Positive-pressure pneumatic conveying skid for oilfield fracturing propping agent

A technology of pneumatic conveying and oilfield fracturing, which is applied in the direction of conveyors, conveying bulk materials, transportation and packaging, etc., which can solve the problems of less land occupation, reduced operating efficiency and safety of operators, and increased difficulty in hoisting tons of bags. Occupies less land, improves work efficiency, and reduces work difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

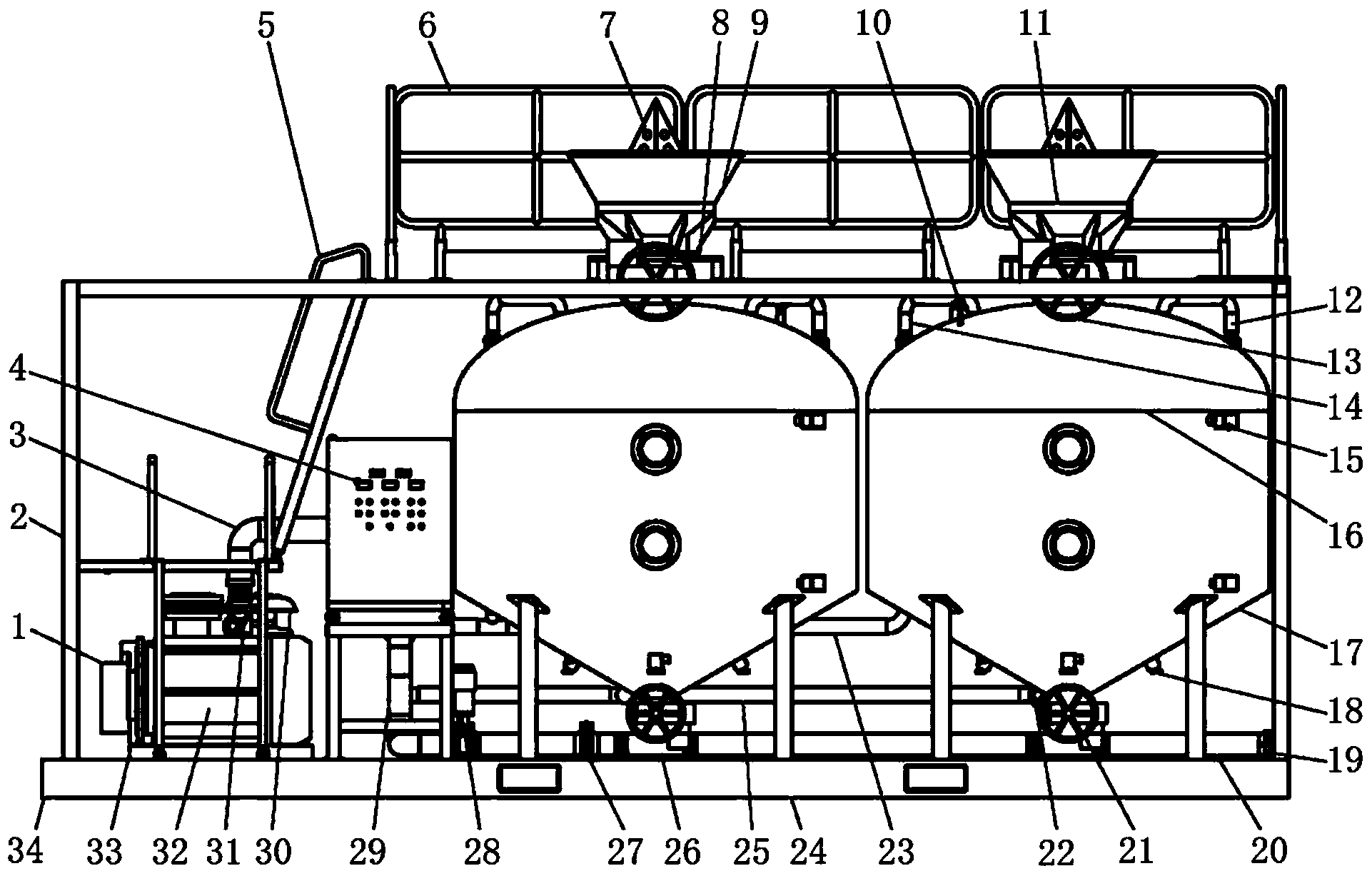

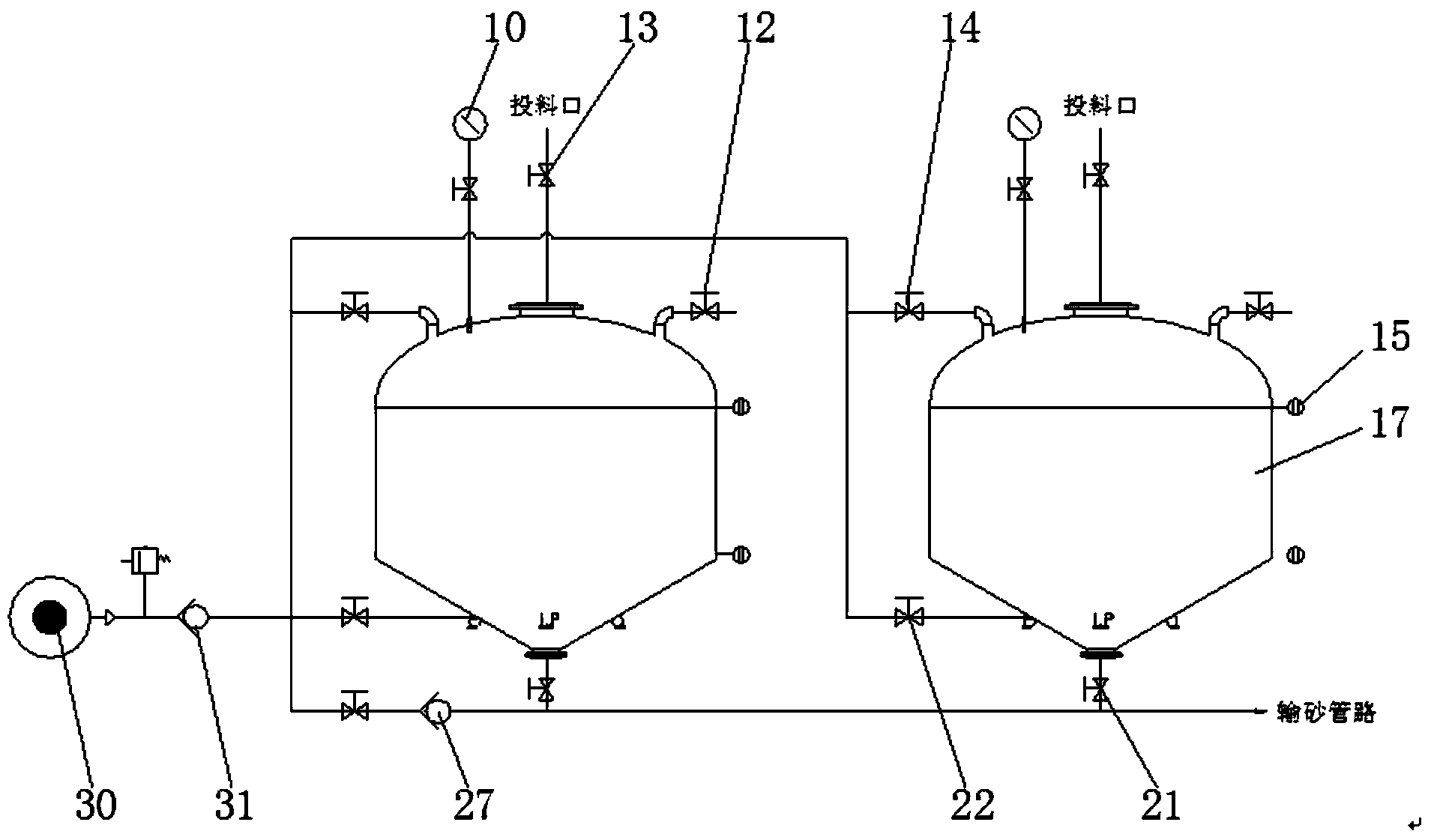

[0022] Such as Figure 1 to Figure 2 As shown, a positive pressure pneumatic conveying skid for oil field fracturing proppant includes a skid frame 24, which is characterized in that the skid frame 24 is equipped with a fan power drive system 1, a gas circuit and a sand delivery system 3, and a sending tank assembly 16. Mobile feeding device 11 and electrical control system 4;

[0023] The fan power drive system 1 includes a bracket 33, a drive motor 32, a fan accessory assembly and a fan 30;

[0024] The sending tank assembly includes two tank bodies 17, the upper part of the tank body is provided with a feed valve 13, an air intake control valve 14, an exhaust control valve 12, and the lower part of the tank body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com