Patents

Literature

394results about How to "Improve punch quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

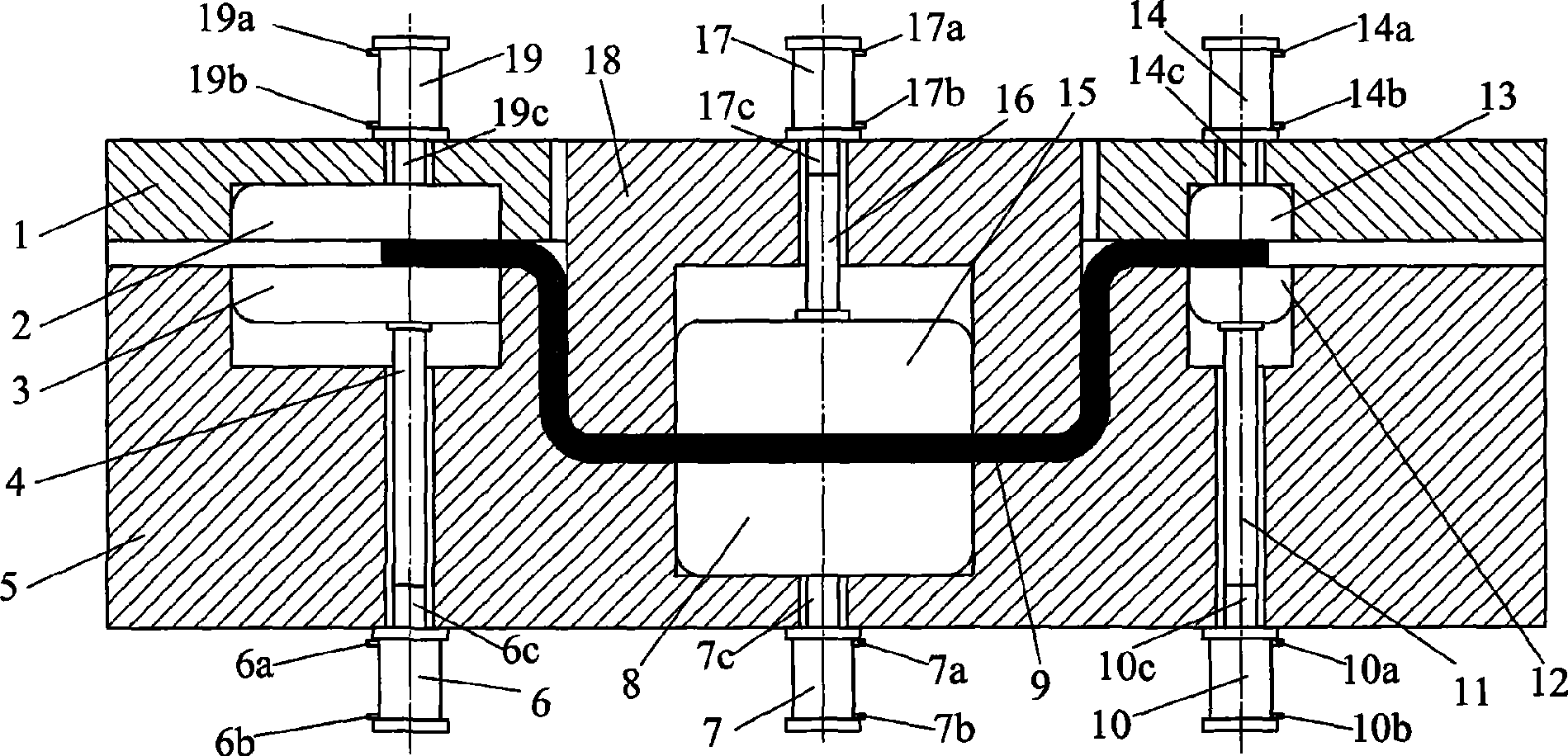

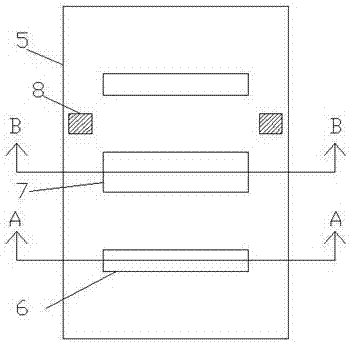

Thermoforming, hole-punching and edge-cutting integrated technique and mold of high-duty steel part

InactiveCN101486061ALess investment in equipmentSmall footprintShaping toolsPerforating toolsSteel platesHot stamping

The invention provides hot-forming, punching and edge-cutting integral technology and a hot-forming, punching and edge-cutting integral die for high strength steel parts. The integral technology comprises the following steps: arranging an edge-cutting and punching tool on a hot-forming die of the high strength steel parts; placing high strength steel plate materials which is heated to be completely austenized into the hot-forming die for punching before hot stamping forming of the high strength steel plate materials; utilizing the edge-cutting and punching tool on the hot-forming die to perform edge-cutting and punching operations on workpieces subjected to stamping after the hot-forming die is closed; cooling the hot-forming die after the operations are over; and utilizing die components which contact formed parts to quench the formed parts. The integral die comprises a forming convex die, a forming concave die, an upper punching tool, a lower punching tool, an upper edge-cutting tool and a lower edge-cutting tool. The integral technology and the integral die reduce the production cost of the hot-formed parts, and shorten the production period of the hot-formed parts; and the hot-formed parts have high edge-cutting and punching quality and high dimension precision and shape precision.

Owner:SHANDONG UNIV

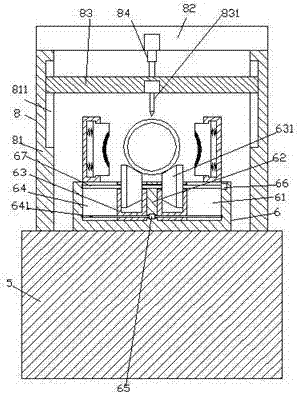

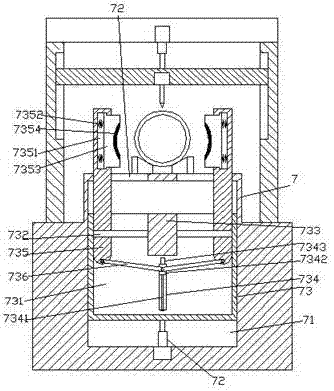

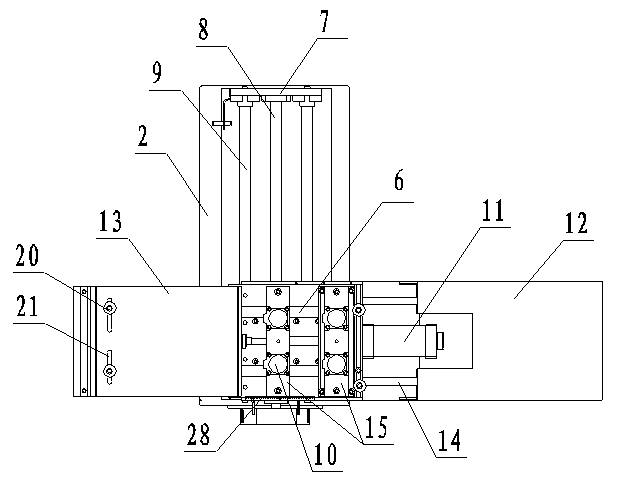

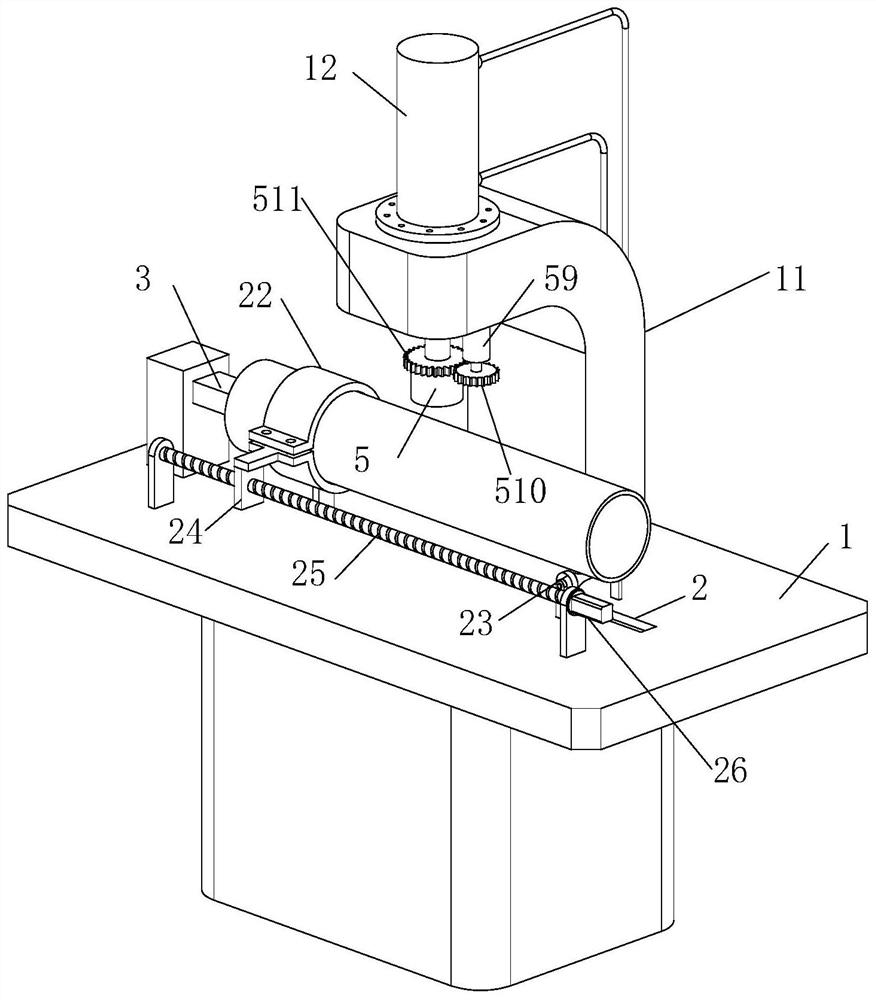

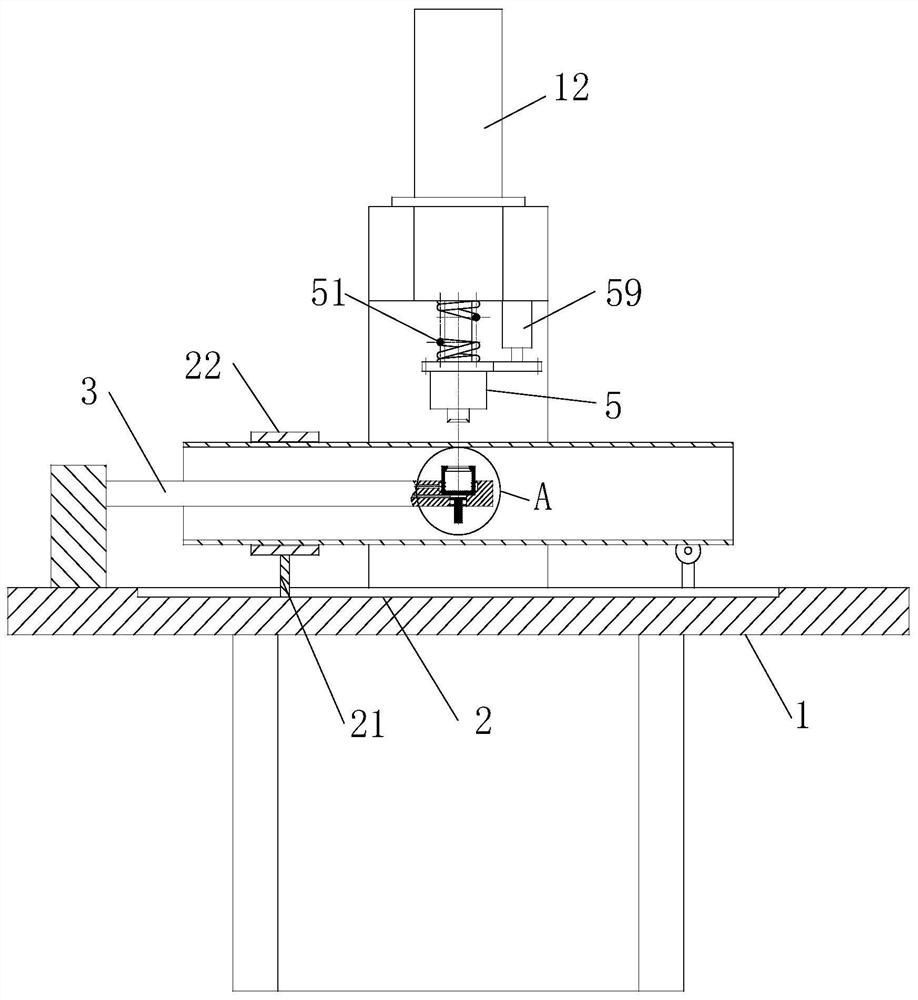

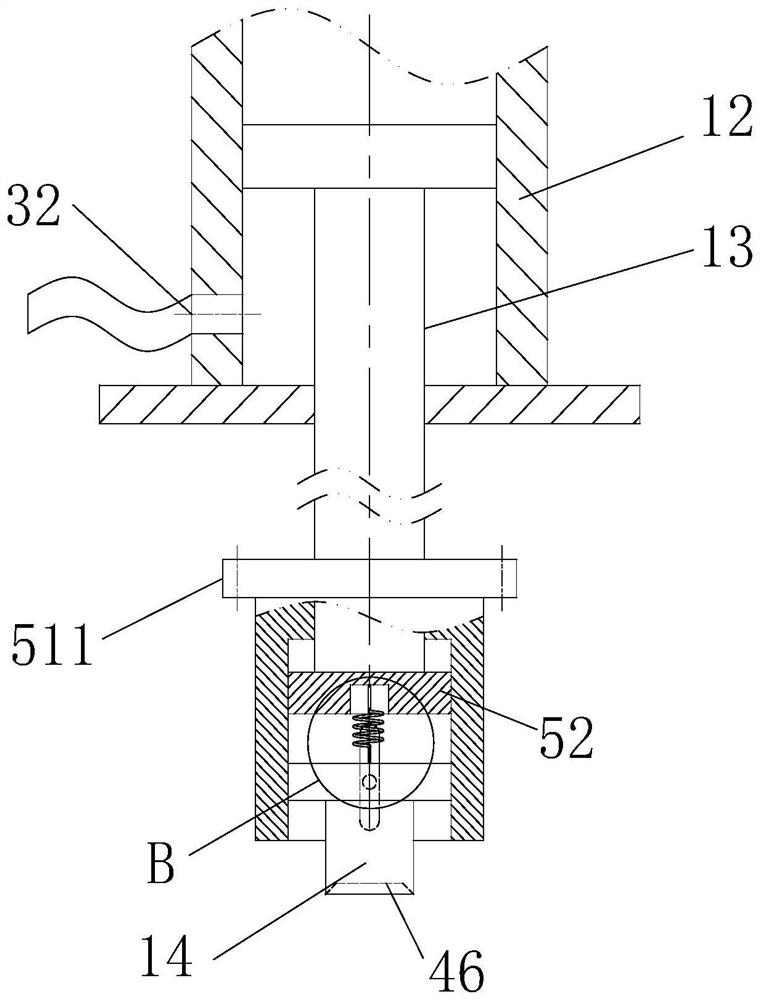

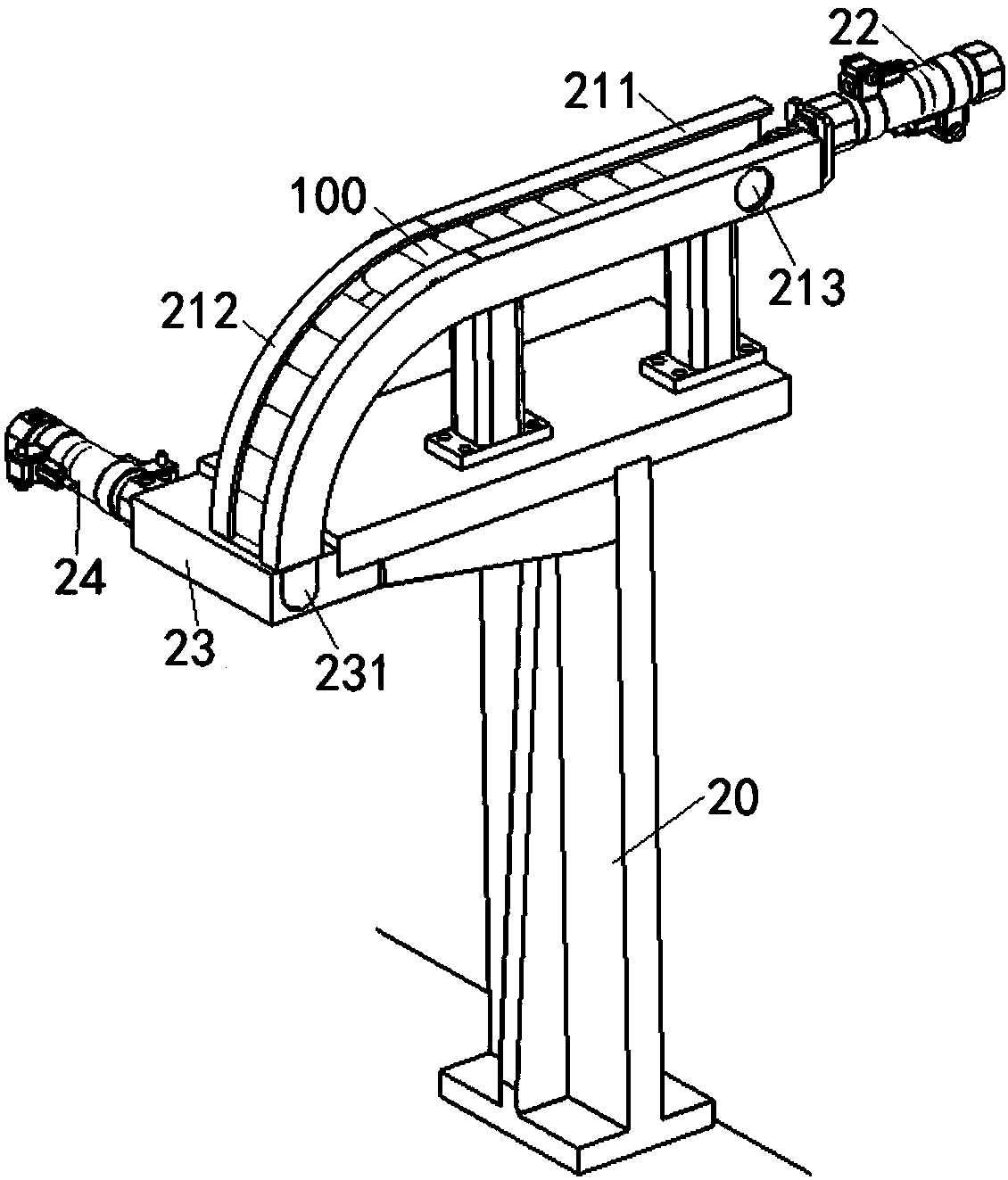

Perforating device suitable for steel tubes with different diameters

ActiveCN107127598AImprove work efficiencyCase against vibrationPositioning apparatusBoring/drilling componentsEngineeringBilateral symmetry

The invention discloses a perforating device suitable for steel tubes with different diameters. The perforating device comprises a base, a clamping device and rolling adjustment devices symmetrically arranged on the front and back sides of the clamping device are arranged at the end face of the top of the base, and a perforating rack is arranged at the position, between the clamping device and the back rolling adjustment device, of the base; a first rolling groove and a second rolling groove which are arranged in a bilateral symmetry manner are arranged in each rolling adjustment device, a separating plate is arranged between each first rolling groove and the corresponding second rolling groove, the first rolling grooves and the second rolling grooves are each internally provided with a bearing piece, and the bearing pieces on the left and right sides are each internally provided with rollers with taper face sides oppositely arranged; a lifting sliding cavity is arranged in the clamping device in a manner of being communicated with the base at the bottom of the clamping device, and a lifting sliding piece is arranged in the lifting sliding cavity; and through grooves are symmetrically arranged on the left and right sides of the top of the clamping device, and a driving sliding cavity is arranged in the lifting sliding piece. The perforating device is simple in structure and convenient to operate, and the perforating accuracy and stability are improved.

Owner:新沂市华洋金属制品有限公司

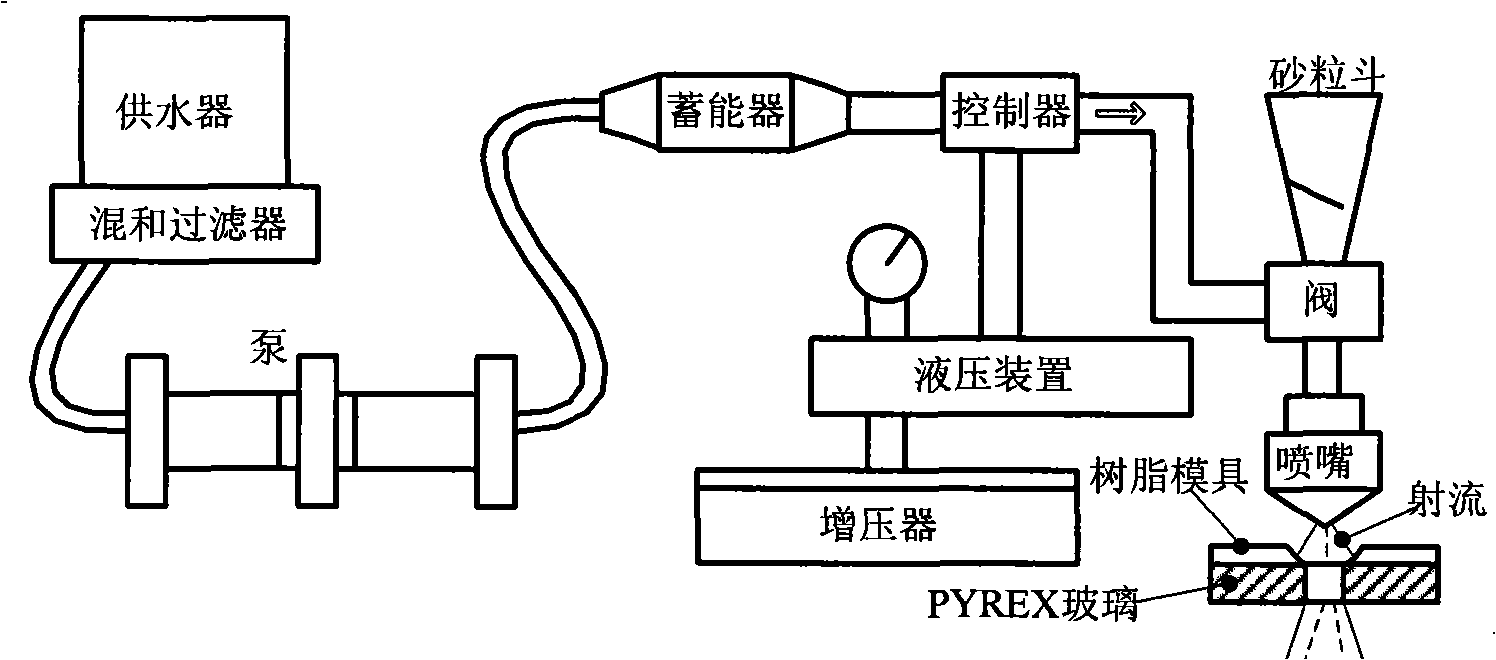

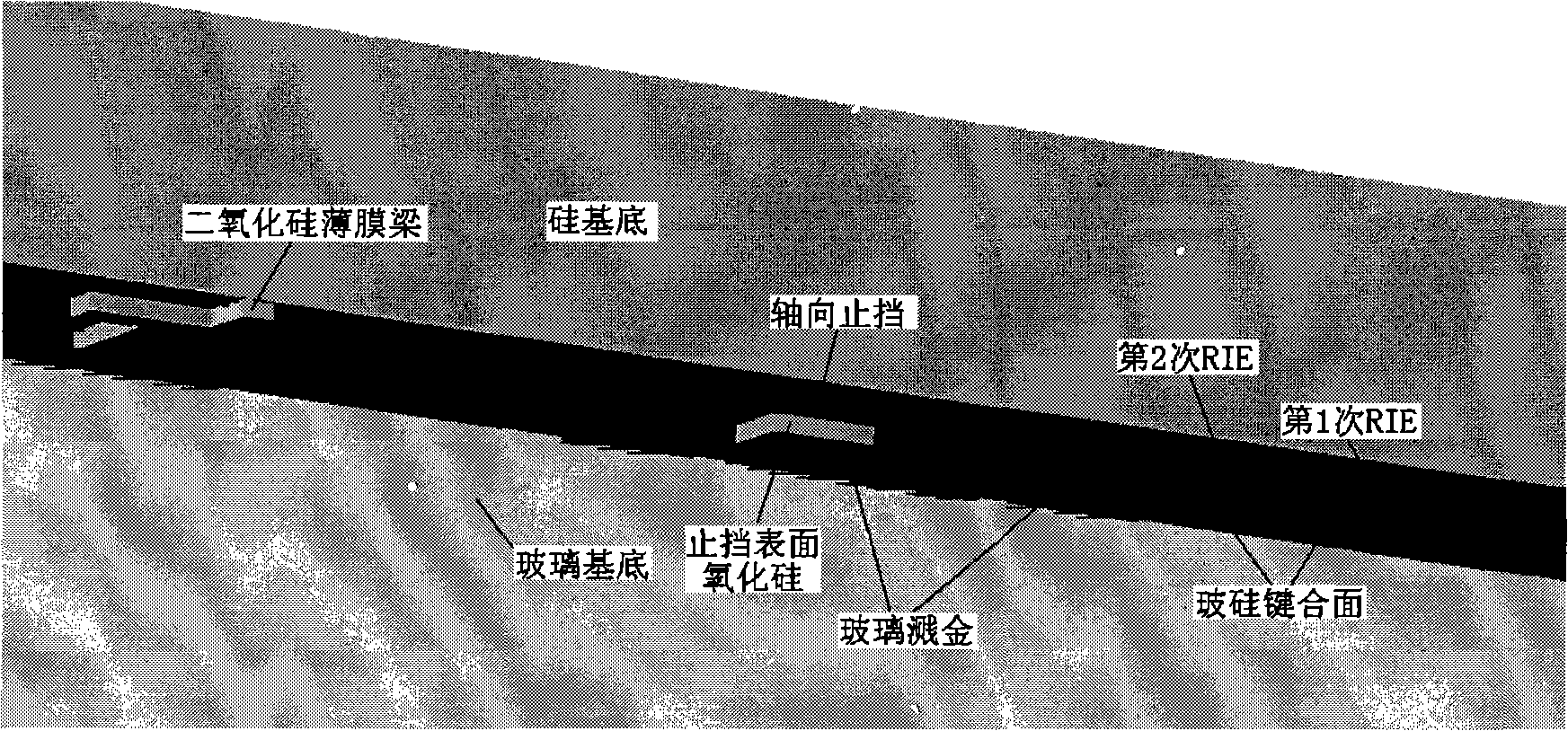

Manufacturing method for floating type micro-silicon electrostatic gyro/accelerometer sensitive structure

InactiveCN101279713AInhibit sheddingThickness loss is negligibleAcceleration measurement using interia forcesDecorative surface effectsLevitationAccelerometer

The invention relates to a method for preparing a levitation-type micro-silicon electrostatic gyro / accelerometer sensitive structure, which belongs to the technical field of silicon structure processing. The method comprises the steps: glass etching; glass gold splashing: a metal layer raising 400-600 tenthmeters higher than a glass surface; perforating the glass; a first and a second RIE etching for the silicon slice; film beam process: high-temperature dry oxidation and surface corrosion; a first electrostatic bonding for glass and silicon; thinning and polishing to the silicon slice; ICP etching for the silicon slice; a third RIE etching for the silicon slice; a fourth RIE etching for the silicon slice; a second electrostatic bonding for glass and silicon; ICP removal for film beam to prepare the levitation-type micro-silicon electrostatic gyro / accelerometer sensitive structure. The method adopts the proposal of sandblasting perforating for perforating the glass, introduces the silicon dioxide film beam as a sacrificial layer and adopts the ICP film beam removal process; the method can effectively solve the problem of adherence of a sandwich microstructure in the second electrostatic bonding and does not need post treatment so that the method has higher efficiency and better compatibility with the MEMS process.

Owner:TSINGHUA UNIV +1

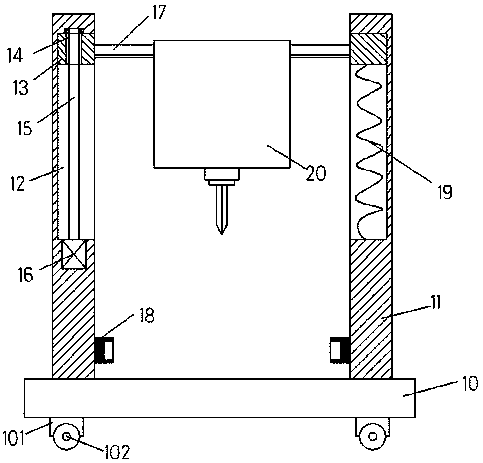

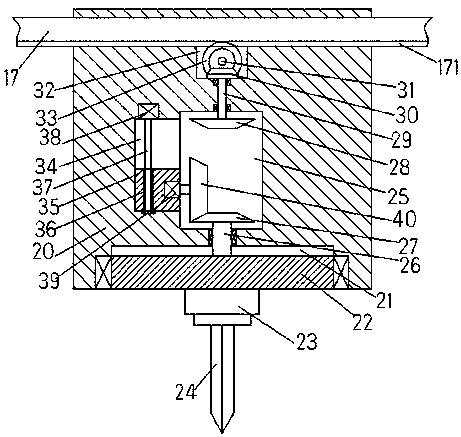

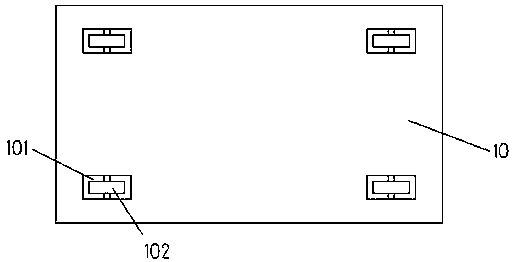

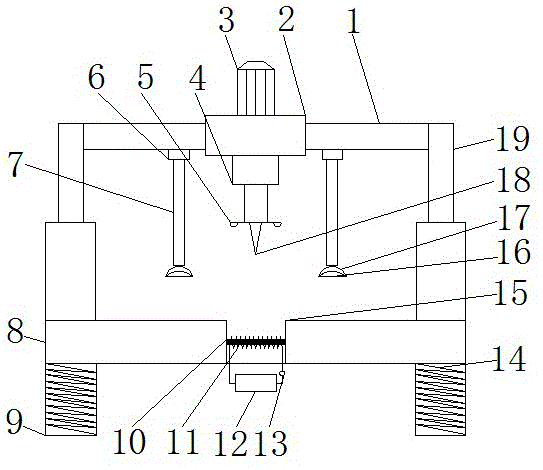

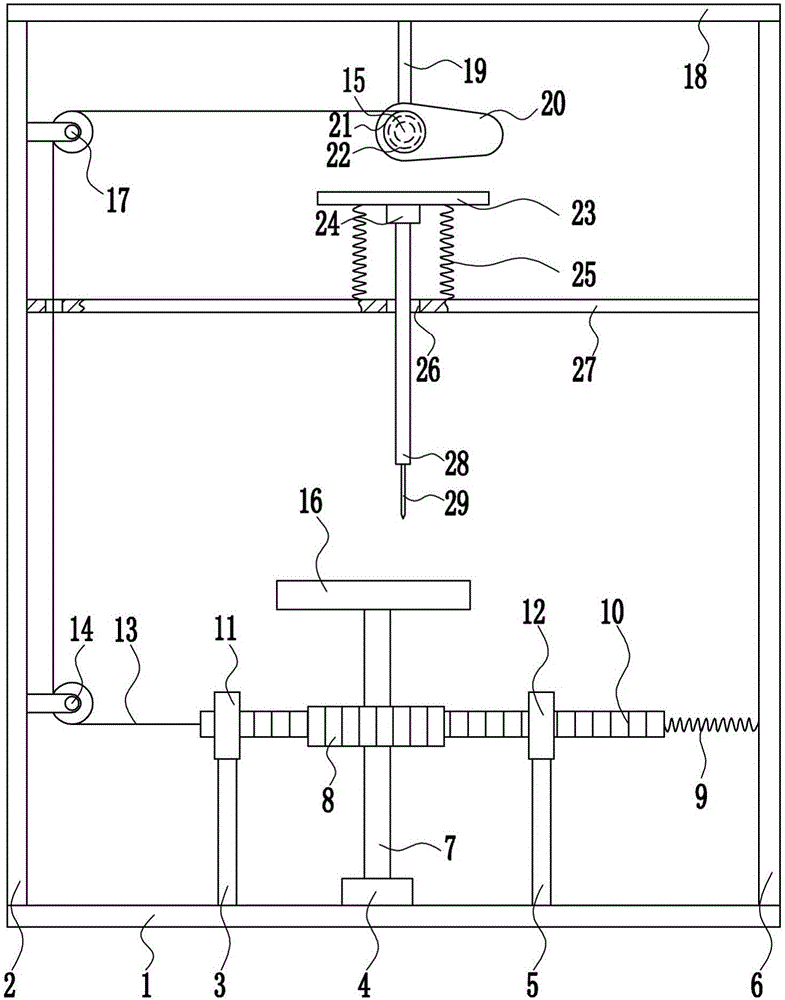

Novel workshop equipment

InactiveCN108311724ASimple structureEasy to useBoring/drilling componentsBoring/drilling machinesEngineeringRotating disc

The invention discloses novel workshop equipment which comprises a machine base, brackets and a tank shell body, wherein the brackets are arranged at two ends of the top of the machine base in a left-right symmetric manner; the tank shell body is arranged between the left and right brackets through a pushing-lifting device; a first rotating cavity of which the end port faces down is arranged at the inner bottom of the tank shell body; a second rotating cavity is arranged in the tank shell body in an up-down extending manner and positioned above the first rotating cavity; a first sliding troughis arranged in the inner wall of the left side of the second rotating cavity in a communicating manner; a rotating disc is rotatably mounted in the first rotating cavity through a bearing; a first rotating shaft which extends into the second rotating cavity is fixedly arranged at the top of the rotating disc; a first conical wheel is fixedly mounted on the first rotating shaft in the second rotating cavity; and a first sliding block is arranged in the first sliding trough in an up-down slidable manner.

Owner:楼碧云

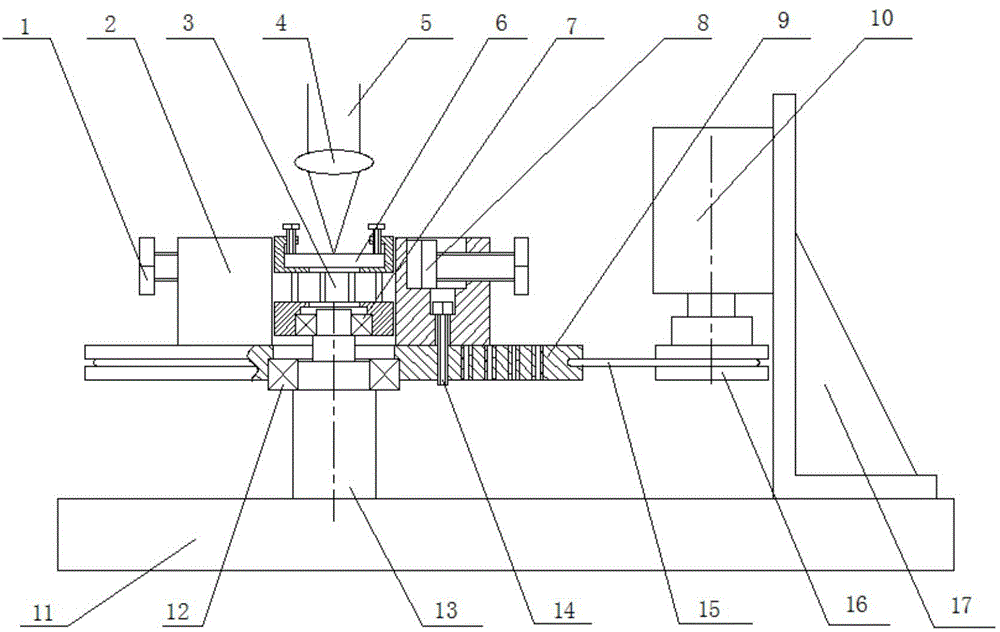

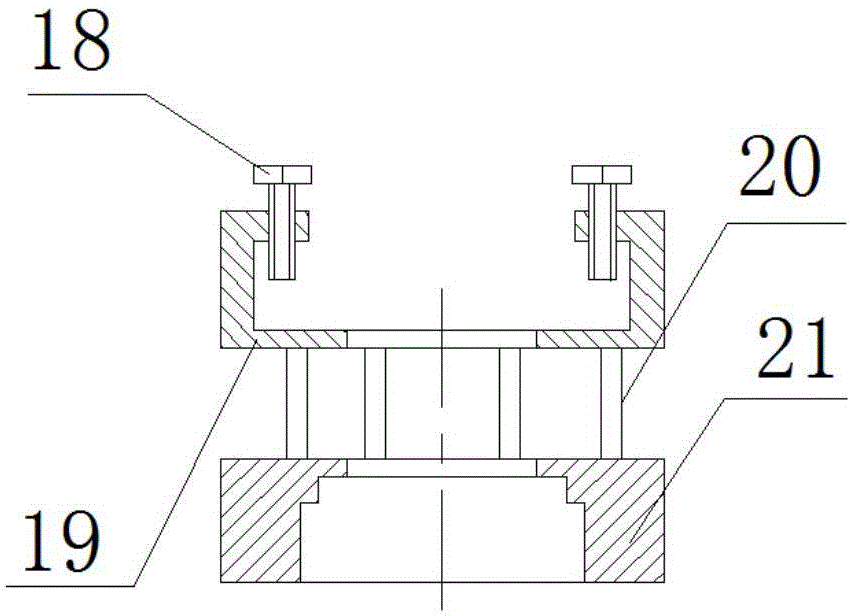

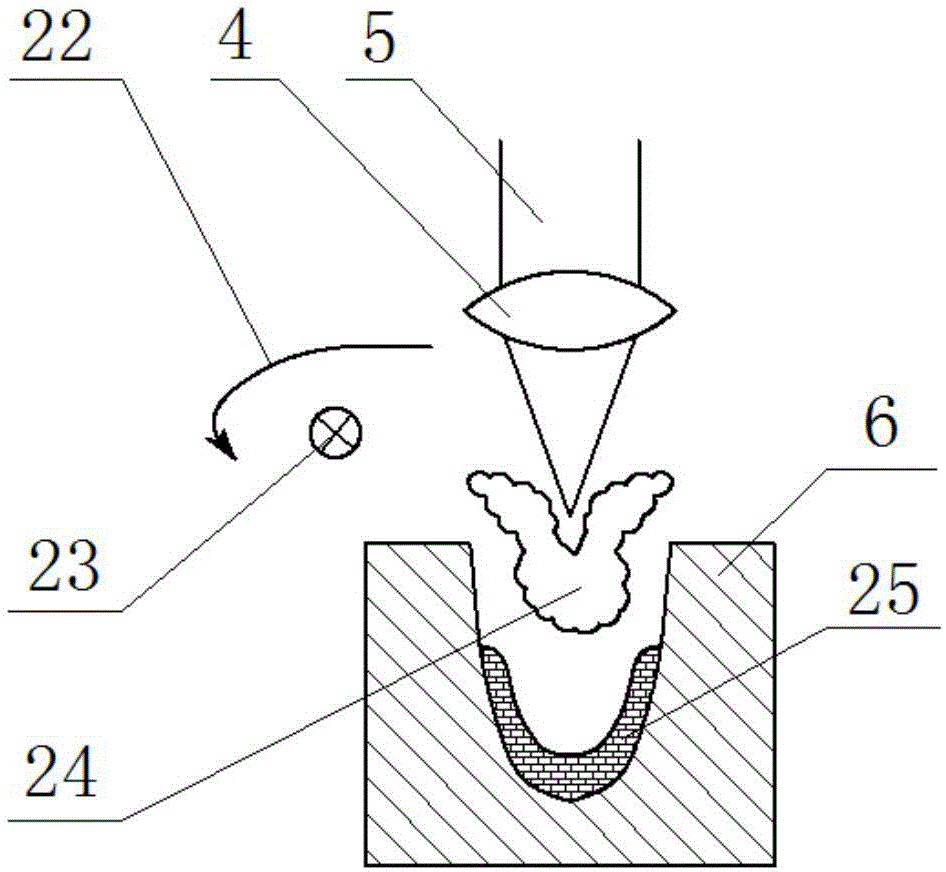

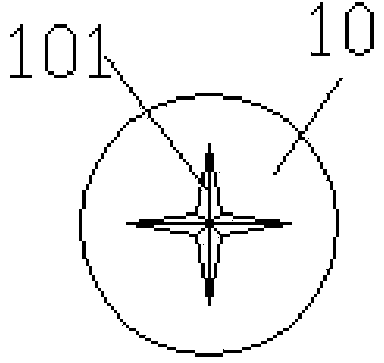

Electromagnetically-assisted laser drilling method and device

ActiveCN103817430ALow densityEnhanced magnetic fieldLaser beam welding apparatusMagnetic tension forceEngineering

The invention provides an electromagnetically-assisted laser drilling method. The method includes the steps of 1, clamping a workpiece to be processed onto an electromagnetically-assisted laser drilling device; 2, driving a fixture base to rotate by a motor so that a permanent magnet clamped on the fixture base rotates at high speed and forms a rotational magnetic field; meanwhile, allowing a mouse cage in the rotational magnetic field to produce electromagnetic force whereby the workpiece rotates in sync with the mouse cage; 3, after the speed of the motor stabilizes to a preset value, starting a laser, which generates a laser beam acting on the surface of the workpiece via a focusing lens so as to finish the electromagnetically-assisted laser drilling process. According to the method, the application of the operating method of rotating the workpiece enhances the assistance of the magnetic field in laser drilling; meanwhile, the rotational magnetic field can control motion of plasma and molten metal generated in the laser drilling process, so that laser drilling effect is optimized. The invention further provides the electromagnetically-assisted laser drilling device.

Owner:上海尚朴光电技术有限公司

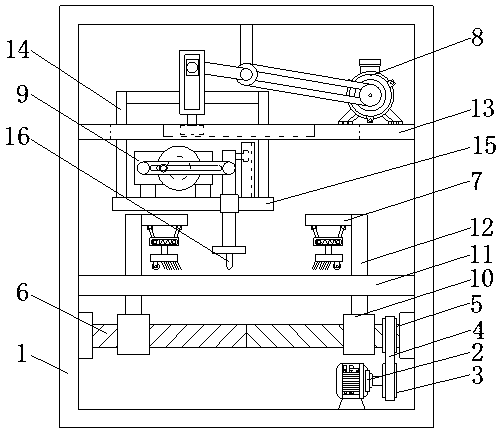

Workshop equipment

InactiveCN108161056ASimple structureEasy to useBoring/drilling componentsBoring/drilling machinesMechanical engineeringEngineering

The invention discloses workshop equipment. The equipment comprises a machine base, supports which are left and right symmetrically arranged at the two ends of the top of the machine base and a box shell which is arranged between the left and right supports through a pushing device; a first rotation cavity with a downward port is formed in the inner bottom of the box shell, a second rotation cavity which extends up and down is formed in the portion, above the first rotation cavity, in the box shell, and a first sliding groove is communicated with the interior of the inner wall of the left sideof the second rotation cavity; a rotation disc is rotatably arranged in the first rotation cavity through bearings, a first rotation shaft which extends into the second rotation cavity is fixedly arranged at the top of the rotation disc, a first conical wheel is fixedly arranged on the first rotation shaft in the second rotation cavity, and a first sliding block which can slide up and down is arranged in the first sliding groove.

Owner:楼碧云

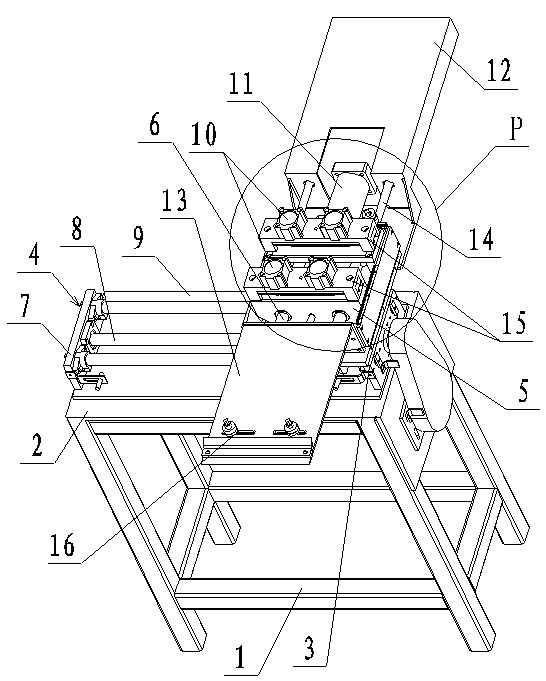

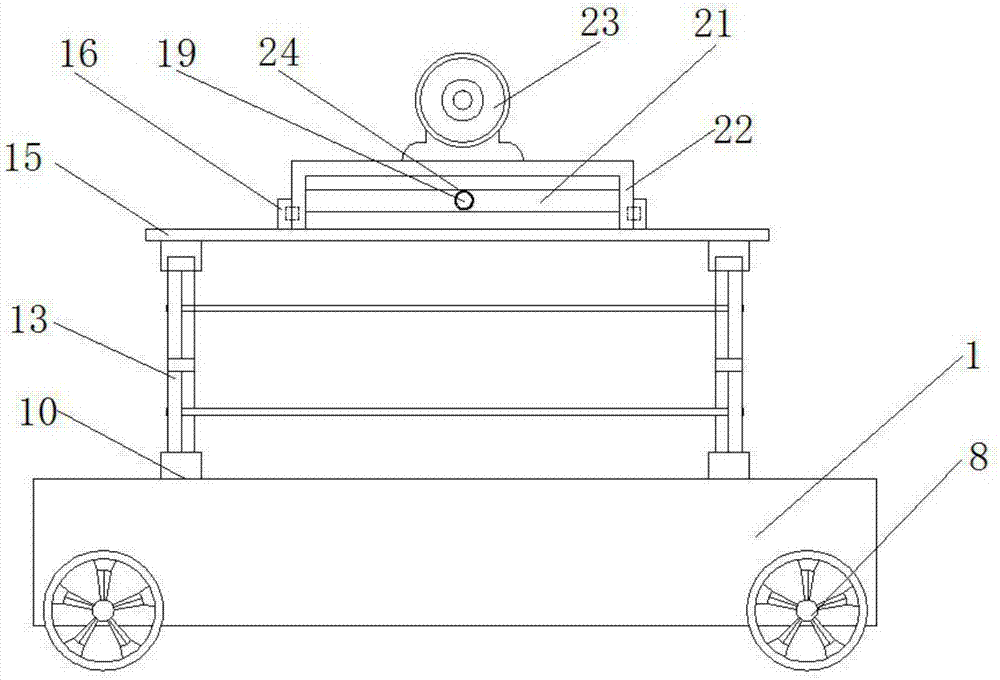

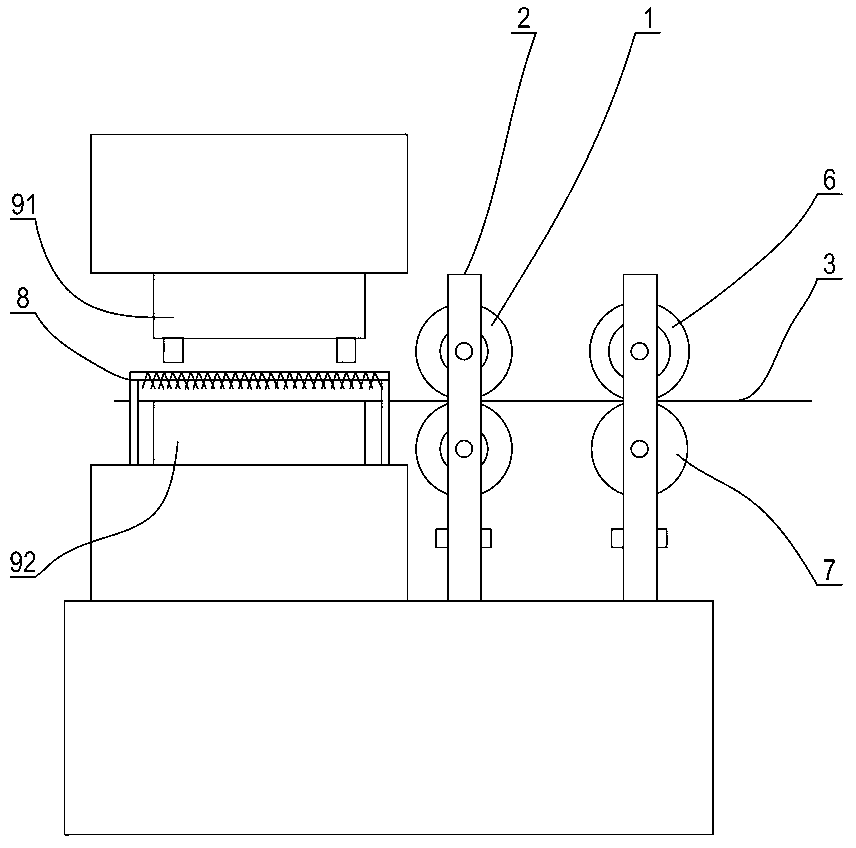

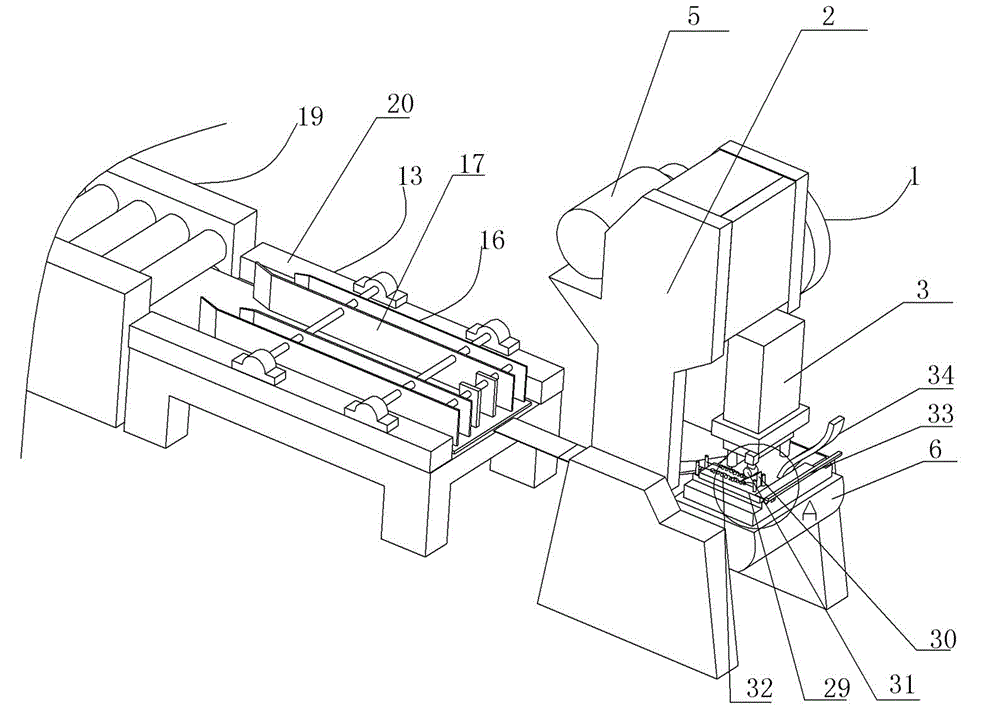

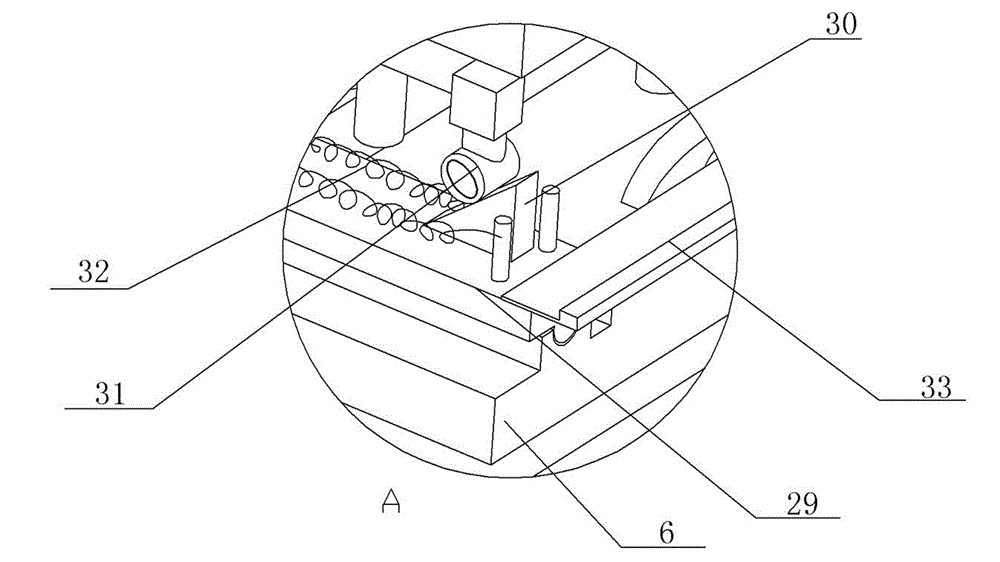

Automatic feeding device, automatic feeding-type punch press and automatic feeding method

InactiveCN103480762AReduce sizeShorten the lengthMetal-working feeding devicesPositioning devicesPunch pressControl system

The invention relates to an automatic feeding-type punch press which comprises automatic feeding devices. The automatic feeding devices are mounted on two sides of a die of the punch press in an alignment manner respectively. Each automatic feeding device comprises a support provided with a worktop on the top face; sliding seats are arranged on screw rod transmission mechanisms mounted on the worktops; feeding sliders are mounted on the sliding seats through guide sliding rails perpendicular to the screw rod transmission mechanisms; plate fixing devices are arranged above the feeding sliders; each feeding slider slides on the corresponding guide sliding rail through two feeding cylinders respectively arranged on two sides of the feeding slider; motors of the automatic feeding devices are controlled by a control system of an electrical control cabinet to drive the screw rod transmission mechanisms to enable the sliding seats to slide, and the feeding cylinders are utilized to control the feeding sliders to slide to complete automatic feeding of plates. The automatic feeding-type punch press is adopted to punch workpieces, the automatic feeding devices are simple in structure, small in occupied space and applicable to processing of various plates, and the die of the punch press is convenient to maintain and easy for workers to operate.

Owner:HANGZHOU KINGNET ELECTROMECHANICAL

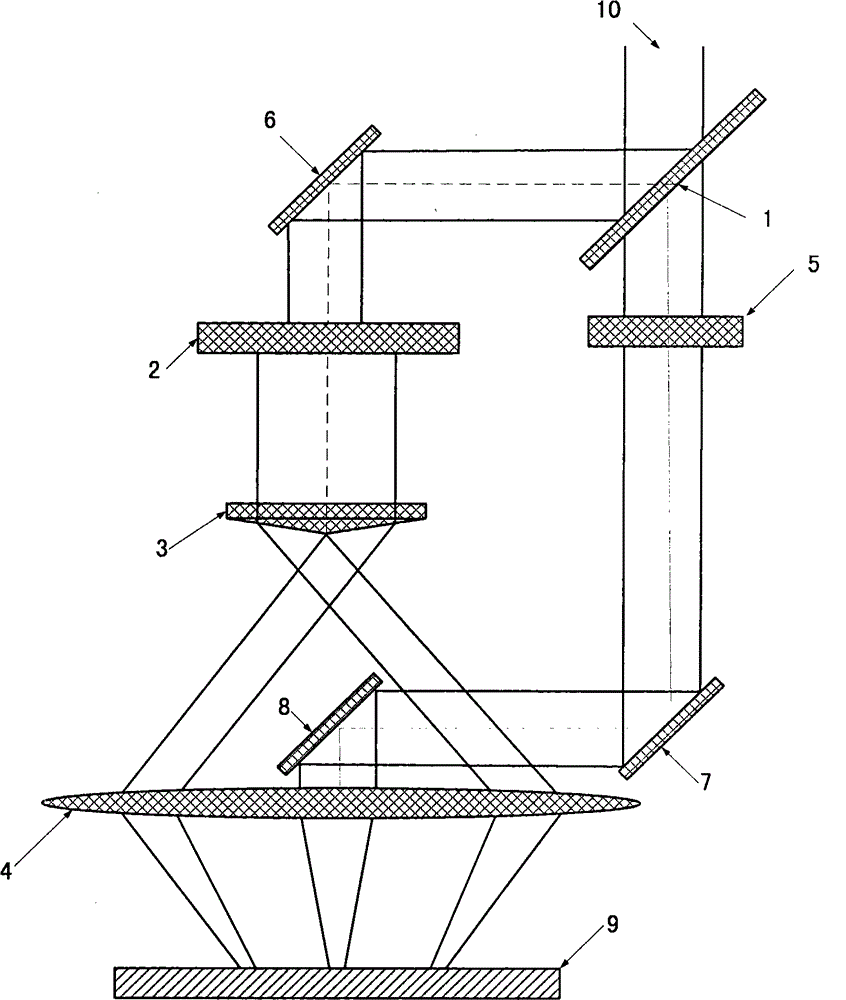

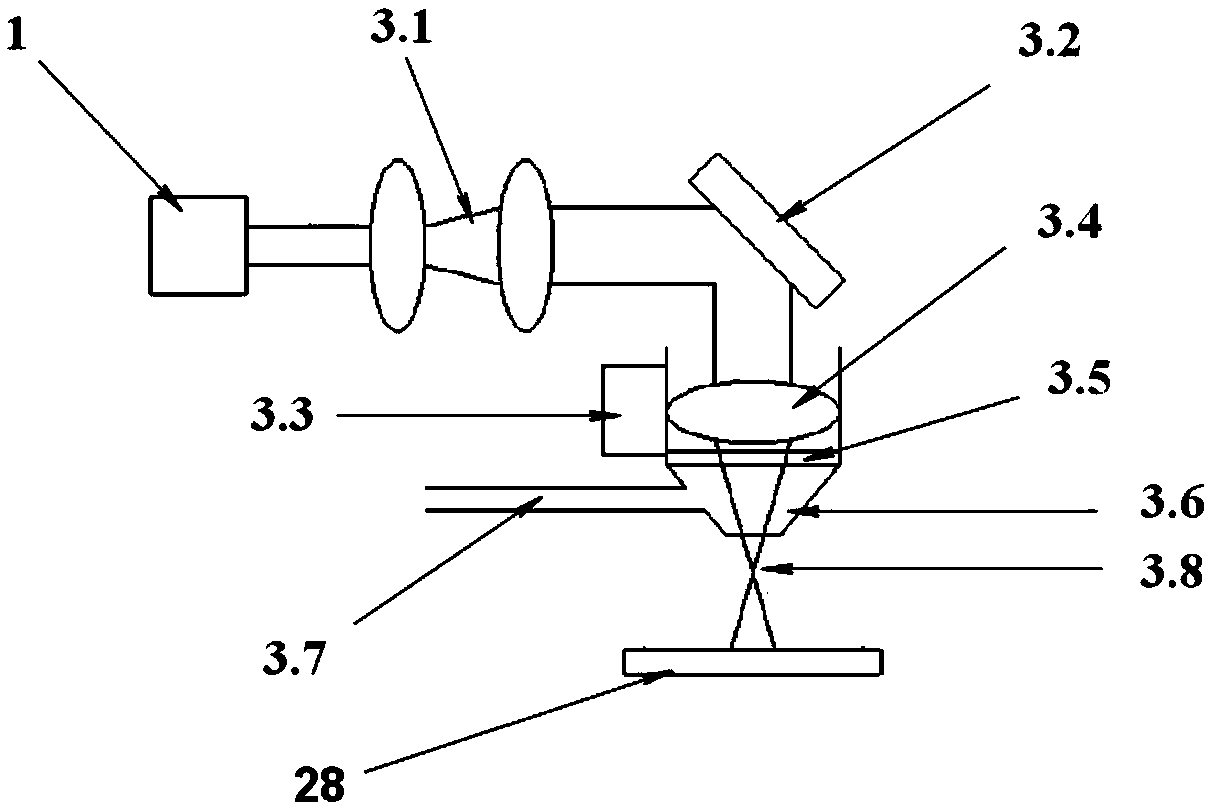

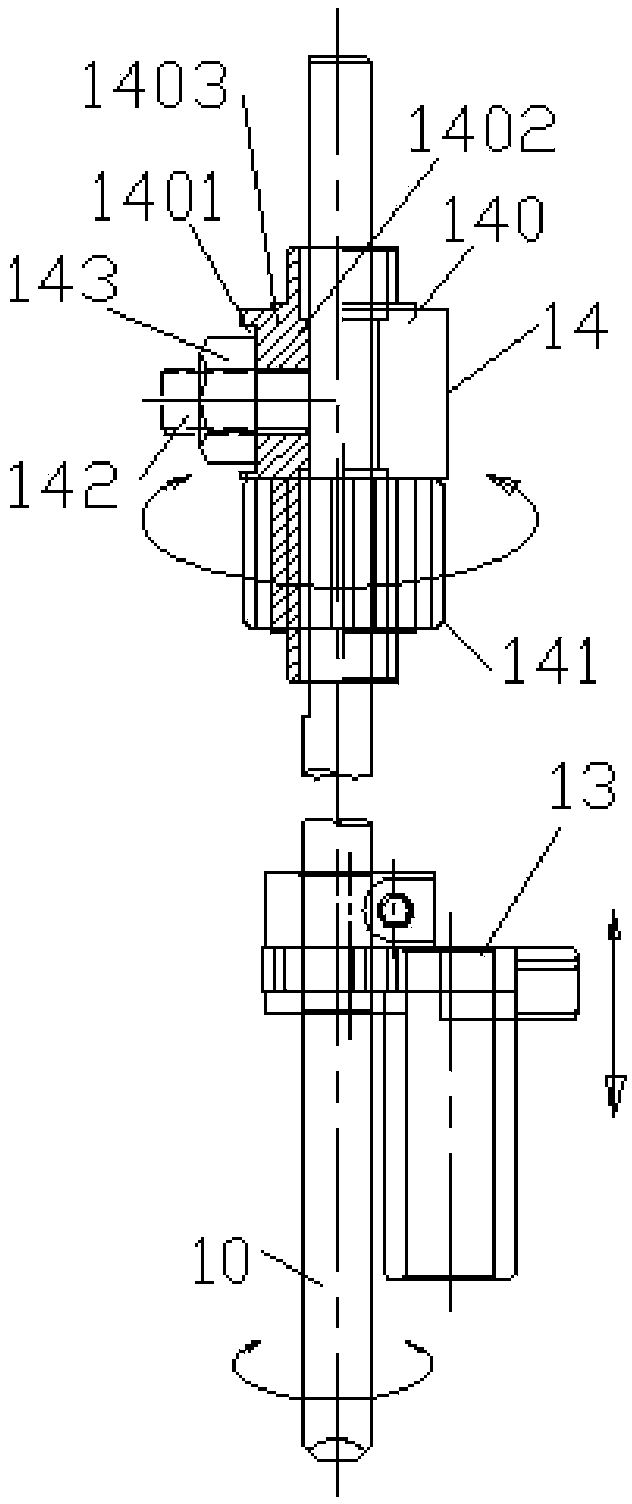

Laser processing head based on single-beam time-space characteristic regulation

ActiveCN104816087AGood hole roundnessGood ring accuracyLaser beam welding apparatusLaser processingPlane mirror

The invention provides a laser processing head based on single-beam time-space characteristic regulation. The laser processing head comprises a beam-splitting lens, an annular optical path system and a central optical path system; the annular optical path system comprises a first plane mirror, a conical lens group and a focusing objective; the central optical path system comprises a second plane mirror and a third plane mirror; a first laser beam split by the beam-splitting lens is reflected by the first plane mirror and then is incident into the conical lens group; the conical lens group generates a non-diffracted annular light beam for outputting to the focusing objective; the focusing objective outputs a fine annular focal spot obtained by focusing the non-diffracted annular light beam to the surface of a workpiece; a second laser beam split by the beam-splitting lens is reflected by the second plane mirror and the third plane mirror and then is incident into the focusing objective, and the focusing objective focuses the laser beam and then outputs a central fine circular spot to the surface of the workpiece. During laser boring by use of the laser processing head, excellent circular ring precision can be guaranteed, the heat effect area can be reduced and the hole edge quality can be improved.

Owner:WENZHOU UNIVERSITY

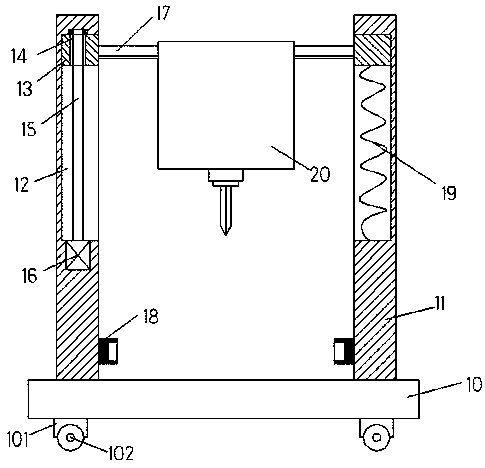

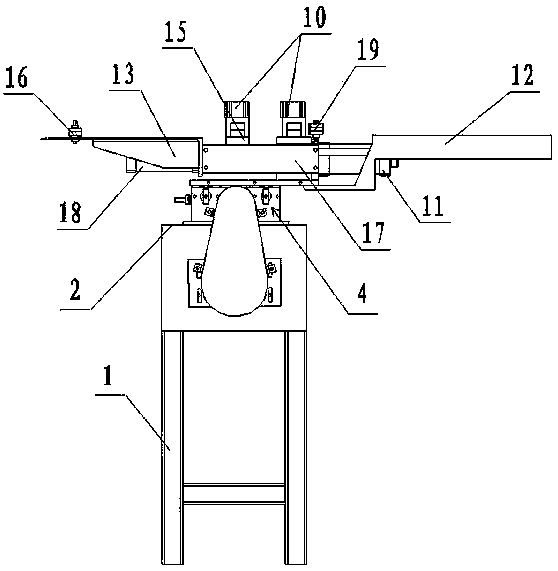

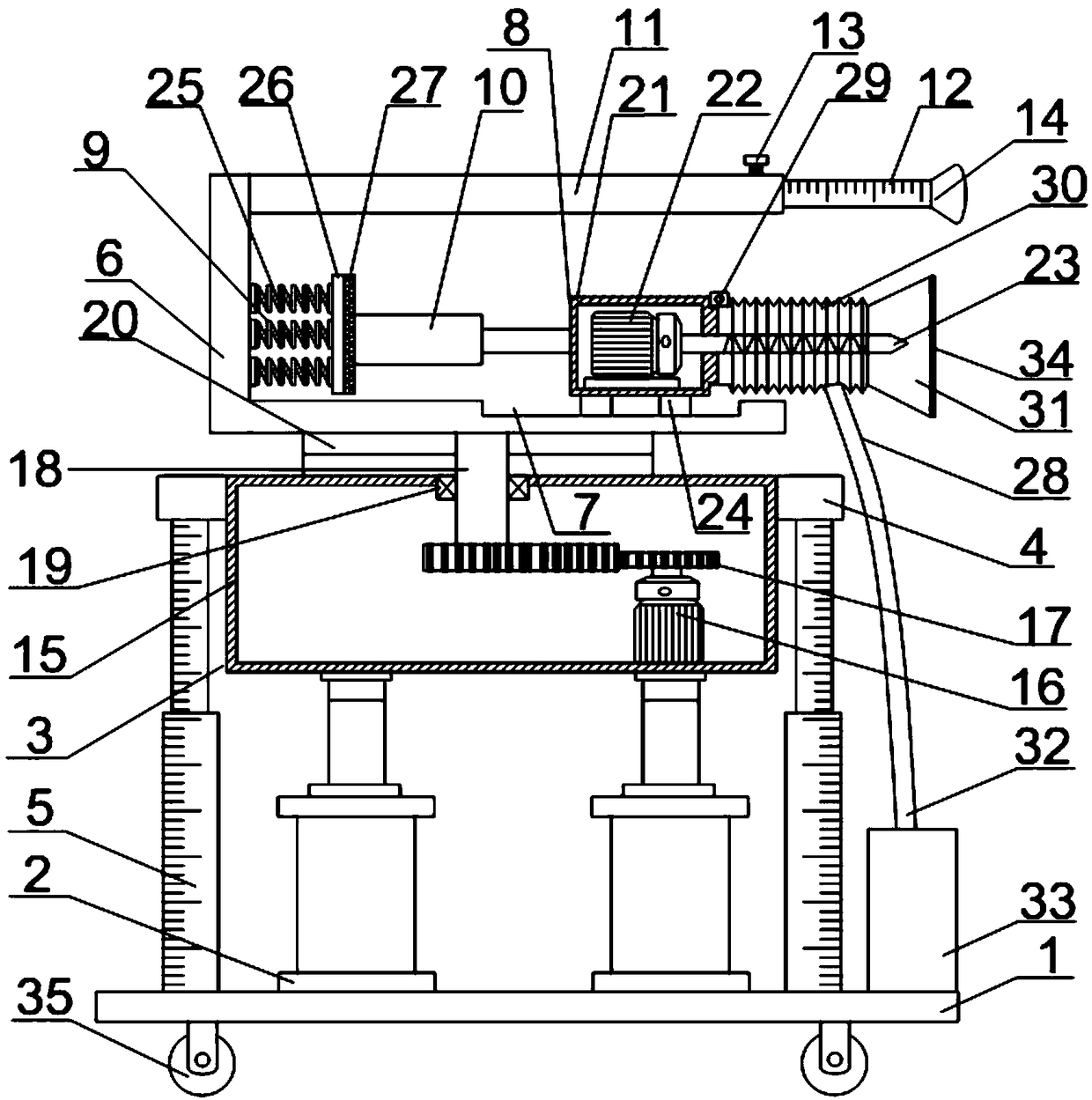

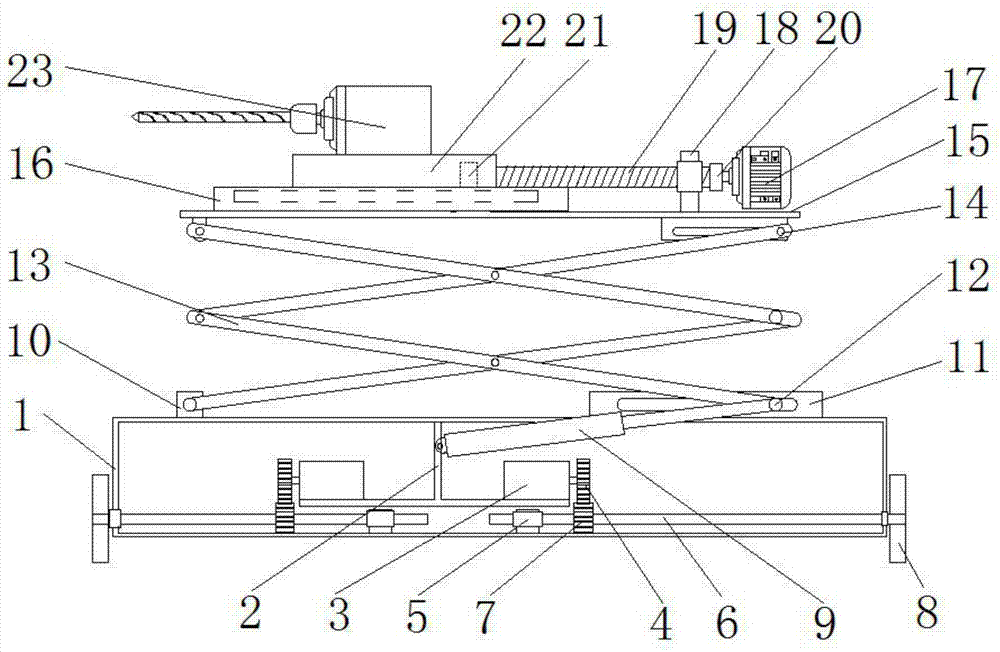

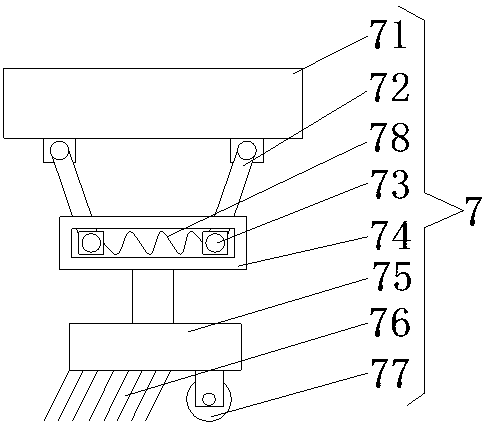

Efficient wall drilling machine

ActiveCN109227965AControl altitudeImprove stabilityWorking accessoriesStone-like material working toolsFixed frameEngineering

An efficient wall drilling machine comprises a base, a first cylinder is arranged on the base, and a piston rod of the first air cylinder is fixedly connected to the lower side of a rotating device; fixing frames are arranged on the two sides of the rotating device, and a telescopic scale rod is fixedly connected between each fixing frame and the base; the upper end of the rotating device is connected with a fixing base, and a sliding groove is formed in the horizontal direction of the fixing base; a drilling device is slidably connected with the interior of the sliding groove, and a damping device is connected to the vertical direction of the fixing base; the damping device is connected with a second cylinder, and a piston rod of the second cylinder is connected with the drilling device;a hollow connecting pipe is fixedly connected to the upper end of the fixing base, and a scale rod is inserted into the front end of the connecting pipe; the scale rod is fixed into the connecting pipe through a locking bolt, and a vacuum suction cup is arranged at the front end of the scale rod. The drilling machine is reasonable in design, the working efficiency can be effectively improved, thedrilling positioning precision and quality are improved, and the flexibility and the safety are achieved.

Owner:王勇

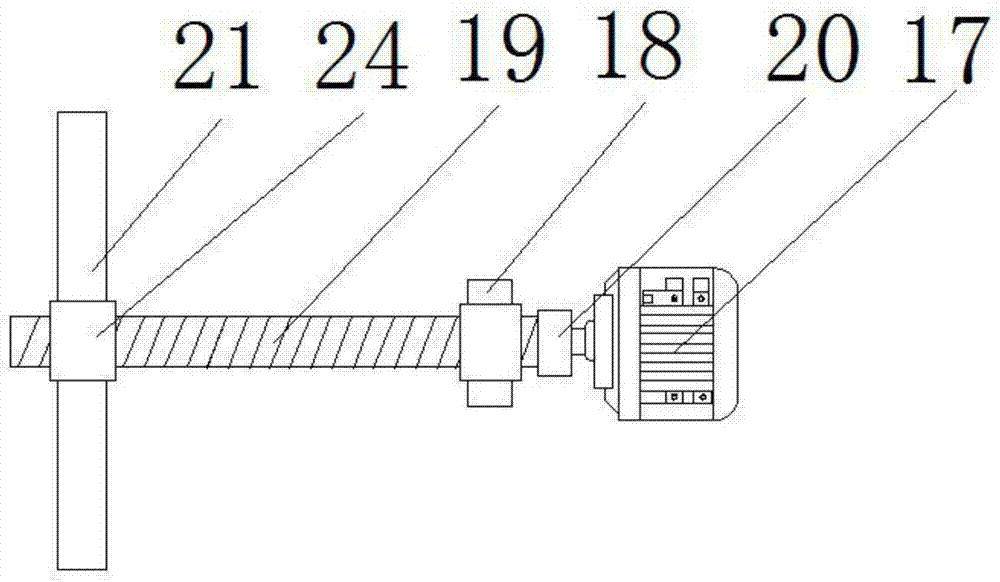

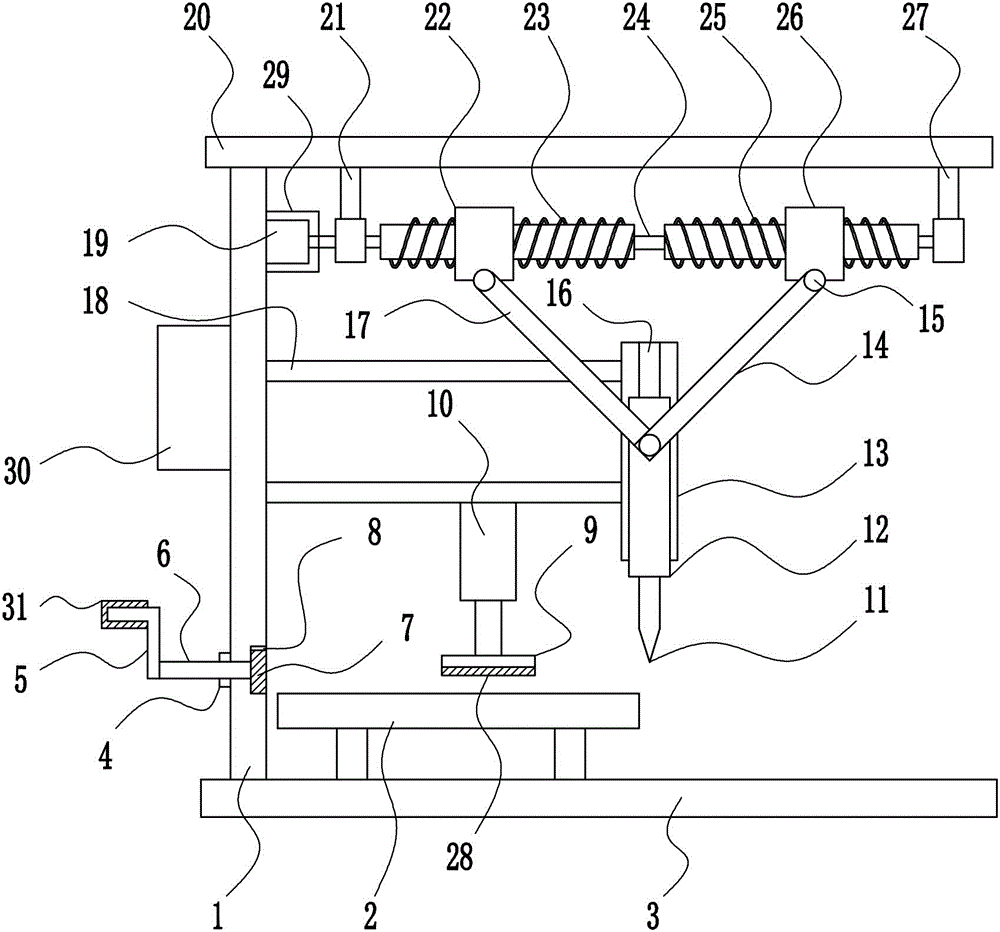

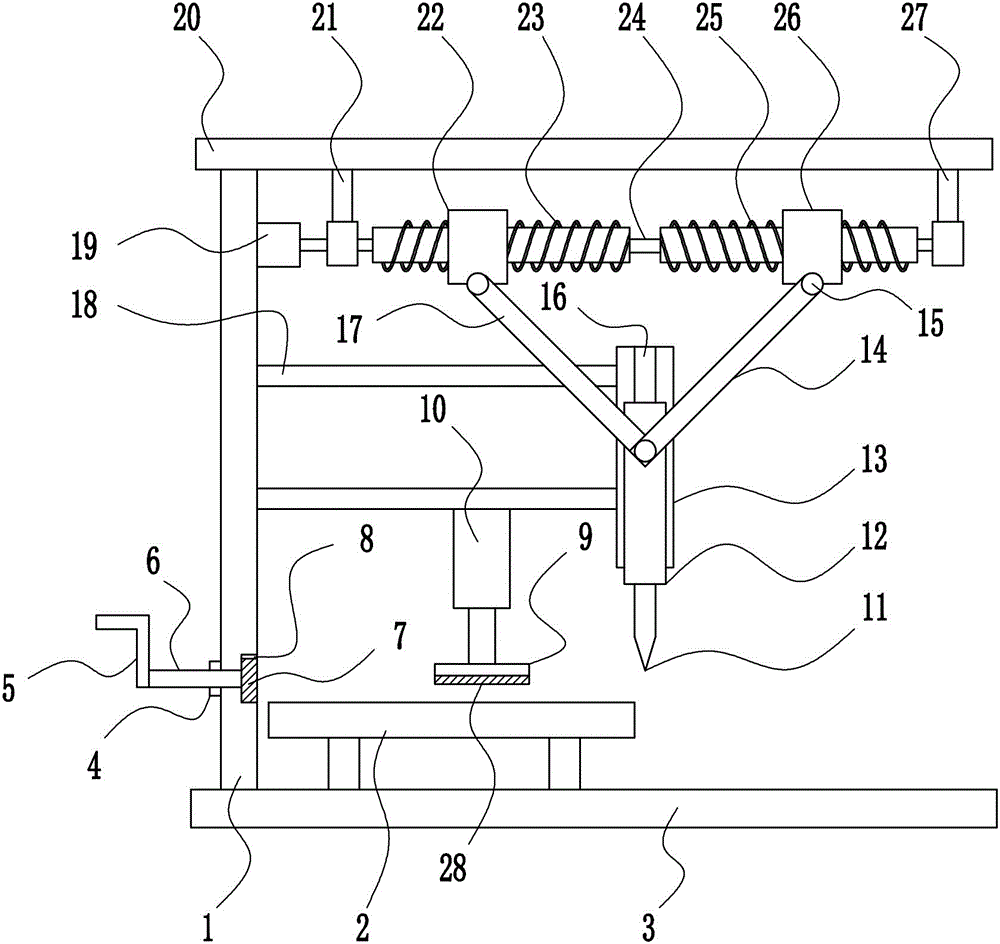

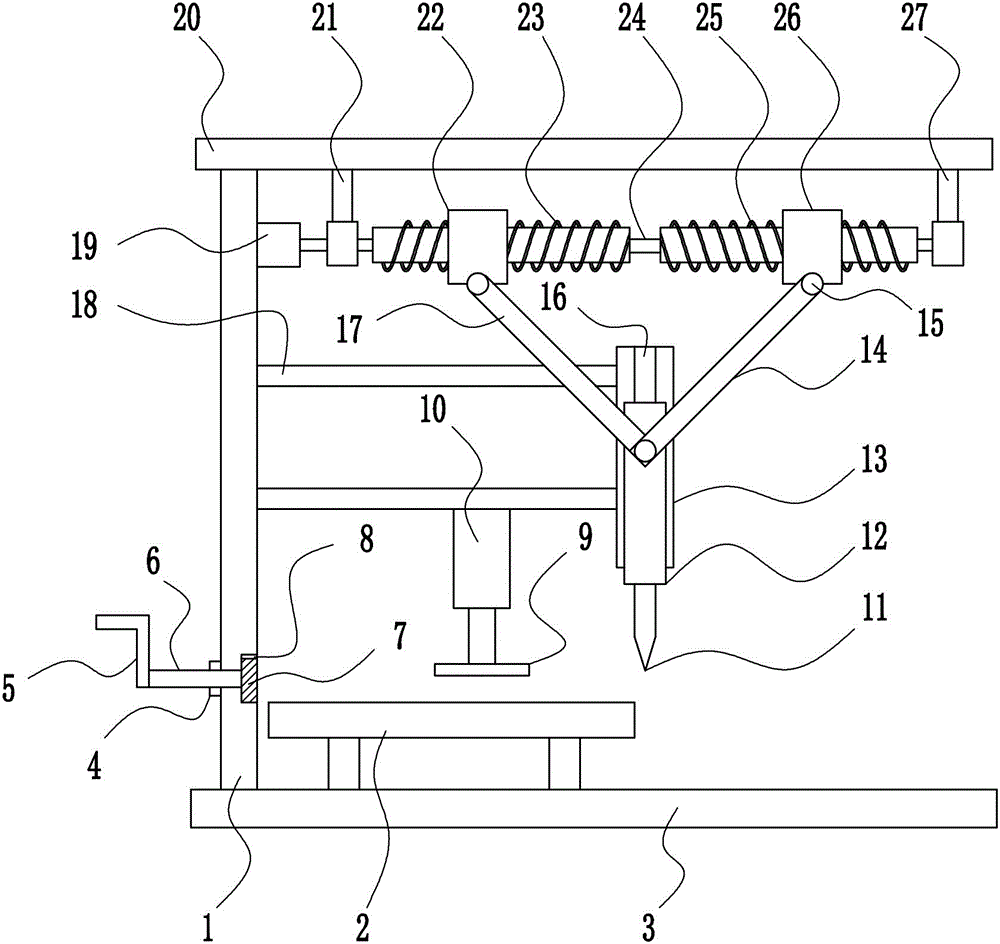

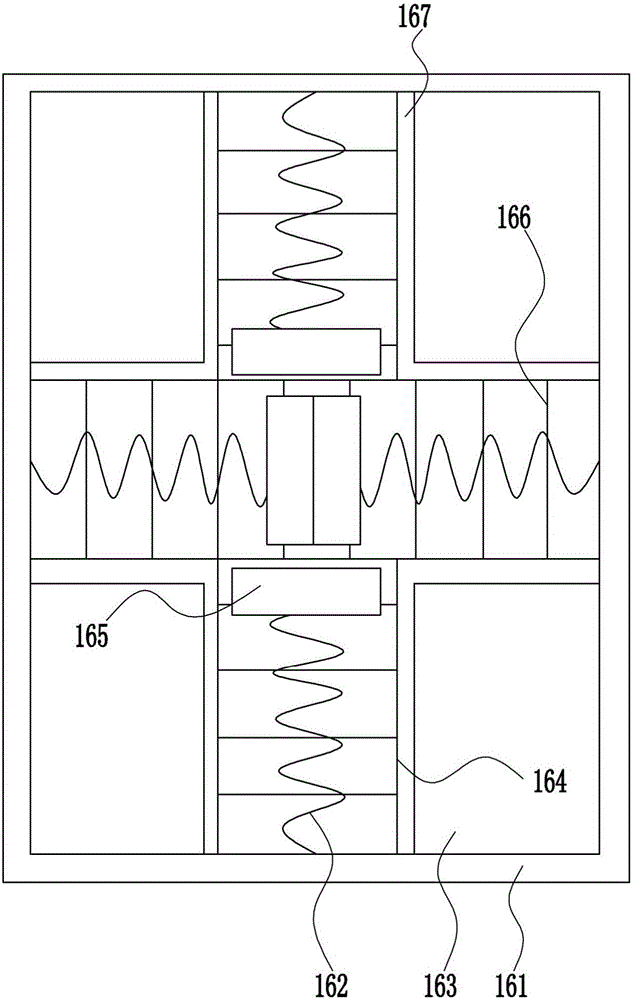

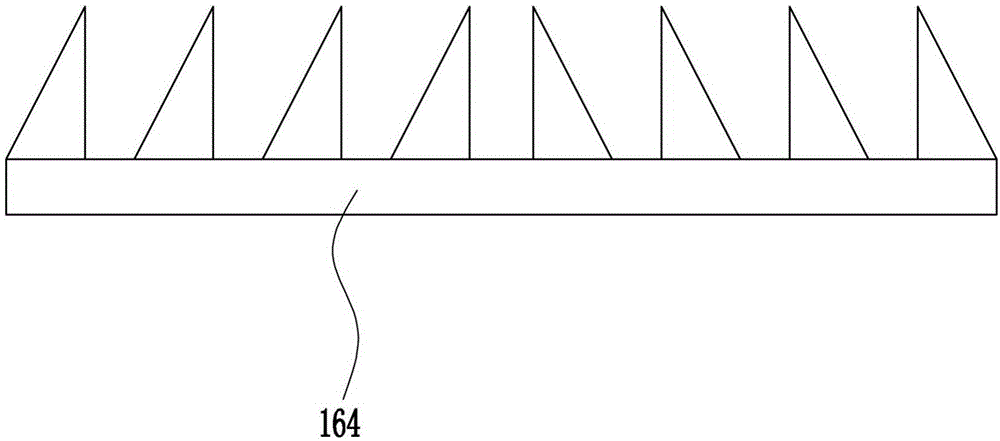

Automatic punching equipment for seamless steel tube

InactiveCN112222287AReduce distortionImprove punching efficiencyPerforating toolsMetal-working feeding devicesPunchingBall screw

The invention belongs to the technical field of automatic equipment, and particularly relates to automatic punching equipment for a seamless steel tube. The automatic punching equipment comprises a machine frame; an oil cylinder is fixedly connected to the top of the machine frame through a vertical rod; a punch is fixedly connected to the bottom of a piston rod of the oil cylinder; a sliding groove is formed in the position, corresponding to the oil cylinder, of the top of the machine frame; a fixing ring is fixedly connected to the top of a sliding block which is connected in the sliding groove in a sliding mode; a support plate is fixedly connected to one side of the fixing ring; a lead screw is connected to the position, corresponding to the support plate, of the machine frame in a rotating mode and is driven by a servo motor to rotate; the lead screw is connected to the support plate through a ball screw nut pair; a supporting rod is fixedly connected to the position, on one sideof the sliding groove, of the machine frame through a support; and a supporting column is arranged at the position, corresponding to the punch, of the supporting rod. According to the automatic punching equipment, the supporting column is inserted into the steel tube to support the punching position of the steel tube, and then deformation of the steel tube in the punching process is reduced.

Owner:温州莜例贸易有限公司

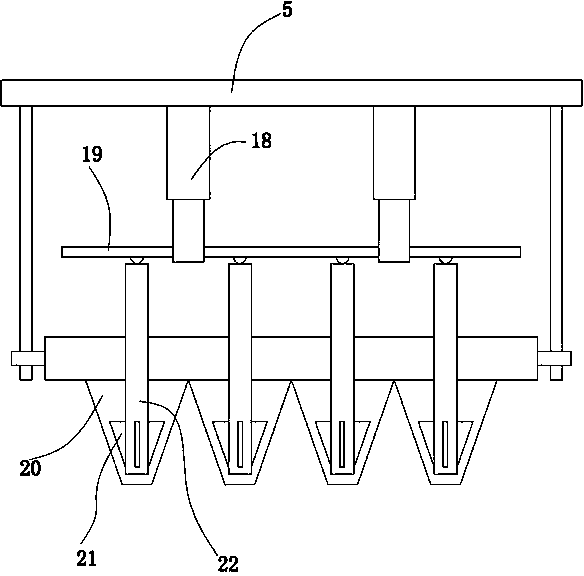

Automatic punching device for fastening pieces

InactiveCN107627134AFast and efficient drillingReduce labor intensityPositioning apparatusMetal working apparatusPunchingTransfer mechanism

The invention discloses an automatic punching device for fastening pieces. The automatic punching device comprises a working table, a feeding mechanism, a transferring mechanism, a positioning mechanism and a punching mechanism, wherein the feeding mechanism comprises a feeding support, a feeding chute and a temporary storage tank; the fastening pieces are fed into the feeding chute through a vibrating feeding disc and further fed into the temporary storage tank through a first pushing cylinder; a second pushing cylinder pushes the fastening pieces out to be transferred; the positioning mechanism comprises a positioning seat, a clamping disc and a positioning sleeve rod; the clamping disc can effectively fix the positioning sleeve rod; the transferring mechanism comprises a transferring frame, a grabbing cylinder and a grabbing component; the transferring frame drives the grabbing component to perform vertical or horizontal movement; and the grabbing cylinder drives the grabbing component to grab or release the fastening pieces. According to the automatic punching device for fastening pieces, the structure is compact, the degree of automation is high, the fastening pieces can be effectively punched, the punching efficiency is high, and the punching quality is good.

Owner:嘉善翱鹰五金制品厂

Automatic wall face drilling device

InactiveCN107378057AAvoid health effectsAvoid influencePortable power-driven toolsFeeding apparatusDrive wheelDrive shaft

The invention discloses an automatic wall drilling device, which comprises a box body, first motors are fixedly connected to both sides of the top of a T-shaped fixed plate on the inner wall of the box, and a shaft seat is fixedly connected to the bottom of the inner wall of the box, and the shaft seat rotates. A drive shaft is connected, one end of the drive shaft is fixedly connected to the drive wheel, the first motor is connected to the drive wheel through gear transmission, one side of the T-shaped fixed plate is connected to the hydraulic rod, and the top of the box is connected to the lifting frame in rotation. The top is rotatably connected with a lifting platform, one side of the top of the lifting platform is fixedly connected with a support plate, the support plate is slidingly connected with a moving frame, the top of the moving frame is fixedly connected with a drilling device, and the top of the lifting platform is fixedly connected with a second motor. One end of the output shaft of the second motor is fixedly connected with a screw rod. The invention relates to the field of electromechanical tools. The wall surface automatic drilling device realizes automatic feeding, improves hole quality and work efficiency, and protects the safety of construction personnel.

Owner:合肥恩腾电子科技有限公司

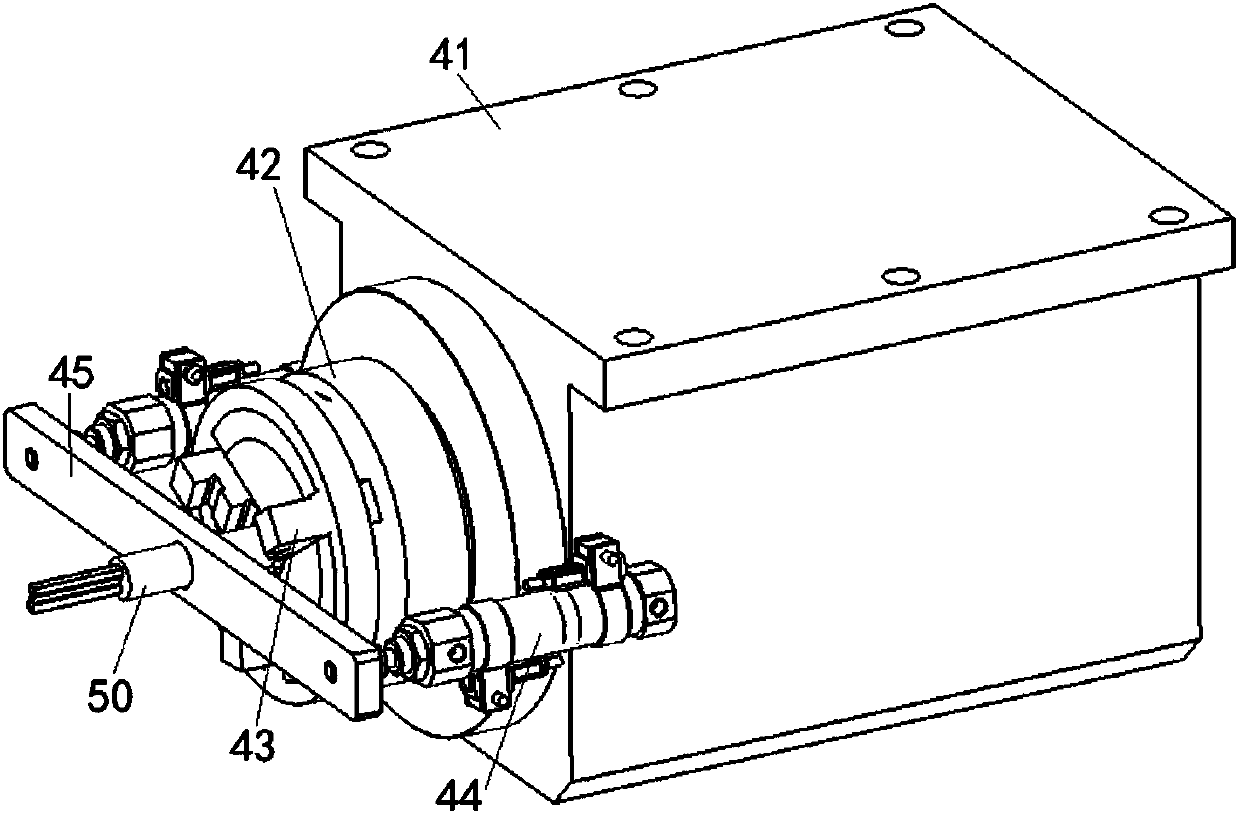

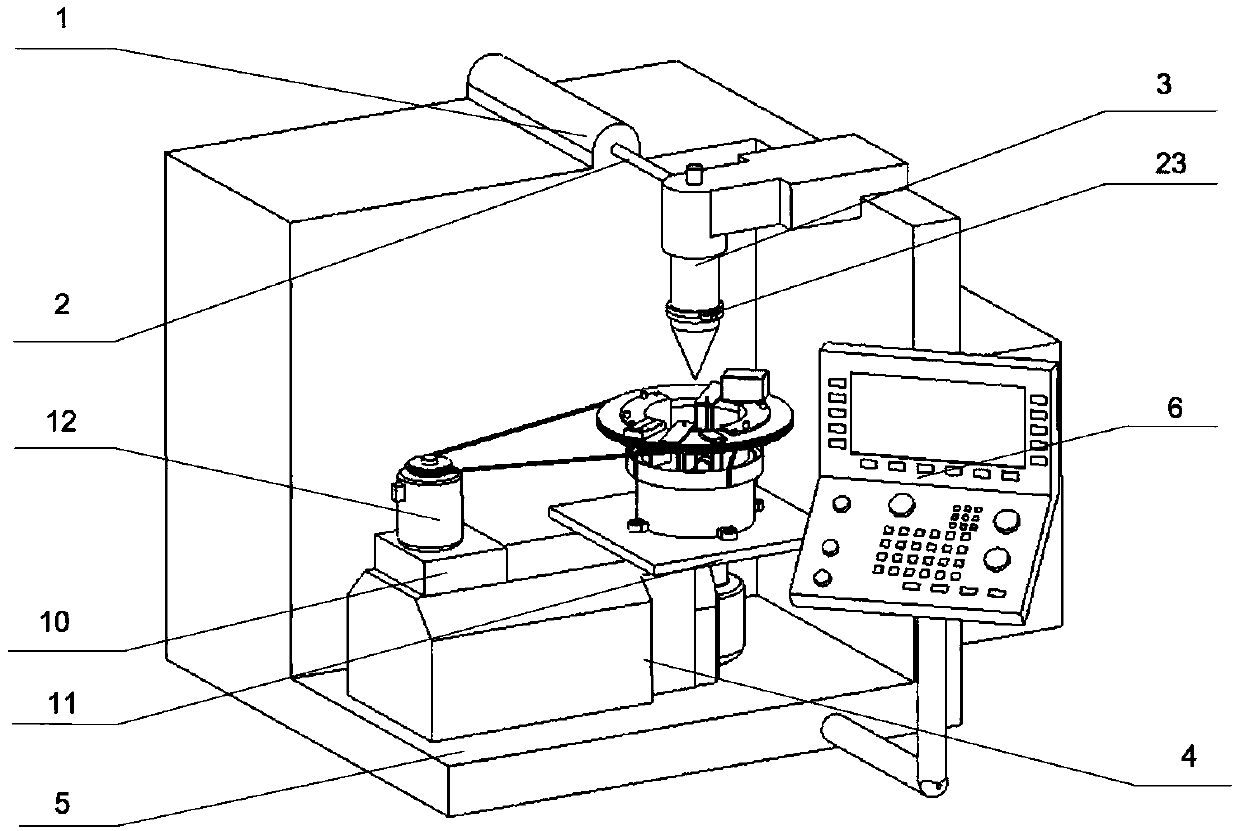

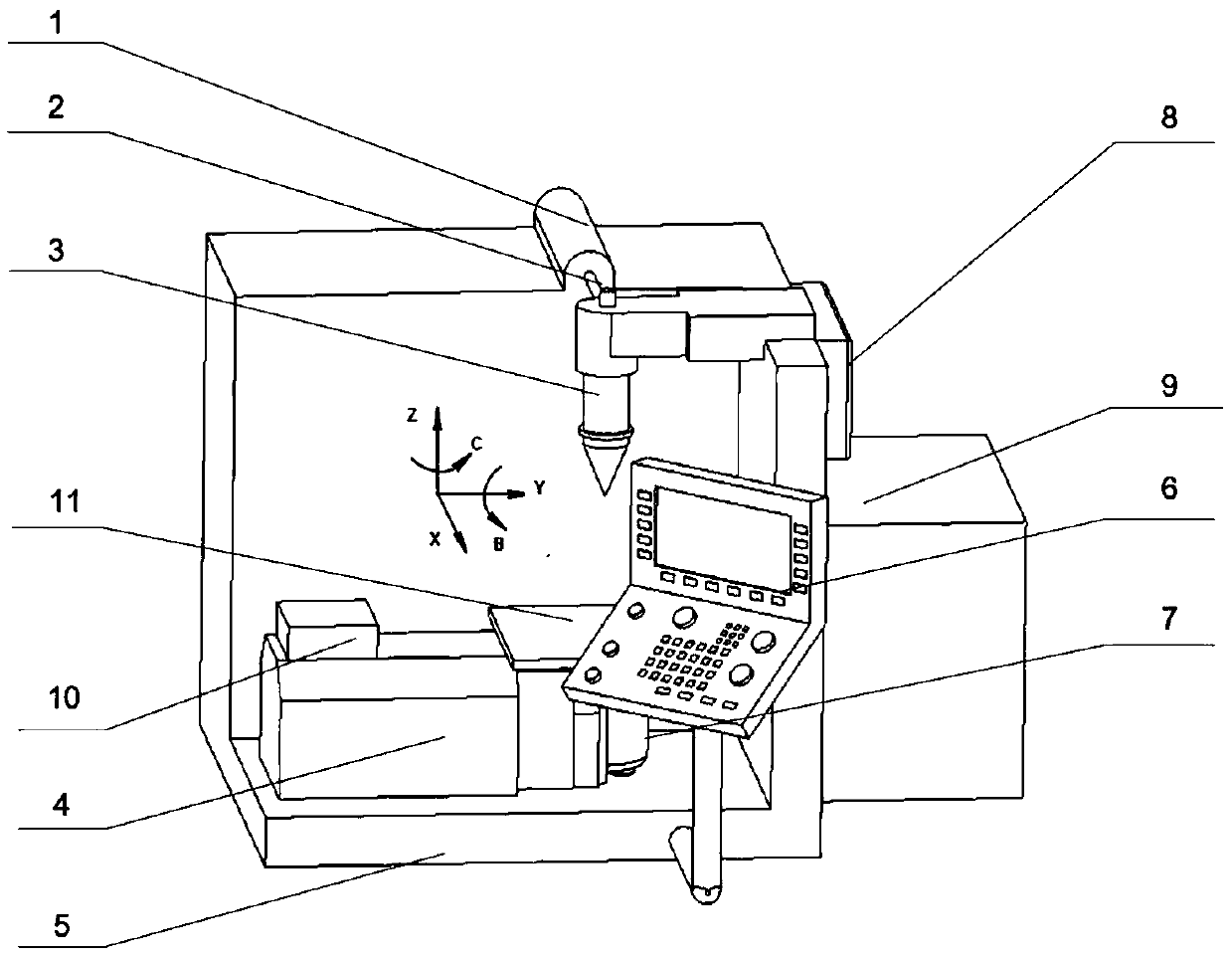

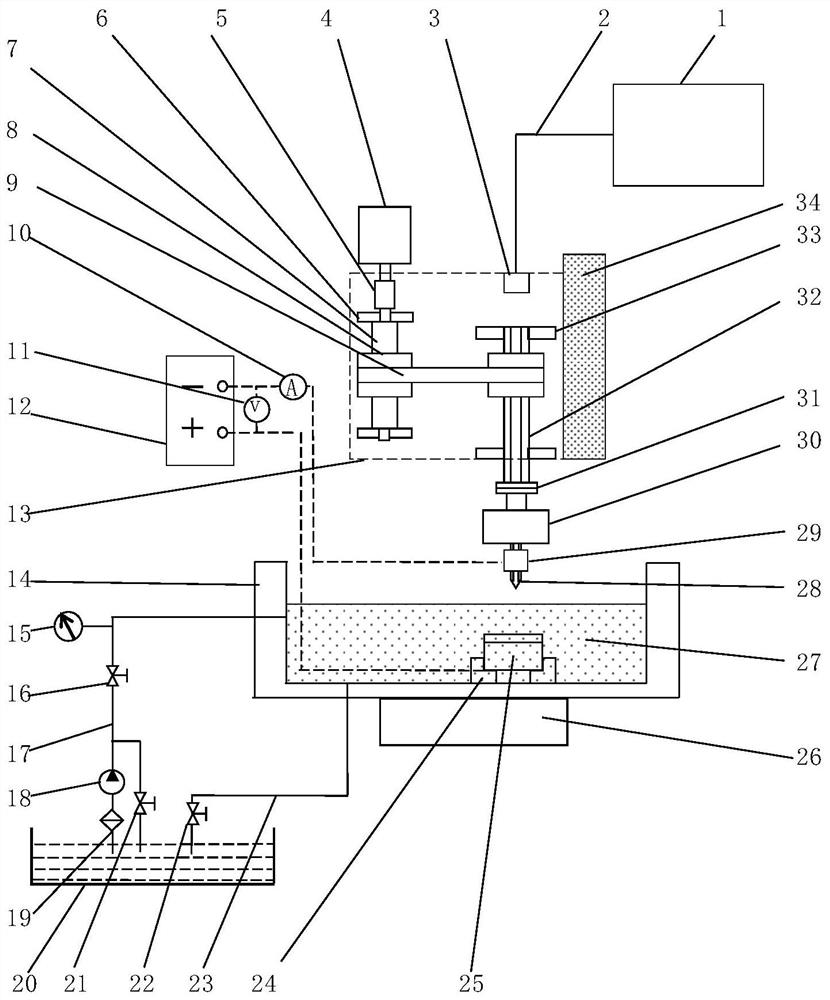

Laser shock punching device based on rotating electromagnetic field and water-based ultrasonic vibrating

ActiveCN109648215AReduced shieldingImprove distributionLaser beam welding apparatusWater basedEngineering

The invention provides a laser shock punching device based on a rotating electromagnetic field and a water-based ultrasonic vibrating. The device comprises a laser machining center, an ultrasonic auxiliary unit, an electromagnetic auxiliary unit and a workpiece clamping unit, wherein the electromagnetic auxiliary unit comprises a driving mechanism, a bracket, an electric field generating device, two electrode plates, two electromagnets and an electromagnetic adjusting device, wherein the bracket is a rotary body, the driving mechanism is used for driving the bracket to rotate around the axis of the bracket, the two electrode plates and the two electromagnets are uniformly distributed on the inner surface of the bracket in the circumferential direction by taking the axis of the bracket as the center, and the electrode plates and the electromagnets are arranged at intervals. According to the device, the shielding, scattering and refraction effects of the plasma can be weakened, the heatinput efficiency of a laser beam is improved, electromagnetic stirring can be generated in molten metal, micro cracks of the wall of the hole can be repaired, and meanwhile grains and tissues can be refined, the mechanical property is improved, the residual stress is effectively reduced, the punching efficiency is improved, the punching depth is increased, and the punching quality is improved.

Owner:JIANGSU UNIV

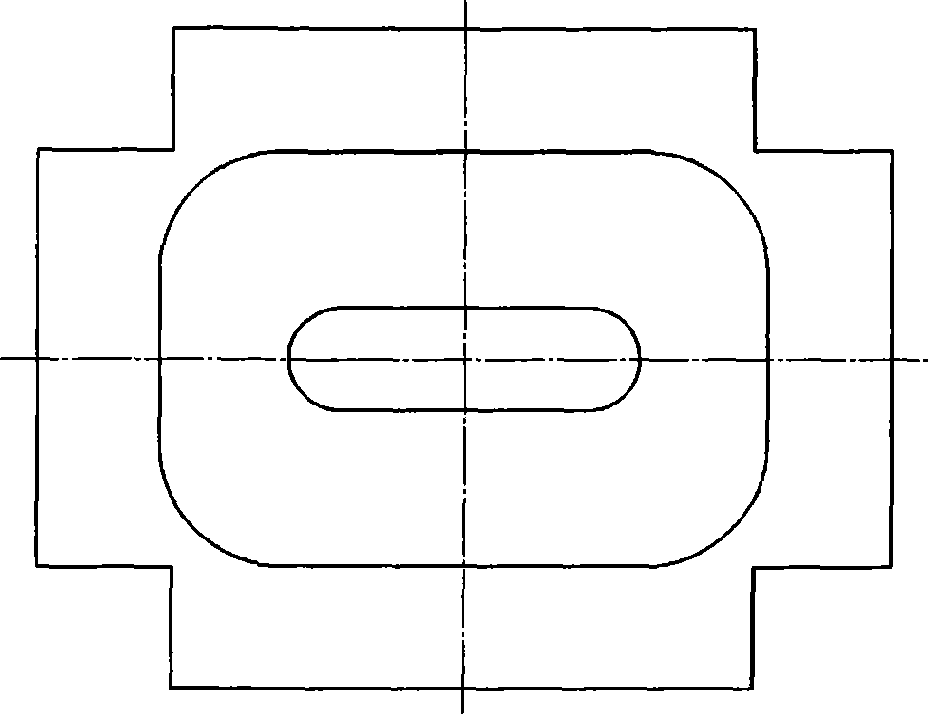

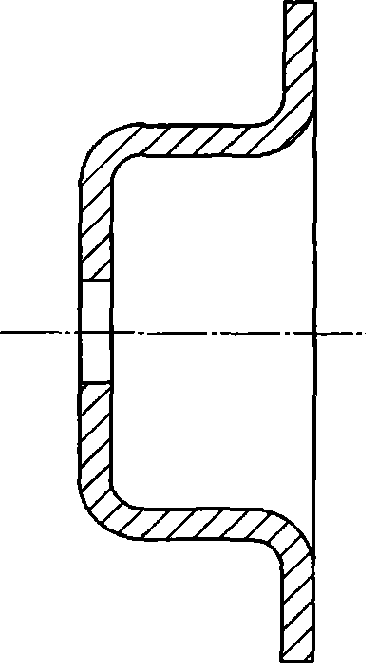

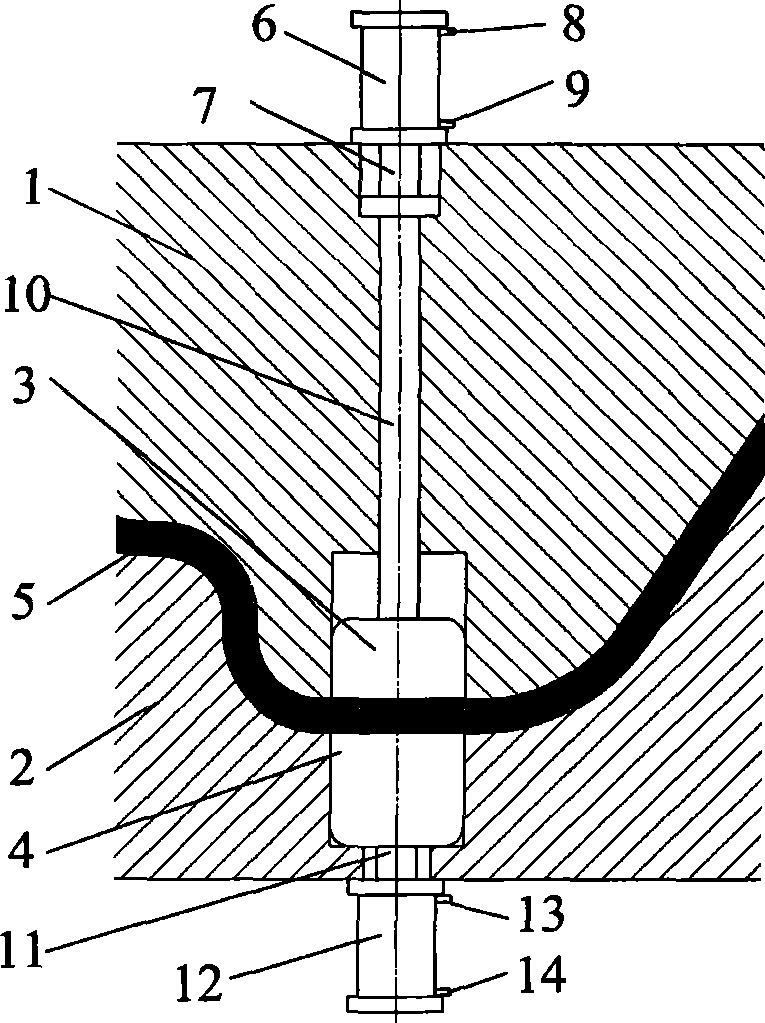

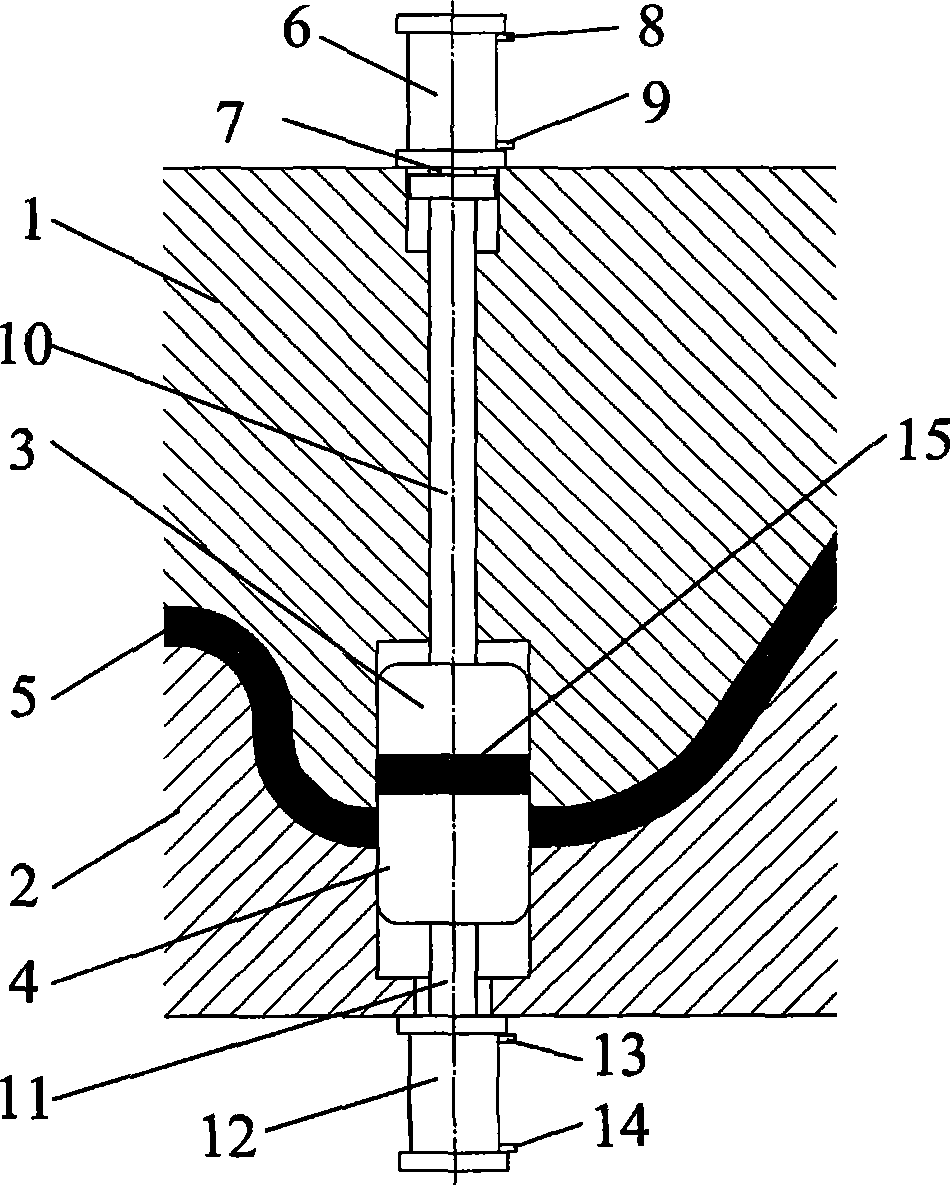

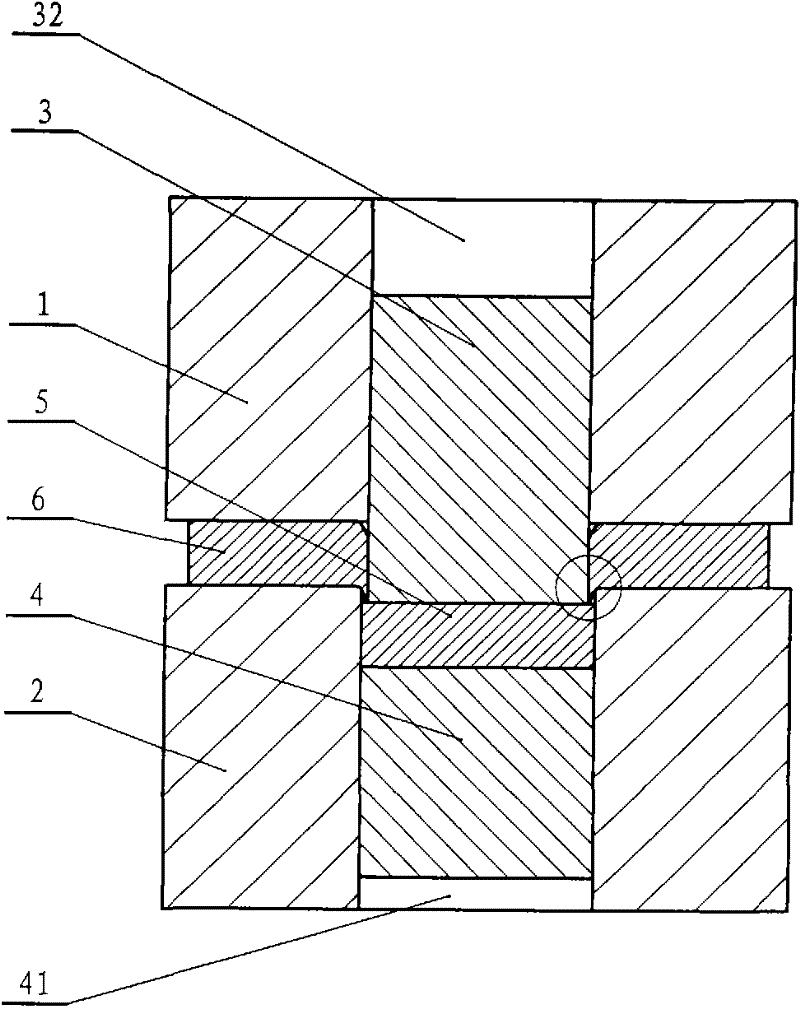

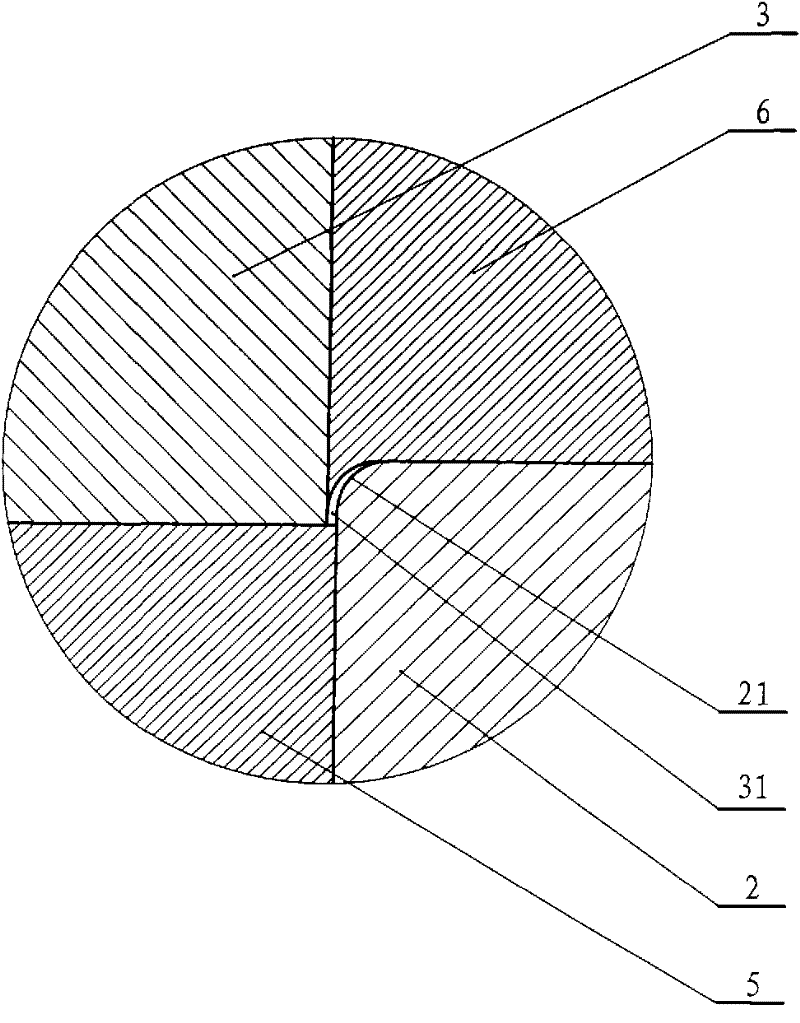

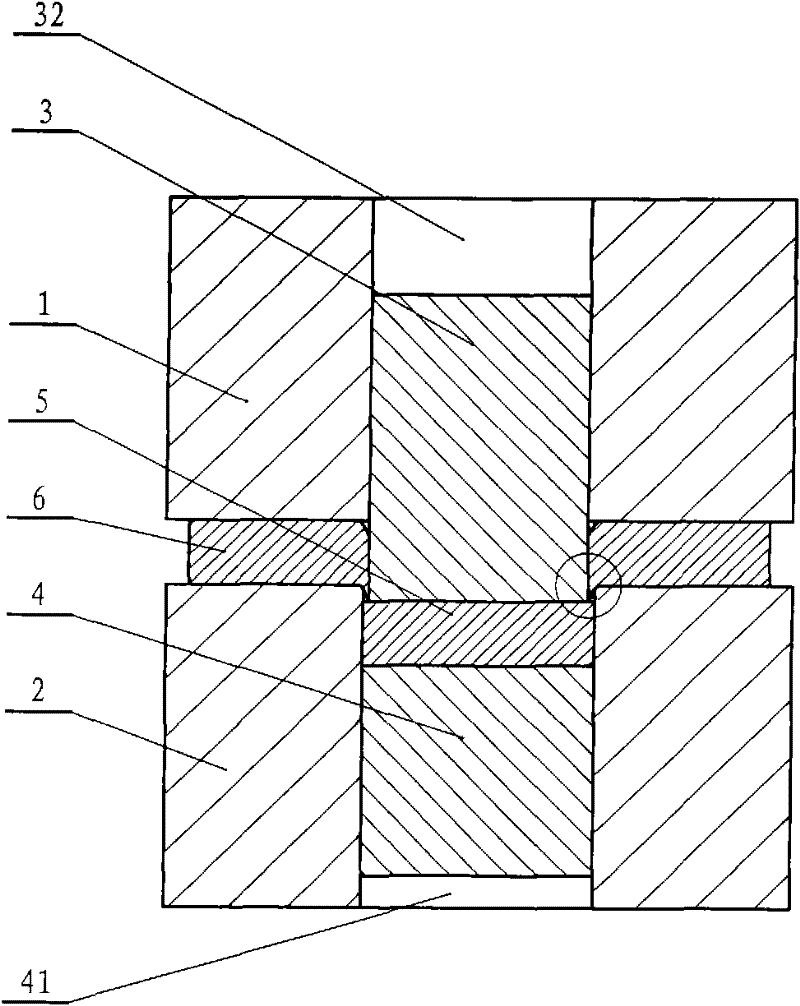

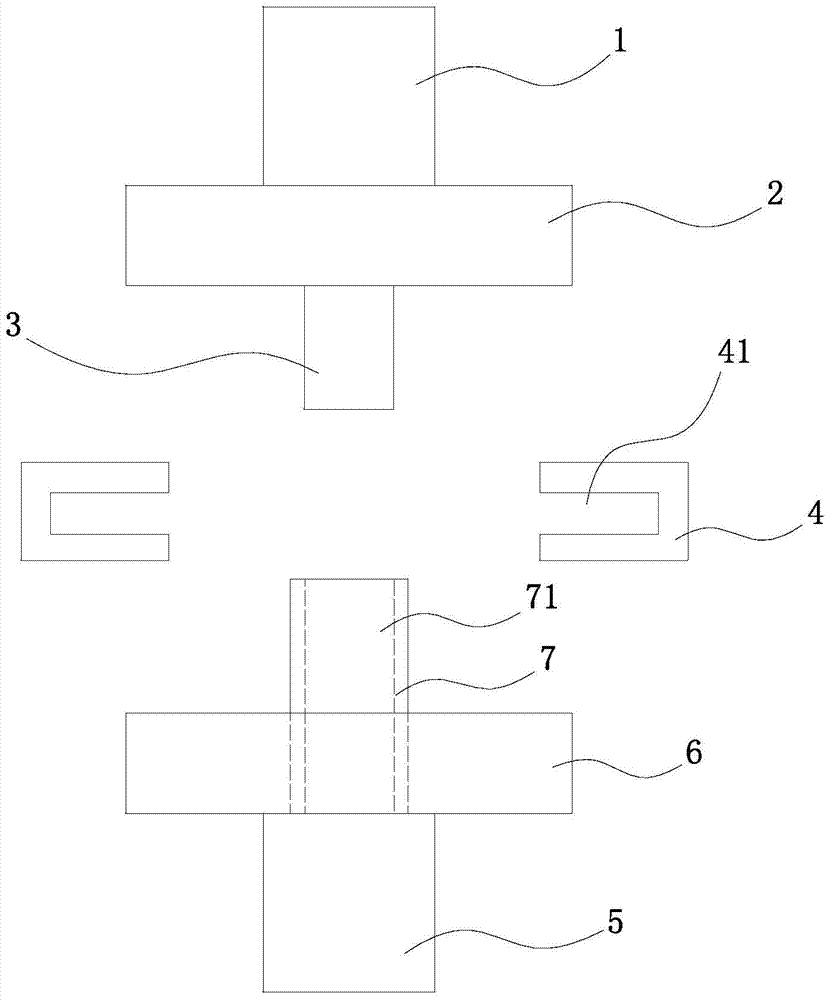

Thermoforming and hole-punching integrated technique and mold of high-duty steel part

InactiveCN101486060ALess investment in equipmentSmall footprintShaping toolsPerforating toolsSteel platesSheet steel

The invention provides an integrative process and a die for hot forming and punching of a high-strength steel part. The integrative process comprises the following steps: providing a punching tool on the hot forming die for the high-strength steel part; before punching and forming a high-strength steel plate, putting the heated fully austenized high-strength steel plate into the hot forming die for punching; and after closing the hot forming die, utilizing the punching tool on the hot forming die to carry out punching operation for a punched work piece. The integrative die comprises an upper die, a lower die, an upper punching tool and a lower punching tool, wherein the upper end of the upper die is provided with an upper die oil cylinder, a piston rod of the upper die cylinder is connected with the upper punching tool through a post rod, the lower end of the lower die is provided with a lower die cylinder, and a piston rod of the lower die oil cylinder is connected with the lower punching tool. The process and the die reduce equipment investment and production cost for hot forming, shorten production period, and have high punching quality, and high dimension precision and shape precision of parts.

Owner:SHANDONG UNIV

Plane edge-pressing and semi-fine blanking device and method

The invention relates to a plane edge-pressing and semi-fine blanking device and a method. The device is provided with a plane pressure plate and a concave die, when a workpiece is punched, the plane pressure plate needs to enable edge-pressing force to press on the outer edge of a profile of the workpiece on a workpiece blank, and the edge-pressing force can generate great friction force betweenthe surface of the workpiece blank and the plane pressure plate and between the surface of the workpiece blank and the concave die, so as to prevent the material of the workpiece blank from flowing out of the profile of the workpiece. The device is matched with punching force, three-dimensional pressure stress is generated in the material of the workpiece blank in an extrusion zone, and plastic flow is generated, so as to enable the numerical values of the pressure stress in the three-dimensional directions to tend to be consistent, enable the material of the workpiece blank in the profile ofthe workpiece to be in the hydrostatic pressure state and have a maximal plastic deformation range, reduce a region for generating tensile stress in a shearing deformation zone and prevent the emergence of cracks on the surface of a cross section of the workpiece. By using the plane edge-pressing and semi-fine blanking device and the method, an ordinary punch can be used, the processing of a die is simple, a pressurization region on the workpiece blank can not cause damages, the processing cost is low, the quality of the workpiece is high, and the device and the method are convenient to popularize and apply in the punching industry.

Owner:CHONGQING UNIV OF TECH

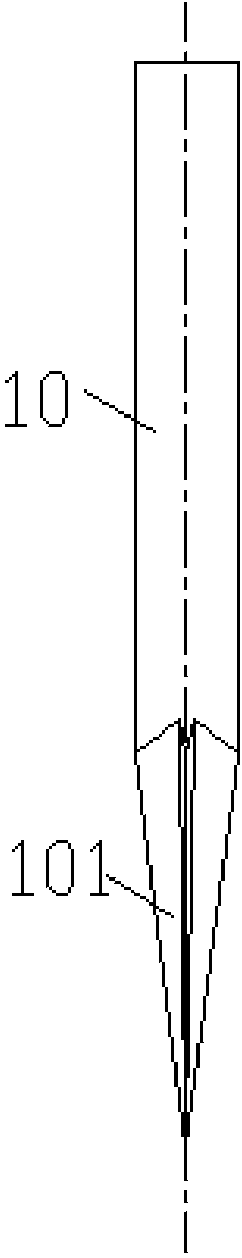

Eyelet embroiderer

The invention discloses an eyelet embroiderer. The eyelet embroiderer comprises a cutter bar. The bottom of the cutter bar is provided with a cutter head. The top end of the cutter head is provided with a cutting edge part. The cutter bar above the cutter head is provided with upper and lower driving mechanisms. The cutter bar above the upper and lower driving mechanisms is provided with a rotation driving mechanism. The cross section of the cutting edge part is rhombic. An angle of the cutting edge part in a width direction is in a range of 20-90 degrees and an angle of the cutting edge part in a thickness direction is in a range of 5-20 degrees. The eyelet embroiderer is provided with the rotation driving mechanism except the upper and lower driving mechanisms and thus the cutter bar drives the cutter head to punch upward and downward and to carry out rotation cutting. The angle of the cutting edge part in the thickness direction is in a range of 5-20 degrees so that cutting-off efficiency is improved and the angle of the cutting edge part in the width direction is in a range of 20-90 degrees so that eyelet width is adjusted easily and cutting-off efficiency is improved. The eyelet embroiderer improves a cutting-off rate, guarantees cut surface cleanliness and obviously improves punching efficiency and punching quality.

Owner:ZHEJIANG XINSHENG SEWING EQUIP

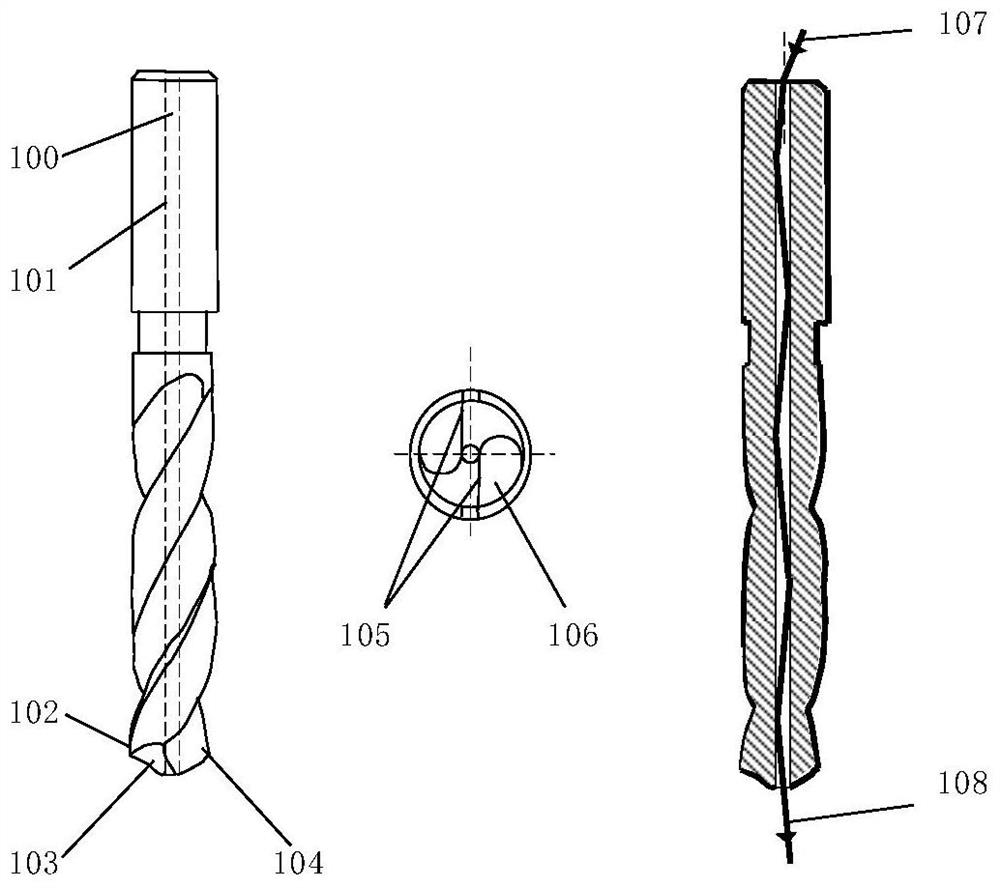

Combined machining method for blade air film holes and device thereof

ActiveCN112171184AReduce drilling difficultyImprove drilling efficiencyMetal working apparatusElectrolytic agentHeat-affected zone

The invention discloses a combined machining method for blade air film holes and a device thereof, and relates to the field of non-traditional machining. The combined machining method comprises the steps that the air film holes with the needed size are rapidly drilled in a thermal barrier coating high-temperature alloy matrix through laser heating auxiliary drilling; secondly, a drill bit rotatingat a high speed serves as a cathode, blades serve as an anode, the drill bit moves up and down, online electrolysis aftertreatment is conducted on part of the air film holes of the metal matrix, andthe defects of residual stress, a heat affected zone and the like in the drilling process are eliminated; and meanwhile, tiny abrasive particles are suspended in the electrolyte, tiny impact scratching is conducted on the hole wall under the driving of the drill bit rotating at a high speed, the similar grinding and polishing effect is achieved, and the quality of the whole inner wall of the air film holes including the thermal barrier coating is further improved. The method is simple and easy to implement, laser transmission is not affected by the surrounding environment, the environmental adaptability is high, repeated tool setting is not needed, and the defects that the thermal barrier coating cannot be machined through a conventional electric machining method, the single crystal alloylaser machining efficiency is low, and thermal damage is likely to be generated are overcome.

Owner:JIANGSU UNIV

Leather punching equipment for luggage manufacturing

InactiveCN107745417ANo creasesQuality assuranceMetal working apparatusManufacturing technologyPunching

The invention discloses a leather punching device for making bags, which comprises a casing, a workbench is fixedly connected between the two sides of the inner wall of the casing, a motor is fixedly connected to the bottom of the inner wall of the casing, and a motor is fixedly connected to the bottom of the inner wall of the casing. The output shaft is fixedly connected with a first pulley, the surface of the first pulley is connected with a second pulley through the first belt transmission, the shaft center of the second pulley is fixedly connected with a screw rod, and the two surfaces of the screw rod Rotating blocks are provided on both sides, and the invention relates to the technical field of bag manufacturing. The leather punching equipment for luggage manufacturing ensures that the leather will not wrinkle when punching holes, ensures the quality of leather punching, facilitates subsequent processing, and facilitates adjusting the position of the punching device. It can punch holes in different positions of the leather. The use effect is good, the punching head is prevented from scratching the leather during the movement, the position of the punching head is conveniently adjusted, the punching quality is improved, and the manual labor is reduced.

Owner:陈华

Precision hardware punching device

The invention relates to a punching device, in particular to a precision hardware punching device and aims at achieving the technical purpose of providing the precision hardware punching device convenient to operate and capable of punching flat sections and reducing burrs. To achieve the above technical purpose, the precision hardware punching device is provided and comprises a left frame, a containing table, a bottom plate, a first nut, a rocking handle, a screw, a push block, a pressing block, an electric push rod, a cutter, a sliding block, a fixing plate, a first connecting rod and the like. The left frame is welded to the left side of the top of the bottom plate. The containing table is welded to the left side of the top of the bottom plate and located on the right side of the left frame. A groove is formed in the lower portion of the right side of the left frame. The first nut is welded to the lower portion of the left side of the left frame. A rotation motor is used for driving a first rotation shaft to rotate, the first rotation shaft drives a first bolt and a second bolt to rotate, and the first bolt and the second bolt drive a second nut and a third nut to move towards the middle from the two sides correspondingly.

Owner:渡边精密金属(珠海)有限公司

Iron plate punching equipment

InactiveCN106734532ANo deviationImprove punch qualityMetal-working feeding devicesDirt cleaningPunchingPhysical health

The invention discloses iron plate punching equipment which comprises a bracket. The middle of the bracket is provided with a motor base. The top of the motor base is connected with a motor. The bottom of the motor base is connected with a telescopic cylinder. The bottom of the telescopic cylinder is connected with a punching plunger chip. A fixing block is connected with each of the two sides of the bottom of the bracket. The bottoms of the fixing blocks are connected with supporting columns. The bottoms of the supporting columns are connected with suction discs. The two sides of the bracket are each provided with a telescopic stand column. The bottoms of the telescopic stand columns are provide with a worktable. The middle of the worktable is provided with a dust collection trough. An inner cavity of the dust collection trough is provided with an iron core. The surface of the iron core is connected with a coil in a winding mode. The bottom of the coil is connected with a power supply. The right side of the coil is provided with a switch. By adoption of the iron plate punching equipment, metal dust in the air is reduced and prevented from affecting physical health conditions, deviation cannot occur when the punching plunger chip punches an iron plate, and the punching quality of the iron plate is improved.

Owner:WUXI CAIYUN MACHINERY & EQUIP

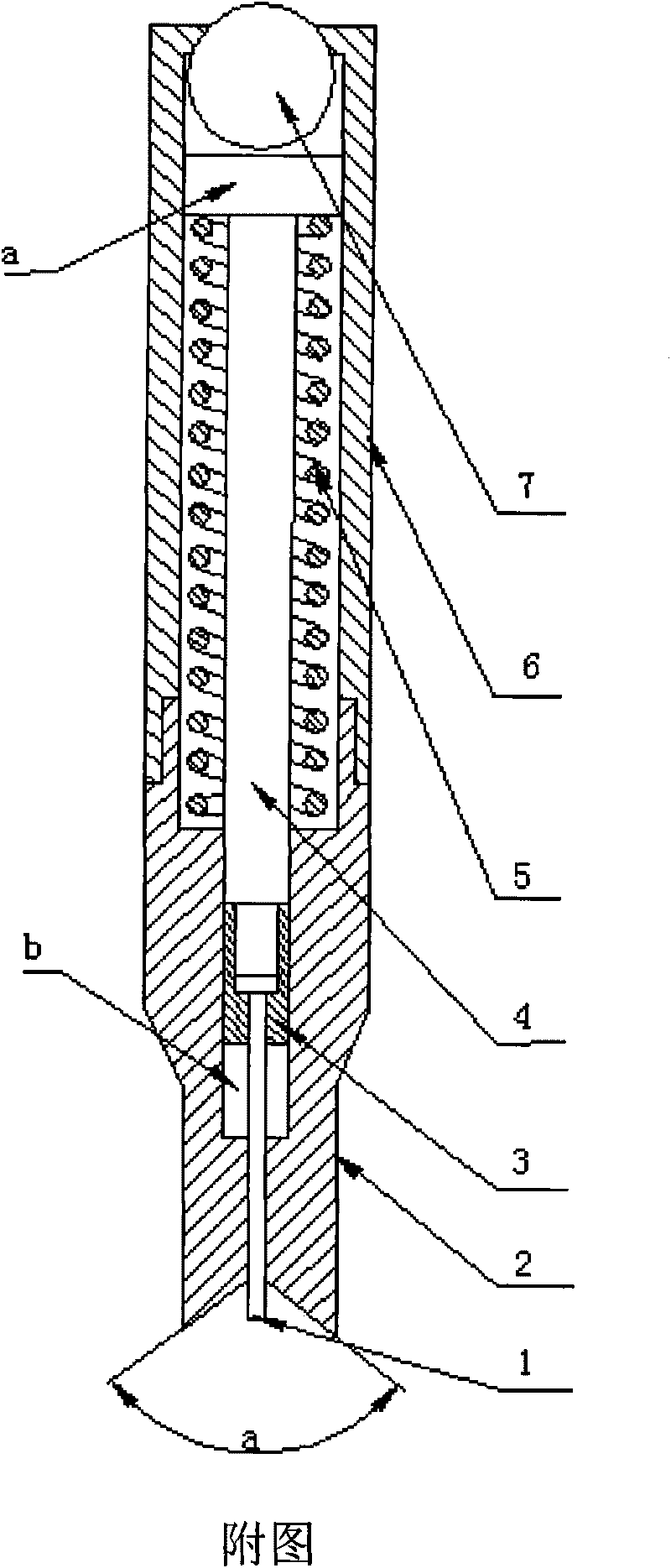

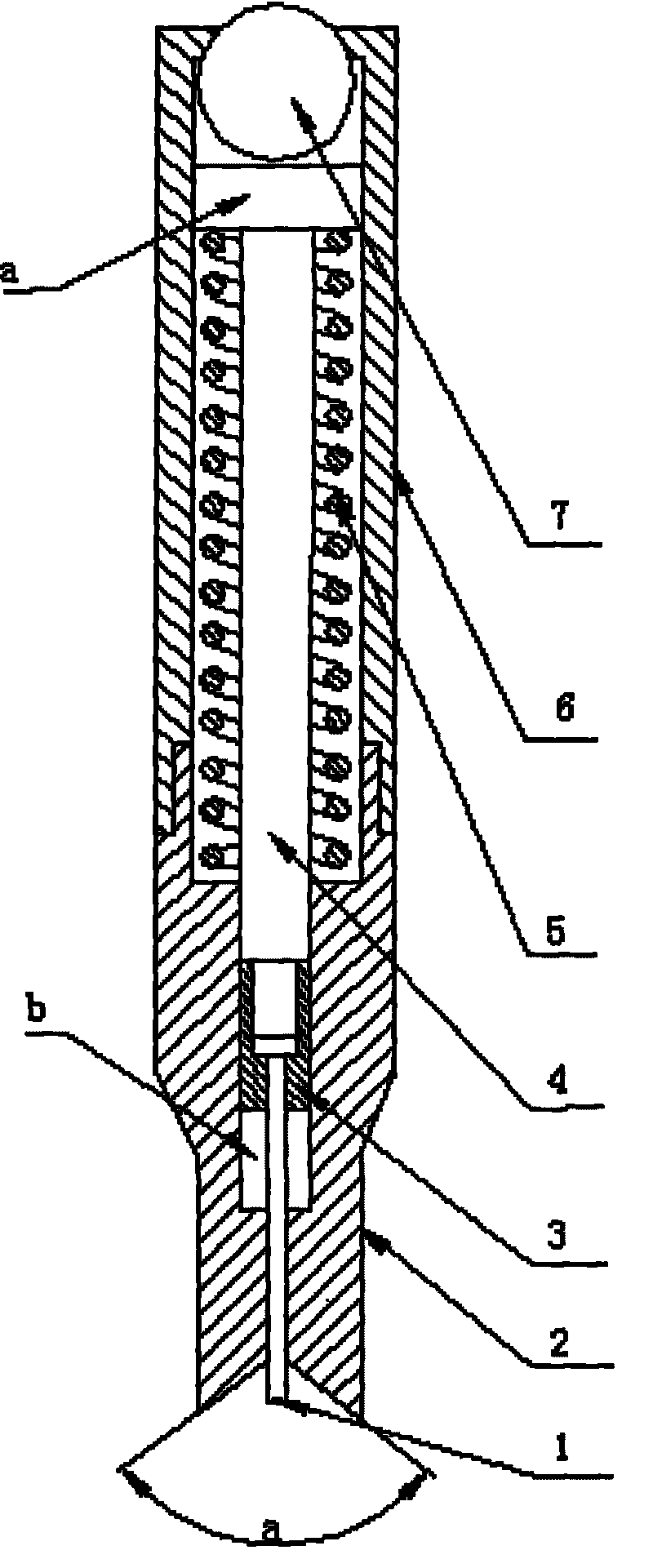

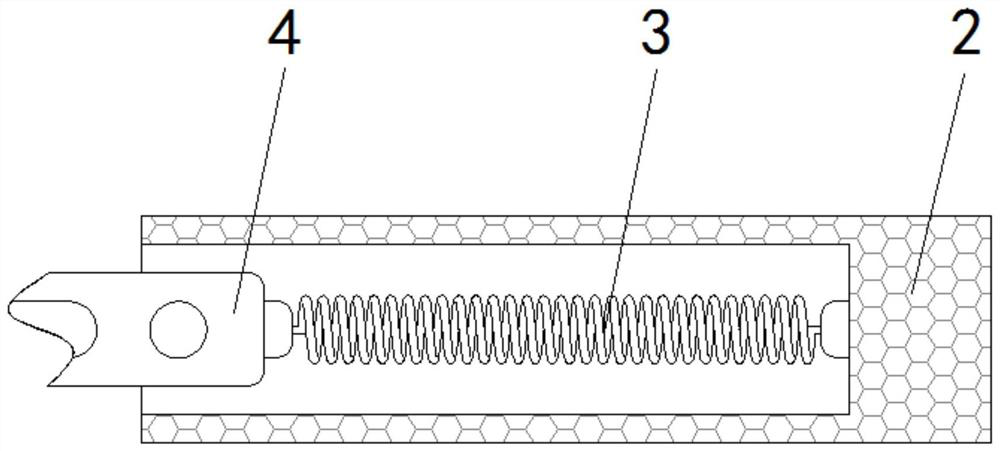

Novel wall tube punching tool

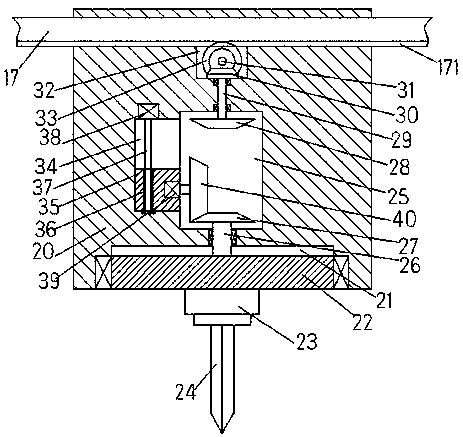

InactiveCN101733323AEasy to useImprove punching efficiencyPerforating toolsMetal working apparatusPunchingSteel ball

The invention relates to a novel wall tube punching tool, a plunger chip is arranged in a hole of a guide column, and external threads at the lower end of a guide rod are screwed in internal threads of the guide column, and a punching needle is tightly fixed; and then a steel ball is arranged in an inner hole of an upper sleeve, and an assembly which integrates the plunger chip, the guide column and the guide rod is arranged, and after a spring is sheathed outside the assembly piece which integrates the plunger chip, the guide column and the guide rod, an upper sleeve and a lower locating sleeve are connected into one body by the internal and external threads; in order to have better guiding function, a proper clearance exists between an outer circle a of the guide rod and an inner hole of the upper sleeve, and a gap exists between the outer circle of the guide column and an inner hole b of the lower locating sleeve; when in use, a V-shaped button of the lower locating sleeve spans at the proper position of the tube wall and is knocked to a steel ball by a hammer, so as to punch a hole, and the punching needle with different diameter can be punched into the corresponding bore diameter.

Owner:杨苏军

Stampings bonding prevention device for stamping die

ActiveCN103157728AAvoid it happening againAvoid downtime for cleaningShaping toolsCleaning using toolsPunchingTerete

The invention discloses a stampings bonding prevention device for a stamping die and is suitable for punching of coiled materials. The stampings bonding prevention device for the stamp die comprises two rotary cylinders which are located on one side of the die, and the coiled materials go in from the side. The two rotary cylinders are tightly attached to each other and arranged up and down. Each rotary cylinder comprises an oil storage drum with two sealed ends and an oil impregnating layer which is arranged on the outer side of the oil storage cylinder. The oil impregnating layer has elasticity. A plurality of oil impregnating holes are uniformly formed in the circumferential surface of each oil storage cylinder. One ends of the oil storage cylinders are connected with a punching oil conveying system through pipelines. A damping layer with elasticity is arranged between each oil storage cylinder and each oil impregnating layer. A plurality of oil impregnating cylinders are uniformly arranged on the circumferential surface of each damping layer and embedded in each oil impregnating layer. Oil outlet holes which penetrate through the inner surface of each damping layer are formed in each oil impregnating cylinder. Kerfs which are communicated with the oil outlet holes are uniformly arranged on the circumferential surface of each oil impregnating cylinder. The stampings bonding prevention device for the stamp die can prevent stampings from bonding with the die, and therefore continuous punching can be achieved, and influence of machine halt on production efficiency is avoided. Besides, the stampings bonding prevention device for the stamp die is beneficial for prolonging service life of the die and improving punching quality of products.

Owner:WANXIANG 123 CO LTD

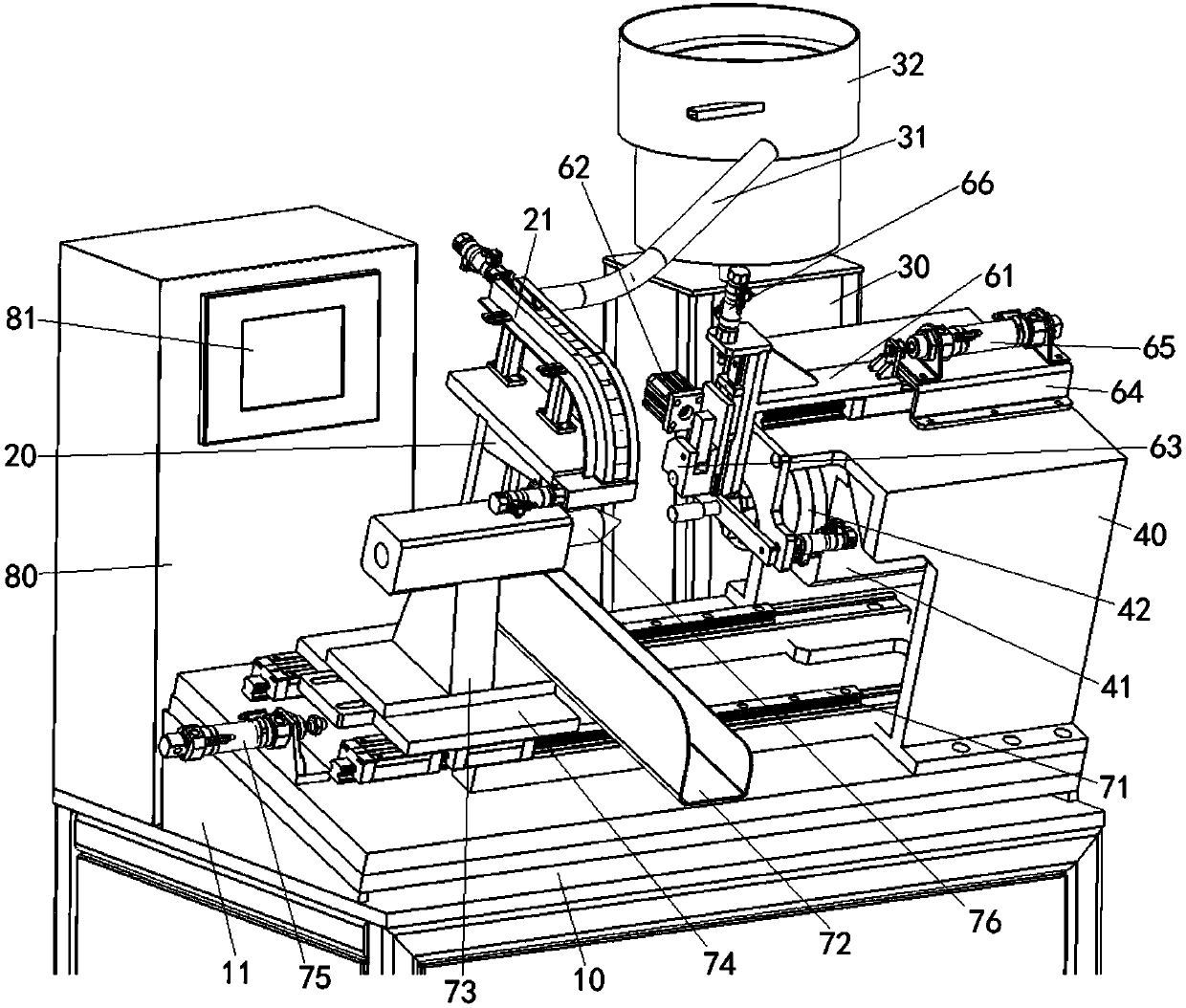

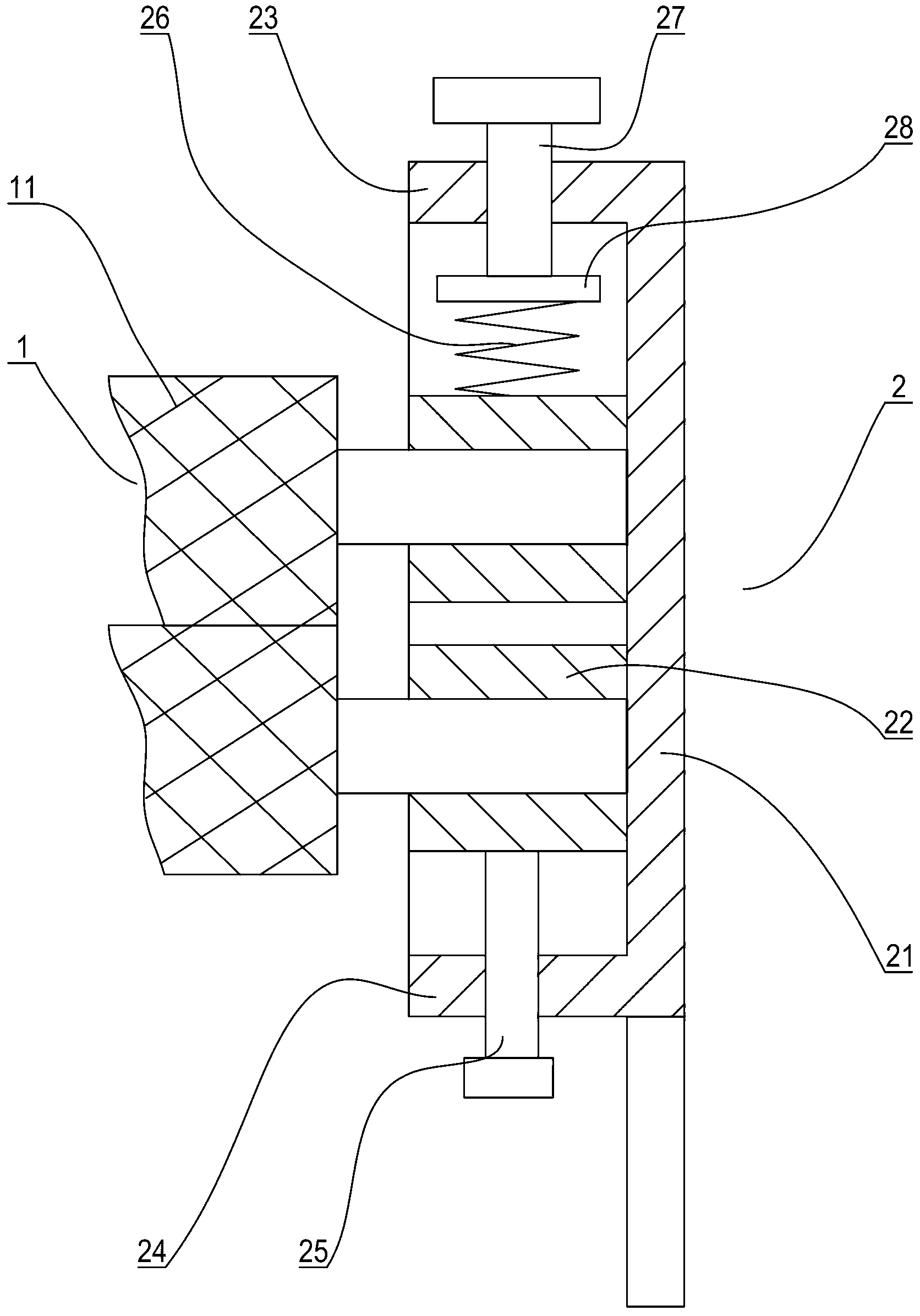

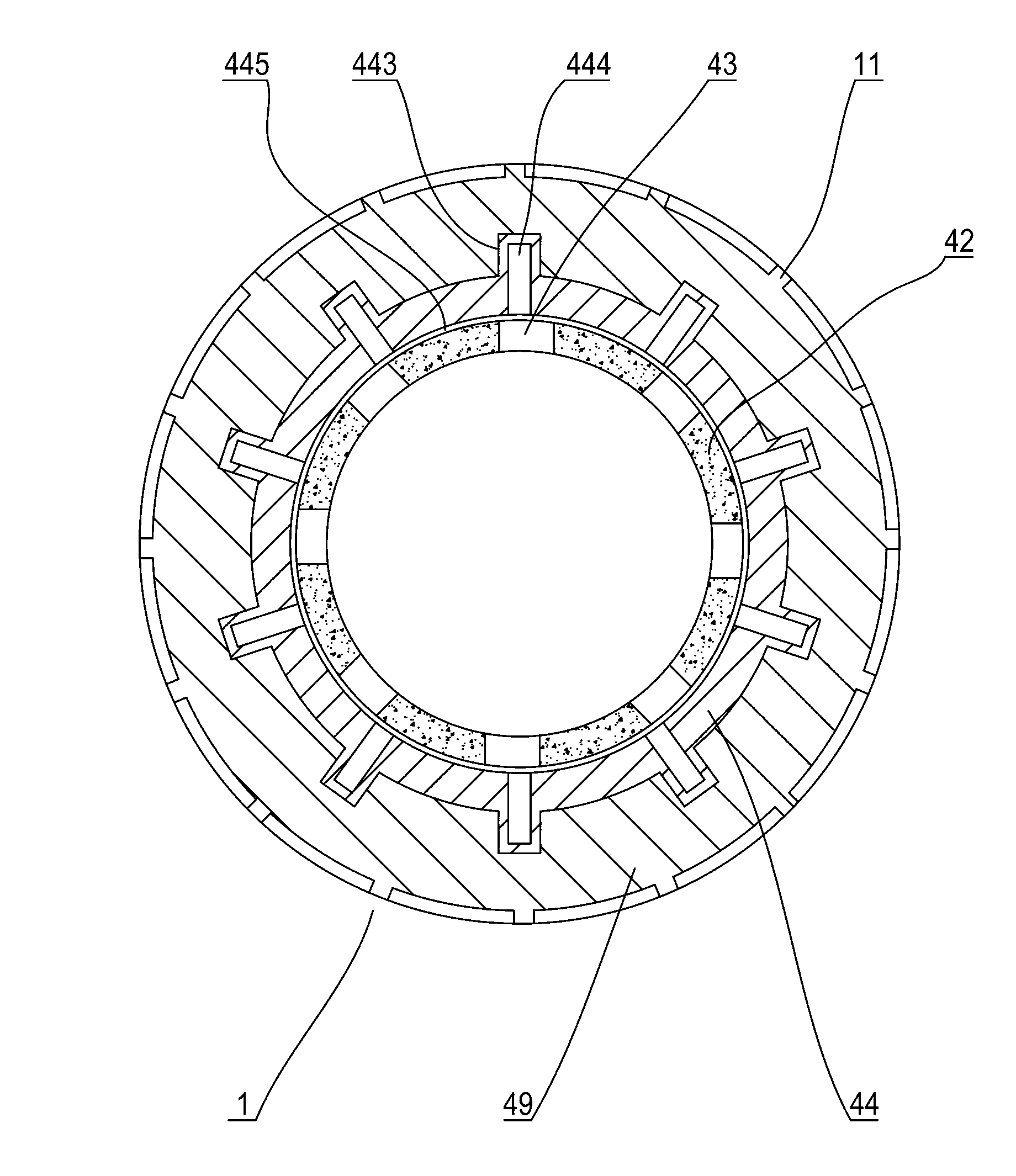

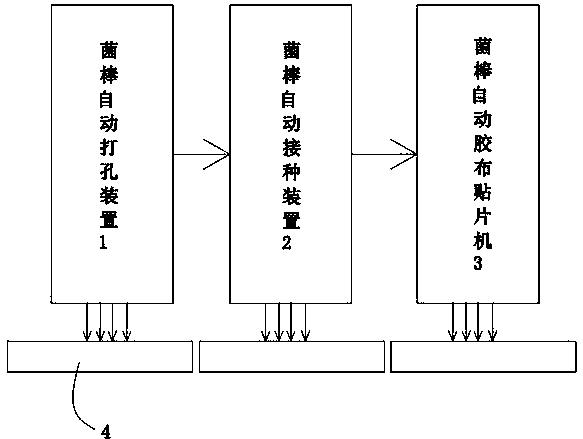

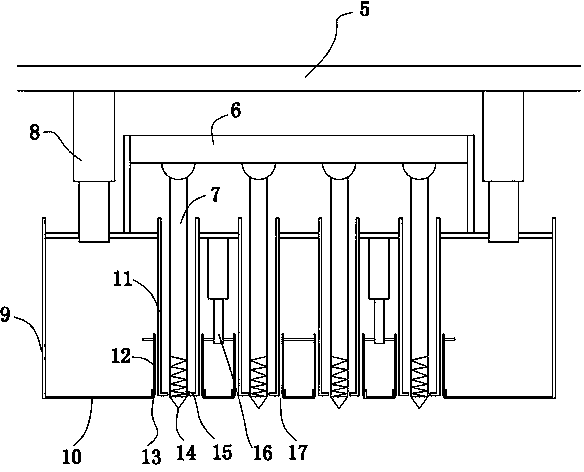

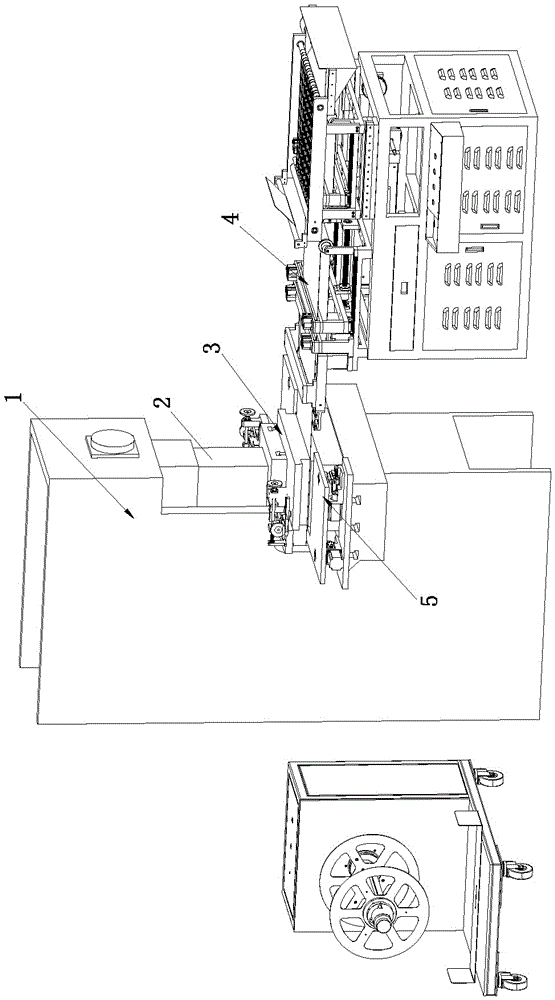

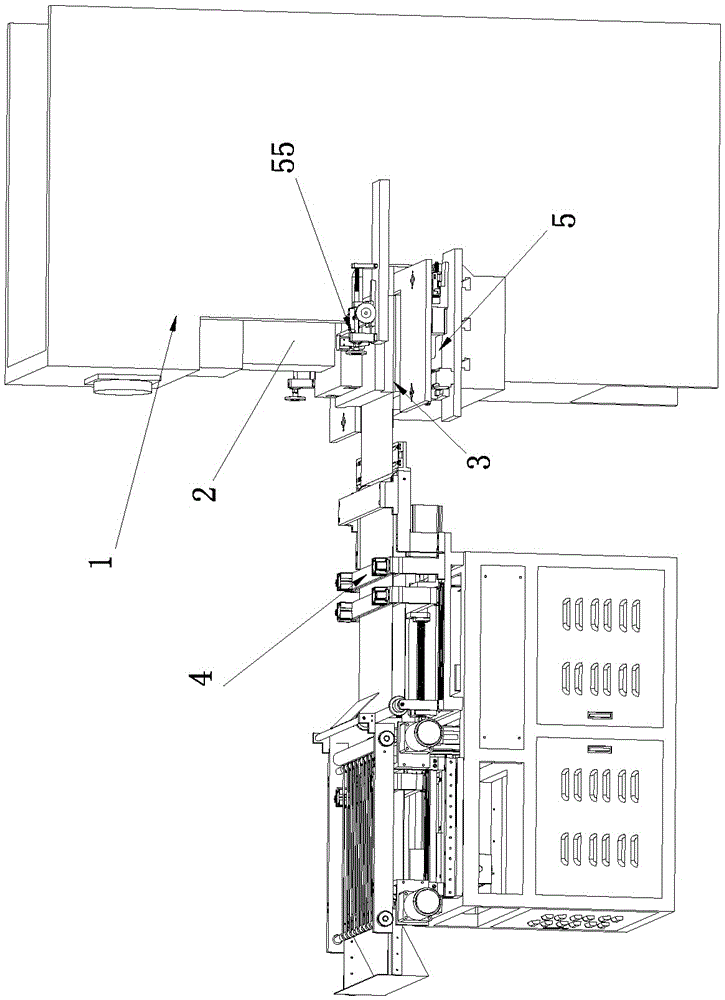

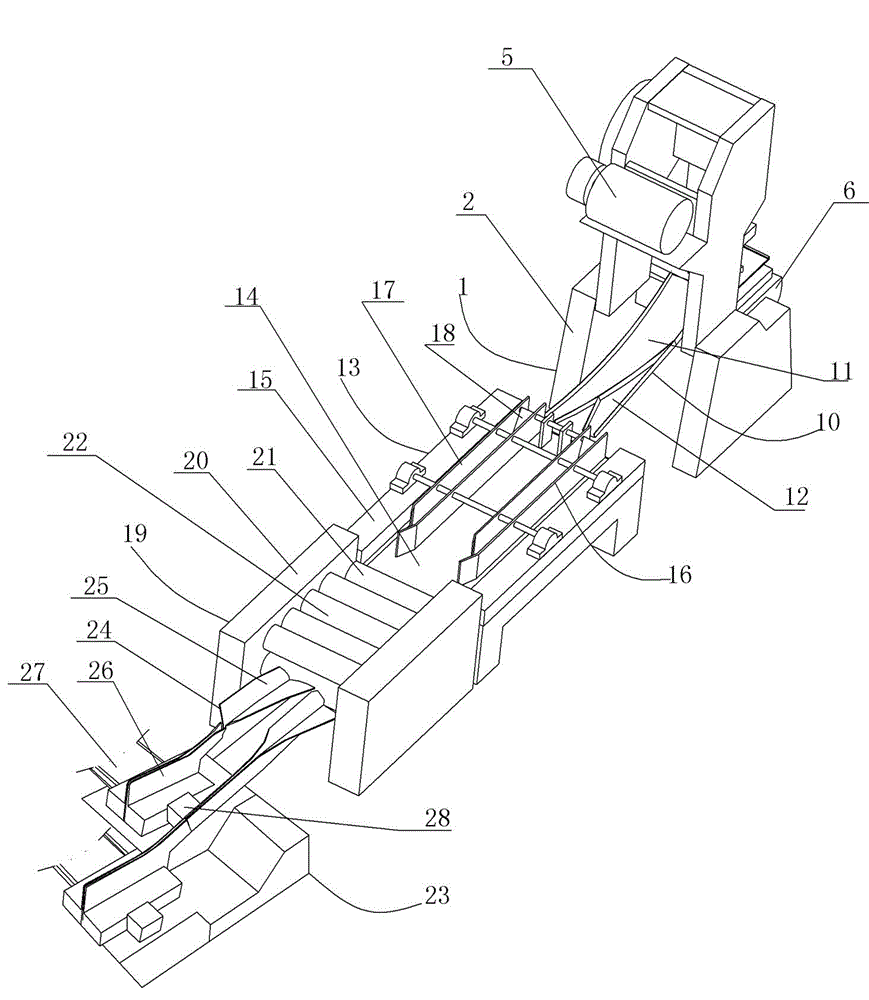

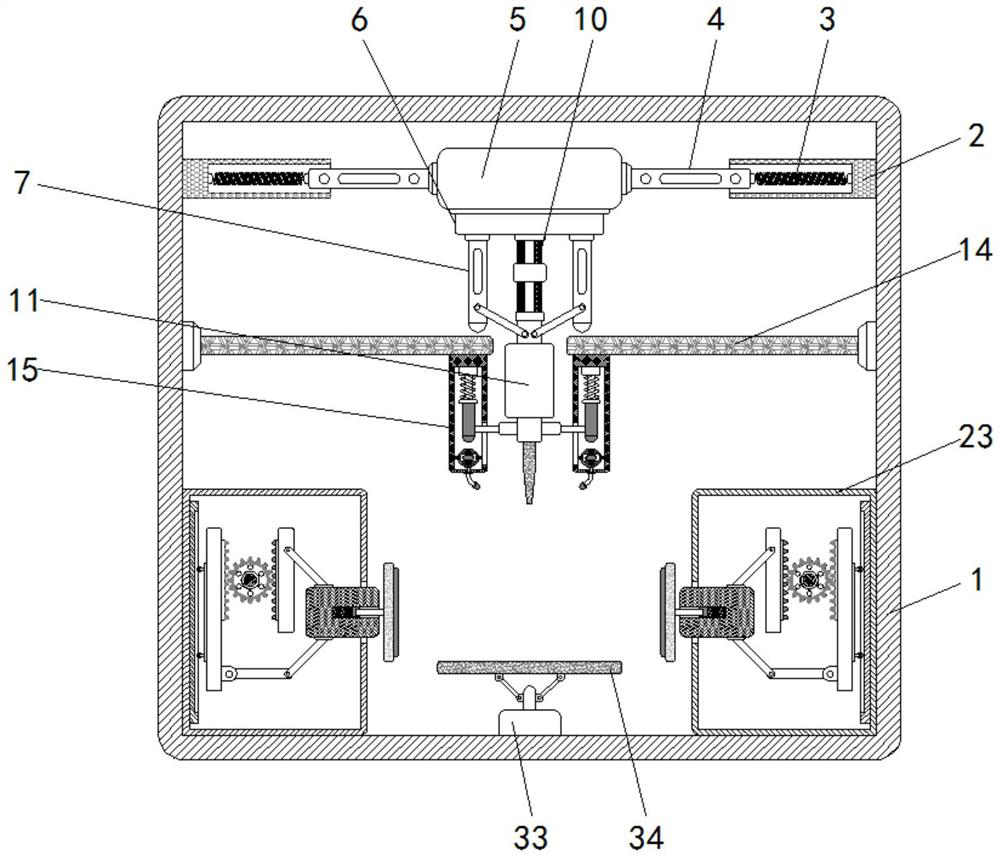

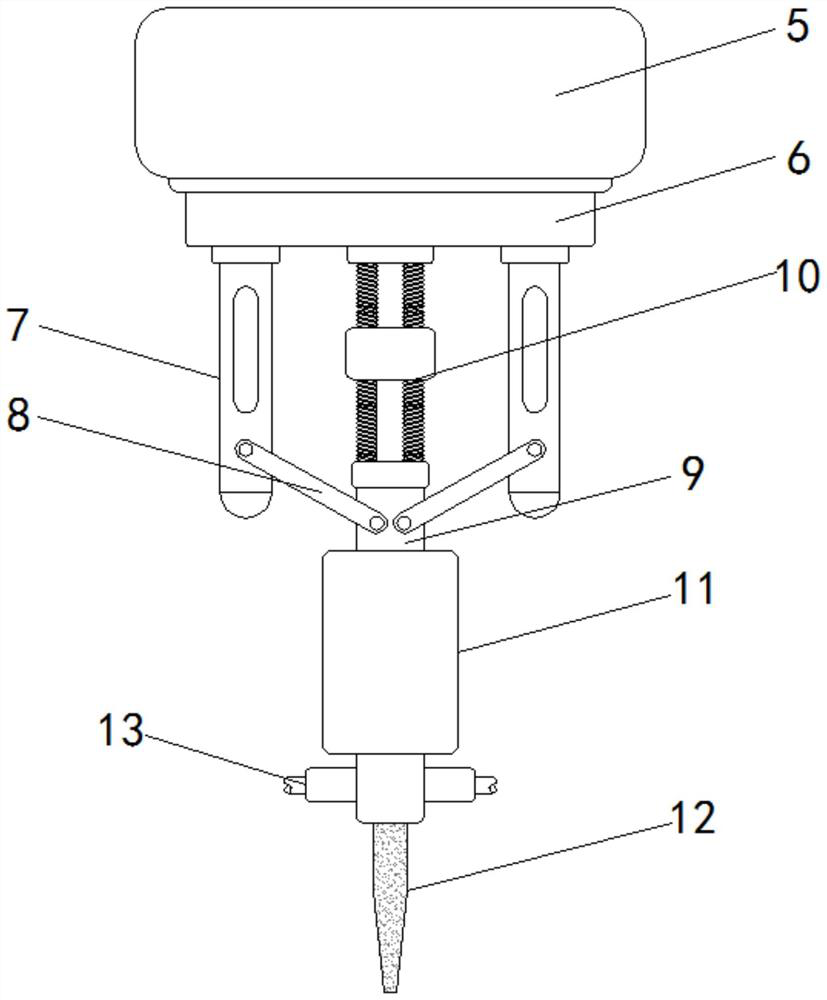

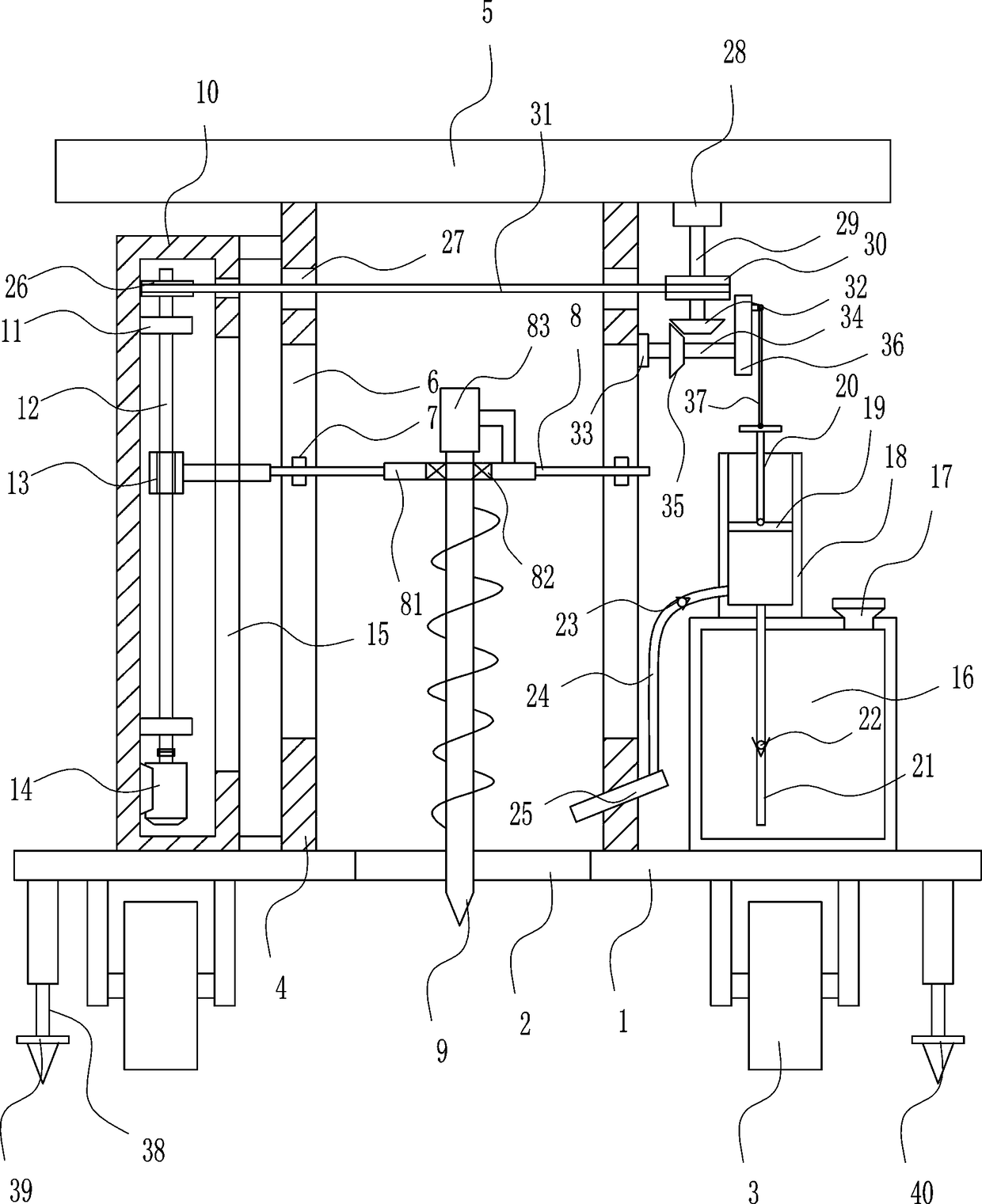

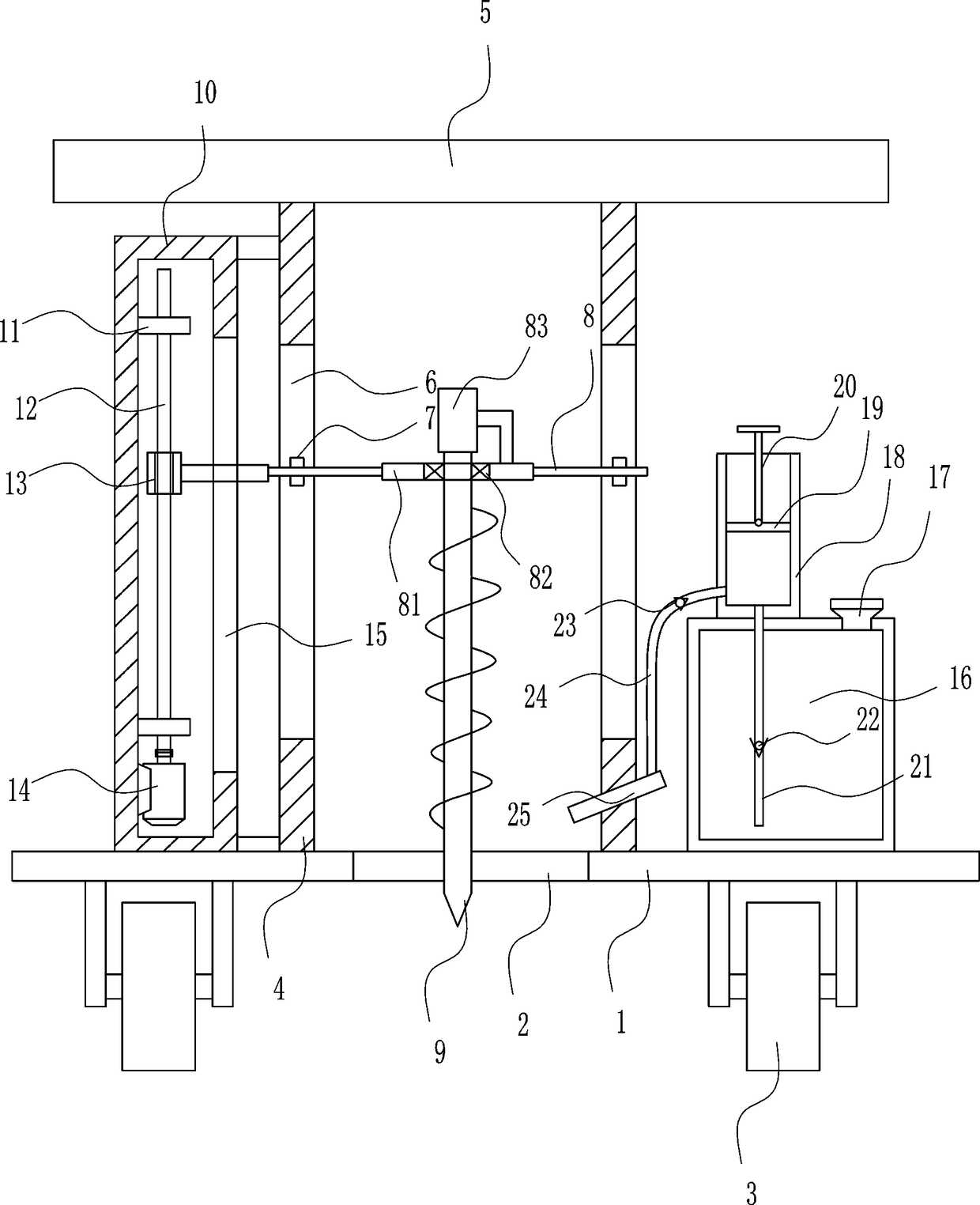

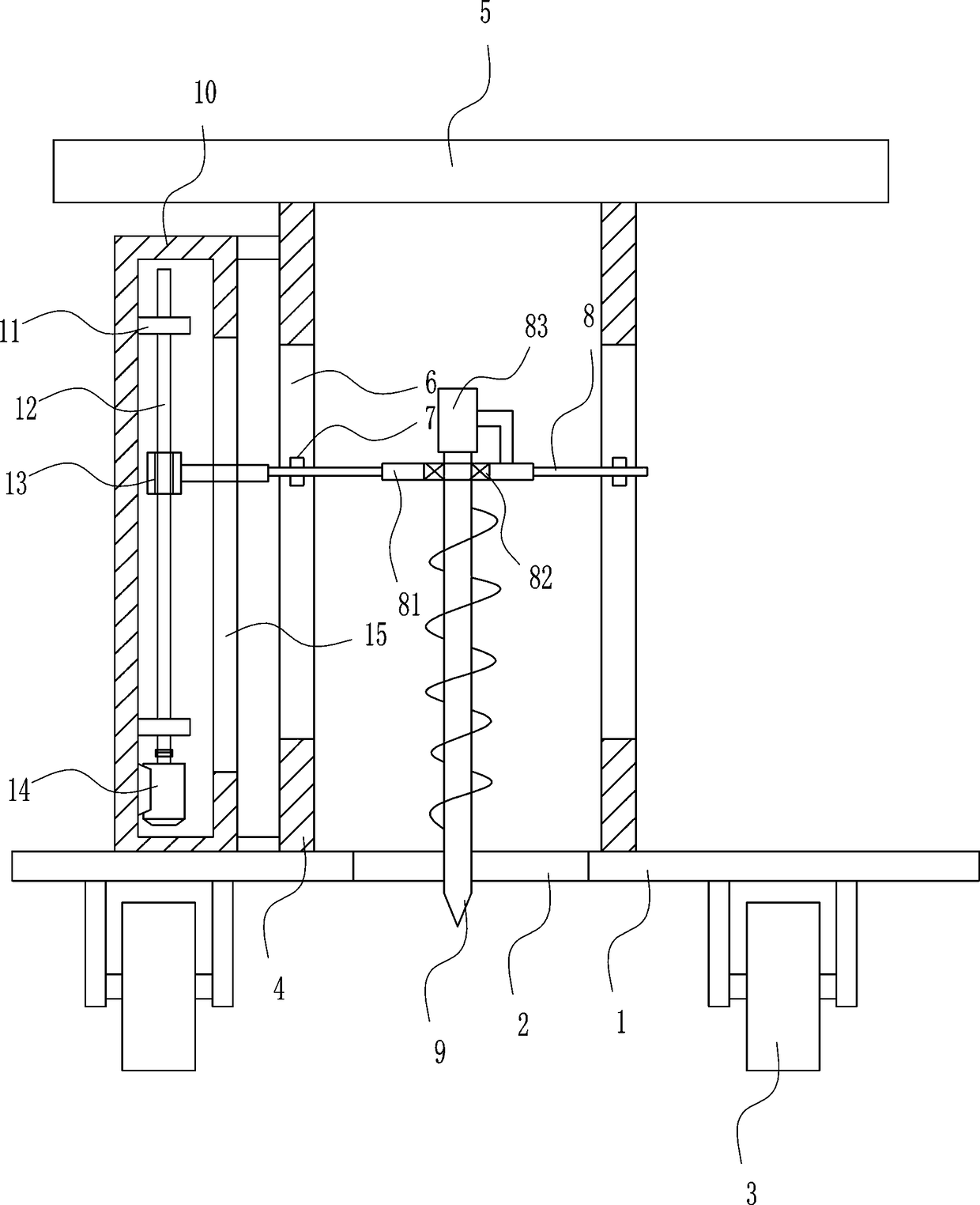

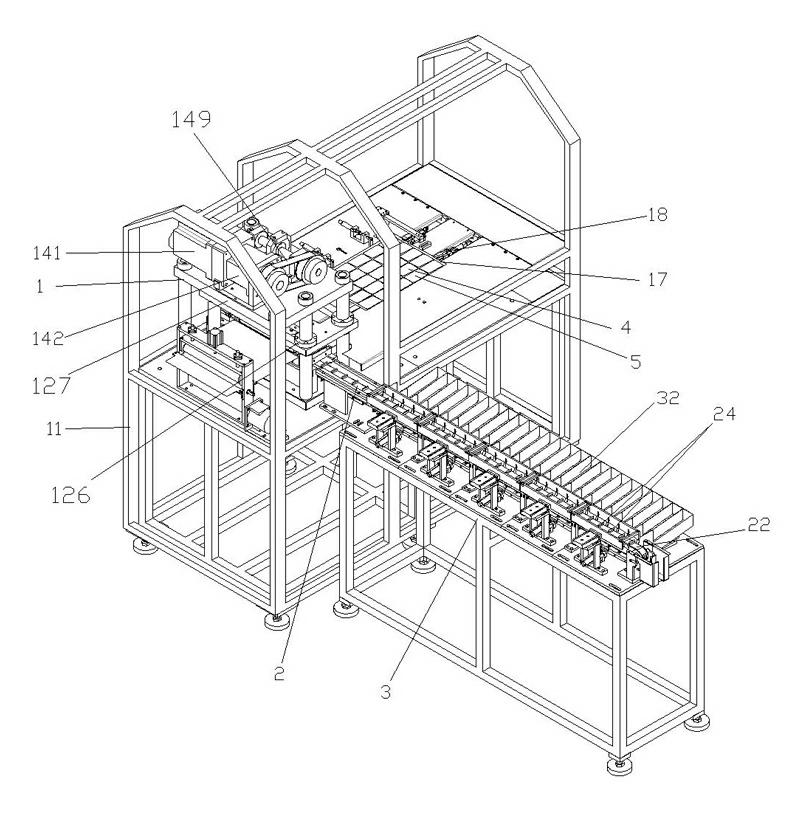

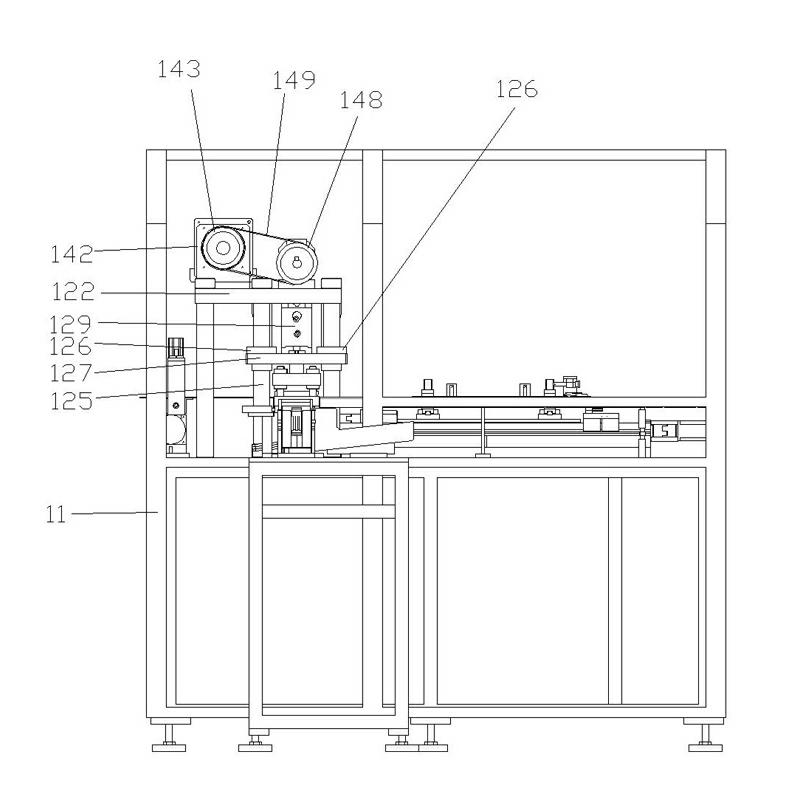

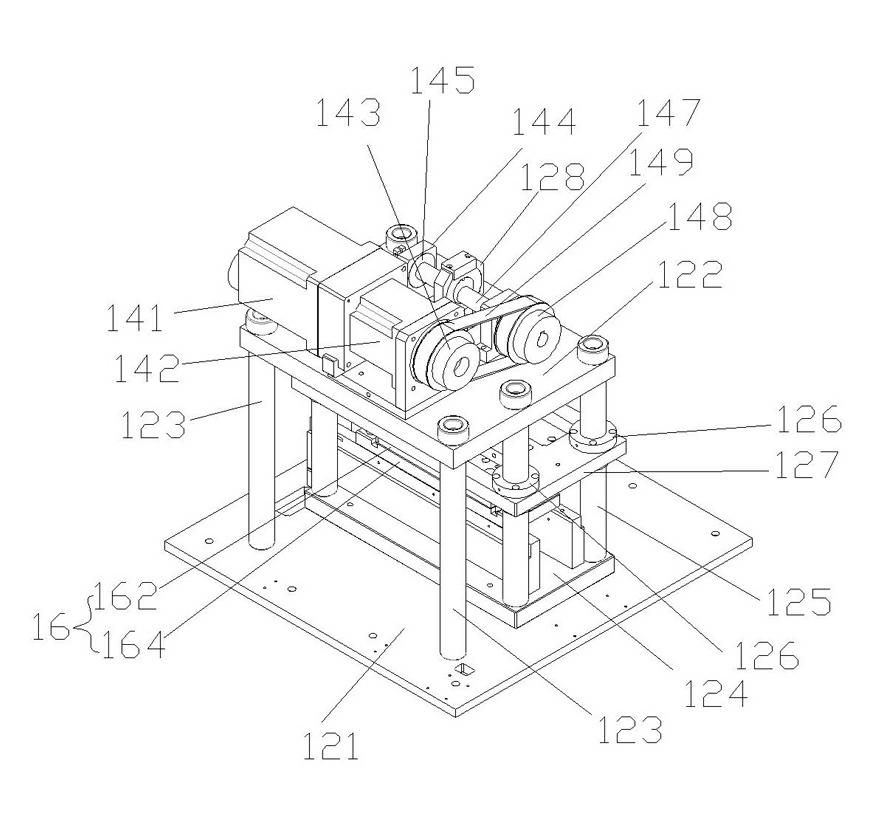

Full-automatic tremella mushroom-stick inoculation machine

ActiveCN104381012AImprove punch qualityImprove yieldCultivating equipmentsMushroom cultivationPunchingTremella

The invention relates to a full-automatic tremella mushroom-stick inoculation machine. The machine comprises an automatic mushroom-stick punching device, an automatic mushroom-stick inoculating device, an automatic mushroom-stick tape mounter and a mushroom-stick transfer mechanism, wherein the automatic mushroom-stick punching device comprises a mushroom-stick punching pipe and a mushroom-stick film raising rod; the mushroom-stick punching pipe and the mushroom-stick film raising rod are driven by respective driving mechanisms; the mushroom-stick punching pipe has a closed cutting edge; the end part of the mushroom-stick film raising rod is provided with a film raising component; and the mushroom-stick film raising rod is located in the mushroom-stick punching pipe. The mushroom-stick transfer mechanism enables mushroom-sticks to successively move according to production processes. In the process of movement, the automatic mushroom-stick punching device carries out punching on the mushroom-sticks; the automatic mushroom-stick inoculating device carries out inoculation on the mushroom-sticks; and the automatic mushroom-stick tape mounter carries out tape sealing on the mushroom-sticks. Mechanized operation is employed for punching; the diameters and the depths of holes are totally identical; high punching quality is obtained; inoculation is facilitated; and the rate of finished products is high.

Owner:QINGYUAN NONGFU EDIBLE MUSHROOMS RES INST

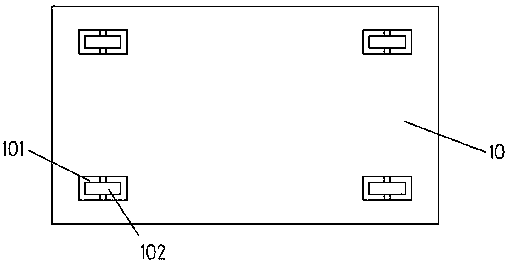

Alignment punch press system

ActiveCN105538410ARealize automatic alignmentReduce labor costsMetal working apparatusPunch pressFlexible circuits

The invention relates to the technical field of flexible circuit board production equipment, in particular to an alignment punch press system. The system comprises a punching device and a four-axis automatic alignment platform, wherein the punching device is provided with a puncher pin for punching, the four-axis automatic alignment platform comprises a bottom plate, a CCD camera assembly, a computer control assembly and an operation table used for adjusting material positions, the bottom plate is arranged on the punching device, a punching station is arranged between the puncher pin and the operation table, four groups of X-Y-theta alignment units used for driving the operation table to achieve X-Y-axis horizontal movement and rotation are arranged between the bottom plate and the operation table, the four groups of X-Y-theta alignment units are distributed on the bottom plate in a rectangular shape, rotary shafts of the four groups of X-Y-theta alignment units are rotationally connected with the operation table, the CCD camera assembly and at least three groups of X-Y-theta alignment units are connected with the computer control assembly through electric signals, and the CCD camera assembly shoots materials on the operation table. The punch press system is high in alignment efficiency and accuracy and improves punching quality and punching efficiency.

Owner:SHENZHEN VILITY AUTOMATION EQUIP

Cutter blade punching device

InactiveCN103143615AReduce manufacturing costImprove punch qualityMetal-working feeding devicesPositioning devicesPunchingTransmission belt

The invention discloses a cutter blade punching device which comprises a punching machine and a programmable controller; the punching machine comprises a frame, a punching cutter holder, a punching cutter, a driving motor and a workbench; a feed opening, a discharge port, a feeding channel and a pushing mechanism which pushes a cutter blade in the feeding channel to move to a position below the punching cutter are arranged on the workbench; the feed opening and the discharge port are communicated with the feeding channel; a chute which is inclined from top to bottom is arranged at the discharge port; the lower end of the chute is provided with a transmission mechanism; an outlet on the lower end of the chute is positioned above a transmission belt of the transmission mechanism; the outer end of the transmission mechanism is connected with a leveling mechanism; the inlet of the leveling mechanism is horizontally opposite to the transmission direction of the transmission belt of the transmission mechanism; and the outlet end of the leveling mechanism is provided with a cutter blade collection mechanism. The cutter blade punching device has the advantages of manpower saving, high production efficiency, low production cost and high cutter blade punching quality.

Owner:宁海县虹湾机械制造有限公司

Efficient self-cleaning perforating device for hardware machining

InactiveCN112170883AAchieve self-cleaning abilityImprove punch qualityPositioning apparatusMaintainance and safety accessoriesEngineeringMachining

The invention provides an efficient self-cleaning perforating device for hardware machining. The perforating device comprises a main body, wherein fixing parts are fixedly arranged on the left inner wall and the right inner wall of the main body correspondingly; extension springs are arranged in the two fixing parts correspondingly; moving rods are fixedly connected to the opposite sides of the two extension springs correspondingly; installation parts are fixedly connected to the opposite ends of the two moving rods; and installation components are fixedly connected to the lower sides of the installation parts. According to the efficient self-cleaning perforating device for hardware machining, a perforating mechanism is driven by an electric push rod to move downwards, and when the perforating mechanism moves downwards, an extrusion part is driven by a fixing rod to move downwards at the same time, so that the extrusion part extrudes an extrusion mechanism, the extrusion mechanism presses an air bag mechanism through a spring mechanism, air pressure in the air bag mechanism cleans up scraps generated by perforation through a spray head, the self-cleaning capacity of equipment during hardware machining is achieved, and the hardware perforation quality is improved.

Owner:温杨兰

Rotary type punching equipment for gardens

ActiveCN108450088AReduce workloadRealize automatic water sprayPlantingFurrow making/coveringPunchingElectric machine

The invention relates to punching equipment, in particular to rotary type punching equipment for gardens. The invention aims to provide the rotary type punching equipment for the gardens, which is simple to operate and has high punching efficiency and high punching quality. In order to achieve the above aim, the invention provides the rotary type punching equipment for the gardens. The rotary typepunching equipment for the gardens comprises a bottom plate, wheels, mounting frames, a top plate, sliding rails, a sliding block, a first connecting rod, a mounting plate, a first bearing pedestal,a first motor, a spiral rotary drill bit and the like; a small hole is formed in the center of the bottom of the bottom plate; the wheels are arranged at the bottom of the bottom plate in a bilaterally symmetrical mode; the mounting frames are arranged at the top of the bottom plate in a bilaterally symmetrical mode; the top plate is arranged at the tops of the mounting frames; and the sliding rails are arranged on the front sides of the mounting frames. The rotary type punching equipment for the gardens achieves the effects of simplicity in operation, high punching efficiency and high punching quality, realizes automatic punching, is simple to operate, has high punching efficiency of mechanical punching, can punch holes with uniform size, and is novel in structure and high in practicability.

Owner:姚啸啸

Drilling equipment of plastic suction die

InactiveCN106738035AUniform punching effectLess prone to deviationMetal working apparatusCamMechanical engineering

The invention relates to drilling equipment, in particular to drilling equipment of a plastic suction die, which aims at solving the technical problem to provide drilling equipment of a plastic suction die, with capability of uniform drilling on a gypsum die. To solve the technical problem, the drilling equipment of the plastic suction die comprises a bottom plate, a left frame, a first bracket, a bearing block, a second bracket, a right frame, a first rotary shaft, a gear, a first spring, a first gear rack, a first guide sleeve, a second guide sleeve and the like, wherein the left frame and the first bracket are welded at the left side of the top part of the bottom plate; the left frame is positioned at the left side of the first bracket; the second bracket and the right frame are welded at the right side of the top part of the bottom plate; the right frame is positioned at the right side of the second bracket. The drilling equipment has the advantages that the uniform drilling effect is realized by the uniform-speed rotation of a cam and a fixing device; by specially adding a slide rail and a slide block on the device, the descending of a twist drill is stabilized, so that the easiness in deviation of drilling is avoided.

Owner:东莞市杰出塑胶科技有限公司

Metal plate punching device

InactiveCN104117570AReduce distortionReduce glitchesMetal-working feeding devicesPositioning devicesPunchingSurface mounting

The invention relates to a metal plate punching device which comprises a punching drive device, an upper die plate and a punching head. The metal plate punching device further comprises clamping blocks located below the punching head, and a fixing block. The clamping blocks are symmetrically arranged on the two sides of the punching head. The fixing block is of a cylindrical structure with a through hole. The inner diameter of the through hole is larger than or equal to the outer diameter of the punching head. The fixing block is fixedly connected into an installation hole of the base. The lower surface of the base is provided with a waste barrel communicated with the through hole of the fixing block. The metal plate punching device is ingenious in structure; the punching head of the upper portion and the fixing block of the bottom are combined for punching, deformation of a machined part is reduced, the punching quality is improved, and burrs on the edges of holes are reduced.

Owner:SUZHOU CHENXITE SHEET METAL PROD

Card manufacturing machine and guide mechanism employing same

A card manufacturing machine comprises a punching device, wherein, the punching device comprises a guide mechanism, an eccentric shaft mechanism and a punching die; the guide mechanism comprises a top plate, a base, a swinging arm, a guide block and a bar end oscillating bearing; the swinging arm can be rotatablely connected with the guide block; the guide block is rotatablely connected with the bar end oscillating bearing; the eccentric shaft mechanism is connected with the swinging arm so as to lead the swinging arm, the guide block and the bar end oscillating bearing to move up and down; the punching die comprises a male die and a female die, and the female die is installed on the base; the four guiding posts are sleeved with the four guide sleeves; the four guide sleeves are separately installed on the four corners of guiding pressure plate; the bar end oscillating bearing is connected with the guiding pressure plate so as to the guiding pressure plate to move up and down; and the male die is installed on the lower surface of the guiding pressure plate. The card manufacturing machine has the advantage of good punching quality.

Owner:SHENZHEN XINSAI AUTOMATION EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com