Patents

Literature

301 results about "Annular beam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

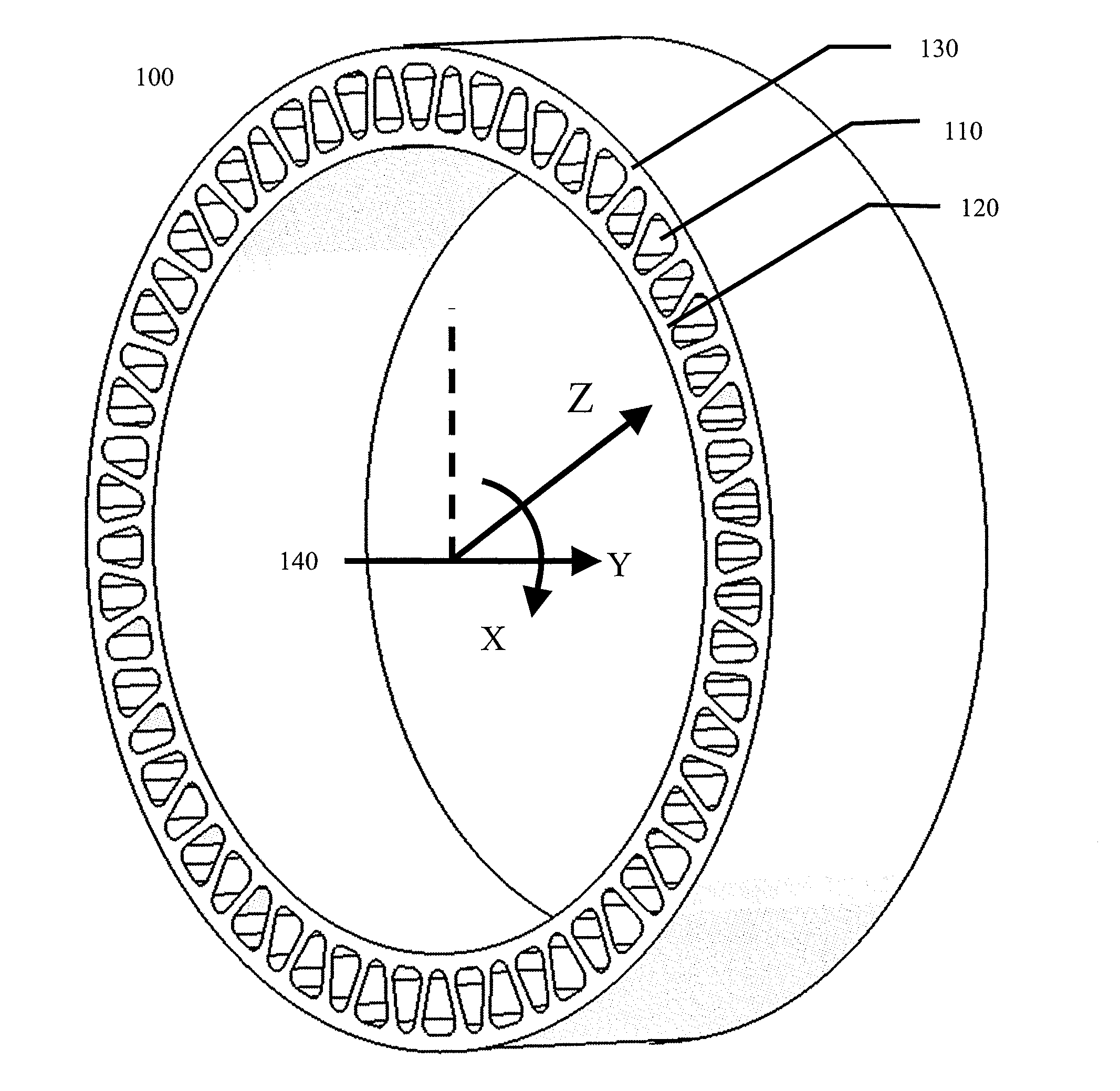

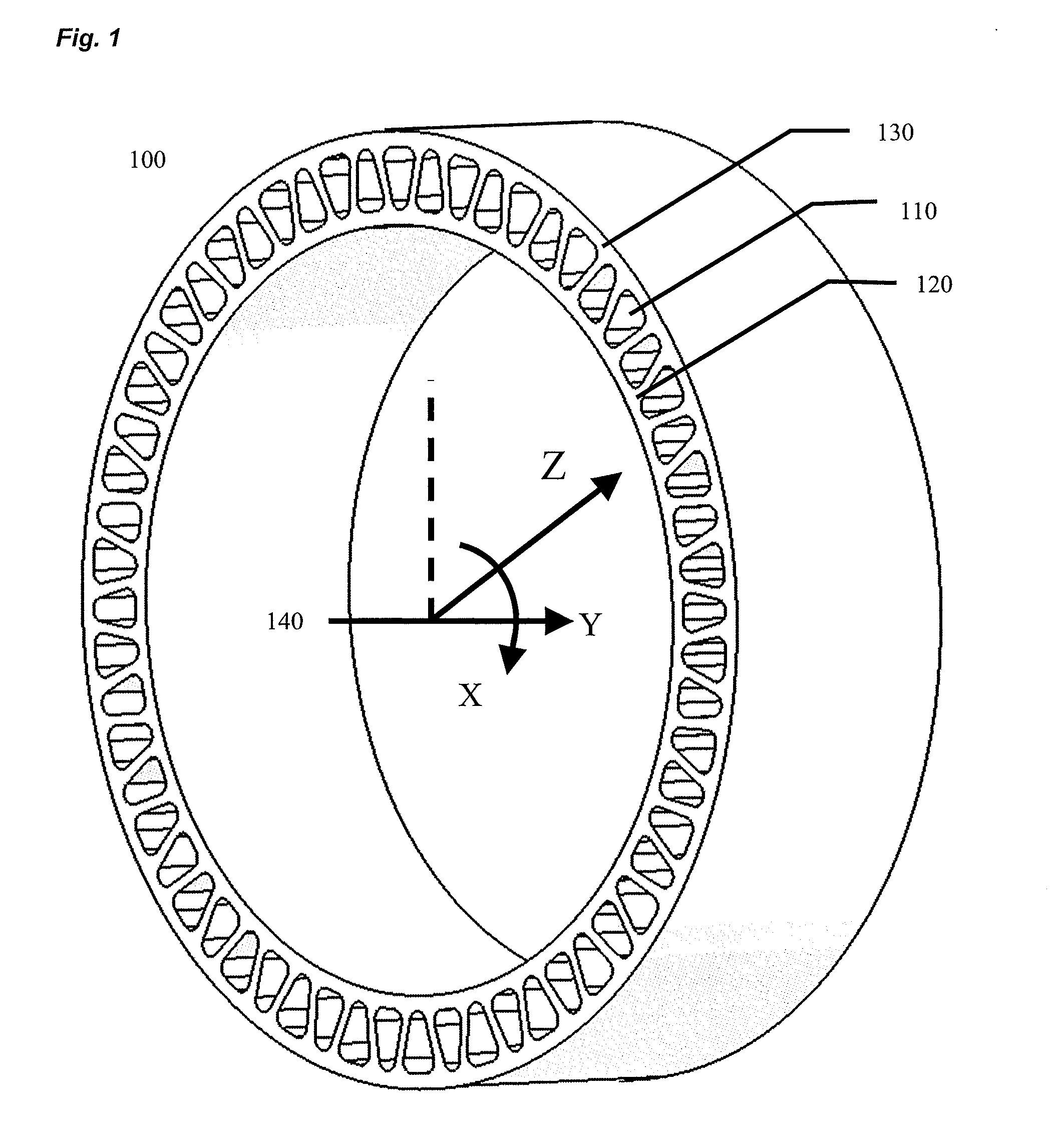

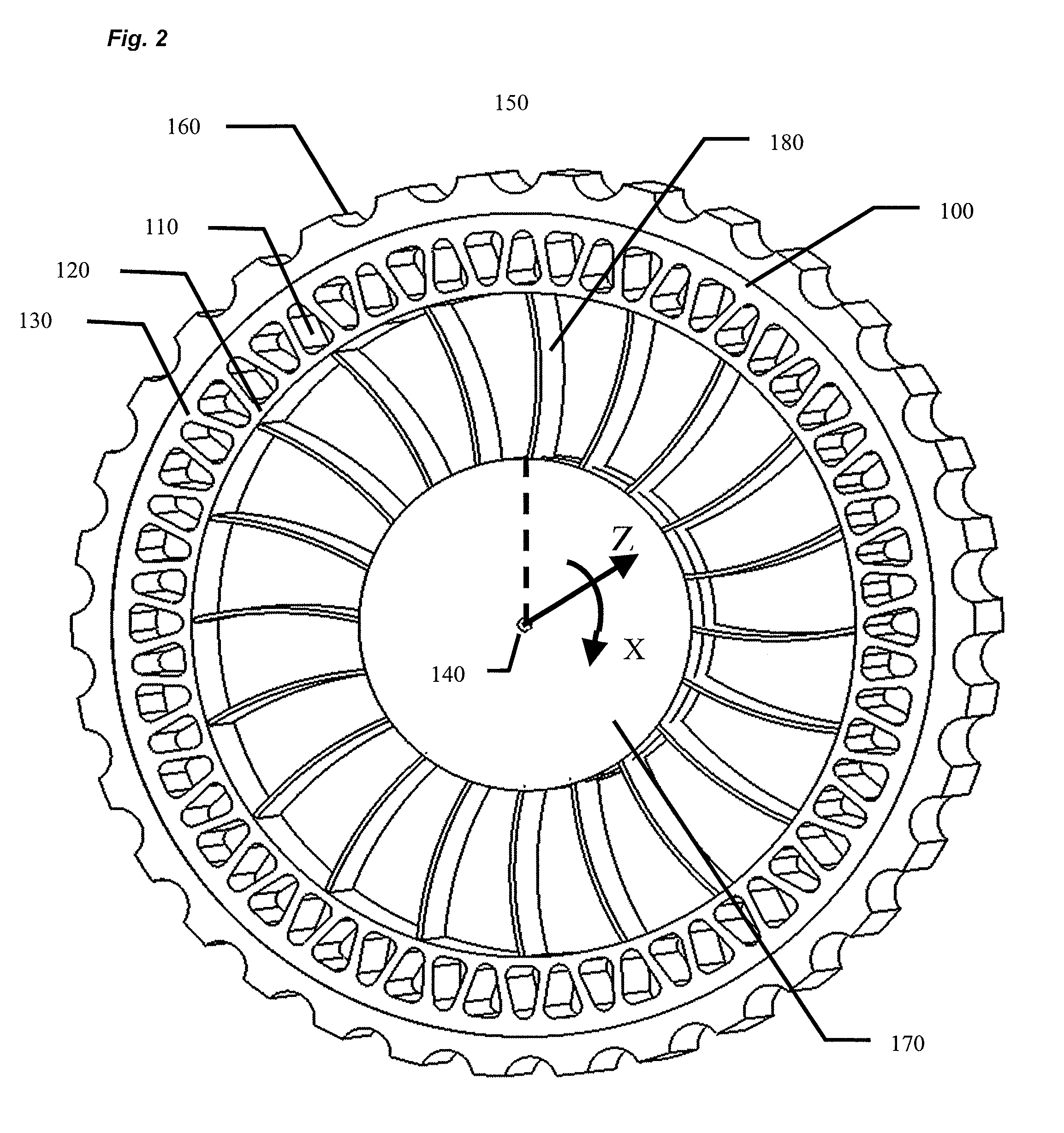

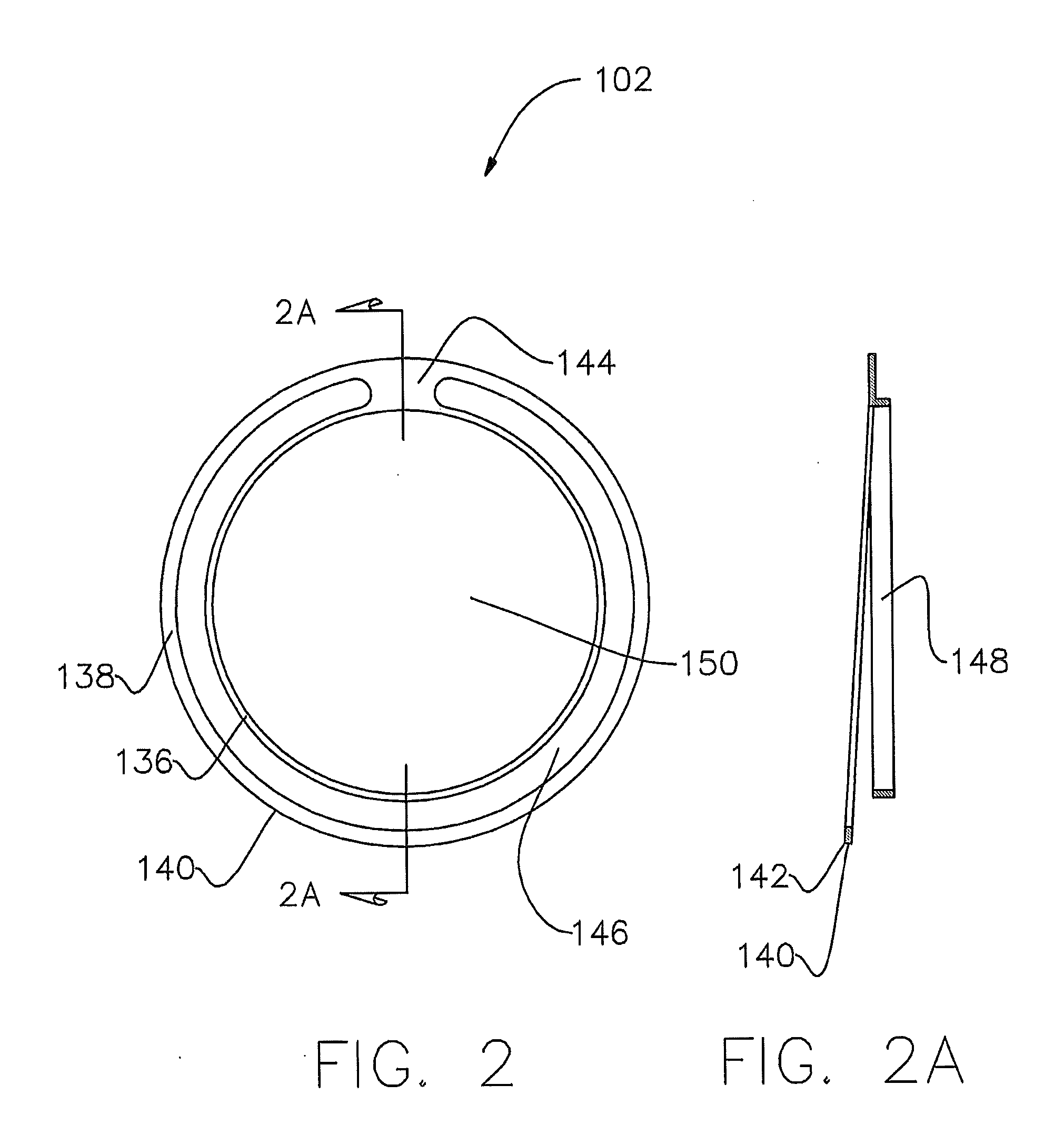

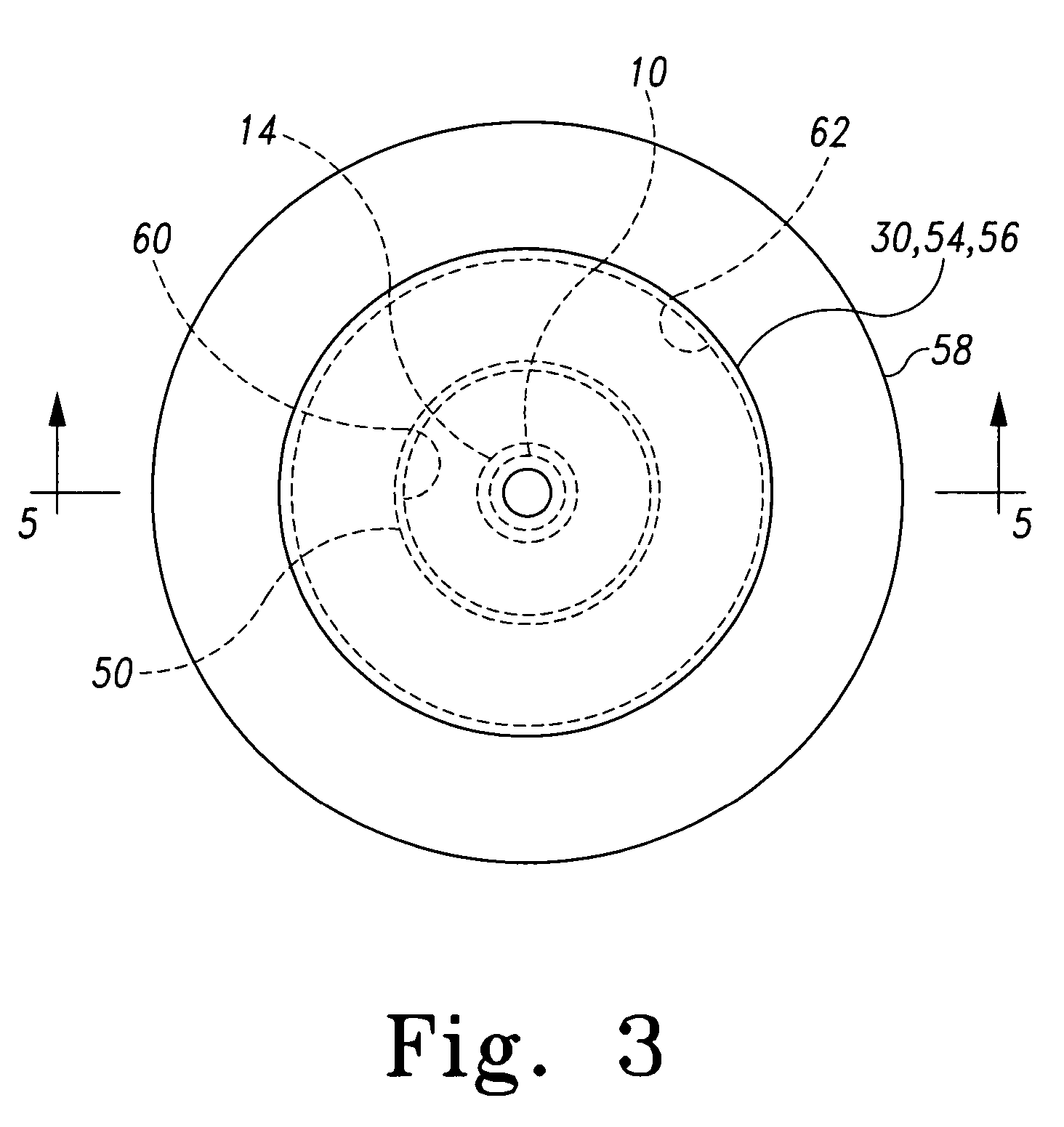

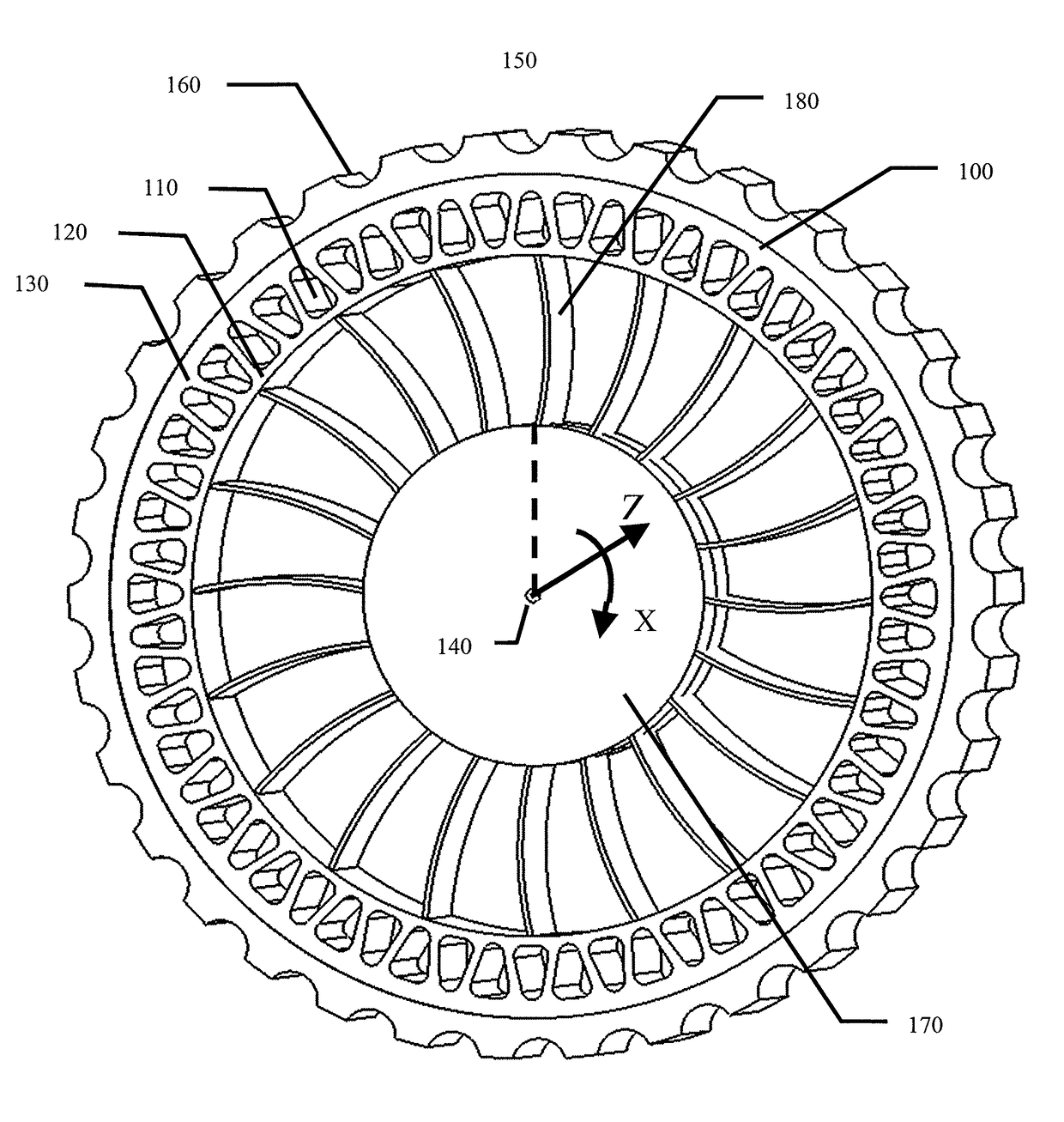

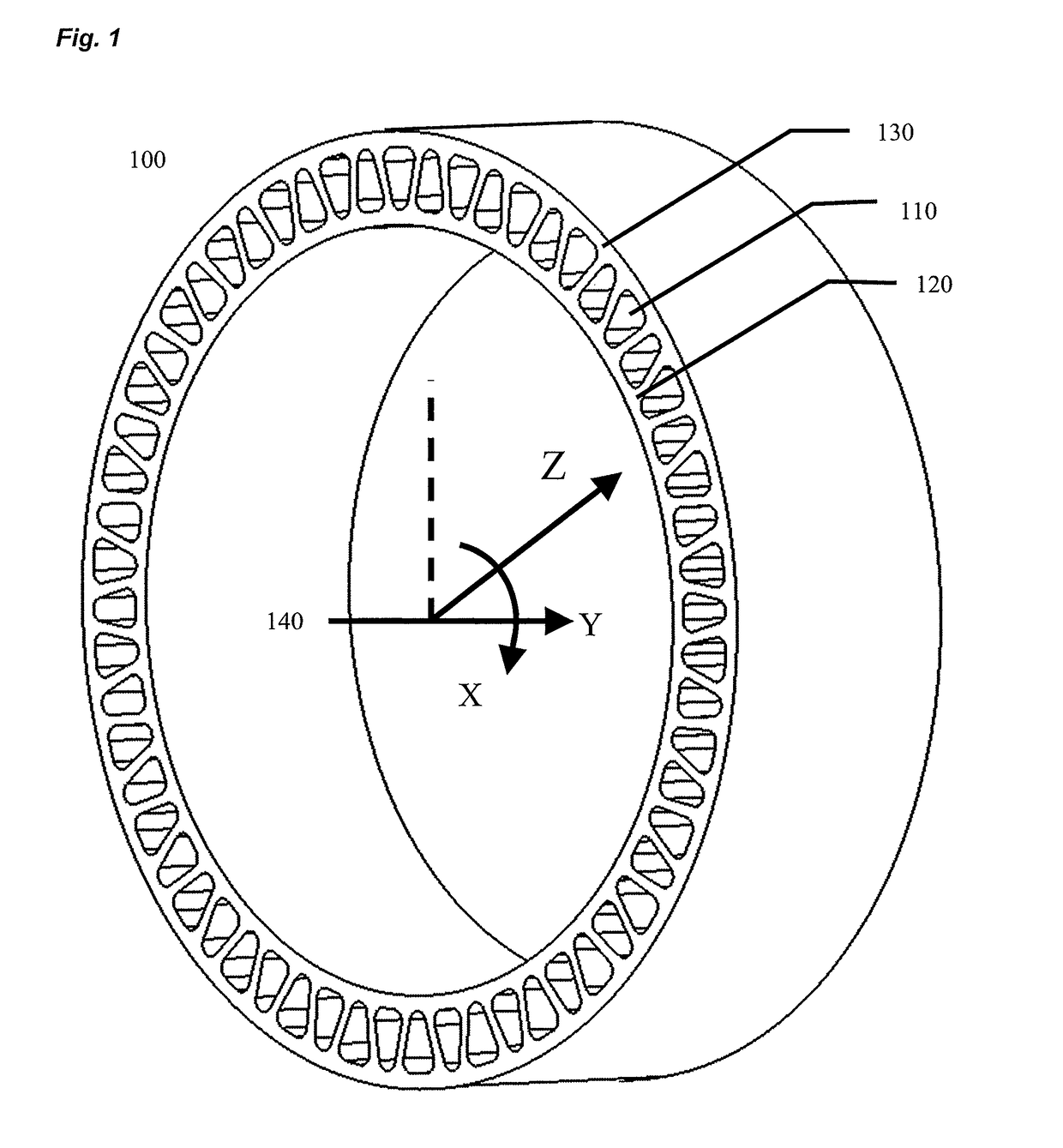

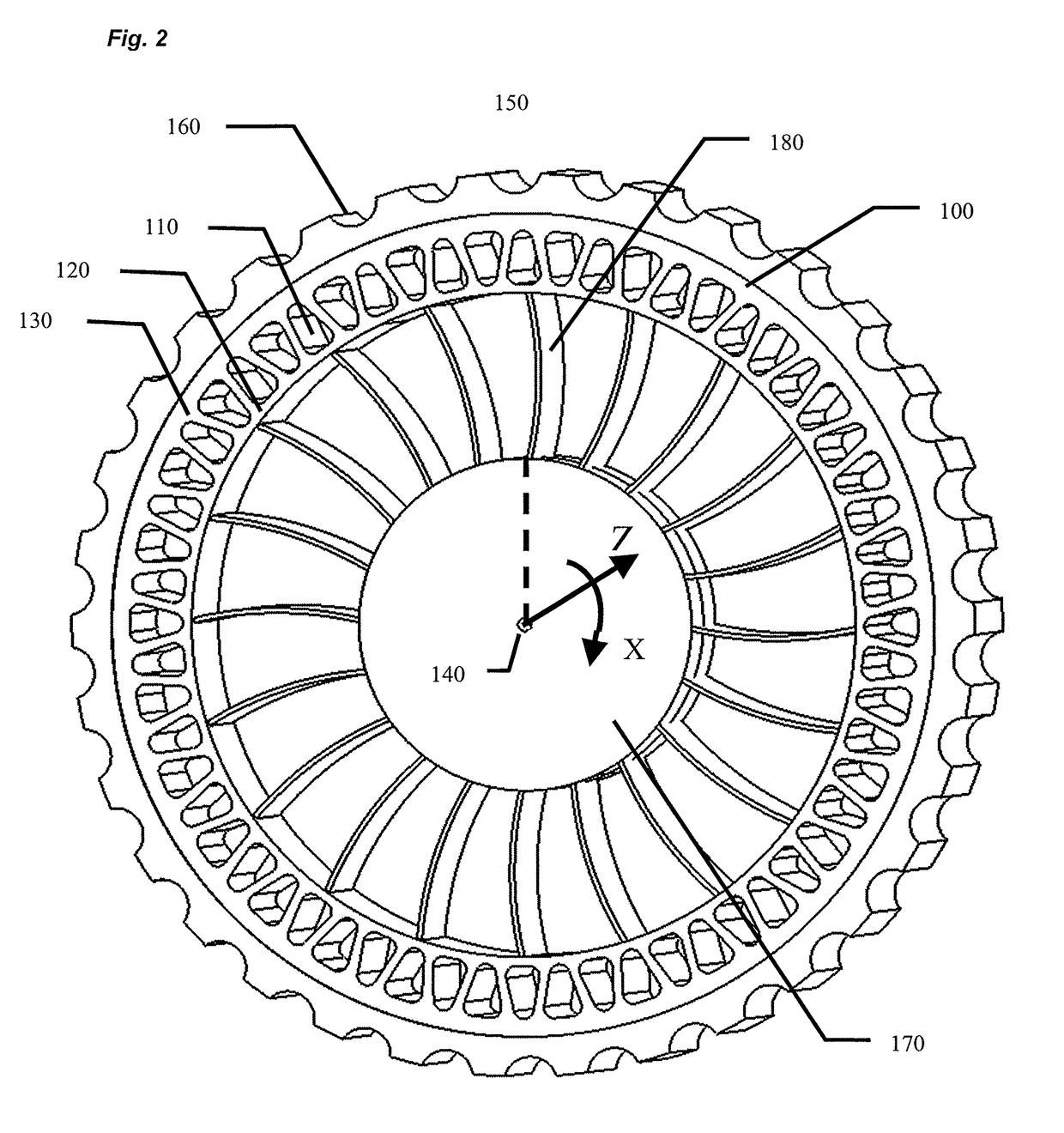

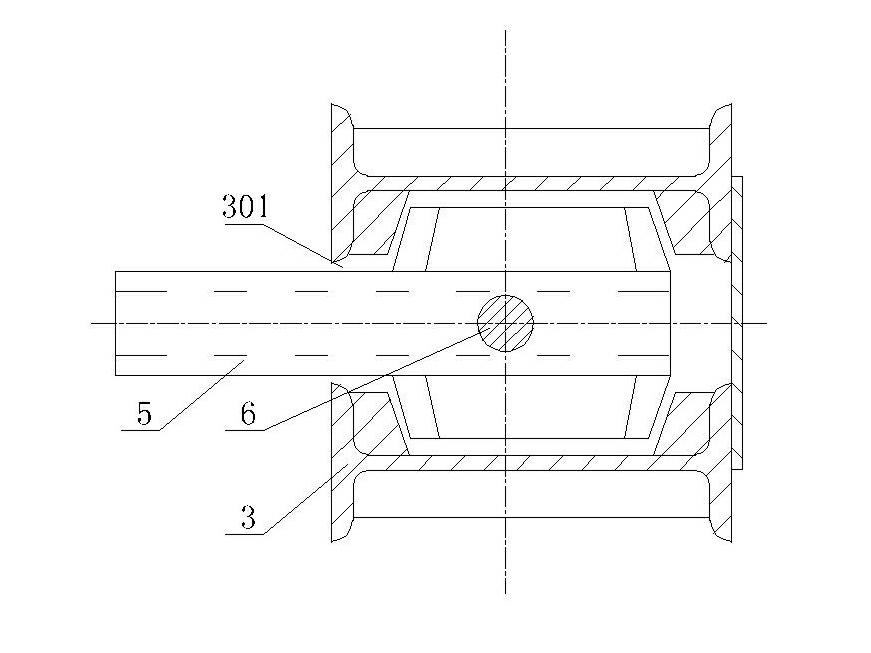

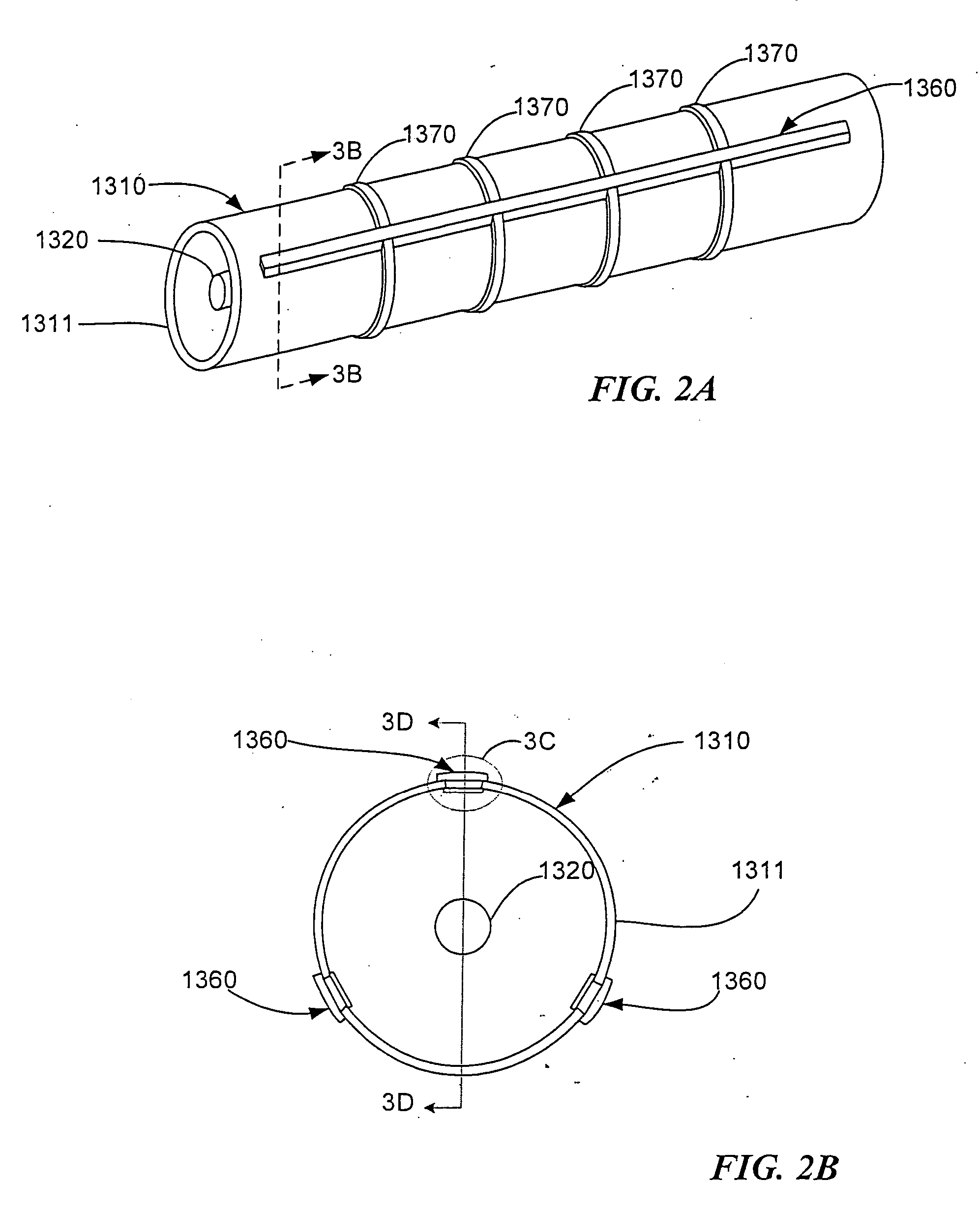

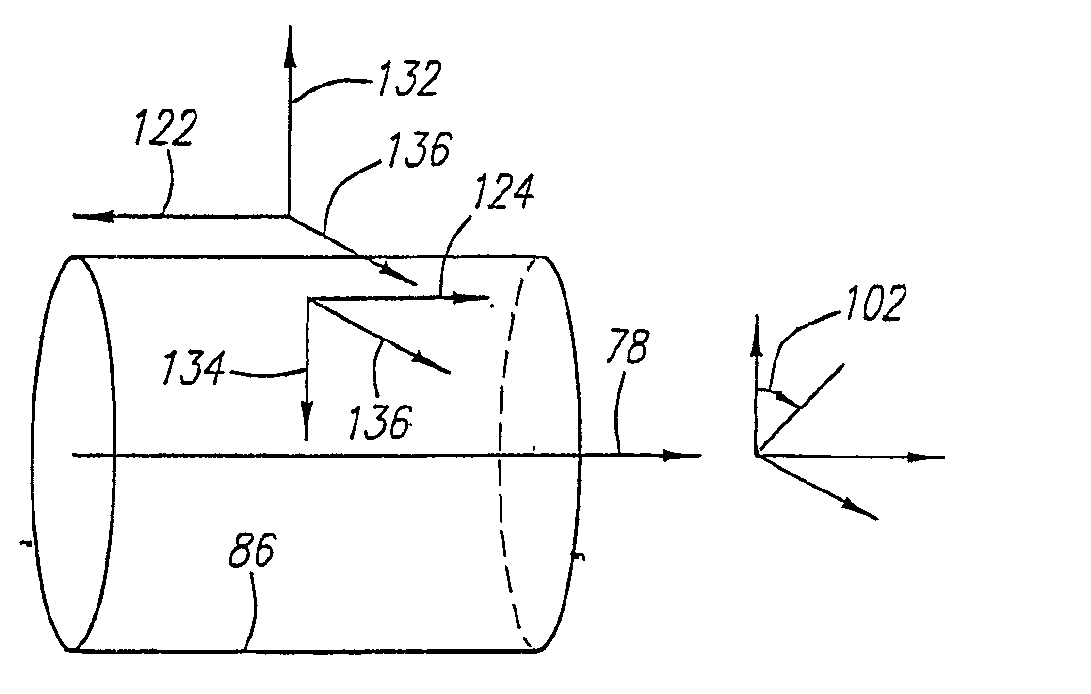

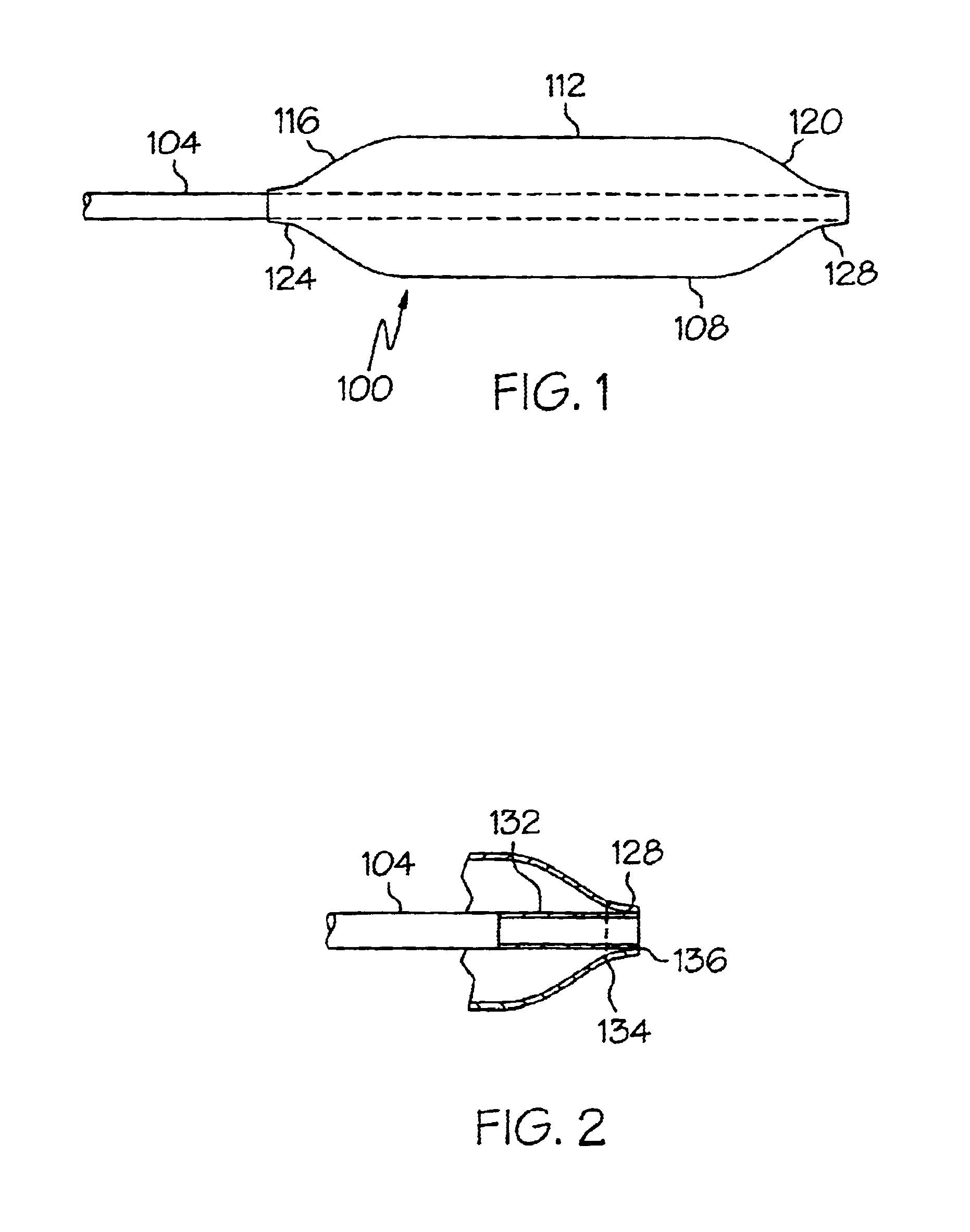

Annular ring and non-pneumatic tire

The present invention provides an annular beam of monolithic construction of one homogeneous material and a related efficient, low-cost non-pneumatic tire. Specific geometric design, combined with nonlinear elastomer physical properties, enable the suppression of all reinforcing belts, continuous fibers, or other strengthening layers in the annular beam. The annular beam consists of at least two bands that are continuous in the circumferential direction and connected by a web geometry. The non-pneumatic tire consists of the annular beam, a ground contacting portion, a central wheel, and a plurality of web spokes that connect the wheel and beam. When the tire is loaded to a design load against a flat surface over a design contact length, a contact area of essentially uniform pressure is produced, while the load is transmitted from the beam to the hub via tension in the web spokes. The tire can be economically manufactured.

Owner:CAMOPLASY INC

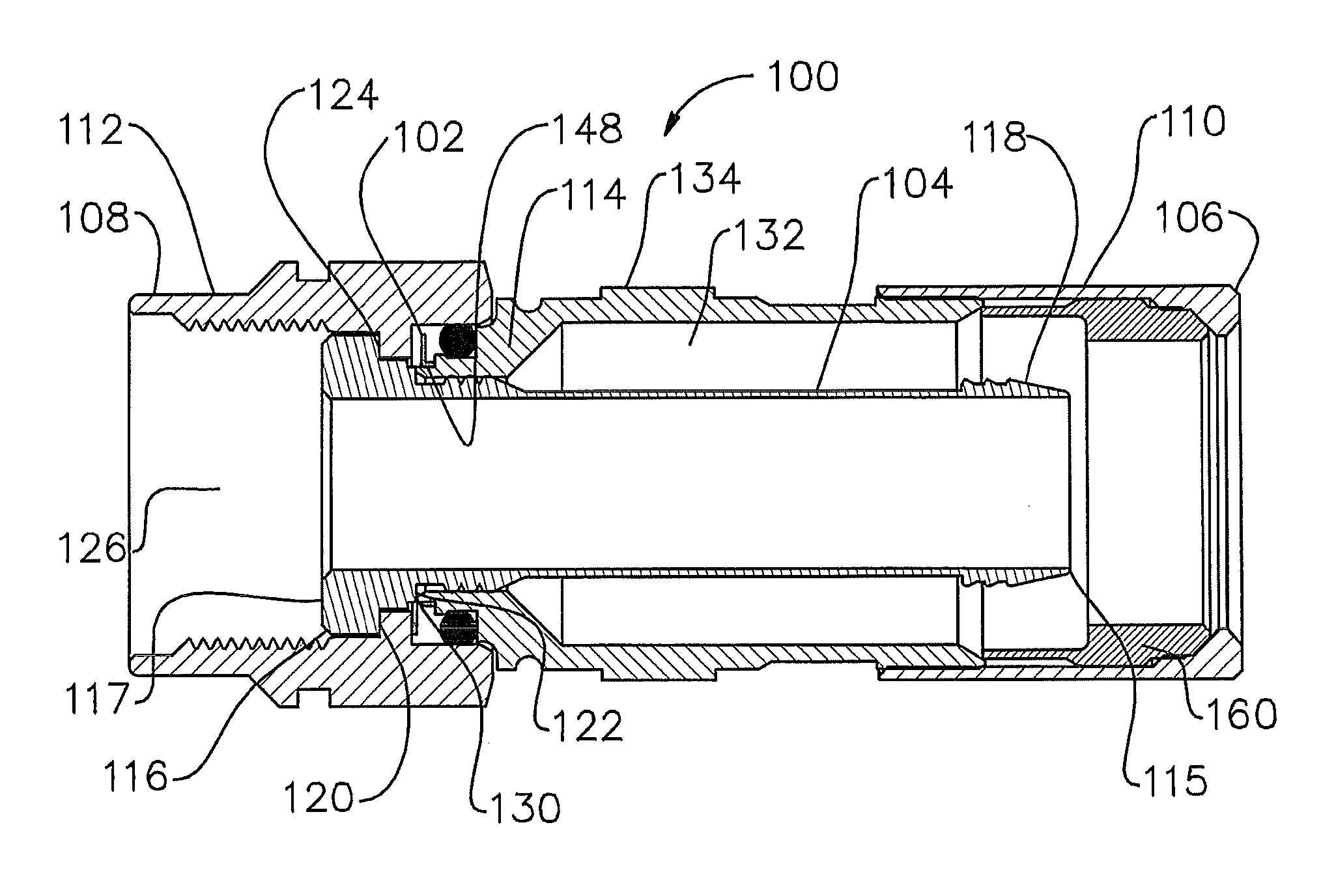

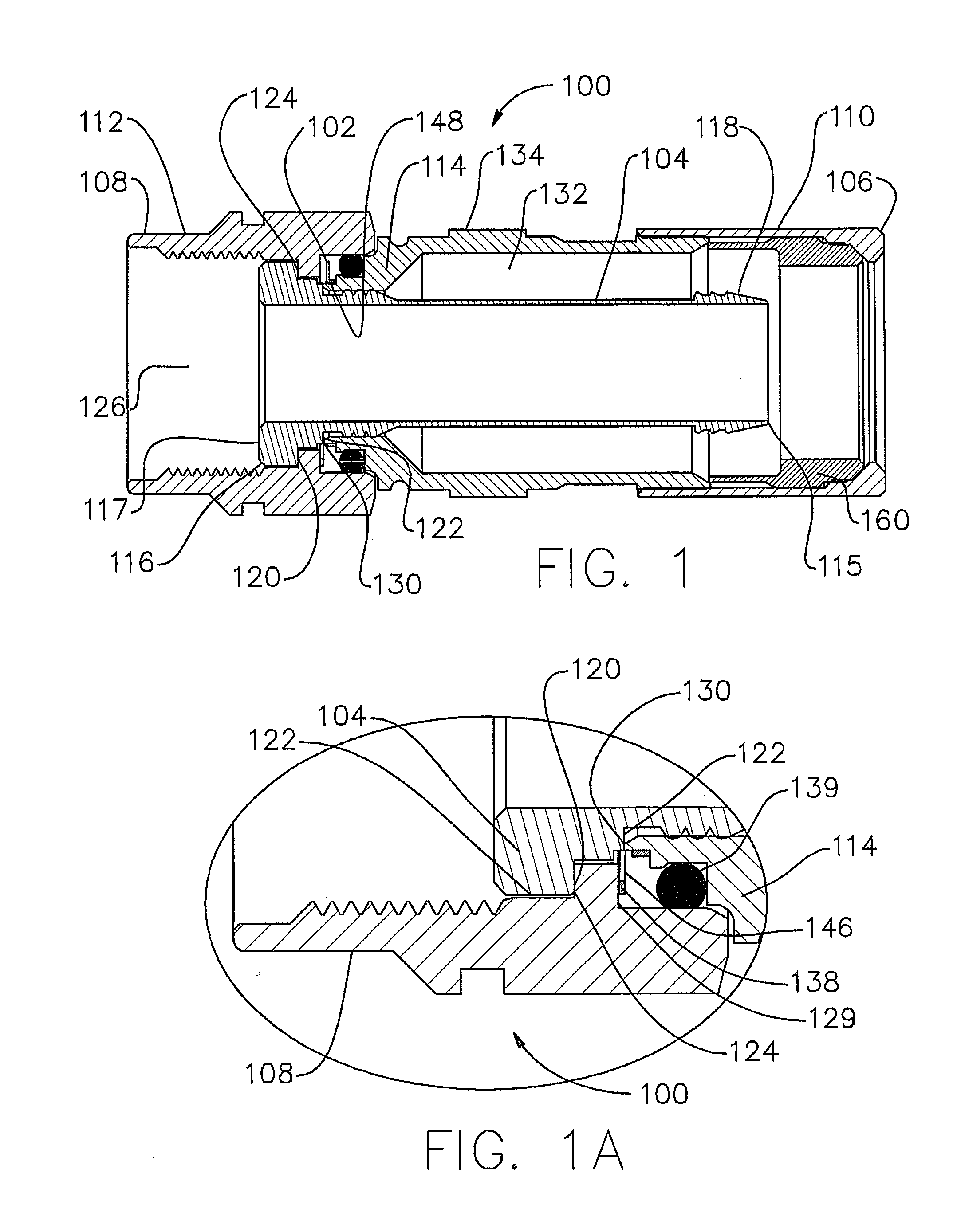

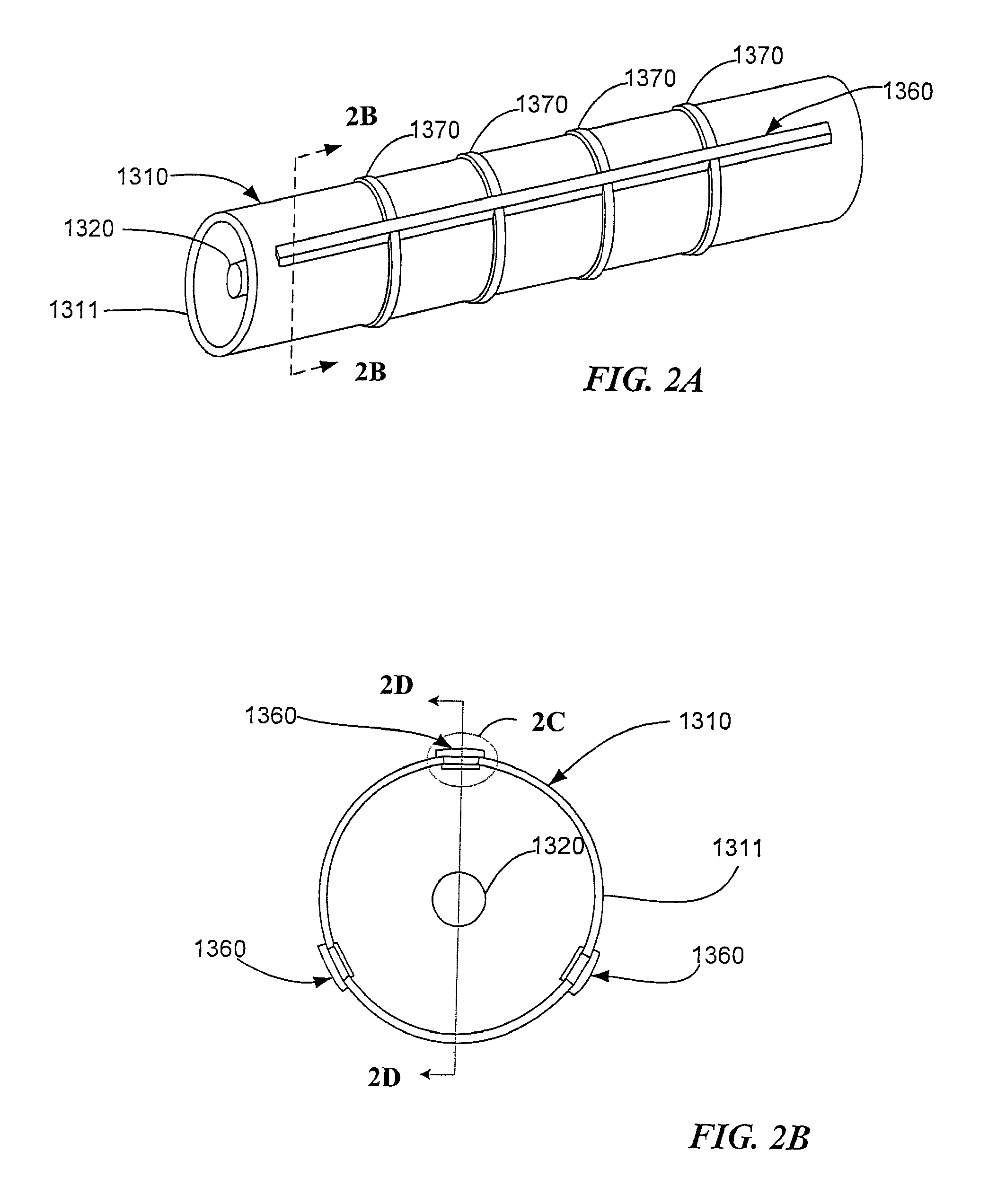

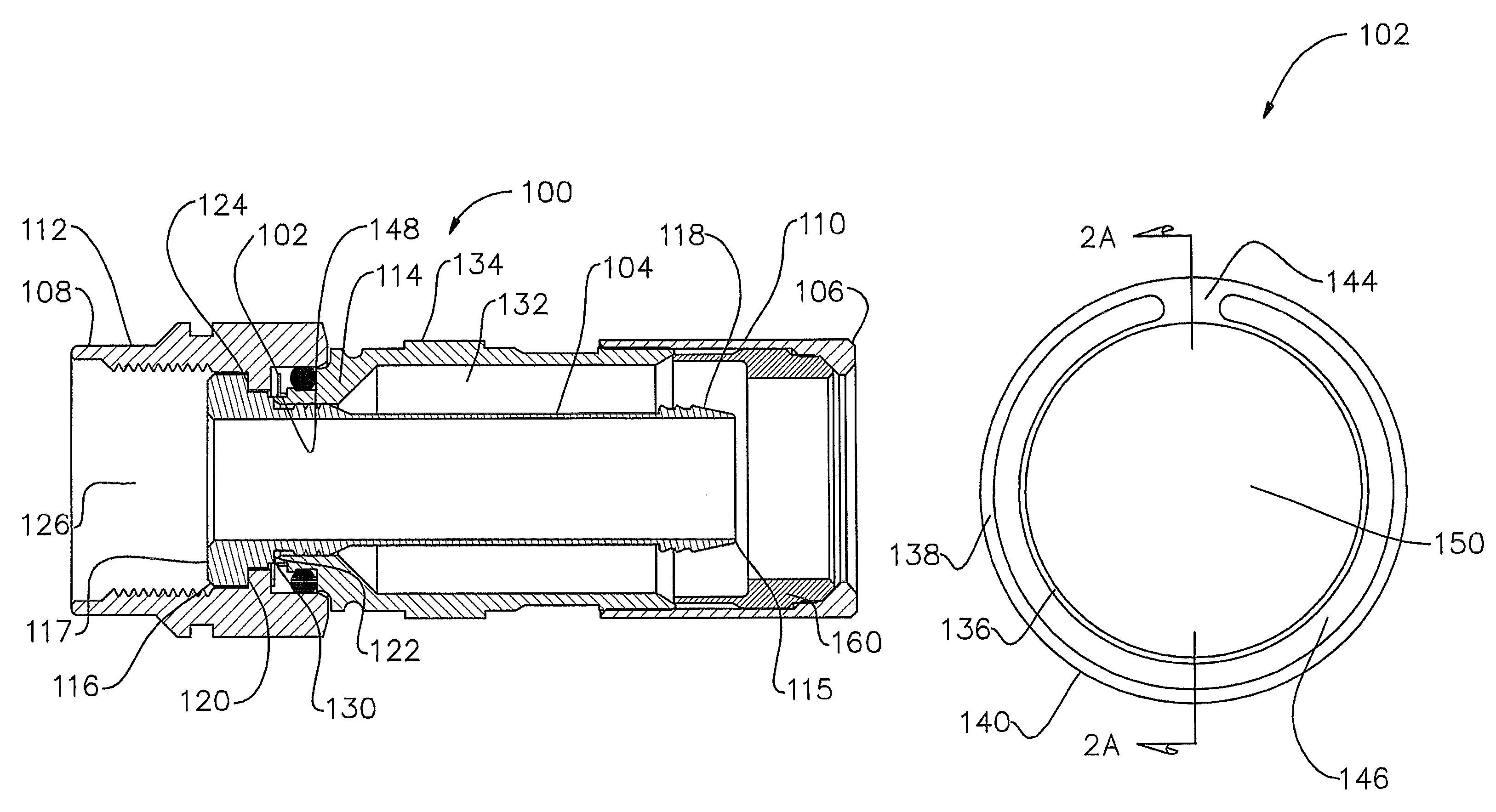

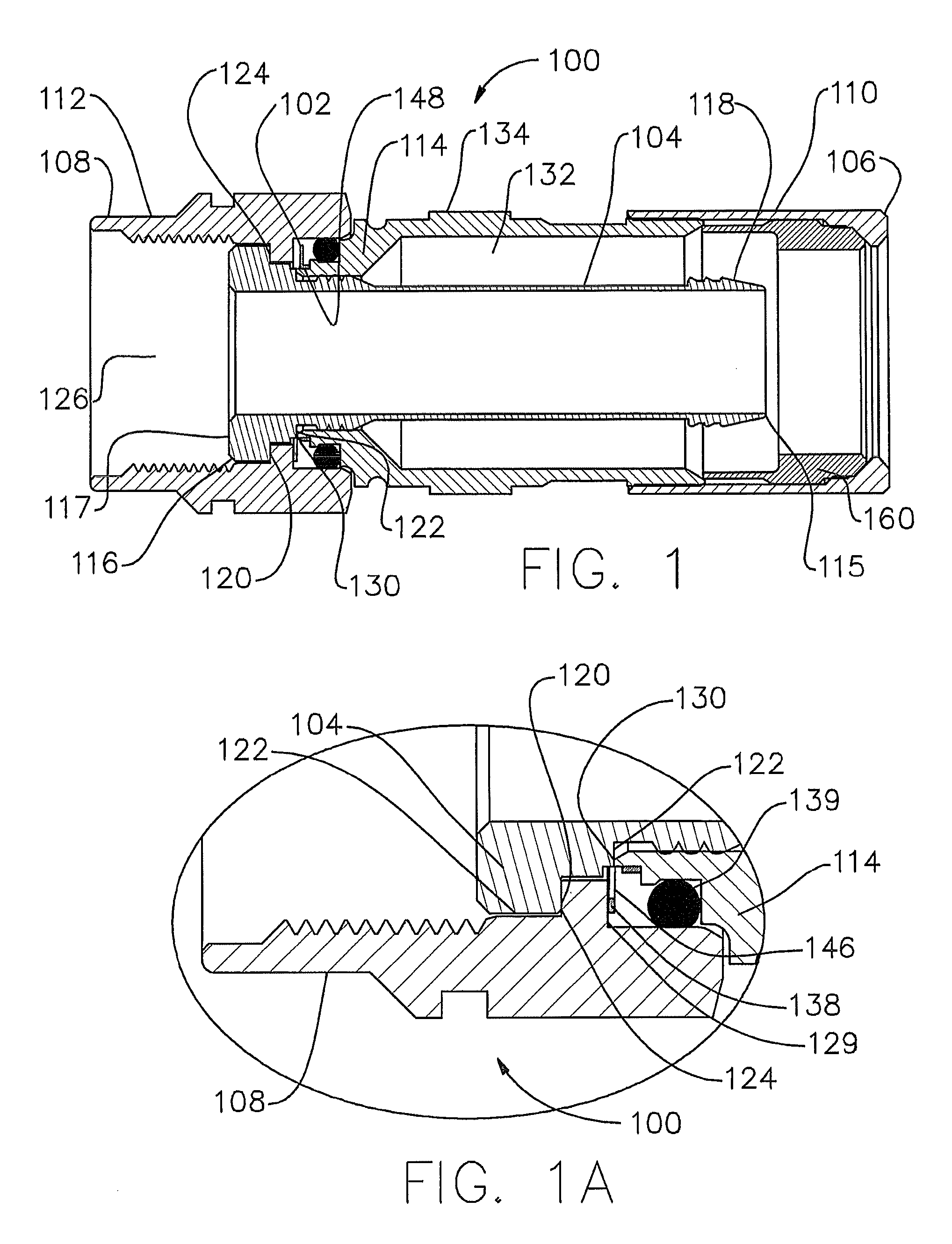

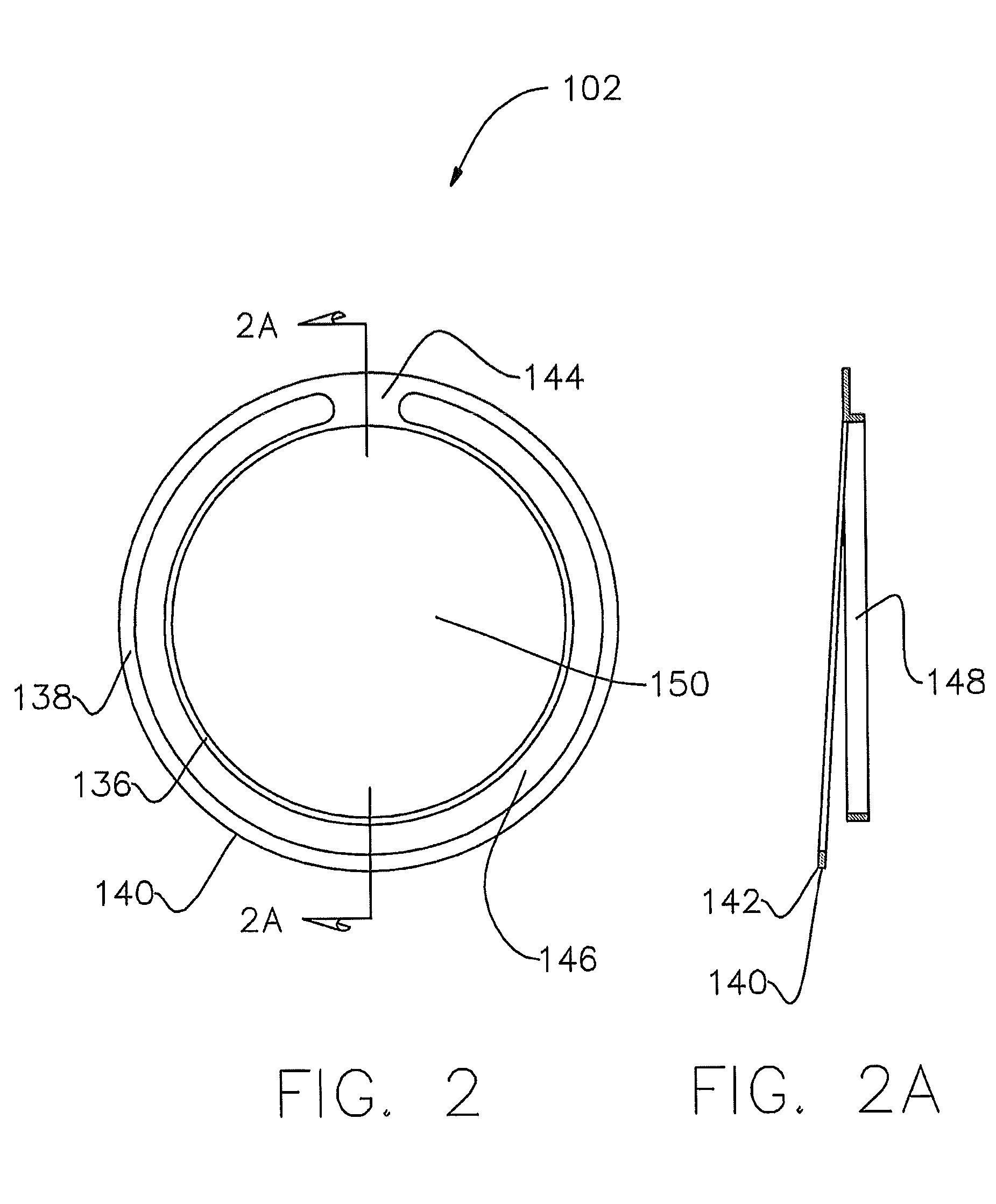

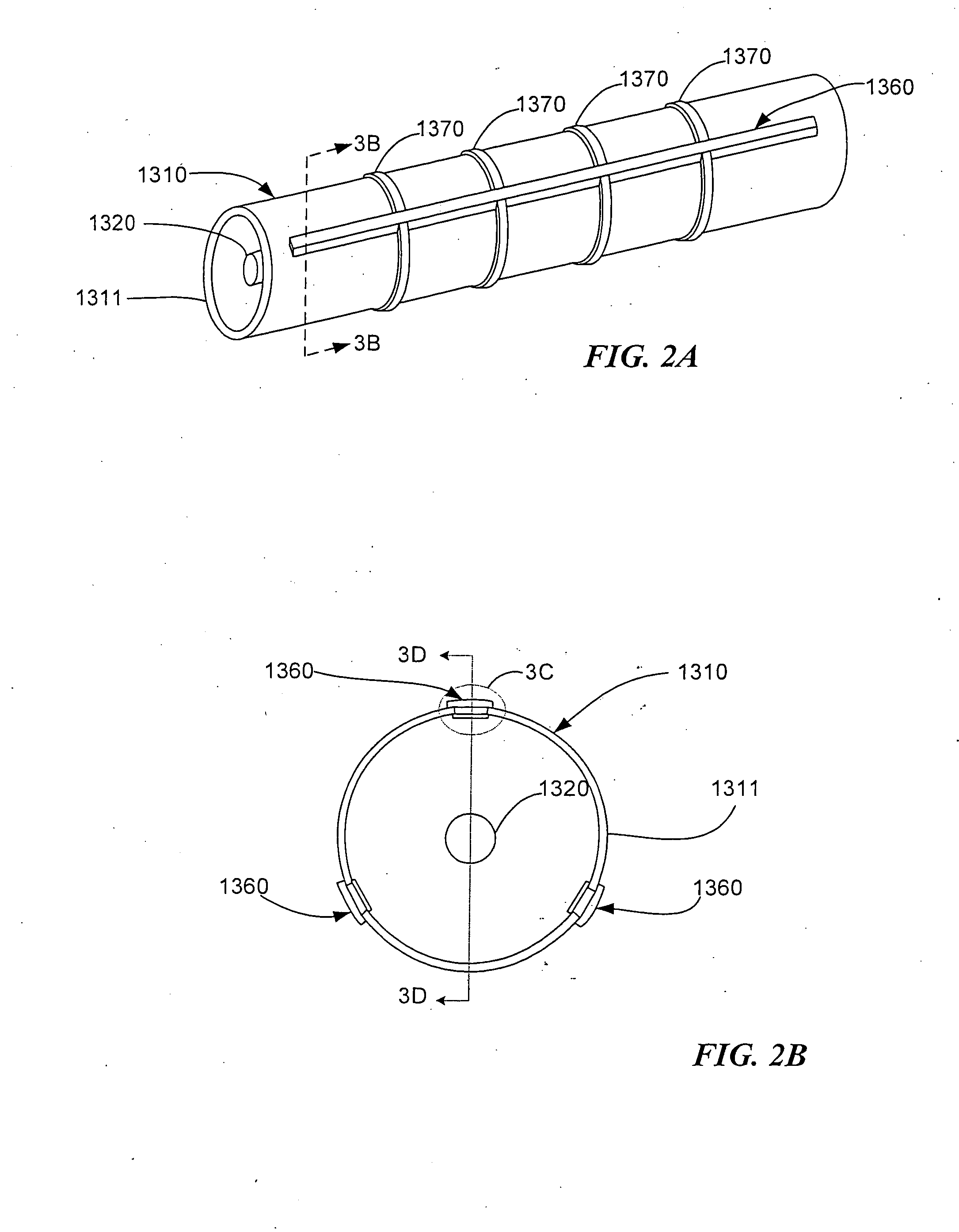

Coaxial cable connector with radio frequency interference and grounding shield

ActiveUS20130065433A1Smooth rotationCoupling device detailsClamped/spring connectionsCoaxial cableSpring force

A radio frequency interference (RFI) and grounding shield for a coaxial cable connector is disclosed. The shield comprises a circular inner segment and at least one arcuately shaped pre-formed cantilevered annular beam attached to the circular inner segment by a joining segment. The at least one pre-formed cantilevered annular beam extends angularly from a plane of the circular inner segment. The at least one pre-formed cantilevered annular beam applies a spring-force to a surface of the surface of a component of the coaxial cable connector establishing an electrically conductive path between the components. The at least one pre-formed cantilevered annular beam comprises an outer surface with a knife-like edge that provides a wiping action of surface oxides on component surfaces of the coaxial cable connector and allows for unrestricted movement when the coaxial cable connector is attached to an equipment connection port of an appliance.

Owner:PPC BROADBAND INC

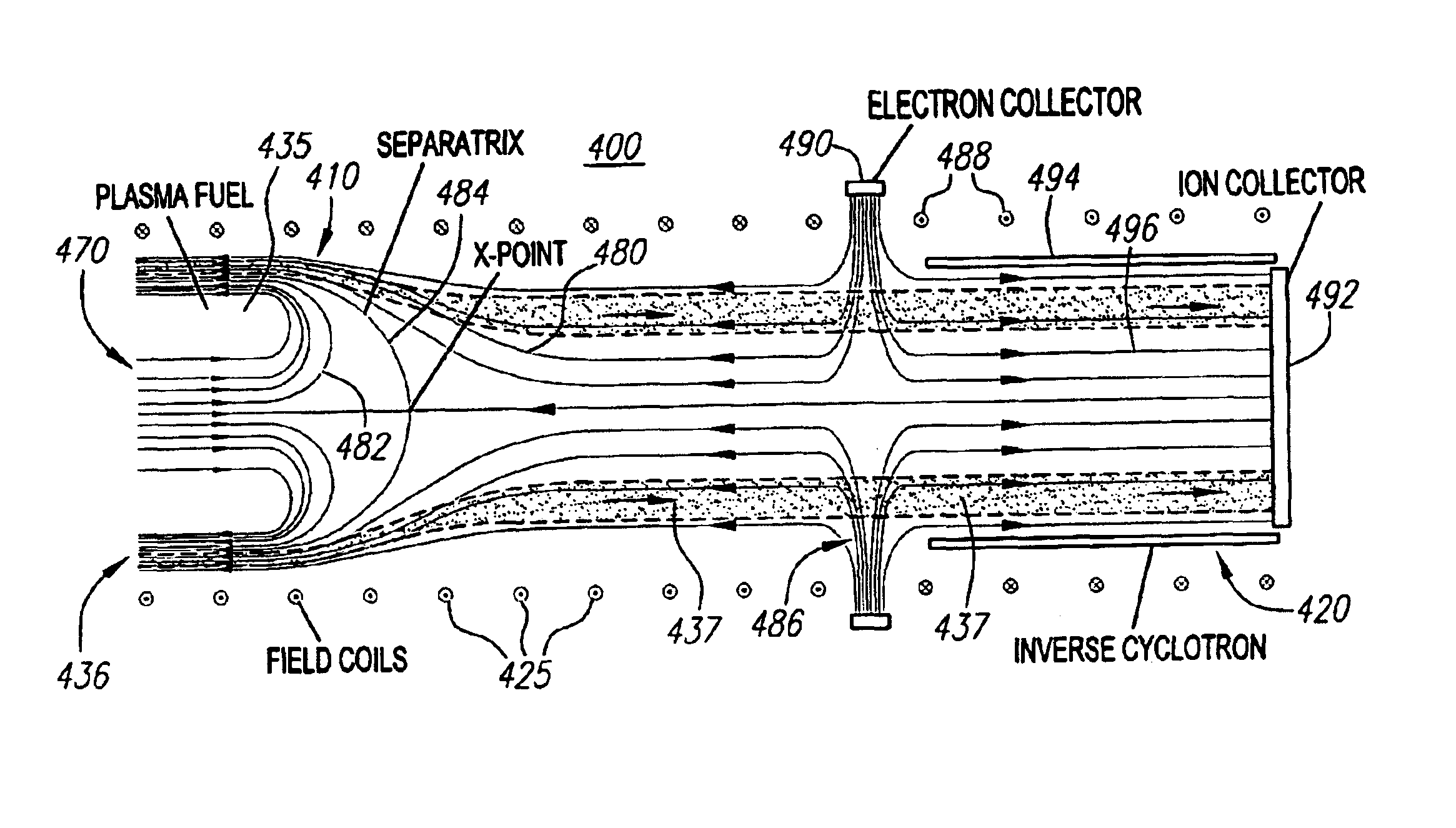

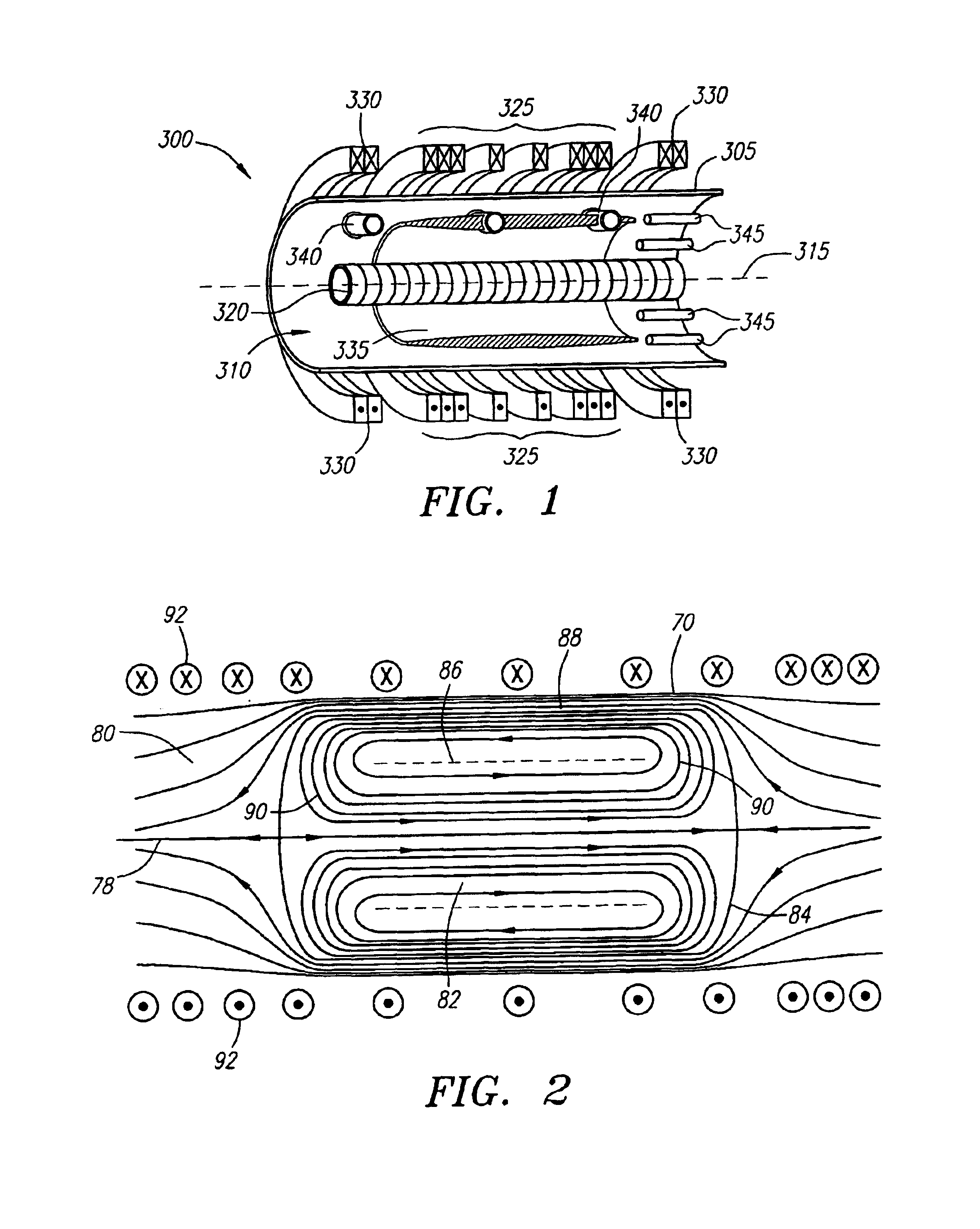

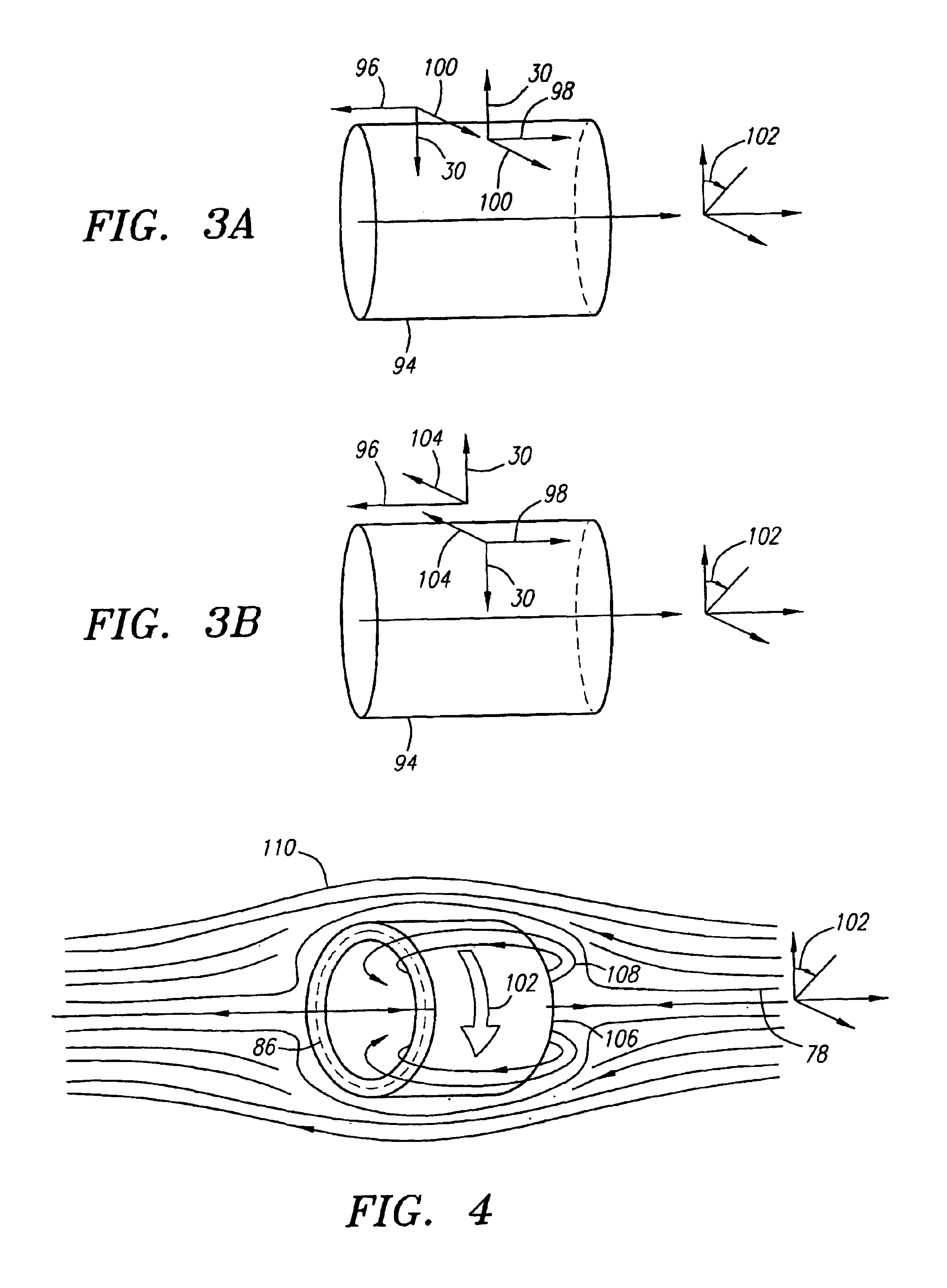

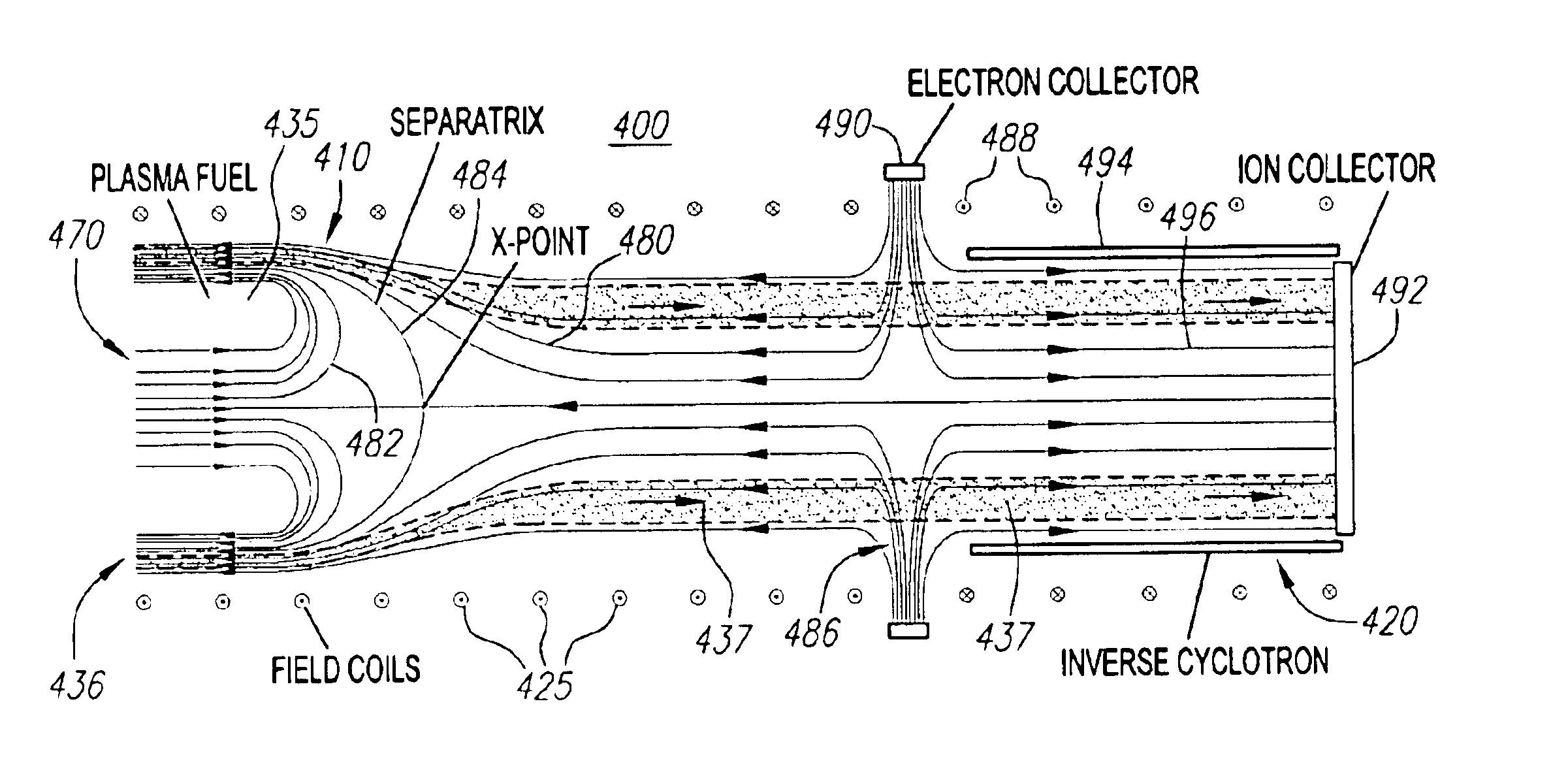

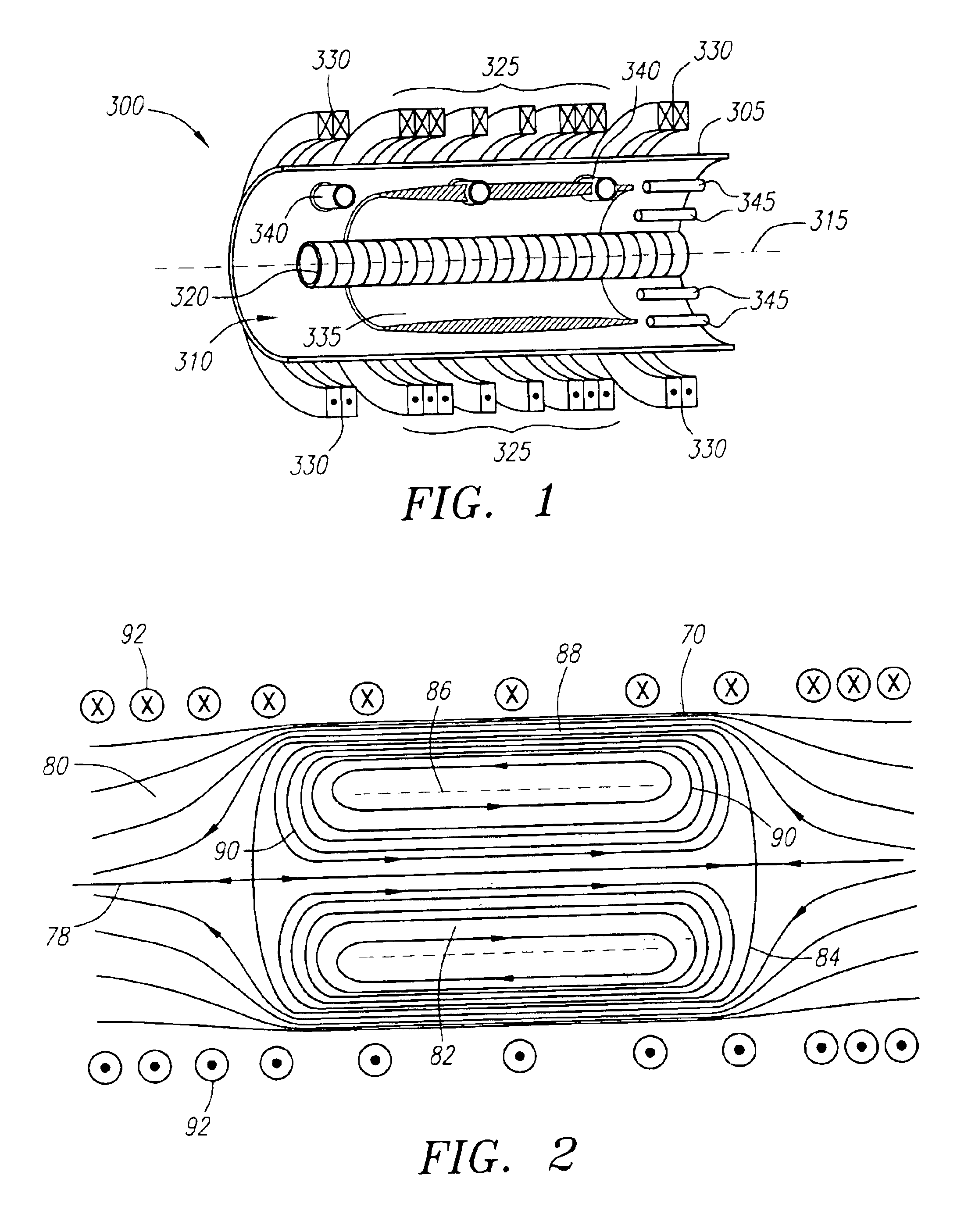

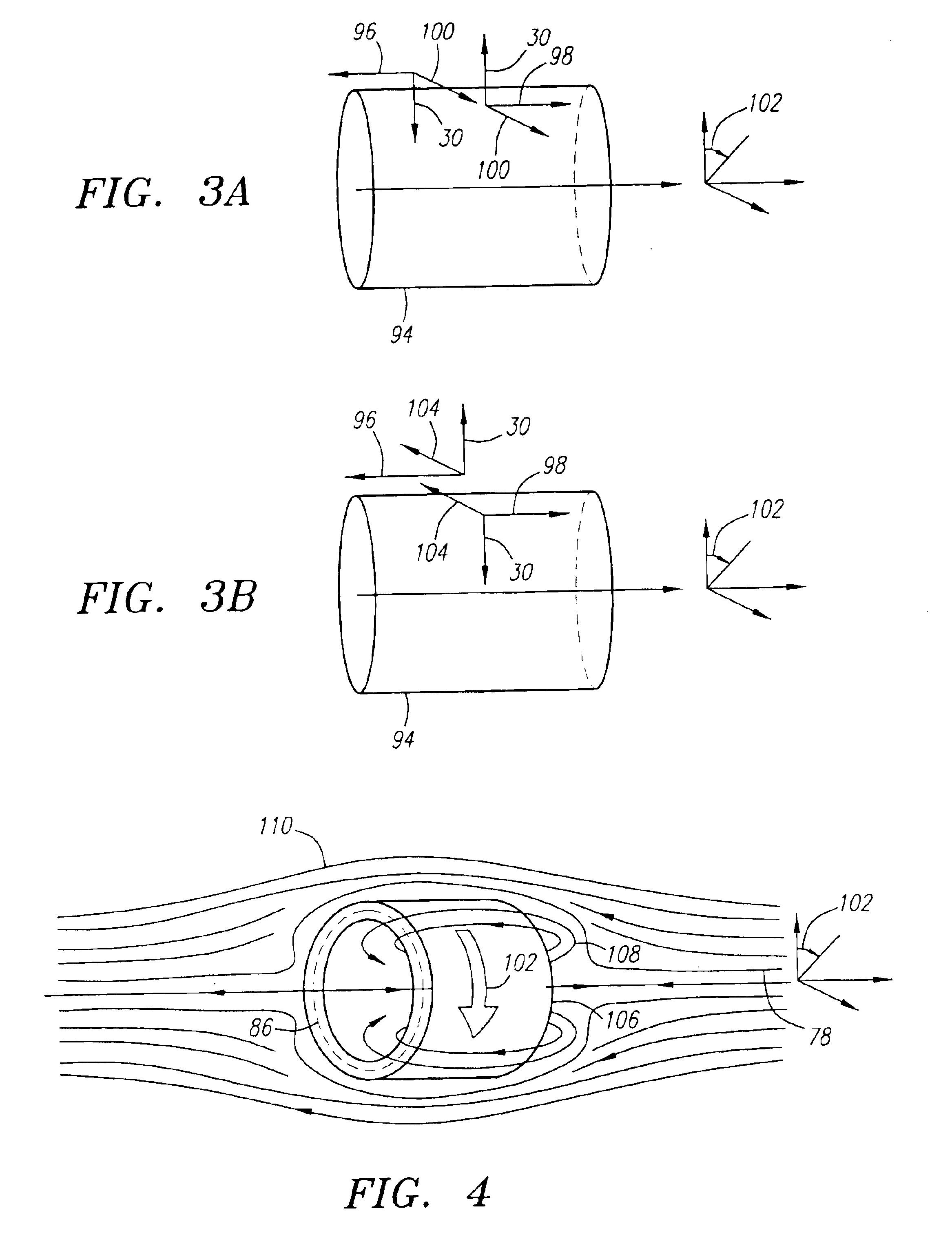

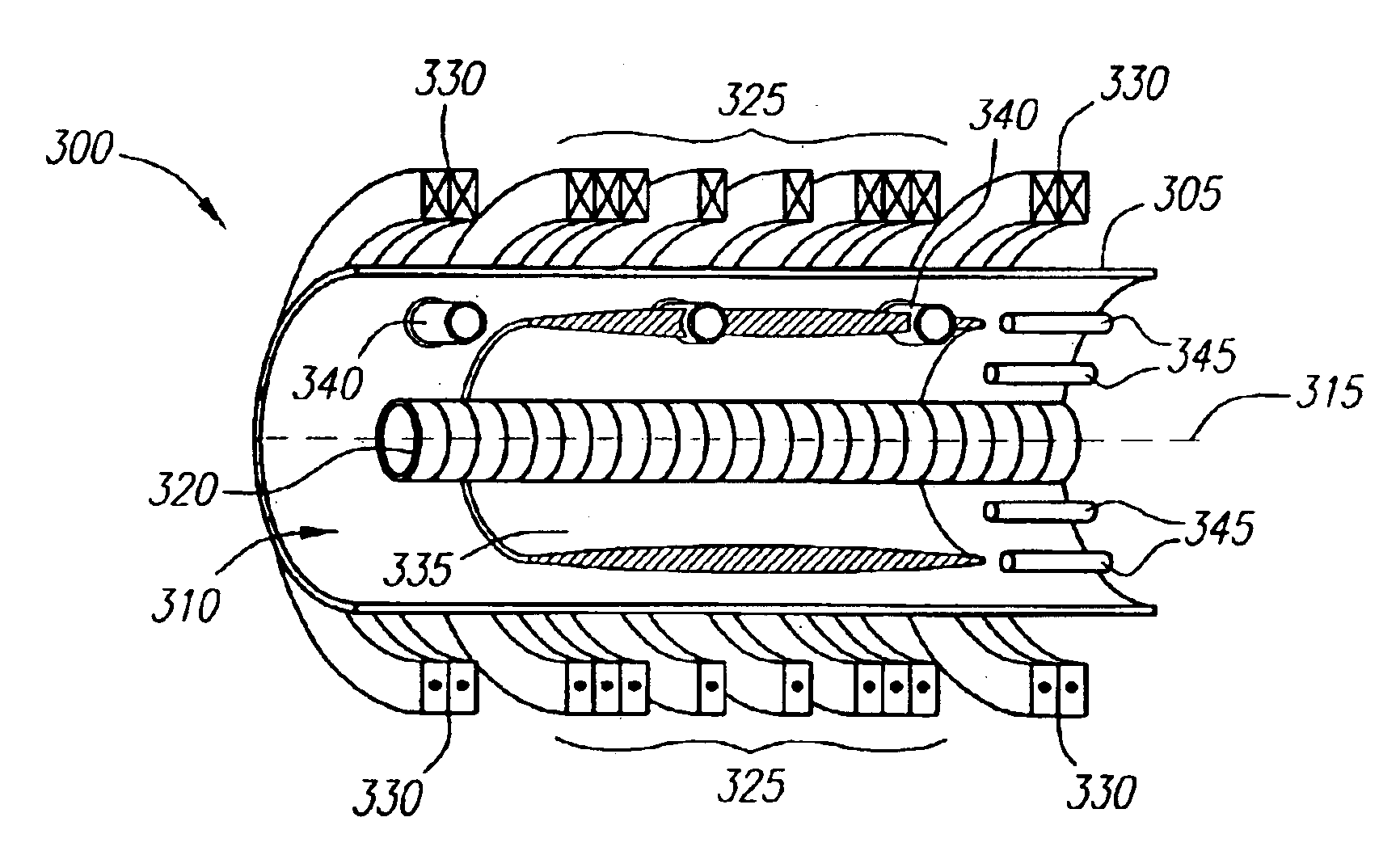

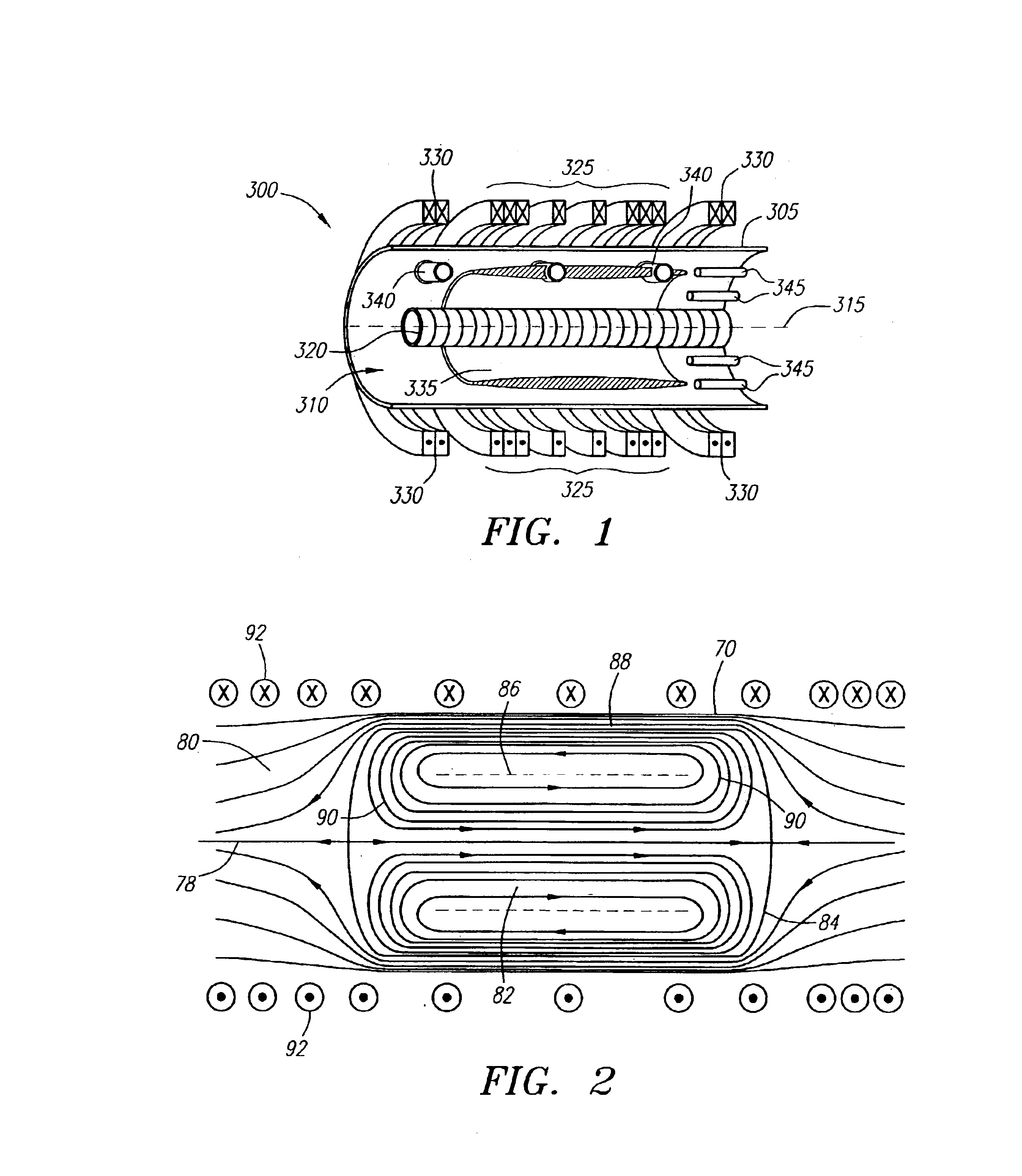

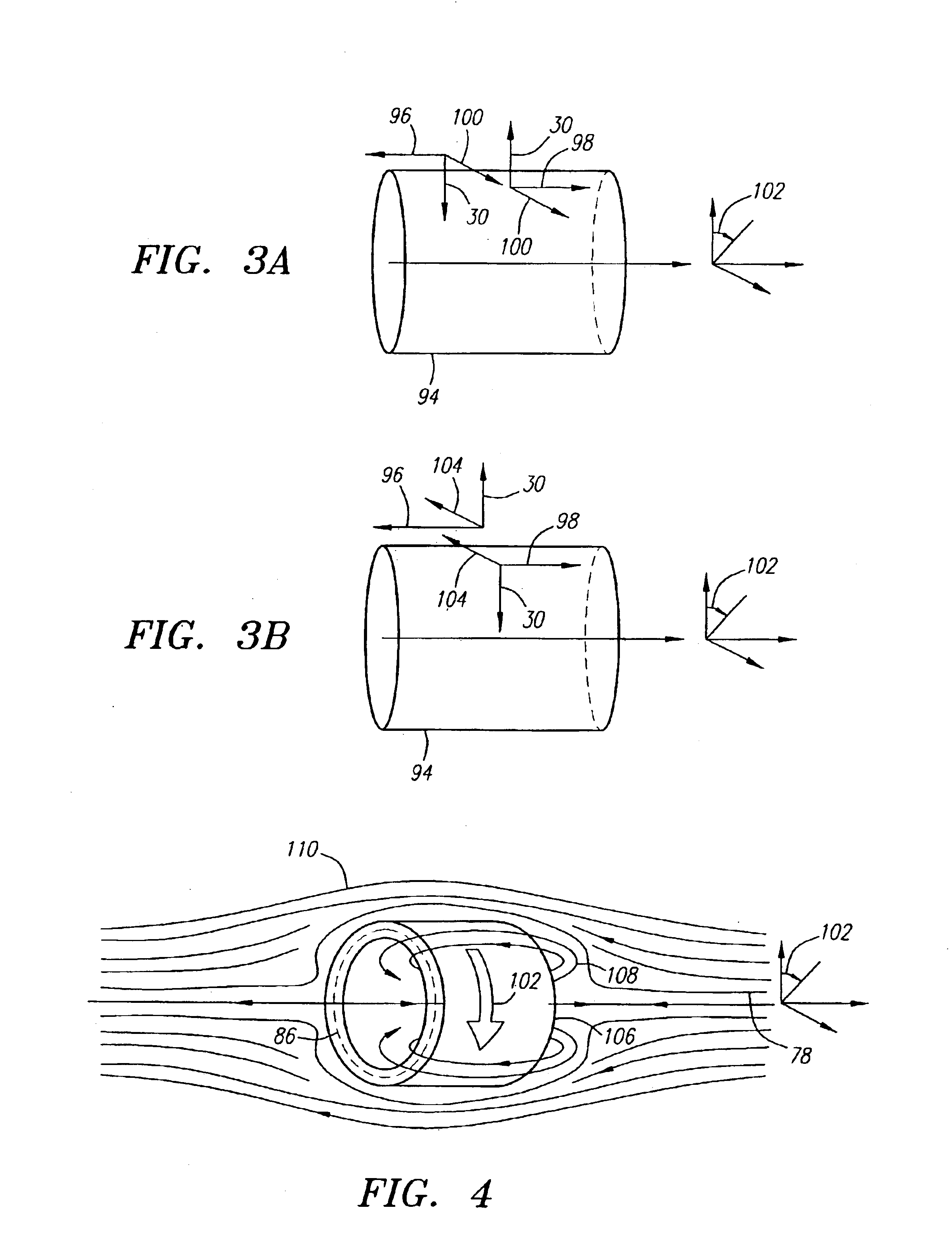

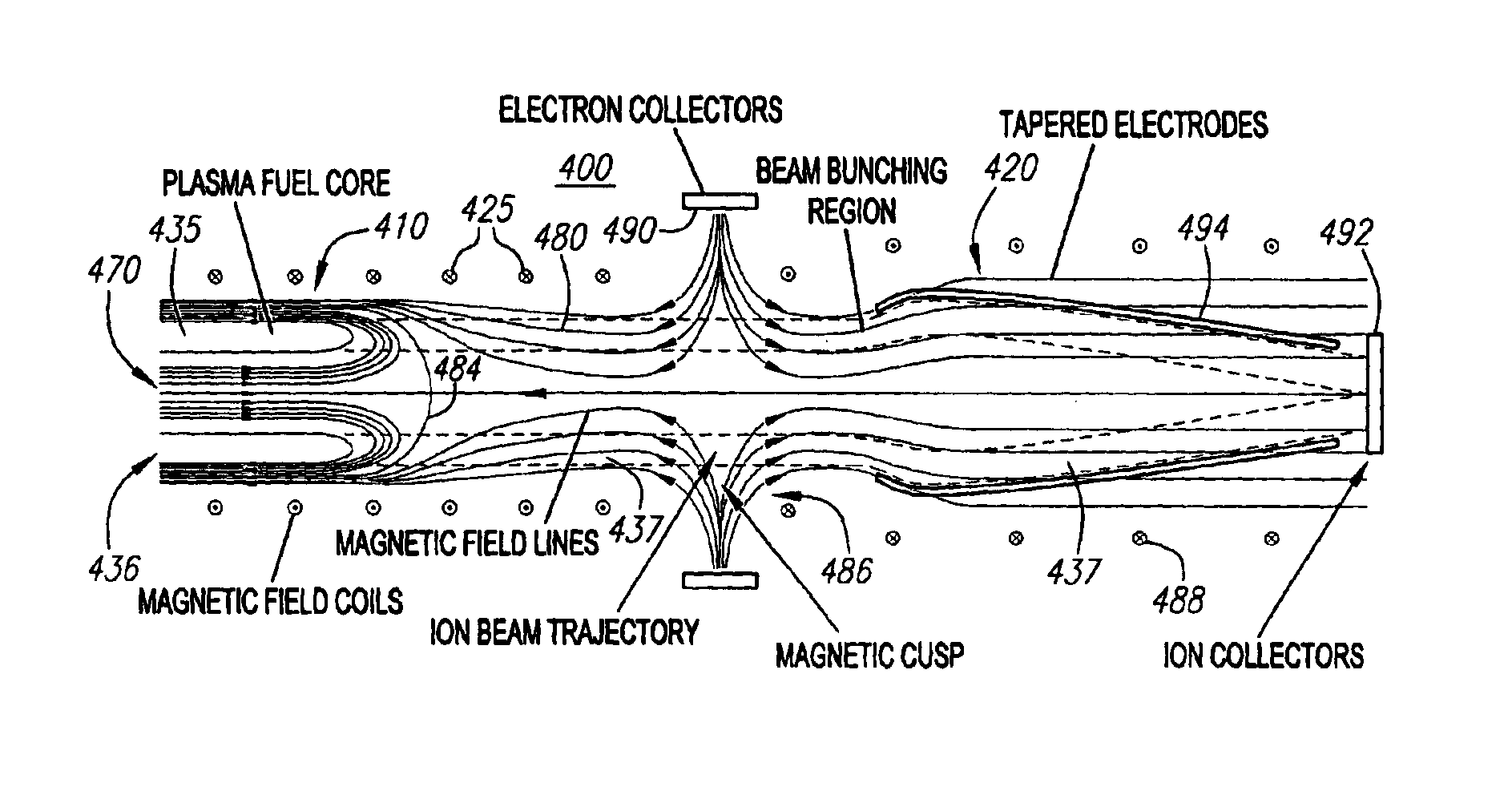

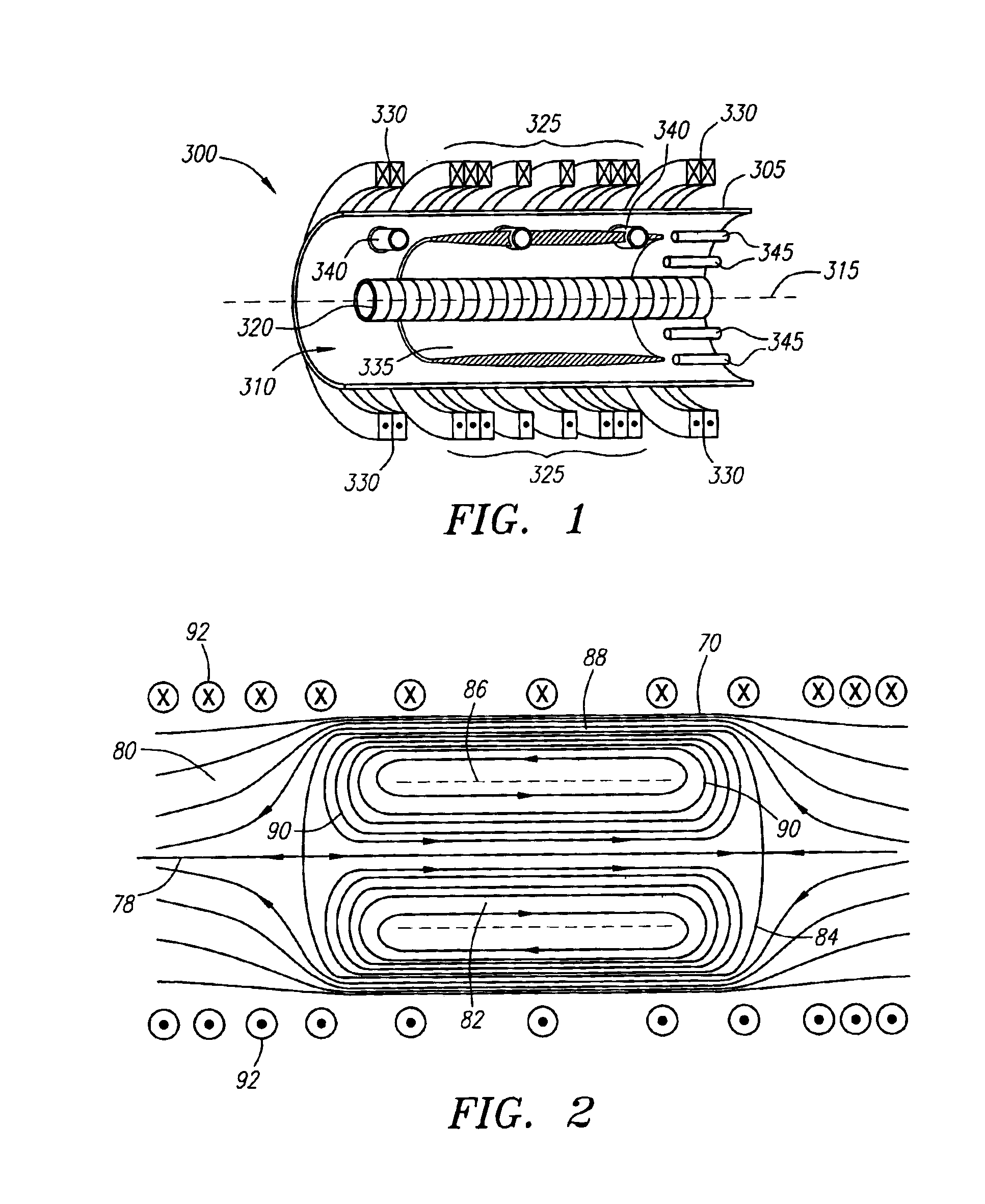

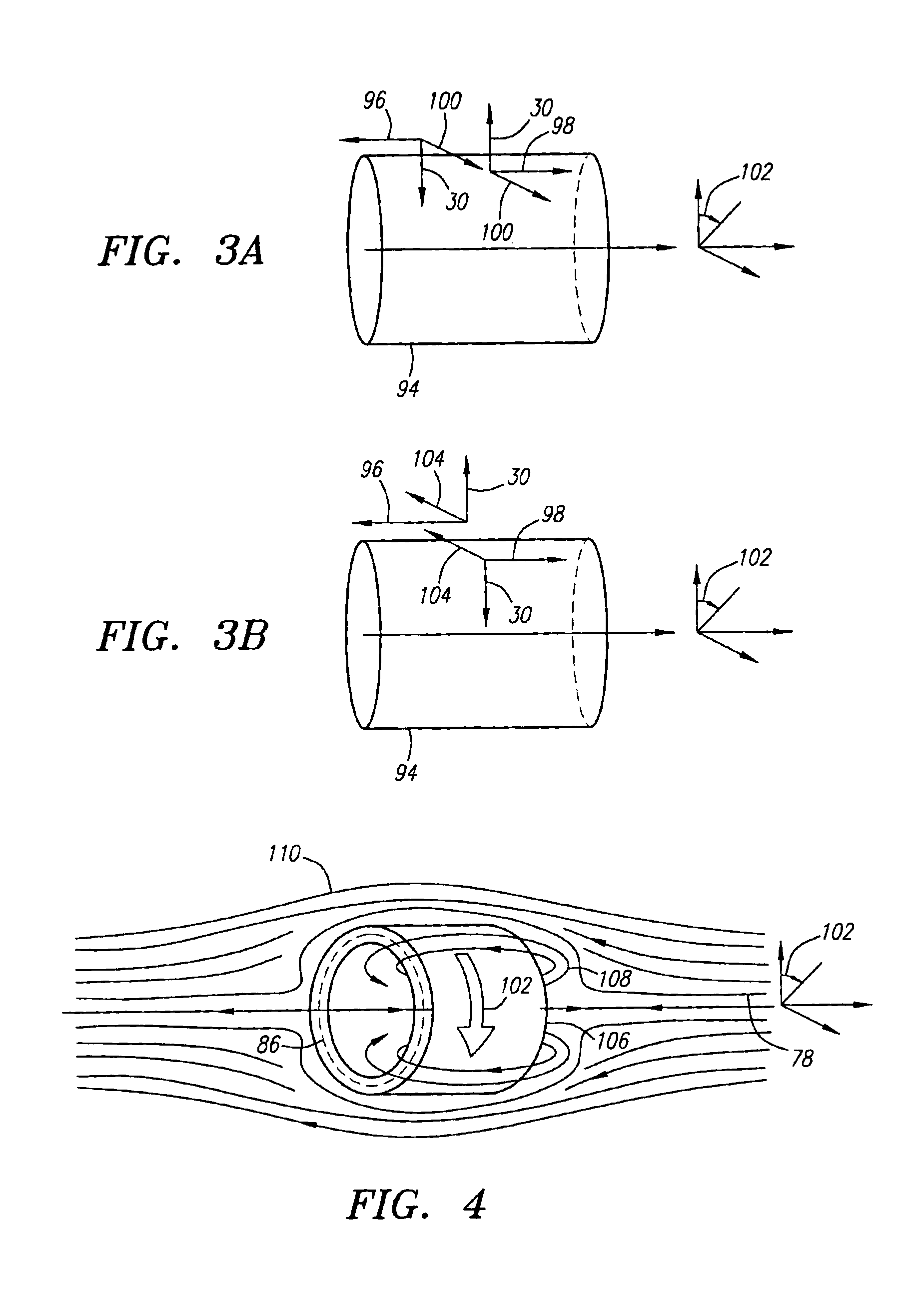

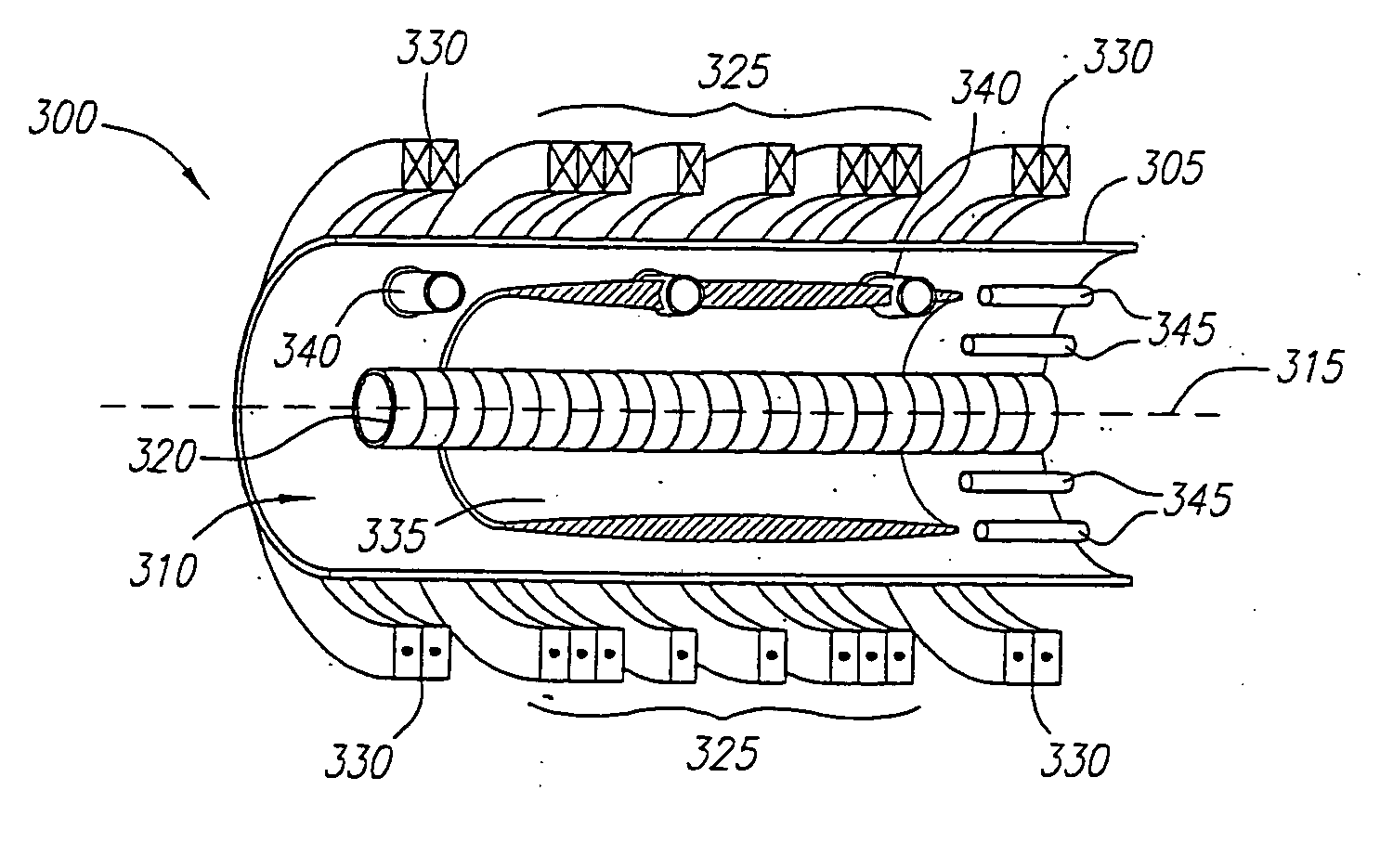

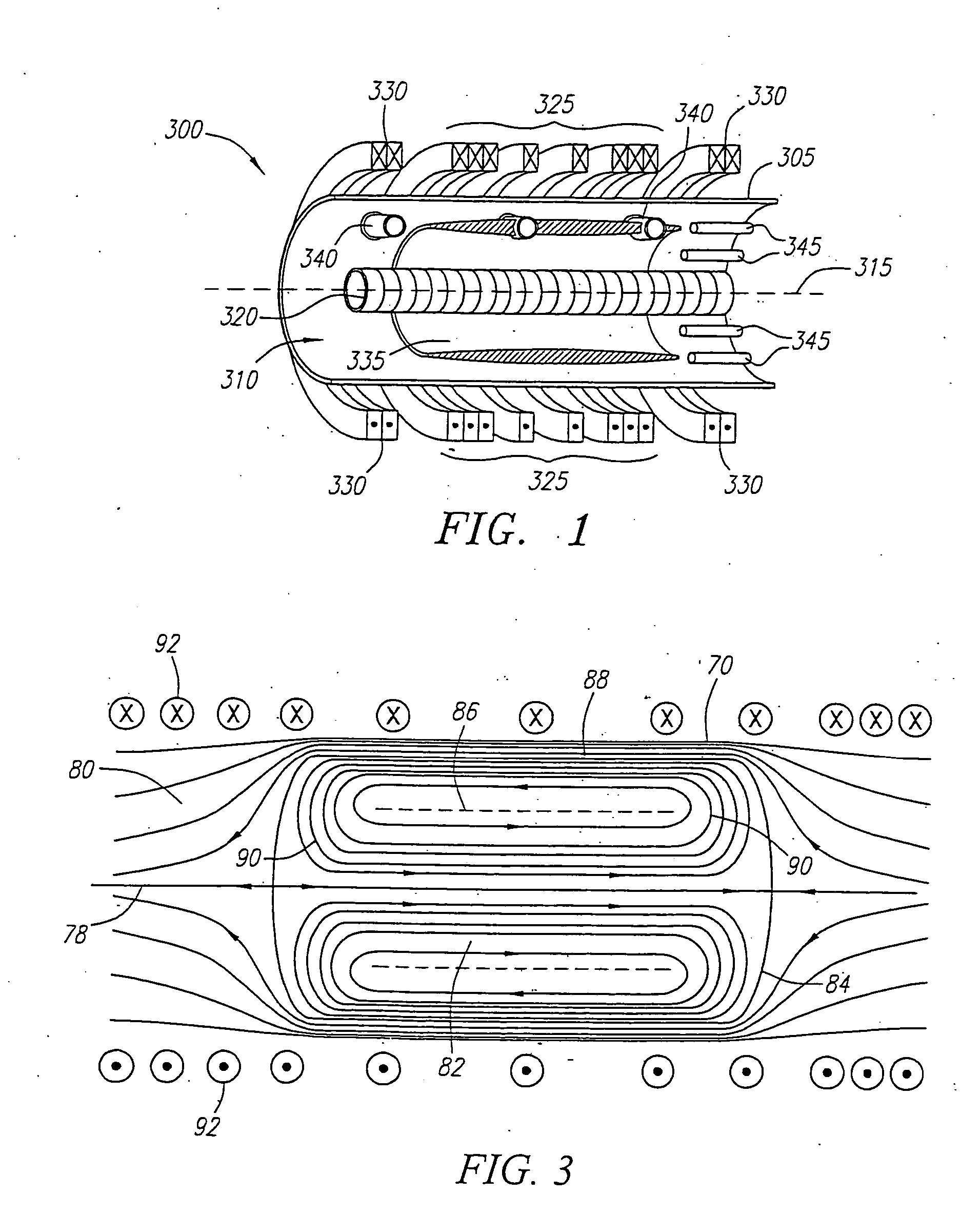

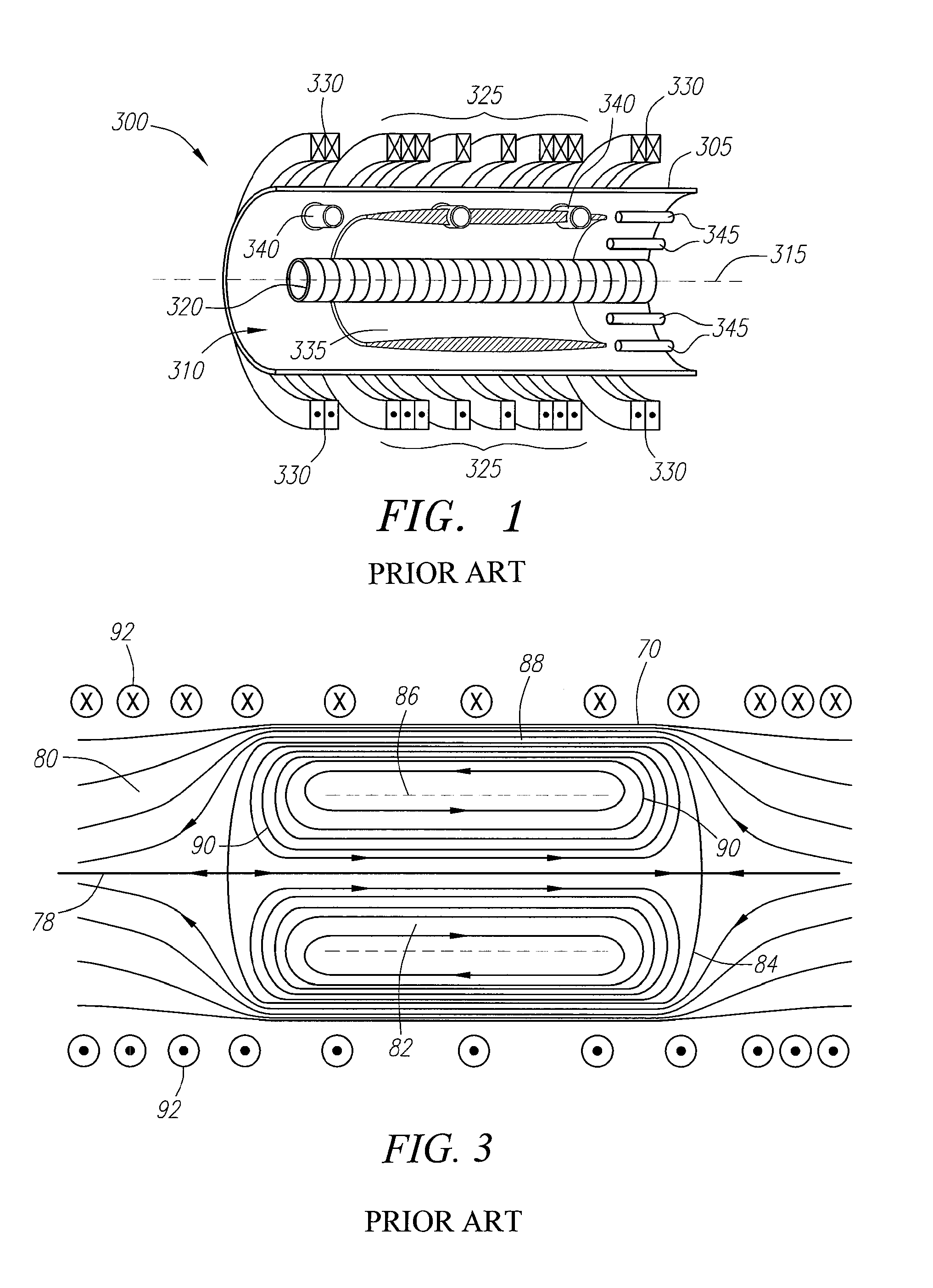

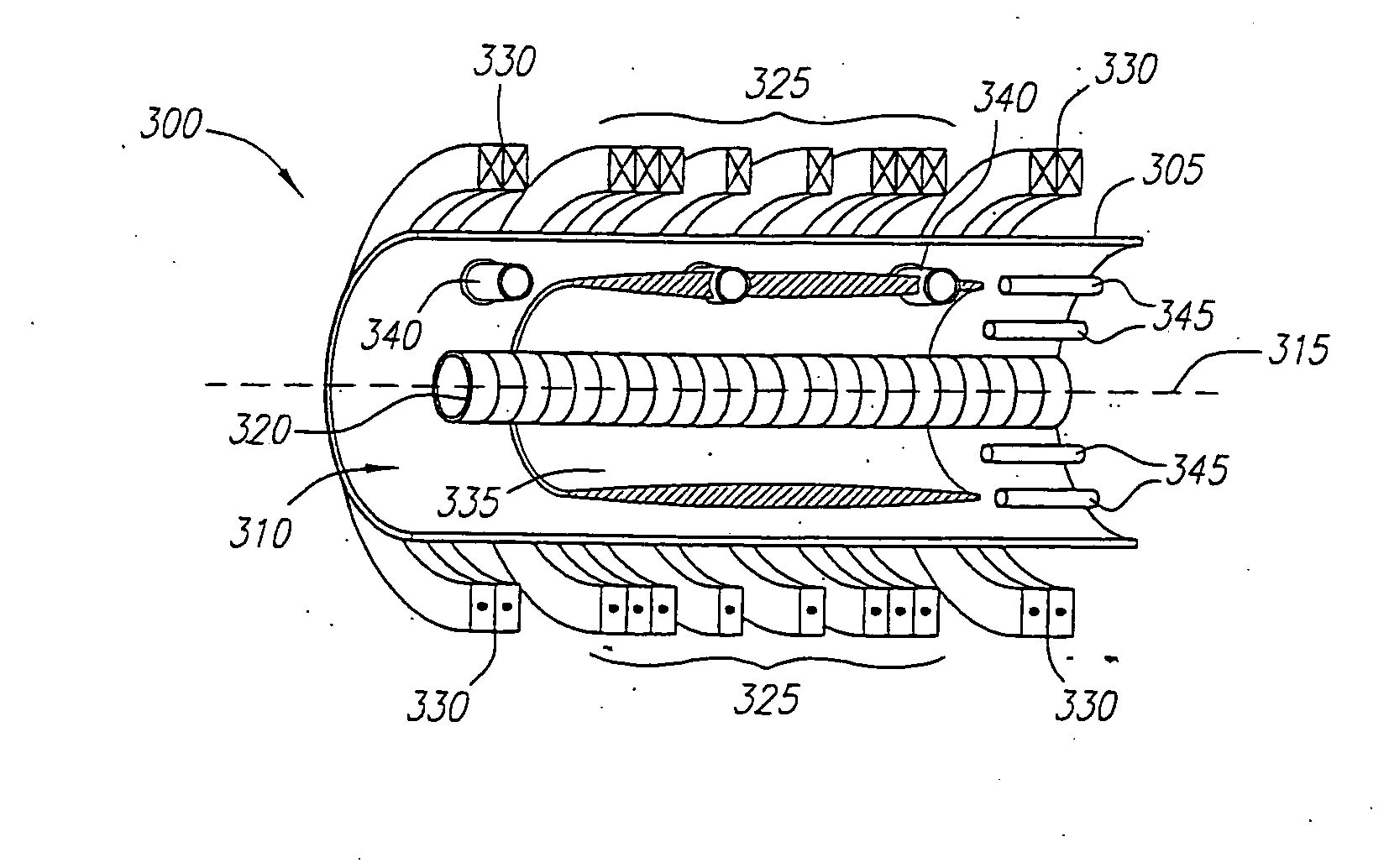

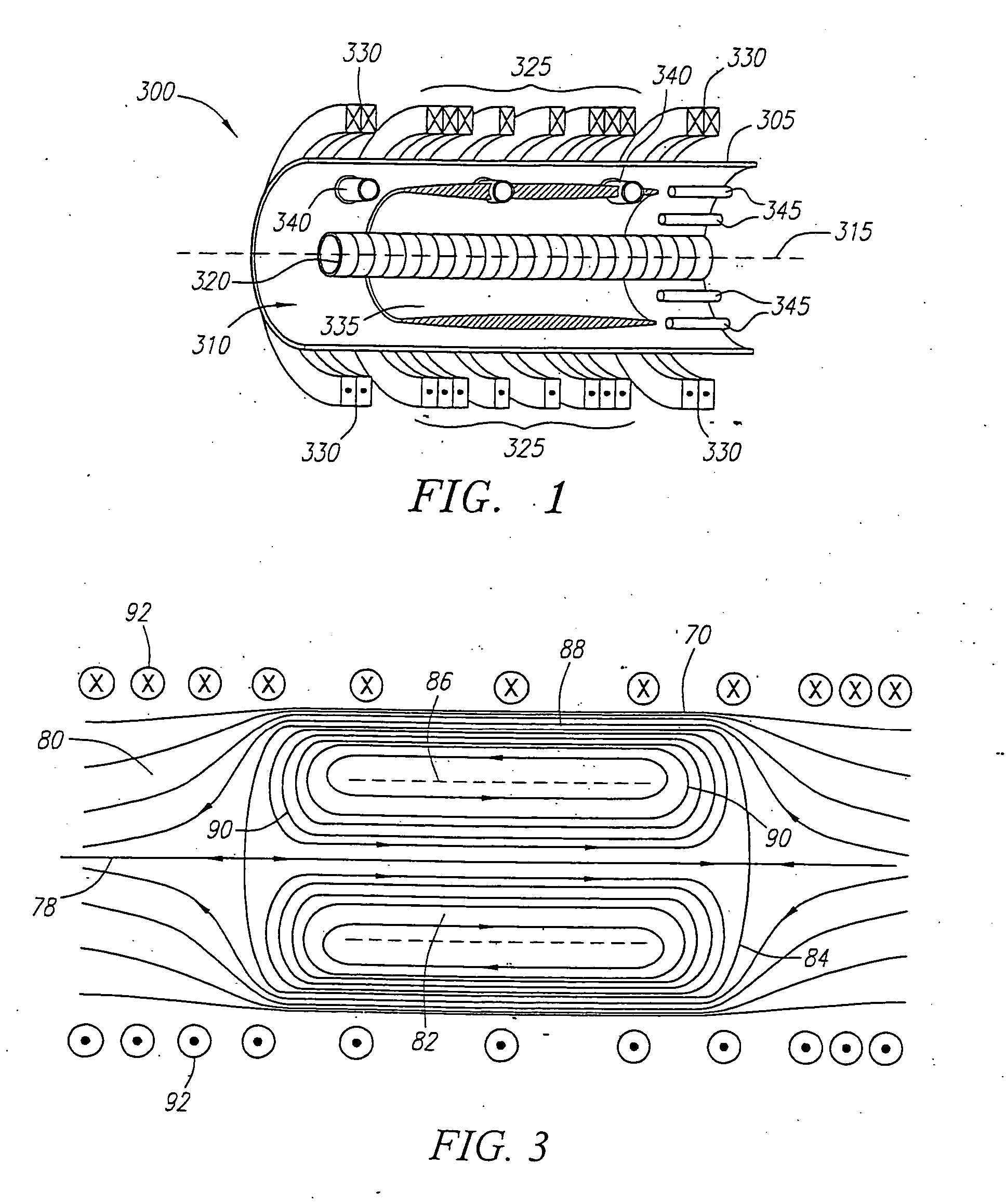

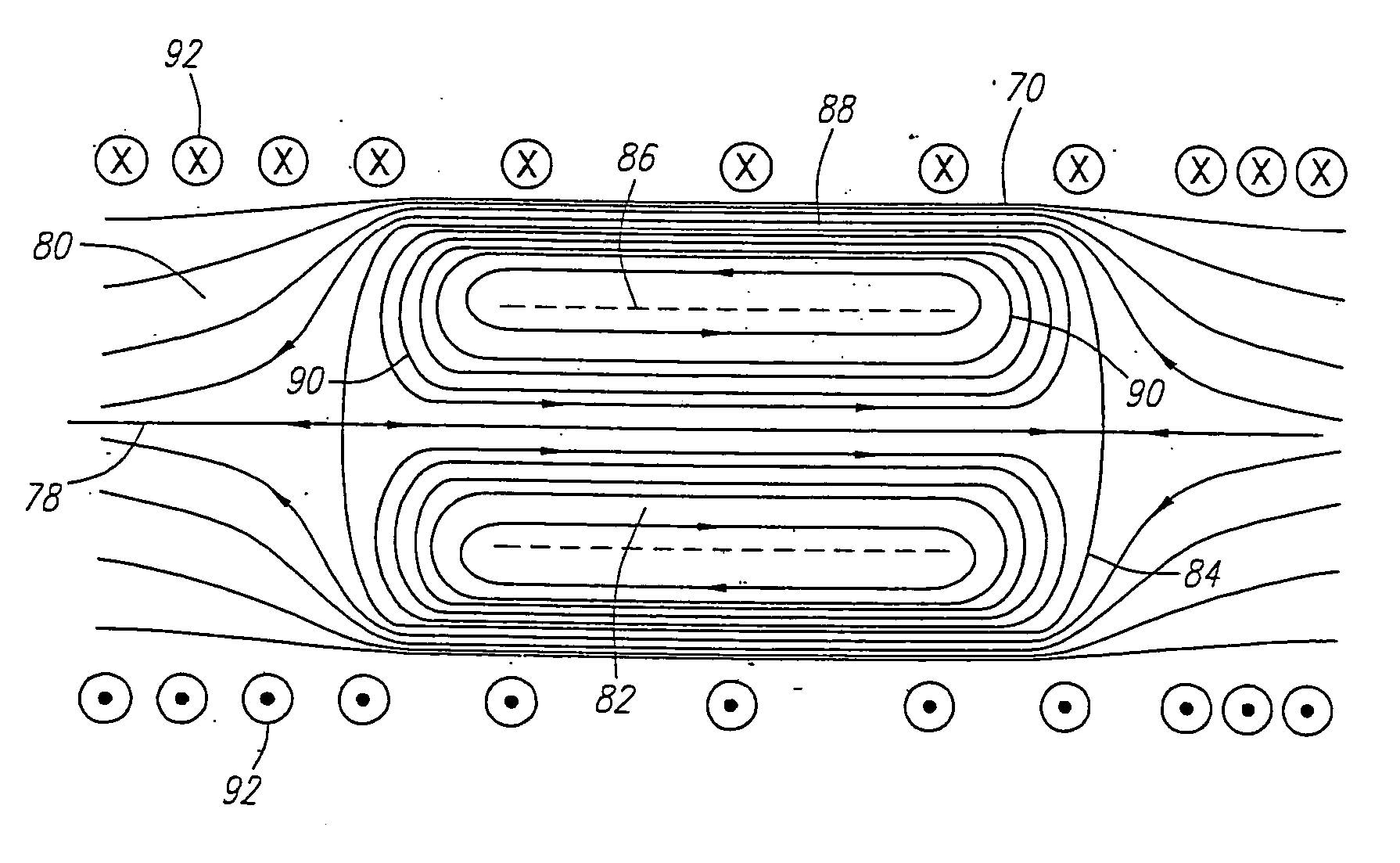

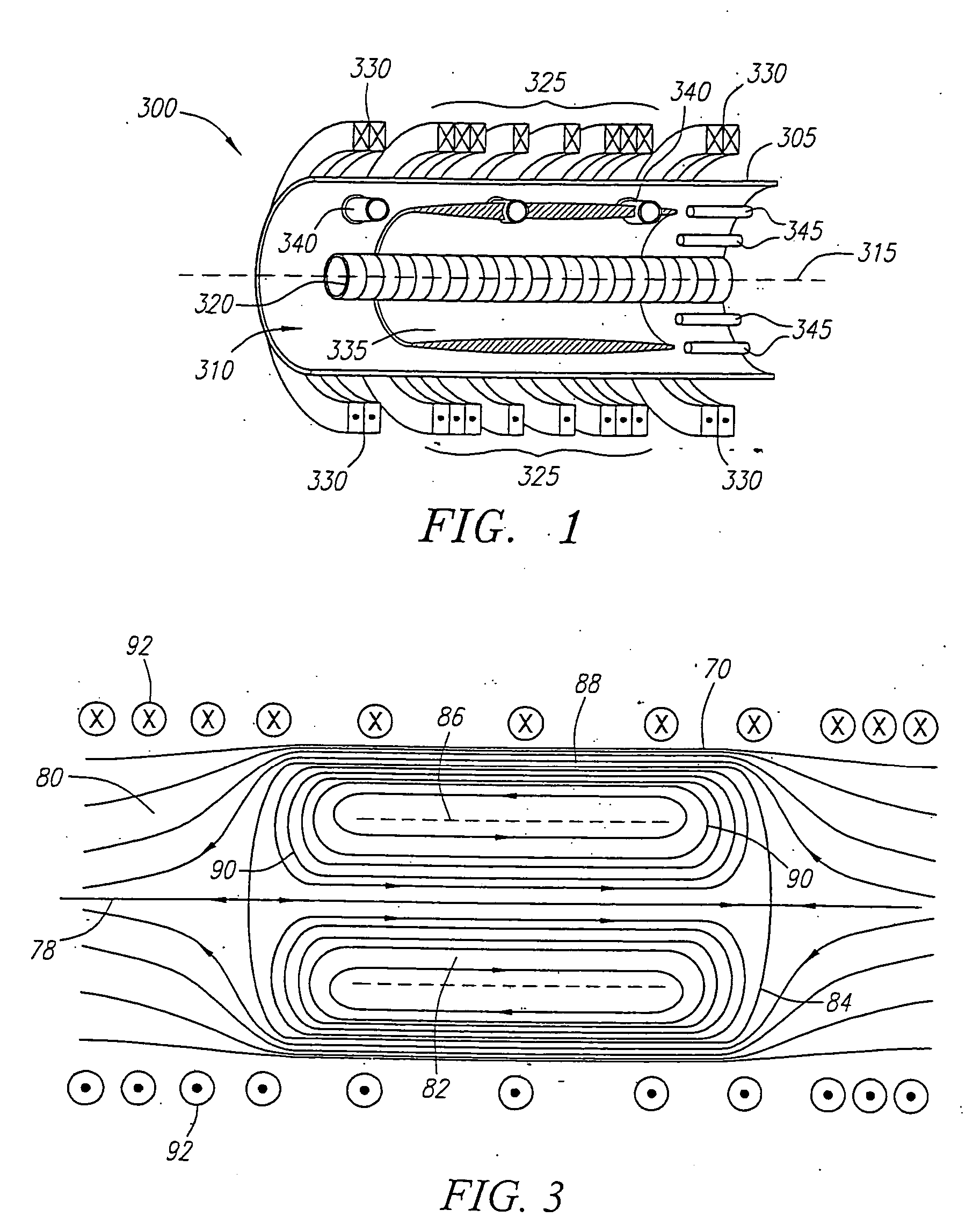

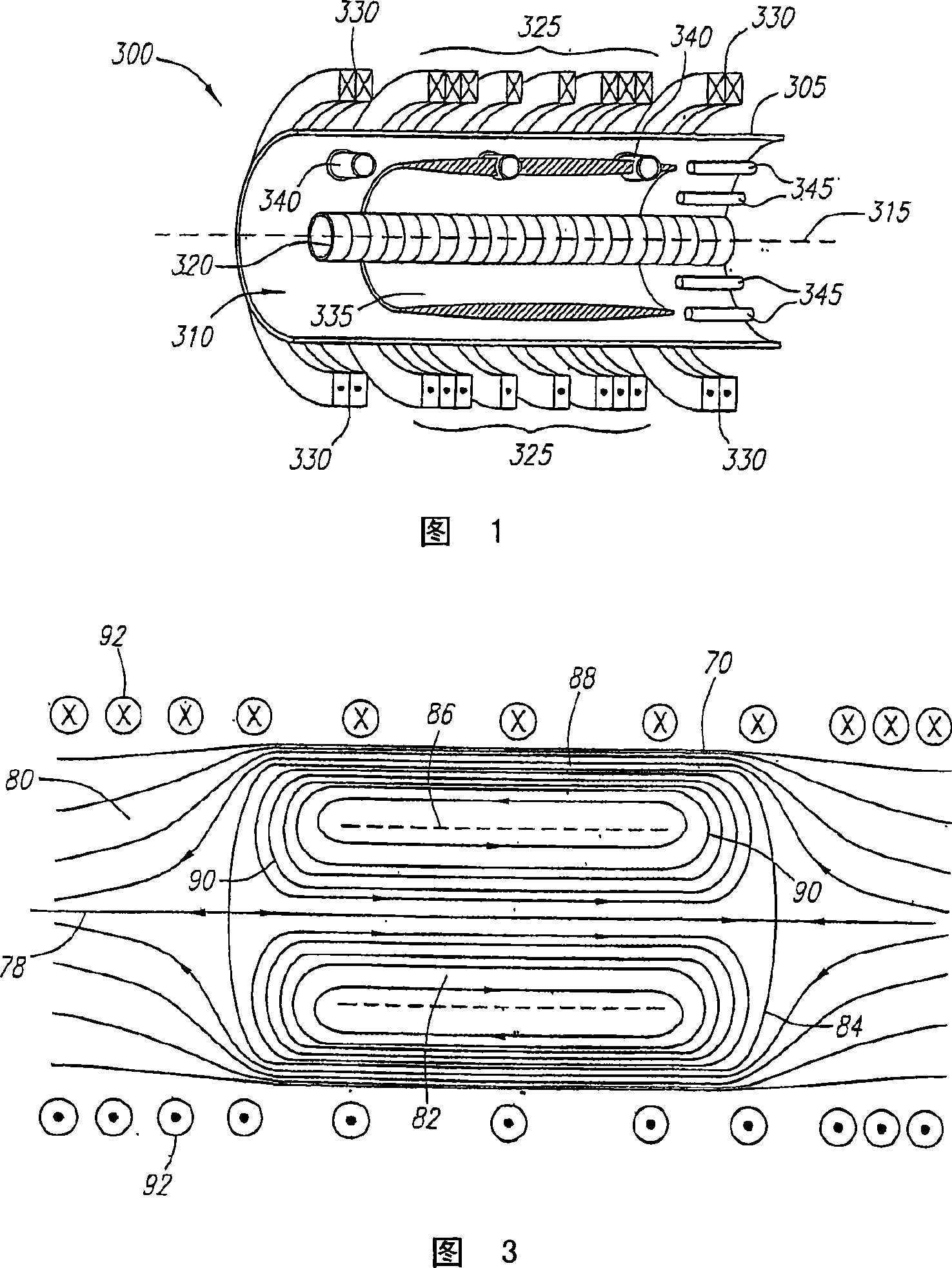

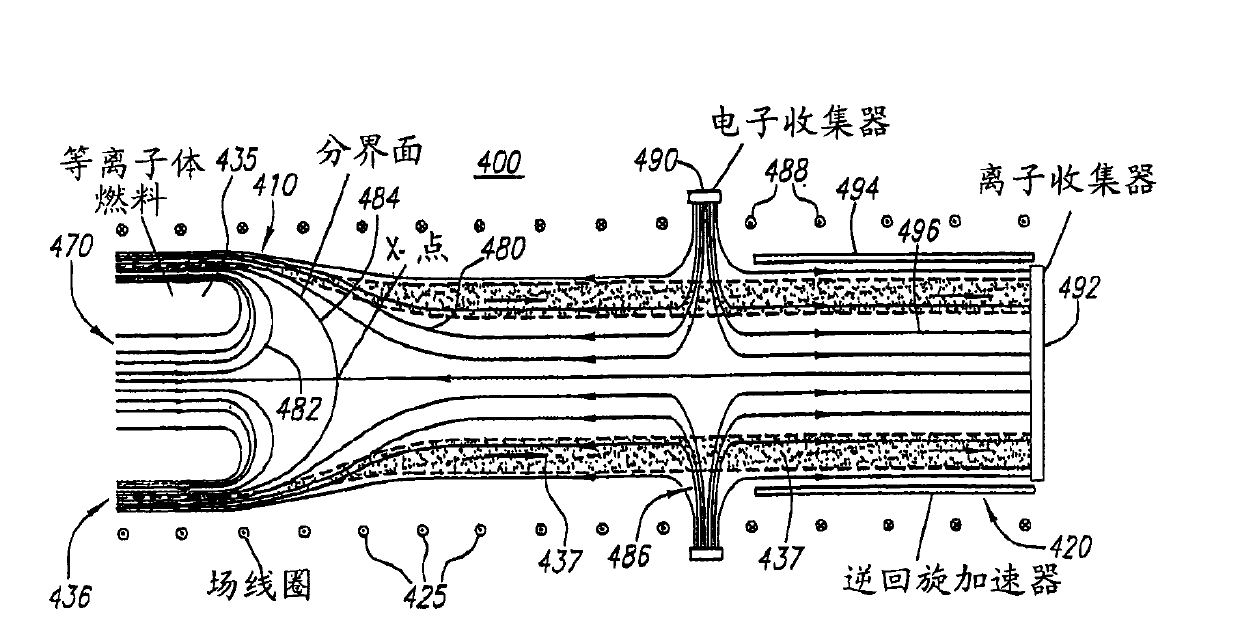

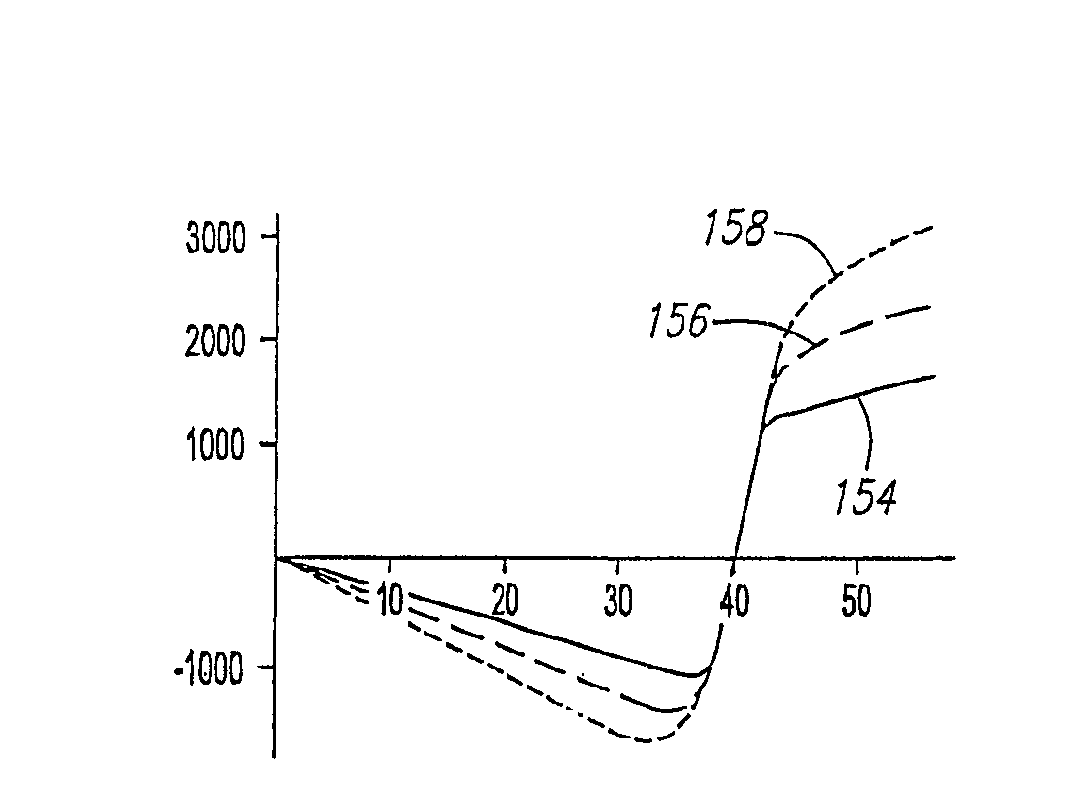

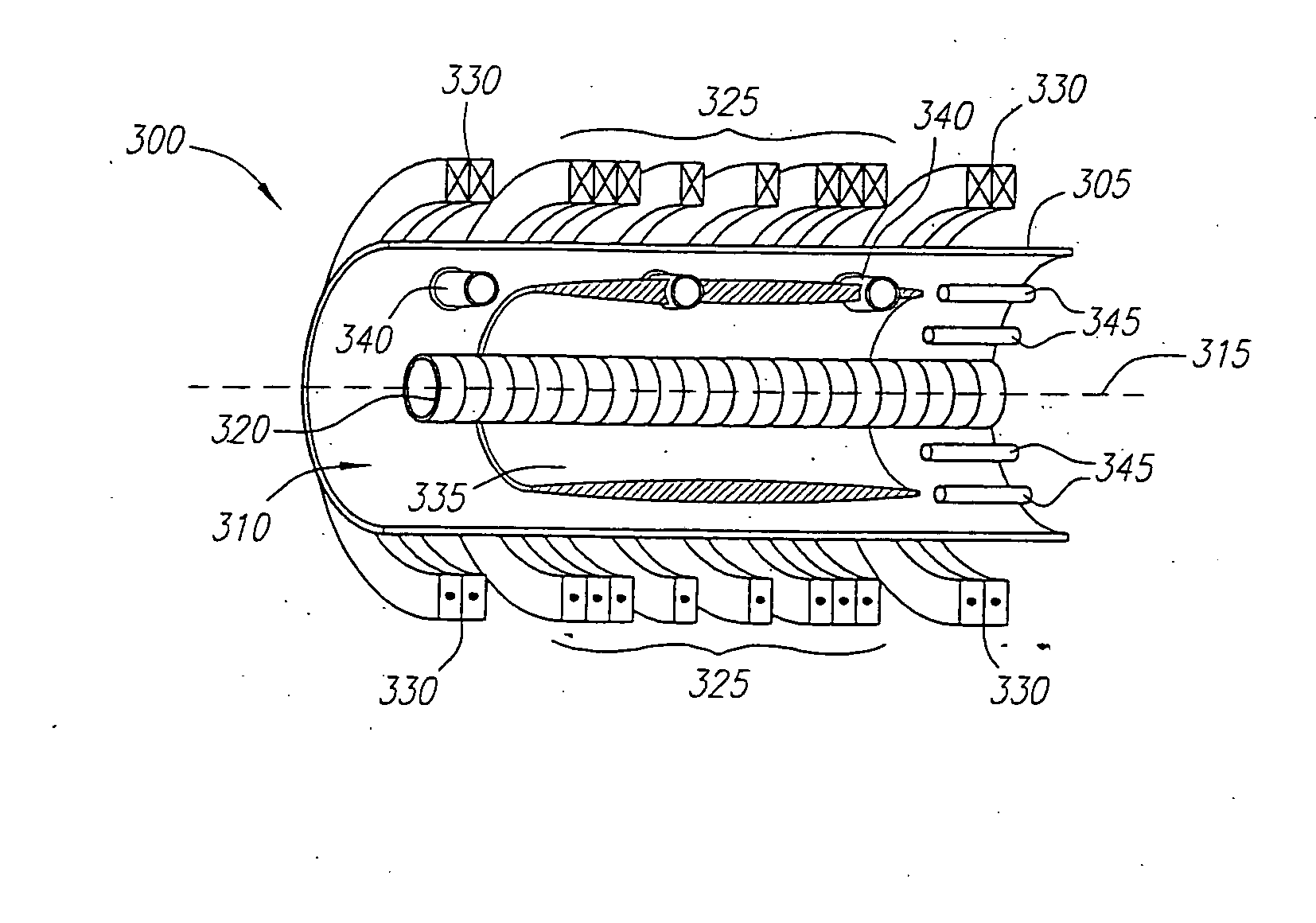

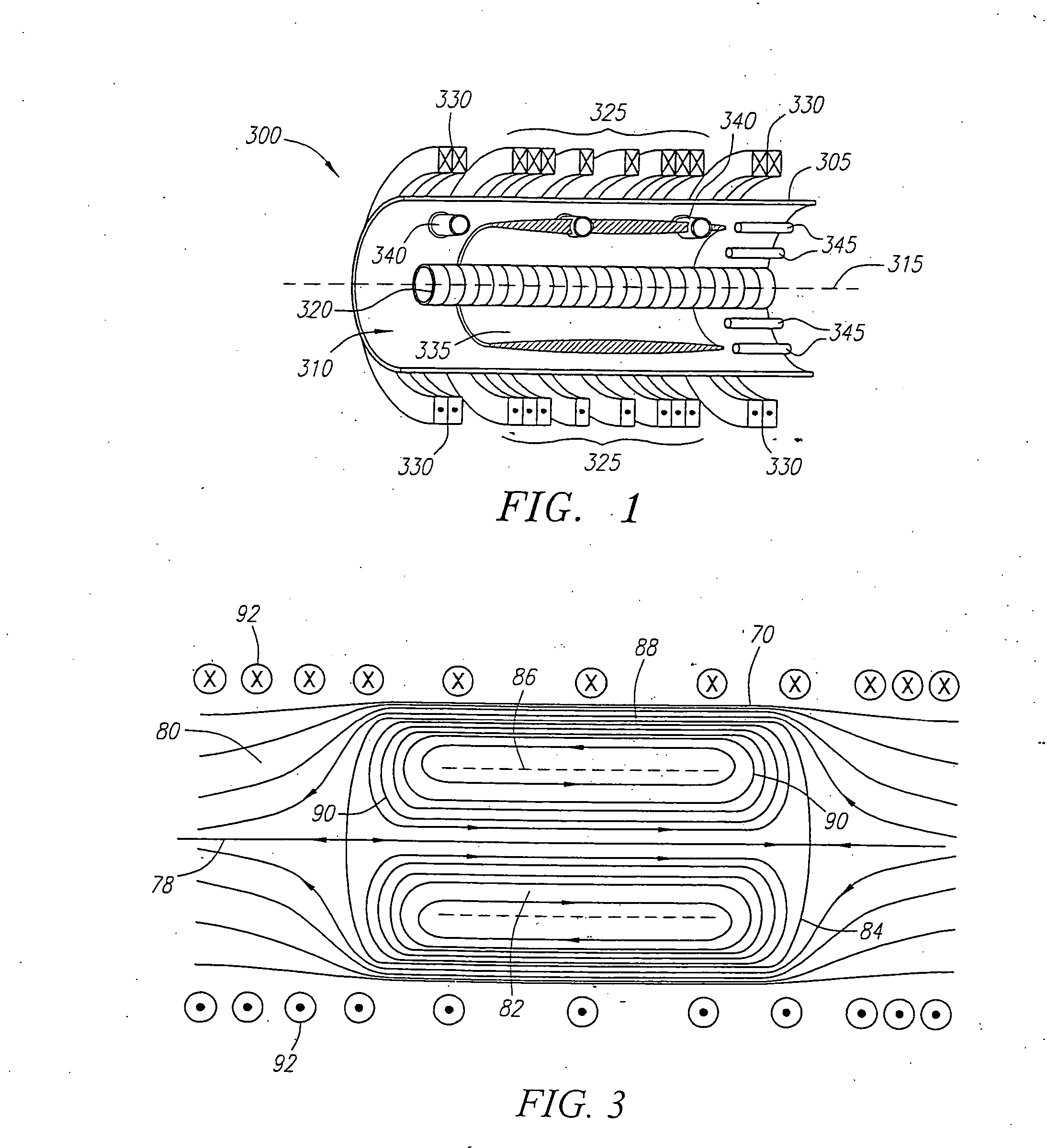

Controlled fusion in a field reversed configuration and direct energy conversion

InactiveUS6850011B2Facilitates controlled fusionReduce eliminate anomalous transportElectric discharge tubesNuclear energy generationNuclear forcePlasma electron

A system and apparatus for controlled fusion in a field reversed configuration (FRC) magnetic topology and conversion of fusion product energies directly to electric power. Preferably, plasma ions are magnetically confined in the FRC while plasma electrons are electrostatically confined in a deep energy well, created by tuning an externally applied magnetic field. In this configuration, ions and electrons may have adequate density and temperature so that upon collisions they are fused together by the nuclear force, thus forming fusion products that emerge in the form of an annular beam. Energy is removed from the fusion product ions as they spiral past electrodes of an inverse cyclotron converter. Advantageously, the fusion fuel plasmas that can be used with the present confinement and energy conversion system include advanced (aneutronic) fuels.

Owner:RGT UNIV OF CALIFORNIA +1

Controlled fusion in a field reversed configuration and direct energy conversion

InactiveUS6894446B2Facilitates controlled fusionReduce eliminate anomalous transportNuclear energy generationMagnetic resonance acceleratorsNuclear forcePlasma electron

A system and apparatus for controlled fusion in a field reversed configuration (FRC) magnetic topology and conversion of fusion product energies directly to electric power. Preferably, plasma ions are magnetically confined in the FRC while plasma electrons are electrostatically confined in a deep energy well, created by tuning an externally applied magnetic field. In this configuration, ions and electrons may have adequate density and temperature so that upon collisions they are fused together by the nuclear force, thus forming fusion products that emerge in the form of an annular beam. Energy is removed from the fusion product ions as they spiral past electrodes of an inverse cyclotron converter. Advantageously, the fusion fuel plasmas that can be used with the present confinement and energy conversion system include advanced (aneutronic) fuels.

Owner:RGT UNIV OF CALIFORNIA +1

Controlled fusion in a field reversed configuration and direct energy conversion

InactiveUS6852942B2Facilitates controlled fusionReduce eliminate anomalous transportLaser detailsParticle separator tubesNuclear forcePlasma electron

A system and apparatus for controlled fusion in a field reversed configuration (FRC) magnetic topology and conversion of fusion product energies directly to electric power. Preferably, plasma ions are magnetically confined in the FRC while plasma electrons are electrostatically confined in a deep energy well, created by tuning an externally applied magnetic field. In this configuration, ions and electrons may have adequate density and temperature so that upon collisions they are fused together by the nuclear force, thus forming fusion products that emerge in the form of an annular beam. Energy is removed from the fusion product ions as they spiral past electrodes of an inverse cyclotron converter. Advantageously, the fusion fuel plasmas that can be used with the present confinement and energy conversion system include advanced (aneutronic) fuels.

Owner:RGT UNIV OF CALIFORNIA +1

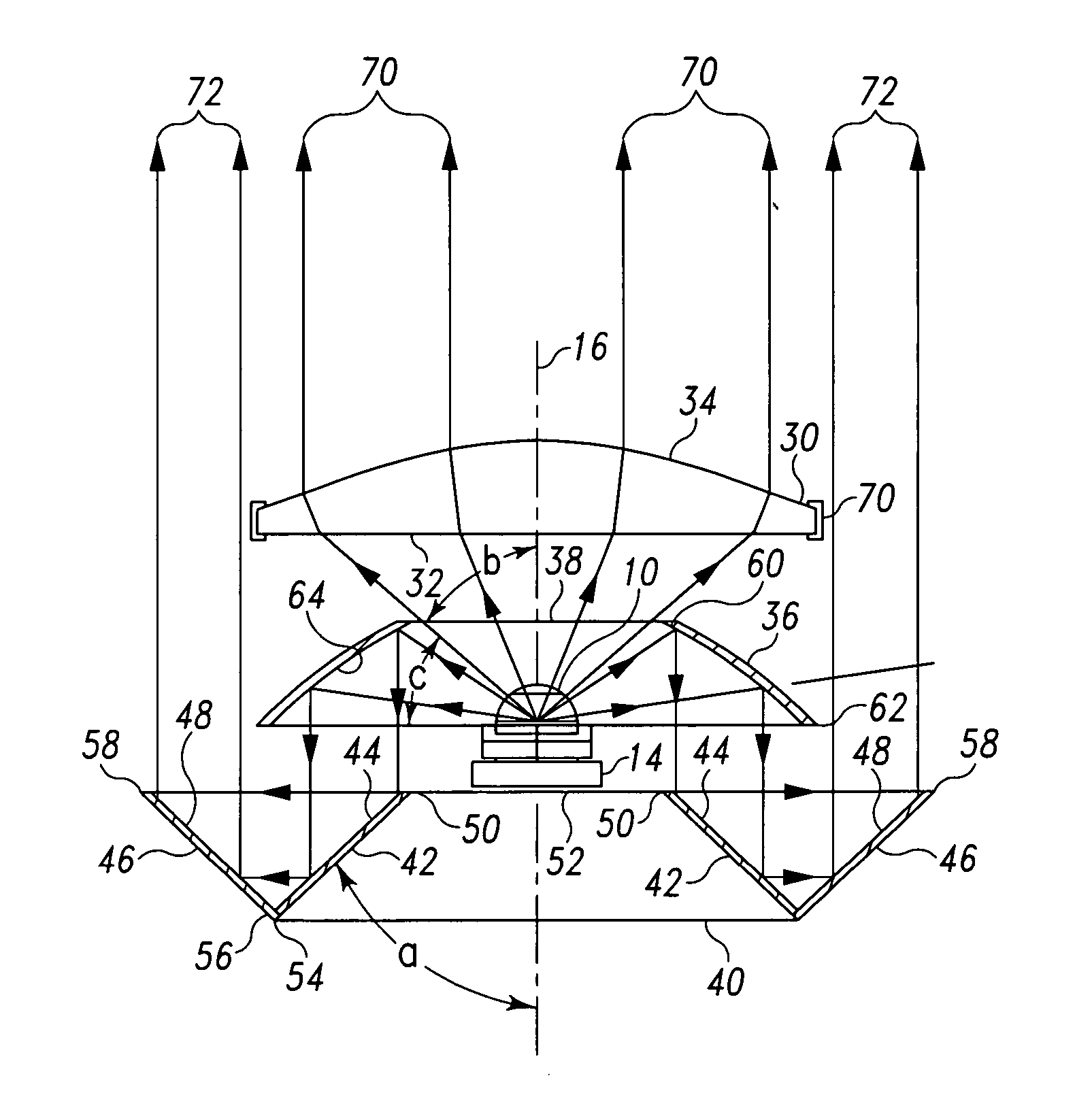

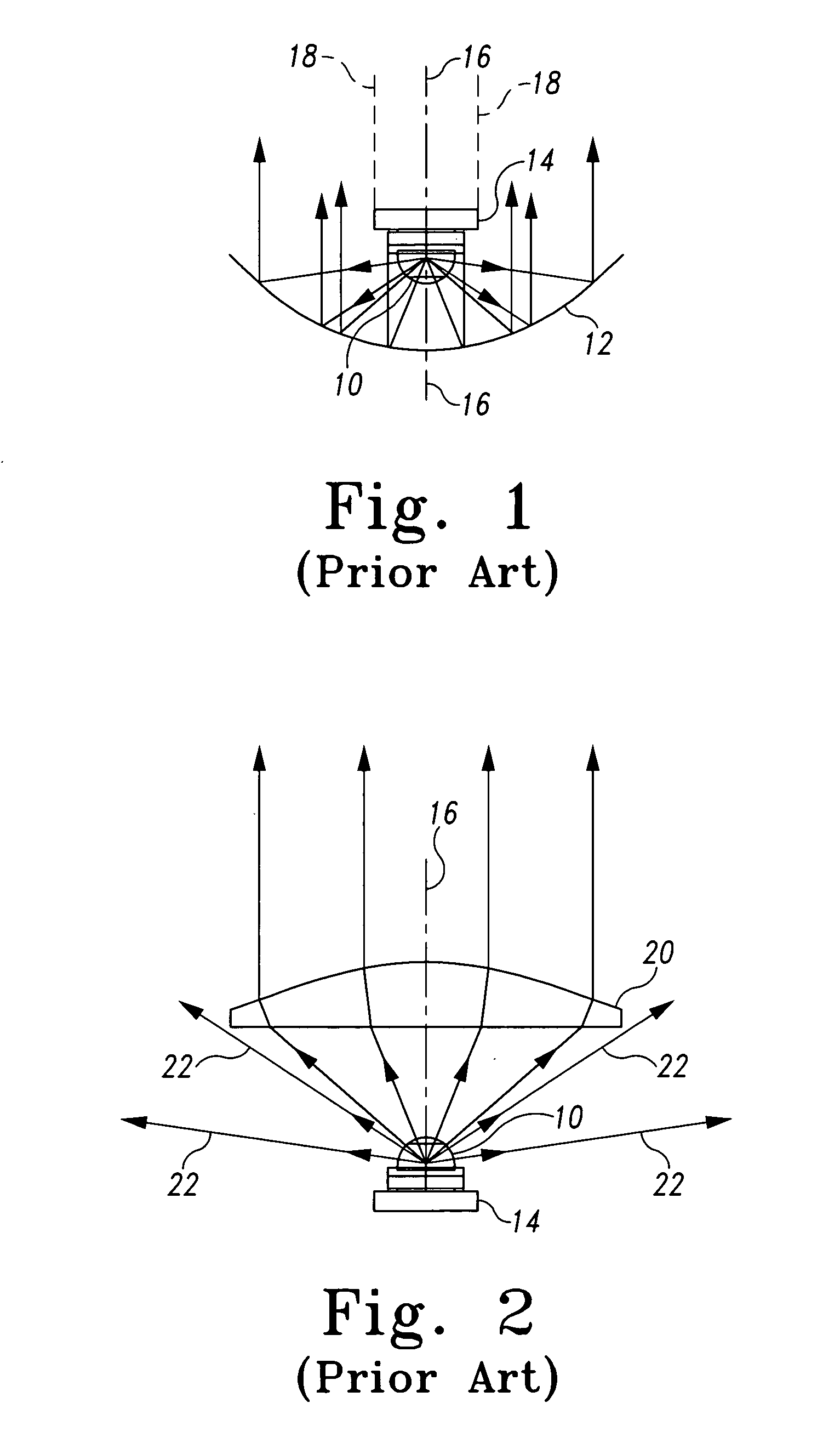

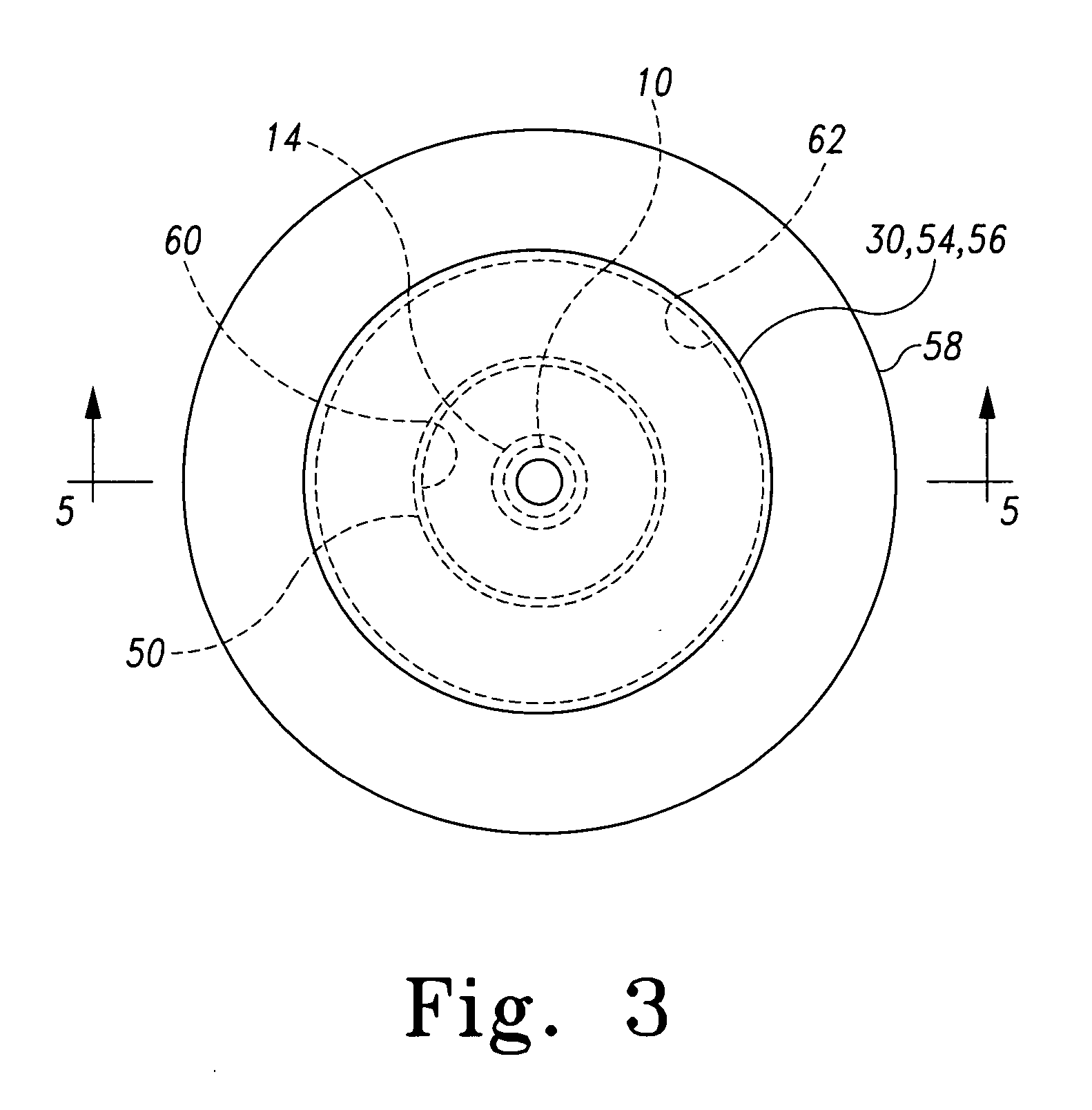

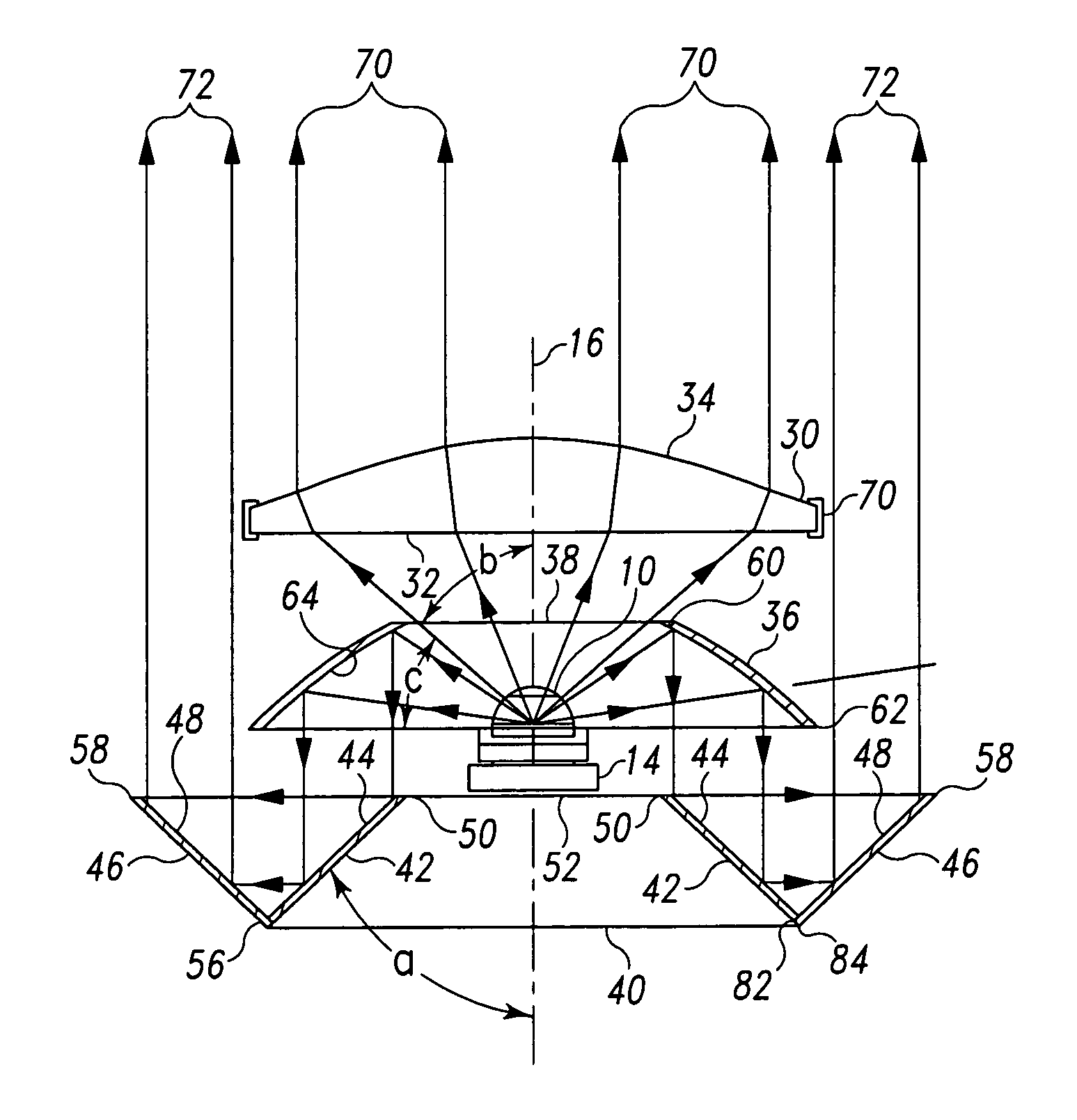

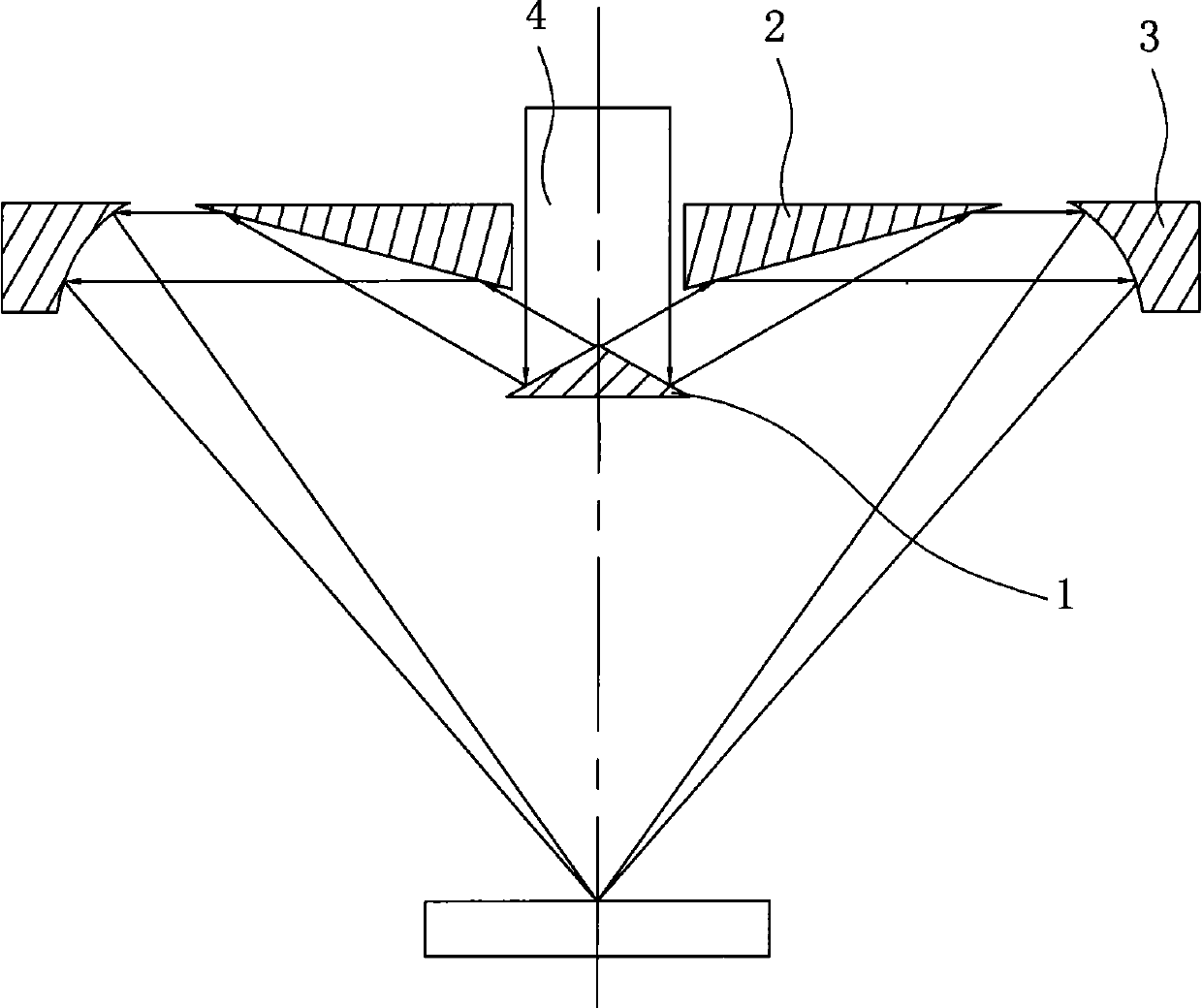

Catadioptric light distribution system

A Catadioptric Light Distribution System is disclosed. The system collects and collimates the hemispherical pattern of light emitted by a Lambertian light emitting diode (LED) into a collimated beam directed essentially parallel to the optical axis of the LED. The system comprises a circular condensing lens having a center axis that is aligned with the optical axis of the LED and which is configured to receive an collimate a portion of the light from the LED defined by a central cone of light centered around the optical axis. A parabolic reflector having circular opening formed therethrough is centered on the center axis of the parabolic reflector and is positioned around the LED to receive and redirect the light which does not form the cone that impinges upon the condensing lens in a collimated annular beam in a direction away from the condensing lens. The light reflected and culminated by the parabolic reflector is directed onto a circular annular double bounce mirror which is configured and positioned to receive the annular beam from the parabolic reflector and reflect that beam of light 180° so that it is collimated in an annular beam which passes around the edge of the condensing lens. Thus, substantially all the light emitted by the LED is culminated into a beam of light that is substantially parallel to the optical axis of the LED by either the condensing lens or by the combination of the parabolic reflector and the double bounce mirror.

Owner:GM GLOBAL TECH OPERATIONS LLC

Catadioptric light distribution system

A Catadioptric Light Distribution System that collects and collimates the hemispherical pattern of light emitted by a Lambertian light emitting diode (LED) into a collimated beam directed essentially parallel to the optical axis of the LED. The system comprises a circular condensing lens having a center axis that is aligned with the optical axis of the LED parabolic reflector having circular opening formed therethrough which is centered on the center axis of the parabolic reflector and a double bounce mirror. The light reflected and culminated by the parabolic reflector is directed onto the circular annular double bounce mirror so that this light is collimated in an annular beam which passes around the edge of the condensing lens.

Owner:GM GLOBAL TECH OPERATIONS LLC

Controlled fusion in a field reversed configuration and direct energy conversion

InactiveUS6888907B2Facilitates controlled fusionReduce eliminate anomalous transportDischarge tube luminescnet screensNuclear energy generationNuclear forcePlasma electron

A system and apparatus for controlled fusion in a field reversed configuration (FRC) magnetic topology and conversion of fusion product energies directly to electric power. Preferably, plasma ions are magnetically confined in the FRC while plasma electrons are electrostatically confined in a deep energy well, created by tuning an externally applied magnetic field. In this configuration, ions and electrons may have adequate density and temperature so that upon collisions they are fused together by the nuclear force, thus forming fusion products that emerge in the form of an annular beam. Energy is removed from the fusion product ions as they spiral past electrodes of an inverse cyclotron converter. Advantageously, the fusion fuel plasmas that can be used with the present confinement and energy conversion system include advanced (aneutronic) fuels.

Owner:RGT UNIV OF CALIFORNIA +1

Plasma electric generation and propulsion system

InactiveUS20060198485A1Facilitates controlled fusionReduce eliminate anomalous transportNuclear energy generationThermonuclear fusion reactorNuclear forcePlasma electron

A system and apparatus for controlled fusion in a field reversed configuration (FRC) magnetic topology and conversion of fusion product energies directly to electric power. Preferably, plasma ions are magnetically confined in the FRC while plasma electrons are electrostatically confined in a deep energy well, created by tuning an externally applied magnetic field. In this configuration, ions and electrons may have adequate density and temperature so that upon collisions they are fused together by the nuclear force, thus forming fusion products that emerge in the form of an annular beam. Energy is removed from the fusion product ions as they spiral past electrodes of an inverse cyclotron converter. Advantageously, the fusion fuel plasmas that can be used with the present confinement and energy conversion system include advanced (aneutronic) fuels.

Owner:RGT UNIV OF CALIFORNIA

Inductive plasma source for plasma electric generation system

ActiveUS8031824B2Facilitates controlled fusionReduce eliminate anomalous transportElectric discharge tubesNuclear energy generationNuclear forcePlasma electron

Owner:RGT UNIV OF CALIFORNIA

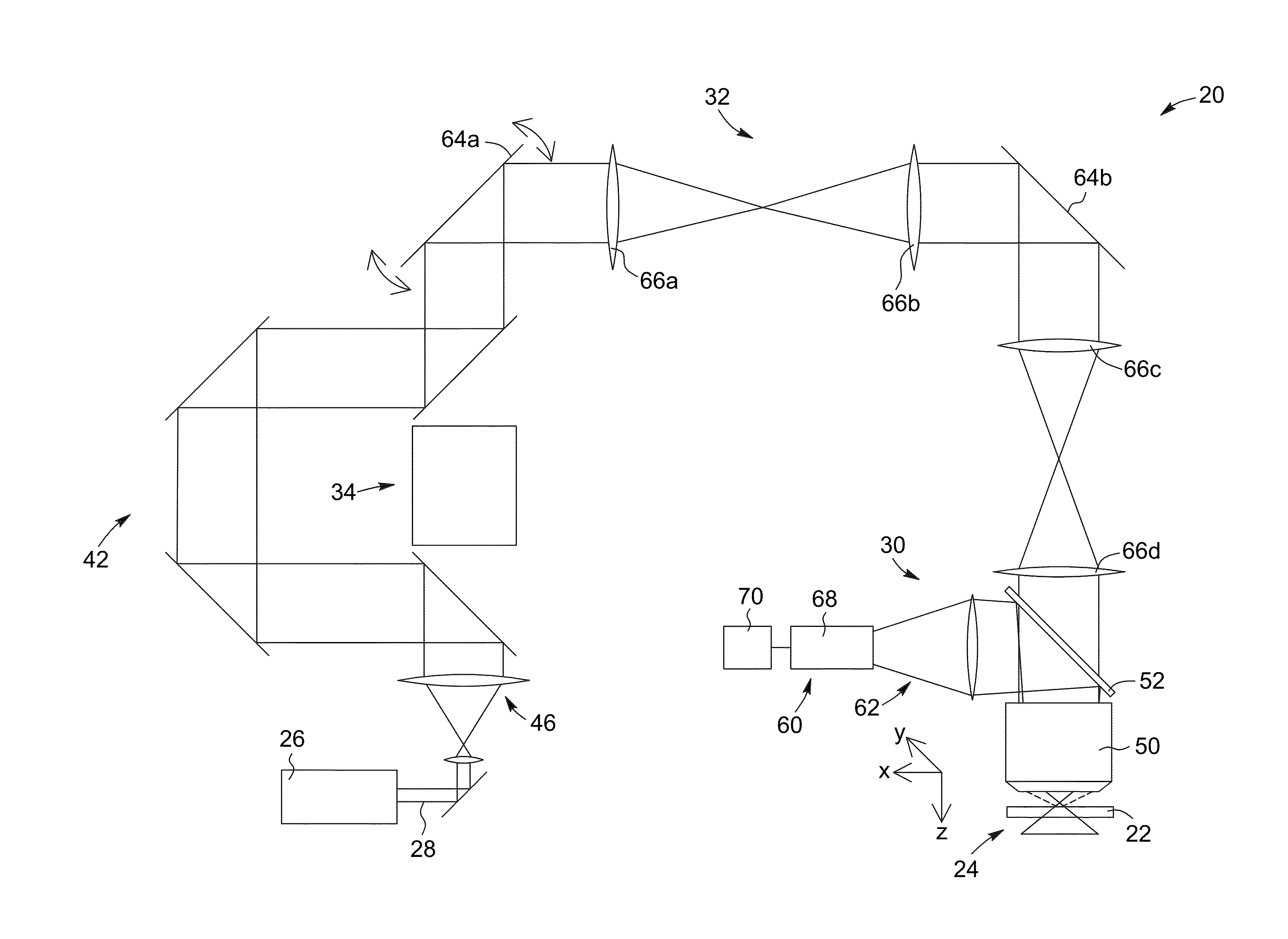

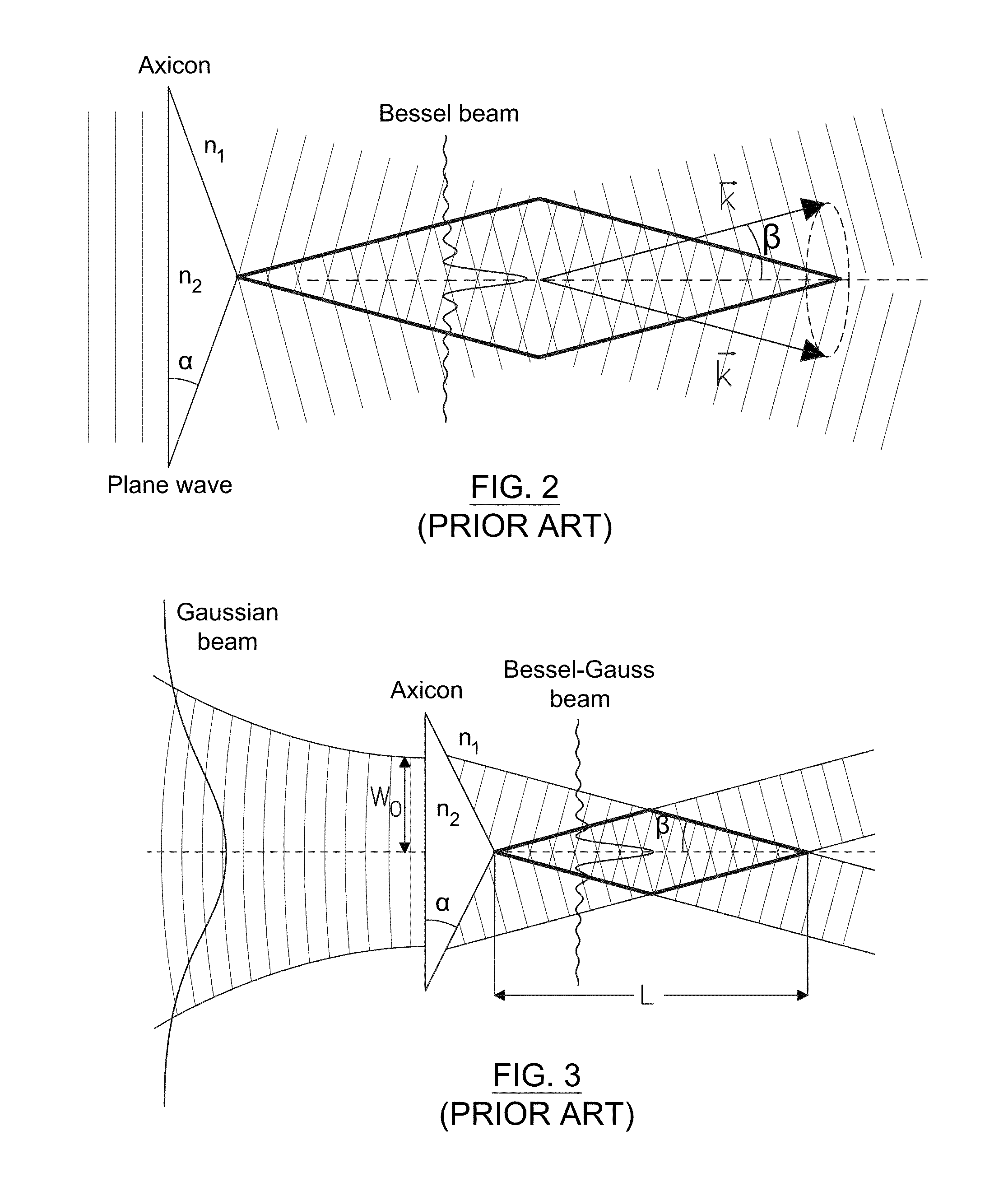

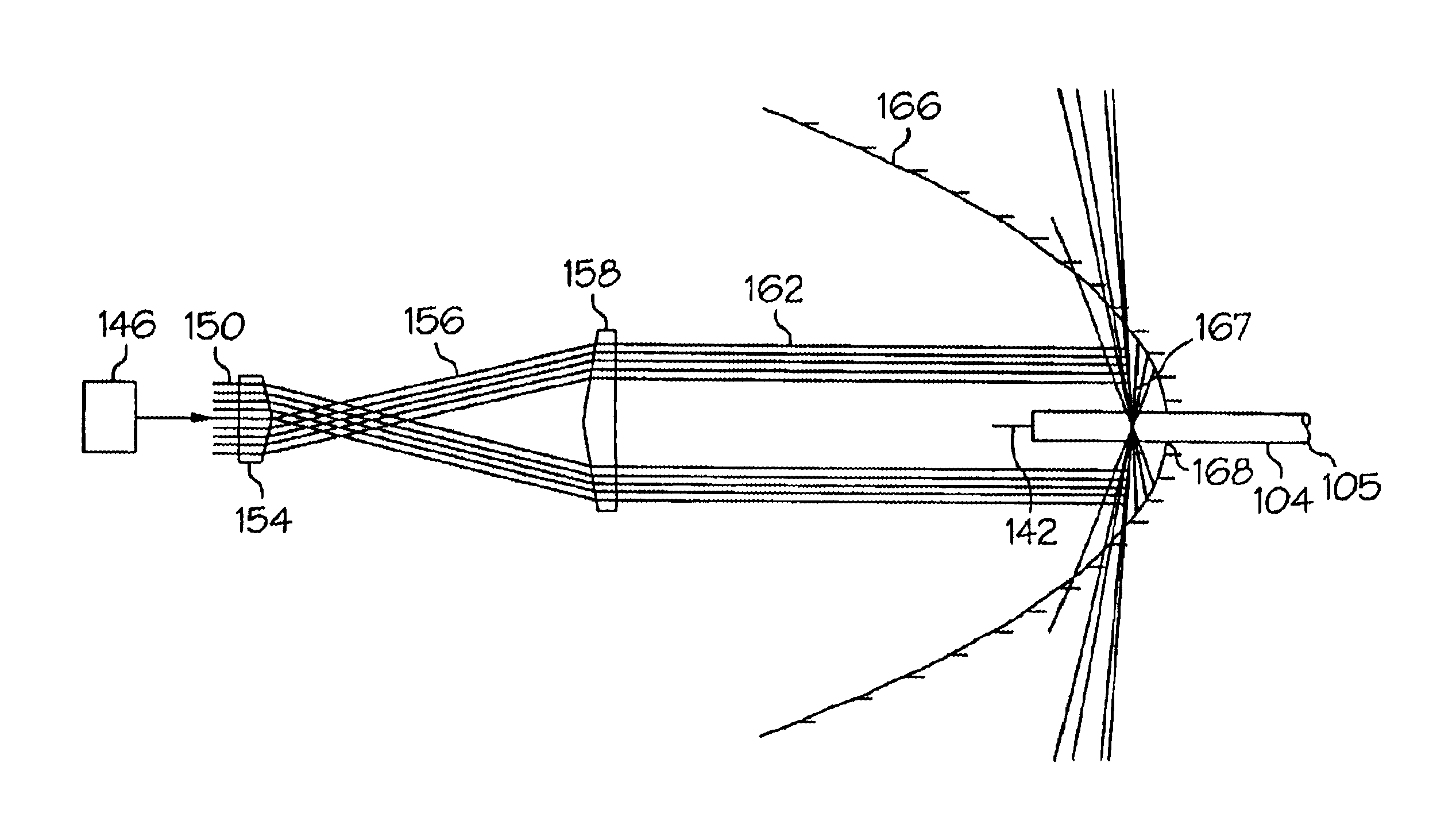

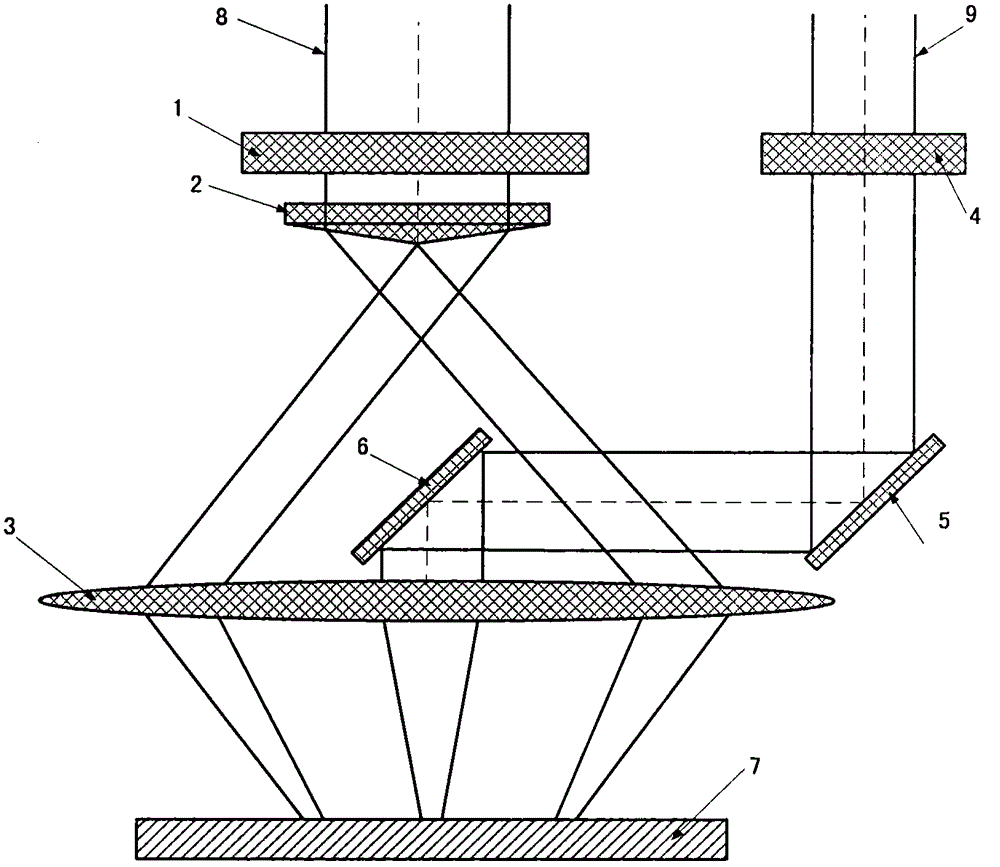

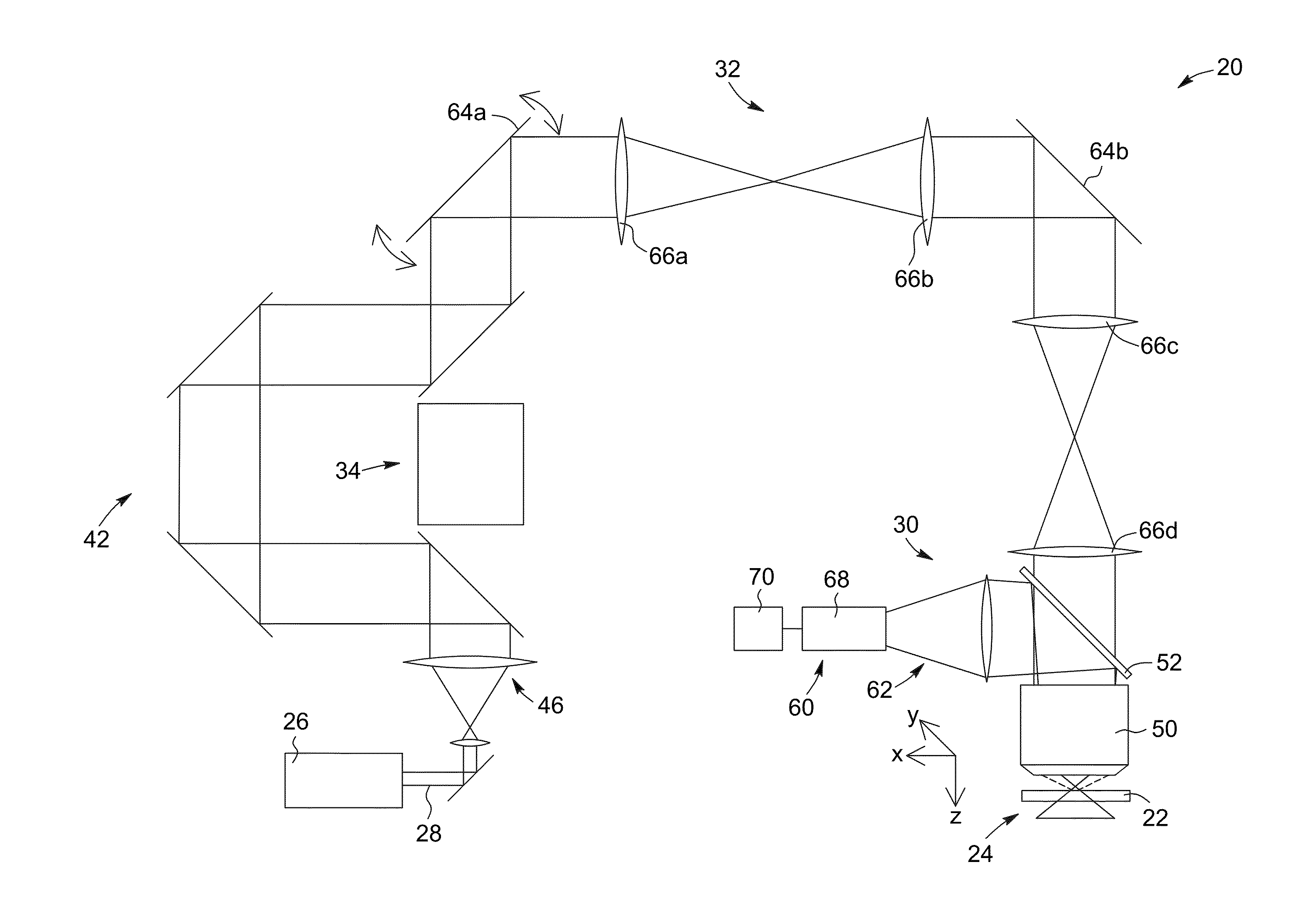

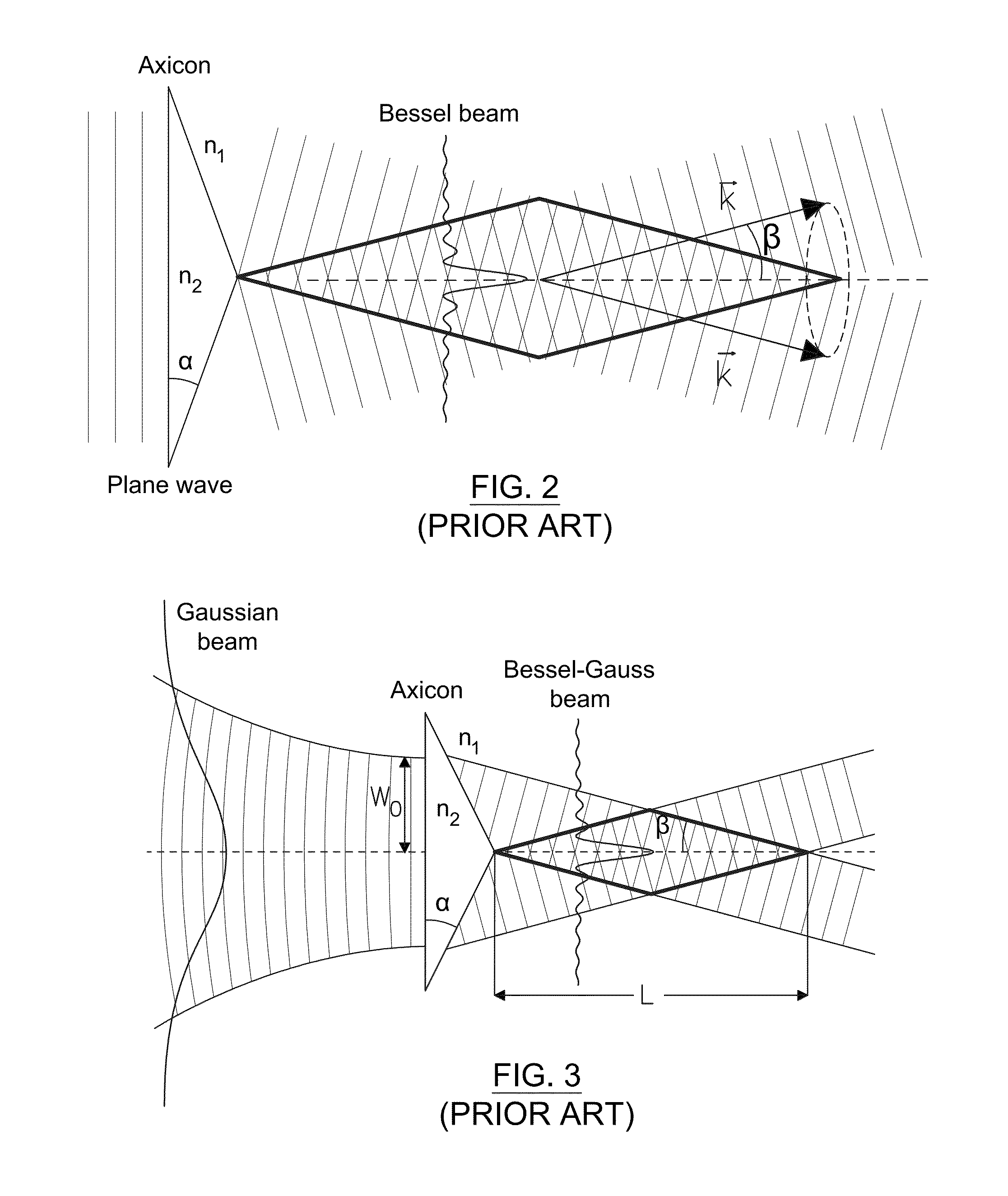

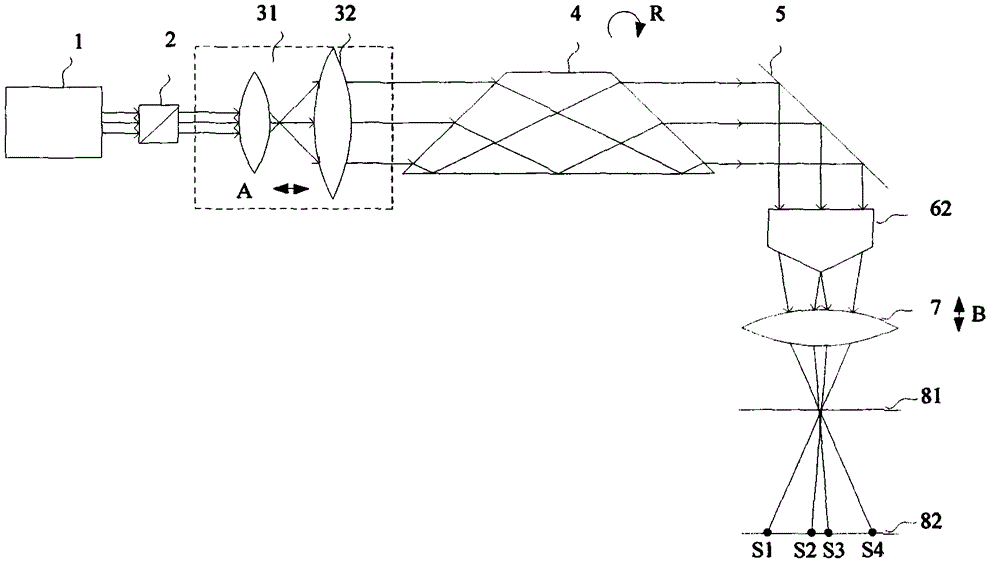

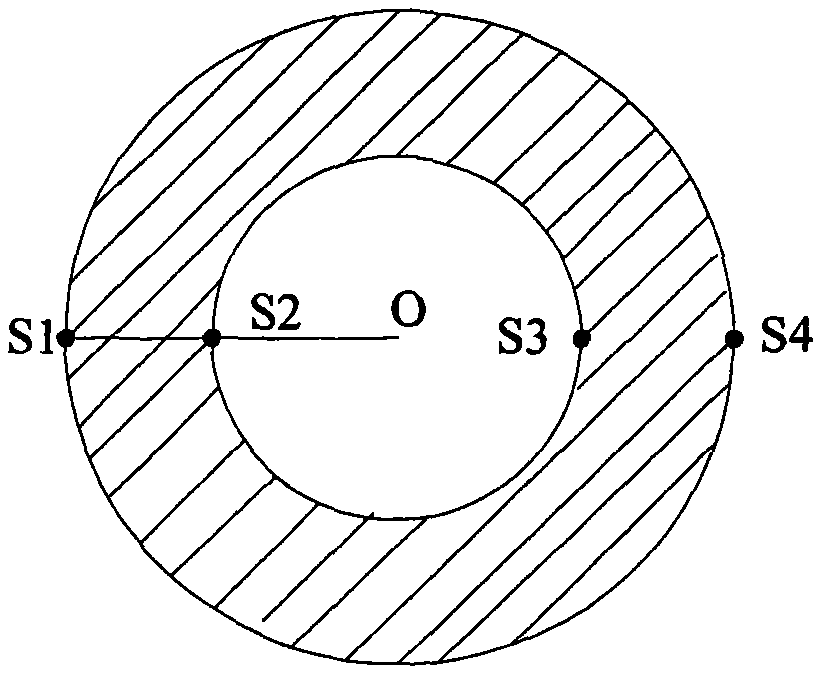

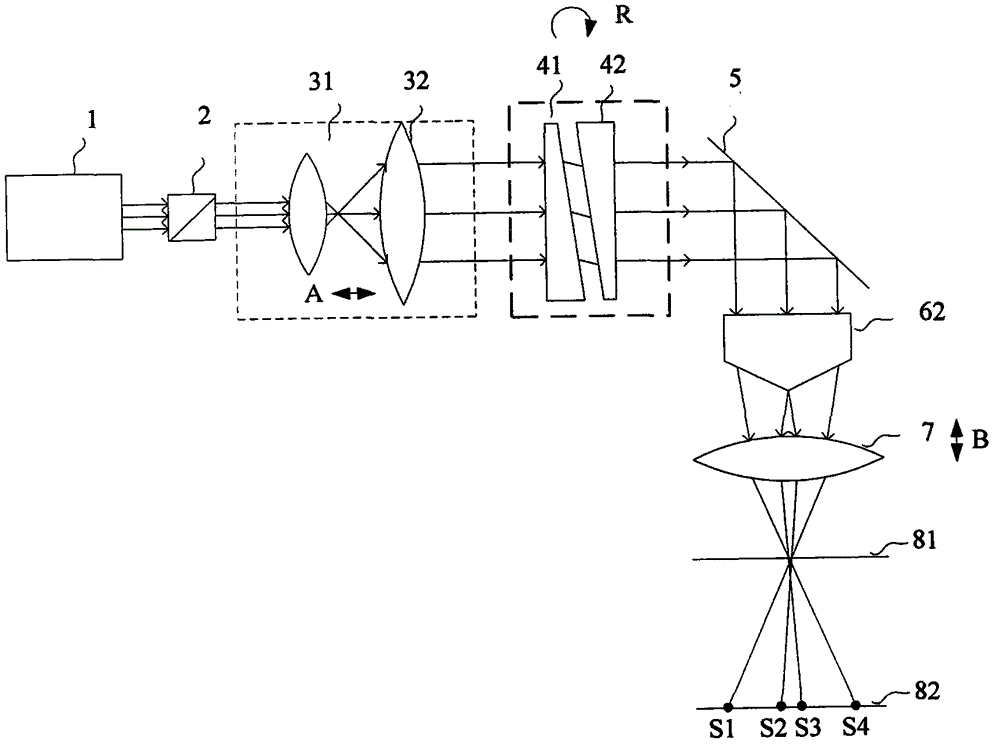

Method and system for obtaining an extended-depth-of-field volumetric image using laser scanning imaging

A laser scanning imaging system and method for obtaining an extended-depth-of-field image of a volume of a sample are provided. The system includes a laser module generating an input laser beam, a beam shaping module including an axicon and a Fourier-transform lens, and an imaging module including an objective lens and a detecting assembly. The axicon, Fourier-transform lens and objective lens are formed and disposed to successively convert the input laser beam into an intermediate non-diffracting beam, an intermediate annular beam, and an excitation non-diffracting beam. The excitation beam is projected onto the sample and has a depth of field and transverse resolution together defining a three-dimensional excitation region. The detecting assembly collects electromagnetic radiation from the excitation region to obtain one pixel of the extended-depth-of-field image. The system further includes a two-dimensional scanning module for scanning the excitation beam over the sample and build, pixel-by-pixel, the extended-depth-of-field image.

Owner:UNIV LAVAL

Vacuum chamber for plasma electric generation system

ActiveUS20060267504A1Facilitates controlled fusionReduce eliminate anomalous transportElectric discharge tubesNuclear energy generationNuclear forcePlasma electron

A system and apparatus for controlled fusion in a field reversed configuration (FRC) magnetic topology and conversion of fusion product energies directly to electric power. Preferably, plasma ions are magnetically confined in the FRC while plasma electrons are electrostatically confined in a deep energy well, created by tuning an externally applied magnetic field. In this configuration, ions and electrons may have adequate density and temperature so that upon collisions they are fused together by the nuclear force, thus forming fusion products that emerge in the form of an annular beam. Energy is removed from the fusion product ions as they spiral past electrodes of an inverse cyclotron converter. Advantageously, the fusion fuel plasmas that can be used with the present confinement and energy conversion system include advanced (aneutronic) fuels.

Owner:RGT UNIV OF CALIFORNIA

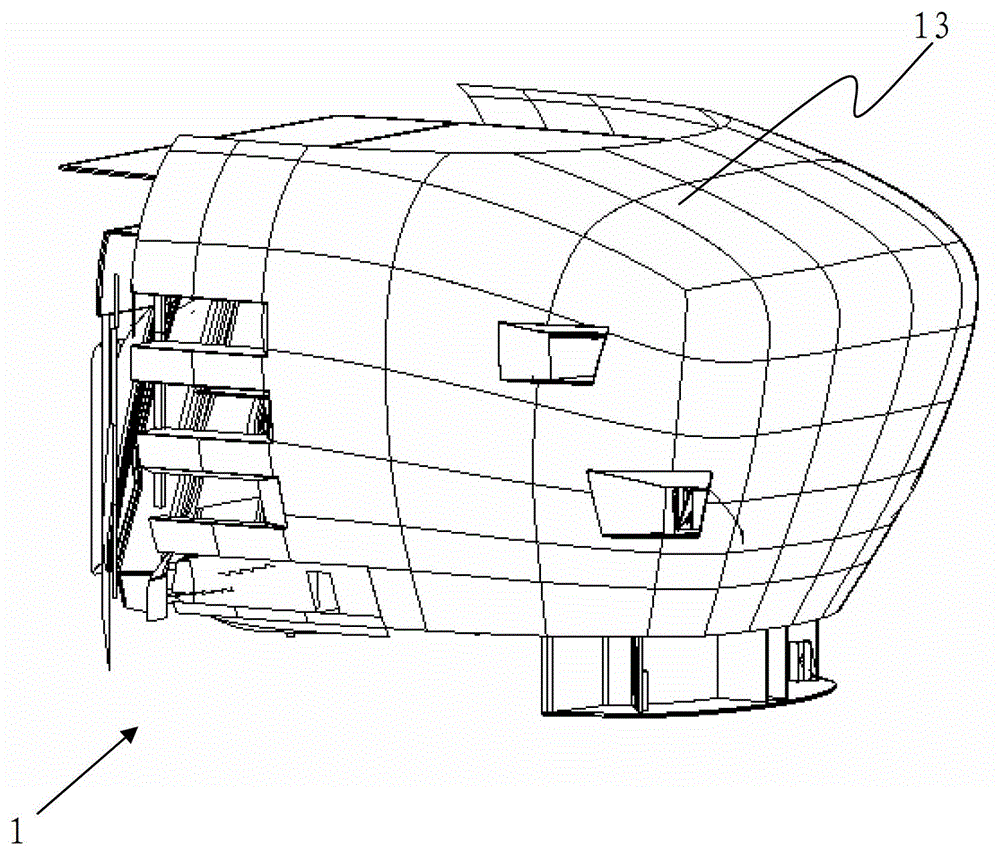

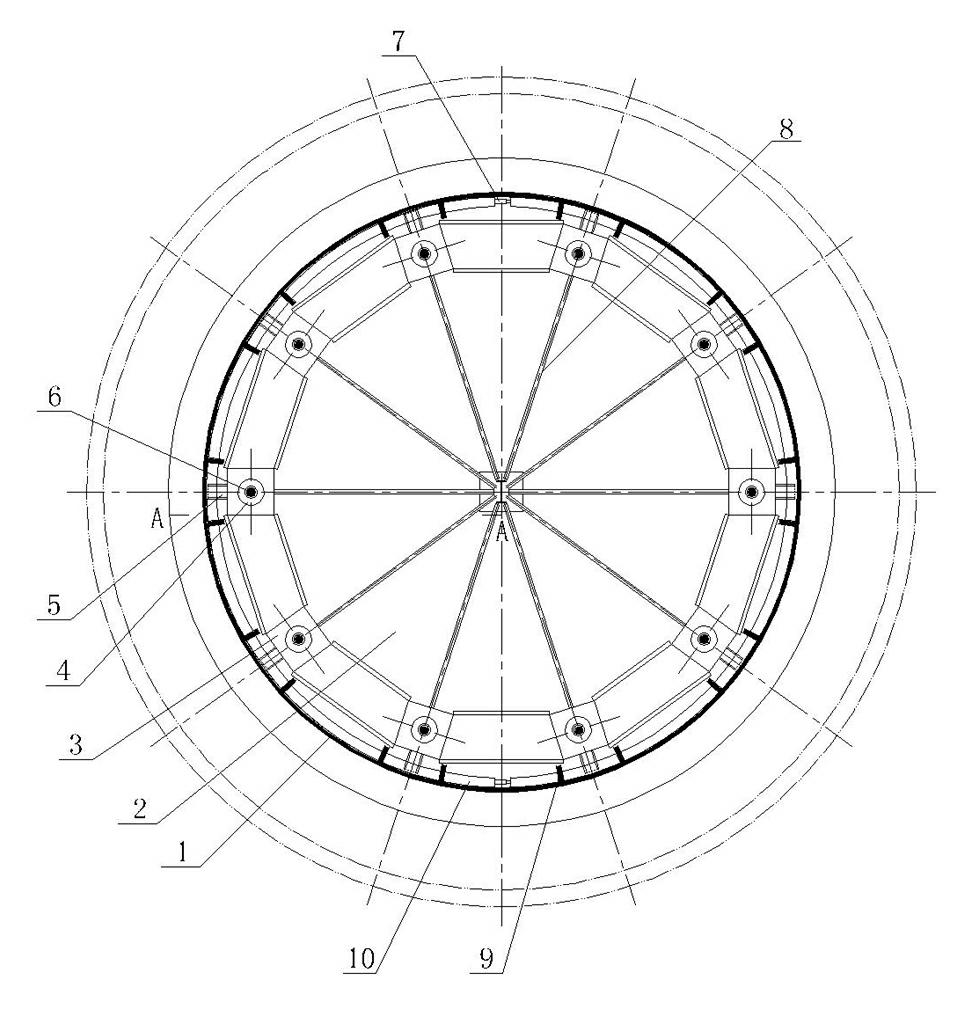

Annular ring and non-pneumatic tire

The present invention provides an annular beam of monolithic construction of one homogeneous material and a related efficient, low-cost non-pneumatic tire. Specific geometric design, combined with nonlinear elastomer physical properties, enable the suppression of all reinforcing belts, continuous fibers, or other strengthening layers in the annular beam. The annular beam consists of at least two bands that are continuous in the circumferential direction and connected by a web geometry. The non-pneumatic tire consists of the annular beam, a ground contacting portion, a central wheel, and a plurality of web spokes that connect the wheel and beam. When the tire is loaded to a design load against a flat surface over a design contact length, a contact area of essentially uniform pressure is produced, while the load is transmitted from the beam to the hub via tension in the web spokes. The tire can be economically manufactured.

Owner:CAMOPLASY INC

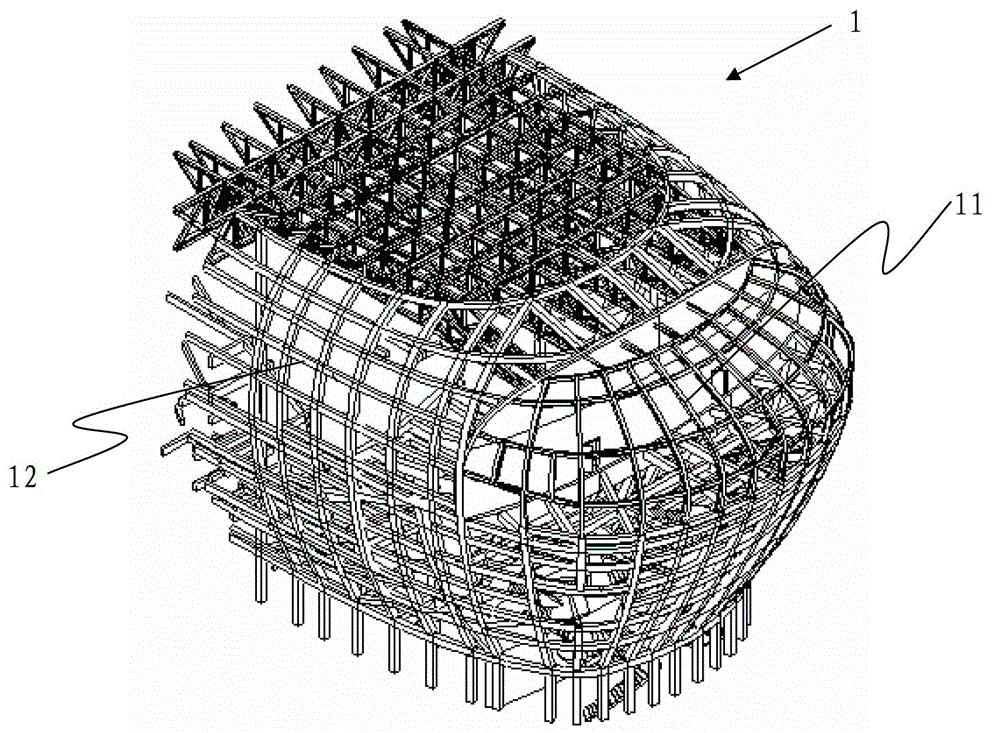

Construction method of large-sized arc-shaped wall

The invention discloses a construction method of a large-sized arc-shaped wall. The method mainly comprises the following steps of: measuring and positioning; erecting a scaffold; mounting an arc-shaped in-column section steel column; binding a steel bar on the periphery of the section steel column; measuring and positioning, mounting an arc-shaped annular beam inner steel bar on the section steel column, and binding and fixing; mounting and fixing an arc-shaped column and an arc-shaped annular beam template on the steel bar; pouring concrete to form the arc-shaped column and an arc-shaped annular beam; measuring and manufacturing an arc-shaped plate; and mounting and fixing the arc-shaped plate on the arc-shaped column and the arc-shaped annular beam. According to the construction method of the large-sized arc-shaped wall, vertical sectioned construction is adopted, inner section steel and a steel bar structure of the arc-shaped column and the arc-shaped annular beam are erected layer by layer; the template is bound and is poured and molded; the poured arc-shaped column and the arc-shaped annular beam are continually provided with the upper-layer arc-shaped column and the arc-shaped annular beam; and finally, the arc-shaped plate which is designed and manufactured outside a field is mounted on the arc-shaped column and the arc-shaped annular beam, and process improvement can be carried out according to implementation effects.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

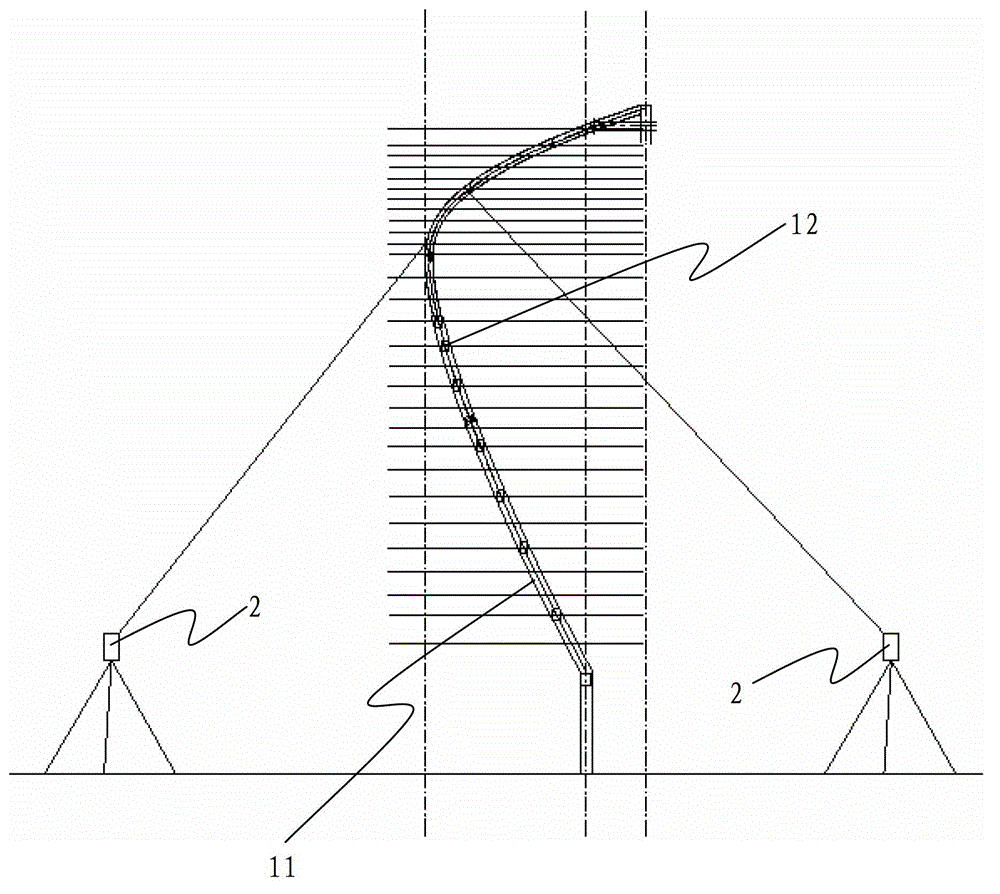

Hydraulic lifting inverted construction method for steel inner cylinder of chimney in thermal power plant

InactiveCN102108737AReduce investmentReduce construction costsBuilding constructionsTowersAnnular beamHydraulic pressure

The invention discloses a hydraulic lifting inverted construction method for a steel inner cylinder of a chimney in a thermal power plant, which comprises the following steps: (1) dividing the steel inner cylinder into a plurality of cylinder sections, and dividing each cylinder section into a plurality of cylinder sheets; (2) manufacturing a jack stand base in the steel inner cylinder, and mounting a hydraulic lifting device and a construction platform on the jack stand base; (3) beginning to assemble the first cylinder section of the steel inner cylinder, welding a plurality of sets of door-shaped clips on the inner wall of the first cylinder section along a circumferential direction, and clipping the horizontal annular beam by the door-shaped clips; (4) lifting the assembled cylinder section to the height of the first cylinder section by using the hydraulic lifting device, assembling a next cylinder section and welding the next cylinder section with the previous cylinder section; (5) cutting off the door-shaped clips and transferring and mounting the door-shaped clips and the horizontal annular beam to the corresponding position of the next cylinder section; and (6) repeatedly circulating the steps (4) and (5), and mounting the subsequent cylinder sections in turn. The method has the advantages that: the construction cost is low; the stress is definite, the operation is simple and convenient, and the safety factor is high; and the construction period is short and the project quality is high.

Owner:DONGDIAN YANTA ENG

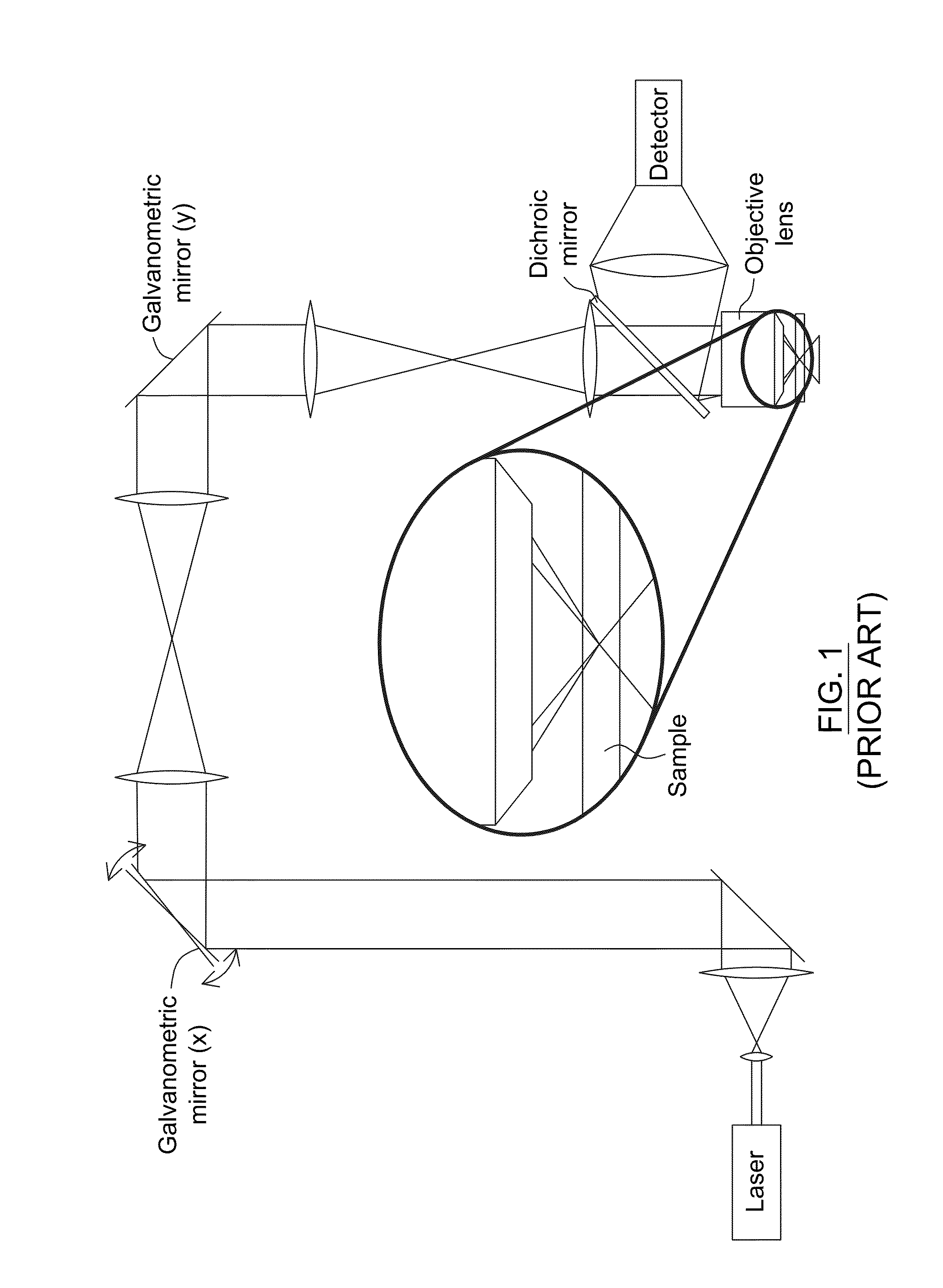

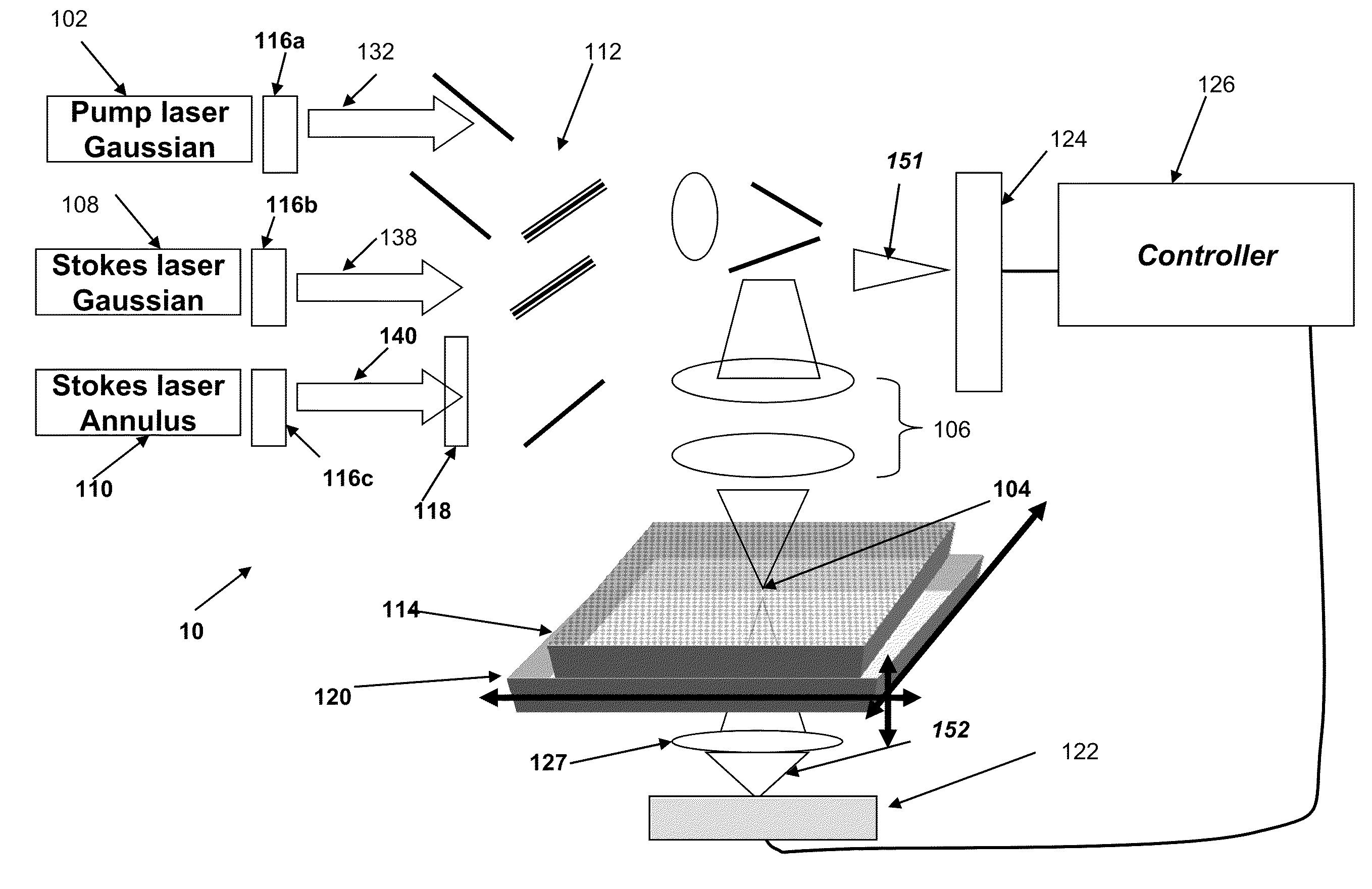

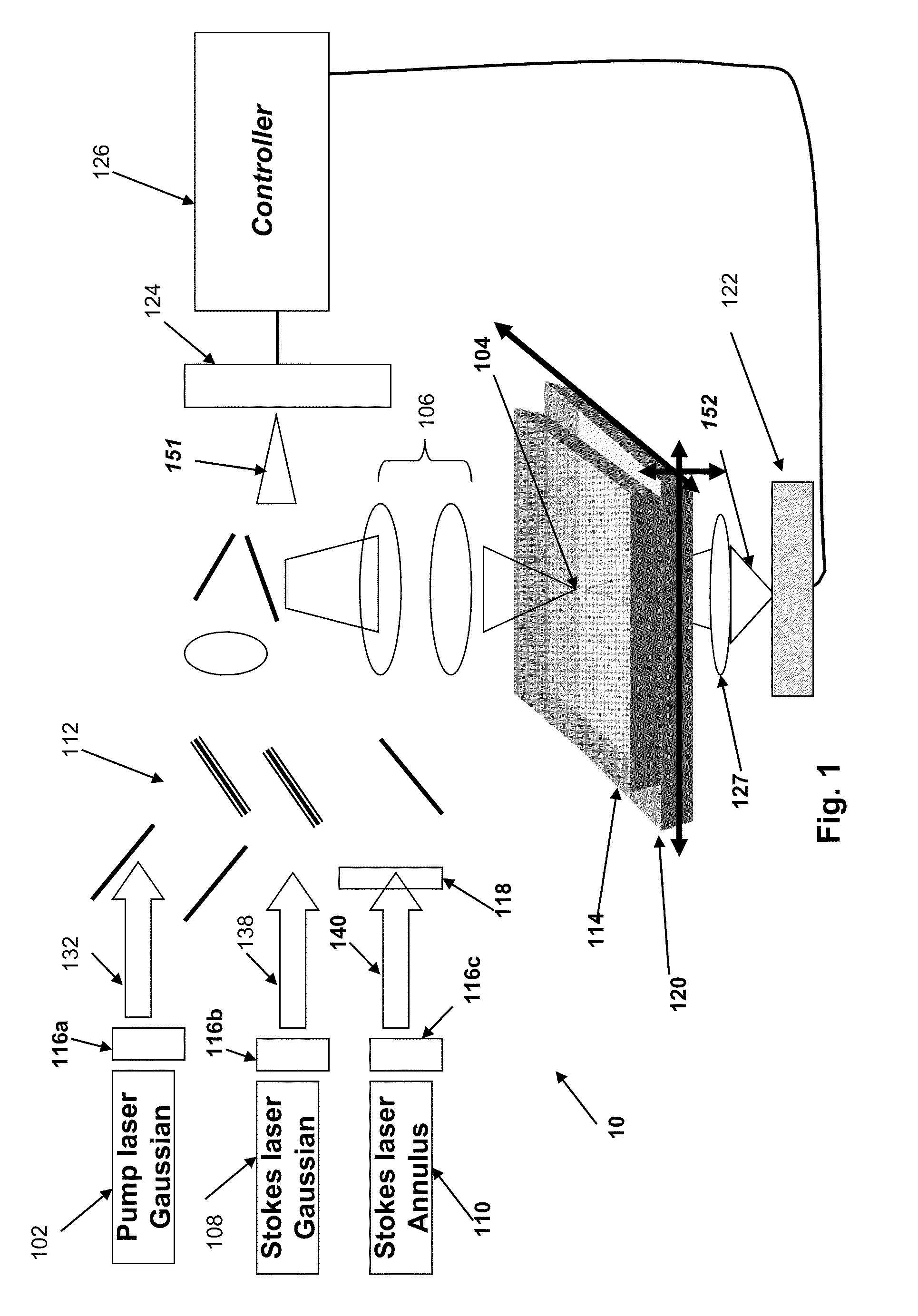

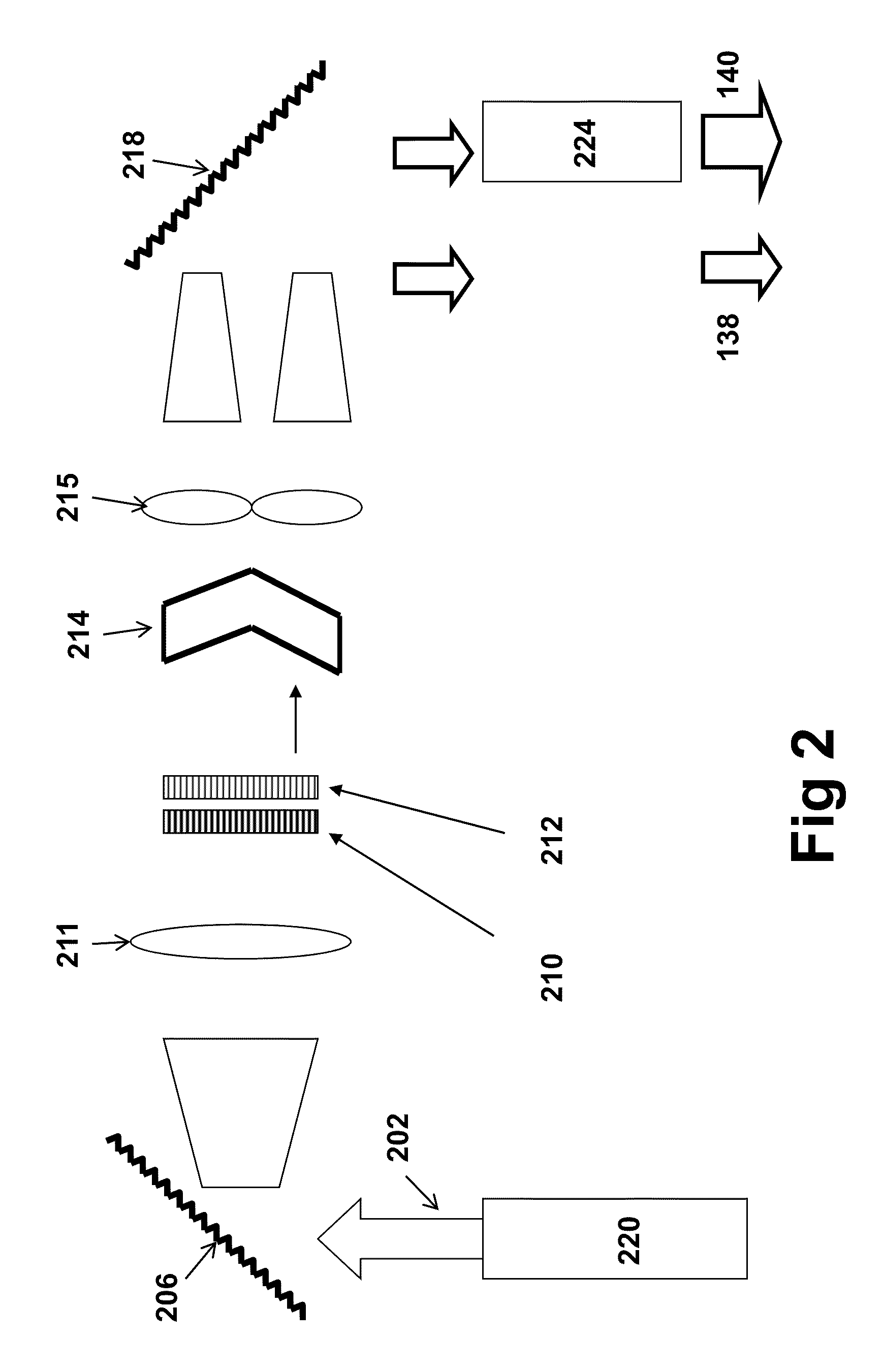

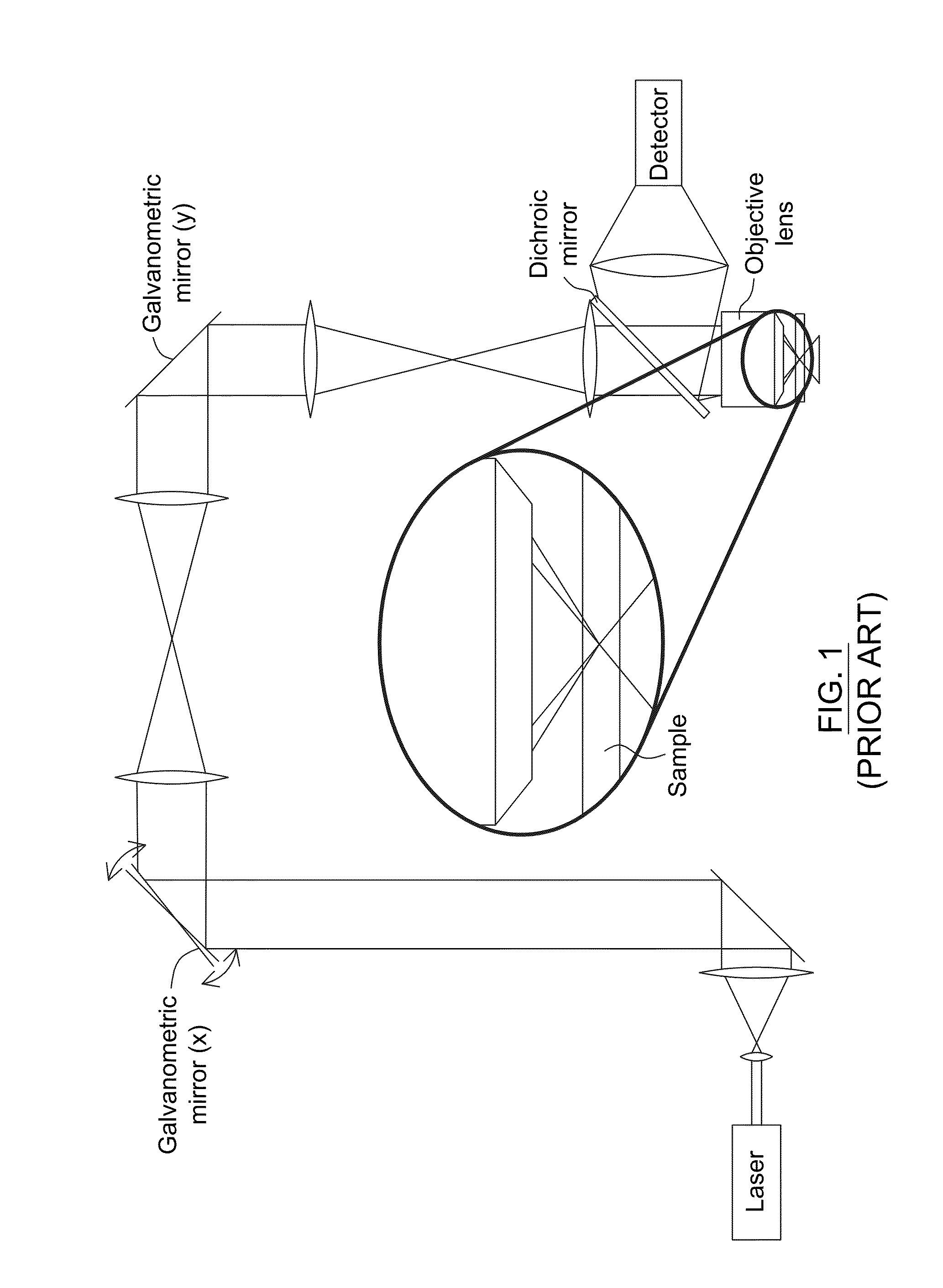

Method and system for stimulated Raman microscopy beyond the diffraction limit

Systems and methods for probing a Raman signature of a sample with a resolution exceeding the diffraction limit are described. These systems, called GASSE (Gain Saturated Stimulated Emission) and iGASSE (interferometric GASSE), are detecting a Raman signal produced in a sample located at the focal spot of a Gaussian pump pulse. Two additional pulsed laser beams (Stokes beams), a central Stokes beam having a Gaussian beam profile and another Stokes beam having an annular beam profile, are also focused to the focal spot. The spatial and temporal phases of the laser pulses are adjusted to produce destructive interference over most of the temporal width of Stokes pulses, which causes emission from the central Stokes beam to narrow well below the diffraction limit. A two-dimensional image of the sample is produced by scanning the combined beams across the sample. The system may find applications in biomedical and semiconductor technology.

Owner:FREL ROBERT D

RF current drive for plasma electric generation system

ActiveUS20060254520A1Facilitates controlled fusionReduce eliminate anomalous transportElectric discharge tubesNuclear energy generationNuclear forcePlasma electron

A system and apparatus for controlled fusion in a field reversed configuration (FRC) magnetic topology and conversion of fusion product energies directly to electric power. Preferably, plasma ions are magnetically confined in the FRC while plasma electrons are electrostatically confined in a deep energy well, created by tuning an externally applied magnetic field. In this configuration, ions and electrons may have adequate density and temperature so that upon collisions they are fused together by the nuclear force, thus forming fusion products that emerge in the form of an annular beam. Energy is removed from the fusion product ions as they spiral past electrodes of an inverse cyclotron converter. Advantageously, the fusion fuel plasmas that can be used with the present confinement and energy conversion system include advanced (aneutronic) fuels.

Owner:RGT UNIV OF CALIFORNIA

Coaxial cable connector with radio frequency interference and grounding shield

ActiveUS9190744B2Smooth rotationCoupling device detailsClamped/spring connectionsCoaxial cableSpring force

A radio frequency interference (RFI) and grounding shield for a coaxial cable connector is disclosed. The shield comprises a circular inner segment and at least one arcuately shaped pre-formed cantilevered annular beam attached to the circular inner segment by a joining segment. The at least one pre-formed cantilevered annular beam extends angularly from a plane of the circular inner segment. The at least one pre-formed cantilevered annular beam applies a spring-force to a surface of the surface of a component of the coaxial cable connector establishing an electrically conductive path between the components. The at least one pre-formed cantilevered annular beam comprises an outer surface with a knife-like edge that provides a wiping action of surface oxides on component surfaces of the coaxial cable connector and allows for unrestricted movement when the coaxial cable connector is attached to an equipment connection port of an appliance.

Owner:PPC BROADBAND INC

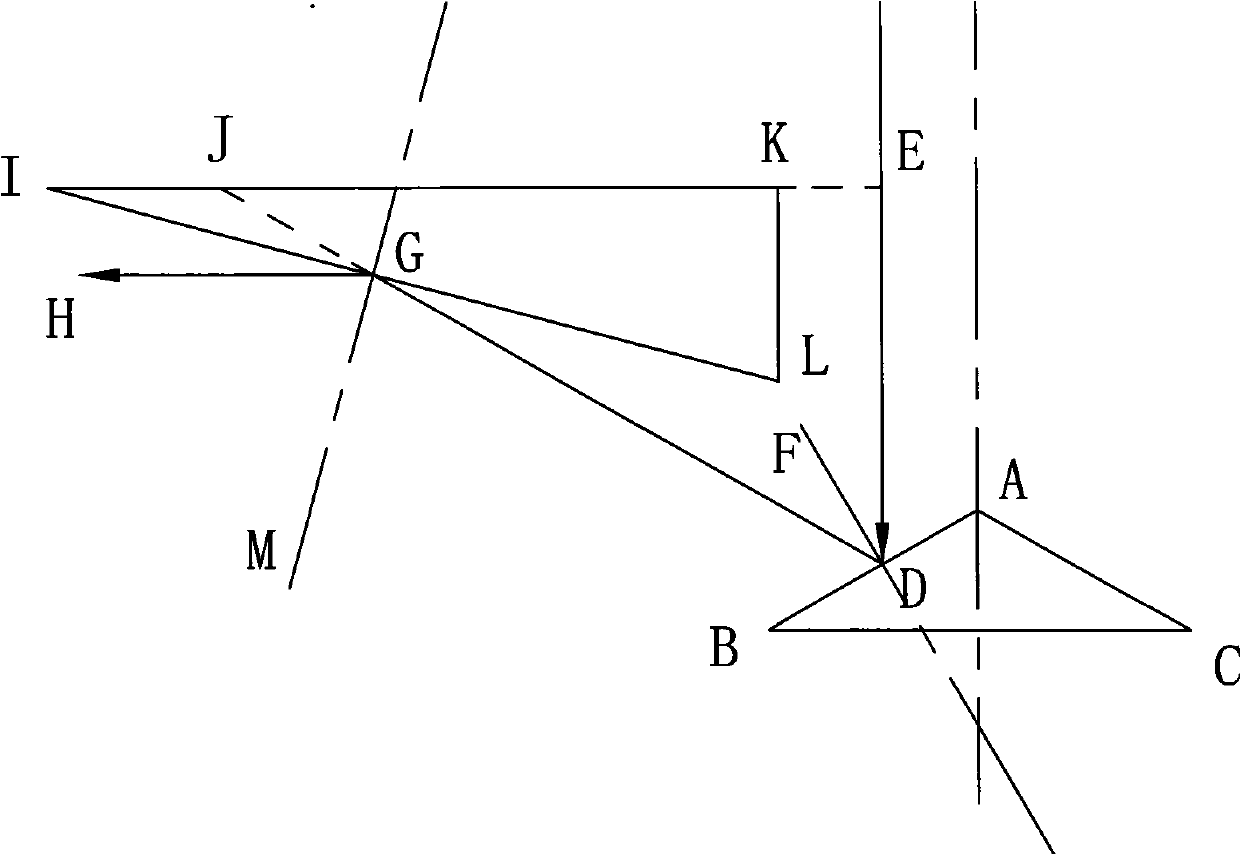

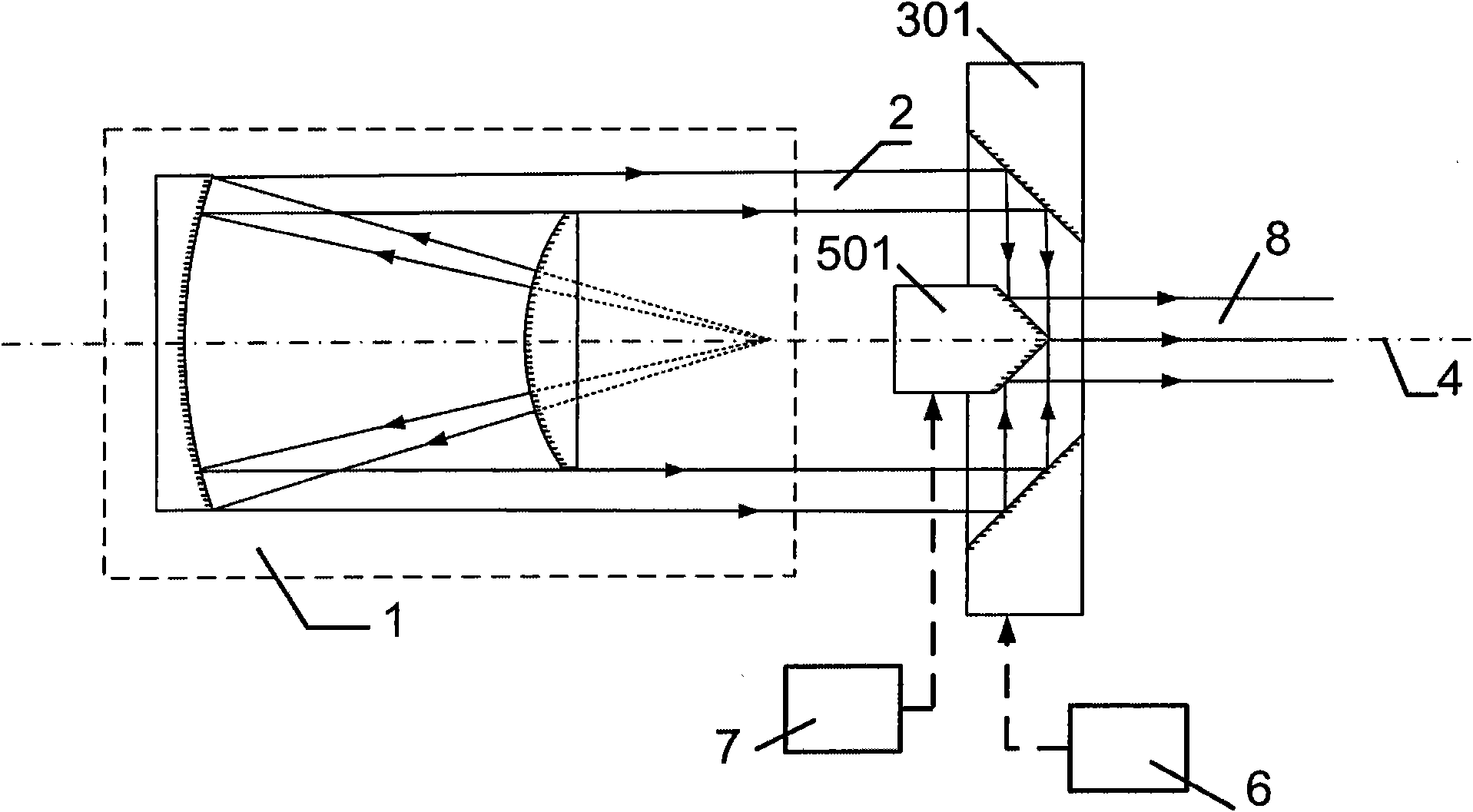

Method and device for realizing laser focusing

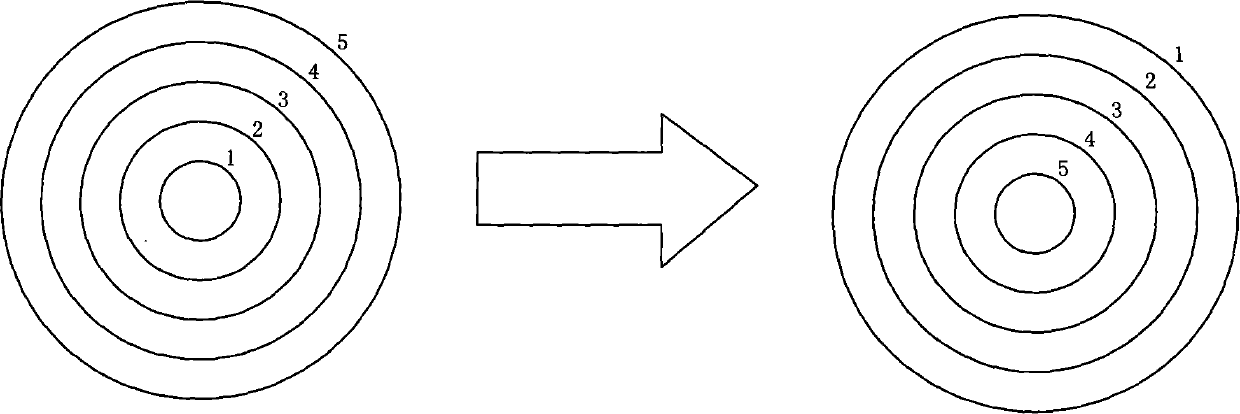

InactiveCN101770076APlay a focal roleFocusLaser beam welding apparatusOptical elementsLight spotLight beam

The invention discloses a method for realizing laser focusing, which utilizes reflection of a reflector and focusing of a focus lens to exchange an inner position and an outer position of a light spot of a laser beam in rings along the radial direction and to focalize. The method is characterized by comprising the following steps: the laser beam is reflected to a turbinate annular beam; the turbinate annular beam is converted into an annular beam; the annular beam is focused, so as to form an annular conical beam, and a hollow conical dark area is formed in the middle of the annular conical beam, thus obtaining a focusing spot of hollow annular light. The method solves the defects of laser focusing in the prior art and obtains a focusing spot with strong light encompassing weak light, almost uniform energy distribution and small gradient, thus improving the processing effect.

Owner:SUZHOU LEAD LASER TECH

Plasma electric generation system

A system and apparatus for controlled fusion in a field reversed configuration (FRC) magnetic topology and conversion of fusion product energies directly to electric power. Preferably, plasma ions are magnetically confined in the FRC while plasma electrons are electrostatically confined in a deep energy well, created by tuning an externally applied magnetic field. In this configuration, ions and electrons may have adequate density and temperature so that upon collisions they are fused together by the nuclear force, thus forming fusion products that emerge in the form of an annular beam. Energy is removed from the fusion product ions as they spiral past electrodes of an inverse cyclotron converter. Advantageously, the fusion fuel plasmas that can be used with the present confinement and energy conversion system include advanced (aneutronic) fuels.

Owner:RGT UNIV OF CALIFORNIA

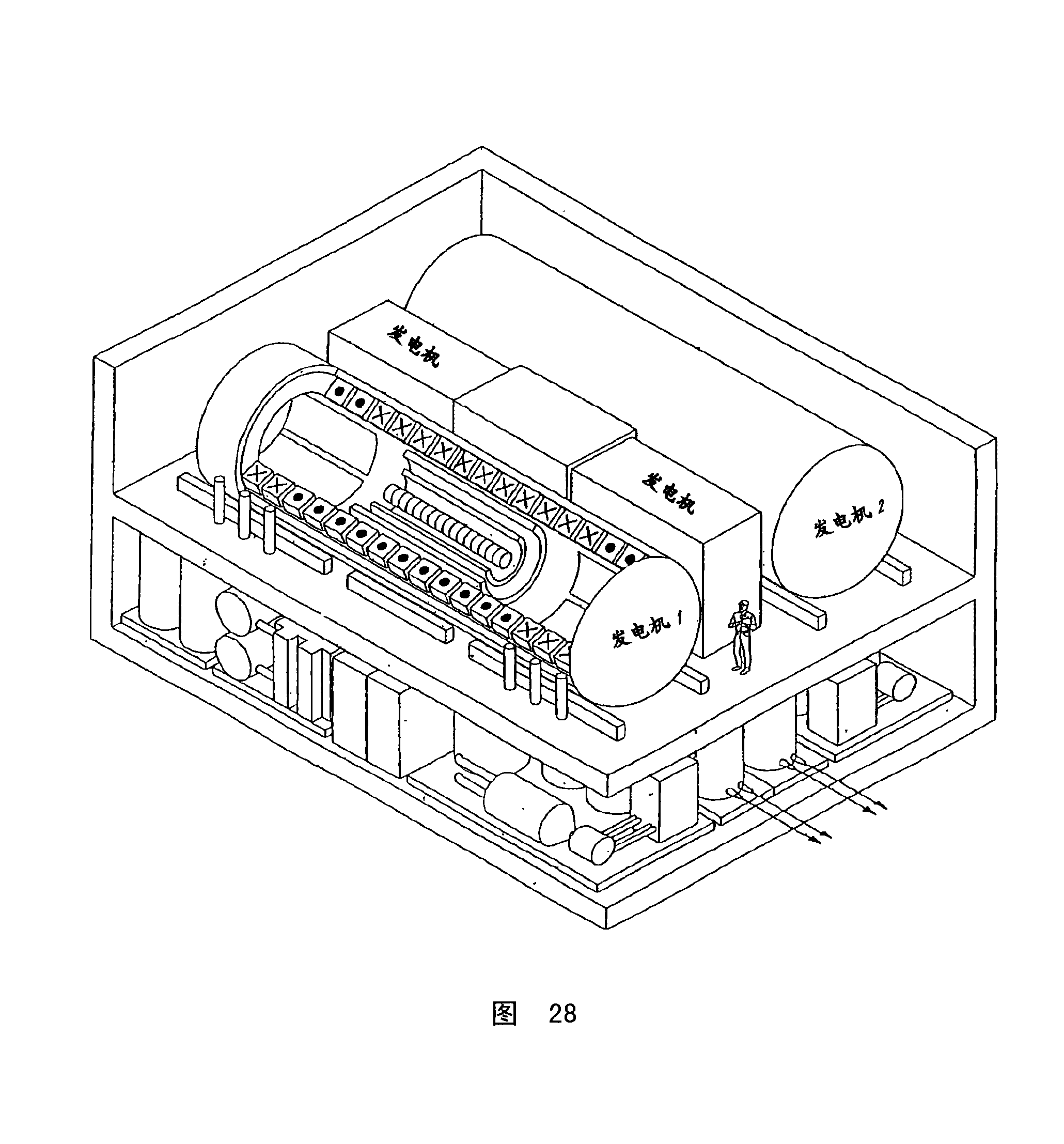

Plasma Power Generation System

The present invention relates to a plasma power generation system. A system and device for controlling fusion and direct-to-electricity conversion of fusion product energy in a field reverse configuration (FRC) magnetic topology. Preferably, the plasma ions are magnetically confined in the FRC, while the plasma electrons are electrostatically confined in a deep energy well created by tuning the applied magnetic field. In this configuration, the ions and electrons can be of such density and temperature that upon collision they are fused together by nuclear forces to form fusion products in the form of a ring beam. As the fusion product ions spiral through the electrodes of the inverse cyclotron converter, energy is removed from them. Advantageously, fusion fuel plasmas usable with the present confinement and energy conversion system include advanced (non-neutron) fuels.

Owner:RGT UNIV OF CALIFORNIA

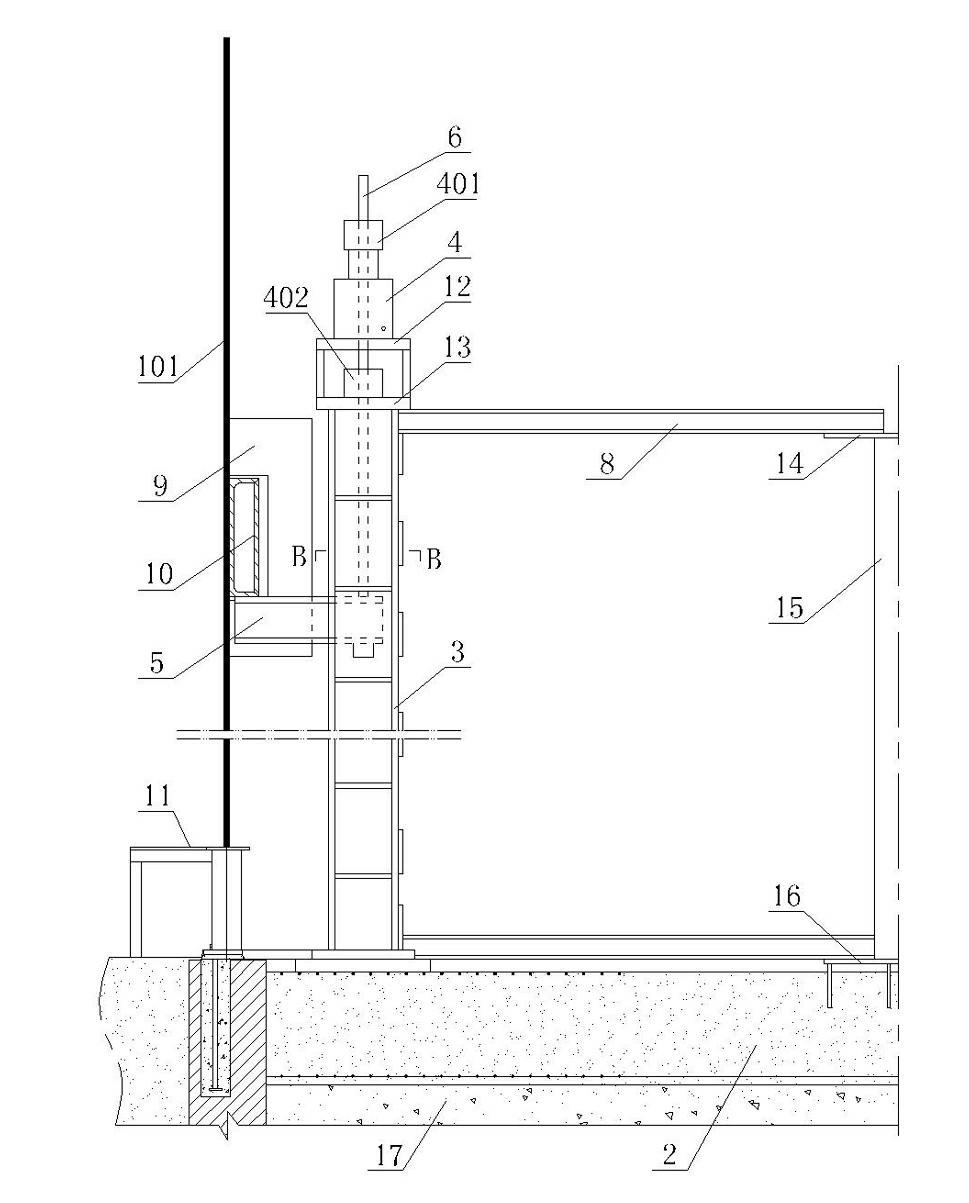

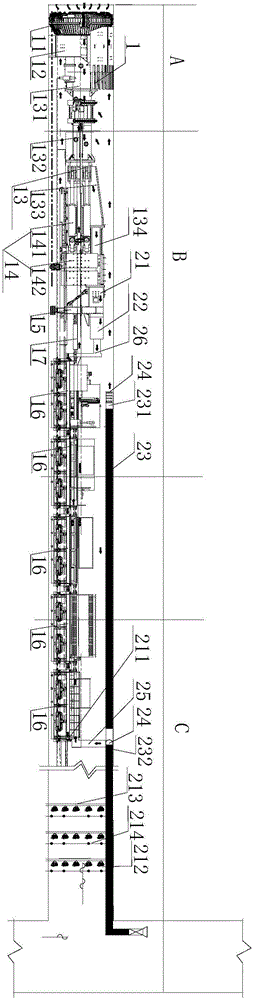

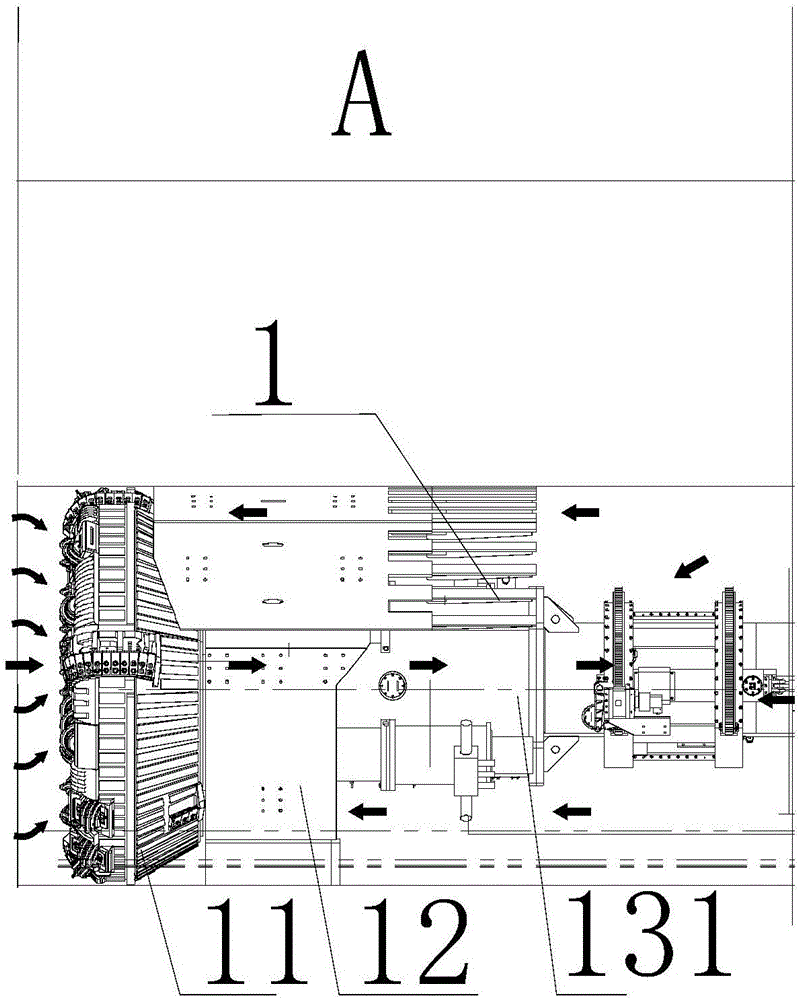

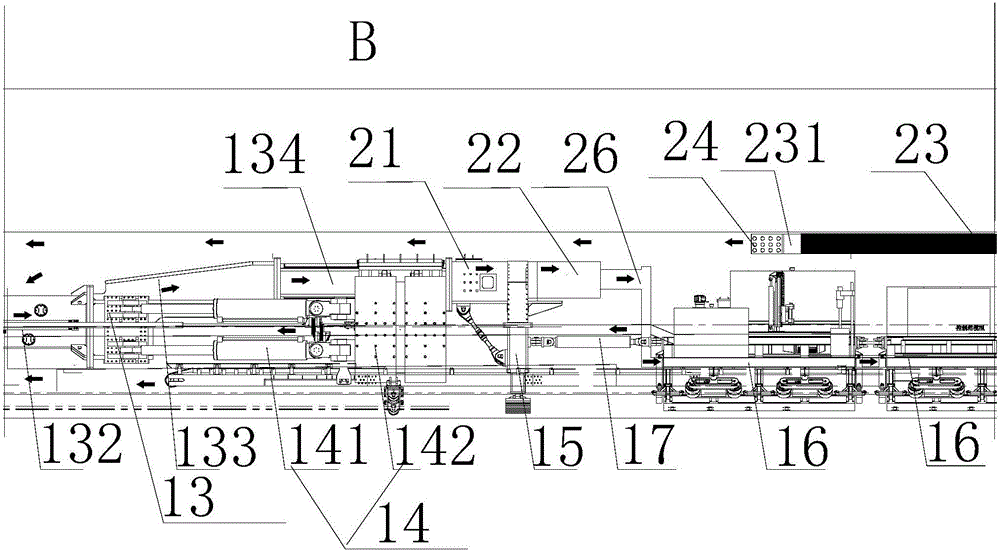

Mining whole-section hard rock tunneling machine and circulative tunneling method

ActiveCN106640106ARealize a reasonable layoutMeet shipping needsDust removalFire preventionEngineeringAnnular beam

The invention discloses a mining whole-section hard rock tunneling machine and a circulative tunneling method. The mining whole-section hard rock tunneling machine comprises a tunneling machine main machine, the tunneling machine main machine comprises a tunneling cutter head, a shield and driving part, a beam body, a bracing thrust mechanism, a back supporting mechanism and a back matching component which are connected in sequence; the bracing thrust mechanism comprises a thrust cylinder and a gripper shoe which is arranged in the horizontal direction of the tunneling machine main machine; the beam body comprises a main beam, an annular beam, an excessive beam and a sliding beam which are connected in sequence, one end of the thrust cylinder is connected with the beam body, the other end of the thrust cylinder drives the gripper shoe which is arranged on the sliding beam in a sleeving mode, and the back supporting mechanism is connected with the back matching component through a drawing oil cylinder. According to the mining whole-section hard rock tunneling machine and the circulative tunneling method, high mechanization, automation and informationization are achieved, historical breakthrough of a traditional rock roadway tunneling technology and equipment is achieved, a solid foundation is laid for solving the rock roadway bottleneck problem of mine development, and significance in ensuring normal replacement of a mine and achieving high-yield efficient construction goals is achieved.

Owner:HUAINAN MINING IND GRP

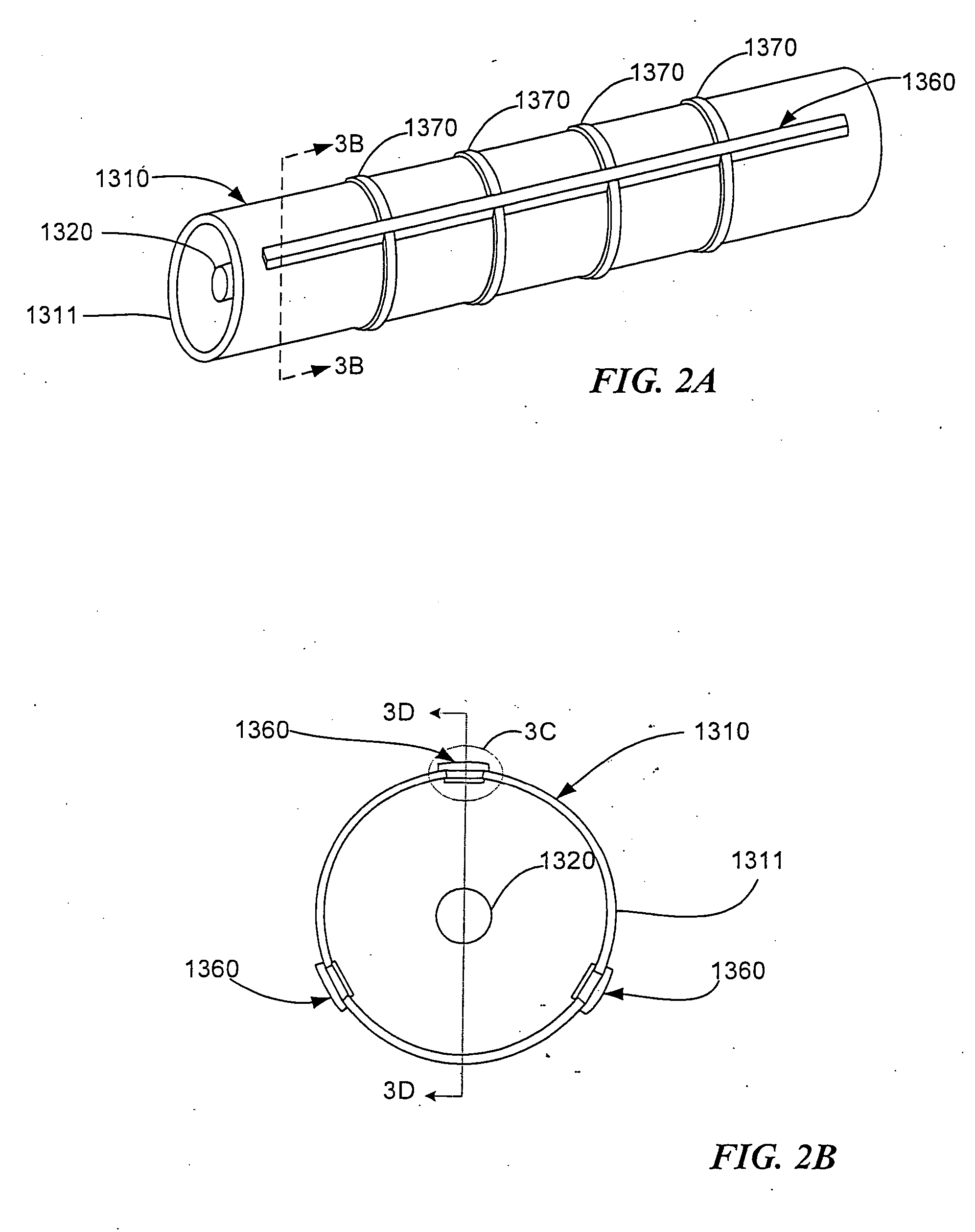

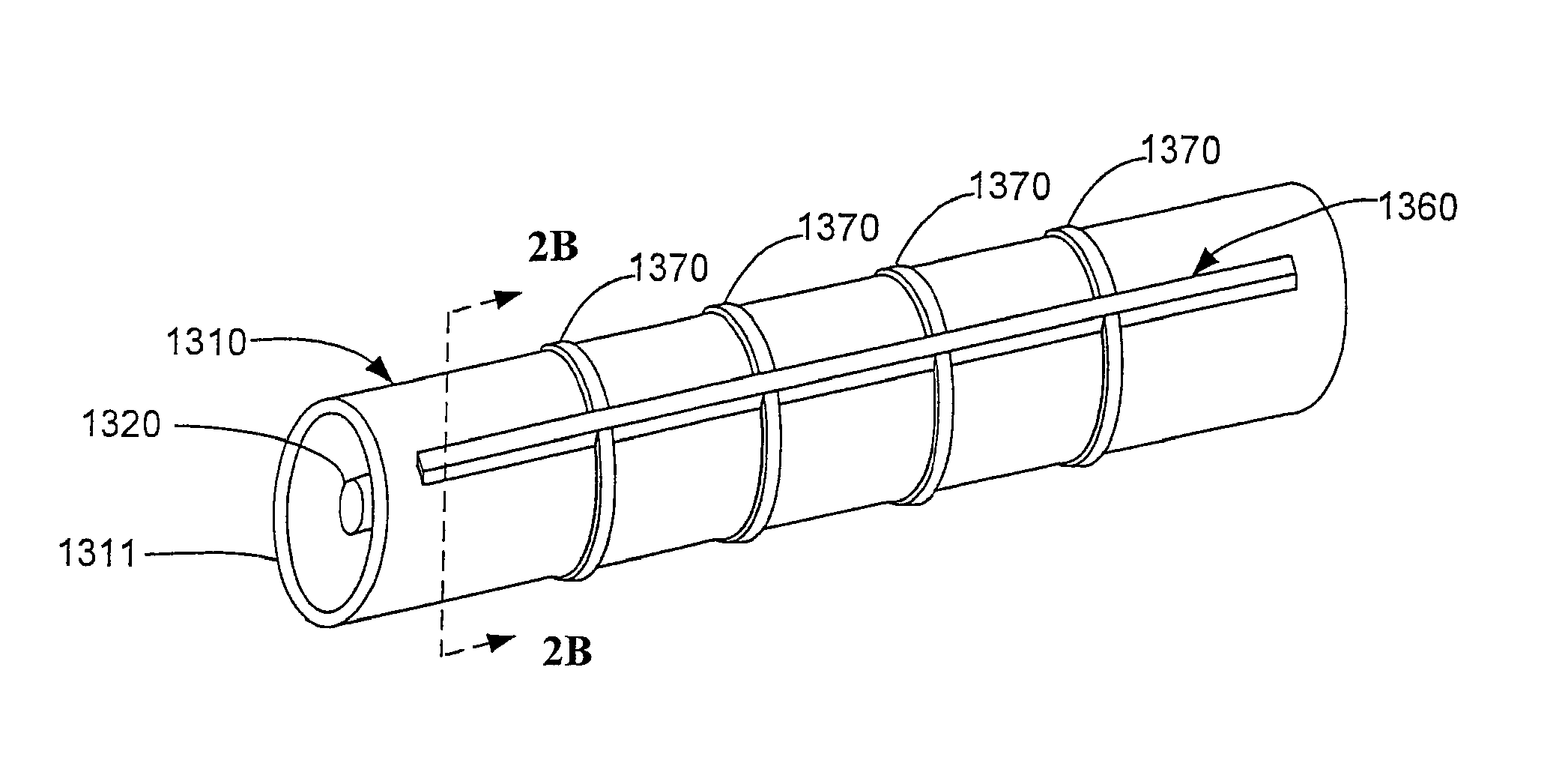

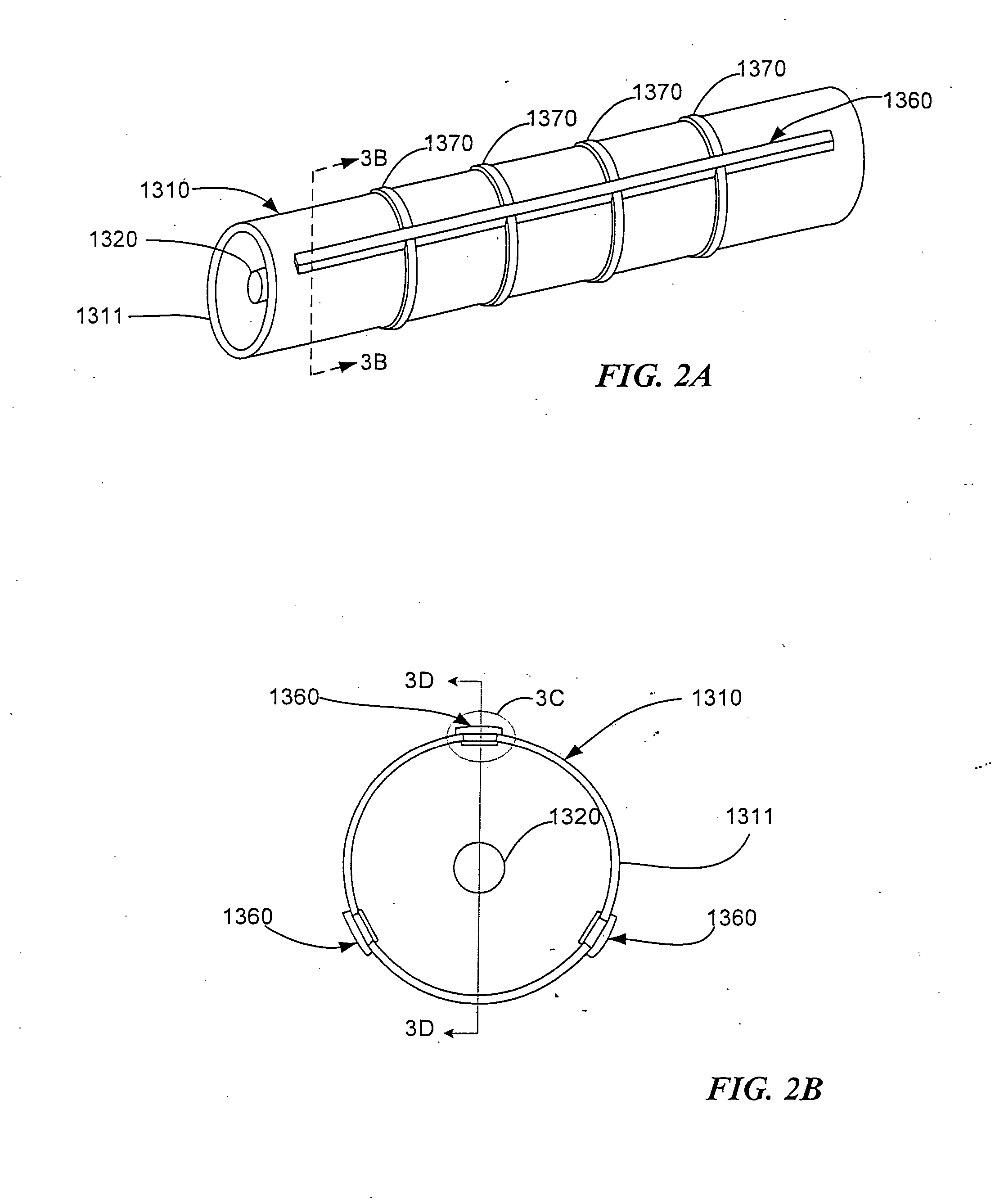

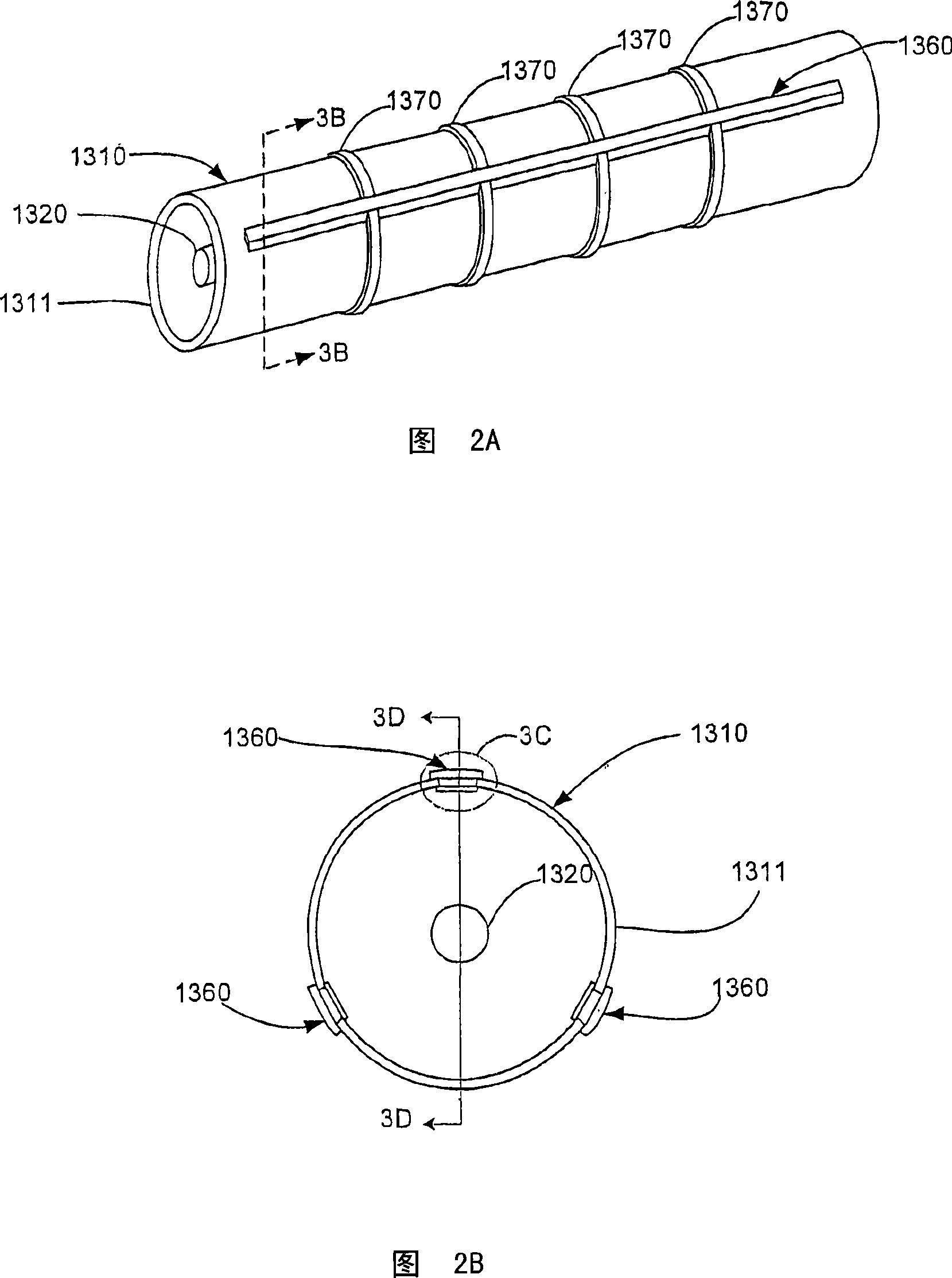

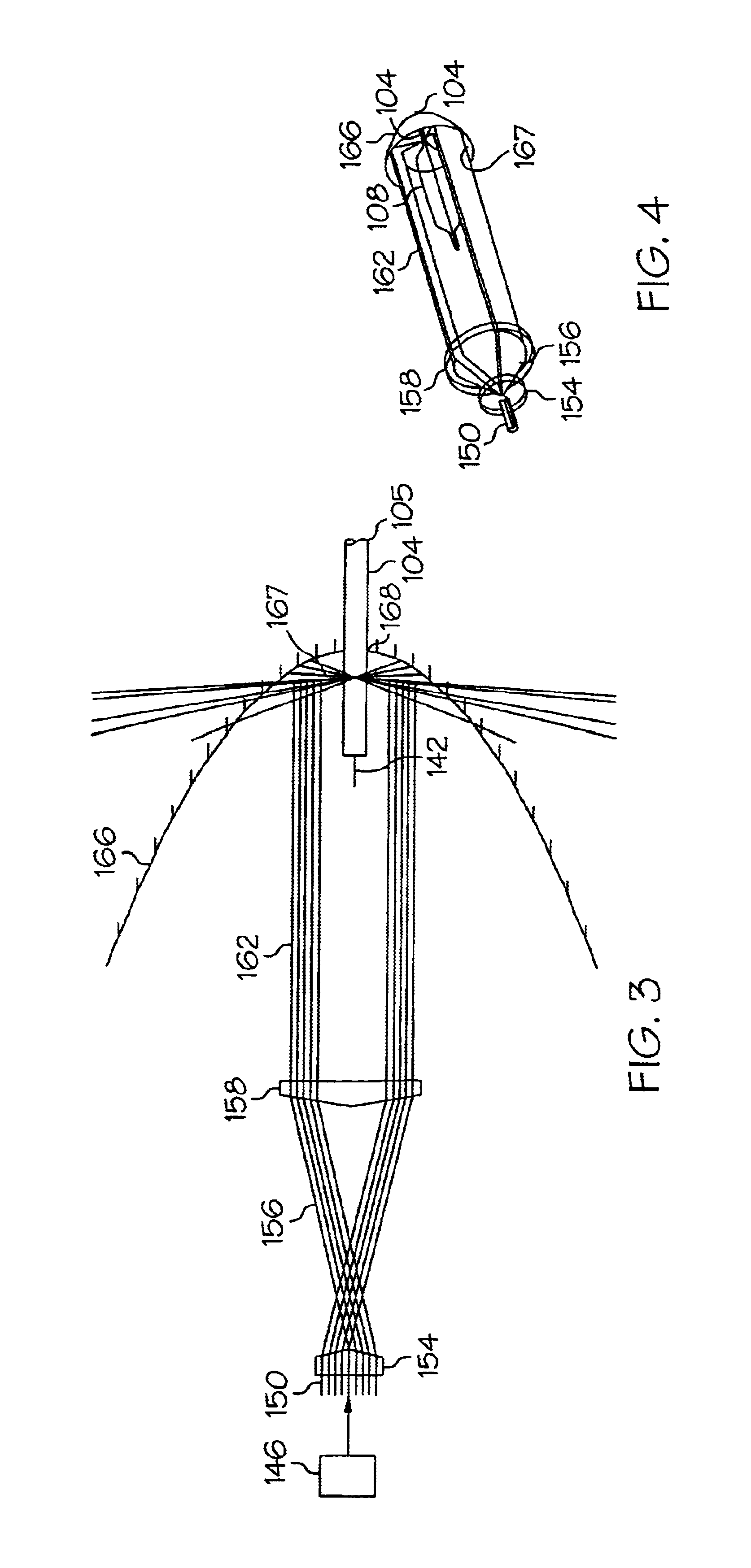

Method of applying a laser beam around the circumference of a catheter

A polymeric material may be bonded to a polymeric catheter tube by generating at least one annular beam of electromagnetic energy at a wavelength that is at least partially absorbed by at least one of the polymeric material and the polymeric catheter tube, controllably directing the annular beam of energy onto the polymeric material to concentrate the energy in a bond site circumscribing the catheter tube to at least partially melt at least one material selected from the group consisting of the polymeric material and the polymeric catheter tube along the bond site and the immediate region thereof and allowing the at least one partially melted polymeric material to cool and solidify to form a fusion bond between the tube and the polymeric material.

Owner:BOSTON SCI SCIMED INC

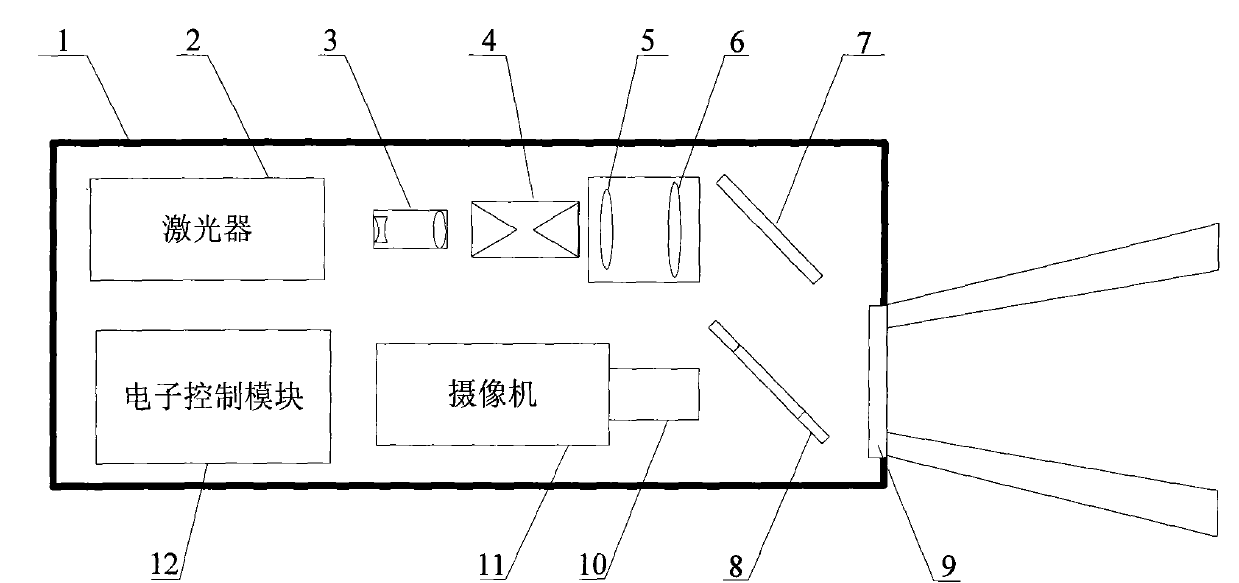

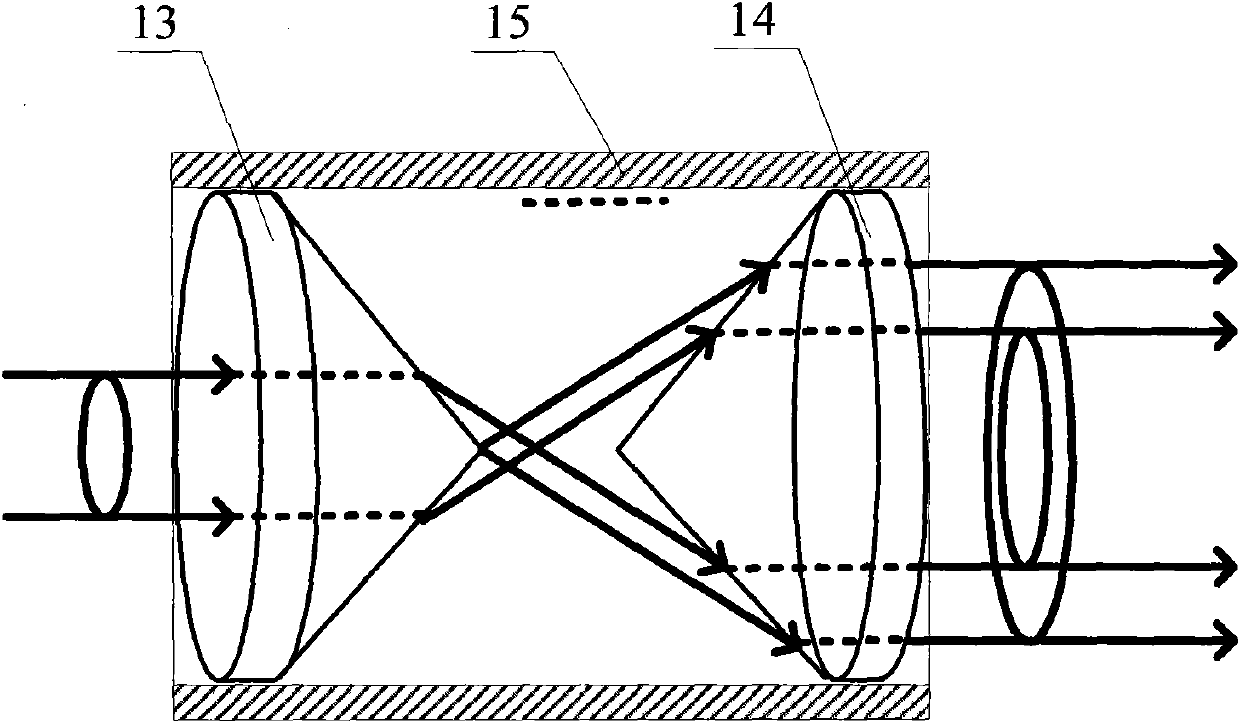

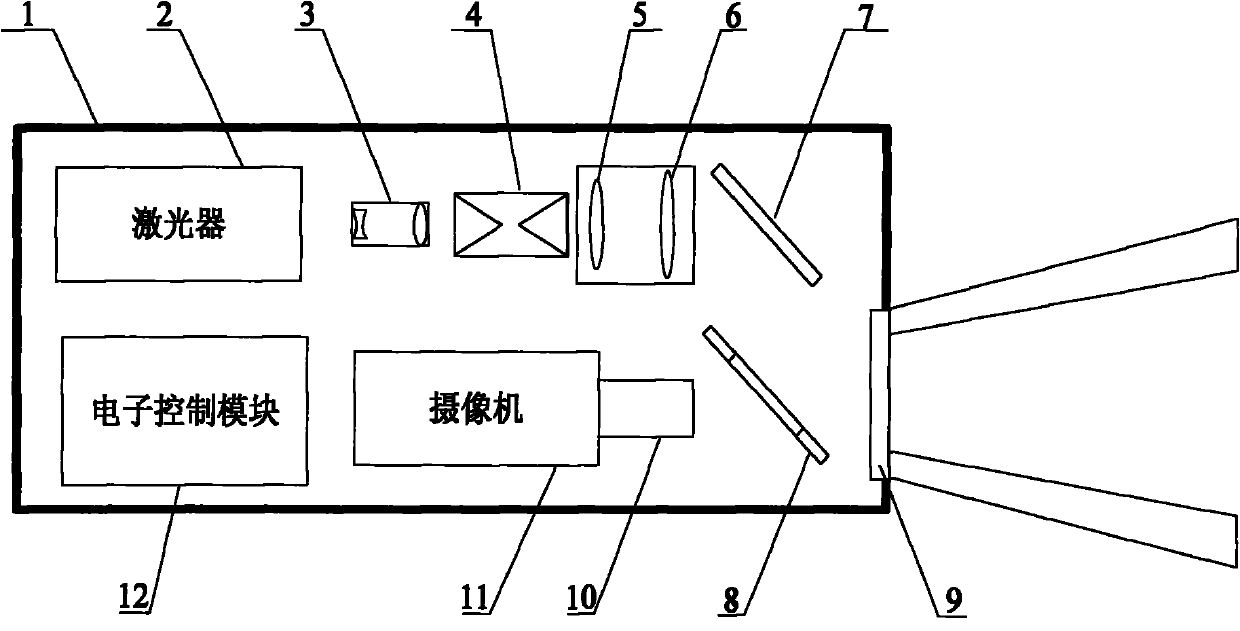

Underwater imaging device for annular laser lighting

InactiveCN102004373AReduce the impactReduce volumeLighting device detailsPhotographyCamera lensImaging quality

The invention relates to an underwater imaging device for annular laser lighting, comprising an optical window, an shell, a lighting optical device, a receiving and detecting device and an electronic control module, wherein the light optical device composed of a laser, a beam expander, a front lens, a rear lens and an all-trans lens is arranged in the shell; and the receiving and detecting device is composed of a zoom lens and a camera. The imaging device is characterized by comprising an annular all-trans lens and a beam-transforming device, wherein the annular all-trans lens is arranged in front of the zoom lens, is coaxial with the zoom lens and the camera, and is placed at an angle of 45 degrees; and the beam-transforming device is arranged between the beam expander and the front lens and causes Gaussian beam sent by the laser to be transformed into annular beams. The imaging device of the invention has high imaging quality, can acquire clearer images under the condition of being far away from turbid body of water, is a novel underwater imaging device for underwater detecting operation, and plays an importation role in ocean detection in our country.

Owner:OCEAN UNIV OF CHINA

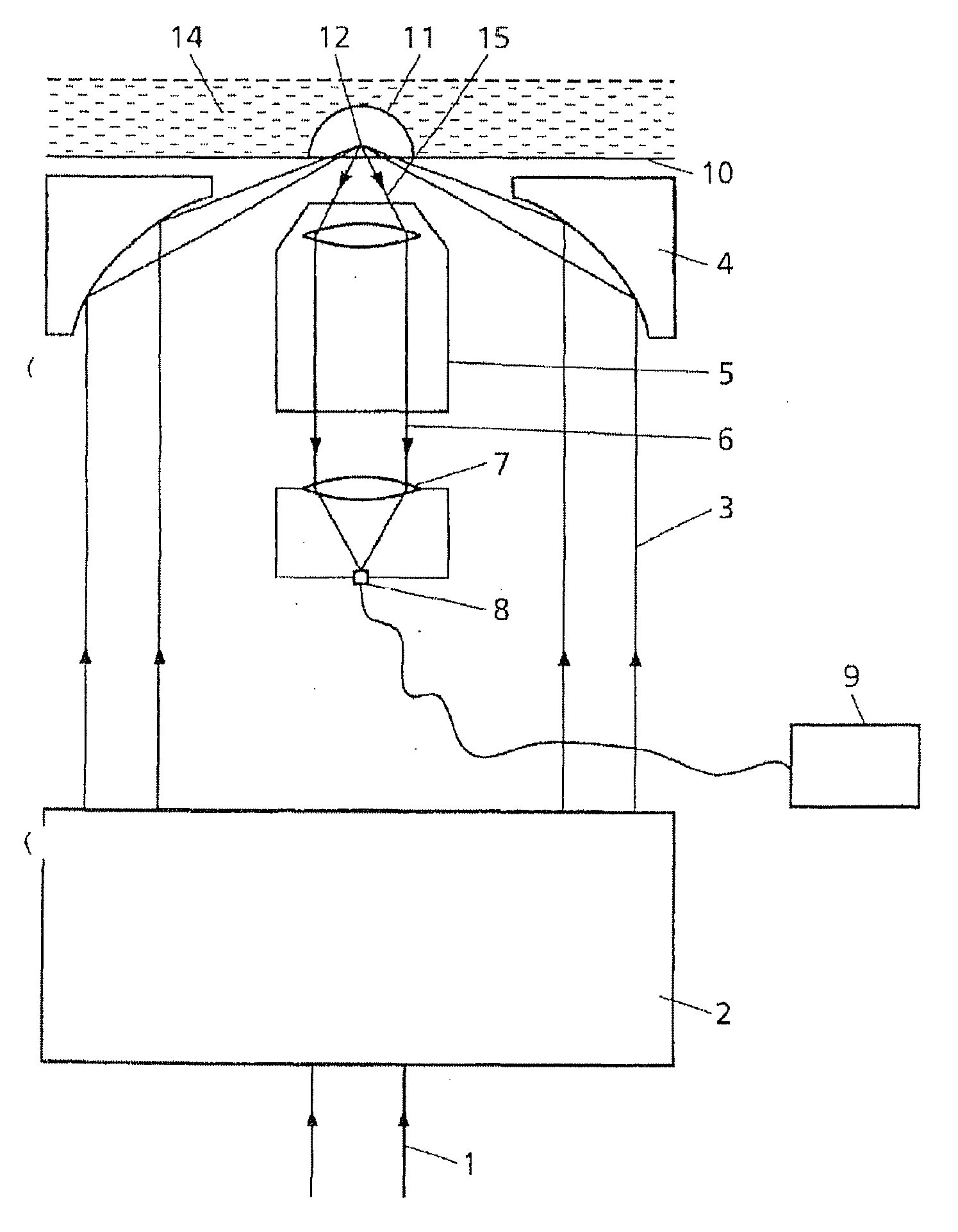

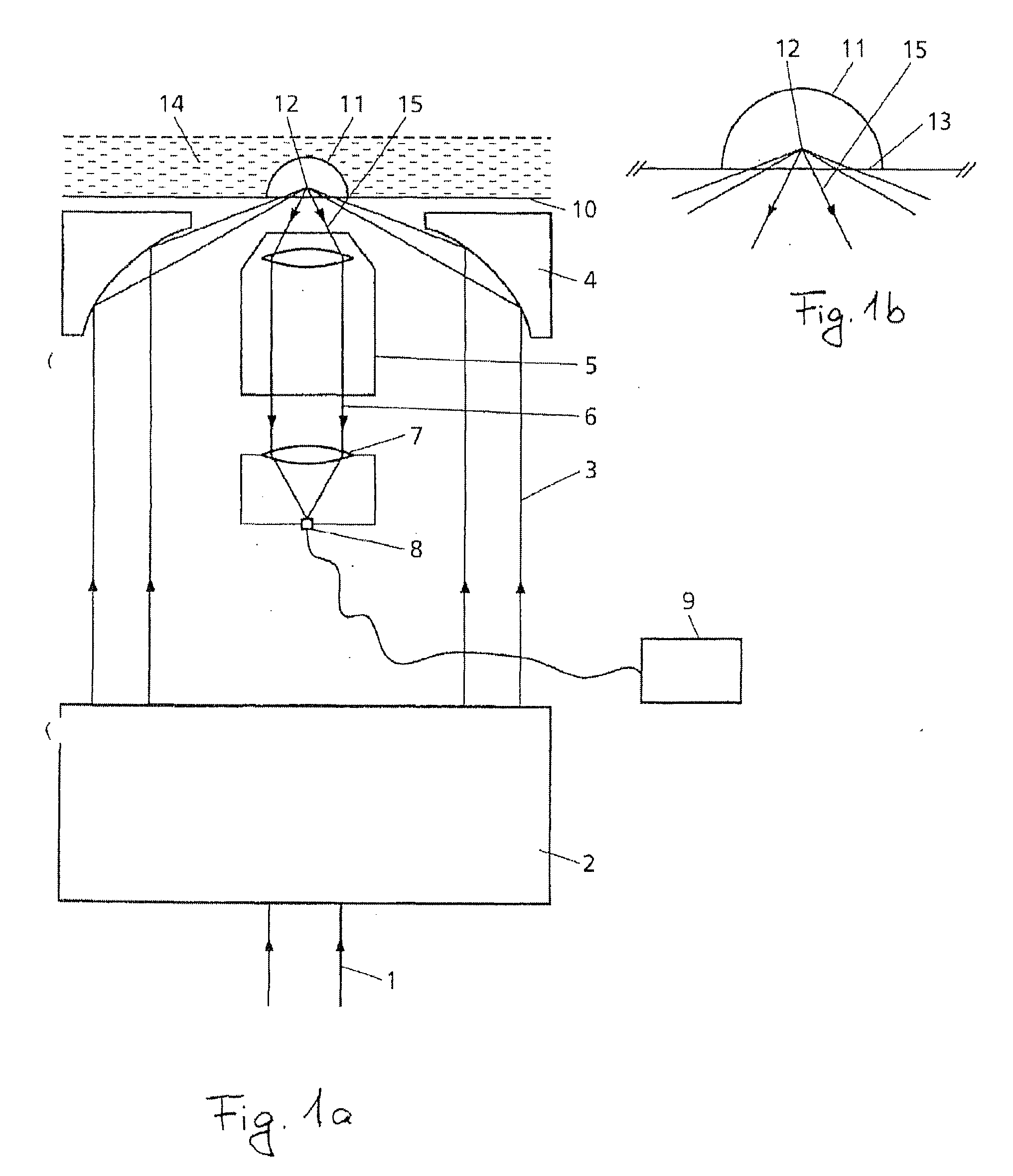

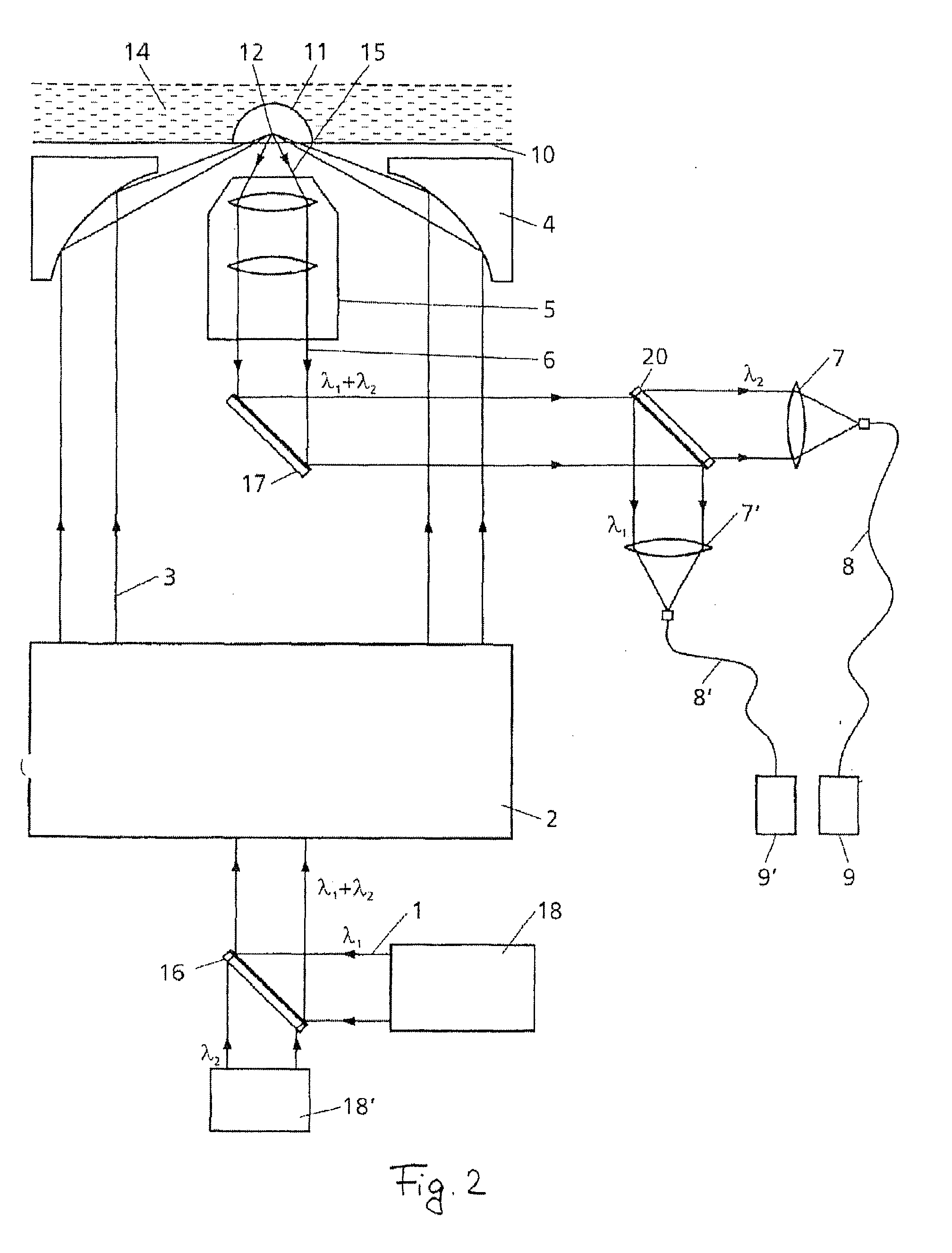

Device and method for measuring static and dynamic scattered light in small volumes

InactiveUS20100315635A1Simple designPrevent coalescingRadiation pyrometrySpectrum investigationLight beamElectromagnetic radiation

The invention relates to a device for measuring scattered light, comprising at least one focusing element provided with electromagnetic radiation that can be focused on a sample, a detector and a detector optical system with which electromagnetic radiation scattered by the sample can be conducted to the detector. The device is characterized in that it comprises means for forming an annular beam such that said annular beam can be focused on a focus point inside the sample by the at least one focusing element and that electromagnetic radiation scattered by the sample can be detected by the detection optical system, said electromagnetic radiation dispersing inside the area surrounded by the annular beam.

Owner:HOFFMANN KURT

Inductive plasma source for plasma electric generation system

ActiveUS20060267503A1Facilitates controlled fusionReduce eliminate anomalous transportElectric discharge tubesNuclear energy generationNuclear forcePlasma electron

A system and apparatus for controlled fusion in a field reversed configuration (FRC) magnetic topology and conversion of fusion product energies directly to electric power. Preferably, plasma ions are magnetically confined in the FRC while plasma electrons are electrostatically confined in a deep energy well, created by tuning an externally applied magnetic field. In this configuration, ions and electrons may have adequate density and temperature so that upon collisions they are fused together by the nuclear force, thus forming fusion products that emerge in the form of an annular beam. Energy is removed from the fusion product ions as they spiral past electrodes of an inverse cyclotron converter. Advantageously, the fusion fuel plasmas that can be used with the present confinement and energy conversion system include advanced (aneutronic) fuels.

Owner:RGT UNIV OF CALIFORNIA

Laser processing head based on double-beam spatial characteristic adjustment

InactiveCN104858547AGuaranteed composite punching effectGood hole roundnessLaser beam welding apparatusPunchingLaser processing

The invention provides a laser processing head based on double-beam spatial characteristic adjustment. The laser processing head comprises an annular light path system and a central light path system, wherein the annular light path system comprises a first beam expansion collimating lens, a cone lens group and a focusing objective lens; the focusing objective lens outputs a fine annular focal spot generated after the focusing of a non-diffraction annular beam to the surface of a workpiece; the central light path system comprises a second beam expansion collimating lens, a first planar reflecting mirror and a planar reflecting mirror; the focusing objective lens focuses laser beams and then outputs a central fine round spot to the surface of the workpiece; the central fine round spot is positioned at the center of the fine annular focal spot output by the annular light path system. When the laser processing head disclosed by the invention is adopted for laser punching, good circular ring precision can be guaranteed, namely the laser processing head is particularly suitable for the processing of ring-shaped blind holes; besides, laser beams with different wavelengths can serve as two incident laser beams, so that the composite punching processing effect, which cannot be realized by the traditional pulse single-point punching and opening-cutting manners, can be achieved.

Owner:WENZHOU POLYTECHNIC

Central part reconstruction method and device of unstable resonator laser annular beam

InactiveCN101806958ASuitable for plastic surgeryIncrease laser powerOptical elementsSolid lightOptical axis

The invention provides a central part reconstruction method and a device of an unstable resonator laser annular beam. The method comprises: an annular beam output by an unstable resonator laser is guided by an inner round table surface annular reflecting mirror and is gradually concentrated towards the optical axis position of the laser; the light beam concentrated on the periphery of the optical axis is reguided by utilizing an external cone surface reflecting mirror to obtain a reshaped light beam output along the optical axis direction; and the relative position of the inner round table surface annular reflecting mirror and the external cone surface reflecting mirror along the optical axis direction is precisely adjusted to realize the circular solid reshaping light beam output along the optical axis direction. The device comprises the unstable resonator laser, the inner round table surface annular reflecting mirror, the external cone surface reflecting mirror, a precise displacement mechanism of the inner round table surface annular reflecting mirror and a precise displacement mechanism of the external cone surface reflecting mirror. Compared with the prior art, the method can utilize an extracavity optical element to change the annular beam output by the unstable resonator laser and obtain circular solid light beam output. The provided device has simple structure and stable operation.

Owner:HUAZHONG UNIV OF SCI & TECH

Method and system for obtaining an extended-depth-of-field volumetric image using laser scanning imaging

A laser scanning imaging system and method for obtaining an extended-depth-of-field image of a volume of a sample are provided. The system includes a laser module generating an input laser beam, a beam shaping module including an axicon and a Fourier-transform lens, and an imaging module including an objective lens and a detecting assembly. The axicon, Fourier-transform lens and objective lens are formed and disposed to successively convert the input laser beam into an intermediate non-diffracting beam, an intermediate annular beam, and an excitation non-diffracting beam. The excitation beam is projected onto the sample and has a depth of field and transverse resolution together defining a three-dimensional excitation region. The detecting assembly collects electromagnetic radiation from the excitation region to obtain one pixel of the extended-depth-of-field image. The system further includes a two-dimensional scanning module for scanning the excitation beam over the sample and build, pixel-by-pixel, the extended-depth-of-field image.

Owner:UNIV LAVAL

Beam forming device and method

ActiveCN104148802AIncrease profitFine hole qualityLaser beam welding apparatusOptical axisPlane mirror

The invention provides a beam forming device and method. The beam forming device is formed by arranging a laser device, a pair of lenses, a Dove prism, a plane mirror, a regular axicon and a focusing lens in sequence in the direction of an optical axis. The distance between the lenses is adjustable so that the spot size and divergence angle of outgoing beams of the laser device can be adjusted. The Dove prism is installed in a hollow shaft rotary motor and rotates with the optical axis serving as the center, and the outgoing beams from the Dove prism also rotate with the Dove prism. The plane mirror is used for deflecting the transmission direction of the beams. The position of the focusing lens in the transmission direction of the beams is adjustable, and the outgoing beams are a bunch of rotary hollow annular beams after passing through the focusing lens.

Owner:北京中科镭特电子有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com