Thorium-containing fluoride fused salt and/or uranium-containing fluoride fused salt and preparation method

A fluoride and molten salt technology, which is applied in the fields of reactor fuel material, nuclear power generation, climate sustainability, etc., can solve the problem that thorium and/or uranium elements cannot be uniformly distributed in fluoride molten salt, etc., and achieves a simple and easy-to-operate preparation method. , the effect of not easy to reunite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

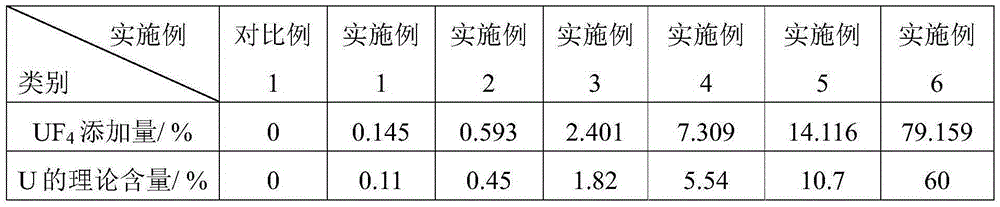

[0031] The product that embodiment 1~6 makes is FLiNaKU molten salt, and its difference is only in UF 4 The addition amount is different, UF in the embodiment 1~6 4 The amount of addition is as described in Table 1.

[0032] Table 1

[0033]

[0034] Note: UF 4 The percentages in the added amount of U are all mass percentages relative to the total amount of LiF, NaF and KF; the percentages in the theoretical content of U are all mass percentages relative to the total amount of the sample.

[0035] The preparation method of FLiNaKU molten salt in embodiment 1~6 all comprises the following steps:

[0036] Using the ball mill crushing and mixing method, weigh 15g of three kinds of fluorides LiF, NaF and KF according to the mass ratio of 29.3:11.7:59 and mix them into the ball mill. After grinding for 3 hours, the particle size is 0.2 ~ 1μm; 1 in UF 4 The raw materials were put into the ball mill respectively, and after being ground by the ball mill for 3 hours, the partic...

Embodiment 7~12

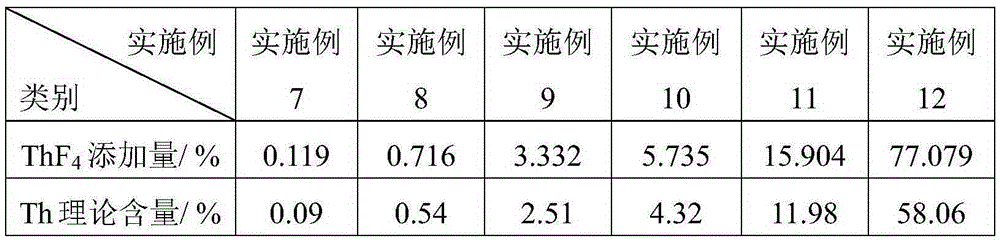

[0040] The products obtained in Examples 7-12 are all FLiNaKTh molten salts, and the difference is only that ThF 4 The amount of addition is different, ThF in Examples 7-12 4 The amount of addition is as described in Table 2.

[0041] Table 2

[0042]

[0043] Note: ThF 4The percentages in the added amount of Th are all mass percentages relative to the total amount of LiF, NaF and KF; the percentages in the theoretical content of Th are all mass percentages relative to the total amount of the sample.

[0044] The preparation method of FLiNaKTh molten salt in embodiment 7~12, compared with embodiment 1~6, except UF 4 Replaced by ThF 4 Except, other operations or conditions are all the same as in Examples 1-6.

Embodiment 13~16

[0046] The products obtained in Examples 13 to 16 are all mixed homogeneous molten salts containing Th and U, and the only difference is that UF 4 and ThF 4 The addition amount is different, UF in the embodiment 13~16 4 and ThF 4 The amount of addition is as described in Table 3.

[0047] table 3

[0048]

[0049]

[0050] Note: UF 4 and ThF 4 The percentages in the added amount are all mass percentages relative to the total amount of LiF, NaF and KF; the percentages in the theoretical content of Th and U are all mass percentages relative to the total amount of the sample.

[0051] The preparation method of molten salt in embodiment 13~16, compared with embodiment 1~6, except UF 4 Replaced by UF 4 and ThF 4 Except the mixture, all the other operations or conditions are the same as in Examples 1-6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com