Wind turbine rotor and wind turbine rotor maintenance method

A technology of wind turbines and wind turbine blades, applied to wind engines, machines/engines, and wind engines in the same direction as the wind, which can solve problems such as increasing operating loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

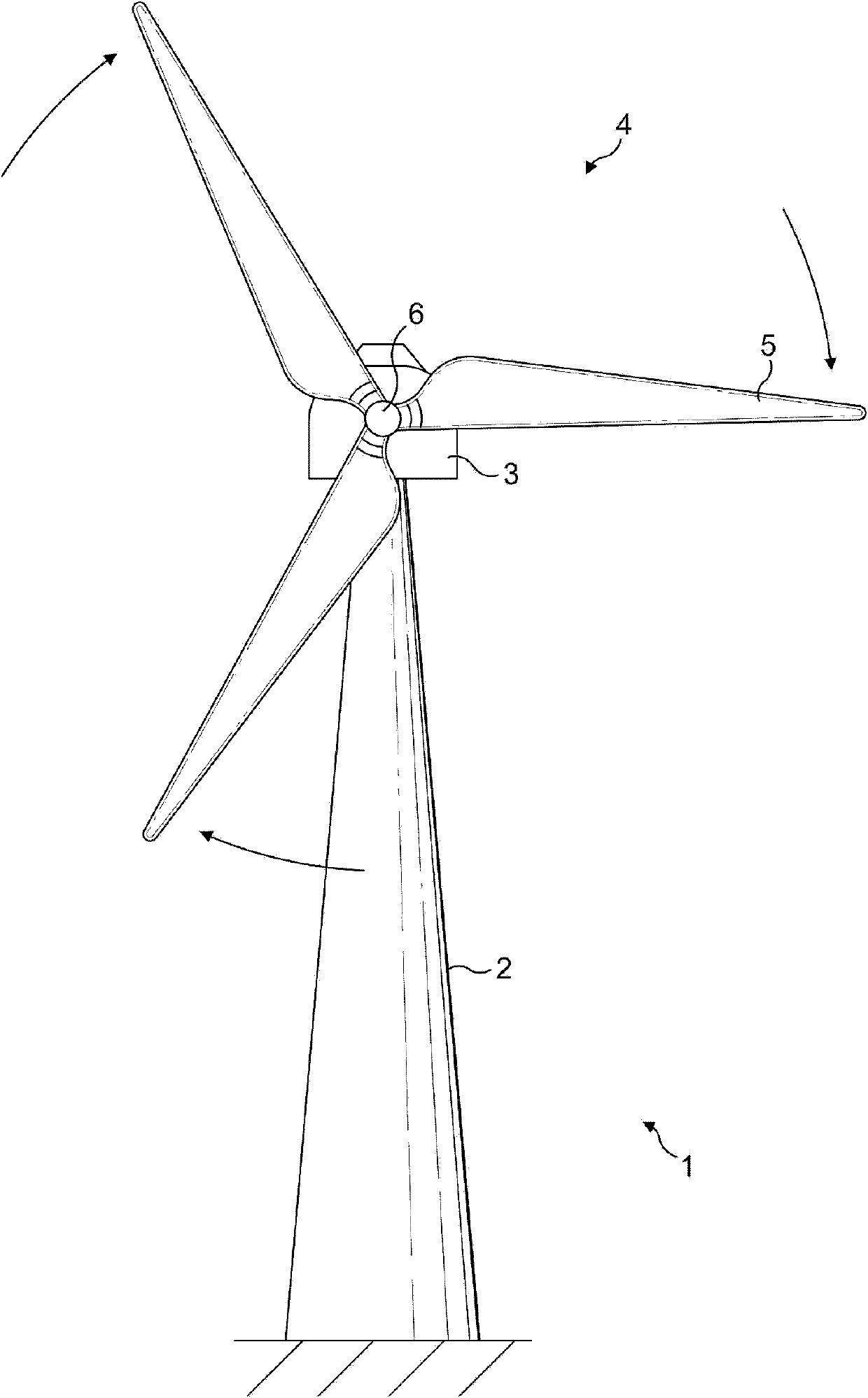

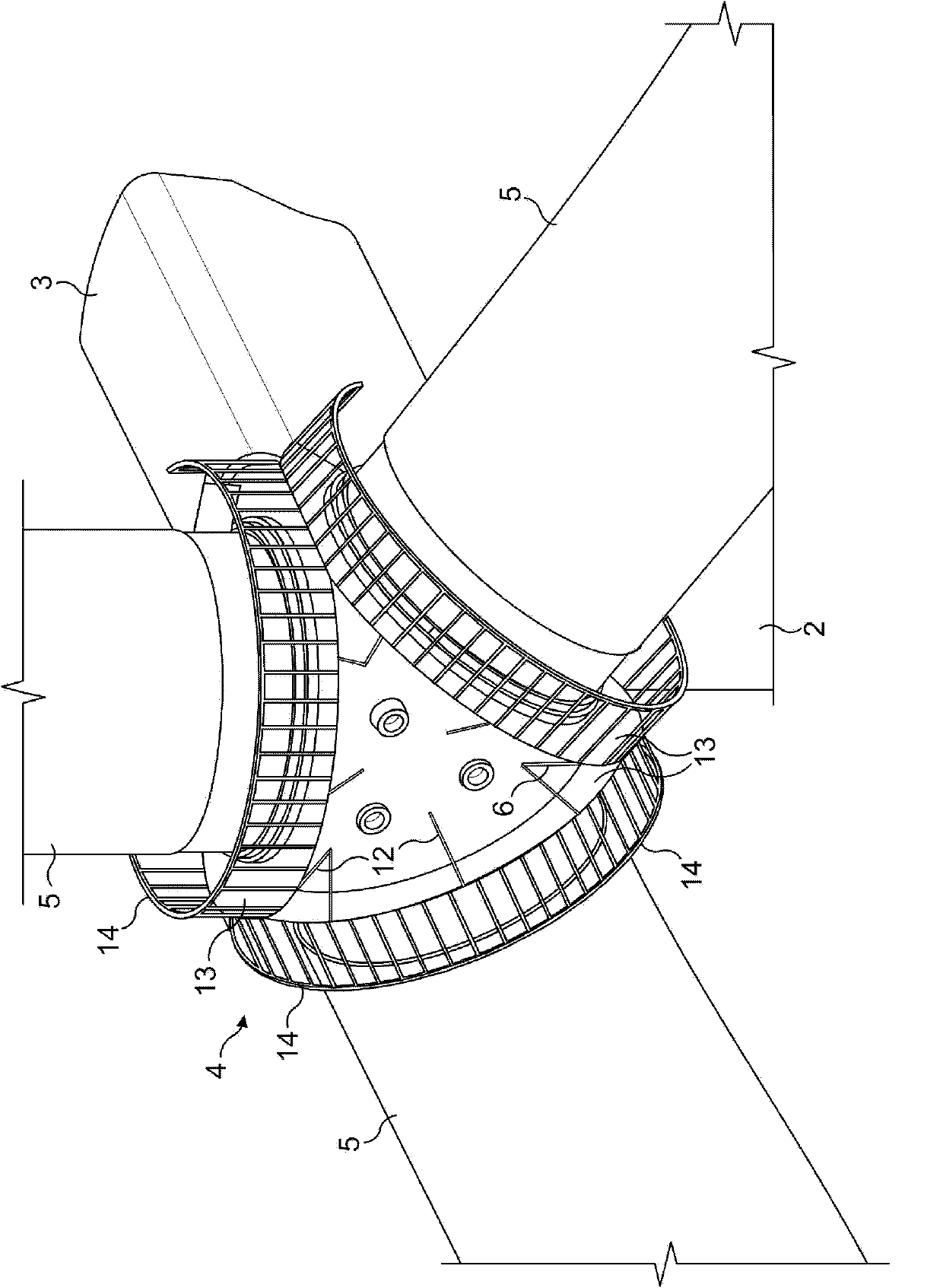

[0024] figure 2 is a close up perspective view of the nacelle and hub area of a wind turbine in an exemplary embodiment of the invention. The rotor 4 comprises three wind turbine blades 5 attached to a hub 6 . Only the blade root of each blade 5 is shown. The rotor 4 is attached to the nacelle 3 which in turn is attached to the tower 2 .

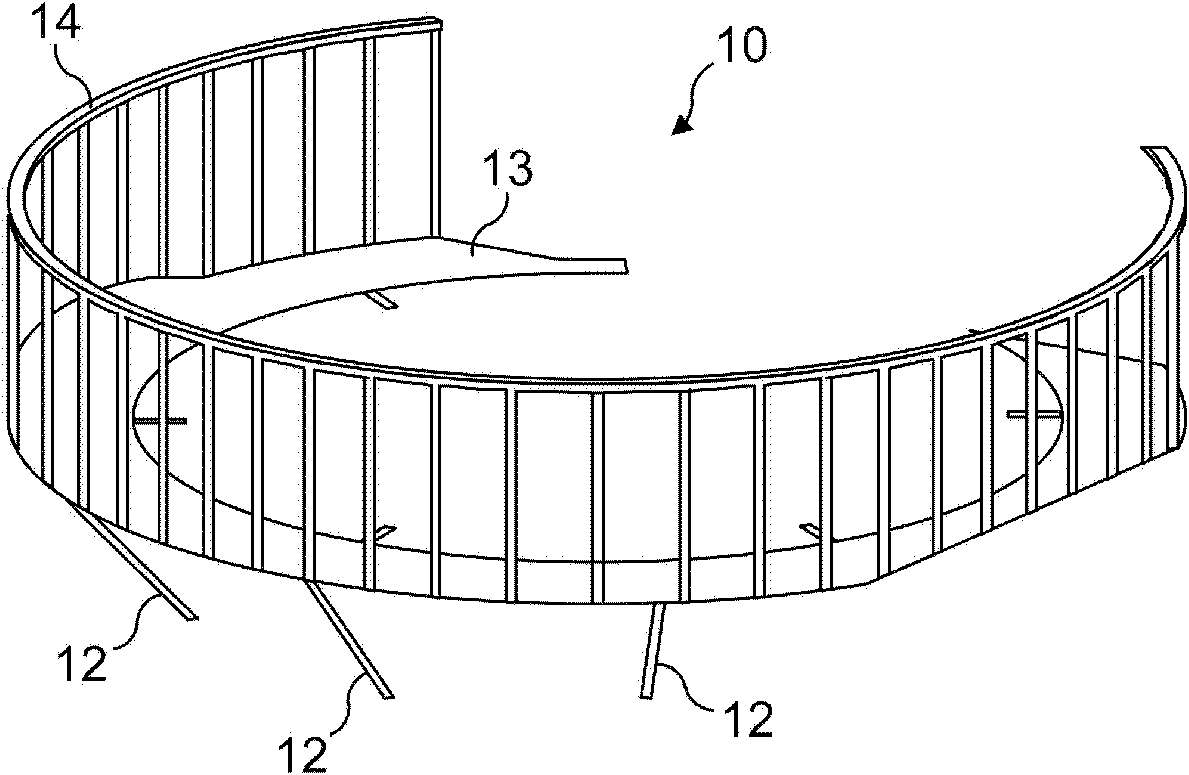

[0025] Bearings (not shown) are provided at the junction between the blades 5 and the hub 6 to enable rotation of the blades 5 relative to the hub 6, allowing the pitch of the blades to be adjusted. A maintenance platform 10 is attached to the hub 6 at the base of each blade 5 by struts 12 . The struts may be connected to the hub by fasteners or by a welded joint, as is known in the art. Therefore, preferably the service platform is permanently and immovably attached to the wind turbine hub for use.

[0026] In this embodiment, the walkway surrounds the blade root, leaving clearance for the blade root to rotate for pitch control. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com