Preparation method of diamond coating wire-drawing die with small aperture

A technology of diamond coating and wire drawing die, applied in the direction of wire drawing die, metal material coating process, coating, etc., can solve the problems of die ablation, difficulty in neutral operation, difficulty in forming diamond film, etc., and achieve dimensional accuracy High, good surface quality, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

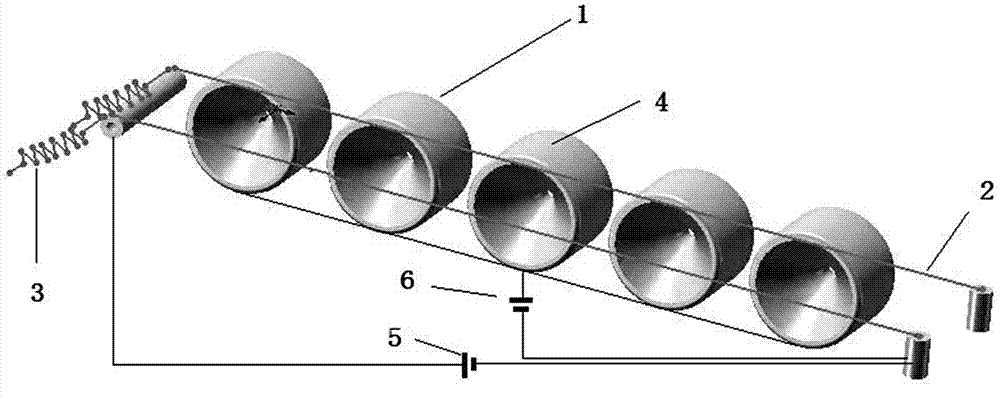

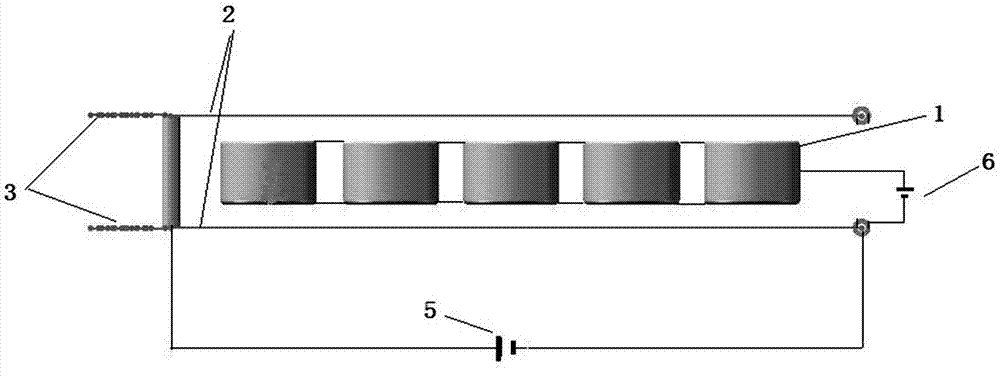

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

[0020] figure 1 As shown, after the surface decarburization and acid treatment of the wire drawing die base 1 to remove cobalt, a layer of insulating silicon dioxide 4 is brushed on the outer periphery of the wire drawing die, and then neatly arranged on the fixture on the cooling platform in the reaction chamber. A heating wire 2 is respectively arranged at the exit and entrance of the mould, one end is fixed on the electrode, and the other end is tensioned by a high temperature spring 3 . At both ends of the hot wire, a DC power supply is used to heat the hot wire 2 to decompose the gas and radiate to heat the wire drawing die base 1. At the same time, a negative bias voltage 6 is applied between the hot wire and the wire drawing die base to make the gas decompose more fully and make the decomposition reaction The atmosphere moves directionally to areas not brushed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com