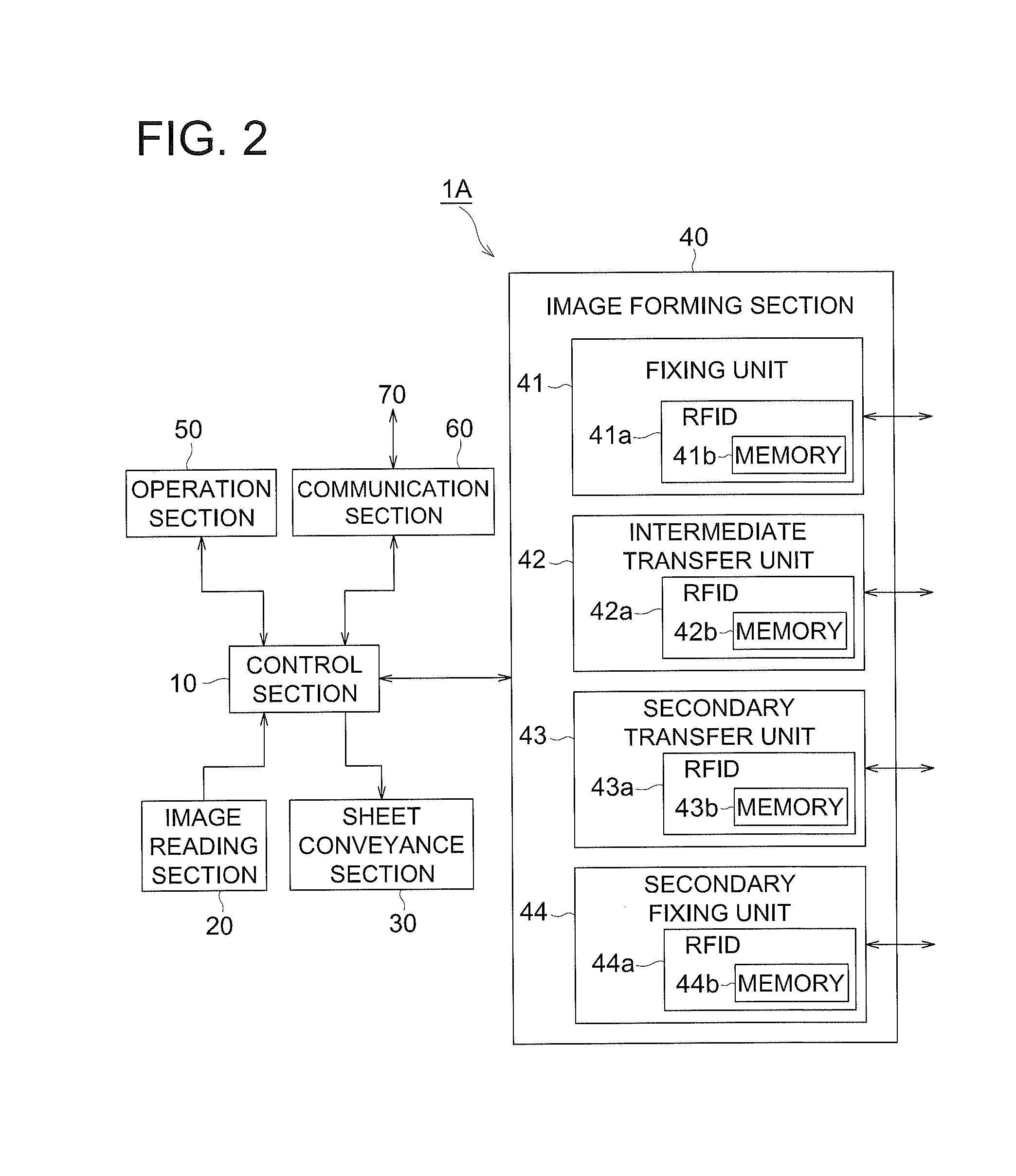

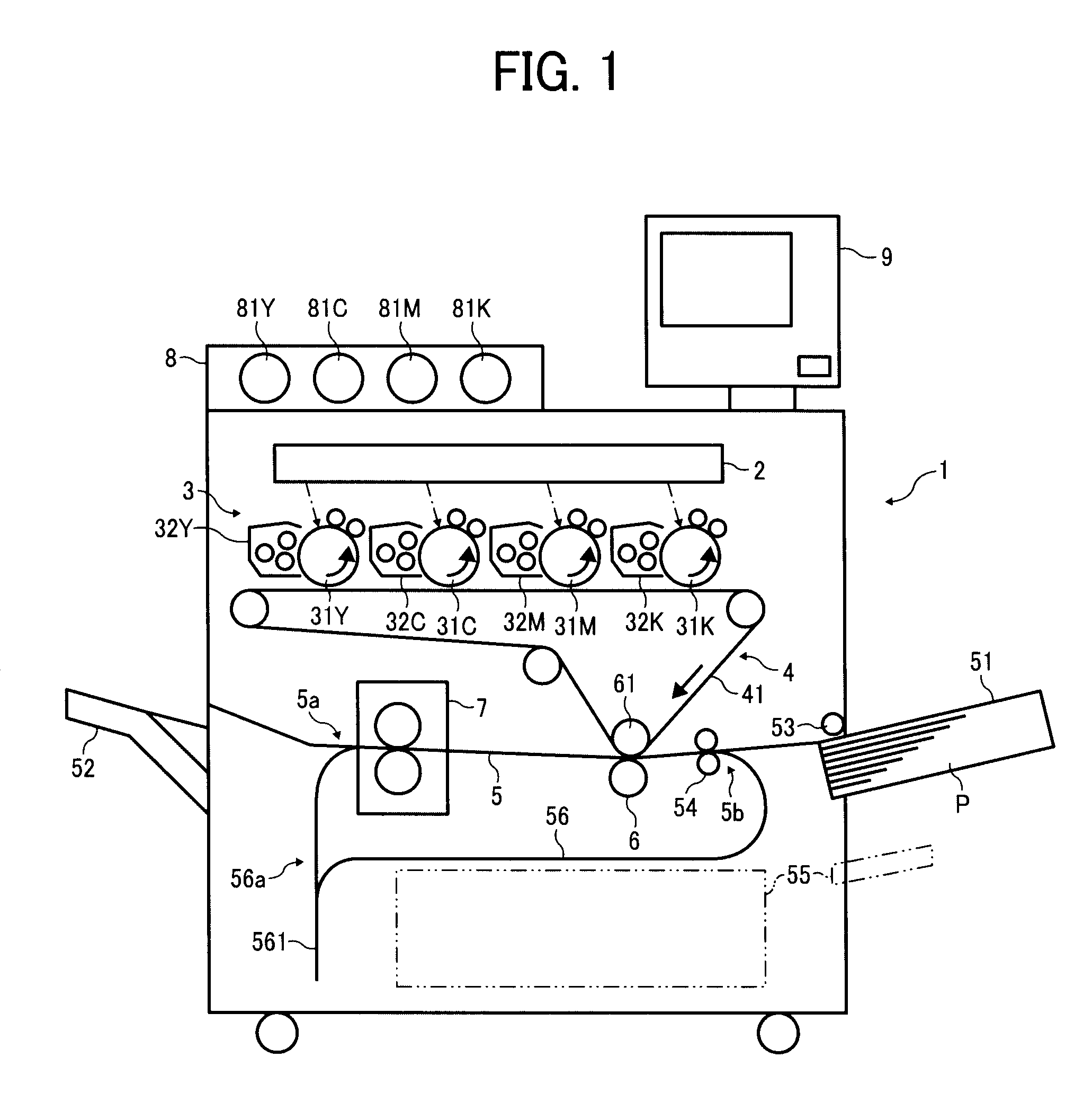

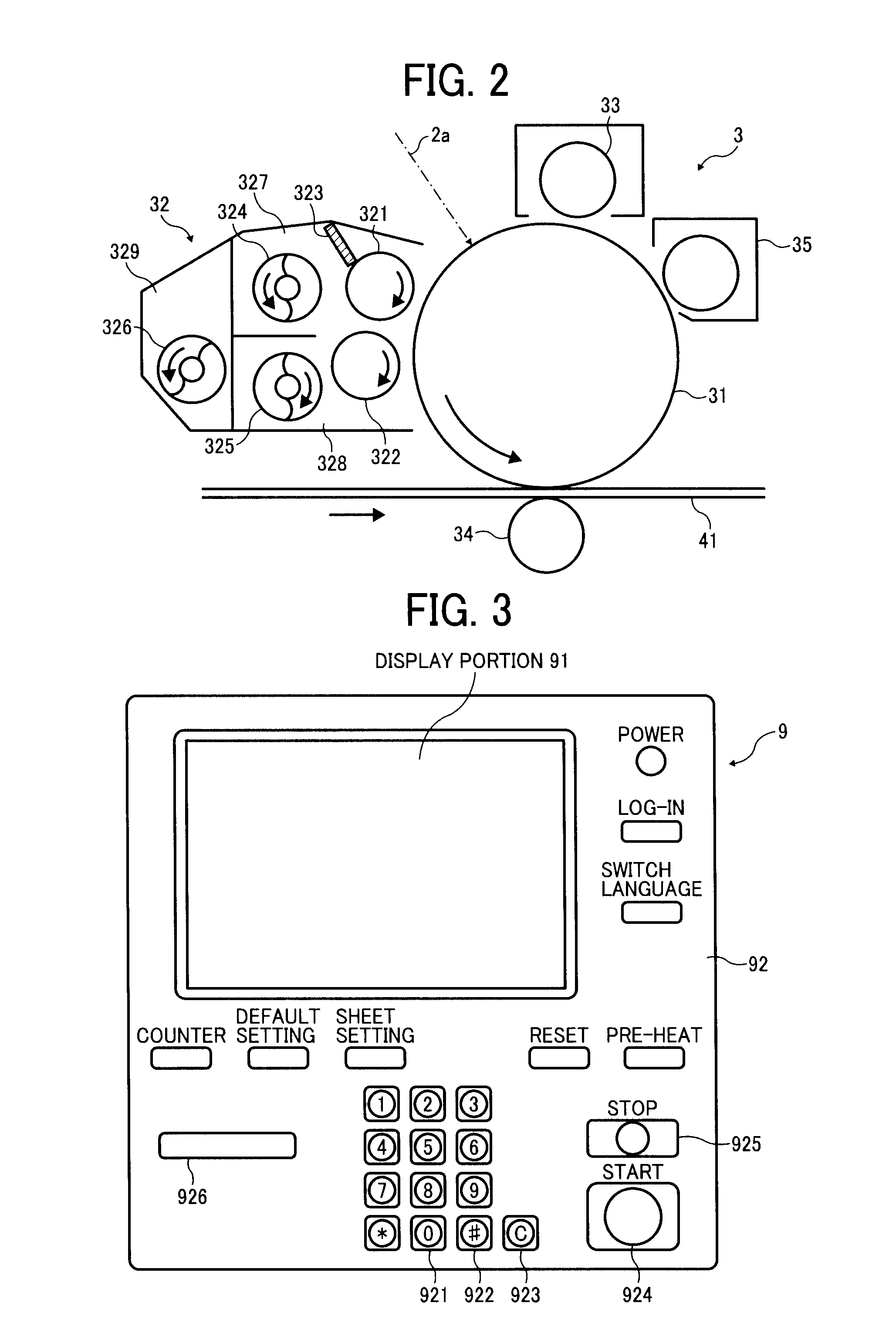

Image forming apparatus and image forming system

InactiveUS20110157641A1Reduce the burden onElectrographic process apparatusPictoral communicationImage formationThe Internet

In an image forming system configured with image forming apparatuses and an administration server connected with the image forming apparatuses thereof via Internet, the image forming unit, mounted at the image forming section in a detachable manner, stores unit information which includes identification data and information of times of use. An operation section creates unit replacing permission information to permit the image forming unit to be dismounted from the image forming section. A control section receives the unit replacing permission information and reads out the unit information. The communication section transmits the unit information to the administration server. Whereby, the administration server can recognize the image forming unit dismounted from the image forming section and the times of used of the image forming unit just before dismounting, therefore the burden of the service engineer can be reduced.

Owner:KONICA MINOLTA BUSINESS TECH INC

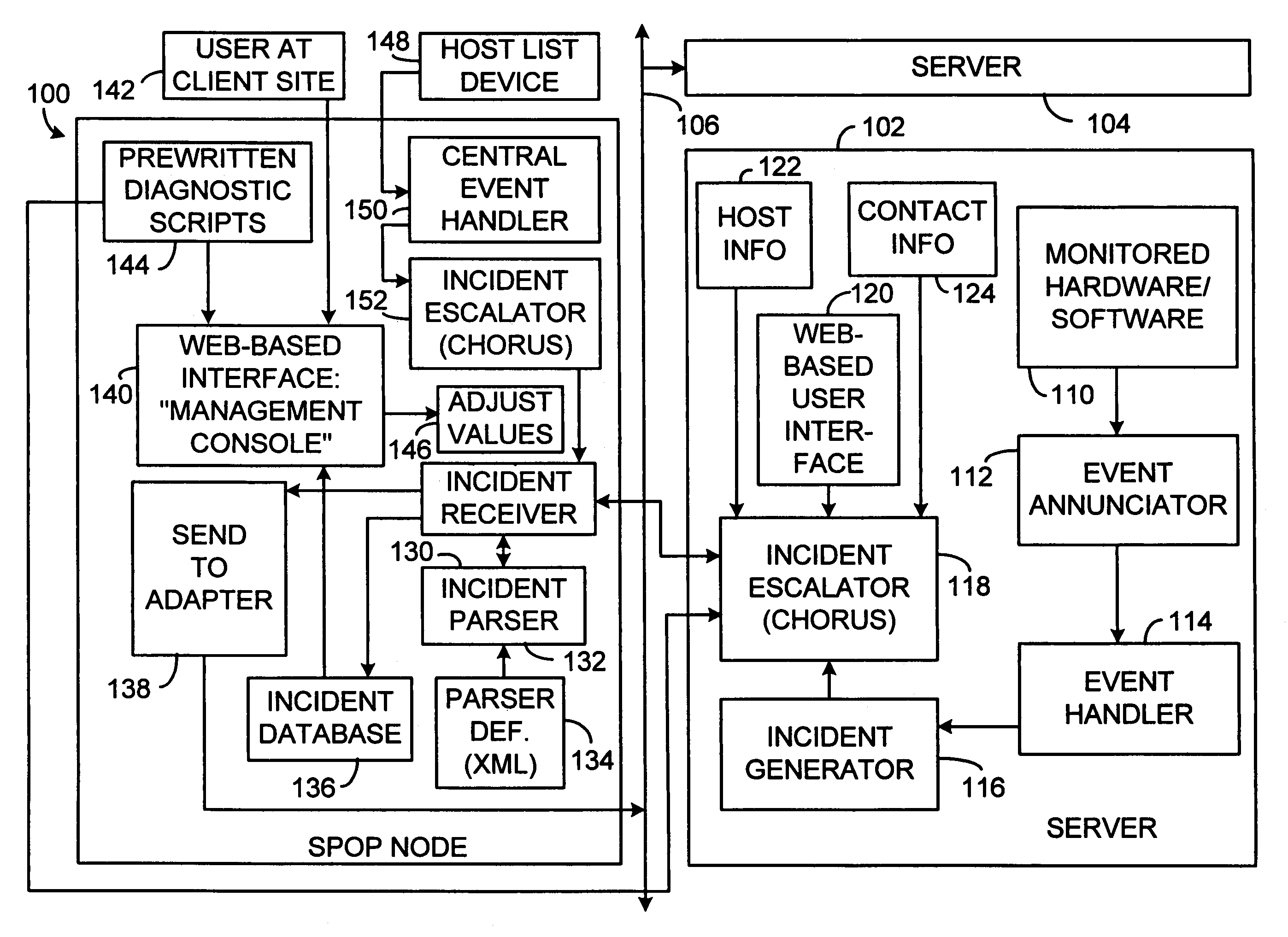

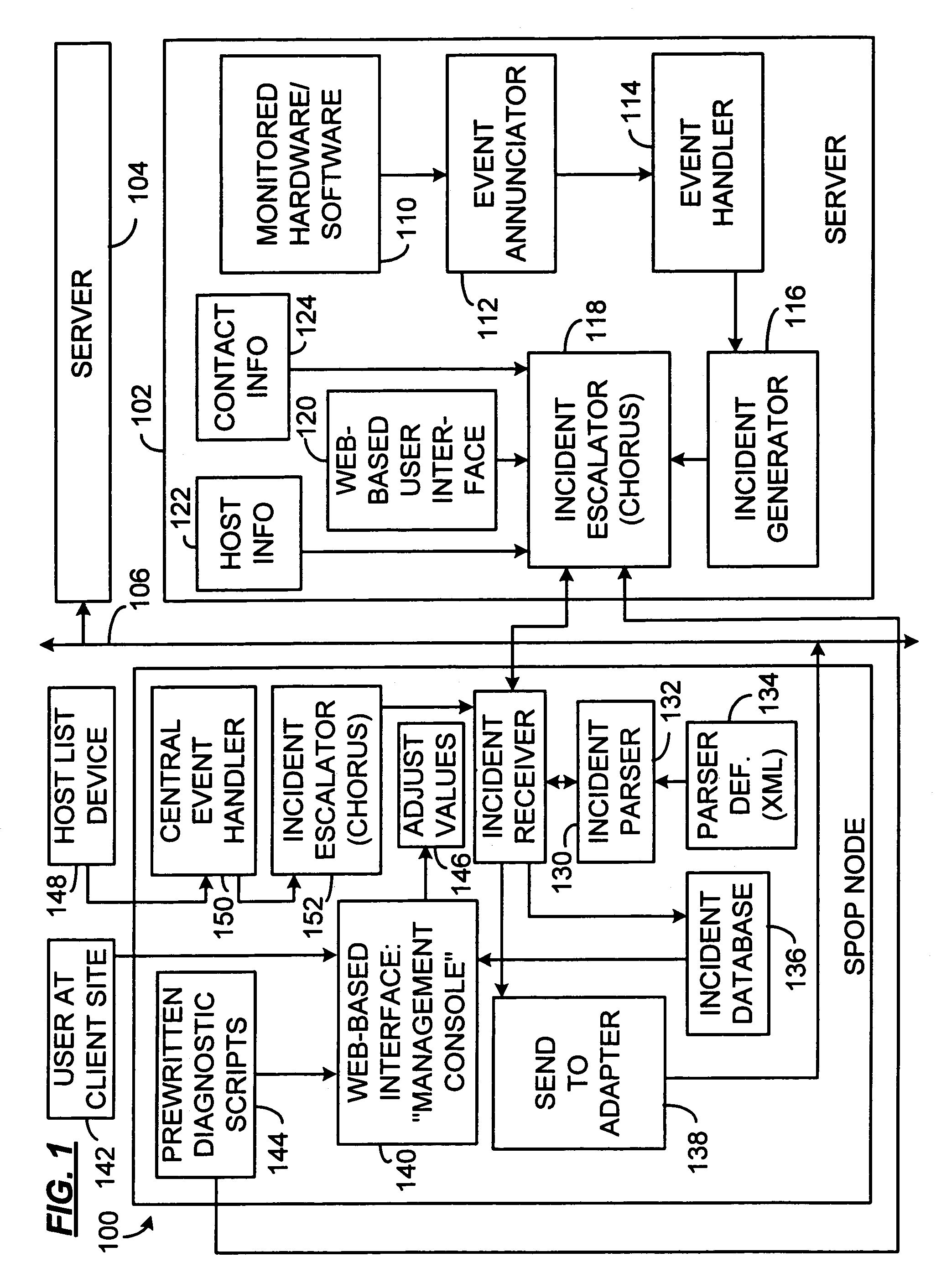

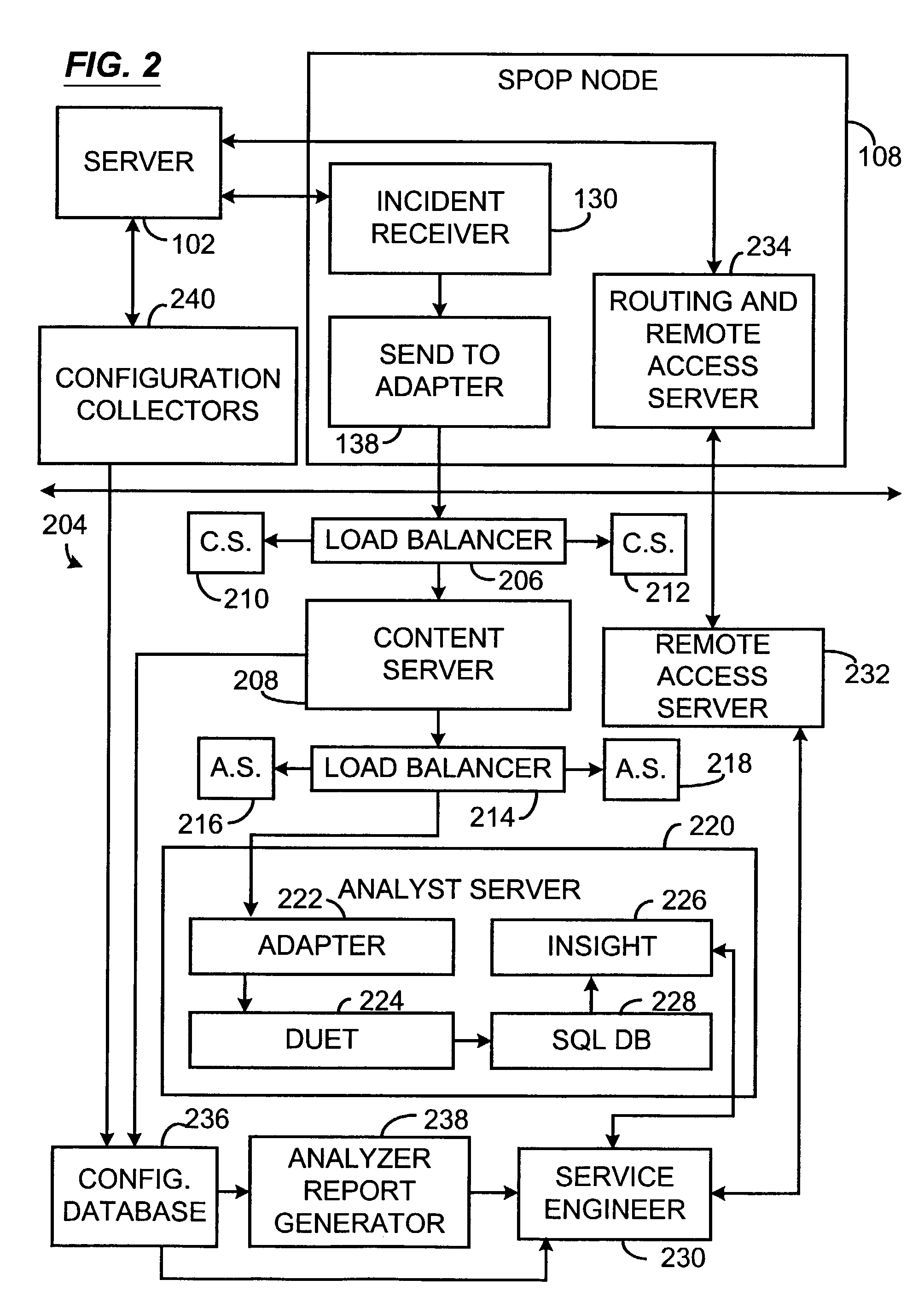

Method for using self-help technology to deliver remote enterprise support

In a service-based remote support delivery system and method, service engineers supported by an analysis server receive incident reports from both personal computers and from unmanned servers within an enterprise. The incidents arise both from user-created reports of problems, from event annunciators that monitor hardware and software to report events as they occur, and from the periodic gathering of configuration data. These incident reports are combined with host information and contact information and are transmitted to the analysis server.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

Wind turbine rotor and wind turbine rotor maintenance method

The invention relates to a wind turbine rotor having one or more wind turbine blades mounted on a rotor hub, the blades having a tip portion and a root portion; a service platform mounted on the wind turbine rotor providing access to the blade root portion of a wind turbine blade, wherein the service platform comprises: a walkway for a wind turbine service engineer.

Owner:VESTAS WIND SYST AS

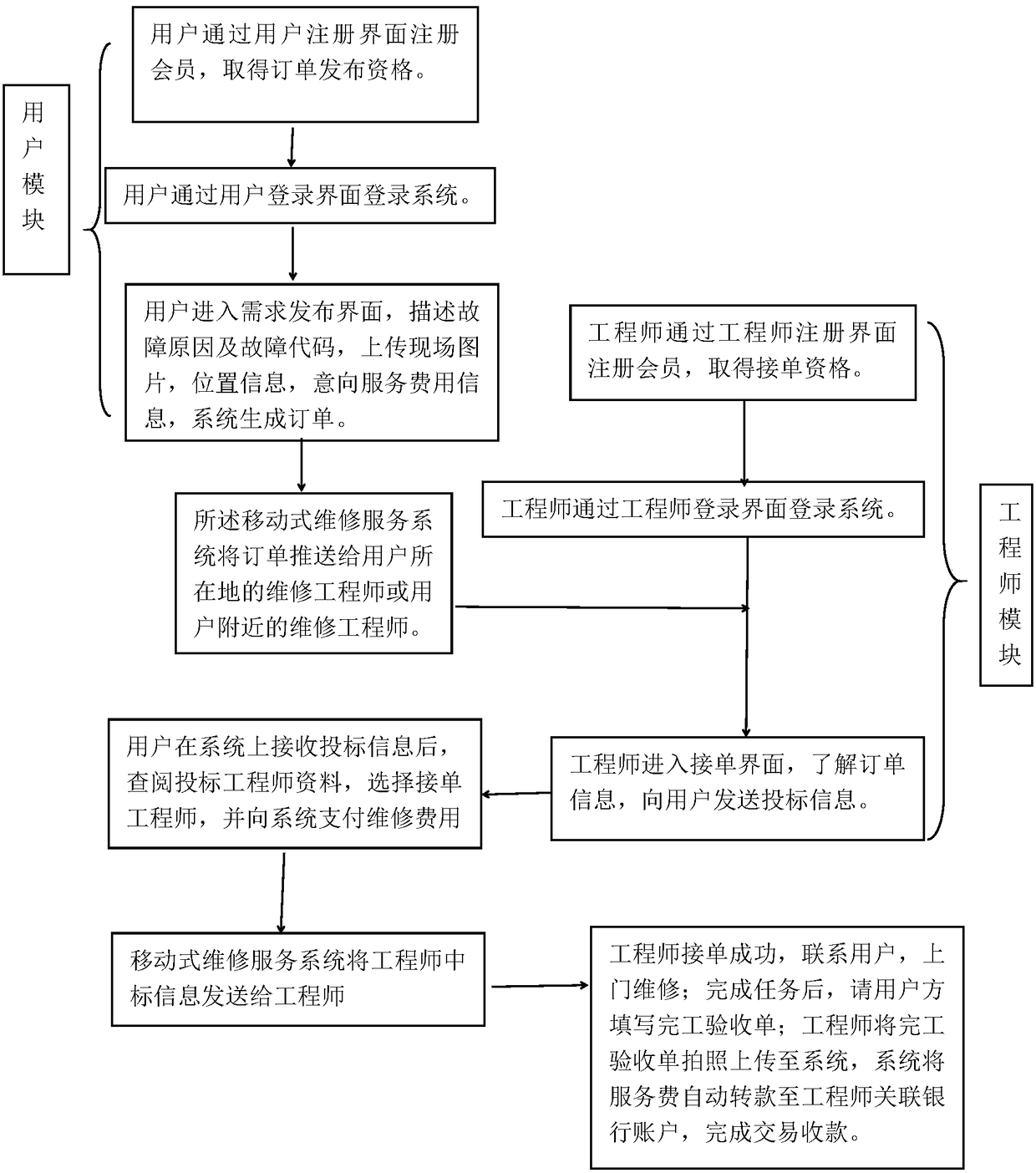

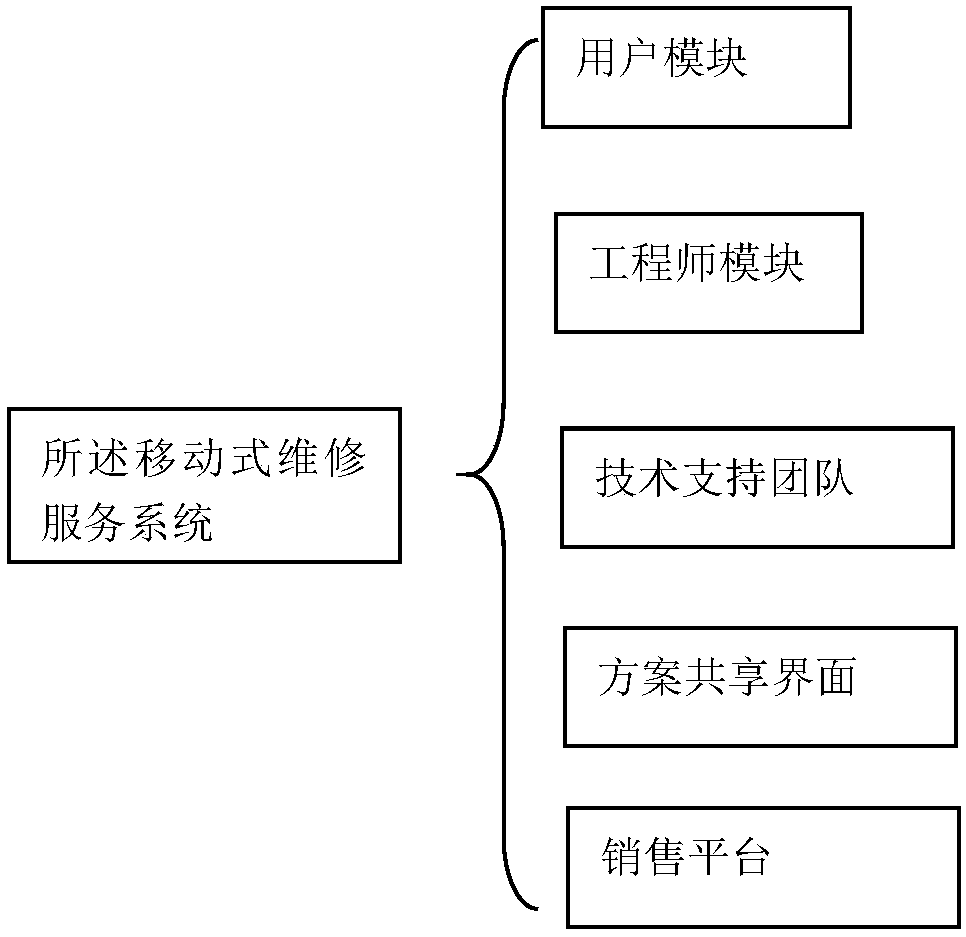

Mobile maintenance service system for automatic equipment

PendingCN108197720ASolve the practical problems of difficult maintenanceImprove efficiencyBuying/selling/leasing transactionsAutomatic test equipmentBank account

The invention provides a mobile maintenance service system for automatic equipment, which comprises a user module and an engineer module, wherein a user publishes an order through the system; the system pushes the order to a maintenance engineer in a place where the user is or a maintenance engineer near the user; the engineer receives the order pushed by the system through an order receiving interface and sends bidding information to the user; the user selects an order-receiving engineer and pays the maintenance fee to the system; the system sends engineer bid winning information to the engineer; the engineer succeeds in receiving the order and on-site maintenance is carried out; and after the task is completed, the engineer takes a photo of a completion acceptance sheet and uploads the sheet to the system, the system automatically transfers the service fee to a bank account associated with the engineer, and the transaction is completed and the fee is received. According to the mobilemaintenance service system for automatic equipment, the Internet technology is used to provide mobile maintenance service, the practical problem of difficult maintenance of the automatic equipment issolved, the efficiency is high, the cost is low, and the maintenance is convenient.

Owner:东莞市索康智能科技有限公司

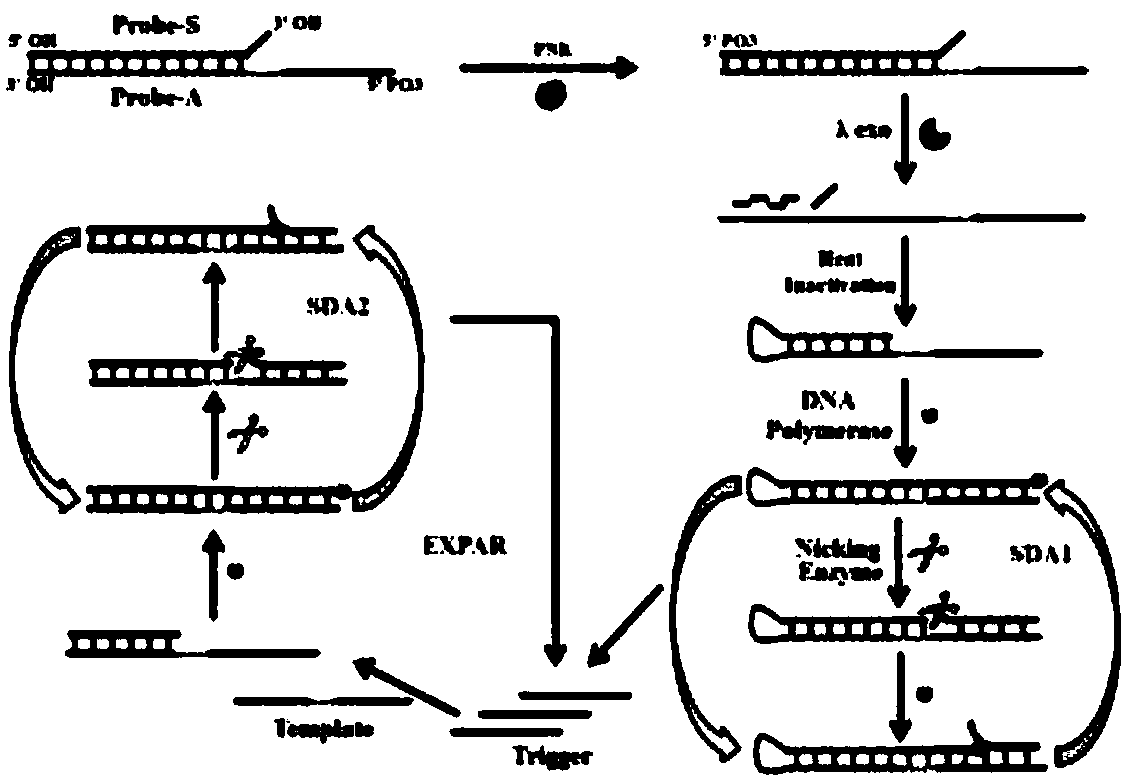

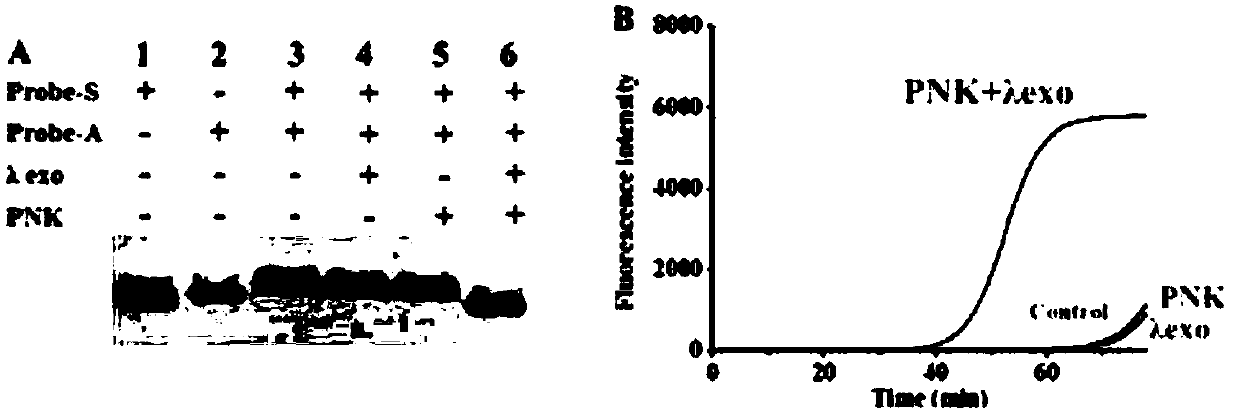

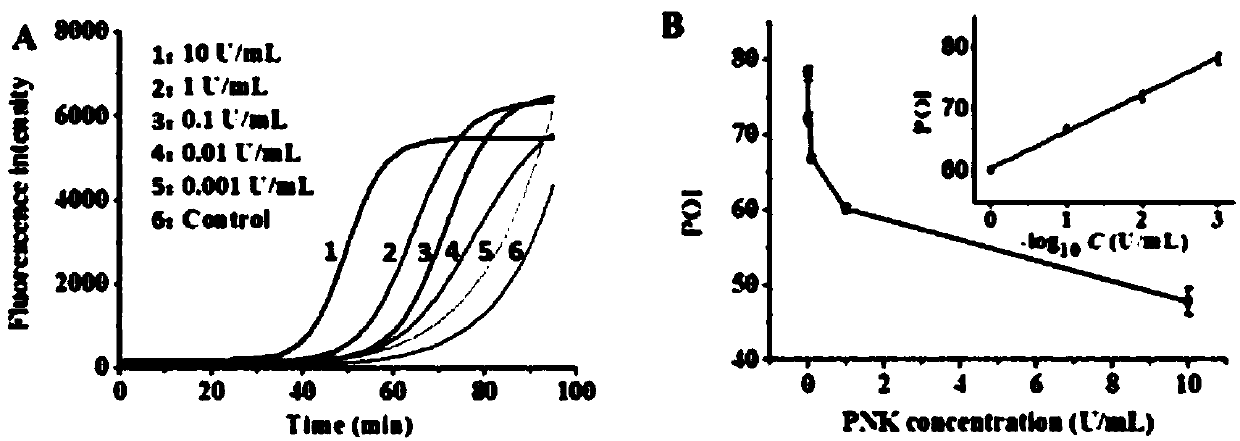

Kit for detecting polynucleotide kinase (PNK) and detection method for kit

ActiveCN107937482AEasy to operateLow costMicrobiological testing/measurementBiological material analysisService engineerPolynucleotide

The invention belongs to the technical field of bioanalysis and particularly relates to a kit for detecting polynucleotide kinase (PNK) and a detection method for the kit. The kit disclosed by the invention comprises a probe A, a probe S, a mixed solution A, a template DNA (Deoxyribonucleic Acid), lambda exonucleautomotive service engineers, a polynucleotide kinase standard substance and 1xNEBuffer and 10mM triphosadenine. The detection method for the kit disclosed by the invention has the advantages of simple operation, reduction of detection cost, high sensitivity and high specificity, and can be applied to detection of complex samples. In addition, the kit disclosed by the invention is also applied to PNK activity inhibitory detection.

Owner:SHANDONG NORMAL UNIV

Intelligent maintenance method of washing machine

InactiveCN103334261AShorten the timeReduce mental distressControl devices for washing apparatusTextiles and paperHotlineComputer terminal

The invention discloses an intelligent maintenance method for a washing machine. The intelligent maintenance method comprises the following steps that (1) when faults occur, the washing machine performs self detection, and begins reporting errors and generating corresponding fault signals after detection is finished; (2) the washing machine communicates with a mobile terminal and transmits the fault signals to the mobile terminal; (3) the mobile terminal detects corresponding fault types and fault maintenance methods according to the fault signal, wherein in the step (2), communication modes established between the washing machine and the mobile terminal comprise bluetooth, infrared and 3G (The 3rd Generation Telecommunication) network; in the step (3), fault maintenance methods output by the mobile terminal comprise a text-description-based maintenance method and a video-display-based maintenance method, when the fault maintenance methods output by the mobile terminal are difficult to implement, and the mobile terminal displays as initiatively calling manufacture service hotline. The intelligent maintenance method has the obvious advantages that a maintenance engineer does not need to spend a lot of time and physical effort in detecting faults, and the time consumption brought by browsing a maintenance handbook with numerous and diverse content is reduced.

Owner:NANJING LG PANDA APPLIANCES

Image forming apparatus having improved serviceability

An image forming apparatus including maintenance function for maintaining the image forming apparatus at a given operating condition includes an operation screen unit. The operation screen unit is useable for conducting maintenance on the image forming apparatus. The maintenance is categorized into a service-maintenance work conductable by a service engineer within service-operation content, and a user-maintenance work conductable by a user within user-allowed-operation content. The operation screen unit includes a user-specific operation screen, with which the user-maintenance work is conductable for adjusting the maintenance function within the user-allowed-operation content. The user-specific operation screen displays the user-allowed-operation content, which is different from the service-operation content.

Owner:RICOH KK

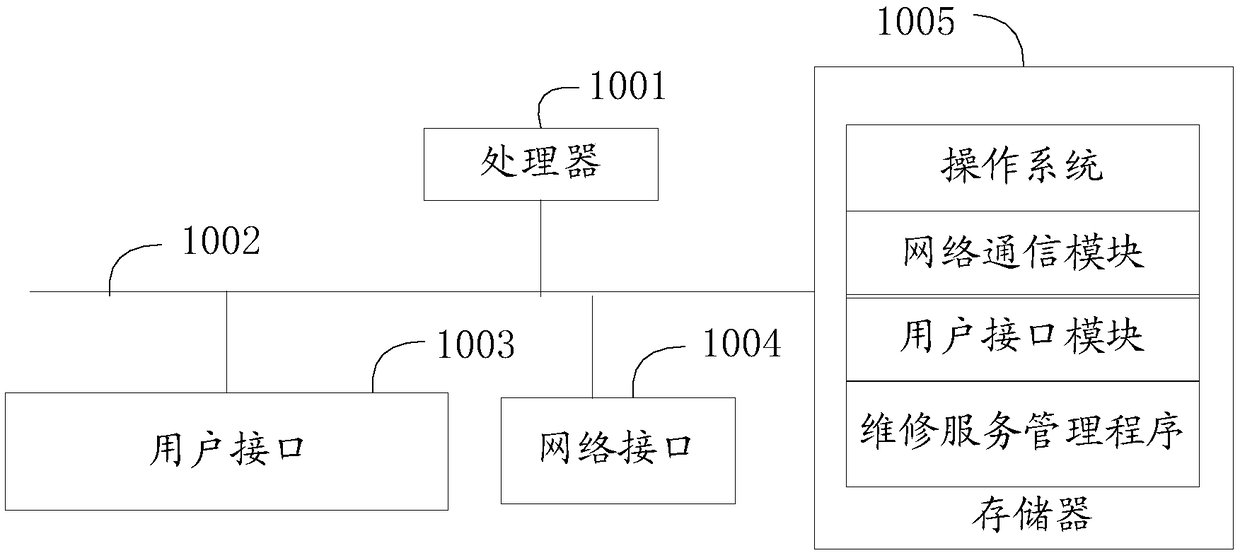

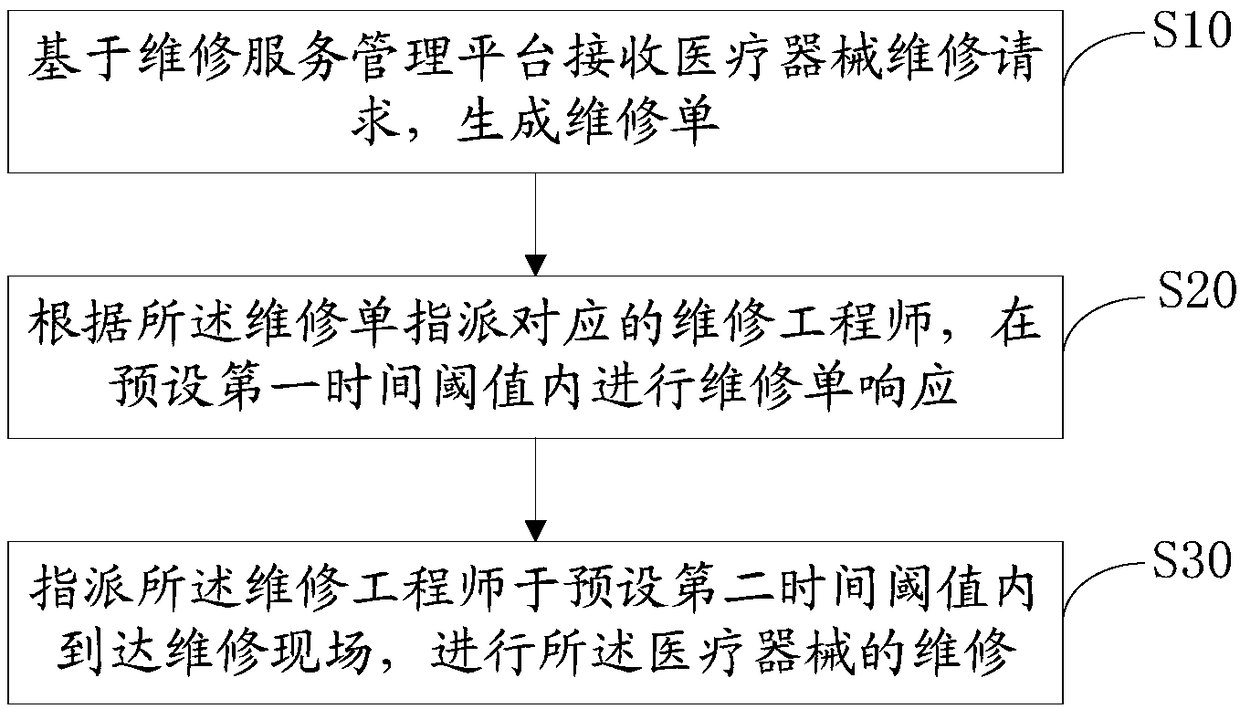

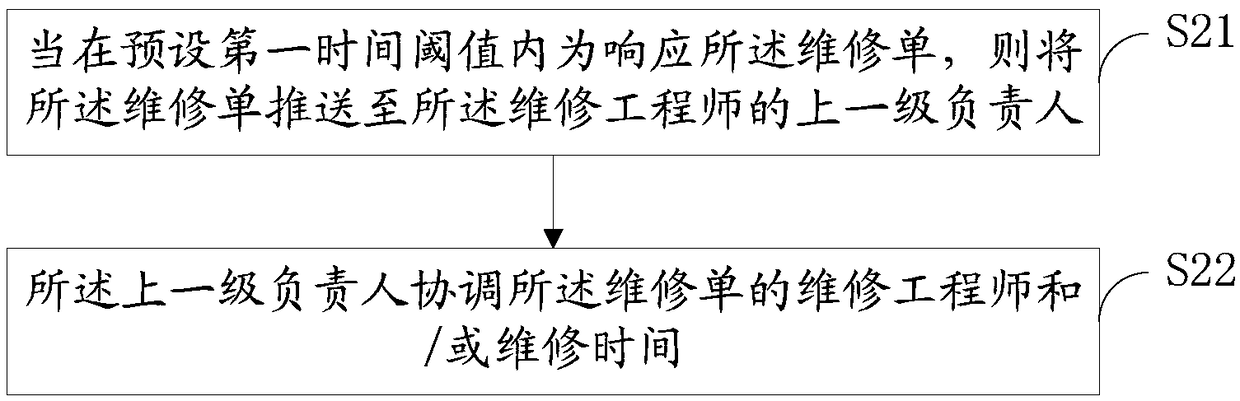

Maintenance service management method and system, terminal and computer readable storage medium

InactiveCN108899082ATimely processingImprove experienceMedical equipmentInstrumentsComputer terminalService engineer

The invention discloses a maintenance service management method and system, a terminal and a computer readable storage medium, wherein the maintenance service management method comprises receiving a medical device maintenance request based on a maintenance service management platform and generating a maintenance order; instructing a corresponding maintenance engineer to respond to the maintenanceorder within a preset first time threshold according to the maintenance order; instructing the maintenance engineer to arrive at a maintenance site within a preset second time threshold to maintain amedical device. The system receives the failure information of a hospital medical device through the maintenance service management platform, responds to the maintenance order within a specified time,instructs the maintenance engineer to arrive at the maintenance site within a specified time to maintain the medical device, receives the maintenance application issued by a hospital according to thetime limit and the command dispatch of a management layer, instructs the maintenance engineer to arrive at the maintenance site to maintain the medical device, ensures timely handling of the hospitalmedical device failure, and improves the maintenance service user experience.

Owner:深圳倍佳医疗科技服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com