Organic electroluminescent element and its manufacturing method

An electroluminescent device and electroluminescent technology, which can be used in the manufacture of semiconductor/solid-state devices, electric solid-state devices, electrical components, etc., and can solve problems such as insufficient durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

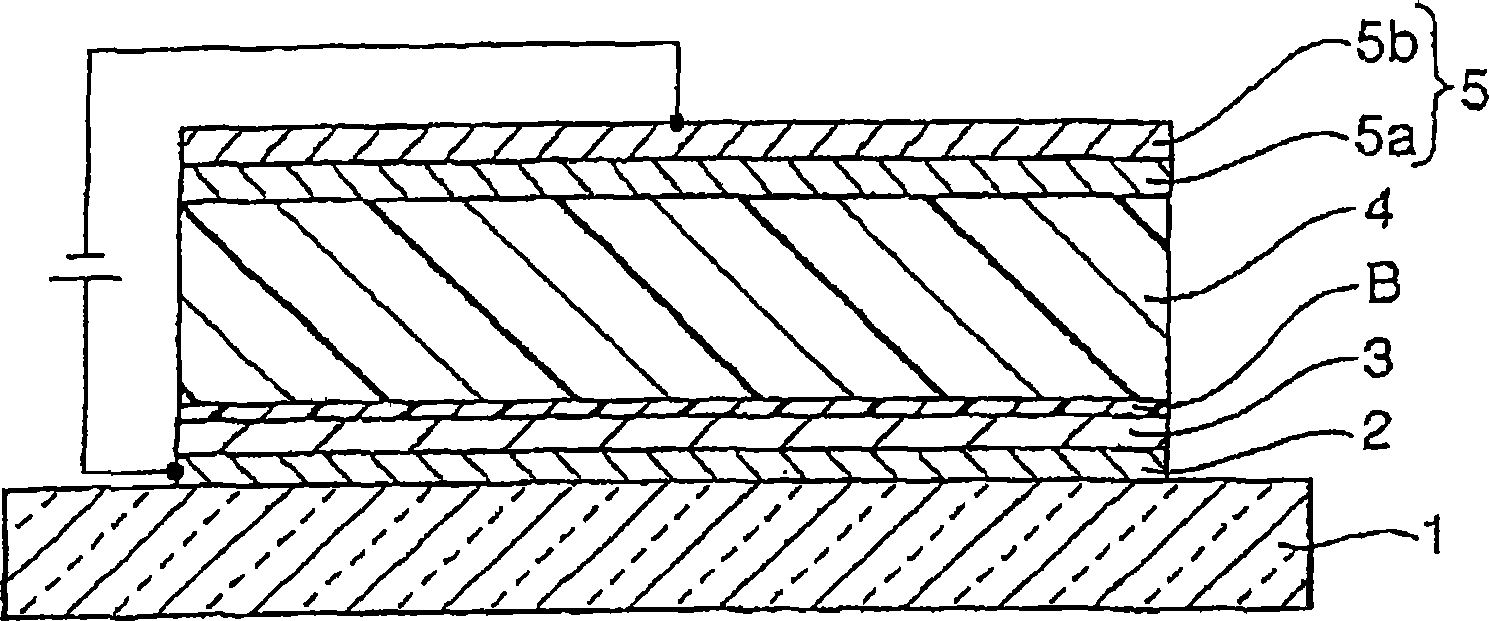

[0076] figure 1 It is a schematic diagram of a polymer organic EL device according to an embodiment of the present invention.

[0077] The present embodiment is characterized in that a metal oxide thin film is formed on the transparent anode 2 on the light-transmitting substrate 1 as the charge injection layer 3, and a polymer material layer as the buffer layer B having an electron blocking function and a polymer material layer as the buffer layer B having an electron blocking function are laminated thereon. Another polymer material layer of the light-emitting layer 4, the cathode 5 is formed above all of them.

[0078] That is, if figure 1 As shown, the organic electroluminescence device of the embodiment is made of a substrate 1 made of a transparent glass material, an ITO layer (indium titanium oxide) formed on the substrate 1 as the anode 2, and a charge injection layer 3 formed thereon. The metal oxide film is composed of an electron blocking layer made of a polymer mat...

Embodiment 1

[0086] Next, embodiments of the present invention are described.

[0087] structure and figure 1 given the same structure and will refer to figure 1 do explain.

[0088] The organic electroluminescent device of embodiment 1 is made by the substrate 1 that is called Corning 7029# 1mm thick glass sheet, is formed on it and is formed on the anode 2 that is made of 20nm thick ITO thin film, is formed on the anode 2 and is made of 20nm A charge injection layer 3 composed of a thick molybdenum oxide film, a polyfluorene-based compound formed on the charge injection layer 3 (especially poly[9,9-dioctylfluorene-2,7-diyl]-alternating-co- (N, N'-diphenyl)-N, N'-two (p-butyl-oxyphenyl)-1,4-diaminobenzene) (poly[9,9-dioctylfluorenyl-2,7-diyl ]-alt-co-(N,N′-diphenyl)-N,N′-di(p-butyl-oxyphenyl)-1,4-diaminobenzene) 20nm thick buffer layer B, made of polyfluorene-based compound ( Especially poly[(9,9-dioctylfluorene-2,7-diyl)-co-1,4-benzo-{2,1'-3}-thiadiazole] (poly[(9, 9-dioctylfluoreny...

Embodiment 2

[0129] Next, Embodiment 2 of the present invention will be discussed.

[0130] In the above Example 1, the polyfluorene-based compound was used in the light-emitting layer, but this example uses a PPV-based material in the light-emitting layer 4, poly[2-methoxy-5-(2-ethylhexyloxy base)-1,4-phenylenevinylene](poly[2-methoxy-5-(2-ethylhexyloxy)-1,4-phenylenevinylene]). Like Example 1, this material is also commercially available from Nihon SiberHegner K.K.

[0131] Other structures are constituted the same as in Embodiment 1.

[0132] In this case, the luminous intensity can generally be increased further.

[0133] In addition, in Example 1 and Example 2, a glass substrate was used as the substrate 1, but it is not limited to glass. Usually glass is used. Also in this embodiment, a glass substrate is used. Various materials have been suggested as the substrate material, including glass, plastic film, and the like, and these can be used as the substrate 1 of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com