Hexagonal boron nitride/polypropylene polymer composite and preparation method

A technology of hexagonal boron nitride and composite materials, which is applied in the field of hexagonal boron nitride/polypropylene polymer composite materials and its preparation, can solve the problems of poor insulation performance, complicated processing technology, and low thermal conductivity, and achieve bending strength and flexural modulus improvement, the preparation method is simple and easy to operate, and the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1 Hexagonal boron nitride / polypropylene polymer composite material

[0025] (1) The preparation method is as follows:

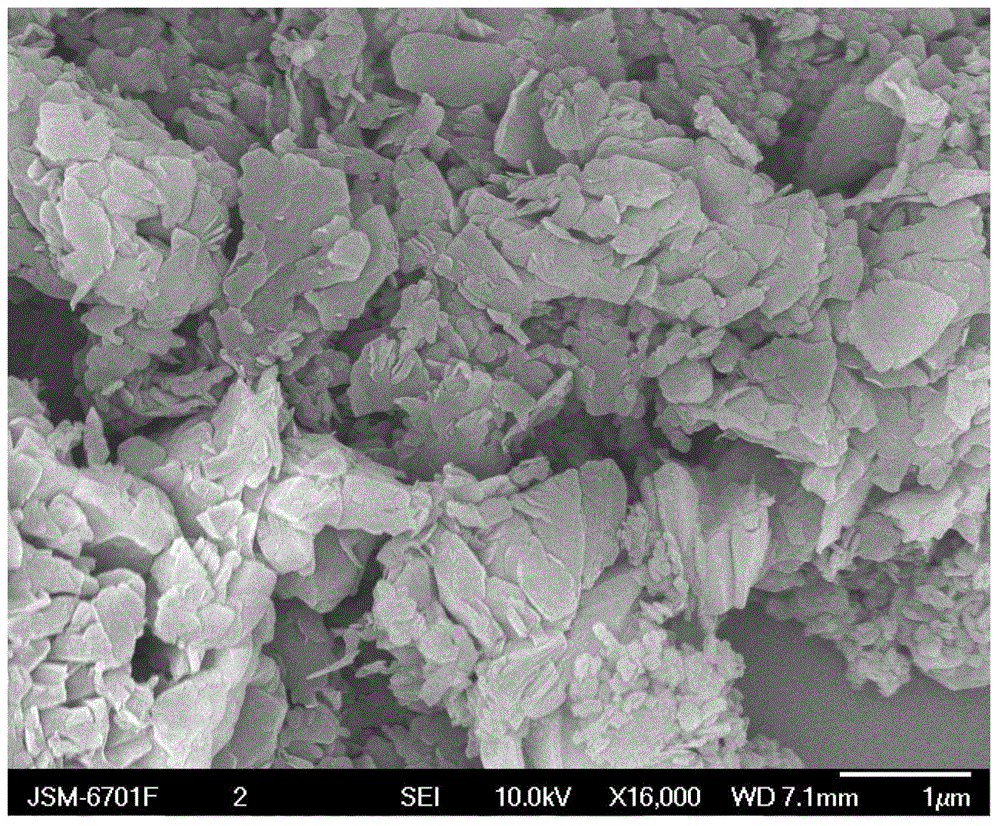

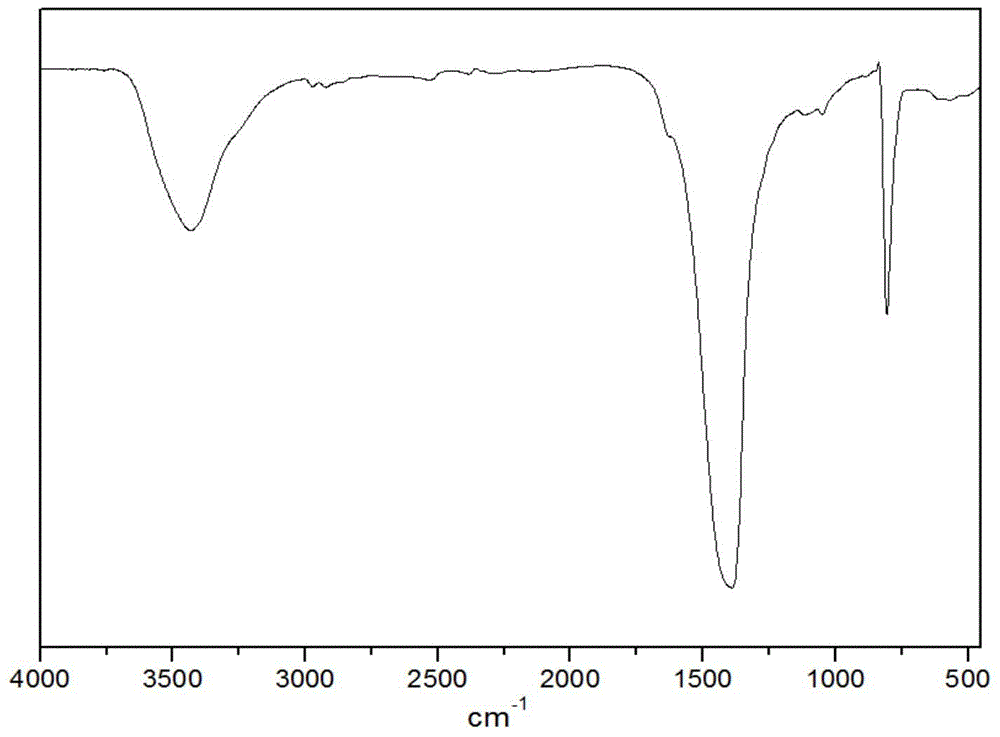

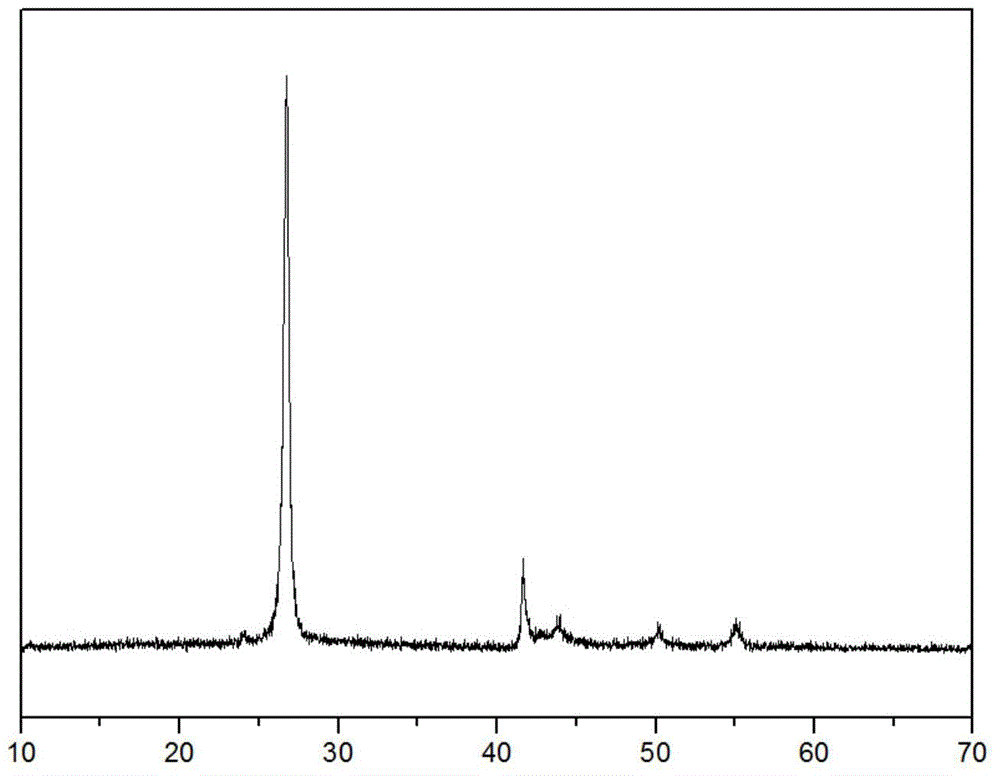

[0026] 1) Pretreatment of hexagonal boron nitride: dry the hexagonal boron nitride in a vacuum drying oven at 90°C for 8 hours. Then add 30% hydrogen peroxide to the dried hexagonal boron nitride to prepare a mixed solution with a concentration of 0.1g / mL, ultrasonicate for 30min, put it into the reaction kettle and stir at 100°C for 24h, after the reaction kettle is cooled to room temperature, The reactant was filtered, washed with deionized water until neutral, and then dried in a vacuum oven at 50° C. for 24 hours for later use.

[0027] 2) According to the following ratio, put the treated hexagonal boron nitride, polypropylene, antioxidant, lubricant and compatibilizer into the high-speed mixer and mix for 3-5 minutes, and put the evenly mixed materials into the same direction Melt extrusion in a screw extruder. The extruder adopts four-...

Embodiment 2

[0033] Example 2 Hexagonal boron nitride / polypropylene polymer composite material

[0034] The preparation method is the same as in Example 1, except that the mass ratio of hexagonal boron nitride and polypropylene is 1:15. The hexagonal boron nitride / polypropylene polymer composite material obtained in this example was tested for mechanical properties and thermal conductivity, and the results are shown in Table 1.

Embodiment 3

[0035] Example 3 Hexagonal boron nitride / polypropylene polymer composite material

[0036] The preparation method is the same as in Example 1, except that the mass ratio of hexagonal boron nitride and polypropylene is 1:10. The hexagonal boron nitride / polypropylene polymer composite material obtained in this example was tested for mechanical properties and thermal conductivity, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com