Patents

Literature

78results about How to "Even grouting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

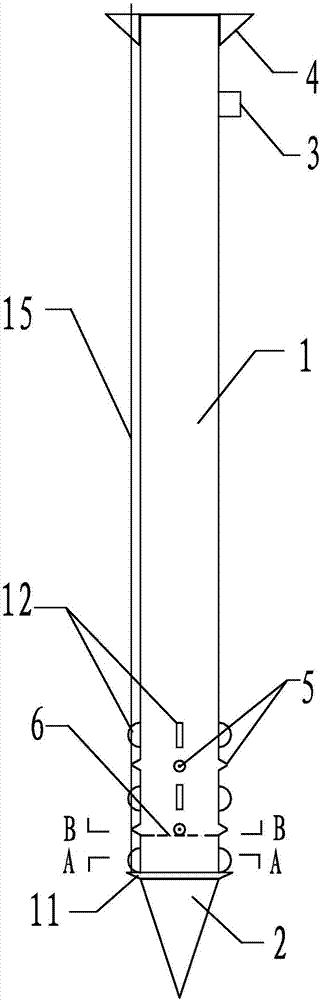

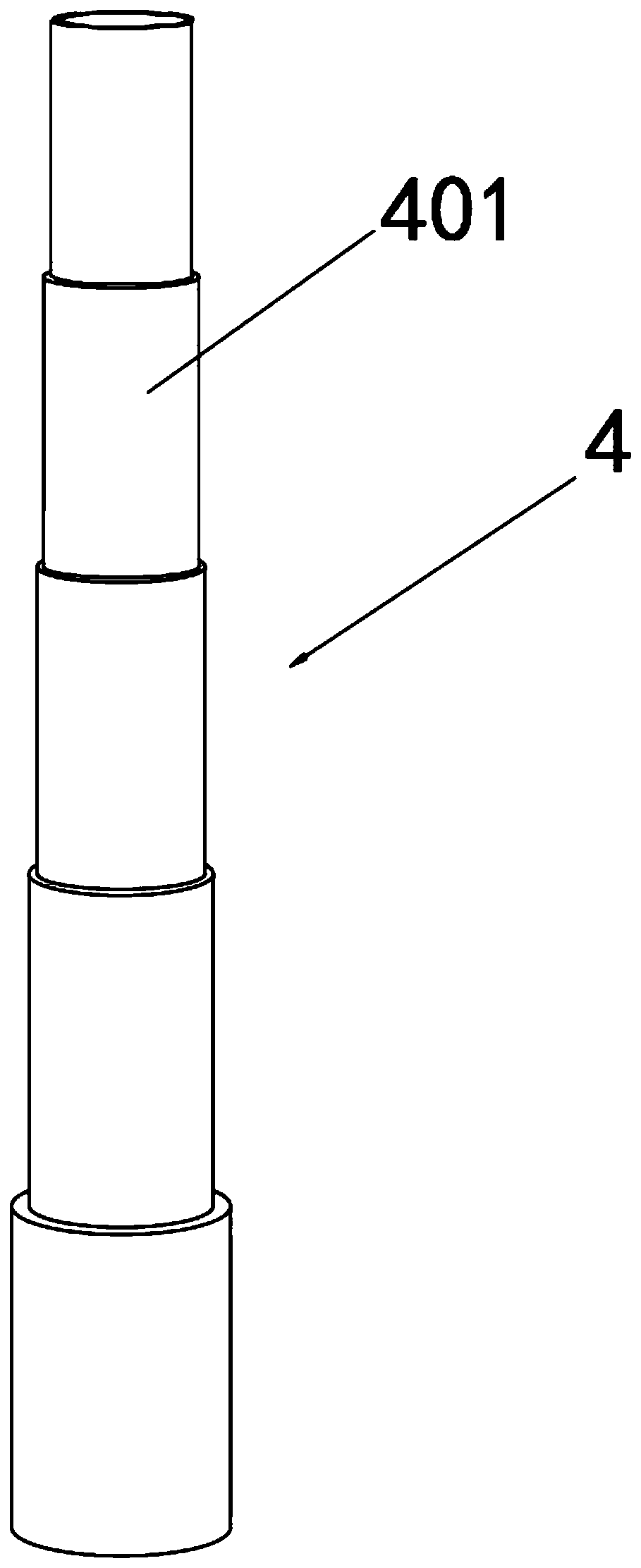

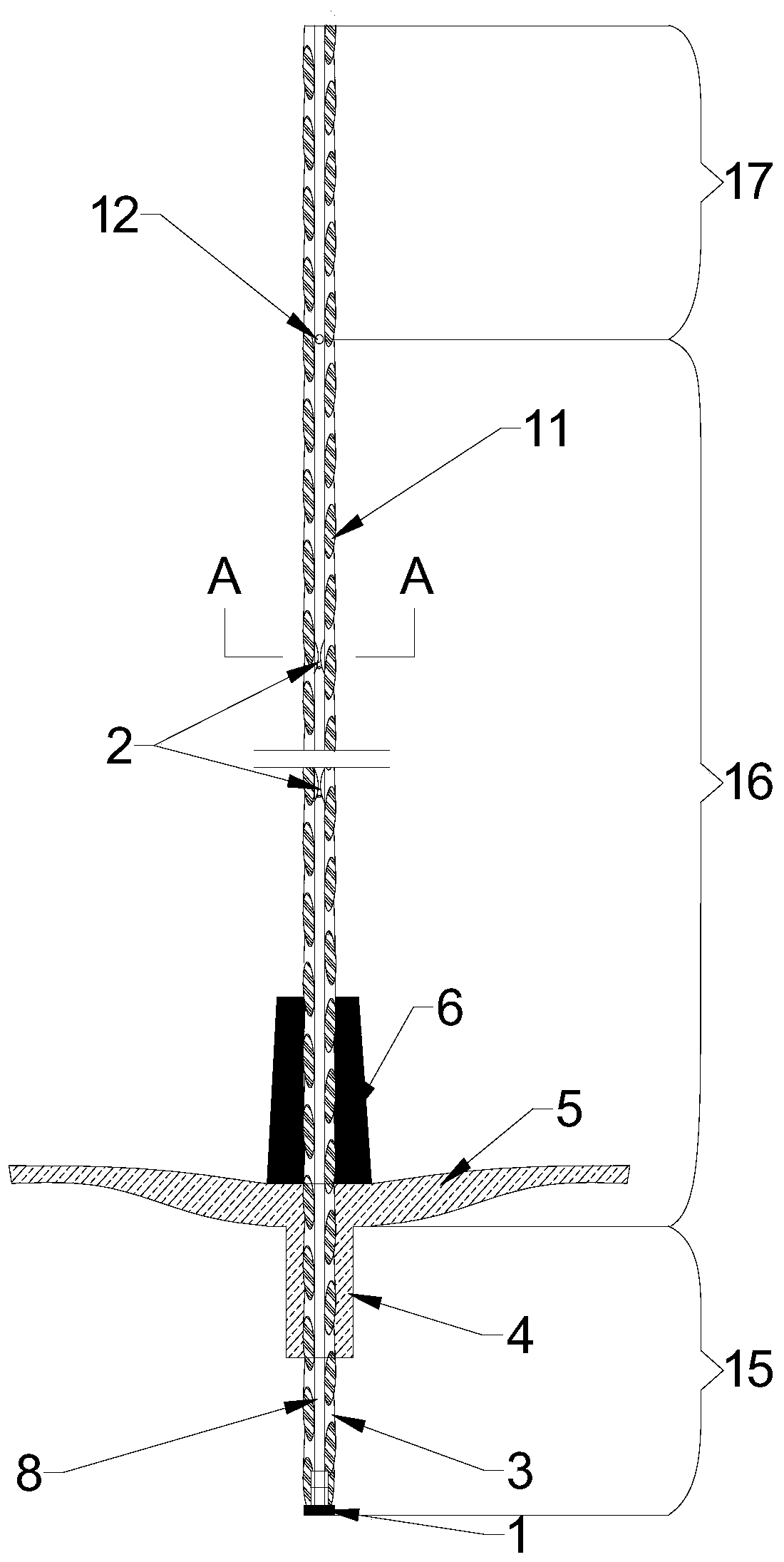

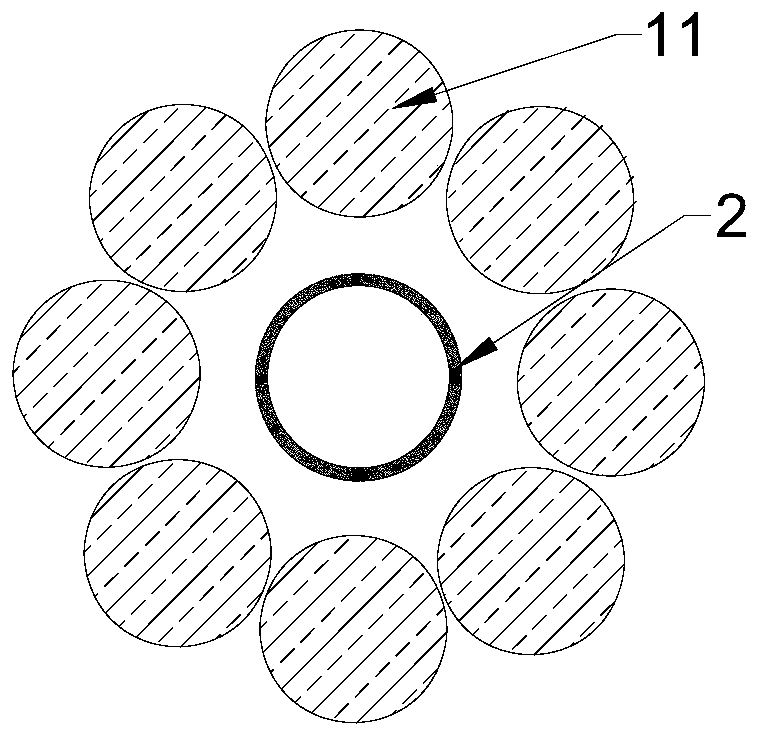

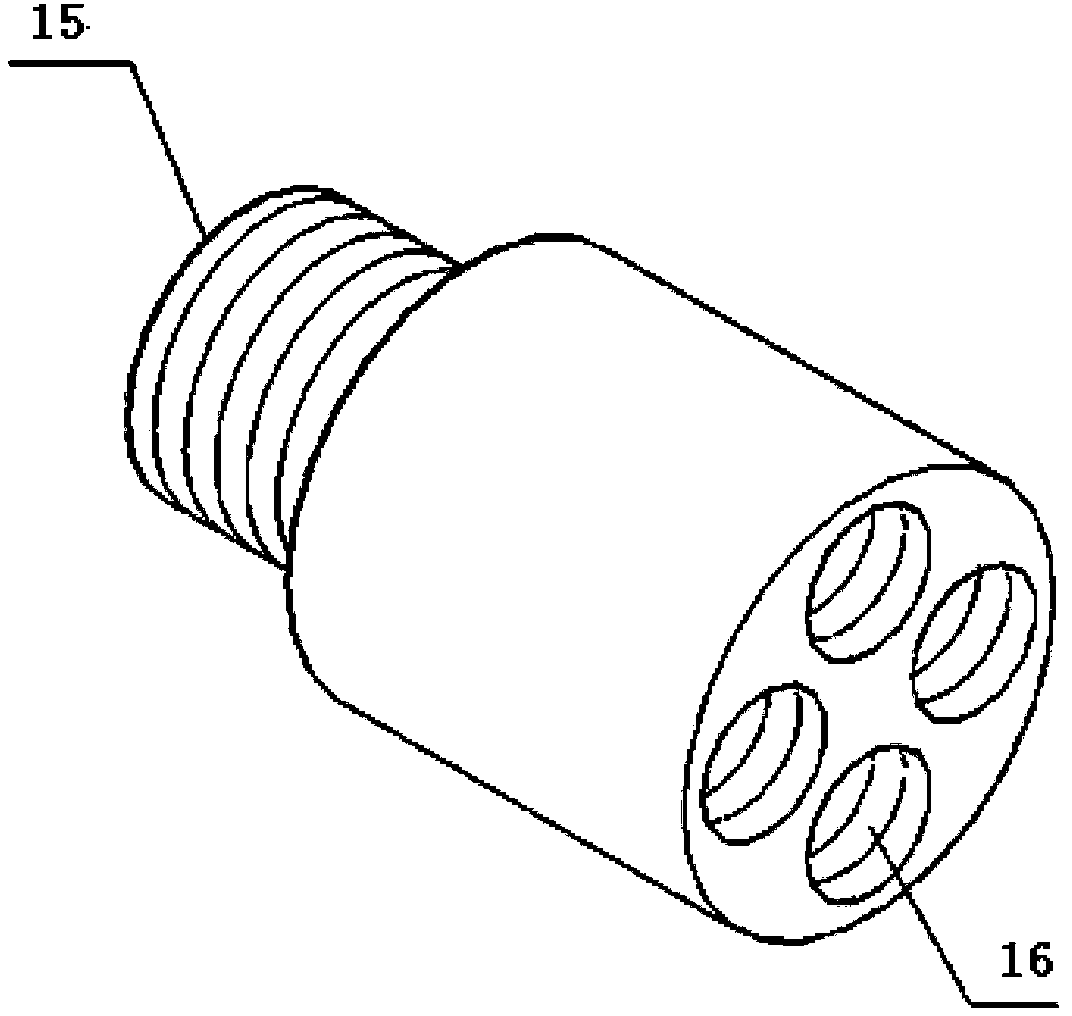

Block assembly type yielding hollow grouting anchor rod and construction method thereof

PendingCN107829767AHigh initial preloadImprove stabilityAnchoring boltsClimate change adaptationRock boltArchitectural engineering

The invention discloses a block assembly type yielding hollow grouting anchor rod. The block assembly type yielding hollow grouting anchor rod comprises a hollow anchor rod body, a hollow anchor cablerod body, a yielding device, a tray, a nut, a slurry stopping plug, an anchor cable hoop sleeve and a chambering device, wherein the yielding device, the tray, the nut and the slurry stopping plug are arranged on the hollow anchor rod body, the anchor cable hoop sleeve and the chambering device are arranged on the hollow anchor rod body, and the hollow anchor rod body is connected with the hollowanchor cable rod body through a connecting sleeve. The block assembly type yielding hollow grouting anchor rod can give full play to the advantages of an anchor rod and an anchor cable, not only canthe hanging action of the anchor rod to shallow surrounding rock be utilized, but also the stability of deep surrounding rock can be improved by utilizing the anchor cable, favorable independent and multipoint yielding effects on the hollow anchor rod body can be achieved by the yielding device, the whole harmony of the hollow anchor cable rod body is improved by a anchor cable hoop, multipoint grouting is realized by the chambering device, the rod body length can be freely adjusted according to requirement, and on-site construction and adjustment are convenient.

Owner:ANHUI UNIV OF SCI & TECH

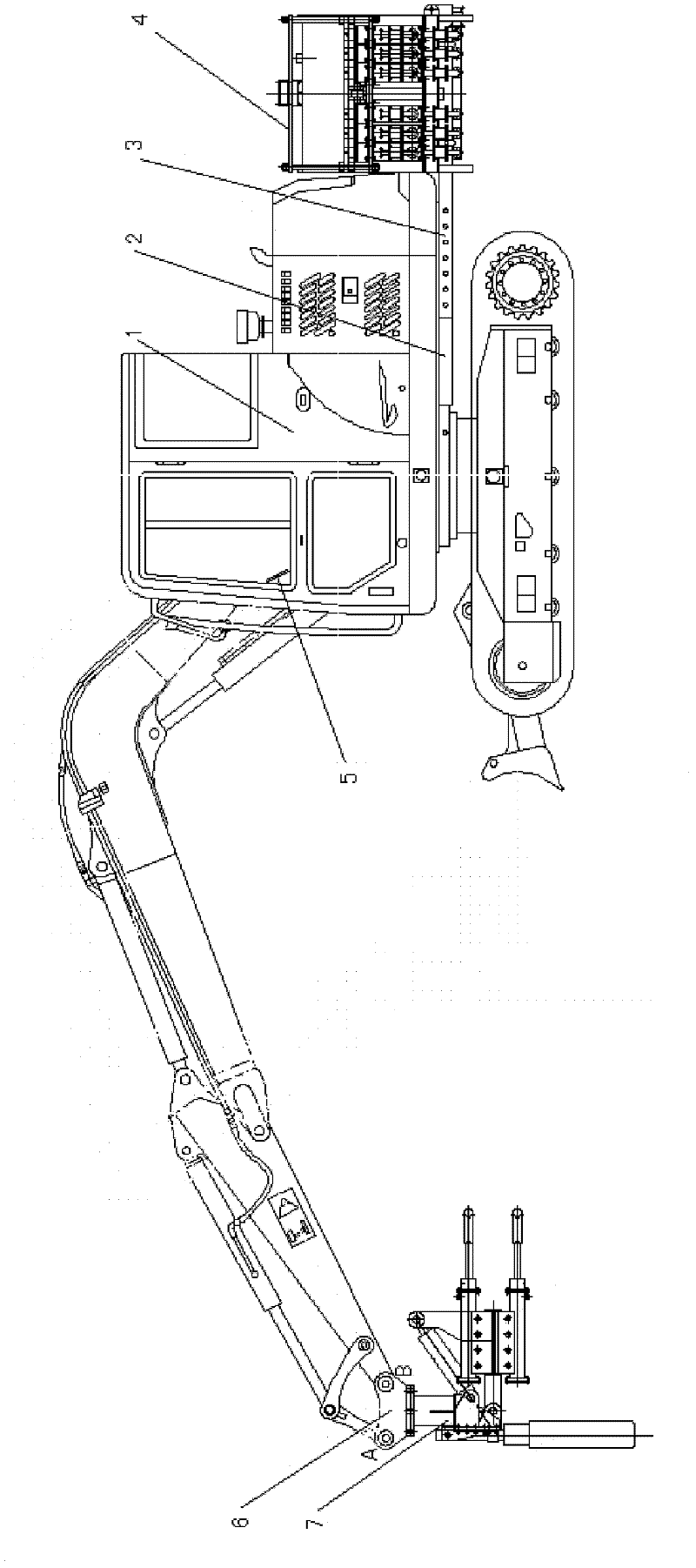

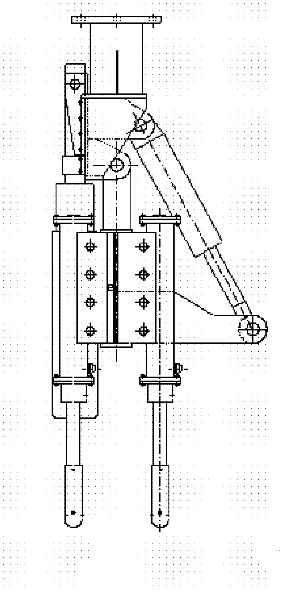

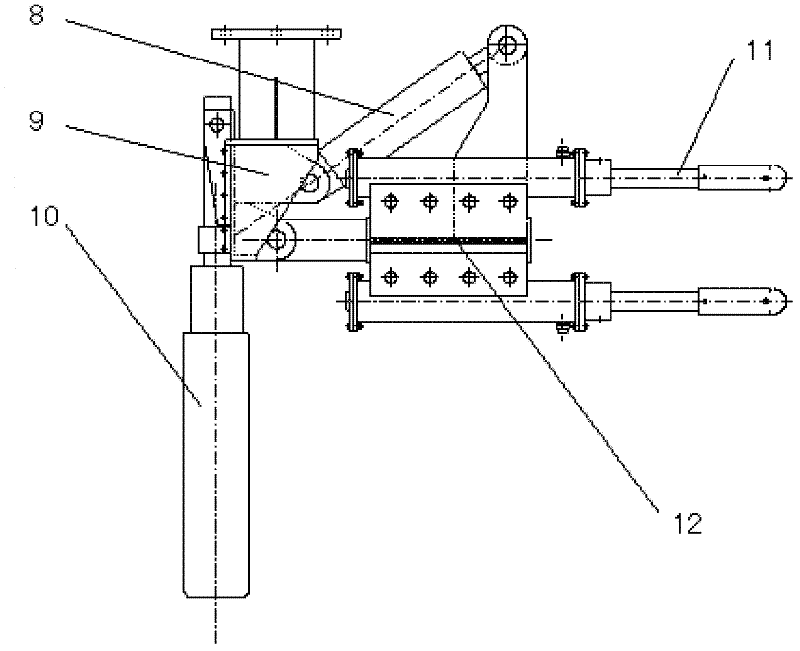

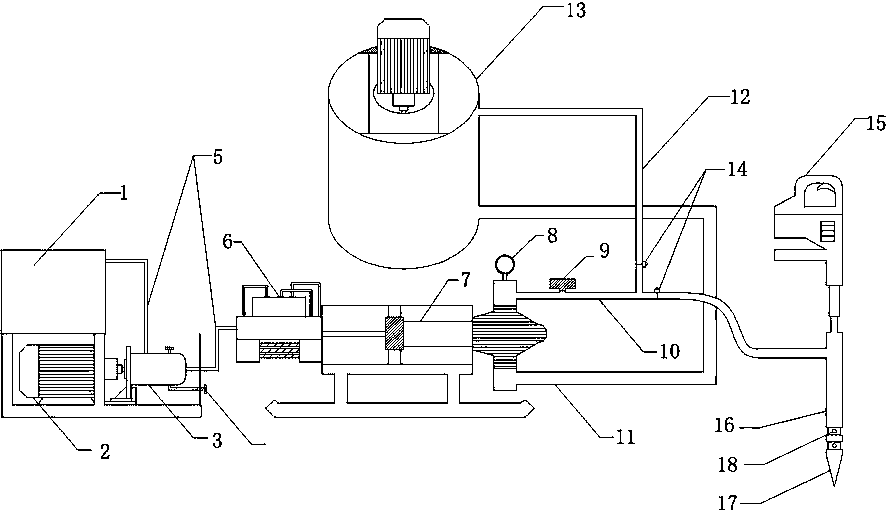

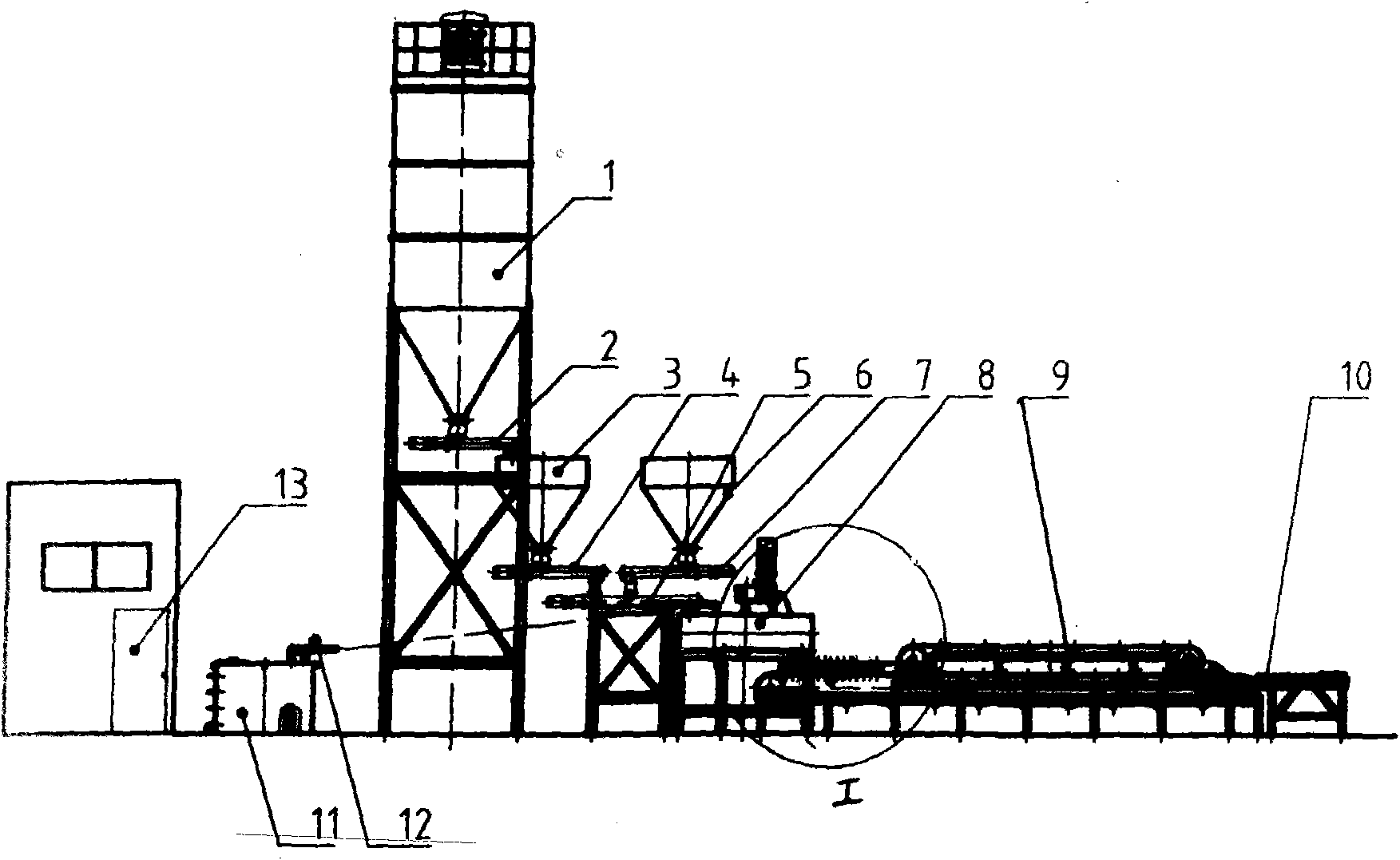

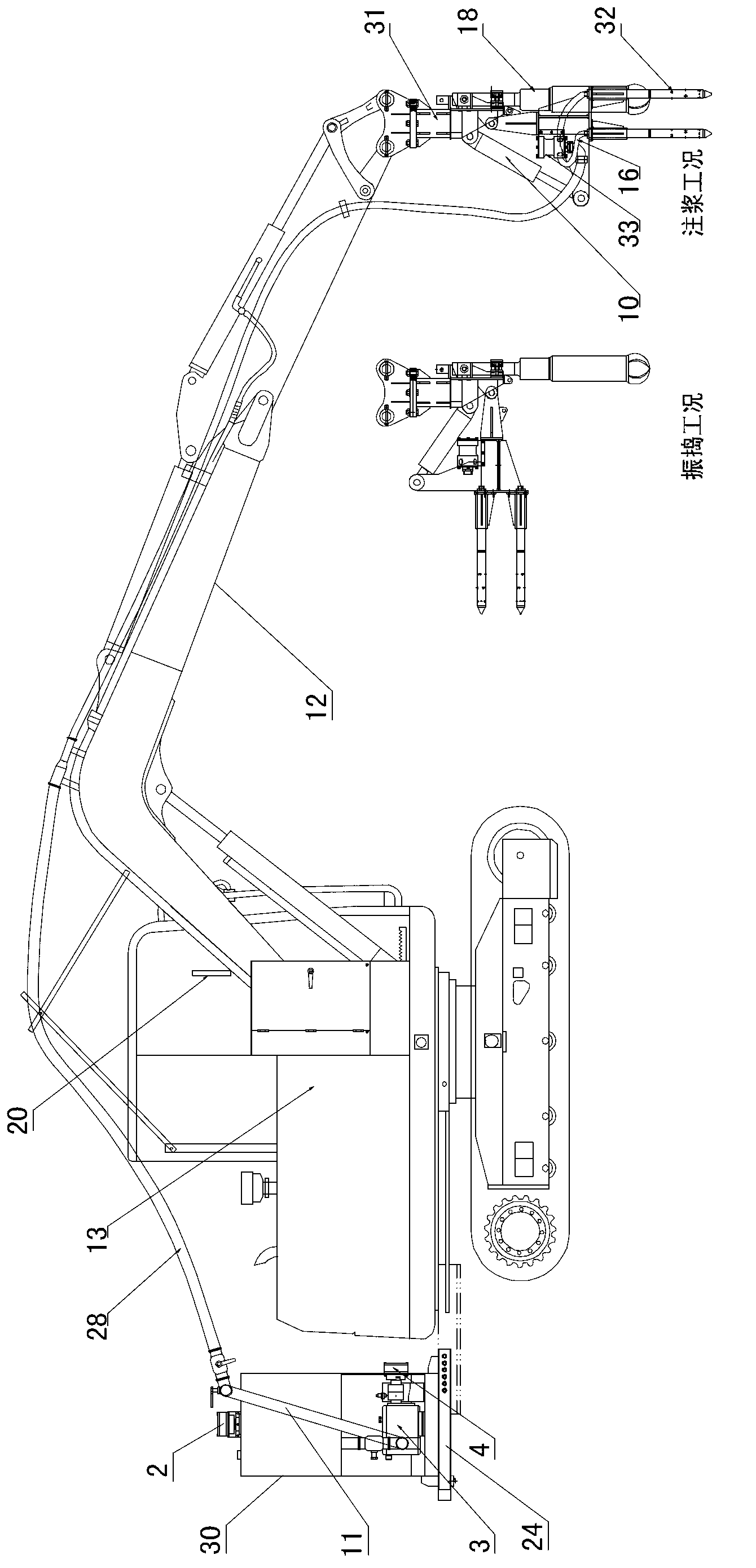

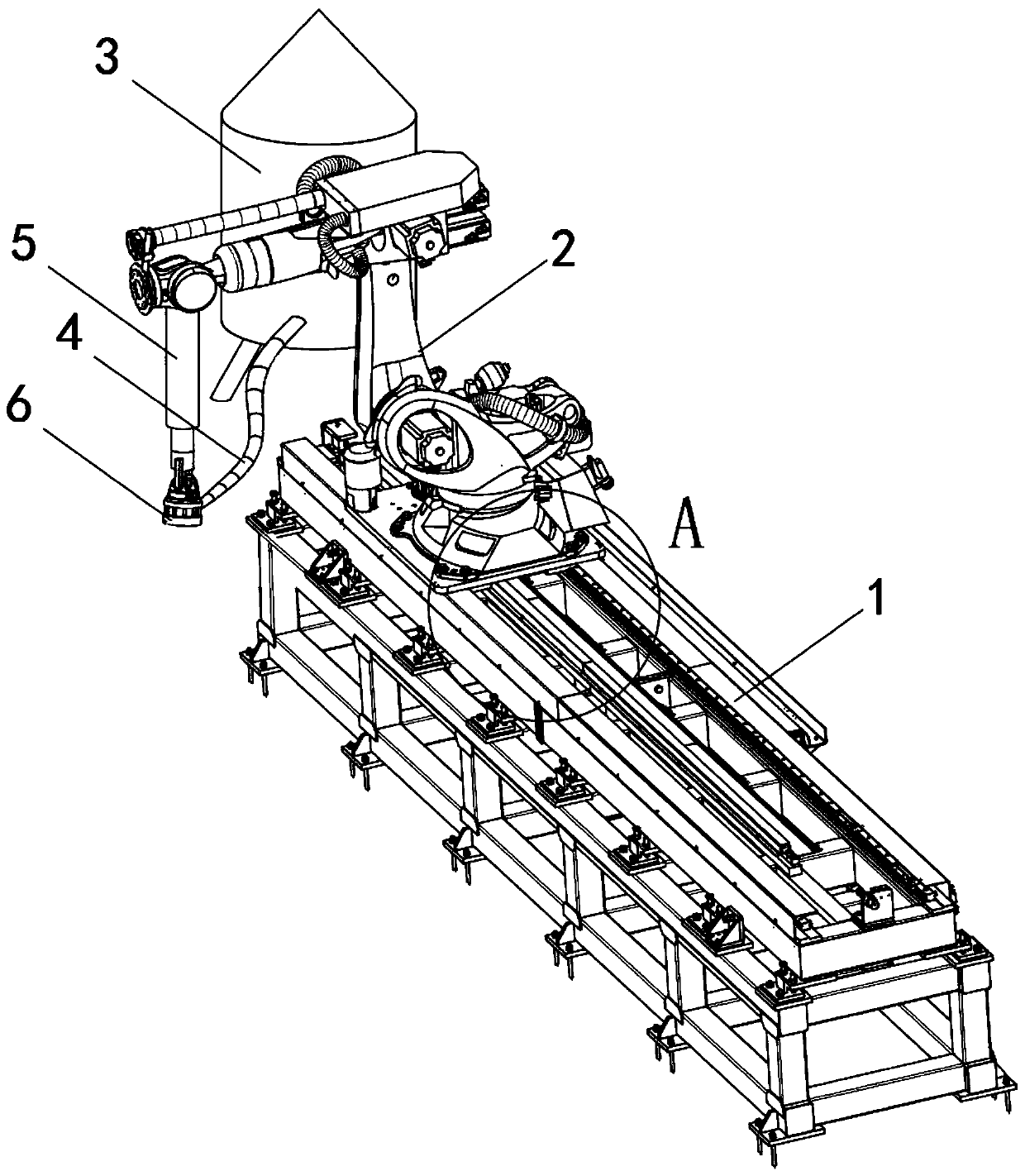

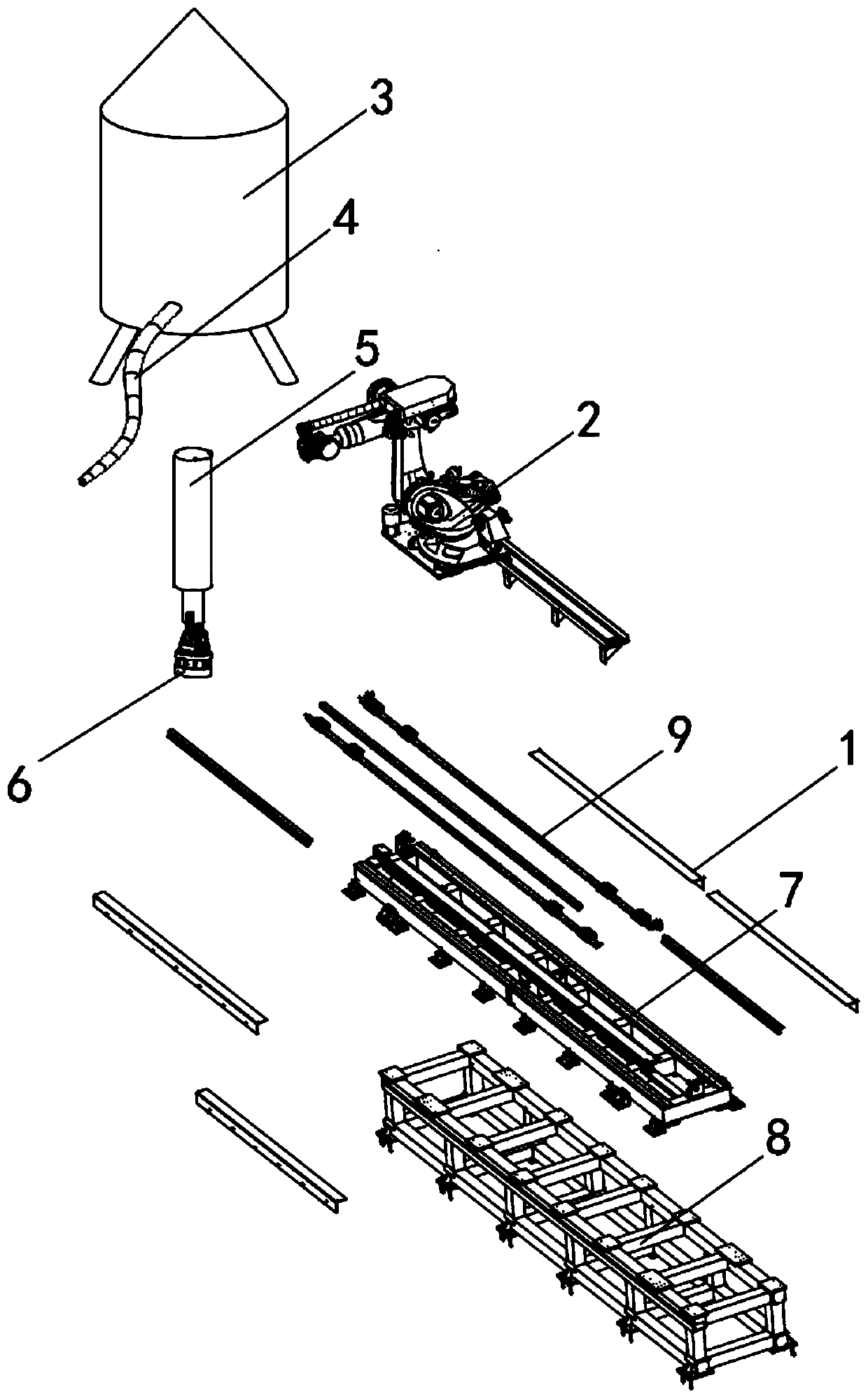

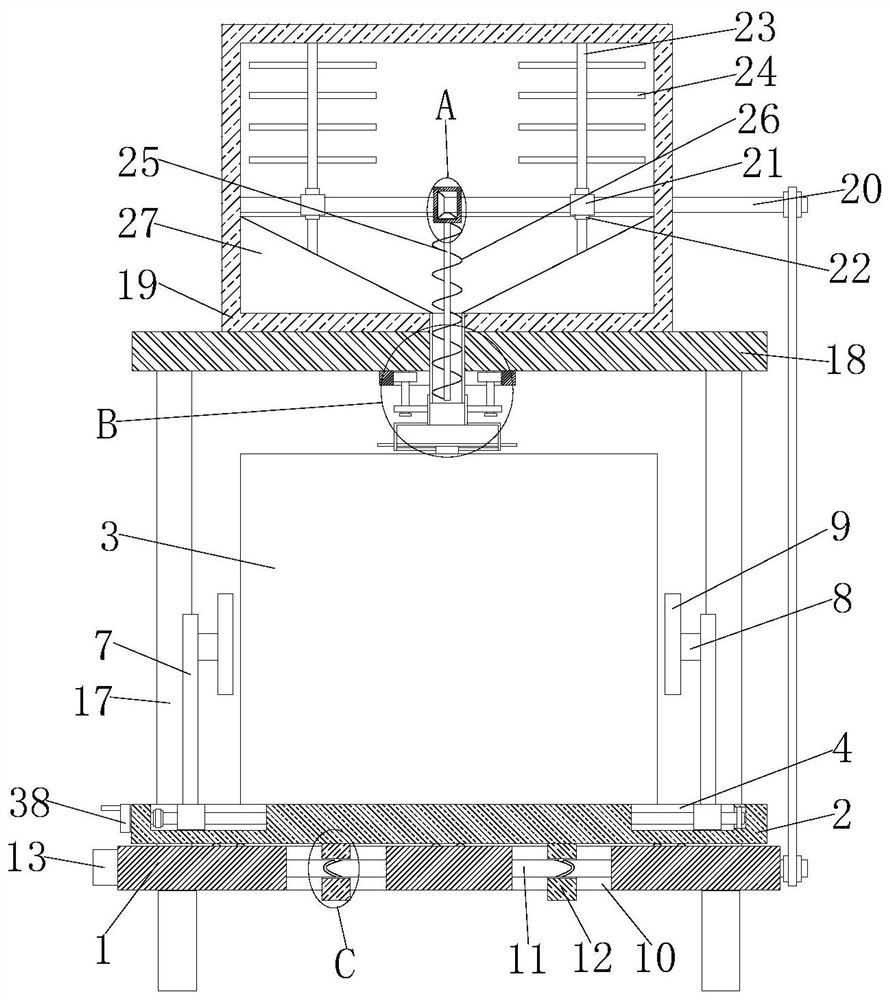

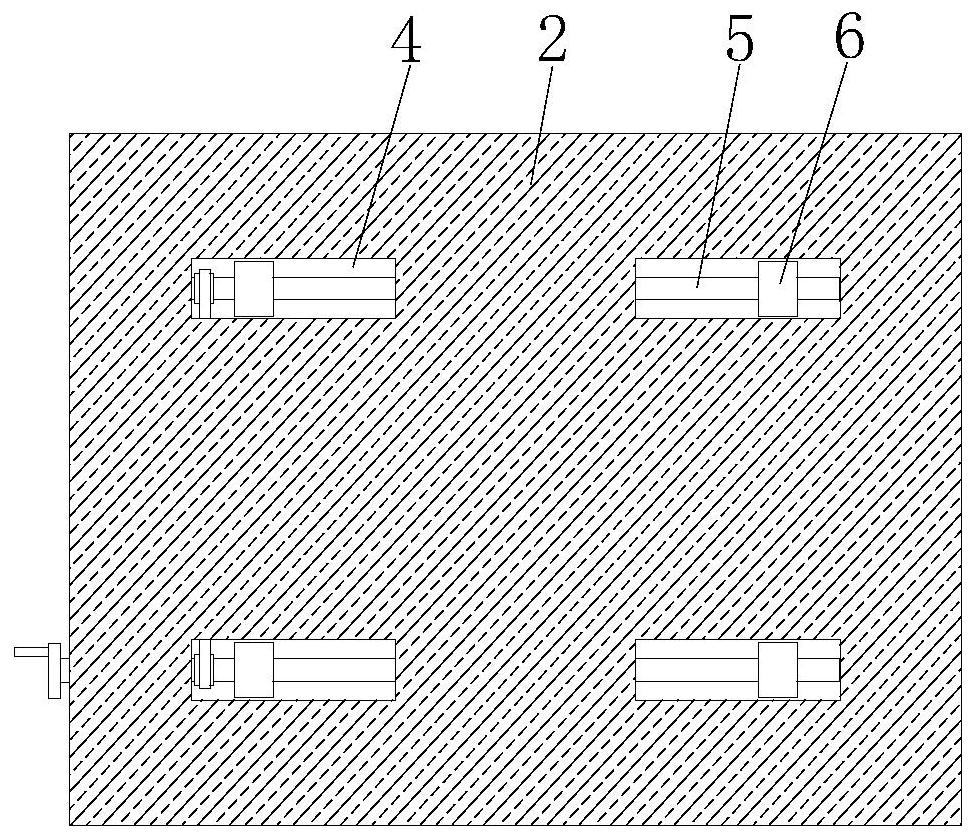

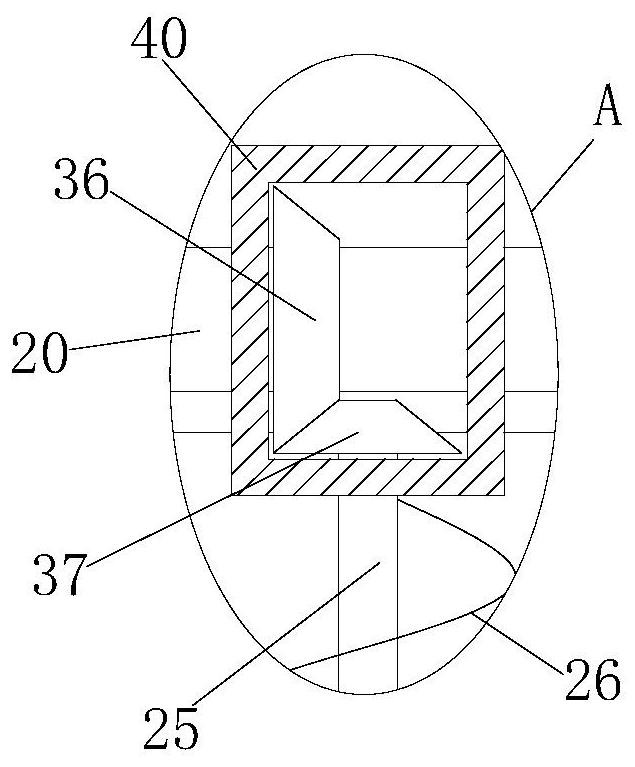

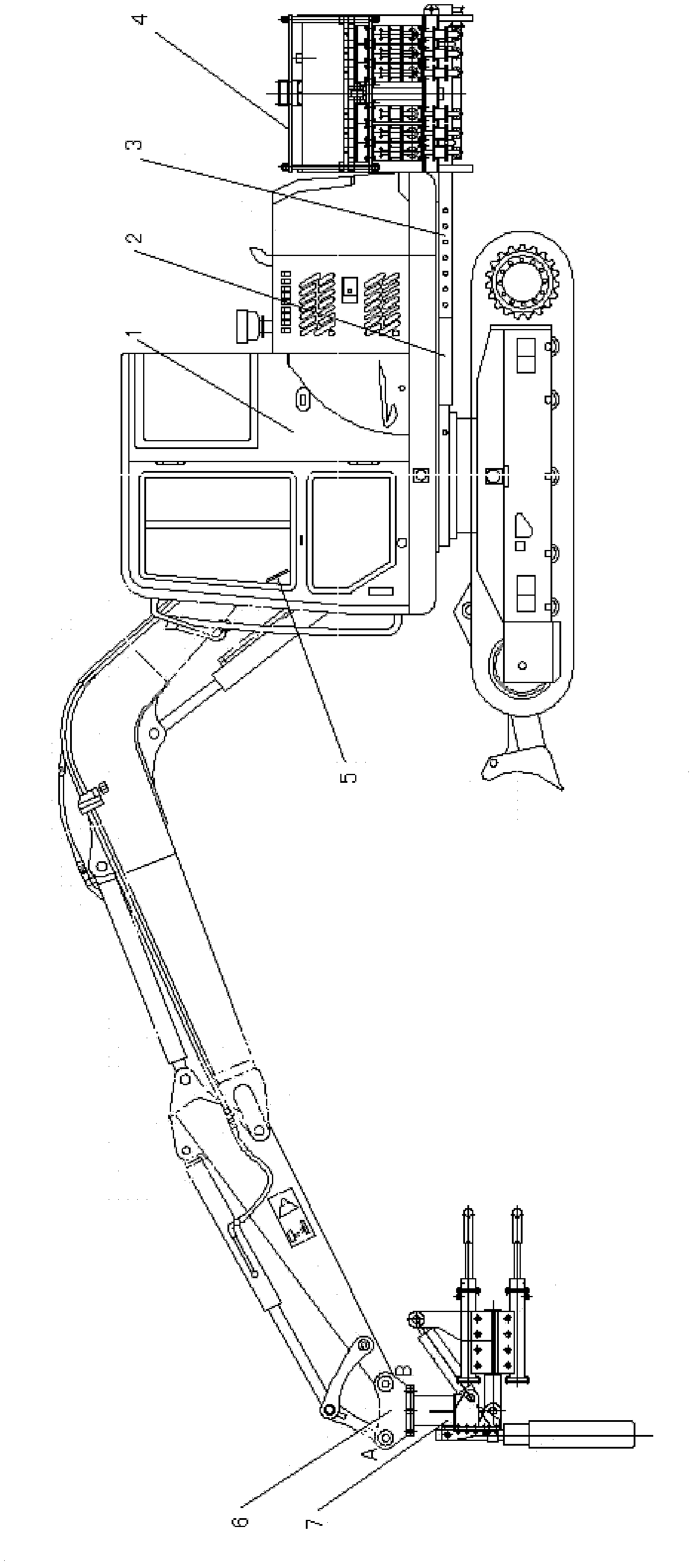

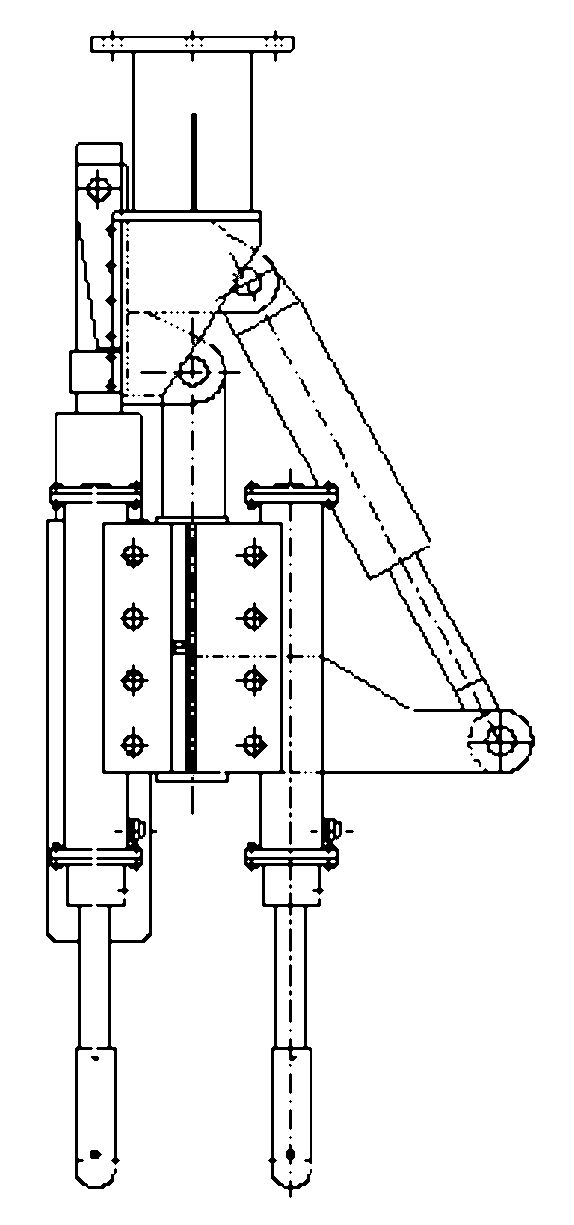

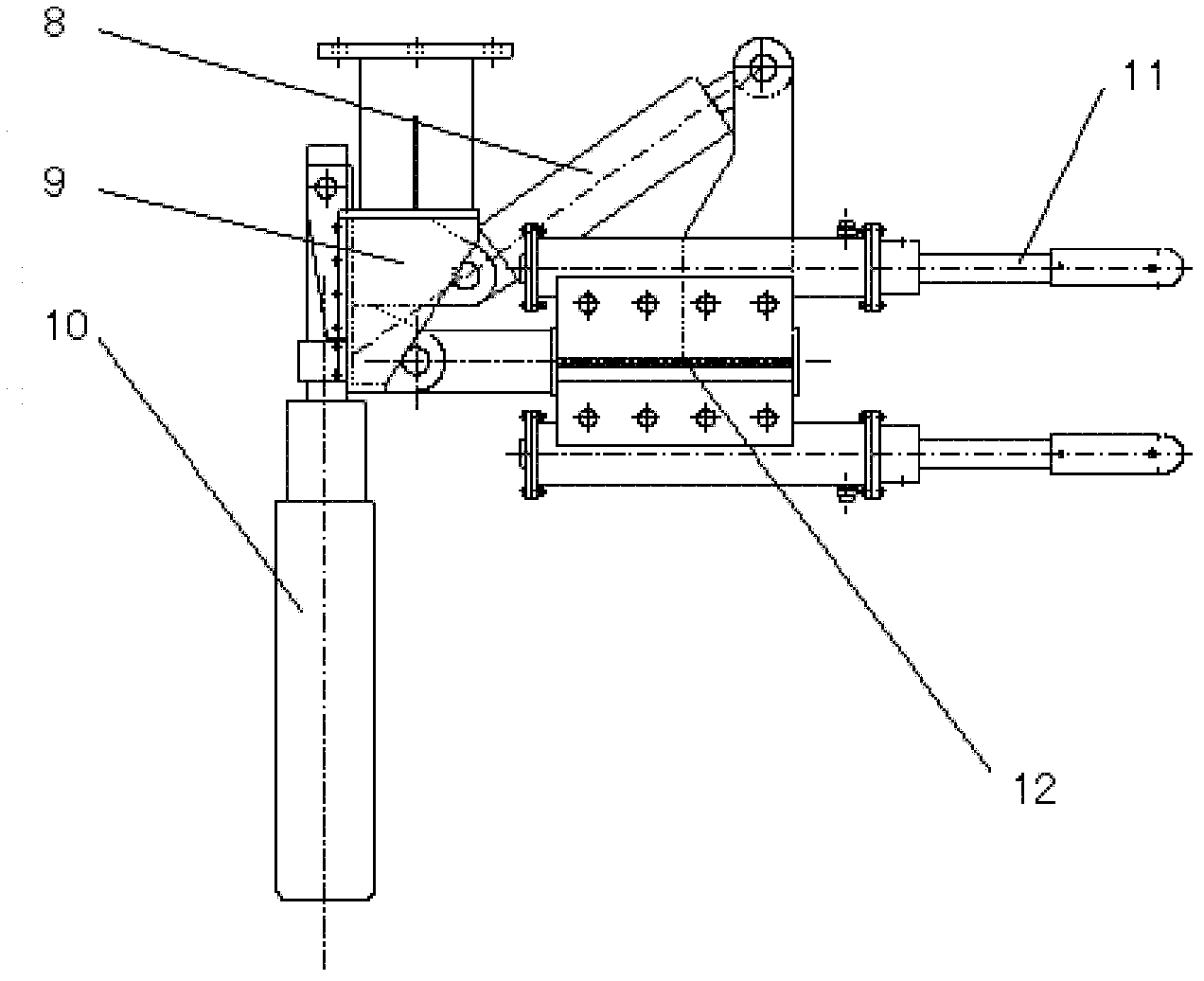

Automatic distorted concrete grouting and vibrating equipment

ActiveCN102505694ARealize free switchingRealize automatic alignmentFoundation engineeringControl systemProgrammable logic controller

The invention discloses automatic distorted concrete grouting and vibrating equipment, which belongs to the technical field of construction and comprises an excavator, a hydraulic system, a slurry supply station, a grouting and vibrating device, a PLC (programmable logic controller) control system and an operation screen. The slurry supply stations is connected with a load-bearing main beam of the excavator via a slurry supply station bracket, the grouting and vibrating device is connected with a four-rod mechanism rocker arm of the excavator by a connecting part via a hinge pin, the PLC control system is located on a rotary worktable of the excavator, and the operation screen is mounted in a driving cab of the excavator. The automatic distorted concrete grouting and vibrating equipment simultaneously has grouting and vibrating functions, can realize free switching between a grouting work state and a vibrating work state, automatic alignment of working devices, accurate control of grouting quantity and the like, is flexible in movement, uniform in grouting, large in vibrating force and simple in operation, increases construction speed and quality, reduces labor intensity of workers, and is applicable to distorted concrete grouting and vibrating construction in various work places.

Owner:SINOHYDRO BUREAU 7 CO LTD +1

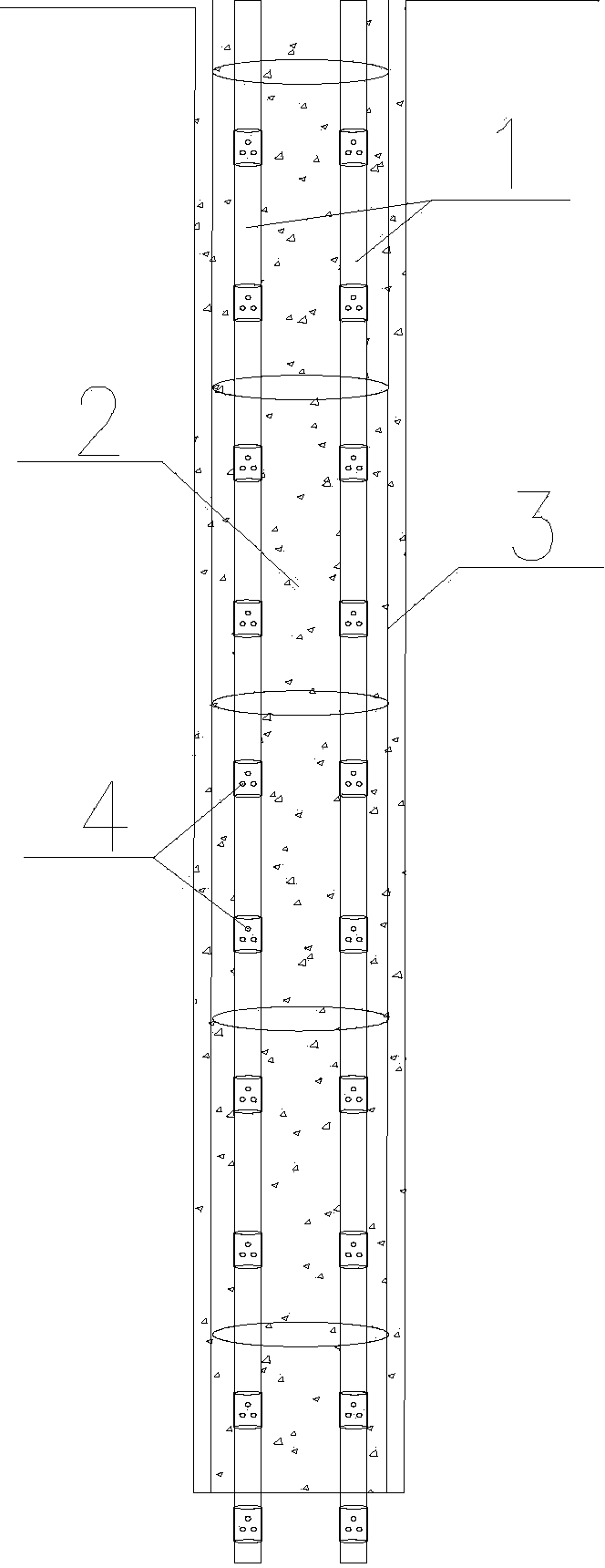

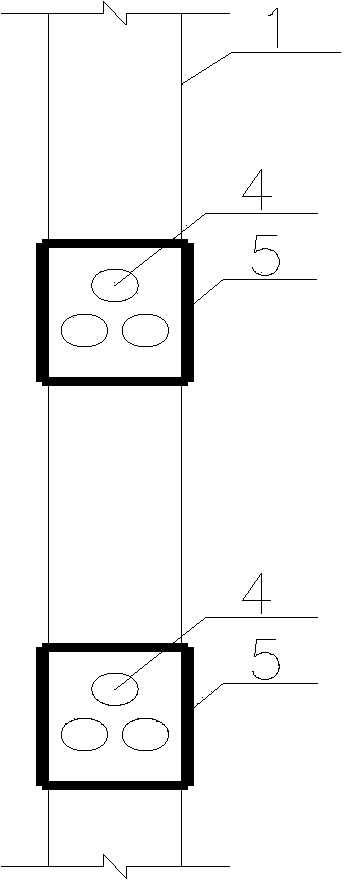

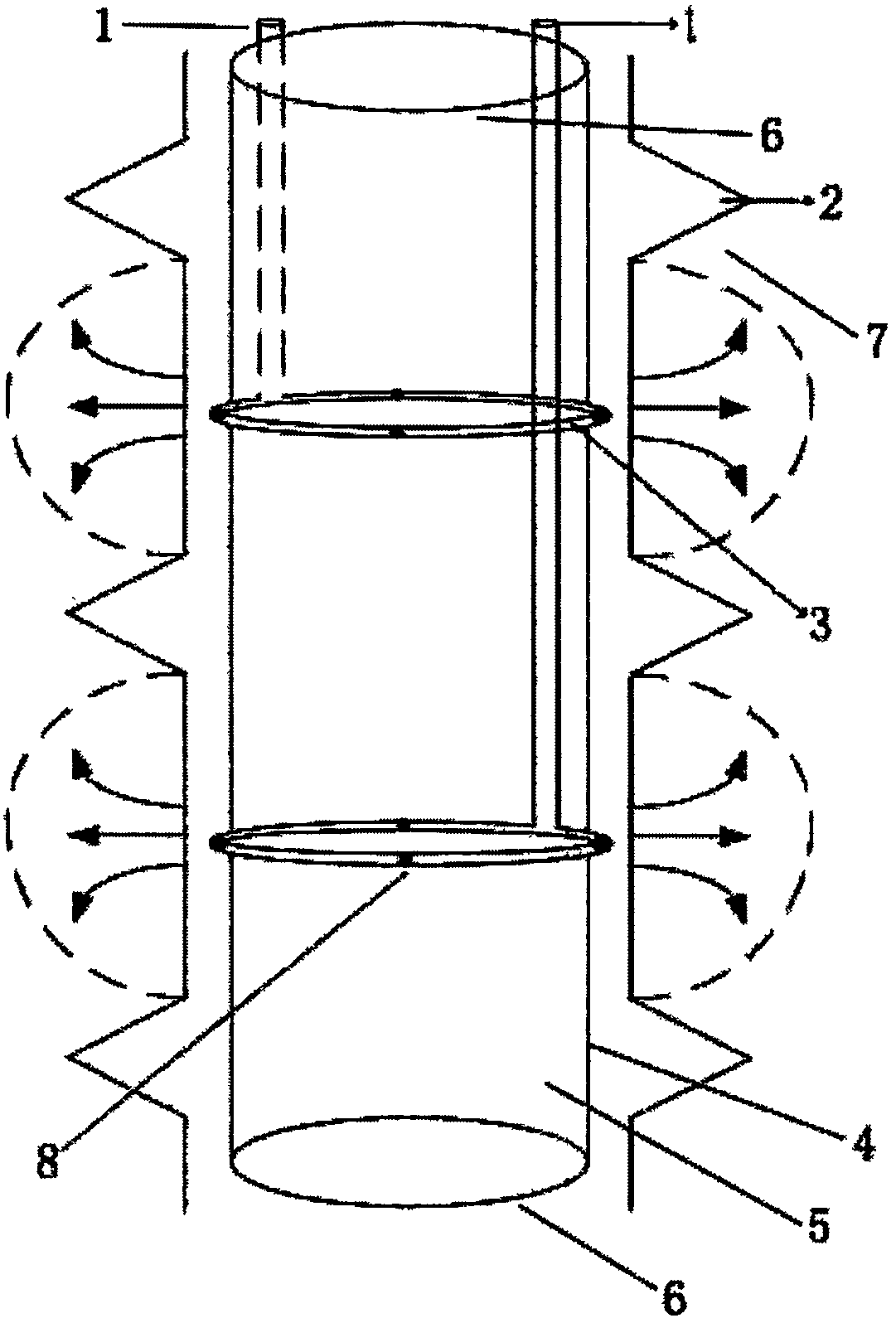

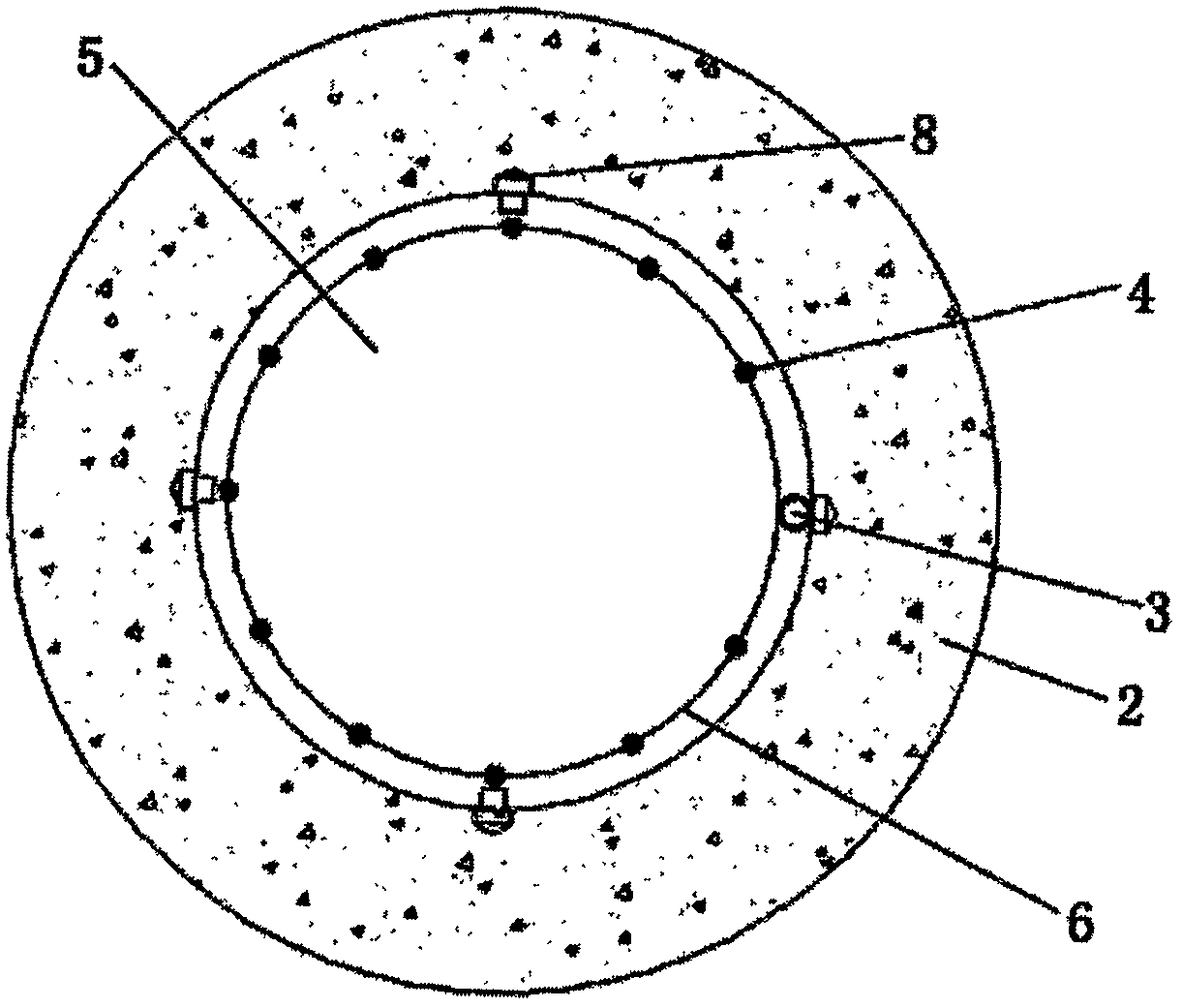

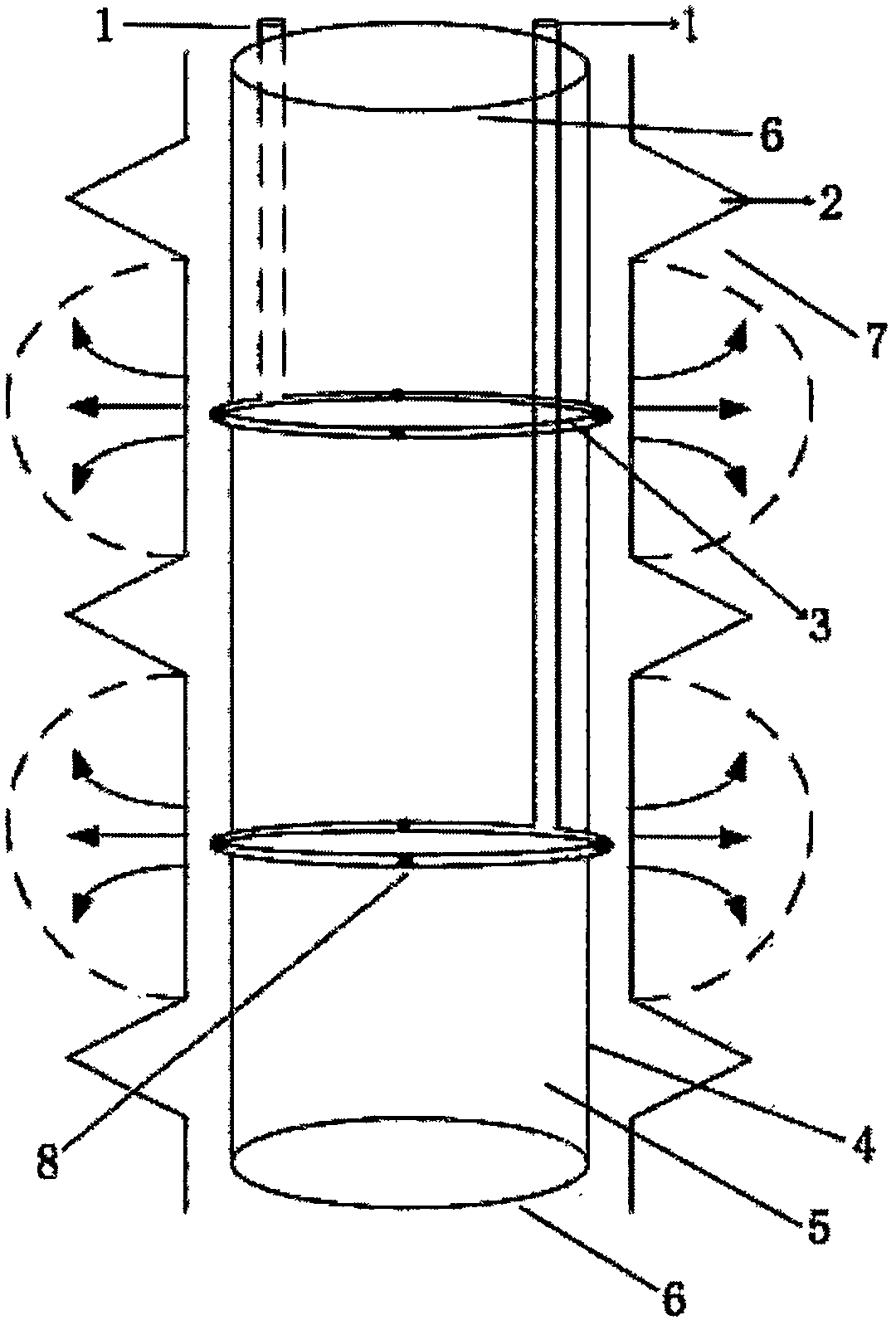

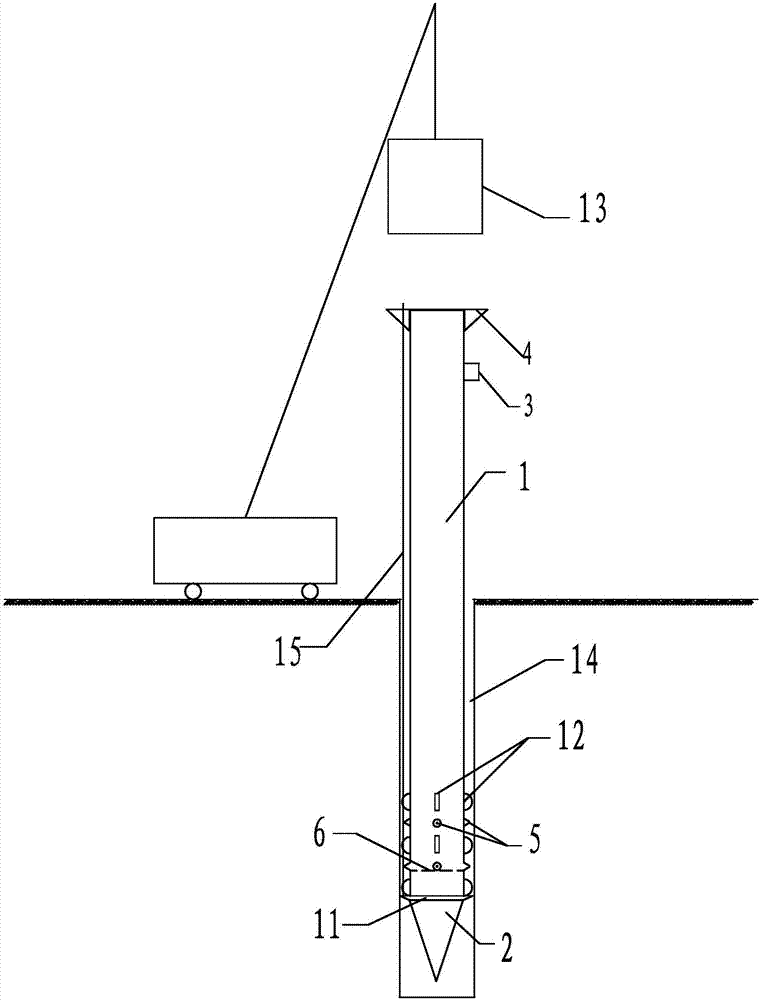

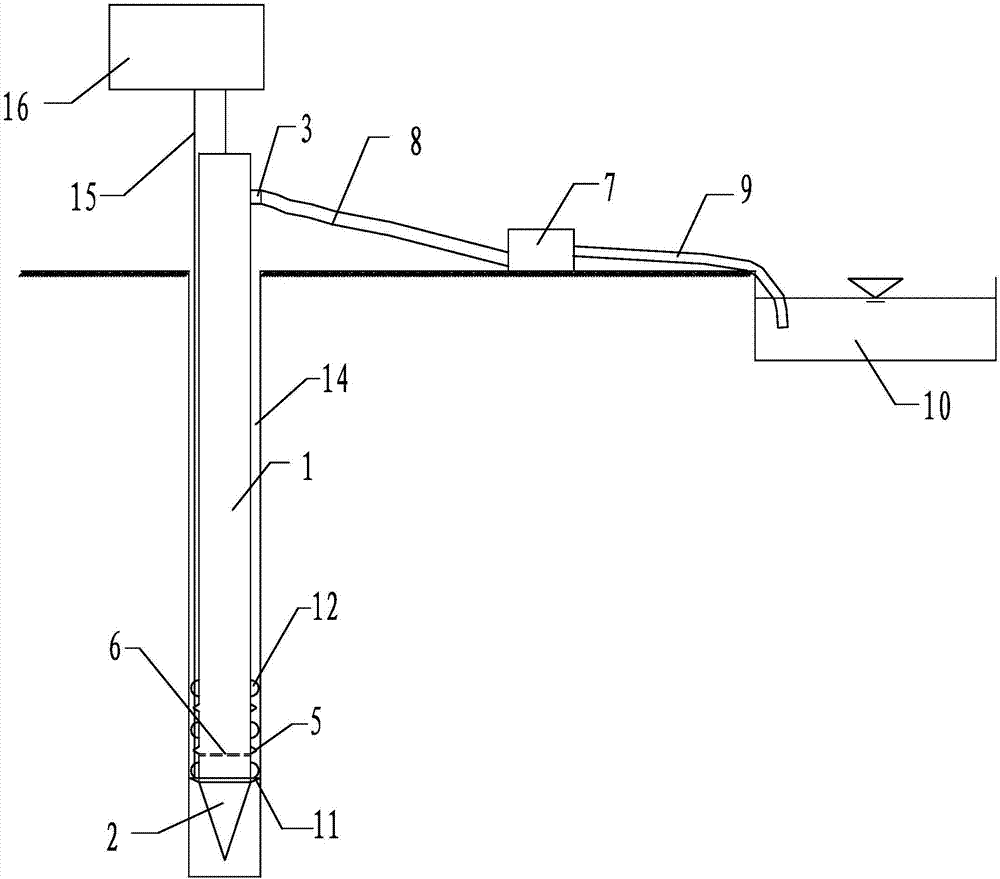

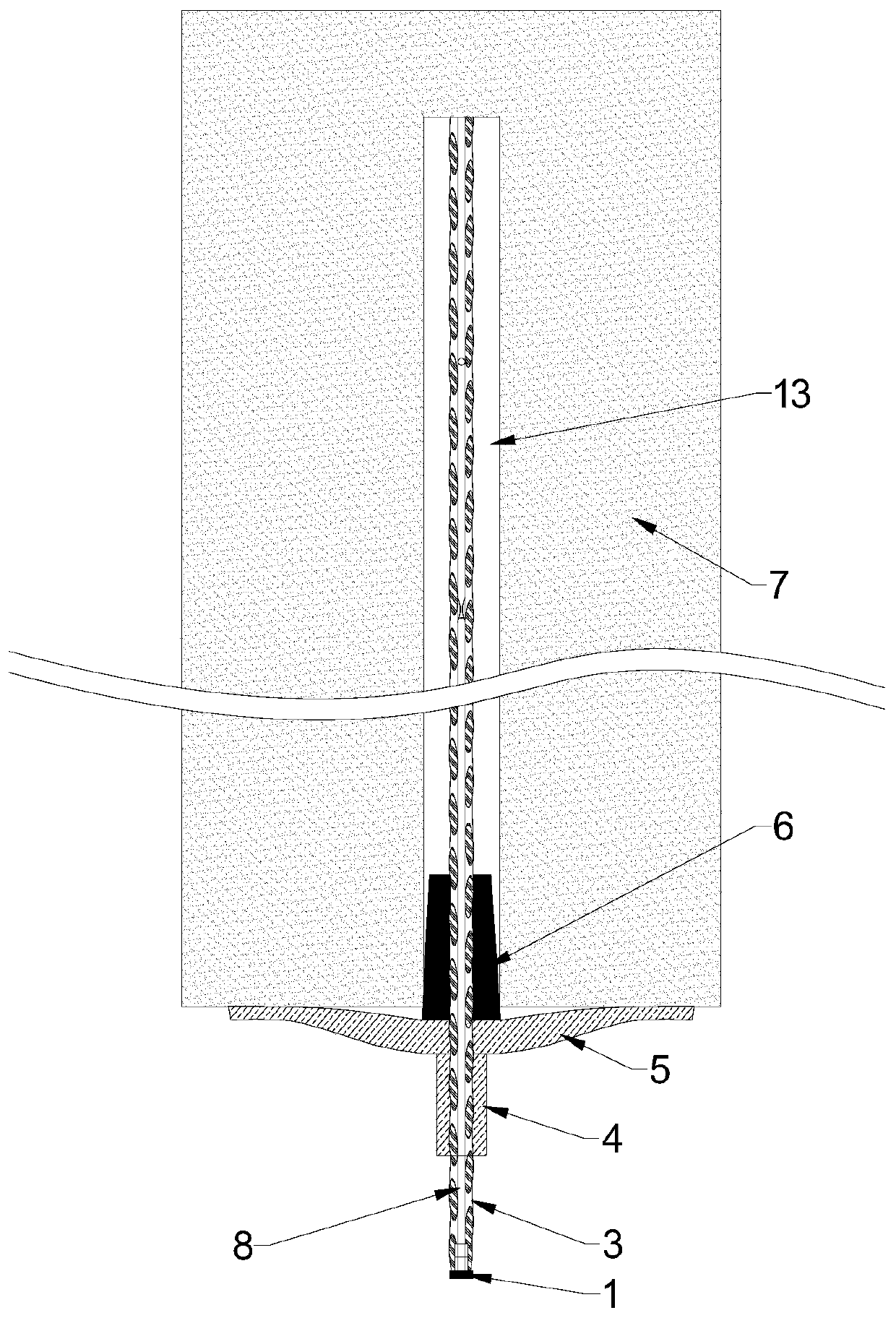

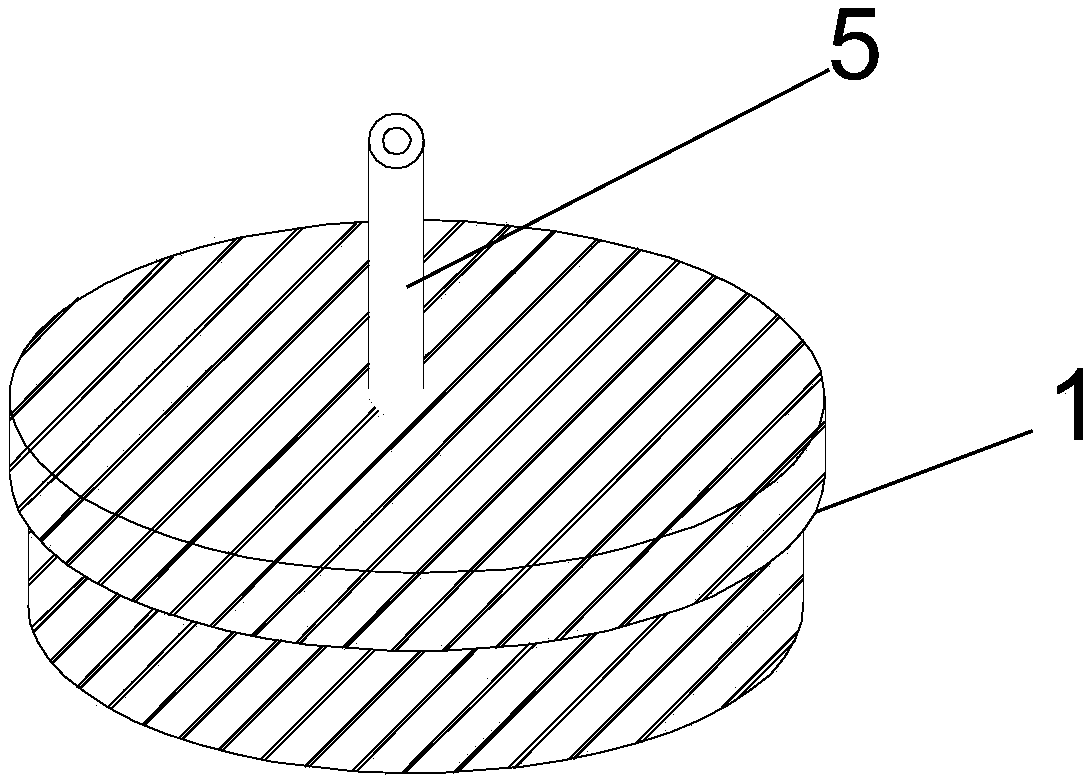

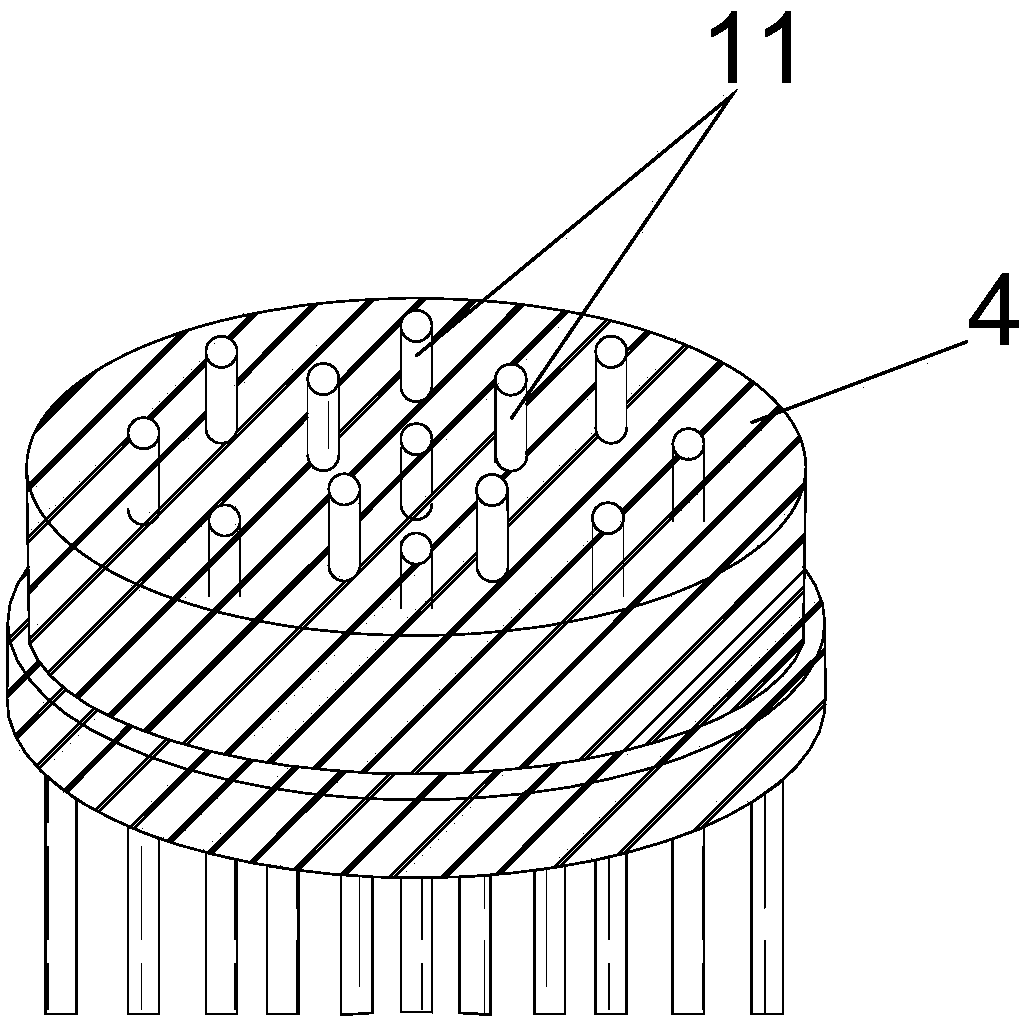

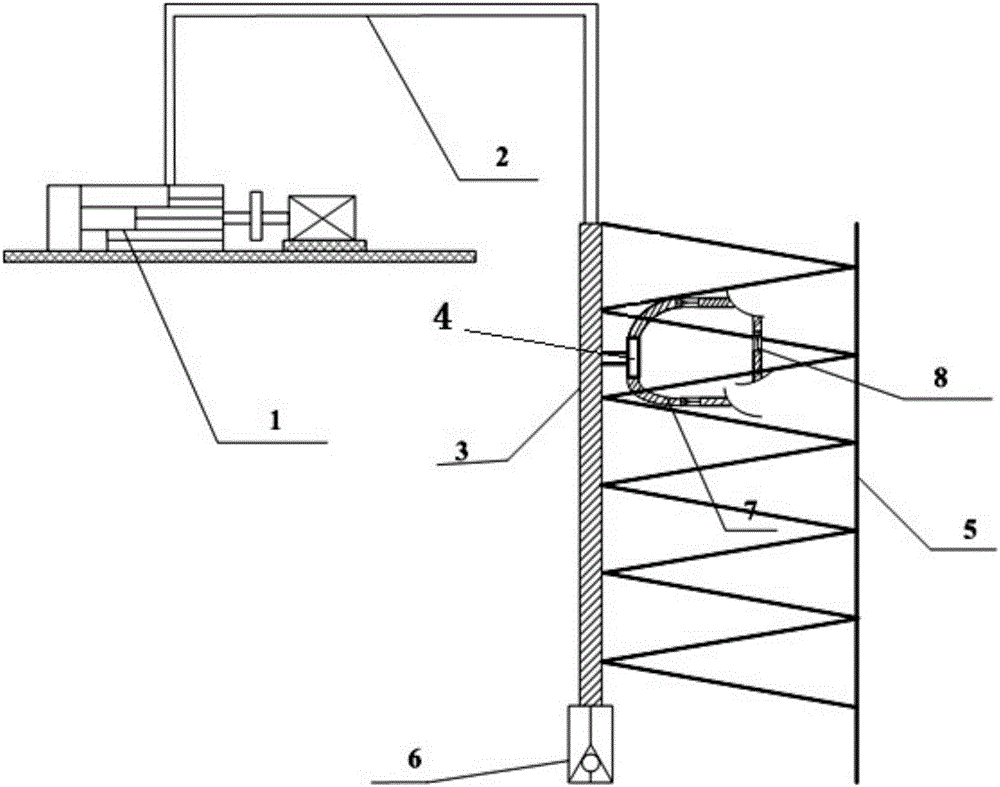

Pile body longitudinal multipoint grouting device

The invention belongs to grouting devices behind cast-in-place concrete piles, and discloses a pile body longitudinal multipoint grouting device. The device can be widely applied to pile foundations adopted by building pressure bearing or extraction resisting. The device is provided with a grouting guide pipe extending from the ground to a pile end, guide pipe side wall grouting holes and a controllable grouting core pipe which can move vertically and be inserted into the guide pipe. According to the device, grouting is achieved on pile side grouting devices with different elevations at the pile end and the guide pipe, pile body grouting is more uniform, the effect is more reliable, and building quality can be guaranteed conveniently.

Owner:EAST CHINA ARCHITECTURAL DESIGN & RES INST

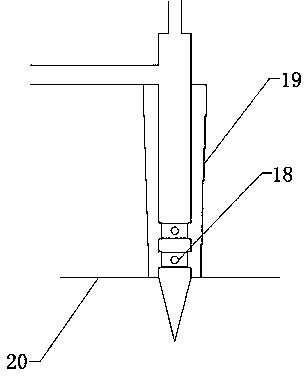

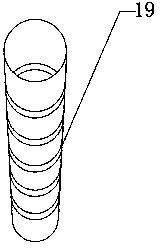

Portable intelligent high-pressure grouting system and grouting method of metamorphic concretes

ActiveCN104196030AReduce dosageEnsure construction efficiencyFoundation engineeringEngineeringHigh pressure

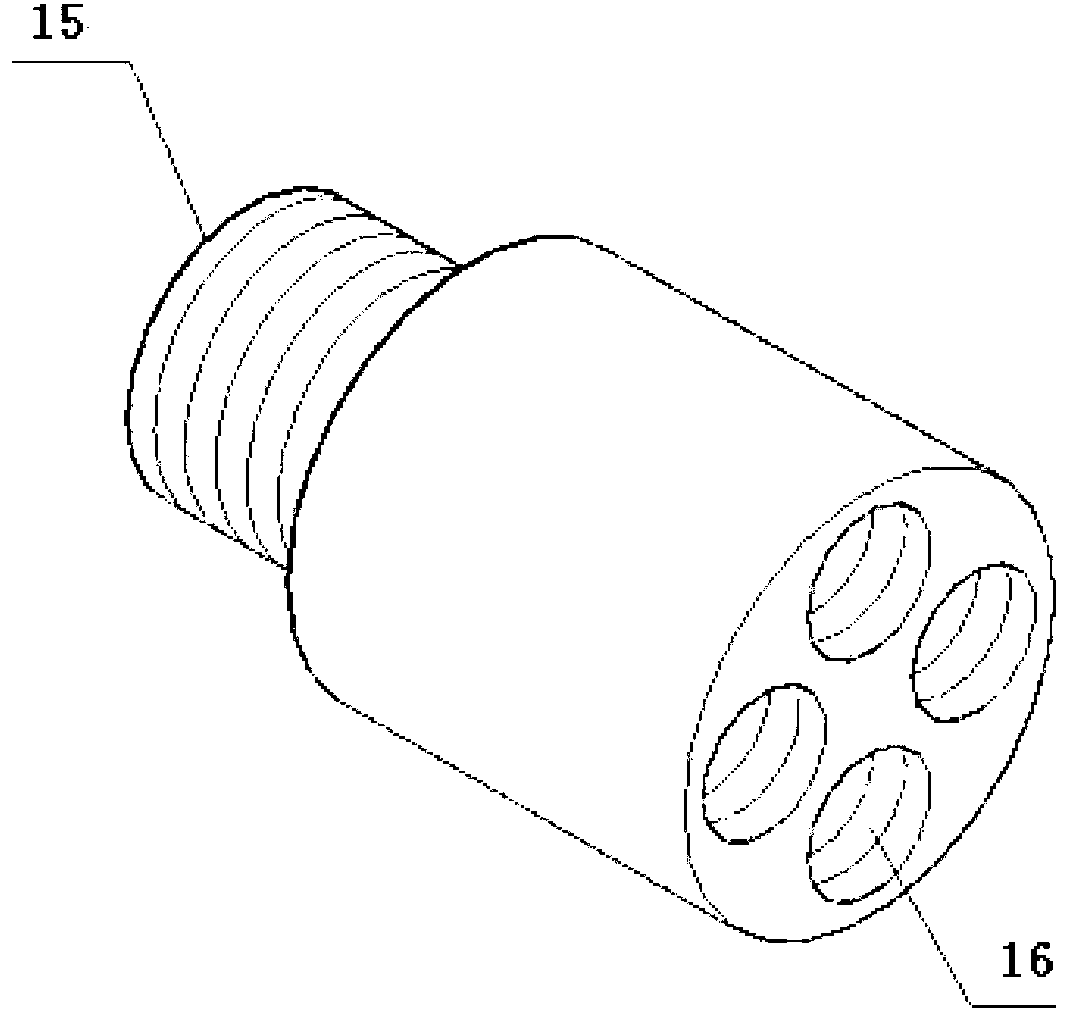

The invention discloses a portable intelligent high-pressure grouting system and a grouting method of metamorphic concretes. The portable intelligent high-pressure grouting system comprises a pulp feeding barrel, a pulp pump and a grouting bar which are connected though pipelines. A grouting head in a tapered shape is arranged on the grouting bar. Circular grooves are formed in the upper portion of the grouting head and internally provided with grouting holes. The tail end of the grouting bar is connected with an electric hammer. The grouting method includes the steps such as grouting and backflowing. The portable intelligent high-pressure grouting system and the grouting method are applied to automatic construction of the metamorphic concretes, construction efficiency is improved, construction workers are fewer, and grouting quantity of the metamorphic concretes is saved.

Owner:SINOHYDRO BUREAU 7 CO LTD +1

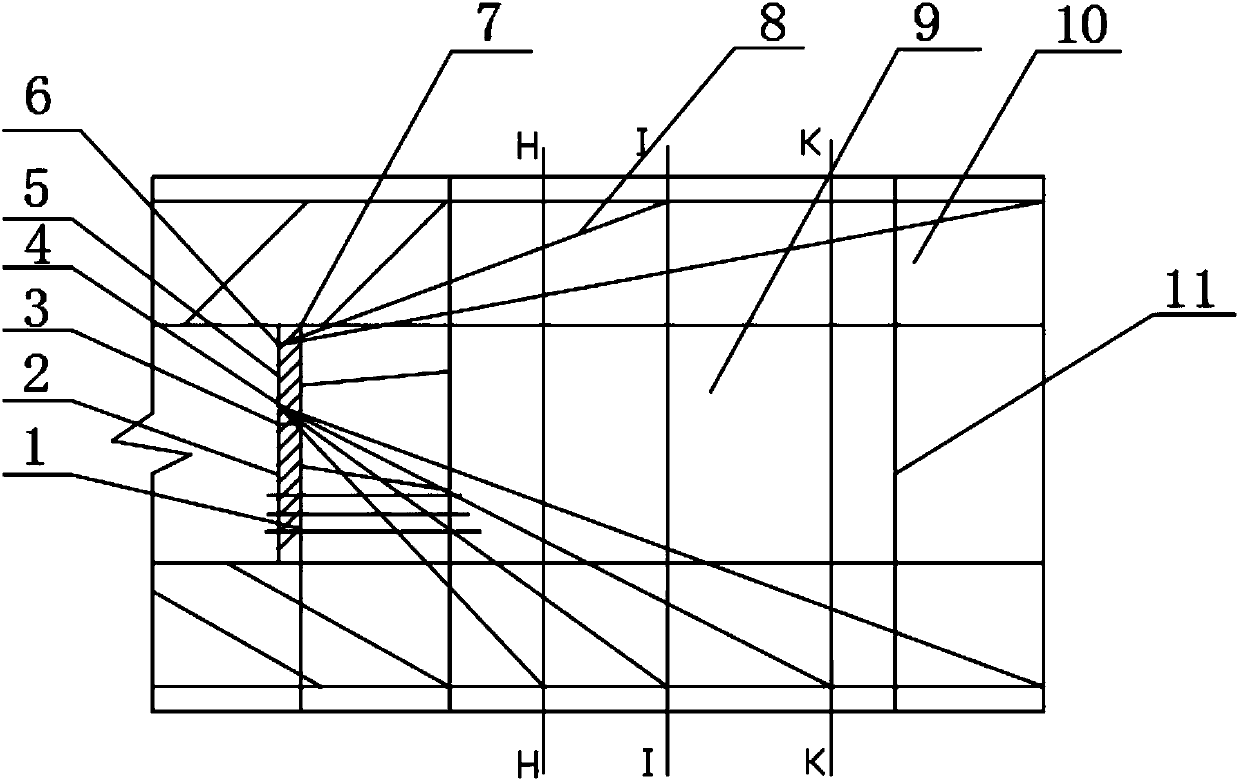

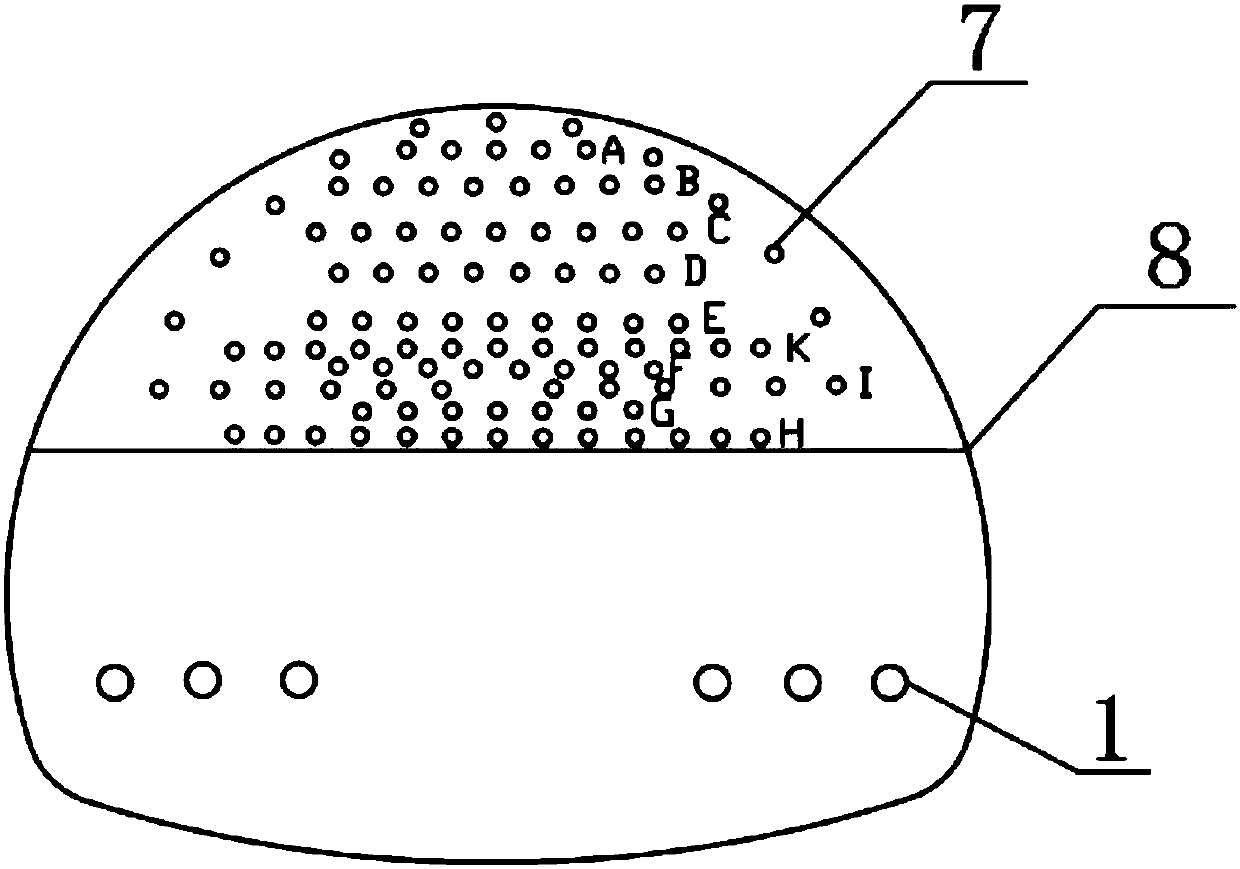

Advanced pre-grouting method for high-pressure water-rich soft surrounding rock mountain tunnel

ActiveCN107762533AEven groutingReinforce weak surrounding rockUnderground chambersDrainageGeomorphologyGrout curtain

The invention discloses an advanced pre-grouting method for a high-pressure water-rich soft surrounding rock mountain tunnel. Drainage holes, a lower fracture face, a tunnel face, a grout stopping laccolith, a grout stopping wall, an upper fracture face, upper-stage grouting holes, a tunnel, an advanced grouting area, a grouting curtain reinforcing area and a lower-stage grouting area are included. The advanced pre-grouting method has the beneficial effects that surrounding rock located in front of the tunnel face is reinforced through an upper-blocking and lower-draining grouting method, andthe grouting holes are formed in the upper fracture face to conduct full fracture face curtain grouting; the drainage holes are formed in the lower fracture face, the water pressure of the surroundingrock in front of the tunnel face is reduced through the drainage holes, and draining and blocking are conducted simultaneously, so that the effects of uniform and dense grouting and soft surroundingrock reinforcing are achieved; and the problem that the pressure of water in the high-pressure water-rich surrounding rock is high, and thus grouting is difficult is solved, and the grouting construction cost is reduced advantageously.

Owner:中交中南工程局有限公司 +1

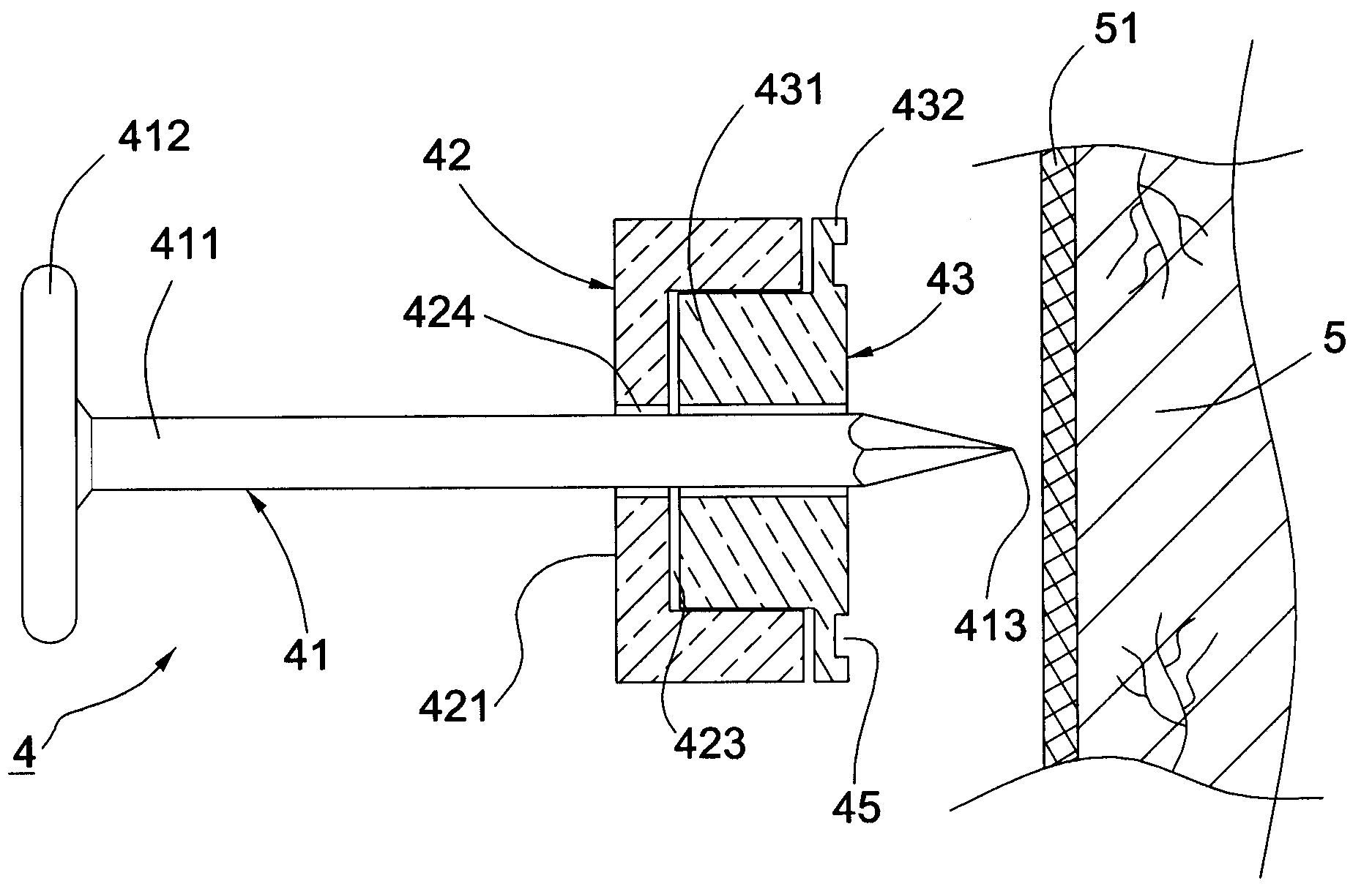

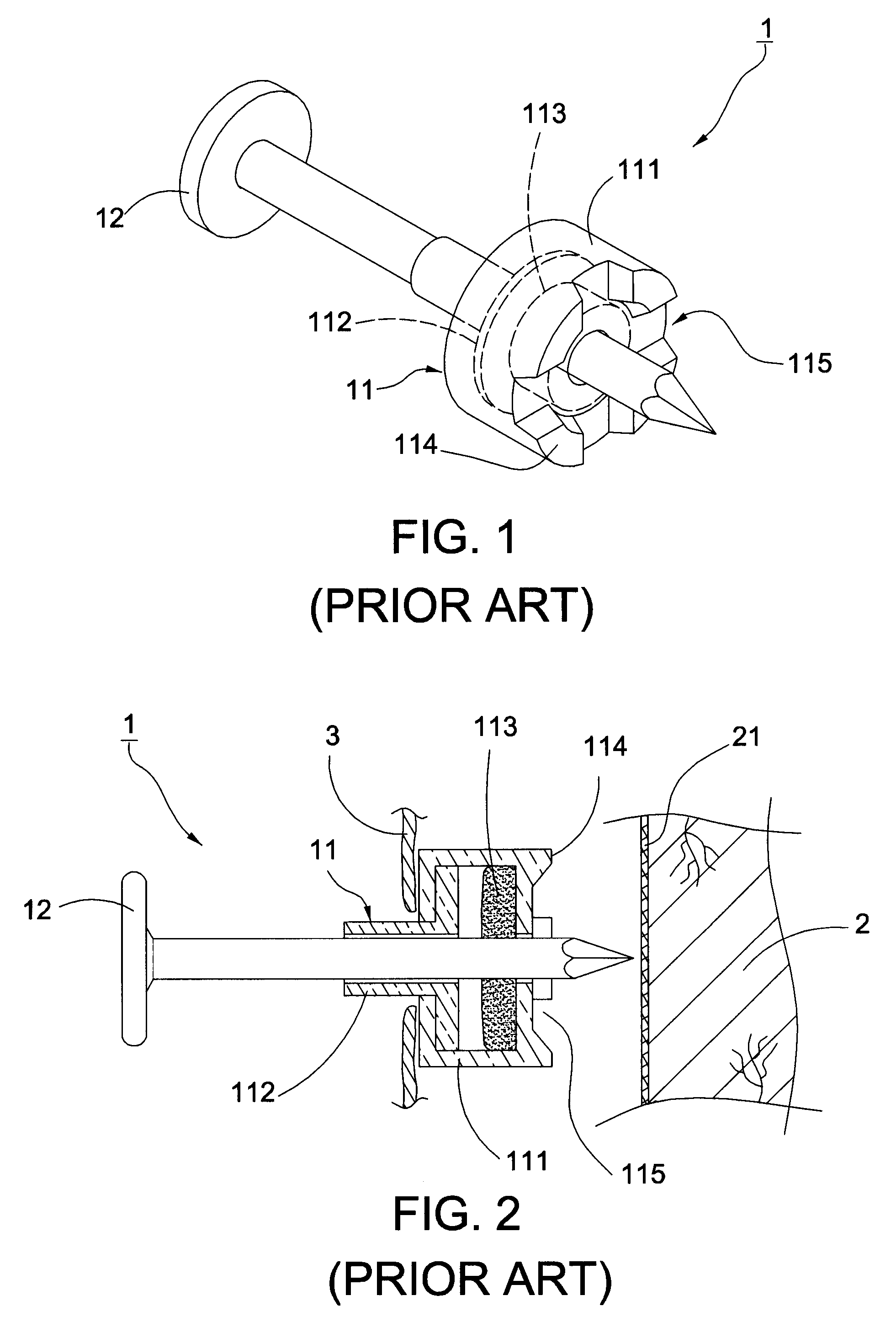

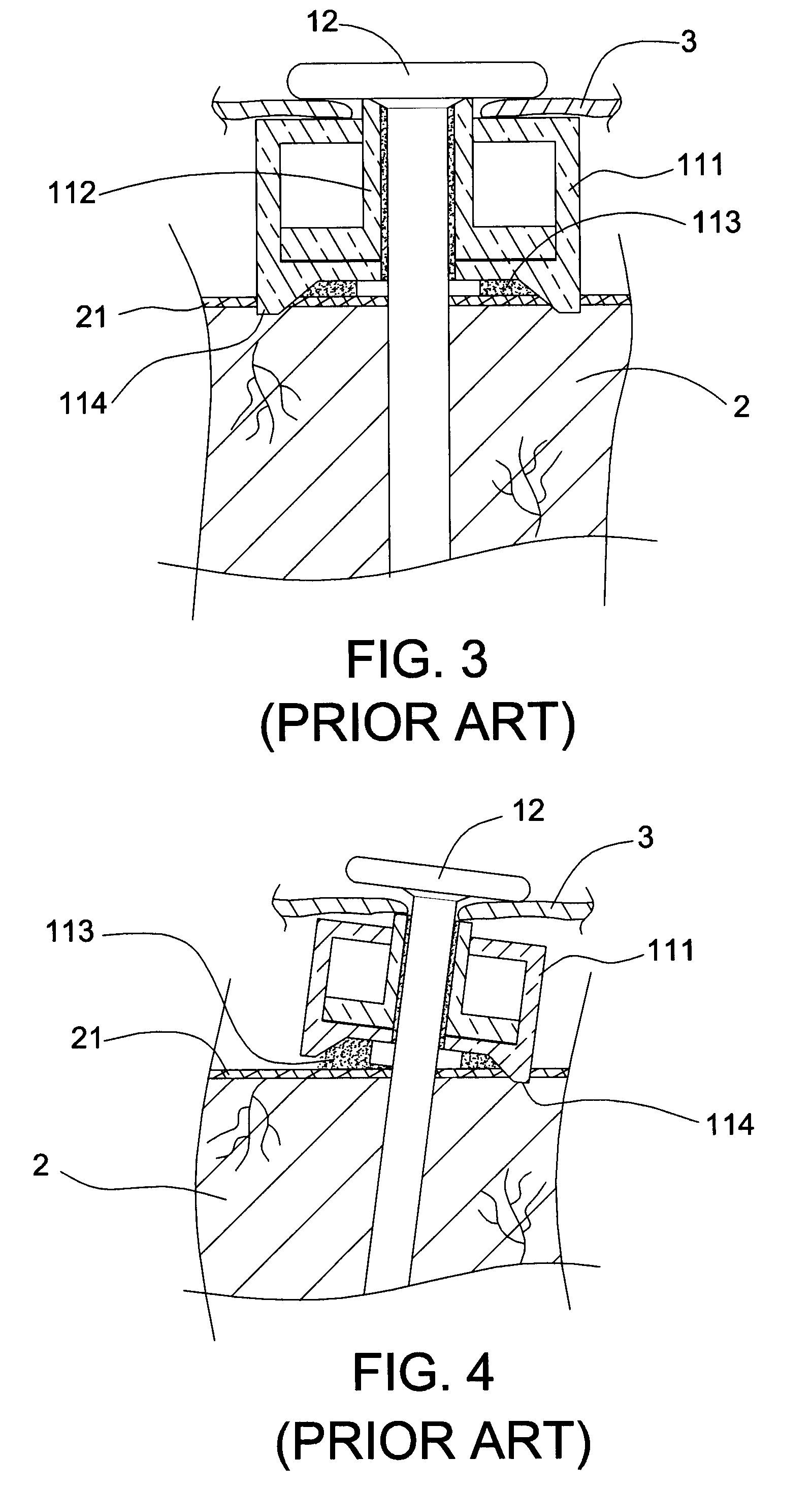

Assemblage of sealing nail

InactiveUS20100212244A1Improve sealing efficiencySmooth hammering operationCeilingsCovering/liningsPropellerEngineering

The present invention pertains to an assemblage of sealing nail essentially containing a nail, a propeller, and a blocker that is partially extended beyond the propeller. Wherein, the nail would sequentially penetrate the propeller, the blocker, and then a plank. By means of the nail entering the plank, the propeller and the blocker would be simultaneously urged to densely cover up where the nail inserted. Therefore, a preferred sealing efficiency between the nail and the plank is achieved to guarantee a favorable grouting on the plank.

Owner:YU BO ZHANG

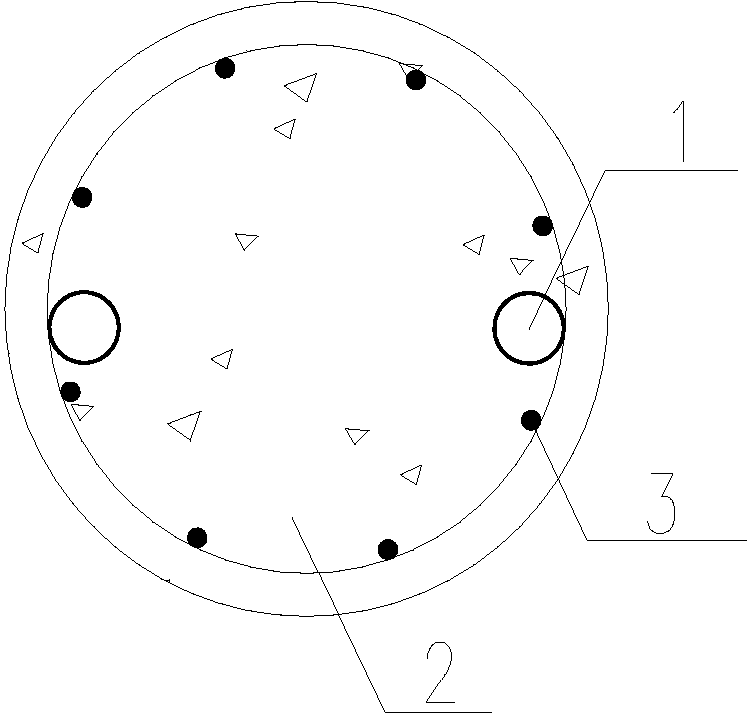

Novel squeeze-expansion branch/plate forming device combined with post-grouting process and operation method thereof

The invention provides a novel squeeze-expansion branch / plate forming device combined with a post-grouting process and an operation method thereof. The novel squeeze-expansion branch / plate forming device structurally comprises a steel reinforcement cage, the outer circumference of the steel reinforcement cage is sleeved by a plurality of transversely-arranged annular grouting pipes from top to bottom, and four one-way throttling grouting valves are evenly arranged on the annular grouting pipes. A plurality of spiral stirrups are arranged on the side wall of the steel reinforcement cage; a plurality of vertically-arranged main reinforcements which are connected with the spiral stirrups in a crossed mode are further evenly distributed on the side wall of the steel reinforcement cage, and a plurality of vertically-arranged galvanized grouting pipes which are fixed to the spiral stirrups and the main reinforcements are further evenly distributed on the side wall of the steel reinforcementcage, and the tops of the galvanized grouting pipes are higher than the top face of the steel reinforcement cage. Due to the design of the four one-way throttling grouting valves, grouting uniformitycan be guaranteed; a protruding slurry ladle stone body can be formed through the squeezing effect of pile side slurry and a soil body, under the combined action of the stone body and upper and lowerbranches / plates under a vertical load of a pile top, a good stress system is formed, the overall firmness and the bearing capacity of the whole branch / plate pile generated after grouting are greatly improved, and the influence of a soil body void area on the bearing capacity of a pile foundation can be greatly reduced.

Owner:HEBEI UNIV OF ENG

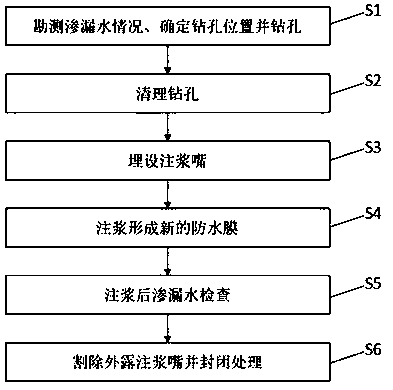

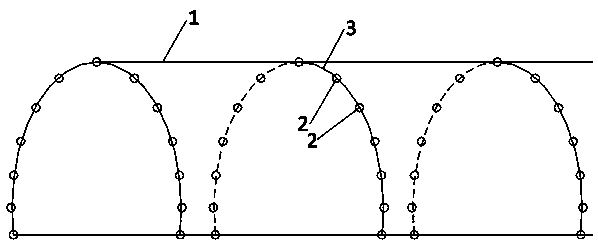

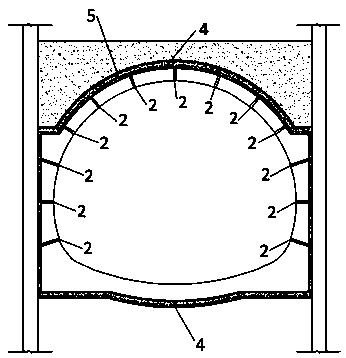

Water seepage and crack regional overall treatment method for open excavation tunnel of high speed railway

ActiveCN109653777AEven groutingEnsure safe serviceUnderground chambersTunnel liningWater leakageUltimate tensile strength

The invention discloses a water seepage and crack regional overall treatment method for an open excavation tunnel of a high speed railway. The method comprises the following steps: surveying a water leakage situation, determining a drilling position and drilling; cleaning the drilled hole; embedding a grouting nozzle; grouting to form a new waterproof membrane; performing water leakage inspectionafter grouting is performed; and cutting and removing the exposed grouting nozzle and performing sealing treatment. The invention provides the water seepage and crack regional overall treatment methodfor the open excavation tunnel of the high speed railway which forms integrated structural strength by lining aiming at the characteristics of the open excavation tunnel of the high speed railway, particularly at the complex tunnel situations of large number of water leakage cracks, wide distribution range and the leakage of unplugged cracks in the periphery caused by plugging one crack; integrated grouting in rings in the overall cross section is adopted, and grouting holes are uniformly distributed in each ring, so that uniform grouting at the positions, such as an arch top, a hance and a side wall, can be realized; and regional overall treatment is performed to form a new waterproof system, so that guarantee is provided for safety service of a tunnel structure.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

Collapsible loess compaction pile construction device and method capable of reducing thickness of falling soil

The invention provides a collapsible loess compaction pile construction device and method capable of reducing the thickness of falling soil. The collapsible loess compaction pile construction device comprises a hammering device and a hole forming pile pipe. A grouting hole is formed in the position, lower than a hammering protective sleeve, of the upper end of the hole forming pile pipe, and the length of a pipe body below the grouting hole is equal to or larger than the depth of pile holes. A plurality of grout spraying holes are formed in the positions, higher than an expansion ring, of the lower end of the hole forming pile pipe. The construction process of a compaction pile comprises the steps that after pile hole construction is completed by hammering the sinking pipe, the grouting hole is connected with a grouting pump, grout spraying operation is uniformly conducted on the walls of the pile holes through the grout spraying holes in the wall of the hole forming pile pipe in the pipe pulling process, the inner wall surfaces of the pile holes are cured, and filling work is conducted after curing. According to the collapsible loess compaction pile construction device and method capable of reducing the thickness of the falling soil, construction is easy, the quantity of the falling soil on the hole walls is decreased through curing of the hole wall surfaces, the situation that layered compaction of plain soil / lime soil subsequently is affected due to the fact that the falling soil is thick in the hole forming process is avoided, the pile hole depth is also ensured, and the construction progress and the construction quality are improved.

Owner:WUHAN SURVEYING GEOTECHN RES INST OF MCC

Construction method for pedestal piles

The invention discloses a construction method for pedestal piles, which includes the following steps that at a predetermined pile position, a drilling machine is utilized to drill a hole to a set depth, and filler is filled into the drilled hole by pressure; a steel casing is inserted into the drilled hole; filler and dry concrete are filled from the opening of the top of the steel casing, and after repetitive ramming, an expanded pedestal is formed and hammering is stopped; a precast tubular pile is put in from the opening of the top of the steel casing; after grouting operation is completed, the steel casing is upwardly pulled out by vibration, and thereby the construction of a pedestal pile is complete. The construction method for pedestal piles designed by the invention has the following advantages that the construction period is short, the efficiency is high, moreover, the quality of the fabricated pile foundation is good, the construction cost is low, and the bearing capability is high.

Owner:张红

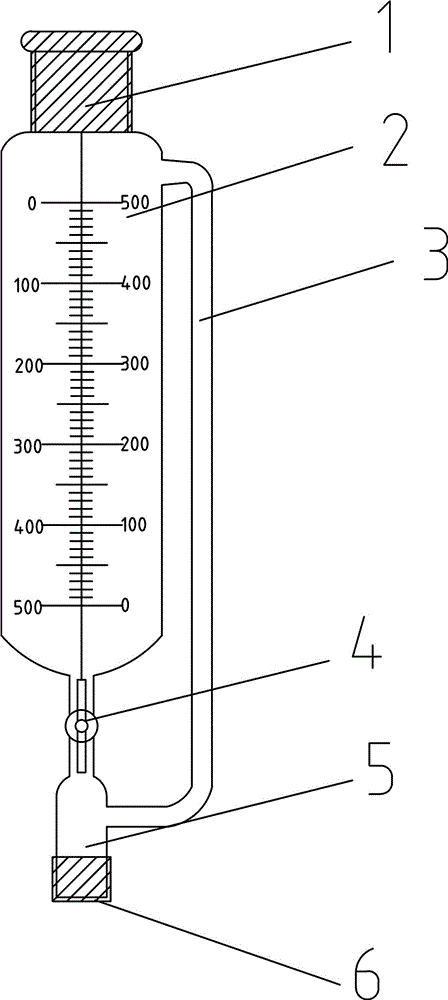

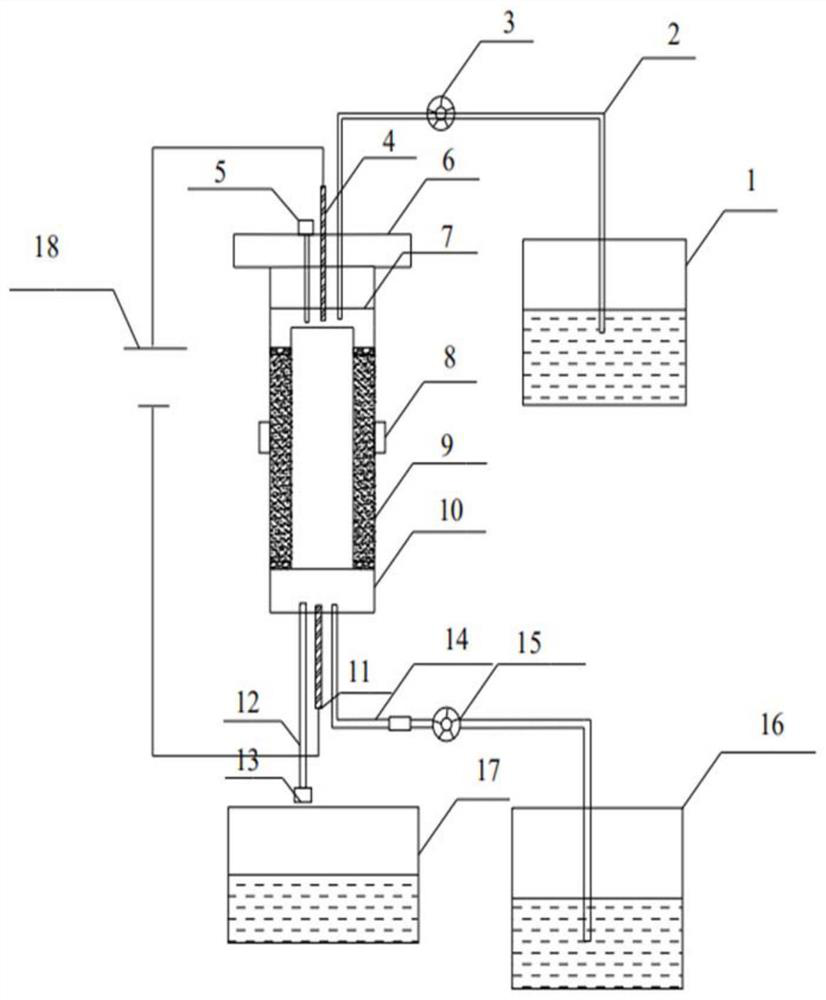

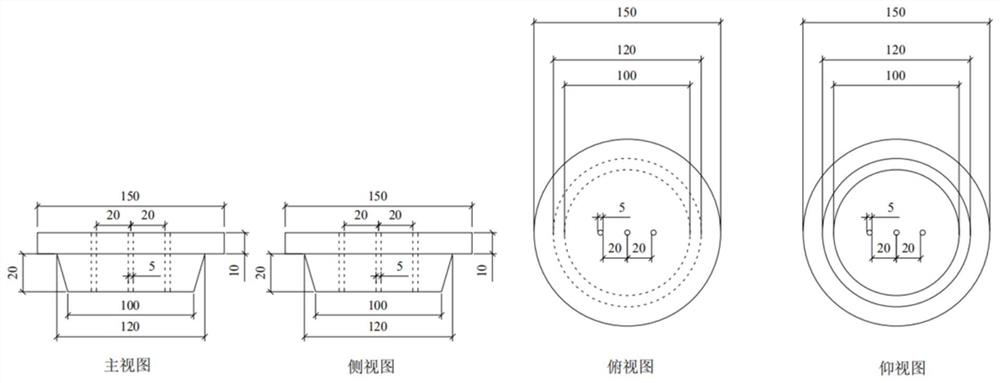

Microbe reinforcing sand column grouting device and test method thereof

PendingCN106771083ARealize visualizationEven groutingEarth material testingEngineeringLaboratory facility

The invention relates to a microbe reinforcing sand column grouting device, which comprises a constant-pressure funnel, wherein the constant-pressure funnel communicates with a grouting spray head through a grouting hose; the grouting spray head communicates with the upper end of a glass sleeve; in the grouting spray head, a liquid inlet pipe communicates with a spray disc body; a water outlet hole regulating switch is arranged on the spray disc body; a plurality of water outlet holes are uniformly distributed in the spray disc body; a plurality of sleeve wall holes are uniformly distributed in the sleeve wall of the glass sleeve; a hollow sleeve cover is matched with two ends of the glass sleeve; a plurality of sleeve cover holes are uniformly distributed in the sleeve cover; a hollow clamp opening plug is matched with the lower end of the glass sleeve; a liquid discharging hole is formed in the middle part of the clamp opening plug; a liquid discharging pipe is connected onto the liquid discharging hole; a rubber sleeve is matched with the glass sleeve. The microbe reinforcing sand column grouting device and a test method thereof provided by the invention have the advantages that the problem of the laboratory microbe reinforcing sand column grouting problem can be solved; the visualization of the whole grouting process can be realized; the probability of unsatisfactory test result or even failure due to nonuniform bonding of the sand column because of the nonuniform grouting is reduced.

Owner:CHINA THREE GORGES UNIV

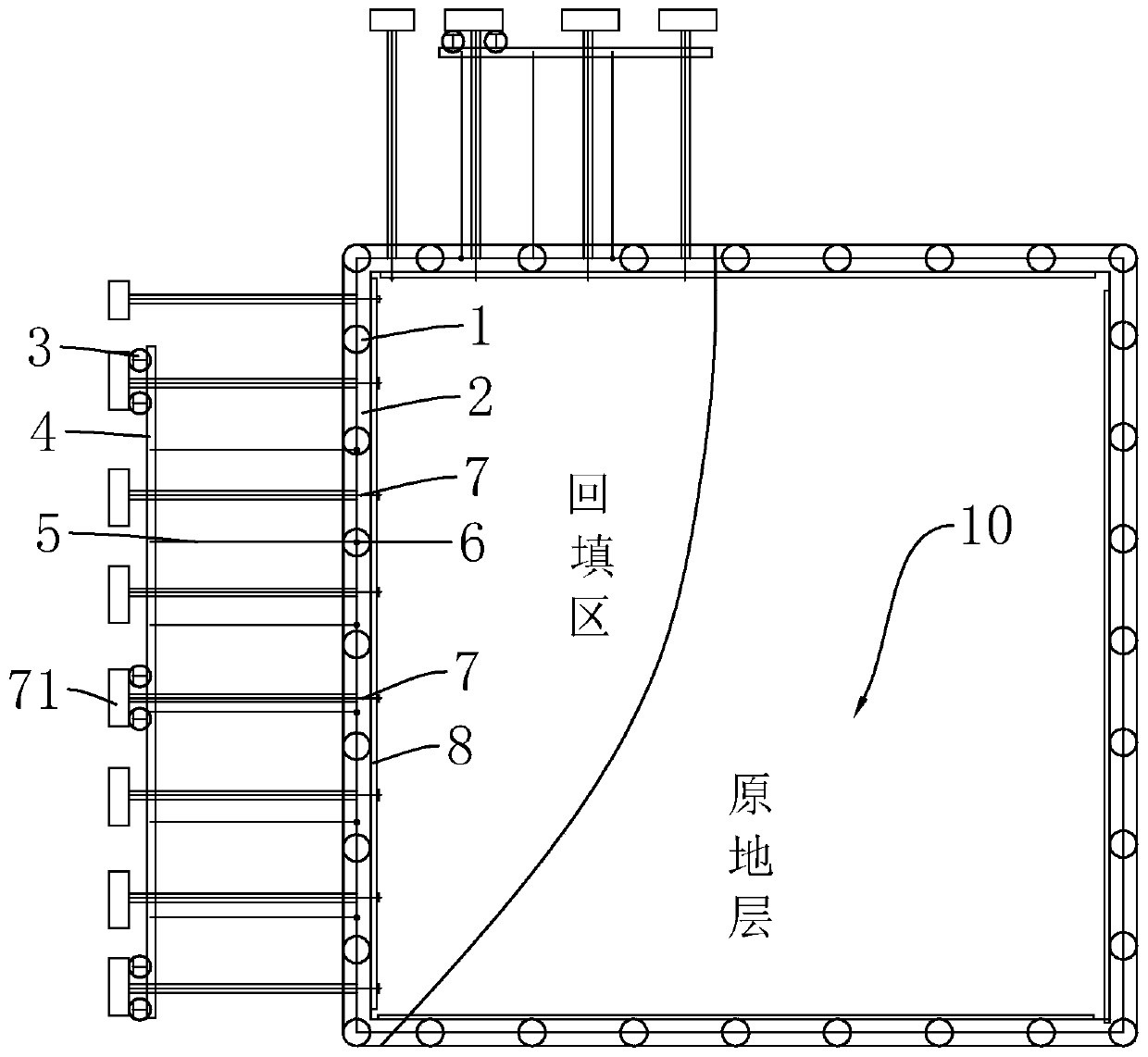

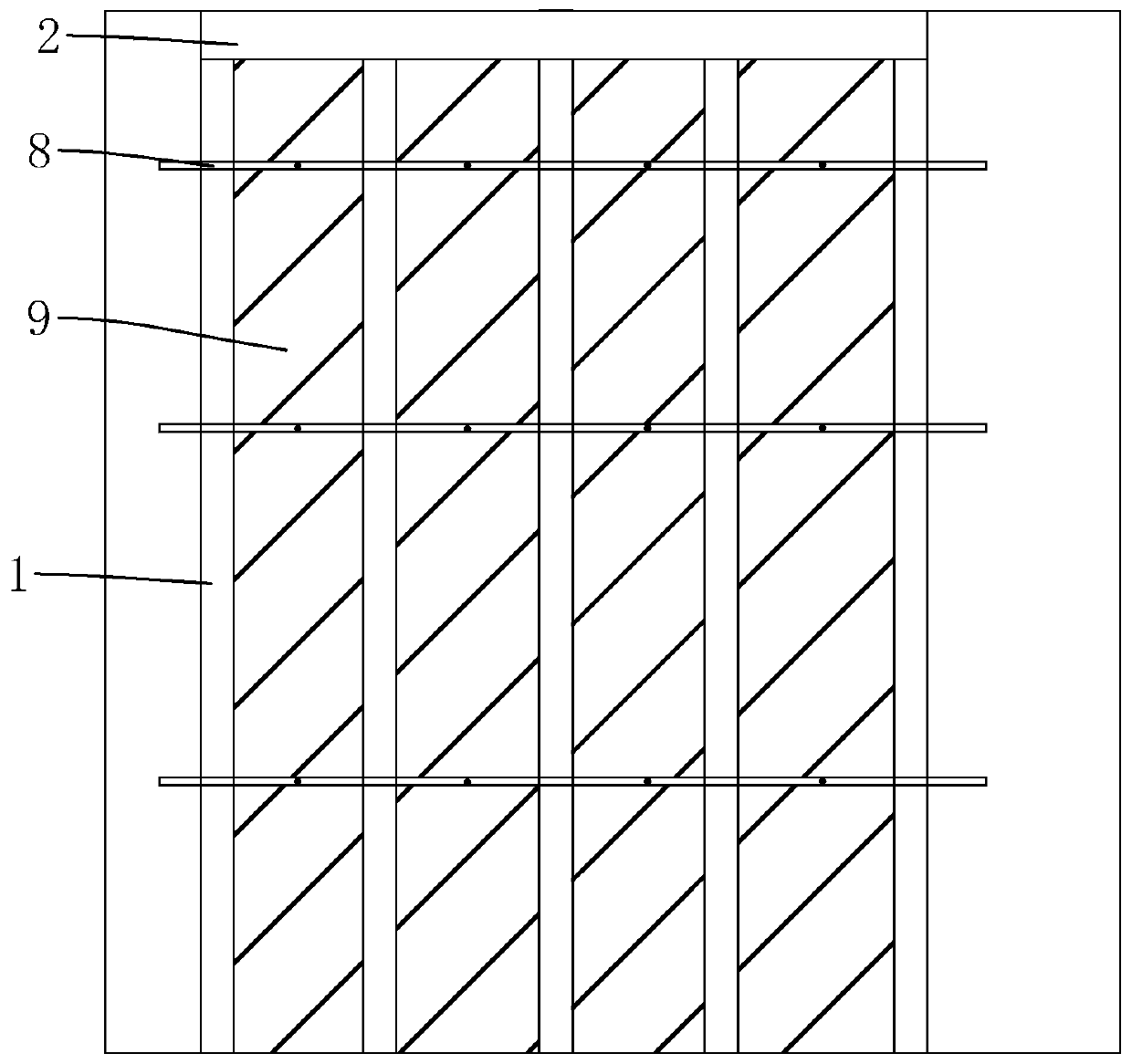

Backfill area foundation pit supporting structure and construction method thereof

InactiveCN111560962AGeneration of controlEasy to control the amount of groutExcavationsBulkheads/pilesSoil mixingRock bolt

The invention relates to a construction method of a backfill area foundation pit supporting structure. The construction method comprises the following steps: S1, constructing slope protection piles and top beams; S2, constructing a plurality of pairs of profile steel cement soil mixing piles on the sides, away from a foundation pit to be excavated, of the slope protection piles, wherein each pairof profile steel cement soil mixing piles are arranged at intervals, the multiple pairs of profile steel cement soil mixing piles are connected into a whole through cross beams, and the cross beams are connected with the top beams of the supporting piles in a pulled mode; S3, excavating the foundation pit in a layered mode, and then carrying out anchor rod construction on the side wall of the foundation pit, wherein the tail ends of the anchor rods penetrate through the space between each pair of profile steel cement soil mixing piles, grouting is carried out in anchor rod holes, sectional grouting is adopted, and expanded heads are formed at the ends, extending out of the profile steel cement soil mixing piles, of the anchor rods; and S4, carrying out waist beam construction, and carryingout excavation of a foundation pit of the next layer. The profile steel cement soil mixing piles are arranged behind the slope protection piles, the pulling and fixing effects on the slope protectionpiles are achieved, meanwhile, anchor rod grouting bodies are matched with the profile steel cement soil mixing piles to increase the pulling resistance of the anchor rods, and therefore the stability of pile-anchor supporting is improved.

Owner:北京市地质工程有限责任公司

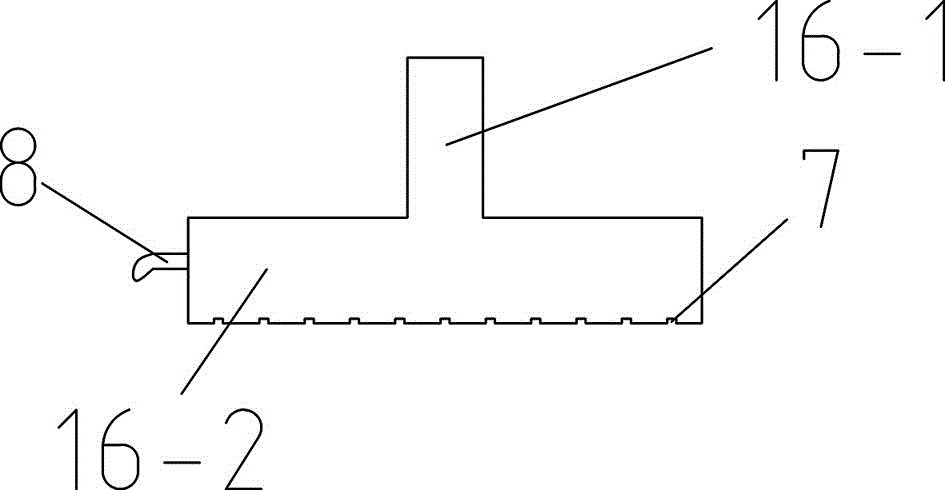

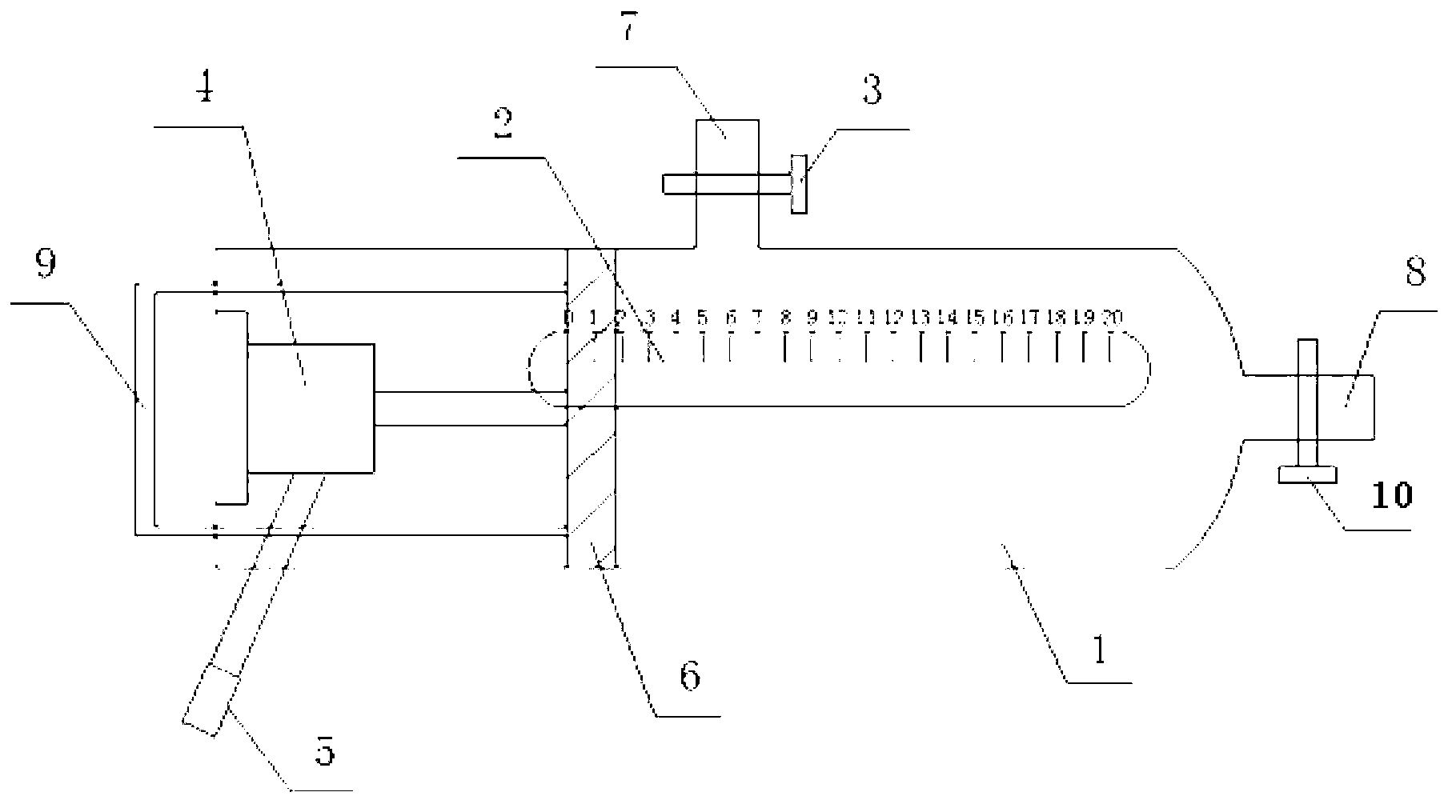

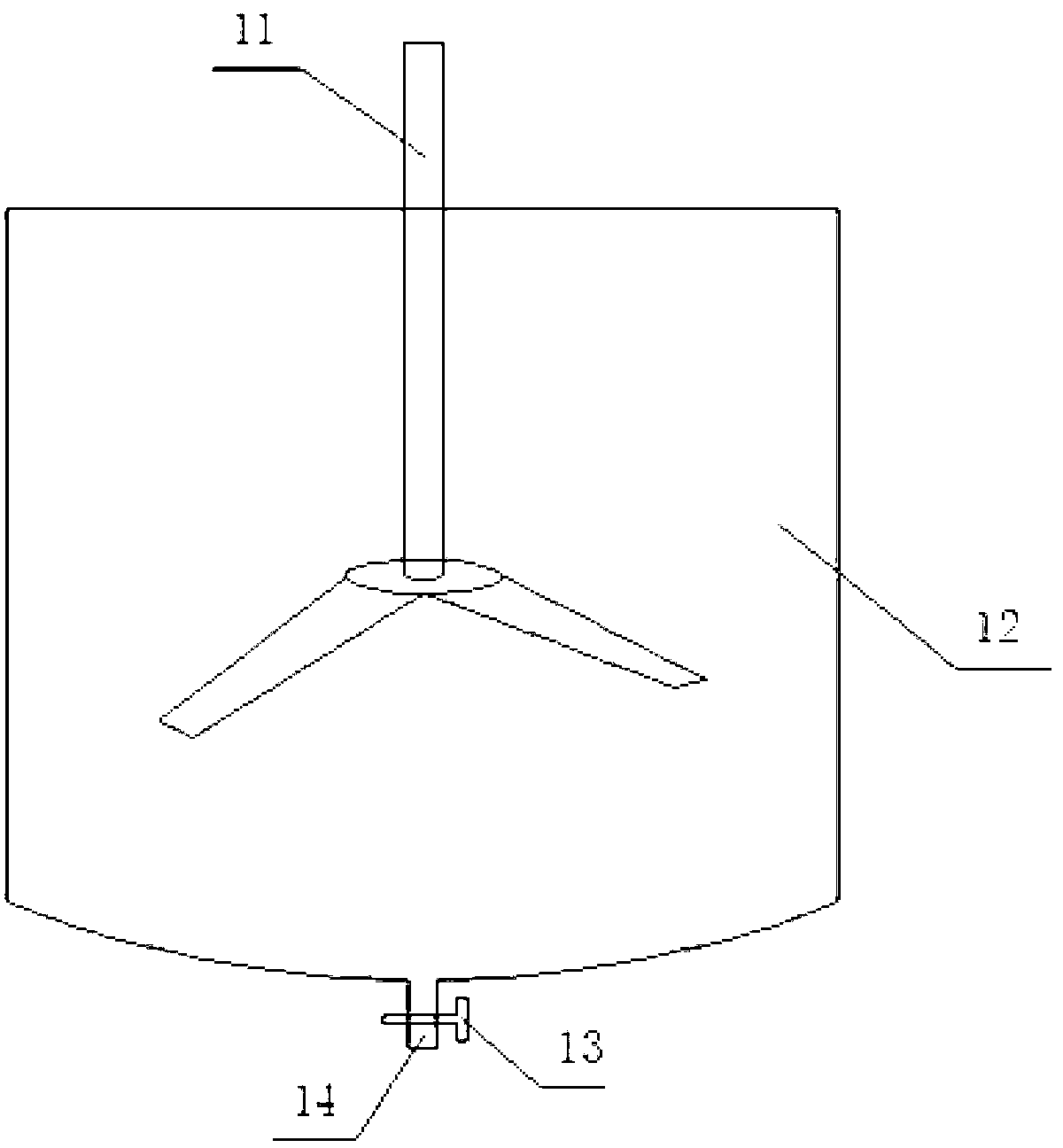

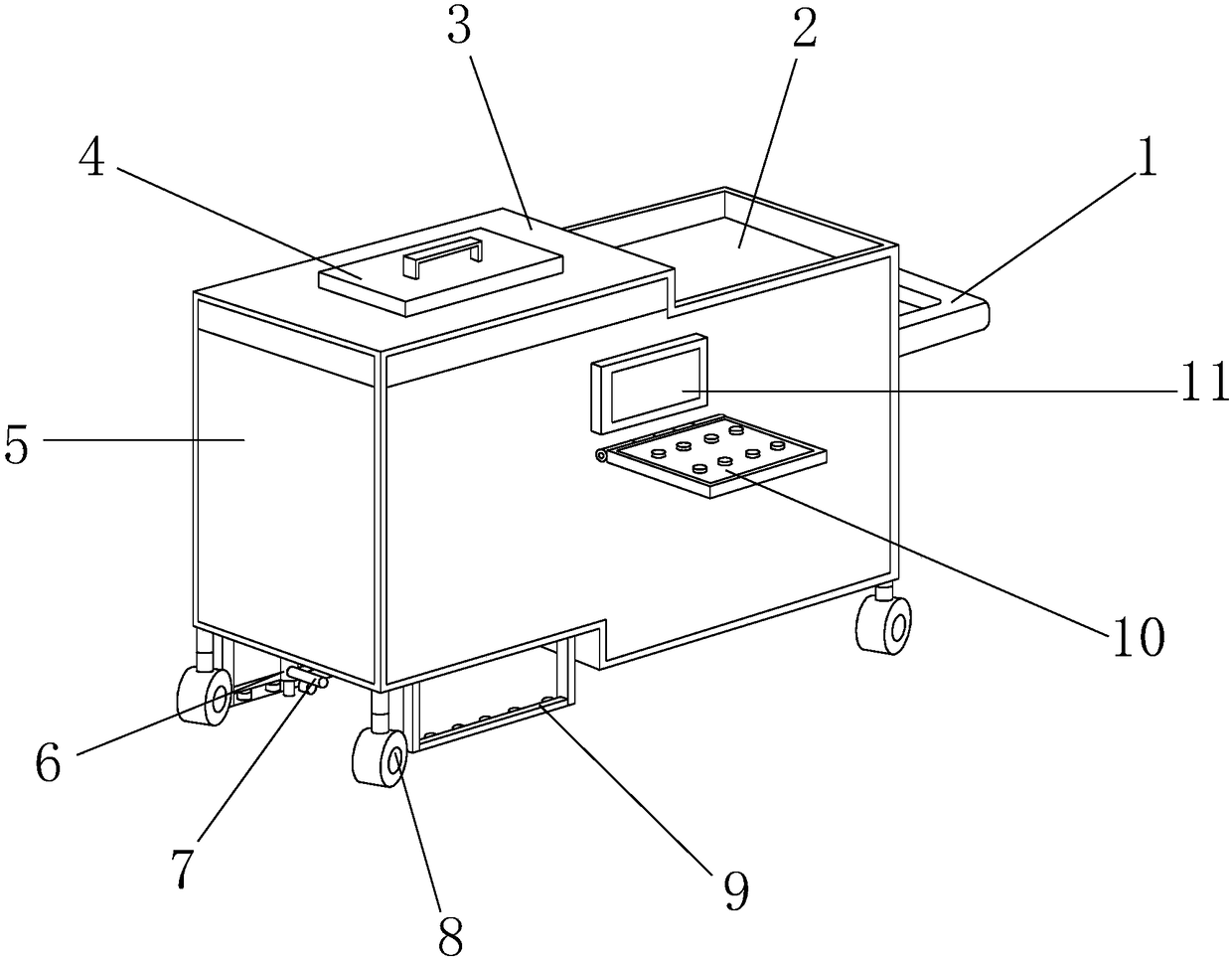

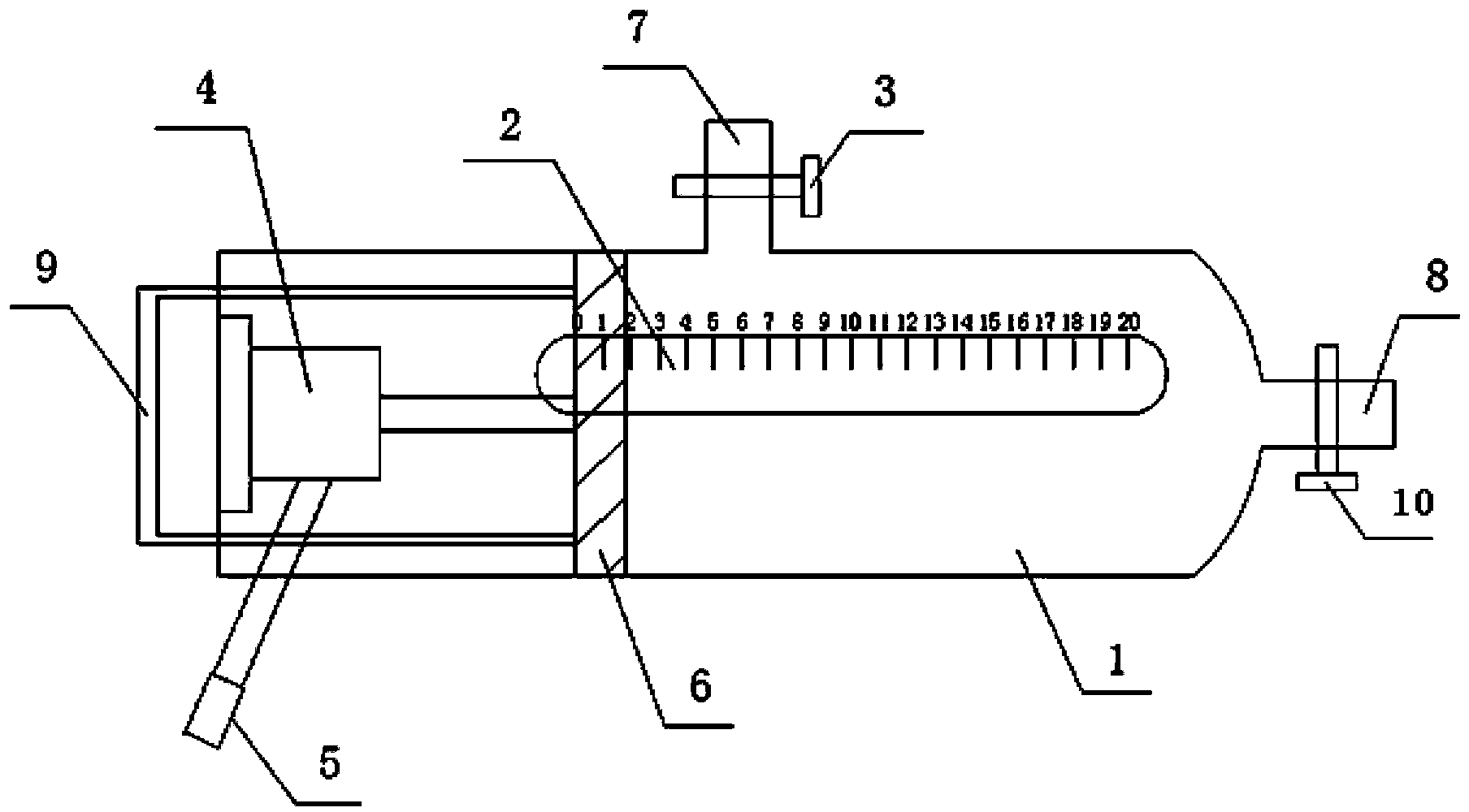

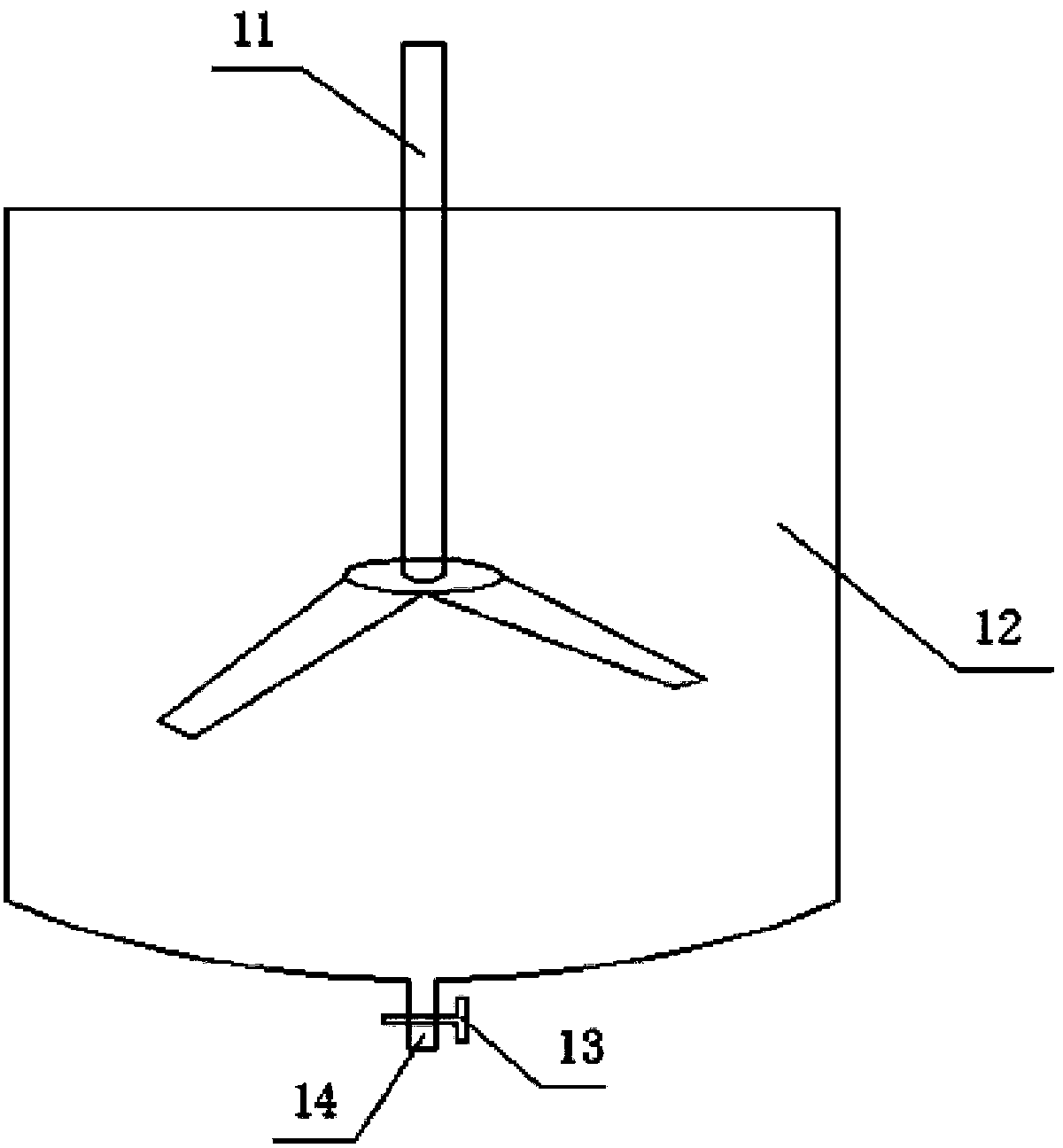

Novel pouring device for model test and application method

The invention discloses a novel pouring device for a model test and an application method. The novel pouring device comprises a slurry stirring device, wherein the slurry stirring device is connected with a pouring pressure device through slurry feeding pipes, the pouring pressure device is connected with a slurry feeding pipe conversion device through the slurry feeding pipes, and the slurry feeding pipe conversion device is connected with pouring pipes through the slurry feeding pipes. The novel pouring device provided by the invention has the advantages that the device is simple, the operation is convenient, the detachability is strong, and the transportation is convenient; the pouring pressure device is provided with marks, the pouring quantity is controlled, the pressurization can be easily and manually carried out and is free from limitation of energy such as power supply; the slurry feeding pipe conversion device can realize simultaneous pouring by using multiple pouring pipes, the number of the starch feeding pipes of pouring is simultaneously controlled, and the pouring efficiency is notably improved; and once uniform pouring can be realized through the bottoms of the pouring pipes and pouring holes in pipe walls, and the pouring effect is notable.

Owner:李泽硕

Continuous production equipment of embossed gypsum ceiling

The invention discloses continuous production equipment of an embossed gypsum ceiling, comprising a raw material conveying mechanism, a stirrer, a water tank, a finished product die assembling and disassembling mechanism, a shaking table, a material-blocking scraping plate, a finished product roller way conveyer and a distribution control tank. The continuous production equipment realizes the continuous production of the embossed gypsum ceiling by utilizing all components. The continuous production equipment has the advantages of simple structure, compact operation, single program, high production efficiency, uniform and thick grouting, high quality of finished products and attractive appearance.

Owner:宁俊岭

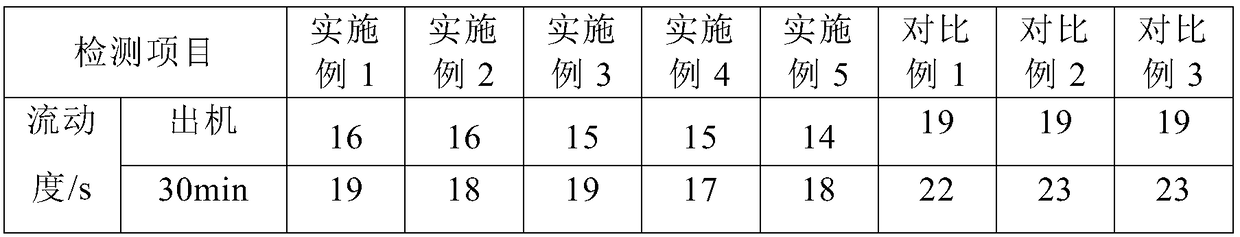

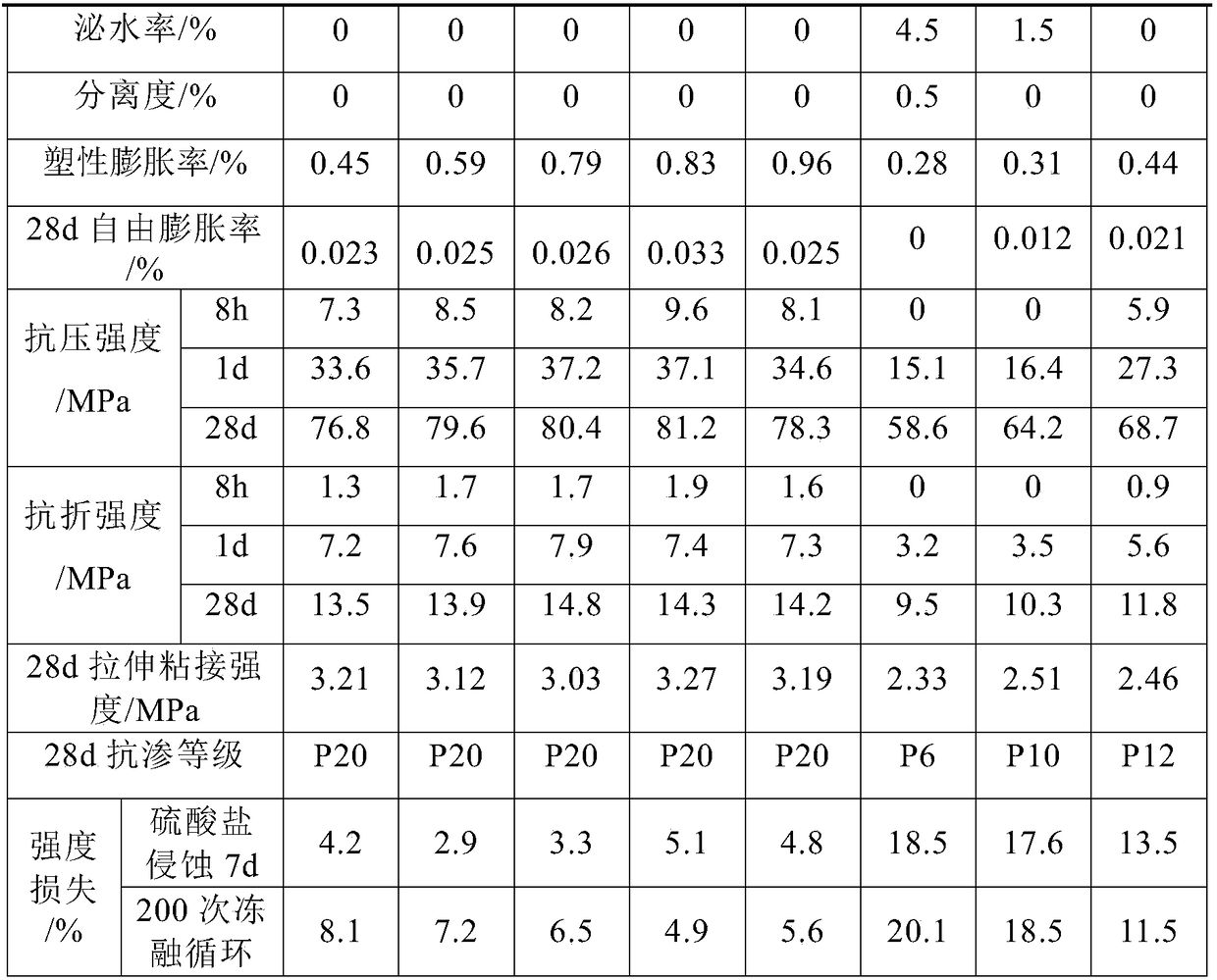

Ultrafine inorganic grouting material for tunnel inverted arches, and preparation method thereof

ActiveCN109020419AGuaranteed mechanical propertiesImprove early strengthWater reducerMaterials science

The invention discloses an ultrafine inorganic grouting material for tunnel inverted arches. The grouting material comprises, by mass, 75-90% of an ultrafine cementing material, 5-20% of a mineral filler, 2.5-7.5% of a composite expansion agent, 0.04-0.08% of a fluid volume stabilizer, 0.5-1.5% of a film forming modifier, 0.4-0.8% of a water reducer, 0.02-0.05% of a defoamer, 0.1-0.4% of a dispersant, 0.05-0.1% of an anti-seepage water repellent and 1-5% of a nano-reinforcing component. Above components are uniformly mixed, water is added according to a water-cement ratio of 0.25-0.30, and stirring is performed to obtain the grouting material which can be used for grouting reinforcement portions and defect parts of the tunnel inverted arches. The inorganic grouting material obtained in theinvention is suitable for repairing and stabilizing defects and dangerous rock bodies of tunnel inverted arches at 5-35 DEG C, has the advantages of high fluidity, high bonding strength, no shrinkage, good impermeability and good durability, and is suitable for being promoted and applied.

Owner:HUBEI UNIV

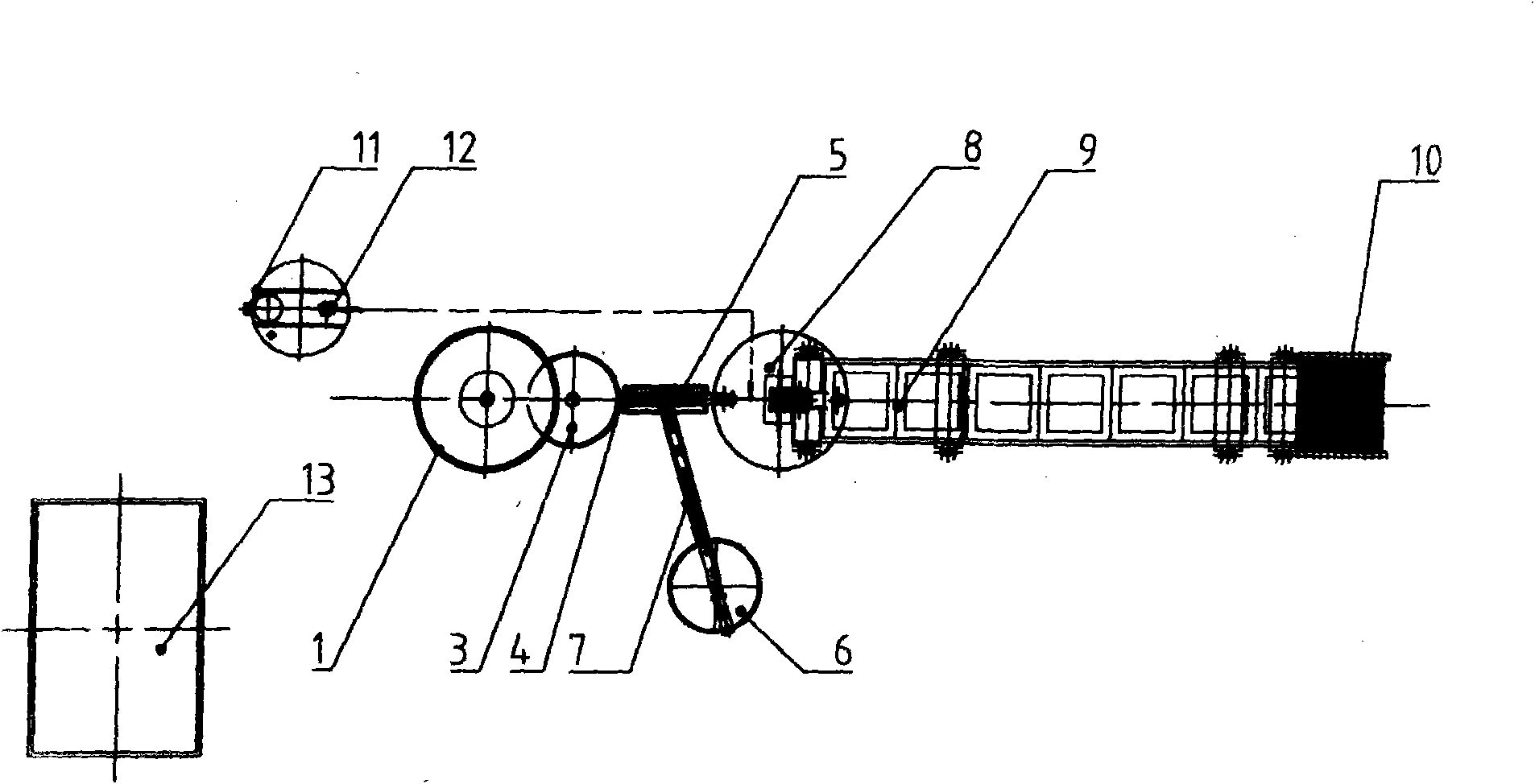

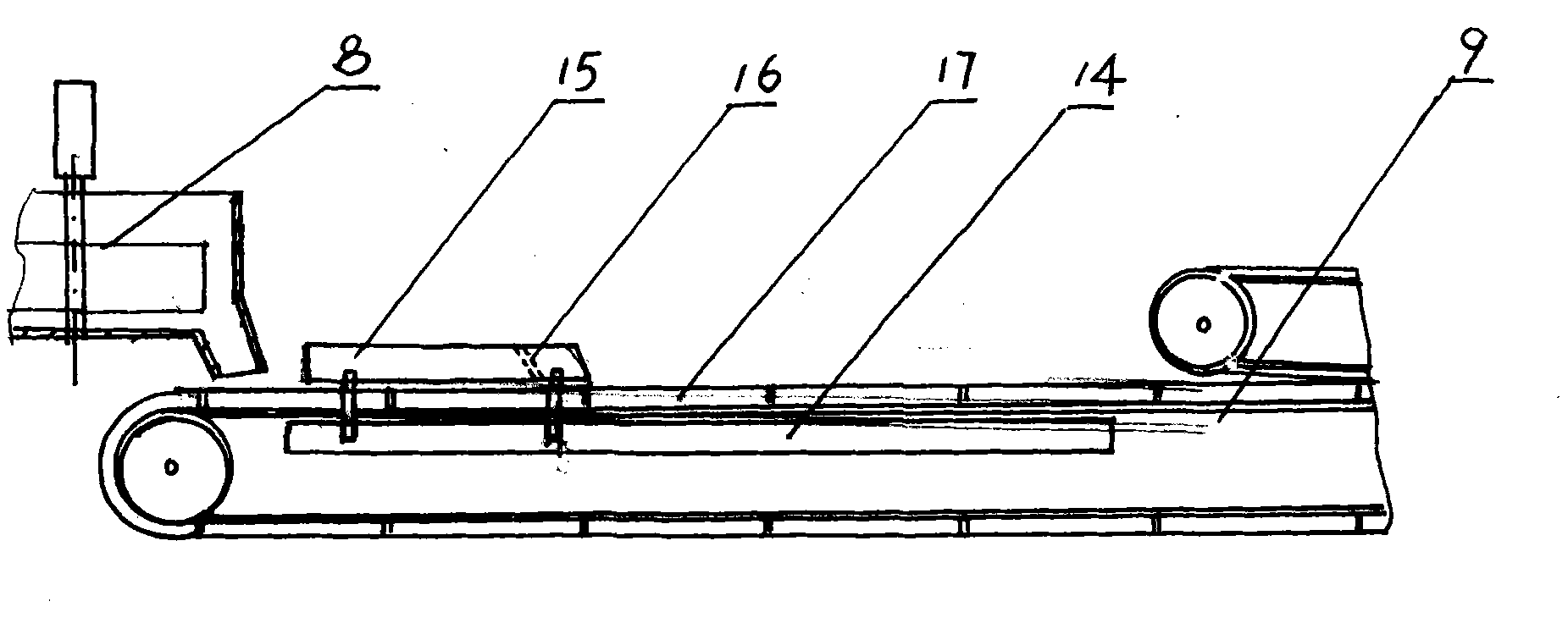

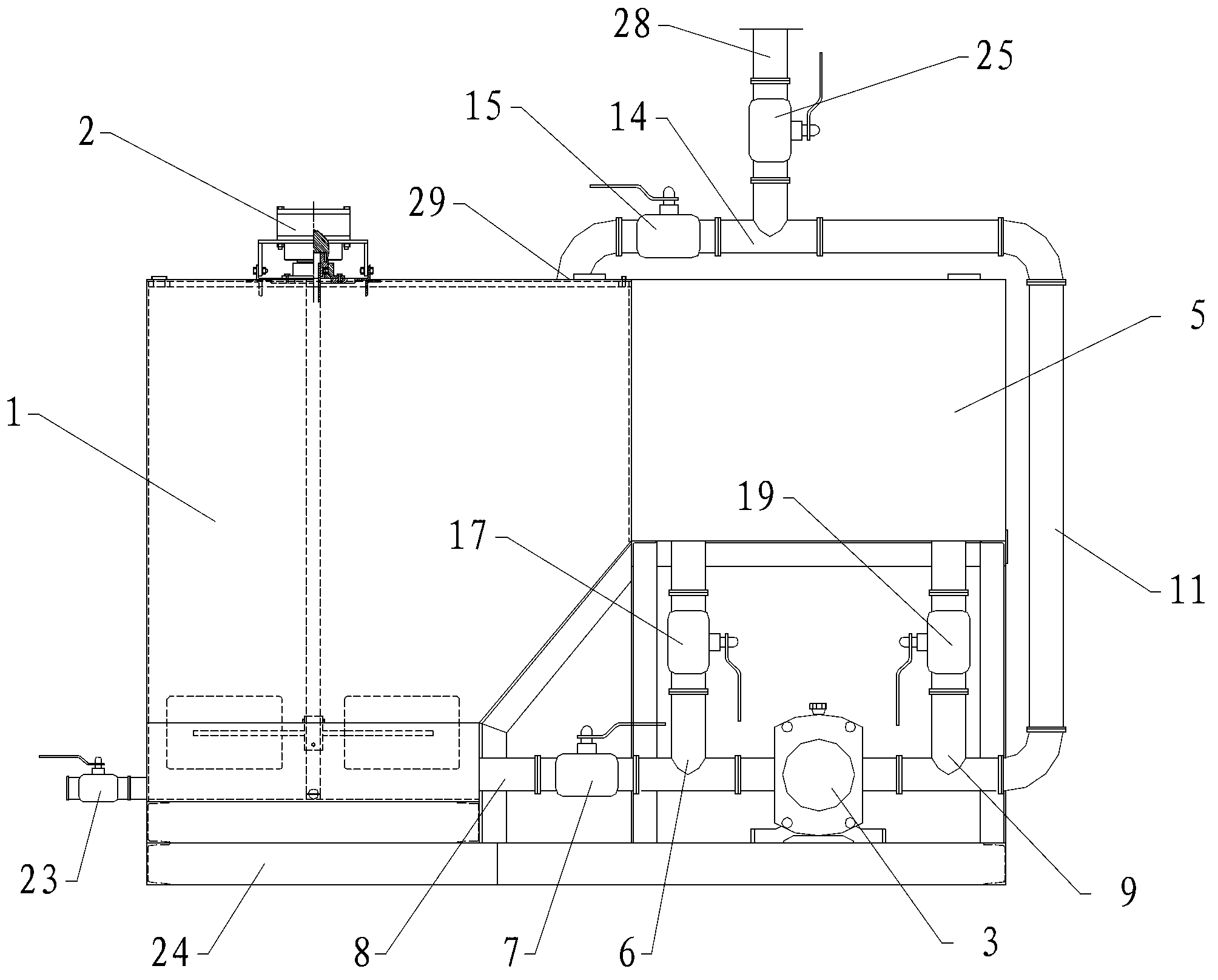

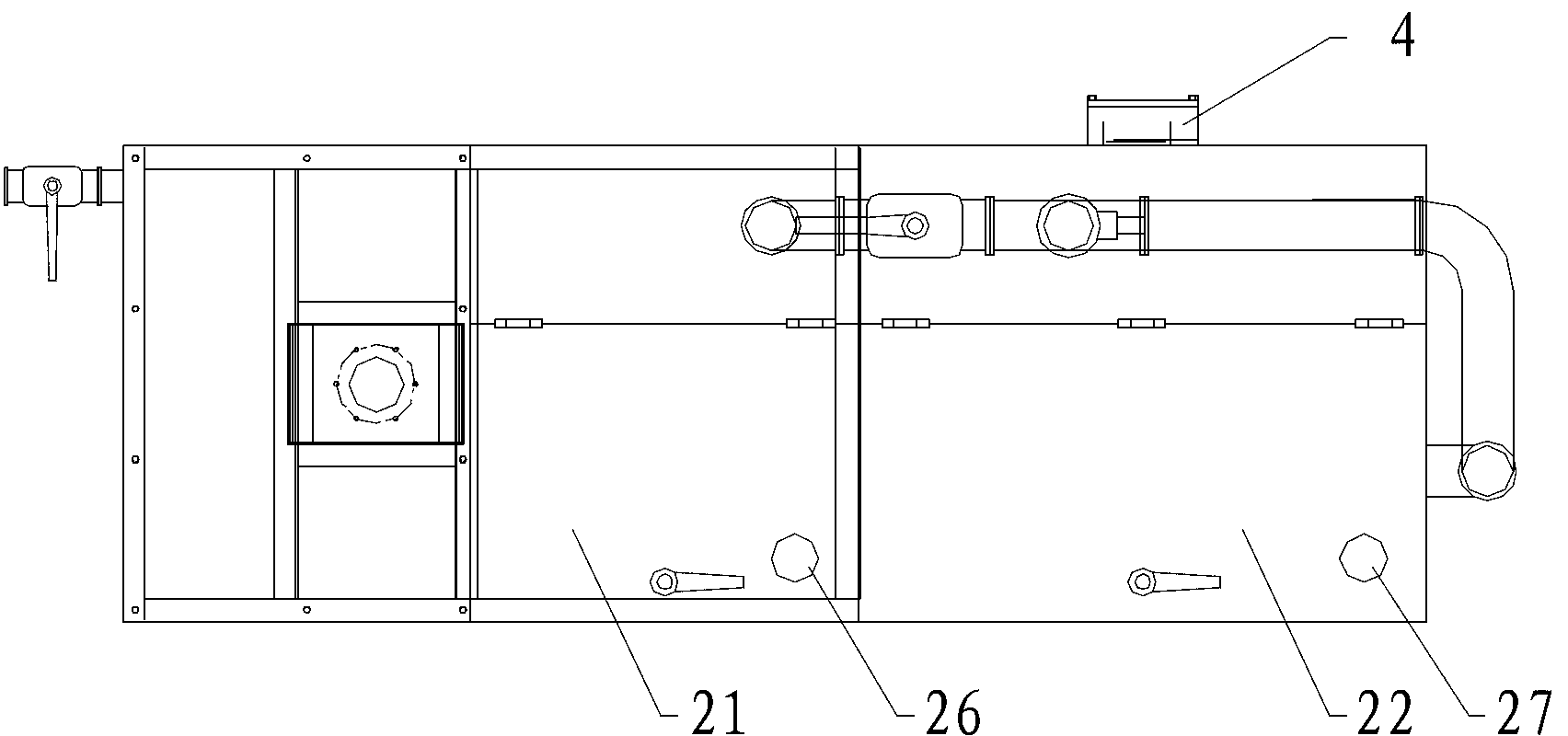

Distorted concrete construction equipment

InactiveCN103174146AEven groutingPrecise control of grouting volumeFoundation engineeringProgrammable logic controllerWater tanks

The invention discloses distorted concrete construction equipment, and belongs to the technical field of construction. The distorted concrete construction equipment comprises a host machine, a programmable logic controller (PLC) system, an action arm, a vibration bar, a grouting device, a turnover oil cylinder, and a mortar pumping device, wherein the action arm is connected with the vibration bar through a connecting piece, and a mortar pumping device is connected with the grouting device through a mortar conveying pipe. The mortar pumping device comprises a machine frame, a mortar liquid box, a stirring machine, a rotor pump and a motor, and further comprises a cleaning water box. A blow-off valve is arranged on the lower portion of the lateral face of the mortar liquid box, a mortar adding hole is formed in a cover of the mortar liquid box, and a water adding hole is formed in a cover of the cleaning water tank. The host machine is used as the basic platform and the motive power source of a mortar liquid conveying and grouting system, a working device and the PLC control system to complete conveying operation and vibrating operation of distorted concrete construction mortar liquid. The distorted concrete construction equipment is even in grouting, accurate in mortar quantity control and simple in operation, guarantees construction quality, simplifies construction processes, improves construction efficiency, and reduces labor intensity of operation personnel. The mortar pumping device can conduct self-cleaning, and therefore the problems that the mortar liquid precipitates and blocks pipes are solved.

Owner:SINOHYDRO BUREAU 7 CO LTD +1

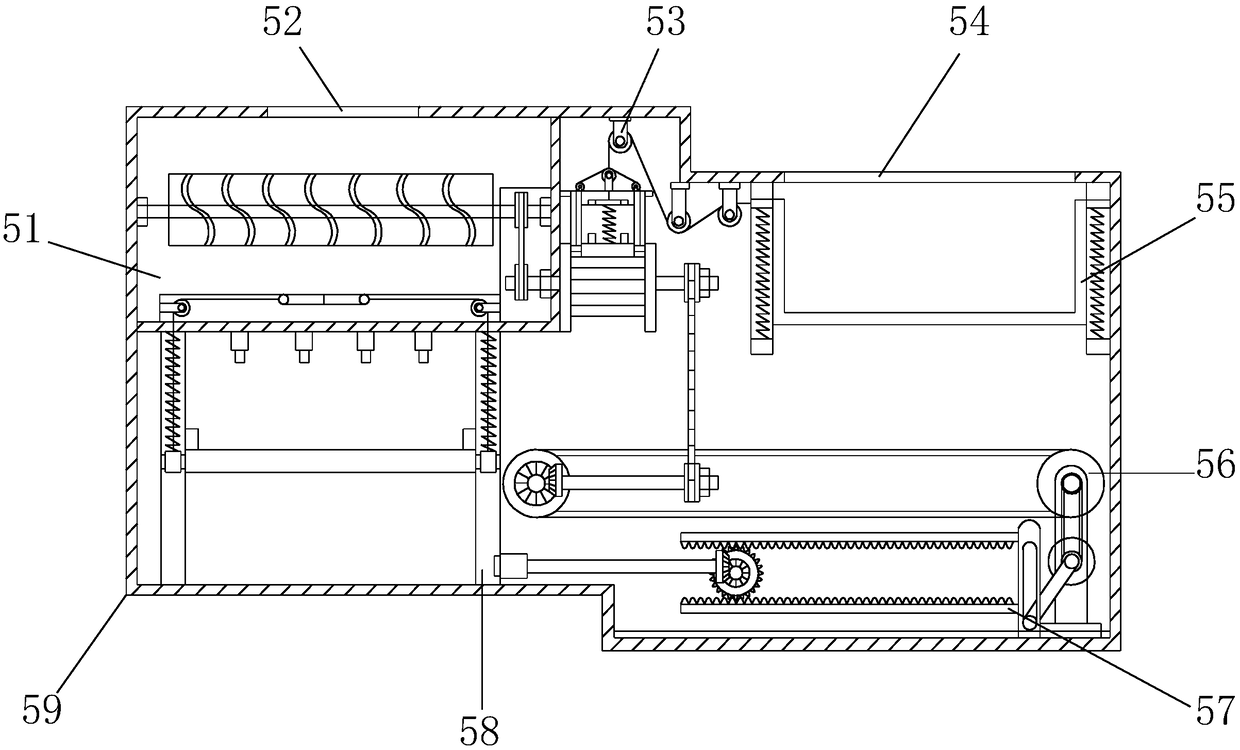

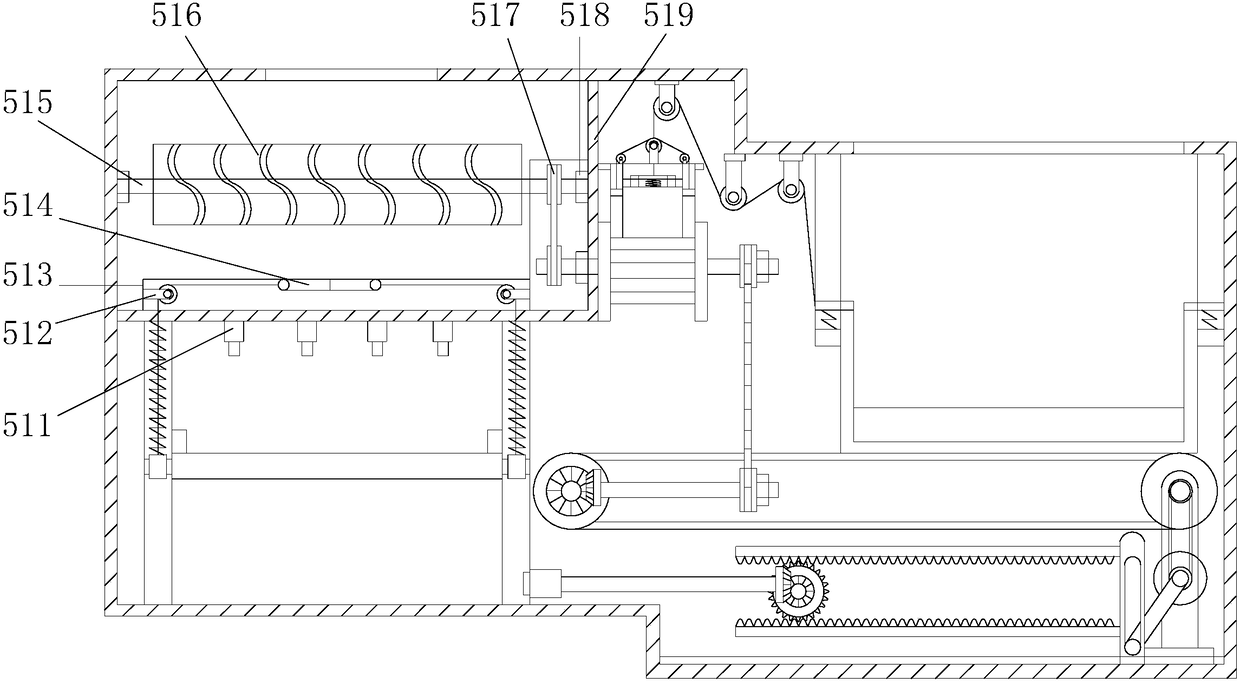

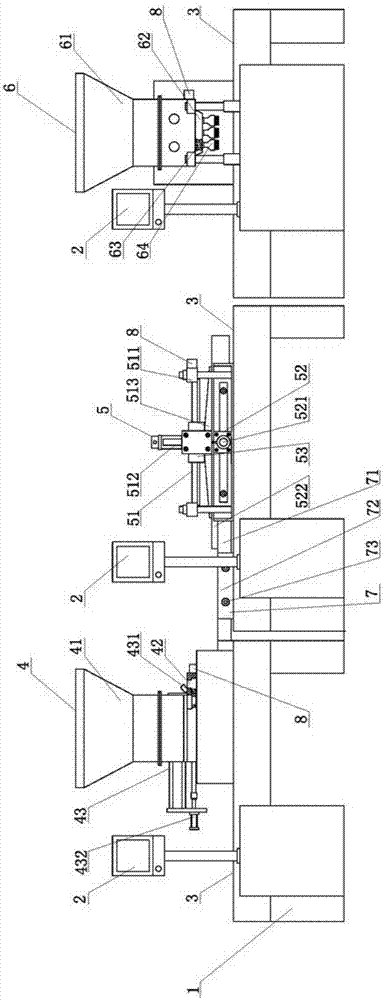

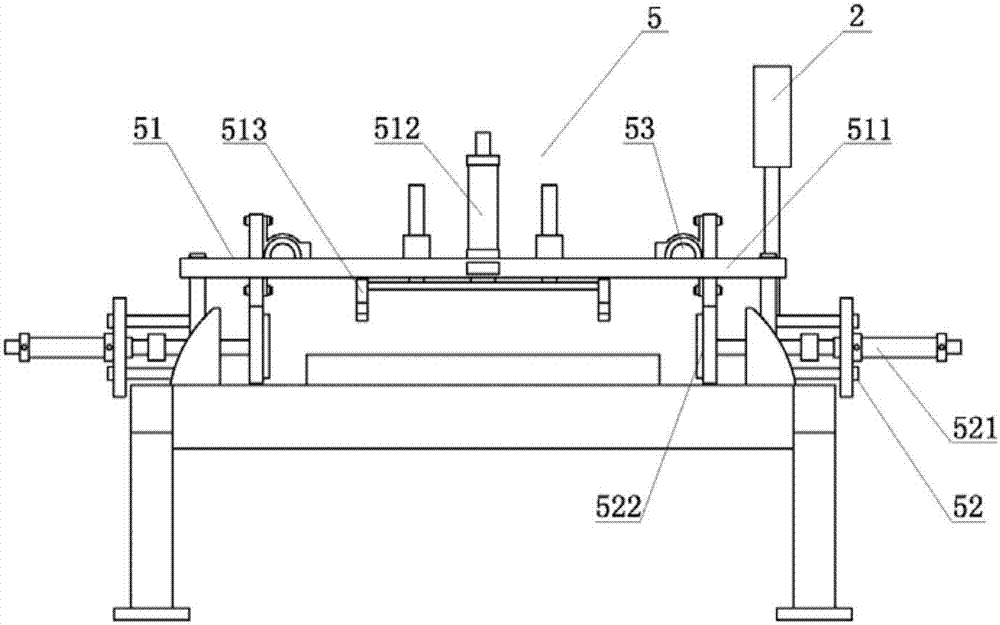

Novel multifunctional full-automatic floor tile paving machine

The invention discloses a novel multifunctional full-automatic floor tile paying machine. The novel multifunctional full-automatic floor tile paving machine is structurally comprises a push-pull handrail, a brick placing groove, a stainless steel sealing cover, a hatch cover, an automatic brick paving device, an infrared rectification locator, a camera probe, foot wheels, a pushing pressing-down bracket, a controller and a display screen. A floor tile is arranged on the brick placing groove in a leveling mode, and the floor tile is conveyed to a brick body transverse conveying mechanism by a brick body longitudinal conveying mechanism, at the moment, a movable contact and a static contact which are arranged on a motor start-stop switch close a intelligent motor to form a loop to start work, the brick body transverse conveying mechanism is driven by the intelligent motor to convey the floor tile to a brick body output mechanism; and when a brick body connection conveying frame descendsto a certain location, the rough surface of the floor tile is subjected to glue injection by a glue injection nozzle; and then, a brick body switching mechanism is used to switch the floor tile to enable the smooth surface to appear upwards; and finally, the brick body is output by the pushing pressing-down bracket and is pressed on the specified position of the ground, so that the speed and quality of the floor tile paying are separately accelerated and improved.

Owner:广东非凡实业投资有限公司

Forming system for baked food

ActiveCN107410410AImprove molding efficiencyEvenly distributedMixing/kneading structural elementsFood processingEngineeringFood products

The invention relates to a forming system for baked food and belongs to the technical field of food production. The forming system comprises a frame and a forming device arranged on the frame and is characterized in that the forming device comprises a conveying mechanism and a fixed-quantity feeding mechanism, a material vibration and flattening mechanism and a thick liquid injecting mechanism. The forming system has the advantages that the system is reasonable in overall structural design, food is sequentially subjected to fixed-quantity feeding, vibration and flattening and pressurized thick liquid injection, manpower is not needed, and food forming efficiency and finished-product quality are increased.

Owner:ANHUI NONG ANKANG FOODS LTD CO

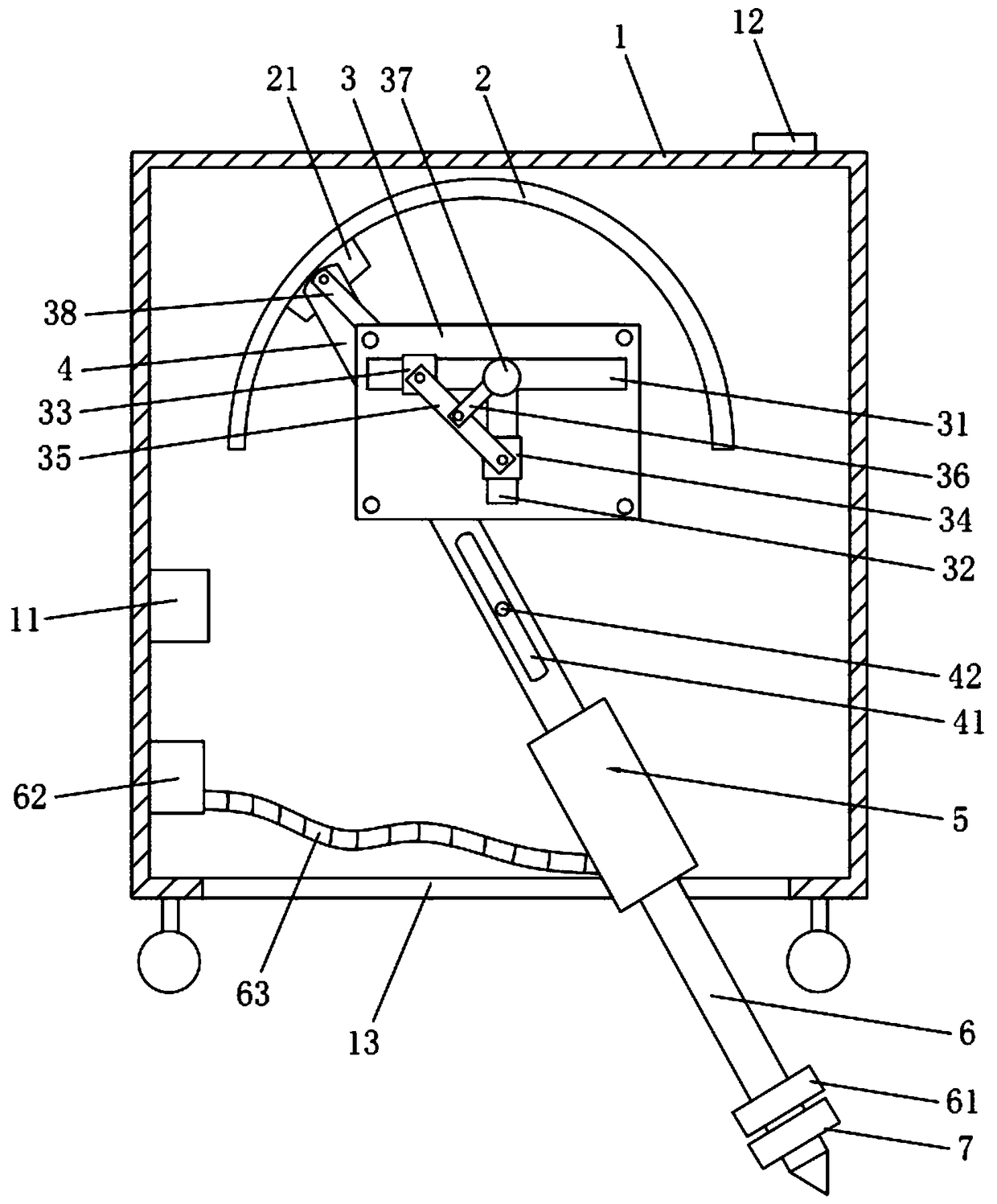

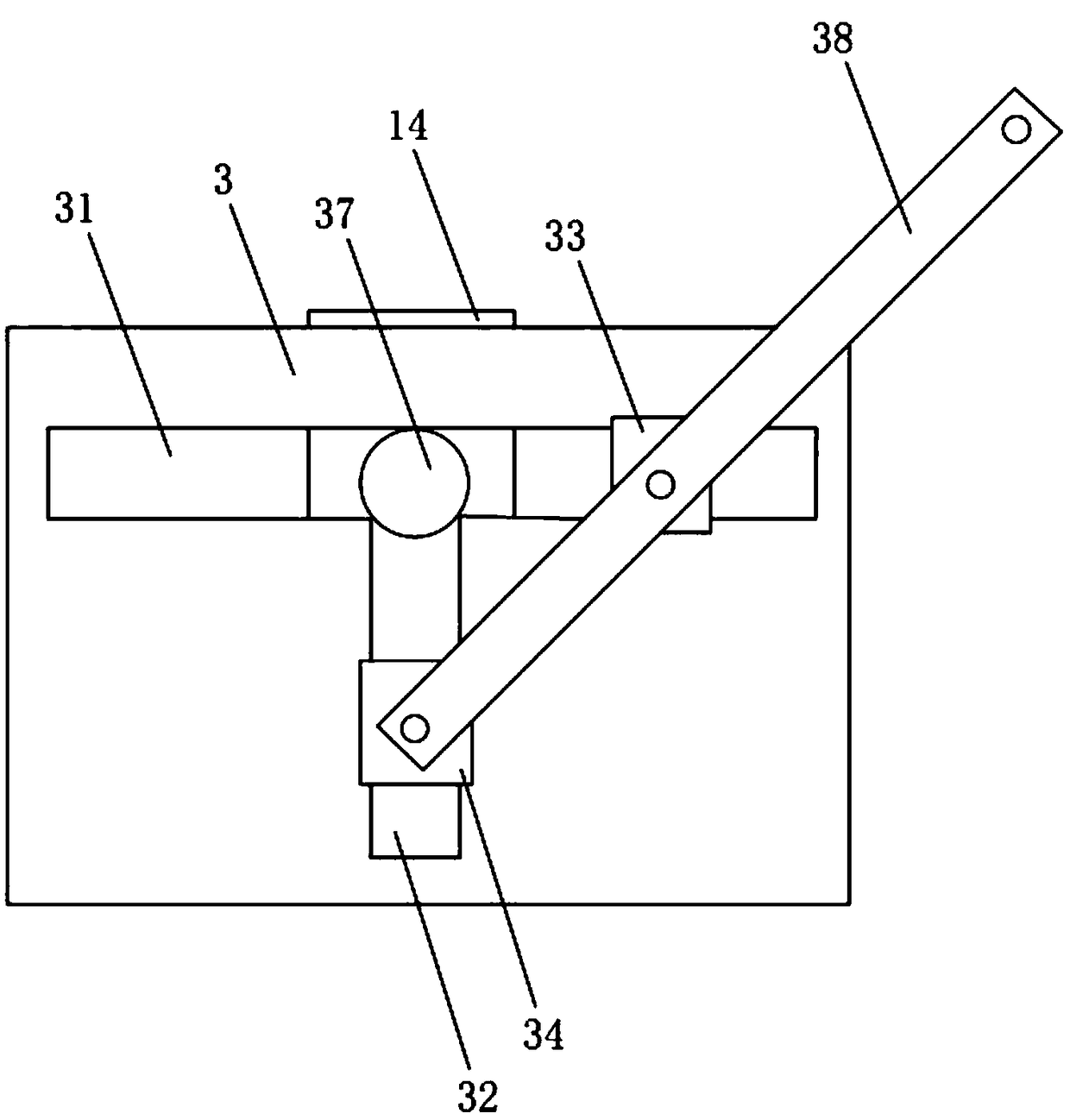

Swing-type gap grouting device for building

The invention discloses a swing-type gap grouting device for a building and relates to the technical field of building equipment. The problem is solved that in the grouting process of a spray nozzle,the spray nozzle and the inner wall of a gap are in contact for a long time, and accordingly the spray nozzle is easily damaged. The swing-type gap grouting device is characterized by comprising a main box, a semi-elliptical slide rail fixedly connected with the inner wall of the main box, a slide block slidingly connected with the semi-elliptical slide rail, a swing rod, a spray nozzle and a driving assembly for driving the slide block to move in the arc track direction of the semi-elliptical slide rail; one end of the swing rod is rotatably connected with the slide block, and the other end of the swing rod is fixedly connected with the spray nozzle; a fixing shaft is fixedly connected to the inner wall of the main box, and a slide groove for the fixing shaft to be inserted in is formed in the swing rod; a hydraulic pump is fixedly connected to the inner wall of the main box, a conveying pipe is arranged between the hydraulic pump and the spray nozzle, and a swing groove for the spraynozzle to swing in runs through the bottom of the main box. The swing-type gap grouting device has the advantages that the spray nozzle does not abut against the inner wall of the gap in the groutingprocess, and the service life of the spray nozzle is prolonged.

Owner:HUNAN CITY UNIV

Concrete grouting equipment for building construction and operation method of equipment

ActiveCN109958132AReduce jitter amplitudeHeight adjustableFoundation engineeringArchitectural engineeringHydraulic pump

The invention discloses concrete grouting equipment for building construction and an operation method of the equipment. The concrete grouting equipment for the building construction comprises a sliding installing platform, a transmission disk, a grout box, a grout dredging pipe and a grouting cylinder; and the transmission disk is installed above the sliding installing platform, the grout box is arranged on one side of the sliding installing platform, and the grout dredging pipe is arranged at one end of the grout box in a penetrating mode. The concrete grouting equipment for the building construction and the operation method of the equipment have the beneficial effects that a second hydraulic pump drives a first hydraulic pump and the grouting cylinder to move back and forth horizontallythrough a hydraulic rod, so that the position of the horizontal grouting in front of a building foundation and behind the building foundation is flexibly adjusted by the device, and it is ensured thatthe equipment makes the horizontal grouting position of the building foundation be more accurate; and a stretching sliding column is matched with the hydraulic rod in the second hydraulic pump and synchronously moves horizontally back and forth, it is ensured that the hydraulic rod drives the grouting cylinder to move more smoothly and firmly, the jitter amplitude is reduced when the grouting cylinder is adjusted to move forward and backward, the grouting cylinder is prevented from wasting or polluting resources due to the fact that grout is shed into non-grouting areas when the grouting cylinder moves forward and backward, and the working stability of the equipment is ensured.

Owner:ANHUI TONGJI CONSTR GRP

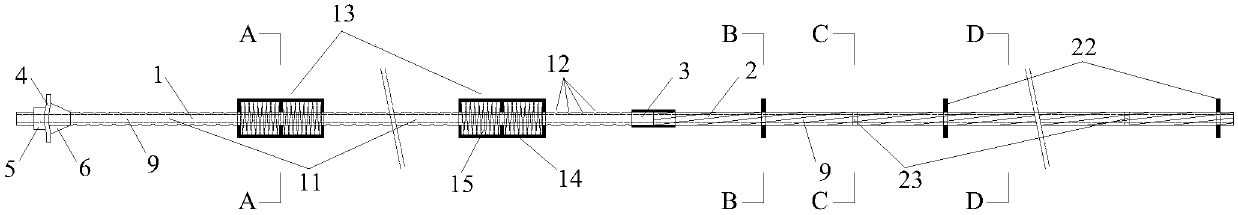

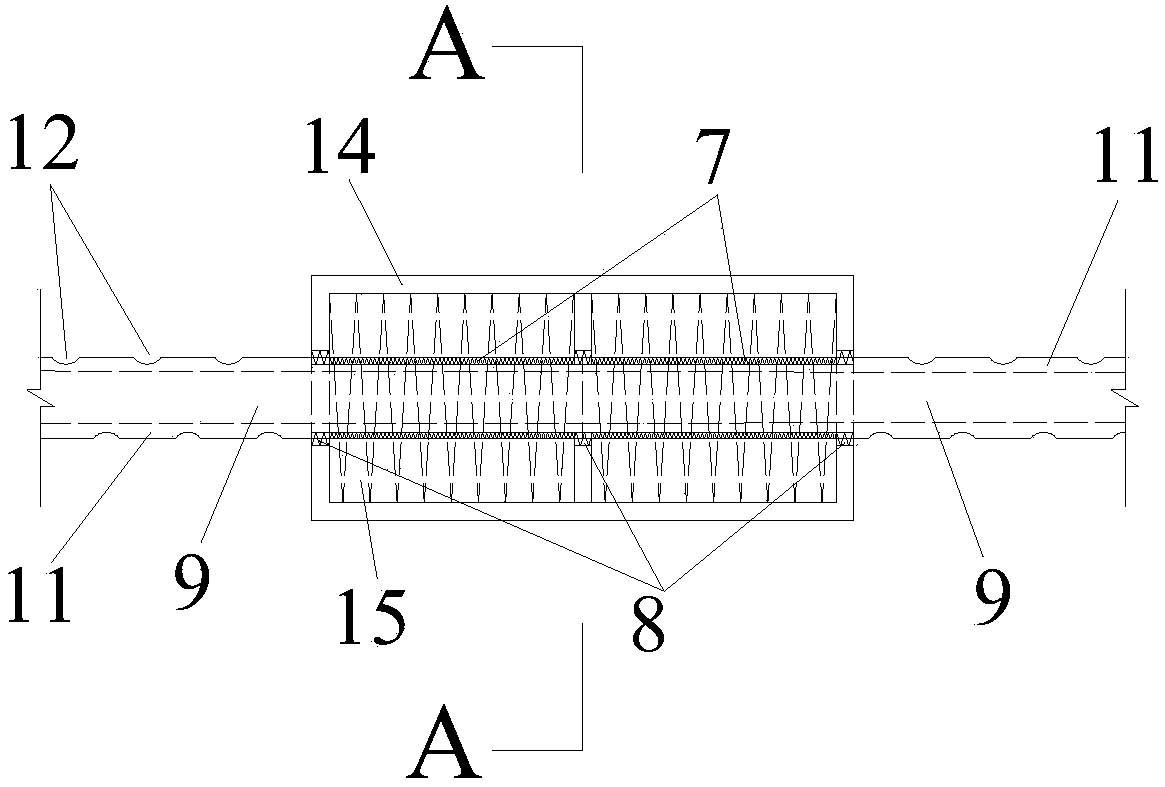

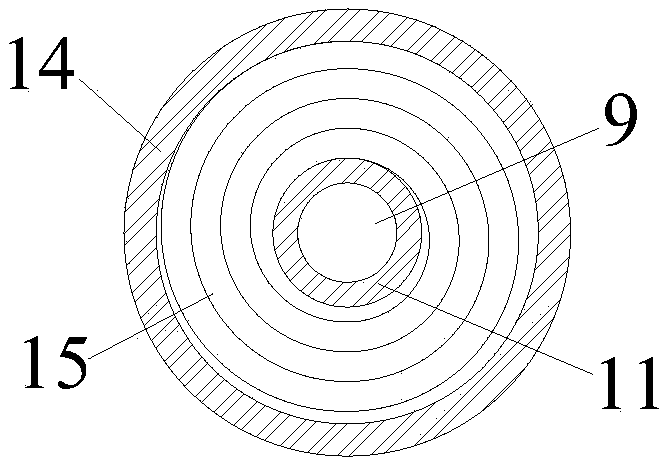

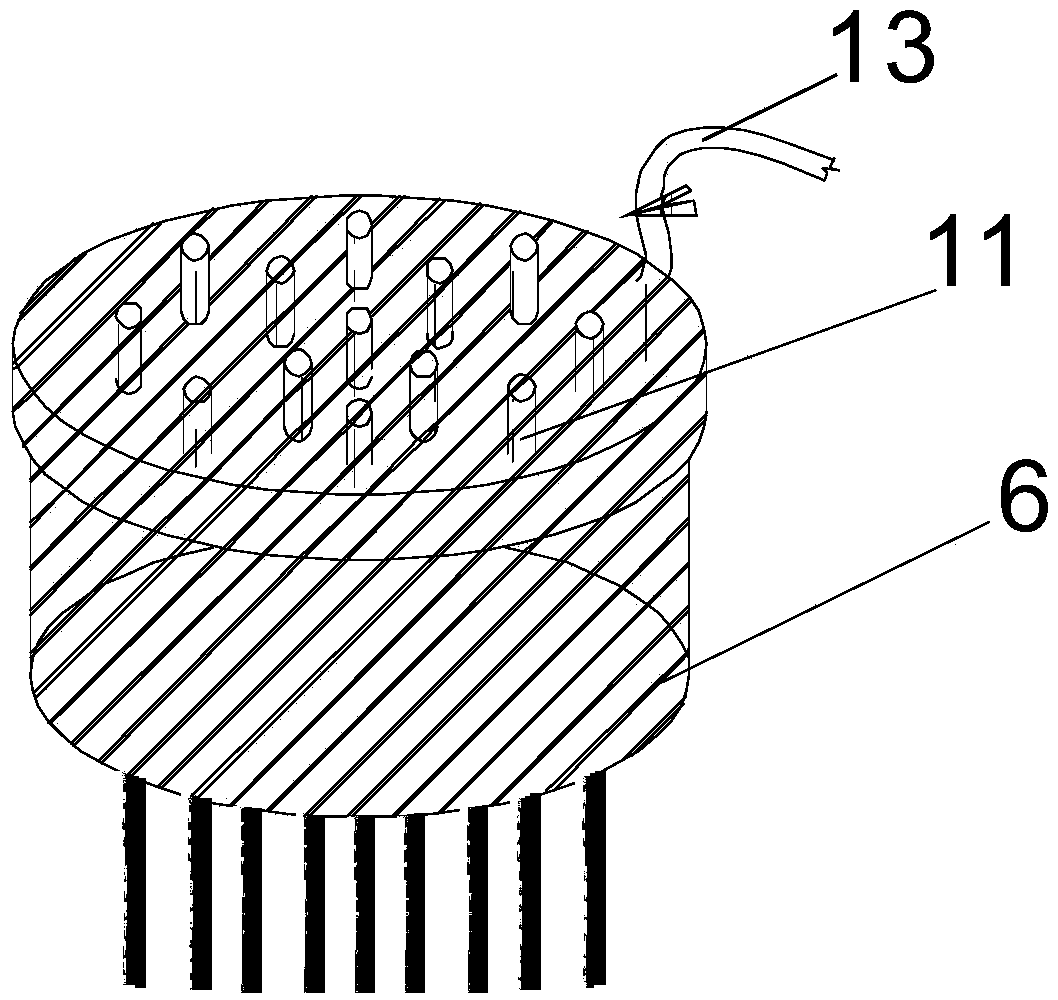

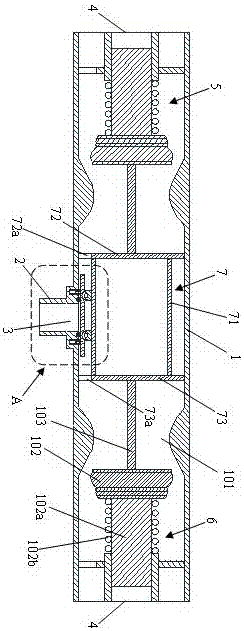

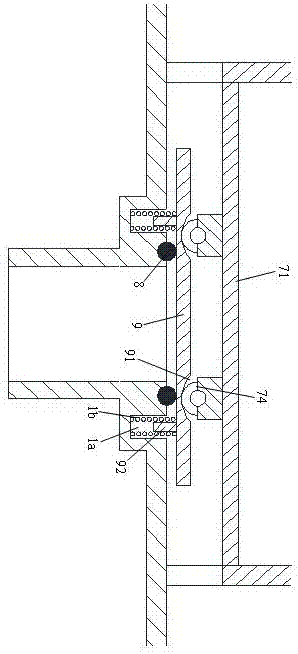

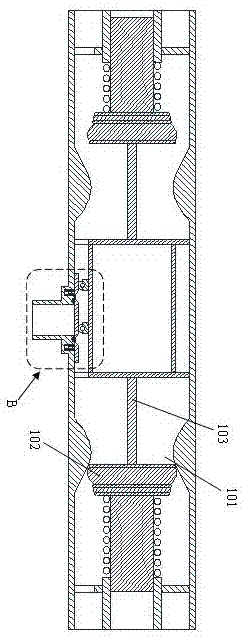

Multi-section type hollow grouting cable anchor and supporting method

ActiveCN110608062AImprove grouting effectImprove carrying capacityAnchoring boltsStructural engineeringSlurry

The invention relates to a multi-section type hollow grouting cable anchor and a supporting method, and belongs to the technical field of tunnel supporting. The problems are solved that an existing grouting cable anchor cannot conduct multi-layer multi-section type grouting reinforcing on deep surrounding rock and slurry in drilled holes cannot be evenly dispersed, so the grouting volume is low and the supporting effect is poor on fractures in a deep rock layer. The multi-section type hollow grouting cable anchor comprises a cable body. The cable body is formed by spirally winding a pluralityof steel strands on a grouting pipe. A plurality of passage limiting assemblies are arranged on the grouting pipe and divide the grouting pipe into a plurality of segmented pipelines. The passage limiting assemblies can partition every two adjacent segmented pipelines and can be opened under the threshold pressure of the passage limiting assemblies so that every two adjacent segmented pipelines can communicate. The multi-section type hollow grouting cable anchor is simple in structure, convenient to operate and good in supporting effect and can conduct multi-layer multi-section type grouting reinforcing on the deep surrounding rock.

Owner:CHINA UNIV OF MINING & TECH

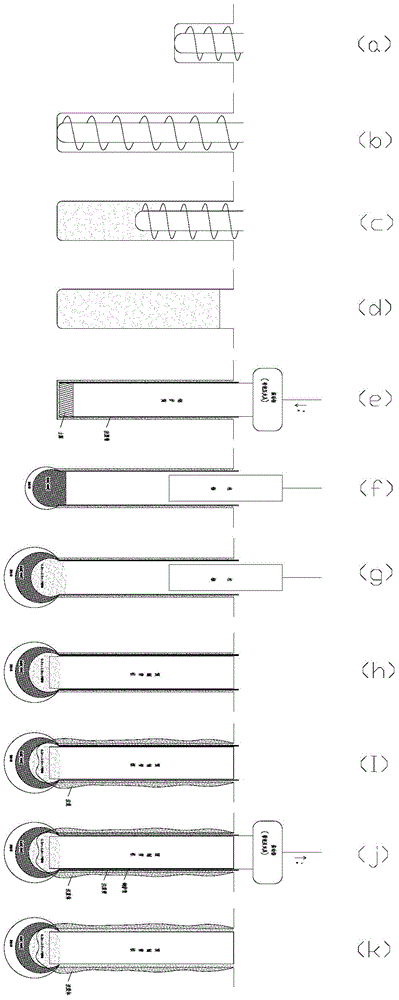

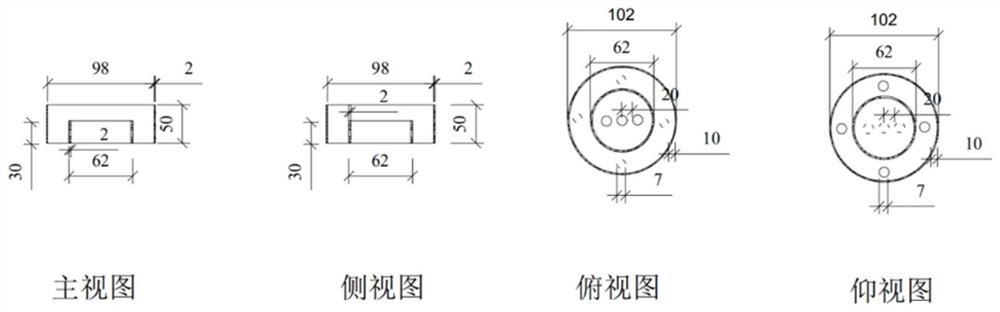

Device and method for microbe stepped grouting to strengthen sand

PendingCN109629570ASolve the influence of crystallization blocking seepage channelsEven groutingSoil preservationEngineeringMechanical engineering

Provided are a device and method for microbe stepped grouting to strengthen sand. The device comprises a first sealing plug, a first glass cylinder, a second sealing plug, a third sealing plug, a second glass cylinder, a fourth sealing plug, a beaker and a gantry. The first sealing plug and the second sealing plug are respectively placed on the upper and lower ends of the first glass cylinder, andthe first glass cylinder is fixed above the gantry by a first fixing clip. A plurality of drilling holes are formed in the second sealing plug, and second capillary tubes penetrate through each of the drilling holes. The third sealing plug and the fourth sealing plug are respectively placed on the upper and lower ends of the second glass cylinder. The plurality of second capillary tubes sequentially penetrate through the second sealing plug, the third sealing plug and the second glass cylinder from top to bottom, and the plurality of second capillary tubes protrude from the upper end surfaceof the second sealing plug. The device changes a test device to better solve the problem of a CaCO3 precipitation blocking a seepage channel in order to obtain a better grouting strengthening effect.The operation method of the device is simple, and the device is simple and easy to manufacture.

Owner:CHINA THREE GORGES UNIV

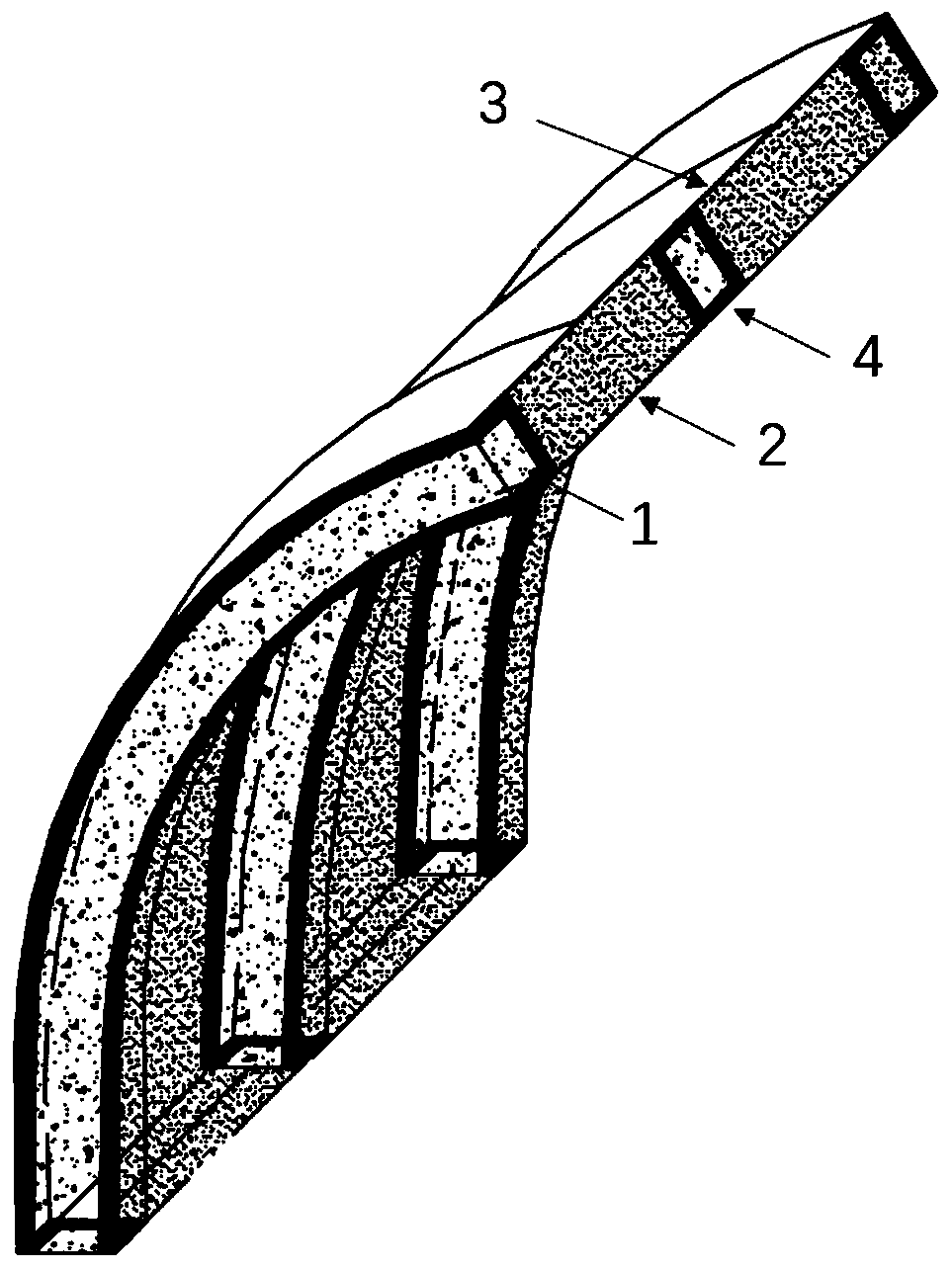

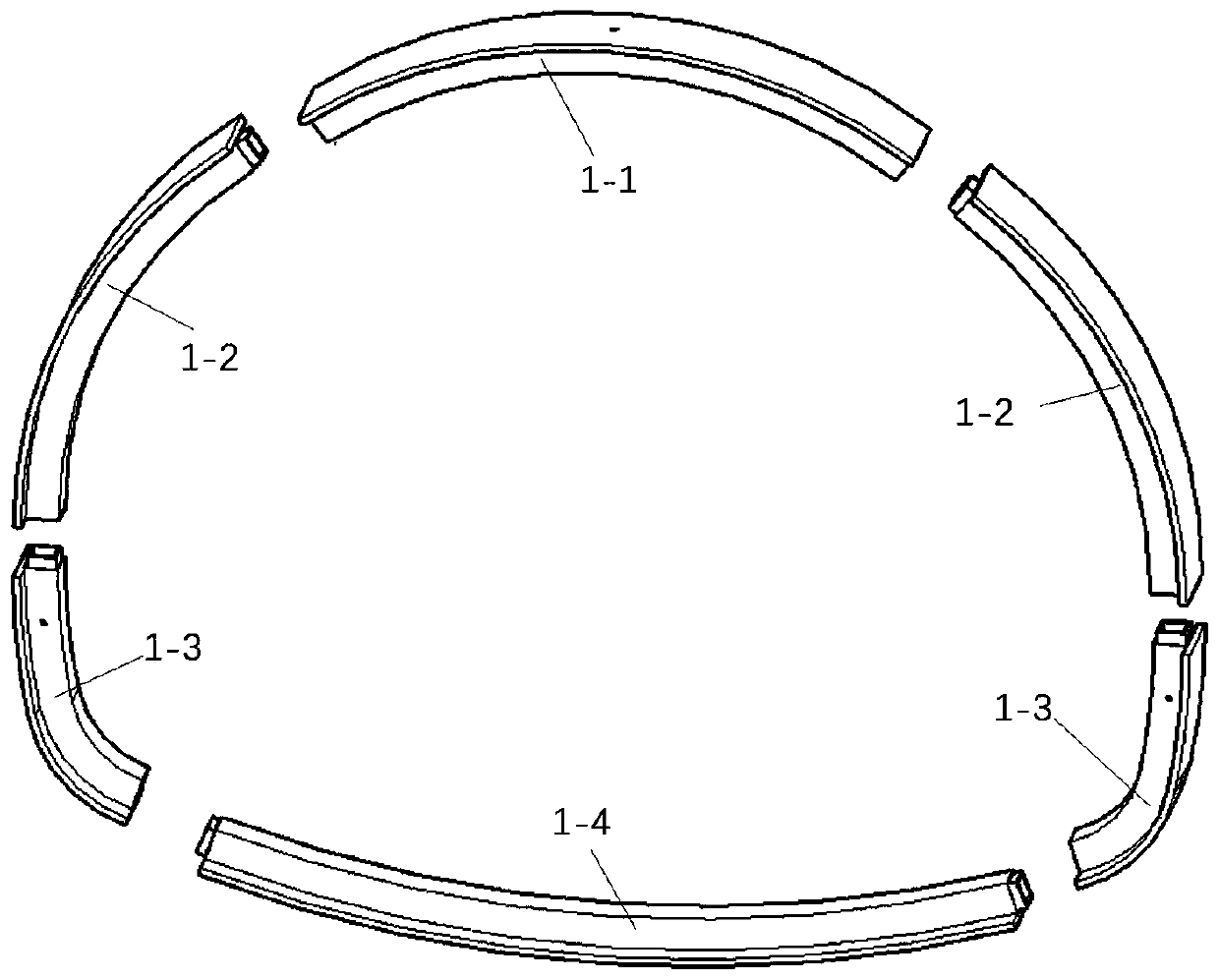

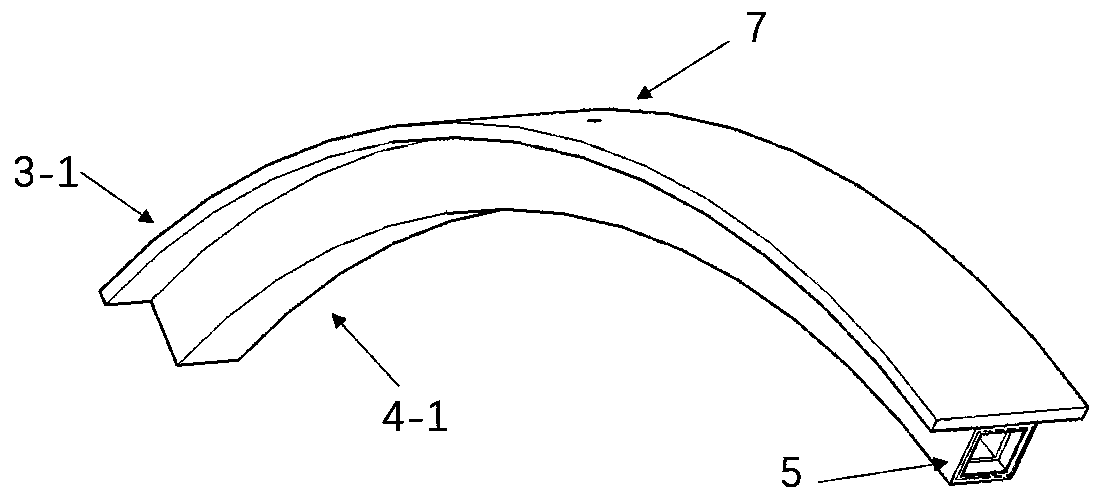

Loess tunnel supporting system and installation method thereof

PendingCN110259485AHigh strengthEasy maintenanceUnderground chambersTunnel liningSupporting systemCarrying capacity

The invention discloses a loess tunnel supporting system and an installation method thereof. The loess tunnel supporting system comprises a plurality of composite structure arches tightly distributed, each composite structure arch comprises a flange and a hollow pipe, the hollow pipe is installed on the inner side of the flange, and in-pipe concrete is poured into the hollow pipe; model-building concrete is poured between every two adjacent composite structure arches; and the composite structure arches are divided into arch top brackets, arch waist brackets, arch foot brackets and arch bottom brackets in the circumferential direction, the brackets are connected in a socket and spigot joint mode, and connection is compact and no gap exists. The composite structure arches, the in-pipe concrete and the model-building concrete act jointly, and the carrying capacity of tunnel preliminary support is improved. The loess tunnel supporting system combines the advantages of steel materials and the concrete and can effectively enable the steel materials and the concrete to be integrated, a composite structure with higher rigidity and high strength is formed, due to the fact that the concrete is wrapped with the steel materials, the concrete is in a triaxial compressive state, and development of the strength is more facilitated.

Owner:CHANGAN UNIV

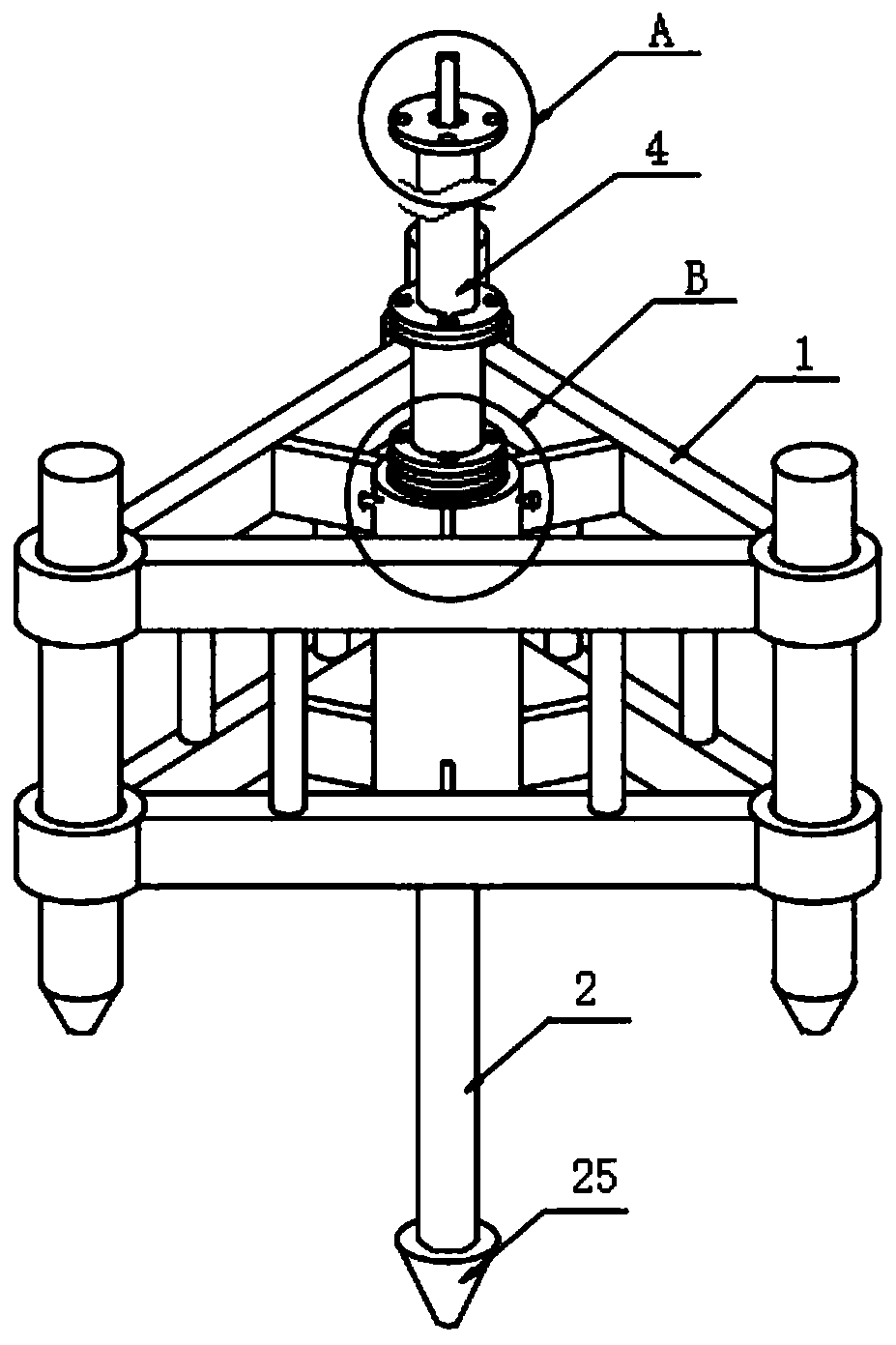

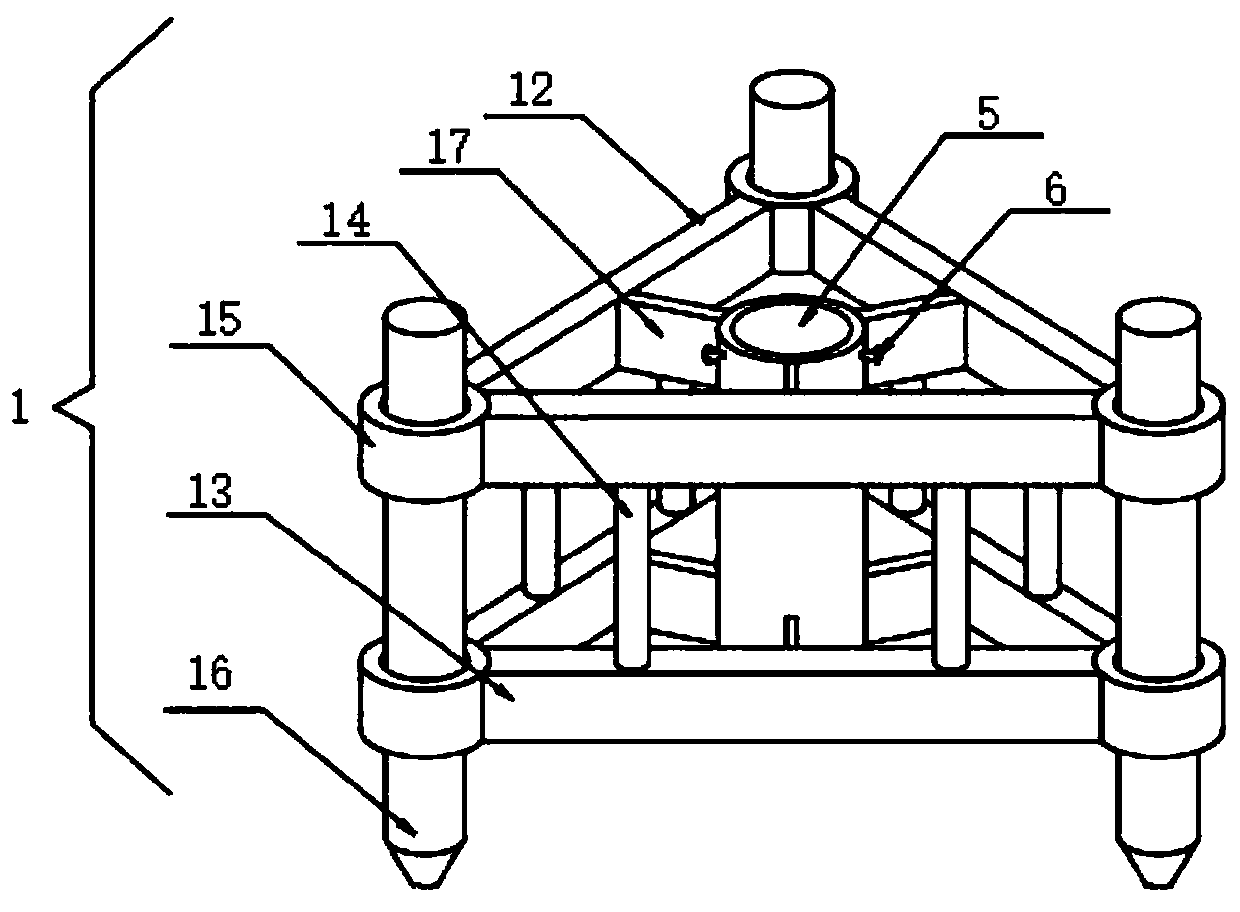

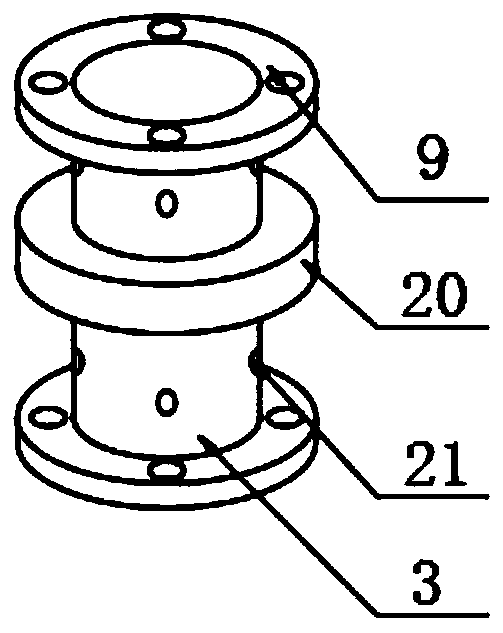

Anchor rod construction device for building engineering

InactiveCN111424658AImprove compactnessEasy to useDerricks/mastsDirectional drillingArchitectural engineeringCement slurry

The invention discloses an anchor rod construction device for building engineering, and relates to the technical filed of building construction. The anchor rod construction device comprises a stabilizing frame, a base rod, a connecting sleeve and a connecting rod, the base rod, the connecting sleeve and the connecting rod are fixedly connected through bolts, a directional cylinder is fixedly installed on the inner surface of the stabilizing cylinder, the inner surface of the directional cylinder is slidably connected with the outer surface of the connecting sleeve, positioning bolts are correspondingly connected to the left and right sides of the directional cylinder in a threaded mode, one ends of the positioning bolts abut against the outer surface of the connecting sleeve, and the innersurface of the connecting sleeve is slidably connected with the outer surface of the base rod. According to the anchor rod construction device for building engineering, the accuracy of the drilling position is ensured by using the stabilizing frame and the directional cylinder, a simple flange fixing structure is utilized to fix the structure, then cement slurry is injected into the base rod, theconnecting sleeve and the connecting rod by being matched with a grouting hole, the stress support strength is increased by using a reinforced threaded rod, the structure is simple grouting is convenient, grouting is uniform, and the cost is low.

Owner:王炳炜 +1

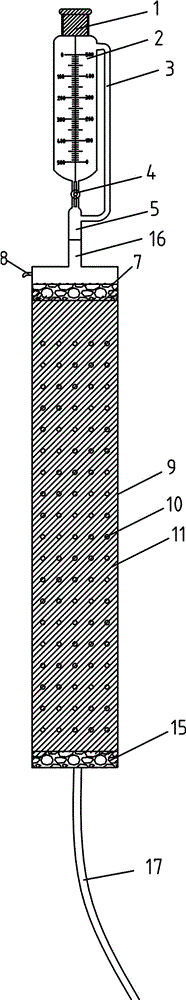

Calcareous sand hollow cylinder sample in-situ curing sample preparation instrument and method

PendingCN112683630AEven groutingLarge void ratioPreparing sample for investigationPeristaltic pumpConverters

The invention discloses a calcareous sand hollow cylinder sample in-situ curing sample preparation instrument and method. The sample preparation instrument comprises a No.1 slurry storage vessel, a No.1 grouting pipe, a No.1 peristaltic pump, a No.1 graphite electrode, a waterproof ventilation valve, a rubber plug, a grouting converter, an organic glass tube, a cylinder assembly, a No.2 graphite electrode, a percolate outlet pipe, a No.2 grouting pipe, a No.2 peristaltic pump, a No.2 slurry storage vessel, a percolate collecting vessel and a direct-current power supply. The sample preparation method is realized by combining an MICP technology with a two-stage grouting method of pressure grouting and electroosmosis grouting, and the sample preparation instrument and the sample preparation method disclosed by the invention can obviously improve the curing effect of the prepared sample, so that the prepared sample has good integrity.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Novel pouring device for model test and application method

The invention discloses a novel pouring device for a model test and an application method. The novel pouring device comprises a slurry stirring device, wherein the slurry stirring device is connected with a pouring pressure device through slurry feeding pipes, the pouring pressure device is connected with a slurry feeding pipe conversion device through the slurry feeding pipes, and the slurry feeding pipe conversion device is connected with pouring pipes through the slurry feeding pipes. The novel pouring device provided by the invention has the advantages that the device is simple, the operation is convenient, the detachability is strong, and the transportation is convenient; the pouring pressure device is provided with marks, the pouring quantity is controlled, the pressurization can be easily and manually carried out and is free from limitation of energy such as power supply; the slurry feeding pipe conversion device can realize simultaneous pouring by using multiple pouring pipes, the number of the starch feeding pipes of pouring is simultaneously controlled, and the pouring efficiency is notably improved; and once uniform pouring can be realized through the bottoms of the pouring pipes and pouring holes in pipe walls, and the pouring effect is notable.

Owner:李泽硕

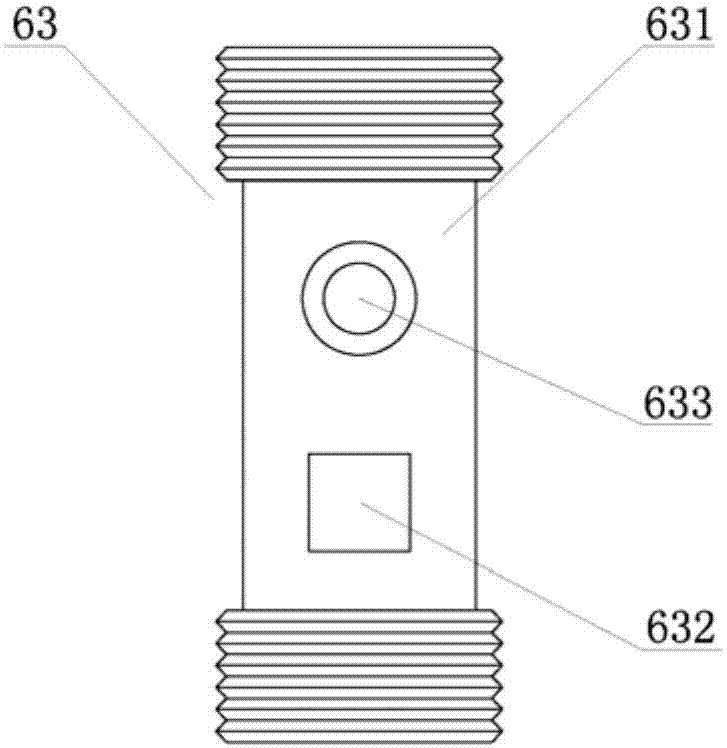

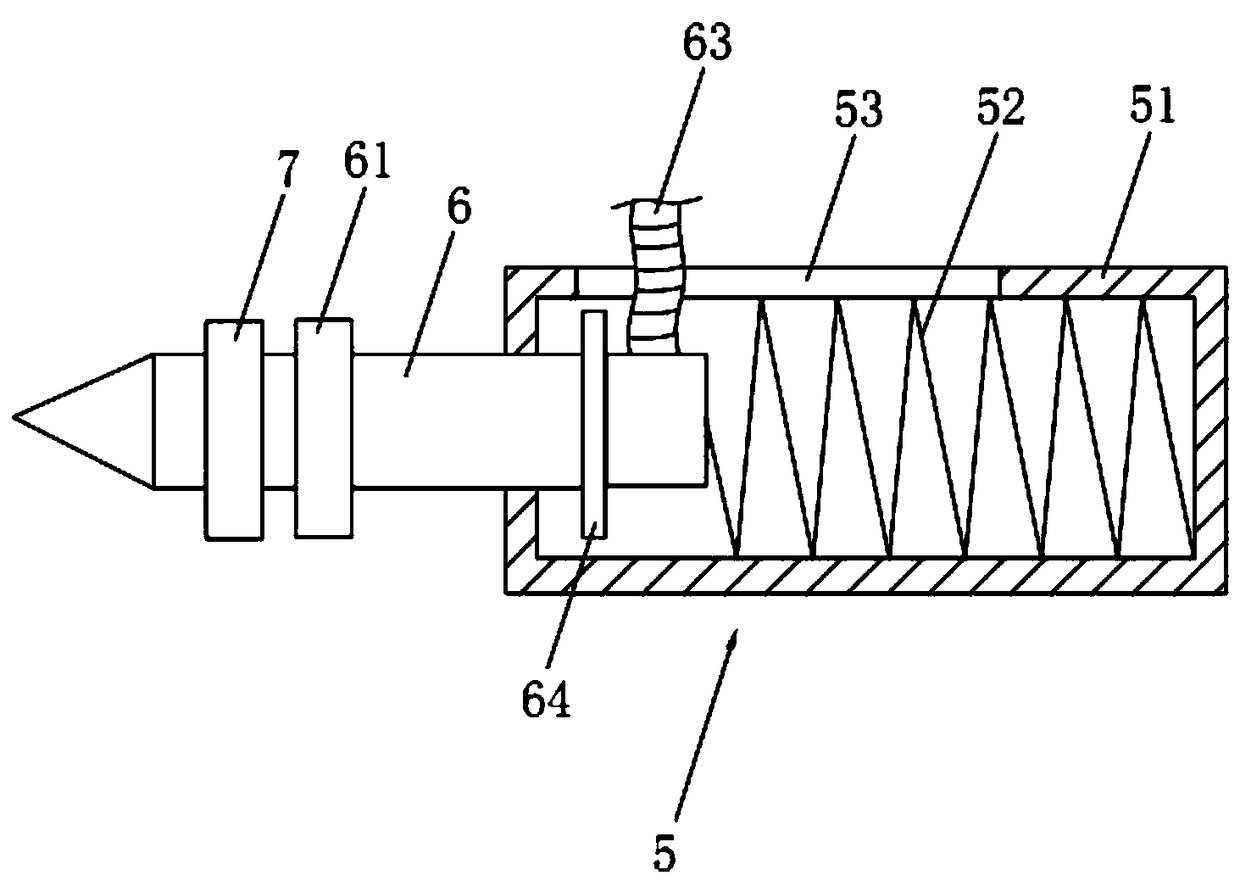

Pile tip grouting device for multipoint pouring

PendingCN107503350APrevent backflowImprove grouting efficiencyFoundation engineeringSlurryMechanical engineering

The invention discloses a pile tip grouting device for multipoint pouring. The pile tip grouting device comprises a conveying master pipe used for conveying slurry, a plurality of conveying branch pipes connected to the conveying master pipe and a grouting device body connected to the conveying branch pipes. The grouting device body comprises a pipe body, a slurry inlet used for being connected with a grouting pipe is formed in the middle of the pipe body, and the two ends of the pipe body are two slurry outlets; each slurry outlet is connected with a slurry outlet pipe, and ports of the two slurry outlet pipes extend to different positions so that grouting can be conducted towards the different positions; and the two slurry outlet pipes are provided with a first one-way valve and a second one-way valve correspondingly. Through the technical scheme, all the conveying branch pipes are inserted in different positions of concrete gaps, the two slurry outlet pipes of the grouting device body connected with all the conveying branch pipes are both inserted in different positions, so that multipoint grouting is achieved, the grouting efficiency is improved, and grouting is more uniform.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

Safe grouting vibration equipment

ActiveCN111975967AEven groutingEasy to operateDischarging apparatusFeeding arrangmentsEngineeringGrout

Owner:裘士兴

Construction complete equipment for erosion-resistant protective layer of concrete foundation in salty soil zone

The invention discloses construction complete equipment for an erosion-resistant protective layer of a concrete foundation in a salty soil zone. The construction complete equipment comprises a grouting pump and an erosion-resistant slurry injection device; the grouting pump and the erosion-resistant slurry injection device are connected through a grouting tube; the erosion-resistant slurry injection device is used for grouting erosion-resistant slurry into a position between the concrete foundation and a surrounding stratum; the erosion-resistant slurry injection device comprises a grouting main pipeline which is connected to the grouting tube; and a plurality of joints are further connected on the grouting main pipeline, and are connected to grouting branch pipelines. The construction complete equipment disclosed by the invention can grout an erosion-resistant material between the periphery of underground construct concrete and a surrounding bottom layer; and the erosion-resistant protective layer is formed at a concrete outer layer. The construction complete equipment solves the problems of high engineering construction cost, not strong adaptability and a complex construction process of an existing erosion-resistant protective technology.

Owner:陕西水木盛元科技工程有限责任公司 +1

Automatic distorted concrete grouting and vibrating equipment

ActiveCN102505694BRealize free switchingRealize automatic alignmentFoundation engineeringControl systemProgrammable logic controller

The invention discloses automatic distorted concrete grouting and vibrating equipment, which belongs to the technical field of construction and comprises an excavator, a hydraulic system, a slurry supply station, a grouting and vibrating device, a PLC (programmable logic controller) control system and an operation screen. The slurry supply stations is connected with a load-bearing main beam of the excavator via a slurry supply station bracket, the grouting and vibrating device is connected with a four-rod mechanism rocker arm of the excavator by a connecting part via a hinge pin, the PLC control system is located on a rotary worktable of the excavator, and the operation screen is mounted in a driving cab of the excavator. The automatic distorted concrete grouting and vibrating equipment simultaneously has grouting and vibrating functions, can realize free switching between a grouting work state and a vibrating work state, automatic alignment of working devices, accurate control of grouting quantity and the like, is flexible in movement, uniform in grouting, large in vibrating force and simple in operation, increases construction speed and quality, reduces labor intensity of workers, and is applicable to distorted concrete grouting and vibrating construction in various work places.

Owner:中国水利水电第七工程局有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com