Swing-type gap grouting device for building

A swinging, construction-use technology, applied in construction, building maintenance, building construction, etc., can solve the problems of nozzle damage and short service life of the nozzle, and achieve the effect of increasing the grouting flow, improving the service life and uniform grouting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

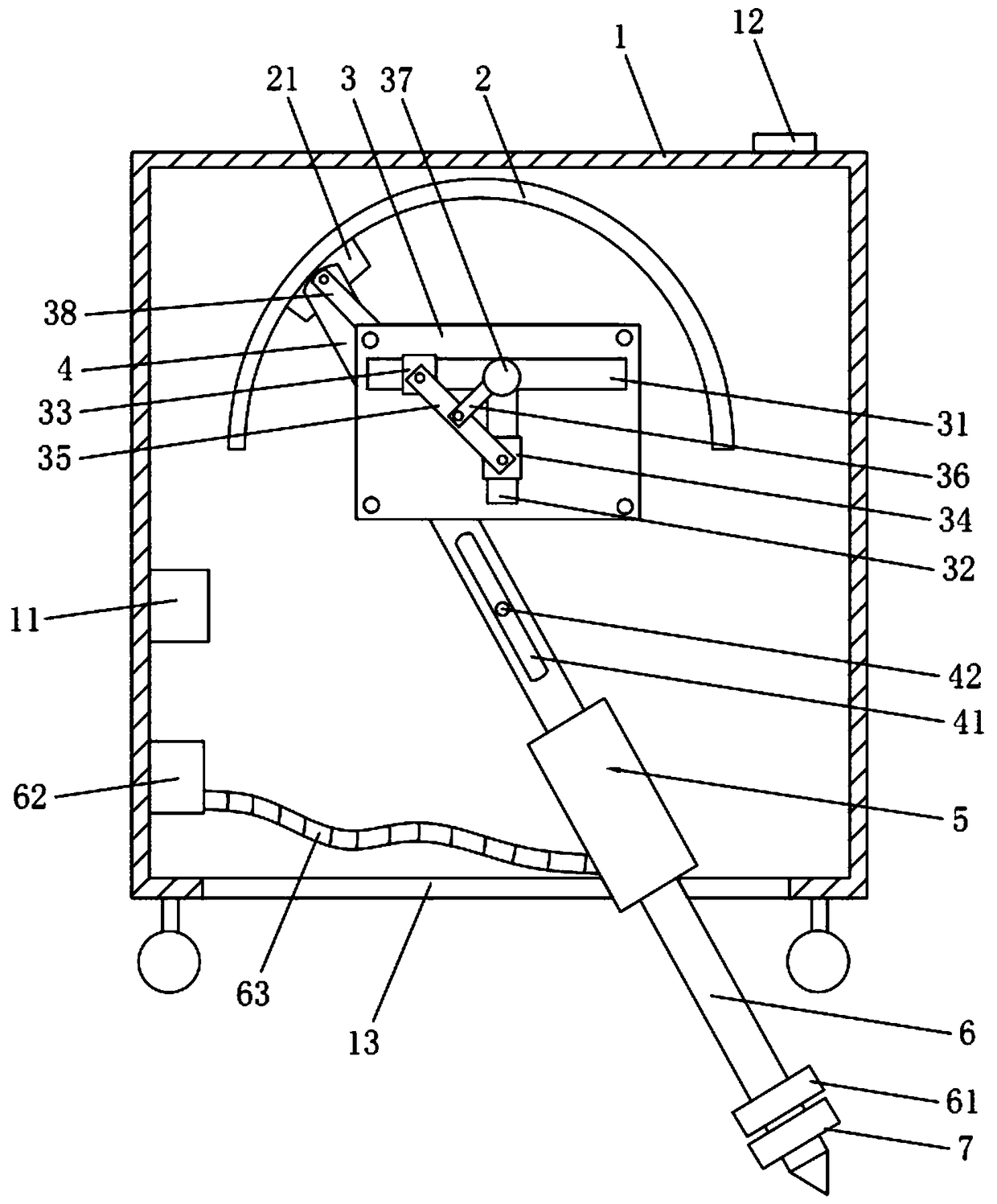

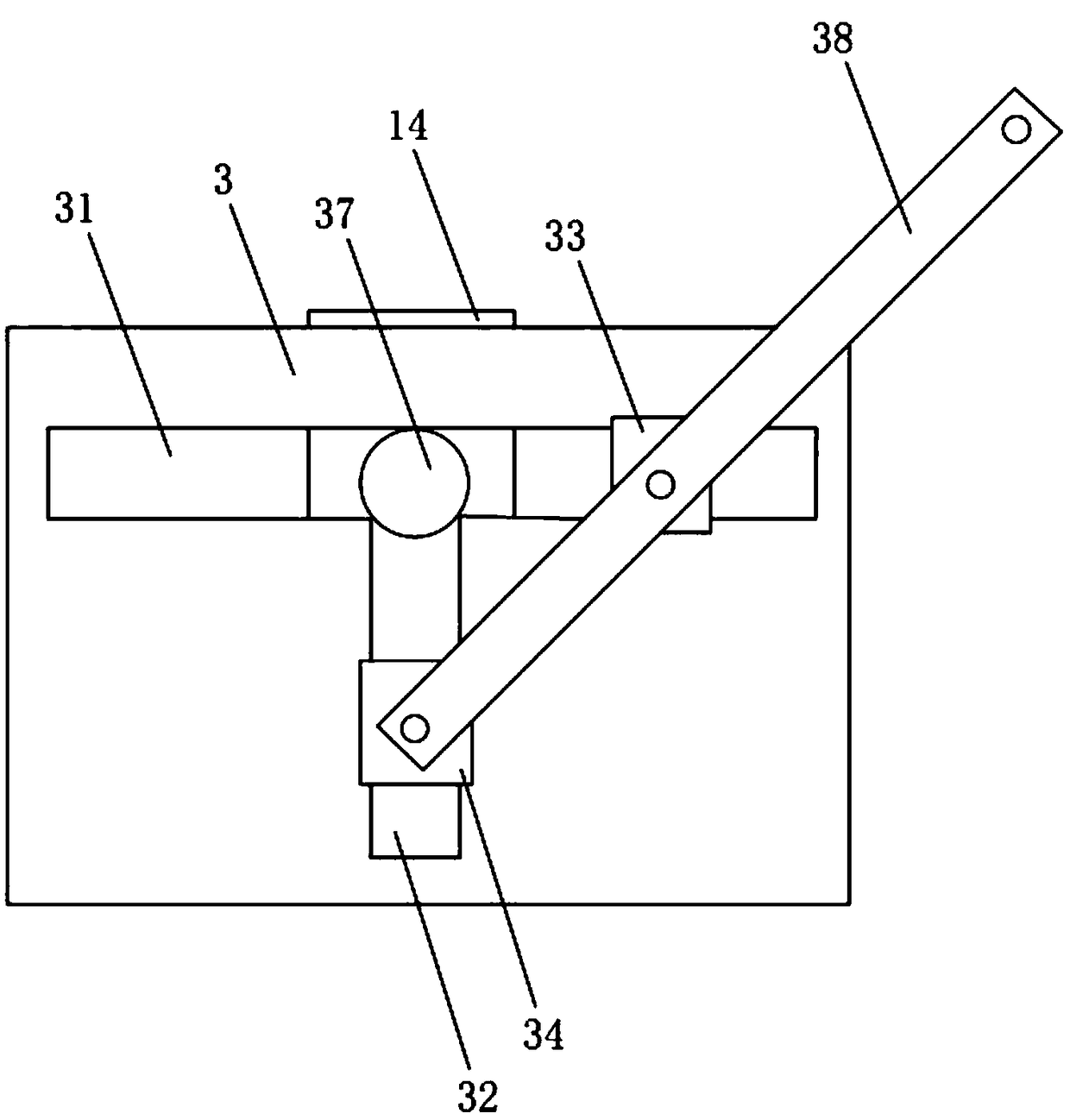

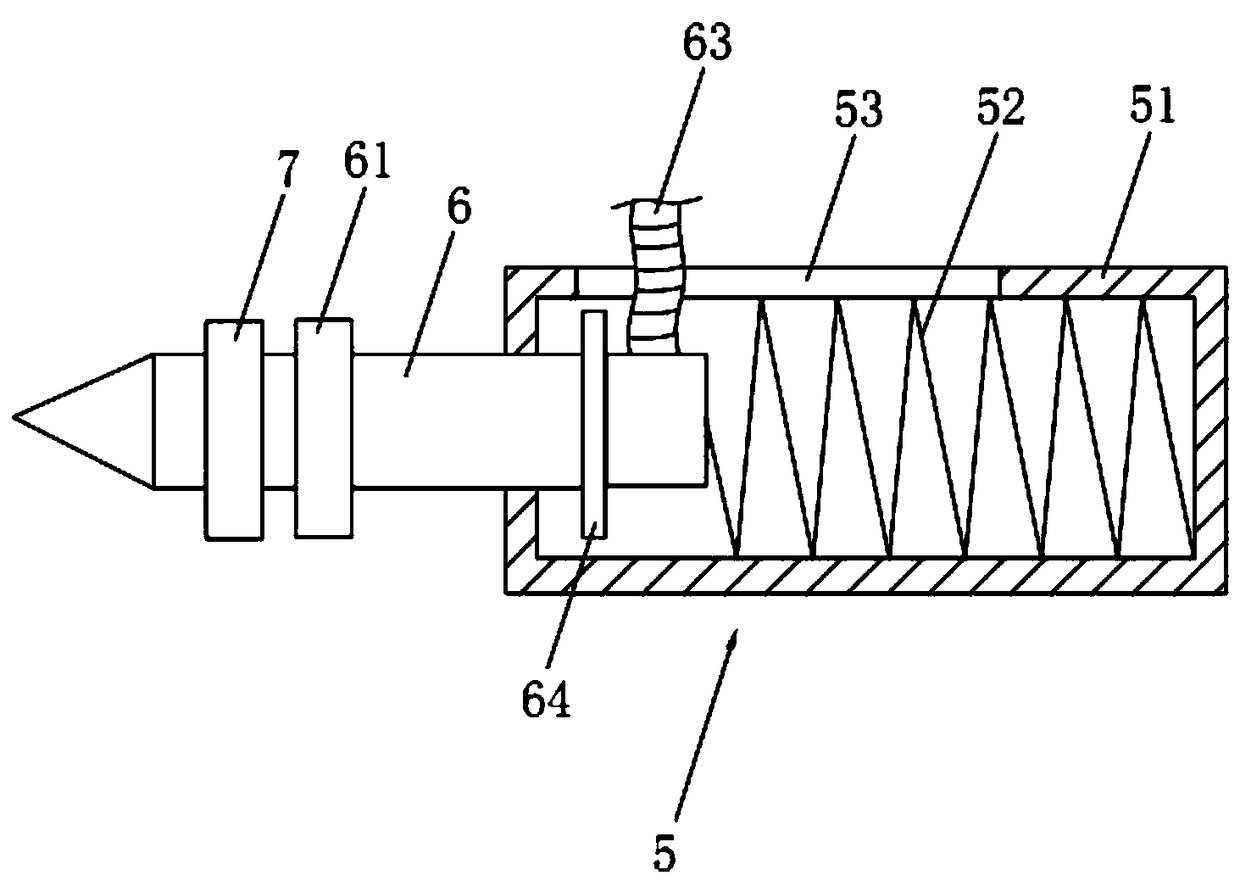

[0024] Embodiment: a kind of swinging type gap grouting device for construction, such as figure 1 As shown, it includes a main box body 1, a semi-elliptical slide rail 2 fixedly connected with the inner wall of the main box body 1, a slider 21 slidingly connected with the semi-elliptical slide rail 2, a swing rod 4, a spray head 6 and a 21 drive assemblies that move along the arc track direction of the semi-elliptical slide rail 2. The arc track of the semi-elliptical slide rail 2 in this embodiment is an arc curve intercepted along the short axis direction of the ellipse track. One end of the swing rod 4 is rotatably connected with the slider 21 , and the other end is fixedly connected with the spray head 6 . The inner wall of the main box body 1 is fixedly connected with a fixed shaft 42 , and the swing rod 4 is provided with a sliding groove 41 for inserting the fixed shaft 42 , and the sliding groove 41 extends along the length direction of the swing rod 4 . A hydraulic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com