Patents

Literature

196results about How to "Realize automatic alignment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

On-line detecting method of machine vision system for printed calico flaw

InactiveCN101158650AReduce testing labor intensityGuaranteed accuracyInspecting textilesMaterial analysis by optical meansVisual perceptionComputer science

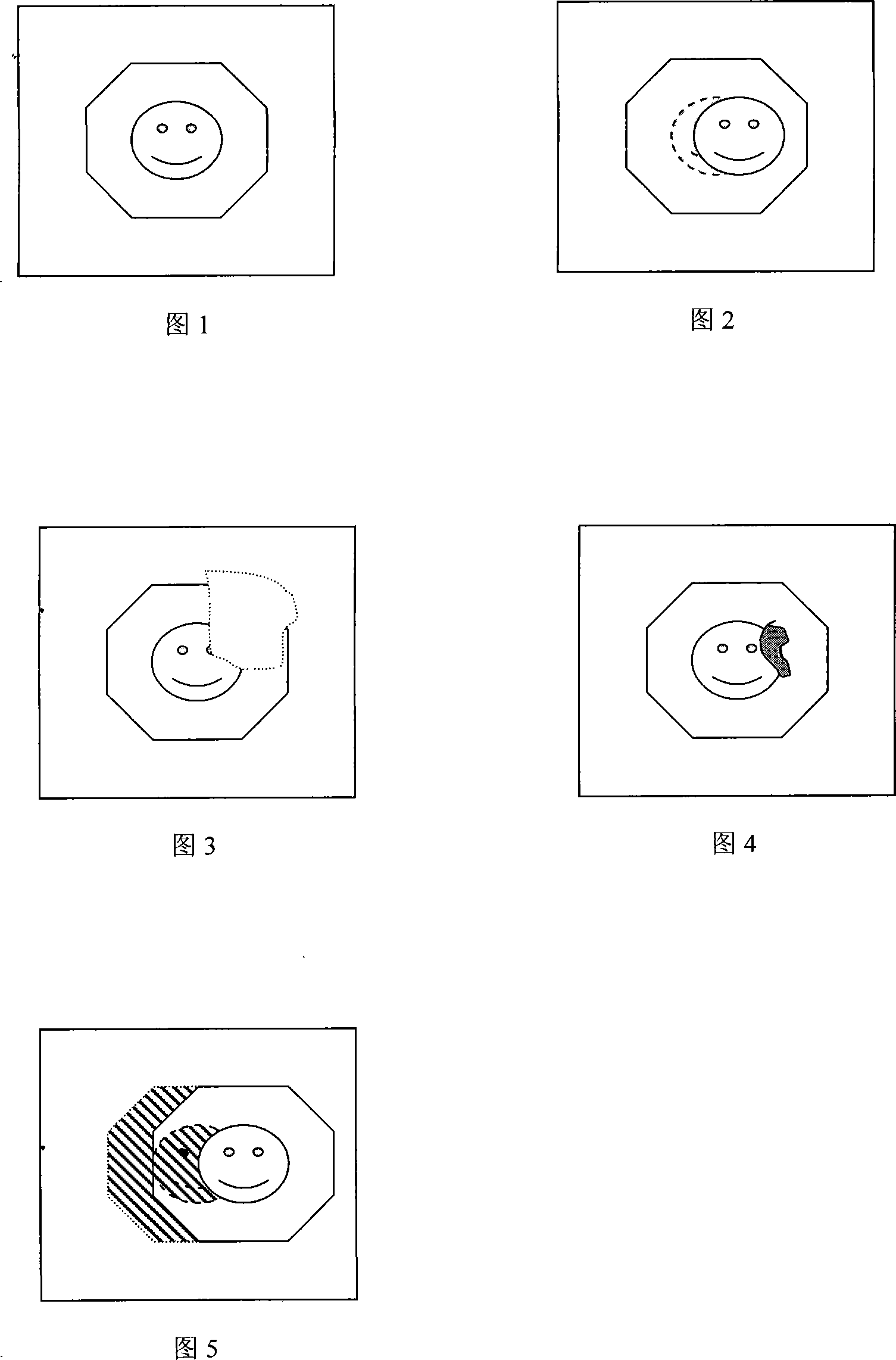

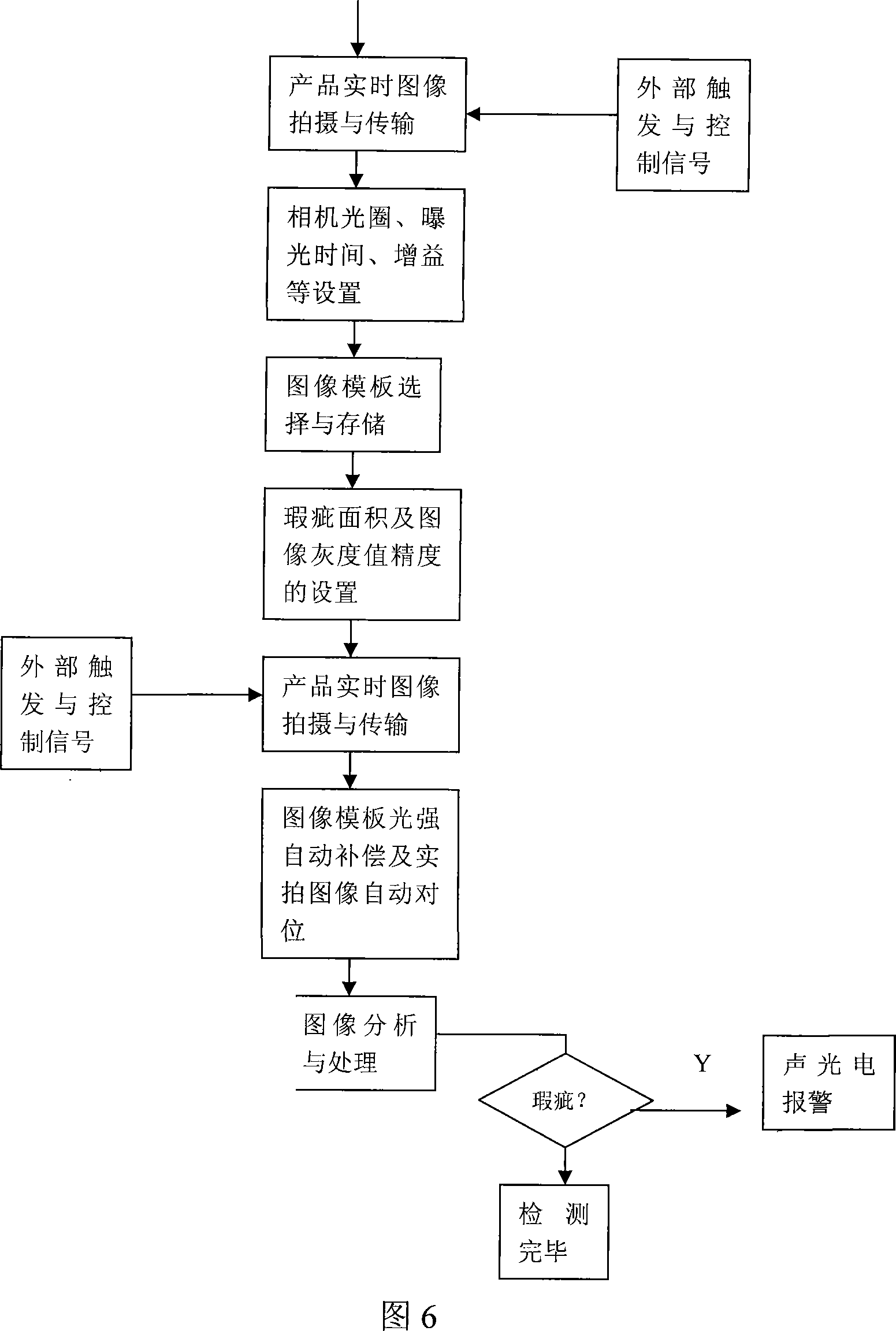

The invention relates to an online detecting method of a machine vision system for detecting blemishes of a printed cloth. The invention aims at solving the problem that the labor intensity of manual online detecting blemishes of the printed cloth is high, and the detecting quality is bad. Clear and thorough, and spotless graphs are shot on the running printed cloth through industrial camera. The clear and thorough, and spotless graphs are stored in the calculating machine as a standard graph molding board. The blemish area and graphic gray value are taken as the detecting parameter of the blemish. The precision scope of the detecting parameter is arranged according to the requirement of the consumer. The graphs of the running printed cloth are shot in real-time, and are conveyed to the calculating machine. The real-timely shot graphs are compared with the standard graph molding board and are dealt with. If a blemish appears, the operating personnel are indicated to deal with the blemish of the printed cloth through an alarm. The alarm is started through the calculating machine. The invention can carry out light intensity self-compensating of the standard graph molding board, and dynamically correcting the shift of the pixel of the real-timely shot printed cloth graphs. The invention has the advantages of high precision and fast speed of detecting blemishes of the printed cloth, and greatly reduced labor intensity of manual detecting.

Owner:WUXI DONGWANG TECH

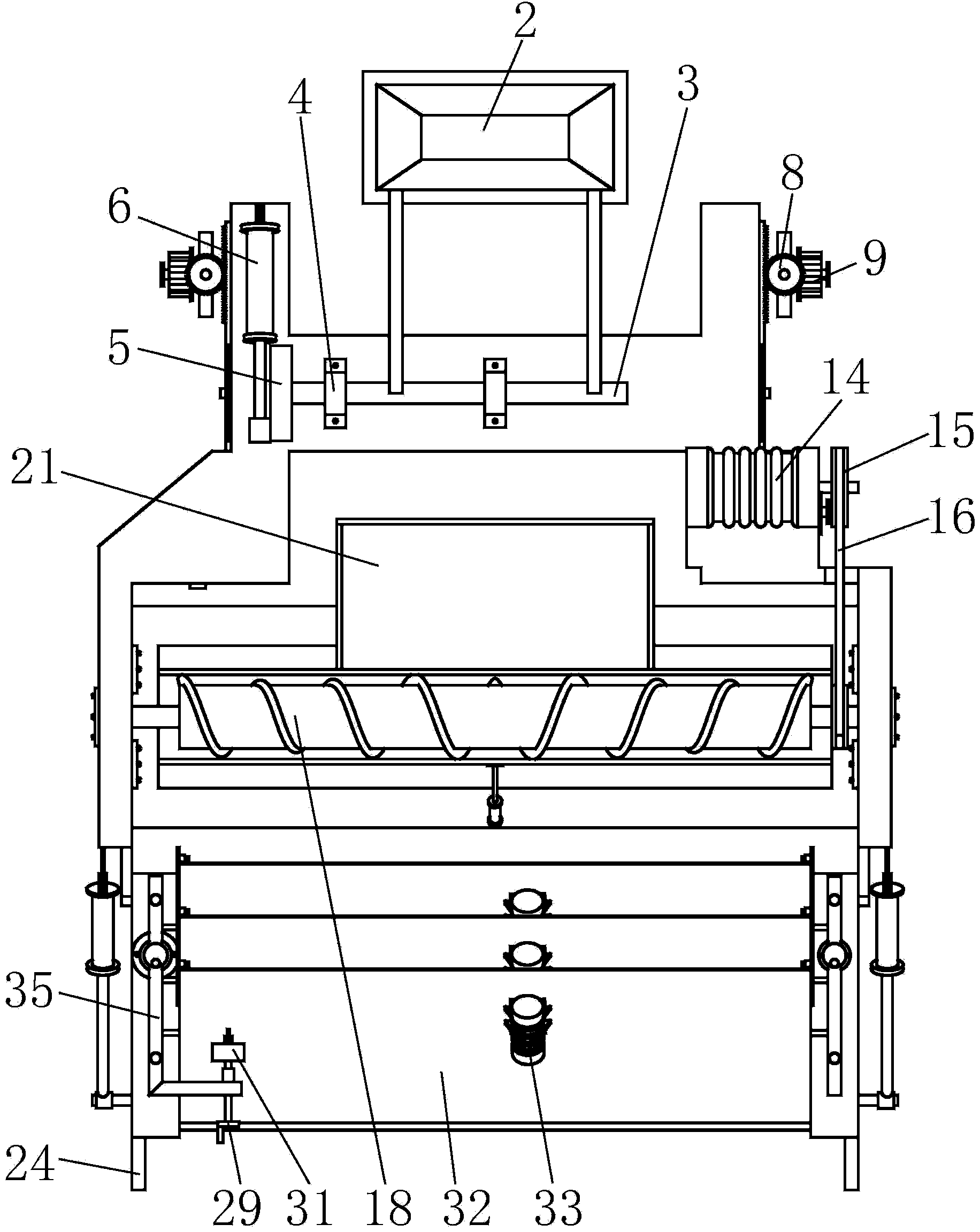

Automatic distorted concrete grouting and vibrating equipment

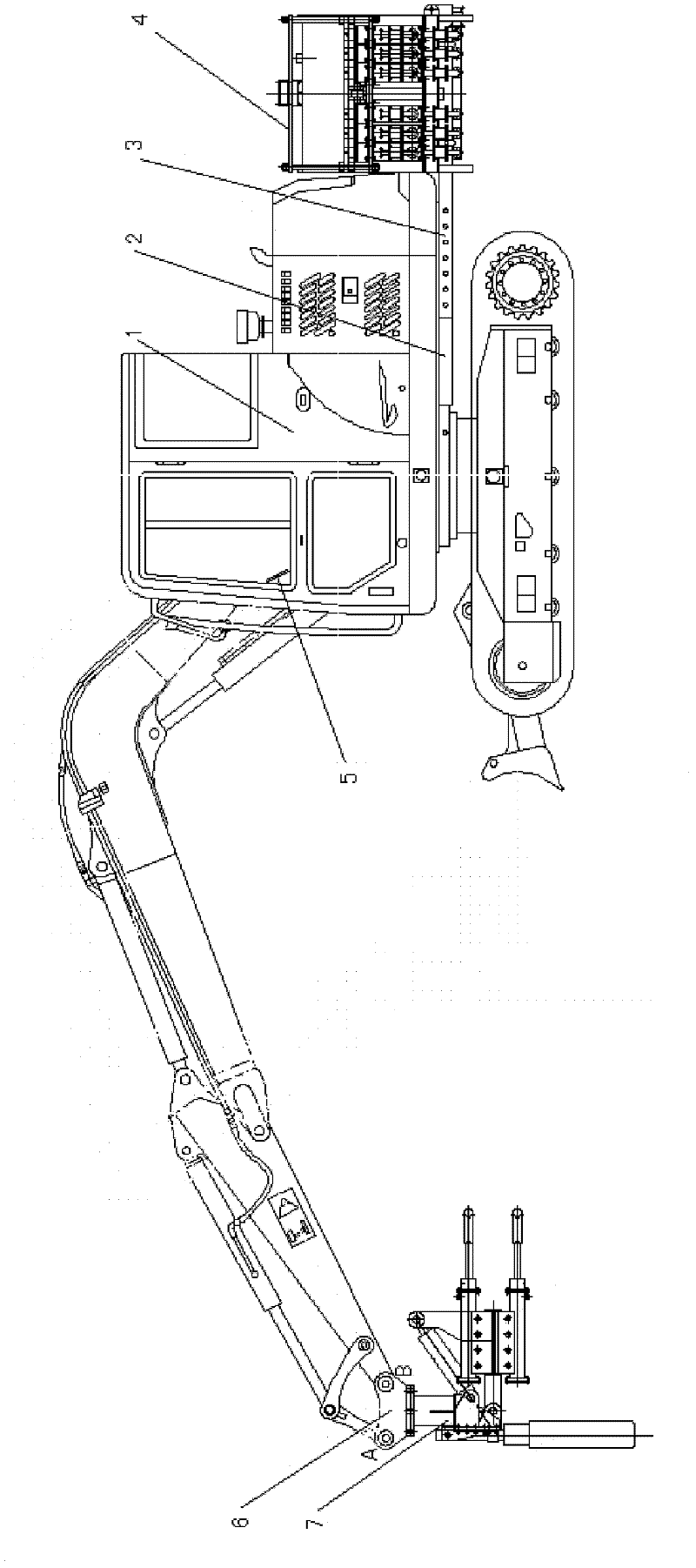

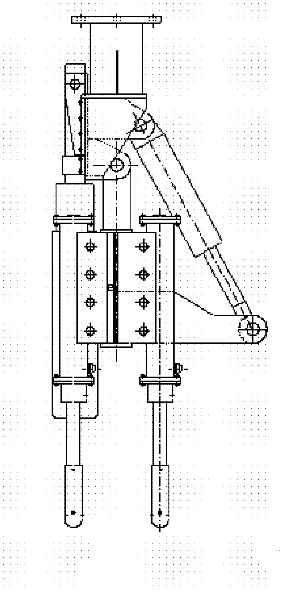

ActiveCN102505694ARealize free switchingRealize automatic alignmentFoundation engineeringControl systemProgrammable logic controller

The invention discloses automatic distorted concrete grouting and vibrating equipment, which belongs to the technical field of construction and comprises an excavator, a hydraulic system, a slurry supply station, a grouting and vibrating device, a PLC (programmable logic controller) control system and an operation screen. The slurry supply stations is connected with a load-bearing main beam of the excavator via a slurry supply station bracket, the grouting and vibrating device is connected with a four-rod mechanism rocker arm of the excavator by a connecting part via a hinge pin, the PLC control system is located on a rotary worktable of the excavator, and the operation screen is mounted in a driving cab of the excavator. The automatic distorted concrete grouting and vibrating equipment simultaneously has grouting and vibrating functions, can realize free switching between a grouting work state and a vibrating work state, automatic alignment of working devices, accurate control of grouting quantity and the like, is flexible in movement, uniform in grouting, large in vibrating force and simple in operation, increases construction speed and quality, reduces labor intensity of workers, and is applicable to distorted concrete grouting and vibrating construction in various work places.

Owner:SINOHYDRO BUREAU 7 CO LTD +1

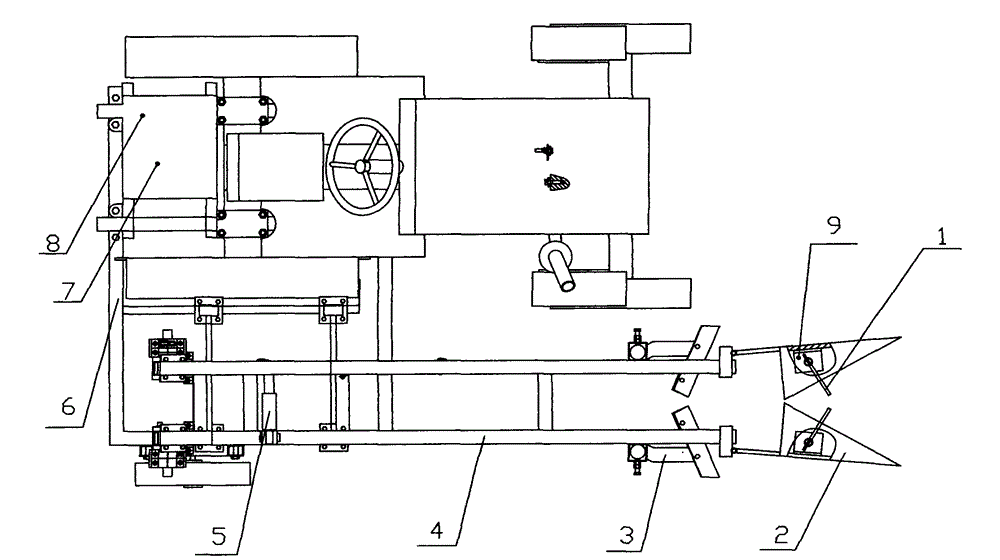

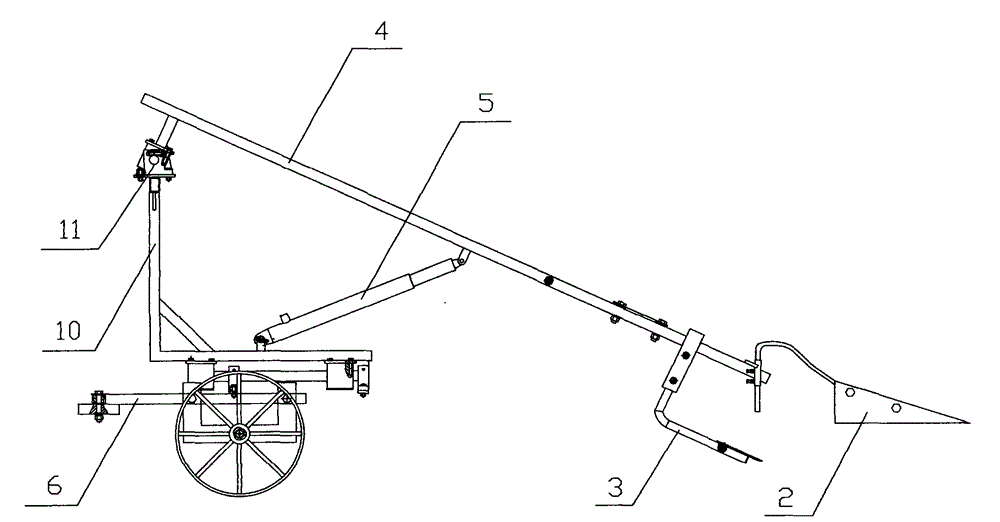

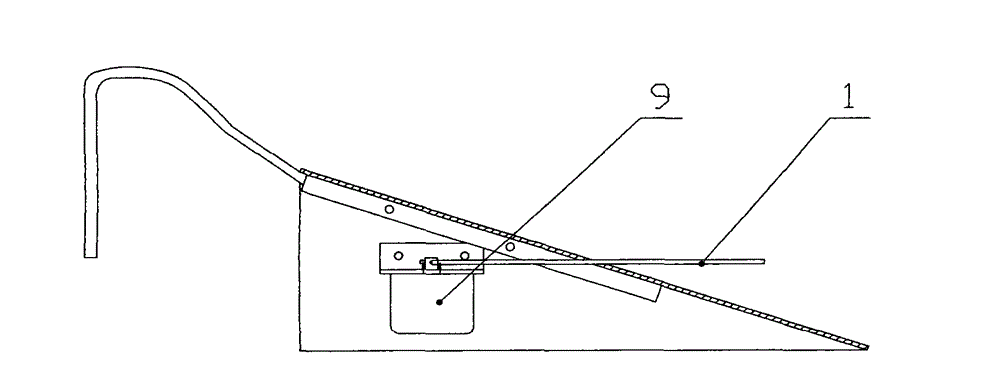

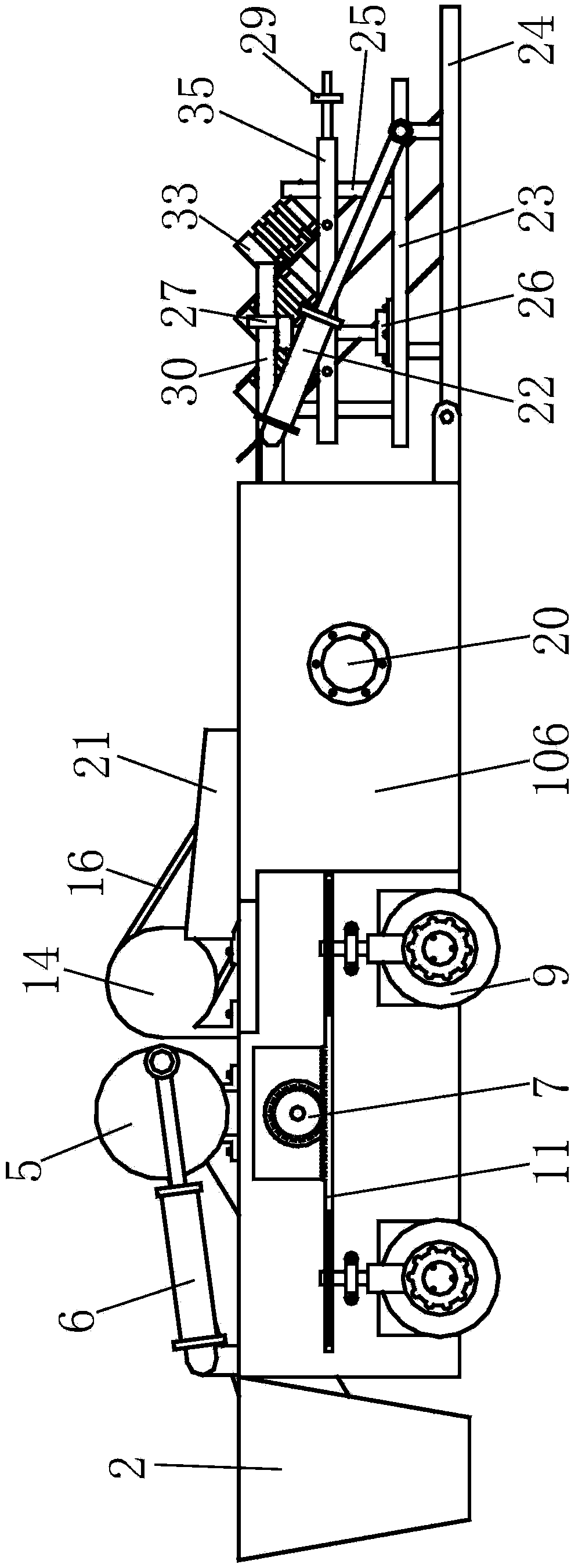

Automatic aligning device

ActiveCN102907205AAchieve left and right movementRealize automatic alignmentDiggersMicrocontrollerHydraulic cylinder

An automatic aligning device comprises a control system, a hydraulic device and a displacement detection device, wherein the control system and the hydraulic device are arranged on a fixing rack at the rear end of a harvest machine, the control system is connected with a harvest frame through a hydraulic cylinder, and an evacuation device and a grain lifter are arranged at the front end of the harvest frame; the displacement detection device is arranged on the grain lifter; and the displacement detection device comprises a swing rod and an angular displacement sensor, and the swing rod is connected with a singlechip used as the control system through the angular displacement sensor. The swinging angle theta of the swing rod is less than or equal to 60 degrees. The displacement detection device consisting of the swing rod and the angular displacement sensor is additionally arranged on the grain lifter and is matched with the control system to control the leftward and rightward movement of the harvest frame, so that the evacuation device can be automatically aligned; and compared with manual regulation, the automatic aligning device is more flexible, the technical requirements on an operator are lowered, and the mechanical damage rate and the fruit loss rate of crops are reduced.

Owner:QINGDAO AGRI UNIV

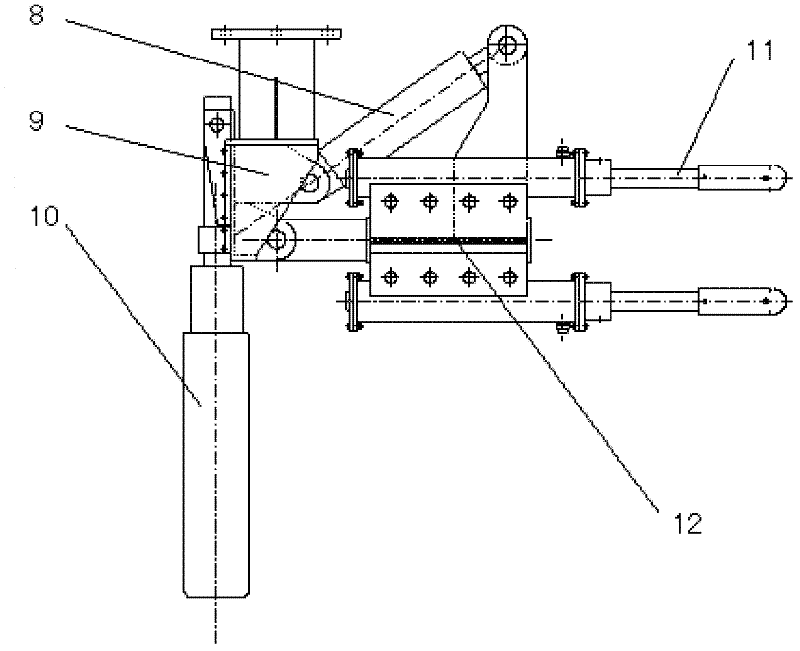

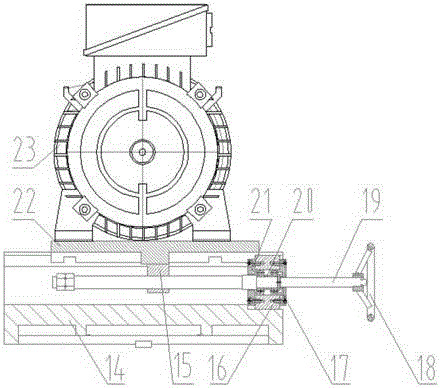

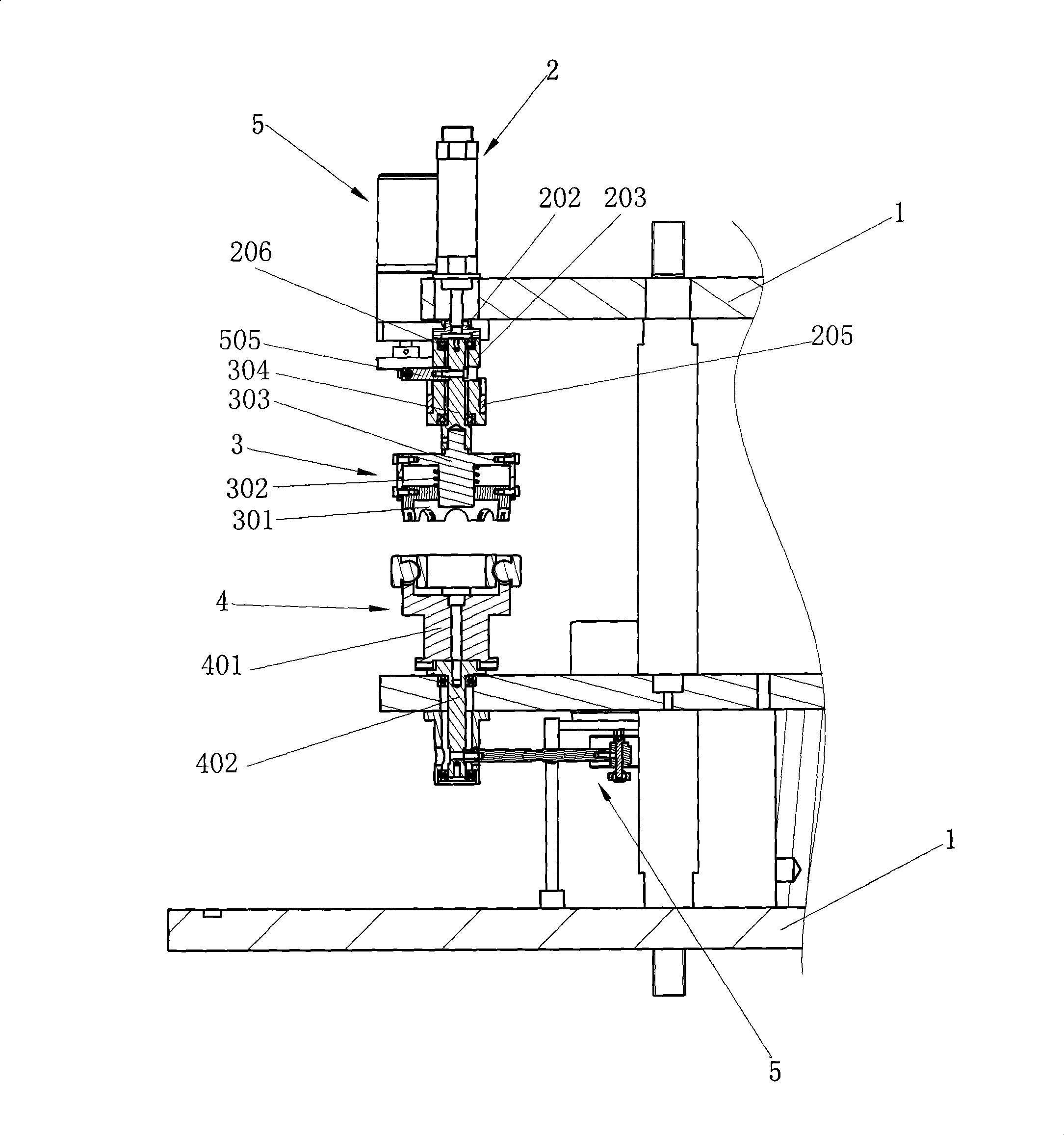

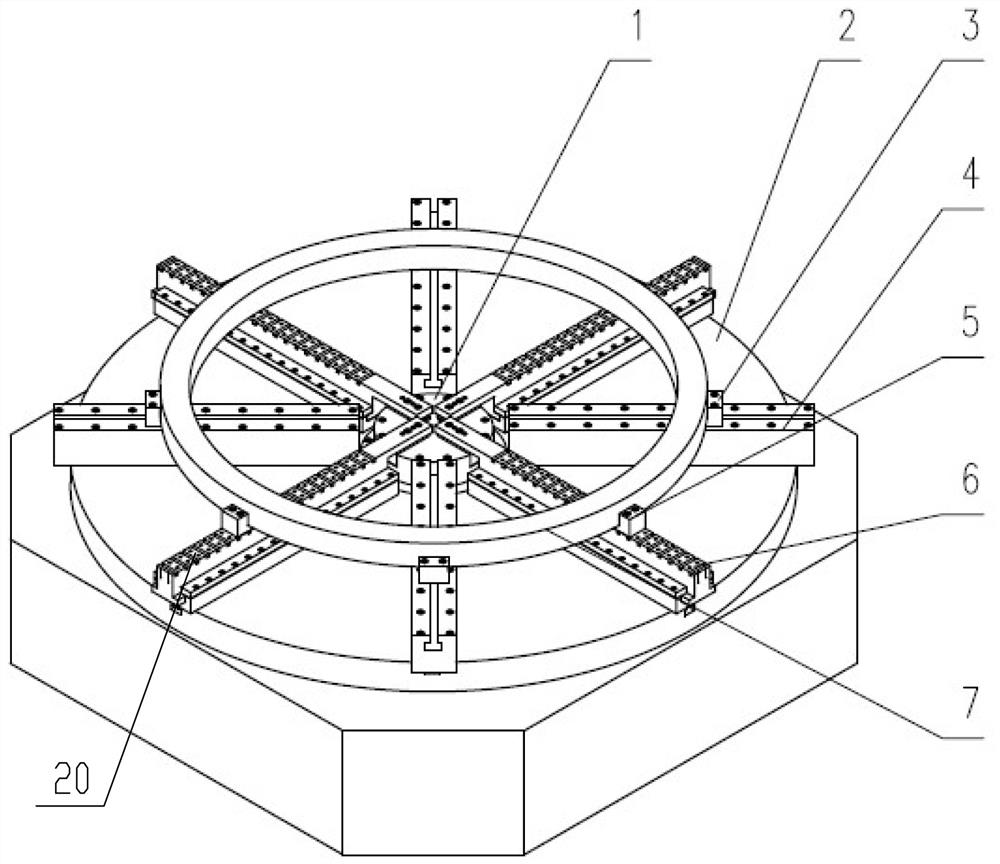

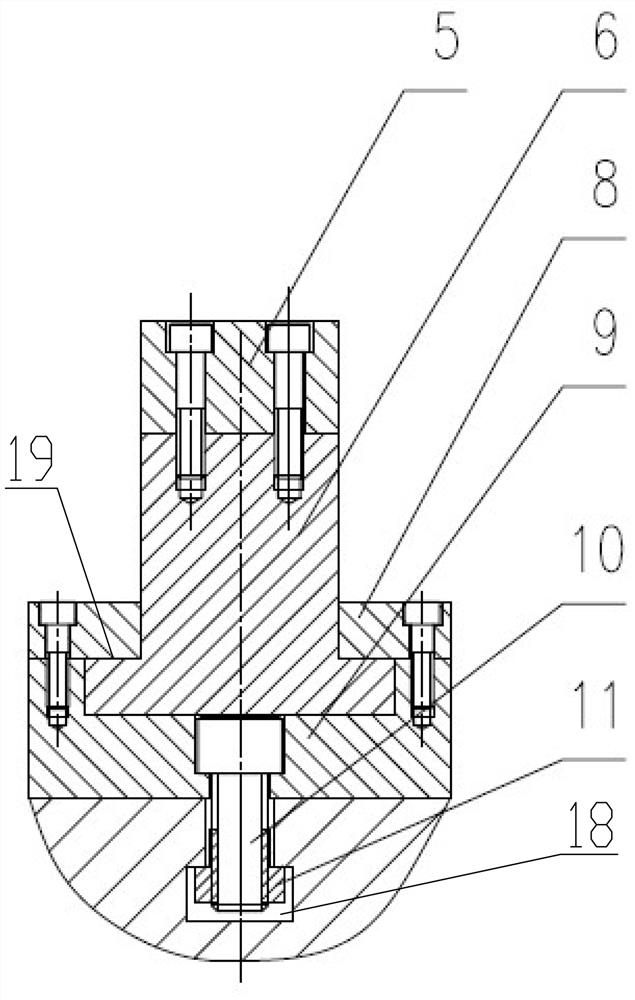

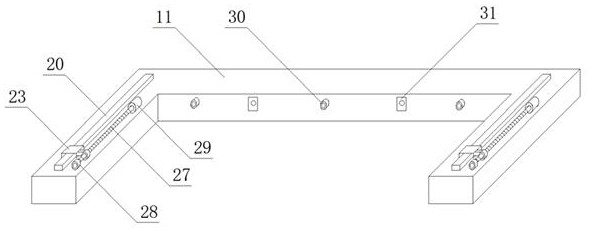

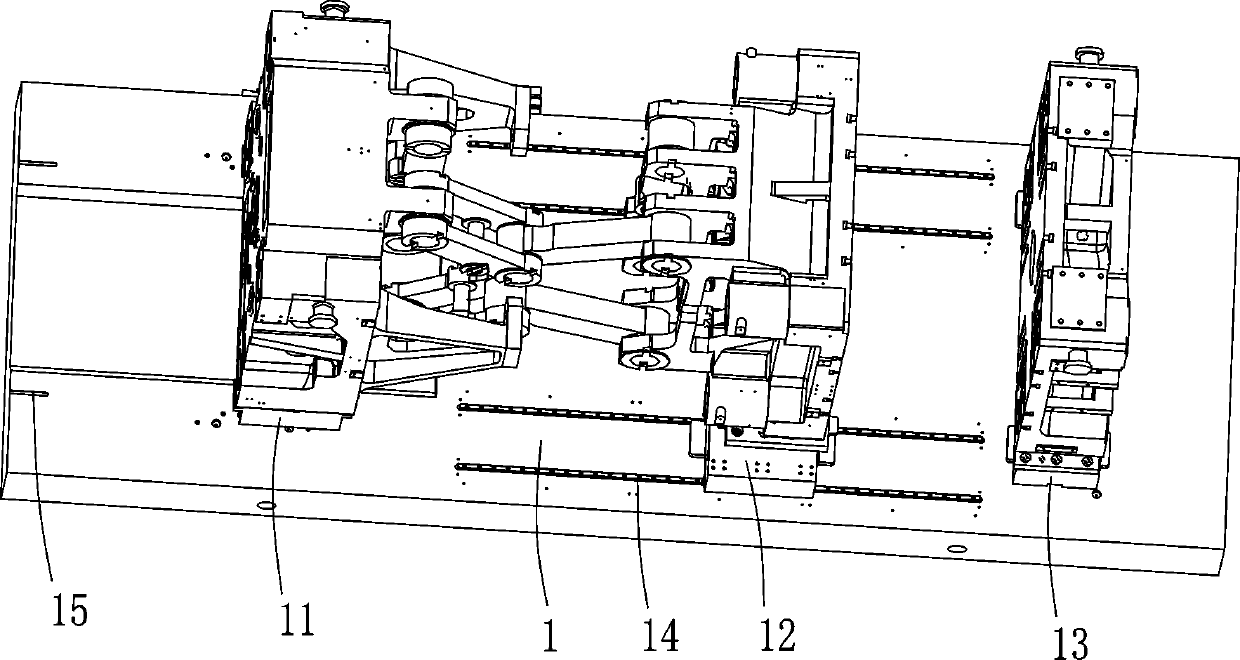

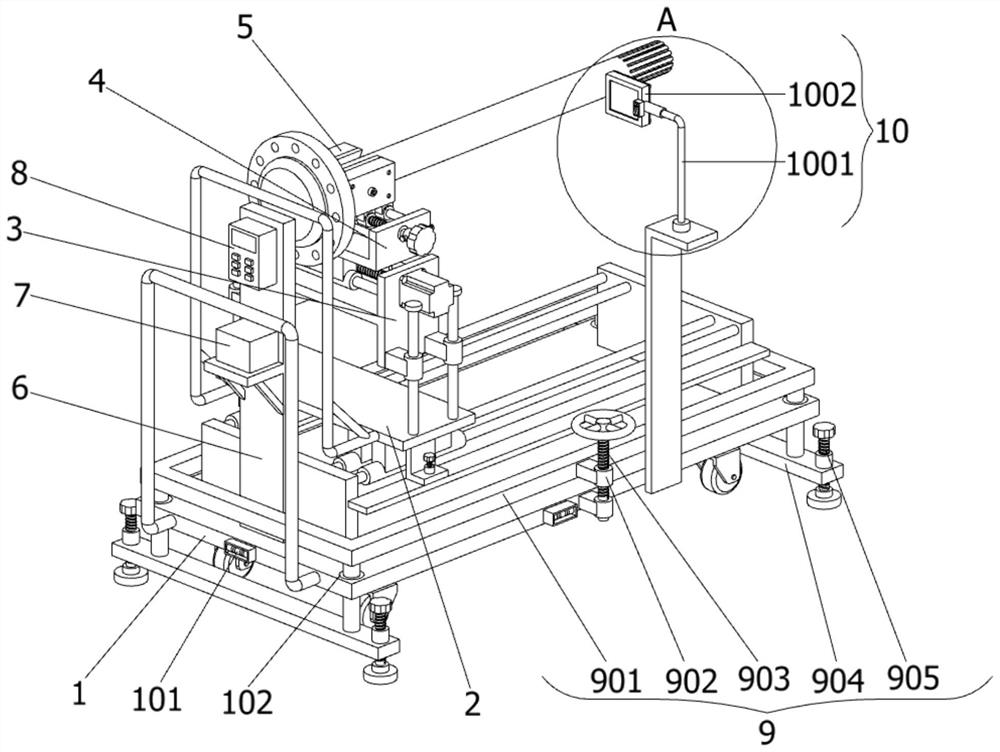

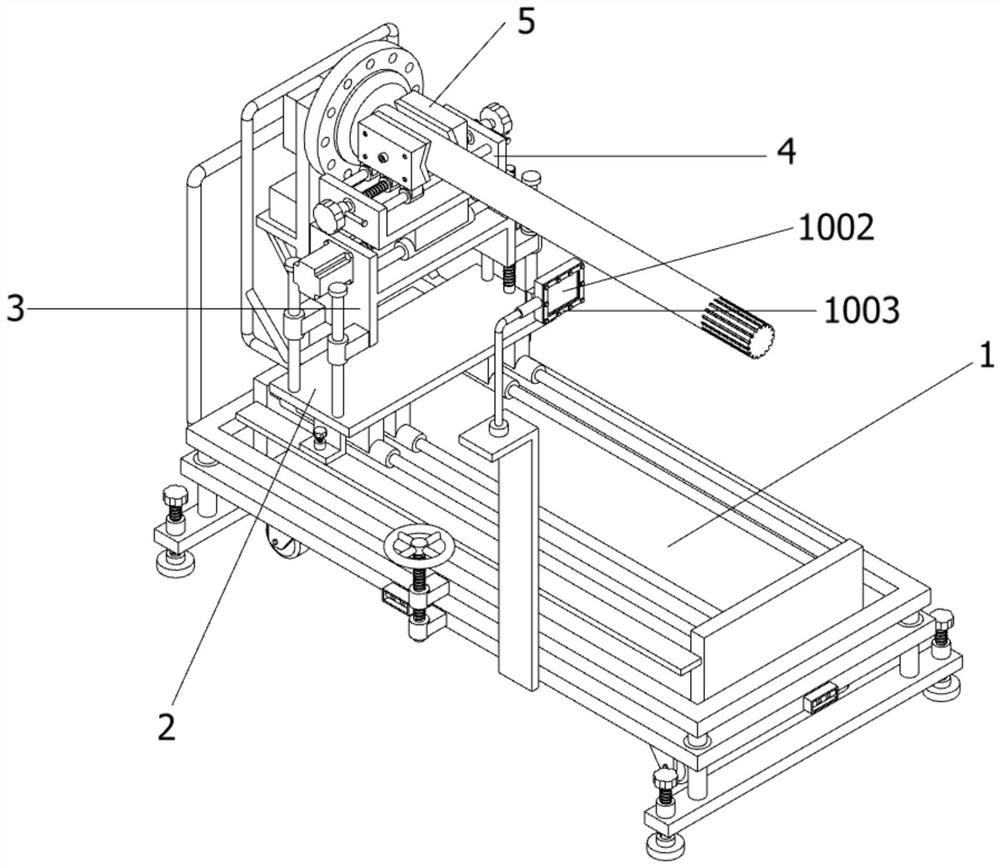

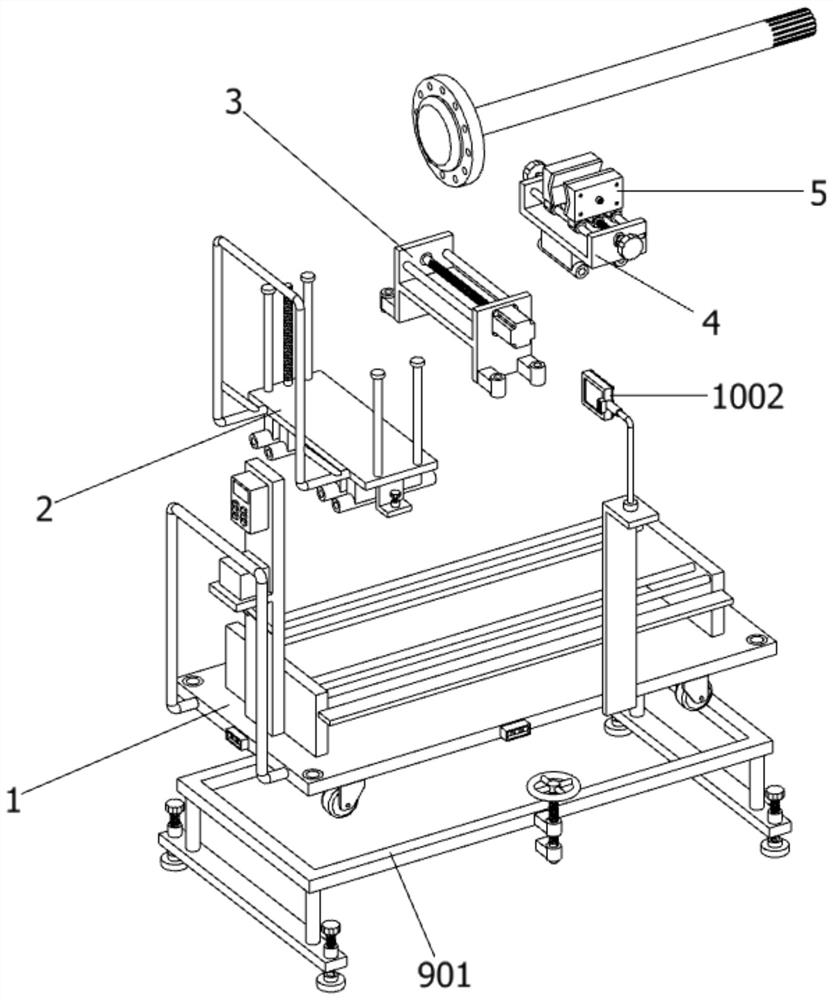

Running attrition testbed compatible with bearing grease uniformizing and non-axle box state idle load of wheel set

PendingCN106706438ASave resourcesStrong functional compatibilityAngle measurementMachine bearings testingMeasurement deviceDrive wheel

A running attrition testbed compatible with bearing grease uniformizing and a non-axle box state idle load of a wheel set comprises a platform assembly, a driving device, a driving wheel set, a driving wheel set supporting device, a wheel set cutting mechanism, a process axle box (the wheel set with a bearing and the wheel set with no bearing), a gear box angle measurement device, a coupling adjustment device, a gear box lifting and fixing device, a process axle box fixing device and a hydraulic loading device. Whether temperature changes of an axle box bearing and a gear box bearing are abnormal or too high can be automatically detected, and the temperature difference of two axle box bearings at two ends can be automatically detected. A running attrition curve, a temperature curve and a running attrition result report of a running attrition test can be recorded and printed in real time.

Owner:QINGDAO SIJI EQUIP PROJECT

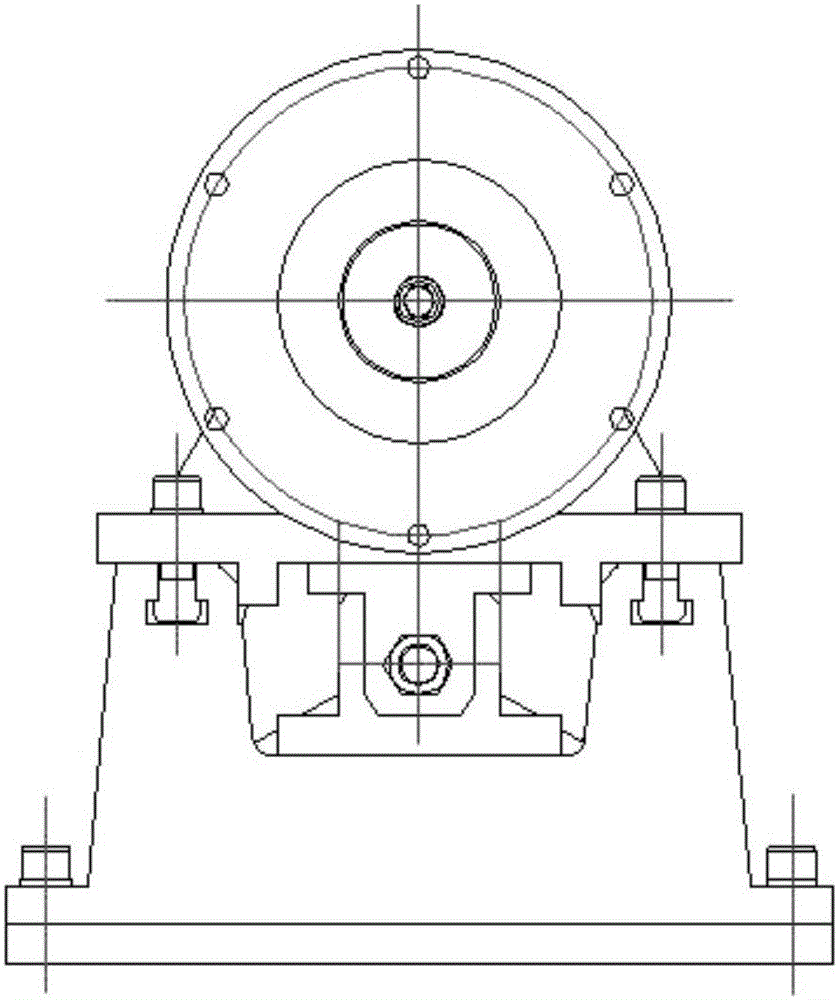

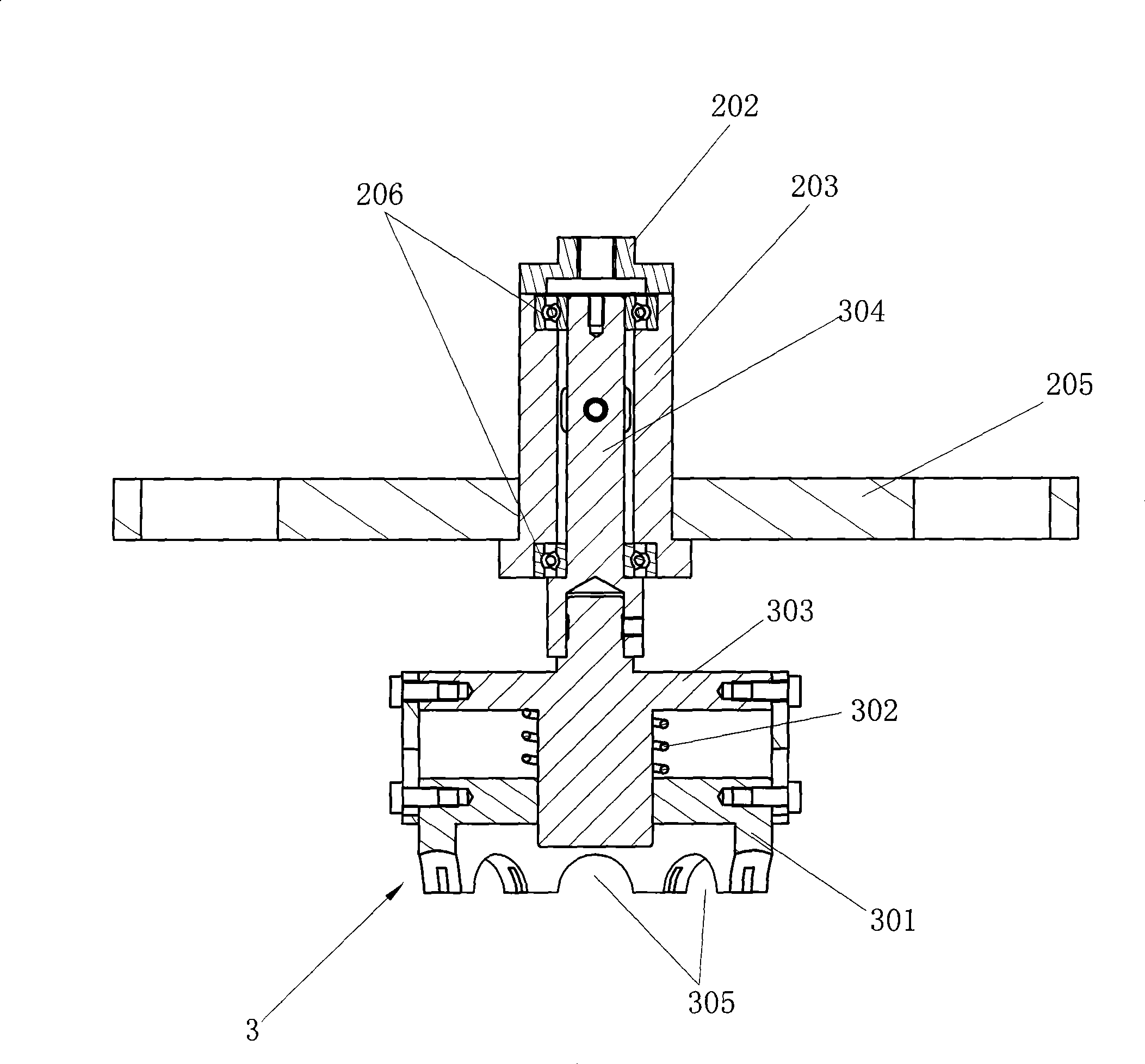

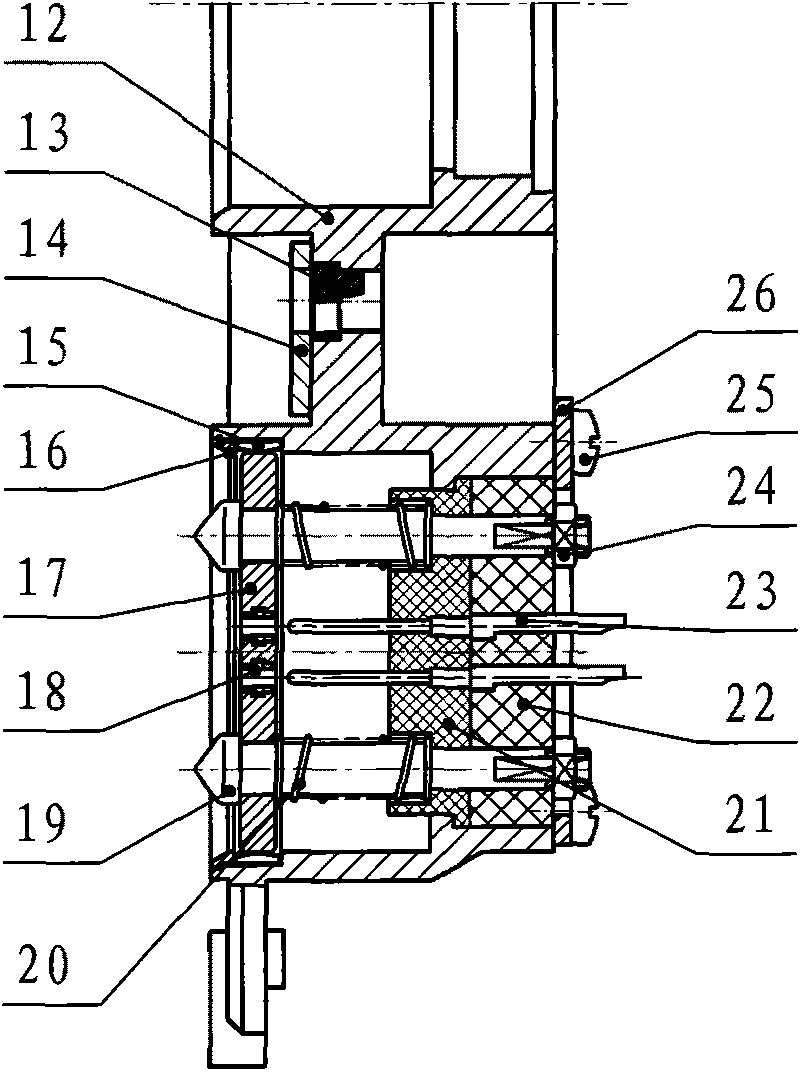

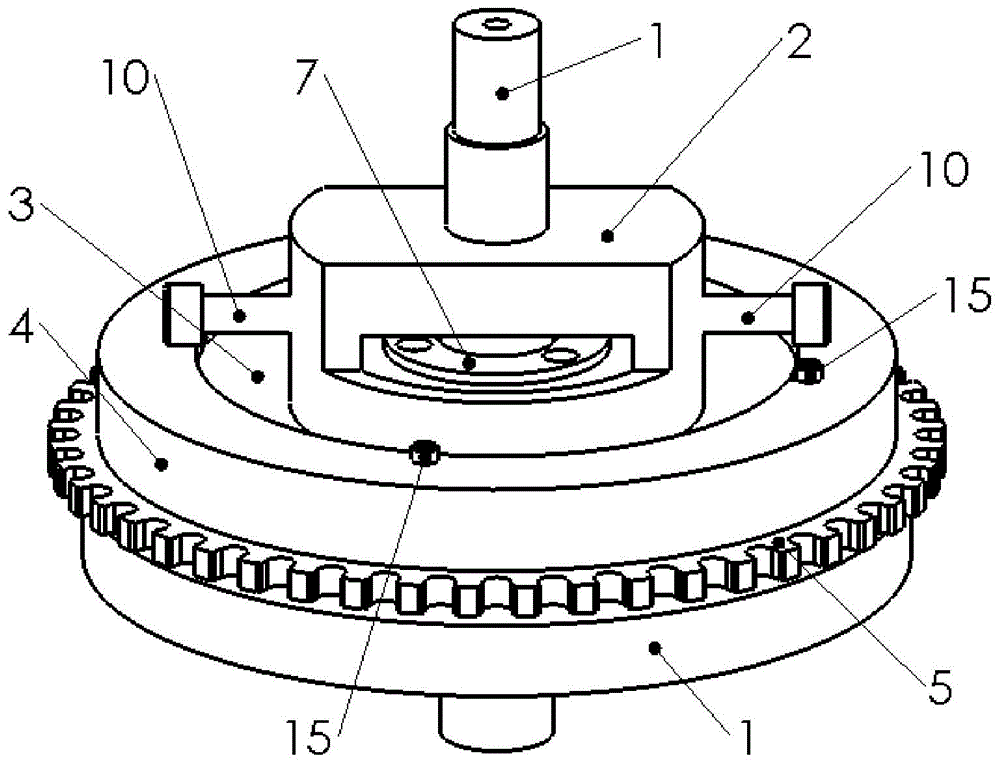

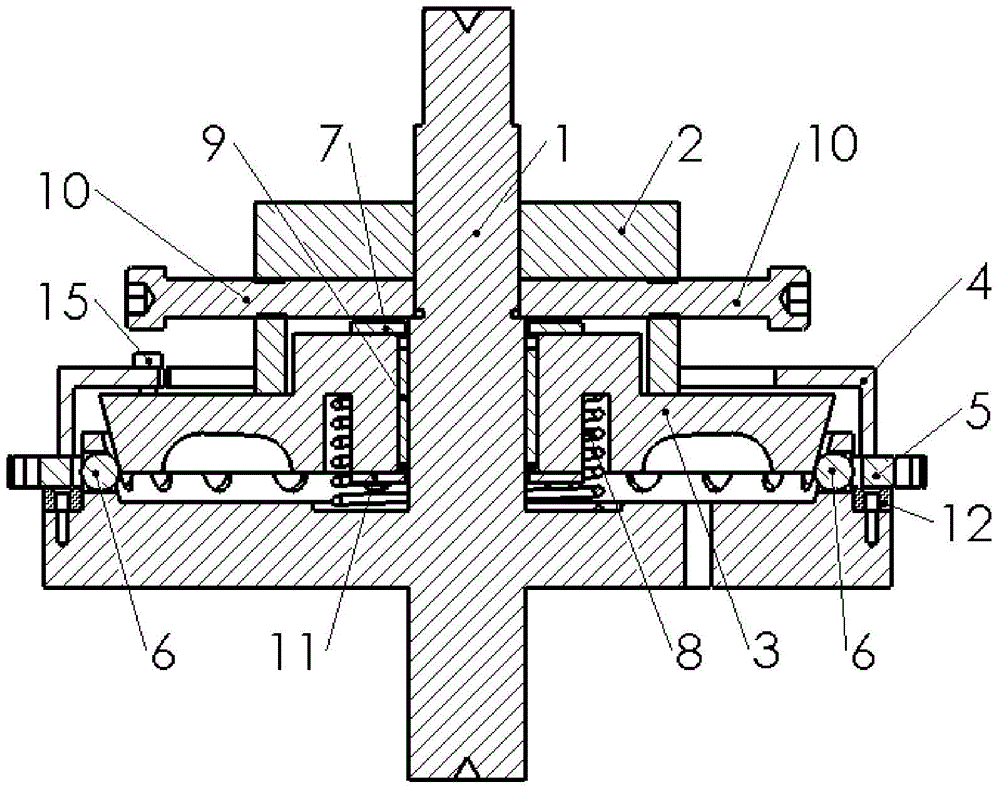

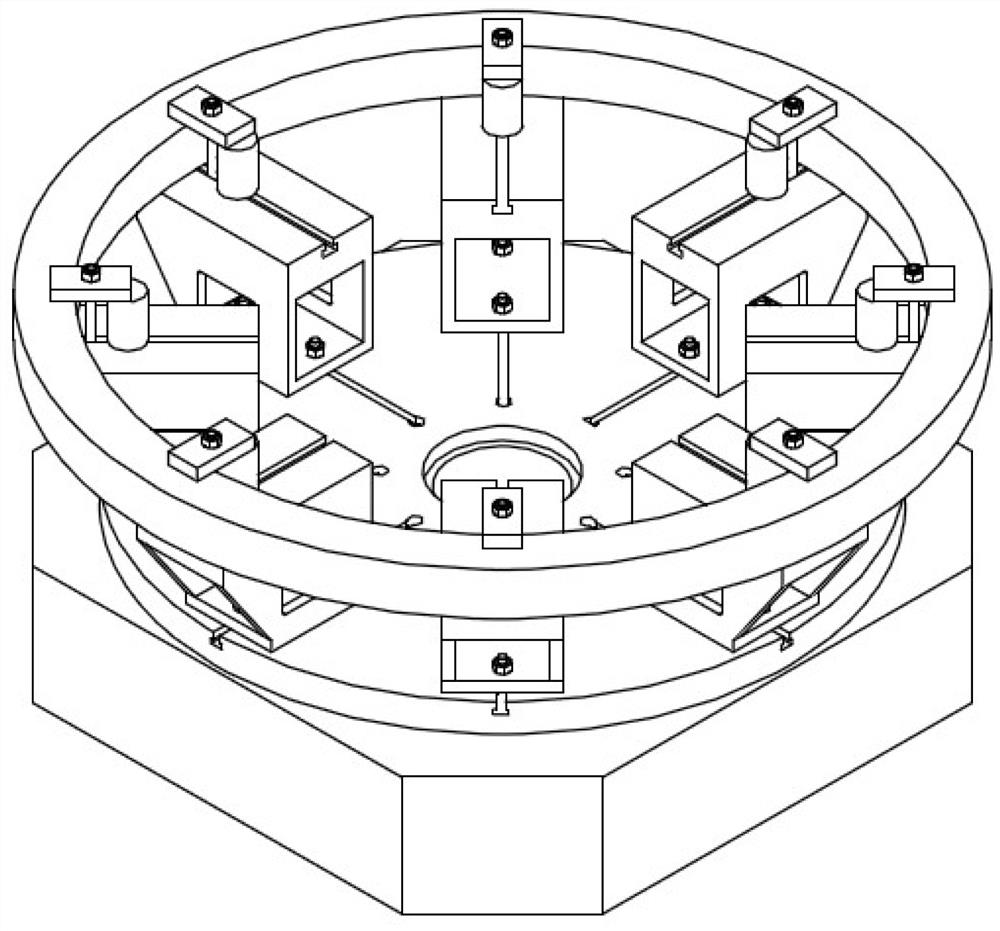

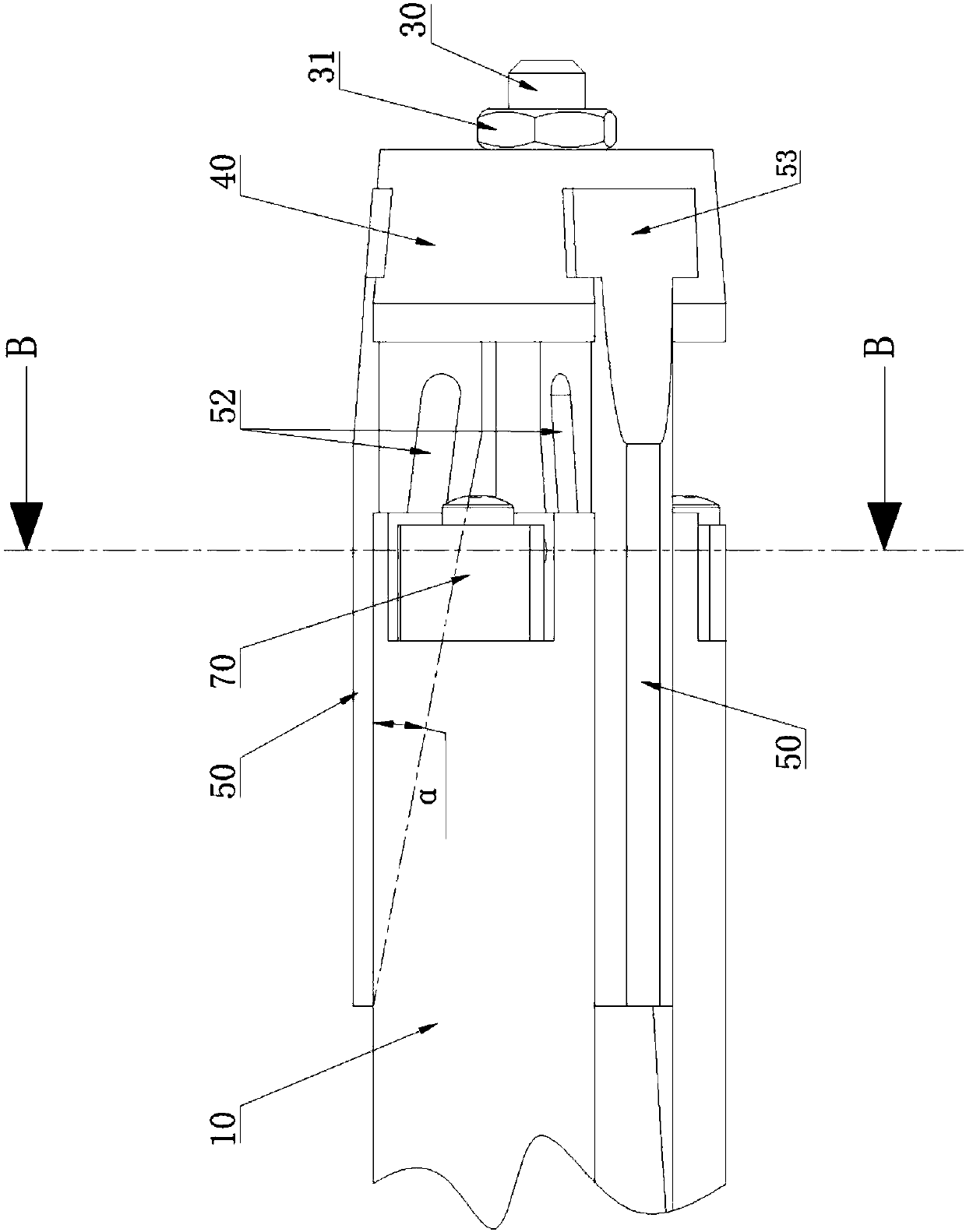

Oscillation positioning device of holder of bearing ball separating holder assembly machine

InactiveCN101363476ARealize automatic alignmentImprove alignment efficiencyBearing componentsEngineeringElectric control

The invention relates to a retainer oscillating alignment device of a bearing ball separating retainer assembly machine, and is characterized in that the retainer oscillating alignment device comprises a frame and an electric control system; an elevating mechanism is arranged at the upper part of the frame, an upper die is pivotally arranged on the elevating mechanism and an oscillating mechanism is connected with the upper die; a lower die is pivotally arranged on the frame and is connected with the oscillating mechanism. The retainer oscillating alignment device of the bearing ball separating retainer assembly machine disclosed in the invention can realize automatic alignment in the installing process of the retainer, improve the alignment efficiency and production efficiency of the bearing retainer and solve the problems of rivet shedding as well as deformation and deadlocking of the retainer.

Owner:无锡市江益轴承自动化设备有限公司

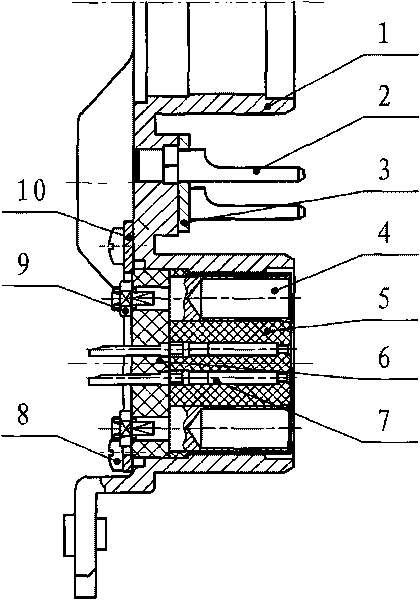

Cabinet-type electric connector

ActiveCN101714727AMeet the needs of the applicationWith electromagnetic shielding functionCoupling protective earth/shielding arrangementsElectricityEngineering

A cabinet-type electric connector consists of a plug and a socket; the plug and a shell of the socket are provided with a plurality of cavities for mounting a plurality of corresponding functional modules; and the abutting end of each functional module is provided with a mobile electromagnetic shielding device and a guide positioning device, wherein the mobile electromagnetic shielding device consists of a shielding plate, an elastic shielding reed, an insulating sleeve and a spring. By using a matching form of the mobile shielding plate and the elastic shielding reed, the electromagnetic shielding function after the connector is plugged and separated is well implemented; meanwhile, the arranged guide positioning device can well implement guiding and positioning when the plug is plugged in the socket so as to realize automatic alignment of the connector; and the cabinet-type electric connector has higher mounting error compensation capability, meets the requirements of cabinet-type application occasions, and has stronger practicability.

Owner:GUIZHOU SPACE APPLIANCE CO LTD

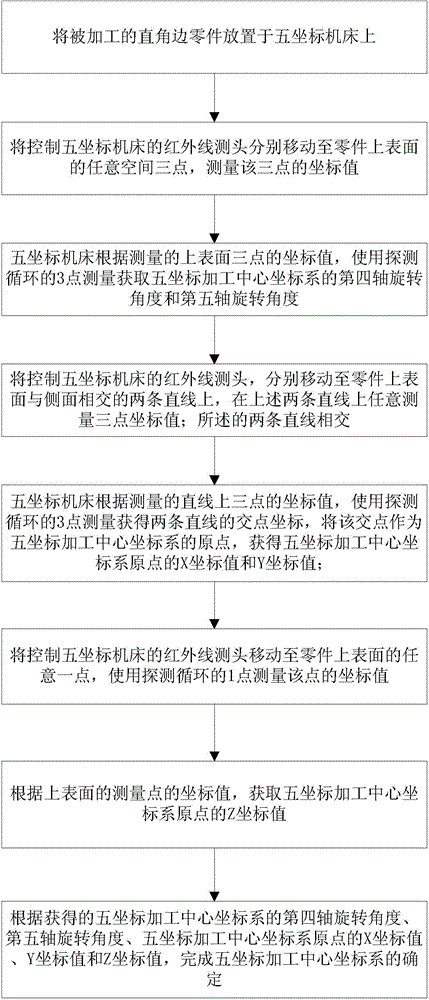

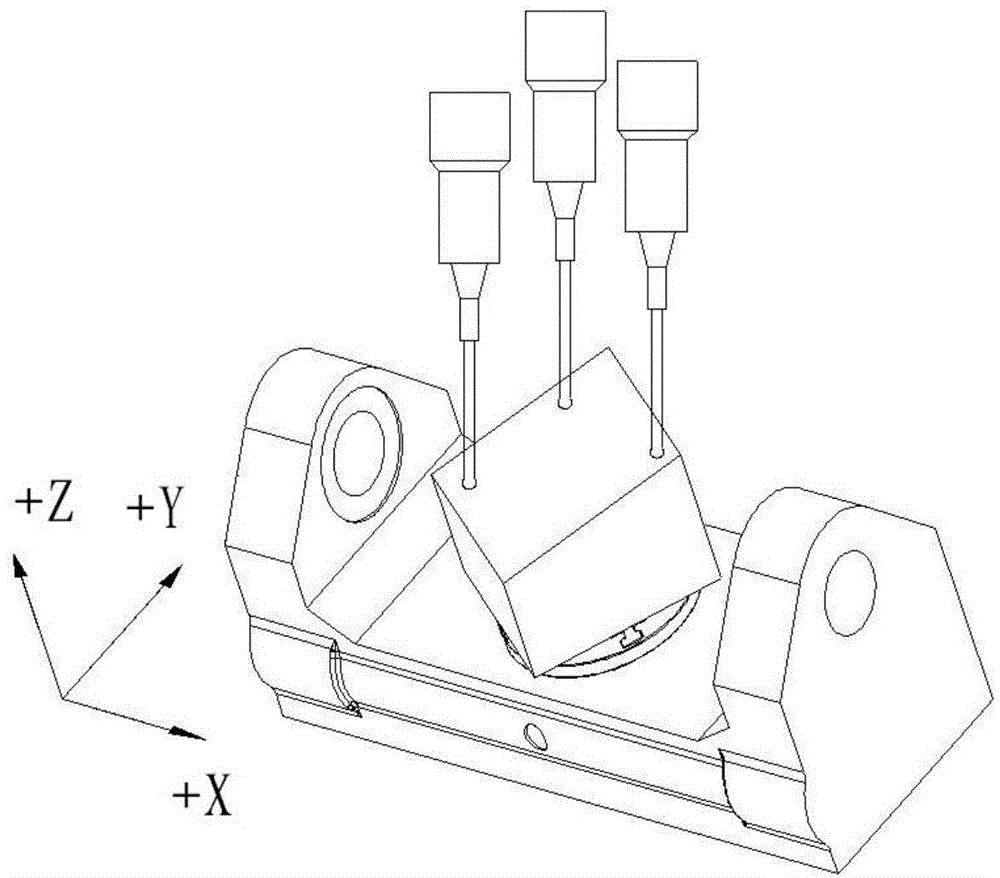

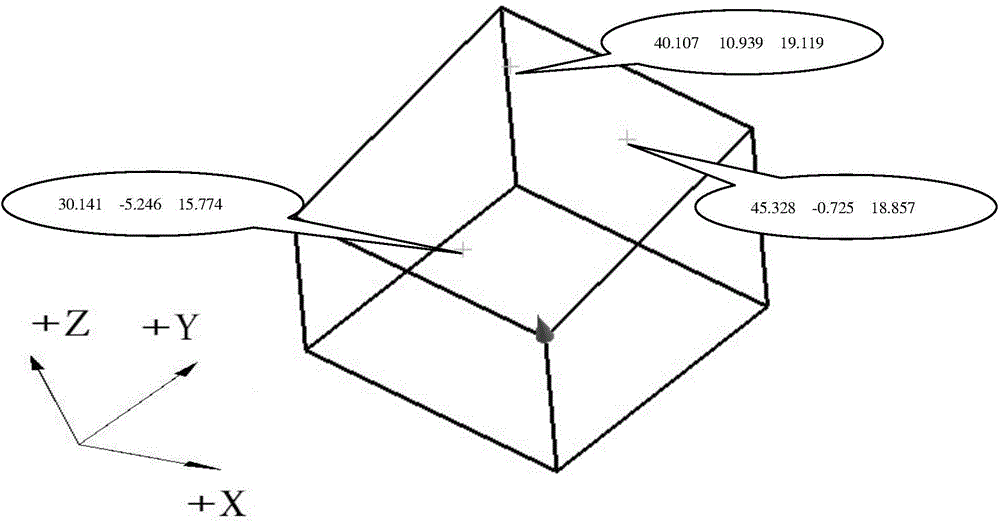

Five-axis machining center coordinate system determination method based on 7-point detection repetition

InactiveCN104476330AReduce processing timeAvoid quality hazardsMeasurement/indication equipmentsNumerical controlRational use

The invention discloses a five-axis machining center coordinate system determination method based on 7-point detection repetition and belongs to the field of online measurement of numerical control machining. The five-axis machining center coordinate system determination method based on the 7-point detection repetition changes the traditional manual coordinate system aligning and machining which waste time and labor, and the aligning quality is partial to the processing experience of an operator. The five-axis machining center coordinate system determination method based on the 7-point detection repetition includes that mounting an infrared measuring head at the five-axis machining center, using the infrared measuring head to measure and sample points, calculating according to mechanical coordinate data of the measured points to obtain the rotating angle and zero point position of each of the fourth axis and fifth axis, and writing in a zero point offset table to realize zero point set. The five-axis machining center coordinate system determination method based on the 7-point detection repetition is simple in application conditions and suitable for the five-axis machining center with two rotary axes at a working table; the machining and detection are integrated through reasonably using an online measurement technology, the automatic alignment of the system is effectively realized, the part machining time is shortened, the workload of the operator is reduced, the potential quality hazard due to the alignment of the part machining is avoided, and the non-intervention processing for the part during the whole process is effectively guaranteed.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Floating connector component and floating connector thereof

InactiveCN102403620ARealize automatic alignmentLow matching accuracy requirementsCoupling parts mountingEngineeringSurface plate

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

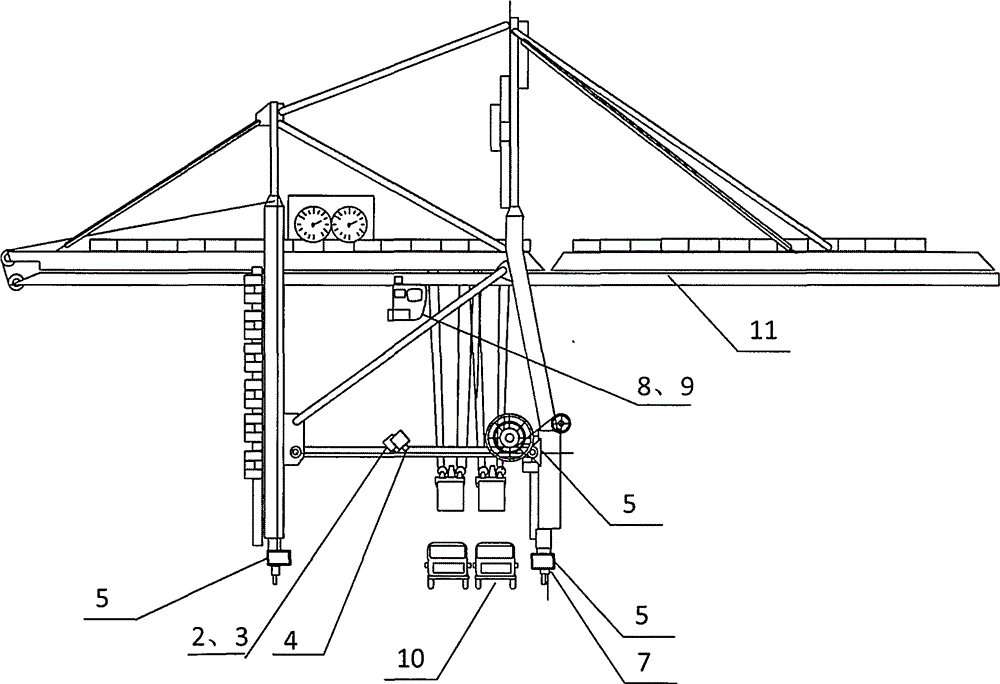

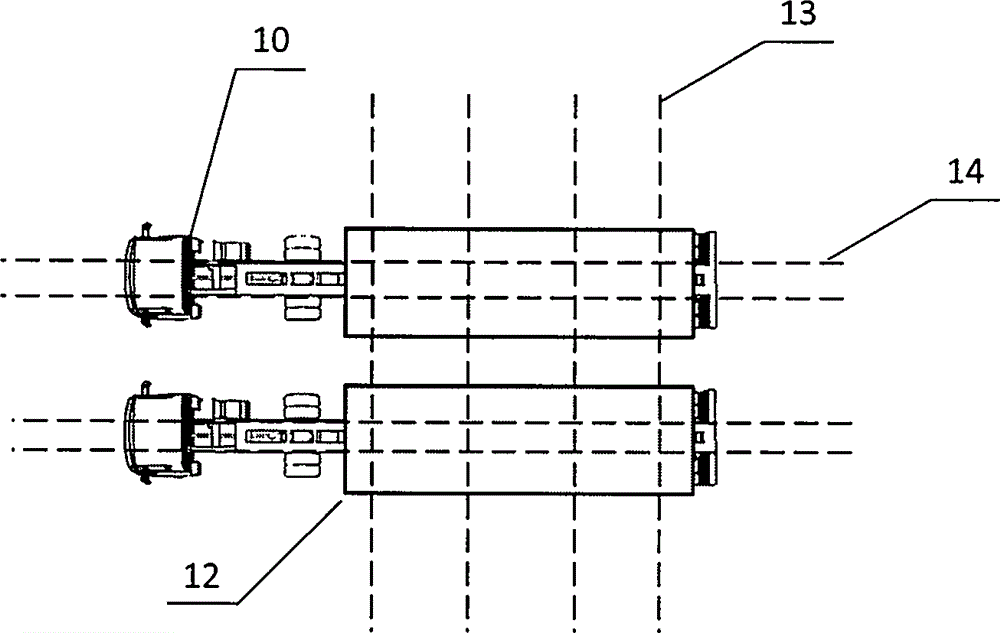

Bridge crane-below multilayer laser scanning container truck and lifting appliance locking head aligning method

ActiveCN106495000ARealize automatic alignmentRealize simultaneous alignmentLoad-engaging elementsLaser scanningEngineering

The invention discloses a bridge crane-below multilayer laser scanning container truck and lifting appliance locking head aligning method. According to the bridge crane-below multilayer laser scanning container truck and lifting appliance locking head aligning method, two multilayer laser scanners are adopted for automatic identifying of working lanes, multilayer orthogonal scanning of heavily-loaded or unloaded container trucks on a plurality of working lanes is carried out at the same time, and container truck and lifting appliance locking head aligning is realized. According to the bridge crane-below multilayer laser scanning container truck and lifting appliance locking head aligning method, one multilayer laser scanner is immobilized, and the scanning surface of the immobilized multilayer laser scanner is designed to be vertical to the forward direction of the lanes; scanning of all the lanes below the bridge crane, automatic identifying of current working lanes, and measuring of the left and right deviation distance of the container trucks on the lanes are carried out at the same time; the other multilayer laser scanner arranged on a holder is driven to rotate accordingly, and the scanning surface of the multilayer laser scanner is designed to be parallel to the forward direction of the lanes; double working lanes below double lifting appliance bridge crane are adopted, so that two scanning surfaces are used for scanning one lane, and scanning of two lanes can be carried out at the same time, and measuring of the front and back deviation distance of the container trucks on the lanes is carried out; a microprocessor is connected with a bridge crane PLC, and is used for sending adjusting commands to the bridge crane PLC based on the position of the container trucks; and the bridge crane PLC is used for adjusting the position of the lifting appliance and oil cylinder telescoping so as to realize aligning of the container trucks with lifting appliance four locking heads.

Owner:NANTONG TONGLEI SOFTWARE

Thin-wall gear ring self-centering tensioning installation fixture

InactiveCN104589230AAvoid deformationReduce distortionMachine gearing/transmission testingWork holdersEngineeringSteel ball

Owner:XI AN JIAOTONG UNIV

Novel soybean seed sorting machine with batch arraying and visual selection functions

InactiveCN105903685ARealize automatic alignmentImprove qualitySortingConveyor partsMachine visionImaging processing

The invention discloses a soybean seed sorting and split charging machine based on embedded machine vision. The machine comprises a main frame, a discharge device, an automatic arraying and transportation system, an embedded vision system, an eliminating mechanism, an intelligent control system, a soybean seed collection device and an automatic split charging device. Through a specially-produced conveyor belt with uniform circular grooves and gravity distribution at the inclined plane, soybean seed automatic arraying is realized. The image processing-based machine vision realizes soybean seed careful selection and greatly improves soybean seed sorting quality. The machine has the characteristics of simpleness, portability, high efficiency and continuity.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

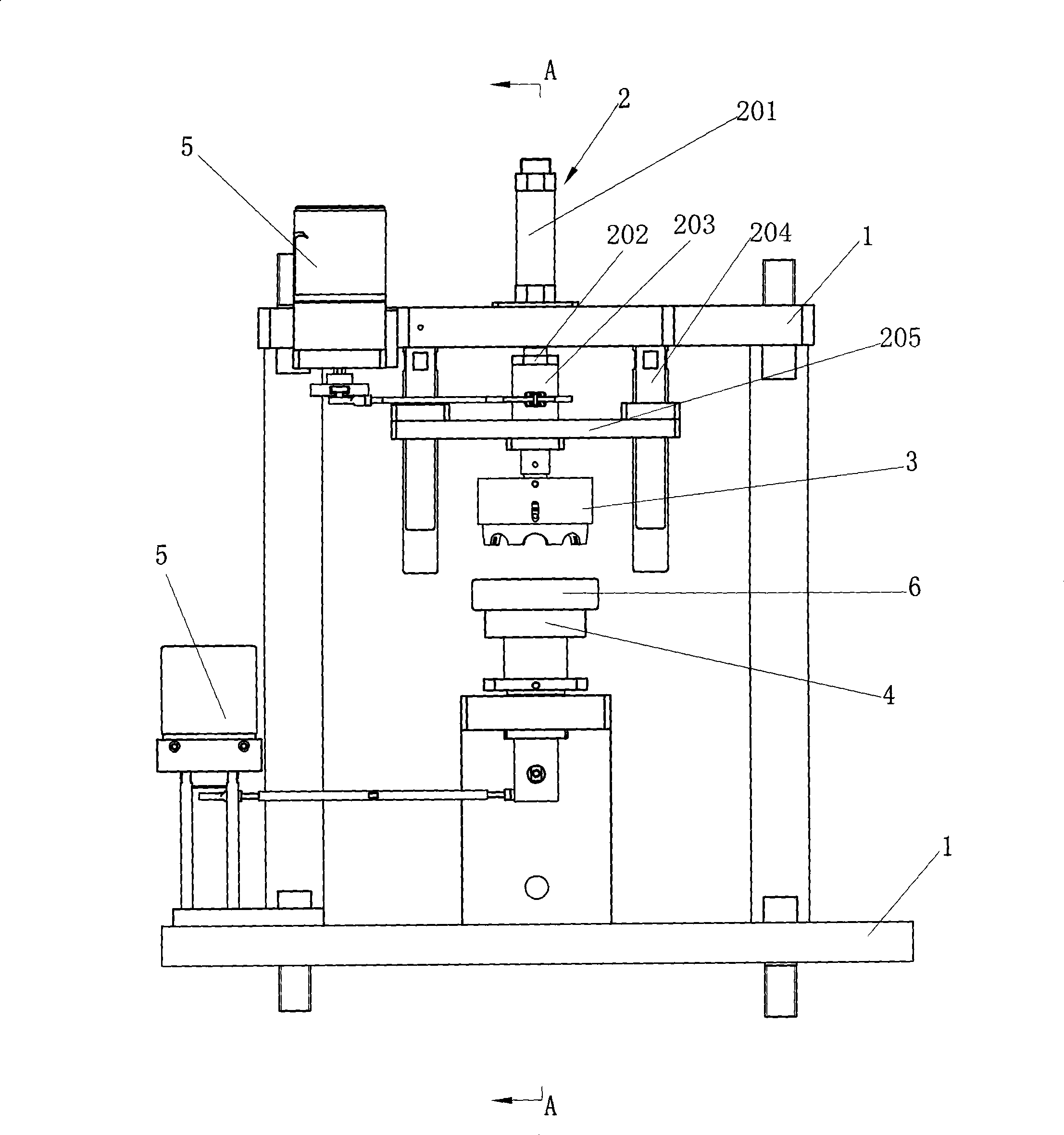

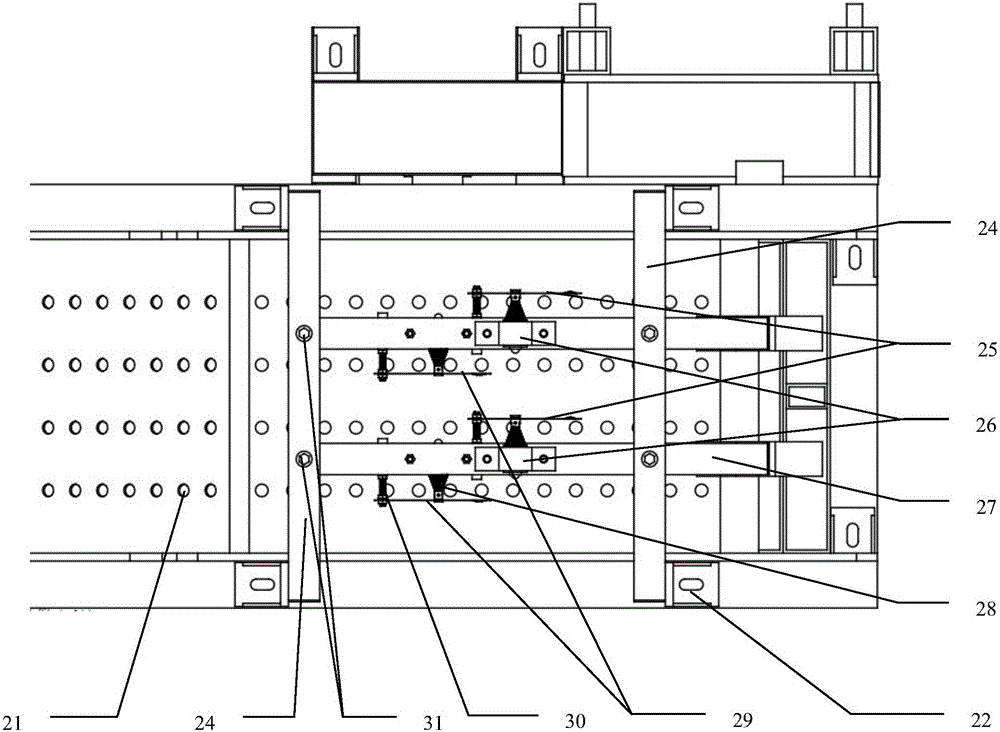

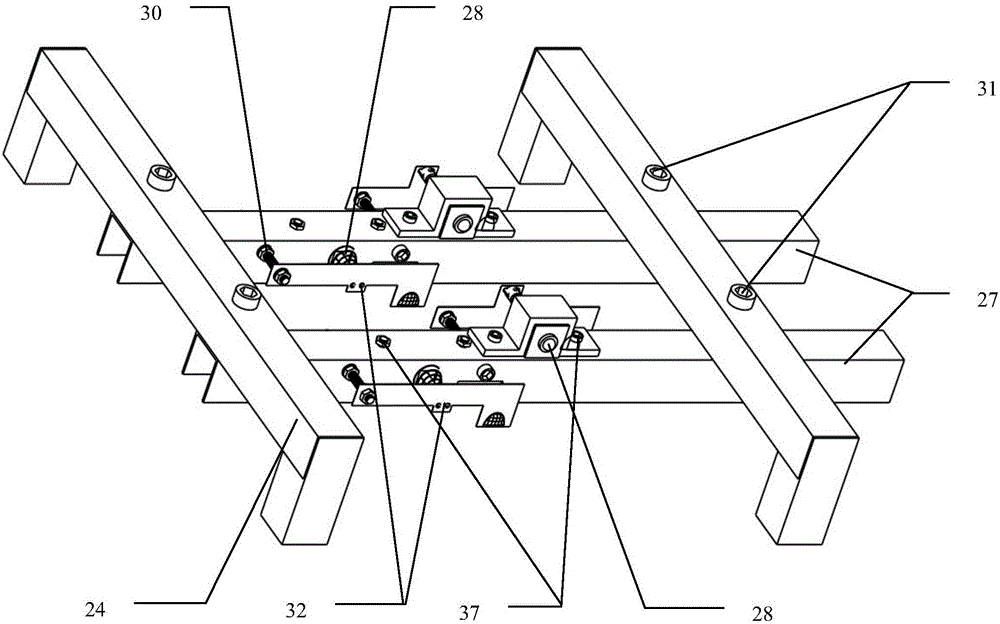

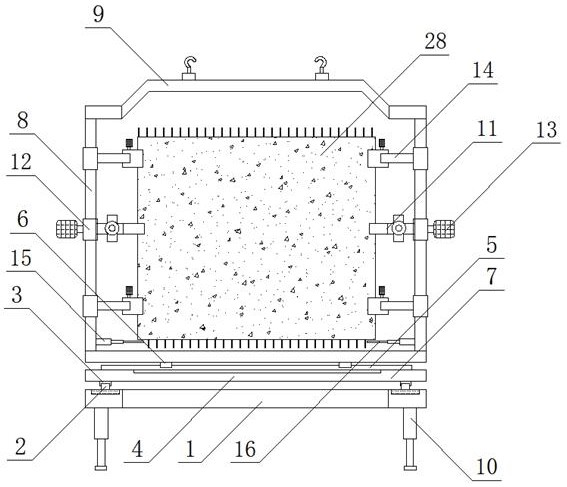

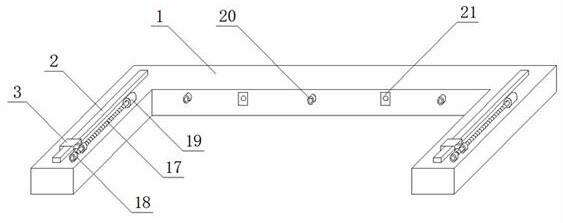

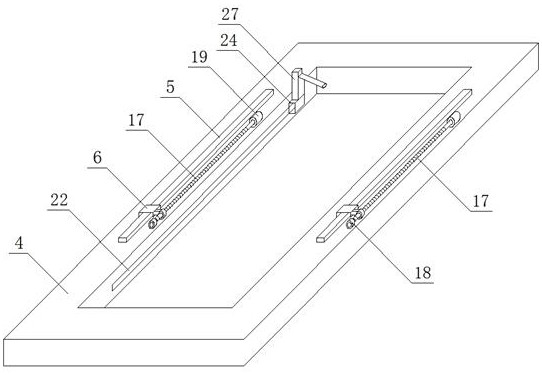

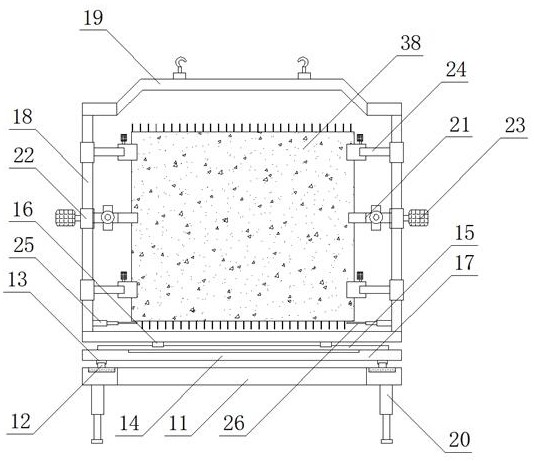

Intelligent alignment assembly equipment and alignment assembly method for prefabricated parts of assembly type shear wall

ActiveCN111764659AWith highly precise adjustment functionRealize automatic alignmentBuilding material handlingMachine visionButt joint

The invention relates to intelligent alignment assembly equipment and an alignment assembly method for prefabricated parts of an assembly type shear wall. The intelligent alignment assembly equipmentis characterized in that frame type prefabricated part carrying equipment consisting of a lifting base, a longitudinal moving platform, a transverse moving platform, a component bearing vertical frameand a hanging cross beam is adopted, so that the equipment has functions of overall height accurate adjustment and transverse and longitudinal high-precision automatic alignment, moreover, limiting fixing clamps and clamping assemblies are adopted for laterally clamping and fixing the prefabricated parts, the anti-falling self-locking function is good, a supporting plate integrally supports the prefabricated parts from the bottom, the suspended large-mass prefabricated parts are prevented from vertically sliding off, and safety is improved. According to the intelligent alignment assembly equipment and alignment assembly method, the structure is reasonable, automatic alignment and assembly in the whole process are achieved by means of machine vision and a sensor, the posture can be automatically adjusted, the butt joint position can be automatically aligned, the alignment and assembly precision is high, the labor intensity of workers is relieved, and the alignment and assembly efficiency is greatly improved.

Owner:HUBEI ZHOUTIAN CONSTR GROUP

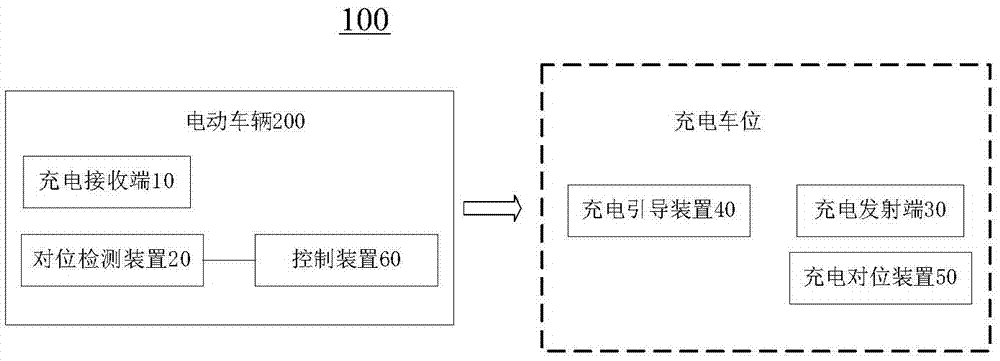

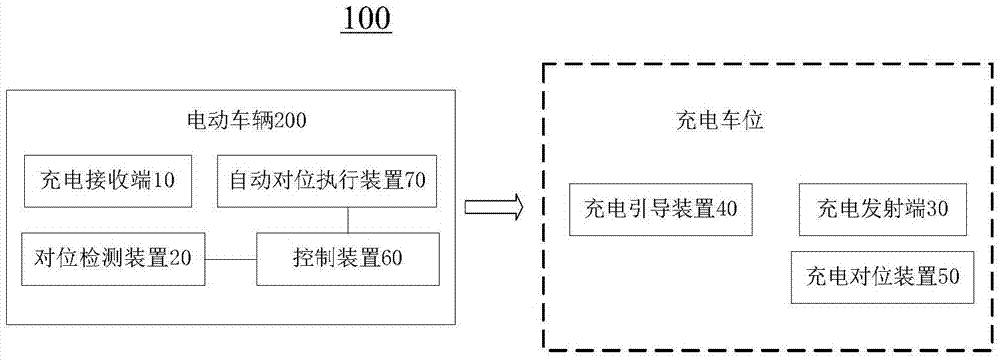

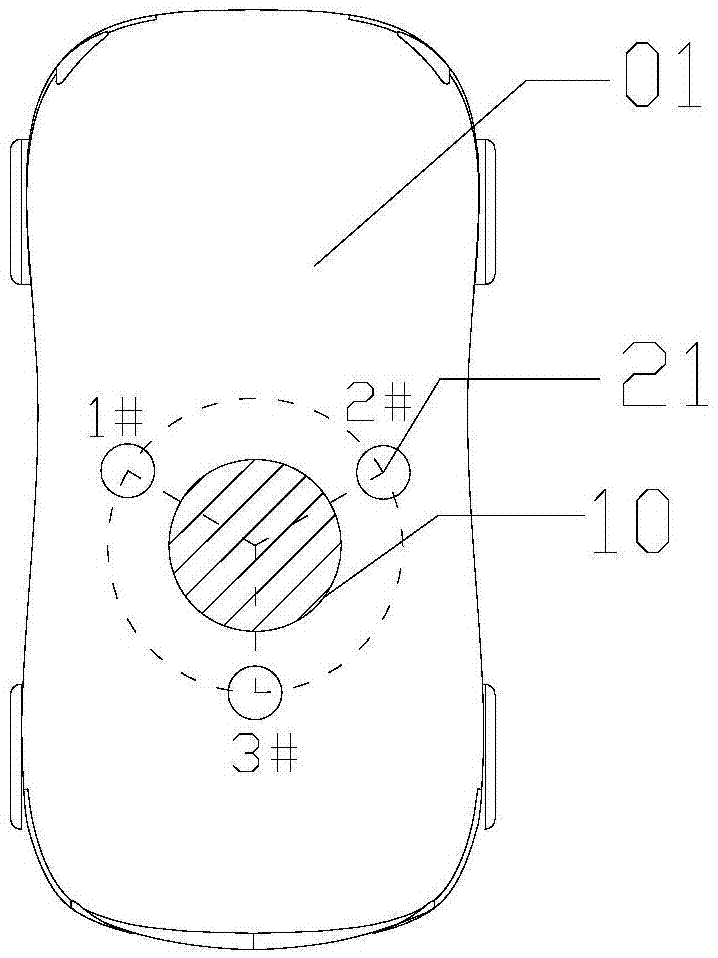

Wireless charging positioning system and method, electric vehicle, and wireless charging emitting system

ActiveCN106891741AReduce wasteImprove alignment accuracyCharging stationsPropulsion by batteries/cellsControl signalEngineering

The invention discloses an electric vehicle wireless charging positioning system. The wireless charging positioning system includes a charging emitting end, a charging guide device, a charging positioning device, a charging receiving end, a positioning detection device, and a control device; the charging guide device generates a charging guide signal; the charging positioning device generates a charging positioning signal; the positioning detection device detects the charging guide signal and the charging positioning signal; the control device acquires a current operation parameter of an electric vehicle after receiving a charging start signal, generates a charging guide control signal according to the current operation parameter and the charging guide signal, generates a charging positioning control signal according to the charging positioning signal so as to position the charging receiving end and the charging emitting end; and the charging receiving end, the positioning detection device and the control device are arranged on the electric vehicle. The wireless charging positioning system is accurate in positioning, and can improve the charging efficiency. The invention also discloses an electric vehicle, a wireless charging emitting system, and a wireless charging positioning method.

Owner:BYD CO LTD

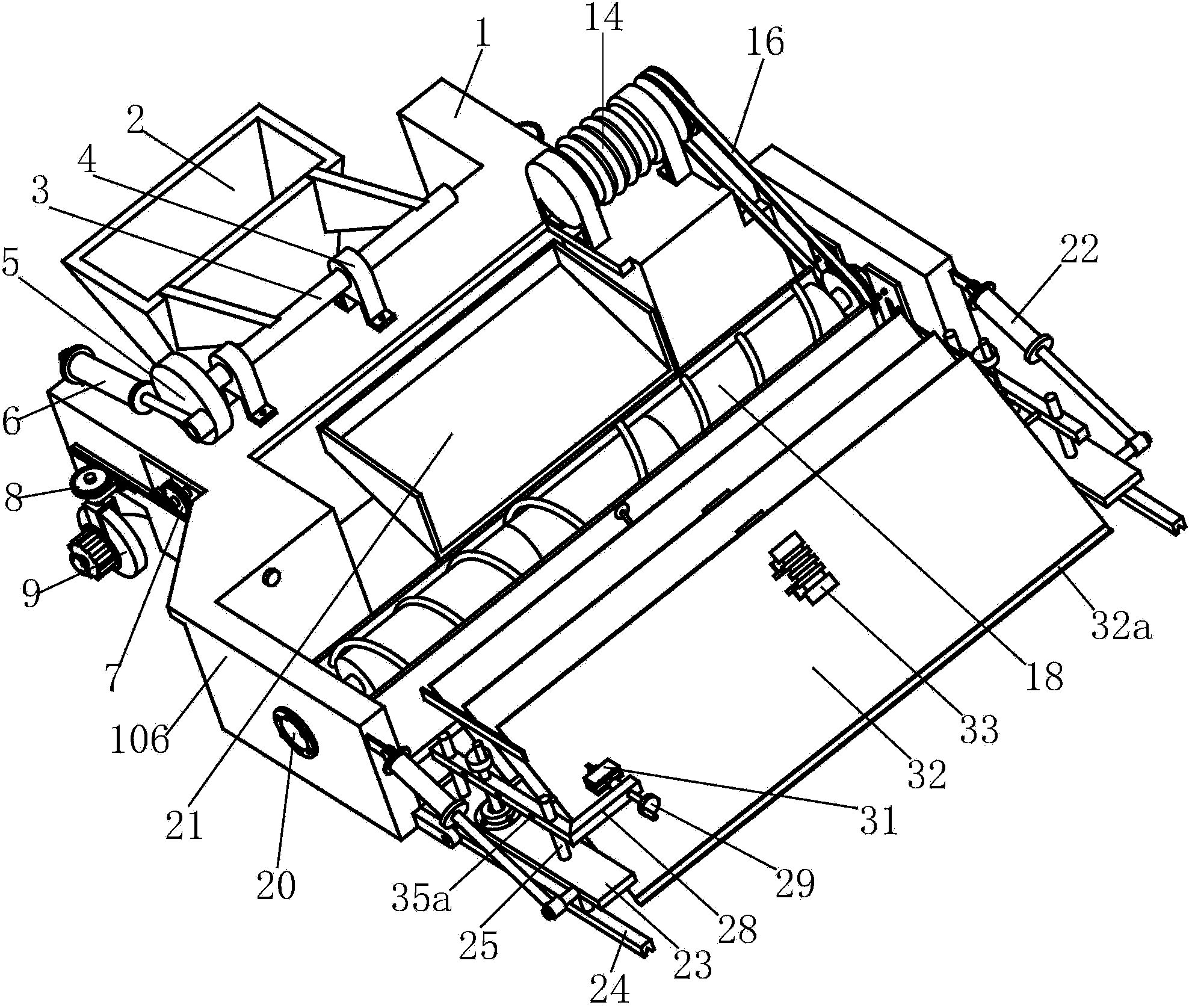

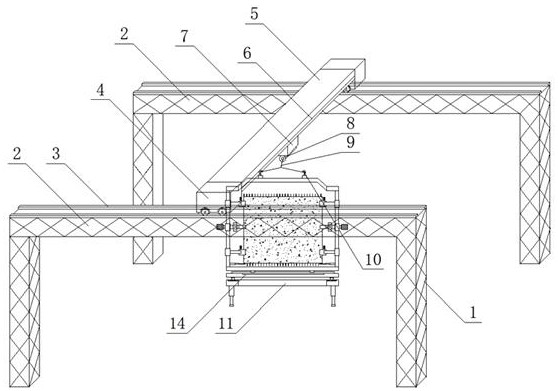

High-efficiency paver for hybrid type plastic runway

InactiveCN104018417AReasonable structural designReduce manufacturing costsGround pavingsRoads maintainenceHybrid typeMaterial resources

The invention relates to a high-efficiency paver for a hybrid type plastic runway. The high-efficiency paver comprises an I-shaped base, walking devices, a turning device, a distributing device and a multilayer paving device, wherein the walking devices are symmetrically arranged at the left side and the right side of the I-shaped base, the turning device is arranged at the middle of the rear side of the I-shaped base, the distributing device is arranged at the middle of the front side of the I-shaped base, and the multilayer paving device is located in front of the distributing device, and is fixedly arranged at the front of the I-shaped base. The high-efficiency paver has the advantages of reasonable structure design, low production and manufacture cost, convenience in use, and the like, is capable of realizing automatic alignment so as to ensure paving flatness and replace manual paving, and is high in automatic degree, thereby increasing the paving efficiency of the hybrid type plastic runway and saving manpower and material resources; and by using vibration paving of the multilayer paving device, slurry is effectively prevented from reflowing, the uniformity of paving thickness is ensured, and the paving quality is ensured.

Owner:陆松

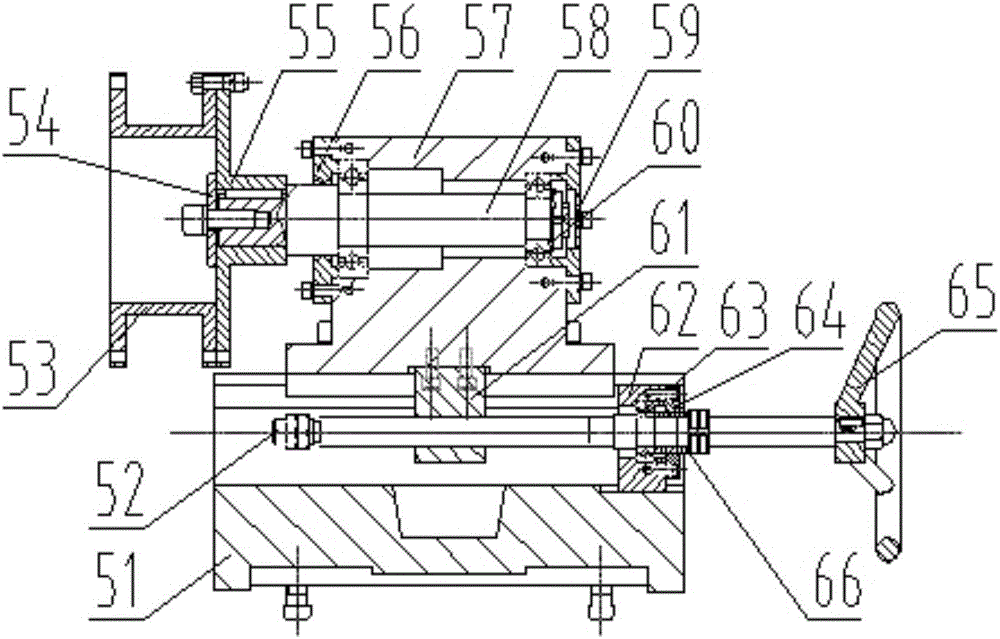

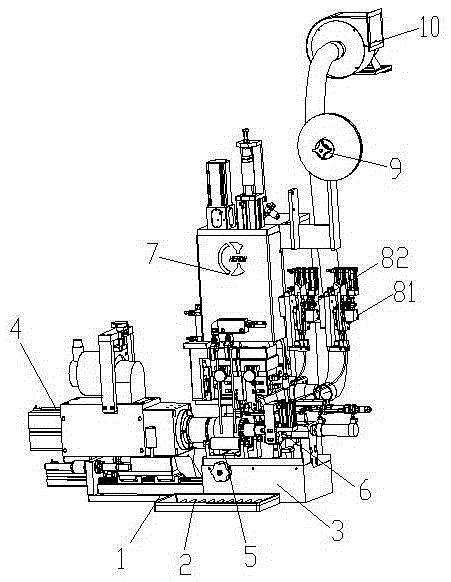

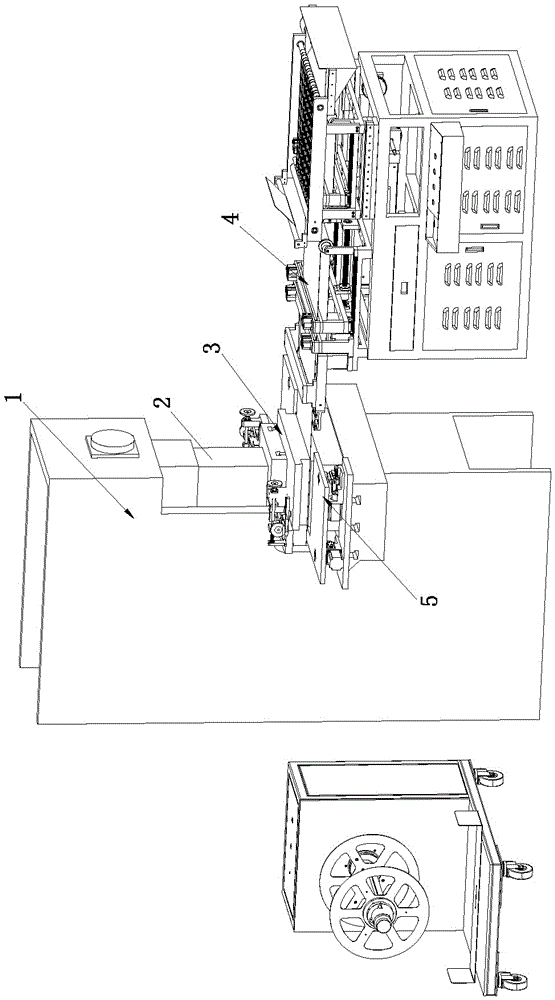

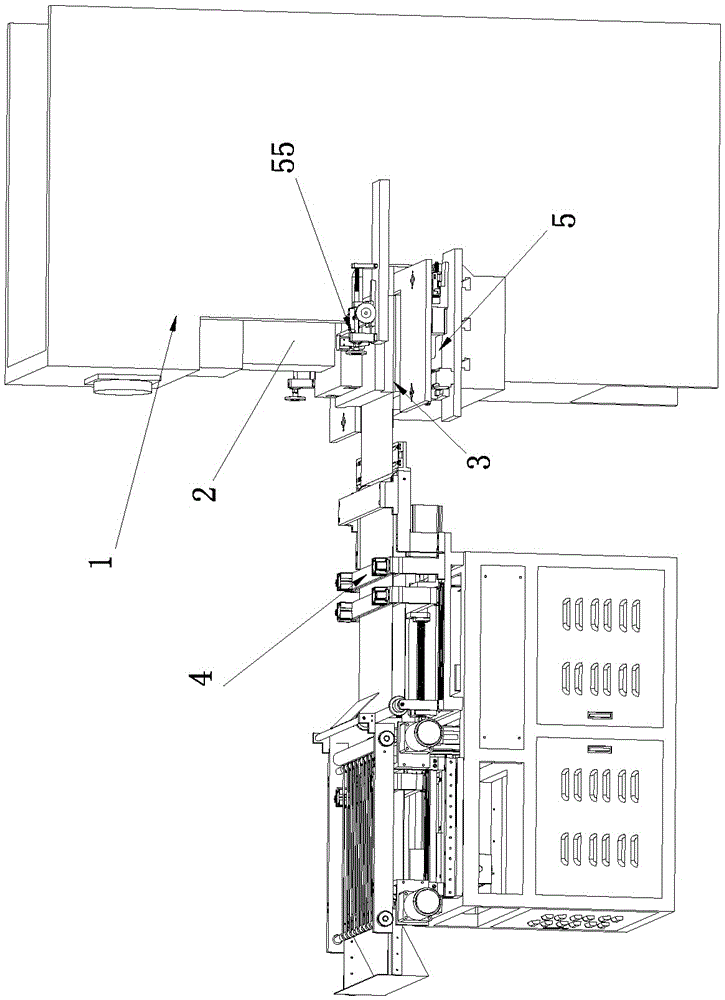

Inverse armature brazing machine with double feeding of brazing wire belts and welding technology thereof

ActiveCN105397229ANo consumptionRealize automatic alignmentMetal working apparatusSolder feeding devicesEngineeringFiller metal

The invention discloses an inverse armature brazing machine with double feeding of brazing wire belts and a welding technology thereof. The inverse armature brazing machine comprises an armature preparation plate, a machine base, a loading supporting base, a servo clamping and indexing mechanism, an armature loading supporting roller mechanism, an armature supporting rectification mechanism, a wire pressing and welding mechanism, a first brazing wire belt feeding mechanism, a second brazing wire belt feeding mechanism, a brazing filler metal plate and a smoke absorption mechanism. According to the machine, the brazing wire belts can be fed to the welding areas between outer-layer wires and inner-layer wires and the welding areas between the inner-layer wires and a commutator segment at the same time so as to be located in the middle of a conducting loop in welding and become the largest heat emission spot, and therefore the problem that a commutator emits heat excessively and then becomes expanded and deformed in the traditional lateral brazing wire belt feeding and welding process is solved, and the problems that temperature rise is excessive and the service life is short due to the small sectional area of arc welding connection and welding spot connection caused by single feeding of the brazing wire belts are solved; two wire processes of argon arc welding are eliminated in the armature welding process, the welding efficiency is high, welding is more reliable, less brazing filler metal is used, and the welding benefit is better.

Owner:HERON INTELLIGENT EQUIP CO LTD

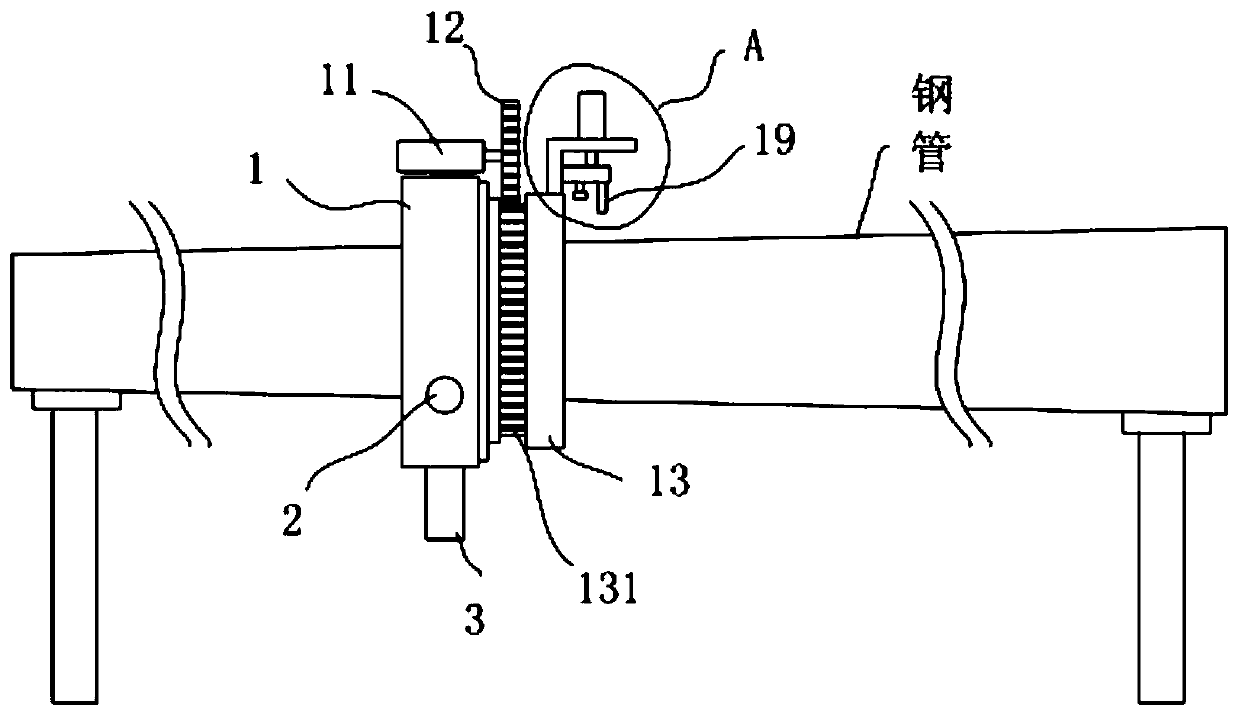

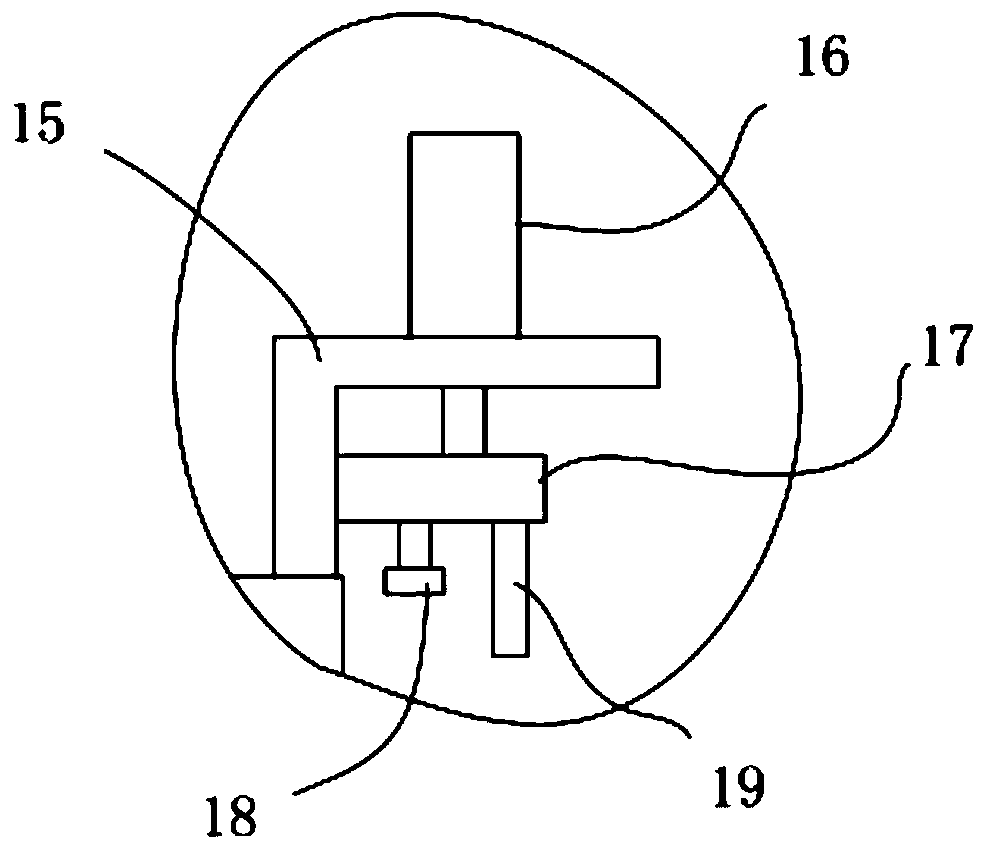

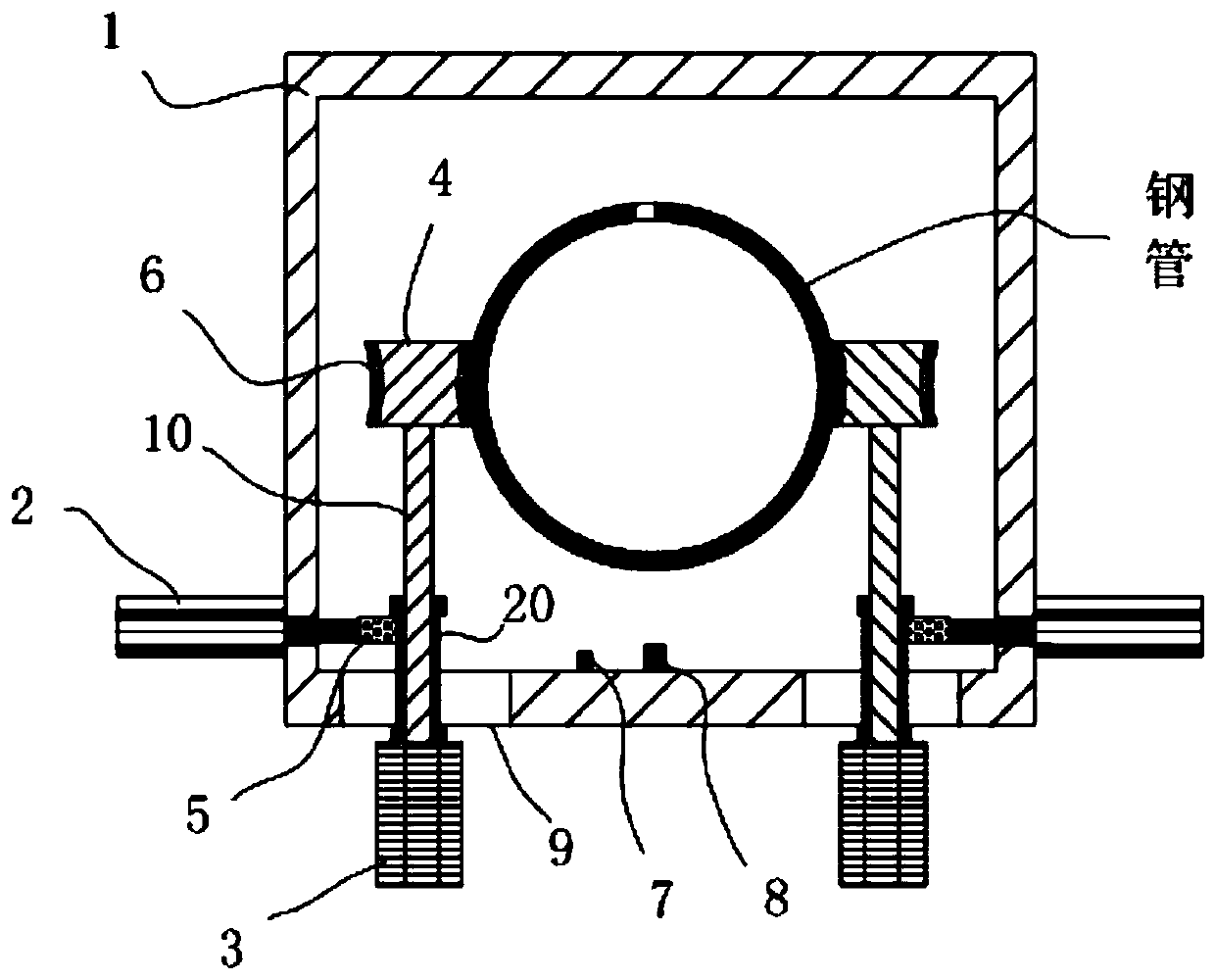

Steel pipe welding device and working method

ActiveCN111055075AAchieve weldingRealize automatic alignmentWelding/cutting auxillary devicesAuxillary welding devicesButt jointControl system

The invention aims to provide a steel pipe welding device and a working method thereof to solve the technical problem of welding steel pipes with different diameters. The steel pipe welding device comprises a control system, a clamping walking mechanism, a rotating mechanism and a welding mechanism, wherein the clamping walking mechanism, the rotating mechanism and the welding mechanism are electrically connected with the control system; the clamping walking mechanism is used for driving the device to longitudinally walk on a steel pipe; the welding mechanism is used for welding longitudinal welding seams on the steel pipe and annular welding seams at butt joint ports of the steel pipe; and the rotating mechanism is installed on the clamping walking mechanism and used for driving the welding mechanism to rotate.

Owner:新疆神州通新材料股份有限公司

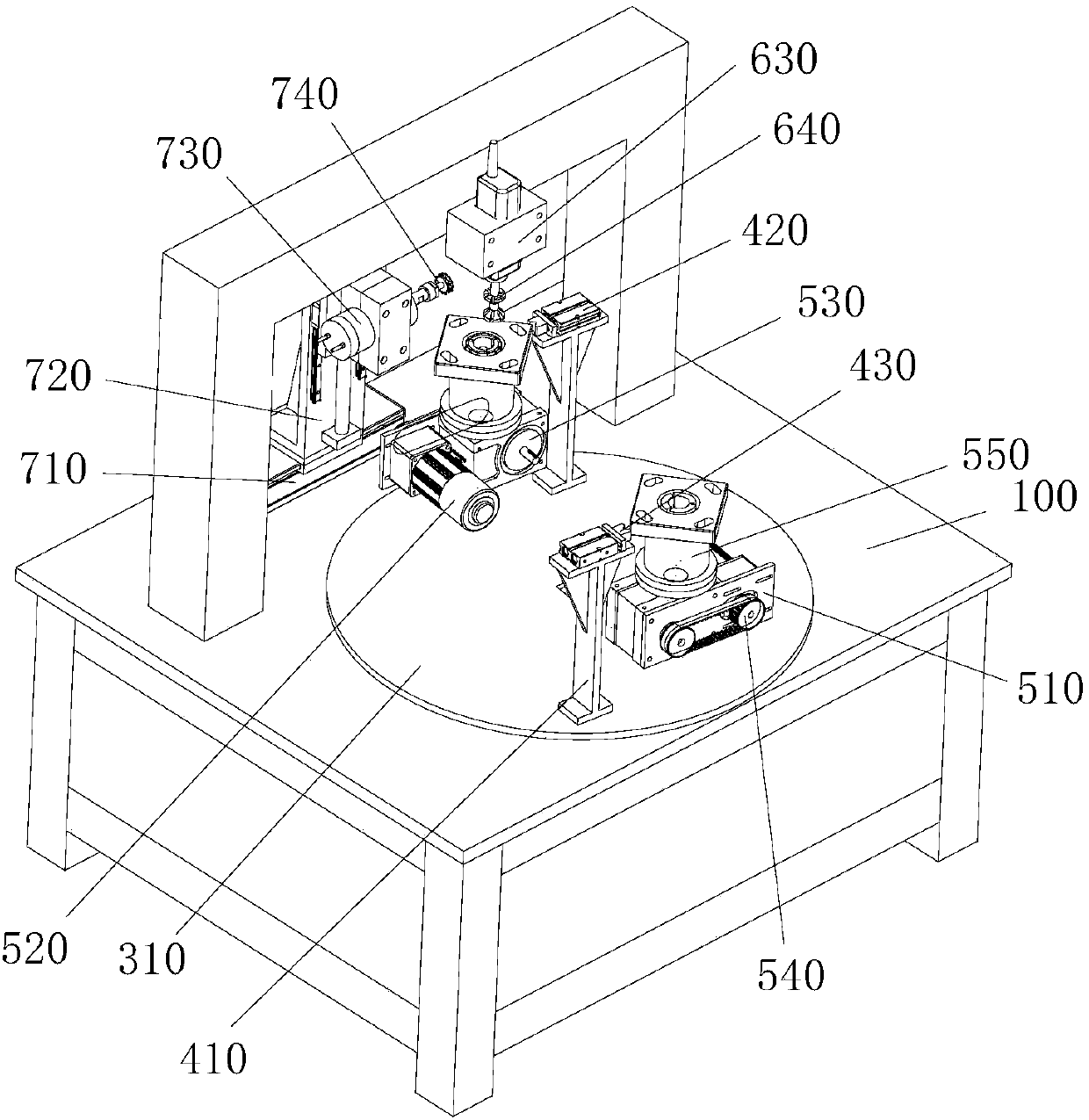

Automatic workpiece chamfering equipment and control method

PendingCN107737980AAutomatic chamferingAchieve positioningMilling equipment detailsLocking mechanismEngineering

The invention discloses automatic workpiece chamfering equipment and a control method. The automatic workpiece chamfering equipment comprises a workbench, a portal frame, a conversion table, a positioning mechanism, a locking mechanism, a first chamfering mechanism and a second chamfering mechanism. Firstly, a workpiece is placed on a hydraulic chuck, and a positioning air cylinder and the hydraulic chuck conduct positioning and locking on the position of the workpiece; then, a rotary disc conveys the workpiece to a chamfering station; then, the first chamfering mechanism conducts R angle chamfering on the edge of the workpiece; then, the second chamfering mechanism conducts chamfering on each edge of the workpiece; and finally, a first motor acts and drives the rotary disc to rotate by 180 degrees again, a to-be-machined workpiece is conveyed to the chamfering station to the machined, the machined workpiece is conveyed to a feeding station, unloading and loading operation is conducted, the process is operated in a full automation manner, manual intervention is not needed, and an alarm can be given for warning when the fault happens or positioning is inaccurate, and accordingly theworkpiece chamfering efficiency and quality are improved. The automatic workpiece chamfering equipment and the control method have the beneficial effects that the structure is simple, manufacturing is easy, control precision is high, and operation is convenient.

Owner:FOSHAN NANHAI GUANGDONG TECH UNIV CNC EQUIP COOP INNOVATION INST +1

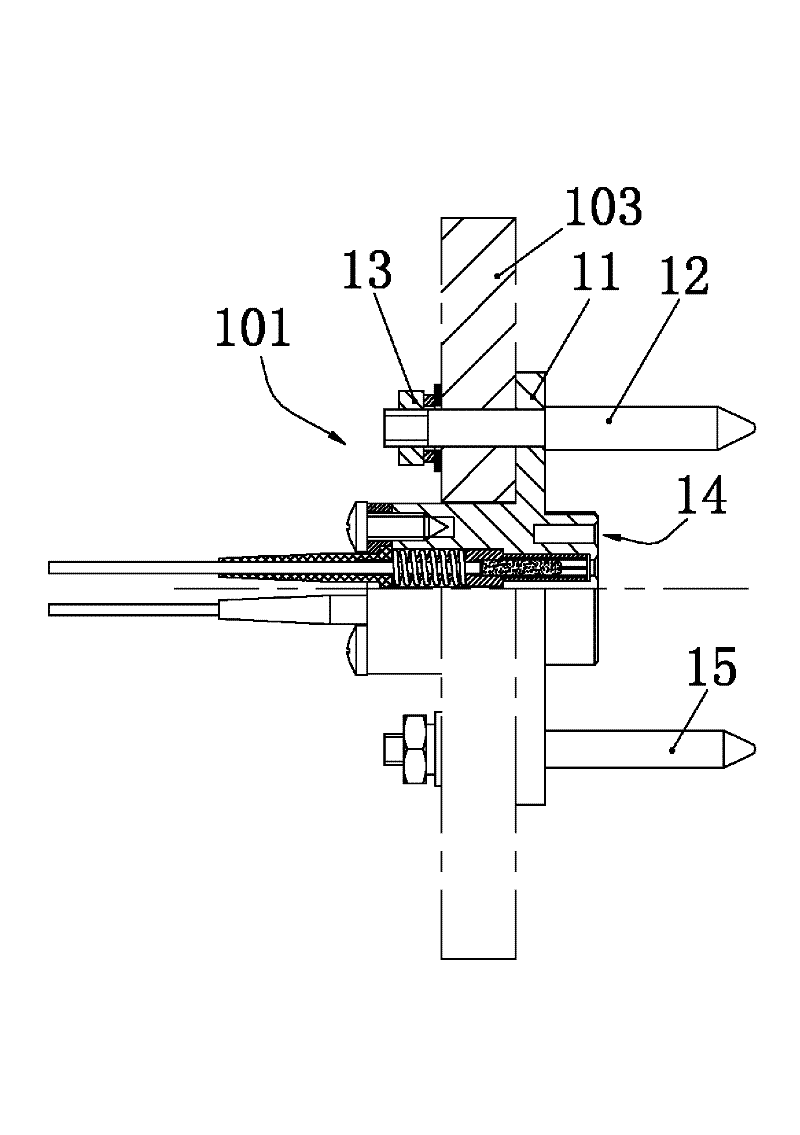

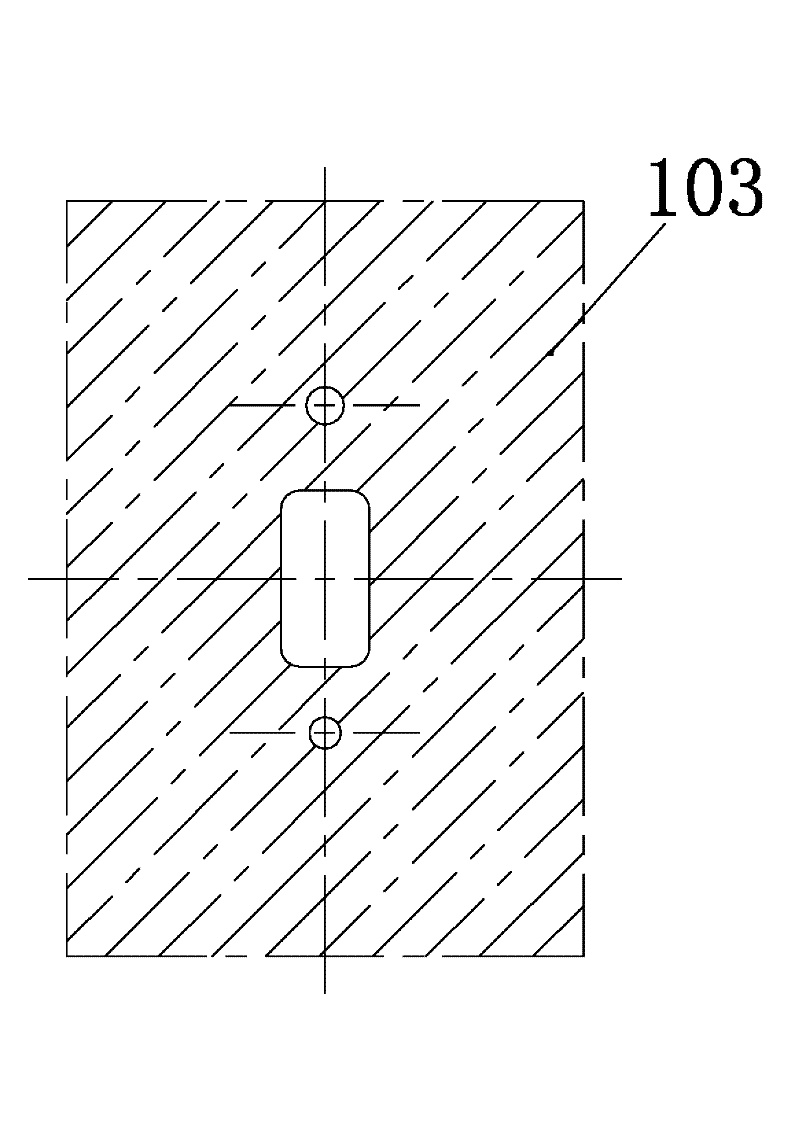

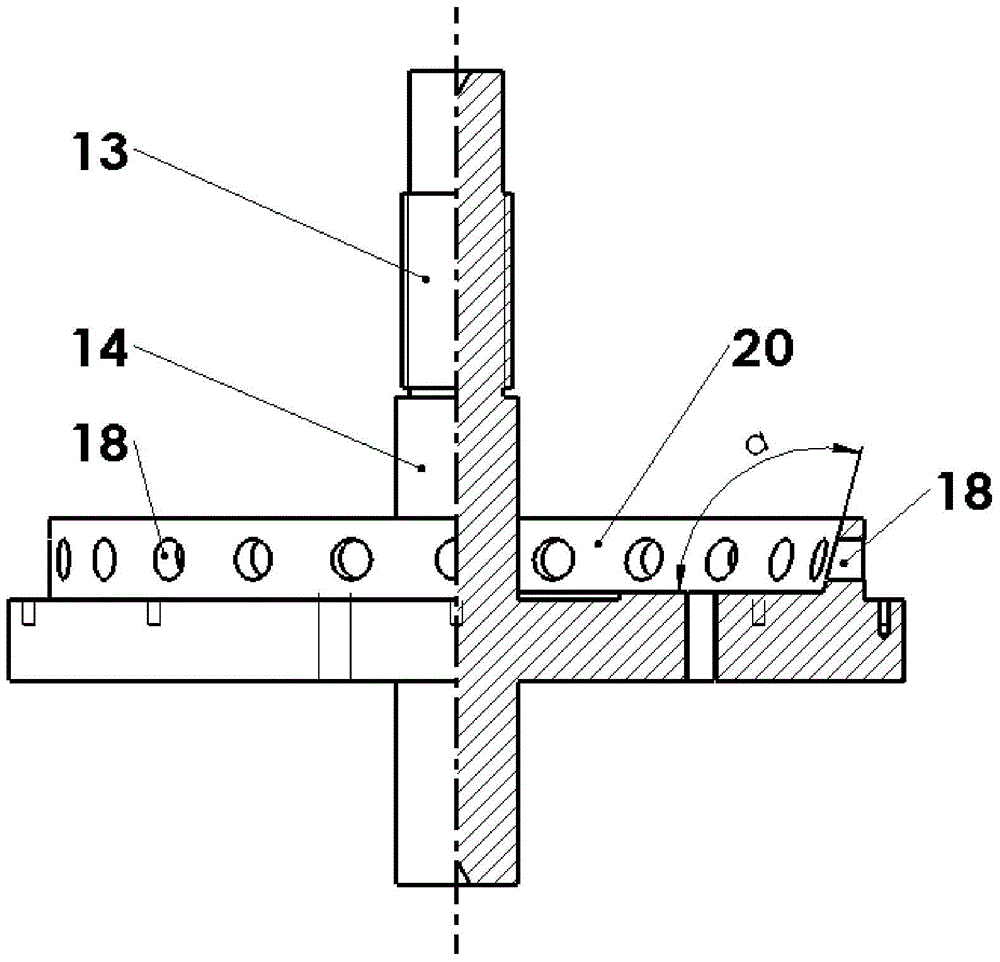

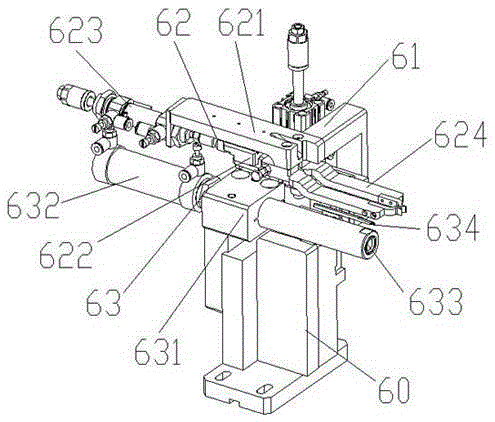

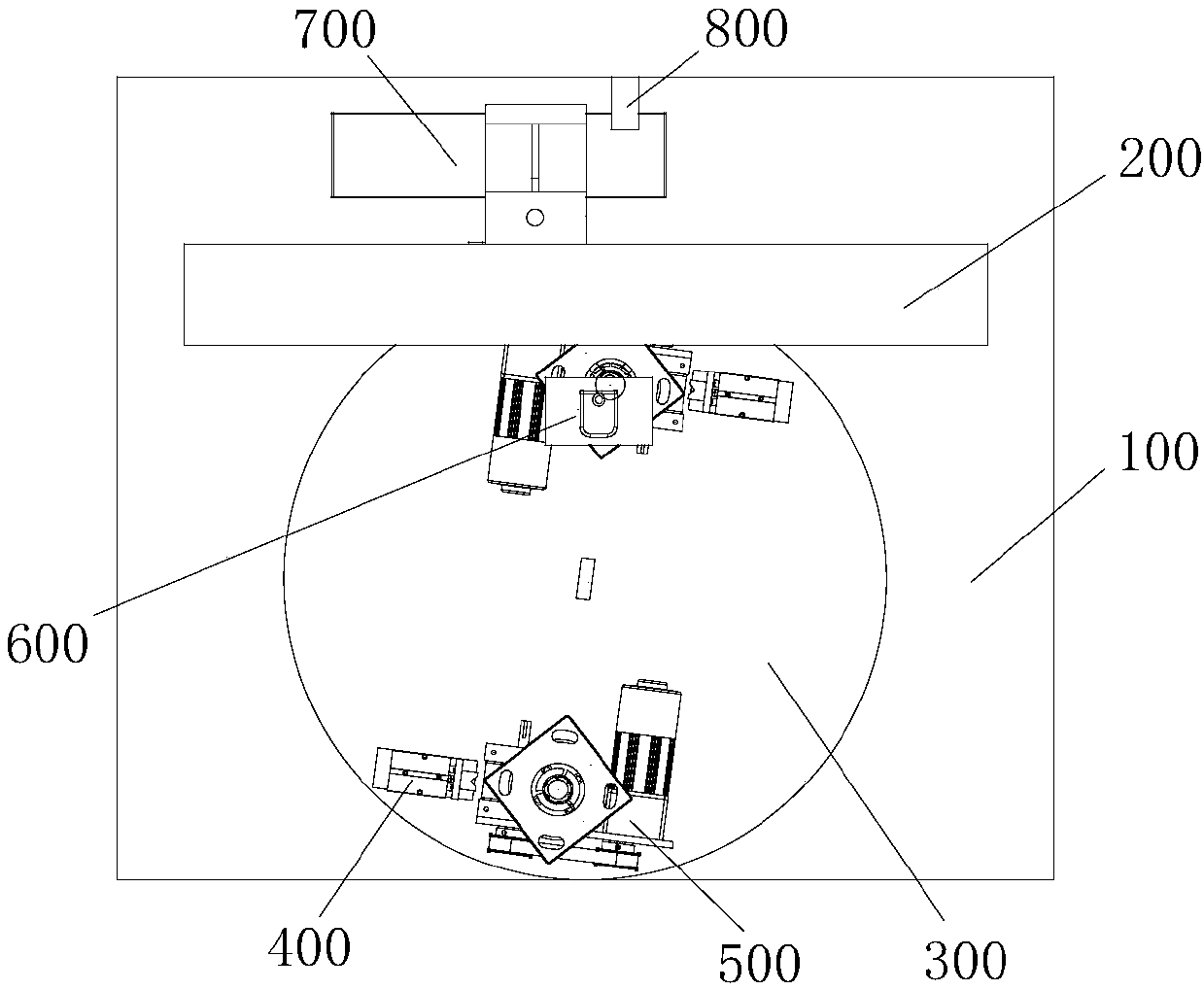

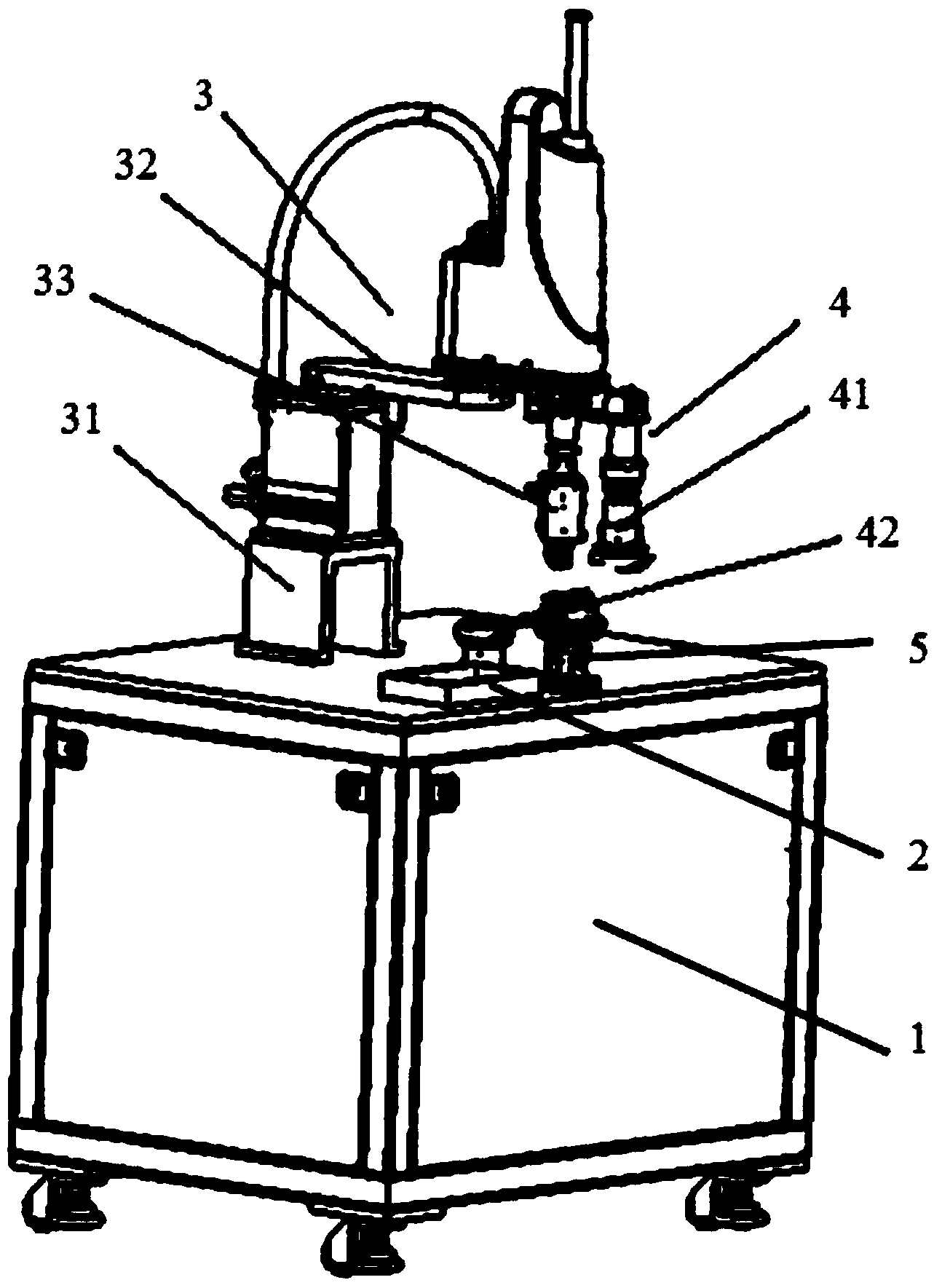

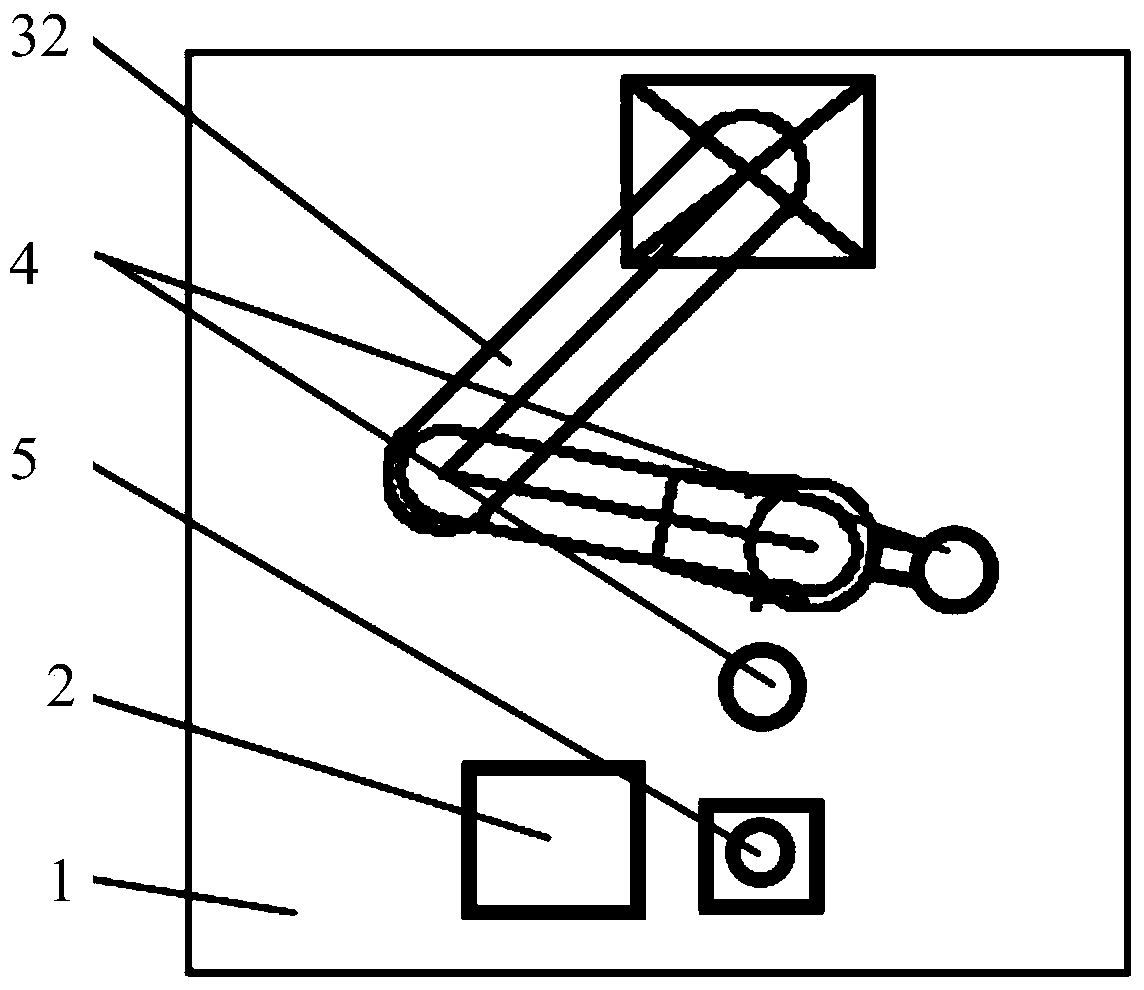

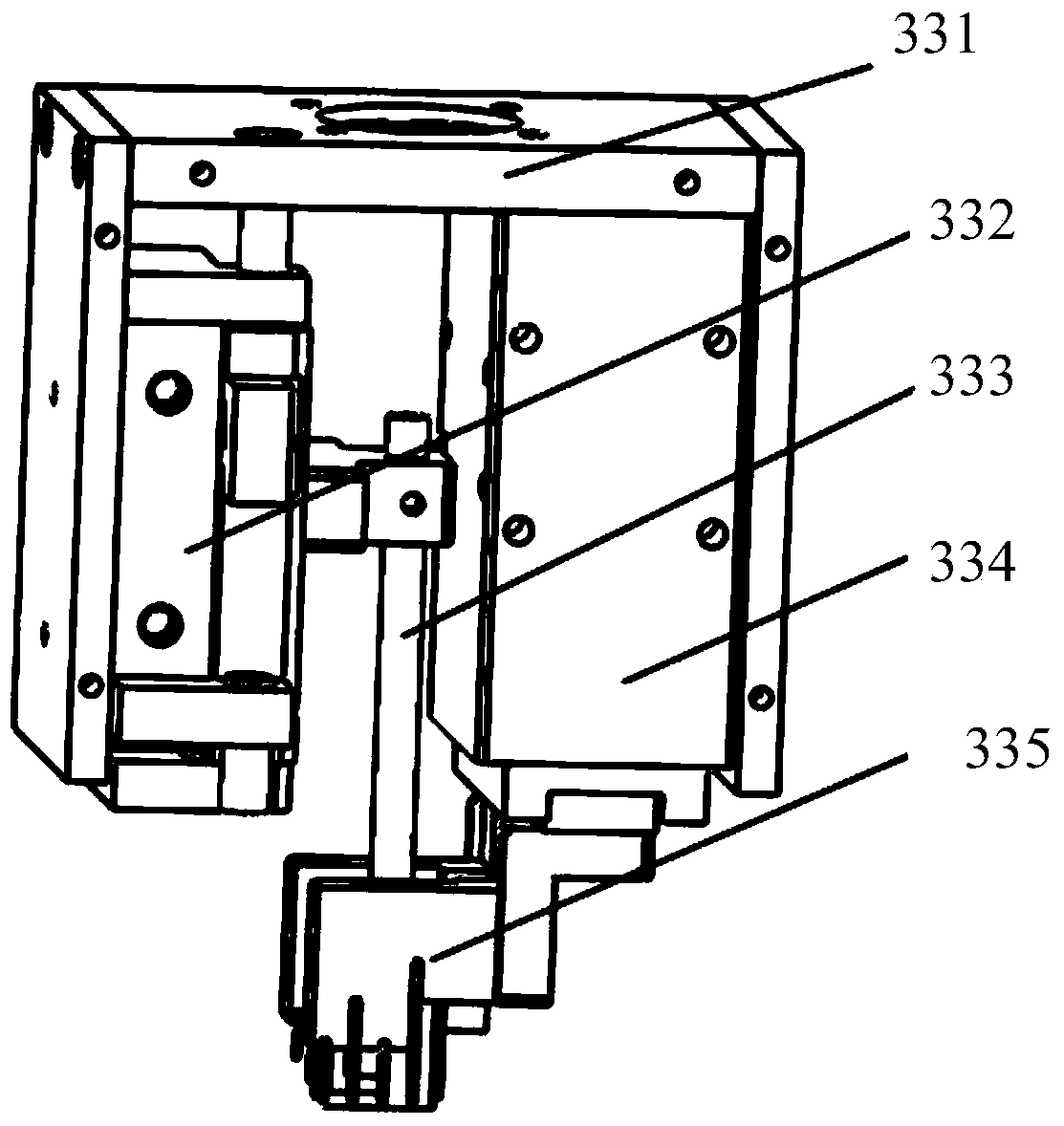

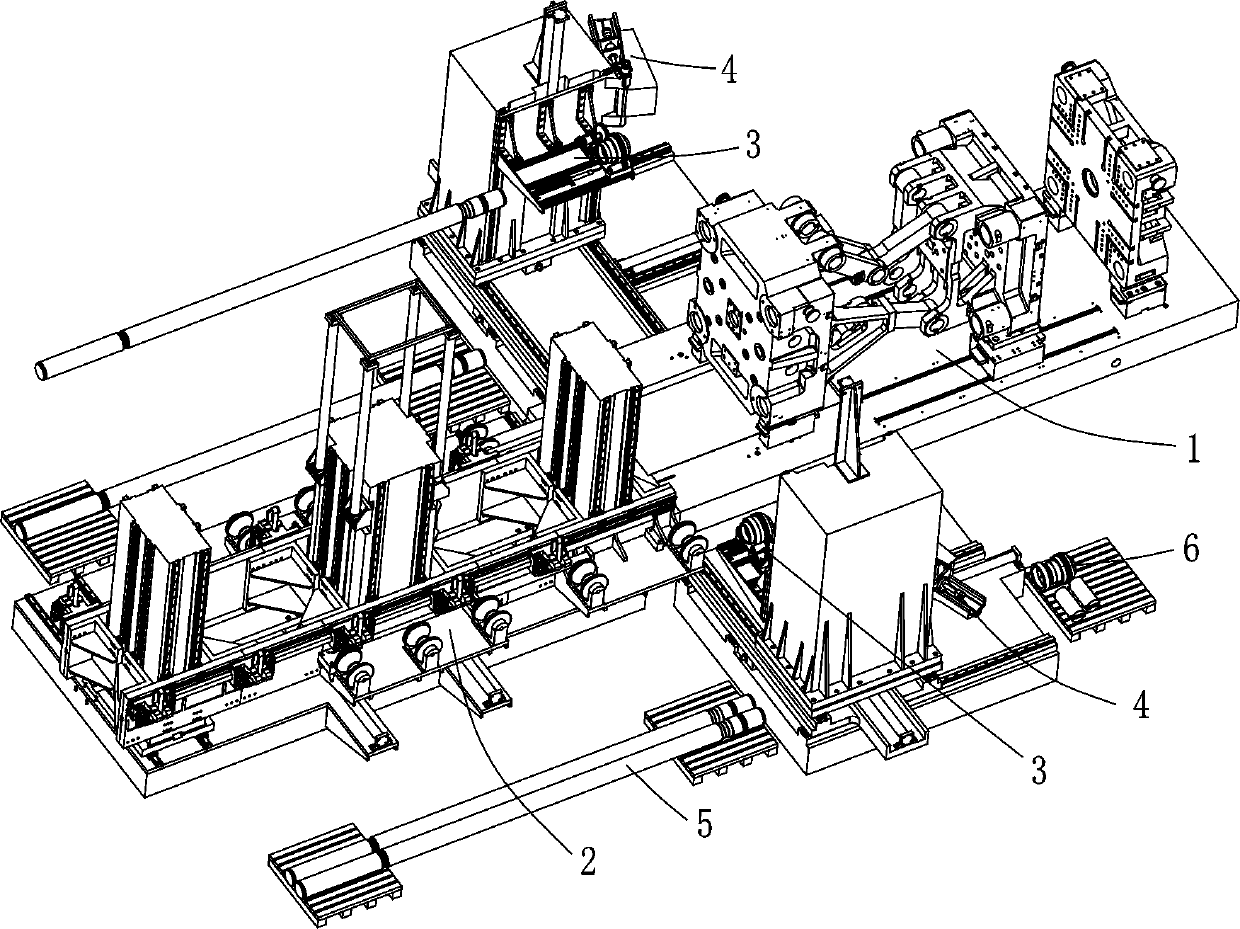

Alignment punch press system

ActiveCN105538410ARealize automatic alignmentReduce labor costsMetal working apparatusPunch pressFlexible circuits

The invention relates to the technical field of flexible circuit board production equipment, in particular to an alignment punch press system. The system comprises a punching device and a four-axis automatic alignment platform, wherein the punching device is provided with a puncher pin for punching, the four-axis automatic alignment platform comprises a bottom plate, a CCD camera assembly, a computer control assembly and an operation table used for adjusting material positions, the bottom plate is arranged on the punching device, a punching station is arranged between the puncher pin and the operation table, four groups of X-Y-theta alignment units used for driving the operation table to achieve X-Y-axis horizontal movement and rotation are arranged between the bottom plate and the operation table, the four groups of X-Y-theta alignment units are distributed on the bottom plate in a rectangular shape, rotary shafts of the four groups of X-Y-theta alignment units are rotationally connected with the operation table, the CCD camera assembly and at least three groups of X-Y-theta alignment units are connected with the computer control assembly through electric signals, and the CCD camera assembly shoots materials on the operation table. The punch press system is high in alignment efficiency and accuracy and improves punching quality and punching efficiency.

Owner:SHENZHEN VILITY AUTOMATION EQUIP

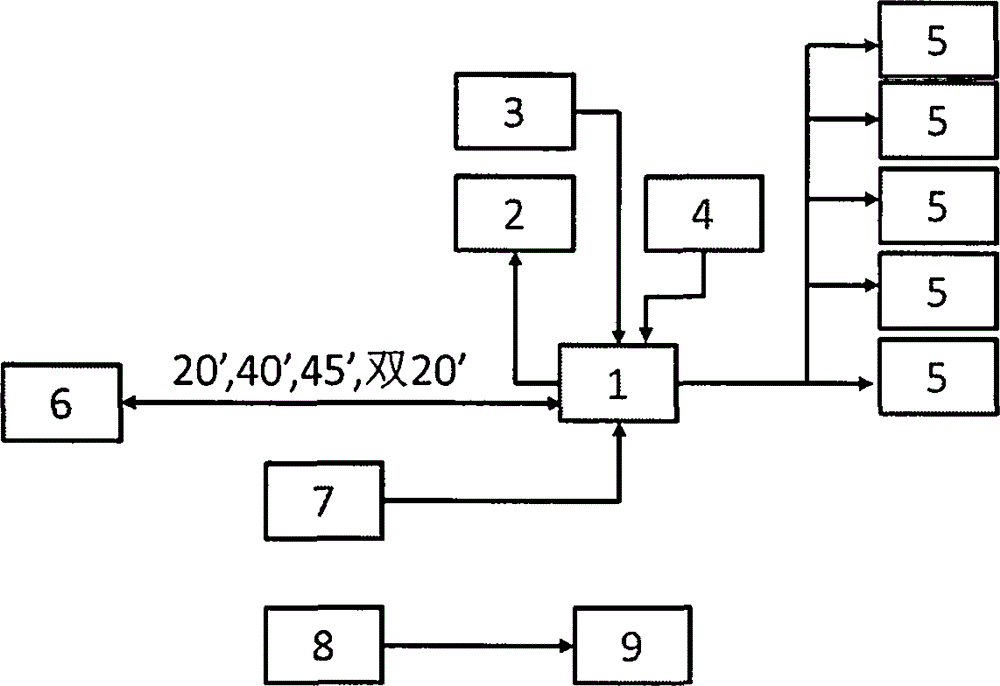

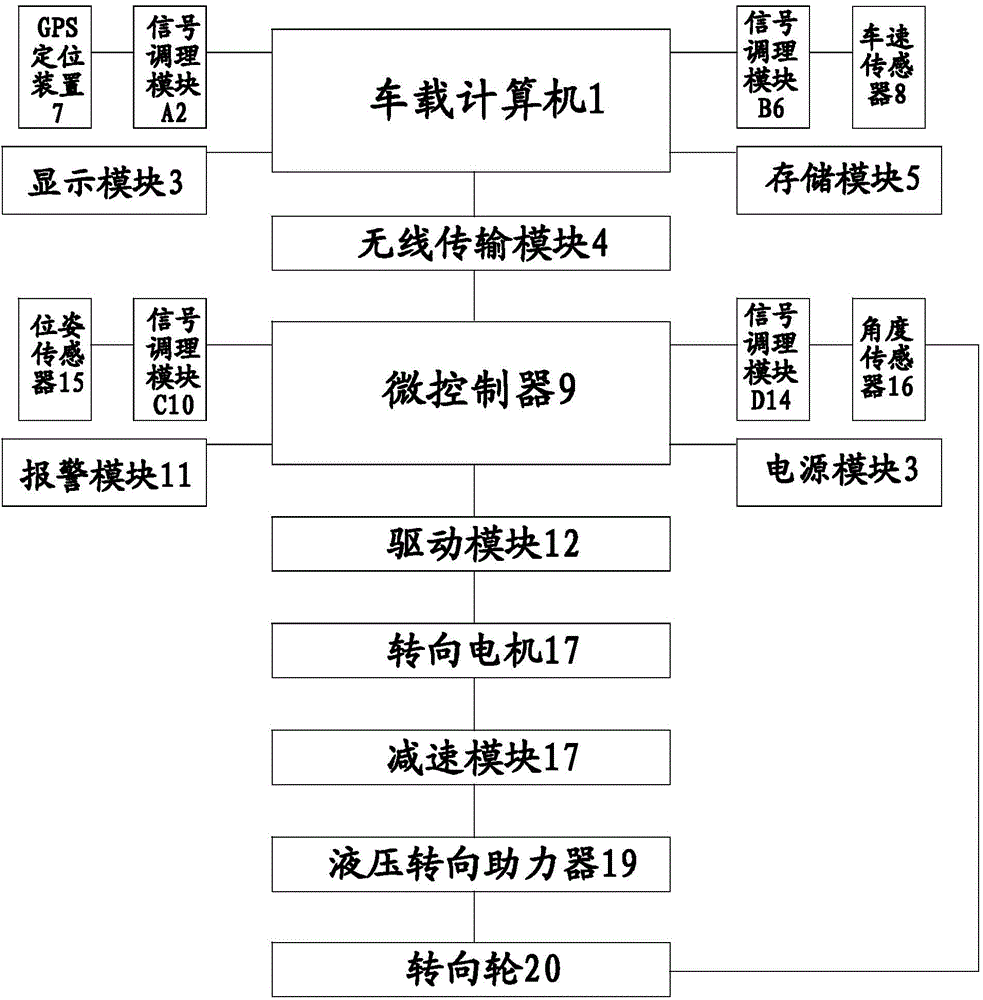

Rice transplanter steering automatic control system

InactiveCN104691615ARealize automatic alignmentImprove reliabilitySteering linkagesFluid steeringMicrocontrollerAutomatic control

The invention discloses a rice transplanter steering automatic control system and belongs to the technical field of agricultural machinery control. The rice transplanter steering automatic control system is characterized by comprising a vehicle-mounted computer (1), a signal conditioning module A (2), a display module (3), a wireless transmission module (4), a storage module (5), a signal conditioning module B (6), a GPS positioning device (7), a vehicle speed sensor (8), a microcontroller (9), a signal conditioning module C (10), an alarming module (11), a driving module (12), a power supply module (13), a signal conditioning module D (14), a position and attitude sensor (15), an angle sensor (16), a steering motor (17), a speed reduction module (18), a hydraulic steering booster (19) and steering wheels (20). Compared with the prior art, the rice transplanter steering automatic control system has the advantages of being simple in system structure, convenient to mount, debug and maintain, high in system reliability and measurement precision, low in power consumption, easy to popularize and the like.

Owner:刘扬

Automatic aligning and clamping device and method for circular parts

ActiveCN112917202ARealize the clamping functionRealize automatic alignmentPositioning apparatusMetal-working holdersStructural engineeringControl theory

Owner:宜昌长机科技有限责任公司

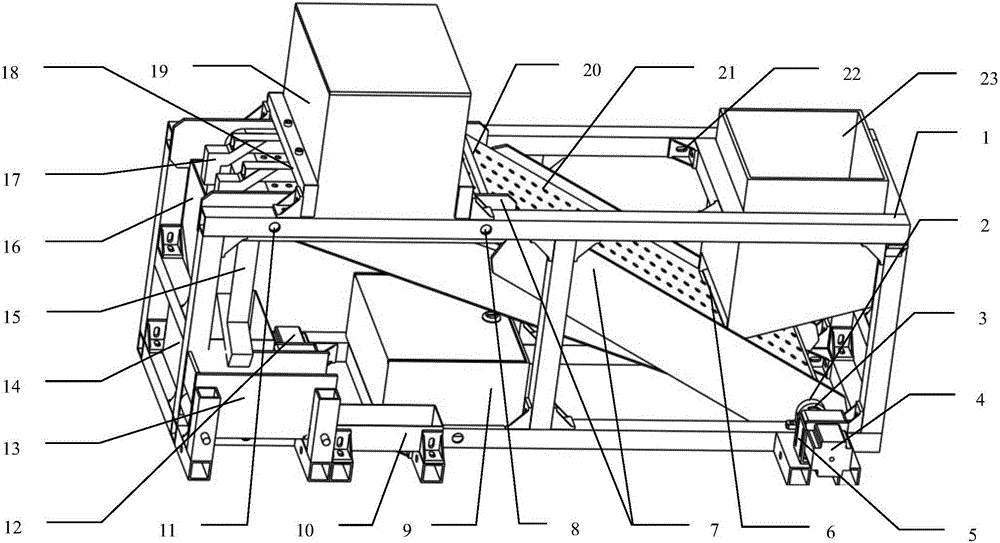

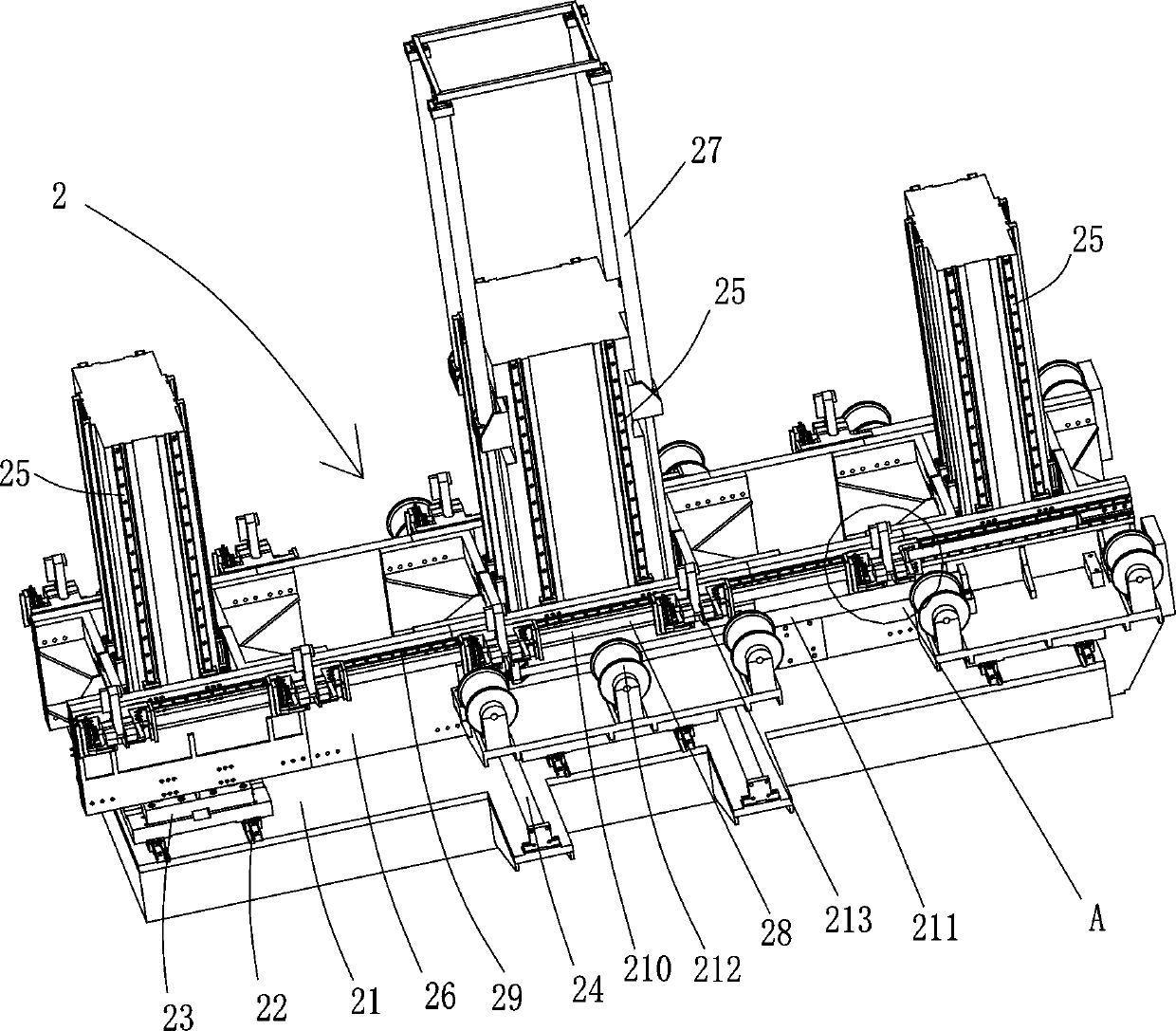

Large-span truss-type prefabricated member conveying and alignment assembly system

ActiveCN111779287AWith highly precise adjustment functionRealize automatic alignmentBuilding material handlingMachine visionMachine

The invention provides a large-span truss-type prefabricated member conveying and alignment assembly system. The conveying and alignment assembly system is characterized by adopting a large-span truss-type conveying system which cooperates with frame-type prefabricated member carrying equipment composed of a lifting base, a longitudinal moving platform, a transverse moving platform, a member bearing stand and a hanging beam, the conveying and alignment assembly system has the functions of overall height precision adjustment and transverse and longitudinal high-precision automatic alignment, automatic alignment and assembly of the whole process are achieved with the help of machine vision and sensors, lifting and conveying are carried out with the help of the large-span truss-type conveyingsystem, a variety of prefabricated members of different sizes can be carried, manual supporting of the prefabricated members during the alignment and assembly process is not required, a clamping mechanism and a limiting mechanism ensure stable postures of the prefabricated members, the precision of alignment and assembly is high, labor intensity of personnel is reduced, and alignment and assemblyefficiency is greatly improved.

Owner:HUBEI ZHOUTIAN CONSTR GROUP

Inner hole clamping device

PendingCN107650138ARealize automatic alignmentRealize automatic centeringGripping headsConveyor partsEngineeringSmall hole

The invention provides an inner hole clamping device. The inner hole clamping device can solve the problem that a traditional spring sleeve cannot conduct reliable clamping or picking on small-inner-hole, large-dead-load and long-inner-hole workpieces, and accordingly the industrial machine automatic production requirement can be met. The inner hole clamping device comprises a core bar and a drivemechanism, the core bar is provided with an axial center through hole, the axial center through hole is internally provided with a pull rod in a penetrating manner, the pull rod can move in the axialdirection, the front end of the pull rod is connected with a pulling block, and the rear end of the pull rod is connected with the drive mechanism. Three sliding grooves which horizontally extend inthe axial direction and are parallel are evenly distributed in the peripheral face of the front end of the core bar in the circumferential direction. The groove bottom faces of the sliding grooves arewedge-shaped groove faces with the radial groove depths gradually increased from back to front. Each of the three sliding grooves internally contains a sliding claw, each sliding claw is provided with a wedge-shaped inclined face which is in sliding fit with the corresponding wedge-shaped groove, and the front end of each sliding claw is fixedly connected with the pulling block.

Owner:昆山巨林科教实业有限公司

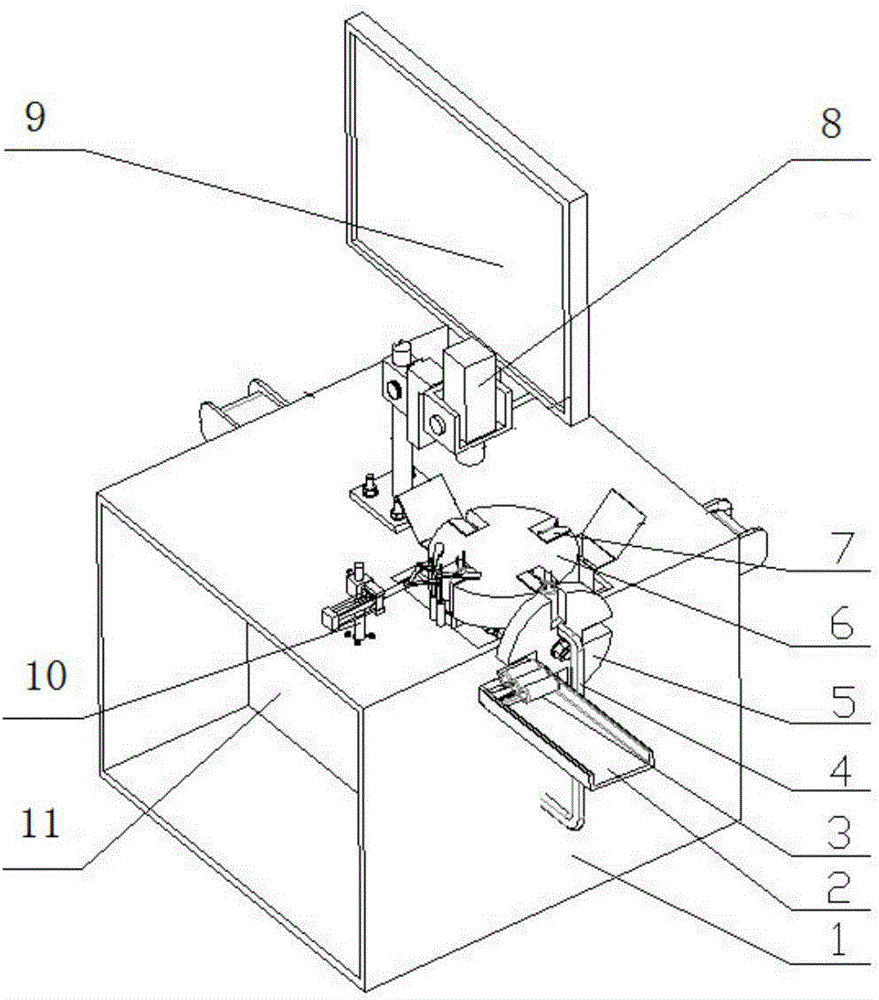

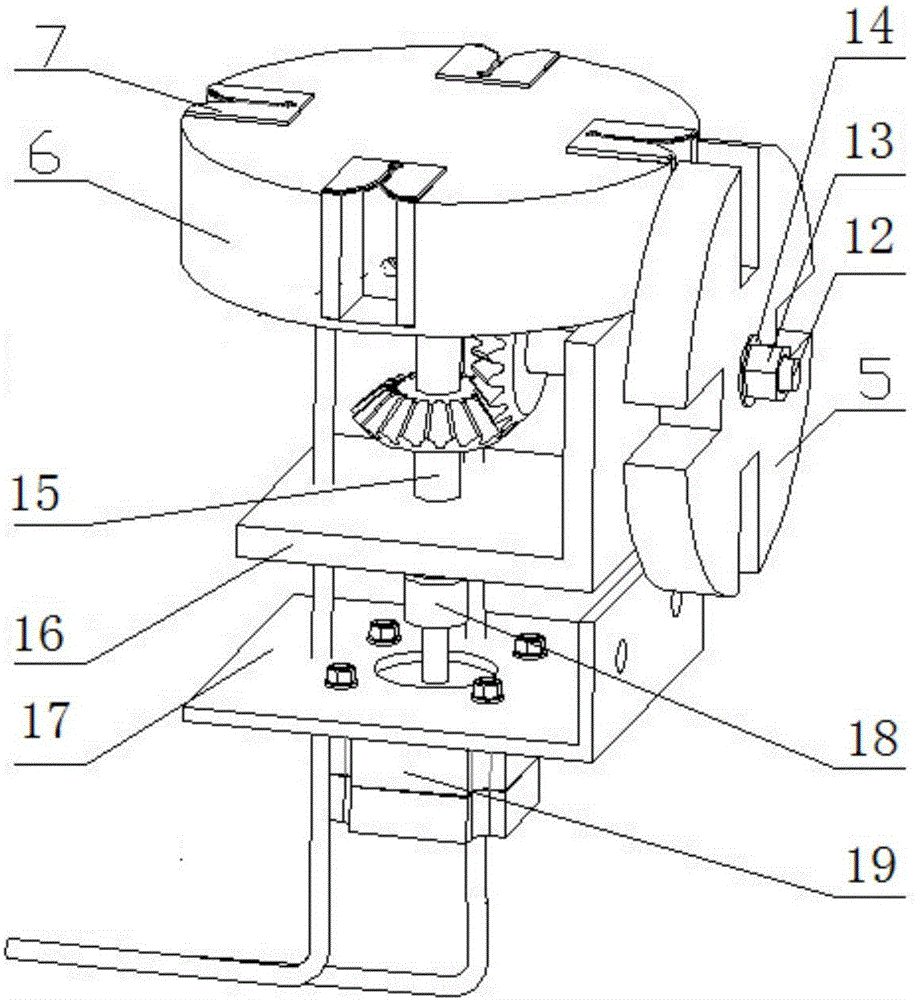

Cylindrical capacitance-type heterotype electronic component whole foot equipment

InactiveCN104882301AImprove the efficiency of the whole footReduce work intensityCapacitor manufactureCapacitanceTransmission system

The invention discloses cylindrical capacitance-type heterotype electronic component whole foot equipment. The equipment comprises a rack, a transmission system, an automatic material distributing system and a whole foot system. The transmission system, the automatic material distributing system and the whole foot system are arranged on the rack. The transmission system comprises a material distributing disc (5), a working disc (6) and a stepping motor (19). The automatic material distributing system comprises a feeding chute (2), a first air blowpipe (4) and an air compressor (11). The whole foot system comprises a first cylinder (20), a second cylinder (22) and a mechanical clamping finger (25) which is provided with a groove (29). By using the equipment in the invention, automation alignment of a cylindrical capacitance pin is realized and manual operation can be completely replaced; whole foot efficiency can be increased and working strength is reduced; precision and whole foot consistency can be increased so that a qualified rate of a subsequent plug-in process is further improved.

Owner:HUBEI UNIV OF TECH

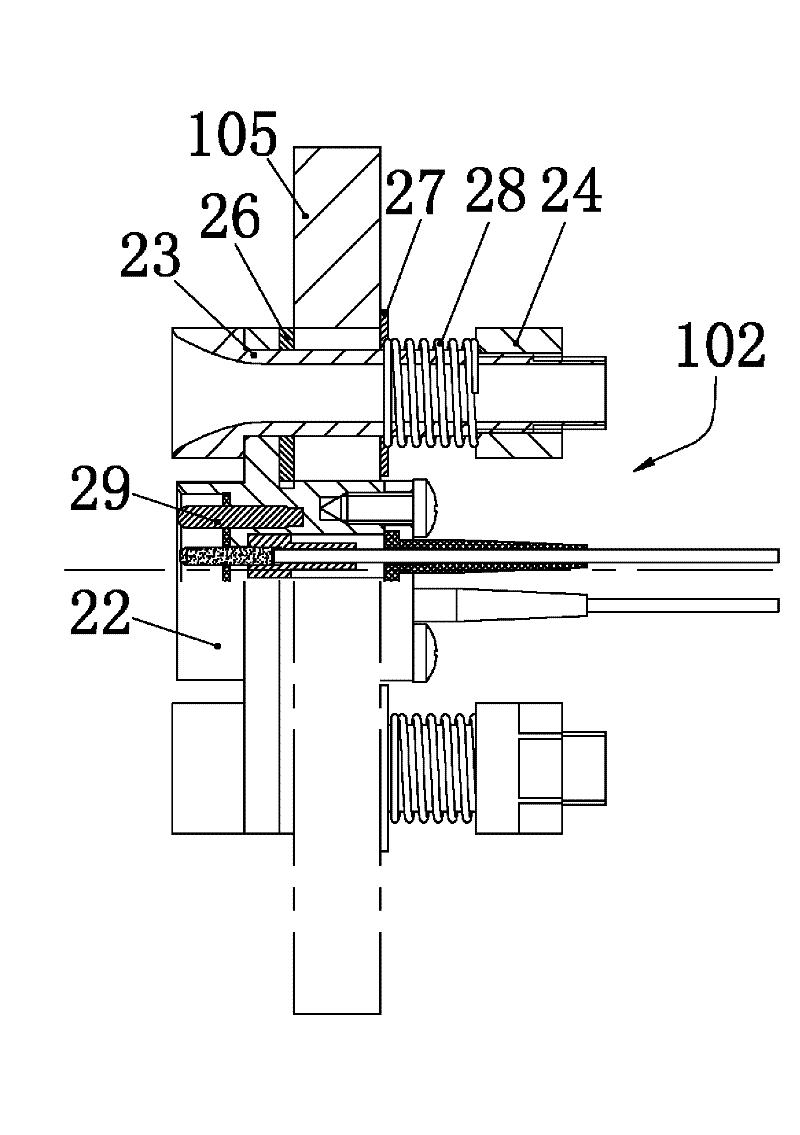

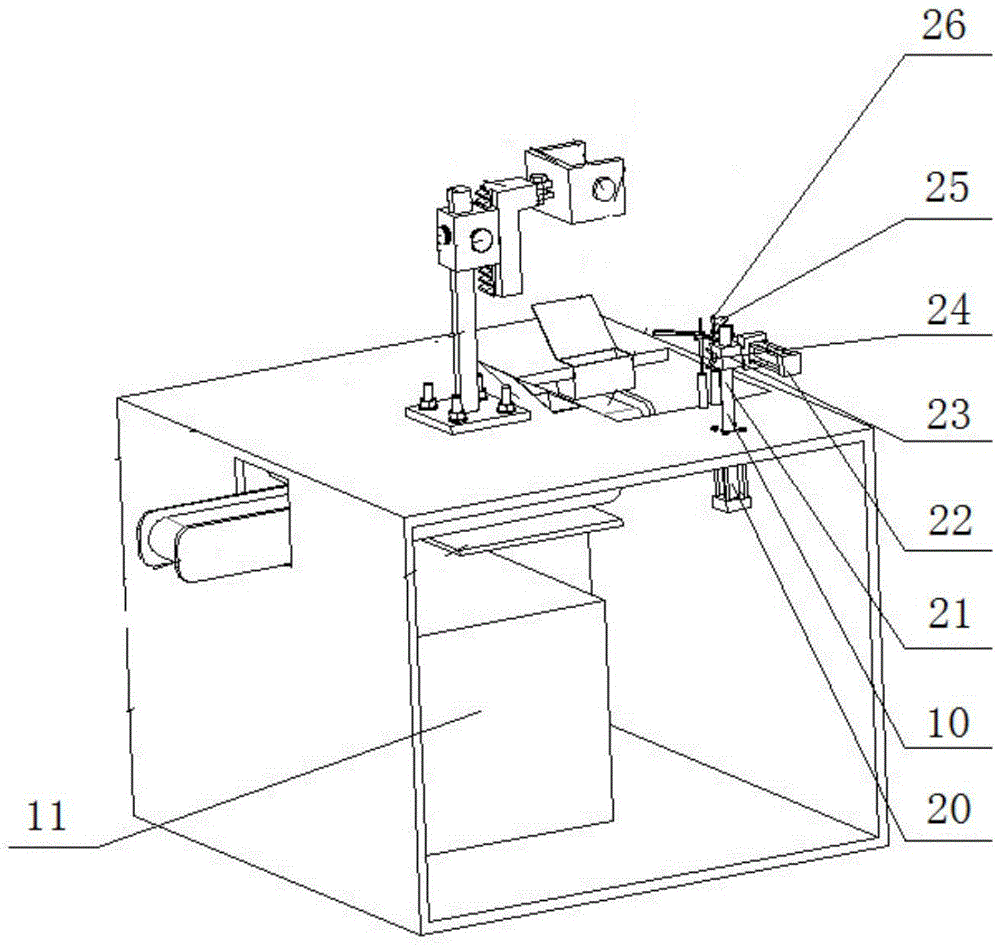

Assembling and packaging system and method of sensor

ActiveCN103723677ALower requirementImprove work efficiencyPrecision positioning equipmentSoldering apparatusManipulatorMicroscope

The invention discloses an assembling and packaging system and method of a sensor. The system integrates equipment of microscopes, a manipulator, a bonding technological platform and the like; the manipulator is controlled to operate by a control mechanism; firstly, a pipe seat is placed on the bonding technological platform to fix; then a chip is installed on the pipe seat; and finally, the bonding packaging is realized. The postures of the pipe seat and the chip are confirmed by adopting the two microscopes respectively, and the automatic alignment and assembling between the chip and the pipe seat are realized; the requirement for operators in the process of manufacturing the sensor is lowered; the working efficiency is improved; meanwhile the effective positioning between the chip and the pipe seat is ensured; the finished product rate is improved; and the integrated operation of the assembling and bonding packaging of sensor components is realized on the same machine for a complex MEMS (micro-electromechanical systems) micro structure by applying the system so as to reach the automation of sensor production.

Owner:SUZHOU SUXIANG ROBOT INTELLIGENT EQUIP CO LTD

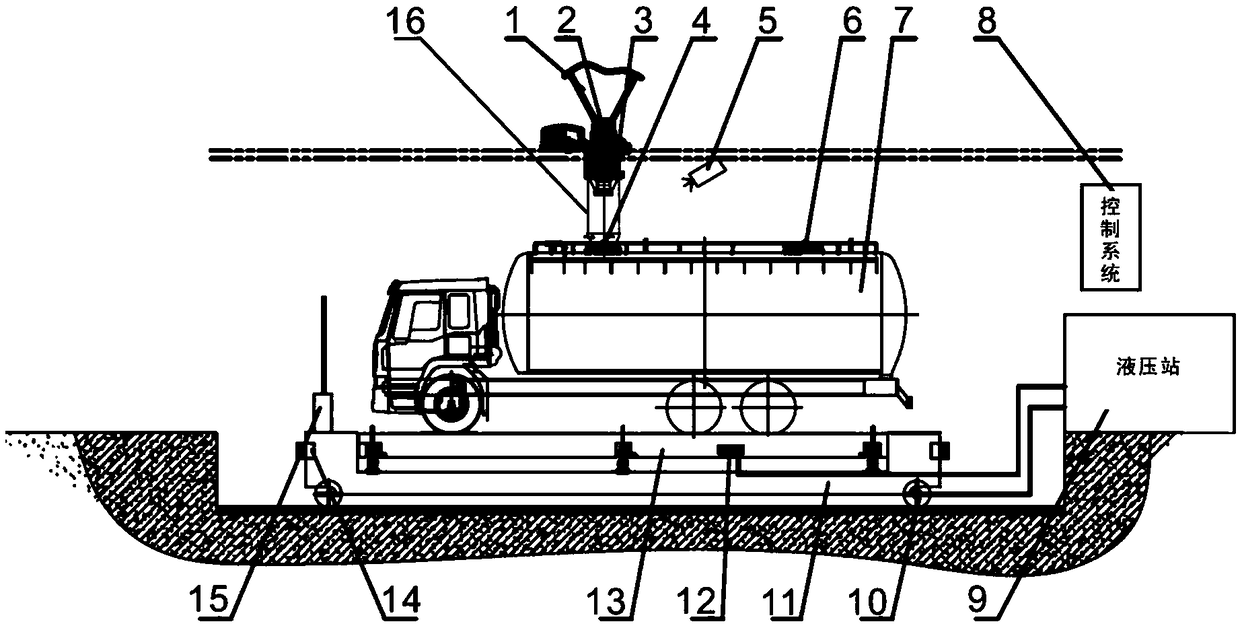

System and method of intelligent bulk loading of dry powder mortar production line

InactiveCN109160315AAccurateReduce parking preparation timeConveyorsControl devices for conveyorsProduction lineControl system

The invention relates to a system and a method of intelligent bulk loading of dry powder mortar production line, and belongs to the technical field of dry powder mortar production and transportation.The problem that an existing loading system cannot carry out rapid and accurate positioning on a material inlet of a bulk vehicle and a material outlet of a bulk machine is solved. The system comprises a loading frame and a control system, wherein the bulk machine and a visual system are arranged on the loading frame, and the control system is used for controlling the loading of dry powder mortar;the loading system further comprises a transversely-moving large crane and a longitudinal-moving small crane, wherein the small crane is arranged on the large crane; the visual system can obtain a coordinates of a center point of the material inlet of the bulk vehicle and the coordinate of the center point of the material outlet of the bulk machine, and the distance which needs to be moved in thetransverse direction and the longitudinal direction of the bulk vehicle is calculated, and the visual system transmits the distance to the control system, and the control system controls the movementof the large crane and the small crane, thus realizing accurate alignment of the material inlet and the material outlet of the bulk machine. The system and the method realize the intelligent rapid loading of the dry powder mortar production line.

Owner:CHINA UNIV OF MINING & TECH

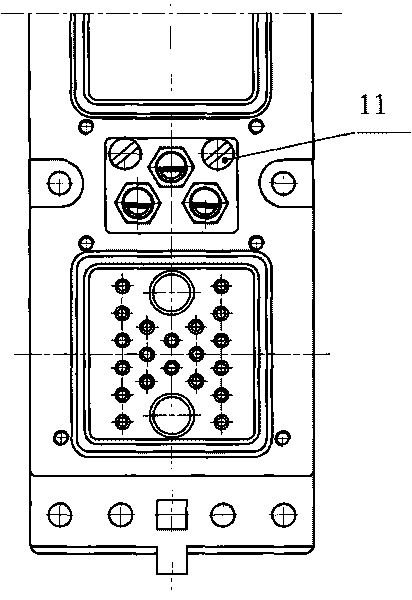

Connecting box bus bar welding machine and welding detecting method thereof

PendingCN107138887AClose contactRealize automatic alignmentWelding/cutting auxillary devicesAuxillary welding devicesCcd cameraStress sensors

The invention provides a connecting box bus bar welding machine and a welding detecting method thereof. The connecting box bus bar welding machine comprises a welding part, a loading part and a conveying mechanism, the welding part is located at the upper portion of the loading part, and the conveying mechanism is located on the side edge of the loading part; the welding part comprises a support, and a horizontal-vertical conveying mechanism is arranged on the support and is provided with a welding mechanism; by means of the welding machine, three-axis positioning is matched with a CCD camera, automatic alignment is achieved, and the automatic degree is improved; in addition, the connecting box bus bar welding machine is more accurate in alignment compared with a traditional machine, a temperature sensor and a pressure sensor are arranged on a welding head, tight contact between the welding head and a welding wire is guaranteed by downwards pressing the welding head, welding is accurate, automatic lifting is carried out after corresponding temperature and pressure values are obtained, and the welding stability is guaranteed.

Owner:KUNSHAN MENGTEZHAN PRECISION ELECTROMECHANICAL CO LTD

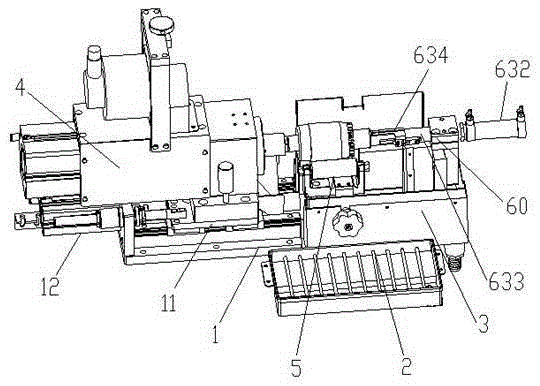

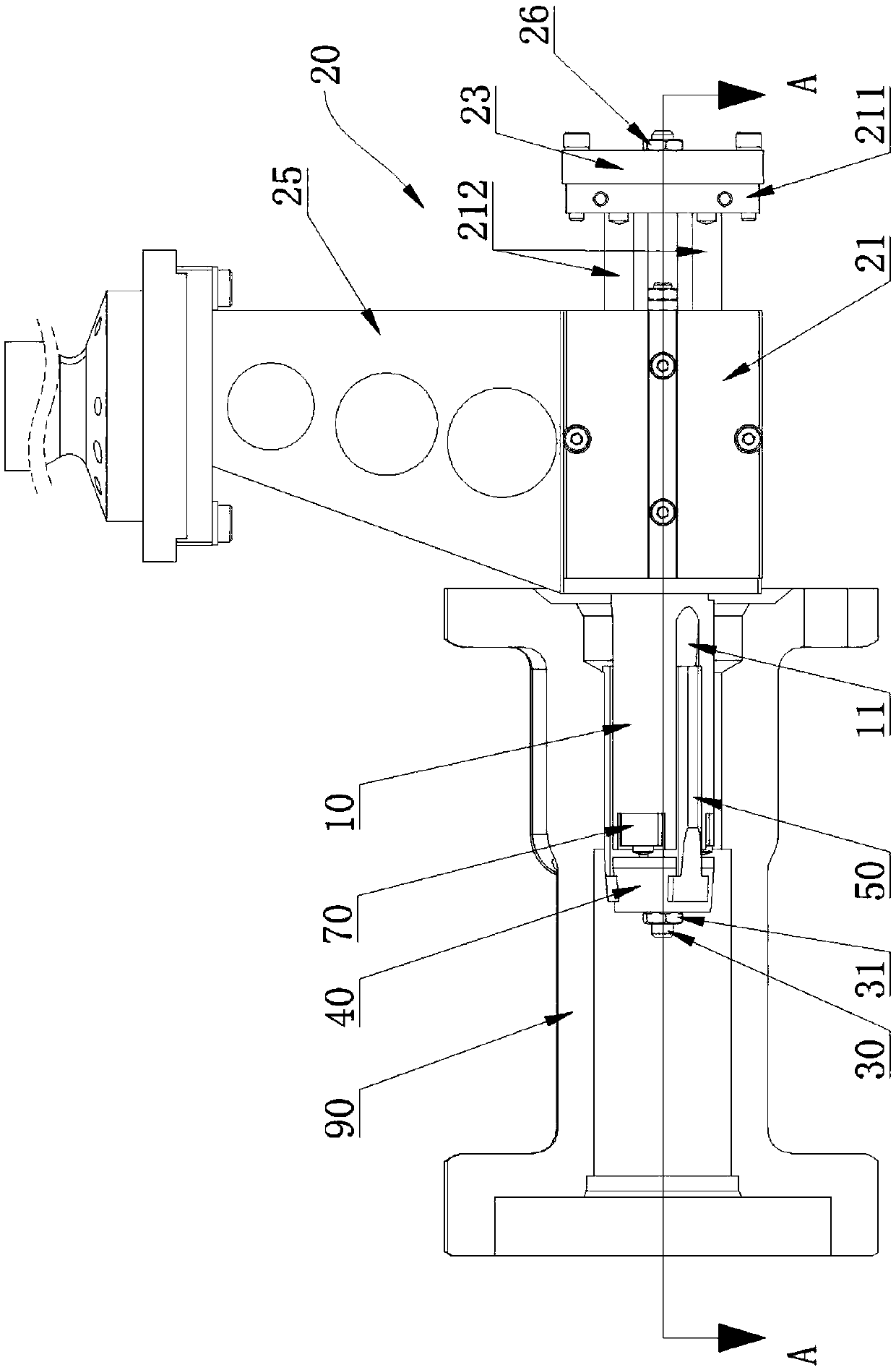

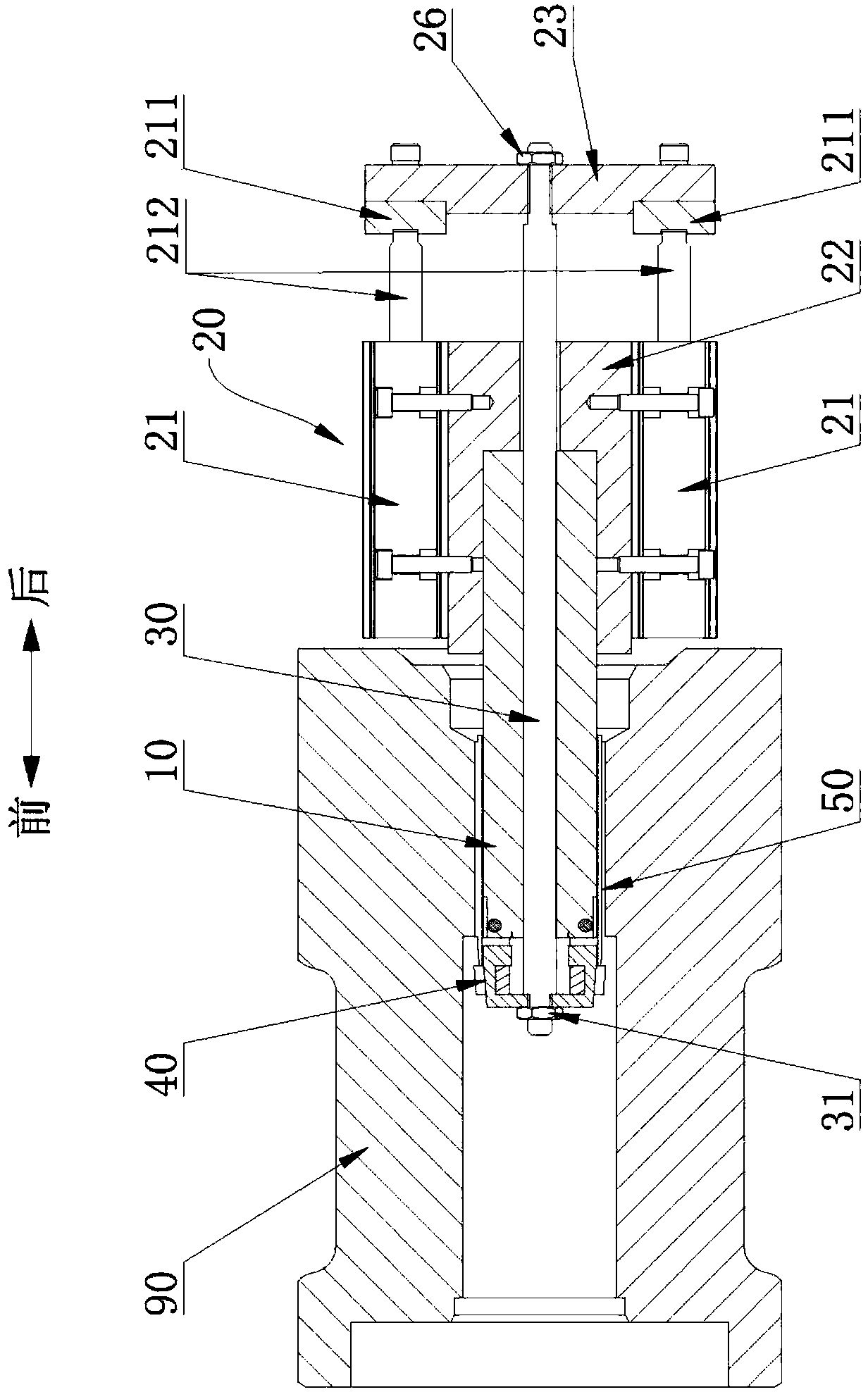

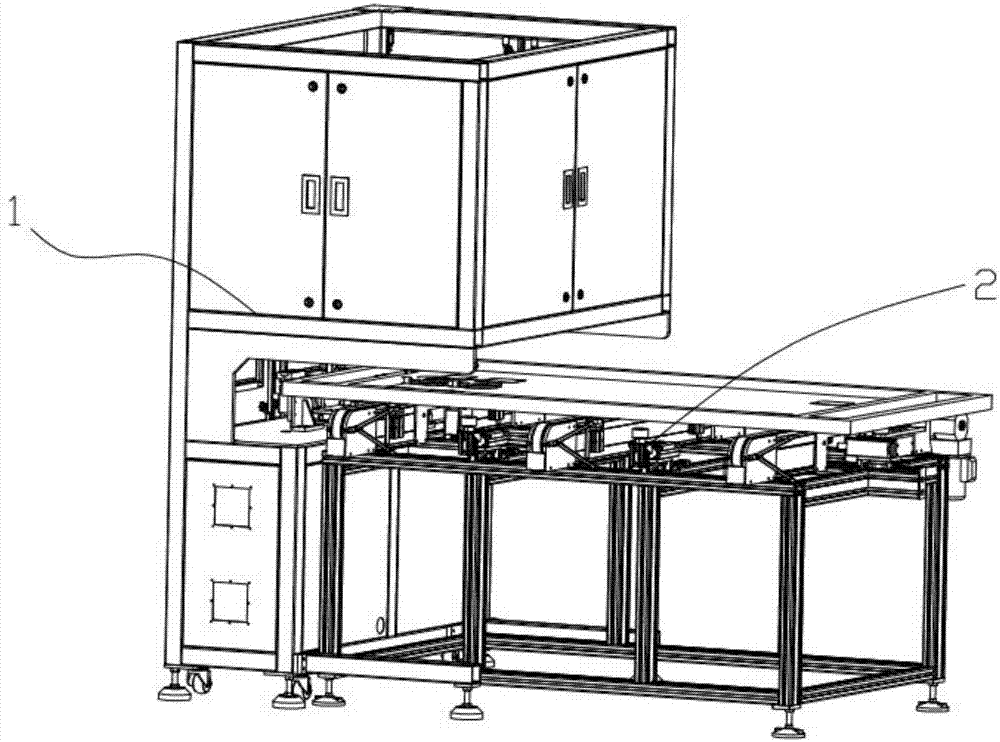

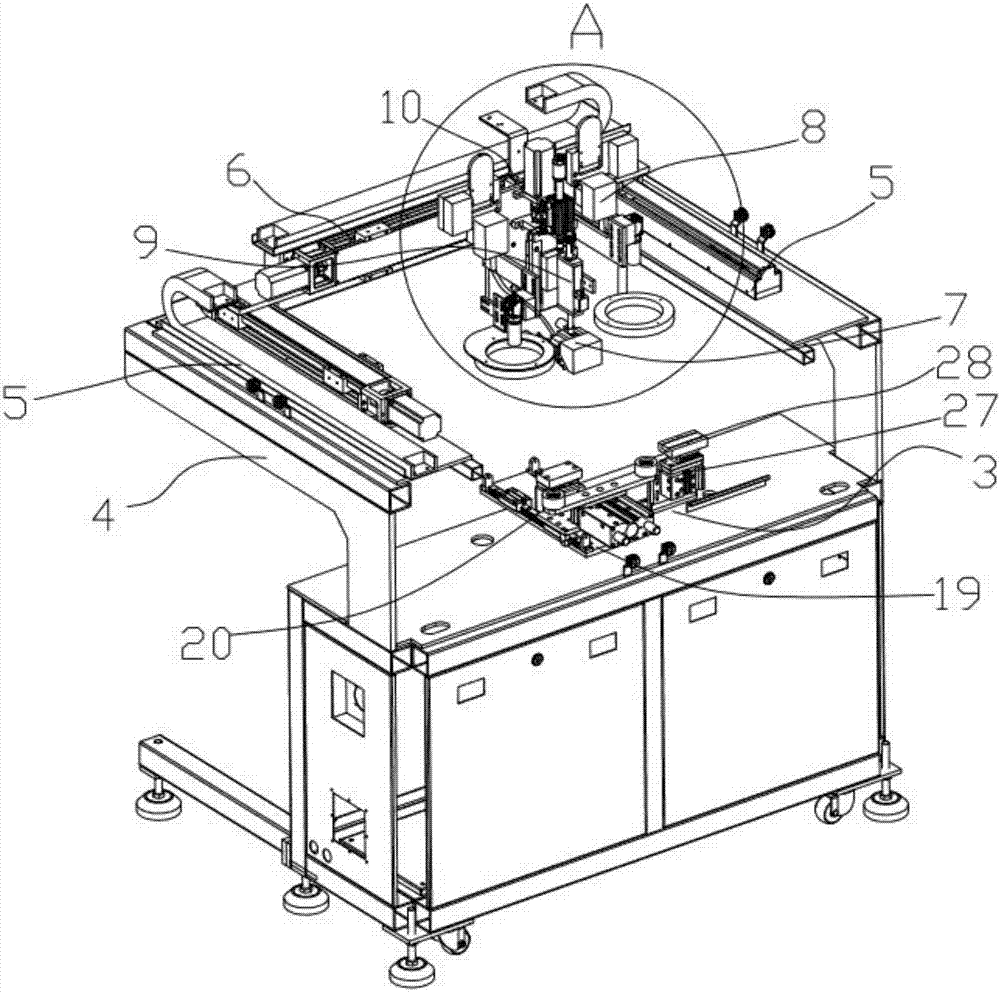

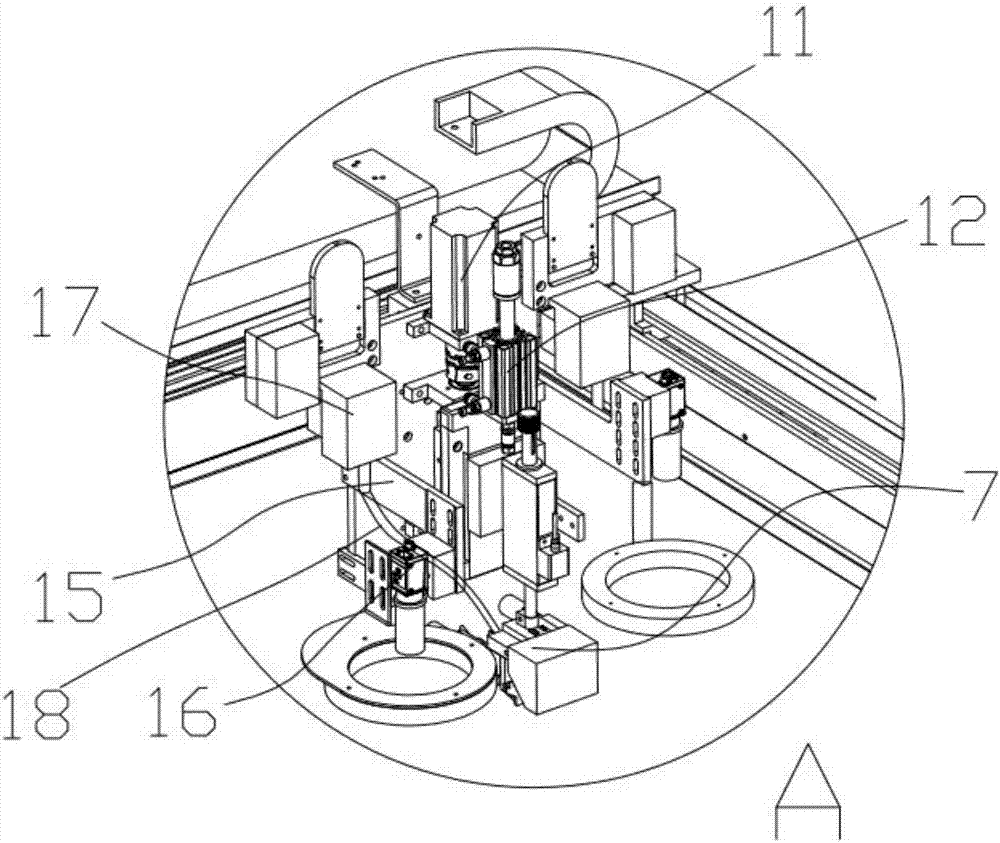

Assembling integrated device of large injection molding machine

PendingCN110893662ARealize automatic alignmentRealize the assemblyEngineeringInjection molding machine

The invention discloses an assembling integrated device of a large injection molding machine. The integrated device comprises a positioning platform, a pull bar stringing device, an automatic mold adjusting nut screwing device, a connecting rod lock shaft installing device and a control device. Via the device, a pull bar can be aligned and assembled automatically, a mold adjusting nut can be aligned and assembled automatically, a lock shaft can be aligned manually and punched automatically, the assembling efficiency is improved, and the labor intensity of workers is reduced.

Owner:HAITIAN PLASTICS MACHINERY GRP

On-line detecting method of machine vision system for printed calico flaw

InactiveCN100593716CReduce testing labor intensityGuaranteed accuracyInspecting textilesMaterial analysis by optical meansComputer scienceVisual perception

Owner:WUXI DONGWANG TECH

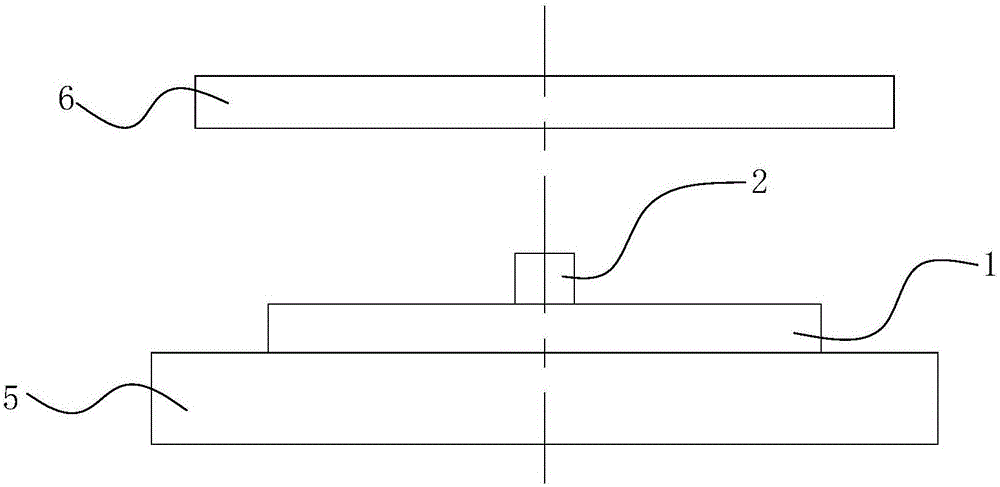

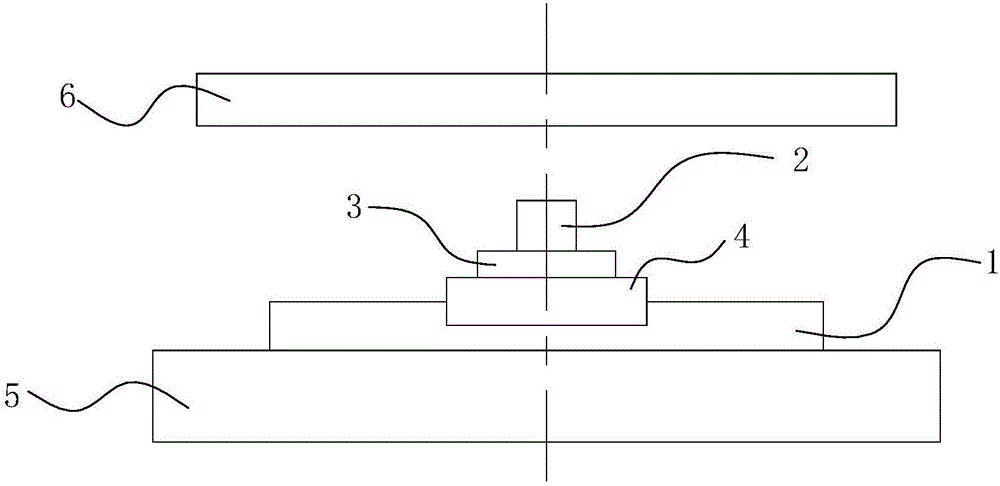

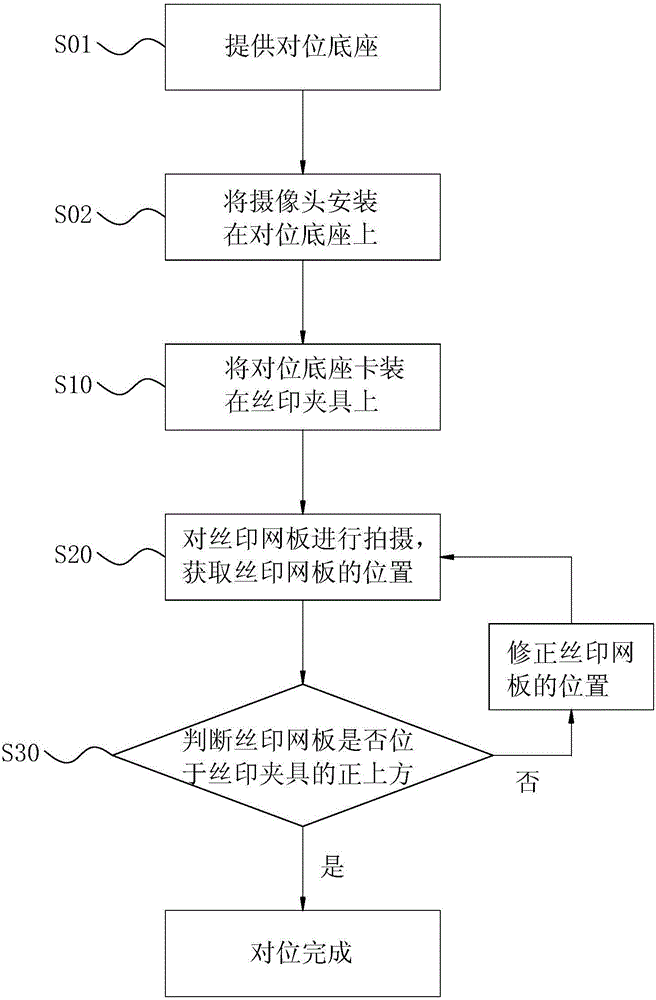

Aligning method and aligning device of silk screen boards

ActiveCN105774197ARealize automatic alignmentIncrease productivityScreen printersPrinting press partsEngineeringImage identification

The invention relates to the technical field of silk screens of glass screens, and discloses an aligning method of silk screen boards. The aligning method comprises the steps of: (S10) clamping an aligning base, provided with a camera, on a silk screen fixture; (S20) the camera shooting the silk screen boards to obtain the positions of the silk screen boards; and (S30) judging if the positions of the silk screen boards are rightly above the position of the silk screen fixture; if so, finishing the alignment; and if not, correcting the positions of the silk screen boards, and returning to the step (S20). The invention further discloses an aligning device of the silk screen boards for performing the aligning method. The aligning method determines the actual positions of the silk screen boards through shooting and image identification of the silk screen boards, and adjusts the positions of the silk screen boards according to the actual positions, so that the automatic alignment of the silk screen boards and the silk screen fixture is realized, the production efficiency and the reliability are improved, no need of consuming glass screens in the aligning process is realized, and the production cost can be reduced.

Owner:东莞市奇声电子实业有限公司

Automatic alignment type auxiliary mounting frame for mounting vehicle roller shaft

ActiveCN112496702AImprove stabilityRealize automatic alignmentMetal working apparatusControl theoryBilateral symmetry

The invention discloses an automatic alignment type auxiliary mounting frame for mounting a vehicle roller shaft. The mounting frame comprises a bottom plate, wherein a sliding mechanism is slidably connected to the upper portion of the bottom plate, and a height adjusting piece is arranged on the upper portion of the sliding mechanism; a left-right adjusting piece is arranged on the upper portionof the height adjusting piece, and a clamping mechanism is arranged at the upper portion of the left-right adjusting piece; the roller shaft is clamped on the clamping mechanism; a mounting plate isfixedly connected to the front side of the upper end surface of the bottom plate, and a storage battery and a controller are arranged at the upper portion of the front end surface of the mounting plate; a supporting mechanism is arranged at the bottom of the bottom plate, and the rear side of the right end face of the bottom plate is connected with an auxiliary mechanism through an L-shaped supporting plate; two anti-skid pieces are symmetrically arranged on the inner side of the clamping mechanism; and the sliding mechanism comprises a sliding table, four first sliding cylinders and an L-shaped brake plate, the four first sliding cylinders are fixedly connected to the bottom of the sliding table in a bilateral symmetry mode, a limiting guide rod is slidably connected to the interior of each first sliding cylinder, and a strip-shaped plate is welded between the right end faces of the two fixing plates, and the L-shaped brake plate in contact with the upper end face of the strip-shapedplate is arranged on the right side of the bottom end face of the sliding table.

Owner:河南工学院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com