Cable penetrating technology for electromagnetic shielding cabin

An electromagnetic shielding and cable technology, which is applied in the field of electromagnetic shielding cabin cable penetration technology, can solve the problems of large occupied volume, high manufacturing cost, and heavy weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

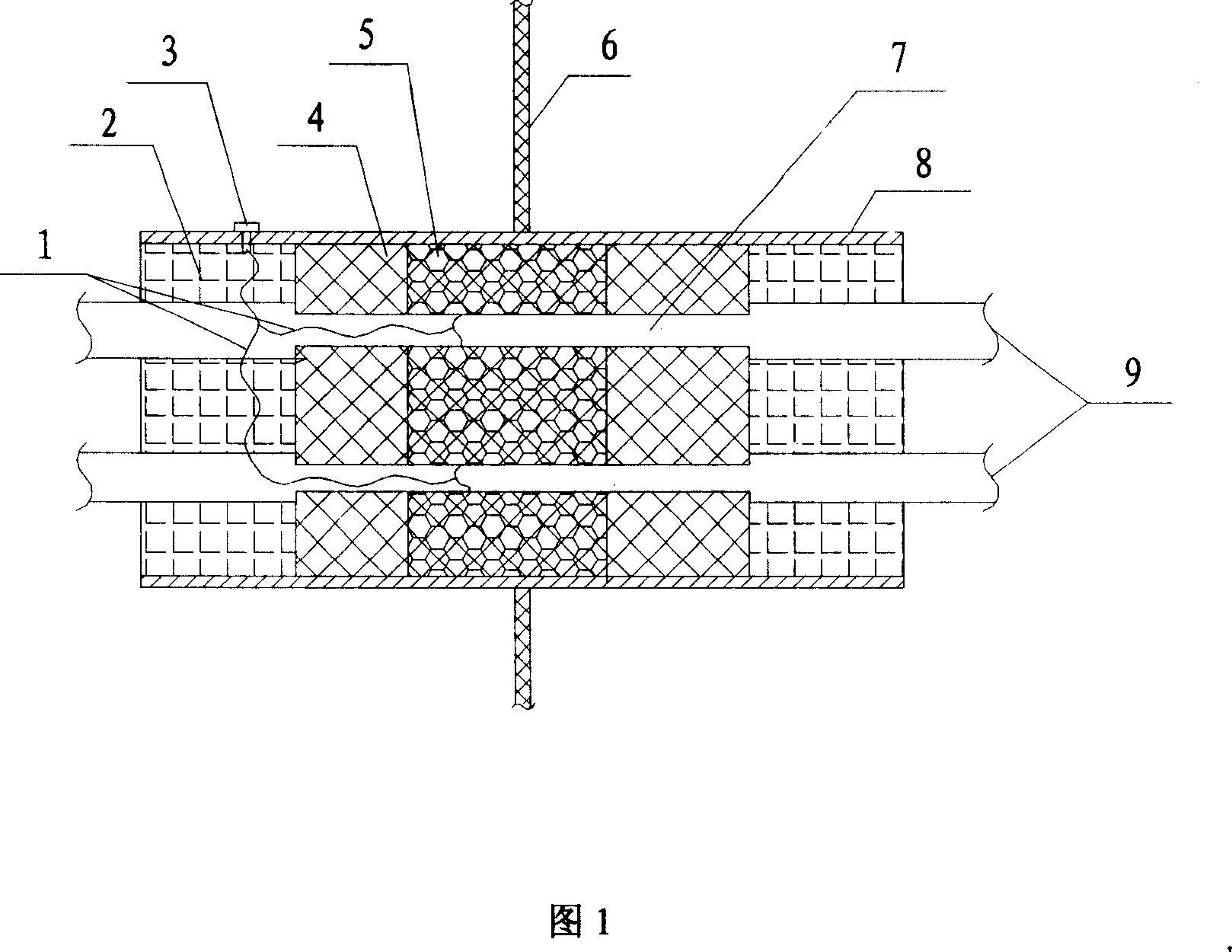

[0016] First select the cable barrel 8 with a barrel length of 80mm, weld it on the bulkhead 6 where the cable 9 needs to pass through, and remove the garbage and oil stains in the cable barrel 8. In order to reliably ground the shielding layer of the cable, if the cable has an outer sheath, it is necessary to strip a 40mm long section of the sheath from the surface of the cable 9 passing through the cable barrel 8. The position where the sheath should be stripped is located at one end of the cable barrel 8 At the depth of 20mm of the barrel mouth, in order to minimize the grounding resistance, tin-weld the ground wire 1 on the outer shield of each cable 9 stripped of the sheath, and connect them to the grounding bolt 3 at the outer port of the cable barrel 8. Pay attention to be careful when stripping the sheath, and must not damage its shielding. When multiple cables run through, the exposed section of the cable should be neat; pay attention not to pull the cable too tightly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com