Deep-sea oil-filled cable quick butt-joint device

A technology of oil-filled cables and docking devices, which is applied in the direction of two-part connecting devices, parts of connecting devices, coupling devices, etc., to achieve the effects of economical and practical, convenient maintenance, and convenient electrical connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

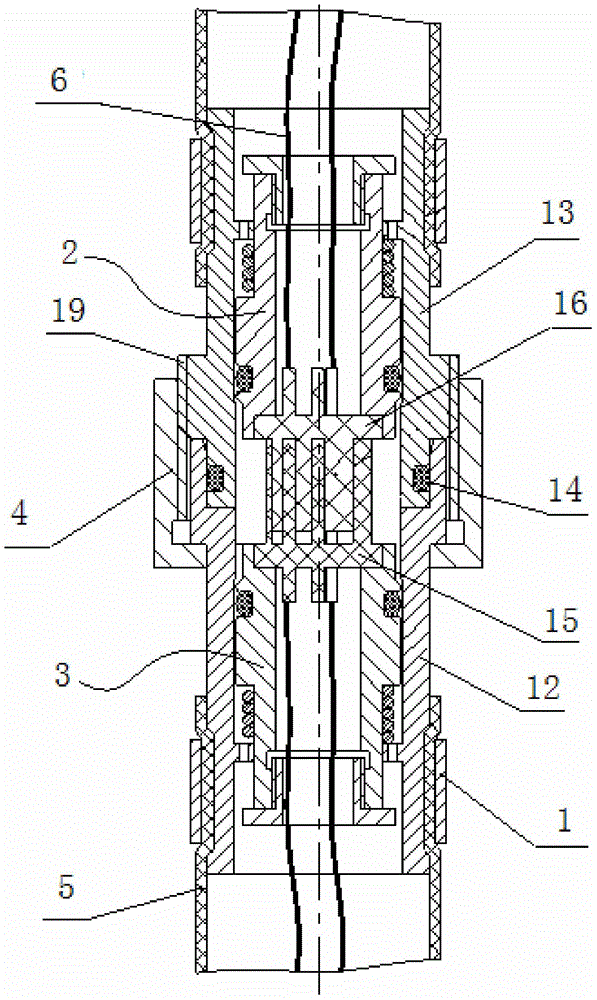

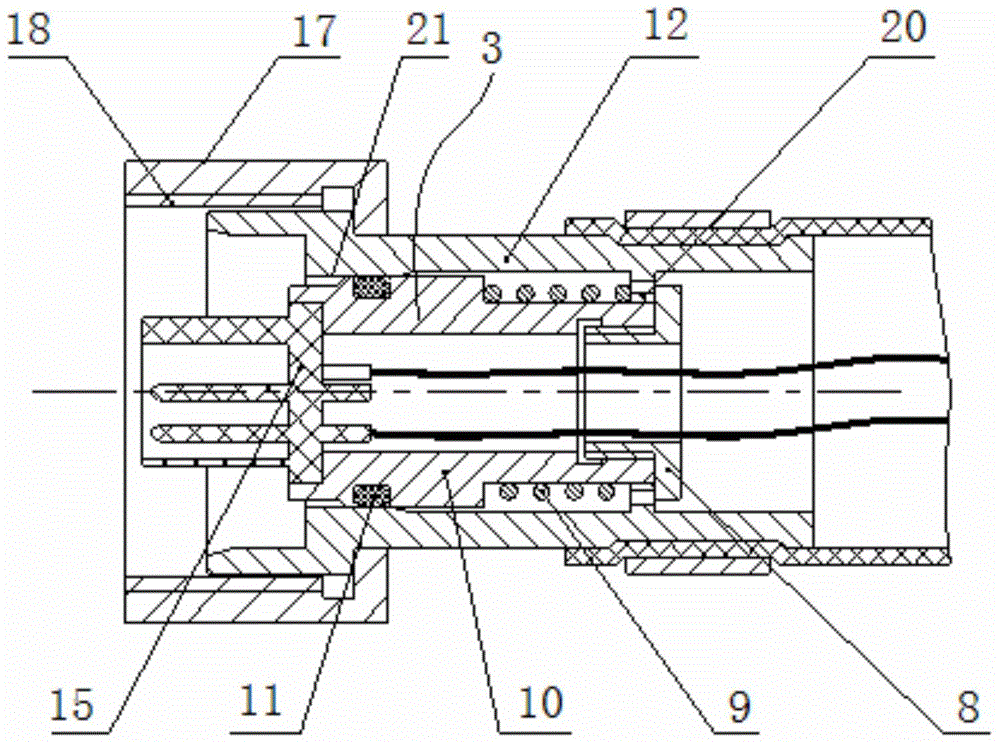

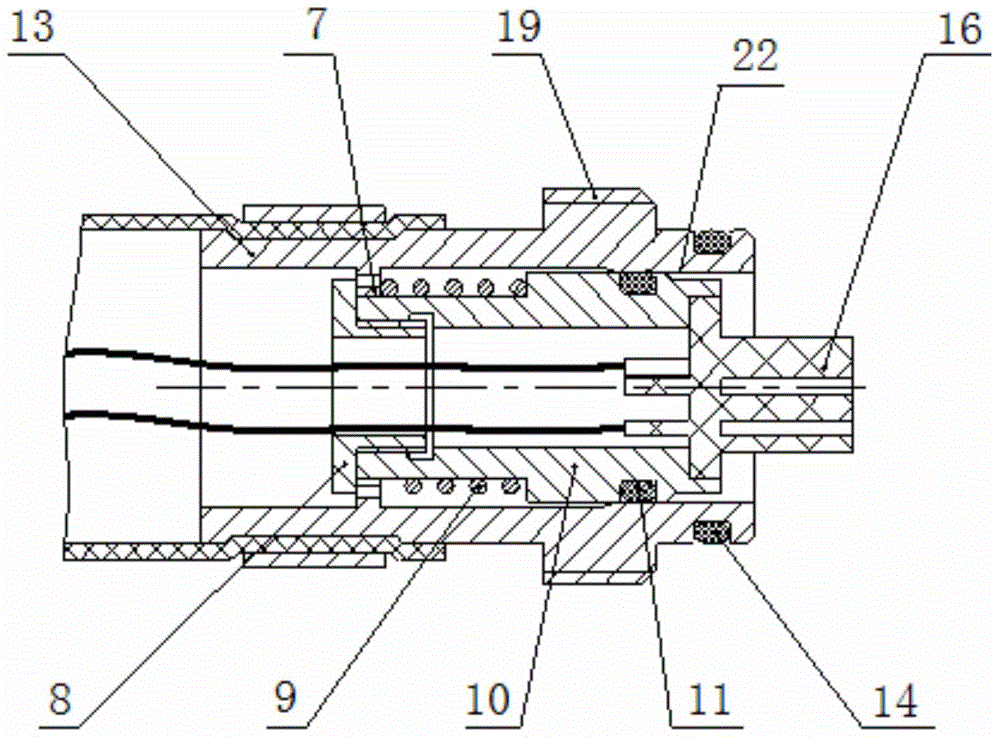

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] Such as figure 1 As shown, the present invention includes a quick-connect socket, a quick-connect ferrule, a locking cap 4 and a hoop 1, wherein the quick-connect socket includes a socket assembly 3 and a sleeve 12, and the socket assembly 3 is movably arranged In the sleeve 12, the quick-connect ferrule includes a plug assembly 2 and a core tube 13, the plug assembly 2 is movably arranged in the core tube 13, and the front end of the socket assembly 3 is provided with a cable The socket 15 connected to the loose wire 6, the front end of the plug assembly 2 is provided with a plug 16 connected to the cable loose wire 6, the socket 15 and the plug 16 are butted and connected to realize the circuit communication between the underwater cabin equipment, and the oil pipe 5. Seal the rear end of the sleeve 12 of the quick-connect socket and the core tube 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com