Laser processing head based on double-beam spatial characteristic adjustment

A technology of laser processing head and spatial characteristics, which is applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., and can solve problems such as unsatisfactory hole roundness, high cost of laser drilling mechanism, thermal stress deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

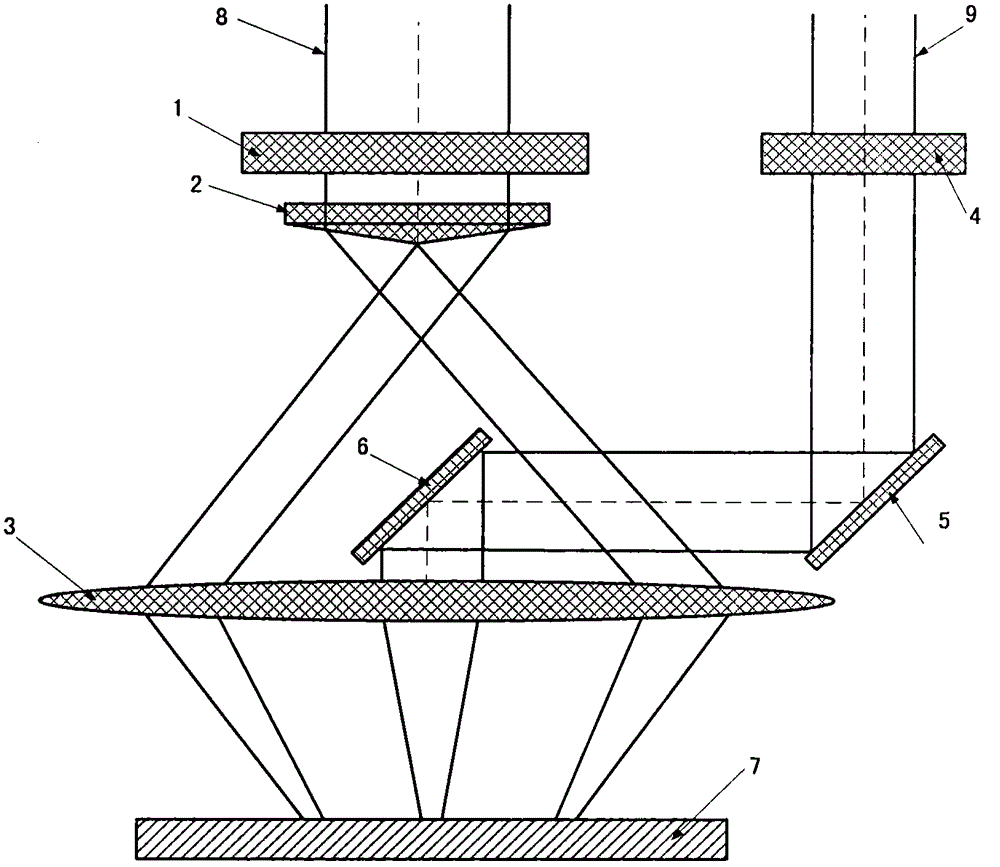

[0022] The invention provides a laser processing head based on the adjustment of the spatial characteristics of the double beams. The laser processing head needs two incident laser beams, one of which uses an axicon lens to form a ring beam, and then after being focused by an objective lens, it forms a thin ring focus spot. Acting on the surface of the workpiece, the other beam is turned by the mirror and then focused by the objective lens to form a central thin circular spot, which acts on the center of the circular hole to be processed (according to geometric optics, it must be inside the area surrounded by the thin annular focal spot). The diameters of the thin annular focal spot and the central thin circular spot can be adjusted by optical lenses (changing the distance between the axicon lens and the objective lens, and selecting d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com