Automatic emergency oil supply system of oil-filling cable

An oil-filled cable and oil supply system technology, applied in the field of cable fault handling systems, can solve the problems of wasting fault repair time, lack of oil pressure compensation devices and systems, etc., and achieve the effects of improving rescue efficiency and reducing failure risk factors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

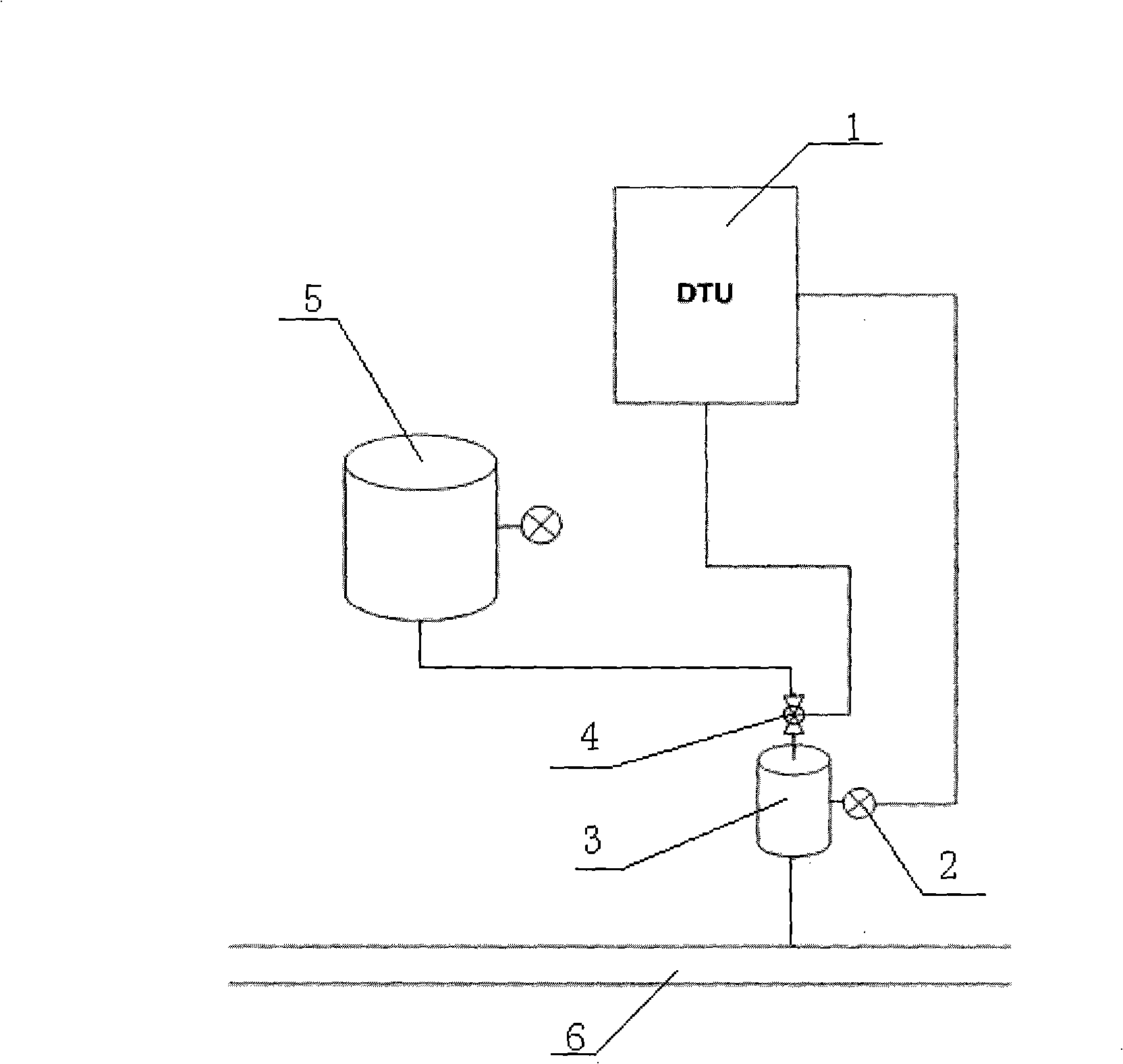

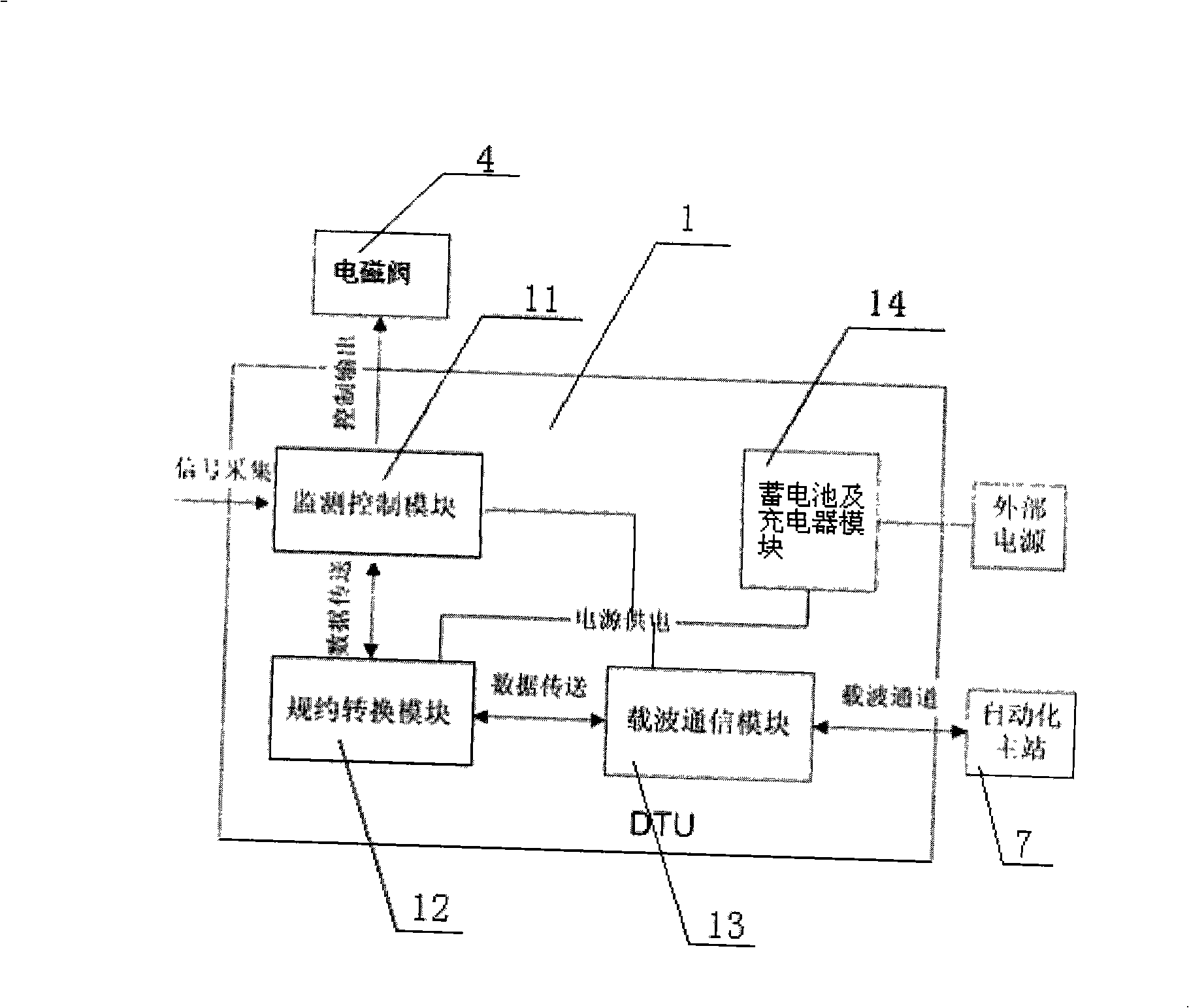

[0022] refer to figure 1 and 2 , an oil-filled cable automatic emergency oil supply system, including an oil-filled cable 6 and several groups of conventional pressure boxes 3 connected thereto, one port of the conventional pressure box 3 is connected with a solenoid valve 4, and the other port is connected with an oil pressure transformer Transmitter 2, between the solenoid valve 4 and the oil pressure transmitter 2 is also connected with a cable fault diagnosis automation device 1, the other port of the solenoid valve 4 is connected with a spare pressure tank 5, also includes a fault diagnosis with the cable The remote automation master station connected to the automation device, wherein,

[0023] The oil pressure transmitter 2 is used to detect the oil pressure of the conventional pressure tank 3 connected to it, and convert the oil pressure data in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com