Manufacturing method for floating type micro-silicon electrostatic gyro/accelerometer sensitive structure

A technology of accelerometer and sensitive structure, which is applied in the manufacture of microstructure devices, velocity/acceleration/impact measurement, microstructure technology, etc. It can solve the problems of prototypes without forming principles and achieve easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0039] Using this process has successfully flowed out the die, such as figure 1 As shown, the planar size of the die is on the order of millimeters, and the thickness is on the order of microns, and the die is packaged with a CQFP, DIP or PLCC shell. This sensitive structure process requires 8 reticles, and Table 1 describes the definition of reticles in detail.

[0040] Table 1 Definition of the mask required for the process

[0041]

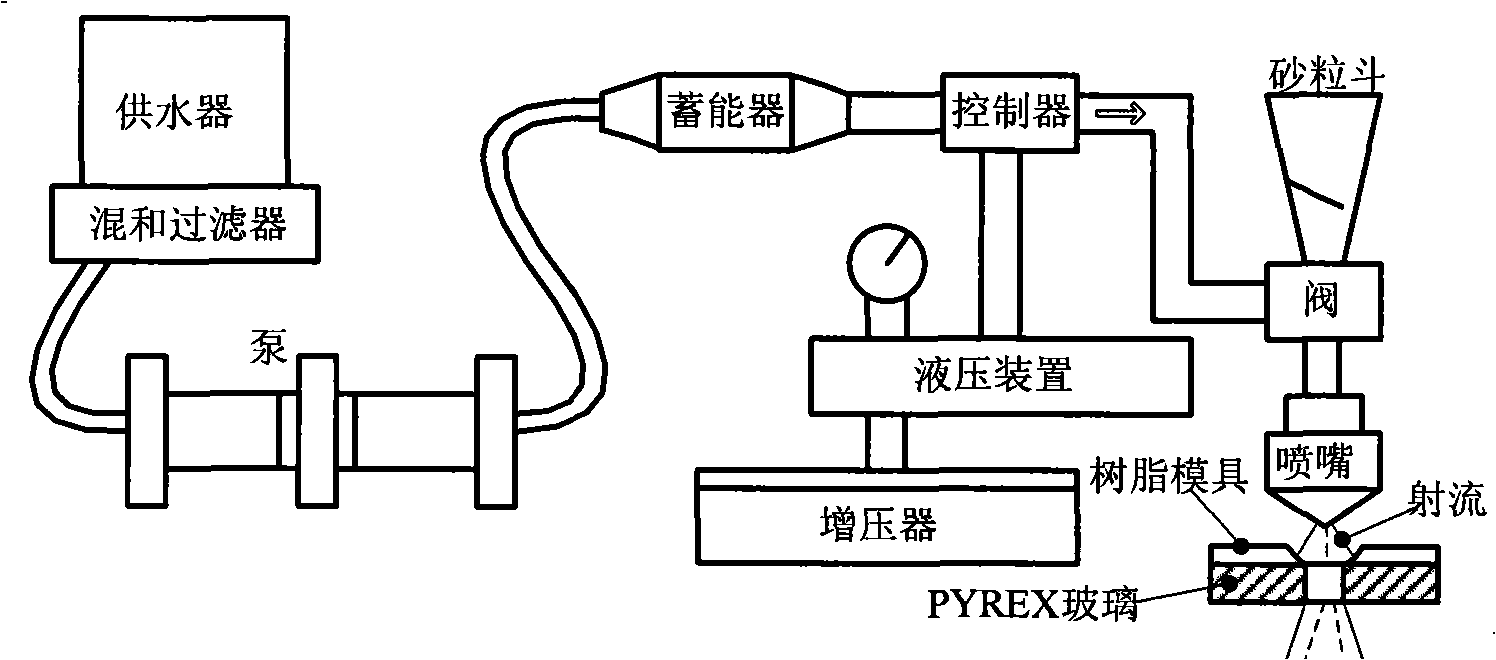

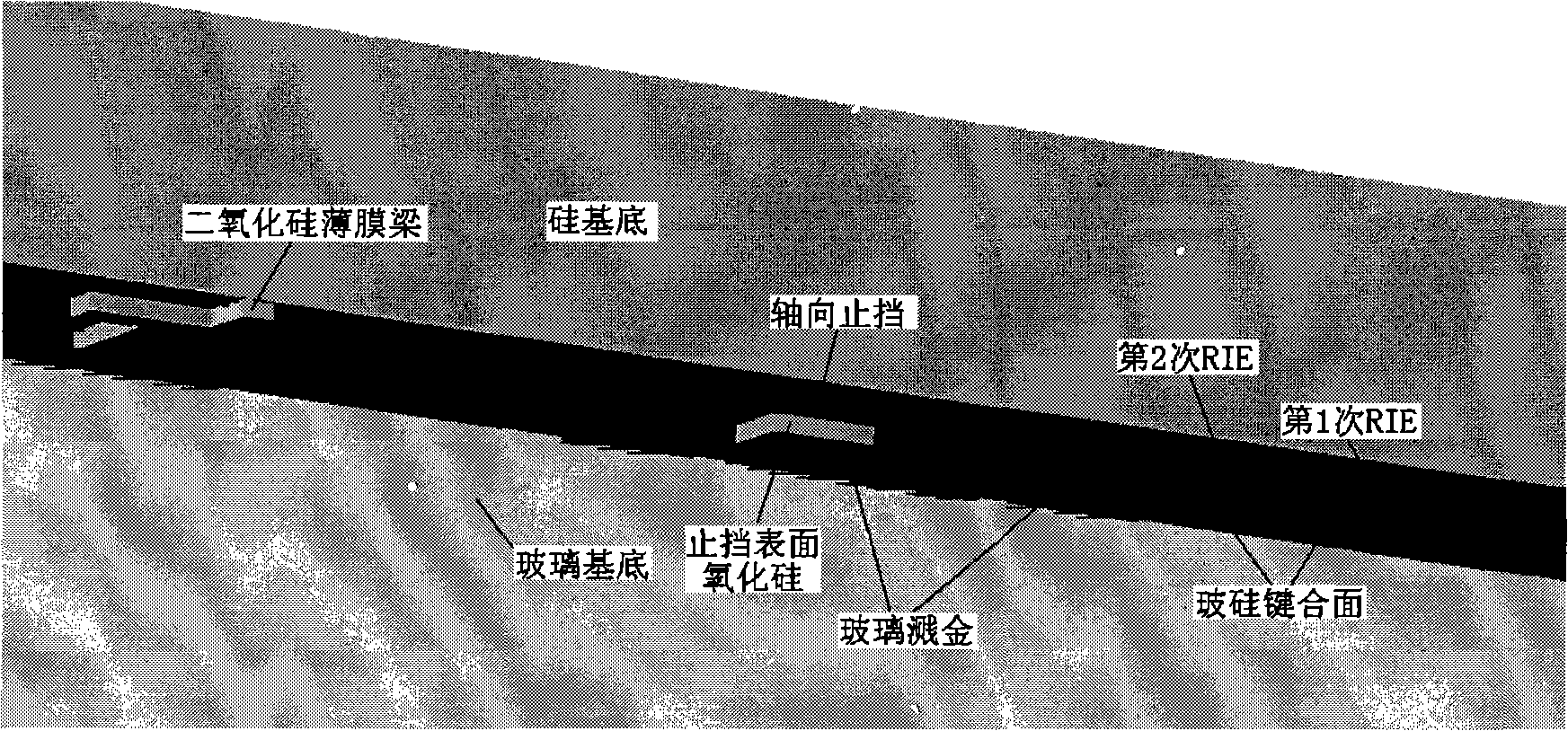

[0042] Image 6 It is a schematic diagram of the process flow of the present invention. In conjunction with the mask plate required for the process in Table 1, the present invention is described as follows:

[0043] 1. Glass etching process and gold sputtering process; standard cleaning of glass, coating of photoresist and photolithography of bottom and top glass according to meml-1 and meml-2 masks, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com