Automatic distorted concrete grouting and vibrating equipment

A technology of abnormal concrete and automatic grouting, applied in construction, infrastructure engineering and other directions, can solve the problems of difficult to control the grouting accuracy, difficult to guarantee the construction quality, uncontrollable vibration time, etc., to improve the construction speed and quality, The effect of reducing the labor intensity of workers and large vibration force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with embodiment the present invention is further described.

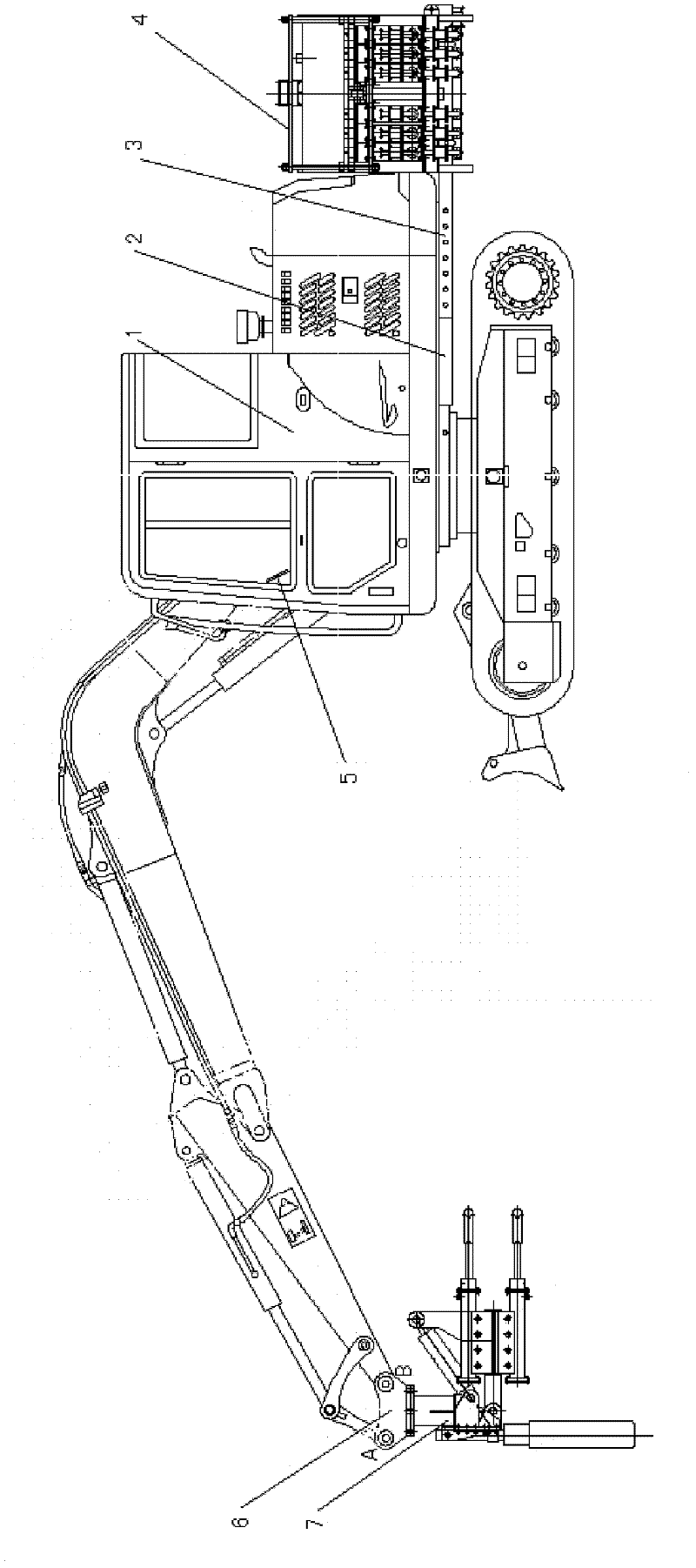

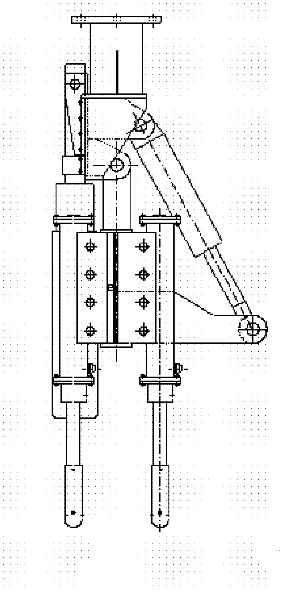

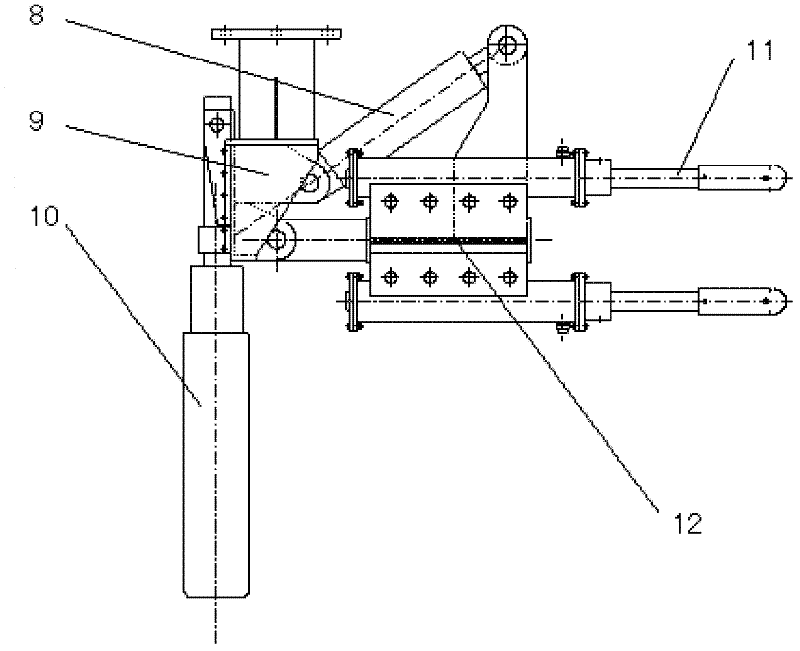

[0014] see Figure 1-4 , abnormal concrete automatic grouting and vibrating equipment, including excavator 1 and hydraulic system; also includes grouting station 4, grouting vibrating device 7, PLC control system and operation panel 5; grouting station 4 is supported by grouting station bracket 3 is connected with the load-bearing main beam 2 of the excavator 1; the grouting and vibrating device 7 is connected by the connecting piece 6 through the pin shaft ( figure 1 Middle A, B) are connected with the rocker arm of the four-bar mechanism of the excavator 1; the PLC control system is located on the rotary table of the excavator 1, and the operation panel 5 is installed in the cab of the excavator 1.

[0015] The slurry supply station 4 includes a slurry supply station frame 13, a one-way valve 14, a plunger pump 15, a guide rod 16, a slurry tank 17, a mixer 18, a hydraulic push-pull cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com