Pile tip grouting device for multipoint pouring

A technology of grouting device and pile tip, which is applied in the field of post-grouting construction of pile tip and pile side of pile foundation, can solve the problems of uneven grouting, backflow of slurry, no anti-reverse function, etc., achieve uniform grouting, avoid backflow of grout, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail through the accompanying drawings and specific embodiments below.

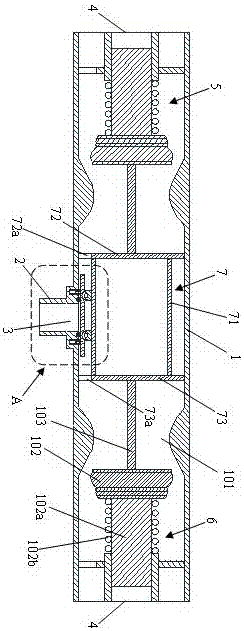

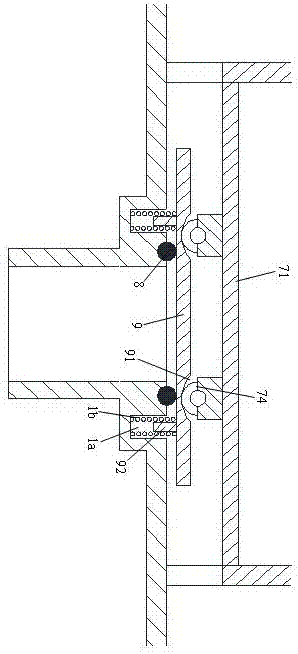

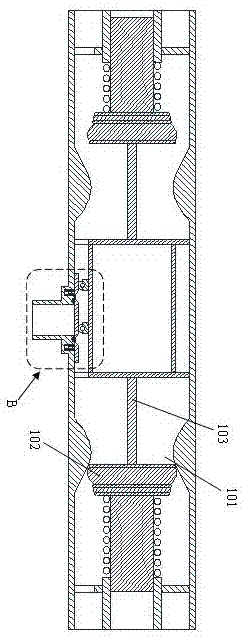

[0014] As shown in the figure, this embodiment provides a pile end grouter for multi-point pouring, which includes a delivery main pipe 200 for delivering slurry, several delivery branch pipes 201 connected to the delivery main pipe 200, connected to the The grouting device on the conveying branch pipe 201, the grouting device includes a pipe body 1, a grout inlet 3 for connecting the grouting pipe 2 is arranged in the middle of the pipe body 1, and at both ends of the pipe body 1 There are two slurry outlets 4, each of which is connected to a slurry outlet 4a, and the ports of the two slurry outlets 4a extend to different positions so that grouting can be carried out to different positions. The slurry outlet 4 is provided with a first one-way valve 5 and a second one-way valve 6, and a piston 7 is provided in the middle of the inside of the pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com