Underwater oil-filled cable and manufacturing method thereof

The technology of an oil-filled cable and its manufacturing method is applied in the direction of circuits, electrical components, circuit/collector components, etc., which can solve the problems of long delivery cycle, inconvenient maintenance, complicated cable manufacturing process, etc., and achieve simple and convenient manufacturing, Use safe and reliable effects suitable for promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0018] 1. The structure of underwater oil-filled cables.

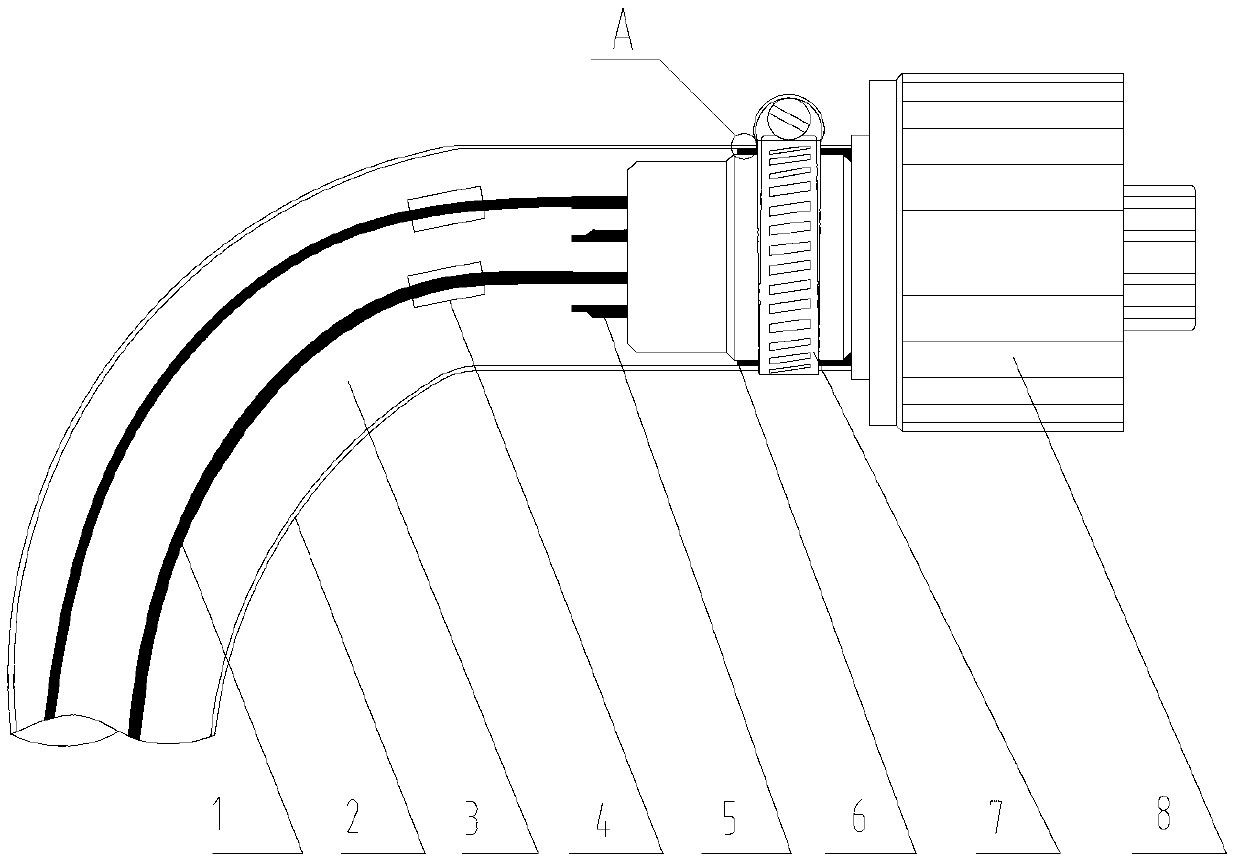

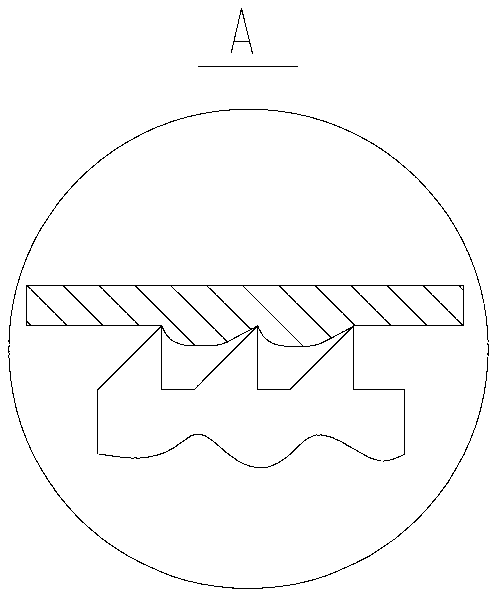

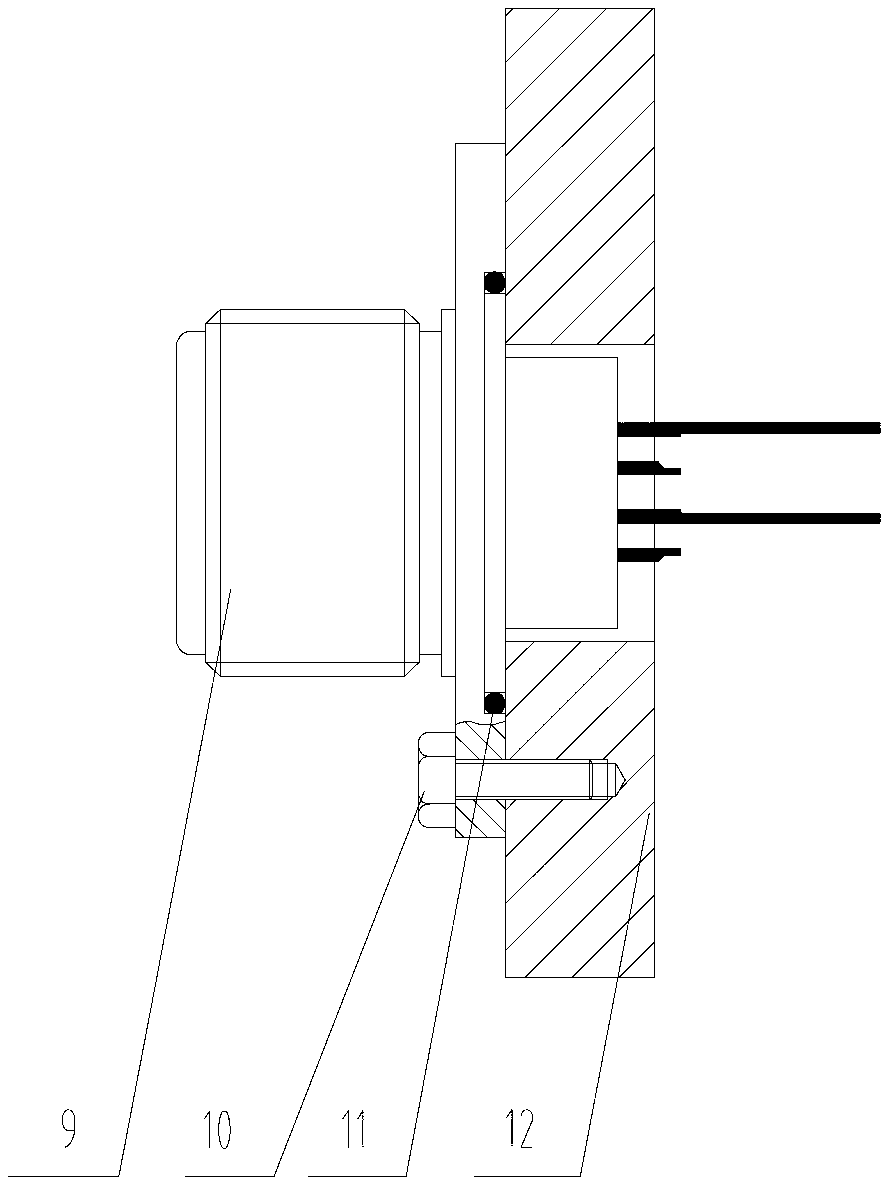

[0019] figure 1 It is a schematic diagram of the underwater oil-filled cable of the present invention. Such as figure 1 As shown, the production of the underwater oil-filled cable of the present invention requires wire 1, plastic hose 2, compensation oil 3, serial number tube 4, welding end 5, AB glue 6 (oil-resistant type), hoop 7 and watertight plug 8.

[0020] The wire 1 is used for power and signal transmission. Its two ends are respectively welded to the tails of the welding ends 5 of two different watertight plugs 8 . One or several types of wires 1 can be selected according to the needs of signal transmission, such as high-temperature wires, shielded twisted-pair wires, coaxial cables, and the like.

[0021] The plastic hose 2 is used for the sealing of the whole cable an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com