Mechanical device maintenance training system and method by using 3D (three-dimensional) technology

A technology of mechanical equipment and training systems, applied in educational appliances, instruments, teaching models, etc., can solve problems such as difficulty in solving faults, losses, and inability to cope with increasing demand, and achieve the effect of shortening maintenance time and reducing losses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to enable those skilled in the art to better understand the solution of the present invention, and to make the above-mentioned purpose, features and advantages of the present invention more obvious and understandable, the present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings of the embodiments.

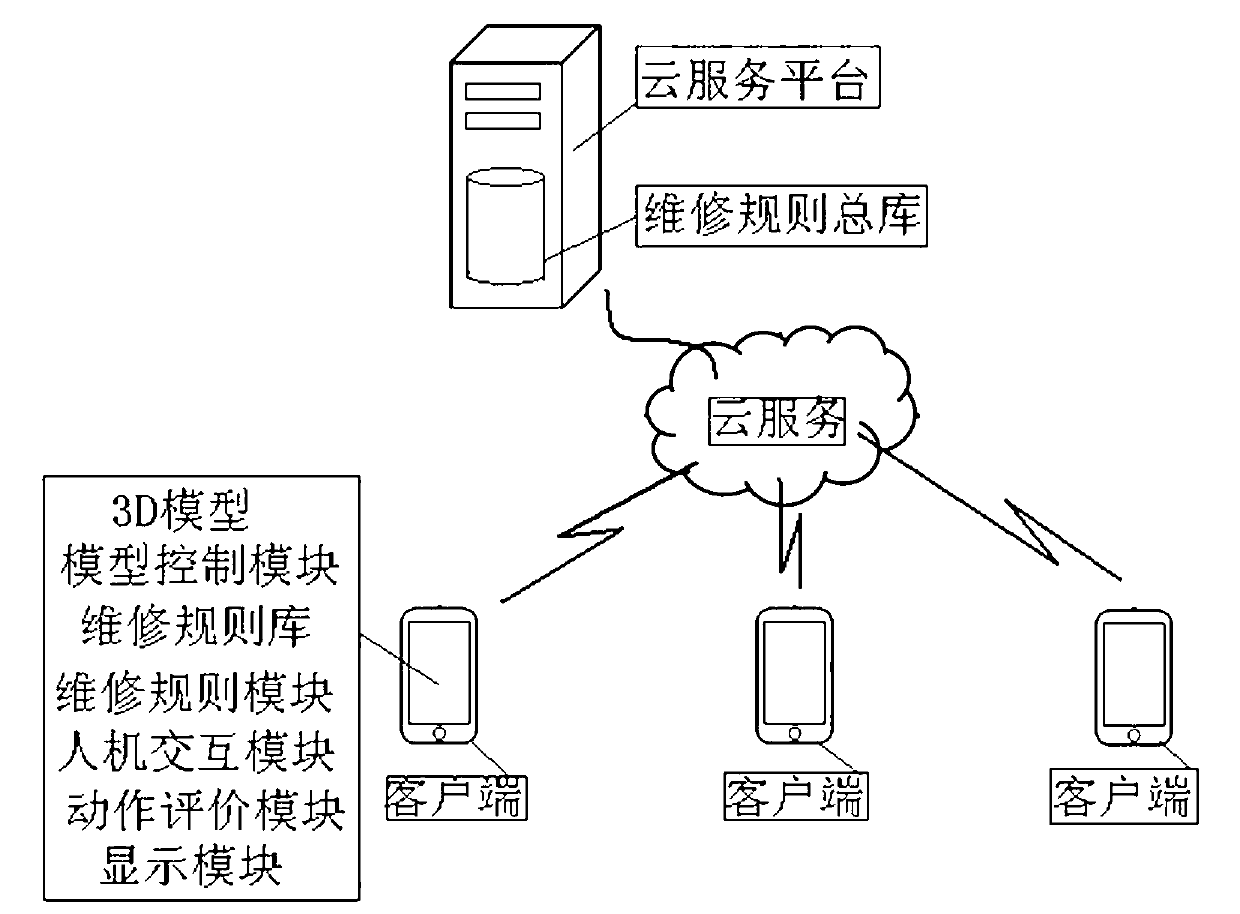

[0025] A 3D model-based engineering equipment maintenance training system of the present invention can be a stand-alone system, or a C / S structure, or even a B / S structure based on cloud services. Below as figure 1 The shown B / S structure based on cloud service is used as an example to introduce the present invention, and those skilled in the art can easily expand it to other common forms according to the inspiration of this specification.

[0026] Such as figure 1 As shown, the present invention includes a cloud service platform and a client, wherein the client can be a computer, a smart phone or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com