Preparation method of CO2 plastic foaming agent and injection system of CO2 plastic foaming agent

A foaming agent, CO2 technology, applied in the field of plastic foaming agent injection system, can solve the problems of low decomposition, dry ice formation, unevenness, etc., and achieve the effect of improving flame retardancy, stable injection, and stable injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

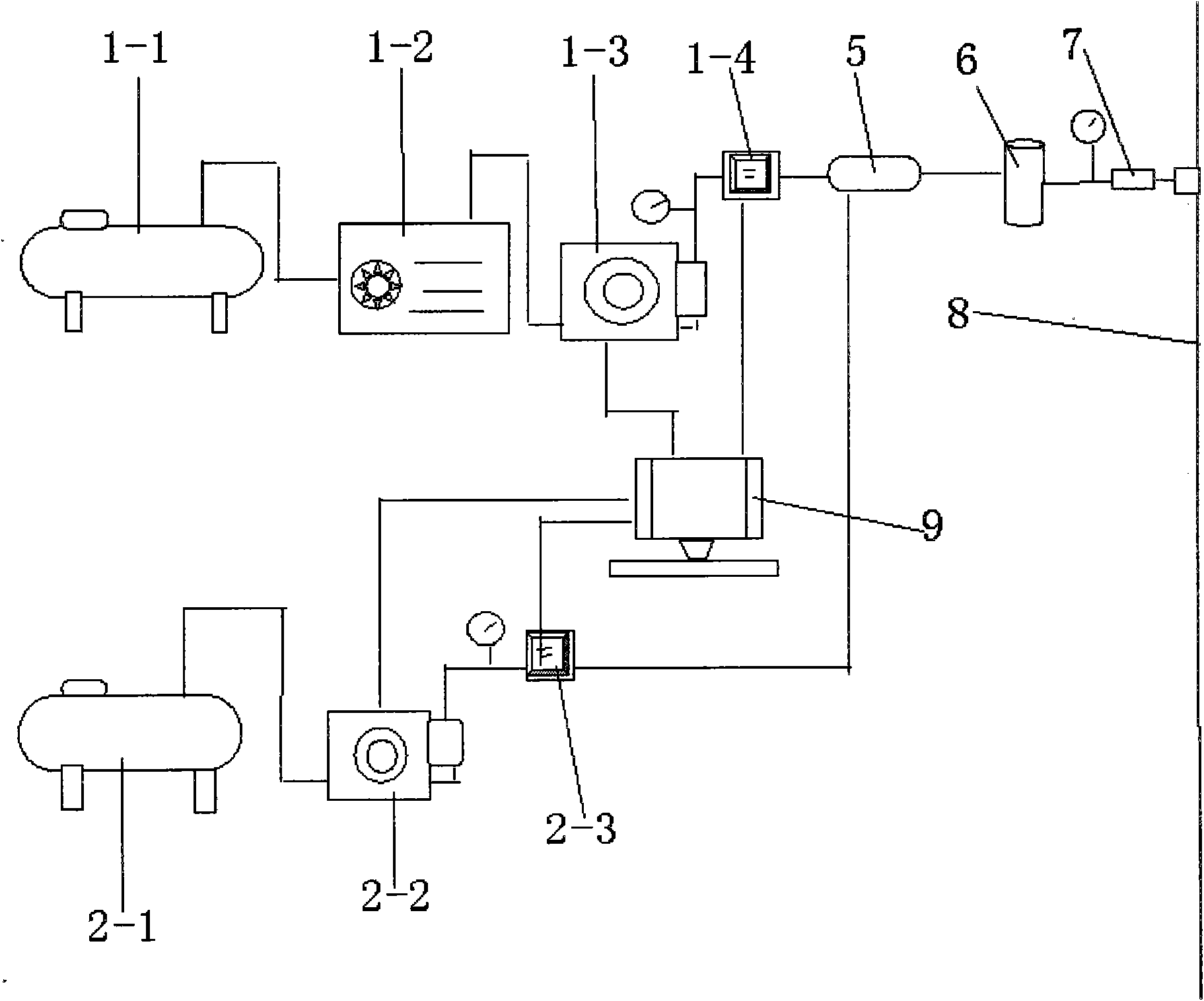

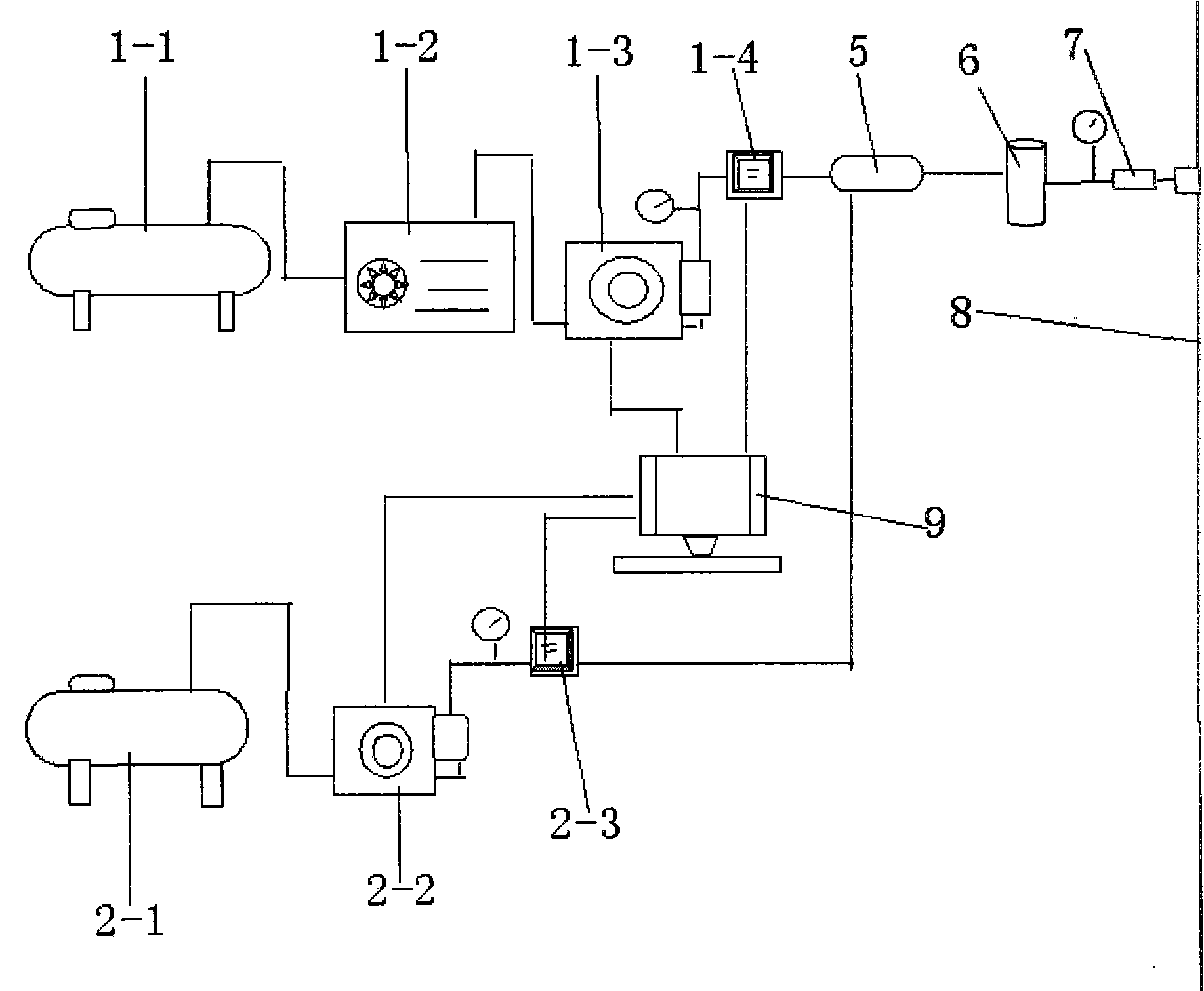

[0019] Such as figure 1 Shown, for the CO described in the present invention 2 Schematic diagram of the plastic blowing agent injection system. The system consists of CO 2 Injection device and ethanol injection device;

[0020] The CO 2 Injection device including liquid CO 2 Storage tank 1-1, the CO 2 The liquid storage tank is connected to the low-temperature refrigeration system 1-2, and the low-temperature refrigeration system is connected to the high-pressure diaphragm cryogenic injection pump 1-3: the high-pressure diaphragm cryogenic injection pump is connected to the CO 2 Data flow sensor 1-4;

[0021] The ethanol injection device includes an ethanol liquid storage tank 2-1, the ethanol liquid storage tank is connected to a high-pressure injection pump 2-2, and the high-pressure injection pump is connected to an ethanol flow data sensor 2-3;

[0022] The CO 2 The data flow sensor and the ethanol data flow sensor are connected to the same static mixer 5 respectiv...

Embodiment 2

[0026] The present invention a kind of CO 2 Preparation method of plastic blowing agent, described blowing agent is made of liquid CO 2 Prepared with food grade ethanol, the weight ratio of the two is: liquid CO 2 3 parts, 2 parts of food grade ethanol; the preparation method is: CO 2 by CO 2 The liquid storage tank enters the high-pressure diaphragm low-temperature injection pump through the refrigeration system and passes through the CO 2 The metering ratio of the flow data sensor enters the static mixer, and the ethanol enters the high-pressure injection pump from the ethanol liquid storage tank and enters the static mixer through the metering ratio of the ethanol flow data sensor. The two enter the energy storage tank after being fully mixed in the static mixer. Under the stable pressure of the energy storage tank, the mixed liquid is continuously injected into the blowing agent body by the one-way injection valve to produce CO 2 Plastic blowing agent.

[0027] The hi...

Embodiment 3

[0029] The present invention a kind of CO 2Preparation method of plastic blowing agent, described blowing agent is made of liquid CO 2 Prepared with food grade ethanol, the weight ratio of the two is: liquid CO 2 4 parts, 1 part of food grade ethanol; the preparation method is: CO 2 by CO 2 The liquid storage tank enters the high-pressure diaphragm low-temperature injection pump through the refrigeration system and passes through the CO 2 The metering ratio of the flow data sensor enters the static mixer, and the ethanol enters the high-pressure injection pump from the ethanol liquid storage tank and enters the static mixer through the metering ratio of the ethanol flow data sensor. The two enter the energy storage tank after being fully mixed in the static mixer. Under the stable pressure of the energy storage tank, the mixed liquid is continuously injected into the blowing agent body by the one-way injection valve to produce CO 2 Plastic blowing agent.

[0030] The hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com