Patents

Literature

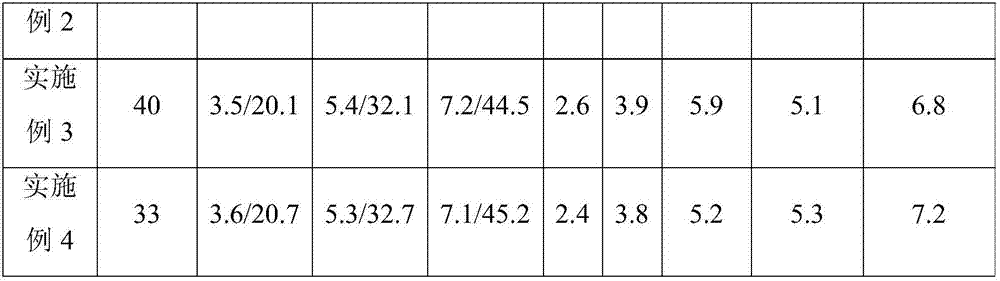

767results about How to "Reduced impact strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

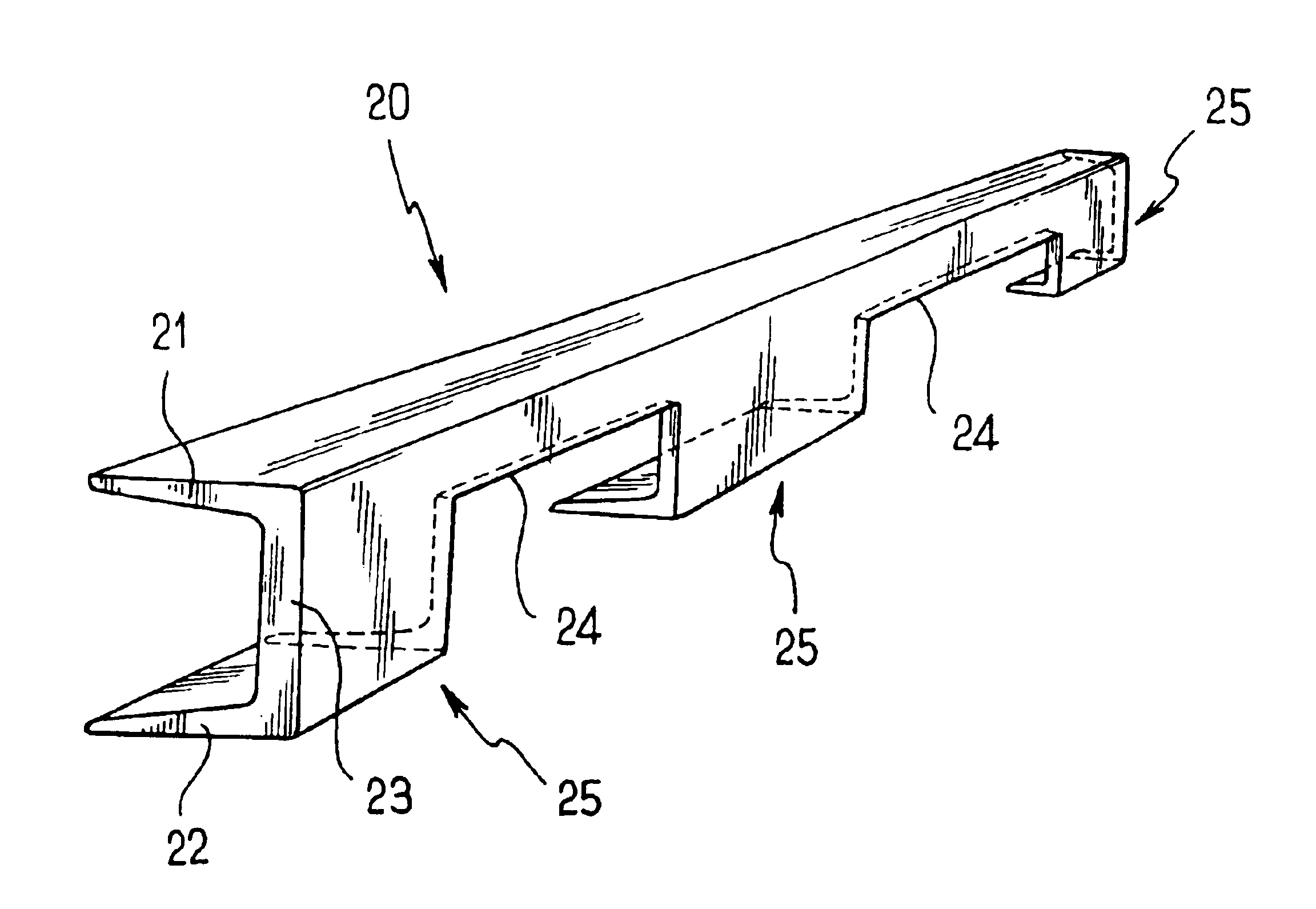

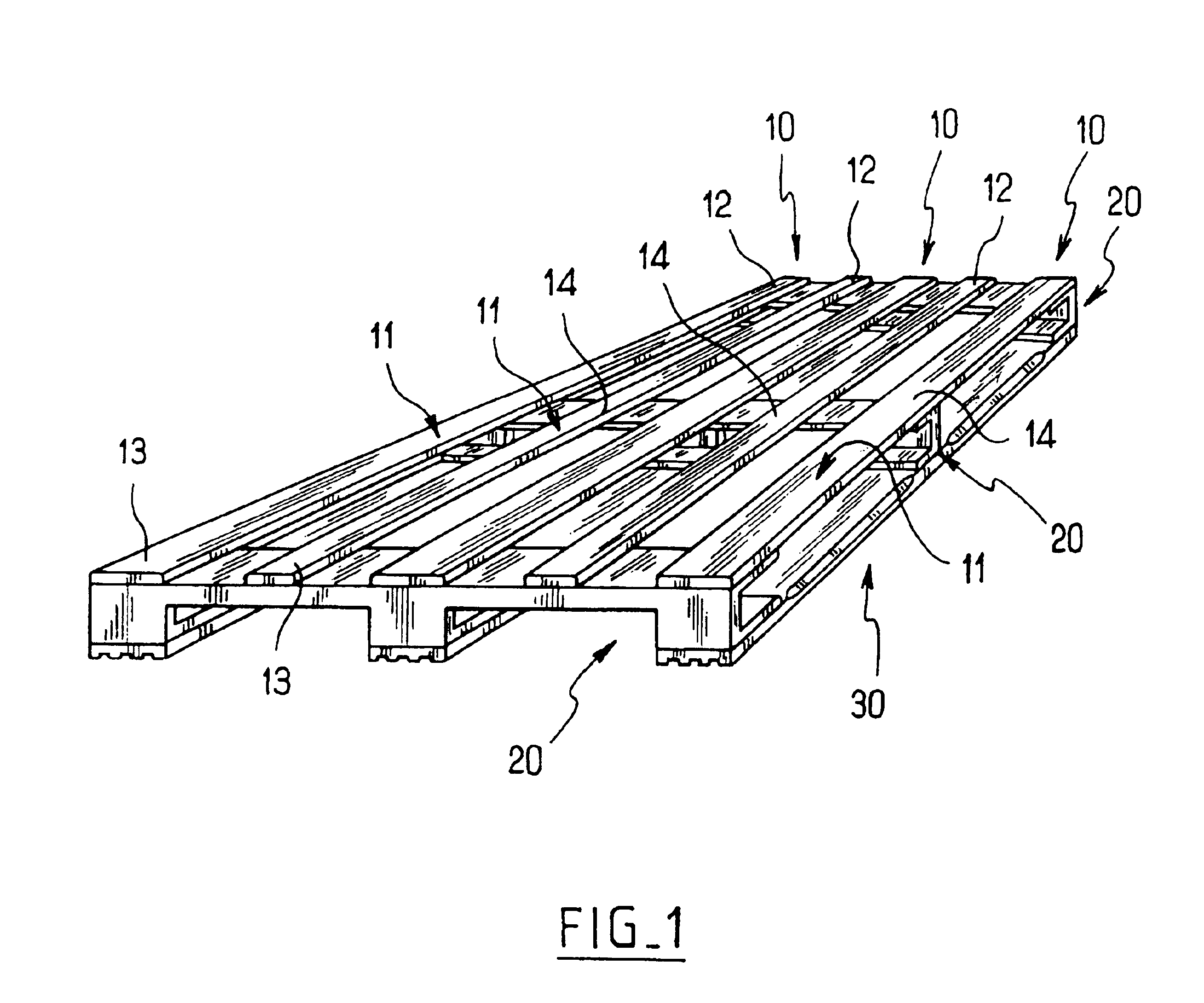

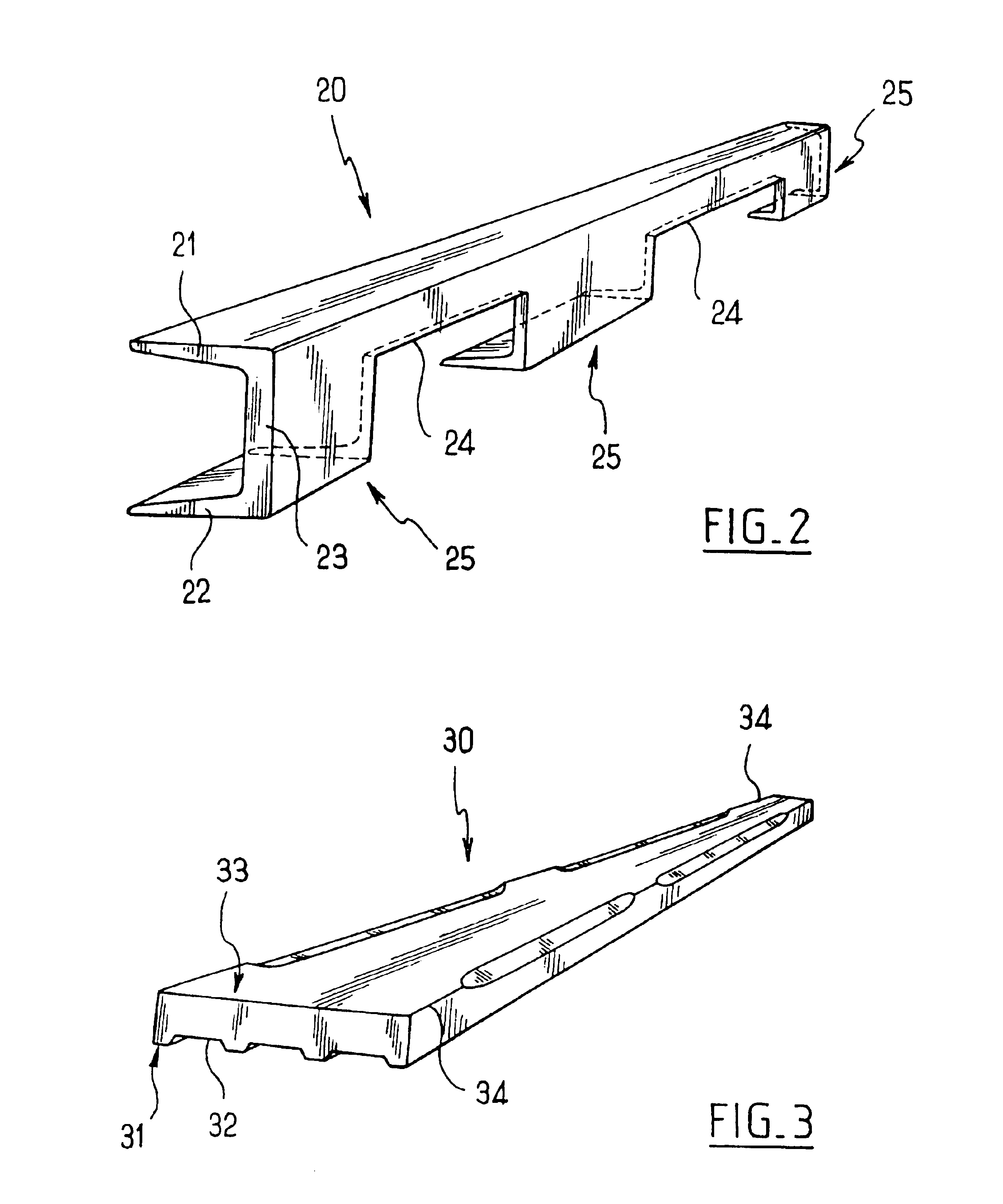

Part made of recycled thermoplastic material, a corresponding method of manufacture, and a pallet comprising at least one bar of this type

InactiveUS6780500B2Improve featuresSatisfactory characteristicSynthetic resin layered productsPlastic recyclingPolyethylene terephthalateEngineering

Owner:DUMOUCHEL CATHERINE +1

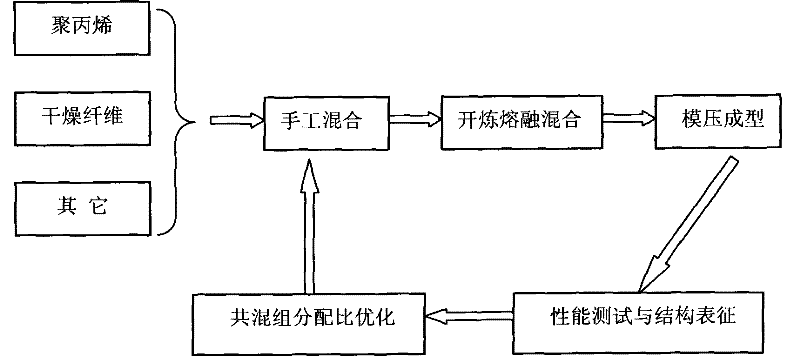

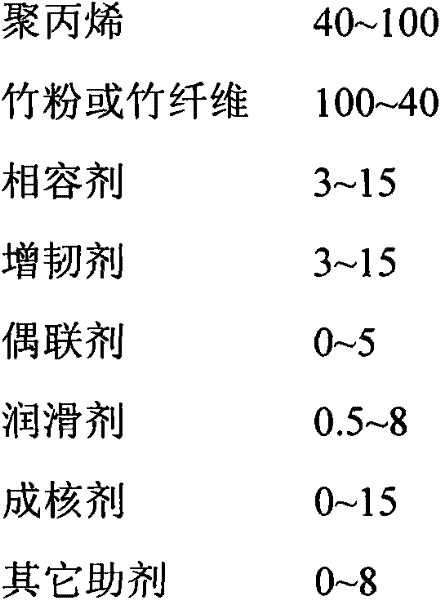

Novel bamboo-plastic composite material

The invention relates to a preparation method of a novel bamboo-plastic composite material, in particular to a bamboo-plastic composite material which has excellent mechanical property and is prepared by the step of adding reinforcing material bamboo powder (or bamboo fabric), a flexibilizer and other assistants to polypropylene used as a substrate resin, wherein the bamboo-plastic composite material comprises the following components in parts by mass: 40-100 parts of polypropylene, 40-100 parts of bamboo powder or bamboo fabric, 3-15 parts of compatilizer, 3-15 parts of flexibilizer, 0-5 parts of coupling agent, 0.5-8 parts of lubricant, 0-15 parts of nucleator and 0-8 parts of other assistants. According to the invention, by selecting proper types and proportions of flexibilizer, compatilizer and other assistants, the defect that the impact strength of the composite material is reduced greatly due to the addition of fiber is overcome.

Owner:EAST CHINA UNIV OF SCI & TECH

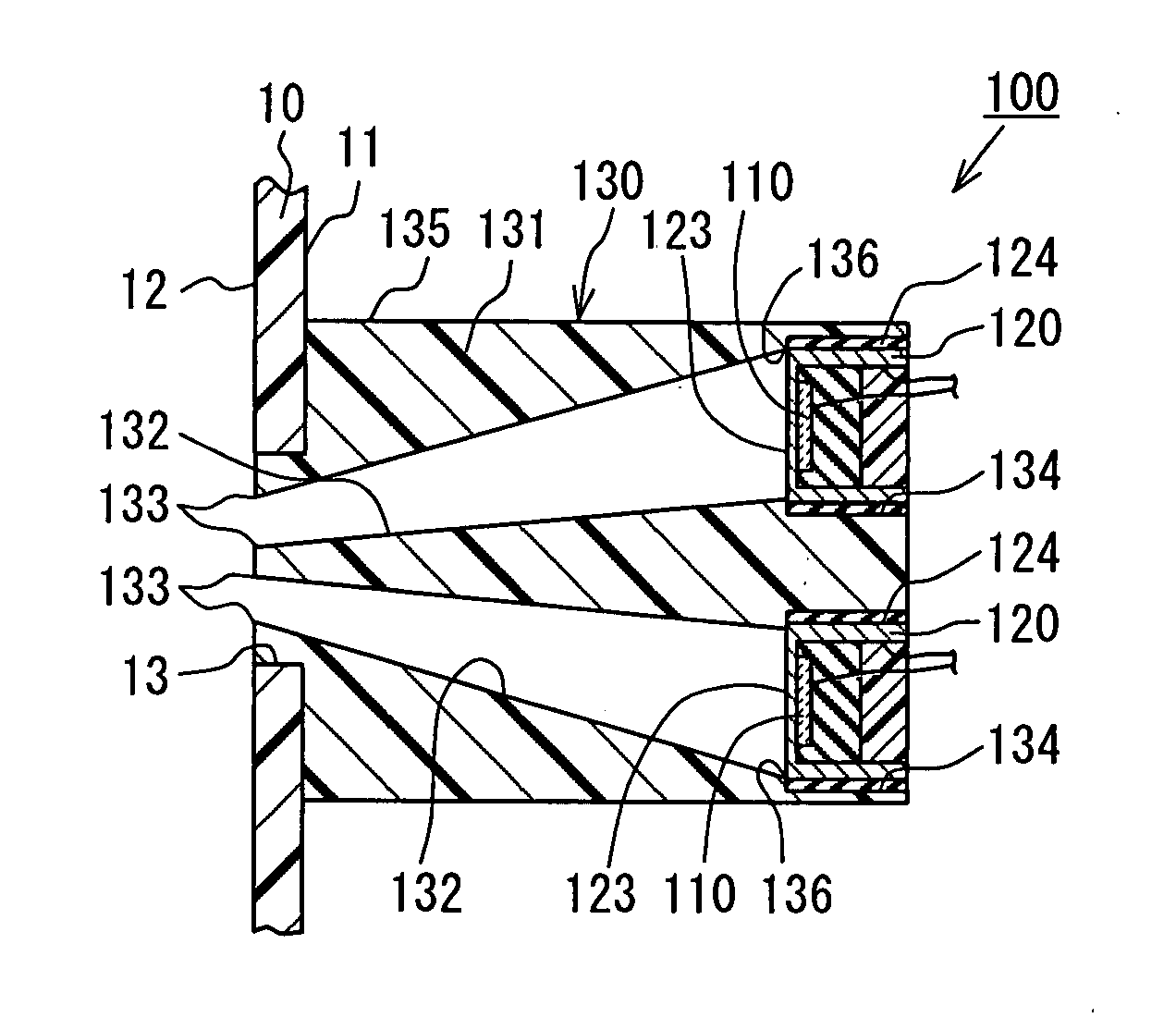

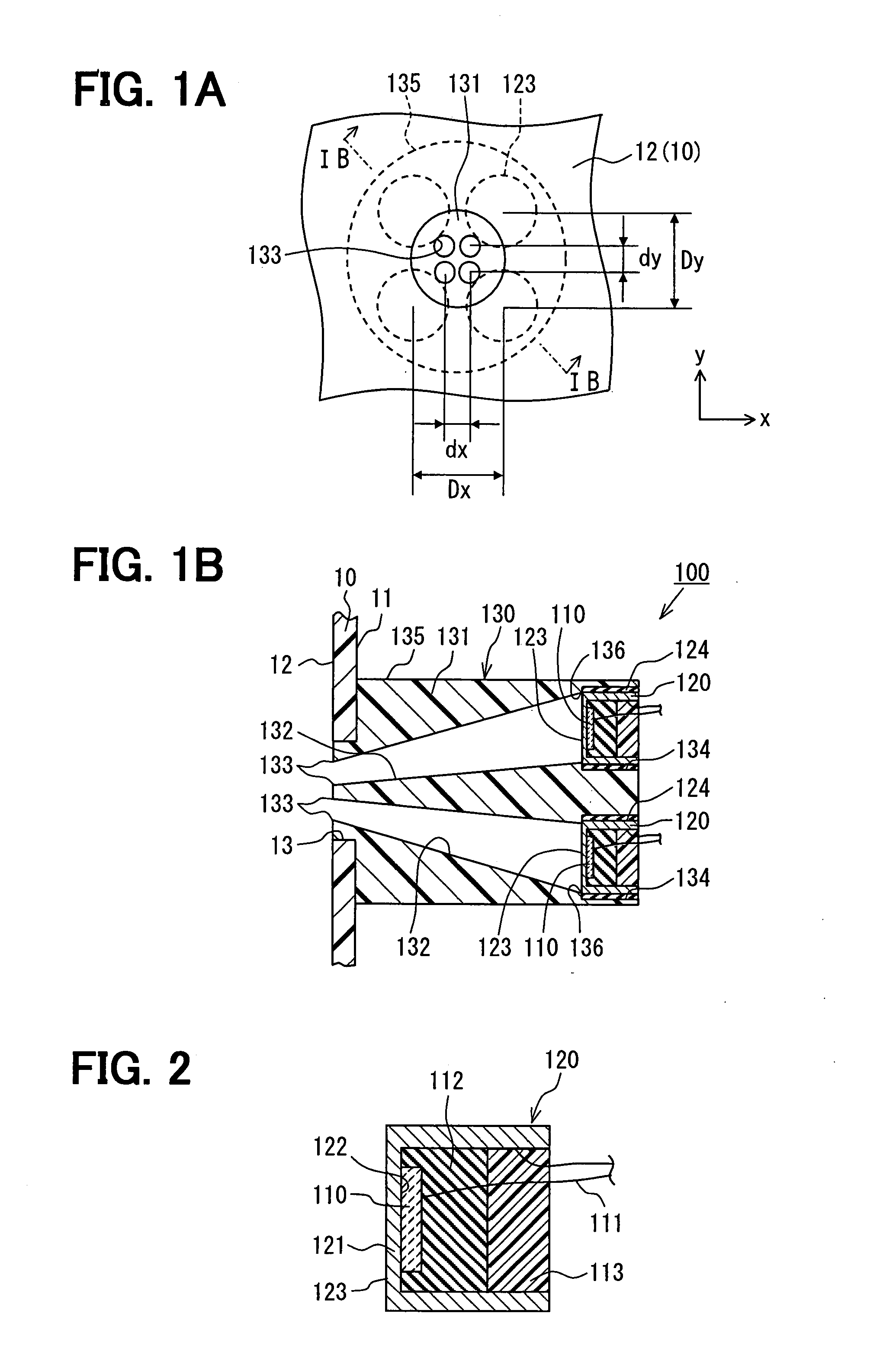

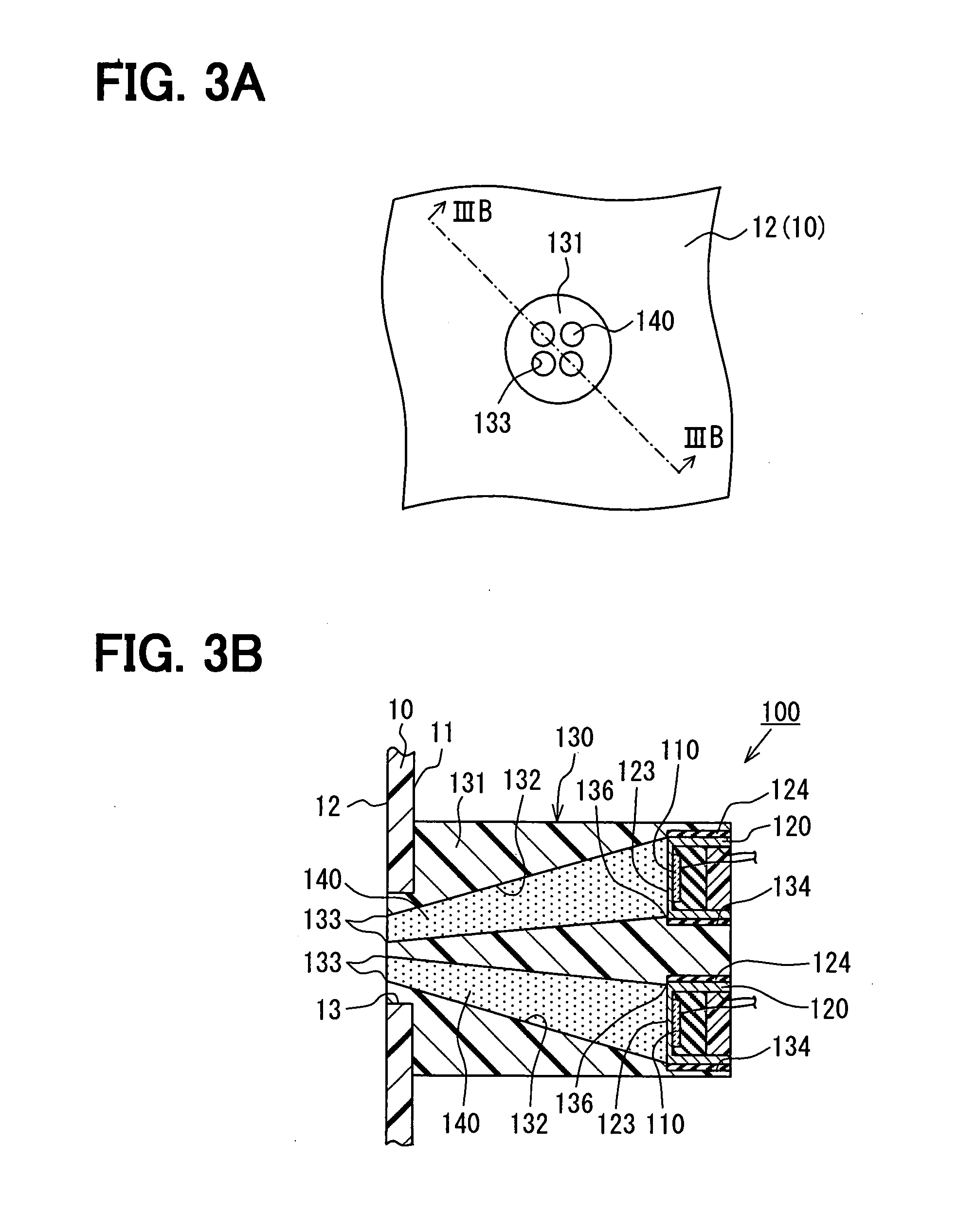

Ultrasonic sensor and obstacle detection device

InactiveUS20080232197A1Reduced impact strengthSimple designPiezoelectric/electrostrictive transducersMechanical vibrations separationUltrasonic sensorPhase difference

An ultrasonic sensor includes: a first vibrator for transmitting an ultrasonic wave; multiple second vibrators for outputting a reception signal of a reflection wave; a casing having a bottom for accommodating the vibrators, an outer surface of the bottom providing a vibrating surface; and multiple tubes for guiding the ultrasonic wave. Each tube has a first opening coupled with an outside of a mobile body. An area of the first opening is smaller than an area of the vibrating surface. A distance between two adjacent first openings is smaller than a distance between two adjacent vibrating surfaces. The length of the tubes is determined to equalize a phase difference of the reflection waves at the first openings is equal to that at the vibrating surfaces.

Owner:DENSO CORP +1

High-performance recovered PET/ABS alloy

The invention discloses a high-performance recycled PET / ABS alloy. The alloy comprises the following components in percentage by weight: 30 to 80 percent of recycled PET, 10 to 50 percent of ABS, 1 to 10 percent of reinforcing agent, 2 to 15 percent of compatilizer, 0.5 to 5 percent of flexibilizer, 0.5 to 3 percent of polyhydroxy chemical coupling agent, and 0.1 to 1 percent of antioxidant. The alloy can improve a recycled PET system by using reasonable matching of additives, effects of the polyhydroxy chemical coupling agent, and excellent physical mechanic properties of an ABS system. Therefore, the recycled PET / ABS alloy has the advantages of high compatibility, high tensile strength, high mobility, good machinability and the like, is particularly suitable for producing complicated components and parts and large plates, has a simple process, is suitable for mass production of medium-sized and small enterprises, and has obvious economic benefit and social benefit.

Owner:SOUTH CHINA NORMAL UNIVERSITY

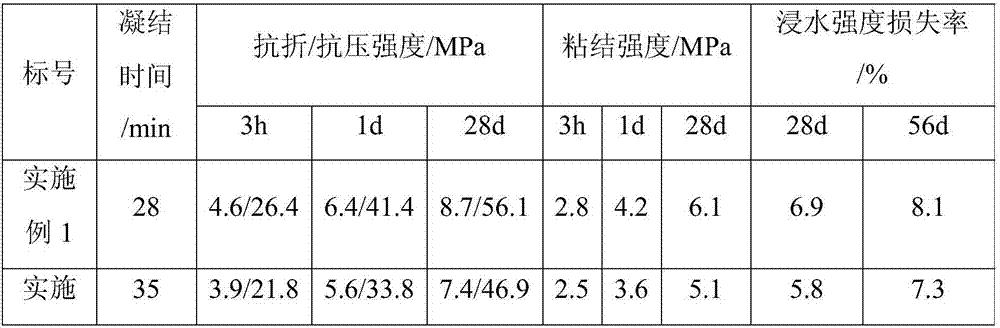

Phosphate cement based patching material and preparation method thereof

The invention relates to a phosphate cement based patching material and a preparation method thereof. The patching material is prepared from the following ingredients in parts by weight: 100 parts of magnesium phosphate cement, 20 to 40 parts of mineral admixtures, 120 to 140 parts of fine aggregates, 0.5 to 1 part of water glass, 0.5 to 1 part of fiber and 20 to 30 parts of water. The preparation method is characterized in that the raw materials are proportionally weighed; magnesium oxide, monopotassium phosphate and composite retarders are firstly stirred and mixed; then, the magnesium phosphate cement is obtained; then, the mineral admixtures and the fine aggregates are added; after uniform stirring, the water glass, the fiber and the water are added; stirring is performed for 3 to 4 minutes by a stirring machine; the phosphate cement based patching material is obtained. The prepared phosphate cement based patching material by the invention has the advantages that the coagulation time is about 30 minutes; the restoration time is short; the construction is not influenced; the restoration effect is obvious; the application requirement of fast patching the damaged road surface is met; the phosphate cement based patching material is applicable to fast restoration projects of cement concrete pavements.

Owner:WUHAN UNIV OF TECH

Polypropylene-based resin composition and injection molded article thereof

InactiveUS6011102AReduced impact strengthInferior appearanceFilm/foil adhesivesMixingPolymer scienceOctene

A polypropylene-based resin composition comprising: (1) 55 to 75% by weight of a polypropylene-based resin (A) selected from the following (i) and (ii); (i) a crystalline propylene-ethylene block copolymer composed of a propylene homopolymer portion as a first segment and a propylene-ethylene random copolymer as a second segment, and (ii) a mixture of the crystalline propylene-ethylene block copolymer (i) and a crystalline propylene homopolymer; (2) 10 to 15% by weight of an ethylene-octene copolymer rubber (B) having a melt flow rate (measured according to JIS-K-6758, 190 DEG C.) of 0.5 to 10 g / min., an octene content of 20 to 25% by weight and a density of 0.860 to 0.875; and (3) 15 to 30% by weight of talc (C) having an average particle diameter of not more than 3 mu m, the total amount of (A), (B) and (C) being 100% by weight, wherein said polypropylene-based resin composition satisfies the following expression:0.25< / =(A)' / [(A)'+(B')]< / =0.40in which (A)' represents an amount by weight of the second segment of the crystalline propylene-ethylene block copolymer (i) in the polypropylene-based resin composition and (B') represents an amount by weight of the ethylene-octene copolymer rubber (B) in the polypropylene-based resin composition, and further has a specific flexural modulus, Izod impact strength, elongation, melt flow rate and density.

Owner:TOYOTA JIDOSHA KK +1

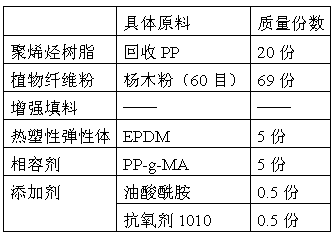

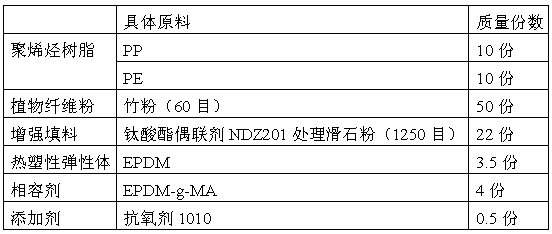

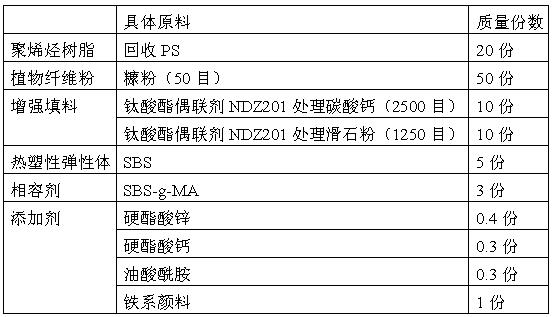

Elastomer toughening wood-plastic composite material and preparation method thereof

An elastomer toughening wood-plastic composite material is composed of, by mass percentage, 15-30% of polyolefin resin, 40-70% of plant fiber powder, 0-30% of reinforcing filler, 1-5% of thermoplastic elastomers, 2-5% of compatilizer, and 0-2% of additives. According to the elastomer toughening wood-plastic composite material and a preparation method of the elastomer toughening wood-plastic composite material, the high fiber content, mechanical strength and rigidity of the wood-plastic composite material are kept, and meanwhile, toughness of the wood-plastic composite material is improved. The cracking and fractured rate of the wood-plastic composite material during the processing and using processes is lowered, and the service life of the wood-plastic composite material is prolonged.

Owner:WUXI SHUNXUAN NEW MATERIALS +1

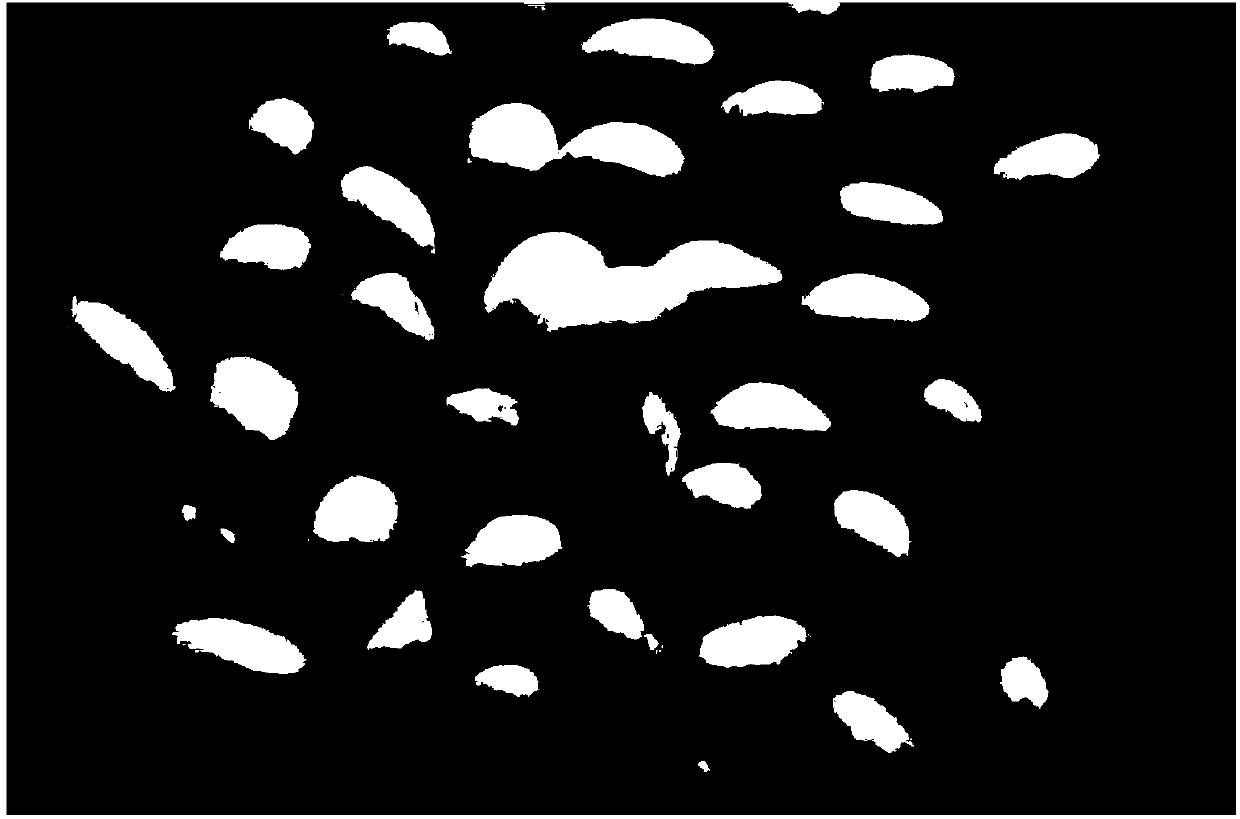

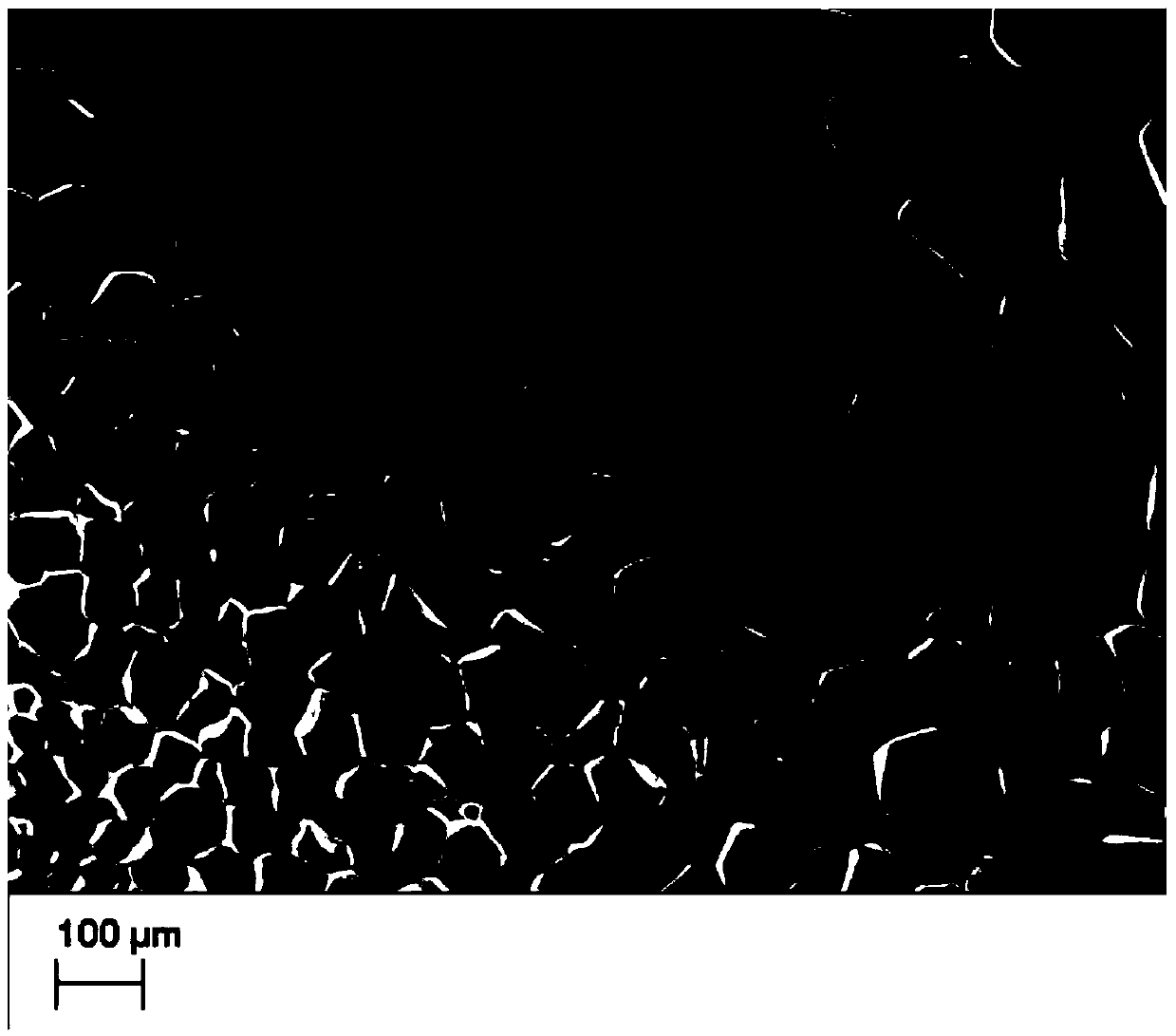

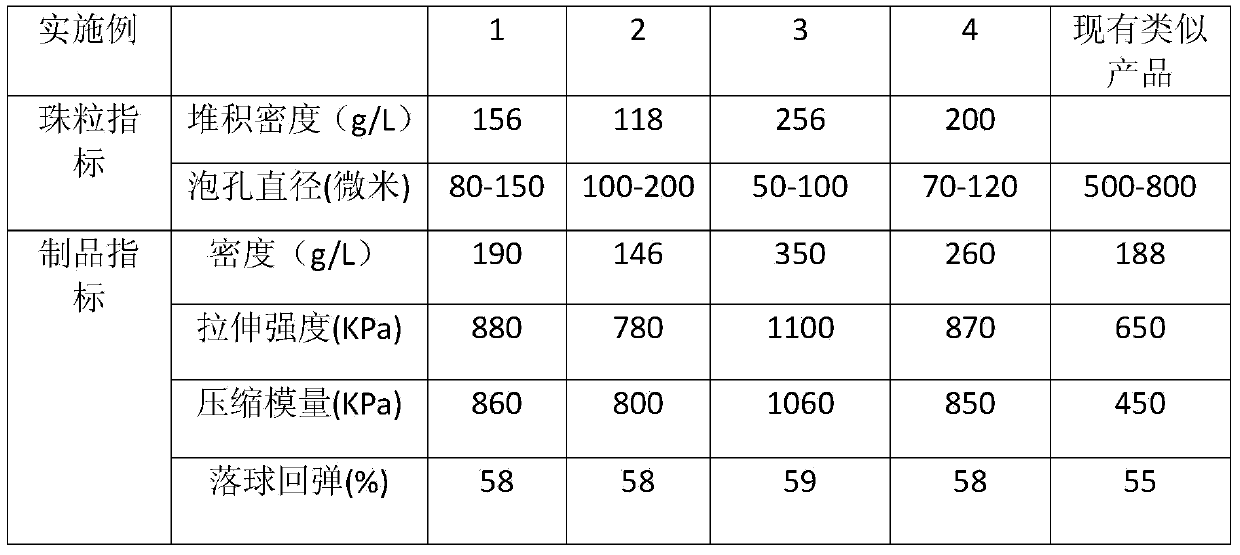

Thermoplastic polyurethane elastomer foam bead and preparation method thereof

The invention discloses a thermoplastic polyurethane elastomer foam bead and a preparation method thereof. The method comprises the following steps: firstly, adding thermoplastic polyurethane particles and water to a reaction kettle according to the mass ratio of 1 to (0.8-4); adding liquid carbon dioxide to the reaction kettle, and controlling the intensity of pressure and the temperature in the reaction kettle, so that the carbon dioxide in the reaction kettle is in a super-critical state; raising the temperature inside the reaction kettle to 90-140 DEG C; carrying out heat preservation; putting the materials in the kettle into a pressure tank, maintaining pressure, and cooling to below 70 DEG C; foaming the thermoplastic polyurethane elastomer particles once, and controlling the volume ratio of the reaction pressure to the pressure tank to be 1 to (15-30); putting the disposable foam particles into a storage tank, and carrying out secondary normal pressure foaming to obtain thermoplastic polyurethane elastomer foam beads; and removing the surface moisture of the foam beads, and curing the foam beads at normal pressure and normal temperature for over 48 hours, so as to obtain the product. The product disclosed by the invention has the characteristics of even and compact cells, small size, high percentage of closed area, high molding product strength, good rebound resilience and the like.

Owner:新辉新材料(常州)有限公司

Method for preparing paraffin/AKD composite neutral paper-making glue blending agent

InactiveCN101168940AImprove retentionLittle impact on physical propertiesWater-repelling agents additionComplex typeParaffin wax

The invention relates to a preparation method of paraffin wax / AKD complex type neutral paper-making sizing agent. The step is as follows: firstly, AKD and paraffin wax powder are melted in AKD solution; secondly, compound emulsifying agent after being heated is added in melted AKD solution and mixed with a quick shearing mixing machine; thirdly, a rotating speed of the quick shearing blending machine is improved and preheating water is added to lead the formed AKD solution to performing emulsification nearby a W / O to O / W inversion point; quick mixing is performed and the preheating water is added and the mixing is continuously performed; fourthly, the water solution of flocculating agent PAC is added, and the mixing is continuously performed; fifthly, the mixing is stopped and the cold water is used for quickly performing cooling and cool down, and then the finished product of the paraffin wax / AKD complex-typed neutral paper-making sizing agent emulsion is produced. The complex-typed neutral sizing agent produced by the invention has the advantages that the holding rate is high, the effect on the physical property of the paper is small, and the emulsion is stable.

Owner:TIANJIN UNIV OF SCI & TECH

Acrylic film and moldings made using the same

InactiveUS6147162ALower glass transition temperatureReduced impact strengthSynthetic resin layered productsPolymer scienceAcrylic resin

PCT No. PCT / JP97 / 00382 Sec. 371 Date Aug. 12, 1998 Sec. 102(e) Date Aug. 12, 1998 PCT Filed Feb. 13, 1997 PCT Pub. No. WO97 / 30117 PCT Pub. Date Aug. 21, 1997An acrylic film or sheet made from a resin composition comprising 95 to 50 wt. % of an acrylic resin which comprises methyl methacrylate as a main component and has a glass transition temperature in the range of 40 to 105 DEG C., and 5 to 50 wt. % of a multilayer-structured acrylic polymer containing an elastomeric layer, wherein the polymer is dispersed in the acrylic resin, a molded article comprising a thermoplastic resin molded material and the above film or sheet which is adhered and unified with the surface of the molded material, and a method for the production of the above molded article are provided. This film or sheet is an excellent film for use in a simultaneous injection molding and lamination method.

Owner:SUMITOMO CHEM CO LTD

Thermoplastic resin composition and production method thereof

InactiveUS7029750B2Good lookingReduced impact strengthLiquid surface applicatorsSynthetic resin layered productsPowder mixtureAcrylic polymer

The present invention provides a thermoplastic resin composition comprising a thermoplastic resin (A), an acrylic polymer (B), a polytetrafluoroethylene-containing powder mixture (C) and a filler (D), the amount of the acrylic polymer (B) being from 0.1 to 400 parts by weight, the amount of the filler (D) being from 1 to 2000 parts by weight, based on 100 parts by weight of the thermoplastic resin (A), and the amount of a polytetrafluoroethylene component in the polytetrafluoroethylene-containing powder mixture (C) is from 0.01 to 400 parts by weight based on 100 parts by weight of the thermoplastic resin (A).

Owner:MITSUBISHI CHEM CORP

Phosphogypsum based plastering gypsum

The invention discloses a phosphogypsum based plastering gypsum, and relates to a plastering material for a building wall. The phosphogypsum based plastering gypsum mainly comprises 75 to 95 percent of phosphogypsum based building gypsum, 1 to 3 percent of sierozem powder, 0.1 to 0.5 percent of retarder, 1.1 to 5.5 percent of composite water retention agent, 0.3 to 1 percent of ethylene-vinyl acetate copolymerized latex powder, and 0 to 20 percent of stuffing. The phosphogypsum based plastering gypsum effectively improves water retention property and lowers cost by adopting the combination of cellulose ether water retention agent and bentonite, effectively adjusts settling time and prolongs operable time by adopting the retarder, improves construction property, cohesive property and cracking resistance by doping the stuffing and the latex powder, and reduces adverse effects of impurities on the strength of plastering gypsum by adding the sierozem powder. The phosphogypsum based plastering gypsum has the advantages of good workability and construction property, long operable time, high breaking resistance, compression resistance and adhesion strength, good volume stability, good cracking resistance and lower cost, and can be used for a plastering layer of the building wall.

Owner:CHONGQING UNIV

Flame retardant thermoplastic compositions having EMI shielding

InactiveUS20080033083A1Good physical propertiesMaintain flame retardant propertiesMetal fibersFire retardant

A flame retardant thermoplastic composition having excellent physical properties that includes 30 to 90 wt. % of a polycarbonate resin; from 1 to 35 wt. % of an impact modifier; from 0.1 to 15 wt. % of a phosphorus-containing flame retardant, from 1 to 30 wt. % of metal fiber, and from 0.002 to 5 wt. % of a processing additive, each based on the total combined weight of the thermoplastic composition, exclusive of any filler. The processing additive permits flame retardant characteristics to be maintained despite lower levels of flame retardant while the lower levels of flame retardant permit the compositions, and molded samples of these compositions, to have higher HDT and / or impact strengths as compared to compositions having higher levels of flame retardants. A molded sample of the thermoplastic composition is capable of achieving UL94 V0 rating at a thickness of 1.5 mm (±10%). The compositions are useful in forming flame retardant articles having EMI shielding characteristics.

Owner:SABIC INNOVATIVE PLASTICS IP BV

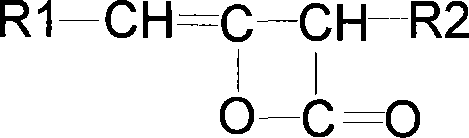

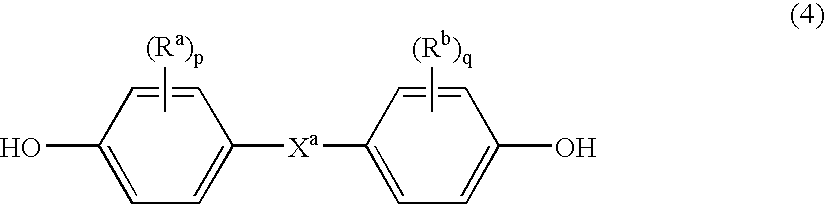

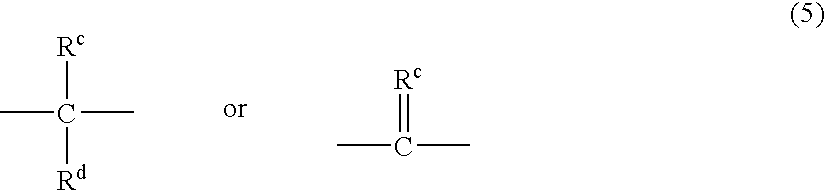

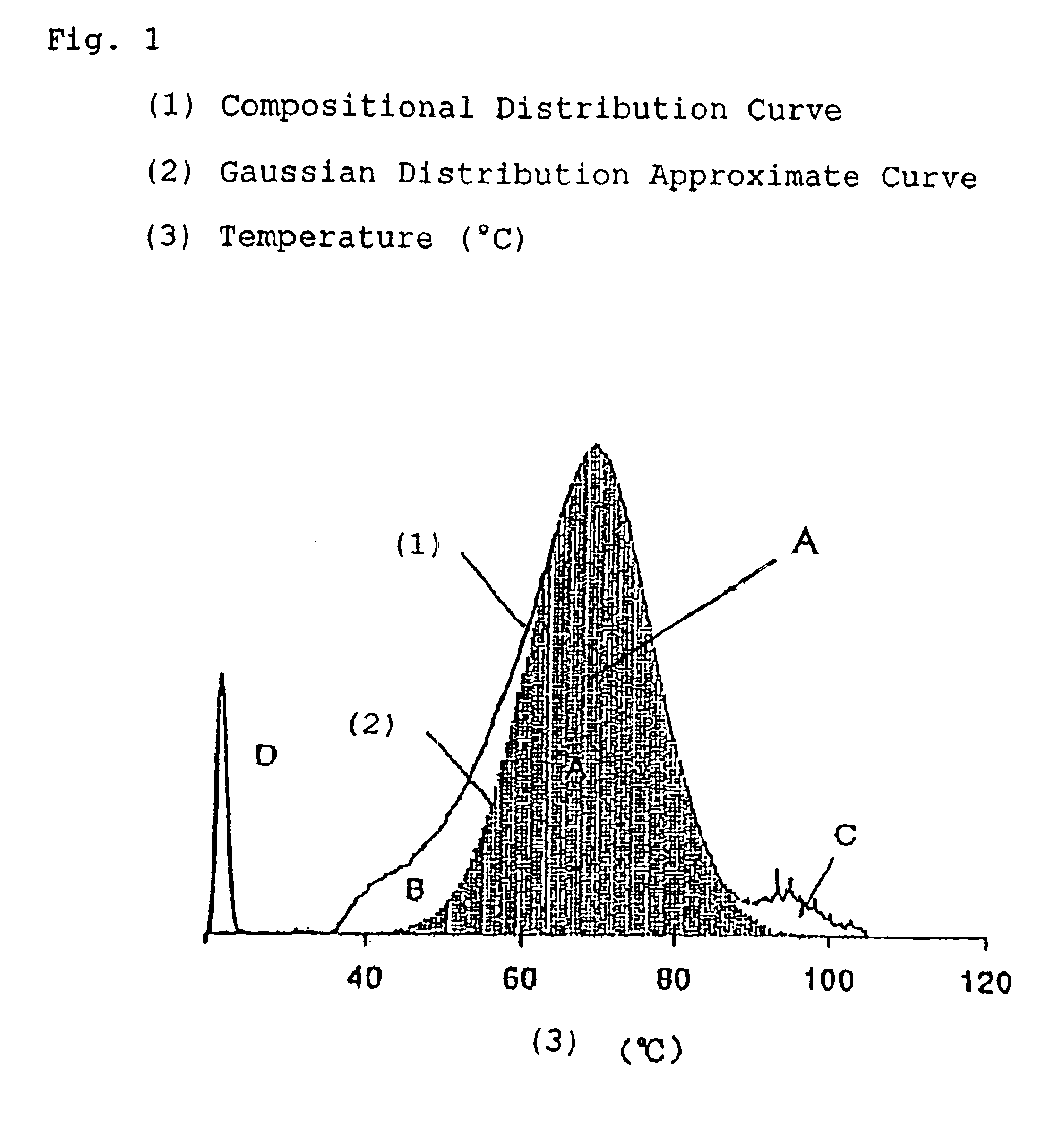

Ethylenic copolymer, composition containing said copolymer, and ethylenic copolymer film

An ethylenic copolymer composition including an ethylenic copolymer having Mw / Mn of 1.5 to 4, Mw of 3,000 to 1,000,000, and a resin density of 0.85 to 0.95 g / cm3. The relationship between the half width at the half maximum [W / 2] of the Gaussian distribution curve, and the average, n, of short-chain branches in the copolymer satisfies the equation,0.704+0.147n=W / 2=−0.055+0.577n. The ethylenic copolymer composition also includes an ethylenic copolymer having an Mw of 3,000 to 1,000,000 and a resin density of 0.85 to 0.95 g / cm3.

Owner:IDEMITSU KOSAN CO LTD

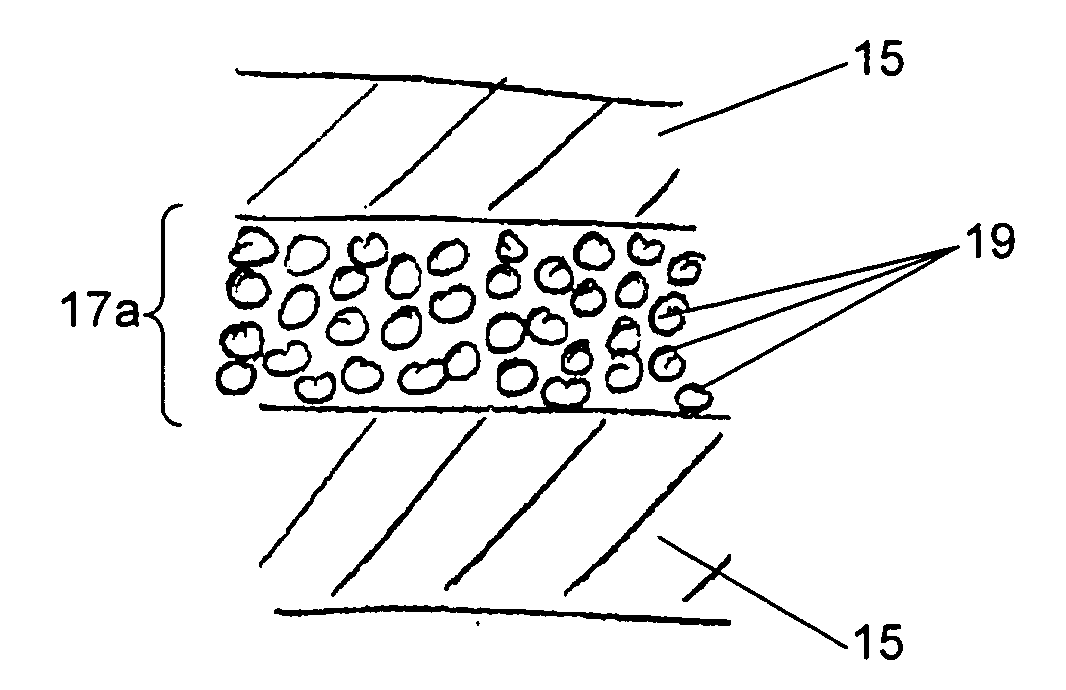

Frit or solder glass compound including beads, and assemblies incorporating the same

InactiveUS20100330309A1Less-expensiveLess-expensive to useClimate change adaptationLaminationFritSquare Shape

Certain example embodiments of this invention relate to frits or solder glass compounds that include beads, and / or assemblies such as, for example, vacuum insulated glass (VIG) units or plasma display panels (PDPs) including the same. In certain example embodiments, the beads may be hollow glass beads of any suitable shape (e.g., substantially spherical, substantially eye shaped, substantially oblong, substantially square shaped, etc.) with or without evacuated cavities. The inclusion of such beads in a frit material may improve the thermal properties of the bulk fired frit in certain example instances. Additionally, the inclusion of such beads in a frit material may take the place of other more expensive materials in the frit, thereby reducing the costs associated with the fabrication of the assemblies.

Owner:GUARDIAN GLASS LLC

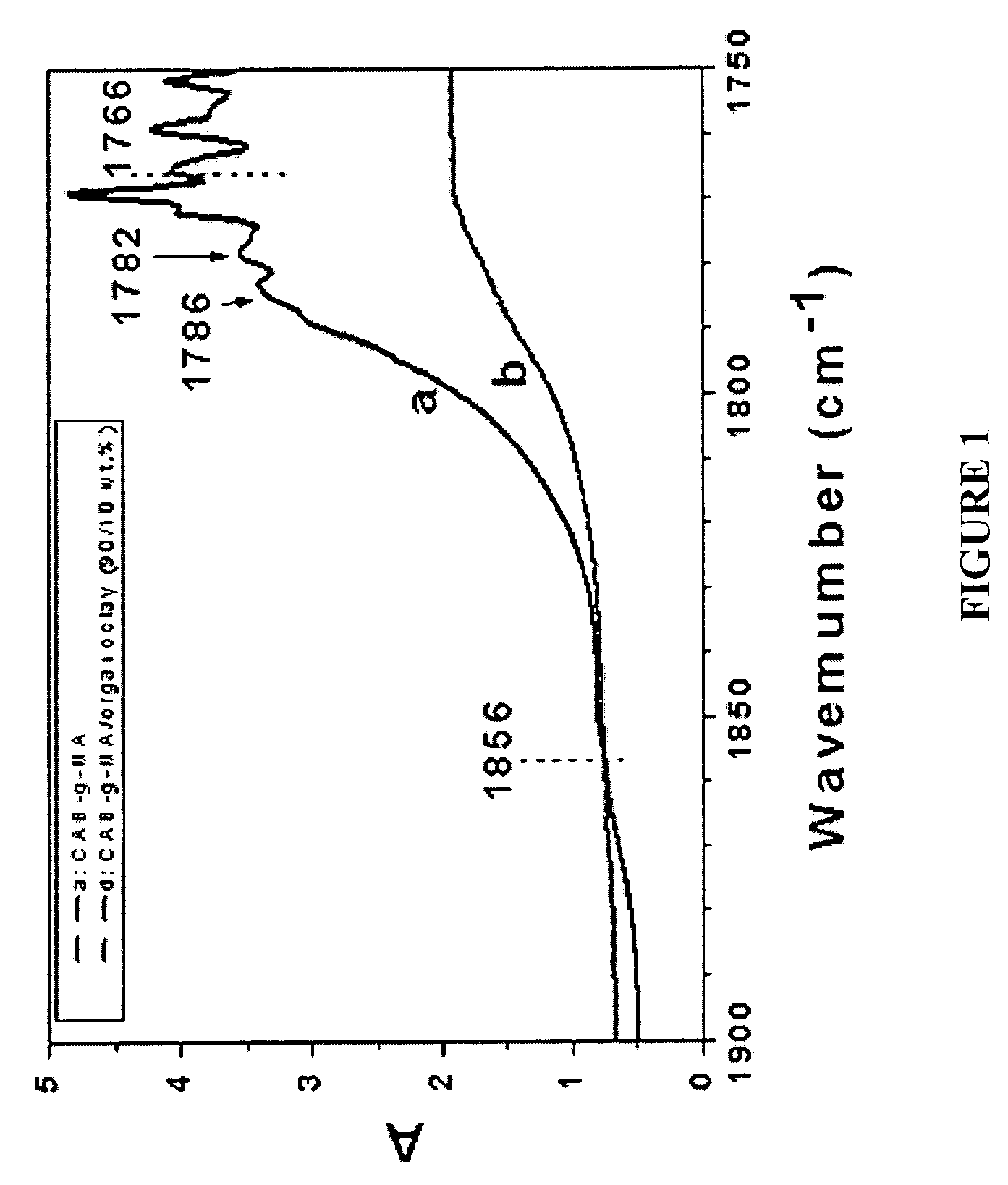

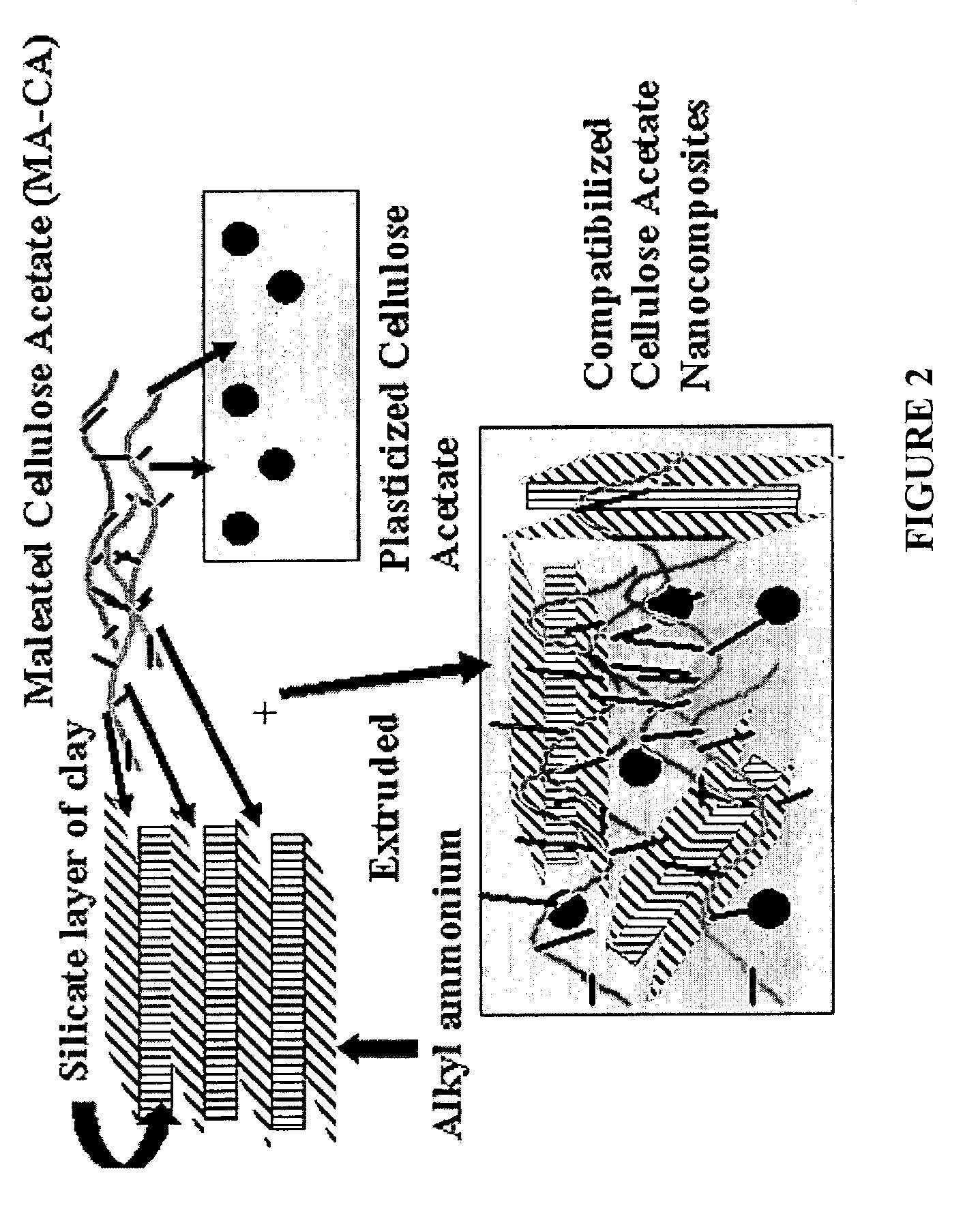

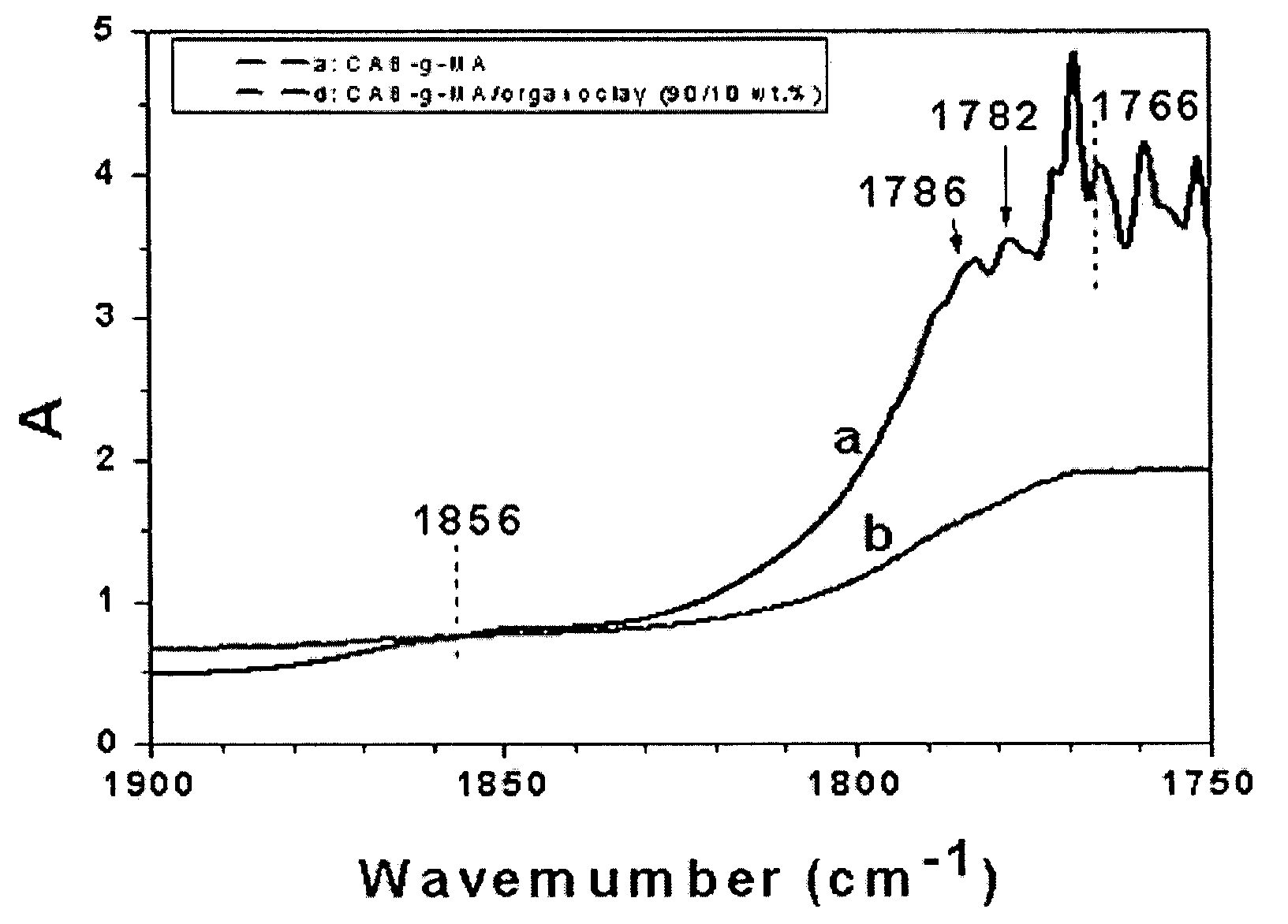

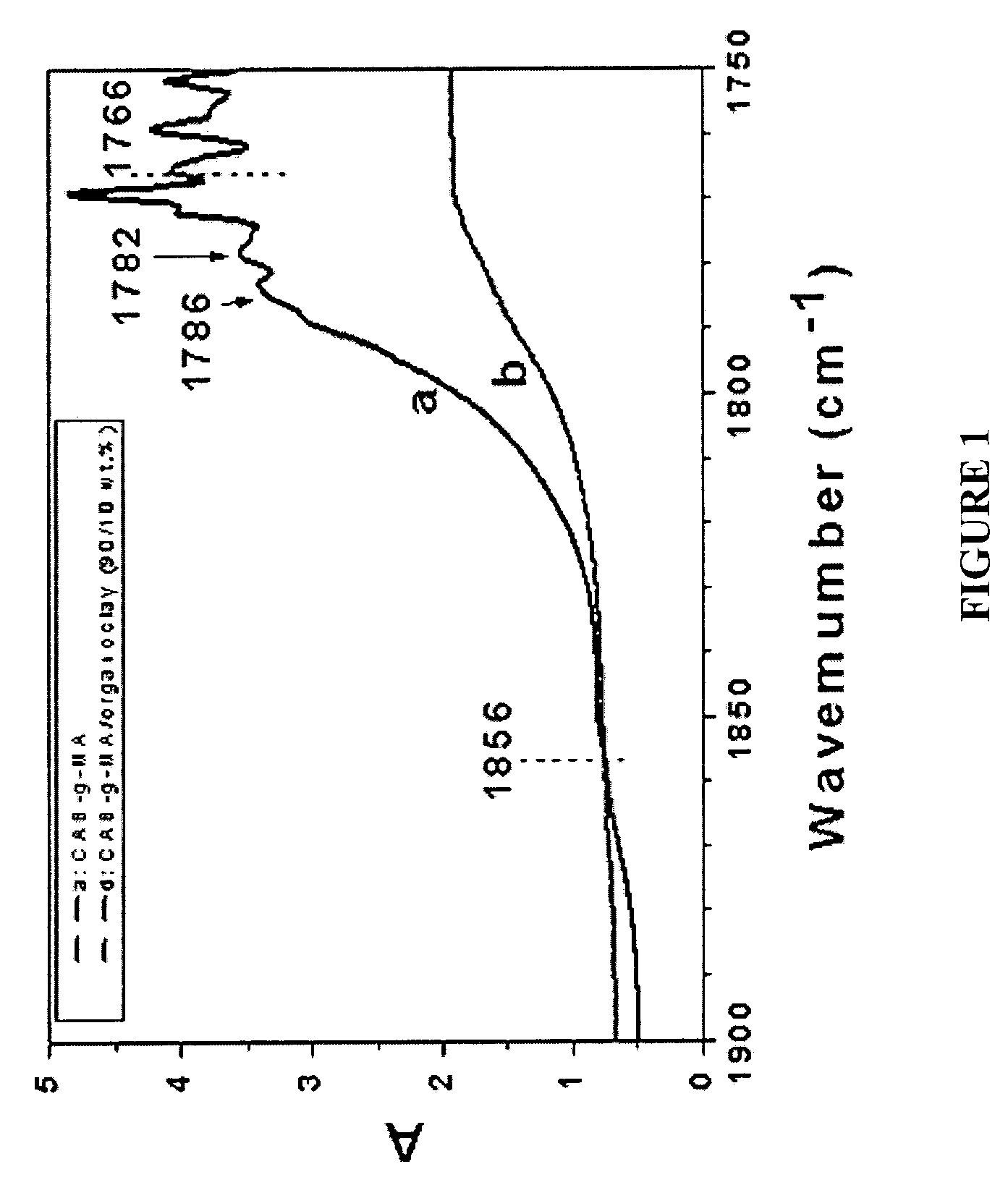

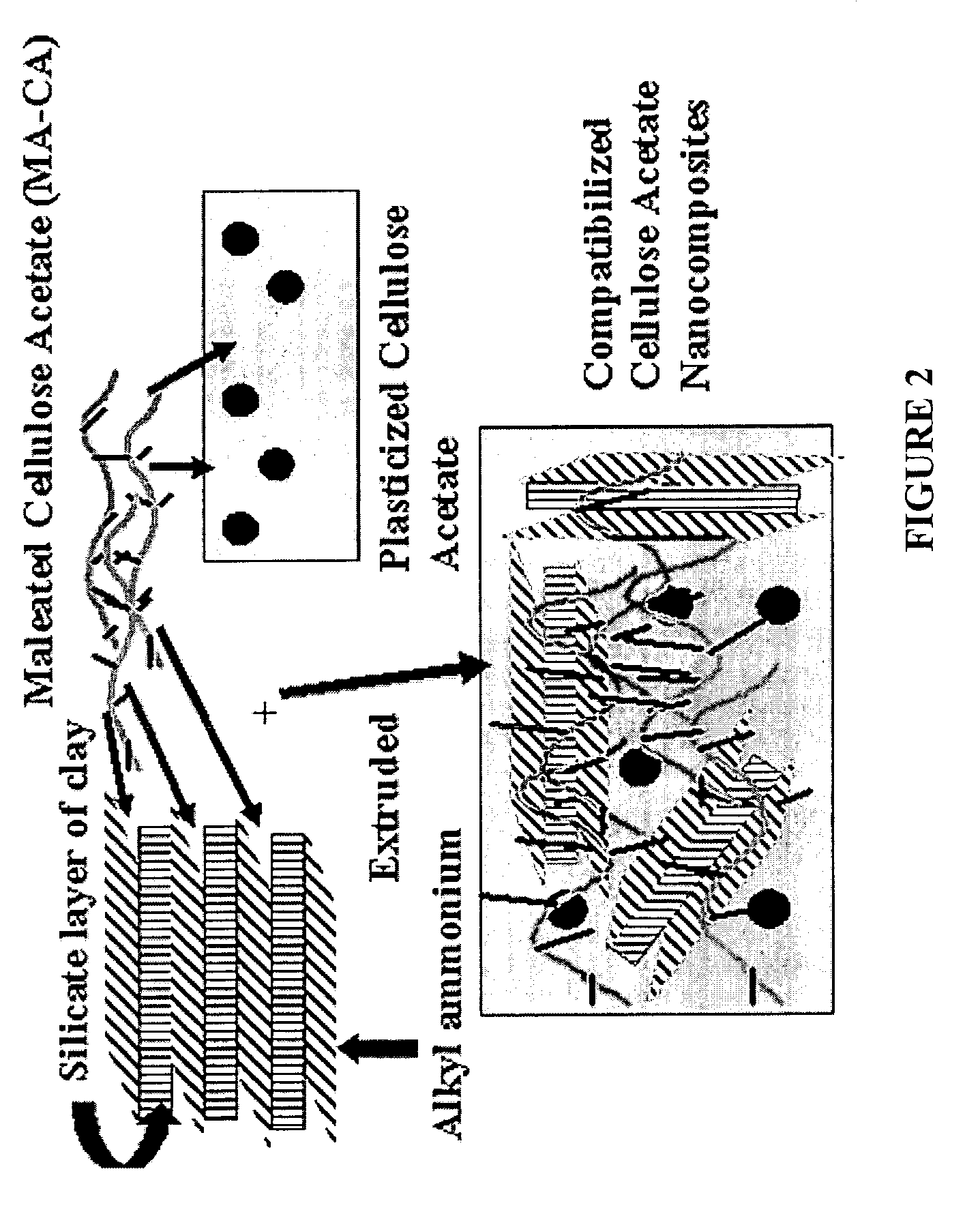

Compositions of cellulose esters and layered silicates and process for the preparation thereof

InactiveUS7253221B2Increase modulusImprove propertiesSurface-active detergent compositionsCoatingsCelluloseHeat deflection temperature

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

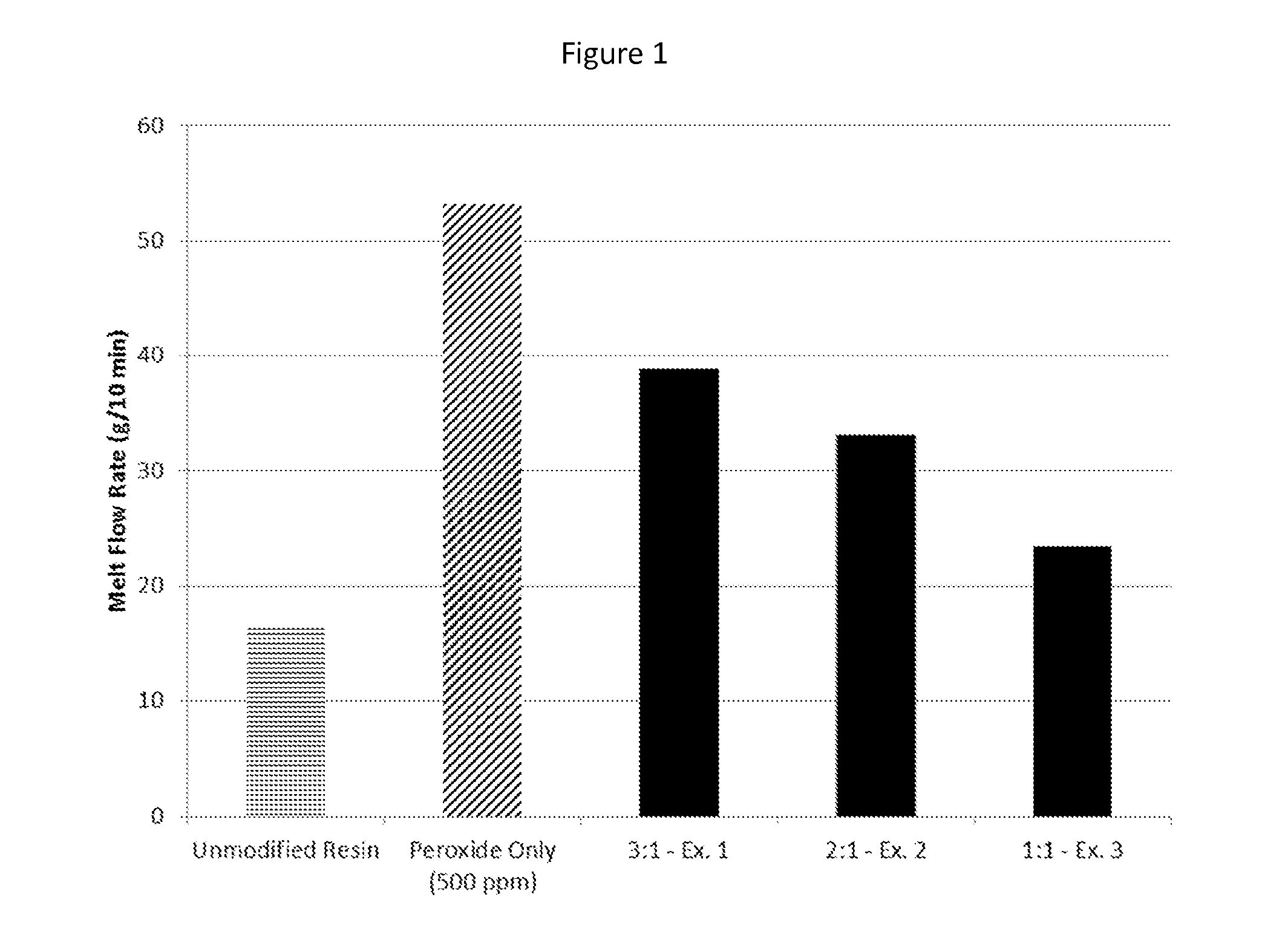

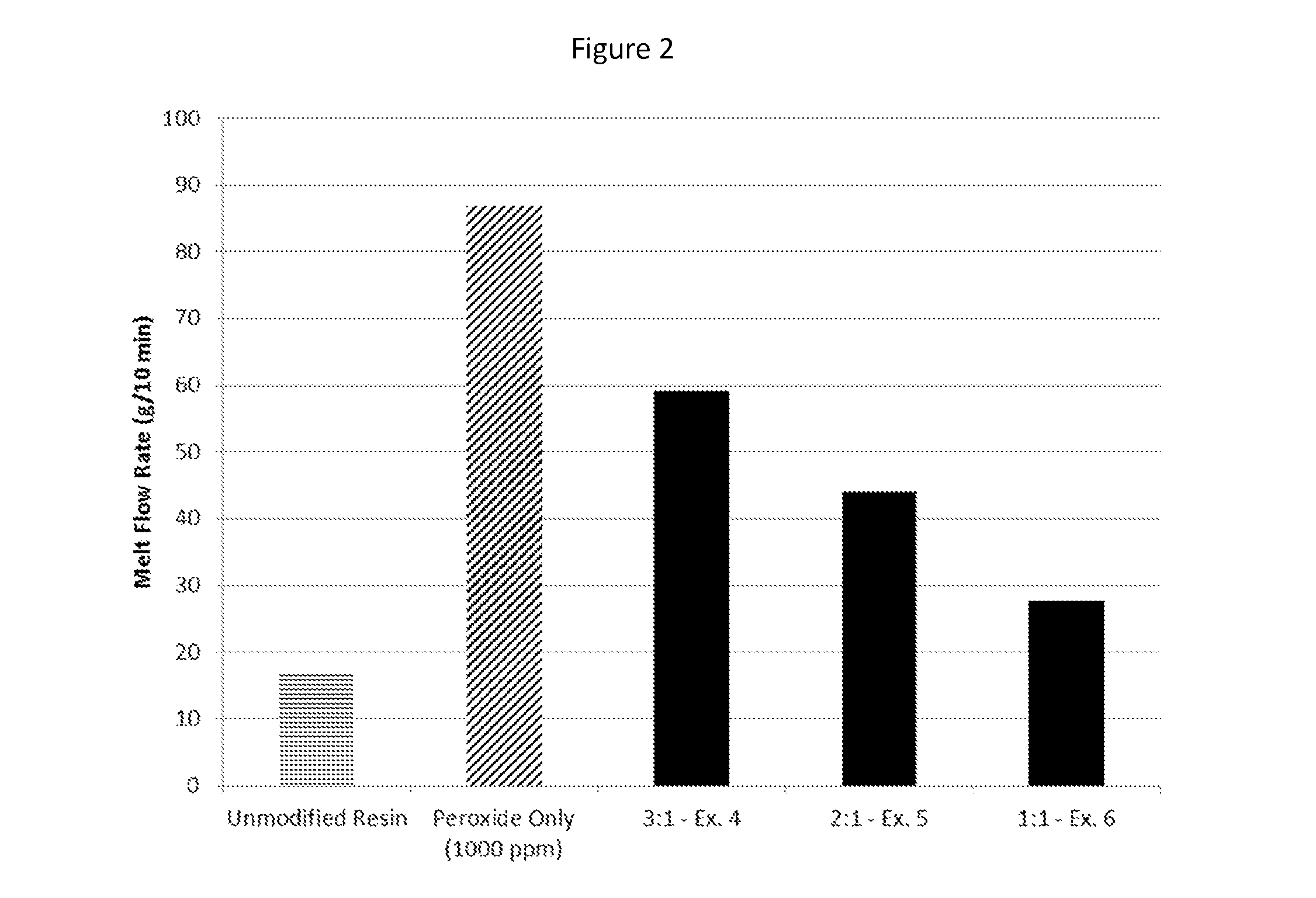

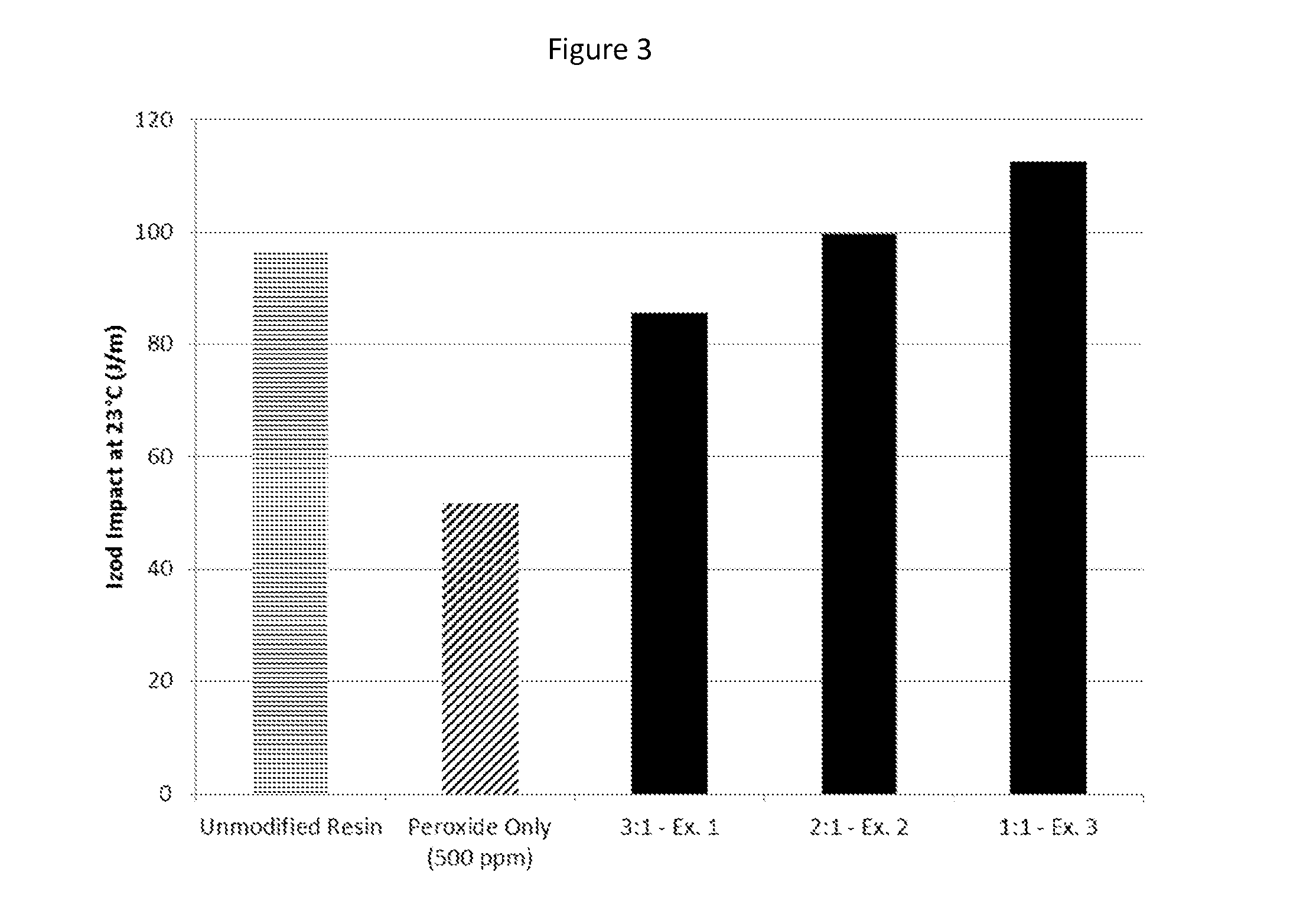

Modified heterophasic polyolefin composition

A method of creating a modified heterophasic polyolefin composition is provided, whereby a polyolefin composition having at least two phases is melt mixed with a free radical generator, such as a peroxide, and a compatibilizing agent characterized by at least one nitroxide radical and at least one unsaturated bond capable of undergoing a radical addition reaction. Modified heterophasic polyolefin compositions with increased melt flow rates, impact strength, and clarity, which incorporate the compatibilizing agent, are also included within the scope of the invention.

Owner:MILLIKEN & CO

Compositions of cellulose esters and layered silicates and process for the prepration thereof

InactiveUS20060058425A1Effective combinationIncreased strength structureSurface-active detergent compositionsCoatingsHeat deflection temperatureCellulose

Composites of cellulose esters, plasticizer, a maleated compatibilizer and organically modified clay are described. The composites have superior tensile and flexural strengths, modulus, dimensional stability and heat deflection temperature (HDT).

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

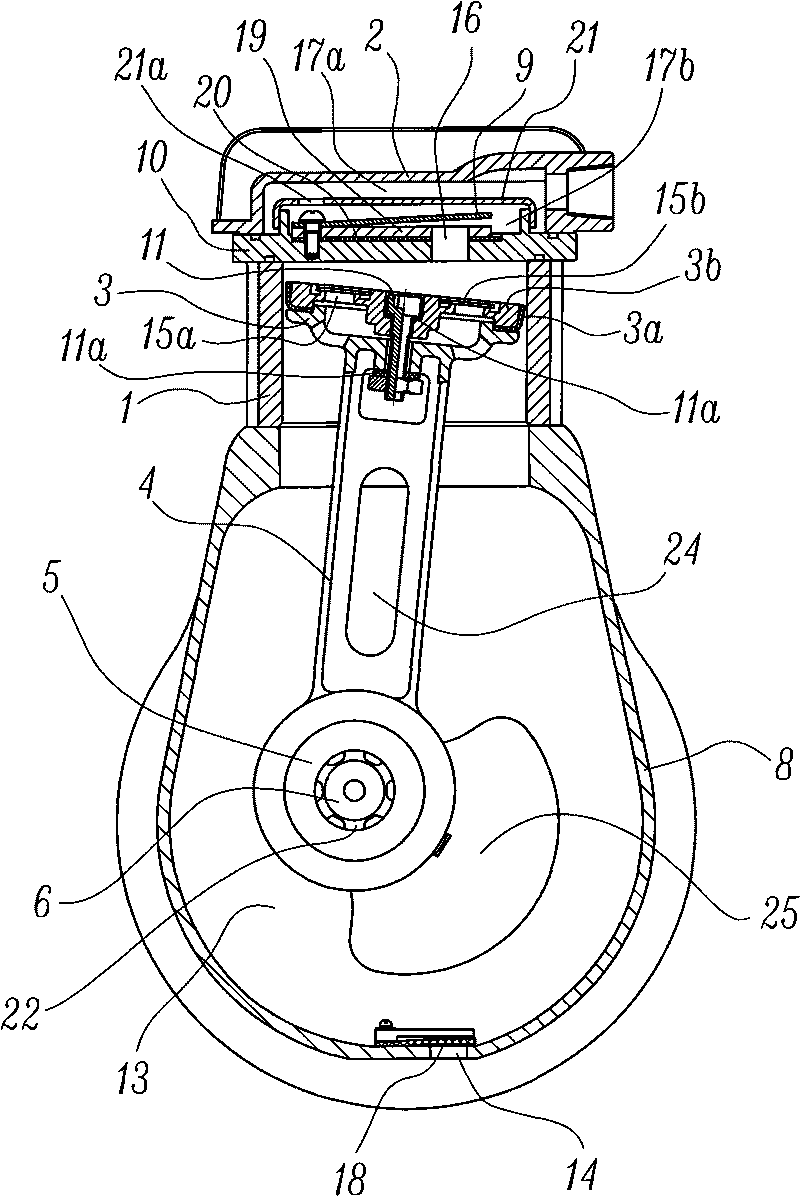

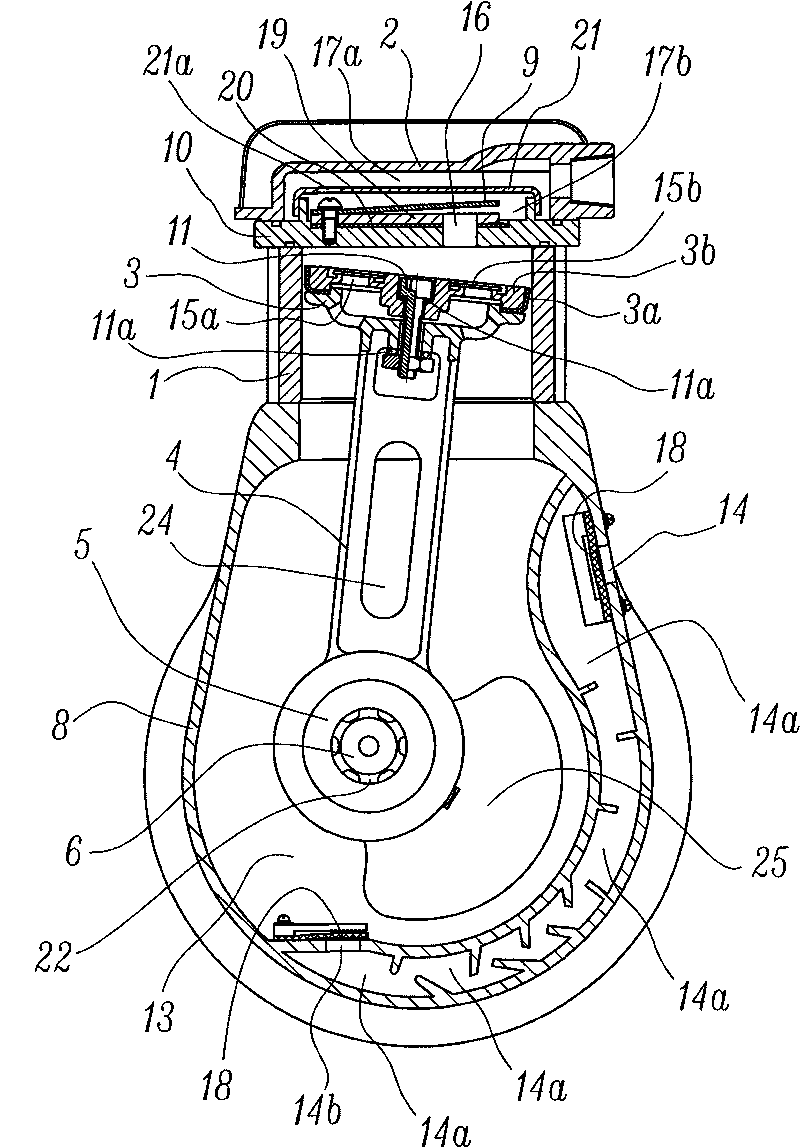

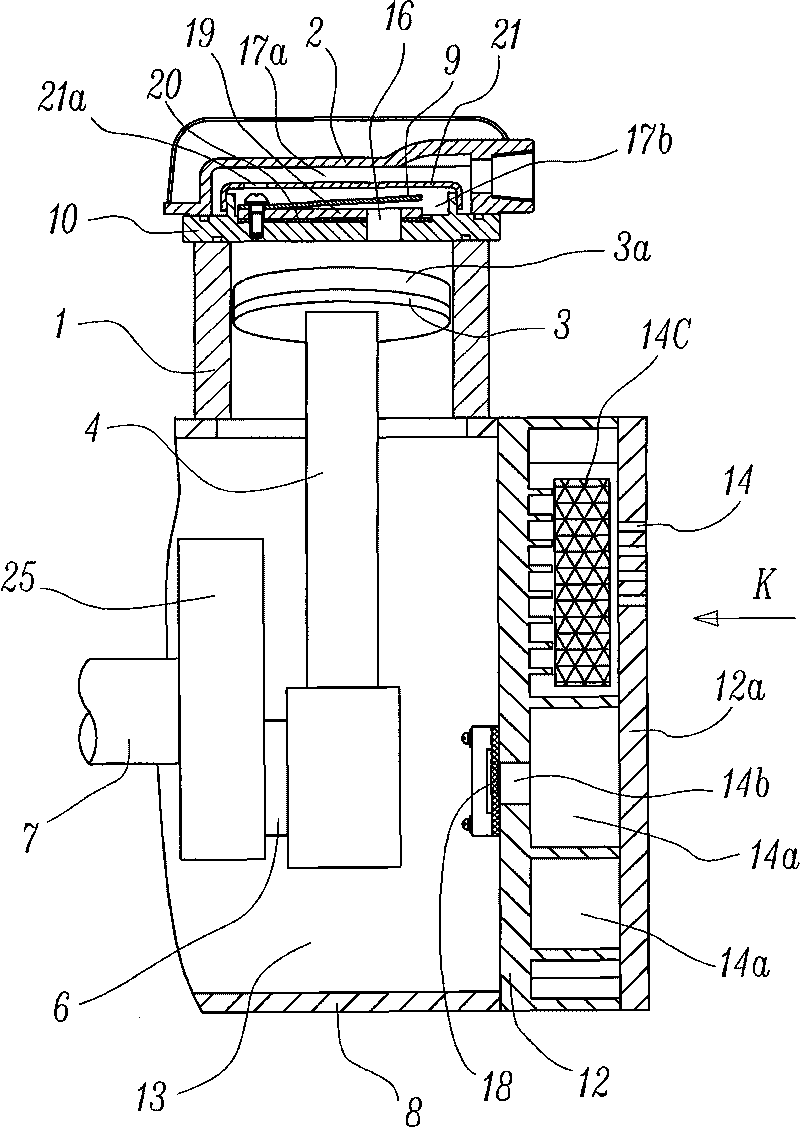

Low-noise structural oilless air compressor

InactiveCN101737296APrevent blowbackEasy to absorbPositive displacement pump componentsPiston pumpsLow noiseVibration amplitude

The invention belongs to the technical field of air compressors, and relates to a low-noise structural oilless air compressor which comprises a cylinder, a cylinder cover and a piston, wherein the piston is provided with a sealing ring or a sealing leather cup made of a self-lubricating material, a crankcase is tightly connected with a crankcase cover plate and forms a crankcase intake muffler, an air intake one-way valve is arranged at an air intake or an air intake passage of the crankcase intake muffler communicated with the outside atmosphere, a damping pad is arranged between an exhaust valve plate and a valve seat, the valve seat is connected with a silencing cap, a crank pin is made into the shape of a spline or similar to the spline, a heat insulation hole or a heat insulation slot is arranged on a connecting rod body, and a heat insulation pad is arranged at the joint of a fastening bolt and the piston or a connecting rod. The low-noise structural oilless air compressor has the advantages that the air intake noise is low, the working temperature and the mechanical noise of a bearing are low, and an auxiliary balance block is arranged on a cooling fan, thereby reducing the vibration amplitude of the compressors, and effectively reducing the body vibration noise.

Owner:ZHEJIANG HONGYOU AIR COMPRESSOR MFG

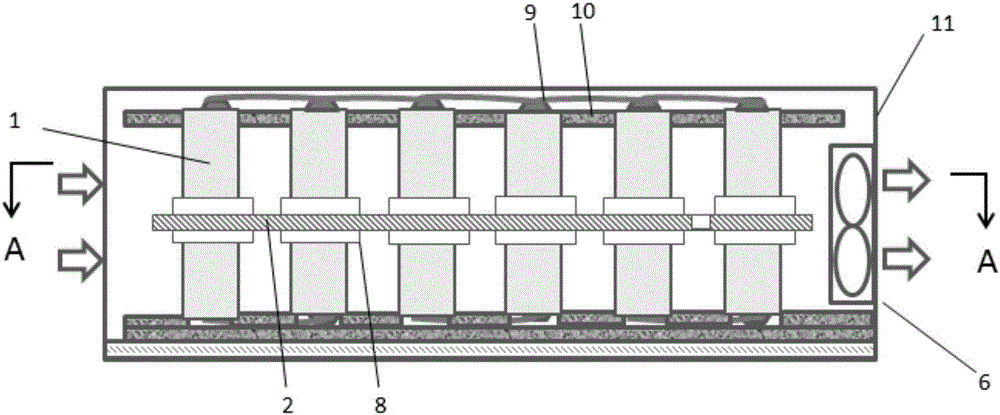

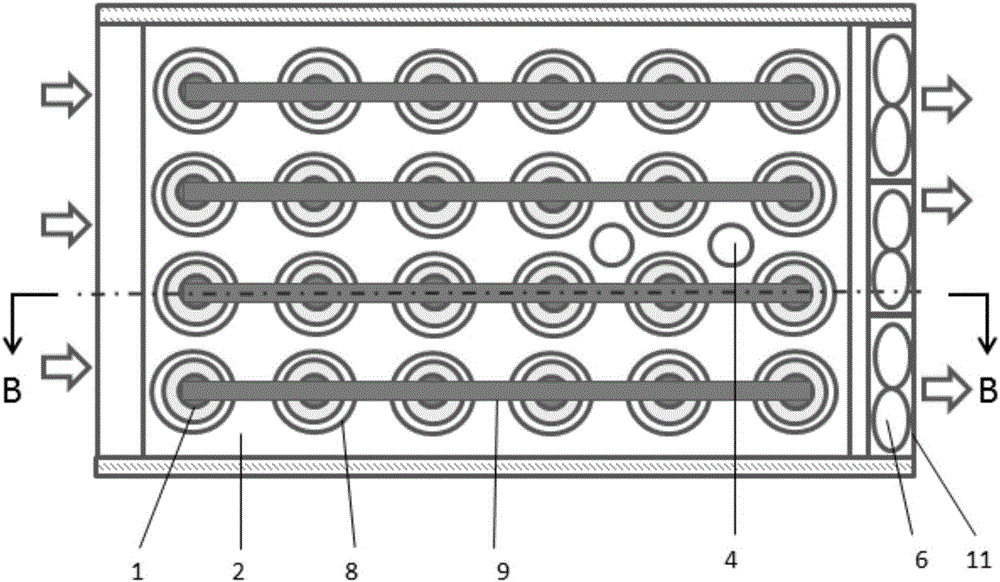

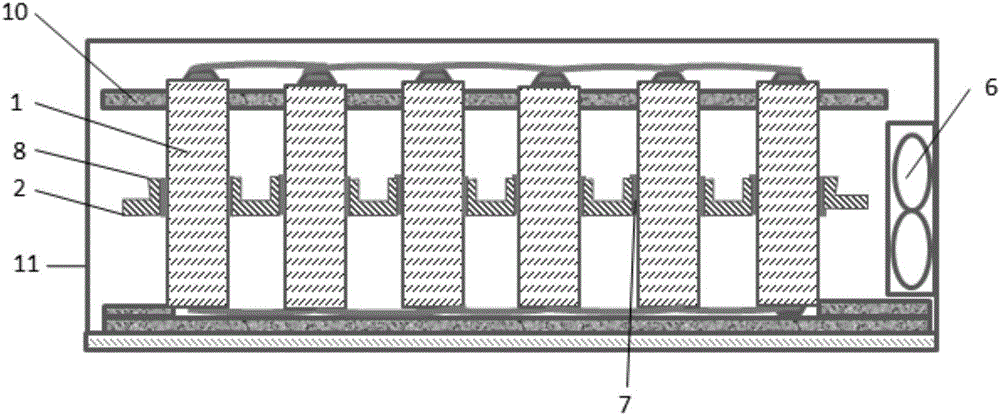

Forced convection power battery heat radiation device

ActiveCN105742542AExcellent heat transfer enhancement effectLarge thermal resistanceSecondary cellsCell component detailsForced convectionElectrical battery

The invention discloses a forced convection power battery heat radiation device. A battery pack box which is opened upwards comprises a plurality of columnar batteries which are arranged at intervals; at least one heat diffusion plate is arranged between the tops and bottoms of the batteries inside the battery pack box; the batteries are tightly sleeved by the heat diffusion plates through sleeves; the space below the heat diffusion plates inside the battery pack box is filled with a heat absorption and conduction material layer; an air inlet and a vent hole are respectively formed in two opposite side walls above the heat diffusion plates of the battery pack box correspondingly; fans are arranged at the air inlet and / or the vent hole; or gaps are formed between the heat diffusion plates and the side walls of the battery pack box; an air inlet and a vent hole are respectively formed in two opposite side walls of the battery pack box; fans are arranged on the air inlet and / or the vent hole; no through holes are / are not formed in the heat diffusion plates. The forced convection power battery heat radiation device can be applied to active air cooling heat exchange and passive heat radiation of a filled phase-change material as well, and is good in heat radiation effect, relatively uniform in temperature distribution, compact in appearance, simple in structure and applicable to power battery systems.

Owner:SHANGHAI UNIV OF ENG SCI

Impact modifier compositions for rigid PVC compositions of hydrocarbon rubbers and chlorinated polyethylene

The present invention is specifically directed to improved polyvinyl chloride compositions having excellent impact strength. In particular, the impact resistant composition comprises a vinyl chloride polymer and 2-8 parts of an impact modifier composition comprising at least one ethylene / alpha-olefin copolymer and at least one chlorinated olefin polymer per 100 parts of the vinyl chloride polymer. Preferably the impact modifier composition comprises less than 1 part of the ethylene / alpha-olefin copolymer and the ratio of said copolymer to the total modifier composition is less than 25%.

Owner:WENBEN +1

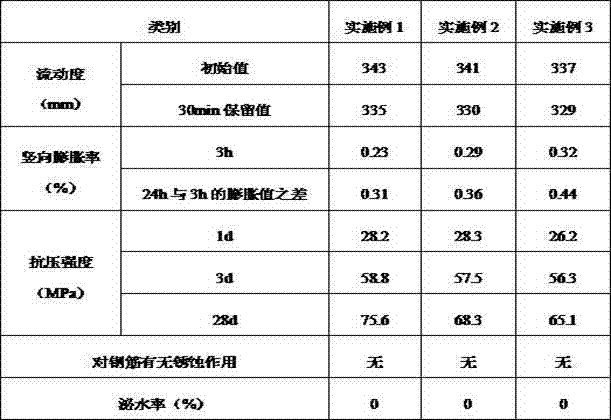

Special plastic expansion agent for cement-based grouting material and preparation method of same

The invention discloses a special plastic expansion agent for cement-based grouting material. The special plastic expansion agent comprises the components by weight percent: 3.0% to 5.0% of plastic expansion source, 0.05% to 0.15% of stearate, 5.0% to 10.0% of catalyst, 25.0% to 50.0% of quick lime and 35.0% to 60.0% of water retaining admixture. The special plastic expansion agent can hydrolyze and give off gas during the initial stage of cement hydration, and the gas which is given off uniformly enables cement slurry to expand slightly in volume, so that settling and cracking of grouting material can be avoided, and the slurry is ensured denseness and fullness. When the special plastic expansion agent is used with efficient water reducer or other admixtures, the purpose of efficiently ensuring that the plastic expansion of cement-based grouting material is greater than 0.1% in 3h under the condition of realizing the fluidness, the strength and the durability of the cement-based grouting material can be achieved, and expansibility that the expansion difference between 3h and 24h is greater than two ten thousandth and smaller than five thousandths can be achieved, so that plastic expansion of the cement-based grouting material can be realized.

Owner:NANJING RUIDI HIGH TECH

Polycarbonate composite material and preparation method thereof and method for manufacturing LED (Light Emitting Diode) lamp housing

ActiveCN102250462AImprove interfacial adhesionReduced solvent stress cracking resistancePoint-like light sourceGlobesEpoxyProcedure Agents

The invention discloses a polycarbonate (PC) composite material and a preparation method thereof and a method for manufacturing an LED (Light Emitting Diode) lamp housing. The composite material is prepared from the following components in percentage by weight: 84-98.59 percent of polycarbonate resin, 0.01-8 percent of light diffusant, 1-5 percent of silicone resin, 0.1-1 percent of processing agent, 0.1-1 percent of thermal stabilizer, 0.1-1 percent of light stabilizer and 0.1-1 percent of processing aid. In the invention, the light diffusant is processed by using epoxy resin, so that the interfacial bond of the light diffusant and polycarbonate is improved, and the solvent-stress-resistant cracking performance of the PC composite material is decreased. Ordered arrangement of polycarbonate molecules is increased and the internal stress is reduced under optimized injection mould temperature; and the minimum influence of a toughening component on the transparency of a final lamp housing product is guaranteed by adding the silicone resin with refractive index of 1.587 and toughening effect. The reduction in impact strength of the lamp housing product brought by higher mould temperature during injection molding can be compensated by adding the silicone resin. The light diffusion PC material with a balance among light transmittance, haze and diffusion angle is obtained by adding the light diffusant, so that an LED lamp emits non-dazzling, soft and pleasant light.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS

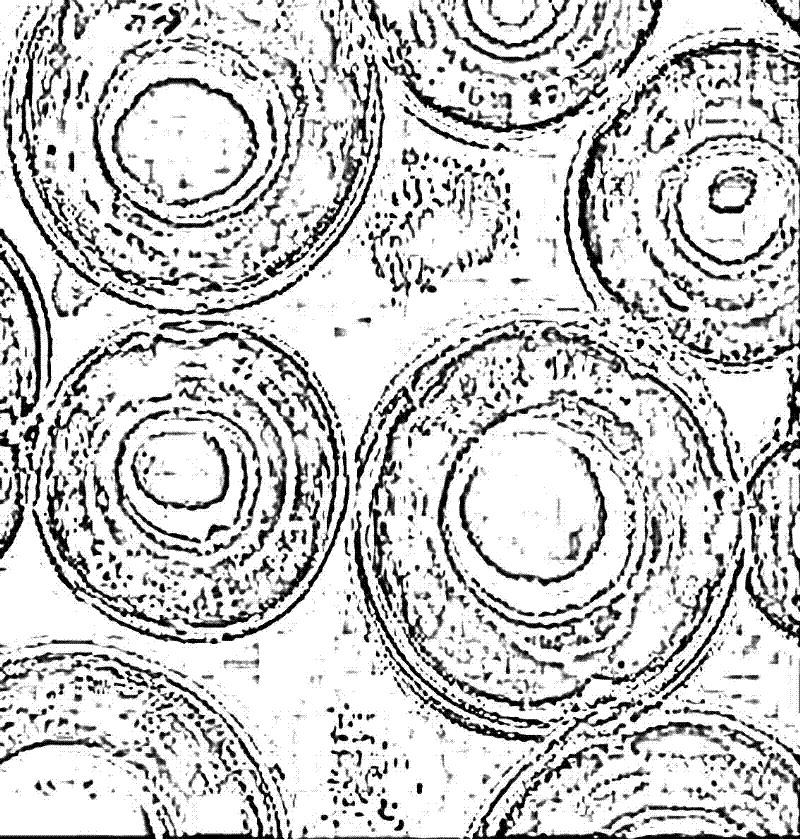

Surface modification method of hollow glass beads

InactiveCN102604439AReduce consumptionImprove adhesionPigment treatment with organosilicon compoundsPigment treatment with non-polymer organic compoundsEpoxyBound property

The invention discloses a surface modification method of hollow glass beads. The method comprises the following steps: firstly, removing surface impurities of the hollow glass beads with absolute ethanol or acetone, and then drying the hollow glass beads for 3 to 5 hours; secondly, adding the dried hollow glass beads into an agitator to be continuously heated after the agitator is preheated, and adding a coupling reagent 0.2-1.5% of the mass of the glass beads after the surface temperature of the hollow glass beads is increased to 95 to 135 DEG C; and thirdly, continuously stirring the hollow glass beads for 10-30min at 95 to 135 DEG C, and then discharging the hollow glass beads to obtain the hollow glass beads with modified surfaces. According to the method, the agitator is adopted to perform dry modification, the technology is simple, the operation is easy, the modification time is short, the cost is low, subsequent drying is not required, and the energy consumption is reduced. The hollow glass beads treated through the method can be better dispersed in epoxy resin, the binding property between the resin and fillers is improved, the material strength is improved, and the mechanical property of the composite material is obviously improved.

Owner:BENGBU HUAYANG POWDER TECH +2

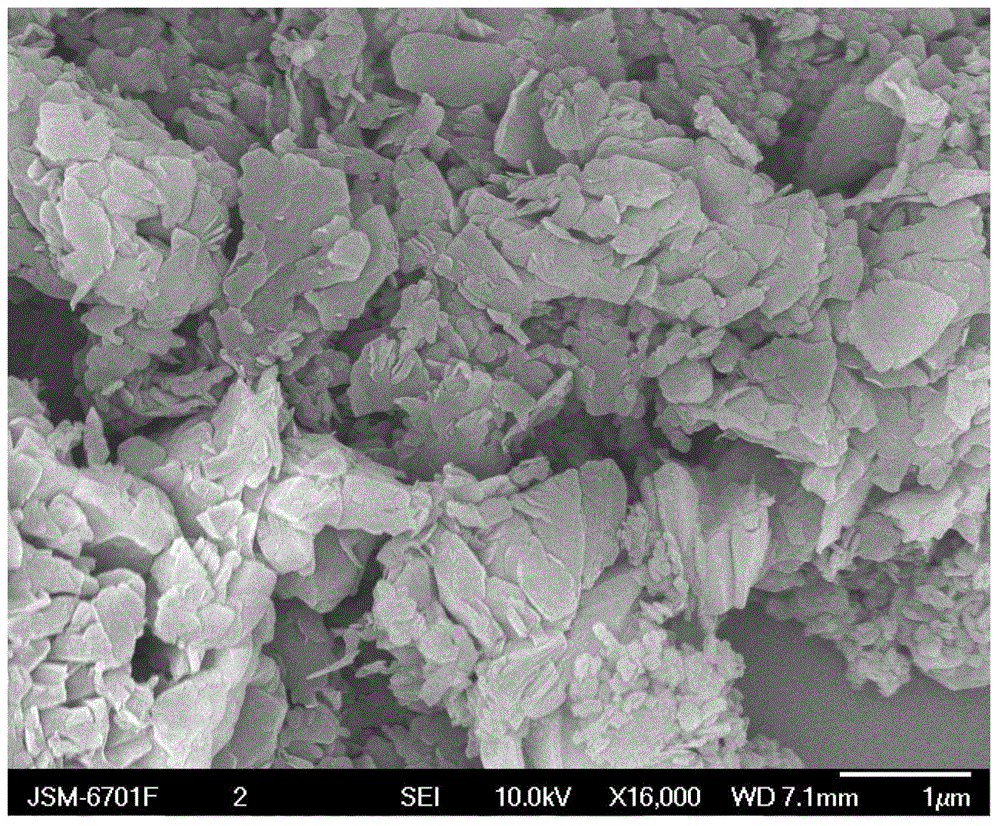

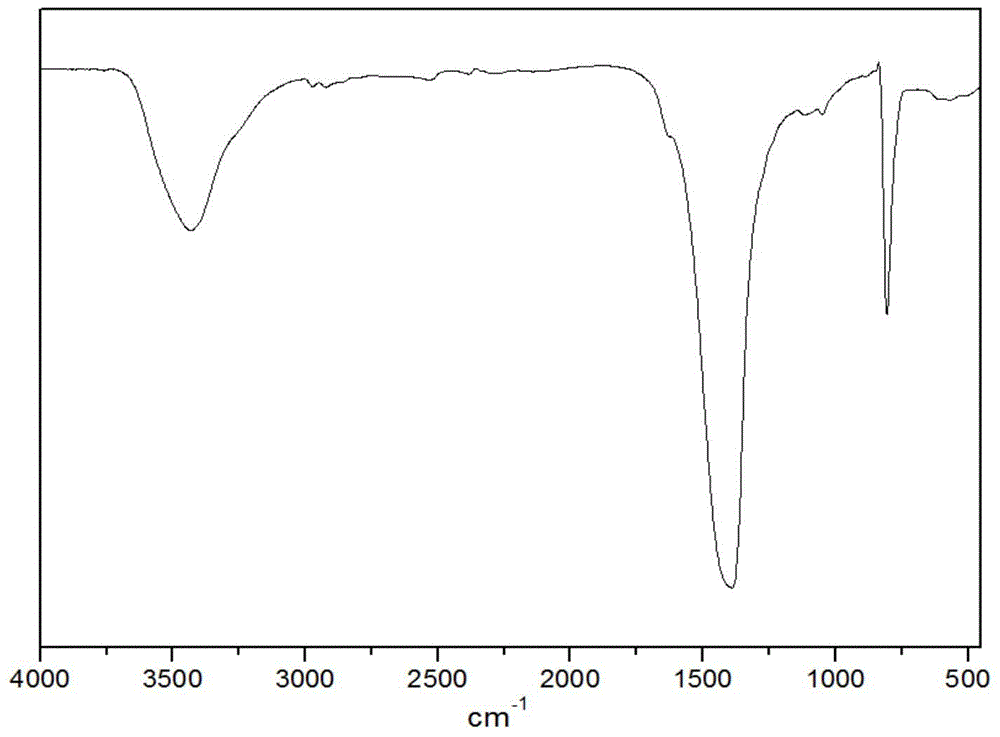

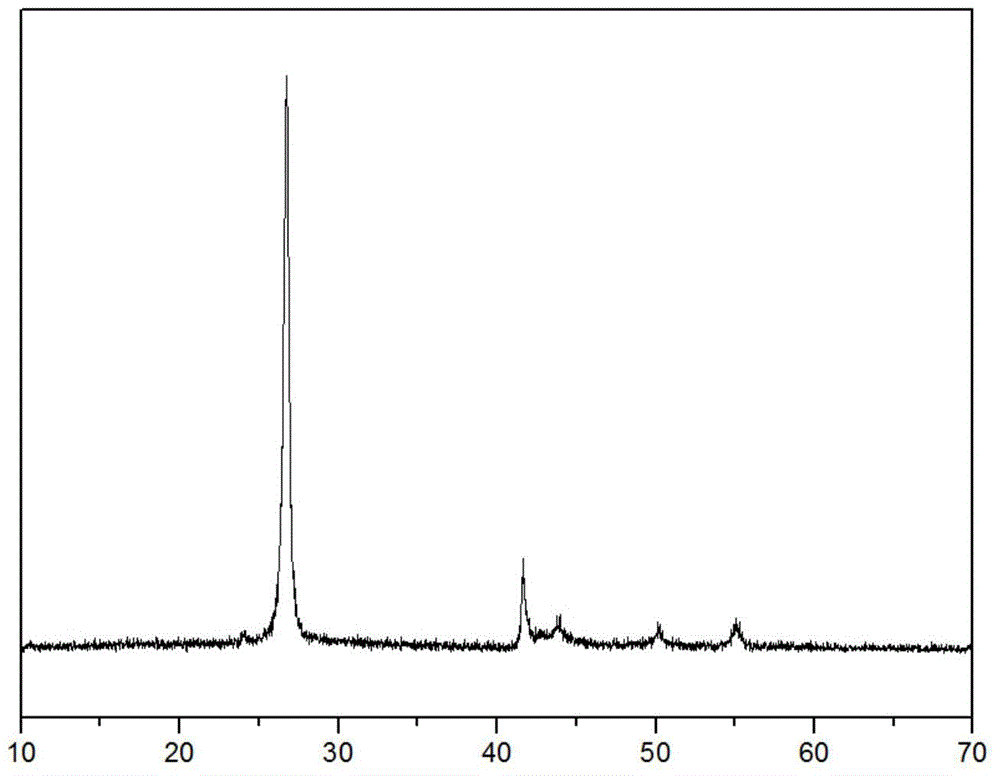

Hexagonal boron nitride/polypropylene polymer composite and preparation method

ActiveCN104861297AThe preparation method is simple and easy to operateStrong controllabilityPolypropyleneThermal conductivity

The invention discloses hexagonal boron nitride / polypropylene polymer composite and a preparation method thereof. According to the composite, polypropylene is taken as a main material, hexagonal boron nitride is taken as filler, an antioxidant, a lubricating agent and a compatilizer are added, and the composite is prepared, wherein the mass ratio of hexagonal boron nitride to polypropylene is 1: (2.2-18.8); the adding amount of the antioxidant accounts for 0.2%-1% of the total weight of hexagonal boron nitride and polypropylene, the adding amount of the lubricating agent accounts for 0.3%-1% of the total weight of hexagonal boron nitride and polypropylene, and the adding amount of the compatilizer accounts for 0.5%-1% of the total weight of hexagonal boron nitride and polypropylene. Compared with a polypropylene material matrix, the hexagonal boron nitride / polypropylene polymer composite prepared through a twin-screw extruder can enhance the mechanical property and can increase the thermal conductivity coefficient. The preparation process of the composite is simple to operate and environment-friendly, and the composite can obtain higher mechanical property and heat conductivity coefficient under the condition of the lower filler mixing amount and has important application value.

Owner:LIAONING UNIVERSITY

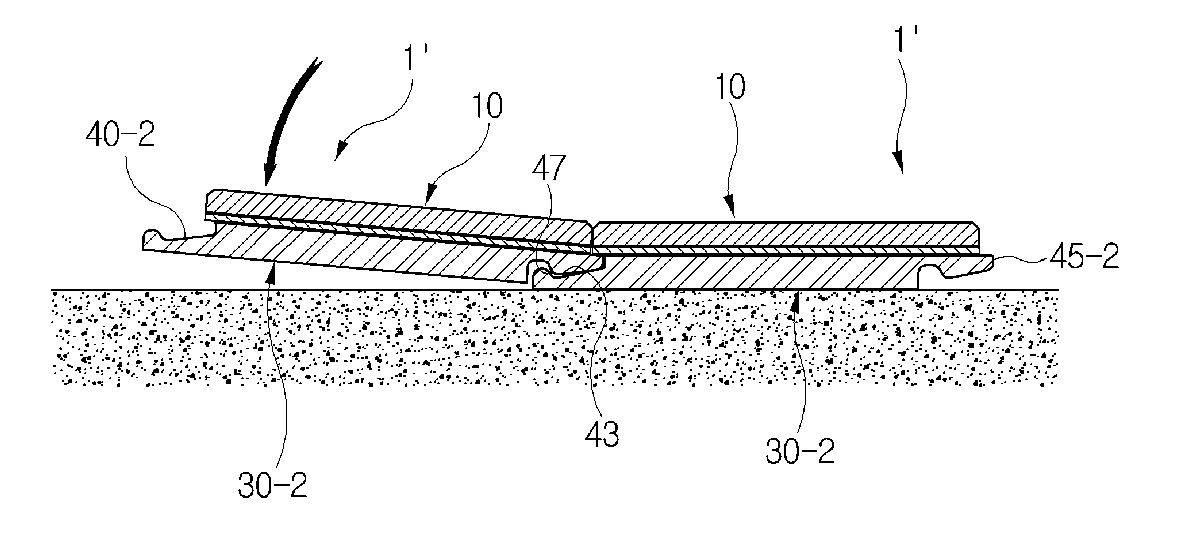

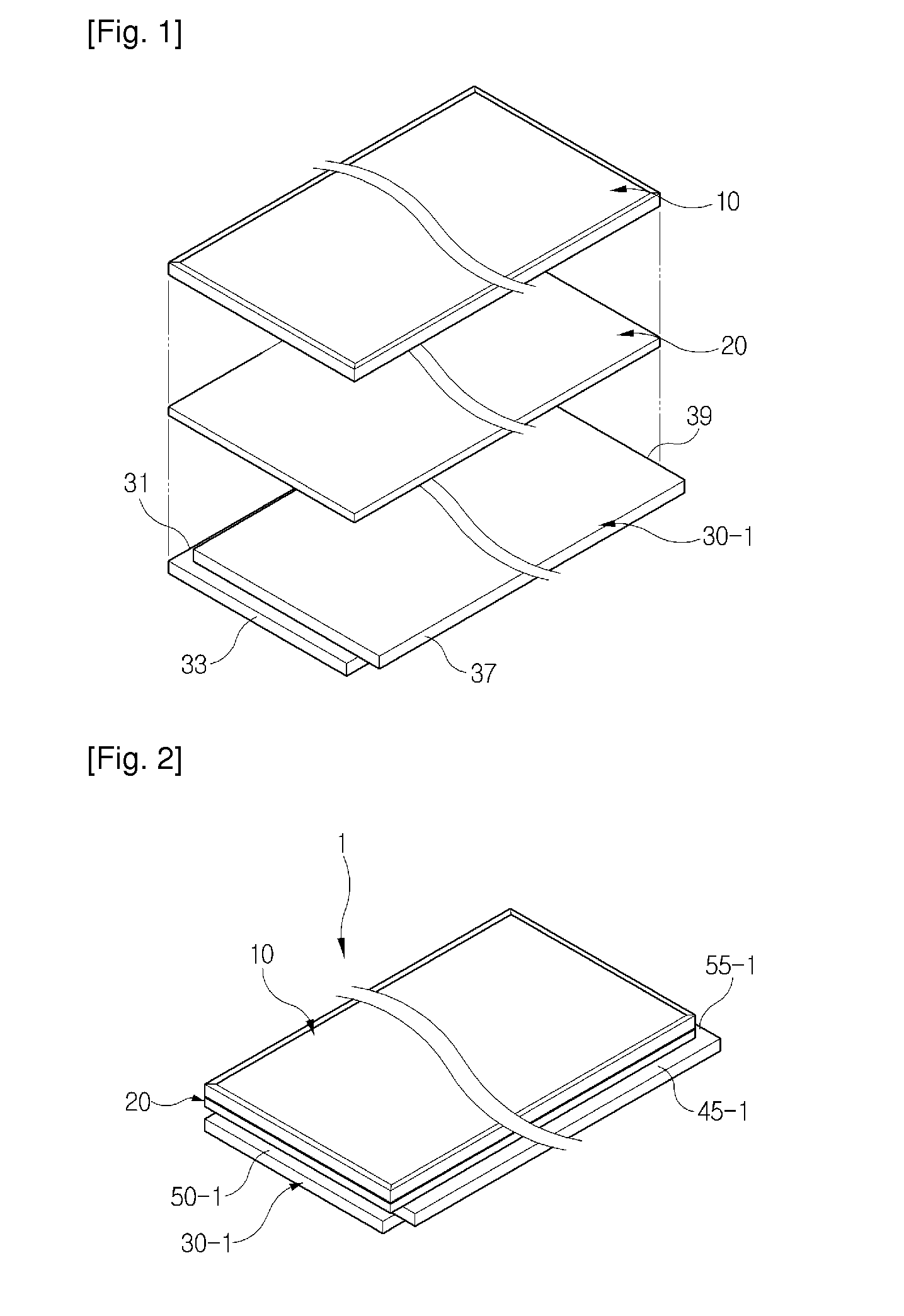

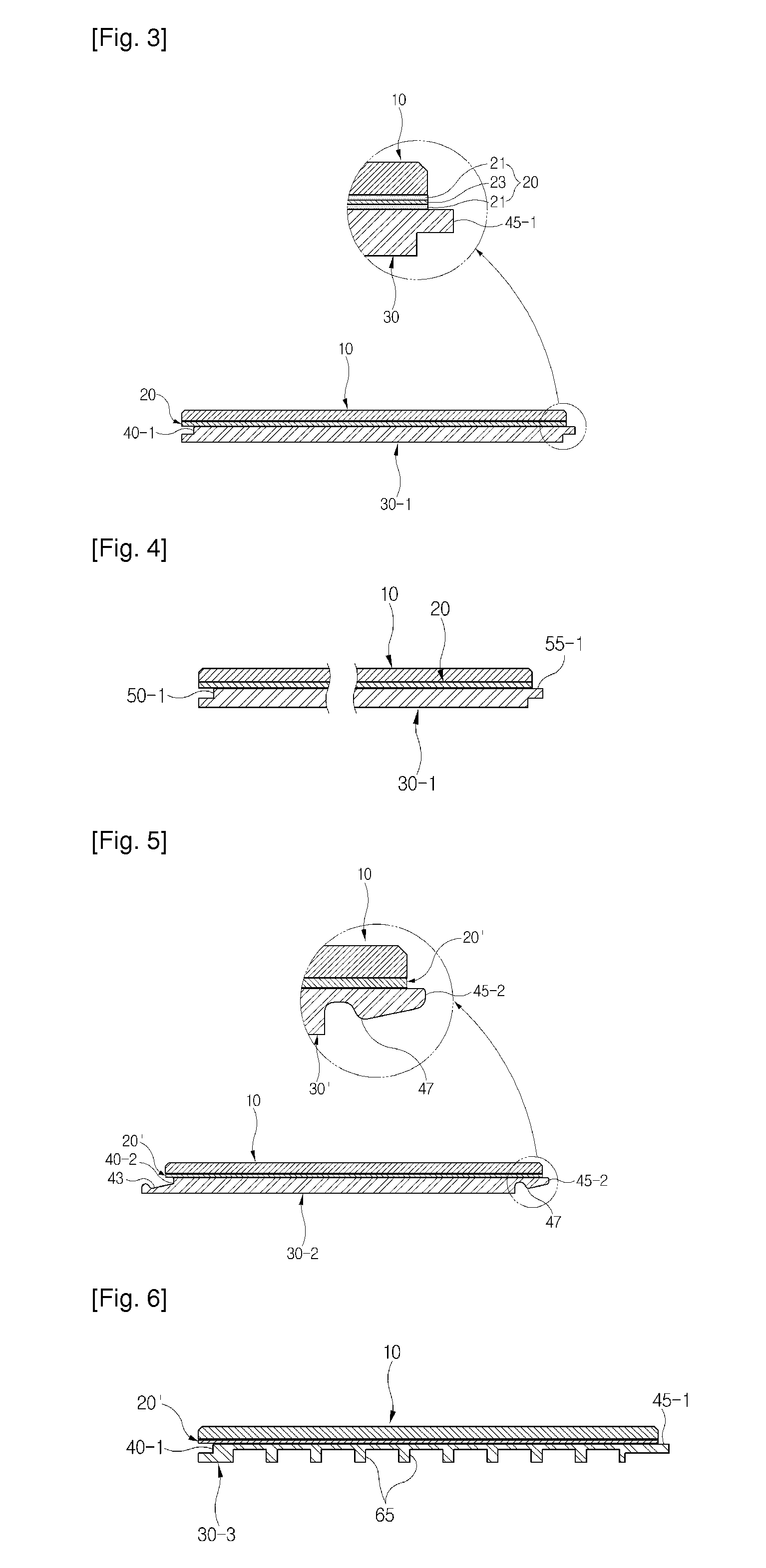

Plate product using natural stone for floor and wall finishing

ActiveUS20100300032A1Reduce load appliedEasy constructionCovering/liningsWallsEngineeringNatural stone

A plate product for finishing a floor or wall is disclosed. The plate product includes a natural-stone surface plate which has a predetermined thickness and is cut to have a predetermined length and width. A reinforcing plate is cut to have a length and width corresponding to those of the natural-stone surface plate and attached to the lower surface of the surface plate. A base plate is cut to have a length and width which are larger than those of the natural-stone surface plate and attached to the lower surface of the reinforcing plate. The upper layer part of the base plate having a predetermined thickness is pushed horizontally at one lengthwise side surface and one widthwise end surface, and the lower layer part having a remaining thickness is pushed horizontally at the other lengthwise side surface and the other widthwise end surface.

Owner:EASYTECH

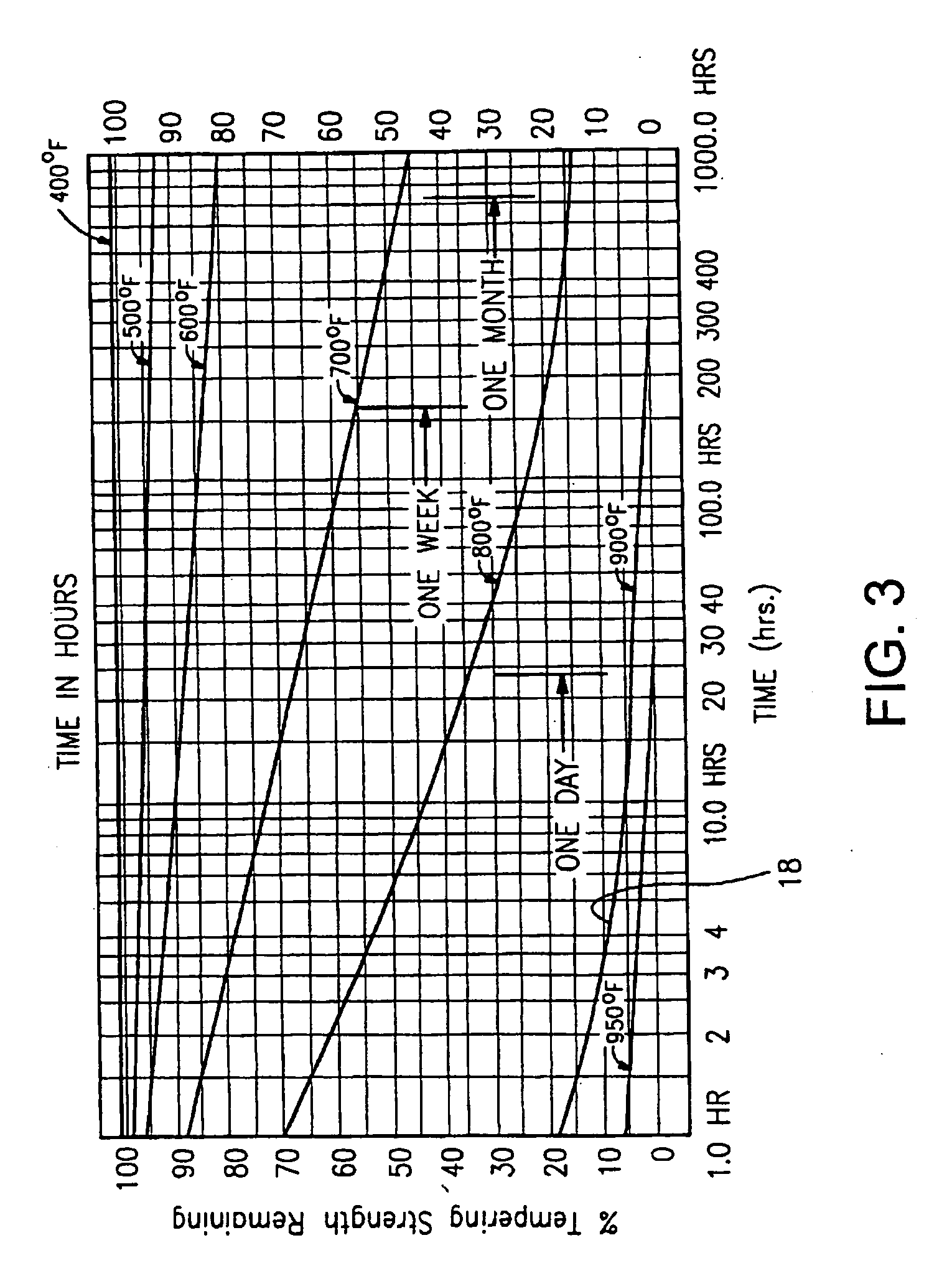

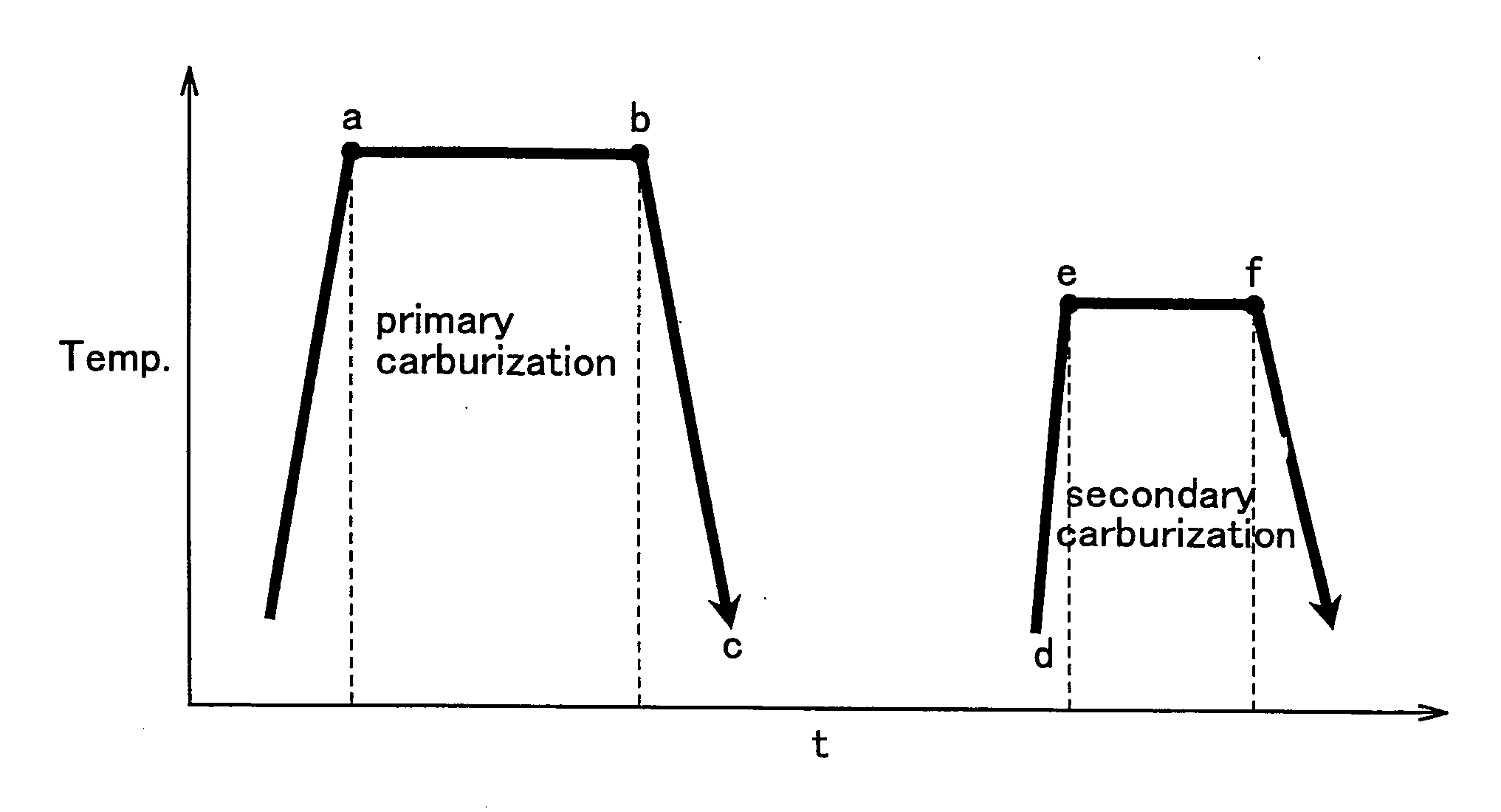

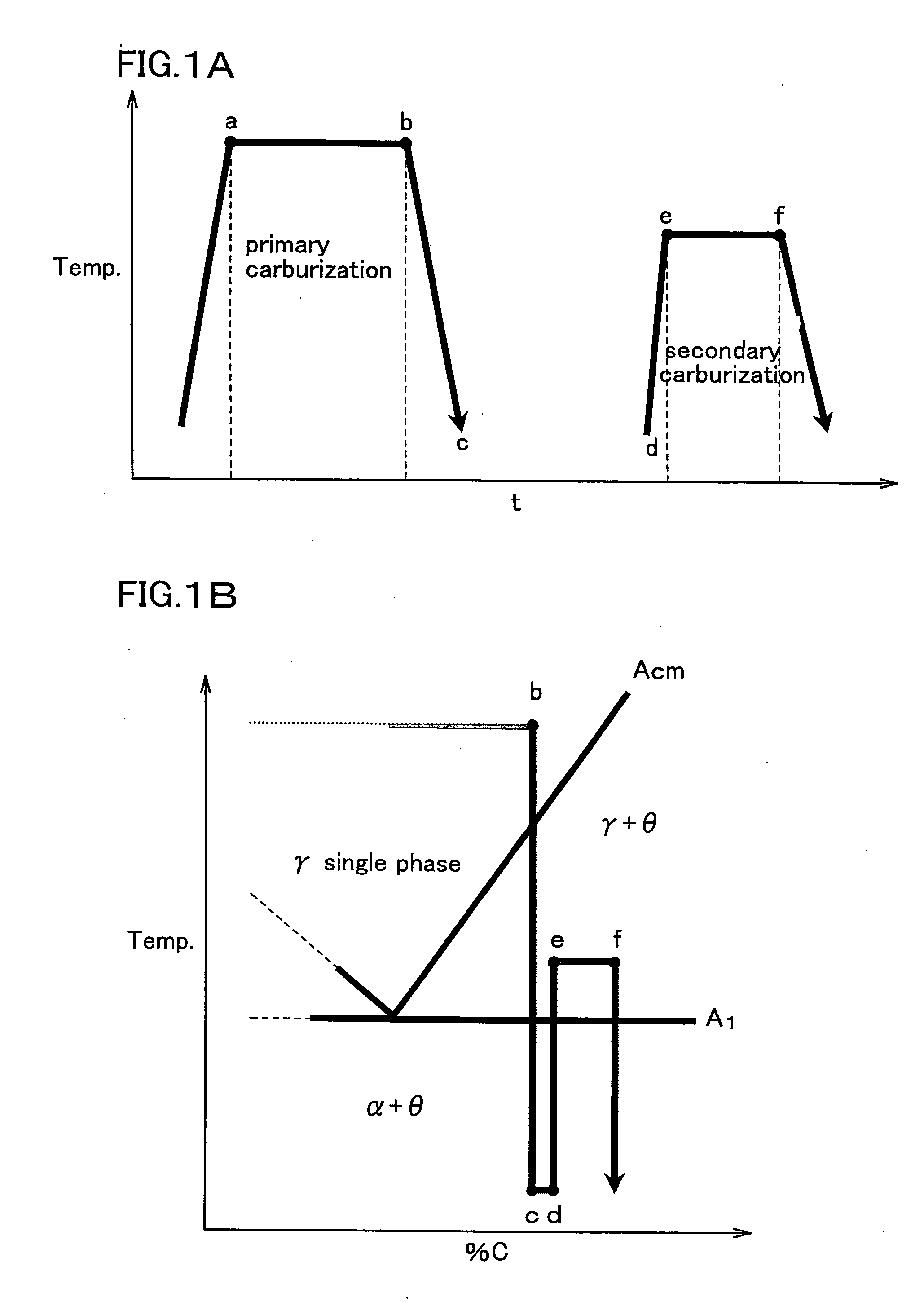

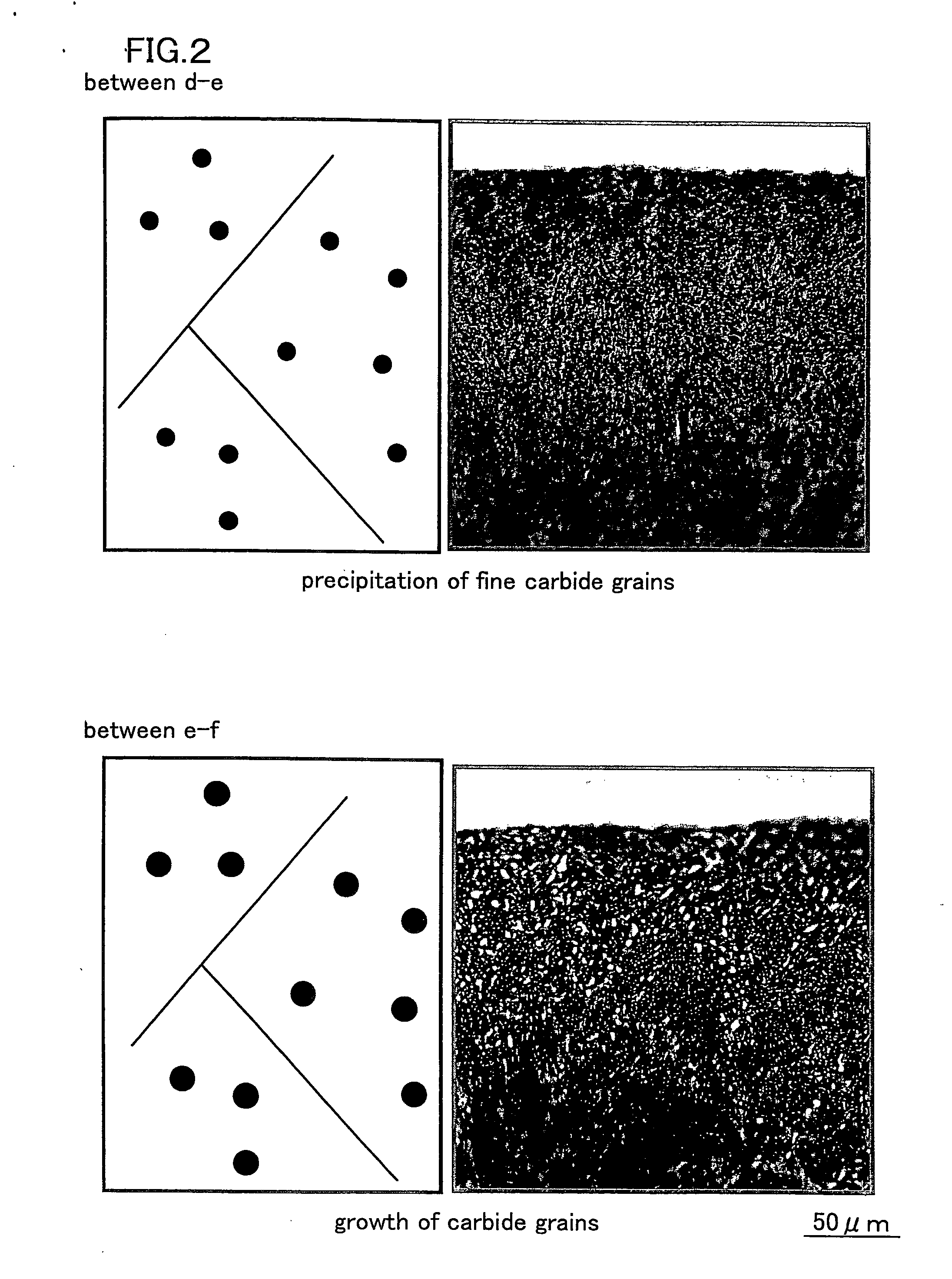

Carburized component and method of manufacturing the same

InactiveUS20060130935A1Reduce the overall heightHigh strengthSolid state diffusion coatingCarbideImpurity

This invention aims to provide a carburized component realizing a larger strength for power transmission components such as gears, and a method of manufacturing the same. The carburized component of this invention, aimed at realizing the object, consists essentially of, in % by mass and both ends inclusive, C: 0.1-0.30%, Si: 0.80-1.50%, Mn: 0.30-1.20%, Cr: 2.0-5.5%, and the balance of Fe and inevitable impurities; has a mean C concentration over the range from the surface of the steel to a depth of 0.2 mm after vacuum carburization of 1.2% or more and 3.0% or less, and has a ratio of a carbide area over the range from the surface to a depth of 50 μm of 15% or more and 60% or less, has the carbide precipitated in a finely dispersed manner so that the carbide having a grain size of 10 μm or less accounts for 90% or more of the entire portion, and has a depth of a grain boundary oxide layer below the surface of 1 μm or less.

Owner:DAIDO STEEL CO LTD +1

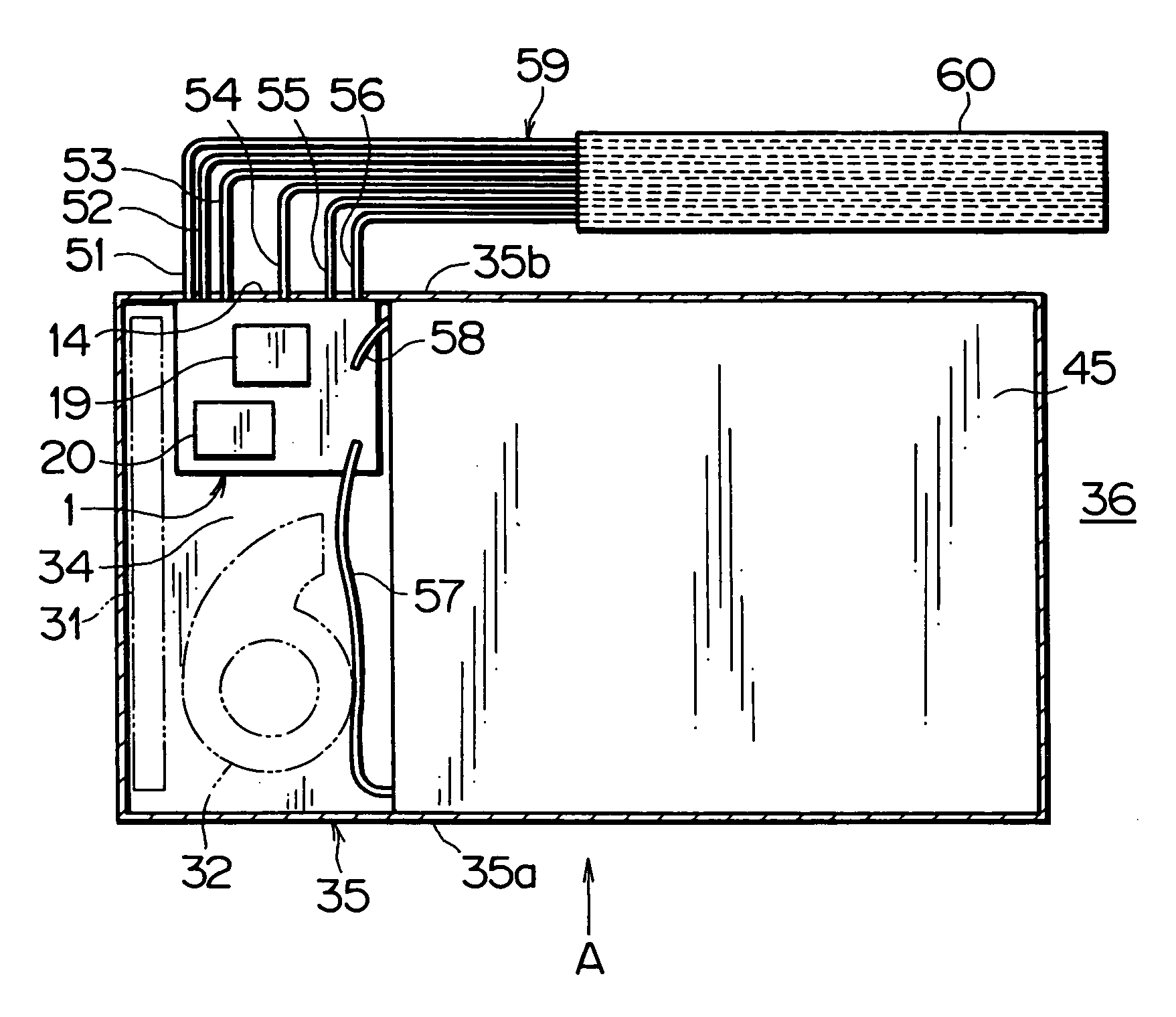

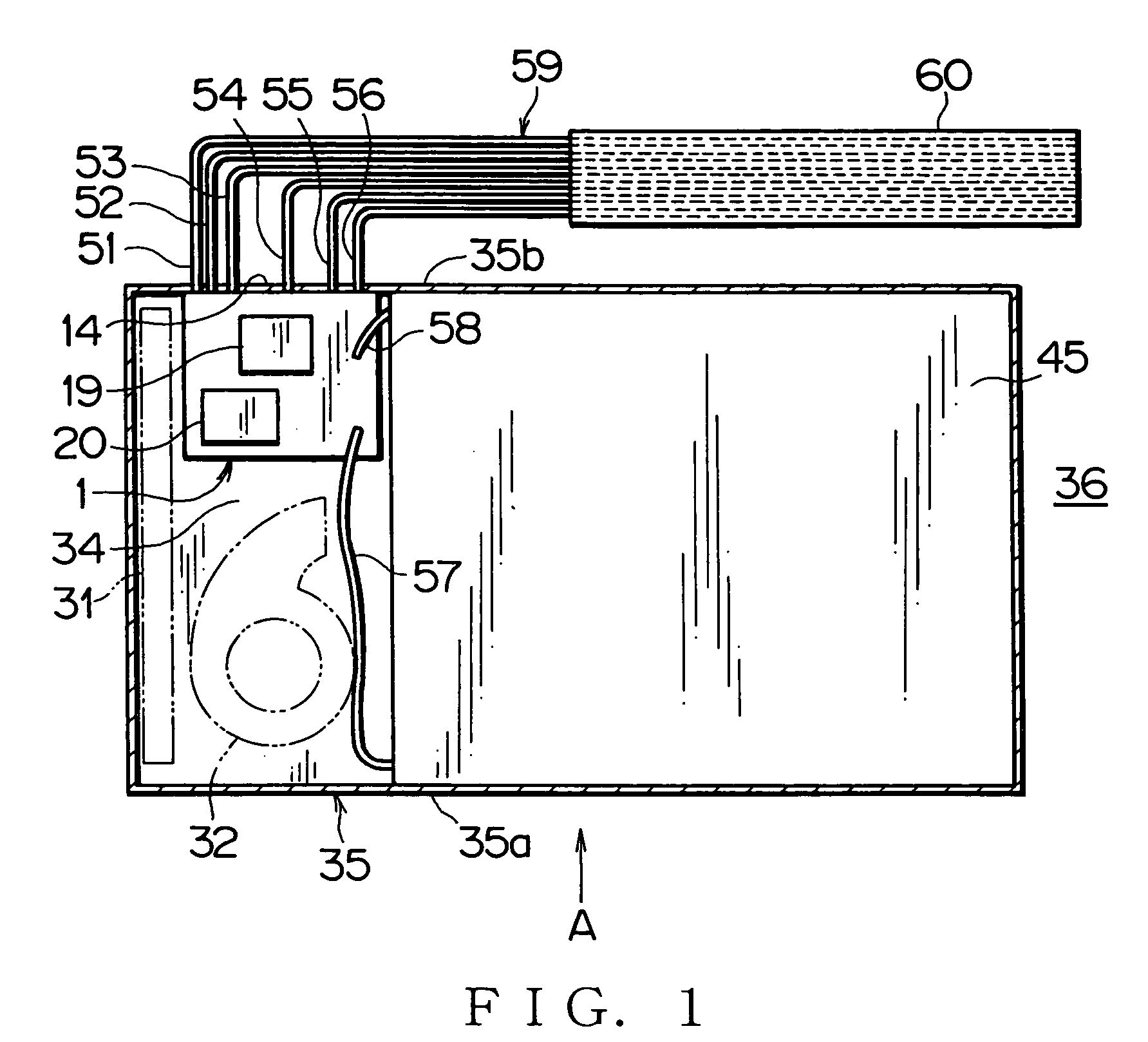

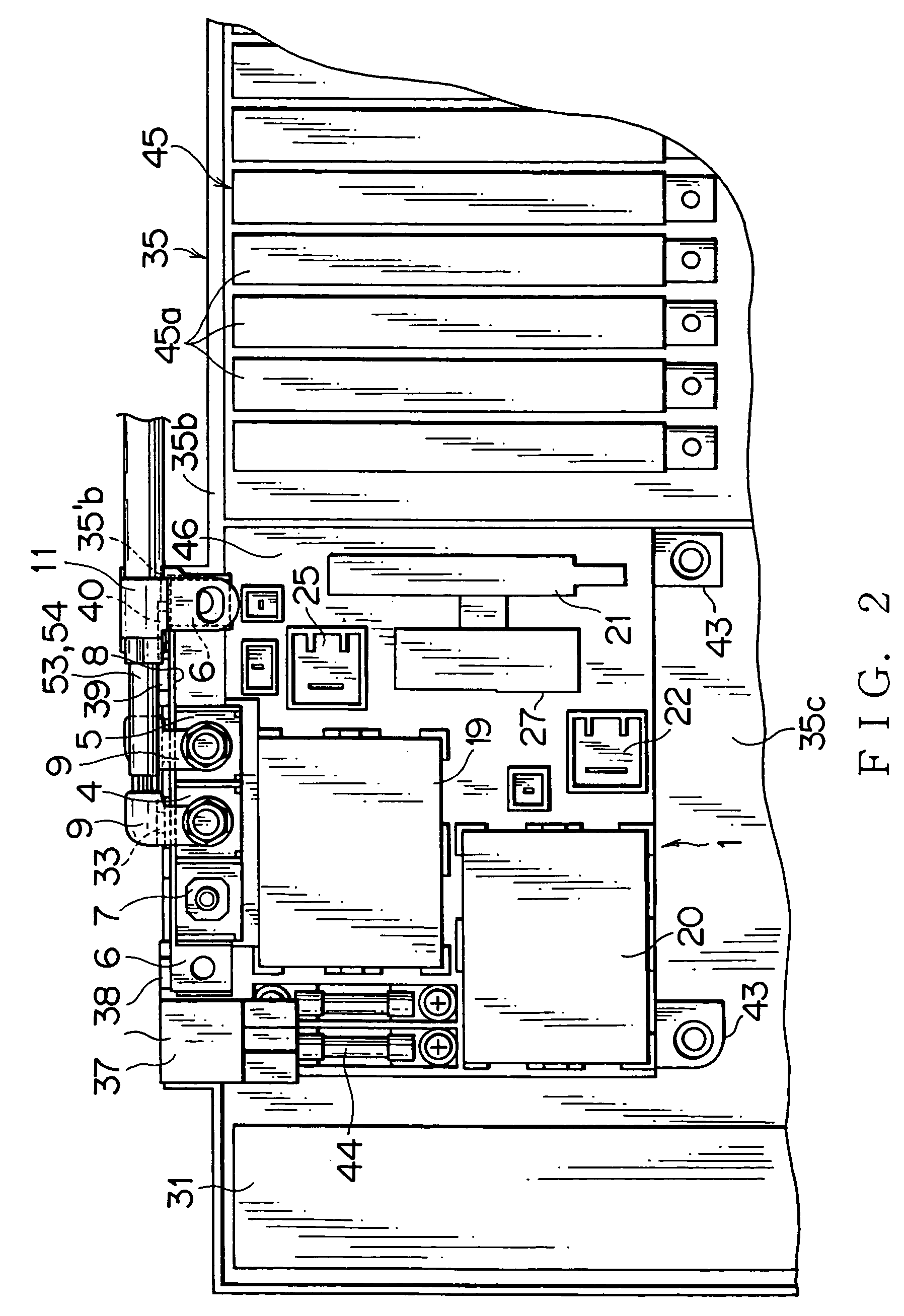

Arrangement structure of electric junction box

ActiveUS20060030176A1Firmly connectedReduce electrical damagePlural diverse prime-mover propulsion mountingCell component detailsElectricityHigh voltage battery

An arrangement structure of an electric junction box is provided, by which damage of the electric junction box in the event of a collision of a vehicle can be reduced and a plurality of electric wires can be easily connected to the electric junction box with good workability. The arrangement structure includes: a high voltage battery; a battery pack for receiving the battery, the battery pack being mounted on a vehicle; and an electric junction box arranged in the battery pack, the electric junction box being connected to the battery, wherein on the assumption that a collision takes place on the battery pack-mounting side of the vehicle, the electric junction box is arranged on the side of a wall of the battery pack, the wall being situated on the side opposite to the collision side of the vehicle.

Owner:YAZAKI CORP +1

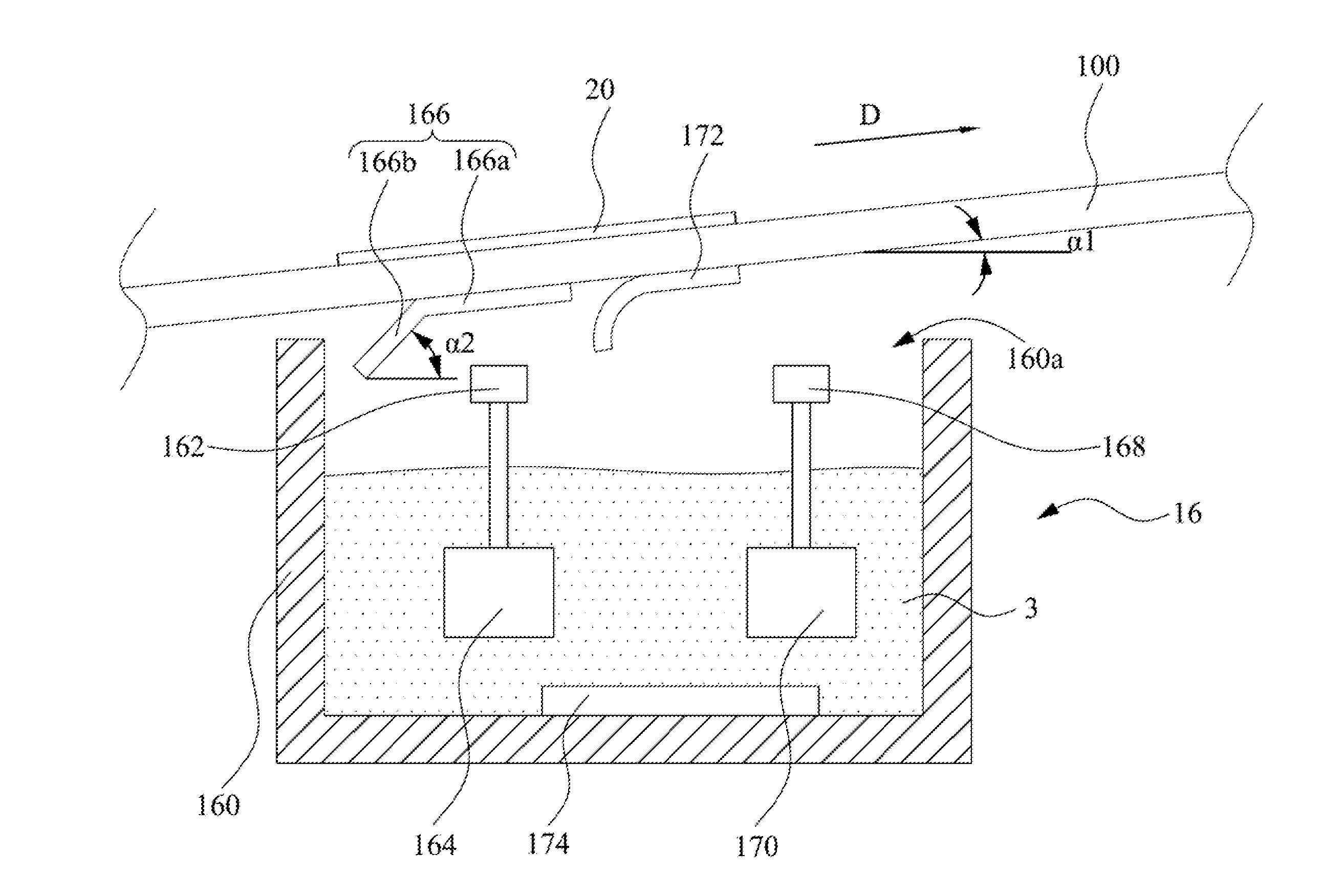

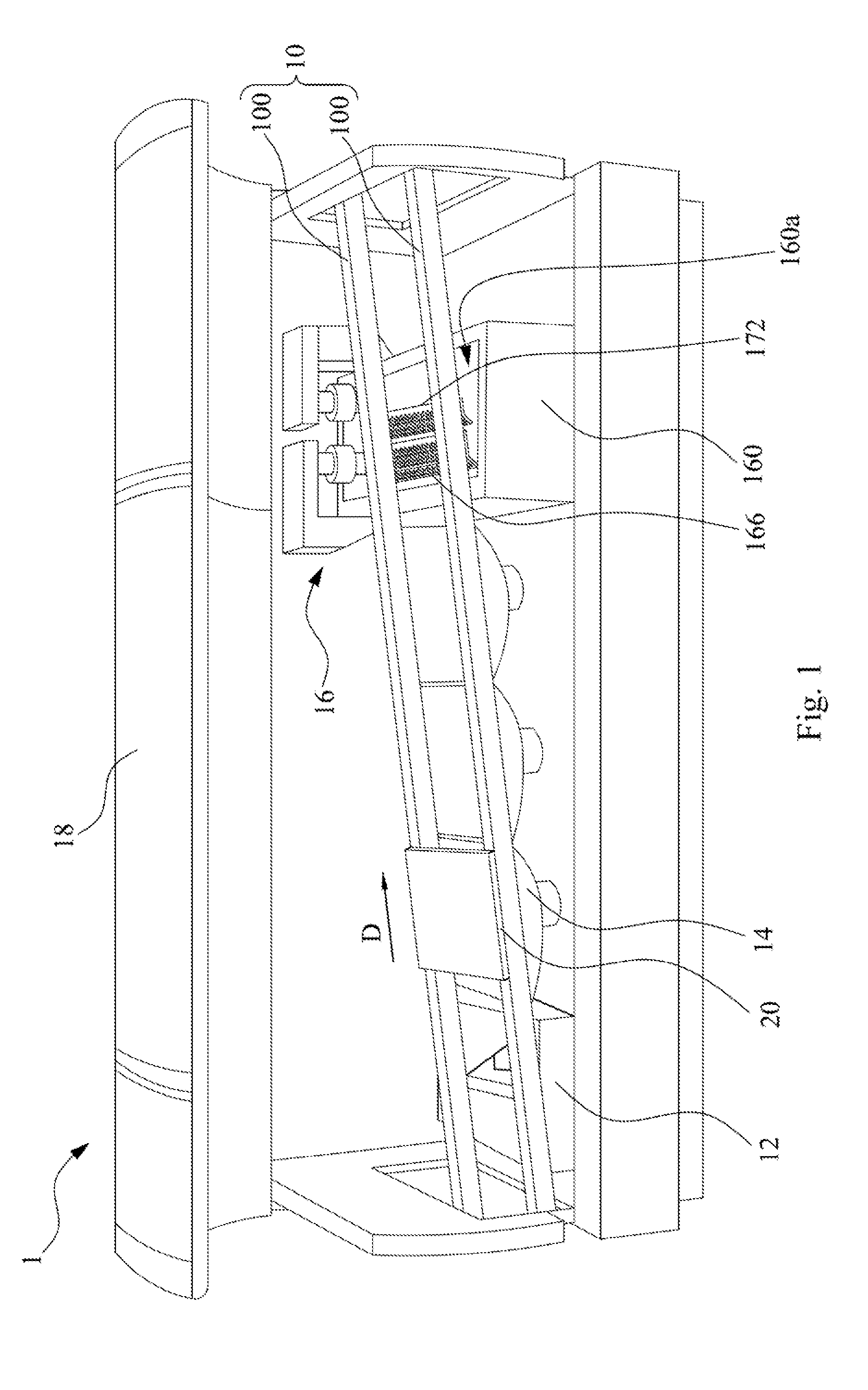

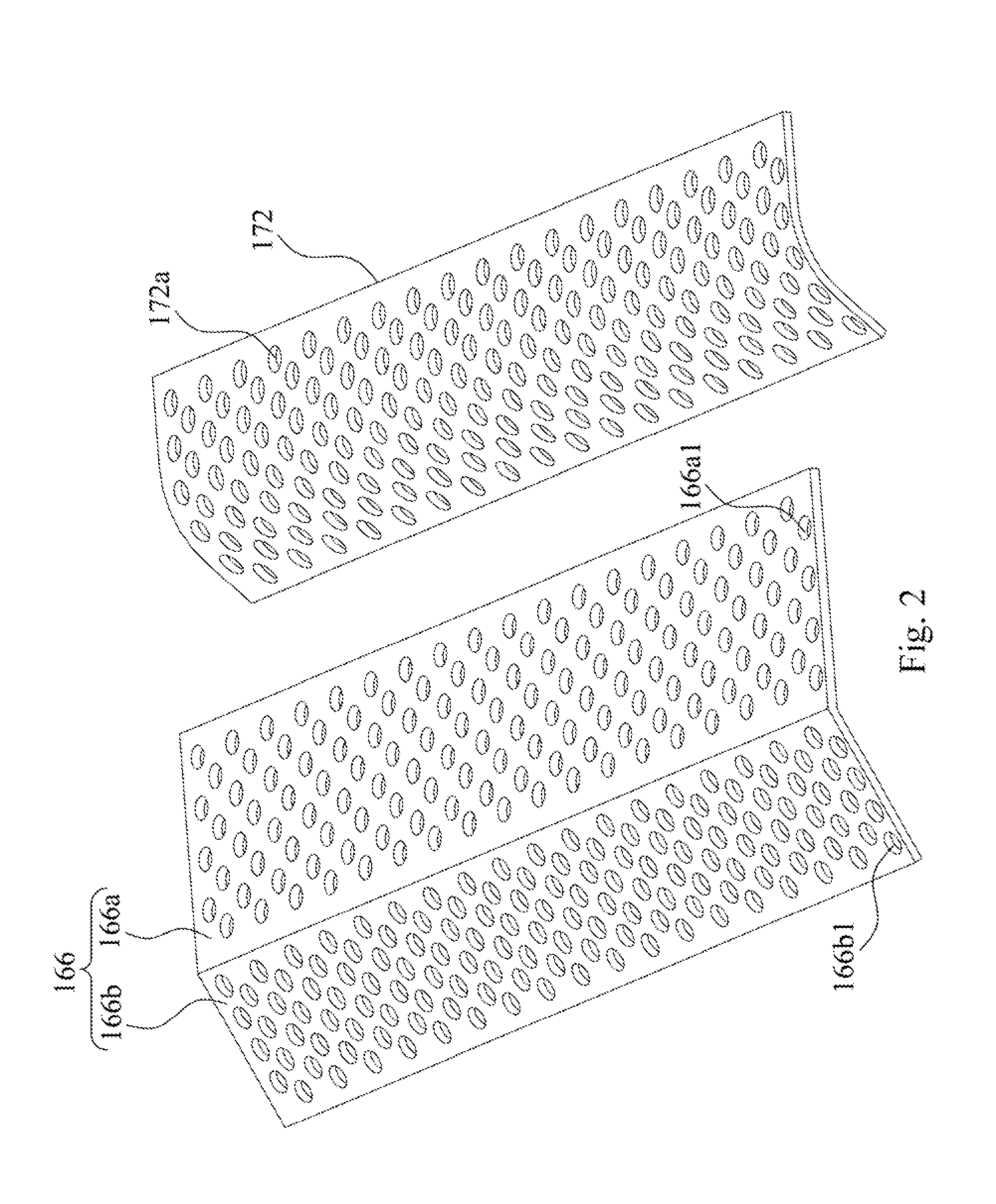

Automatic welding equipment

InactiveUS20140209661A1Reduce a phenomenon of sputtering the solderReduced impact strengthPrinted circuit manufactureSolder feeding devicesEngineeringWelding

Automatic welding equipment includes a wave soldering machine including a tank, a plurality of first nozzles, a first pump, and a first guide plate. The tank has an opening. The first nozzles and melted solder are disposed in the tank. The first pump is disposed in the tank for jetting the solder via the first nozzles. The first guide plate is located at the opening and includes a first plate portion and a second plate portion. The first plate portion is located over the first nozzles and has a plurality of first holes for passed through by the solder jetted from the first nozzles. The second plate portion, connected to the first plate portion, guides the solder to flow out of the first holes. The solder guided by the second plate portion passes through second holes of the second plate portion and returns into the tank.

Owner:INVENTEC CORP

Thermoplastic resin composition and production method thereof

ActiveUS20050014003A1Good lookingReduced impact strengthLiquid surface applicatorsSynthetic resin layered productsPowder mixtureAcrylic polymer

The present invention provides a thermoplastic resin composition comprising a thermoplastic resin (A), an acrylic polymer (B), a polytetrafluoroethylene-containing powder mixture (C) and a filler (D), the amount of the acrylic polymer (B) being from 0.1 to 400 parts by weight, the amount of the filler (D) being from 1 to 2000 parts by weight, based on 100 parts by weight of the thermoplastic resin (A), and the amount of a polytetrafluoroethylene component in the polytetrafluoroethylene-containing powder mixture (C) is from 0.01 to 400 parts by weight based on 100 parts by weight of the thermoplastic resin (A).

Owner:MITSUBISHI CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com