Construction complete equipment for erosion-resistant protective layer of concrete foundation in salty soil zone

A technology for concrete foundations and complete sets of devices, applied in protection devices, infrastructure engineering, construction, etc., can solve the problems of poor adaptability, complex construction process and high construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Take the following components according to the mass percentage: 33.8% cement base material, 45% fine aggregate, 3.75% fly ash, 3.75% expansion agent, 0.53% water reducer, and the balance is water; the mass percentage of the above components The sum is 100%; the fineness modulus of fine aggregate is 2.5; the expansion agent is UEA-SM special high-efficiency concrete expansion agent; 20%; configuration water is ordinary fresh water or brine.

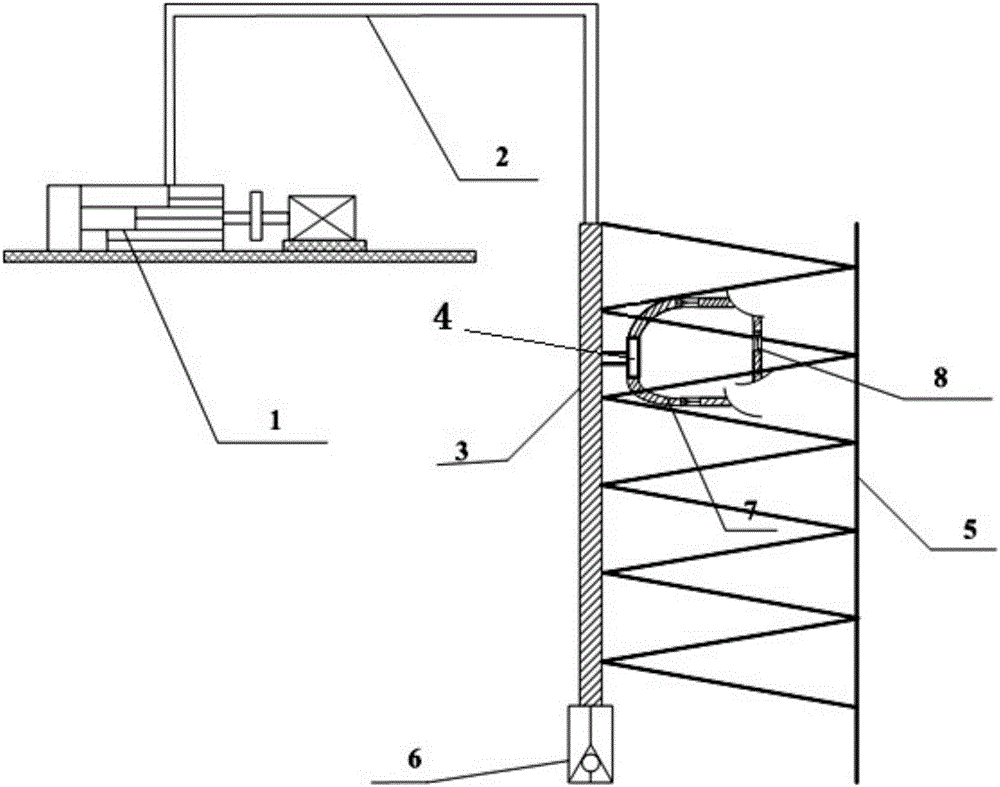

[0031] After the above components are uniformly mixed to obtain the anti-corrosion slurry, using the device of the present invention, the anti-corrosion slurry is injected between the concrete foundation and the surrounding formation through the grouting pump 1 through the grouting pipe 2 and the anti-corrosion slurry injection device, And the anti-corrosion slurry is fully mixed with brine and mud skin on the outer surface of the concrete foundation to form a dense and stable brine corrosion protection layer. The protective layer ...

Embodiment 2

[0033] Take the following components according to mass percentage: 20% cement base material, 30% fine aggregate, 5% fly ash, 5% expansion agent, 0.5% water reducing agent, and the rest is configuration water; the mass percentage of the above components The sum is 100%; the fineness modulus of fine aggregate is 2.0; the expansion agent is UEA-SM special high-efficiency concrete expansion agent; 18%; configuration water is ordinary fresh water or brine.

[0034] After the above components are uniformly mixed to obtain the anti-corrosion slurry, using the device of the present invention, the anti-corrosion slurry is injected between the concrete foundation and the surrounding formation through the grouting pump 1 through the grouting pipe 2 and the anti-corrosion slurry injection device, And the anti-corrosion slurry is fully mixed with brine and mud skin on the outer surface of the concrete foundation to form a dense and stable brine corrosion protection layer. The protective l...

Embodiment 3

[0036] Take the following components according to mass percentage: 30% cement base material, 50% fine aggregate, 3% fly ash, 10% expansion agent, 2% water reducing agent, and the rest is configuration water; the mass percentage of the above components The sum is 100%; the fineness modulus of fine aggregate is 1.8; the expansion agent is UEA-SM special high-efficiency concrete expansion agent; 20%; configuration water is ordinary fresh water or brine.

[0037] After the above components are uniformly mixed to obtain the anti-corrosion slurry, using the device of the present invention, the anti-corrosion slurry is injected between the concrete foundation and the surrounding formation through the grouting pump 1 through the grouting pipe 2 and the anti-corrosion slurry injection device, And the anti-corrosion slurry is fully mixed with brine and mud skin on the outer surface of the concrete foundation to form a dense and stable brine corrosion protection layer. The protective la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com